Audi Air conditioning 2003 A8 Workshop Manual

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

Workshop Manual

Audi A8 2003 ➤

Air conditioning

Edition 09.2010

Service Department. Technical Information

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

87 - Air conditioning system

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2010 Audi AG, Ingolstadt A0051005620

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

Contents

87 - Air conditioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Safety precautions when working on vehicles fitted with an air conditioner and for handling

refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Draining refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Working on refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Painting work on vehicles fitted with an air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Notes on general repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Note on vehicles with auxiliary heater (poor heating output) . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Notes on air conditioner self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Electrical checking of air conditioner components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Servicing refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 General view of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Removing and installing air conditioner high-pressure sender G65 . . . . . . . . . . . . . . . . . . 10

3.3 Checking pressure signal from high-pressure sender G65 . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 O-rings for refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Detaching compressor from holder/attaching on vehicles with 6-cyl. engine, 8-cyl. MPI engine

or 8-cyl. diesel engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 Checking activation signal for air conditioner compressor regulating valve N280 . . . . . . 16

4 Replacing compressor pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Replacing pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Detaching pulley from compressor/re-attaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Replacing pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Detaching pulley from compressor/re-attaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Components for control and regulation of air conditioner not located in passenger

compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1 Components not located in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Removing and installing dust and pollen filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Dust and pollen filter with activated charcoal filter element . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4 Cleaning air conditioner evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.5 Removing and installing air quality sensor G238 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.6 Mode of operation of air quality sensor G238 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7 Checking air quality sensor G238 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.8 Checking vent frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.9 Checking and cleaning plenum chamber water drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.10 Removing and installing intake housing with air flow flap . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.11 Removing and installing air flow flap control motor V71 with potentiometer G113 . . . . . . 45

5.12 Preparing adapter cables for control motor actuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.13 Removing and installing fresh air intake duct temperature sensor G89 . . . . . . . . . . . . . . 47

5.14 Removing and installing air recirculation flap control motor V113 . . . . . . . . . . . . . . . . . . . . 47

5.15 Removing and installing cover with air recirculation flap . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.16 Removing and installing fresh air blower V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.17 Removing and installing fresh air blower control unit J126 . . . . . . . . . . . . . . . . . . . . . . . . 55

5.18 Removing and installing pump valve unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.19 Operation of solar roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6 Heated windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.1 Operation of heated windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7 Electrical checking of components actuated by the air conditioner . . . . . . . . . . . . . . . . . . 65

7.1 Checking of heated rear window Z1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.2 Checking of heated seats and seat ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.3 Checking fuel-driven supplementary heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Contents i

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

7.4 Checking electric supplementary heater for rear footwell . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.5 Checking actuation of heated windscreen Z2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8 Components for control and regulation of air conditioner located in passenger

compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.1 Components located in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2 Removing and installing left centre vent control motor V110 . . . . . . . . . . . . . . . . . . . . . . 76

8.3 Removing and installing right centre vent control motor V111 . . . . . . . . . . . . . . . . . . . . . . 79

8.4 Removing and installing centre vent temperature sender G191 . . . . . . . . . . . . . . . . . . . . 79

8.5 Removing and installing sunlight penetration photosensor G107 . . . . . . . . . . . . . . . . . . . . 80

8.6 Removing and installing temperature sensor blower V42 . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.7 Removing and installing front operating and display unit, Climatronic control unit J255 . . 80

8.8 Removing and installing rear left footwell heater element Z42 / rear right footwell heater

element Z43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.9 Removing and installing rear left centre console temperature sensor G311 and rear right

centre console temperature sensor G312 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.10 Removing and installing rear left vent warm air and cold air flap control motor V220 . . . . 85

8.11 Removing and installing rear right vent warm air and cold air flap control motor V221 . . 87

8.12 Removing and installing rear Climatronic operating and display unit E265 . . . . . . . . . . . . 87

8.13 Removing, checking and installing condensation drain hose . . . . . . . . . . . . . . . . . . . . . . . . 90

8.14 Air conditioning unit components located in passenger compartment . . . . . . . . . . . . . . . . 92

8.15 Removing and installing defroster flap control motor V107 . . . . . . . . . . . . . . . . . . . . . . . . 93

8.16 Removing and installing centre vent control motor V102 . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.17 Removing and installing front left defroster and chest vent shut-off flap control motor V200

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.18 Removing and installing front right defroster and chest vent shut-off flap control motor V199

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.19 Removing and installing left footwell flap control motor V108 . . . . . . . . . . . . . . . . . . . . . . 101

8.20 Removing and installing right footwell flap control motor V109 . . . . . . . . . . . . . . . . . . . . . . 103

8.21 Removing and installing temperature flap control motor V68 . . . . . . . . . . . . . . . . . . . . . . 105

8.22 Removing and installing left vent temperature sender G150 . . . . . . . . . . . . . . . . . . . . . . 106

8.23 Removing and installing right vent temperature sender G151 . . . . . . . . . . . . . . . . . . . . . . 107

8.24 Removing and installing evaporator output temperature sender G263 . . . . . . . . . . . . . . . . 107

8.25 Removing and installing rear left vent control motor V218 and rear right vent control motor

V219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9 Removing and installing heat exchanger of air conditioning unit . . . . . . . . . . . . . . . . . . . . 111

9.1 Preparation for heat exchanger removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.2 Removing and installing right (front passenger side) heat exchanger . . . . . . . . . . . . . . . . 112

9.3 Removing and installing left (driver side) heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10 Block diagram of air distribution system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

10.1 Air intake and air routing in air conditioning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

10.2 Air routing and air distribution in passenger compartment . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11 Checking cooling output of air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11.1 Prerequisites for checking cooling output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

11.2 Checking cooling output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

11.3 Measures to be taken if readout does not match specification . . . . . . . . . . . . . . . . . . . . . . 128

11.4 Measures to be taken in the event of temperature increase downstream of evaporator . . 130

12 Checking heat output of air conditioner and operation of pump valve unit . . . . . . . . . . . . . . 132

12.1 Checking operation of pump valve unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

13 Servicing refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

13.1 Servicing refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

13.2 Detaching refrigerant lines at compressor/attaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

13.3 Removing and installing compressor (basic information) . . . . . . . . . . . . . . . . . . . . . . . . . . 140

13.4 Removing and installing compressor (on vehicles with 8-cyl. FSI engine) . . . . . . . . . . . . 141

13.5 Detaching compressor from holder/removing and installing (on vehicles with 12-cyl.

engine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

13.6 Removing and installing compressor (on vehicles with 10-cyl. engine, Audi S8) . . . . . . . . 153

ii Contents

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

13.7 Checking/replacing compressor drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

13.8 Unfastening and tightening compressor drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

13.9 Removing and installing compressor drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

13.10 Detaching drive plate with overload safeguard/attaching . . . . . . . . . . . . . . . . . . . . . . . . . . 163

13.11 Checking concentricity of drive plate with overload safeguard/adjusting . . . . . . . . . . . . . . 164

13.12 Unscrewing drive plate from compressor/screwing on . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

13.13 Removing and installing drive plate with rolling bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

13.14 Detaching refrigerant lines from condenser/re-attaching . . . . . . . . . . . . . . . . . . . . . . . . . . 166

13.15 Removing and installing condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

13.16 Removing and installing restrictor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

13.17 Removing and installing reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

13.18 Detaching refrigerant lines at evaporator connection/attaching . . . . . . . . . . . . . . . . . . . . . . 171

13.19 Removing and installing evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

13.20 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

13.21 Starting up air conditioner after charging refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . . . 177

14 Removing and installing air conditioning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

14.1 Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

14.2 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

15 Dismantling and assembling air conditioning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

15.1 Removing and installing covers in plenum chamber, fresh air blower and evaporator . . . . 183

15.2 Dismantling and assembling bottom part of housing and air distribution housing . . . . . . . . 187

15.3 Dismantling and assembling air distribution housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Contents iii

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

iv Contents

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

87 – Air conditioning system

1 Safety precautions when working on

vehicles fitted with an air conditioner

and for handling refrigerant

The air conditioner assemblies and piping system are filled with

the following refrigerant:

1.1.1.2 tetrafluoroethane (CF3-CH2F or CH2F-CF3)

This refrigerant is currently known in Germany by the trade names

R134a, H-FKW 134a, SUVA 134a and KLEA 134a (other trade

names may be used in other countries).

1.1 Safety precautions

The following safety precautions are to be heeded in Germany for

this refrigerant (additional regulations may apply in other coun‐

tries).

The refrigerant circuit is to be drained first should repair work re‐

quire the refrigerant circuit to be opened ⇒ page 2 . All contact

with liquid refrigerant or refrigerant vapours is to be avoided.

Should refrigerant escape despite compliance with all safety pre‐

cautions, take care never to inhale the mixture of refrigerant and

air which forms.

Extraction systems are therefore to be switched on and use made

of rubber gloves and safety goggles.

Reason:

Intensive exposure to refrigerant would cause frostbite on unpro‐

tected parts of the body.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

WARNING

It is advisable to keep an eye bath to hand.

Should liquid refrigerant come into contact with the eyes, rinse

them thoroughly with water for about 15 minutes.

Then apply eye drops and consult a doctor immediately, even

if no pain is felt.

The doctor should be informed of the type of refrigerant which

caused the frostbite.

Should refrigerant come into contact with other parts of the body

despite compliance with all safety precautions, these must like‐

wise be thoroughly rinsed without delay for at least 15 minutes

with cold water.

Although refrigerants do not represent a fire hazard, smoking,

welding, soldering and brazing are not permitted in areas exposed

to refrigerant.

Reason:

The high temperature of a naked flame or hot objects causes re‐

frigerant gas to undergo chemical decomposition. The inhalation

of the toxic decomposition products results in dry coughing and

nausea.

1. Safety precautions when working on vehicles fitted with an air conditioner and for handling refrigerant 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

1.2 Draining refrigerant circuit

Refrigerant must not be allowed to escape into the environment.

It should be extracted from the refrigerant circuit by means of a

suction unit or service station. The refrigerant removed is then

either to be re-processed on site or returned to the manufacturer

for proper disposal (different or additional regulations may apply

in other countries). For this reason, the vehicle is to be taken to a

workshop equipped with the necessary tools where the work can

be performed by appropriately qualified personnel ⇒ Air condi‐

tioner with refrigerant R134a .

Reason:

Should it escape into the earth's atmosphere, refrigerant R134a

will have a detrimental effect in terms of »global warming«.

Note

♦

Refrigerant R134a has far less of a greenhouse effect than

refrigerant R12.

♦

The refrigerant R134a does not affect the ozone layer in the

earth's atmosphere ( -R134a- is an H-FC with no chlorine

atoms). The depletion of the ozone in the upper atmosphere

is however only caused by the splitting of carbon-chlorine

bonds (as is the case, for example, with the refrigerant R12).

After draining the air conditioner, unplug the connector from the

air conditioner compressor regulating valve -N280- or from the

high-pressure sender -G65- .

Reason:

The air conditioner compressor regulating valve -N280- is then no

longer actuated and the compressor runs at idle. The compressor

is designed such that lubrication of the compressor components

is guaranteed by way of an internal oil circuit at idle (provided

there is sufficient refrigerant oil in the compressor).

1.3 Working on refrigerant circuit

Work on the refrigerant circuit is only to be performed in well ven‐

tilated areas. Care should be taken to ensure that there are no

inspection pits, shafts or cellar entrances within a radius of 5 me‐

tres. Extraction systems are to be switched on.

Reason:

The refrigerant which emerges is not only colourless and odour‐

less, but also heavier than air and therefore displaces oxygen.

Should refrigerant gas escape despite compliance with all safety

precautions, there will be a previously impercepible risk of as‐

phyxiation in poorly ventilated areas and inspection pits.

Note

The mixture of gas and air which forms when refrigerant gas es‐

capes is not to be inhaled. It must be extracted using suitable

extraction systems (workshop extractor).

Welding, brazing and soldering operations are not to be per‐

formed on air conditioner components when filled. The same

applies to welding and soldering work on the vehicle if there is a

risk that parts of the air conditioner could become warm.

2 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Reason:

Heat generation causes considerable pressure to build up in the

system and this could lead to rupturing of the system.

Remedy:

Drain the refrigerant circuit ( ⇒ page 2 ).

Note

Damaged or leaking air conditioner components are not to be re‐

paired by welding or soldering, but should be replaced.

When servicing the air conditioner, all open components and pipe

connections are to be immediately re-sealed.

Reason:

Moisture will ingress into the air conditioner components if they

are left open for a lengthy period. If this is the case, air condition‐

ers cannot be re-filled without having to replace parts of the

system.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

1.4 Painting work on vehicles fitted with an air conditioner

When performing paintwork repairs, the temperature in the drying

booth or preheating zone must not exceed 80 °C.

Reason:

Heat generation causes considerable pressure to build up in the

system and this could lead to rupturing of the system.

1.5 Further information

♦ In the vehicle diagnostic, testing and information system -

VAS 5051 A- , „Guided fault-finding“ routine ⇒ "Guided faultfinding" function of vehicle diagnostic, testing and information

system VAS 5051.

♦ The appropriate current flow diagrams can be found in the

Current flow diagrams, Electrical fault-finding and Fitting lo‐

cations binder ⇒ Current flow diagrams, Electrical fault finding

and Fitting locations.

♦ A label in the engine compartment indicates the refrigerant

used as well as the capacity.

♦ Further information on repair work for vehicles fitted with an

air conditioner and on handling refrigerant is stored in ⇒ Air

conditioner with refrigerant R134a .

1. Safety precautions when working on vehicles fitted with an air conditioner and for handling refrigerant 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

2 Notes on general repairs

DANGER!

Remove the appropriate fuse(s) before working on wiring.

