Page 1

FOREWORD

This repair manual has been prepared to provide essential information on body panel repair methods (including cutting and

welding operations, but excluding painting) for the TOYOTA

COROLLA

Applicable models: AZE141 series

ZRE142 series

This manual consists of body repair methods, exploded diagrams and illustrations of the body components and other information relating to body panel replacement such as handling

precautions, etc. However, it should be noted that the front fenders of the TOYOTA model is bolted on and require no welding.

When repairing, don’t cut and join areas that are not shown in

this manual. Only work on the specified contents to maintain

body strength.

Body construction will sometimes differ depending on specifications and country of destination. Therefore, please keep in mind

that the information contained herein is based on vehicles for

general destinations.

For the repair procedures and specifications other than collisiondamaged body components of the TOYOTA COROLLA refer to

the repair manuals.

If you require the above manuals, please contact your TOYOTA

Dealer.

All information contained in this manual is the most up-to-date at

the time of publication. However, specifications and procedures

are subject to change without prior notice.

Page 2

Page 3

ABOUT THIS MANUAL

Scope of the repair work explanation

S This text explains the welding panel replacement instructions from the vehicle’s white body condition.

We have abbreviated the explanations of the removal and reinstallation of the equipment parts up to the

white body condition and of the installation, inspection, adjustment and final inspection of equipment

parts after replacing the weld panel.

Section categories

S This manual has been divided as shown below.

Section Title Contents Examples

INTRODUCTION

BODY PANEL REPLACEMENT

BODY DIMENSIONS Body aligning measurements. Dimension diagrams.

PAINT S COATING

Explanation of general body repair.

Views of weld panel replacement instructions.

Instructions for replacing the weld panels

from the white body condition, from which

bolted parts have been removed, with

individual supply parts.

Scope and type of anti-rust treatment, etc.

together with weld panel replacement.

Contents omitted in this manual

S Make sure to perform the following essential procedures, although they are omitted in this manual.

(1) Clean and wash removed parts, if necessary.

(2) Visual inspection

Precaution

About this vehicle

Front side member replacement.

Quarter panel replacement.

Body sealer.

Under coat.

Page 4

Page 5

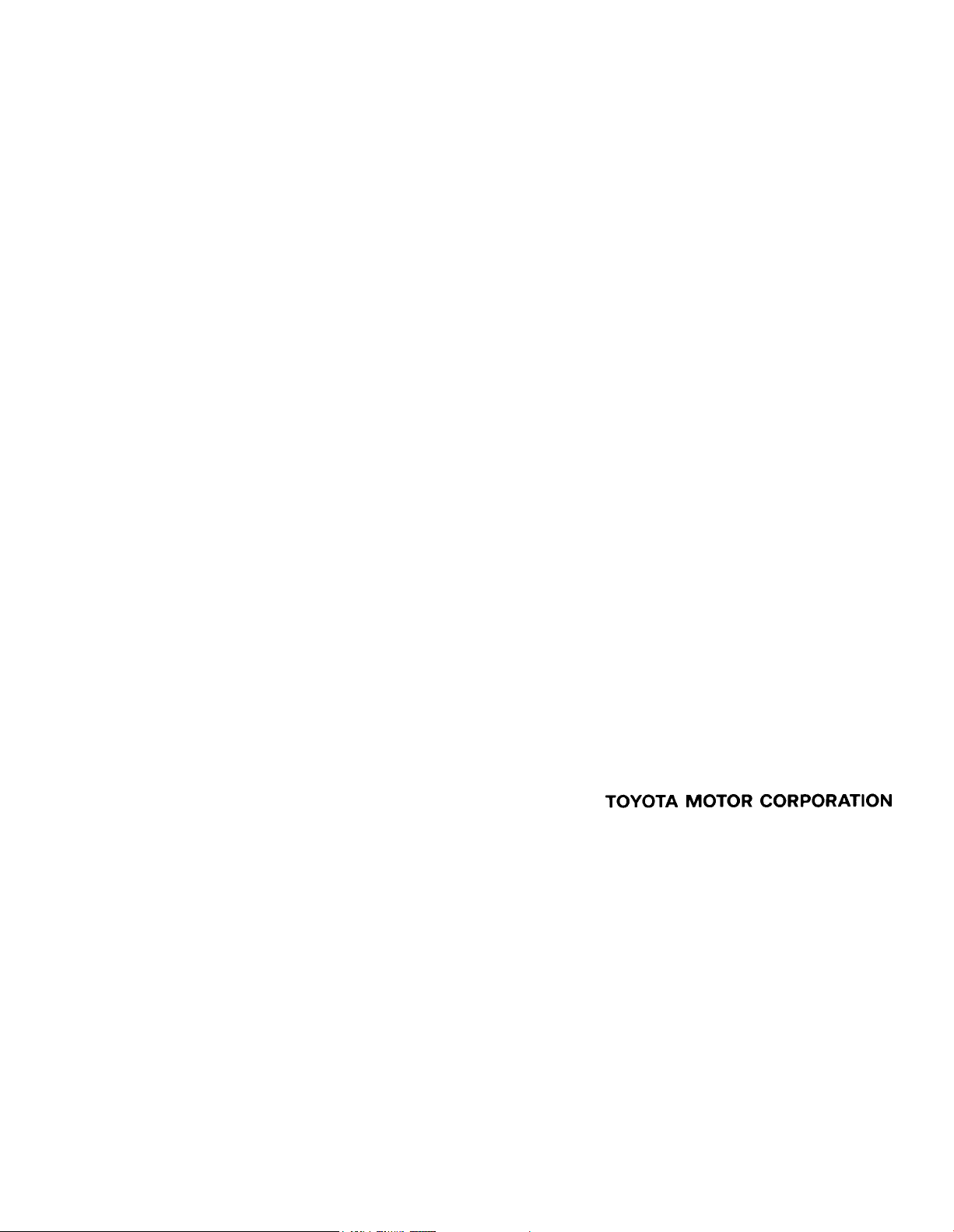

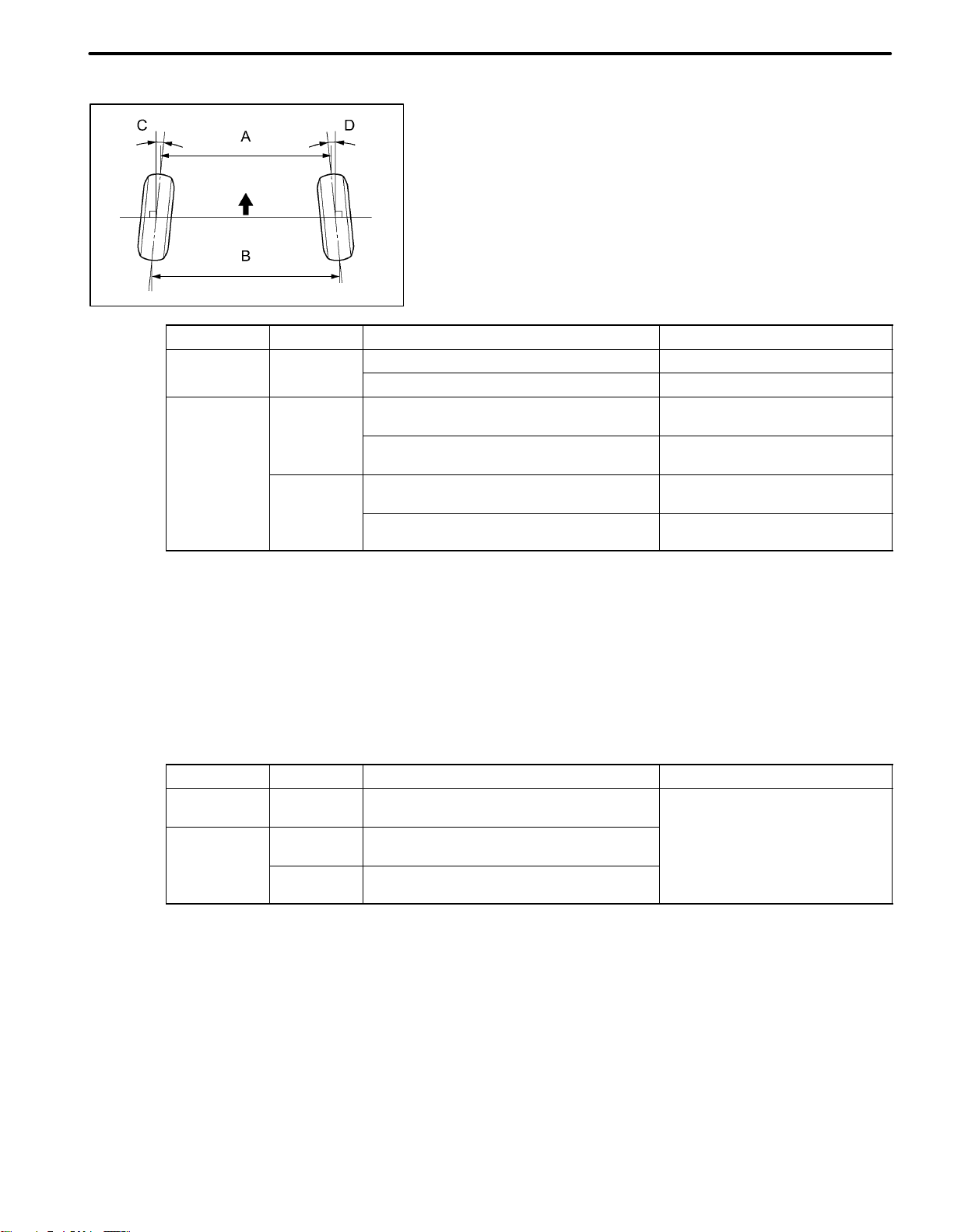

BODY DIMENSIONS

DI-1

Three-dimensional

distance

Two-dimensional

distance

Vertical distance

in center

A mm B mm

Center-to-center

straight-line

distance

Center-to-center horizontal

distance in forward/

rearward direction

Vertical distance

in lower surface

Imaginary Datum Line

Under Surface of

The Rocker Panel

C mm

Imaginary Datum Line

GENERAL INFORMATION

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

(1) (Three-dimensional distance)

S Straight-line distance between the centers of two

measuring points.

(2) (Two-dimensional distance)

S Horizontal distance in forward/rearward direc-

tion between the centers of two measuring

points.

S The height from an imaginary datum line.

(b) In cases in which only one dimension is given, left and right

are symmetrical.

(c) The dimensions in the following drawing indicate actual dis-

tance. Therefore, please use the dimensions as a reference.

(d) The line that connects the places listed below is the imagi-

nary datum line when measuring the height. (The dimensions are printed in the text.)

