Audi A8 292, A8 Service

Service

292

Home study program 292

For internal company use only

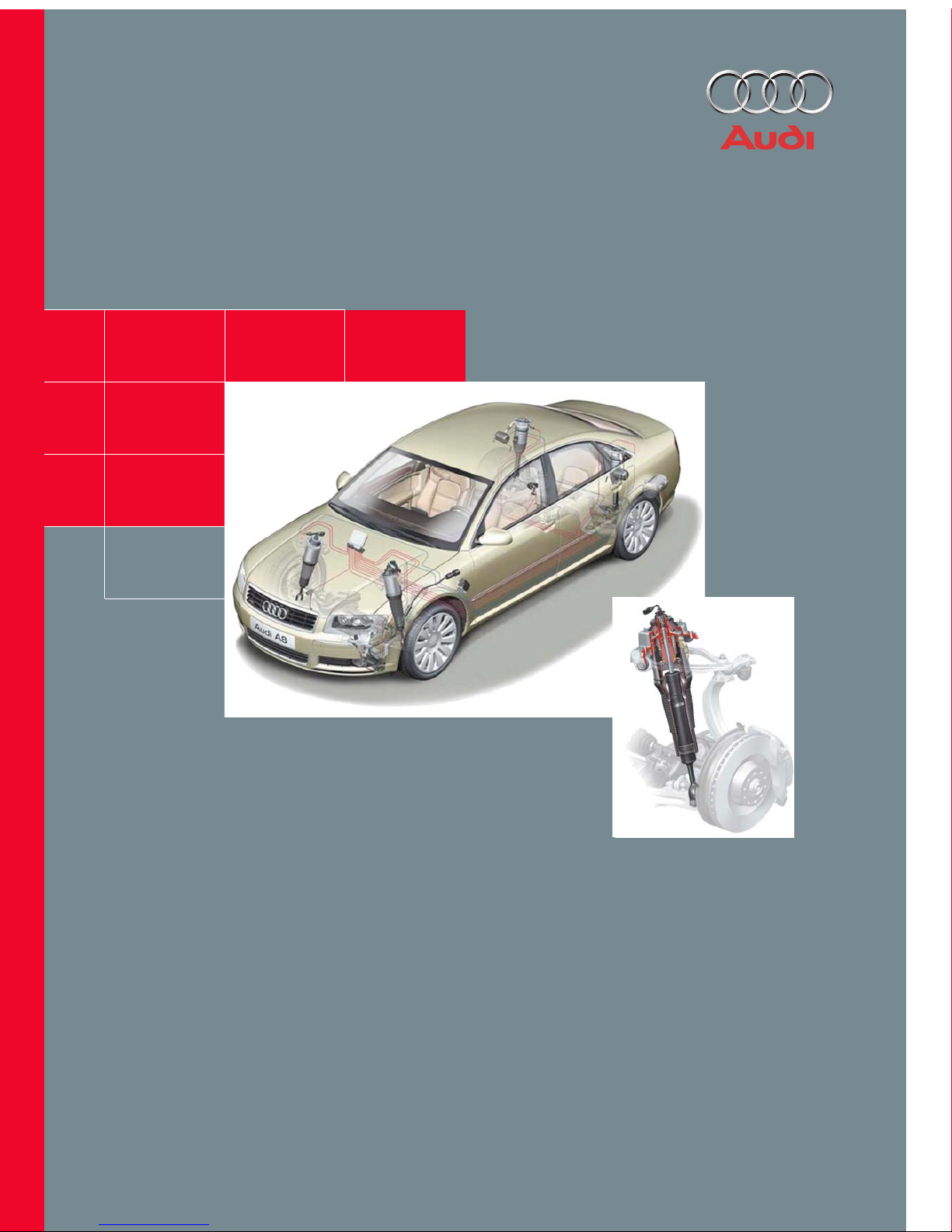

adaptive air suspension

in the Audi A8

The development of the running gear is subject to conflicting objectives. For now, besides

"classic" aims such as function, driving safety, strength and durability, requirements such as

weight reduction, driving comfort and acoustics are increasingly gaining in importance.

At first glance, many requirements appear to be in mutual opposition. A car designed to be

very comfortable will lose out in terms of driving safety when driven at the limit.

On the other hand, a car with very sporty tuning will achieve considerably higher cornering

speeds, and will reach its limit much later. However, this sporty tuning necessarily entails limitations when it comes to comfort.

In the Audi A8 MY 2003, a newly developed, fully bearing air suspension system is used.

In conjunction with the CDC status-dependent electronic damping control, this ensures that

the main - and partly conflicting - requirements are satisfied in an optimum manner within the

limits of the laws of physics.

3

Contents

Page

Caution!

Note!

New!

The home study program informs you about designs and

functions.

The home study program is not a Repair Manual!

All values stated herein are purely intended to facilitate your

understanding of the program, and are based on the software

version valid at the time the SSP was compiled.

For service and repair work, it is important that you please use

the current technical literature.

