Audi AMB Service Manual

cardiagn.com

2005 Audi A4 Quattro

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

00 - GENERAL, TECHNICAL DATA

TECHNICAL DATA

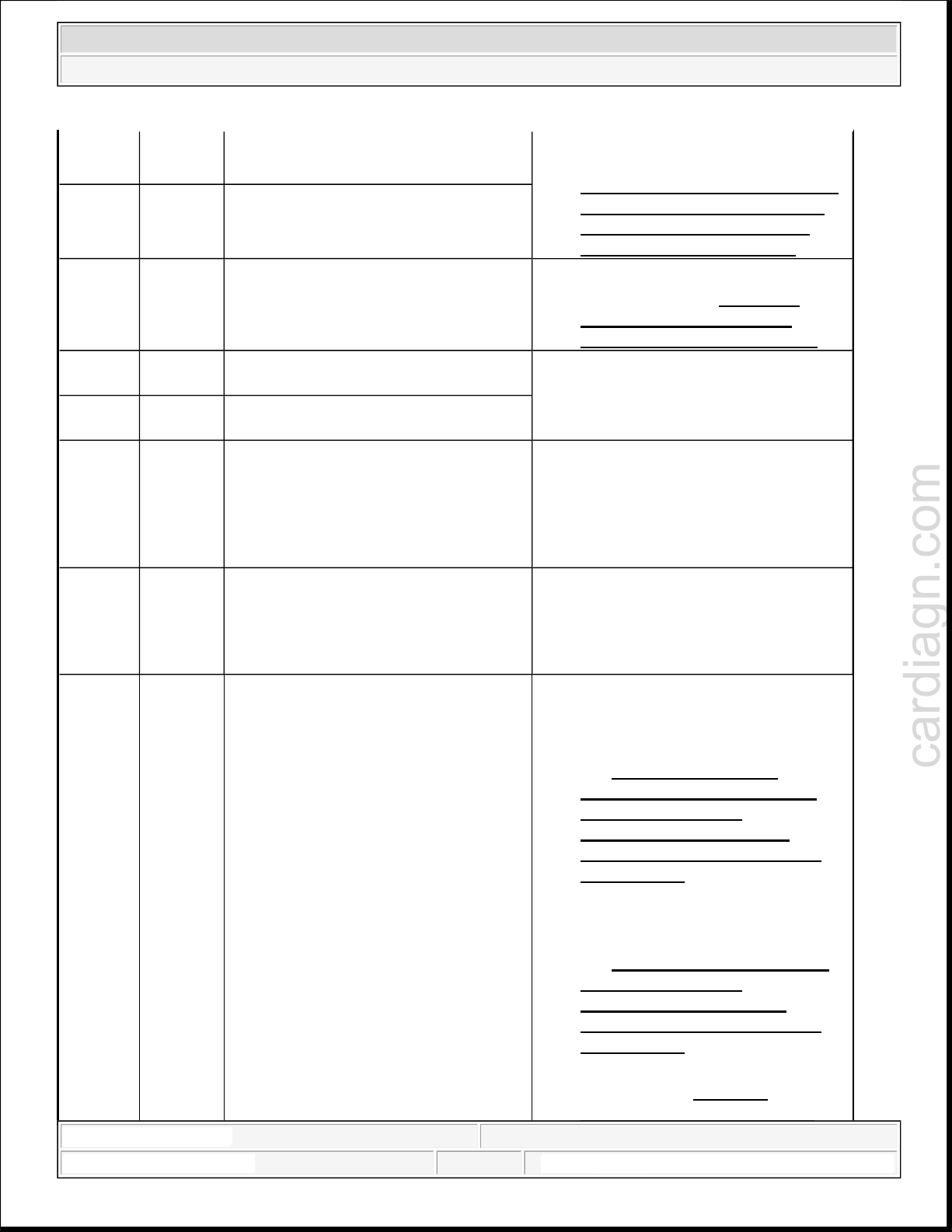

Engine number

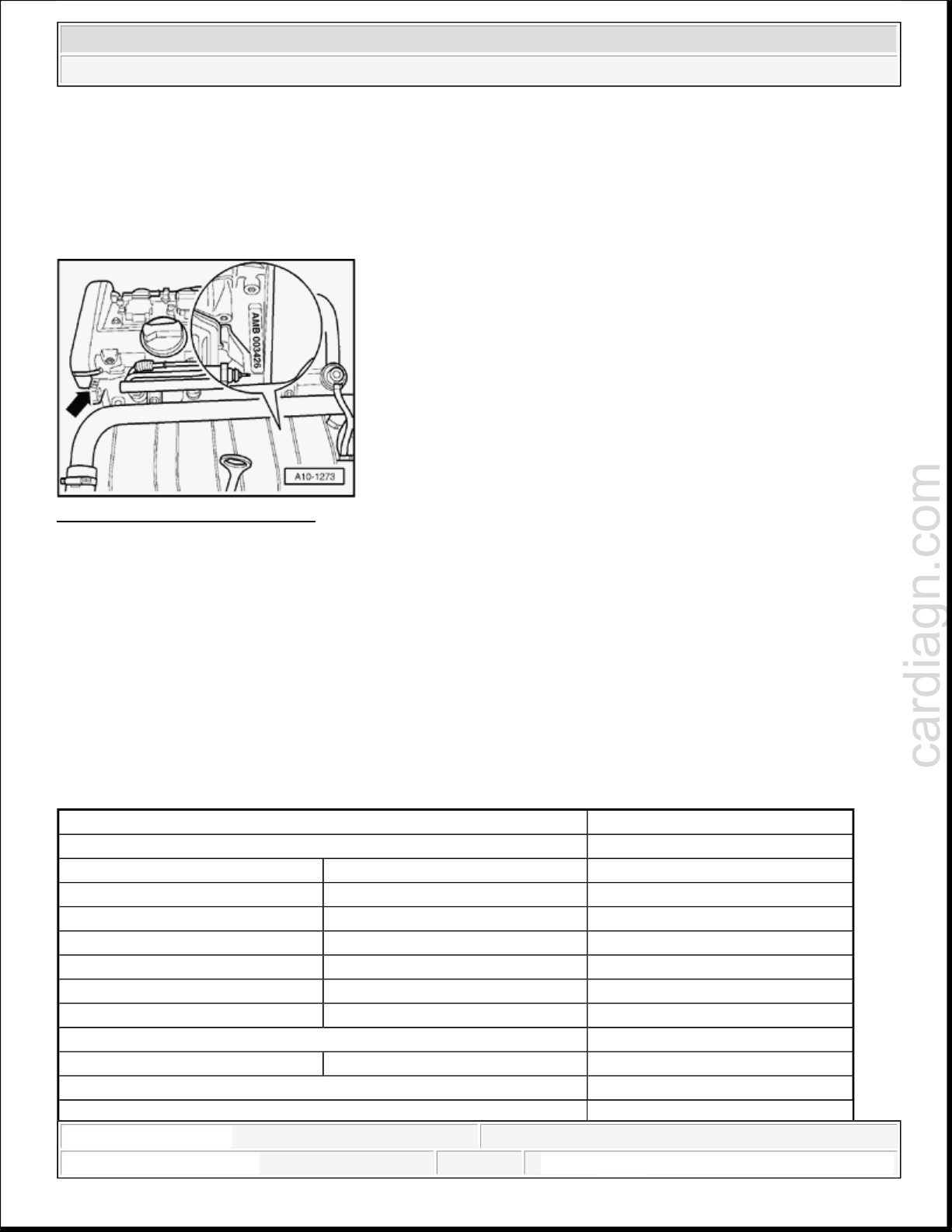

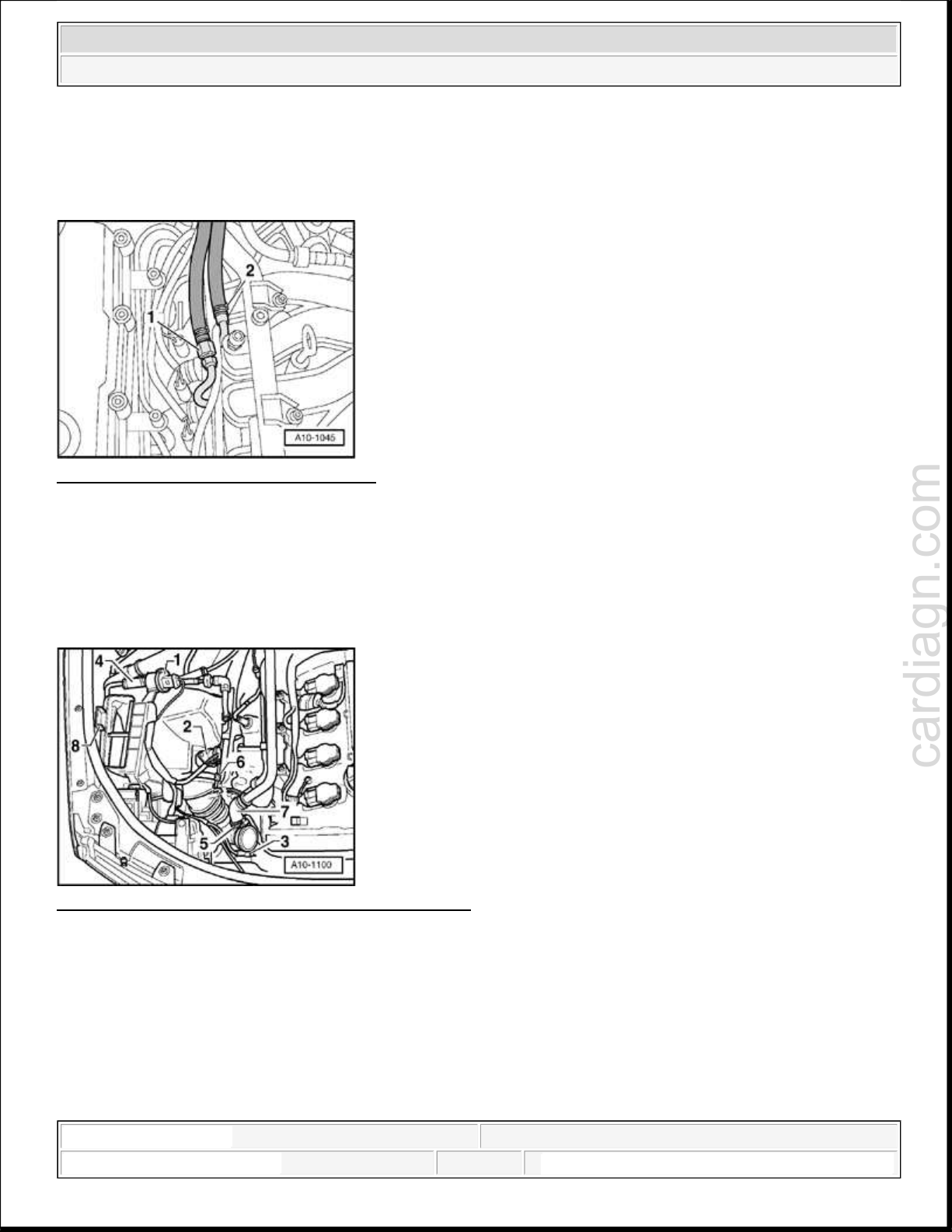

Fig. 1: Locating Engine Number

Courtesy of VOLKSWAGEN UNITED STATES, INC.

The engine number ( "Engine code" and "Serial number" ) can be found on the rear left of the cylinder block.

Additionally there is a sticker on the toothed belt guard giving the "Engine code" and "Serial number".

The engine code is also given on the vehicle data sticker.

NOTE:

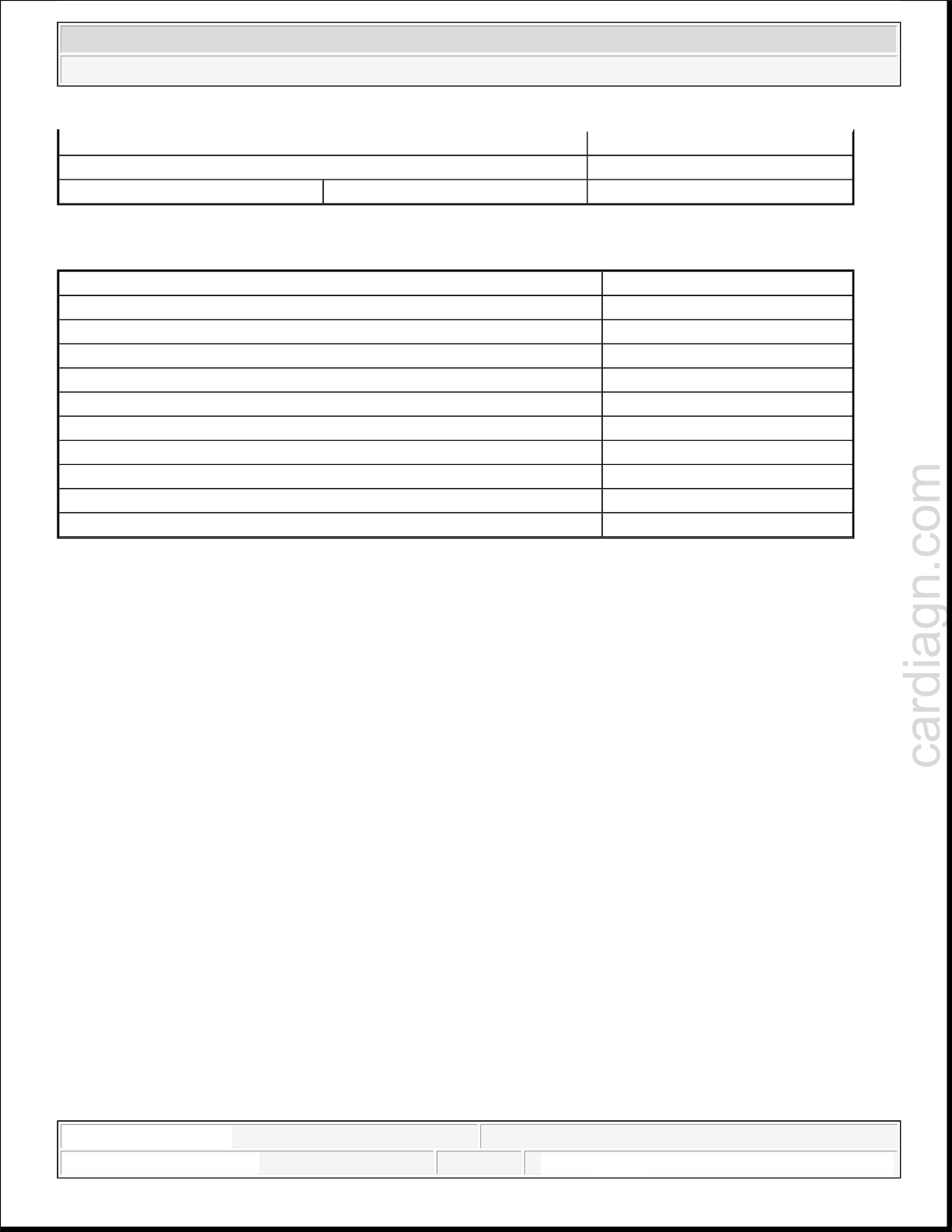

Engine data

Engine code AMB

Manufactured 08.01 -->

Capacity l 1.781

Power kW at RPM 125/5700

Torque Nm at RPM 210/1750 to 4600

Bore diameter mm 81.0

Stroke mm 86.4

Compression ratio 9.5

RON 95 * See note

Injection/ignition system Bosch Motronic

Knock control yes

On Board Diagnostic yes

The engine code is also stamped on the front lifting eye (visible when

engine cover panel is removed).

2:39:49 AM Page 1

2:39:52 AM Page 1

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Oxygen sensor control yes

Catalytic converter yes

Charging yes

*Standard unleaded RON 91 also permitted, however reduced power.

