Page 1

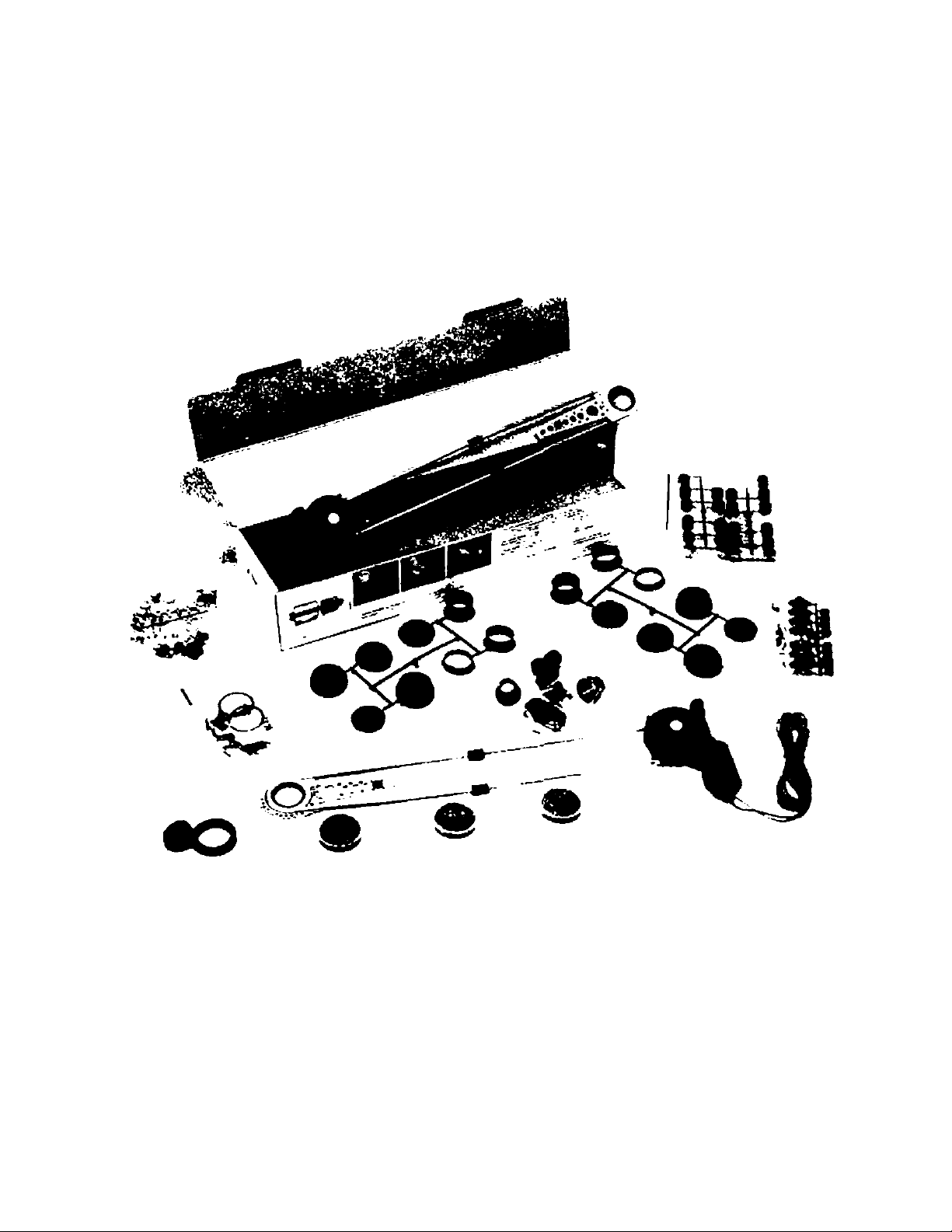

RUDIOUOX

universal power windows

MOUNTING INSTRUCTIONS

DETAILED INSTRUCTIONS FOR

MOUNTING POWER WINDOWS

ON THE U.S. CARS

Page 2

□ ’