Introduction

Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

New technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation and display

Vehicle levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation and display system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System components

Vehicle overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control unit J197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Suspension/shock absorber strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Solenoid valve block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accumulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pneumatic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure build-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Senders (sensors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

System functions

Control concept for standard running gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control concept for sporty running gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Control concept for special operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . 29

Interfaces

System overview of components with bus link (CAN, MOST) . . . . . . . . . . . . . . . 34

System overview of components without bus link . . . . . . . . . . . . . . . . . . . . . . . . 35

CAN information exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Function diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Other interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Service

Control unit code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

System initialisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Final control diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Measured value blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4

Introduction

Basics

The basics for understanding air suspension

systems are contained in home study programs 242 and 243 and are of course also

valid for the system to be introduced in the

A8 from model year 2003.

New technology

The new A8 heralds a new system in terms of

technical content and range of functions. It

differs from the known system of the allroad

quattro in the following features:

CDC instead of PDC damping control:

The control takes account of the current driving status. The wheel movements (unsprung

masses) and body movements (sprung

masses) are recorded.

Within the choice of four programs (modes),

different damping characteristics are

implemented. In this process, each shock

absorber can be controlled independently.

292_001

Therefore, in each mode which is selected

(comfortable or sporty), the maximum degree

of comfort and driving safety is ensured (see

description "Shock absorber" in the "System

components" section).

The term "mode" can therefore be understood

to be the well-balanced combination of the

adaptive air suspension program and the

damping map.

292_025

Enhanced sensor system:

Three acceleration sensors are employed to

record the body movement.

(See description "Body acceleration sender"

in the "System components" section.)

5

Operation:

Integration in the MMI means that operation

is user-friendly, logical and easy to learn.

(See description in the "Operation and display" section.)

292_003

292_002

Residual pressure retaining valves:

Each suspension strut features residual pressure retaining valves directly at the air connection. This ensures that a minimum pressure of approx. 3.5 bar is maintained in the pneumatic

springs. This practically eliminates the risk of damage during storage and assembly to the

greatest possible extent.

Encased pneumatic springs:

The air bellows are encased in an aluminium

cylinder. The result is a considerable improvement in the response characteristic.

(See description "Pneumatic springs" in the

"System components" section.)