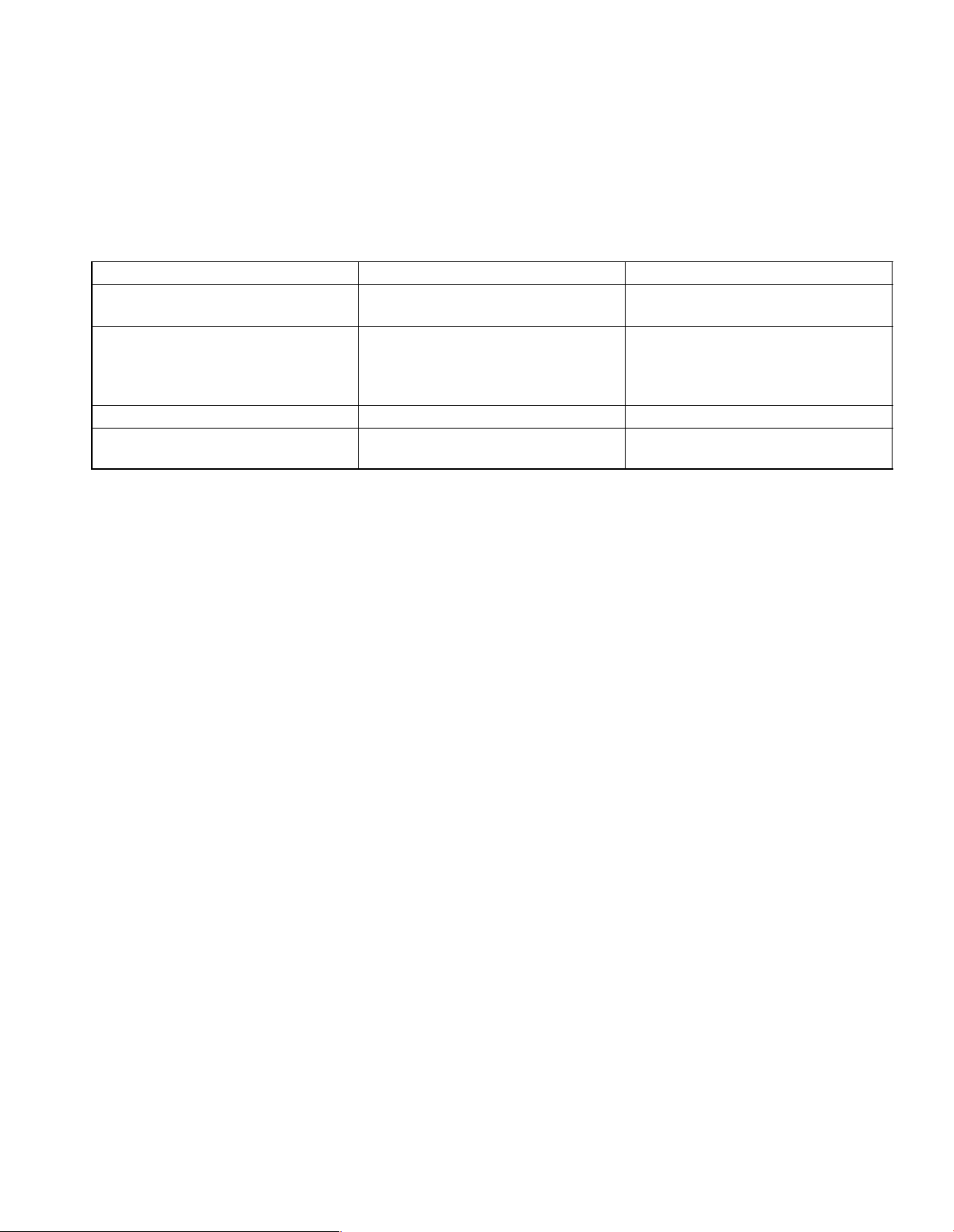

SYMBOL Name

1

2

3

The place that was lowered A mm from the under surface of

the rocker panel centered on the front jack up point.

The place that was lowered B mm from the under surface of

the rocker panel centered between 1 and 3.

The place that was lowered C mm from the under surface of

the rocker panel centered on the rear jack up point.

Page 6

DI-2

BODY DIMENSIONS

Body Looseness

Pointer Looseness

Pointer

Wrong

Pointer

Plate Looseness

Master Gauge

Correct

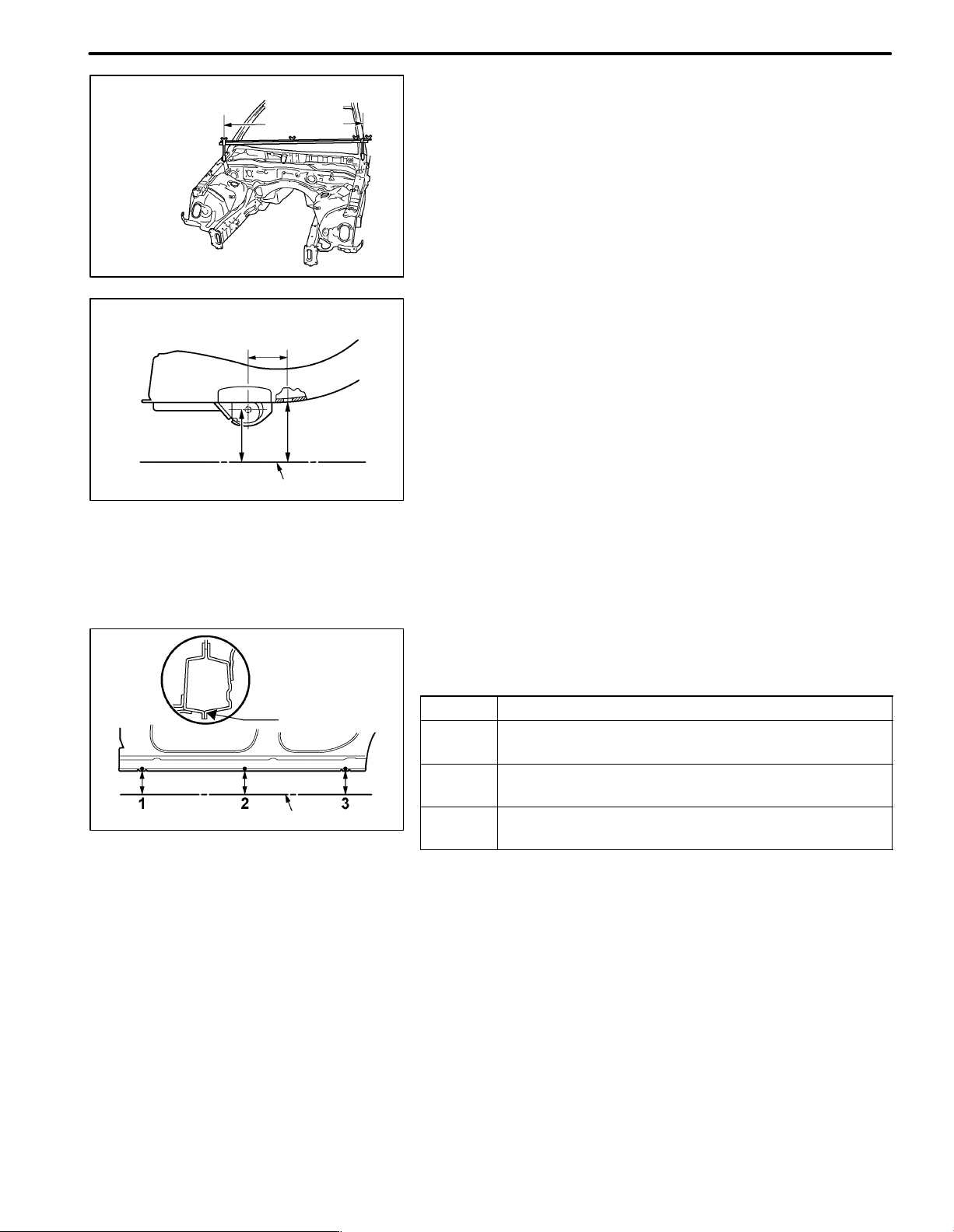

2. MEASURING

(a) Basically, all measurements are to be done with a tracking

gauge. For portions where it is not possible to use a tracking gauge, a tape measure should be used.

(b) Use only a tracking gauge that has no looseness in the

body, measuring plate, or pointers.

HINT:

1) The height of the left and right pointers must be equal.

2) Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3) Take care not to drop the tracking gauge or otherwise

shock it.

4) Confirm that the pointers are securely in the holes.

(c) When using a tape measure, avoid twists and bends in the

tape.