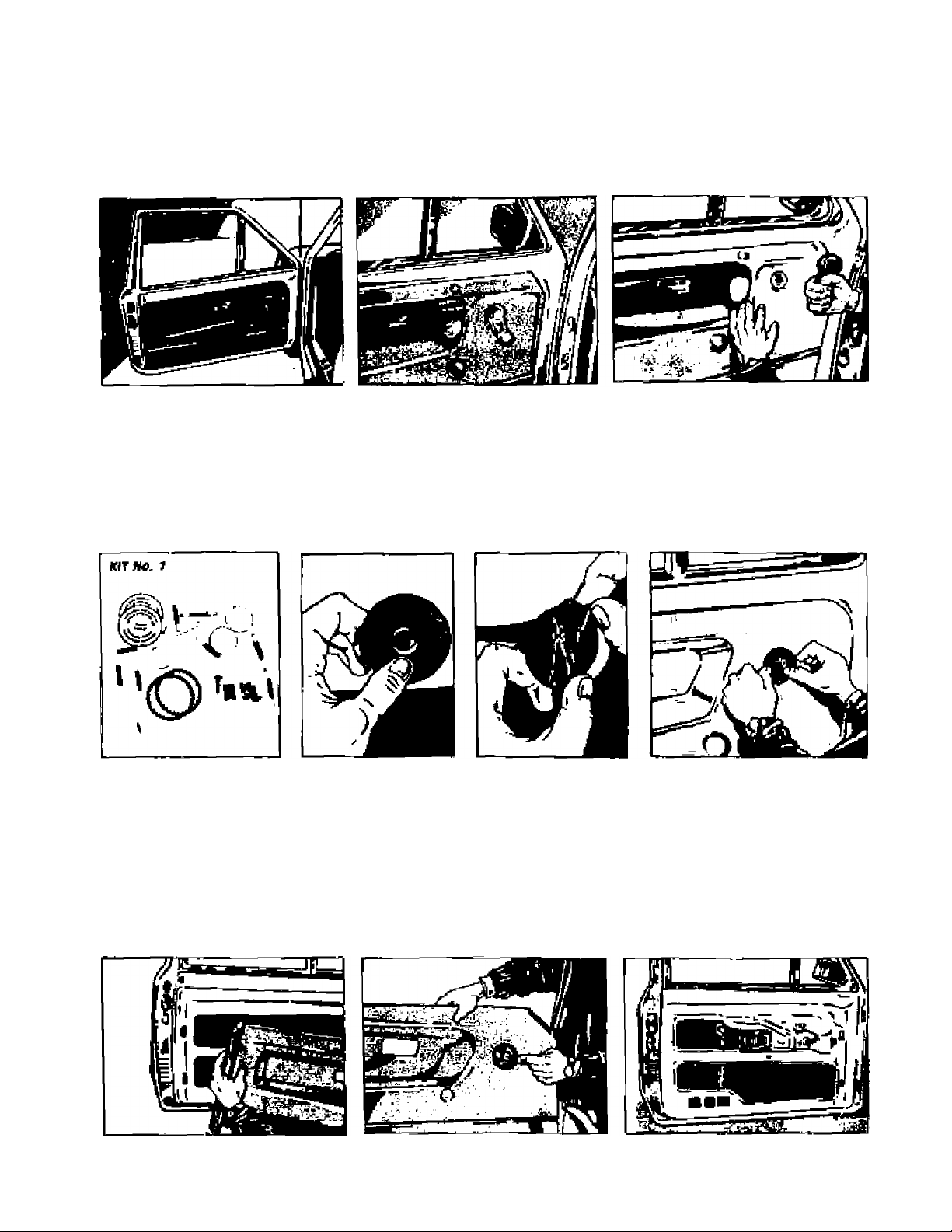

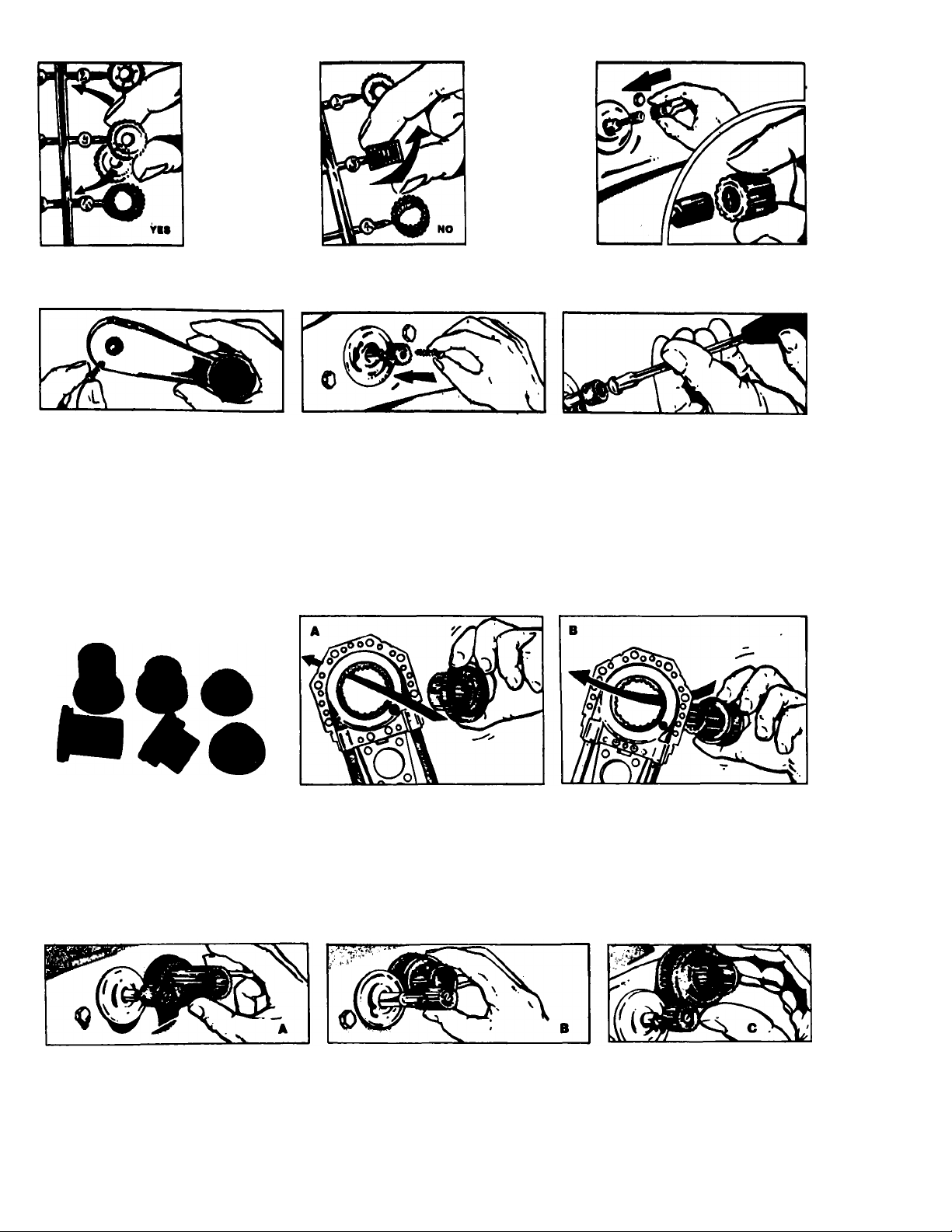

REMOVE HANDLE

FROM WINDOW REGULATOR/PIVOT

g——

APPLY CENTERING ADHESIVE TO THE PANEL

Place adhesive over pivot making sure that it adheres properly to door casing

PANEL DEMOUNTING

Remove door pane!.

f.

sure the centering adhesive is firmly applied to the panel

Page 3

B .