6

Operation and display

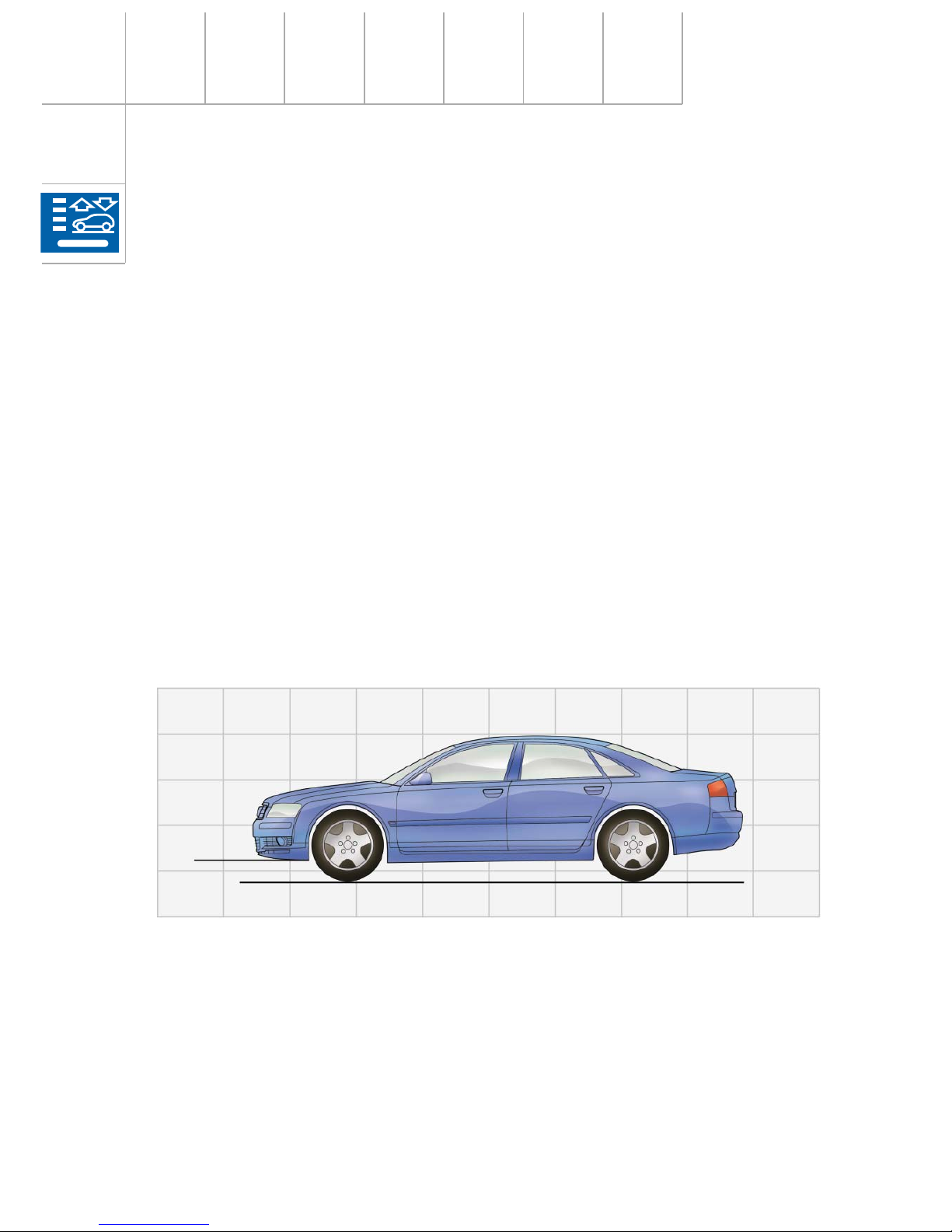

Vehicle levels

The A8 comes either with a standard running gear (adaptive air suspension) or a sporty running gear (adaptive air suspension-sport).

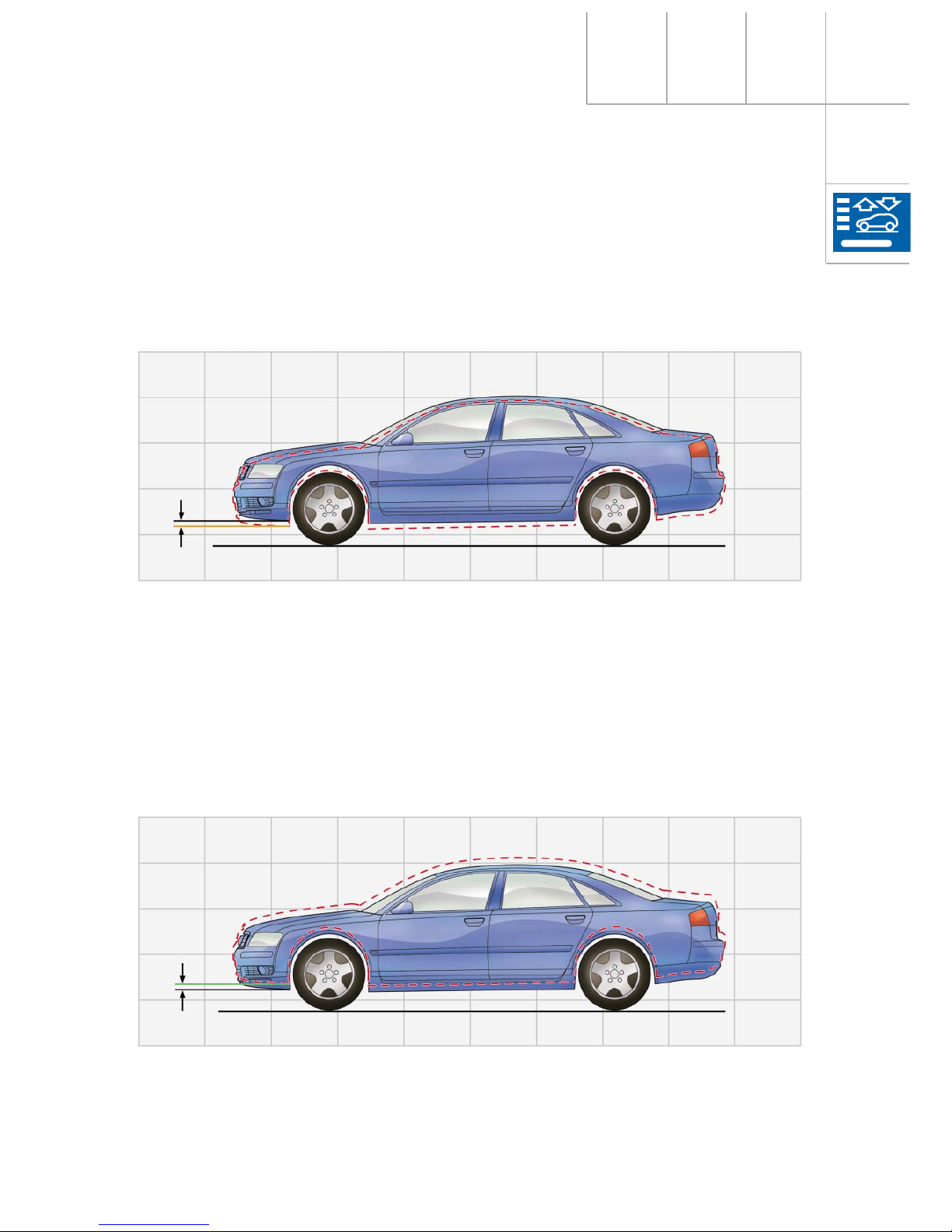

Standard running gear:

The following programs can be selected either manually or automatically:

"automatic" mode:

Basic vehicle level, comfort-oriented suspension with appropriately adapted damper map. The

vehicle is lowered by 25 mm after 30 seconds at speeds of 75 mph (120 km/h) or more ("motorway lowering"). This lowered position improves aerodynamics and reduces fuel consumption.

