Autohelm 100, 300 INSTALLATION GUIDE

Distributed by

Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the

Raytheon Company.

TYPE

100/300

AUTOPILOT

Installation and Set Up

Contents |

3 |

|

|

|

|

Contents

Chapter 1: Introduction .......................................................................... |

9 |

1.1 ST7000 Control Unit ................................................................. |

10 |

1.2 ST6000 Control Unit ................................................................. |

10 |

1.3CourseComputer ..................................................................... |

11 |

1.4FluxgateCompass .................................................................... |

11 |

1.5RotaryRudderReferenceTransducer .......................................... |

12 |

1.6LinearFeedbackTransducer ...................................................... |

12 |

1.7TypeCRInterfaceUnit ............................................................... |

12 |

1.8DriveSystems .......................................................................... |

13 |

RotaryDriveUnits ..................................................................... |

13 |

ReversingHydraulicPump ......................................................... |

14 |

LinearDrive ............................................................................. |

15 |

HydraulicLinear ....................................................................... |

15 |

ConstantRunningHydraulicPump .............................................. |

16 |

Sterndrive ............................................................................... |

16 |

1.9Options ................................................................................... |

17 |

Hand-heldRemote(Z101) .......................................................... |

17 |

NMEAInterface(D153) .............................................................. |

17 |

AuxiliaryAlarm(Z035) ............................................................... |

18 |

Joystick(Z147) ........................................................................ |

18 |

WindTransducer(sailonly) ......................................................... |

19 |

MastheadWindTransducer(Z080,LongArmVersionZ188) ...... |

19 |

PushpitWindTransducer(Z087) ............................................ |

19 |

GyroplusTransducer(Z179) ...................................................... |

20 |

Chapter 2: Installation .......................................................................... |

2 1 |

2. General .................................................................................... |

21 |

PlanningtheInstallation ............................................................. |

21 |

4 |

TYPE100/300 Operation and Installation Handbook |

|

|

2.1CourseComputer ..................................................................... |

21 |

|

Mounting ................................................................................. |

22 |

|

Cabling ................................................................................... |

22 |

|

Type1DriveUnits/SternDrive/ConstantRunningPump ............ |

23 |

|

Type2DriveUnits(12V) ........................................................ |

23 |

|

Type2DriveUnits(24V) ........................................................ |

23 |

|

Type3DriveUnits(12V) ........................................................ |

24 |

|

Type3DriveUnits(24V) ........................................................ |

24 |

|

2.2 ST7000/6000 Control Unit ........................................................ |

25 |

|

Mounting ................................................................................. |

25 |

|

Cabling ................................................................................... |

26 |

|

2.3FluxgateCompass .................................................................... |

28 |

|

Mounting ................................................................................. |

28 |

|

Cabling ................................................................................... |

29 |

|

2.4RotaryRudderReferenceTransducer .......................................... |

30 |

|

Mounting ................................................................................. |

30 |

|

Cabling ................................................................................... |

32 |

|

2.5LinearFeedbackTransducer ...................................................... |

33 |

|

Mounting ................................................................................. |

33 |

|

Cabling ................................................................................... |

34 |

|

2.6HydraulicDriveSystems ............................................................ |

35 |

|

PumptoCylinderSpecifications .................................................. |

35 |

|

ReversingHydraulicPumps(Type1,Type2&Type3) ................... |

35 |

|

Mounting ............................................................................ |

35 |

|

Cabling ............................................................................... |

35 |

|

Type1DriveUnit ........................................................... |

35 |

|

Type2DriveUnit(12V) ................................................... |

36 |

|

Type2DriveUnit(24V) ................................................... |

36 |

|

Type3DriveUnit(12V) ................................................... |

36 |

|

Type3DriveUnit(24V) ................................................... |

36 |

Contents |

5 |

Plumbing ............................................................................ |

37 |

Twolinesystem ................................................................... |

39 |

Twolinepressurisedsystem .................................................. |

39 |

Threelinesystem ................................................................. |

40 |

Bleedingthesystem ............................................................. |

40 |

ConstantRunningHydraulicPump .............................................. |

41 |

Mounting ............................................................................ |

41 |

Cabling ............................................................................... |

42 |

PumpCable ................................................................. |

43 |

SolenoidCable ............................................................. |

43 |

Plumbing ............................................................................ |

44 |

HydraulicLinearActuator ........................................................... |

45 |

Installation .......................................................................... |

45 |

Cabling ............................................................................... |

48 |

FinalPreparationsBeforeuse ................................................ |

48 |

2.8MechanicalDriveSystems ......................................................... |

49 |

RotaryDriveUnit ...................................................................... |

49 |

Mounting ................................................................................. |

49 |

Cabling ................................................................................... |

52 |

Type1DriveUnit .................................................................. |

52 |

Type2DriveUnit(12V) ......................................................... |

52 |

Type2DriveUnit(24V) ......................................................... |

53 |

LinearDriveUnit ....................................................................... |