Note

Disconnect batteries before starting electric welding work on the

vehicle ⇒ Electrical system; Rep. gr. 27

It is only permissible if so required by the pertinent safety regu‐

lations ( ⇒ page 2 ), or if parts of the air conditioner refrigerant

circuit have to be replaced, to drain and open the air conditioner

refrigerant circuit ( ⇒ page 2 ).

The air conditioner refrigerant circuit must remain closed during

all other normal vehicle repair operations.

Service work which can be performed on the heater and air con‐

ditioner without opening the refrigerant circuit is described in this

Workshop Manual ⇒ page 26 .

Note

The connections for the senders/switches described in this Work‐

shop Manual are fitted with a valve which closes automatically

when the switches are unscrewed. These switches can therefore

be replaced at any VW/Audi workshop without draining the re‐

frigerant circuit.

Air conditioner servicing work which requires drainage of the re‐

frigerant circuit and which thus cannot be performed at all Audi

and VW workshops is also described in this workshop manual

⇒ page 135 (for drainage of the refrigerant circuit, the vehicle is

to be taken to a workshop equipped with the necessary tools

where the work can be performed by appropriately qualified per‐

sonnel ⇒ Air conditioner with refrigerant R134a ).

2.1 Note on vehicles with auxiliary heater (poor heating output)

In the event of problems with poor heat output, check the air con‐

ditioner heat output and operation of the pump valve unit

⇒ page 132 .

In the event of problems relating to poor or inadequate heat output

at low engine speeds on vehicles fitted with an auxiliary heater as

optional extra, check actuation of the auxiliary/supplementary

heater circulation pump -V55- by the supplementary heater con‐

trol unit -J364- ⇒ Auxiliary/supplementary heater; Rep. gr. 82

and ⇒ "Guided fault-finding" function of vehicle diagnostic, testing

and information system VAS 5051 (auxiliary heater guided faultfinding).

♦ Actuation of the circulation pump -V55- increases the flow of

coolant through the air conditioner heat exchanger at low en‐

gine speeds and thus improves heat output.

♦ The supplementary heater control unit -J364- switches on the

circulation pump -V55- for example if it receives the following

information via the convenience data bus system (⇒ Auxiliary/

supplementary heater; Rep. gr. 82 and ⇒ "Guided fault-find‐

4 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

ing" function of vehicle diagnostic, testing and information

system VAS 5051 ).

– Ignition on and engine running

– Ambient temperature less than 20 °C

– Engine speed less than 2000 rpm

– Front operating and display unit, Climatronic control unit -

J255- switched on ( OFF button not pressed)

– Heat output requested for at least one side (driver or front

passenger side)

♦ The circulation pump -V55- is switched on as soon as all ac‐

tivation conditions are fulfilled. To stop the circulation pump

being constantly switched off and on, it remains activated for

at least 30 s even if - for example in the event of rapid changes

in vehicle speed - a request is only applied for a few seconds

(e.g. on accelerating after standing at traffic lights).

♦ For incorporation of the auxiliary/supplementary heater (and

circulation pump -V55- ) into the coolant circuit, refer to ⇒

Auxiliary/supplementary heater; Rep. gr. 82

2.2 Notes on air conditioner self-diagnosis

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

♦ There are different versions of the front operating and display

unit, Climatronic control unit -J255- and the rear Climatronic

operating and display unit -E265- . Pay attention to precise

assignment on replacement. ⇒ Electronic parts catalogue

♦ Air conditioner self-diagnosis is to be performed by way of the

„Guided fault-finding“ function using the vehicle diagnostic,

testing and information system -VAS 5051 A- ⇒ "Guided faultfinding" function of vehicle diagnostic, testing and information

system VAS 5051.

♦ Front operating and display units can no longer be exchanged

in the familiar manner. Component protection is activated as

soon as a front operating and display unit, Climatronic control

unit -J255- has been matched to a vehicle. The component

protection feature can only be cancelled by entering certain

vehicle data ⇒ ”Guided fault-finding” function of vehicle diag‐

nostic, testing and information system VAS 5051.

♦ If a front operating and display unit with active component

protection (anti-theft system) is installed in a different vehicle,

the functions required for vehicle security can still be selected,

but not the convenience functions ⇒ "Guided fault-finding"

function of vehicle diagnostic, testing and information system

VAS 5051.

♦ If a front operating and display unit, Climatronic control unit -

J255- (or the rear Climatronic operating and display unit E265- ) is to be replaced, interrogate the encoding (of the front

operating and display unit, Climatronic control unit -J255- ) and

the adaption (of the front operating and display unit, Clima‐

tronic control unit -J255- and the rear Climatronic operating

and display unit -E265- ) by way of the „Control unit replace‐

ment“ function in the guided fault-finding routine for this oper‐

ating and display unit prior to removal ⇒ "Guided fault-finding"

function of vehicle diagnostic, testing and information system

VAS 5051.

♦ The „Electrical checks“ function is not described in this Work‐

shop Manual. When implementing electrical checks by way of

the „Guided fault-finding“ function, information is given on the

functions to be checked ⇒ "Guided fault-finding" function of

vehicle diagnostic, testing and information system VAS 5051.

♦ The temperature-dependent resistance values of the various

temperature sensors are stored in tables which can be called

2. Notes on general repairs 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

up via the „Guided fault-finding“ function ⇒ "Guided fault-find‐

ing" function of vehicle diagnostic, testing and information

system VAS 5051.

♦ Lengthy pressing of the buttons on the front operating and

display unit, Climatronic control unit -J255- or the rear Clima‐

tronic operating and display unit -E265- (e.g. caused by ob‐

jects resting on them) may lead to the fault "buttons sticking"

being stored in the fault memory. If applicable, check operation

of the buttons and erase the fault memory if no problem is

found.

♦ Depending on vehicle equipment, various control units actu‐

ated by the front operating and display unit, Climatronic control

unit -J255- / rear Climatronic operating and display unit -E265are displayed on entering the self-diagnosis routine (e.g. driver

seat ventilation control unit -J672- , heated windscreen control

unit -J505- ).

♦ As of Model Year 2009, front operating and display units, Cli‐

matronic control unit -J255- with part number 4E0 820 043 as

of index „J“ are gradually being introduced ⇒ Electronic parts

catalogue . On vehicles with such front operating and display

units, the screen display for example of the „MMI“ (Multi Media

Interface) is no longer switched to „Air conditioning“ on press‐

ing the buttons and actuating the controls of the front operating

and display unit. The air conditioner functions selected are in‐

corporated into the current display. On these vehicles, certain

air conditioner functions are selected and activated by way of

the rotary knob/pushbutton of the operating unit for the „MMI“

⇒ Owner's manual and ⇒ Operating instructions for „Infotain‐

ment / MMI“ . In addition, front operating and display units of

this type feature an A/C button instead of the Setup button

and an OFF

manual .

♦ Pay attention to correct assignment of the front operating and

display unit, Climatronic control unit -J255- to control unit 1 for

information electronics -J794- (different versions) ⇒ Electronic

parts catalogue . In the event of incorrect assignment, the var‐

ious air conditioner functions cannot be displayed in the MMI

and selected.

♦ With front operating and display units, Climatronic control unit

-J255- as of software version „X078“, the type of engine is en‐

coded (on vehicles with FSI engine, the transmission ratio at

the pulleys and thus the torque for driving the compressor are

different than for other engines) ⇒ "Guided fault-finding" func‐

tion of vehicle diagnostic, testing and information system

VAS 5051.

♦ The assignment and display in the various display groups dif‐

fer depending on whether the rear Climatronic operating and

display unit -E265- was installed prior to or as of November

2002. On the version fitted as of November 2002, certain dis‐

play groups are also no longer used ⇒ "Guided fault-finding"

function of vehicle diagnostic, testing and information system

VAS 5051.

button instead of the ON/OFF button ⇒ Owner's

2.3 Electrical checking of air conditioner components

♦ The air conditioner „Electrical checks“ function is not descri‐

bed in this Workshop Manual. When implementing electrical

checks by way of the „Guided fault-finding“ function, informa‐

tion is given on the functions to be checked ⇒ "Guided faultfinding" function of vehicle diagnostic, testing and information

system VAS 5051.

♦ The temperature-dependent resistance values of the various

temperature sensors are stored in a table which can be called

up via the „Guided fault-finding“ function ⇒ "Guided fault-find‐

6 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

ing" function of vehicle diagnostic, testing and information

system VAS 5051.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

2. Notes on general repairs 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

3 Servicing refrigerant circuit

Note

♦

For servicing work on refrigerant circuit, refer to

⇒ page 135 .

♦

All parts/operations marked

1)

can be serviced and replaced/performed in any workshop

(work not involving the refrigerant circuit).

♦

All parts of the refrigerant circuit not marked 1) as well as all

refrigerant hoses and lines pipes can only be serviced or re‐

placed at workshops equipped with the necessary tools where

the work can be performed by appropriately qualified person‐

nel (the refrigerant circuit has to be drained) ⇒ Air conditioner

with refrigerant R134a .