Engine code AMB

Exhaust gas recirculation no

Intake manifold change-over function no

Camshaft timing control yes

Secondary air system yes

Valve timing

at 1 mm valve lift and 0 mm valve clearance

Intake opens after TDC 18 °

Intake closes after BDC 28 °

Exhaust opens before BDC 28 °

Exhaust closes before TDC 8 °

2:39:49 AM Page 2

DTC INDEX

Bank 1, camshaft retardation adjustment

BEHIND

oxygen sensor control behind Three

2005 Audi A4 Quattro

cardiagn.com

2005 Audi A4 Quattro

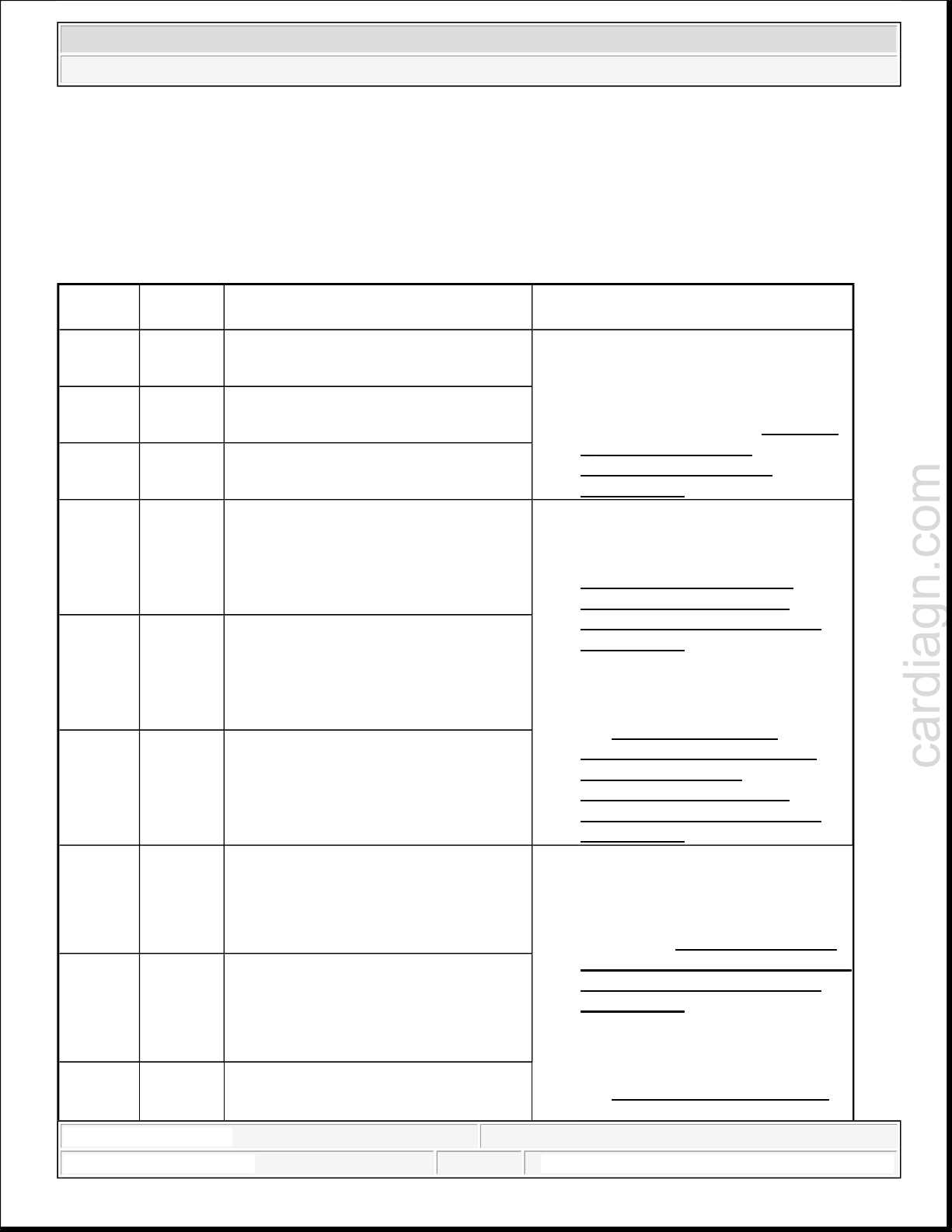

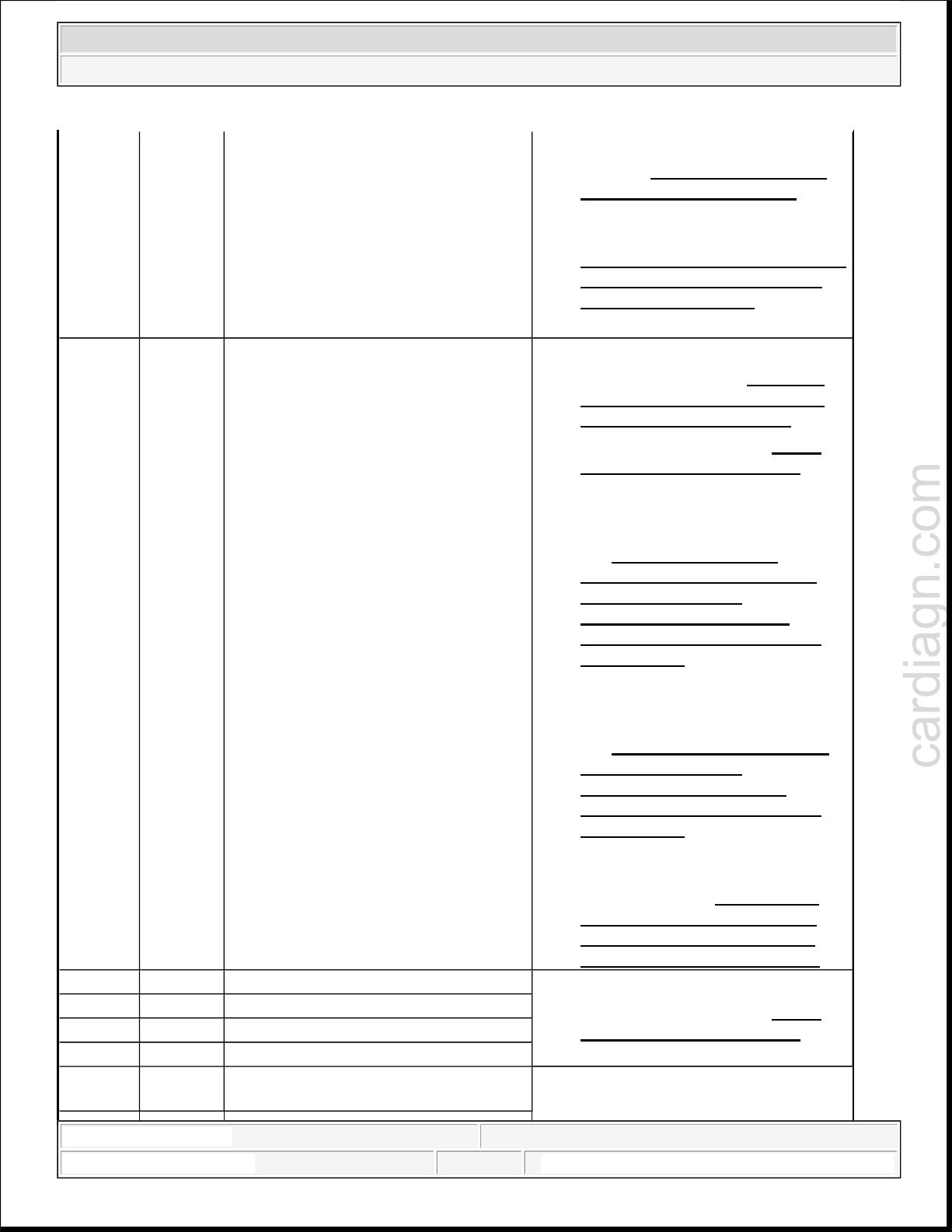

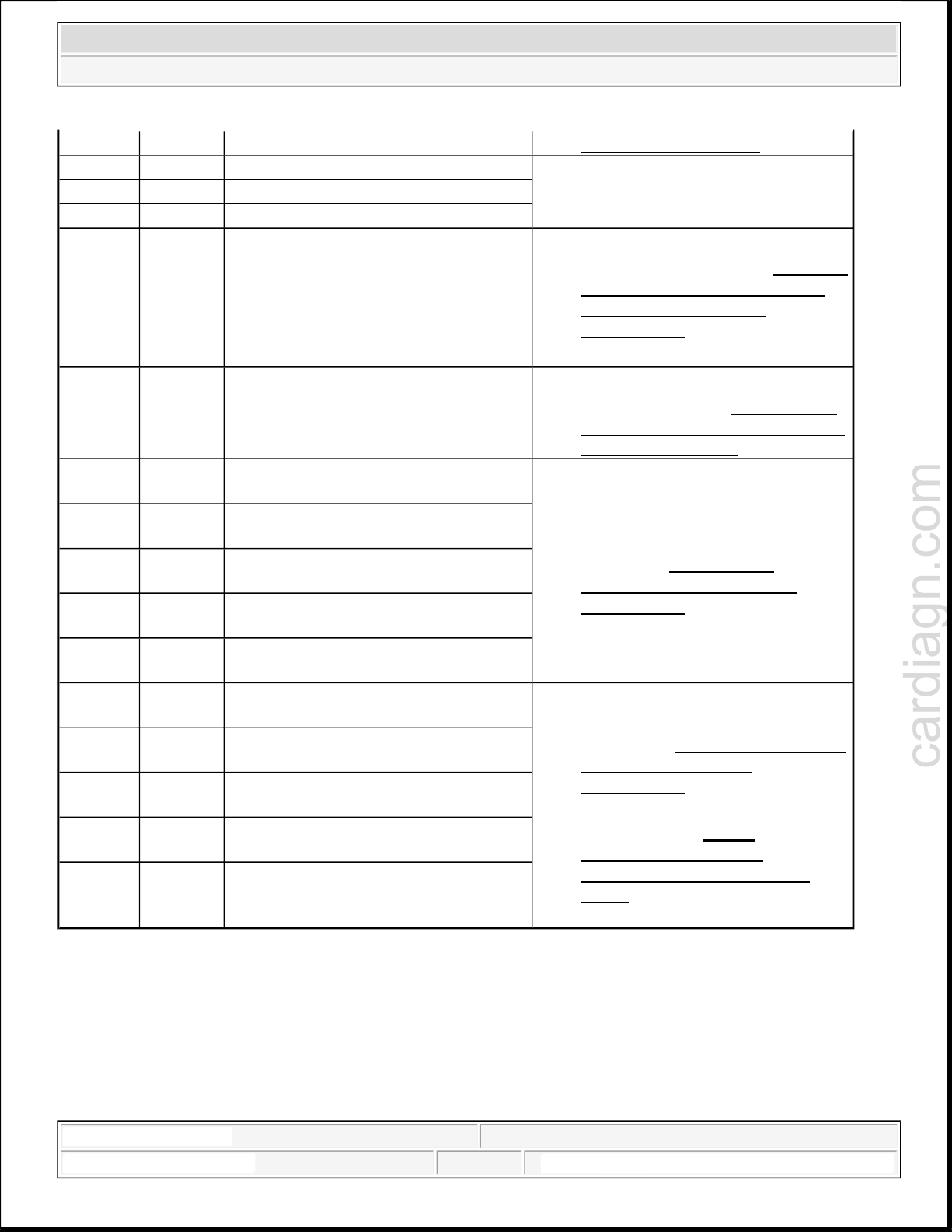

DTC INDEX DTC Index - 1.8L (AMB Engine)

DTC INDEX DTC Index - 1.8L (AMB Engine)

DTC Index - 1.8L (AMB Engine)

D

IAGNOSTIC TROUBLE CODES (DTC) INDEX

DTC Index - 1.8L (AMB Engine)

SAE

C

ode

VAG

C

ode

Code Description Corrective Action

Bank 1, Camshaft adjustment

P0010 16394

m

alfunction

Camshafts and camshaft adjuster

r

emoving and installing

P0011 16395

P0012 16396

P0030 16414

P0031 16415

P0032 16416

P0036 16420

P0037 16421

Specification not reached

Bank 1, camshaft advance adjustment

S

pecification not reached

HO2S Heater Control Circuit, Bank 1

S

ensor 1

HO2S Heater Control Circuit Low,

B

ank 1 Sensor 1

HO2S Heater Control Circuit High,

B

ank 1 Sensor 1

HO2S Heater Control Circuit Bank, 1

S

ensor 2

HO2S Heater Control Circuit Low,

B

ank 1 Sensor 2

Check Valve -1- for camshaft

adjustment -N205-. See VALVE

1- FOR CAMSHAFT

ADJUSTMENT -N205-,

CHECKING .

C

heck oxygen sensor heater for

oxygen sensors before Three Way

Catalytic Converter (TWC). See

OXYGEN SENSOR (O2S)

HEATER -Z19- BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

oxygen sensor control before Three

Way Catalytic Converter (TWC).

See HEATED OXYGEN

SENSOR (HO2S) -G39- AND

OXYGEN SENSOR

REGULATION BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck oxygen sensor heater for

Oxygen Sensors (O2S) behind

Three Way Catalytic Converter

(TWC). See OXYGEN SENSOR

(O2S) HEATER 1 -Z29CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

-

HO2S Heater Control Circuit High,

Bank 1 Sensor 2

11:32:47 PM Page 1

11:32:51 PM Page 1

Way Catalytic Converter (TWC).