Page 7

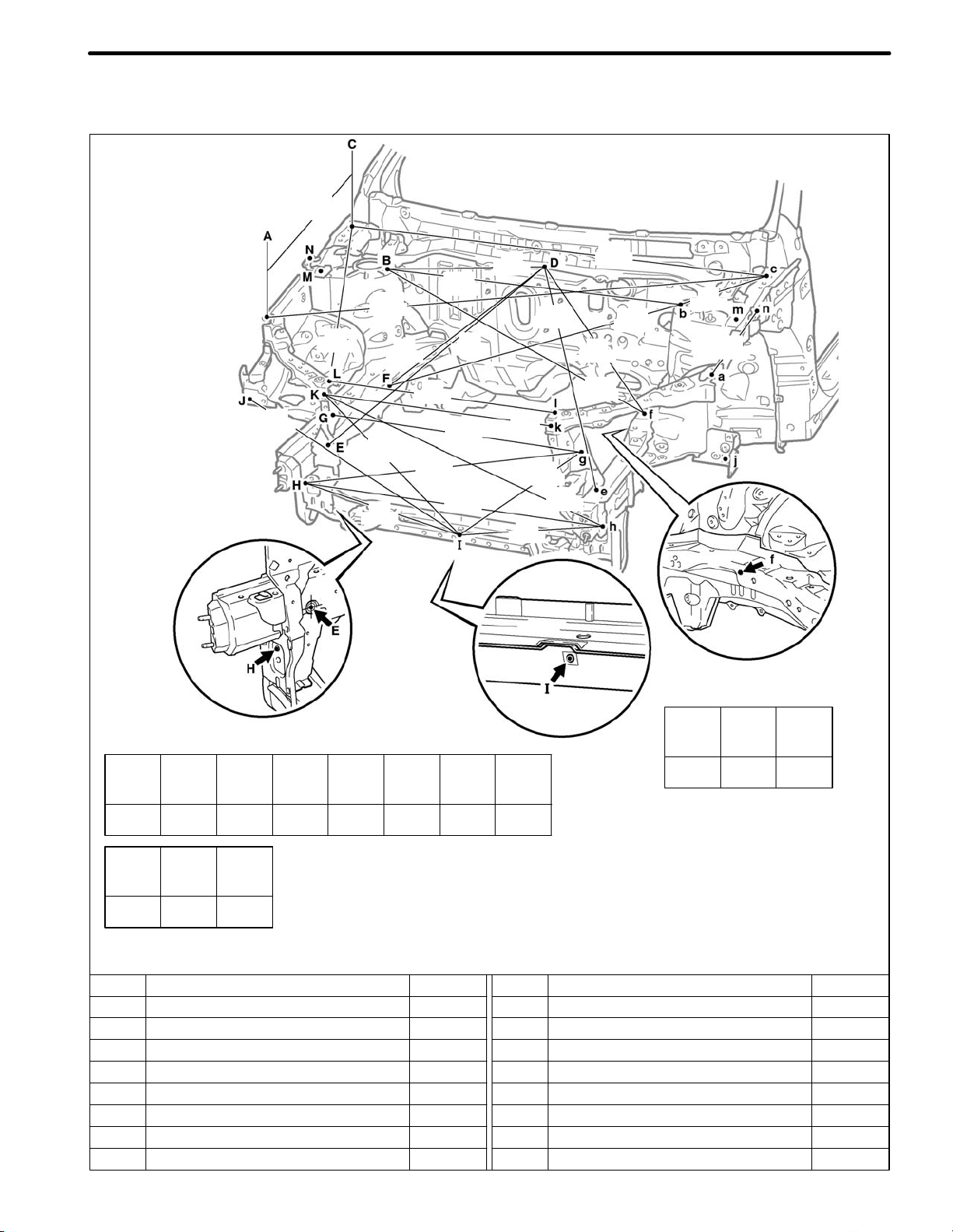

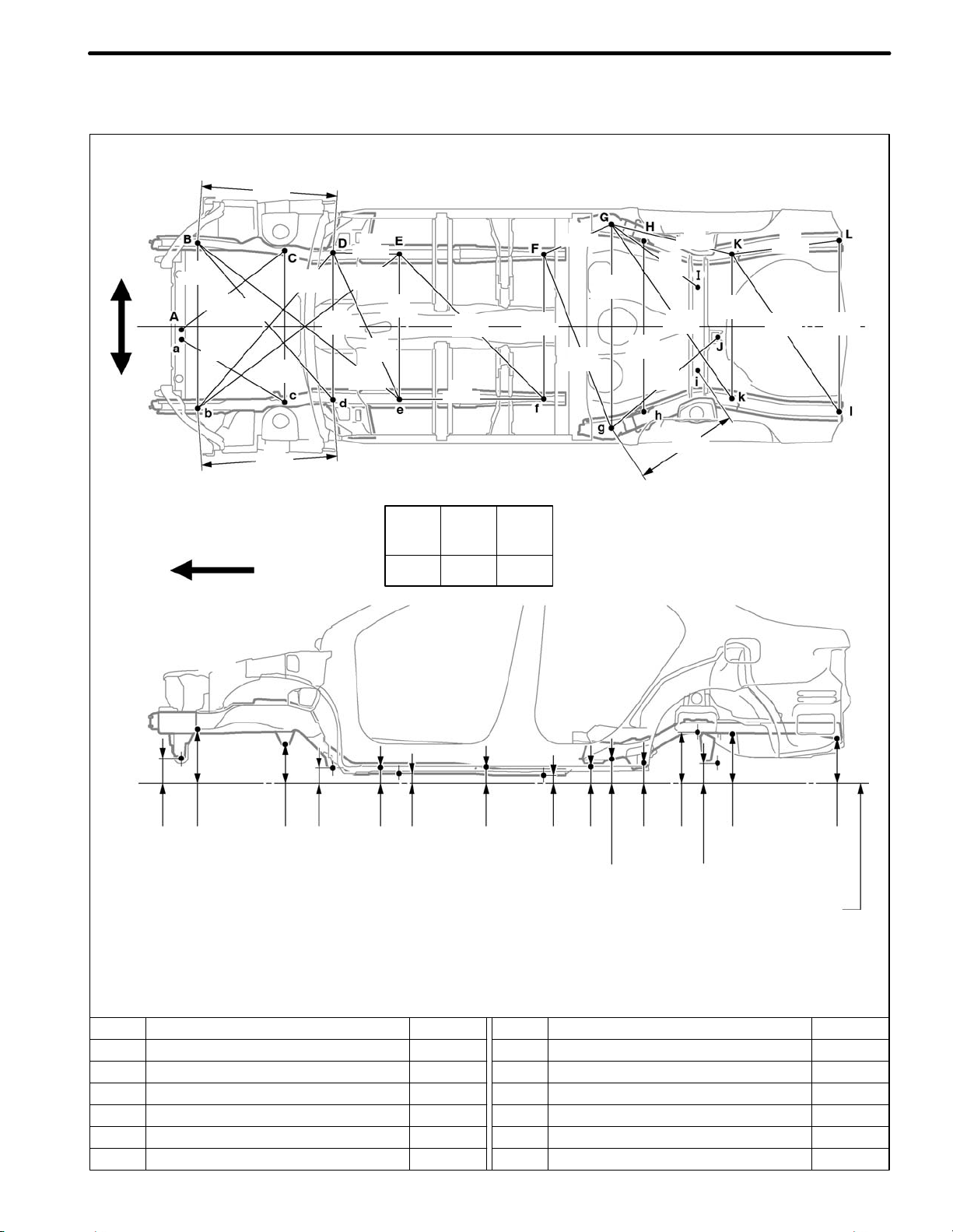

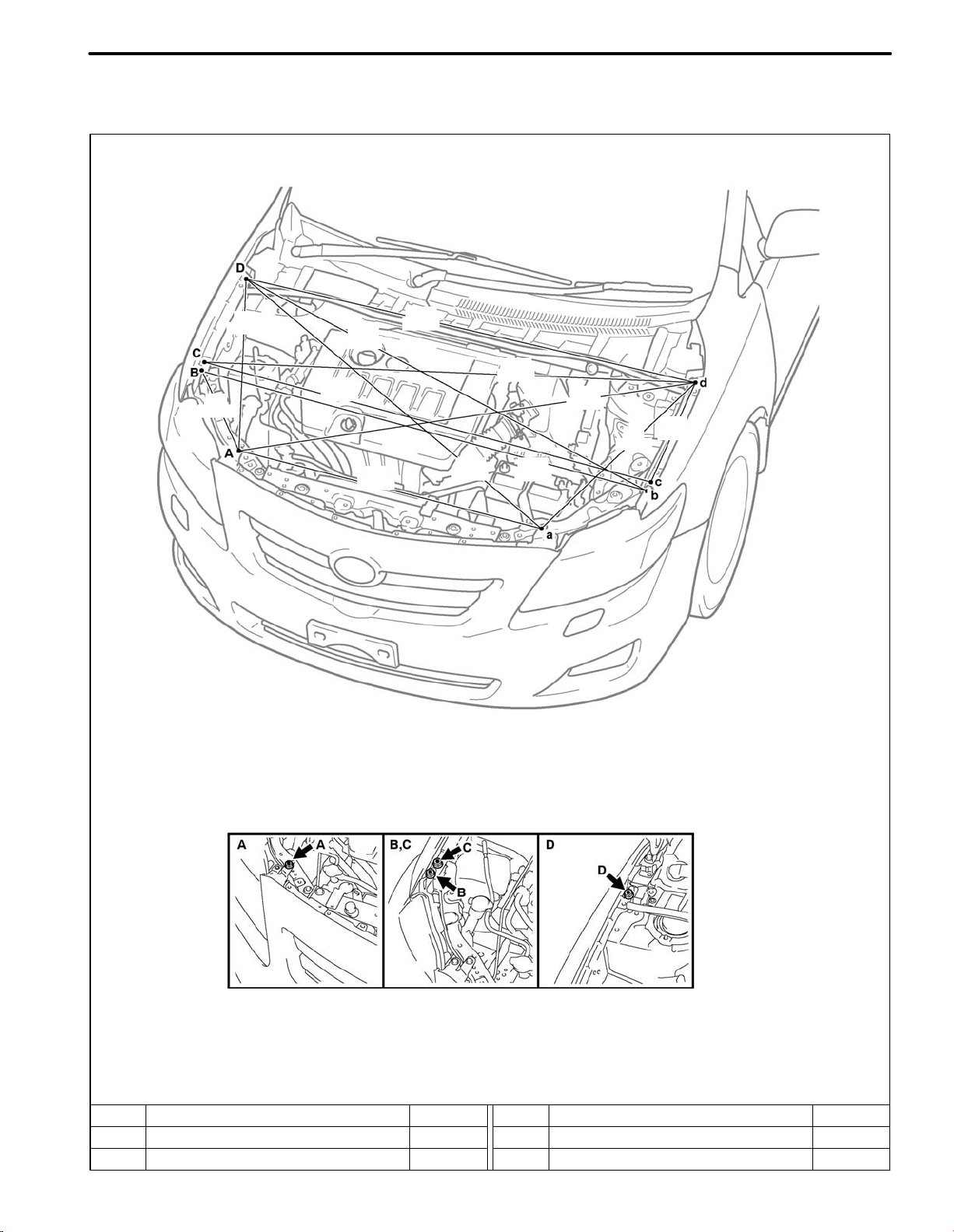

BODY DIMENSIONS DI-3

BODY DIMENSION DRAWINGS

ENGINE COMPARTMENT

(Three-Dimensional Distance)

568

(22.36)

845

(33.27)

937

(36.89)

1,575

(62.01)

592

(23.31)

501

(19.72)

638

(25.12)

728

(28.66)

929

(36.57)

1,023

(40.28)

906

(35.67)

830

(32.68)

960

(37.80)

519

(20.43)

728

(28.66)

(19.13)

(21.02)

486

891

(35.08)

534

908

(35.75)

1,456

(57.32)

604

(23.78)

1,010

(39.76)

1,038

(40.87)

269

(10.59)

339

(13.35)

Height from Imaginary Datum Line

Vehicle Dimensions

A-n B-c C-l C-M C-m

or or or or or I-j J-j M-m

a-N b-C c-L c-m c-M

1,537 1,250 1,392 263 1,457 852 1,561 1,410

(60.51) (49.21) (54.80) (10.35) (57.36) (33.54) (61.46) (55.51)

N-n or or

L-N L-n

l-n l-N

1,517 747 1,290

(59.72) (29.41) (50.79)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

Symbol Name Hole dia.

A, a

B, b

C, c

D

E, e

F

f

G, g

Front fender installation nut

Front suspension support installation hole-inner

Hood hinge installation nut-erar

Cowl top panel center mark

Front side member standard hole

Front side member standard hole

Engin mounting installation nut

Radiator support standard hole

M6 (0.24)

ø11 (0.43)

M8 (0.31)

–

ø18 (0.71)

ø12 (0.47)

M12 (0.47)

ø10 (0.39)

A,a C,c L,l

700 783 666

(27.56) (30.83) (26.22)

mm (in.)

Symbol Name Hole dia.

H, h

I

J, j

K, k

L, l

M, m

N, n

–

Front cross member side gusset standard hole

Hood lock support brace installation nut

Front fender extension standard hole

Radiator upper support installation nut

Radiator upper support installation nut

Front apron to cowl side membe upper standard hole

Front fender installation nut

–

ø10 (0.39)

M6 (0.24)

ø10 (0.39)

M6 (0.24)

M6 (0.24)

ø10 (0.39)

M6 (0.24)