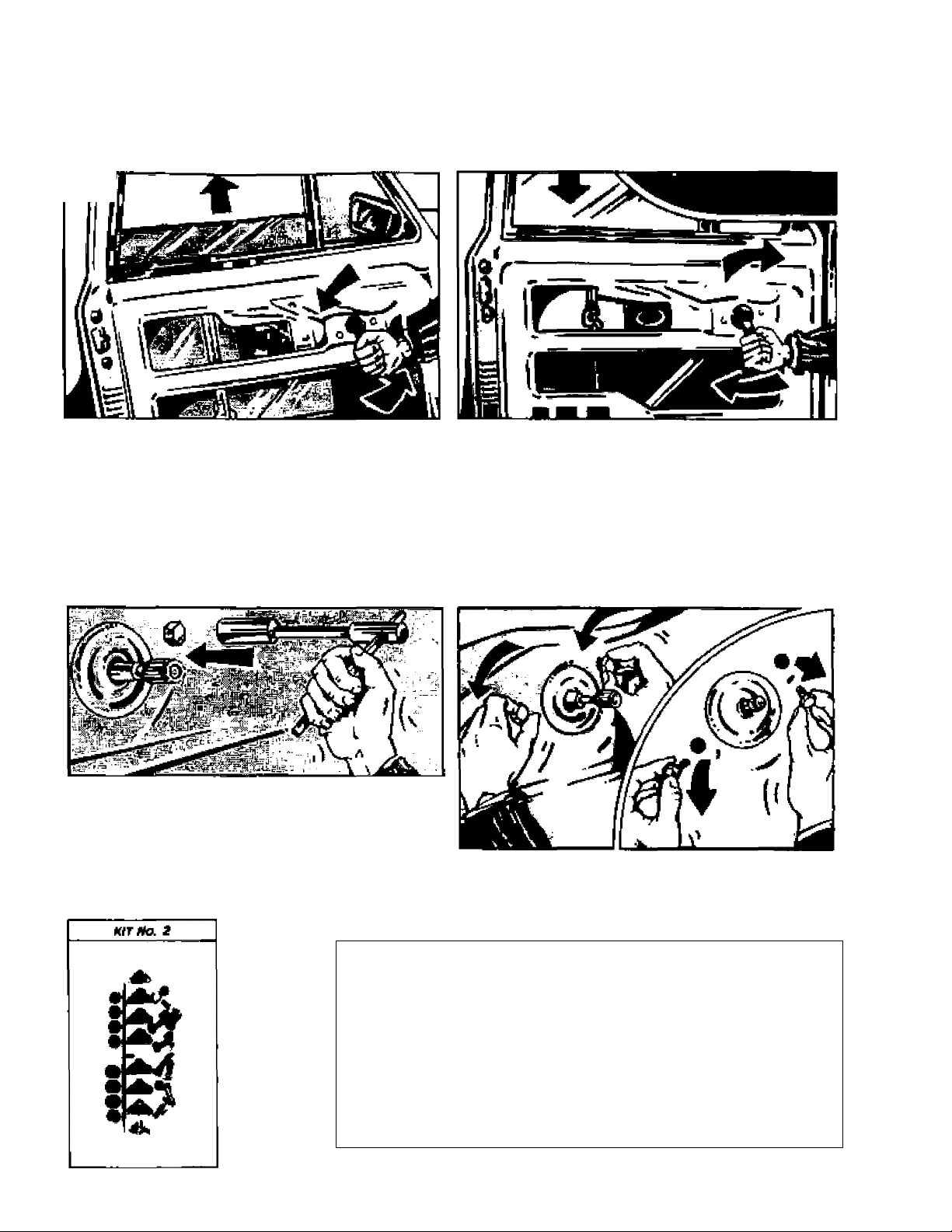

MANUALLY CHECK

THE MOVEMENT OF THE WINDOW

nw

Adjust the registers or guides if the window does not operate freely

0

OPTIONAL OPERATION:

A • IN ORDER TO USE THE SMALLEST CAP ON SOME VEHICLES, IT MAY BE NECESSARY TO

MOVE BACK THE WINDOW REGULATOR ASSEMBLY.

B - AFTER REMOVING ORIGINAL BOLTS FROM THEIR SEATS, REFER TO THE TABLE BELOW

TO CHOOSE SUITABLE SPACERS AND BOLTS (SUPPLIED IN KIT NO.

KIT NO. 2

2).

Trapezoidal spacers h. 5/16"

Trapezoidal spacers h. 3/16” Bolts h. 9/16"

Trapezoidal spacers h. 3/8”

Bolts h. 3/8”

Bolts h. 3/4”