53 |

Mounting ................................................................................. |

54 |

Cabling ................................................................................... |

55 |

Type1DriveUnit .................................................................. |

55 |

Type2DriveUnit(12V) ......................................................... |

55 |

Type2DriveUnit(24V) ......................................................... |

56 |

SterndriveActuator .................................................................. |

56 |

Mounting ................................................................................. |

56 |

6 |

TYPE100/300 Operation and Installation Handbook |

|

|

Volvo(Pretype872215) ....................................................... |

56 |

|

Volvo(Posttype872215) ..................................................... |

58 |

|

Mercruiser/OMC/Yamaha ..................................................... |

61 |

|

MountinginaRestrictedArea ................................................. |

63 |

|

Cabling ................................................................................... |

64 |

|

2.9AuxiliaryAlarm ......................................................................... |

65 |

|

Cabling ................................................................................... |

65 |

|

2.10 Joystick ................................................................................ |

66 |

|

Cabling ................................................................................... |

66 |

|

2.11MastheadTransducer(sailonly) ................................................ |

67 |

|

Mounting ................................................................................. |

67 |

|

Cabling ................................................................................... |

68 |

|

2.12Interfacingtoothermanufacturer'sequipment(NMEA) ................. |

69 |

|

CourseComputerNMEAports ................................................... |

69 |

|

InputPort ............................................................................ |

69 |

|

OutputPort ......................................................................... |

70 |

|

Cabling ............................................................................... |

70 |

|

ST6000/ST7000ControlUnitNMEAInput ................................... |

71 |

|

Cabling ............................................................................... |

72 |

|

NMEAInterface ........................................................................ |

73 |

|

Cabling ............................................................................... |

74 |

|

Chapter 3: Functional Test ................................................................... |

7 6 |

|

3.1 System test ............................................................................. |

76 |

|

3.2Switch-on ................................................................................ |

76 |

|

3.3Rudderanglesense .................................................................. |

77 |

|

ST7000 control unit .................................................................. |

77 |

|

ST6000 control unit .................................................................. |

77 |

|

3.4Rudderanglealignment ............................................................. |

77 |

|

3.5Operatingsense ....................................................................... |

78 |

|

3.6Rudderdeadband ..................................................................... |

78 |

Contents |

7 |

3.7Mechanicaltest(Linear,Rotary&HydraulicDrives) ........................ |

78 |

Currentlimitandcutout ............................................................. |

78 |

3.8MechanicalTest(SternDrive) ..................................................... |

79 |

3.9SettingtheAutopilotRudderLimit(Alldrives) ................................. |

79 |

3.10GyroPlusOffsetandDriftCompensation .................................... |

80 |

Procedure ............................................................................... |

80 |

Chapter 4: Calibration .......................................................................... |

8 1 |

4.1RecommendedSettings ............................................................ |

81 |

4.2Selectingcalibration .................................................................. |

82 |

4.3Adjustingcalibration .................................................................. |

83 |

RudderGain ............................................................................. |

83 |

RateLevel ............................................................................... |

84 |

RudderOffset(HelmAdjust) ....................................................... |

84 |

RudderLimit ............................................................................ |

84 |

TurnRate ................................................................................ |

85 |

CruiseSpeed ........................................................................... |

85 |

OffCourseLimit ....................................................................... |

85 |

TrimLevel ............................................................................... |

86 |

JoystickMode(ManualType) ...................................................... |

86 |

DriveOption ............................................................................. |

86 |

RudderDeadband(RudderDamping) .......................................... |

87 |

MagneticVariation .................................................................... |

87 |

AutoAdapt .............................................................................. |

87 |

Latitude .................................................................................. |

88 |

WindTrim ................................................................................ |

88 |

ResponseLevel ........................................................................ |

88 |

AutoRelease(manualoverride) ................................................... |

89 |

4.4SavingCalibrationMode ............................................................ |

89 |

4.5DisplayContrastAdjustment(ST7000only) .................................. |

90 |

4.6PermanentWatchAlarm(SFIA) ................................................... |

90 |

4.7RecordingCalibrationSettings .................................................... |

90 |

8 |

TYPE100/300 Operation and Installation Handbook |

|

|

Chapter 5: Initial Sea Trials ................................................................... |

9 1 |

|

5.1InitialSeaTrials ........................................................................ |

91 |

|

5.2AutomaticCompassHeadingAlignmentandDeviationCorrection ... 91 |

|

|

5.3CompassAlignment(withoutdeviationcorrection) ......................... |

93 |

|

5.4FirstSeaTrials ......................................................................... |

93 |

|

5.5ResponseControl ..................................................................... |

94 |

|

Level1-AutomaticSeaStateControl .......................................... |

94 |

|

Level2-AutomaticSeaStateInhibit ............................................ |

94 |

|

Level3 -AutomaticSeaStateInhibitandcounterrudder ................ |

94 |

|

5.6AutomaticTrimControl ............................................................. |