–

Page 8

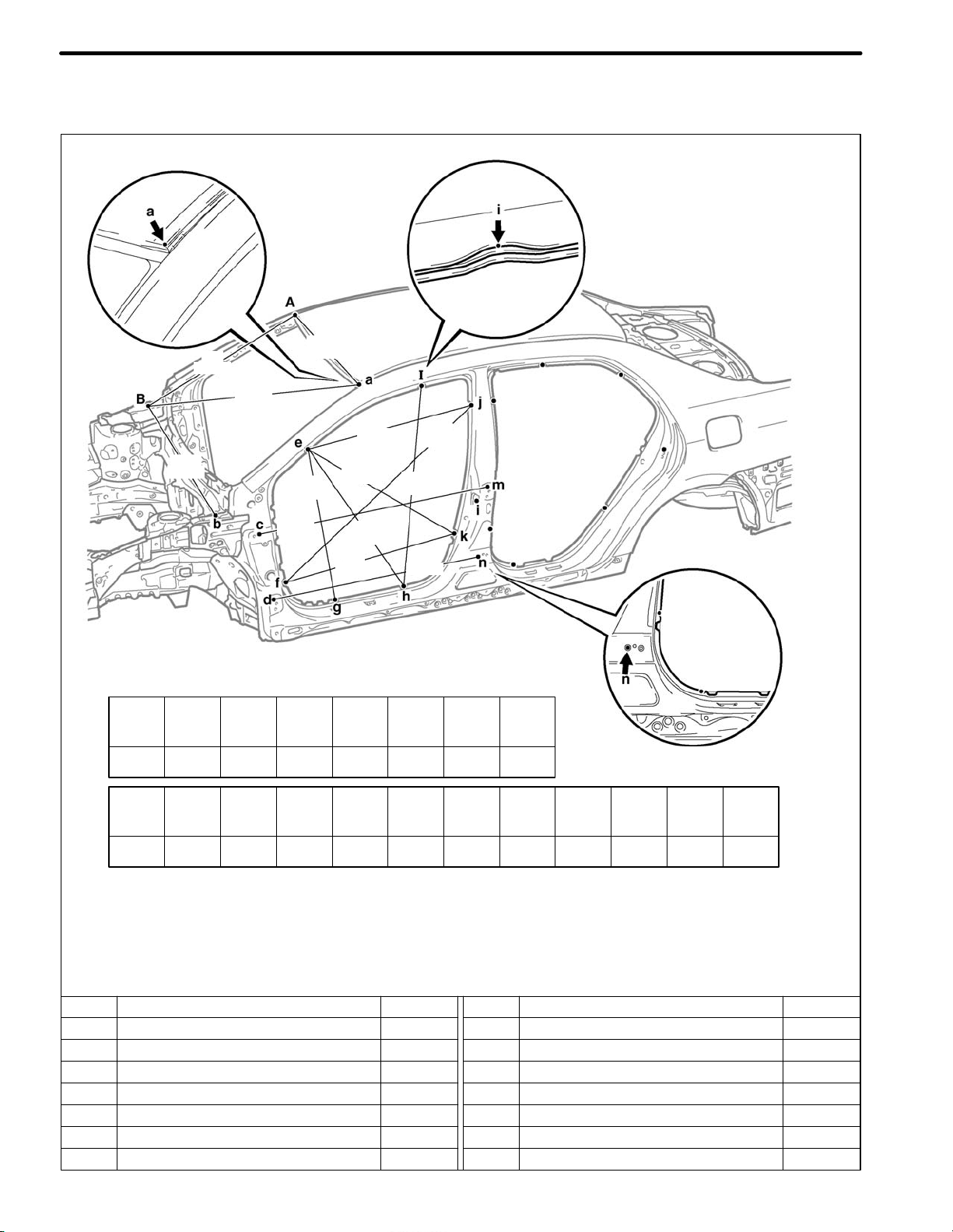

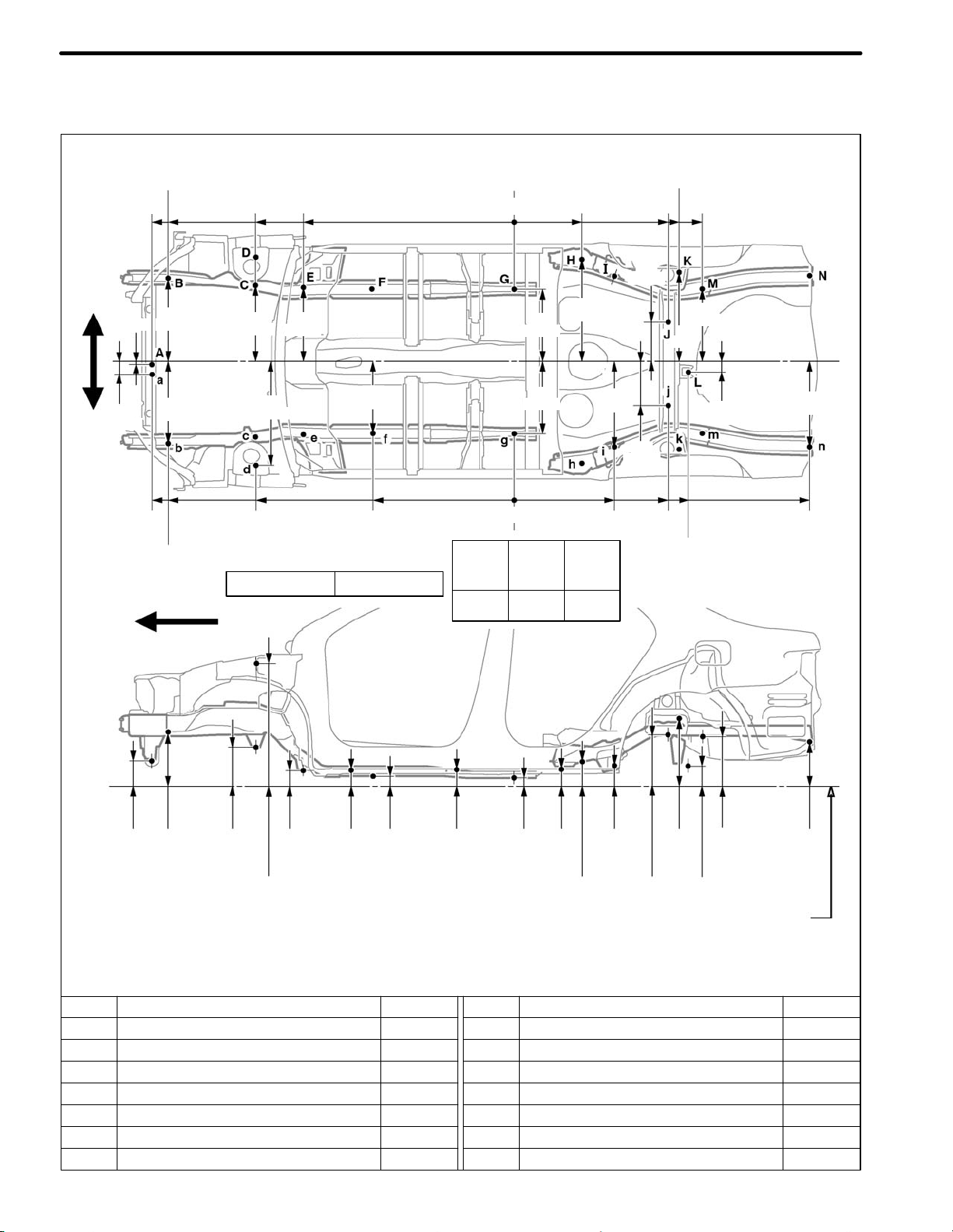

BODY DIMENSIONSDI-4

BODY OPENING AREAS (Side View: Front)

(Three-Dimensional Distance)

1,092

775

(30.51)

1,109

(43.66)

(42.99)

861

(33.90)

877

(34.53)

857

(33.74)

813

(32.01)

986

(38.82)

1,016

(40.00)

1,217

(47.91)

1,456

(57.32)

919

(36.18)

1,561

(61.46)

Vehicle Dimensions

E-e F-f G-g H-h I-i J-j K-k L-l

1,327 1,417 1,420 1,418 1,159 1,280 1,448 1,563

(52.24) (55.79) (55.91) (55.83) (45.63) (50.39) (57.01) (61.54)

E-f E-h E-i E-k F-j F-k H-i C-L C-N D-L D-M G-I

or or or or or or or or or or or or

e-F e-H e-I e-K f-J f-K h-I c-l c-n d-l d-m g-i

1,519 1,629 1,389 1,632 1,815 1,670 1,617 1,062 1,101 1,069 1,135 1,104

(59.80) (64.13) (54.68) (64.25) (71.46) (65.75) (63.66) (41.81) (43.35) (42.09) (44.68) (43.46)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

Symbol Name Hole dia.

A, a

B, b

C, c

D, d

E, e

F, f

G, g

Roof panel corner

Hood hinge installation nut-rear

Front door hinge installation nut

Front door hinge installation nut

Front body pillar assembly mark

Front body pillar assembly mark

Rocker panel assembly mark

Ċ

M8 (0.31)

M8 (0.31)

M8 (0.31)

Ċ

Ċ

Ċ

mm (in.)

Symbol Name Hole dia.

H, h

K, k

M, m

N, n

Rocker panel assembly mark

Roof side rail assembly mark

I,i

Center body pillar assembly mark

J, j

Center body pillar assembly mark

Front door lock striker installation nut

L, l

Rear door hinge installation nut

Rear door hinge installation nut

Ċ

Ċ

Ċ

Ċ

M8 (0.31)

M8 (0.31)

M8 (0.31)

Page 9

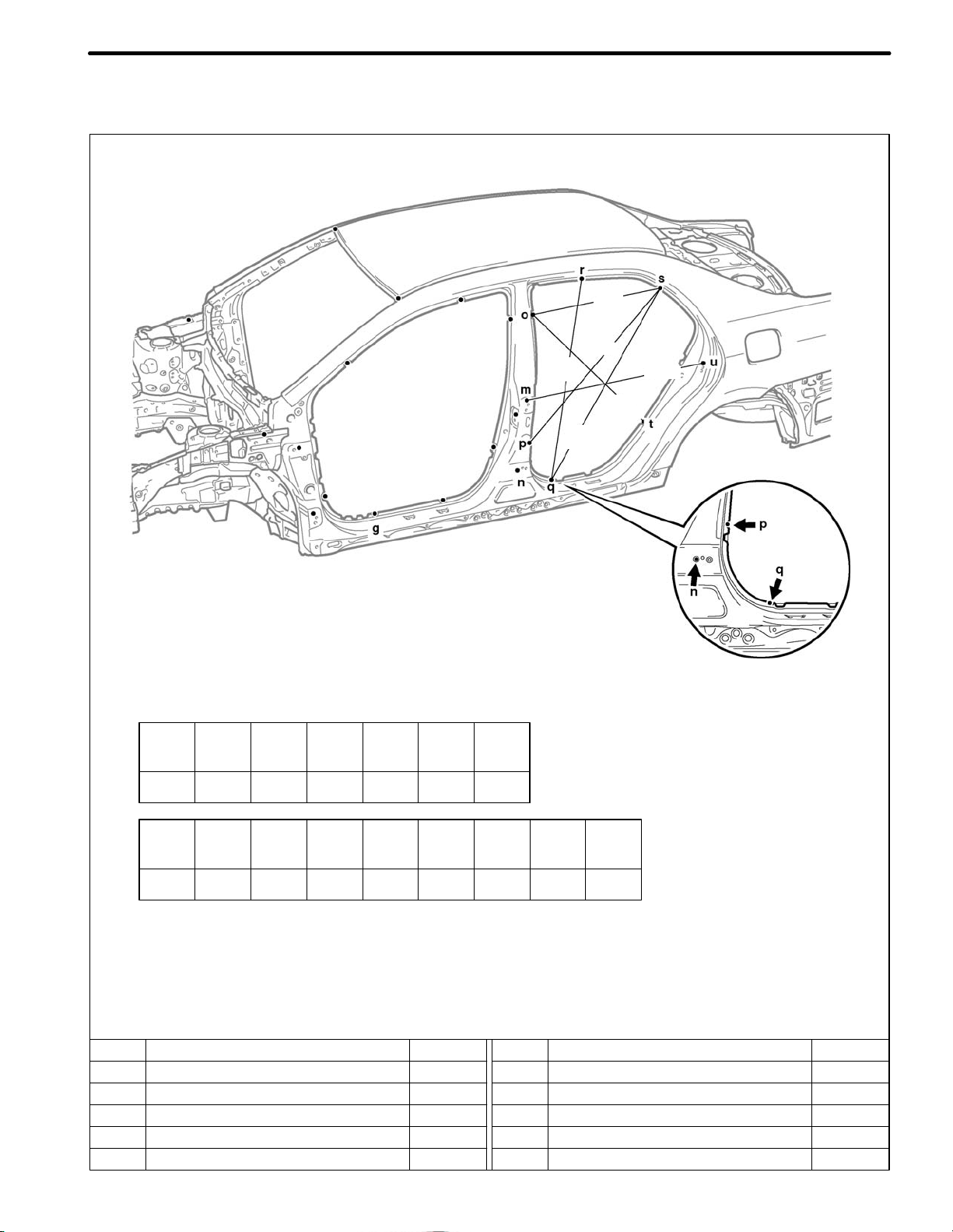

BODY DIMENSIONS DI-5

BODY OPENING AREAS (Side View: Rear)

Sedan

(Three-Dimensional Distance)

999

(39.33)

(38.62)

1,062

(41.81)

671

(26.42)

981

(32.99)

838

947

(37.28)

Vehicle Dimensions

O-o P-p Q-q R-r S-s T-t U-u

1,280 1,450 1,418 1,145 1,226 1,421 1,526

(50.39) (57.09) (55.83) (45.08) (48.27) (55.94) (60.08)

G-q O-q O-s O-t P-s P-t Q-r S-t N-U

or or or or or or or or or

g-Q o-Q o-S o-T p-S p-T q-R s-T n-u

1,702 1,603 1,421 1,588 1,656 1,559 1,619 1,478 1,066

(67.01) (63.11) (55.94) (62.52) (65.20) (61.38) (63.74) (58.19) (41.97)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

Symbol Name Hole dia.

G, g

M, m

N, n

O, o

Rocker panel assembly mark

Rear door hinge installation nut

Rear door hinge installation nut

Center body pillar assembly mark

P, p

Center body pillar assembly mark

Ċ

M8 (0.31)

M8 (0.31)

Ċ

Ċ

mm (in.)

Symbol Name Hole dia.