See OXYGEN SENSORS AND

OXYGEN SENSOR

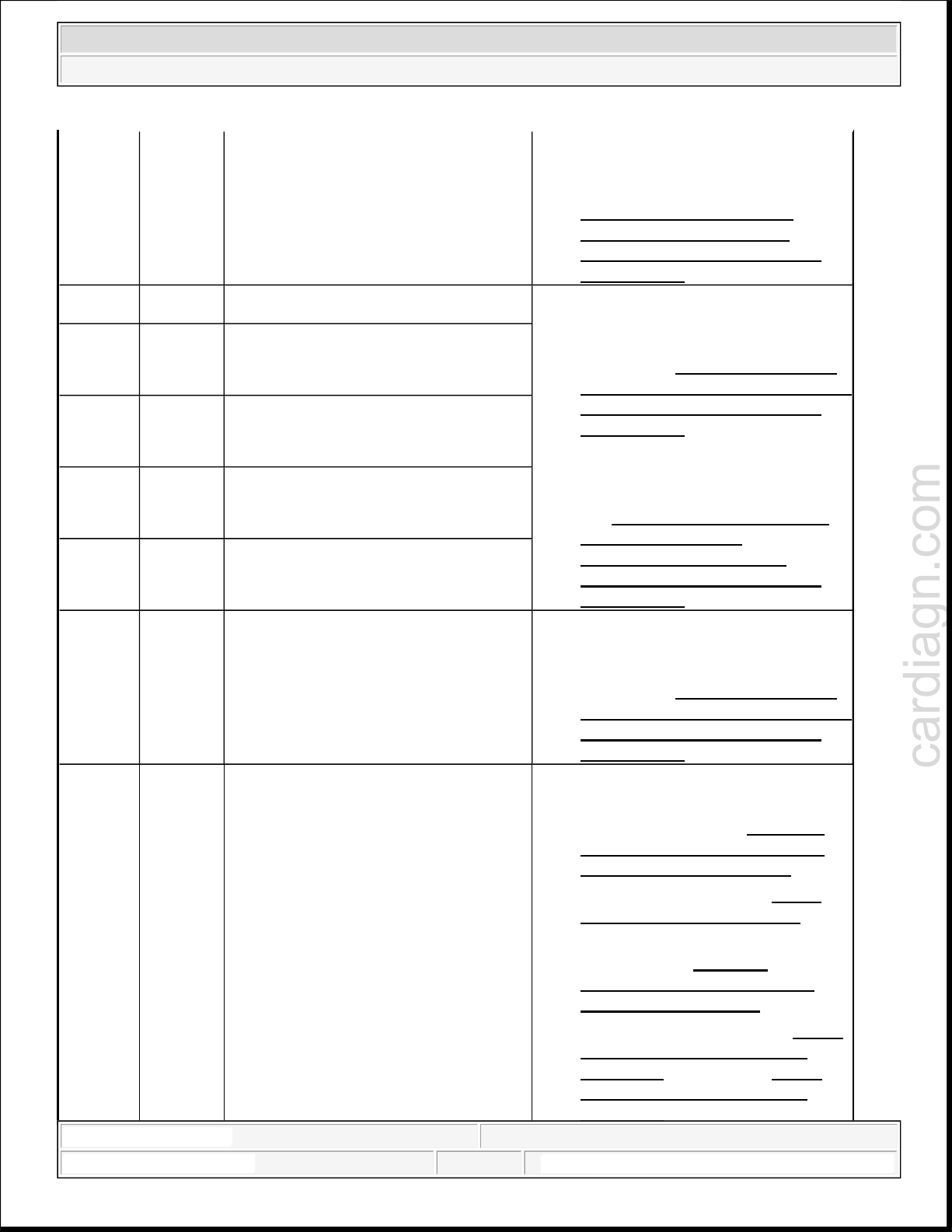

P0038 16422

Check Engine Coolant Temperature

O2 Sensor Circuit Slow Response, Bank

cardiagn.com

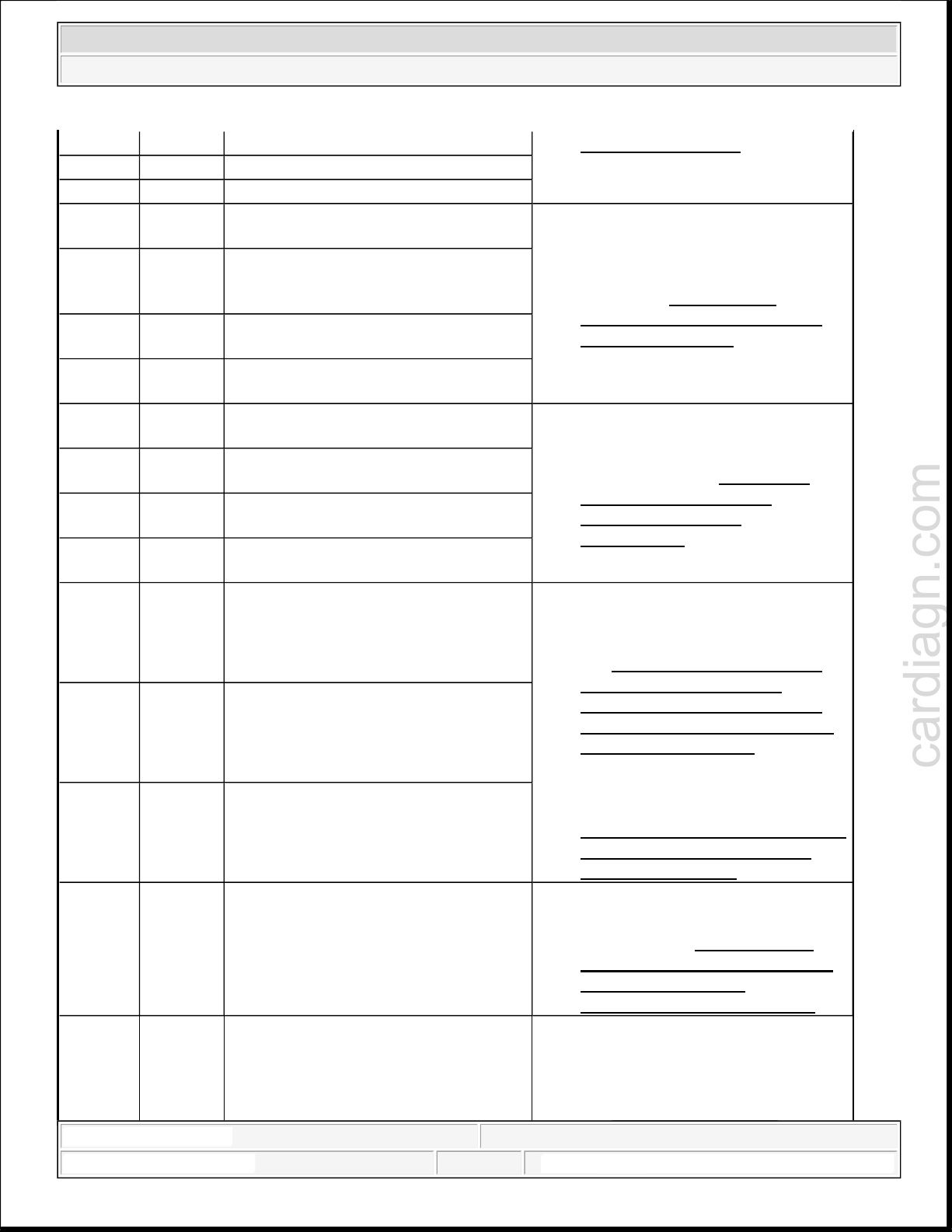

P0101 16485

P0102 16486

P0103 16487

P0106 16490

P0116 16500

P0117 16501

P0118 16502

P0121 16505

P0122 16506

P0123 16507

P0130 16514

P0133 16517

2005 Audi A4 Quattro

DTC INDEX DTC Index - 1.8L (AMB Engine)

Mass or Volume Air Flow Circuit

R

ange/Performance

Mass or Volume Air Flow Circuit Low

I

nput

Mass or Volume Air Flow Circuit High

I

nput

Manifold Absolute Pressure/Barometric

P

ressure Circuit Range/Performance

Engine Coolant Temperature Circuit

R

ange/Performance

Engine Coolant Temperature Circuit

L

ow

Engine Coolant Temperature Circuit

H

igh

Throttle/Pedal Position Sensor/Switch

"

A" Circuit Range/Performance

Throttle/Pedal Position Sensor/Switch

"

A" Circuit Low

Throttle/Pedal Position Sensor/Switch

"

A" Circuit High

O2 Sensor Circuit, Bank 1 Sensor 1

1 Sensor 1

O2 Sensor Heater Circuit, Bank 1

REGULATION BEHIND

CATALYTIC CONVERTER,

CHECKING .

C

heck Mass Air Flow (MAF)

Sensor -G70-. See MASS AIR

FLOW (MAF) SENSOR -G70-,

CHECKING .

C

heck intake air system for leaks

(false air). See INTAKE

SYSTEM, CHECKING FOR

LEAKS (FALSE AIR) .

S

ee appropriate SYSTEM WIRING

DIAGRAMS article.

Note

(ECT) Sensor -G62-. See E

COOLANT TEMPERATURE

(ECT) SENSOR -G62-,

CHECKING .

C

heck Throttle Valve Control

Module -J338-. See THROTTLE

VALVE CONTROL MODULE J338-, CHECKING .

C

heck oxygen sensor heater for

oxygen sensors before Three Way

Catalytic Converter (TWC). See

OXYGEN SENSOR (O2S)

HEATER -Z19- BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

oxygen sensor control before Three

Way Catalytic Converter (TWC).

See HEATED OXYGEN

SENSOR (HO2S) -G39- AND

OXYGEN SENSOR

REGULATION BEFORE

CATALYTIC CONVERTER,

CHECKING .

NGINE

11:32:48 PM Page 2

BEHIND

oxygen sensor control behind Three

O2 Sensor Circuit High Voltage, Bank 1

O2 Sensor Circuit Slow Response, Bank

O2 Sensor Circuit No Activity Detected,

BEHIND

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

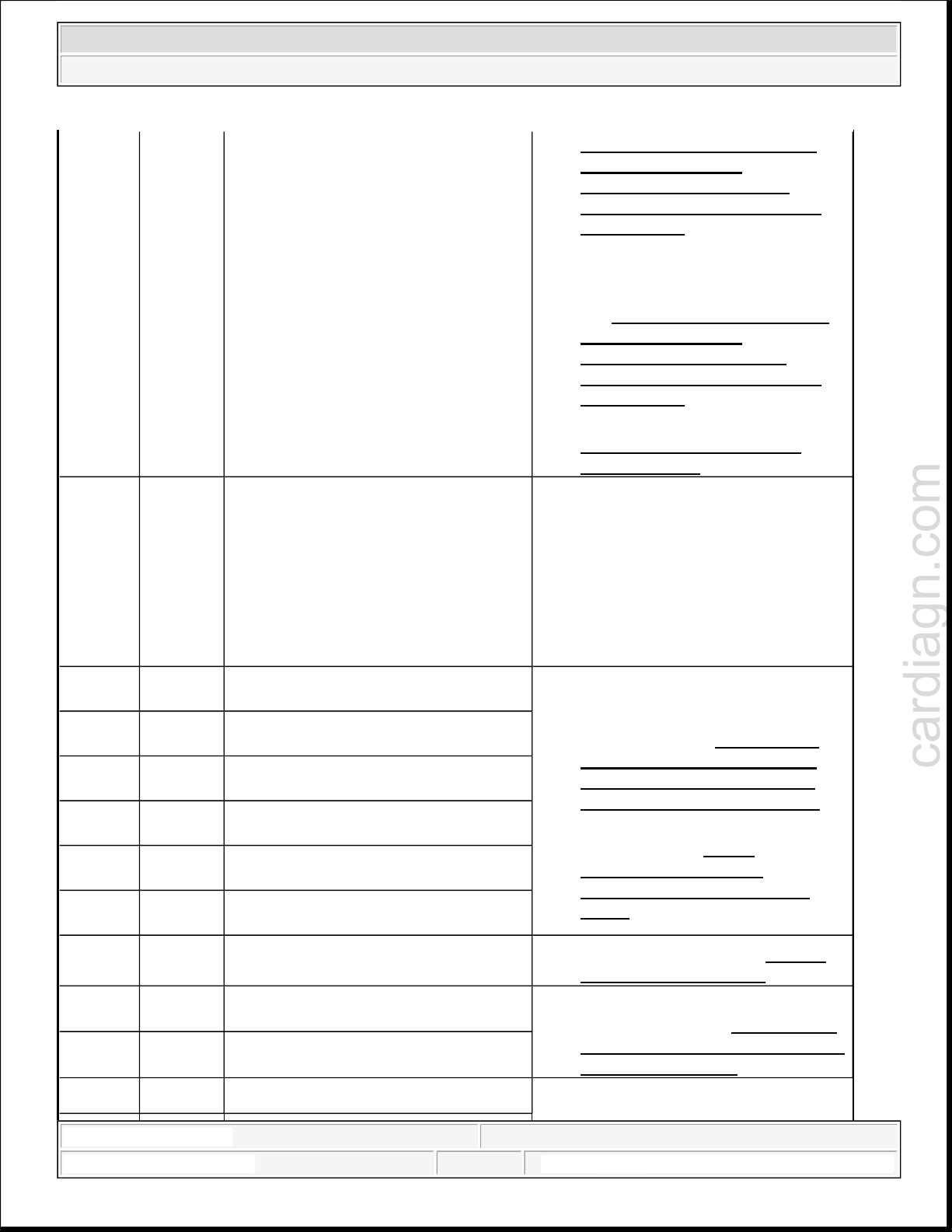

P0135 16519

P0136 16520

P0137 16521

P0138 16522

P0139 16523

P0140 16524

P0141 16525

Sensor 1

O2 Sensor Circuit, Bank 1 Sensor 2

O2 Sensor Circuit Low Voltage, Bank 1

S

ensor 2

Sensor 2

1 Sensor 2

Bank 1 Sensor 2

O2 Sensor Heater Circuit, Bank 1

S

ensor 2

System Too Lean, Bank 1

C

heck oxygen sensor heater for

oxygen sensors before Three Way

Catalytic Converter (TWC). See

OXYGEN SENSOR (O2S)

HEATER -Z19- BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck oxygen sensor heater for

Oxygen Sensors (O2S) behind

Three Way Catalytic Converter

(TWC). See OXYGEN SENSOR

(O2S) HEATER 1 -Z29CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

Way Catalytic Converter (TWC).

S

ee OXYGEN SENSORS AND

OXYGEN SENSOR

REGULATION BEHIND

CATALYTIC CONVERTER,

CHECKING .

C

heck oxygen sensor heater for

Oxygen Sensors (O2S) behind

Three Way Catalytic Converter

(TWC). See OXYGEN SENSOR

(O2S) HEATER 1 -Z29CATALYTIC CONVERTER,

CHECKING .

P0171 16555

11:32:48 PM Page 3

C

heck fuel pressure regulator and

residual pressure. See SYSTEM

PRESSURE AND RESIDUAL

PRESSURE, CHECKING .

C

heck fuel injectors. See FUEL

INJECTORS, CHECKING .

C

heck intake air system for leaks

(false air). See INTAKE

SYSTEM, CHECKING FOR

LEAKS (FALSE AIR) .

C

heck Fuel Pump (FP). See FUEL

PUMP (FP), ELECTRICAL

TESTING for FWD and FUEL

PUMP (FP), ELECTRICAL

TESTING for AWD.

oxygen sensor control behind Three

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

System Too Rich, Bank 1

C

heck exhaust system for proper

seal. See EXHAUST SYSTEM,

CHECKING FOR LEAKS .

C

heck Secondary Air Injection

(AIR) system for proper seal. See

SECONDARY AIR INJECTION

(AIR) SYSTEM, CHECKING

FOR PROPER SEAL .

C

heck vacuum lines for leaks

C

heck fuel pressure regulator and

residual pressure. See SYSTEM

PRESSURE AND RESIDUAL

PRESSURE, CHECKING .

C

heck fuel injectors. See FUEL

INJECTORS, CHECKING .

P0172 16556

P0201 16585 Injector Circuit/Open - Cylinder 1

P0202 16586 Injector Circuit/Open - Cylinder 2

P0203 16587 Injector Circuit/Open - Cylinder 3

P0204 16588 Injector Circuit/Open - Cylinder 4

P0221 16605

Throttle/Pedal Position Sensor/Switch

"B" Circuit Range/Performance

C

heck Oxygen Sensor (O2S) and

oxygen sensor control before Three

Way Catalytic Converter (TWC).

See HEATED OXYGEN

SENSOR (HO2S) -G39- AND

OXYGEN SENSOR

REGULATION BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

Way Catalytic Converter (TWC).

S

ee OXYGEN SENSORS AND

OXYGEN SENSOR

REGULATION BEHIND

CATALYTIC CONVERTER,

CHECKING .

C

heck Evaporative Emission

(EVAP) Canister Purge Regulator

Valve -N80-. See CHECKING

EVAPORATIVE EMISSION

(EVAP) CANISTER PURGE

REGULATOR VALVE -N80- .

C

heck fuel injectors. See FUEL

INJECTORS, CHECKING .

Check Throttle Valve Control

11:32:48 PM Page 4

Check Engine Speed (RPM) Sensor

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

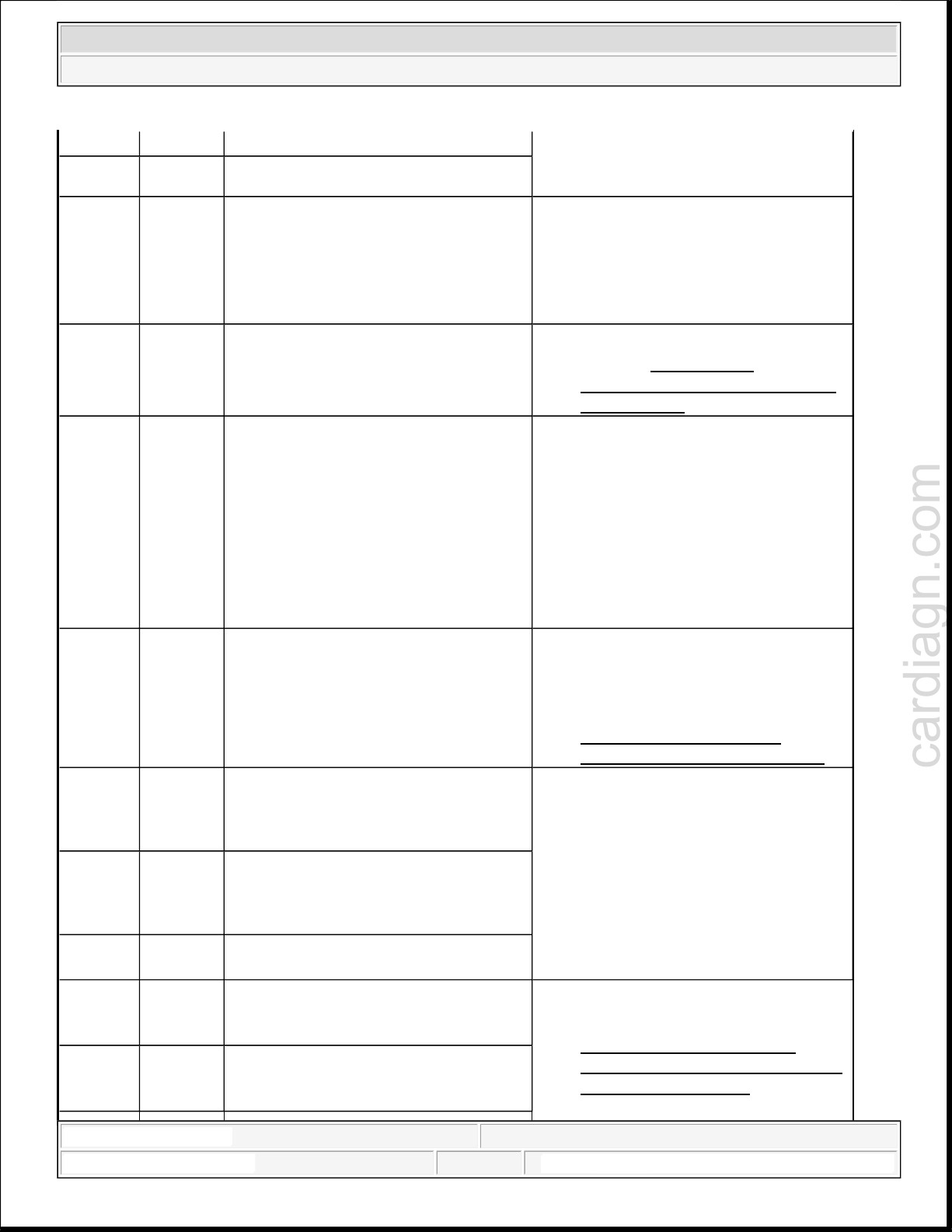

P0222 16606

P0223 16607

Throttle/Pedal Position Sensor/Switch

"