"comfort" mode:

Vehicle height as in "automatic" mode, less damping at lower speeds than in "automatic"

mode, resulting in even greater driving comfort than in "automatic" mode.

There is no automatic motorway lowering.

292_005

"automatic" and "comfort" mode: Basic level

Basic level

of standard

running

gear

7

292_006

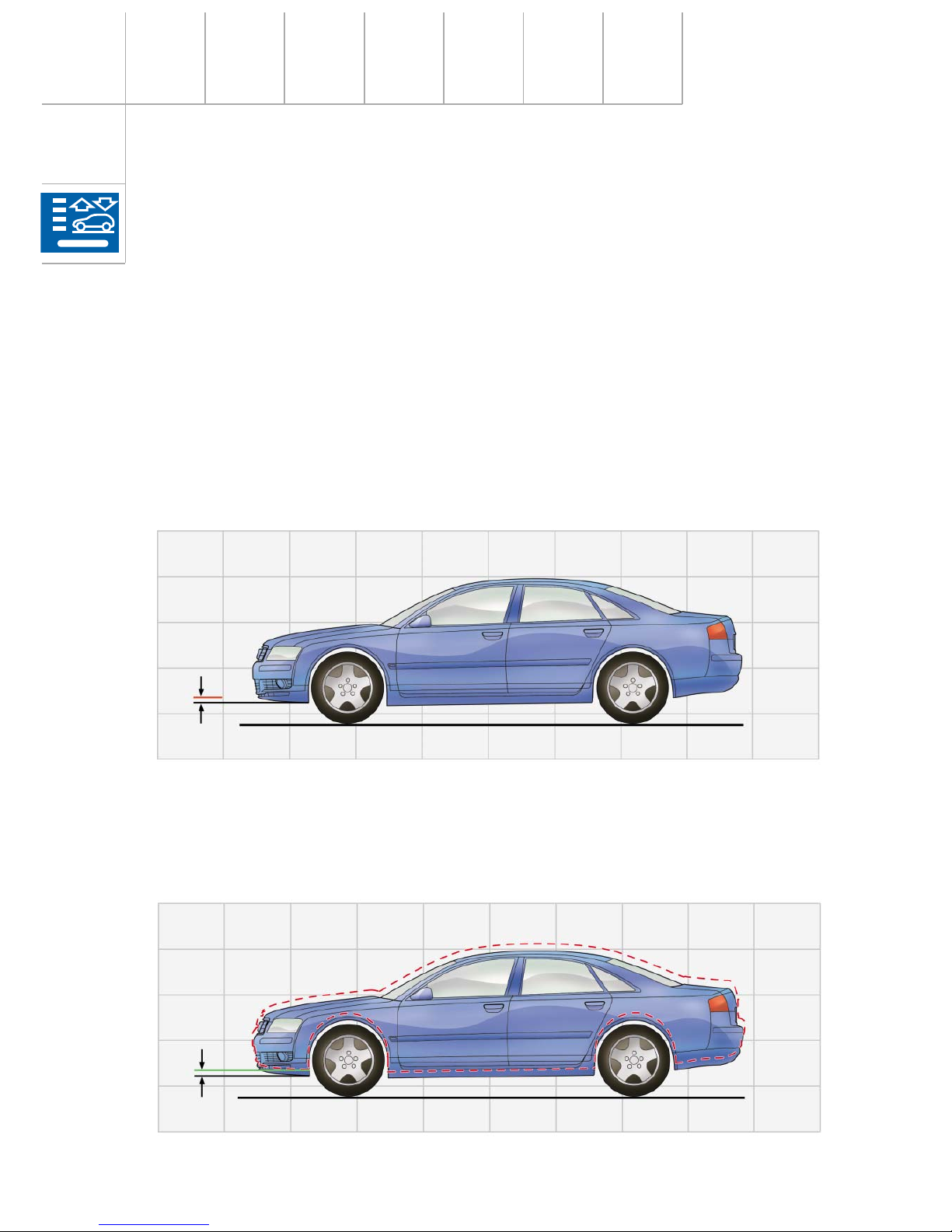

"lift" mode: + 25 mm

+ 25 mm

"lift" mode:

Vehicle level is 25 mm higher than in "automatic" mode, comfort-oriented suspension like

"automatic" mode.

292_004

"dynamic" mode: - 20 mm

- 20 mm

"dynamic" mode:

Vehicle level is 20 mm lower than in "automatic" mode. The damper map is automatically set to

sporty. After 30 seconds at speeds of 75 mph (120 km/h) or more, the car is lowered by another

5 mm ("motorway lowering").

8

Operation and display

"lift" mode:

Level 25 mm higher than "automatic" mode of sporty running gear, sporty suspension.

Sporty running gear:

"automatic" mode:

Basic vehicle level corresponds to "dynamic" mode in the standard running gear, sporty

suspension with appropriately adapted damper map (more comfortable than "dynamic"

mode). The vehicle is lowered by another 5 mm after 30 seconds at speeds of 75 mph

(120 km/h) or more ("motorway lowering").