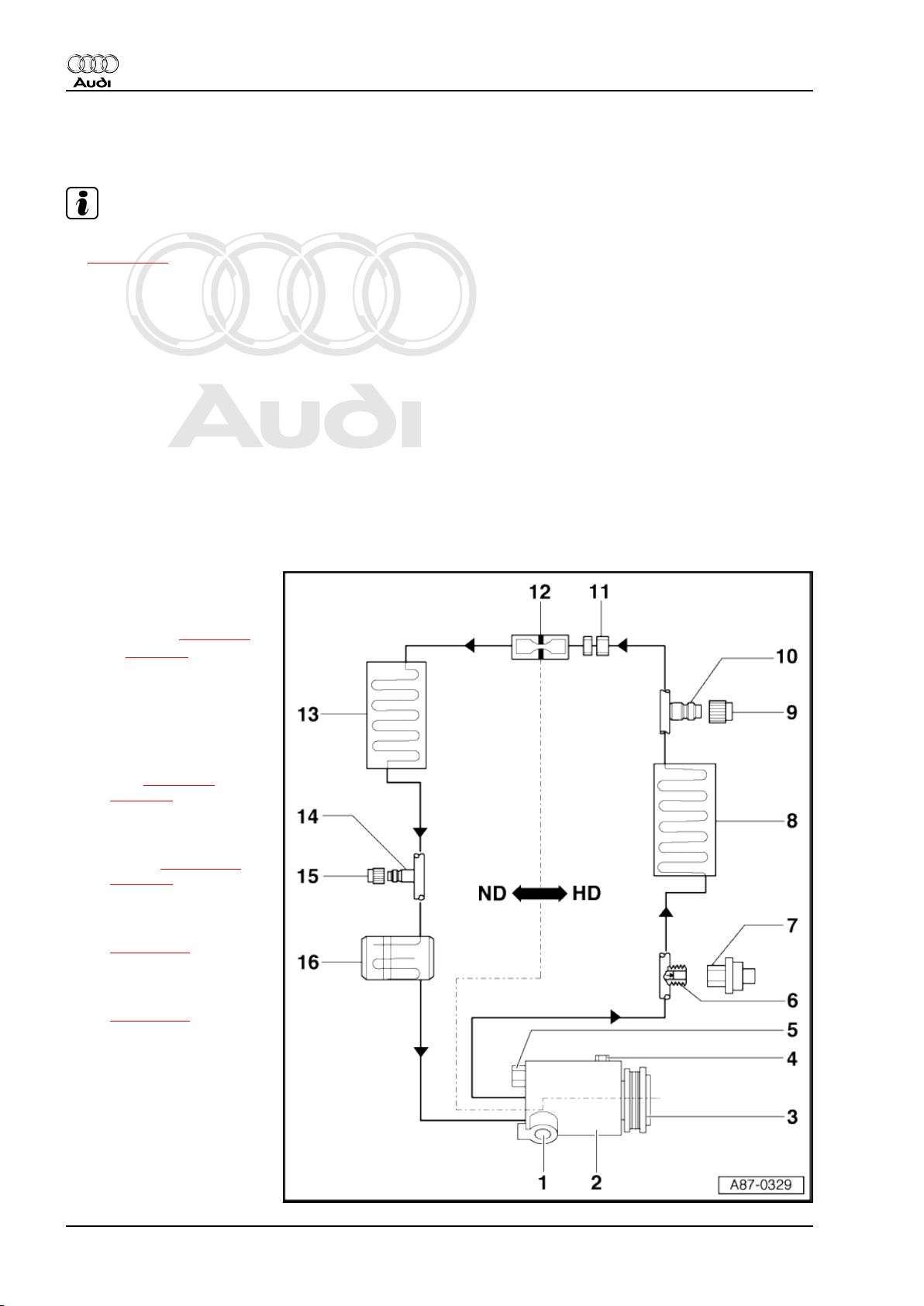

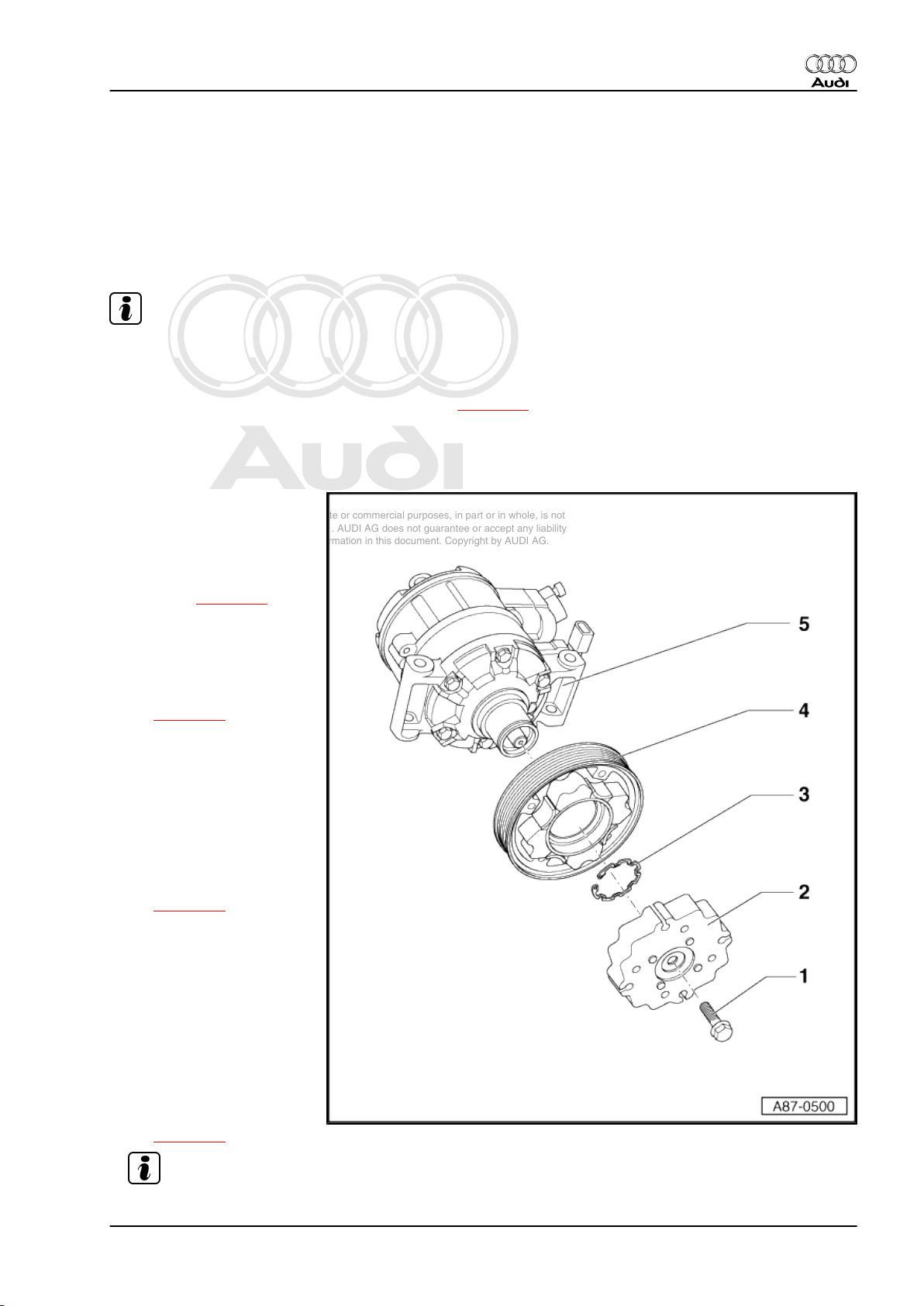

3.1 General view of components

HD = High-pressure end

ND = Low-pressure end

1 - Air conditioner compressor

regulating valve -N280-

❑ Checking actuation and

operation ⇒ page 16

1)

⇒ page 8

2 - Compressor

❑ Detaching compressor

from holder/re-attaching

on vehicles with 6-cyl.

engine, 8-cyl. MPI en‐

gine or 8-cyl. diesel en‐

gine ⇒ page 14 1) and

⇒ page 8

❑ Detaching compressor

from holder/re-attaching

on vehicles with 12-cyl.

engine ⇒ page 149 and

⇒ page 8

❑ Removing and installing

compressor on vehicles

with 8-cyl. FSI engine

⇒ page 141

❑ Removing and installing

compressor on vehicles

with 10-cyl. engine

⇒ page 153

❑ When installing the re‐

frigerant lines and the

corresponding holder,

make sure there is suffi‐

cient distance between

the belt, holder and pul‐

ley.

❑ The type of compressor

differs depending on the

engine (6, 8, 10 or 12cyl. engine, diesel or

8 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

petrol engine) ⇒ Elec‐

tronic parts catalogue

Different refrigerant oil capacities apply to the refrigerant circuit depending on the type of compressor („6 SEU

14“, „7 SEU 16“ or „7 SEU 17“) ⇒ Electronic parts catalogue and ⇒ Air conditioner with refrigerant R134a

3 - Pulley/drive unit for compressor

❑

Replacing compressor pulley 1) ⇒ page 19

❑

Removing and installing poly V-belt 1) ⇒ Engine, mechanics; Rep. gr. 13

❑ Poly V-belt assignment ⇒ Electronic parts catalogue

❑ Replacing compressor drive unit (vehicles with 8-cyl. FSI or 10-cyl. engine) ⇒ page 161

Note

4 - Oil drain plug

5 - Pressure relief valve

6 - Connection with valve

❑ Use an adapter from the adapter set for service connections -T10364- for example for removing and

installing the valve insert with the refrigerant circuit drained.

WARNING

The refrigerant circuit

must always be drained

before removing the

valve insert.

7 - High-pressure sender -G65- 1) ⇒ page 8

❑ Removing and installing ⇒ page 10

❑ Checking signal ⇒ page 10

8 - Condenser

9 - Cap

❑ With seal

❑ Always to be screwed on

10 - Service connection

❑ High-pressure end

❑ For service station for measuring, draining and filling ⇒ Air conditioner with refrigerant R134a

❑ For measurement, drainage and filling; the vehicle is to be taken to a workshop equipped with the nec‐

essary tools where the work can be performed by appropriately qualified personnel ⇒ Air conditioner

with refrigerant R134a

❑ Different versions (with primary sealing valve or Schrader valve) depending on the refrigerant line; dis‐

tinguishing features ⇒ Air conditioner with refrigerant R134a

❑ Use an adapter from the adapter set for service connections -T10364- for example for removing and

installing the service connection or valve insert with the refrigerant circuit drained.

11 - Union in refrigerant line

12 - Restrictor

❑ Fitted in union ⇒ Item 11 (page 9)

13 - Evaporator

14 - Service connection

❑ Low-pressure end

❑ For service station for measurement and drainage ⇒ Air conditioner with refrigerant R134a

❑ For measurement and drainage; the vehicle is to be taken to a workshop equipped with the necessary

tools where the work can be performed by appropriately qualified personnel ⇒ Air conditioner with re‐

frigerant R134a

3. Servicing refrigerant circuit 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

❑ Different versions (with primary sealing valve or Schrader valve) depending on the refrigerant line; dis‐

tinguishing features ⇒ Air conditioner with refrigerant R134a

❑ Use an adapter from the adapter set for service connections -T10364- for example for removing and

installing the service connection or valve insert with the refrigerant circuit drained.

WARNING

The refrigerant circuit

must be drained before

removing the service

connections (the con‐

nection has no valve).