95 |

|

5.7RudderGainAdjustment(DisplacementCraft) ............................... |

96 |

|

5.8RudderGainAdjustment(HighSpeedPlanningCraft) ..................... |

97 |

|

5.9RudderGain-AdjustmentwithSpeed ........................................... |

97 |

|

5.10ManualOverride (SternDriveActuatorsonly) .............................. |

98 |

|

Chapter 6: Track Control ...................................................................... |

9 9 |

|

Chapter 7: Windvane Control (Sail Only) ............................................. |

101 |

|

Index .................................................................................................. |

103 |

Chapter 1: System Components |

9 |

|

|

|

|

Chapter 1: Introduction

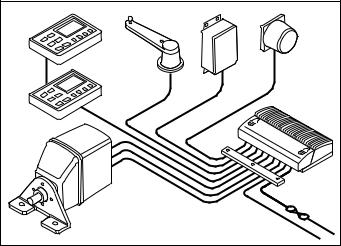

TheAutohelmType100/300autopilotsaremodularsystemsthatcanbe configured tosuittheindividualrequirementsofalltypesofvessels,using arangeofhighefficiencyrotary,linearorhydraulicrudderdriveunitsto matchvarioustypesofsteeringsystems.

The Autohelm system in its most basic form consists of a control unit, coursecomputer,driveunit,fluxgatecompassandarudder referencetransducer.

Afullrangeofaccessoriesarealsoavailableandinclude:

•Joystick(manualsteeringunit)

•Main alarm and interface

•Rate gyro

•Hand held remote control unit

•SeaTalkinstrumentation

•Interface leads

Control |

|

|

Unit |

Rudder |

|

|

|

|

|

Reference |

Fluxgate |

|

Unit |

|

|

Compass |

|

Control |

Gyro |

|

|

|

|

Unit |

|

Course |

|

|

|

|

|

Computer |

|

|

Cable |

|

Drive Unit |

Clamp |

|

|

|

|

|

D726-1 |

10 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

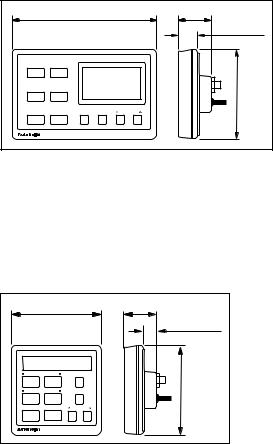

1.1 ST7000 Control Unit

TheST7000controlunitisfullyweatherprotectedanddesignedforabove orbelowdeckistallation.Theunitisconnected tothecoursecomputervia theSeaTalkbus.NMEAnavigation,speedandwindinformationcanbe received via a fixed socket on the rear of the case.

Note: AdditionalcontrolunitscanalsobeconnectedviatheSeaTalkbus.

|

|

177.8mm (7in) |

38.75mm (1.5in) |

||

|

|

|

|

|

24mm (0.95in) |

● |

–1 |

+1 |

● |

|

|

● |

–10 |

+10 |

● |

|

110mm |

|

|

|

|

|

|

|

|

|

|

|

(4.33in) |

STAND BY |

AUTO |

DISPLAY |

TRACK |

RESPONSE |

|

|

|

|

|

|

ST7000 |

|

|

|

|

|

D727-1 |

1.2 ST6000 Control Unit

The ST6000 control unit, like the ST7000, is fully weather protected and alsodesignedforaboveorbelowdeckinstallation.Theunitisconnected tothecoursecomputerviatheSeaTalkbus.NMEAnavigation,speedand windinformationcanbereceivedviaafixedsocketontherearofthecase.

Note: AdditionalcontrolunitscanalsobeconnectedviatheSeaTalkbus.

110mm (4.33in) |

38.75mm (1.5in) |

|||

|

|

|

24mm(0.95in) |

|

–1 |

+1 |

DISPLAY |

|

|

–10 |

+10 |

TRACK |

110mm |

|

(4.33in) |

||||

|

|

|

||

STAND BY |

AUTO |

RESPONSE |

|

|

|

|

ST6000 |

|

|

|

|

|

D728 -1 |

|

Chapter 1: System Components |

11 |

|

|

|

|

1.3 Course Computer

Thecoursecomputer,availableinboth12Vor24Vversions,housesa microprocessor, drive unit electronic control circuitry and power amplifier. It is the central distribution point for the autopilot, electrical wiring and ship’spowerconnectionpoint.

ThecoursecomputeralsohasNMEAinputandoutputstoallowoperation withothermanufacturer'sequipment.

Theunitisonlysplashproofandmust,therefore,beinstalledinadry, protected location.

Type100isusedforType1andTypeCR12Vdrives.Type300isused withType2andType3drives.