Page 4

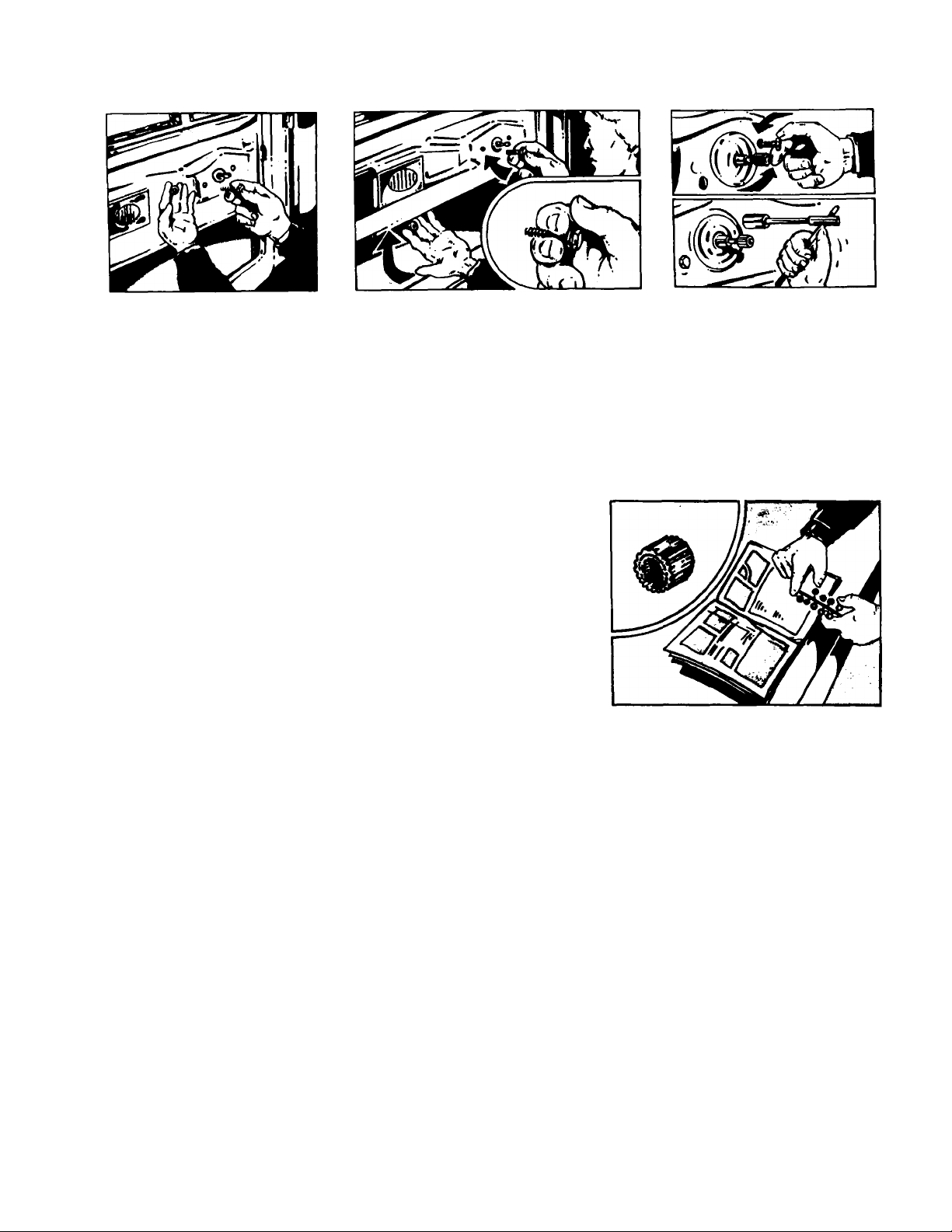

C • INSERT SPACERS BETWEEN MANUAL MECHANISM AND DOOR-PANEL

Check that the bolts of the window assembly are tight

0

FIT ADAPTOR ON REGULATOR PIVOT

iÉÉJtâÂ.

STWTfn

From Kit No. 3, choose the correct adaptor for the model of vehicle. See adaptor Table

below.

Adaptor table (Kit No. 3)

N. 1 ALFA ROMEO - AUTOBIANCHI - BEDFORD - DAF

DATSUN - FIAT - LANCIA - MERCEDES - NISSAN

OPEL - PORSCHE - SUBARU

N. 2 ARO - CITROËN - PEUGEOT - RENAULT - SEAT

TALBOT

N. 3 AUDI - BMW - FIAT - FORD (EUROPE)

PORSCHE - VOLKSWAGEN - VOLVO

N. 4 AUSTIN ROVER

N. 5 VAUXALL - JAGUAR - BEDFORD - ROVER

N. 6 FORD (UK)

N. 7 OPEL

N. 8 DAIHATSU - MITSUBISHI - TOYOTA - SUZUKI

CHEVROLET - G.M.

N. 9 HONDA

N. 10 MAZDA

N. 11 ISUZU

N. 12 FORD (U.S.A.)

N. 13 DODGE - CHRYSLER

Page 5

Take caution in removing adaptor from Kit. Do not twist-off,

If the handle is fixed with a screw, use it to fix the adaptor

0

INSERT GEAR SLEEVE

INTO THE TRANSMISSION

KIT NO. 4

Geared sleeve to be inserted towards inside of vehicle

A) Insertion from the red marked side.

B) Insertion from the opposite side of the red mark.

Gear conversion

A) Wrong: too long.

B) Wrong: too short.

C) Right: length of geared sleeve and pivot are the same.

If a standard is not available for your car, gear H = 37 should be used after cutting it to

match regulator pivot.