15 - Cap

❑ With seal

❑ Always to be screwed on

16 - Reservoir

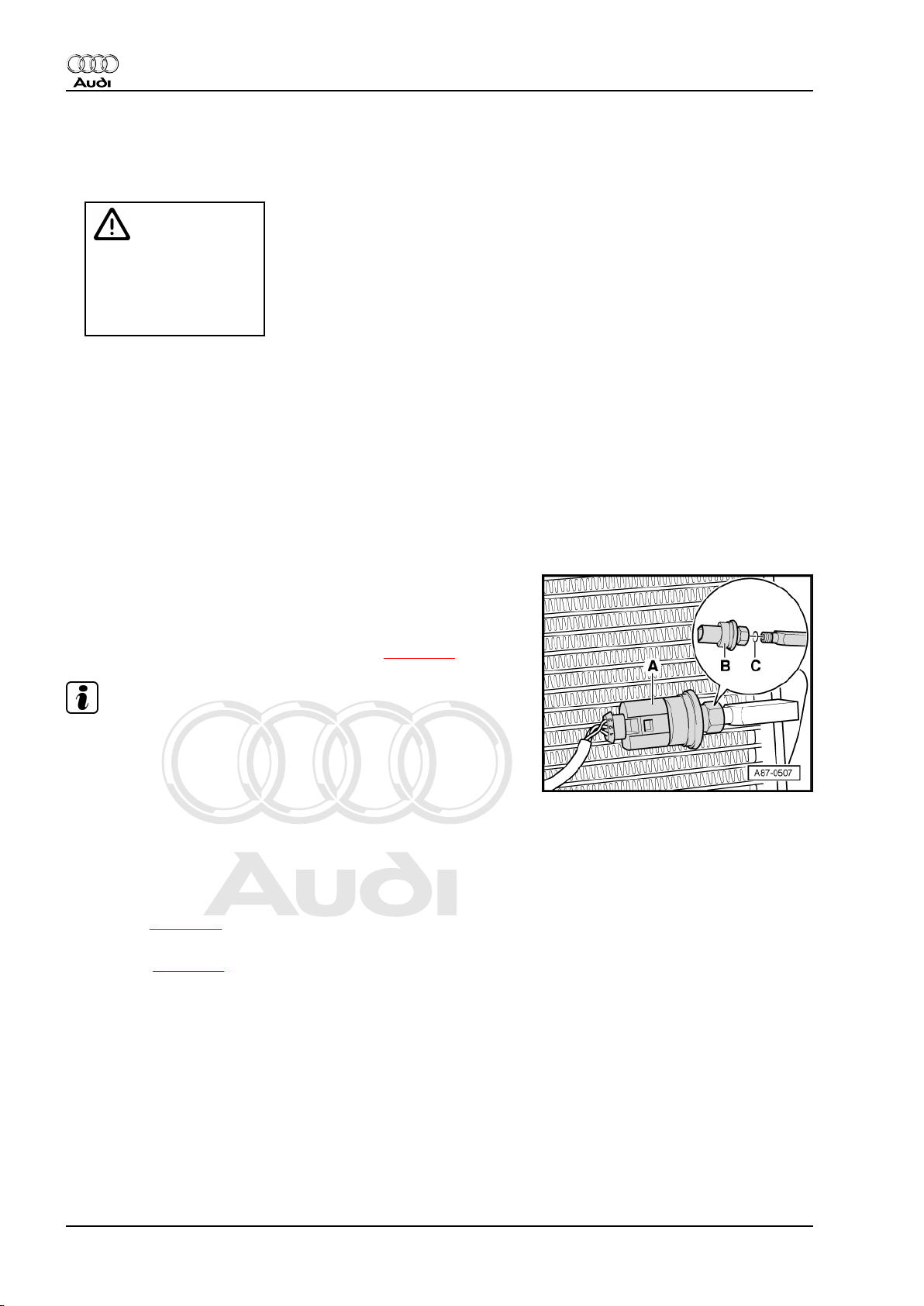

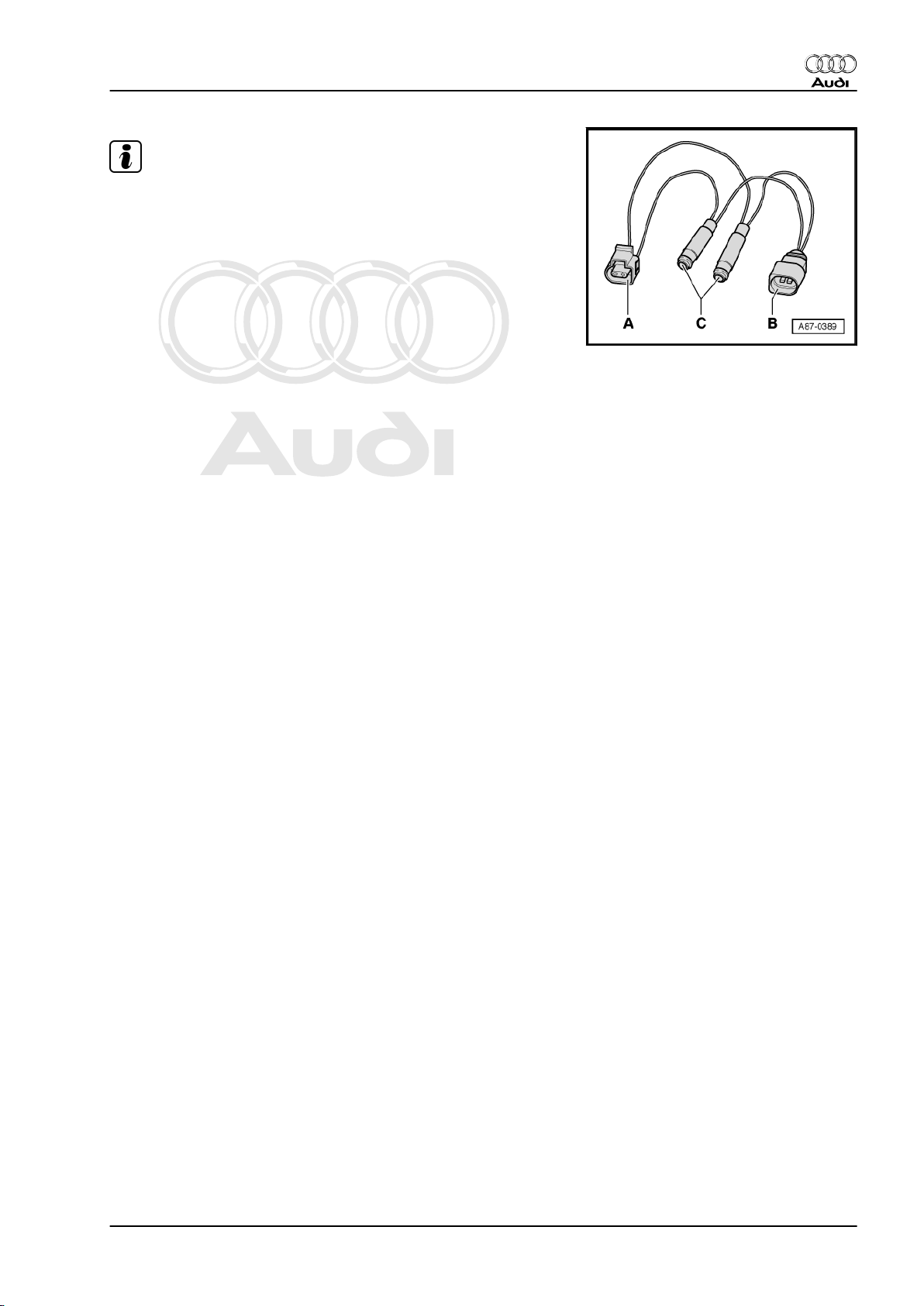

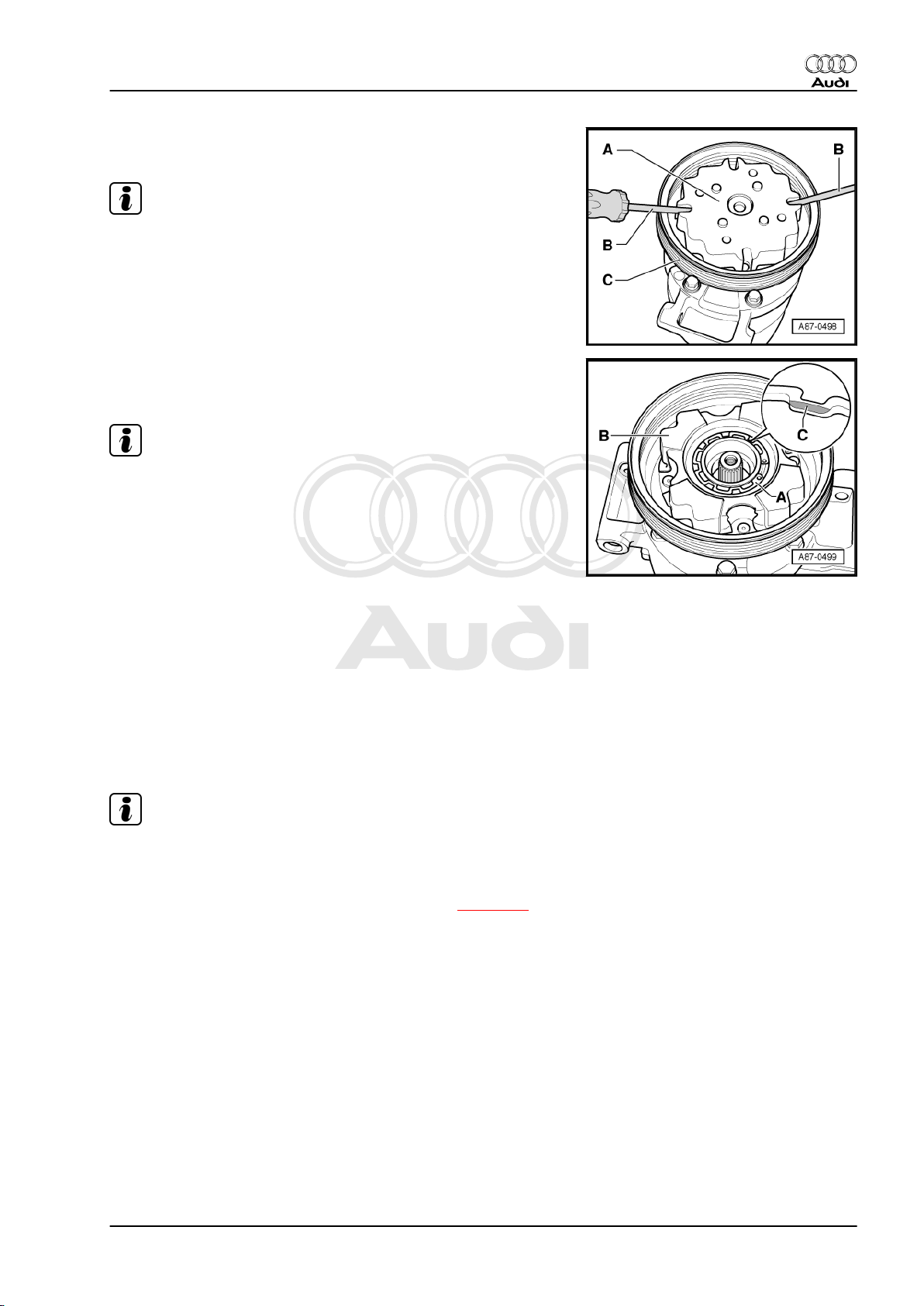

3.2 Removing and installing air conditioner high-pressure sender -G65-

– Remove the radiator grille ⇒ General body repairs, exterior;

Rep. gr. 50 .

– Unplug the connector -A-.

– Remove the high-pressure sender -G65- -B- (tightening tor‐

que: 5 Nm).

– Replace the O-ring -C- (10.8 mm; 1.8 mm) ⇒ page 13 .

Note

♦

The cooling output cannot be checked with the high-pressure

sender -G65- removed. The front operating and display unit,

Climatronic control unit -J255- does not switch on the com‐

pressor.

♦

There are different versions of the high-pressure sender -G65(different signals). Attention is therefore to be paid to correct

assignment ⇒ Electronic parts catalogue .

♦

The refrigerant circuit is to be left closed, connection with

valve.

♦

Checking operation of high-pressure sender -G65- and signal

supplied ⇒ page 10 .

♦

Moisten the O-ring with a small quantity of refrigerant oil before

installing ⇒ page 13 .

3.3 Checking pressure signal from highpressure sender -G65-

– Remove the radiator grille ⇒ General body repairs, exterior;

Rep. gr. 50 .

10 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Unplug the connector -A-.

3.3.1 Pin assignment at high-pressure sender

-G65-

-Contact 1- Earth

-Contact 2- Signal output (square-wave signal to front operating

and display unit, Climatronic control unit -J255- )

-Contact 3- Positive (terminal 75)

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

Note

♦

The compressor is not switched on if the connector -B- is un‐

plugged.

♦

The high-pressure sender -A- is an electronic control unit

which generates a square-wave signal with a ratio which var‐

ies with the pressure in the refrigerant circuit ⇒ page 12 .