233mm (9.2in) |

45mm (1.8in) |

|

130mm (5.1in) |

|

D865-1 |

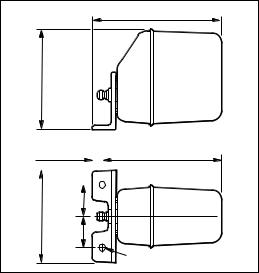

1.4 Fluxgate Compass

Thefluxgatecompasscontainsagimbalmechanismthatpermits accurate readings with pitch and roll movements up to +/- 35 degrees. Thecompassisdesignedforbelowdeck,bulkheadmountingand connects directly to the course computer.

Onsteeldeckedvesselsthecompasscanbemountedabovedeck, however,autopilotperformancemaybeaffectedduetotheincreased motion.

76mm (3in)

TM

76mm (3in)

D729-1

12 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

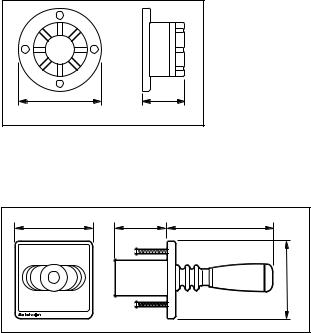

1.5 Rotary Rudder Reference Transducer

Therudderreferencetransducerprovidesthecoursecomputerwiththe precisepositionofthevesselsrudder.Theunitismountedonasuitable baseadjacenttotherudderstock.Itsuseismandatoryonallinstallations, exceptwhenalinearrudderreferencetransducerisconnected.

152mm (6in) |

139.7mm (5.5in) |

61mm (2.4in) |

69.5mm (2.7in) |

D730-1 |

1.6 Linear Feedback Transducer

Thelinearfeedbacktransducerisdesignedforinstallationson‘bullhorn’ stylehydraulicoutboardsteeringsystems.Theunitistotallyweatherproof andmountedonthebullhornram.Itsuseismandatoryonallhydraulic outboardinstallations.

425mm (16.75in) |

|

TM |

(1.3in) |

|

32mm |

|

D869-1 |

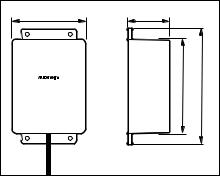

1.7 Type CR Interface Unit

Thecoursecomputercanbeconnectedtothesolenoidsonaconstant runninghydraulicpumpusingthetypeCRinterface.Theunitalsoprovides connectionstoenergiseasolenoidoperatedbypassvalve.

125mm (5.9in) |

|

|

100mm (3.95in) |

60mm |

(2.37in) |

|

D734-1 |

|

Chapter 1: System Components |

13 |

|

|

|

|

1.8 Drive Systems

Arangeofmechanical(rotary,linearandsterndrive)andhydraulicdrive units are available for use with the Type 100/300 system. Rotary drives arecoupledtothesteeringsystembyasimplechaindrive,lineardrives directly to the rudder stock at the tiller arm radius and stern drives directly tothepowersteeringvalveblock.

Thetypeofhydraulicdriveusedisdependentonthesizeofthevessels hydrauliccylinder.

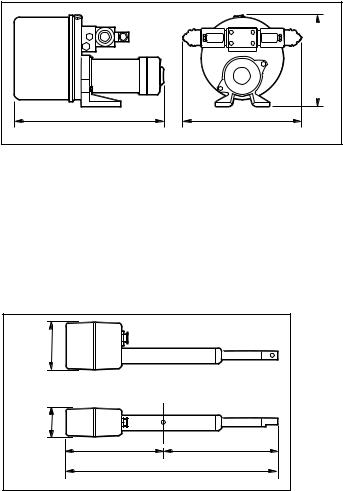

Rotary Drive Units

Autohelmrotarydriveunitsprovidesmooth,powerfulsteeringcommands withalmostsilentoperation.Aruggedelectricmotordrivesaprecision epicyclicgearboxviaahightensiledrivebelt.Anelectronicclutch transmitshightorqueloadswithnoslippage.Thedriveunitcanbe mountedinanyattitudetosimplifyinstallation.

274mm (10.8in)

195mm

(7.7in)

20mm (0.8in) |

|

|

|

|

256mm (10in) |

||

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60mm

184mm (2.4in)

(7.2in)

60mm

(2.4in)

2 holes 12.5mm (0.5in) diameter

D736-1

14 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

Reversing Hydraulic Pump

Thereversinghydraulicpumpconsistsofaprecisiongearpumpandan integralcheckvalveblockdrivenbyacontinuouslyratedservomotor.The pumpisconnecteddirectlytothevesselssteeringcylinder,withthe coursecomputerregulatingthepeakpumppressure.

There are three types of pump: type 1, type 2 and type 3. The different type relates to the steering ram capacity, which is directly related to the displacementofthevessel.