B" Circuit Low

Throttle/Pedal Position Sensor/Switch

"

B" Circuit High

Fuel Pump Primary Circuit

P0230 16614

P0236 16620

P0237 16621

P0238 16622

P0243 16627

P0245 16629

P0246 16630

Charge air pressure sensor G31

i

mplausible signal

Charge air pressure sensor G31 signal

t

oo low

Charge air pressure sensor G31 signal

t

oo high

Wastegate bypass regulator valve N75

O

pen / Short to Ground

Wastegate bypass regulator valve N75

S

hort to Ground

Wastegate bypass regulator valve N75

S

hort to positive

P0261 16645 Cylinder 1 Injector Circuit Low

P0262 16646 Cylinder 1 Injector Circuit High

P0264 16648 Cylinder 2 Injector Circuit Low

P0265 16649 Cylinder 2 Injector Circuit High

P0267 16651 Cylinder 3 Injector Circuit Low

P0268 16652 Cylinder 3 Injector Circuit High

P0270 16654 Cylinder 4 Injector Circuit Low

P0271 16655 Cylinder 4 Injector Circuit High

Random/Multiple Cylinder Misfire

P0300 16684

P0301 16685

P0302 16686

P0303 16687

P0304 16688

P0321 16705

P0322 16706

D

etected

Cylinder 1 Misfire Detected

Cylinder 2 Misfire Detected

Cylinder 3 Misfire Detected

Cylinder 4 Misfire Detected

Ignition/Distributor Engine Speed Input

C

ircuit Range/Performance

Ignition/Distributor Engine Speed Input

C

ircuit No Signal

P0324 16708 Knock Control System Error

P0327 16711

Knock Sensor 1 Circuit Low, Bank 1 or

Single Sensor

Knock Sensor 1 Circuit High, Bank 1 or

Module -J338-. See T

HROTTLE

VALVE CONTROL MODULE J338-, CHECKING .

C

heck Fuel Pump (FP) Relay -J17-

and activation. See FUEL PUMP

(FP) RELAY -J17- AND

ACTIVATION, CHECKING .

C

heck Charge Air Pressure Sensor -

G31-. See CHARGE AIR

PRESSURE SENSOR -G31-,

CHECKING .

C

heck Wastegate Bypass Regulator

Valve -N75-. See WASTEGATE

BYPASS REGULATOR VALVE

-N75-, CHECKING .

C

heck fuel injectors. See FUEL

INJECTORS, CHECKING .

C

heck fuel injectors. See FUEL

INJECTORS, CHECKING .

C

heck ignition coils with power

output stages. See IGNITION

COILS WITH POWER

OUTPUT STAGES,

CHECKING .

-G28-. See ENGINE SPEED

(RPM) SENSOR -G28-,

CHECKING .

Check knock sensors. See CHECK

11:32:48 PM Page 5

system for function and proper seal.

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

P0328 16712 Single Sensor KNOCK SENSORS .

P0332 16716 Knock Sensor 2 Circuit Low, Bank 2

P0333 16717 Knock Sensor 2 Circuit High, Bank 2

P0340 16724

Camshaft Position Sensor "A" Circuit,

B

ank 1 or Single Sensor

Camshaft Position Sensor "A" Circuit

C

P0341 16725

P0342 16726

P0343 16727

P0351 16735

P0352 16736

P0353 16737

P0354 16738

P0411 16795

R

ange/Performance, Bank 1 or Single

Sensor

Camshaft Position Sensor "A" Circuit

L

ow, Bank 1 or Single Sensor

Camshaft Position Sensor "A" Circuit

H

igh, Bank 1 or Single Sensor

Ignition Coil "A" Primary/Secondary

C

ircuit

Ignition Coil "B" Primary/Secondary

C

ircuit

Ignition Coil "C" Primary/Secondary

C

ircuit

Ignition Coil "D" Primary/Secondary

C

ircuit

Secondary Air Injection System

I

ncorrect Flow Detected

heck Camshaft Position (CMP)

sensor. See CAMSHAFT

POSITION (CMP) SENSOR G40-, CHECKING .

C

heck ignition coils with power

output stages. See IGNITION

COILS WITH POWER

OUTPUT STAGES,

CHECKING .

C

heck combination valves for

Secondary Air Injection (AIR)

P0413 16797

P0414 16798

P0418 16802

Secondary Air Injection solenoid valve

N

112 Open

Secondary Air Injection solenoid valve

N

112 Short circuit

Secondary Air Injection System Control

"

A" Circuit

Catalyst System, Bank1, Efficiency

B

elow Threshold

See C

OMBINATION VALVE

FOR SECONDARY AIR

INJECTION (AIR) SYSTEM,

CHECKING FUNCTION AND

FOR PROPER SEAL .

C

heck Secondary Air Injection

(AIR) Solenoid Valve -N112-. See

SECONDARY AIR INJECTION

(AIR) SOLENOID VALVE N112- CHECKING .

C

heck Secondary Air Injection

(AIR) Pump Relay -J299- and

activation. See SECONDARY

AIR INJECTION (AIR) PUMP

RELAY -J299- AND

ACTIVATION, CHECKING .

Check Oxygen Sensor (O2S) and

oxygen sensor control before Three

Way Catalytic Converter (TWC).

See HEATED OXYGEN

11:32:48 PM Page 6

oxygen sensor control behind Three

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

SENSOR (HO2S) -G39- AND

OXYGEN SENSOR

REGULATION BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

P0420 16804

P0440 16824

P0441 16825

P0442 16826

P0444 16828

P0445 16829

P0455 16839

P0456 16840

P0501 16885

P0506 16890

P0507 16891

P0560 16944

Way Catalytic Converter (TWC).

S

ee OXYGEN SENSORS AND

OXYGEN SENSOR

REGULATION BEHIND

CATALYTIC CONVERTER,

CHECKING .

C

heck catalytic conversion. See

TEST

-ID 01: CATALYTIC

CONVERTER .

Evaporative Emission System EVAP System

C

hecking Evaporative Emission (EVAP)

canister purge regulator valve -N80EVAP canister system checking for

proper seal

Evaporative Emissions (EVAP) system

diagnostic leak test

Note

Overview of component locations

Evaporative Emission System Incorrect

C

P

urge Flow

Evaporative Emission System Leak

D

etected (small leak)

Evaporative Emission System Purge

C

ontrol Valve Circuit Open

Evaporative Emission System Purge

C

ontrol Valve Circuit Shorted

Evaporative Emission System Leak

D

etected (large leak)

Evaporative Emission System Leak

D

etected (very small leak)

Vehicle Speed Sensor "A"

R

ange/Performance

Idle Air Control System RPM Lower

T

han Expected

Idle Air Control System RPM Higher

Than Expected

Voltage supply signal implausible

J220 - Motronic Engine Control Module

heck Evaporative Emission

(EVAP) Canister Purge Regulator

Valve -N80-. See CHECKING

EVAPORATIVE EMISSION

(EVAP) CANISTER PURGE

REGULATOR VALVE -N80- .

E

VAP canister system, check for

proper seal. See EVAP

CANISTER SYSTEM,

CHECKING FOR PROPER

SEAL .

C

heck speed signal. See SPEED

SIGNAL, CHECKING .

C

heck Throttle Valve Control

Module -J338-. See THROTTLE

VALVE CONTROL MODULE J338-, CHECKING .

(ECM)

11:32:48 PM Page 7

Internal Control Module Memory Check

ECM/PCM Power Relay Control Circuit

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

P0562 16946

P0563 16947

P0571 16955

P0600 16984

P0601 16985

Voltage supply too low Motronic Engine Control Module (ECM)

pow

Voltage supply too high

er supply checking

Overview of component locations

Brake light switch F F - Brake Light Switch -F-

B

rake Light Switch -F- and Brake Pedal

Switch -F47F47 - Brake Pedal Switch

Brake Light Switch -F- and Brake Pedal

Switch -F47-

Data bus drive missing message

C

heck terminal resistance for CAN-

Bus. See TERMINAL

RESISTANCE FOR CAN-BUS,

CHECKING .

J220 - Motronic Engine Control Module

Sum Error

(

ECM) [2]

Replacing Engine Control Module

(ECM) (with metal anti-theft

housing)

Replacing Engine Control Module

(ECM) (without metal anti-theft

housing)

Control Module Programming

E

rror/Malfunction

P

rocedure to code Engine Control

Module (ECM):

P0602 16986

P0604 16988

P0605 16989

P0606 16990

P0685 17069

P0686 17070

Internal Control Module Random

A

ccess Memory (RAM) Error

Internal Control Module Read Only

M

emory (ROM) Error

ECM/PCM Processor

ECM/PCM Power Relay Control

C

ircuit/Open

Low

Motronic Fuel Injection and

Ignition (4-cylinder Turbo); See

ENCODING II ENGINE

CONTROL MODULE (ECM) .

J220 - Motronic Engine Control Module

(

ECM) [2]

Replacing Engine Control Module

(ECM) (with metal anti-theft

housing)

Replacing Engine Control Module

(ECM) (without metal anti-theft

housing)

C

heck voltage supply for Engine

Control Module (ECM). See

VOLTAGE SUPPLY FOR

ENGINE CONTROL MODULE

(ECM), CHECKING .

Check Motronic Engine Control

11:32:48 PM Page 8

ECM/PCM Power Relay Control Circuit

sensor 1, heating circuit short to

Overview of component locations Oxygen

sensor 2, heating circuit short to

and

oxygen sensor control behind Three

2005 Audi A4 Quattro

cardiagn.com

DTC INDEX DTC Index - 1.8L (AMB Engine)

P0687 17071

P0688 17072

P0704 17088

P1102 17510

P1103 17511

P1105 17513

P1111 17519

P1176 17584

High

Power supply relay J271 , load circuit

ope

n

Clutch Switch Input Circuit Malfunction

Bank 1 B+

Bank 1 -sensor 1, heating circuit, output

t

oo low

Bank 1 B+

Oxygen sensor control Bank 1 system

t

oo lean

Bank 1 oxygen sensor correction behind

c

at. control limit reached

Control limit reached

Module (ECM) Power Supply

R

elay -J271- and activation. See

CHECK MOTRONIC ENGINE

CONTROL MODULE (ECM)

POWER SUPPLY RELAY J271- AND ACTIVATION .

C

heck Clutch Vacuum Vent Valve

Switch -F36-. See CLUTCH

VACUUM VENT VALVE

SWITCH -F36-, CHECKING .

Z19 - Oxygen Sensor (O2S) Heater

Sensor (O2S) Heater -Z19- before

c

atalytic converter checking

Z29 - Oxygen Sensor (O2S) Heater 1

(

behind Three Way Catalytic Converter

(TWC))

Overview of component locations

Oxygen Sensor (O2S) Heater 1 -Z29behind catalytic converter checking

G39 - Heated Oxygen Sensor (HO2S)

H

eated Oxygen Sensor (HO2S) -G39oxygen sensor regulation before catalytic

c

onverter checking

Overview of component locations

C

heck Oxygen Sensor (O2S) and

oxygen sensor control before Three

Way Catalytic Converter (TWC).

See HEATED OXYGEN

SENSOR (HO2S) -G39- AND

OXYGEN SENSOR

REGULATION BEFORE

CATALYTIC CONVERTER,

CHECKING .

C

heck Oxygen Sensor (O2S) and

11:32:48 PM Page 9

Way Catalytic Converter (TWC).

S

ee OXYGEN SENSORS AND

OXYGEN SENSOR

REGULATION BEHIND

CATALYTIC CONVERTER,

CHECKING .

Check intake air system for leaks

(false air). See INTAKE

SYSTEM, CHECKING FOR

P1292 17700

Check Engine Coolant Temperature

cardiagn.com

P1293 17701

P1294 17702

P1296 17704

P2101 18533

P2122 18554

P2123 18555

P2127 18559

P2128 18560

P2138 18570

P2400 18832

P2401 18833

P2402 18834

P2403 18835

P2404 18836

2005 Audi A4 Quattro

DTC INDEX DTC Index - 1.8L (AMB Engine)

Malfunction in cooling system

Throttle Actuator Control Motor Circuit

R

ange/Performance

Throttle/Pedal Position Sensor/Switch

"

D" Circuit Low Input

Throttle/Pedal Position Sensor/Switch

"

D" Circuit High Input

Throttle/Pedal Position Sensor/Switch

"

E" Circuit Low Input

Throttle/Pedal Position Sensor/Switch

"

E" Circuit High Input

Throttle/Pedal Position Sensor/Switch

"

D" / "E" Voltage Correlation

Evaporative Emission System Leak

D

etection Pump Control Circuit/Open

Evaporative Emission System Leak

D

etection Pump Control Circuit Low

Evaporative Emission System Leak

D

etection Pump Control Circuit High

Evaporative Emission System Leak

D

etection Pump Sense Circuit/Open

Evaporative Emission System Leak

D

etection Pump Sense Circuit

Range/Performance

LEAKS (FALSE AIR) .

F265 - Map Controlled Engine Cooling

T

hermostat

Cooling system components, overview

(ECT) Sensor -G62-. See E

NGINE

COOLANT TEMPERATURE

(ECT) SENSOR -G62-,

CHECKING .

C

heck coolant regulator:

C

heck Throttle Valve Control

Module -J338-. See THROTTLE

VALVE CONTROL MODULE J338-, CHECKING .

C

heck Throttle Position (TP)

sensor. See THROTTLE

POSITION (TP) SENSOR,

CHECKING .

C

heck Leak detection pump (LDP)

-V144-. See LEAK DETECTION

PUMP (LDP) -V144-,

CHECKING .

E

VAP canister system, check for

proper seal. See EVAP

CANISTER SYSTEM,

CHECKING FOR PROPER

SEAL .