Q, q

R, r

S, s

U, u

Rocker panel notch edge

Roof side rail assembly mark

Quarter panel assembly mark

T, t

Quarter panel assembly mark

Rear door lock striker installation nut

Ċ

Ċ

Ċ

Ċ

M8 (0.31)

Page 10

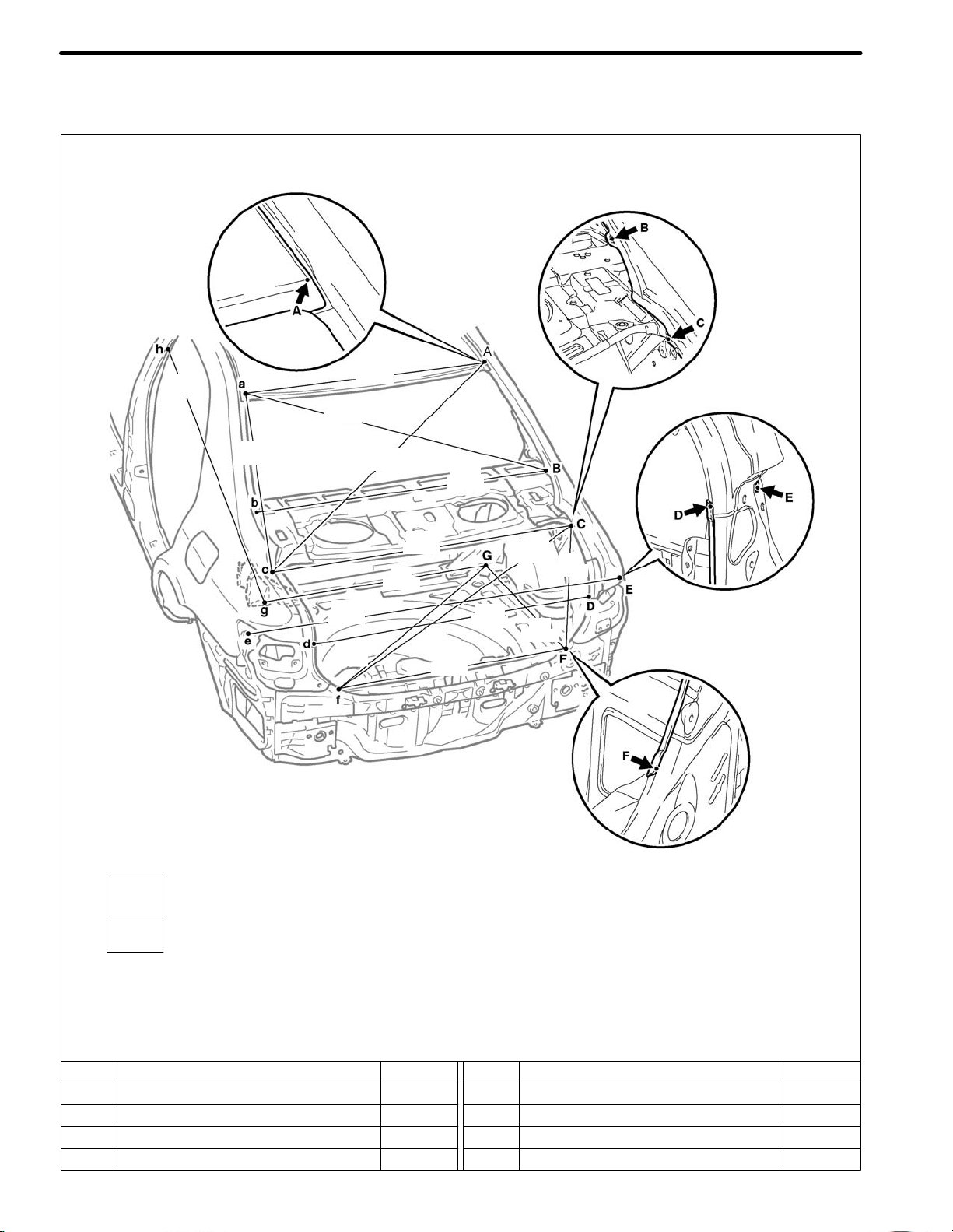

BODY DIMENSIONSDI-6

BODY OPENING AREAS (Rear View)

Sedan

(Three-Dimensional Distance)

1,035

1,240

(48.82)

(40.75)

1,200

(47.24)

Vehicle Dimensions

D-c

or

d-C

1,284

(50.55)

841

(33.11)

1,474

(58.03)

1,284

(50.55)

1,386

(54.57)

(38.74)

(46.14)

984

1,172

1,189

(46.81)

922

(36.30)

1,103

(43.43)

1,144

(45.04)

862

(33.94)

479

(18.86)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

Symbol Name Hole dia.

A, a

B, b

C, c

D, d

Roof panel corner

Quarter panel standard hole

Quarter panel / upper back panel adjoining portion

Quarter panel end housing / Luggage compartment opening

trough adjoining portion

Ċ

13.5 x 10.5

(0.53 x 0.41)

Ċ

Ċ

mm (in.)

Symbol Name Hole dia.

E, e

G, g

H, h

Quarter panel standard hole

Quarter panel end housing/ Body lower back panel adjoining

F, f

portion

Rear suspension installation hole

Center body pillar assembly mark

ø13 (0.51)

Ċ

ø16 (0.63)

Ċ

Page 11

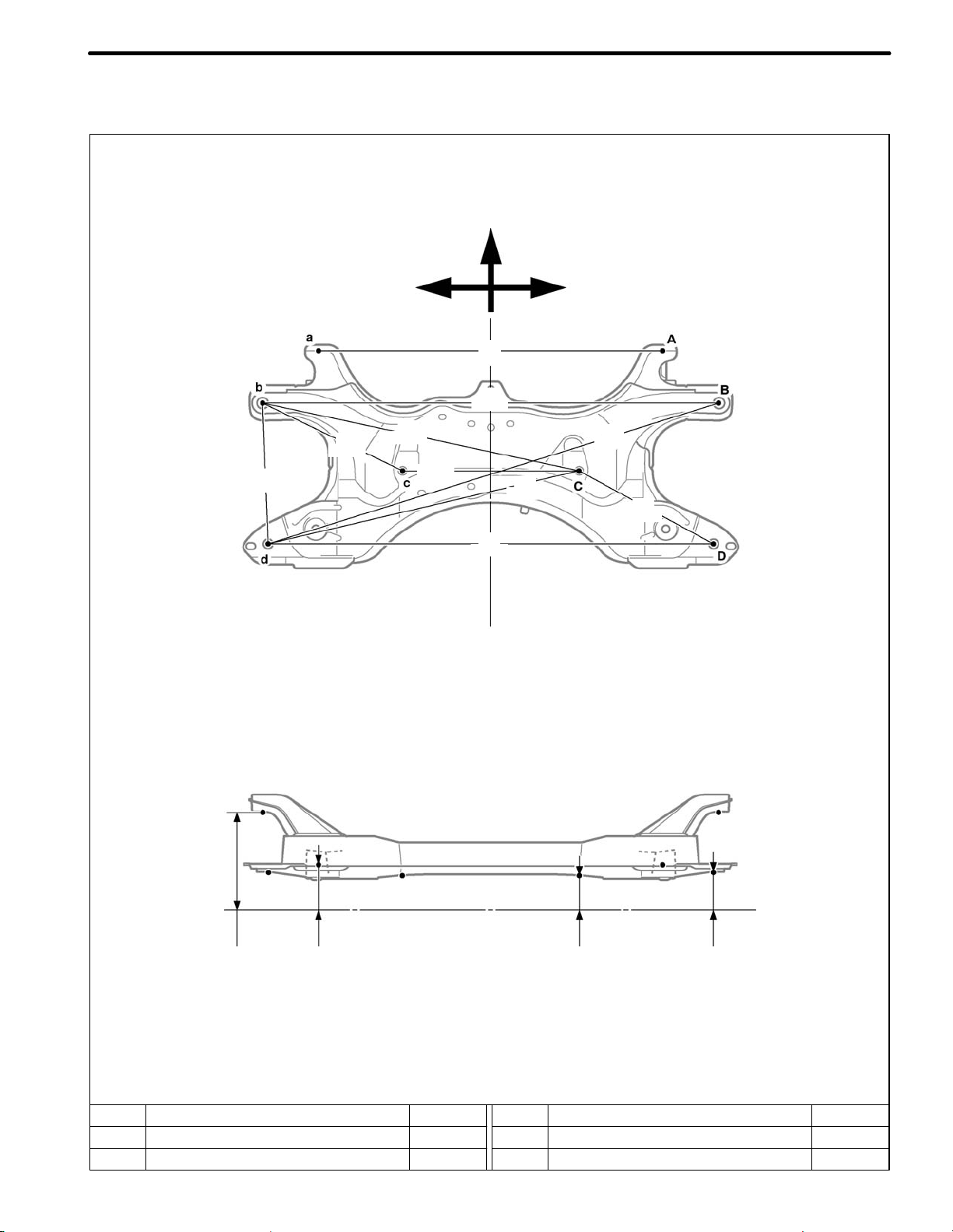

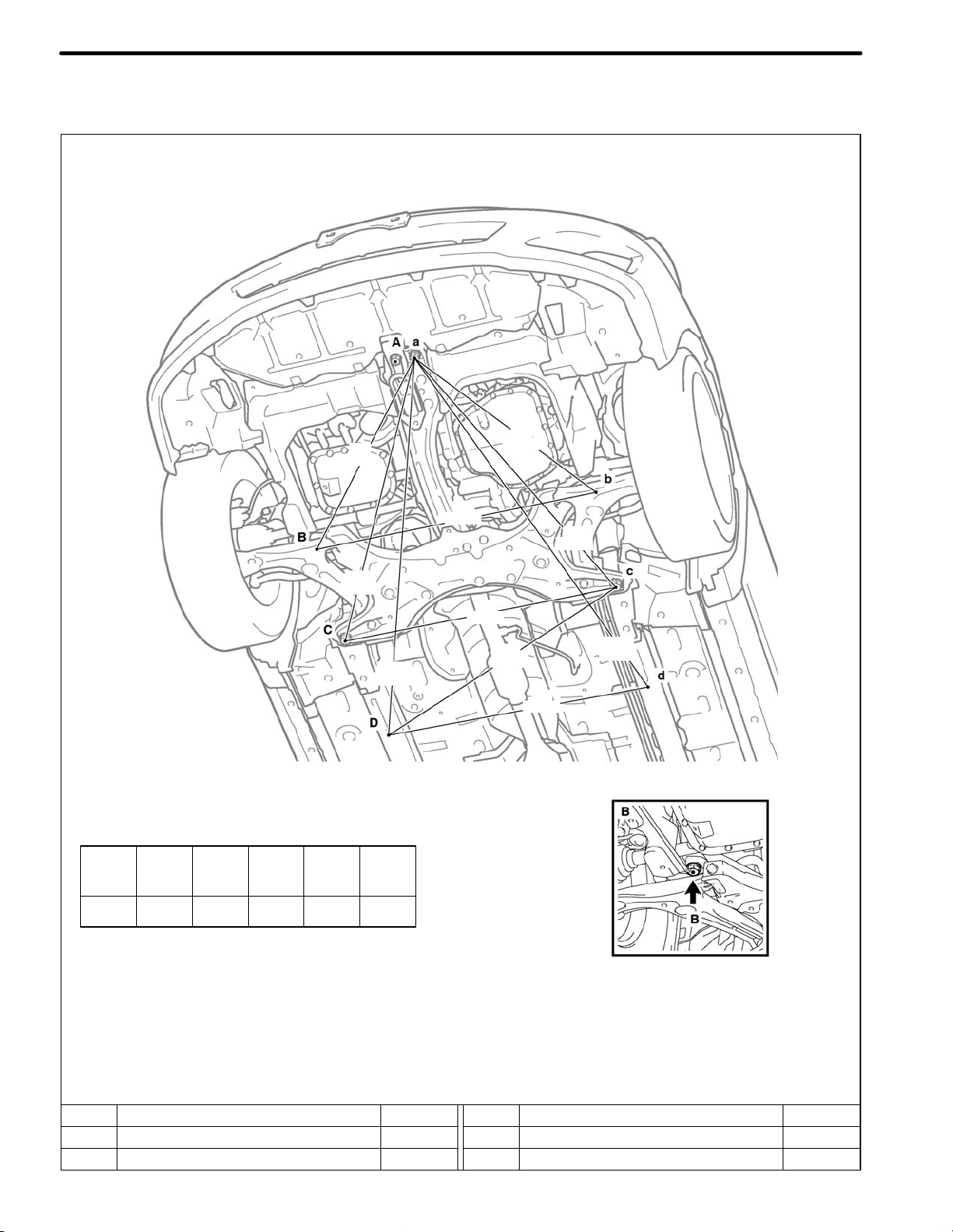

UNDER BODY

(Three-Dimensional Distance)

840

(33.07)

BODY DIMENSIONS DI-7

RH

LH

Front

985

(38.78)

(30.94)

786

730

(28.74)

1,263

(49.72)

912

(35.91)

839

(33.03)

1,252

(49.29)

890

(35.04)

400

(15.75)

1,538

(60.55)

966

(38.03)

1,547

(60.91)

870

(34.25)

1,223

(48.15)

860

(33.86)

123

100 100 100

(3.94) (3.94) (3.94)

870

(34.25)

455

(17.91)

1,129

(44.45)

1,228

(48.35)

1,035

(40.75)

656

(25.83)

1,282

(50.47)

835

(32.87)

754

(29.68)

641

(25.24)

874

(34.41)

641

(25.24)

1,147

(45.16)

1,035

(40.75)

A,a

149

(5.87)

B,b

320

(12.60)

C,c

232

(9.13)

D,d

91

(3.58)

E,e

123

57

(2.24)

HINT:

1) For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

2) Point A,a, B,b, I,i on the vehicle are asymmetrical.

Symbol Name Hole dia.