Page 6

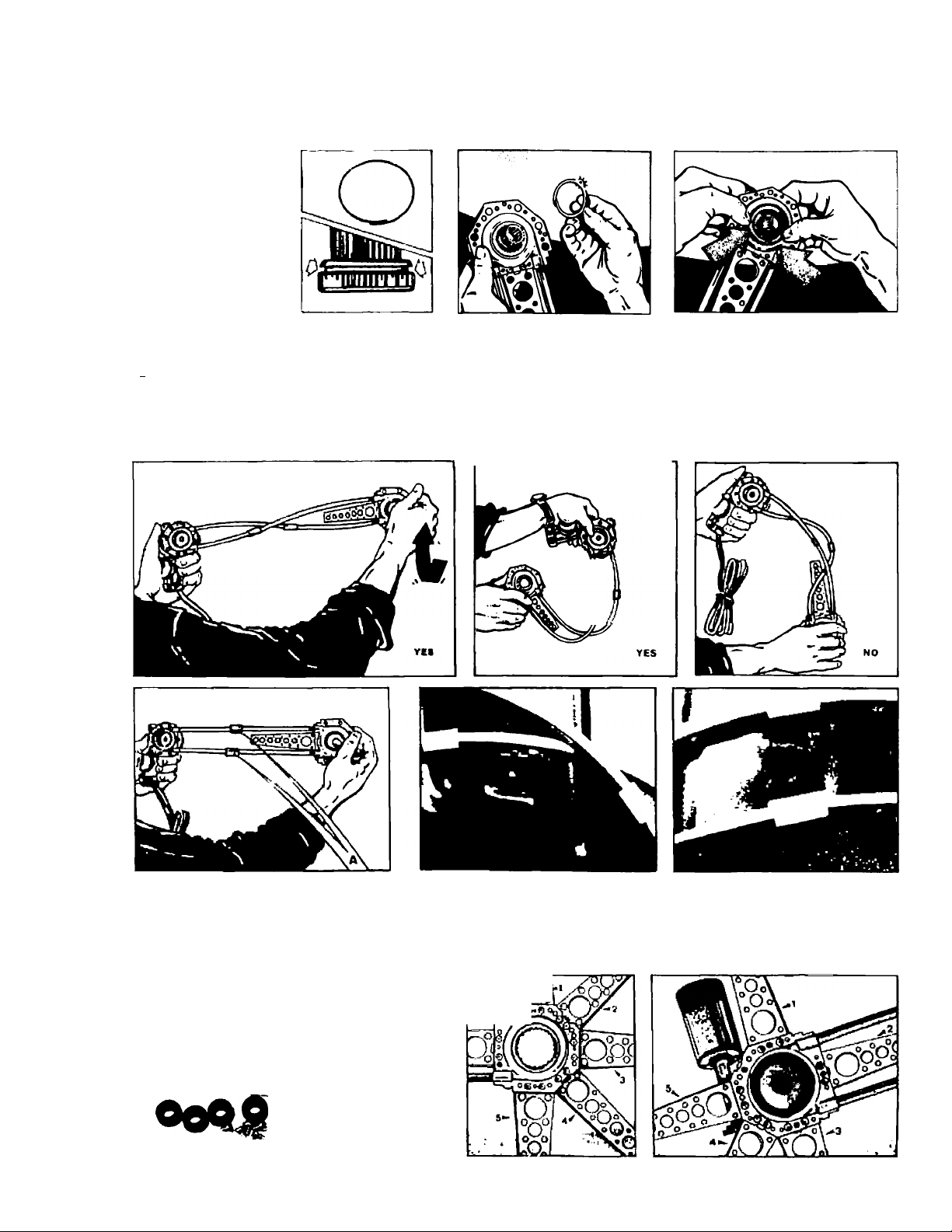

0

SECURE GEAR TO THE TRANSMISSION

WITH CIRCLIP

KIT NO. 1

' Tb^V

'©

(Circlip included in KIT No

0 "

INSTALLATION OF THE ELECTRIC POWER

WINDOW MECHANISM INTO THE DOOR

Fixing or shifting of transmission bracket.

KIT NO. 5

It is possible to mount one or more brackets in pos. 1 2, 3, 4, 5, as shown above 7

Page 7

Motor may be rotated on transmission in order to

faciiitate a secure mount

©

A

A) Remove the screws.

Rotate the geared motor to the required position

C) Retighten the screws in their seats.

FASTENING OF GEARED MOTOR

Drill door panel to hook*up springs.

IMPORTANT:

The power cable for the motor must always be positioned downwards

Fastening of geared motor with brackets

A) Fastening with two brackets,

6) Fastening with brackets and springs.

C) Fasten geared motor behind door panel with one bracket.

Page 8

Fastening of geared motor with springs

Take springs and wire clip out of KIT No 1

1) Spring,

2) Wire c!ip-

Hook up springs and lock hooks

a

APPLY PADDING TO THE GEARED MOTOR

IN CASE THE MOTOR, OR PARTS OP IT, ARE IN DIRECT CONTACT WITH ANY

METAL PARTS, THE SUPPLIED PADDING SHOULD BE USED AS SHOWN BELOW.

SS -

Page 9

POSITION AND FIX BRACKET

Position the bracket without forcing the transmission

Fasten bracket through one of the holes (Use the outer ones, where possible).

1) Internal metal bushing

2) External rubber bushing

Drill 7/64” holes to fasten bracket

1) Screw

2) Speed nut.