Type1: 80 to 230 cc (4.9 to 14cu in)

Type2: 160 to 350 cc (9.8 to 21cu in)

Type3: 250 to 460 cc (15 to 28cu in)

103mm (4.07in)

103mm (4.07in)

|

'A' |

|

117mm (4.62in) |

|

|

||

Pump |

Dimension 'A' |

|

|

Type 1 |

177mm (6.96in) |

|

|

Type 2 |

177mm (6.96in) |

|

|

Type 3 |

235mm (9.25in) |

|

|

D738-1

Chapter 1: System Components |

15 |

|

|

|

|

Linear Drive

TheAutohelmlineardriveunit isofoutstandingdesignwhichfeatures powerfulthrust,fasthardovertimesandnearsilentoperation.When backdriventhemovementissmoothwithminimalbackdrivenforce.Using ahightensilebeltdriveandepicyclicreductiongearboxthepowerful electric motor is controlled by an electronic fail-safe clutch.

Thedesignishighlyefficientandprovideshighperformanceforminimum currentconsumption.

(7.8in)197mm

79mm (3.1in) (4.5in)114mm

4 off fixing holes suitable for 10mm (0.4in) bolts

|

A |

|

|

|

|

|

50mm (2in) |

|

|

90° |

|

Drive |

|

Dimension 'A' |

|

Type 1 |

|

700mm (27.5in) |

|

Type 2 |

(short) |

700mm (27.5in) |

|

Type 2 |

(long) |

850mm (33.5in) |

D1010-1 |

|

|

|

Hydraulic Linear

Thehydrauliclineardriveunitisaselfcontainedsecondarysteering cylinder(withabuilt-insolenoidbypassvalve).Theunitisdrivenbya reversinghydraulicpumptoprovideatotallyisolatedautopilotsteering system.

|

|

|

|

A |

|

|

|

457mm (18in) |

|

80mm |

(3.15in) |

|

|

|

|

152mm (6in) |

101.6mm (4in) |

Drive |

Dimension 'A' |

|

|

|

Type 2 |

540mm (21.25in) |

|

|

|

Type 3 |

690mm (27.15in) |

|

|

|

|

D877-1 |

16 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

Constant Running Hydraulic Pump

Whensteeringloadsrequirearamcapacityofover460cc(28cuin)the constantrunninghydraulicpumpprovidestheidealautopilotdrivesystem.

Hydraulicfluidissuppliedfromaselfcontainedreservoirandflowtothe steeringramiscontrolledbyintegralsolenoidoperatedvalves.

Usedwithasolenoidoperatedbypassvalveandaseparatehydraulicram, thissystemisrecommendedforheavydutyapplicationsonlarge mechanicallysteeredvessels.

224mm (8.8in)

224mm (8.8in)

356mm (14in) |

262mm (10.3in) |

D740-1

Stern drive

Thesterndriveactuatormustonlybeusedonsterndriveswithcable operated,powerassistedsteering.

Thedriveunitoperatesthepowersteeringvalveinexactlythesameway asthesteeringcable.Aclutchdisengagesthedriveunittoallowmanual steeringwhentheautopilotisdisengaged.

Installationkitsareavailableformostpopulartypesofsteeringmanufacturers.

102.5mm |

|

(4.0in) |

|

63.4mm |

|

(2.5in) |

|

220mm (8.66in) |

240mm (9.45in) |

460mm (18.1in) mid-stroke |

|

|

D743-1 |

Chapter 1: System Components |

17 |

|

|

|

|

1.9 Options

TheType100/300autopilotsystemisavailablewiththefollowingoptional systemcomponents:

Hand-held Remote (Z101)

Thehand-heldremoteallowscoursechangingfromapositionawayfrom thesteeringstation.Thehandheldremoteisconnectedtotheautopilotvia theSeaTalkbus.

–1 +1

–10 +10

138mm (5.4in)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

65mm (2.5in) |

|

14.5mm (0.6in) |

|||||

D1011-1

NMEA Interface (D153)

AlthoughtheType100/300hasitsownNMEA0183inputandoutput ports,youmaywishtoreceiveinformationfromadditionalequipment transmittingNMEA.TheNMEAinterfaceconnectstotheSeaTalkbusand convertsincomingdatatoSeaTalk.TheinterfacealsoconvertsSeaTalk data to NMEA 0183 format.

117.5mm (4.6in) |

37mm (1.5in) |

87.5mm (3.4in)

87.5mm (3.4in)

D873-1

18 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

Auxiliary Alarm (Z035)

Theautopilotisprovidedwithacomprehensiveautomaticoff-coursealarm systemthatsoundsfromallcontrolunits.Thisprovidessufficientaudible warningundermostconditions.However,incaseswhereahighpowered alarmisrequired,anauxiliaryalarmcanbefitted.Theauxiliaryalarmis connectedtotheSeaTalkbusviatheNMEAinterfaceboxandwillsound whenevertheautopilottransmitsoneofthefollowingalarmconditions.