♦

3. Servicing refrigerant circuit 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

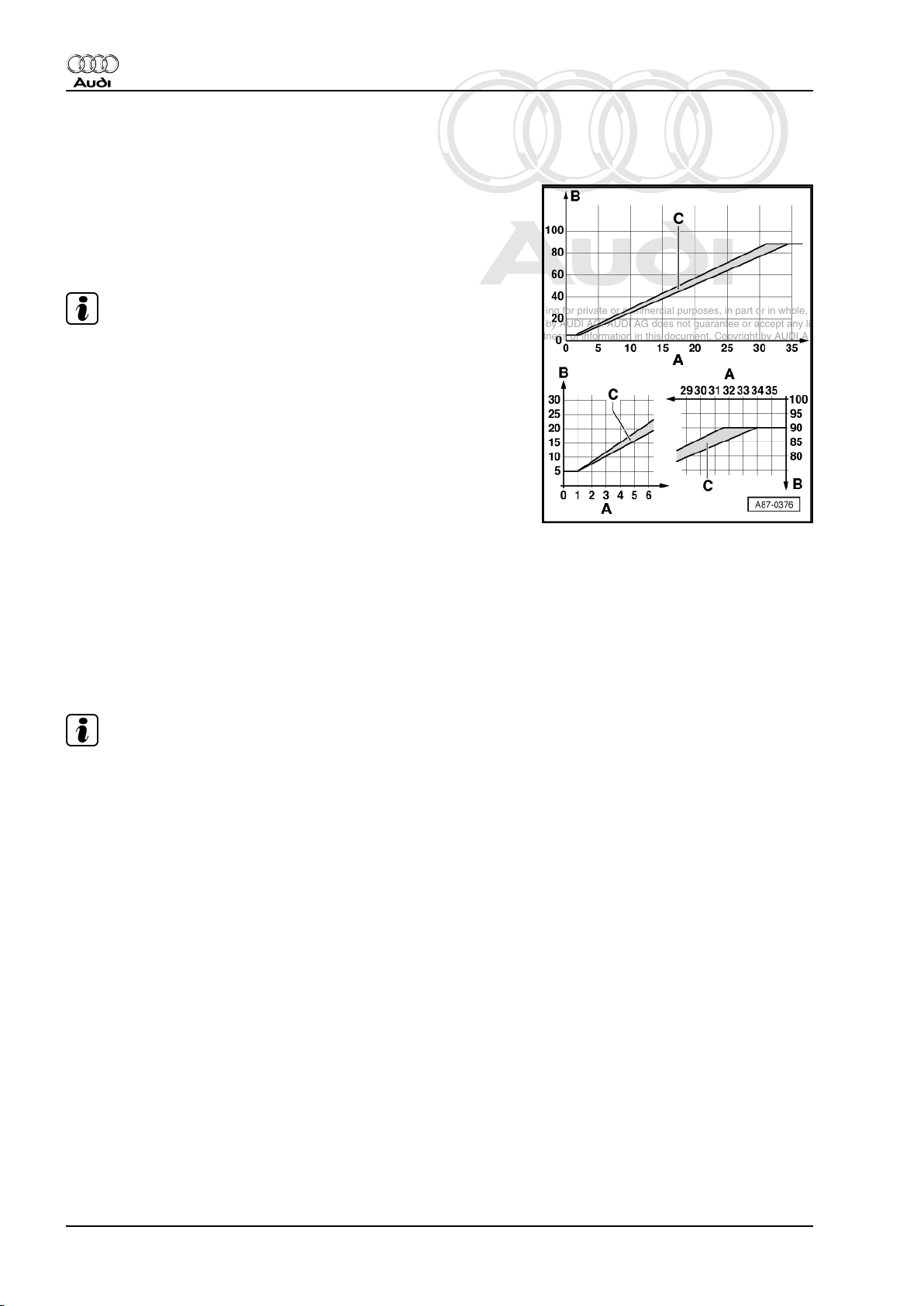

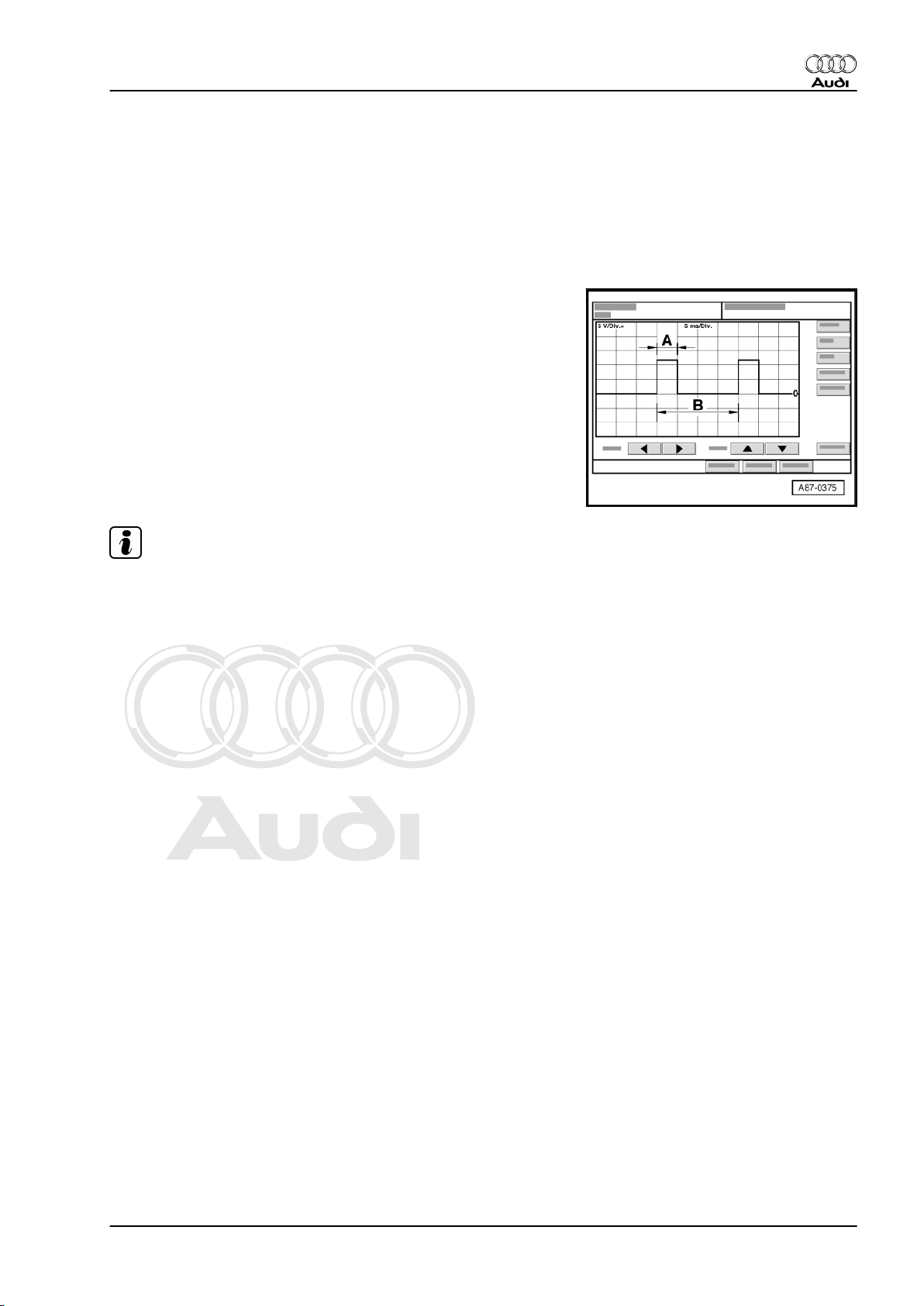

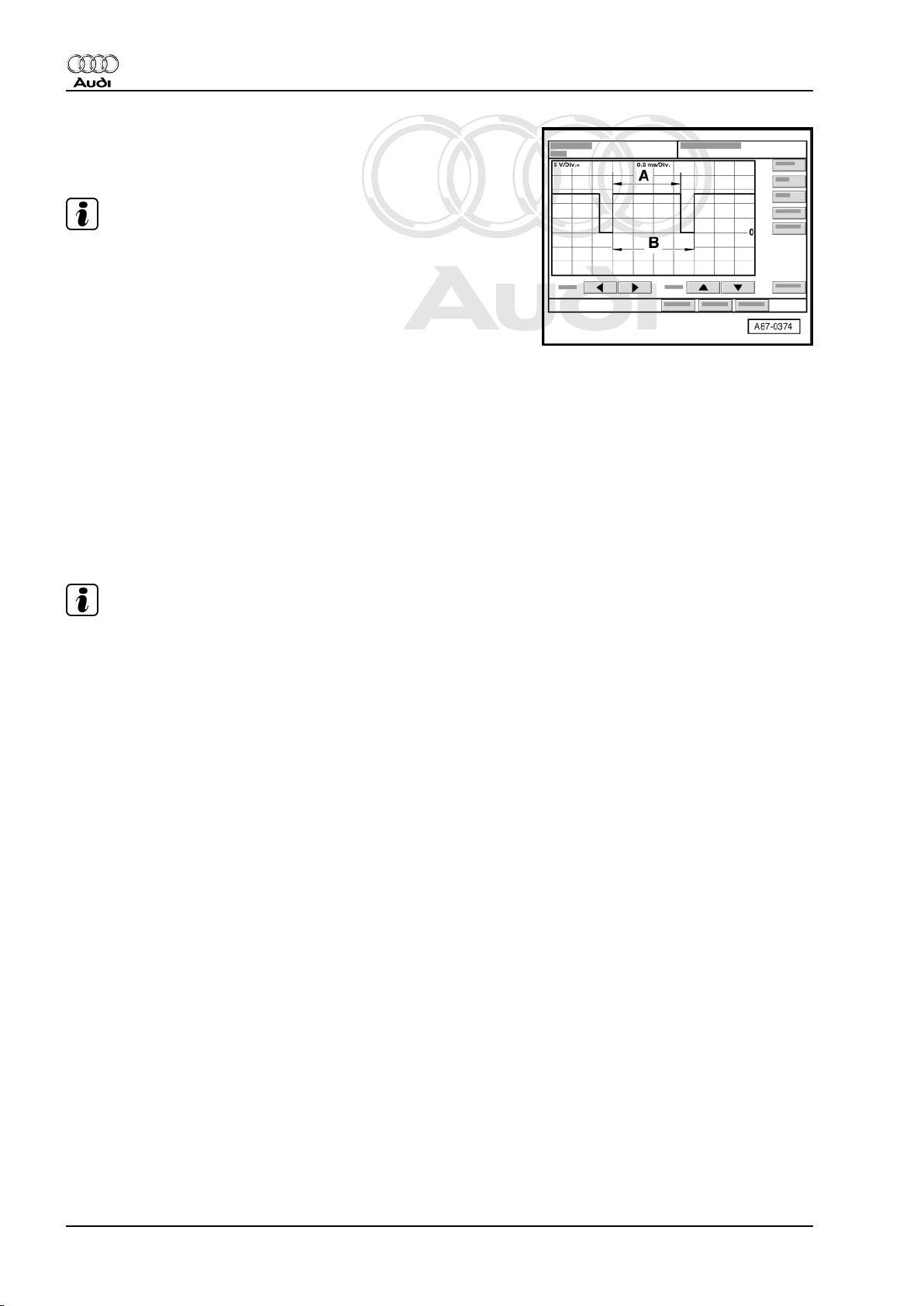

3.3.2 Pressure signal from high-pressure sender -G65-

-A- Pressure on high-pressure end of refrigerant circuit in bar

(absolute)

-B- Ratio of square-wave signal

-C- Characteristic curve

Note

♦

As soon as there are no compressor shut-off criteria, the front

operating and display unit, Climatronic control unit -J255switches on the compressor (by actuating the air conditioner

compressor regulating valve -N280- ):

♦

The signal generated by the high-pressure sender -G65- is

also used for engine control. The front operating and display

unit, Climatronic control unit -J255- transmits the information

via the convenience data bus system to the engine control unit

(the torque required for driving the compressor is governed by

the pressure in the refrigerant circuit). Depending on the ver‐

sion of the engine control unit, the signal is displayed as a ratio

in the measured value block ⇒ "Guided fault-finding" function

of vehicle diagnostic, testing and information system

VAS 5051 (for engine control unit)

♦ The pressure in the refrigerant circuit is OK (the front operating

and display unit, Climatronic control unit -J255- does not de‐

tect any compressor shut-off criteria)

– If the ratio is greater than 12 % (corresponding to approx. 1.8

bar absolute) and less than 87.5% (corresponding to approx.

32 bar absolute)

Note

♦

If the signal ratio is less than 12 % or greater than 87.5%, the

compressor is not switched on (the air conditioner compressor

regulating valve -N280- is not actuated).

♦

The signal ratio and the pressure calculated by the front op‐

erating and display unit, Climatronic control unit -J255- are

indicated in the measured value block ⇒ "Guided fault-finding"

function of vehicle diagnostic, testing and information system

VAS 5051.

♦

At absolute pressure, 0 bar corresponds to an absolute vac‐

uum. Normal ambient pressure thus corresponds to roughly 1

bar absolute. On the scales of most pressure gauges, 0 bar

corresponds to an absolute pressure of one bar (can be seen

from -1 mark below 0).

♦ The front operating and display unit, Climatronic control unit -

J255- transmits the request for radiator fan actuation via the

convenience data bus system to the engine control unit, which

then switches on the radiator fan by way of the fan control unit:

– Irrespective of the pressure in the refrigerant circuit as soon

as the compressor is switched on

12 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Depending on the pressure calculated in the refrigerant circuit,

the front operating and display unit, Climatronic control unit J255- transmits the request for increased radiator fan speed

to the engine control unit via the convenience data bus system

with the compressor actuated. The fan speed determined by

the front operating and display unit, Climatronic control unit J255- is displayed in the measured value block ⇒ "Guided

fault-finding" function of vehicle diagnostic, testing and infor‐

mation system VAS 5051.

This pattern will appear on the oscilloscope screen (e.g. on the

vehicle diagnostic, testing and information system -VAS 5051 A- )

if the following conditions are satisfied.

– Ignition on (positive at contact „3“ and earth at contact „1“ at

high-pressure sender -G65- )

– Setting on oscilloscope: 5 V/div. DC (5 V per unit DC voltage)

5 ms/div. (5 milliseconds per unit)

– Test lead (signal wire) connected to contact „2“ at high-pres‐

sure sender -G65-

– Test lead (screen) connected to contact „1“ (earth at high-

pressure sender -G65- )

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

Note

♦

Use can be made for connection of the high-pressure sender

-G65- of test leads from the Adapter set -V.A.G 1594 C- for

example.

♦

The illustration shows the signal transmitted at a refrigerant

circuit pressure of approx. 7 bar absolute, corresponding to a

signal ratio of approx. 25% (level occurring with compressor

not running, ambient temperature of 30 °C and refrigerant cir‐

cuit charged).

♦

The pulse width -A- is governed by the pressure in the refrig‐

erant circuit (area -A- becomes broader as pressure increa‐

ses).

♦

The signal distance -B- is always 20 milliseconds (correspond‐

ing to a frequency of 50 hertz).

♦

The signal ratio is derived from the ratio of pulse width -A- to

signal distance -B-.

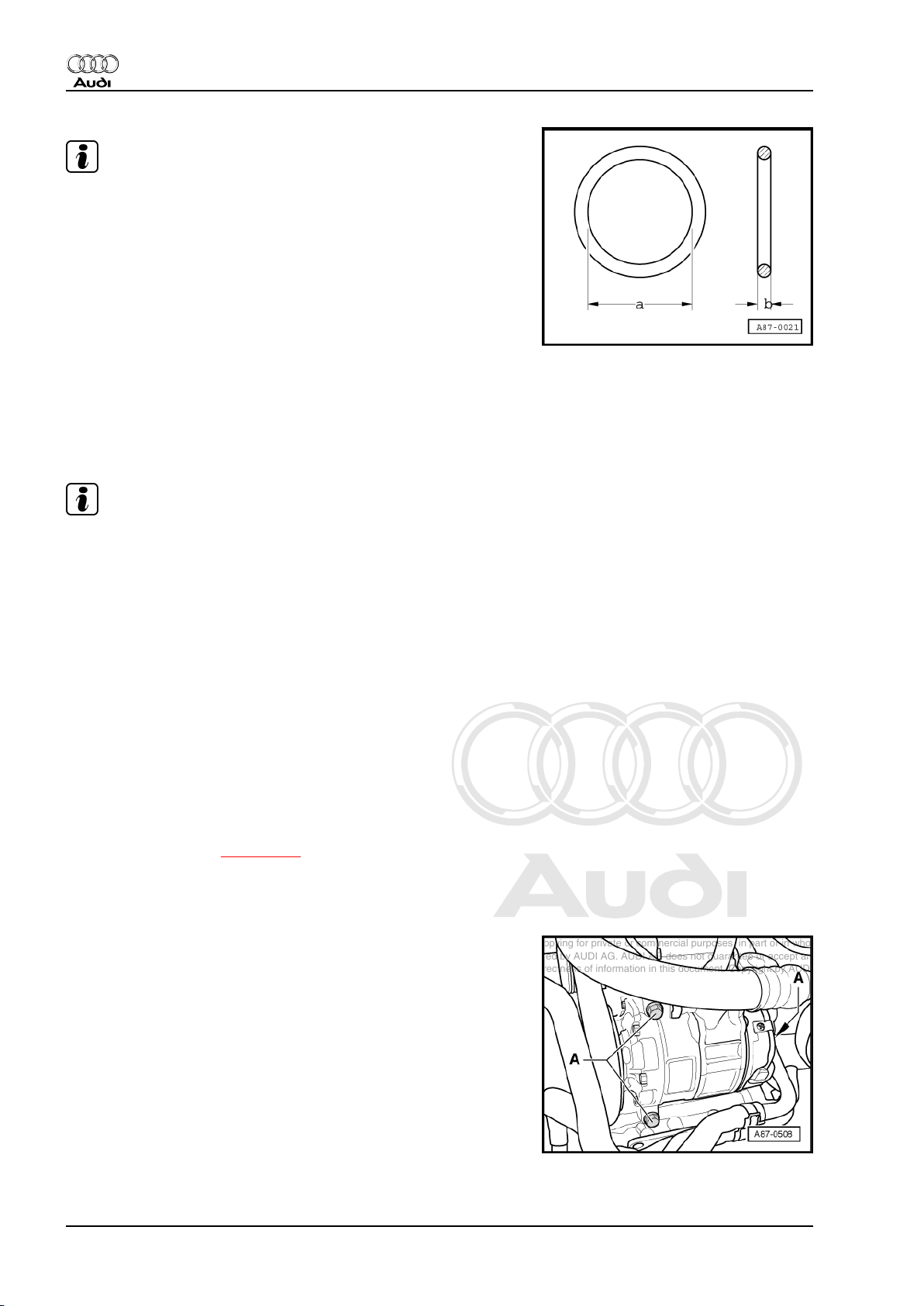

3.4 O-rings for refrigerant circuit

♦ Always replace, only to be used once.

♦ Moisten with refrigerant oil before fitting.

♦ Ensure correct positioning on pipe/in groove.

♦ Ensure cleanliness when working.

3. Servicing refrigerant circuit 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

Note

♦

Use is only to be made of O-rings which are resistant to re‐

frigerant R134a and the corresponding refrigerant oil. Such Orings are colour coded to prevent mix-ups (currently „red“,

„lilac“ or „violet“): ⇒ Electronic parts catalogue

♦

Dimensions -a- and -b- differ depending on the fitting location

of the O-ring: ⇒ Electronic parts catalogue

♦

In addition to the coloured O-rings, use is also made at the

factory of black O-rings for certain connections.

3.5 Detaching compressor from holder/at‐

taching on vehicles with 6-cyl. engine, 8cyl. MPI engine or 8-cyl. diesel engine

Compressor drive via poly V-belt

Note

♦

The compressor can be detached from the holder and re-at‐

tached without opening up the refrigerant lines.

♦

Do not drain the refrigerant circuit, do not detach the refriger‐

ant hoses and lines at the compressor.

♦

After detaching, use a piece of wire for example to attach the

compressor to the longitudinal member. Never leave hanging

from the refrigerant lines.

♦

Before removing, mark the direction of the poly V-belt with

chalk or a felt-tip pen. Running a used belt in the opposite di‐

rection could destroy it.

♦

Different compressors are fitted depending on the engine and

country version (6, 8, 10 or 12-cyl. engine, petrol or diesel en‐

gine). ⇒ Electronic parts catalogue

♦

On vehicles with 8-cyl. diesel engine, the compressor is fitted

at the top between the two cylinder heads.