10

Page 10

LOCK ADAPTOR AND GEAR SLEEVE

Insert the screw in the space between the adaptor and the gear sleeve

CUT DOOR PANEL WITH SPECIAL CUTTER

DOOR PANEL CUTTER TOOL SUPPLIED UPON REQUEST

0

mm]

Center the cutter with the adhesive Tighten with a wrench until the cutter comes free

Remove any remaining adhesive.

To clean out the cutter, do as shown above

t

I

Page 11

FIX GROMMET WITH RETAINER RING

|g

Mo, 1 No. 3

No. 1 Smalt,

No. 2 Medium

No, 3 Larg

NO. 3

The grommet cap locks to panel by means of a

retainer ring

The grommet has to come through the door casing at least 5/32 in order to be locked

with the retainer ring.

To choose the proper grommet cap. follow this procedure:

— Insert grommet cap no. 1 (SMALL) into the panel, if it does not come through, try

no P (MEDIUM) and then, if necessary, no. 3 (LARGE) ’

NO. 1

10 MAJC

5/32"

Na. 1

A) No. 1 SMALL (wrong; too short).

NO 1

V»!

No. 2 MEDIUM (wrong: too short)

No. 3 LARGE (yes),

B) if the door casing is less tham 5/32" thick a perfect tit between cap and grommet can

be obtained by inserting a sponge from the rear of the door casing.

1?

Page 12

UNIVERSAL ELECTRIC WINDOWS

WITHOUT CLUTCH

ART.5S000013

0

FIT CAP ON DOOR PANEL

Fii Ihe Cap on the grommel and fit the panel on the door

NOTE!

A t B

% ^

Ho. &

When the regulator pivot does not come out from the pane! (photo A and B) you can use

cap No. 0 tor a better appearance.

__

Q_

^ n

^ n

L0_

Page 13

INSTALLATION EXAMPLE FOR ELECTRIC POWER WINDOWS * \

IN SOME CARS IN THE U.S.

BUICK CENTURY (4 Doors) front iefl

— in&sri gaar H 15 (insert trcjm red marked side)

— aclapter Me. 9

— turn tranernission aids of geared motor towards inside of car

— affix geared motor wilh springs

— grommet No, T

— cap No. 1

BUICK CENTURY (4 Doors} rear righi

” adjust bracket on transmission shortened 1“

— Ir^&erl gear H 16 finsert from red marked side)

— adapter No. 9

— turn IransmissiDn side of geared motor lowards inside of car

— affix geared motor wlh plastic lasiener

™ grommet No. 1

— cap No. 1

CHEVROLET FULL SIZE mod. ’66 front left

— insert gear H 15 (nnserl from red marked side)

^ adapl« No. 9

— turn transmission side of geared motor towards inside of car

— afllx geared motor with springs

— grommet No. 1

— cap No. 1

14

FORD MUSTANG troni righi

— adjust bracket on transmission

^ insert gear H 16 (insert from red marked side)

— adaplot No. 12

— apply paddings to geared motor

— turn transrriFssioii side of geared motur towards Inside of car

— affix geared motor with two brackets

— gnommet No. 1

— cap Ng. 1

Page 14

FORD TEMPO front right

— adjust bracket on transmission

— rotate geared motor 180° on transmission

— insert gear H 15 (insert from red marked side)

— adaptor No. 12

— apply paddings to geared motor

— turn transmission side of geared motor towards inside of car

— affix geared motor with bracket shortened 2.2”

— grommet No. 1

— cap No. 1

HONDA ACCORD front right

— adjust bracket on transmission

— insert gear H 15 (insert from red marked side)

— adaptor No. 9

— apply paddings to geared motor

— turn transmission side of geared motor towards inside of car

— affix geared motor with plastic fastener '

— grommet No. 1

— cap No. 2

* Bend door panel in area where cables cross. Affix cables to

door panel with plastic fastener.

* Care should be taken to not damage the geared motor with

door stopper

HONDA CIVIC CRX front right

— adjust bracket on transmission

— rotate geared motor 90° on transmission

— insert gear H 15 (insert from red marked side)

— adaptor No. 9

— apply paddings to grill of geared motor

— turn transmission side of geared motor towards inside of car

— affix geared motor with bracket (affix support arm screw)

— grommet No. 1

— cap No. 1

MAZDA 626 4 Doors (U.S.) mod. ’89 front right

— adjust bracket on transmission shortened 1"

— rotate geared motor 90° on transmission

— insert gear H 15 (insert from red marked side)

— adaptor No. 10

— turn transmission side of geared motor towards inside of car

— affix geared motor with two brackets after having shortened

one off 1”

— grommet No. 1

— cap No. 1

15

Page 15

MAZDA 626 4 Doors (U.S.) mod. ’89 rear nghi

—> adjust bracket on transmission and bend appropriately

— insert gear H 15 (insert from red marked side)