A, a

B, b

C, c

D, d

E, e

F, f

Engine mounting center member installation nut

Front side member standard hole

Front suspension crossmember installation nut

Front suspension crossmember installation nut

Front side member standard hole

Front floor under reinforcement standard hole

M10 (0.39)

ø18 (0.71)

M14 (0.55)

M14 (0.55)

ø18 (0.71)

ø10 (0.39)

F, f

48

(1.89)

G,g

146

(5.75)

H,h

123

(4.84)

I,i

307

(12.09)

J

119

(4.69)

K,k

297

(11.69)

Imaginary

L,l

271

(10.67)

Datum Line

mm (in.)

Symbol Name Hole dia.

G, g

H, h

K, k

Rear floor side front member standard hole

Trailing arm installation hole

I,i

Rear floor NO. 2 crossmember standard hole

J

Rear floor centermember NO. 4 reinforcement standard hole

Rear floor side rear member standard hole

L, l

Transport hook installation hole-rear

ø25 (0.98)

ø13 (0.51)

ø10 (0.39)

ø8 (0.31)

19 x 16

(0.75 x 0.63)

ø15 (0.59)

Page 12

UNDER BODY

BODY DIMENSIONSDI-8

(Two-Dimensional Distance)

2,064

RH

LH

(3.15)

Front

2,162

(85.12)

20

(0.79)

80

2,162

(85.12)

(81.26)

500

(19.69)

485

(19.09)

2,064

(81.26)

1,542

(60.71)

456

(17.95)

626

(24.65)

1,539

(60.59)

Wheel base 2,600 (102.36)

1,258

(49.53)

445

(17.52)

435

(17.13)

860

(33.86)

407

435

(17.13)

435

(17.13)

(16.02)

614

(24.17)

512

(20.16)

599

(23.58)

0

0

123

100 100 100

(3.94) (3.94) (3.94)

(36.22)

238

(9.37)

265

(10.43)

(38.82)

920

920

(36.22)

986

1,125

(44.29)

(17.20)

536

(21.10)

1,038

(40.87)

437

67

(2.64)

517

(20.35)

1,760

(69.29)

A,a

149

(5.87)

B,b

320

(12.60)

C,c

232

(9.13)

D,d

736

(28.98)

E,e

91

(3.58)

F, f

1

57

(2.24)

HINT:

1) For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

2) Point A,a, B,b, J,j on the vehicle are asymmetrical.

Symbol Name Hole dia.

A, a

B, b

C, c

D, d

E, e

G, g

Engine mounting center member installation nut

Front side member standard hole

Front suspension crossmember installation nut

Front suspension support installation hole

Front suspension crossmember installation nut

F, f

Front side member standard holet

Front floor under reinforcement standard hole

M10 (0.39)

ø18 (0.71)

M14 (0.55)

ø11 (0.43)

M14 (0.55)

ø18 (0.71)

ø10 (0.39)

2

G,g

(1.89)

3

48

H,h

146

(5.75)

I,i

123

(4.84)

J,j

307

(12.09)

K,k

404

(15.91)

L

119

(4.69)

M,m

297

(11.69)

Imaginary

N,n

271

(10.67)

Datum Line

Symbol Name Hole dia.

H, h

K, k

M, m

N, n

Rear floor side front member standard hole

I,i

Trailing arm installation hole

J, j

Rear absorber mounting member standard hole

Rear spring bracket installation hole

L

Rear floor centermember NO. 4 reinforcement standard hole

Rear floor side rear member standard hole

Transport hook installation hole-rea

ø25 (0.98)

ø13 (0.51)

ø10 (0.39)

ø15 (0.59)

ø8 (0.31)

19 x 16

(0.75 x 0.63)

ø15 (0.59)

mm (in.)

Page 13

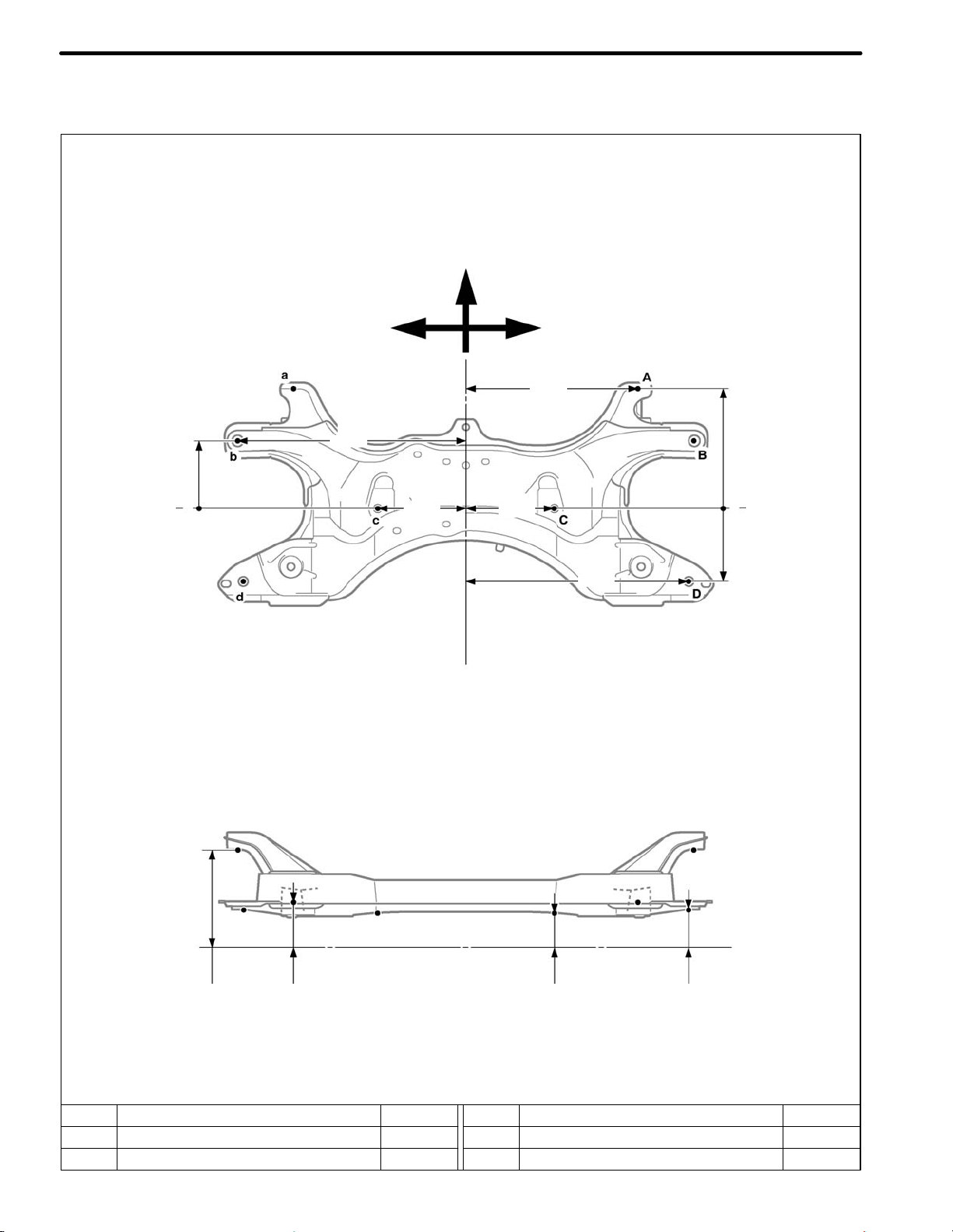

BODY DIMENSIONS DI-9

FRONT SUSPENSION CROSSMEMBER

(Three-Dimensional Distance)

Front

309

(12.17)

335

(13.19)

LH

660

(25.98)

354

(13.94)

689

(27.13)

912

(35.91)

890

(35.04)

639

(25.16)

RH

952

(37.48)

306

(12.05)

B,b

194

(7.64)

A,a

89

(3.50)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

Symbol Name Hole dia.

A, a

Lower arm installation hole

B, b

Front suspension crossmember installation hole

ø15.5 (0.61)

ø22 (0.87)

Imaginary

Datum Line

C,c

67

(2.64)

Symbol Name Hole dia.

C, c

D, d

Front suspension crossmember standard hole

Front suspension crossmember installation hole

D,d

73

(2.87)

mm (in.)

ø13 (0.51)

ø20 (0.79)

Page 14

BODY DIMENSIONSDI-10

FRONT SUSPENSION CROSSMEMBER

(Two-Dimensional Distance)

Front

B,b

136

(5.35)

177

(6.97)

RH

344

(13.54)

445

(17.52)

0

A,a

242

(9.53)

D,d

148

(5.83)

LH

456

(17.95)

0

177

(6.97)

B,b

194

(7.64)

A,a

89

(3.50)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

Symbol Name Hole dia.

A, a

B, b

Lower arm installation hole

Front suspension crossmember installation hole

ø15.5 (0.61)

ø22 (0.87)

Imaginary

Datum Line

C,c

67

(2.64)

Symbol Name Hole dia.

C, c

D, d

Lower arm installation hole

Front suspension crossmember installation hole

D,d

73

(2.87)

mm (in.)

ø13 (0.51)

ø20 (0.79)

Page 15

REFERENCE VALUE

ENGINE COMPARTMENT

(Three-Dimensional Distance)

BODY DIMENSIONS

DI-11

316

(12.44)

627

(24.68)

1,482

(58.35)

1,542

(60.71)

987

(38.86)

1,517

(59.72)

1,375

(54.13)

1,537

(60.51)

1,478

(58.19)

1,375

(54.13)

627

(24.68)

339

(13.35)

HINT:

1) For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

2) These values are actual measurements made on model. Use these reference values.

Symbol Name Hole dia.

A, a

Front bumper cover installation bolt

B, b

Headlight installation bolt

Ċ

Ċ

Symbol Name Hole dia.

D, d

E, e

Front fender installation bolt

Front fender installation bolt

mm (in.)

Ċ

Ċ

Page 16

UNDER BODY

(Two-Dimensional Distance)

821

(32.32)

BODY DIMENSIONSDI-12

726

(28.58)

1,048

(41.26)

(55.20)

Vehicle Dimensions

A-B A-b A-C A-c A-D A-d

782 759 1,020 1,002 1,382 1,369

(30.79) (29.88) (40.16) (39.45) (54.41) (53.90)

1,402

912

(35.91)

890

(35.04)

966

(38.03)

870

(34.25)

978

(38.50)

1,352

(53.23)

HINT:

1) For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (seen from rear).

2) These values are actual measurements made on model. Use these reference values.

Symbol Name Hole dia.

A, a

B, b

Center member installation bolt

Front suspension crossmember installation bolt

–

–

Symbol Name Hole dia.

C, c

D, d

Front suspension crossmember installation bolt

Front side member installation hole

mm (in.)