♦

Detaching compressor from holder/re-attaching on vehicles

with 12-cyl. engine ⇒ page 149

3.5.1 Detaching compressor from holder/reattaching

14 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

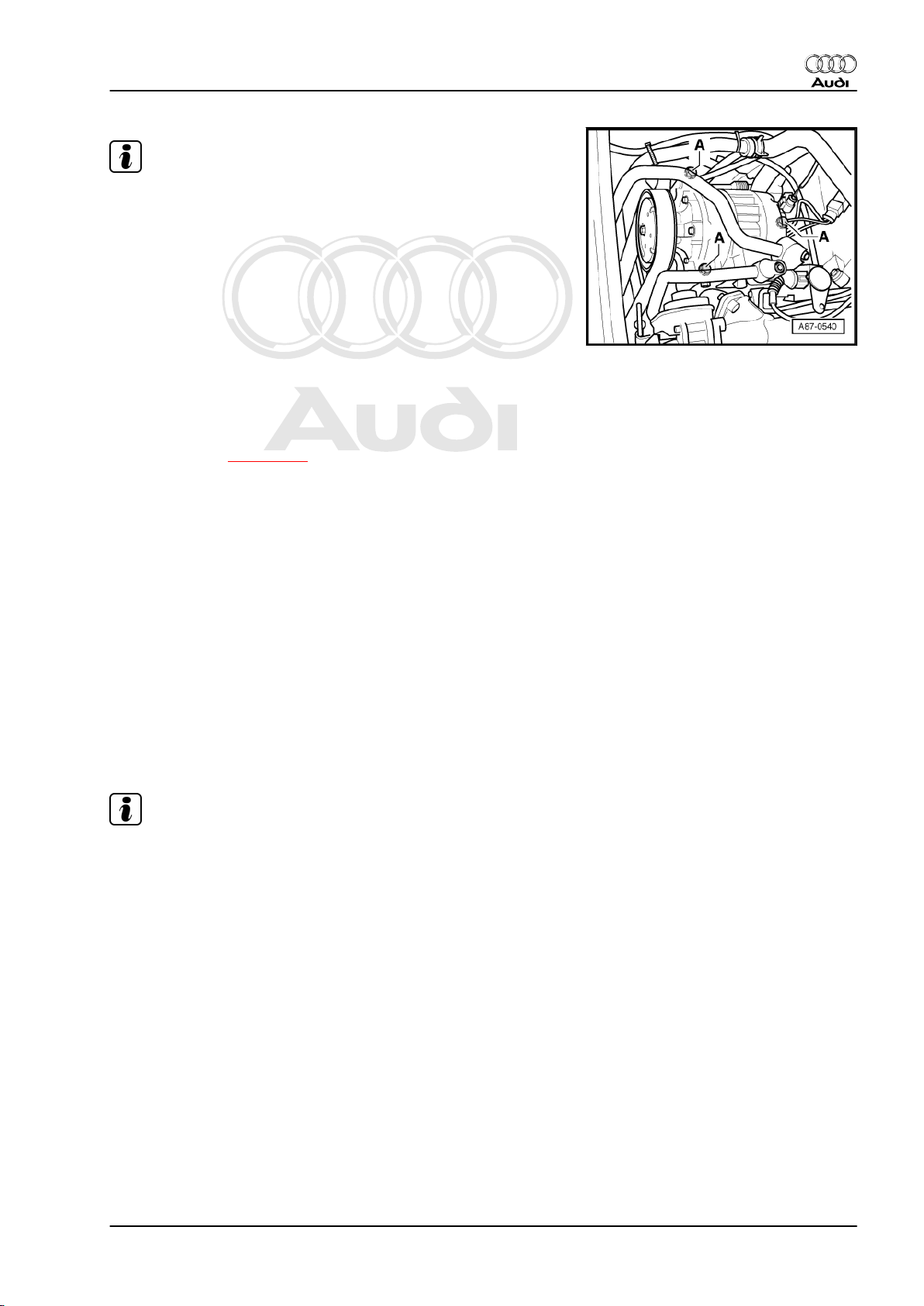

Note

♦

Do not unfasten the refrigerant lines and corresponding

clamps.

♦

This illustration shows the compressor for the 8-cyl. MPI en‐

gine. The layout for the other engine versions only differs

slightly from this illustration (e.g. different refrigerant lines). ⇒

Engine, mechanics; Rep. gr. 13

♦

Depending on the vehicle model, it may be necessary to press

aside or detach certain hoses in the area of the compressor.

♦

This illustration shows the compressor for the 8-cyl. diesel en‐

gine.

♦

Depending on the type of bolts -A- and the routing of the re‐

frigerant line, it may be necessary to detach the refrigerant

lines from the compressor (drain the refrigerant circuit) to

slacken off and remove the bolts -A- on vehicles with an 8-cyl.

diesel engine ⇒ page 138 .

– Remove the top engine cover (vehicles with 8-cyl. diesel en‐

gine only): ⇒ Engine, mechanics; Rep. gr. 13

– Remove the noise insulation ⇒ General body repairs, exterior;

Rep. gr. 50 .

– Move the lock carrier to the service position ⇒ General body

repairs, exterior; Rep. gr. 50 .

– Remove the oil filter if necessary. Protect the sealing surfaces

to prevent damage (certain vehicles with 6-cyl. petrol engine

only). ⇒ Engine, mechanics; Rep. gr. 17

– Slacken off the poly V-belt (poly V-belt for air conditioner com‐

pressor on vehicles with 6-cyl. diesel engine) and detach the

belt. ⇒ Engine, mechanics; Rep. gr. 13

– Mark the connector to the air conditioner compressor regulat‐

ing valve -N280- to prevent possible interchange with the

connector to the electric engine mounting.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

Note

If the connectors to the air conditioner compressor regulating

valve -N280- and the electric engine mounting are interchanged,

no entry is made in the fault memory, but the evaporator could ice

up as the compressor is constantly actuated.

– Unplug the air conditioner compressor regulating valve -N280-

at the connector.

3. Servicing refrigerant circuit 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

– Screw out the bolts -A- (25 Nm).

Note

♦

Fit one washer -B- at each of the bolts -A-.

♦

Before attaching the compressor, check the position of both

bushes -C- in the holder or compressor.

♦

After attaching the compressor, check the routing of the re‐

frigerant lines -D- and -E-. They must be inserted in the holders

provided (if fitted, depends on engine).

♦

After attaching the compressor, also check the refrigerant

lines and the corresponding holders for adequate clearance

with respect to the other components, ensuring a sufficient

distance between the belt, holder and pulley.