— adaptor No. to

— apply paddings to geared motor

— turn transmission side o( geared motor towards inside ott car

— affix geared motor vnth bracket shortened i "

— grommet No. t

— cap No. 1

PONTIAC 6000 from right

— insert gear H 37 (insert from red marked side)

— adaptor No 8

— turn transmission side o( geared motor towards inside ot car

— affix geared motor with Iwo brackets

— grommet No 1

— cap No t

PONTIAC 6000 rear right

— shorten bracket on transmission 6"

—> insert gear H 15 (insert from red marked side)

~ adaptor No. 8

— apply paddings to geared motor

— turn transmission side of geared motor towards inside of car

— affix geared motor with two bracket shortened 2.2"

— grommet No. t

— cap No, 1

PONTIAC GRAN PRIX front left

— adiusi bracket on iransniission and add a r\ew one

— insert gear H 25 (insert from red marked side)

— adaptor No. 8

^ apply paddings to geared motor

^ turn grill Side of geared motor towards inside of car

— affix geared motor with bracket shortened 2.2"

— grommet No. t

— cap No 1

Page 16

CHEVnOLET/QMC S-10/15 PJCKUP rront left

— shorlftn bratkQi on trarsmisBioo 1.6"

— gaor H 15 (insart from rad marked side)

— edaplor No. B

— apply paddings to geared motor

— lufo transmission side of geared motor towards inside of tar

— atfl* geared mo(oi with two brackets

— grommai No. 1 (may need To use with 2.9" plastit round

washer)

— cap No. 1

DODQE CARAVAN front left

— shorten bracket on iransmiaaion 1.6"

— rpiBla geared motor 9D* on transmisaion

— Inesrt gear H 1S flnsari from rod marked side)

— adaptor No. 13

— lorn trarsmiaslon side of geared motor towards inside of oar

— etfia geared motor with two brackata shodened 2.2"

— grommet No 1

— oap No. 1

FORD AEROSTAR front left

— adiLdsi bracket on transmission

— Insert gear H 15 (irisert from red marked side)

— adaptor No 12

^ turn transmission side of geared motor towards inside of car

— atfi* geared motor with two brackets

— grorrifflot No. t

— cap No. 1

FORD RANGER mod. front right

— insert gear H 15 (insert (tom rad marked side)

— adaptor No. 1E

— turn transmission side Of geared motor towards

— affiiK geared motor with two brackets alter having sboriened

one off 1"

— grommet iMo. i

— cap No. 1

Page 17

ISU2U PICKUP front left

— rotate geared motor 90* on transmission

— Insert gear H 15 (insert from c^posito side ot red marked side)

^ adaptor No. i

— apply paddings to geared motoc

— turn grill side of geared motor towards inside ol cat

— affix geared motor with bracket

— grommet No. i

— cap No. 1

SWITCH CONNECTION DIAGRAMS

NOTE! Make sure that the seats where the switches are housed are not narrow in order

to avoid malfunctions, jamming or are not too tight causing damage to the motor

Whenever possible, use the TEMPLATE set with the KIT

Ligtitod swiicn witn 6 coniacrs

Ek ah 1740004S<1B49^5051-52

motor

1

i 1

♦

♦ noni

-L-L

motor

LtQniea swiicn with 6 coniacis

Switcri w<h 6 contdcts wtfh faght separated

Ex AH 17JI0004754

bttCk.bn.« n>

1 i^d

b'Unn

r

-1|

—Ihidt.k.bive

, I

ia

Page 18

ELECTRICAL WIRING DIAGRAMS

Listed here are wiring diagrams of typical installations for the Electric window

kits using the wiring kits.

NOTE! For safety reasons it is necessary that the power supply to the windows be con

nected to the appropriate terminal of the ignition side of the ignition relay block.

It is recommended that onty wiring kits be used. Whenever this is not possi

ble, proper wiring of at least 16 AWG must be used with the suitable in-line fuse.

assumes no liability in case of non-compliance with the above mentioned note.

□ .

ELECTRICAL CIRCUIT: 2 SWITCH WITH 6 CONTACTS AND SEPARATE LICHT

* Use original wiring, Art. 33020009 complete with 25 Amp. fuse.

r ust »

Page 19

□* ~

ELECTRICAL CIRCUIT: 3 SWITCH WITH 6 CONTACTS AND SEPARATE LIGHT

* Use original wiring. Art 33020010 complete with 25 Amp, fuse.

FUSE it

Page 20

ga£iZKl$3L^'

ZI

Loading...

Loading...