–

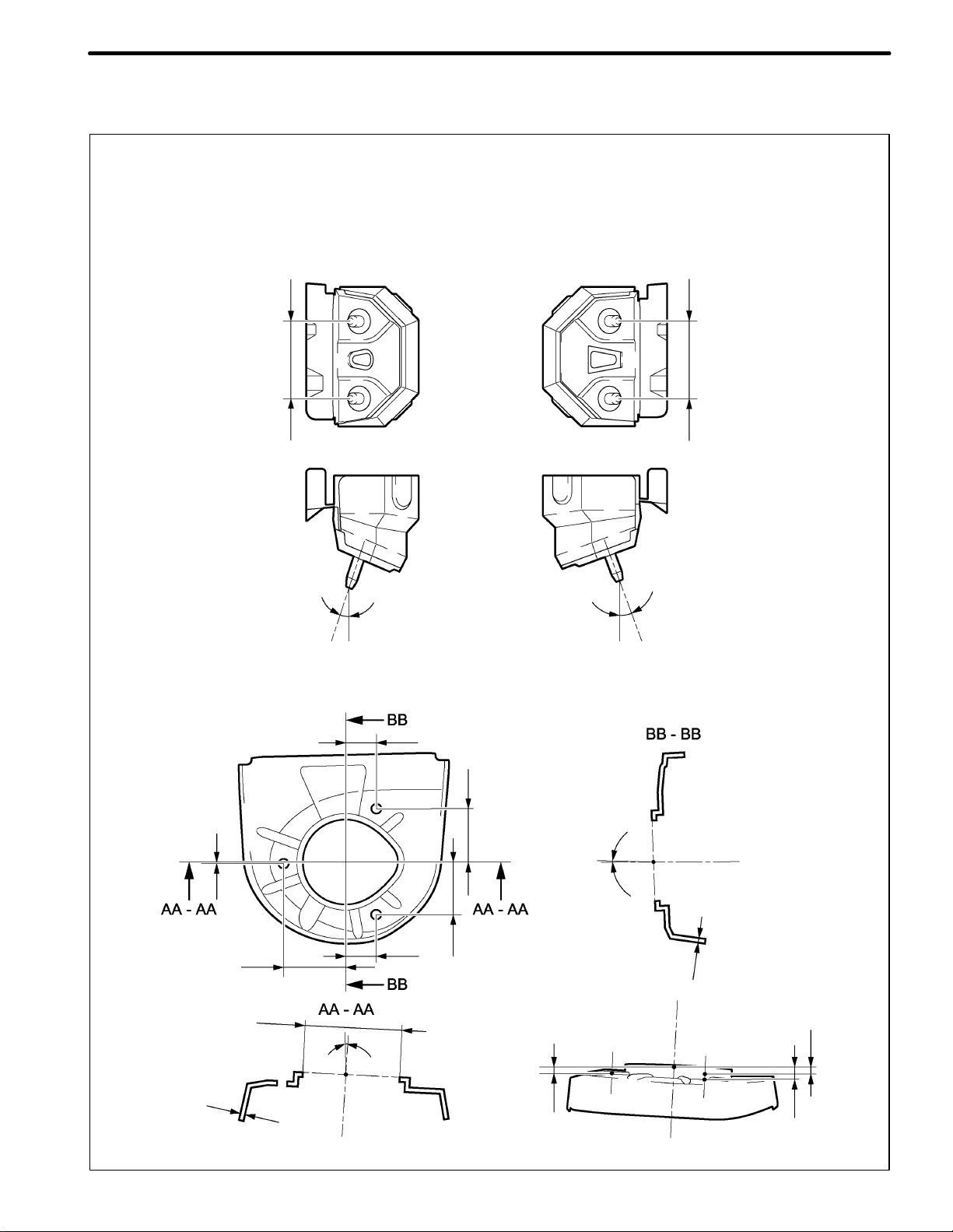

ø18 (0.71)

Page 17

UNDER BODY

(Two-Dimensional Distance)

BODY DIMENSIONS DI-13

Front bumper reinforcement

59.8

[RH]

13.10_

Front suspension support

[LH]

59.8

12.3_

0.4

2.3

66.4

102

3_

32.6

32.3

56.7

57.5

6.6

2.3_

2.3

9.4

13.9

Unit: mm

Page 18

DI-14

MEMO

Page 19

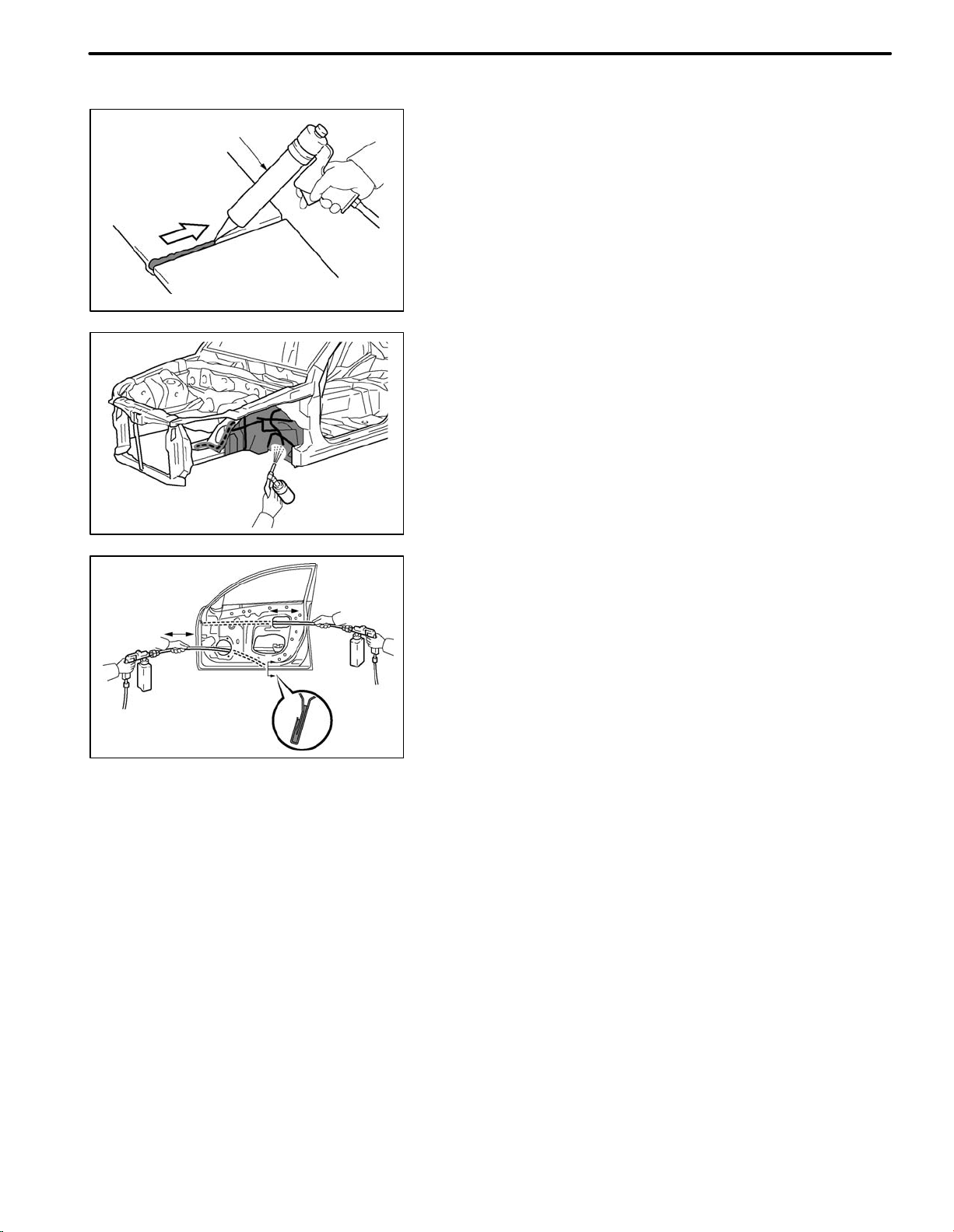

INTRODUCTION

4. ANTI-RUST TREATMENT AFTER INSTALLATION

Sealer Gun

F33011

(a) BODY SEALER APPLICATION

PURPOSE:

For water-proofing and anti-rust measures, always

apply the body sealer to the body panel seams and

hems of the doors, hood, etc.

NOTICE:

Apply body sealer neatly to parts that require a

high quality appearance.

(b) UNDERCORT APPLICATION

PURPOSE:

To prevent corrosion and protect the body from gravel,

always apply a sufficient undercoating to the areas indicated.

IN-1

F33012

F33013

(c) VEHICLE BODY ANTI-RUST AGENT

APPLICATION

PURPOSE:

The purpose is to protect areas from rust which are difficult to paint such as the backside of the box-shaped

cross section frame parts.

METHOD:

Apply anti-rust agent through the service holes and/or

installation holes of the parts.

Page 20

INTRODUCTIONIN-2

5. HEADLIGHT BRACKET REPAIR

HINT:

S If the installation area of the headlight assembly is damaged, use the supply retainer for low-cost

repair.

S Ensure that the headlight assembly is not damaged.

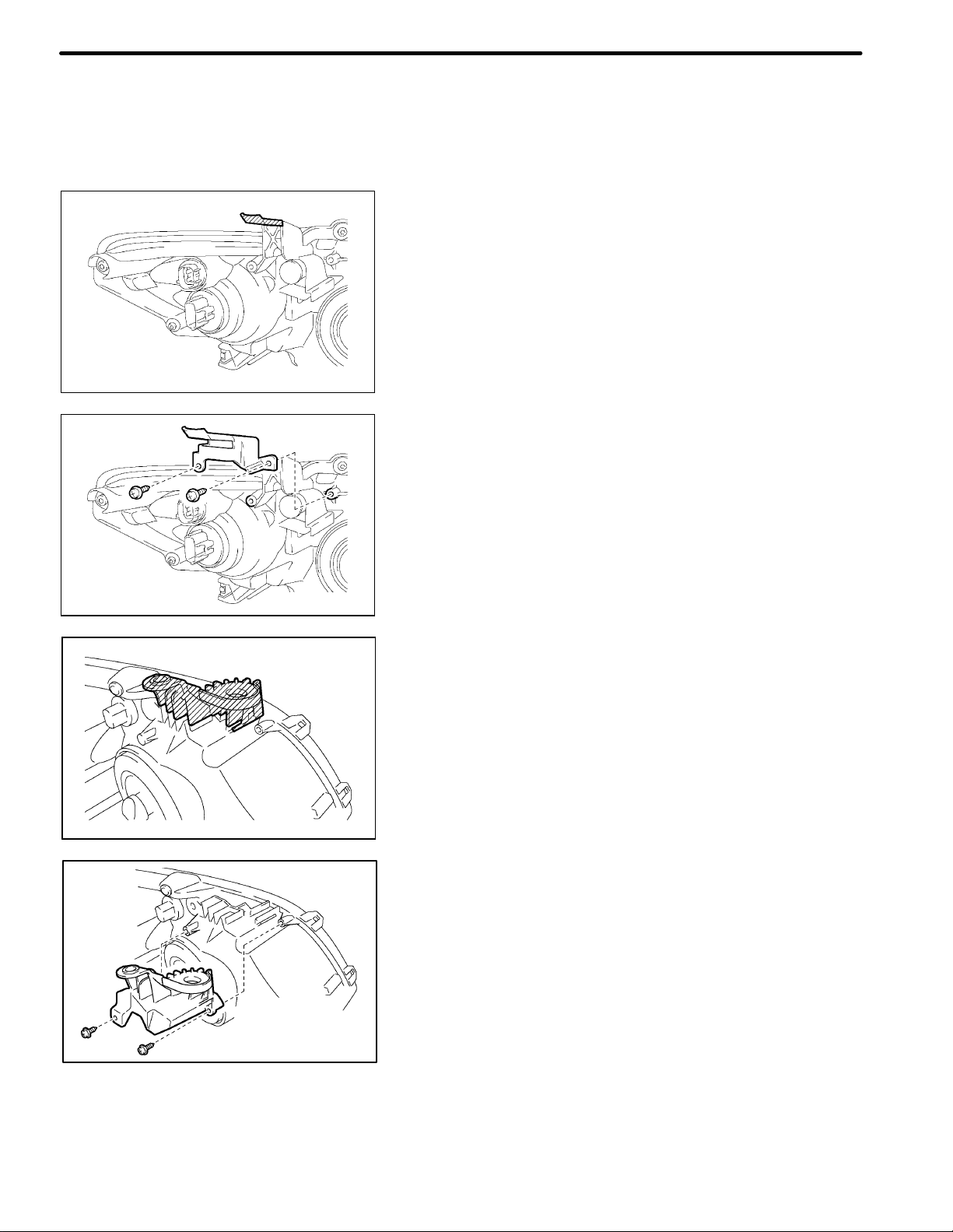

(a) INSTALL UPPER HEADLIGHT PROTECTOR

RETAINER

(1) Cut off the part shaded in the illustration and smooth

with sandpaper.

NOTICE:

After cutting off the part, place the upper headlight protector retainer against the bosses and

gradually file away the old bracket if it interferes

E163300

with the installation of the supply bracket.

(2) Install the upper headlight protector retainer with the

2 screws.