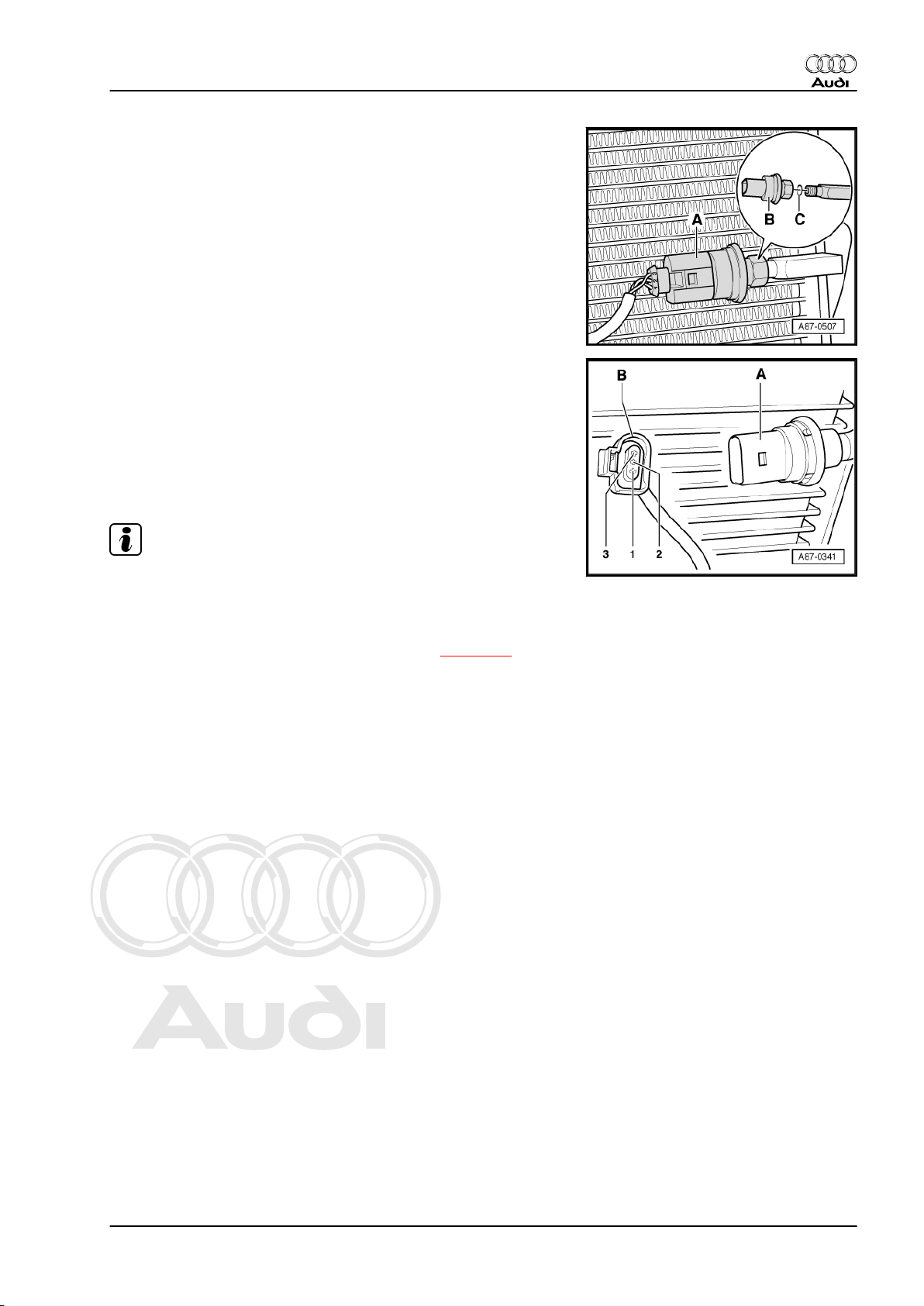

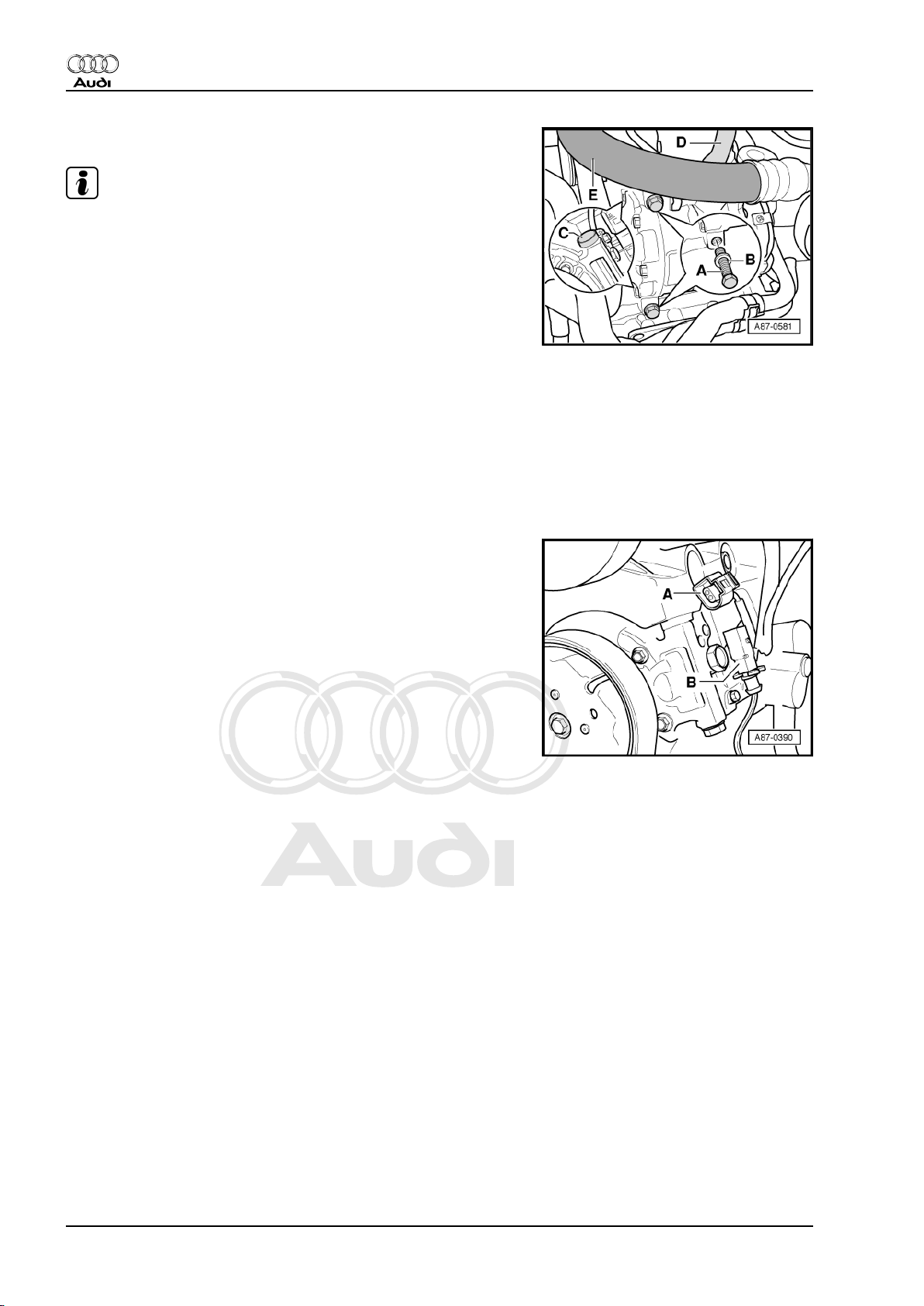

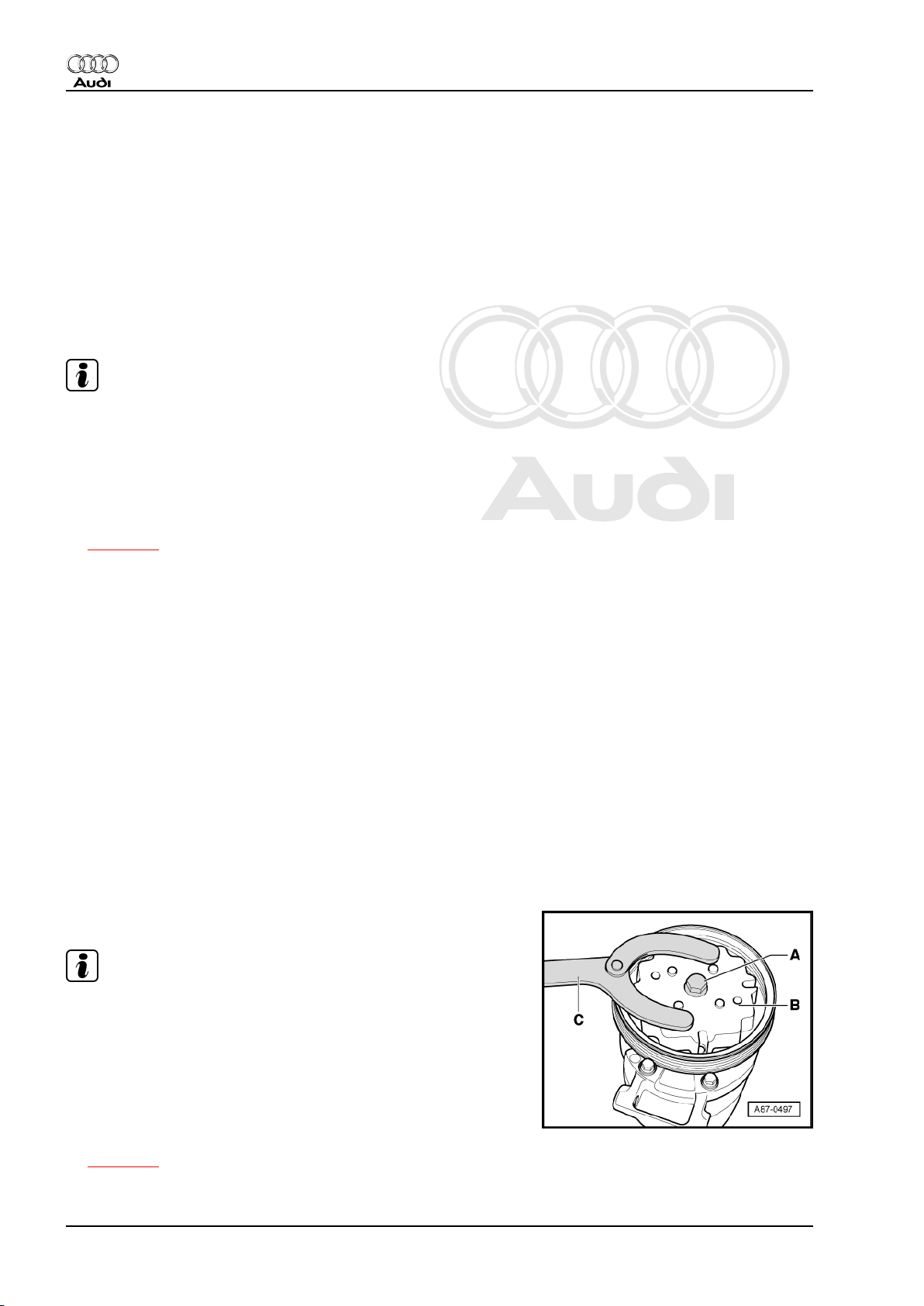

3.6 Checking activation signal for air condi‐

tioner compressor regulating valve N280-

– Switch off ignition.

– Unplug the connector at the air conditioner compressor.

– Use an adapter cable from the adapter set -V.A.G 1594 C- to

re-establish the connection between connector -A- and con‐

nector -B- at the regulating valve.

16 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Note

♦

Actuation of the air conditioner compressor regulating valve N280- and the current measured by the front operating and

display unit, Climatronic control unit -J255- which flows via the

air conditioner compressor regulating valve -N280- are dis‐

played in the measured value block of the front operating and

display unit, Climatronic control unit -J255- ⇒ "Guided faultfinding" function of vehicle diagnostic, testing and information

system VAS 5051.

♦

An adapter cable can also be produced for this test. This re‐

quires, for example, one connector -A- and -B- each (with part

number 1J0 973 702 and 1J0 973 802 and the corresponding

plug contacts), two commercially available sockets for banana

plugs -C- and two wires with a cross section of 0.5 mm2.

– Connect the probe -VAS 5051/8- to the adapter leads.

– Test lead (signal wire) to contact -2-

– Test lead (screen, earth) to contact -1-

– On the vehicle diagnostic, testing and information system -

VAS 5051 A- , set Measurement mode: DSO (digital storage

oscilloscope).

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

– Settings 5V/div DC, 0.5 ms/div (5 V DC and 0.5 milliseconds

per unit)

– Start the engine.

– On the front operating and display unit, Climatronic control unit

-J255- , set the temperature to „Lo“.

– On the front operating and display unit, Climatronic control unit

-J255- , press the buttons „Auto“ and „Off/On“ to activate and

deactivate the air conditioner compressor regulating valve N280- .

The display on the oscilloscope screen will be as follows depend‐

ing on the setting on the front operating and display unit, Clima‐

tronic control unit -J255- :

– In „OFF“ mode: No square-wave signal (regulating valve is not

actuated)

3. Servicing refrigerant circuit 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

– In „Auto“ mode and „Lo“ temperature setting: Square-wave

signal with pulse width -A- between 75% and 100% (regulating

valve is actuated)

Note

♦

The illustration shows a signal with a signal ratio of approx.

80%.

♦

The pulse width -A- is governed by the required cooling output,

the electrical system voltage etc. (over the width of area -A-,

the current is controlled via the air conditioner compressor

regulating valve -N280- by the front operating and display unit,

Climatronic control unit -J255- ).

♦

The signal distance -B- is always 2 milliseconds (correspond‐

ing to a frequency of 500 hertz).

♦

The signal ratio is derived from the ratio of pulse width -A- to

signal distance -B-.

– The setting on the front operating and display unit, Climatronic

control unit -J255- and the measured ambient influences gov‐

ern the pulse width of the square-wave signal (signal ratio

between 100% and greater than 30%, the regulating valve is

actuated such that the compressor output required to obtain

the specified temperatures is achieved).

Note

♦

In „Auto“ mode with „Lo“ temperature setting, the air condi‐

tioner compressor regulating valve -N280- is actuated such

that the maximum permissible current of approx. 0.65 A flows

via the air conditioner compressor regulating valve -N280(maximum compressor output).

♦

In control mode, the actuation time is governed by the required

cooling output and the vehicle electrical system voltage, for

example. It is however always of sufficient duration to achieve

a mean current of 0.3 A.

18 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

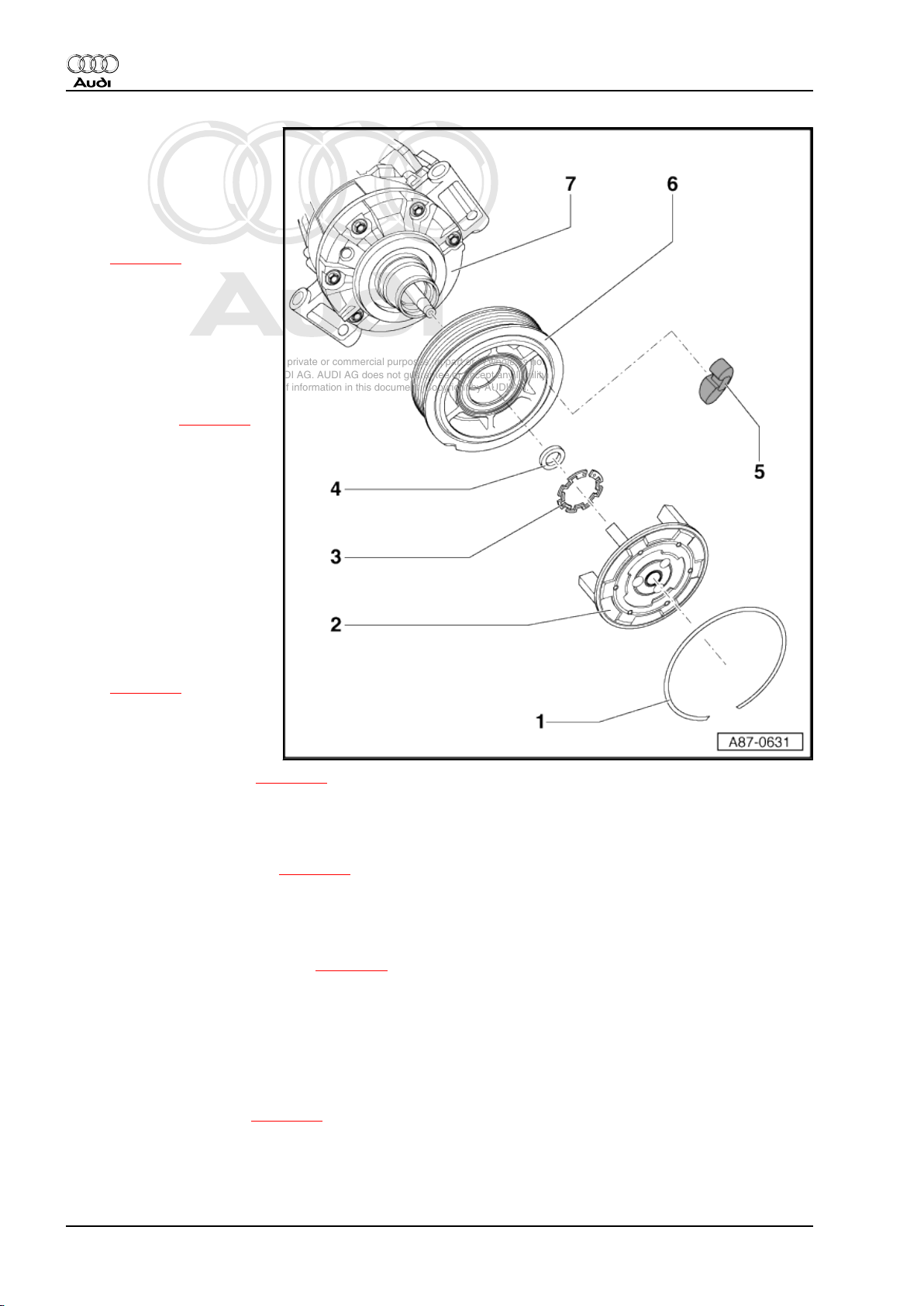

4 Replacing compressor pulley

4.1 Replacing pulley

(Version „1“ )

Note

♦

Various pulley designs are fitted depending on the type of

compressor and the engine version ⇒ Electronic parts cata‐

logue .

♦

Detaching pulley from compressor/re-attaching ⇒ page 20

♦

Pulley version „1“ is attached for example to the type „7 SEU

16“ compressor.

1 - Bolt

❑ Replace

❑ Tightening torque 20

Nm

❑ Slackening off and tight‐

ening ⇒ page 20

2 - Drive plate

❑ Different versions ⇒

Electronic parts cata‐

logue

❑ Detaching/attaching

⇒ page 20

❑ Tripped in the event of

excessive torque (e.g.

compressor stiff)

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

3 - Circlip

❑ Replace

❑ Ensure correct position‐

ing (flat side facing com‐

pressor)

❑ Removing and installing

⇒ page 20

4 - Pulley

❑ Rubber element of pul‐

ley is tripped in the event

of excessive torque

(e.g. stiff compressor)

and pulley just turns

without driving com‐

pressor

❑ Different versions ⇒

Electronic parts cata‐

logue

❑ Detaching/attaching

⇒ page 20

Note

4. Replacing compressor pulley 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

5 - Compressor

❑ Different models are fitted depending on engine and country version of vehicle ⇒ Electronic parts cata‐

logue

❑ Clean the flange of the compressor before fitting the pulley.

4.2 Detaching pulley from compressor/reattaching

(Version „1“ )

Note

♦

If the pulley overload safeguard has been tripped, check the

freedom of movement of the compressor before replacing the

pulley. Replace the entire compressor if stiff.

♦

The pulley overload protection function is described e.g. in

⇒ Self-study programme No. 240 ; Audi A2 Technology .

♦

Depending on the engine version, detachment of the pulley

may involve separating the compressor from the engine

⇒ page 14 .

♦

On most vehicles (except certain vehicles with 8-cyl. diesel

engine), the compressor can be detached from the holder and

re-attached without opening up the refrigerant lines.

♦

Prior to removal, mark the direction of the poly V-belt with chalk

or a felt-tip pen. Running a used belt in the opposite direction

could destroy it.

♦

Different compressors are fitted depending on engine and

country version (6, 8 or 12-cyl. engine, petrol or diesel engine)

⇒ Electronic parts catalogue

– Remove the top engine cover (vehicles with 8-cyl. diesel en‐

gine only): ⇒ Engine, mechanics; Rep. gr. 13

– Remove the noise insulation ⇒ General body repairs, exterior;

Rep. gr. 50 .

– Move the lock carrier to the service position ⇒ General body

repairs, exterior; Rep. gr. 50 .

– Slacken off and detach the poly V-belt. ⇒ Engine, mechanics;

Rep. gr. 13

– Screw out the bolt -A- (tightening torque 20 Nm).

Note

♦

When slackening off and tightening the bolt -A-, provide sup‐

port with a commercially available pin wrench -C- (pin diame‐

ter 5.0 mm) at the drive plate -B-.

♦

The bolt -A- is to be replaced (on account of locking fluid).

♦

Clean the thread in the shaft of the compressor before insert‐

ing the new bolt.