•Autopilot Off Course

•WatchAlarm

•Wind Shift

•Low Battery

•Large Cross Track Error

•NMEADataError

•NoAutopilotActuatorConnected

•SterndriveAutoRelease

•WaypointChangeAlarm

85mm (3.35in) |

45mm (1.8in) |

D732-1

Joystick (Z147)

TheJoystick isanelectromechanicalremotesteeringunitthatusesthe coursecomputer and itsdriveunittopowersteerthevesselsrudder.

110mm (4.3in) |

76mm (3in) |

157mm (6.2in) |

|

|

110mm (4.3in) |

JOYSTICK |

|

|

|

|

D734a-1 |

Chapter 1: System Components |

19 |

|

|

|

|

Wind Transducer (sail only)

IftheinstallationdoesnotincludeaSeaTalkWindinstrumenteitherthe mastheadorpushpit windtransducercanbeconnecteddirectlytothe NMEAinterfaceboxtosupplywindangleinformation.

Masthead Wind Transducer (Z080, Long Arm Version Z188)

371mm (14.6in)

D733-1

Pushpit Wind Transducer (Z087)

D1075-1

20 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

Gyroplus Transducer (Z179)

TheAutohelmGyroplusisatransducerthatmeasurestherateofturnof thevessel.Thisis usedbythe autopilottogiveevenbettercorrectionfor boat yawinadverseweatherconditions.Itisparticularlybeneficial downwardandinfollowingseaconditions.

90mm (3.5in)

GYROPLUS

51mm (2in)

115mm (4.5in) |

140mm (5.5in) |

D872-1

Chapter 2: Installation |

21 |

|

|

|

|

Chapter 2: Installation

2. General

Thissectiondescribeshowtoinstalltheautopilotandsystemcomponents describedinchapter1.

Planning the Installation

Whenselectingpowercableitisimportanttousethestatedwiregauge. Thecableyouchoosemaymeettherequiredcurrentspecification, however,iftoosmall,thevoltagewilldropbetweenthesupplyandthe coursecomputer.Thiswillreducethepowerofthedriveunitandmay causetheelectronicstomalfunction.

2.1 Course Computer

The course computer must be located in a dry, protected location free fromhighoperatingtemperaturesandexcessivevibration.Theunitmust bemountedverticallywithfreeairflowtoallowheatdissipationfromthe poweramplifier.

Avoidmountingthecoursecomputer:

•in an engine room

•where there is water splash/spray from bilge’s or hatches

•whereitcanbesubjectedtophysicaldamagefromheavyitems(such as hatch covers, tool boxes etc.)

•whereitwillbecoveredbyotheron-boardequipment

•whereitwillbeclosetosourcesofhighRFenergytransmissions (generators/SSBradios/antennacablesetc.)

22 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

Mounting

Vertical |

D881-1 |

1.Withthecoursecomputerlocatedasrequired,outlinethetwo mountingholes.

2.Drill two pilot holes for the fixing screws.

3.Securethecoursecomputertothevesselusingthetwoscrews provided.

Note: If the mounting surface is less than 3mm (1/8in) thick, use the U clipsprovided.

4.Drill three pilot holes for the cable clamp bar.

5.Securethecableclampasshown.

Cabling

Note: If you are installing the Type 100/300 system with a constant runninghydraulicpump,refertopage40beforerunningthepowercable.

1.Havingsitedthecoursecomputer,measurethetotalcablelength betweenthecoursecomputerandthevesselscentralpower distributionpanel.Usingthefollowingtables,selecttheappropriate cable size and circuit breaker relative to the type of drive unit used.