292_049

"dynamic", "automatic" and "comfort" mode: Basic level for sporty running gear

Basic level of sporty

running gear (-20 mm)

Basic level

of standard

running

gear

292_006

"lift" mode: + 25 mm

+ 25 mm

"dynamic" mode:

Level as for "automatic" mode of sporty running gear, hard, sporty suspension with appropriately adapted damper map. The vehicle is lowered by 5 mm after 30 seconds at speeds of 75

mph (120 km/h) or more ("motorway lowering").

"comfort" mode:

Level as for "automatic" mode of sporty running gear, less damping at lower speeds than in

"automatic" mode. There is no automatic motorway lowering.

9

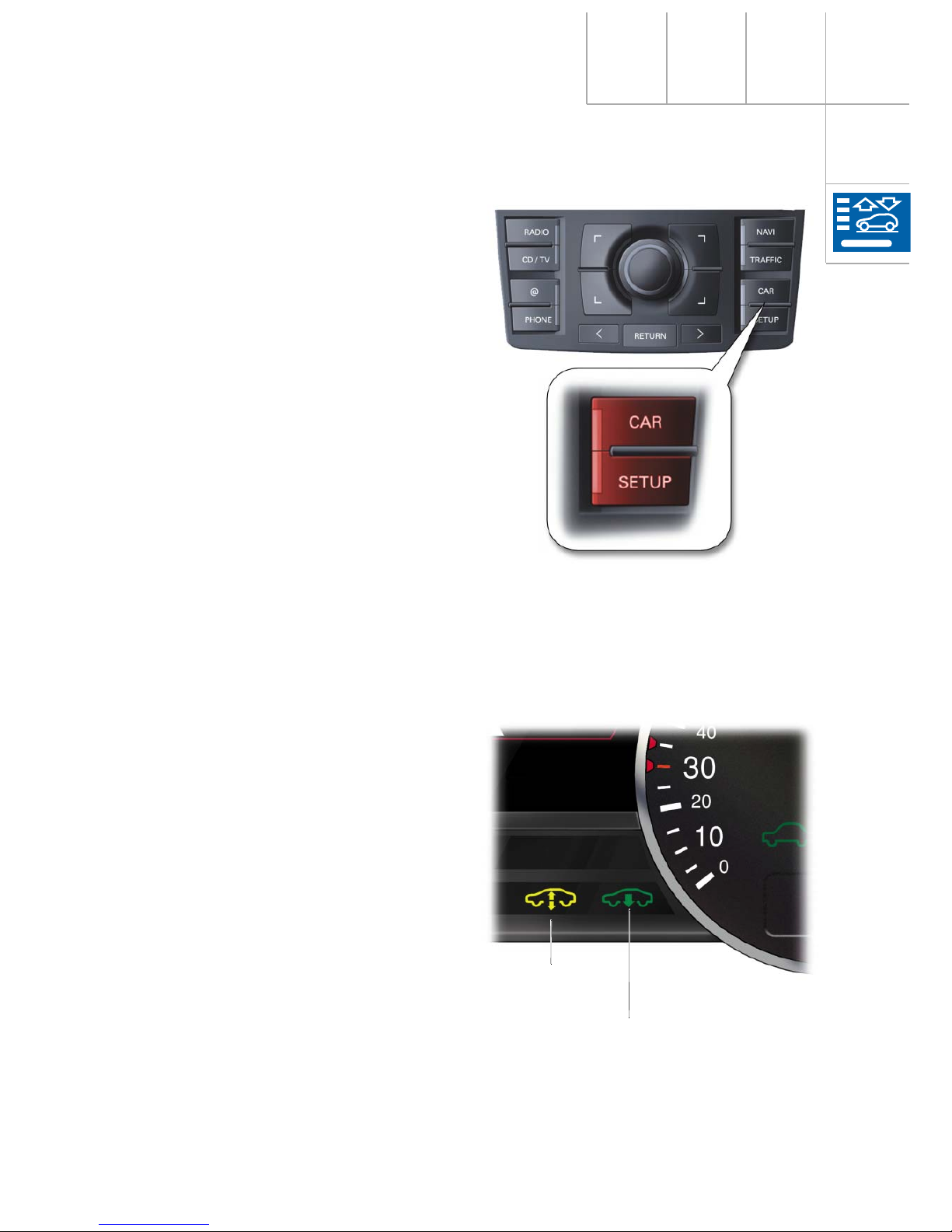

Operation and display system

The process of switching from one mode to

another and the display/monitoring of the

system status all form part of the MMI operating system.

The adaptive air suspension menu is opened

directly in the MMI display in the centre console when the "CAR" button is pressed. This

ensures that adaptive air suspension has first

priority. This means that any other functions

already in the display are blanked out in

favour of the adaptive air suspension operating/status display.

Turning the control knob to a different mode

and then pressing the control knob activates

a new mode.

System status information can be requested

and special settings undertaken by pressing

the SETUP button.

(See current Owner’s Manual and "Control

strategy" in the "Special system states" section.)

292_010

With the standard running gear, the

"dynamic" mode (low level) is additionally displayed as driver information by an indicator

lamp in the dash panel insert.

An extremely low or extremely high level is

displayed by the indicator lamp and the warning lamp in the dash panel insert.