11:32:48 PM Page 10

cardiagn.com

2005 Audi A4 Quattro

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

00 - GENERAL, TECHNICAL DATA

TECHNICAL DATA

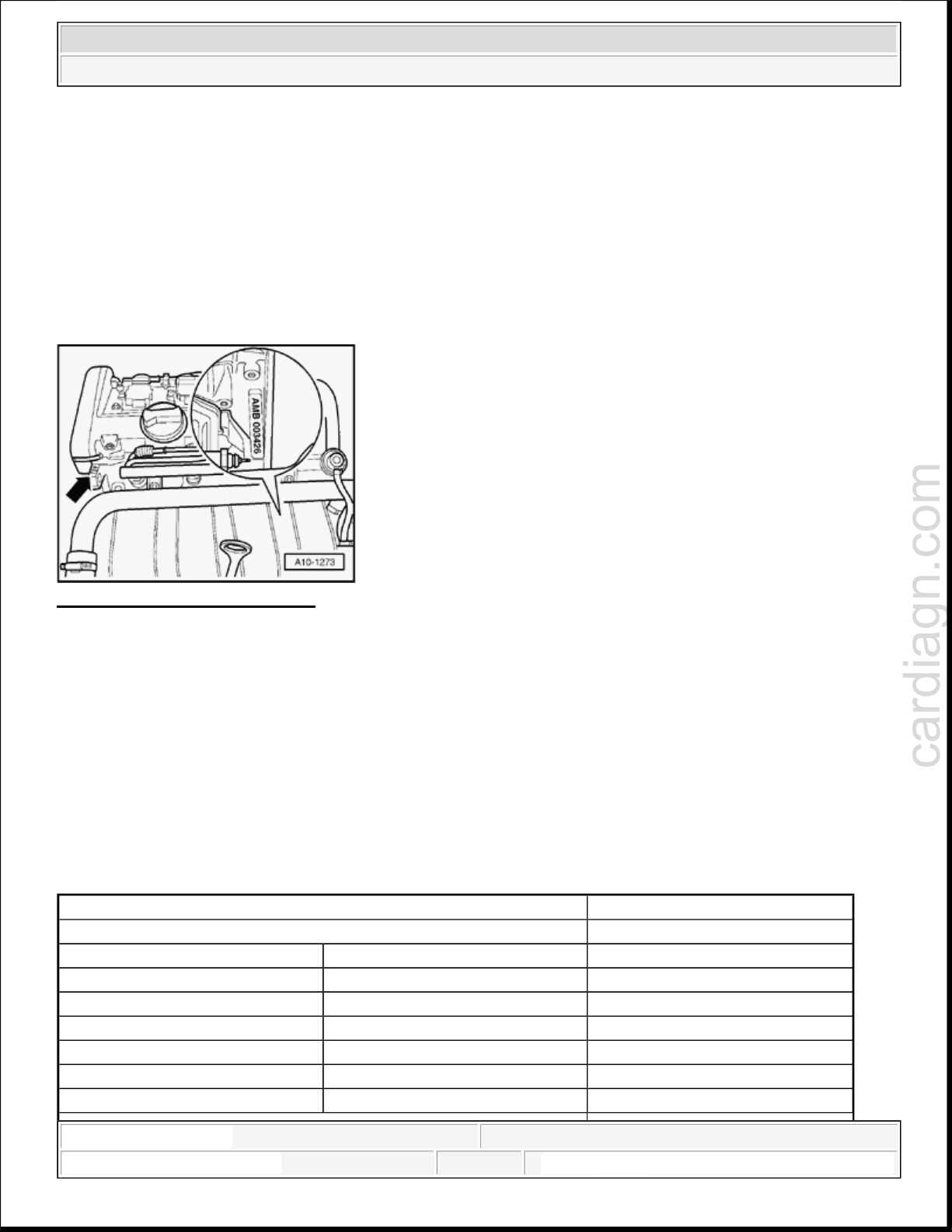

Engine number

ENGINE

Fig. 1: Locating Engine Number

Courtesy of VOLKSWAGEN UNITED STATES, INC.

The engine number ( "Engine code" and "Serial number" ) can be found on the rear left of the cylinder block.

Additionally there is a sticker on the toothed belt guard giving the "Engine code" and "Serial number".

The engine code is also given on the vehicle data sticker.

NOTE:

Engine data

Engine code AMB

Manufactured 08.01 -->

Capacity l 1.781

Power kW at RPM 125/5700

Torque Nm at RPM 210/1750 to 4600

Bore diameter mm 81.0

Stroke mm 86.4

Compression ratio 9.5

RON 95 * See note

The engine code is also stamped on the front lifting eye (visible when

engine cover panel is removed).

1:00:55 AM Page 1

1:01:41 AM Page 1

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Injection/ignition system Bosch Motronic

Knock control yes

On Board Diagnostic yes

Oxygen sensor control yes

Catalytic converter yes

Charging yes

*Standard unleaded RON 91 also permitted, however reduced power.

Engine code AMB

Exhaust gas recirculation no

Intake manifold change-over function no

Camshaft timing control yes

Secondary air system yes

Valve timing

at 1 mm valve lift and 0 mm valve clearance

Intake opens after TDC 18 °

Intake closes after BDC 28 °

Exhaust opens before BDC 28 °

Exhaust closes before TDC 8 °

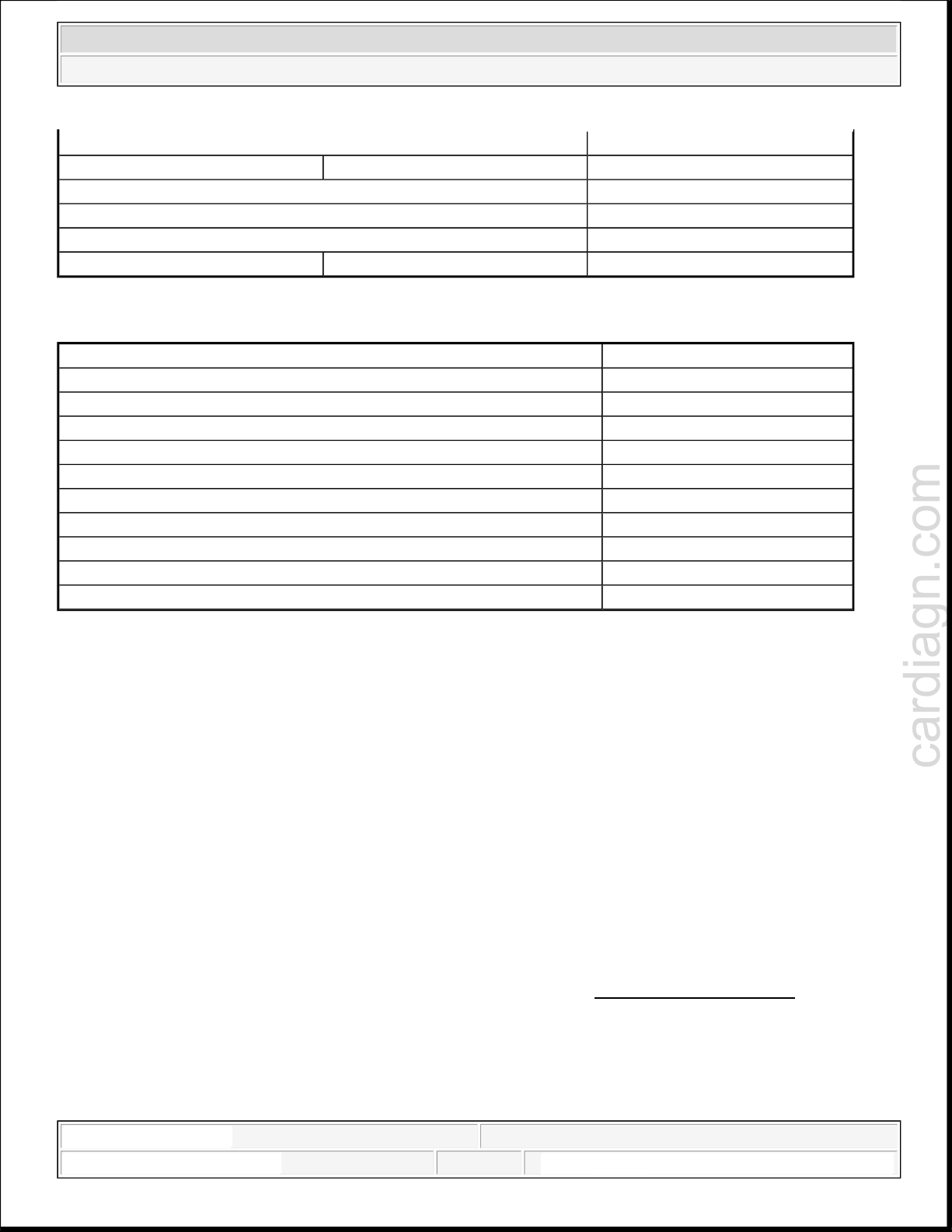

10 - ENGINE - ASSEMBLY

ENGINE, REMOVING AND INSTALLING

Engine, removing and installing

CAUTION: Before beginning repairs on the electrical system:

Obtain the anti-theft radio security code.

Switch the ignition off.

Disconnect the battery Ground (GND) strap.

On vehicles equipped with Audi Telematics by OnStar, switch-off the

emergency (back-up) battery for the Telematic/Telephone Control Module

prior to disconnecting vehicle battery --> 91 - COMMUNICATION

After reconnecting vehicle battery, re-code and check operation of antitheft radio. Also check operation of clock and power windows according

to Repair Article and/or Owners Manual.

1:00:55 AM Page 2

cardiagn.com

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

After reconnecting vehicle battery on vehicles equipped with Audi

Telematics by OnStar, switch-on the emergency (back-up) battery for the

Telematic/Telephone Control Module --> 91

Engine, removing and installing

2005 Audi A4 Quattro

- COMMUNICATION

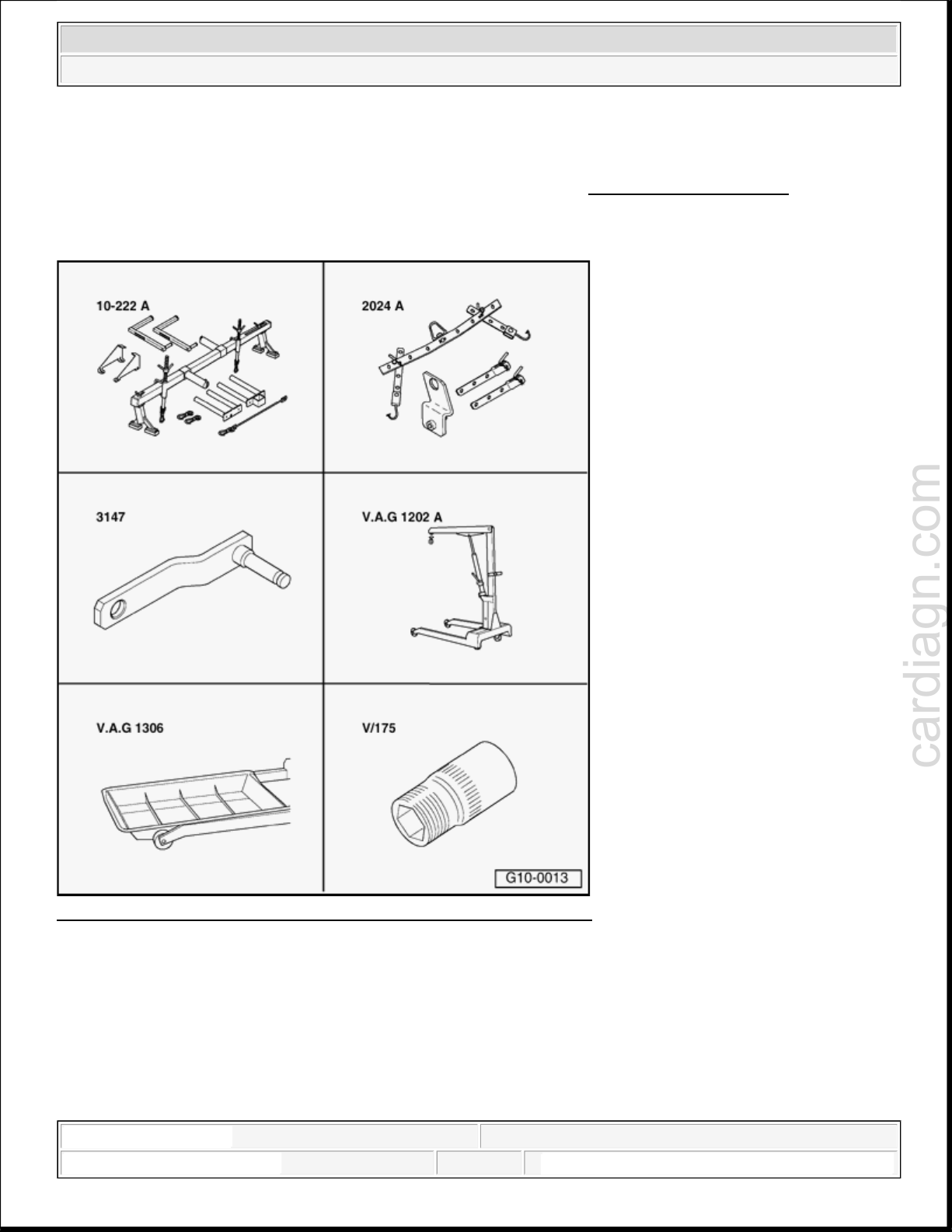

Fig. 2: Identifying Special Tools - Engine, Removing And Installing

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Special tools, testers and auxiliary items required

Support bar 10-222A

Lifting tackle 2024A

Special tool 3147

Workshop crane VAG1202A

1:00:55 AM Page 3

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Drip tray VAG1306

Socket attachment 15 mm A/F Matra V/175

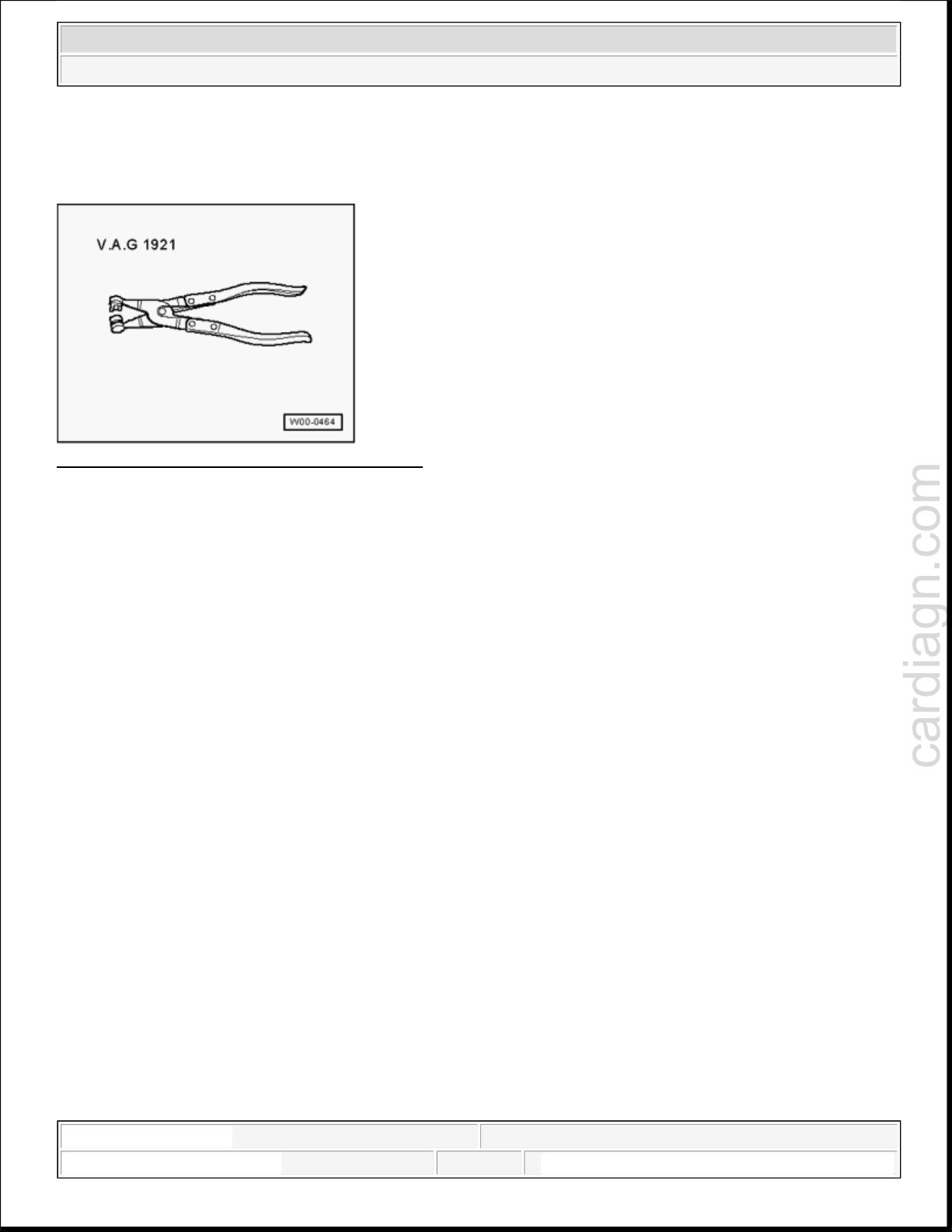

Fig. 3: Identifying Hose Clip Pliers VAG 1921

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Hose clip pliers VAG5024

Engine, removing

NOTE:

All cable ties unfastened or cut when removing engine are to be

reattached in same position during installation.

Engine must be removed without transmission from front of vehicle.

Catch drained coolant in a clean container for re-use or disposal.