Chapter 2: Installation |

23 |

|

|

|

|

Type 1 Drive Units/Stern Drive/Constant Running Pump

|

Cable Length |

Cable Gauge |

Copper Area |

|

(Distribution |

|

|

|

panel to Course Computer) |

|

|

|

|

|

|

|

Up to 3m (10ft) |

12 AWG |

2.5 mm |

|

|

|

|

|

Up to 5m (16ft) |

10 AWG |

4 mm |

|

|

|

|

|

Up to 7m (23ft) |

8 AWG |

6 mm |

|

|

|

|

|

Up to 10m (32ft) |

6 AWG |

10 mm |

|

|

|

|

|

Up to 16m (52ft) |

4 AWG |

16 mm |

|

|

|

|

|

|

|

81004-01 |

Type 2 Drive Units (12V) |

|

|

|

|

|

|

|

|

Cable Length |

Cable Gauge |

Copper Area |

|

(Distribution |

|

|

|

panel to Course Computer) |

|

|

|

|

|

|

|

Up to 5m (16ft) |

8 AWG |

6 mm |

|

|

|

|

|

Up to 7m (23ft) |

6 AWG |

10 mm |

|

|

|

|

|

Up to 16m (52ft) |

4 AWG |

16 mm |

|

|

|

|

|

|

|

81004-02 |

Type 2 Drive Units (24V) |

|

|

|

|

|

|

|

|

Cable Length |

Cable Gauge |

Copper Area |

|

(Distribution |

|

|

|

panel to Course Computer) |

|

|

|

|

|

|

|

Up to 3m (10ft) |

12 AWG |

2.5 mm |

|

|

|

|

|

Up to 5m (16ft) |

10 AWG |

4 mm |

|

|

|

|

|

Up to 7m (23ft) |

8 AWG |

6 mm |

|

|

|

|

|

Up to 10m (32ft) |

6 AWG |

10 mm |

|

|

|

|

|

Up to 16m (52ft) |

4 AWG |

16 mm |

|

|

|

|

|

|

|

81004-01 |

24 TYPE 100/300 Operation and Installation Handbook

Type 3 Drive Units (12V)

|

Cable Length |

Cable Gauge |

Copper Area |

|

(Distribution |

|

|

|

panel to Course Computer) |

|

|

|

|

|

|

|

Up to 5m (16ft) |

8 AWG |

6 mm |

|

|

|

|

|

Up to 7m (23ft) |

6 AWG |

10 mm |

|

|

|

|

|

Up to 16m (52ft) |

4 AWG |

16 mm |

|

|

|

|

|

|

|

81004-02 |

Type 3 Drive Units (24V) |

|

|

|

|

|

|

|

|

Cable Length |

Cable Gauge |

Copper Area |

|

(Distribution |

|

|

|

panel to Course Computer) |

|

|

|

|

|

|

|

Up to 5m (16ft) |

8 AWG |

6 mm |

|

|

|

|

|

Up to 7m (23ft) |

6 AWG |

10 mm |

|

|

|

|

|

Up to 16m (52ft) |

4 AWG |

16 mm |

|

|

|

|

|

|

|

81004-02 |

2.Removetheconnectorcoverfromthecoursecomputer.

3.Connectthepowersupplycabletothecoursecomputerpower terminals.

Note: The cable must be protected by a circuit breaker (seetableforsize).

– |

|

|

|

Power |

|

|

|

Supply |

|

|

|

+ |

– + |

– + |

1 2 |

Circuit |

CLUTCH |

POWER |

MOTOR |

breaker |

|

|

|

D882-1

Chapter 2: Installation |

25 |

|

|

|

|

|

|

Drive Unit |

Circuit Breaker Size |

Type 1 |

25 |

|

|

Type 2 (12V) |

40 |

|

|

Type 2 (24V) |

25 |

|

|

Type 3 |

40 |

|

|

Sterndrive |

25 |

|

|

Type CR |

25 |

81004-03

2.2 ST7000/6000 Control Unit

TheST6000andST7000controlunitsareidenticalinoperationand installation.ThemainST7000/6000controlunitshouldbemountedclose to the steering station where it is:

•normally viewed straight on for the best display legibility

•well protected against physical damage

•at least 9in (230mm) from a compass

•at least 20in (500mm) from radio receiving equipment

•accessible from behind to install and run cables

Note: Therearcaseisdesignedtobreathethroughasmallductinthe cable boss to prevent the accumulation of moisture.Direct exposure to the rear of the control unit must be avoided.

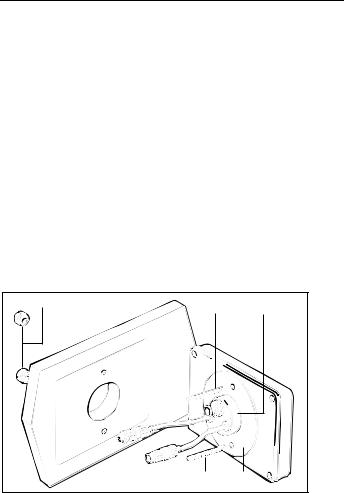

Mounting

3 |

2 |

1 |

2 |

|

4 |

|

|

D746-1 |

1 Cable boss 2 Fixing stud 3 Thumb nut 4 Sealing gasket

26 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

1.Makesurethatthemountingsurfaceissmooth andflat.

2.Use the template provided to mark the centres for the two fixing studs andthecableboss.

Note:Adjacentinstrumentsshouldhave6mm(1/4in)separationtoallow room for the protective covers.

3.Drill two 4mm (5/32in) diameter holes.

4.Using a 50mm (2in) diameter cutter, drill the hole for the cable boss (1).

5.Screw the two fixing studs (2) into the rear case of the control unit.

6.Passthecabletailsthroughthelargeholeandsecurethecontrolunit withthethumbnuts(3)provided.

Note: Thesealinggasket(4),isalreadyattachedtotherearcaseofthe control unit.

Cabling

ThecontrolunitisprovidedwithaSeaTalkcablefittedwitha3pinsocket oneachend.