♦

Should it not be possible to detach the pulley with the com‐

pressor in position, separate the compressor from the engine

⇒ page 14 .

20 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

– Carefully and evenly prise off the drive plate -A- using 2 screw‐

drivers -B-.

Note

♦

When prising off the drive plate -A-, take care not to damage

the collar of the pulley -C-.

♦

There are different types of pulley -C- and drive plate -A-. At‐

tention must therefore be paid to precise assignment. ⇒

Electronic parts catalogue

– Remove the circlip -A-.

– Detach the pulley -B-.

Note

♦

Replace the circlip -A-.

♦

On fitting the circlip -A-, take care not to bend it open more

than necessary.

♦

Ensure correct insertion of the circlip -A-. The bevelled side

-C- faces away from the compressor (flat side faces compres‐

sor).

♦

Make sure the circlip is properly positioned in the groove at the

compressor flange.

♦

Clean the compressor flange before fitting the pulley. The pul‐

ley must be easy to fit (without having to exert force).

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

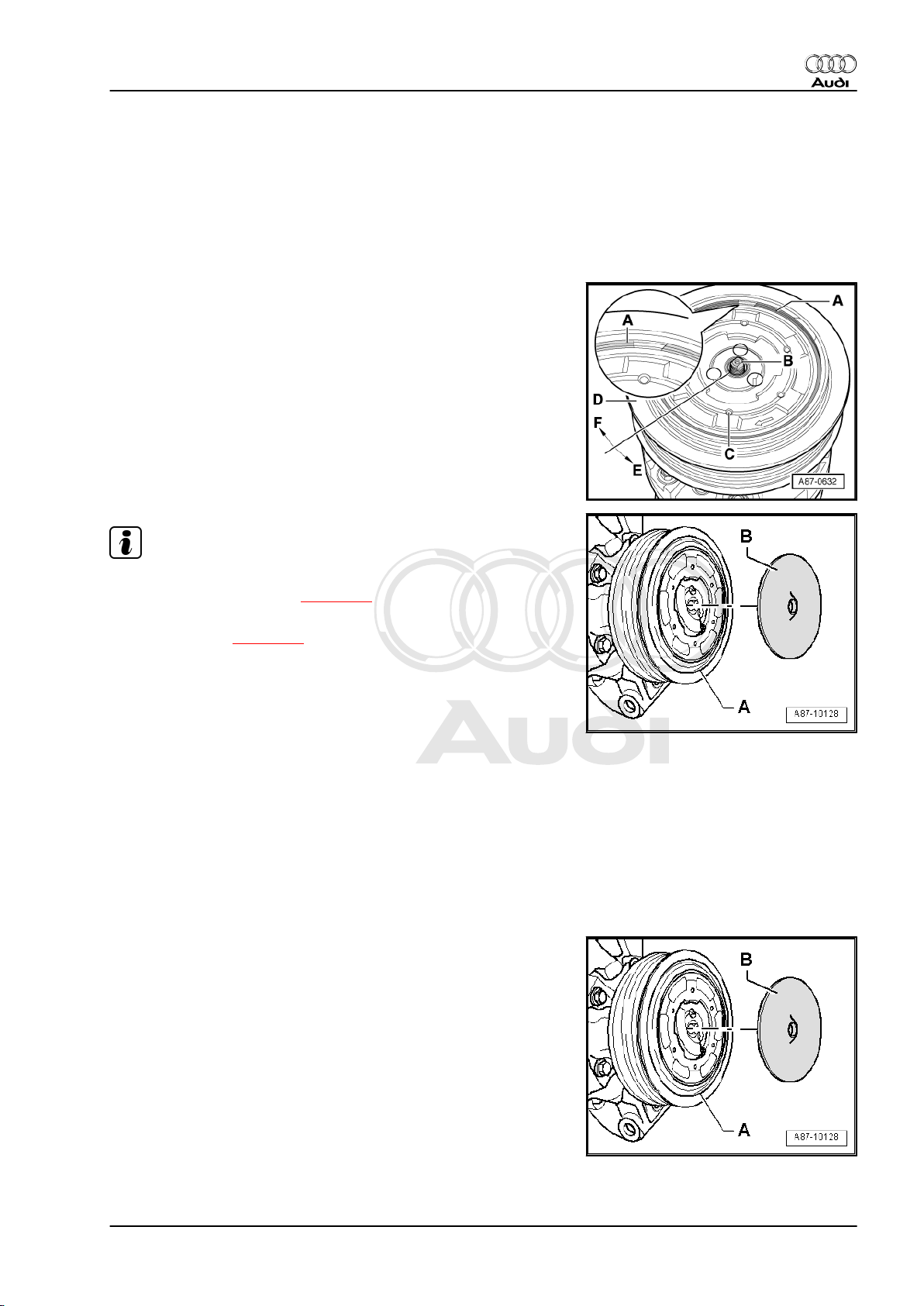

4.3 Replacing pulley

(Version „2“ )

Note

♦

Various pulley designs are fitted depending on the type of

compressor and the engine version ⇒ Electronic parts cata‐

logue .

♦

Detaching pulley from compressor/re-attaching ⇒ page 23

♦

Pulley version „2“ is attached for example to type „6 SEU 14“

and „7 SEU 17“ compressors.

4. Replacing compressor pulley 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

1 - Circlip

❑ Remove carefully using

a small screwdriver or

pointed-nose pliers

(paying particular atten‐

tion to the pulley)

❑ Detaching/attaching

⇒ page 23

❑ As of Model Year 2006,

circlips are being gradu‐

ally introduced which

are provided with a

vulcanised rubber disc

to replace the plastic

disc which may be bon‐

ded on at present (not

applicable to all com‐

pressors) ⇒ page 23

2 - Drive plate

❑ Screwed to compressor

drive shaft

❑ Different versions ⇒

Electronic parts cata‐

logue

❑ With overload safe‐

guard, tripped in the

event of excessive tor‐

que (e.g. stiff compres‐

sor) and pulley just freewheels without driving

compressor

❑ Detaching/attaching

⇒ page 23

❑ Tightening torque 35

Nm

❑ A plastic disc may have

been affixed depending

on production period ⇒ page 23 .

3 - Circlip

❑ Replace

❑ Ensure correct positioning (flat side facing compressor)

❑ Removing and installing ⇒ page 23

4 - Spacer

❑ Dimensions: 17.5 x 10 x 3 mm

5 - Rubber element

❑ 6x, ensure correct installation ⇒ page 23

❑ Decouples pulley from compressor drive shaft, damps vibration and noise

❑ On installation, moisten the rubber elements slightly with tyre assembly paste or soap solution for ex‐

ample to provide lubrication.

6 - Pulley

❑ The pulley is made of plastic, is sensitive to impact and should therefore be treated with extreme care.

❑ Different versions ⇒ Electronic parts catalogue

❑ Detaching/attaching ⇒ page 23

7 - Compressor

❑ Different models are fitted depending on engine and country version of vehicle ⇒ Electronic parts cata‐

logue

22 Rep. gr.87 - Air conditioning system

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

❑ Clean the flange of the compressor before fitting the pulley.

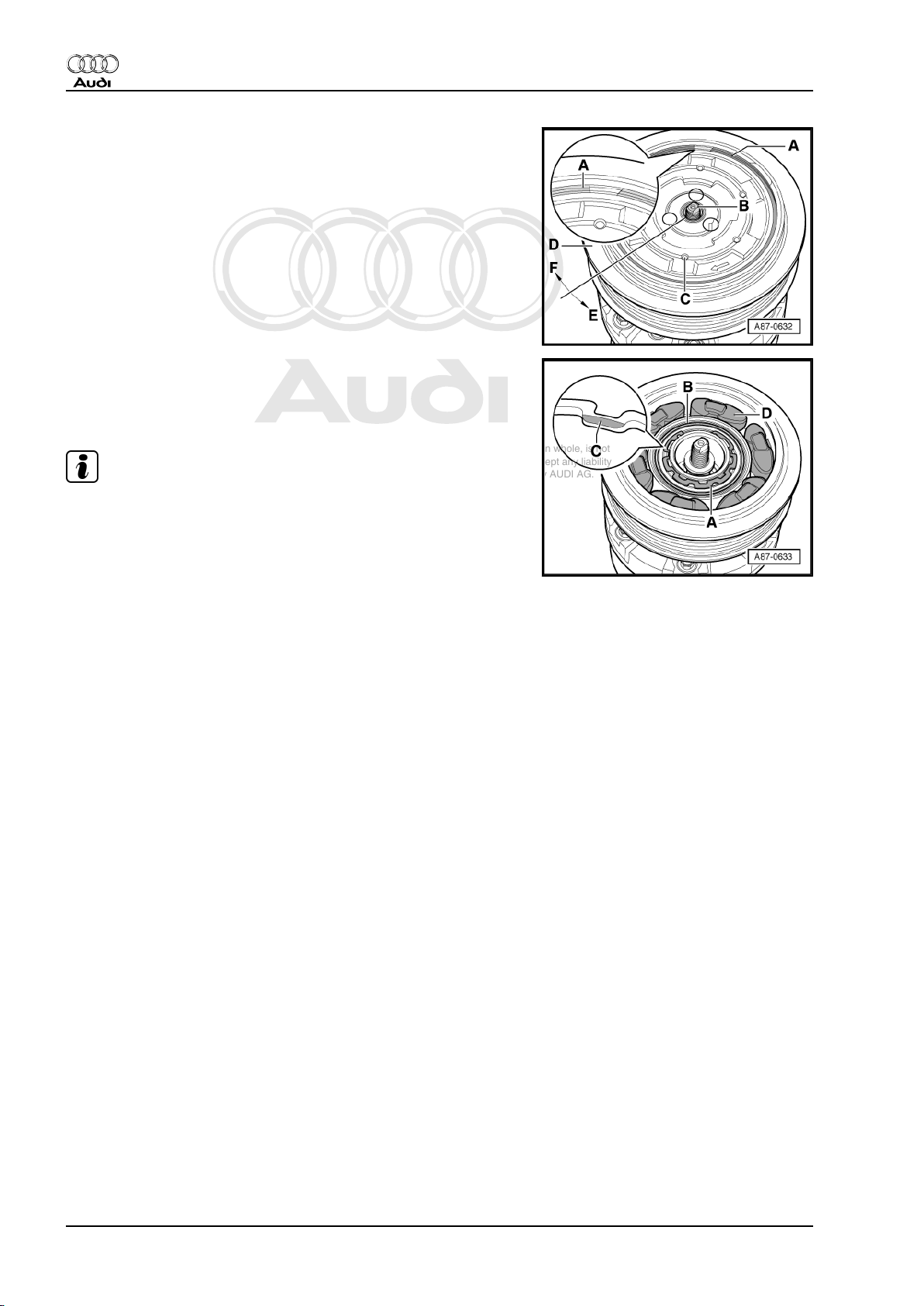

4.4 Detaching pulley from compressor/reattaching

(Version „2“ )

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

Note

♦

Heed the notes on removal of the version „1“ pulley, as these

also apply to version „2“ ⇒ page 20 .

♦

Perform preparatory work as described for detaching the ver‐

sion „1“ pulley ⇒ page 20 .

♦

The pulley is made of plastic, is sensitive to impact and should

therefore be treated with extreme care.

♦

If the overload safeguard of the drive plate -C- has been trip‐

ped, remove the circlip -A- and then prise the drive plate off

the pulley -D-.

♦

For noise optimisation, a plastic disc -B- may have been af‐

fixed to the drive plate of the pulley -A- or a circlip with a

vulcanised rubber disc may have been fitted ⇒ Electronic

parts catalogue . This plastic or rubber disc -B- reduces the

rattling (castanet-like) noise which can occur at the pulley par‐

ticularly in the case of vehicles with diesel engine in air con‐

ditioner „Econ mode“ (A/C mode off) (in air conditioner full load

operation the noise is scarcely audible).

Detaching pulley

– Remove the plastic disc -B- from the pulley -A- (if fitted).

4. Replacing compressor pulley 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Audi A8 2003 ➤

Air conditioning - Edition 09.2010

– Use a small screwdriver or pointed-nose pliers, for example,

to carefully remove the circlip -A- (possibly with vulcanised

rubber disc), taking particular care not to damage the pulley.

– Hold the compressor drive shaft -B- in position for example

with a socket attachment or a socket wrench -T10001/10- from

the wrench set (depending on version) and turn the drive plate

-C- with the pulley -D- in the direction of arrow -E- (tightening

torque 35 Nm).

– Remove the circlip -A-.

– Detach the pulley -B-.

Attaching pulley

Note

♦

Replace the circlip -A-.

♦

Clean the compressor flange before attaching the pulley.

♦

On fitting the circlip -A-, take care not to bend it open more

than necessary.

– Fit the pulley -B-.

– Ensure correct insertion of the circlip -A-. The bevelled side

-C- faces away from the compressor (flat side faces compres‐

sor).

– Insert the rubber elements -D- in the pulley -B- as shown.

– For fitting the drive plate, moisten the rubber elements -D-

slightly with tyre assembly paste or soap solution for example

to provide lubrication.

– Insert the drive plate -C- in the rubber elements -D- (refer to

illustration above) until it makes contact with the shaft of the

compressor -B-.

– Screw the drive plate -C- onto the compressor shaft -B- by

turning it in direction of arrow -F-.

– Tighten the drive plate -C- to 35 Nm by turning it with a com‐

mercially available strap wrench (with fabric strap) in the di‐

rection of arrow -F-. Provide support for the compressor shaft

-A- by applying a counterhold -B- (e.g. socket attachment or

socket wrench -T10001/10- from wrench set) to the compres‐

sor shaft -A-.

– Fit the circlip -A-.

24 Rep. gr.87 - Air conditioning system

Loading...

Loading...