Vehicles with automatic transmission

Move selector lever to position N.

All models

Obtain radio anti-theft code for vehicles with encoded radio.

1:00:55 AM Page 4

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

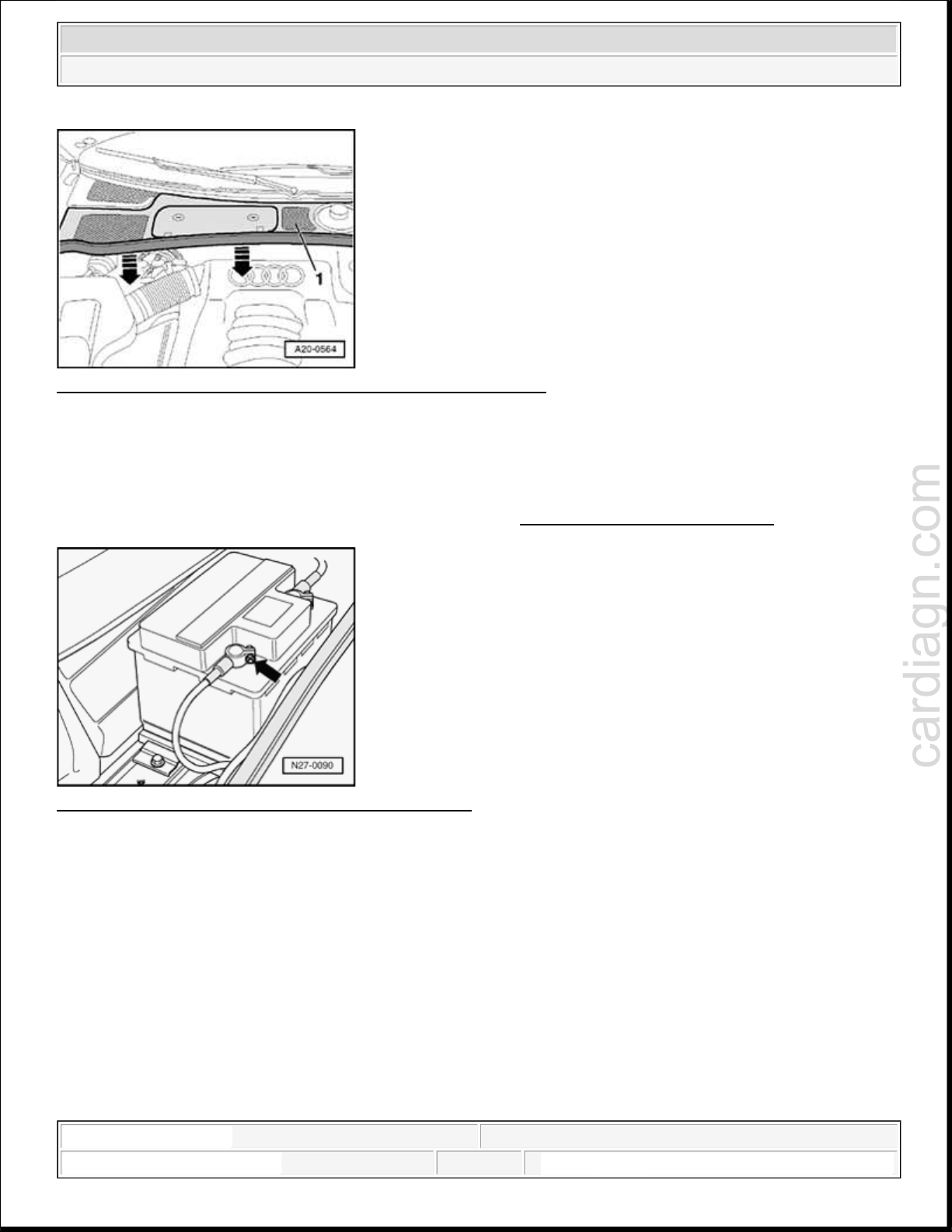

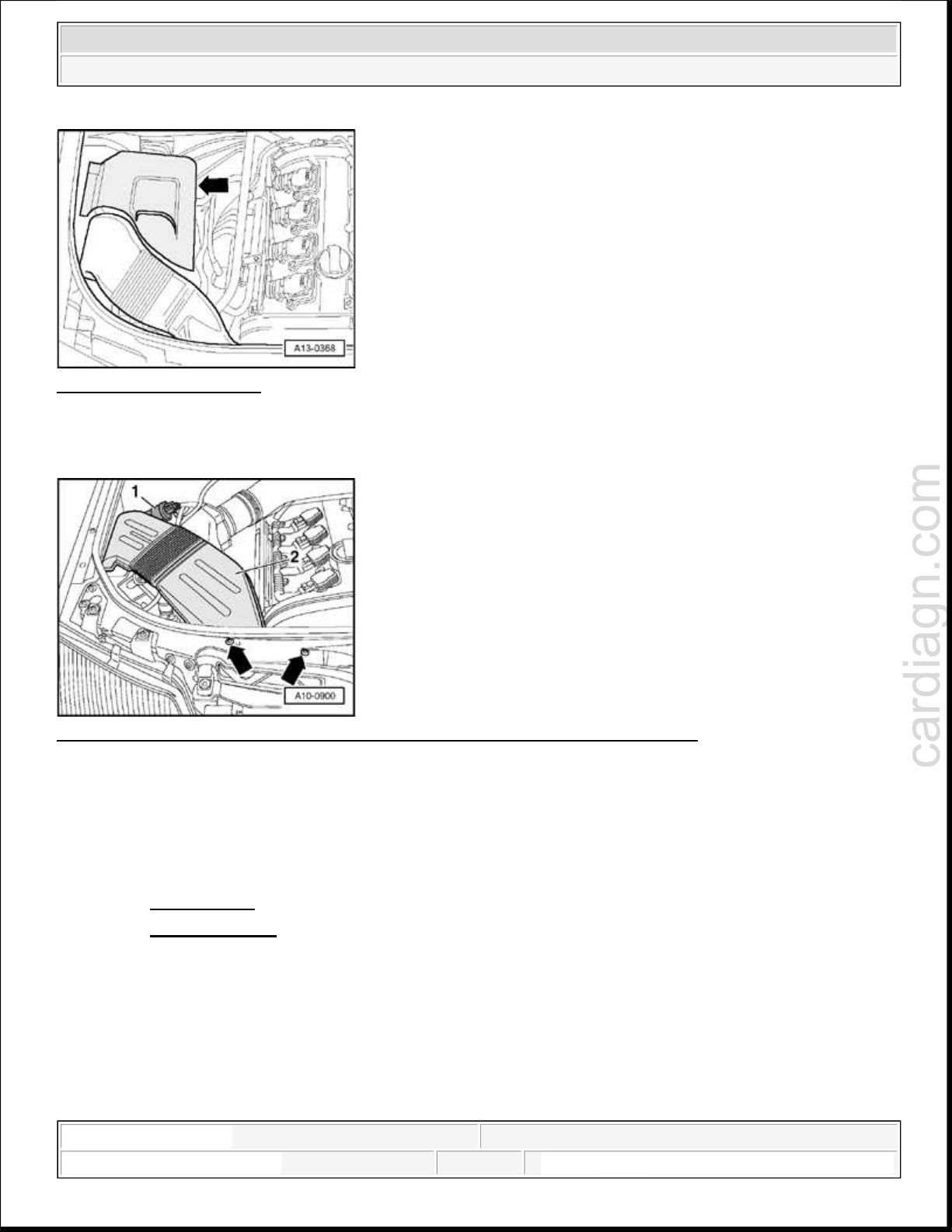

Fig. 4: Removing Rubber Seal From Plenum Chamber Cover

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove rubber seal from plenum chamber cover in direction of - arrow -.

Pull plenum chamber cover - 1 - toward front and remove.

See Caution before beginning repairs on electrical system --> Engine, removing and installing

Fig. 5: Identifying Battery Ground (GND) Terminal

Courtesy of VOLKSWAGEN UNITED STATES, INC.

With ignition switched off, disconnect battery Ground strap - arrow -.

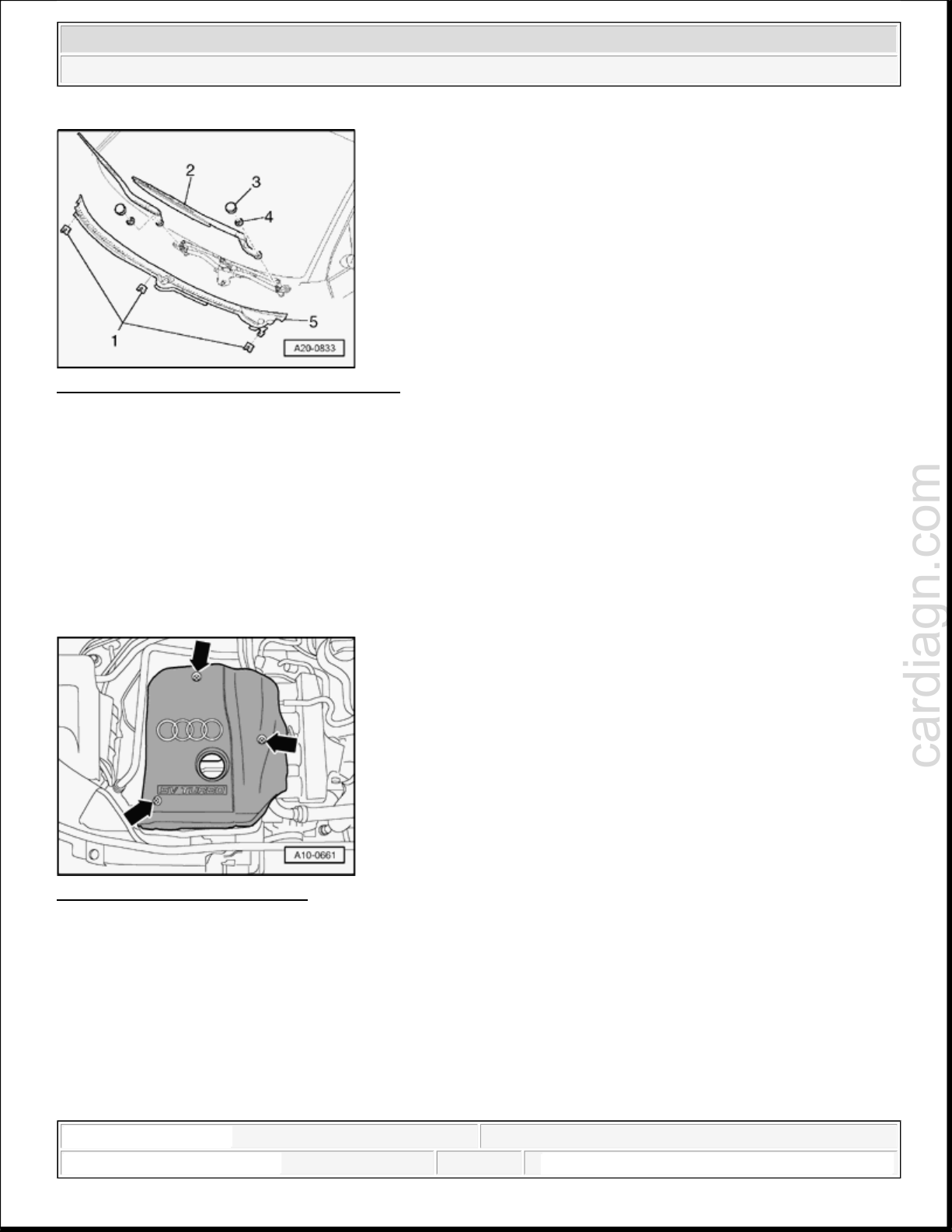

Use screwdriver to pry off caps - 3 - from wiper arms.

1:00:55 AM Page 5

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

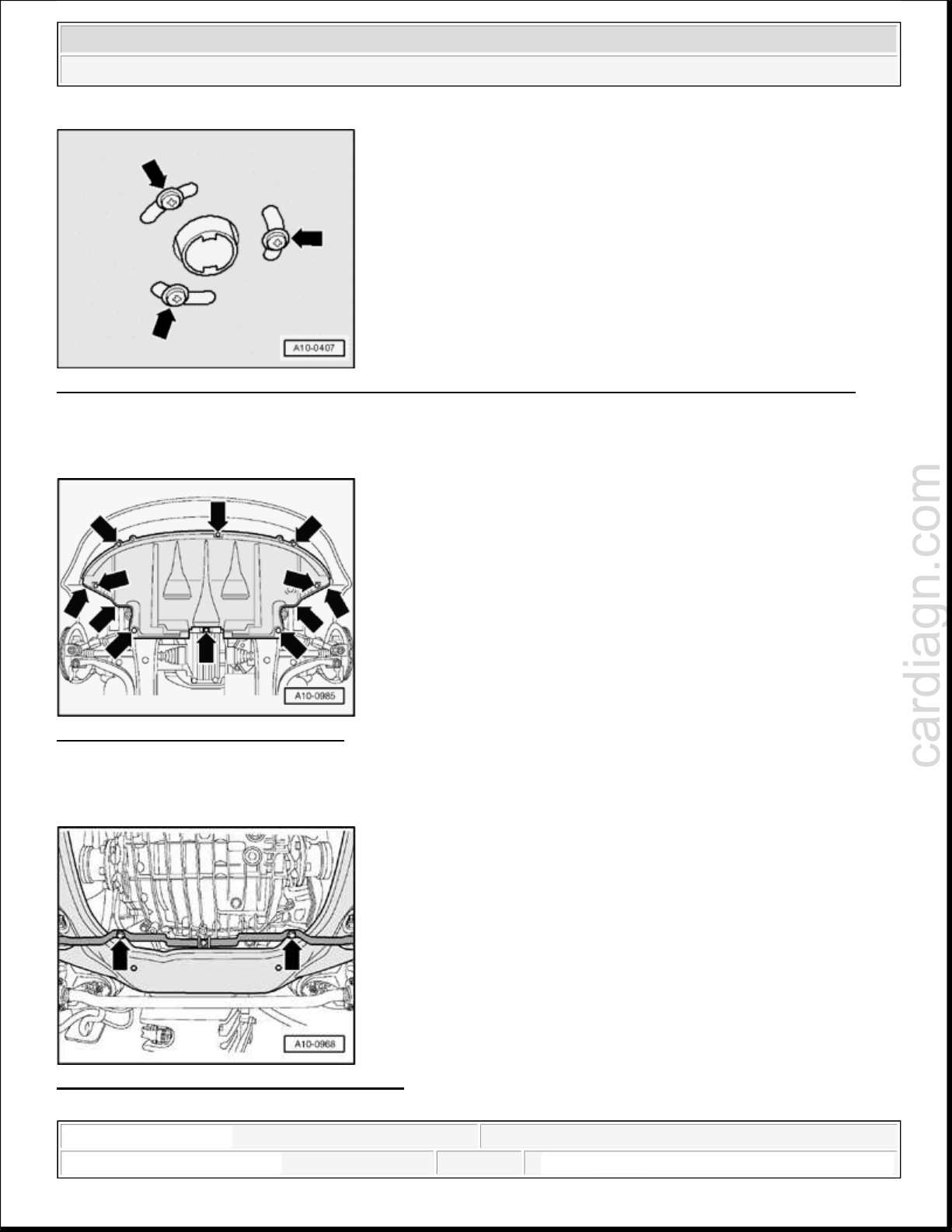

Fig. 6: Removing Securing Clips And Cowl

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Loosen hex nuts - 4 - by a few turns.

Tilt wiper arm - 2 - slightly to remove it from wiper shaft.

Remove hex nuts completely and remove wiper arms.

Pull off securing clips - 1 - and remove panel trim.

CAUTION: Hot steam can escape when cap on expansion tank is opened. Cover cap

with cloth and open carefully.

Fig. 7: Removing Engine Cover

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove engine cover - arrows -.