1.PlugoneendofthecableintooneofthetwoSeaTalksocketsonthe back of the control unit.

2.RuntheSeaTalkcablebacktothecoursecomputer.

Note: Ifmorethanonecontrolunitisfitted,theSeaTalkcablecanbe connected to the free SeaTalk socket on the first control unit.

3.CuttheremainingplugfromtheSeaTalkcableandconnecttothethe SeaTalkterminalsonthecoursecomputer(asshowninthefollowing illustration).

|

|

– |

+ |

– |

+ |

SeaTalk |

SeaTalk CLUTCH |

POWER |

|||

Grey (screen) |

Red |

|

Yellow |

D1012-1 |

|

|

|

|

|

|

|

Chapter 2: Installation |

27 |

|

|

|

|

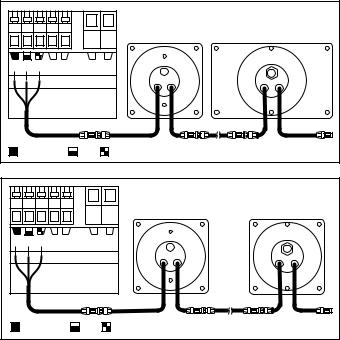

IfthevesselisalreadyfittedwithAutohelminstrumentation,thisshouldbe connectedtothecoursecomputerasshown,usingoneofthestandard SeaTalkinterfacecables.Thecoursecomputerwillthensupplypowerfor thecompletesystem.

|

|

|

ST50 Instrument |

|

ST7000 Control Unit |

|

|

– |

+ |

– |

+ |

+ |

+ |

+ |

+ |

+ |

|

|

|

|

|||

SeaTalk CLUTCH |

POWER |

|

|

|

|

||

|

|

|

+ |

+ |

+ |

+ |

+ |

Grey (screen) |

|

Red |

Yellow |

|

|

|

D1013-1 |

|

|

|

|

|

|

|

|

|

|

|

ST50 Instrument |

ST6000 Control Unit |

|||

– |

+ |

– |

+ |

+ |

+ |

+ |

+ |

+ |

|

|

|

|

|||

SeaTalk CLUTCH |

POWER |

|

|

|

|

||

|

|

|

+ |

+ |

+ |

+ |

+ |

Grey (screen) |

|

Red |

Yellow |

|

|

|

|

|

|

|

|

|

|

|

D1014-1 |

28 |

TYPE 100/300 Operation and Installation Handbook |

|

|

|

|

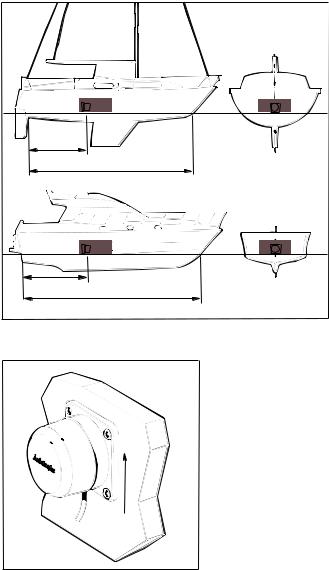

2.3 Fluxgate Compass

Correctpositioningofthefluxgatecompassiscrucialifultimateperformanceistobeachieved.Tominimisegimbaldisturbance,thefluxgate shouldideallybepositionedasnearaspossibletothepitchandrollcentre ofthevessel.

X |

Y |

0.3L to 0.5L

L

X |

Y |

0.3L to 0.5L

L

D194-2

Mounting

Vertical

D193-2

Chapter 2: Installation |

29 |

|

|

|

|

1.Locatethefluxgatecompassonasuitableverticalsurface.

2.Drillfourpilotholesandattachthefluxgatecompassusingtheselftappingscrewsprovided.

3.Makesurethatthefluxgateispositionedatleast0.8m(2ft6in)away fromthevessel’ssteeringcompassinordertoavoiddeviationofboth compasses.Toavoidcompassdeviationandreductioninsensitivity ofthesensor,thefluxgatemustalsobepositionedasfarawayas possiblefromlargeironmasses.

Note: If any doubt exists over magnetic suitability of the chosen site, the positionmaybesurveyedusingasimplehandbearingcompass.Thehand bearingcompassshouldbefixedinthechosenpositionandthevessel swungthrough360degrees.Relativedifferencesinreadingbetweenthe handbearingcompassandthevessel’smainsteeringcompassshould, ideally,notexceed10degreesonanyheading.

Cabling

1.Runthecablebacktothecoursecomputer.

2.Connectthetothefluxgateterminalsonthecoursecomputer.

|

|

FLUXGATE |

JOYSTICK |

|

Grey (screen) |

Red |

Green |

Yellow |

Blue |

|

|

|

|

D890-1 |

Note: A10m(30ft)extensioncableisavailableforlargerinstallations (part no. D174).

Loading...

Loading...