(See "Control strategy" in "Special system

states".)

292_011

Warning

lamp

Indicator lamp for

extreme low level

10

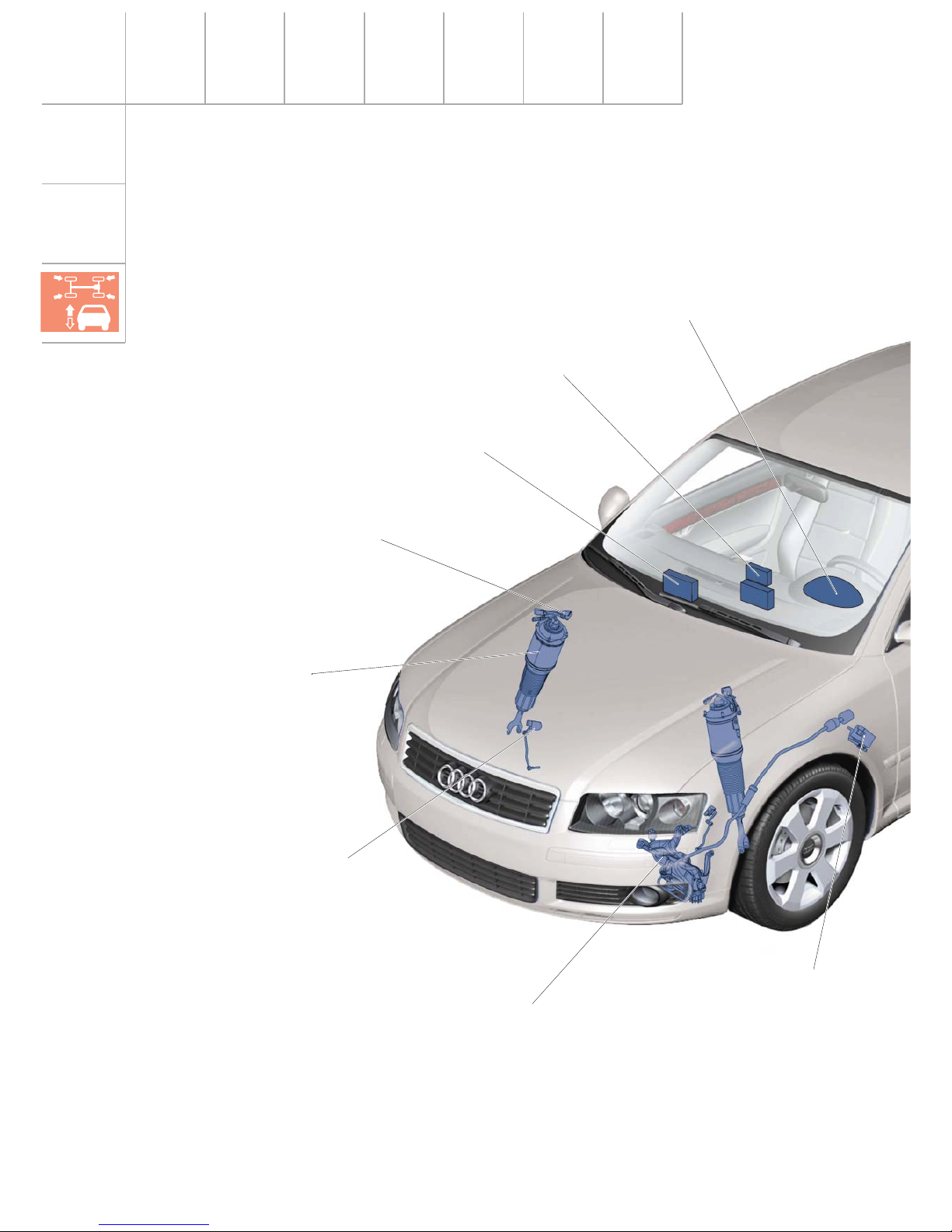

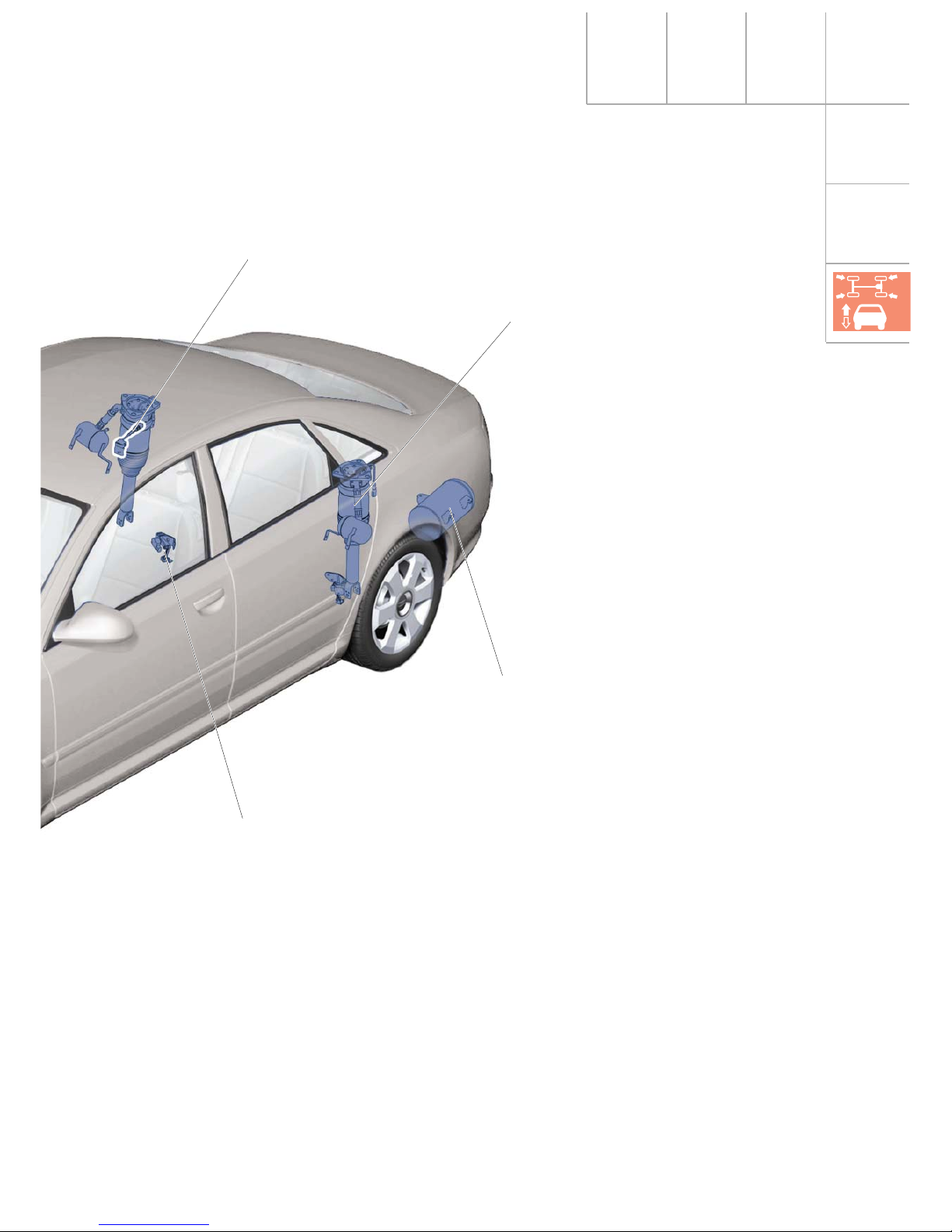

Air supply unit

Solenoid valve block

with pressure sender

Pneumatic struts, FA

Adaptive air suspension

control unit

Vehicle level

sender, FA

Dash panel insert

Front operator/display unit

(MMI)

Body acceleration

sender

System components

Vehicle overview

11

Pneumatic struts, RA

Accumulator

Vehicle level sender, RA

Body acceleration sender

292_012

12

System components

292_013

Hardware

4E0 907 553 C * = Standard running gear

4E0 907 553 D * = Sporty running gear

Control unit J197

The control unit is the central element of the

system. It is installed in the vehicle in front of

the glove box.

It processes the relevant messages from the

other bus users, and the discreet input signals (see function diagram and CAN information exchange).

The principal result of this processing work

are the signals to actuate the compressor, the

solenoid valves and the shock absorbers.

Because of the differences between the

standard and sporty running gears, the control unit had to be produced in two versions

(software application).

* These numbers are correct as at 06/2002. Changes may be made as a result of further

technical developments.

(See current Repair Manual.)