1:00:55 AM Page 6

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

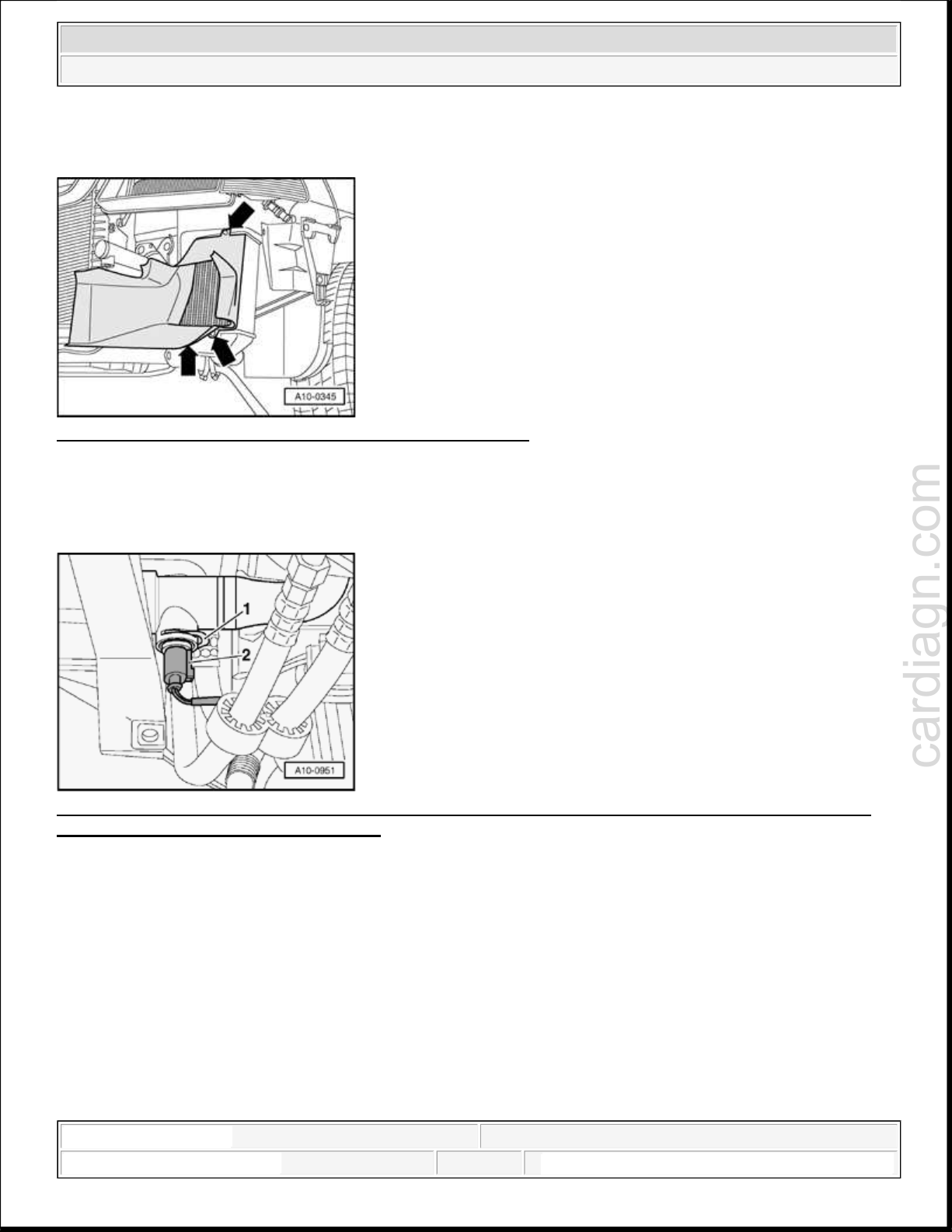

Fig. 8: Air Cleaner Cover

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove air cleaner cover - arrow -.

Fig. 9: Evaporative Emission Canister Purge Regulator Valve N80 And Air Duct

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove bolts - arrows -.

Disengage EVAP canister purge regulator valve N80 - 1 - from air duct - 2 -.

Remove both screws - arrows - for air duct - 2 -.

Remove front bumper: -->

63 BUMPER

63 - BUMPERS for CABRIOLET

Vehicles with auxiliary heater

1:00:55 AM Page 7

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Fig. 10: Removing Bolts Securing Exhaust Pipe Of Auxiliary/Additional Heater To Sound Insulation

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove bolts - arrows - securing exhaust pipe of auxiliary/additional heater to sound insulation.

Fig. 11: Removing Sound Insulation

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove sound insulation - arrows -.

Fig. 12: Unbolting Sound Insulation Holder

Courtesy of VOLKSWAGEN UNITED STATES, INC.

1:00:55 AM Page 8

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Unbolt sound insulation holder.

Fig. 13: Removing Air Duct In Front Of Charge Air Cooler

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove air duct in front of charge air cooler - arrows -.

Place drip tray VAG1306 under engine.

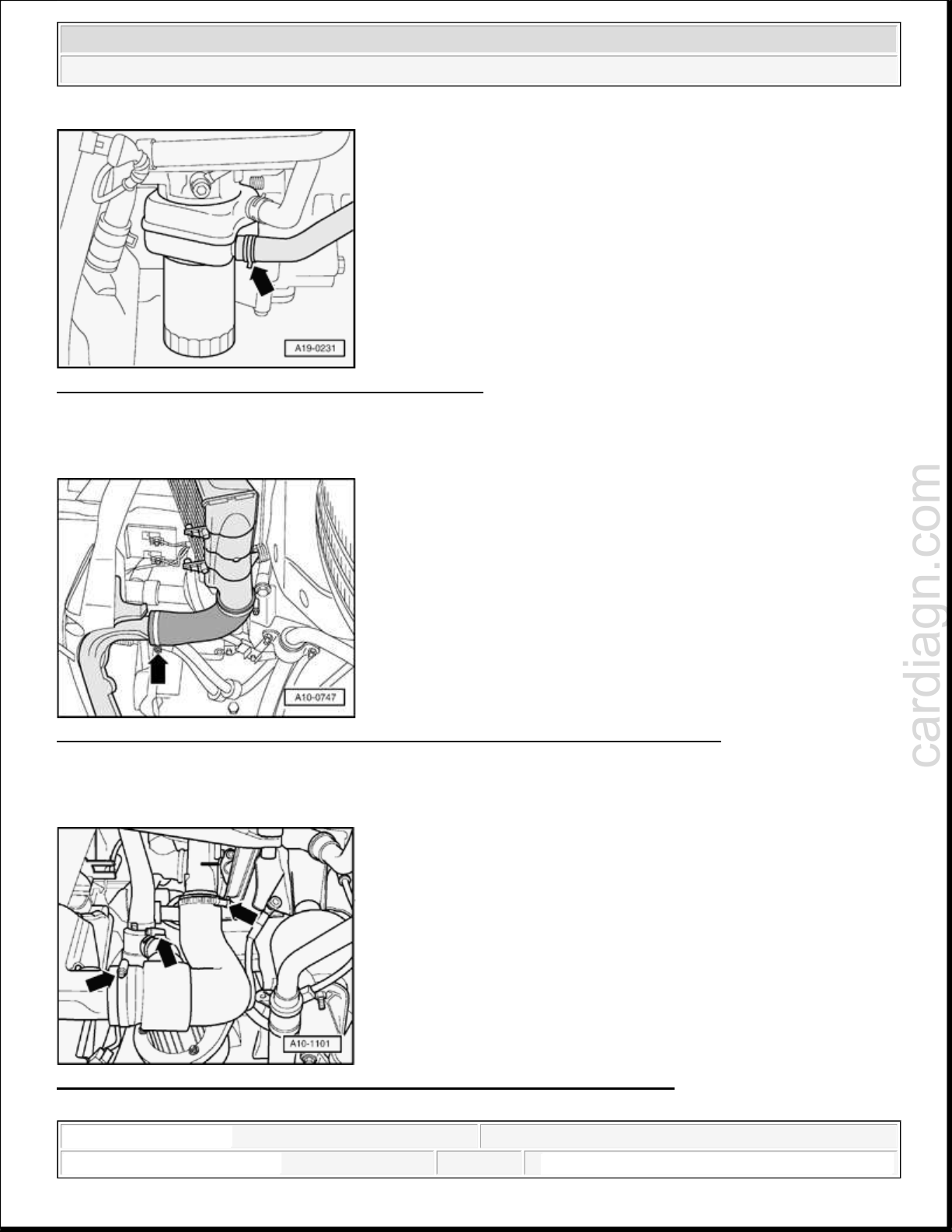

Fig. 14: Pulling Retaining Clip For Engine Coolant Temperature (ECT) Sensor G2 Off Lower Coolant

Hose And Drain Coolant From Radiator

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Pull retaining clip - 1 - for Engine Coolant Temperature (ECT) sensor G2 - 2 - off lower coolant hose and

drain coolant from radiator.

Remove lower coolant hose from radiator.

1:00:55 AM Page 9

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Fig. 15: Disconnecting Coolant Hose From Oil Cooler

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Disconnect coolant hose from oil cooler - arrow - and drain remaining coolant.

Fig. 16: Removing Air Hose To Charge Air Cooler At Bottom Left Of Lock Carrier

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove air hose - arrow - to charge air cooler at bottom left of lock carrier.

Fig. 17: Removing Lower Air Hose Between Turbocharger And Lock Carrier

Courtesy of VOLKSWAGEN UNITED STATES, INC.

1:00:55 AM Page 10

g

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Remove lower air hose - arrow - between turbocharger and lock carrier.

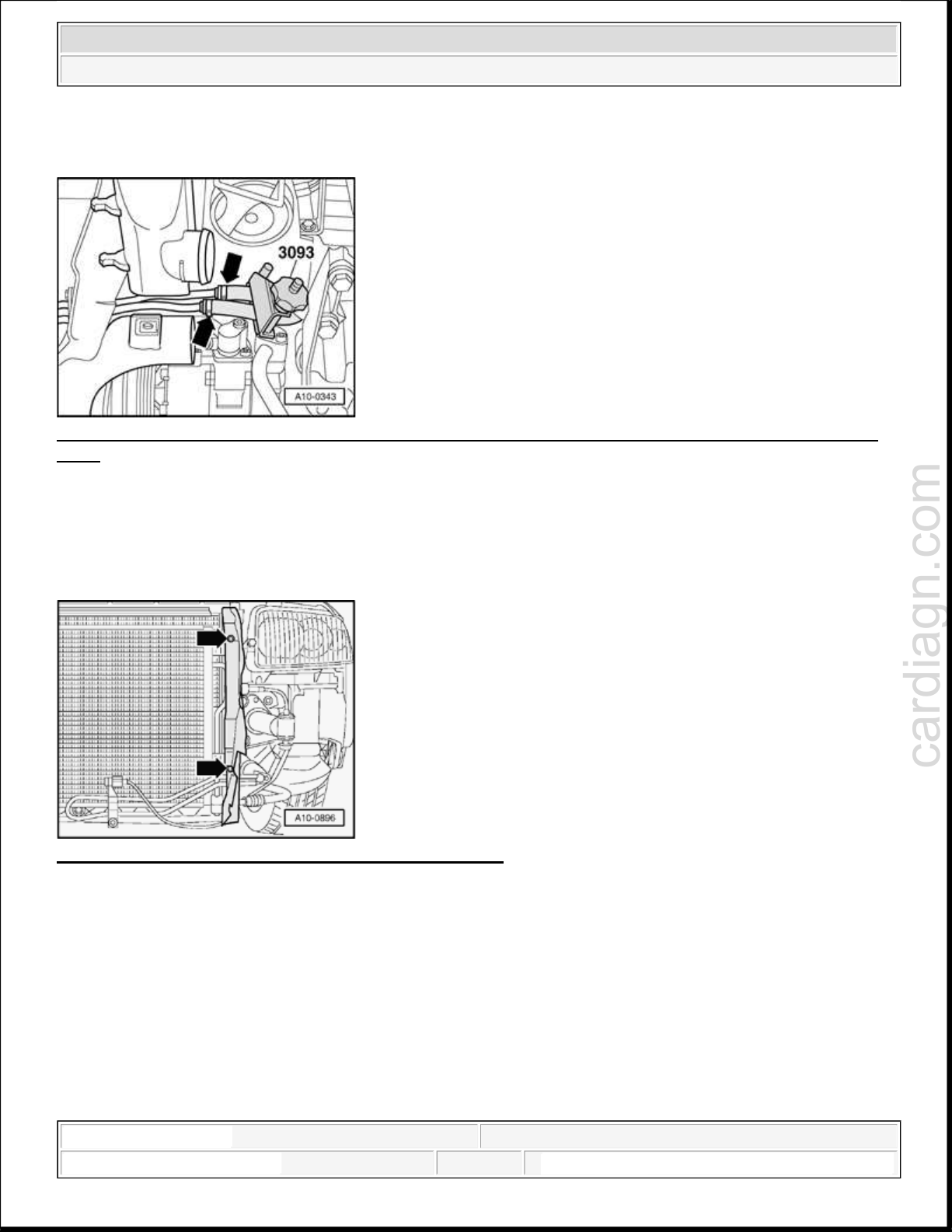

Fig. 18: Using 3093 To Clamp Off Inlet And Outlet Pipe Of Cooling Coil For Power Steering Hydraulic

Fluid

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Use 3093 to clamp off inlet and outlet pipe of cooling coil for power steering hydraulic fluid.

Place suitable container under hoses.

Disconnect hoses from cooling coil.

Fig. 19: Removing Air Ducts On Left/Right Of Radiator

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove air ducts on left and ri

ht of radiator - arrows -.

1:00:55 AM Page 11

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Fig. 20: Disconnecting Connector From A/C Pressure Switch F129 & Ambient Temperature Sensor

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Disconnect connector - 1 - from A/C pressure switch F129.

Disconnect connector - 2 - from ambient temperature sensor.

Move both wires clear.

CAUTION: Air conditioner refrigerant circuit must not be opened.

Unbolt condenser - arrows - from radiator.

NOTE:

To prevent damage to condenser and refrigerant lines/hoses ensure that

lines and hoses are not stretched, kinked or bent.

Carefully swivel condenser downward and set down.

Fig. 21: Removing Impact Absorber Bolts On Left/Right

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove impact absorber bolts on left and right - arrows -.

Remove hood lock cable from lock carrier: -->

1:00:55 AM Page 12

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

55 HOOD, LIDS

55 - HOOD, LIDS for CABRIOLET

Fig. 22: Removing Top Coolant Hose From Radiator & Disconnecting Connectors For Left/Right Airbag

Sensor

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove top coolant hose from radiator - 1 -.

Disconnect connectors - 2 - for left and right airbag sensor.

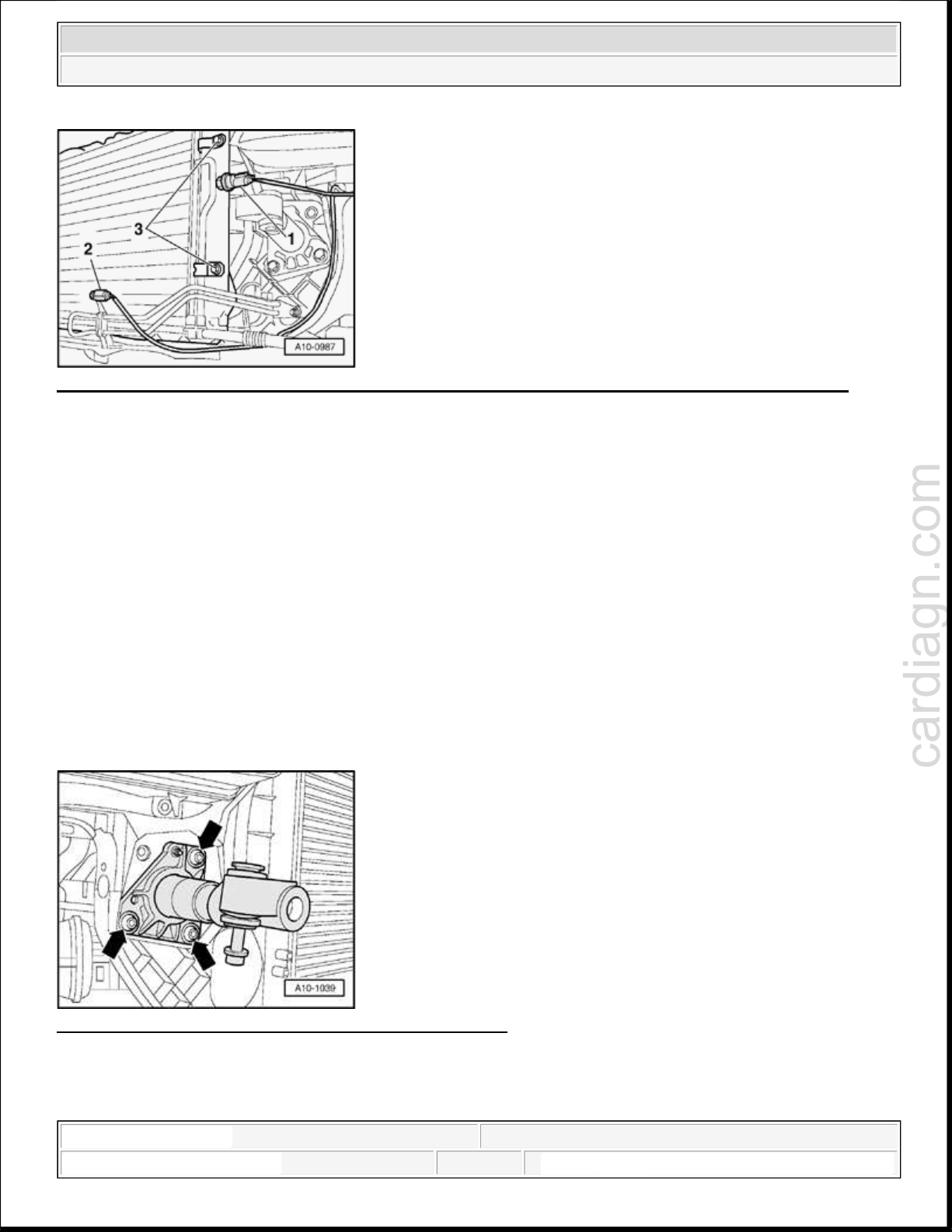

Fig. 23: Unbolting Lock Carrier On Left/Right

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Unbolt lock carrier on left and right - arrows -.