Software

4E0 910 553 C * = Standard running gear

4E0 910 553 D * = Sporty running gear

13

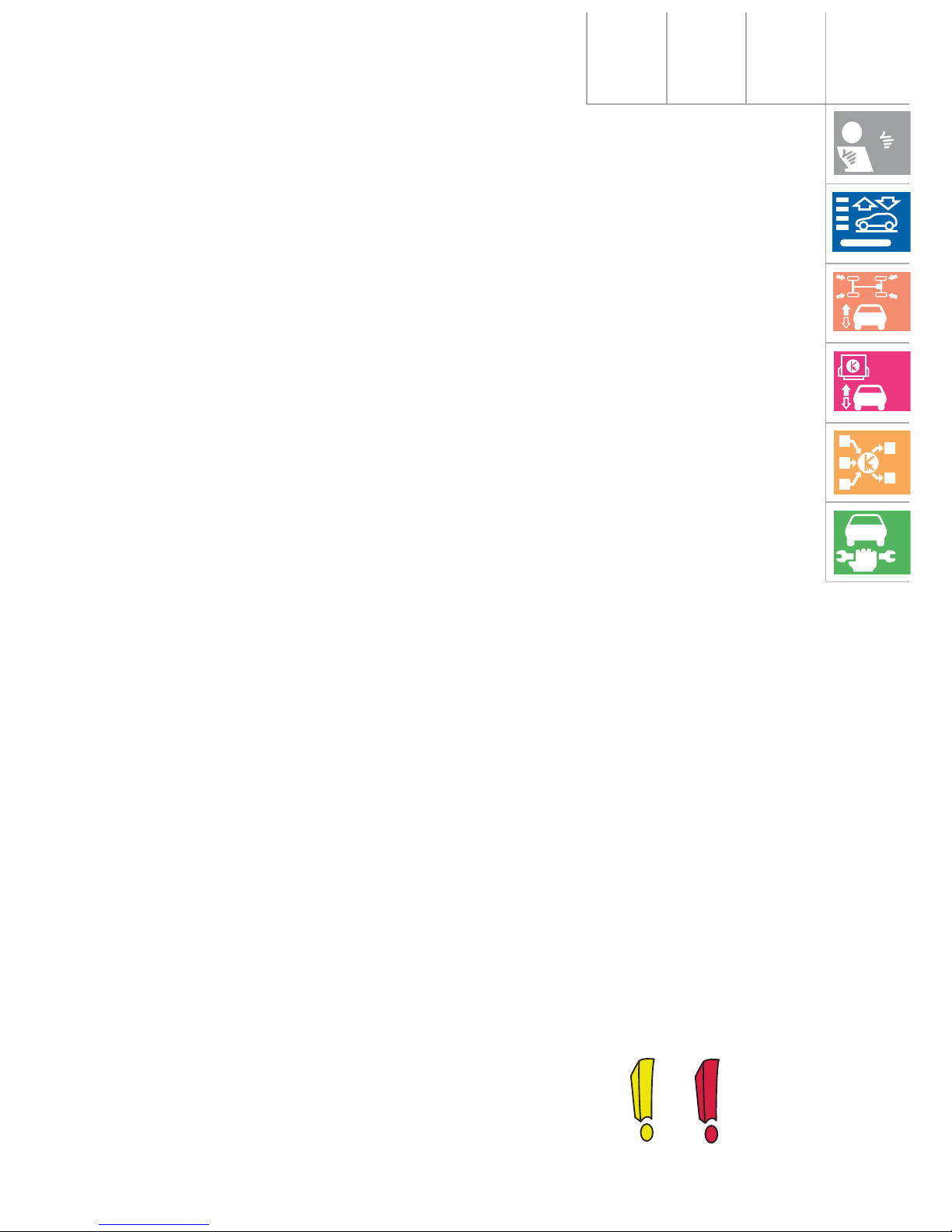

Pneumatic spring

Construction:

The pneumatic spring is encased in an aluminium cylinder. In order to prevent dirt from

getting between the cylinder and the air bellows, the area between the piston and the cylinder is sealed by a sleeve. The sleeve can be

replaced during servicing, but the air bellows

cannot be replaced separately. In the event of

a fault, the entire suspension/shock absorber

strut must be replaced.

In order to provide as much usable space and

loading width in the boot as possible, the

diameter of the rear axle pneumatic springs is

kept to a minimum. However, if demands for

comfort are to be met, a minimum air volume

is required. The solution to this conflict is provided in the form of a reservoir for additional

air, which is connected to the shock absorber.

Suspension/shock absorber strut

All four suspension/shock absorber struts are constructed in the same way.

292_015

Suspension/

shock absorber

strut, rear axle

Additional

air volume

292_014

Aluminium

cylinder

Pneumatic

spring

Suspension/

shock absorber

strut, front axle

Function:

The pneumatic spring not only replaces the

steel spring, it also offers considerable

advantages over the steel version (see

SSP 242). Encasing the pneumatic spring in

an aluminium cylinder enables the wall thickness of the bellows to be reduced. This

results in an even more sensitive response to

bumpy roads.

14

292_016

System components

Shock absorber

Construction:

A twin-tube gas-filled shock absorber with

continuous electrical control is used (ccontin-

uous damping control =CDC shock absorber).

The main damping valve 3 in the piston 1 is

mechanically pre-tensioned by a spring 4. A

solenoid 5 is situated above the valve, and the

connecting cable is routed to the outside

through the hollow piston rod.

Function:

For general information on the function of a

twin-tube gas-filled shock absorber, see

SSP 242.

The damping force is determined to a considerable extent by the flow resistance of the

valves. The greater the flow resistance for the

oil flowing through the valves, the higher the

damping force.

Basic method of operation using bump as an example (= bump absorption):

The entire piston unit 1 is moved downwards

inside the cylinder tube 2 at speed v.

The oil pressure in the chamber below the

main damping valve 3 increases.

Current flows to the solenoid 5. The magnetic

force F

M

counteracts the spring force FF and

partially raises it.

If the sum of the magnetic force and the oil

pressure force (F

M+FP

) exceeds the spring

force F

F

, the resulting force FR opens the

valve. The amount of magnetic force can be

regulated by adjusting the amount of electrical current. The higher the electrical current,

the lower the flow resistance and thus the

damping force.

Info: The highest damping force is achieved when the solenoid is not electrically actuated.

For the lowest damping force, the solenoid must be receiving a current of approx.

1800 mA.

In emergency running mode, the solenoid is not electrically actuated. In this way, the

damping force is set to maximum, ensuring a dynamically stable driving condition.

Loading...

Loading...