NOTE:

A second technician is required to remove the lock carrier.

Place lock carrier in a secure position.

Remove lock carrier.

Vehicles with automatic transmission

1:00:55 AM Page 13

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

NOTE:

Observe the rules for cleanliness when working on an automatic

transmission:

-->

37 - AUTOMATIC TRANSMISSION - CONTROLS, HOUSING for 5 SPD.

37 - AUTOMATIC TRANSMISSION - CONTROLS, HOUSING for 5 SPD.

37 CONTROLS, HOUSING for AUTOMATIC TRANSMISSION 09L,

Place drip tray underneath.

AUTOMATIC TRANSMISSION 01V

AUTOMATIC TRANSMISSION 01V FRONT AND ALL WHEEL DRIVE INTERNAL COMPONENTS, SERVICING

FOUR-WHEEL DRIVE

Fig. 24: Disconnecting ATF Lines

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Disconnect ATF lines - arrows -.

Unbolt bracket for ATF lines on left of engine.

Vehicles up to 06.03

CAUTION: Fuel system is under pressure! Before opening system, place rags around

the connection point. Then release pressure by carefully loosening

connection.

1:00:55 AM Page 14

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

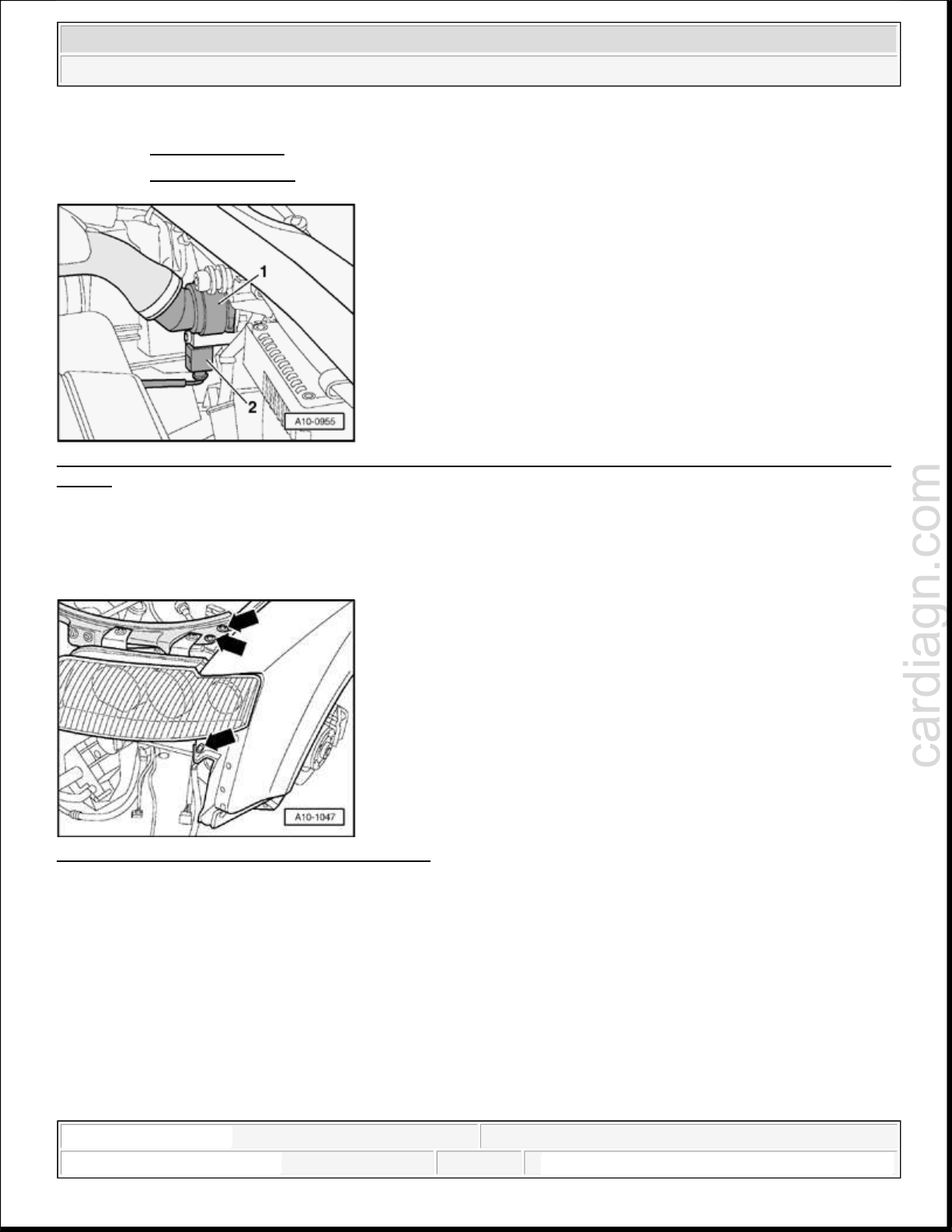

Fig. 25: Disconnecting Fuel Supply Line And Set Aside

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Disconnect fuel supply line - 1 - and set aside.

NOTE:

Disregard - 2 -.

Vehicles as of 07.03

CAUTION: Fuel system is under pressure! Before opening system, place rags around

the connection point. Then release pressure by carefully loosening

connection.

Fig. 26: Counterholding Using An Open

-End Wrench At Each Hex Head & Unscrew Union Nut

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Unscrew fuel hose from connection on fuel rail pipe. To do so, counterhold using an open-end wrench at

each hex head - 1 - and - 3 - and unscrew union nut - 2 -.

All

Seal off line so that no dirt will get into fuel system.

1:00:55 AM Page 15

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

CAUTION: Fuel system is under pressure! Before opening system, place rags around

the connection point. Then release pressure by carefully loosening

connection.

Fig. 27: Disconnecting Fuel Supply Line

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Disconnect fuel supply line.

Seal off line so that no dirt can enter fuel system.

Unbolt Ground connection from plenum chamber.

Remove vacuum line to brake servo from plenum chamber.

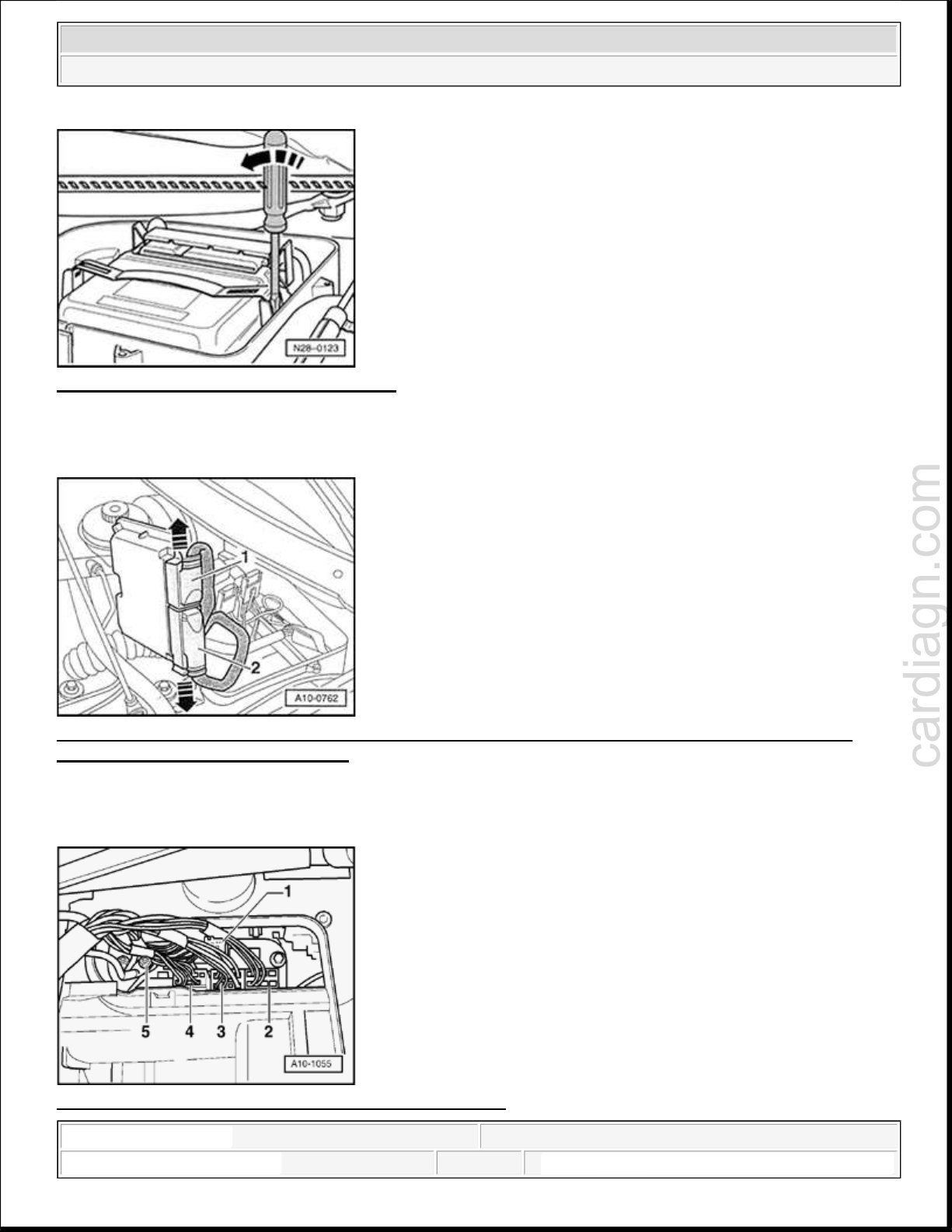

Fig. 28: Disconnect Wires/Unplug Connectors From

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Disconnect wires/unplug connectors from:

1. EVAP canister purge regulator valve

2. Mass air flow sensor

3. Wastegate bypass regulator valve N75

Disconnect hoses 4...7.

1:00:55 AM Page 16

V

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Disconnect hose to secondary air injection pump motor - 8 -.

Move wires clear.

Unbolt air cleaner housing - 9 -.

Remove air cleaner.

NOTE:

acuum pipe to secondary air combination valve is clipped to underside of

air intake hose.

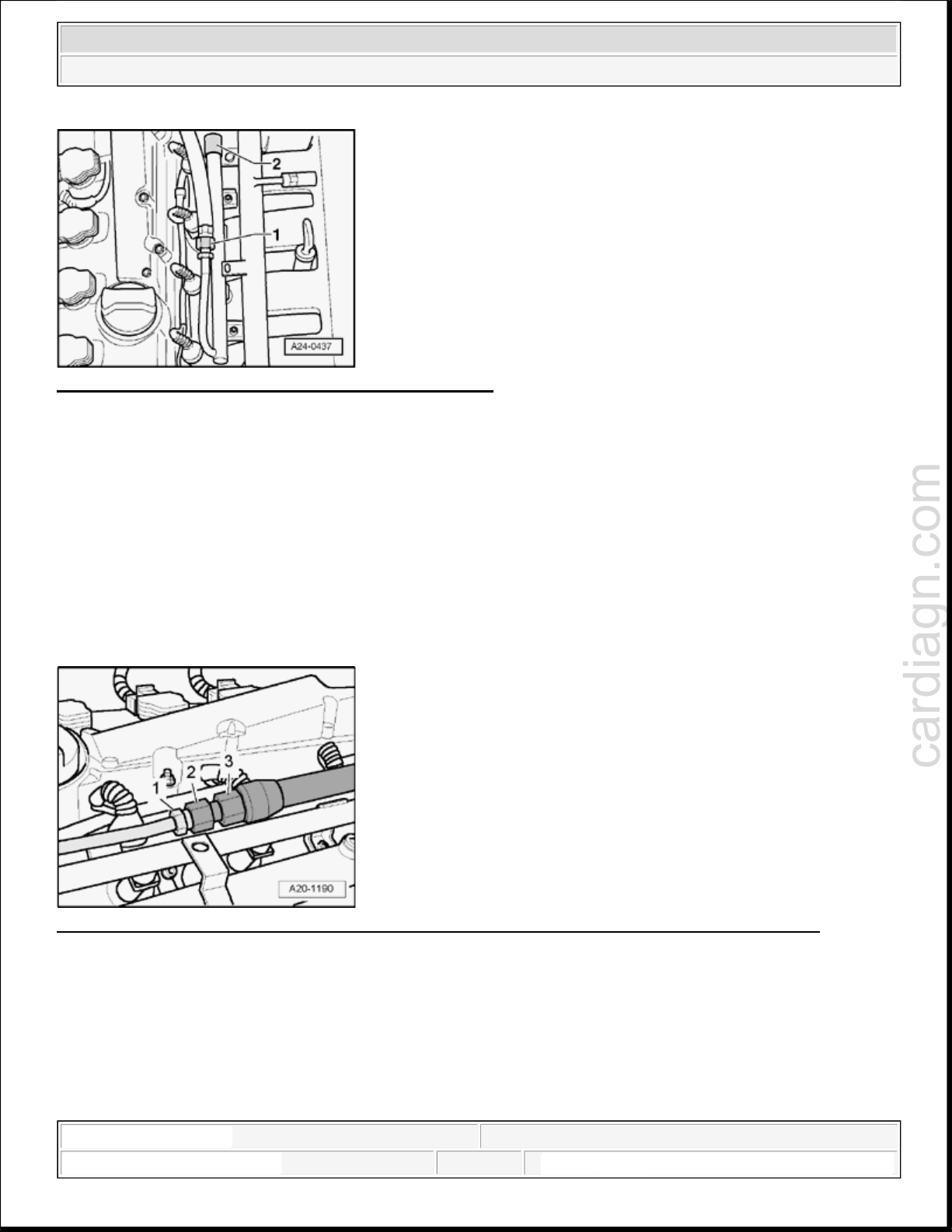

Fig. 29: Removing Both Coolant Hoses From Coolant Expansion Tank

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Remove both coolant hoses from coolant expansion tank.

Unbolt coolant expansion tank.

Lift coolant expansion tank slightly at bolt side and pull it out of catch on plenum chamber side.

Fig. 30: Unbolting Cover Of Electronics Box In Plenum Chamber

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Unbolt cover of electronics box in plenum chamber.

1:00:55 AM Page 17

cardiagn.com

2005 Audi A4 Quattro

ENGINE 1.8 Liter 4-Cyl. 5V Turbo Engine Mechanical, Engine Code(s): AMB

Fig. 31: Removing Engine Control Module

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Carefully pry off retainer bar with screwdriver - arrow -.

Fig. 32: Disengaging Electrical Connector Retainers And Disconnecting Electrical Connectors From

Engine Control Module (ECM) J623

Courtesy of VOLKSWAGEN UNITED STATES, INC.

Release catches - arrows - and disconnect control module connectors - 1 - and - 2 -.

Fig. 33: Disconnecting Connectors From Connector Rail

1:00:56 AM Page 18

Loading...

Loading...