E163301

E160571

E160570

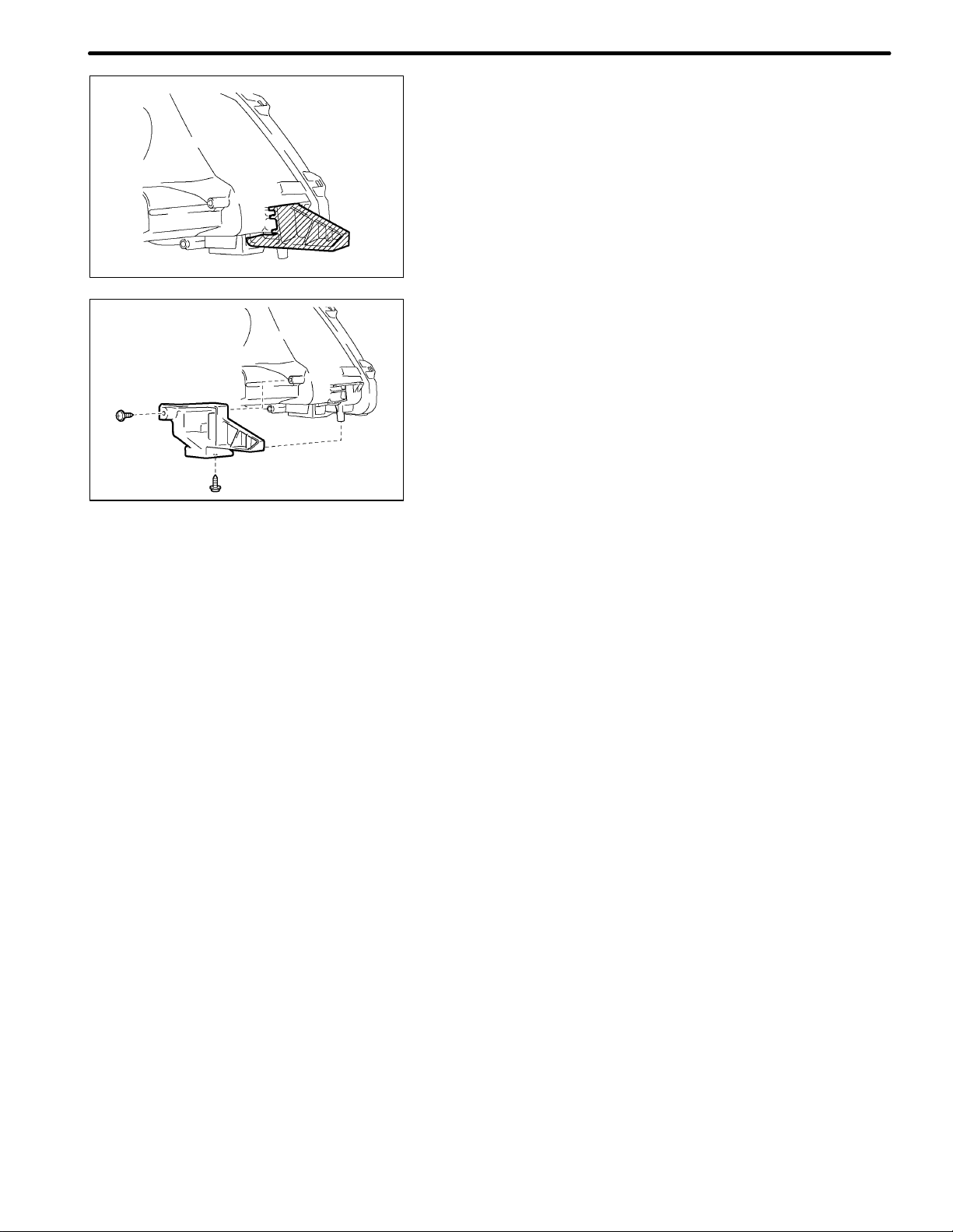

(b) INSTALL LOWER HEADLIGHT PROTECTOR

RETAINER

(1) Cut off the part shaded in the illustration and smooth

with sandpaper.

NOTICE:

After cutting off the part, place the lower headlight

protector retainer against the bosses and gradually file away the old bracket if it interferes with

the installation of the supply bracket.

(2) Install the lower headlight protector retainer with the 2

screws.

Page 21

E160573

E160572

INTRODUCTION IN-3

(c) INSTALL LOWER HEADLIGHT BRACKET

(1) Cut off the part shaded in the illustration and smooth

with sandpaper.

NOTICE:

After cutting off the part, place the lower headlight

bracket against the bosses and gradually file

away the old bracket if it interferes with the installation of the supply bracket.

(2) Install the lower headlight bracket with the 2 screws.

Page 22

INTRODUCTIONIN-4

6. PROCEDURES NECESSARY WHEN ECU OR OTHER PARTS

ARE REPLACED

(a) THE WORK LIST

(1) Each inspection procedure refers to the TOYOTA Repair Manual.

Effect/Inoperative

Replacement Part Necessary Procedure

Vehicle Identification

Number (VIN) registration

ECU commnication ID

ECM

S Automatic transmission

assembly (*1)

S Engine assembly (*1)

Tire pressure warning ECU

Tire pressure warning valve

and transmitter

Brake actuator assembly

(Skid control ECU)

S Yaw rate and

acceleration sensor

S Front wheel alignment

adjustment

S Power steering ECU (*2)

S Steering column (*2)

Power steering ECU (*3)

Steering column (*3)

registration

Reset memory (*1)

Reset memory

1. Register transmitter IDs

2. Initialize tire pressure

warning system

1. Register transmitter IDs

2. Initialize tire pressure

warning system

Perform yaw rate and

acceleration sensor zero

point calibration

1. Clear zero point

calibration data

2. Perform yaw rate and

acceleration sensor zero

point calibration

Perform rotation angle

sensor initialization and

torque sensor zero point

calibration.

1. Assist map writing

2. Torque sensor zero

point calibration

Torque sensor zero point

calibration

MIL comes on Using the Techstream.

S Wireless door lock control system

S Smart key system (*4)

S Engine start

S Large shift shock

S The deterioration of fuel efficien-

S Large shift shock

S The deterioration of fuel efficien-

S When DTC detection conditions

S Tire pressure monitoring function

1. When DTC detection conditions

2. Tire pressure monitoring function

S VSC OFF indicator light blinks

S VSC disabled or malfunctioning

S VSC OFF indicator light blinks

S VSC disabled or malfunctioning

S P / S warning light comes on

S EPS control

S P /S warning light comes on

S EPS control

Steering effort is different between

turning steering wheel to left and

right

Function When

Necessary Procedures

are not Performed

(*4)

cy

cy

of “transmitter ID not received”

DTC are met, TPWS indicator

blinks for 1 minute, and then

illuminates

of “transmitter ID not received”

DTC are met, TPWS indicator

blinks for 1 minute, and then

illuminates

of replaced wheel

Note

—

Using the Techstream.

Using the intelligent tester.

—

Even if only one wheel is

replaced, IDs for all 4

wheels must be registered.

Perform yaw rate and

acceleration sensor zero

point calibration with the

ignition switch on (engine

stopped).

Perform yaw rate and

acceleration sensor zero

point calibration with the

ignition switch on (engine

stopped).

DTC (C1515/C1525) will

be stored when the power

steering ECU is replaced.

DTC (C1515/C1525) will

be stored when the power

steering ECU is replaced.

—

Page 23

Replacement Part Necessary Procedure

1. Perform identification

S Door control transmitter

(*5)

S Door control receiver

(*5)

Steering lock actuator

(Steering lock ECU) (*4)

S Certification ECU (*4)

S Electrical key transmitter

(*4)

ID code box (*4)

Occupant classification

ECU

S Sliding roof drive gear

(Sliding roof ECU)

S Sliding roof housing

S Sliding roof drive cable

code registration (key

code)

2. Refer to wireless door

lock control system

“REGISTRATION”

procedures

ECU code registration Engine start —

Key ID registration

1. ECU code registration

2. ECU communication ID

registration

S Perform zero point

calibration

S Registration ECU data

Perform sliding roof drive

gear reset.

INTRODUCTION IN-5

Effect/Inoperative

Function When

Necessary Procedures

are not Performed

wireless door lock control system —

S Wireless door lock control system

S Smart key system

S Engine start

S Wireless door lock control system

S Smart key system

S Engine start

S Occupant classification system

S Passenger airbag ON / OFF

indicator

S Airbag system

(Front passenger side)

S Seat belt warning system

(Front passenger side)

S Automatic open/close function of

roof glass

S Jam protection function

S Operation function after ignition

switch off

Necessary when removed

and installed (Not

necessary when the sliding

roof drive gear (sliding roof

ECU) is removed and

installed together with the

sliding roof housing.)

Note

—

—

—

*1: for U341E, U250E Automatic Transaxle

*2: for 2AZ−FE

*3: for 2ZR−FE

*4: w/ Smart Key System

*5: w/o Smart Key System

Page 24

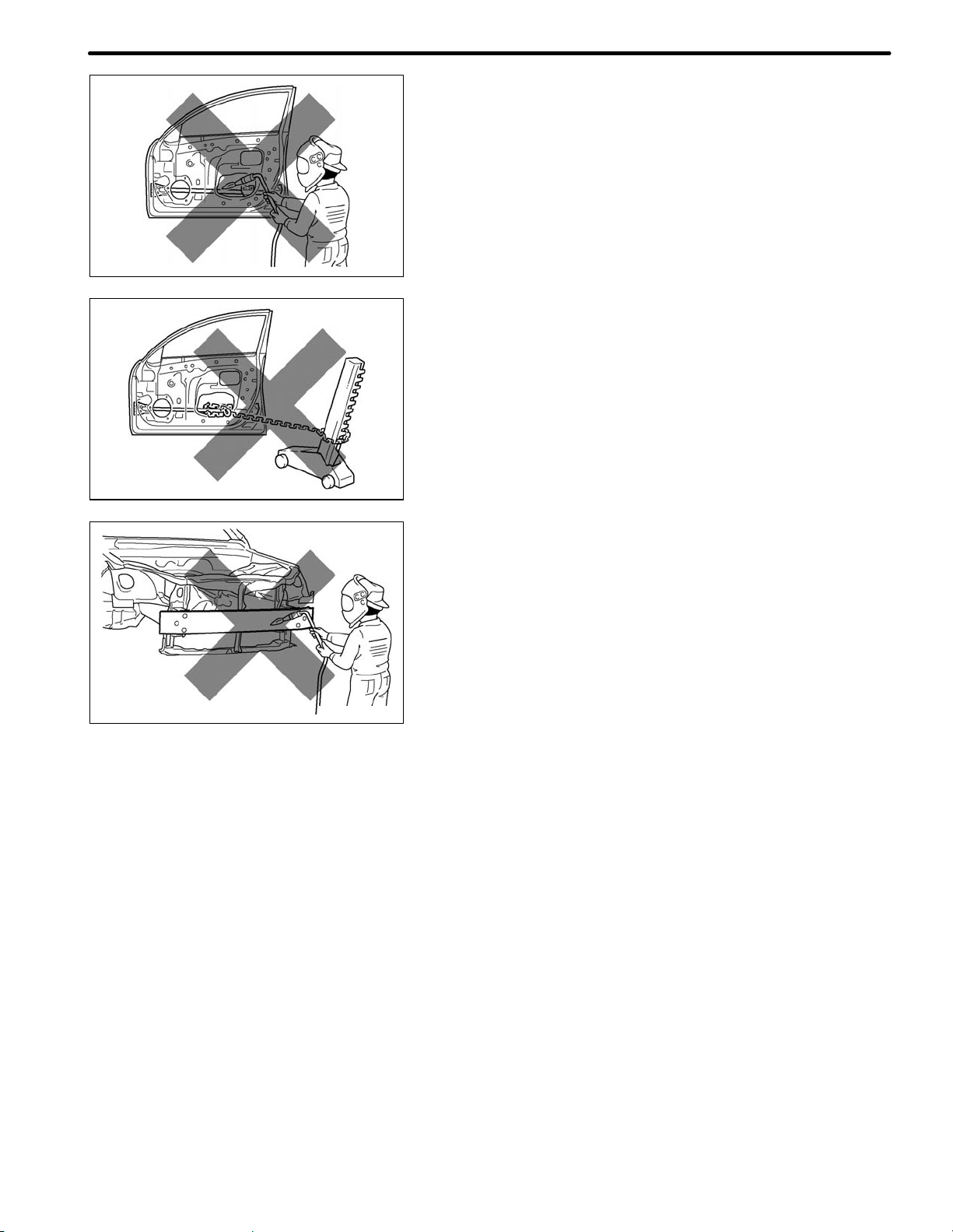

1. WORK PRECAUTIONS

Glass Cover

Seat Cover

F33000

WRONG

INTRODUCTION IN-5

PRECAUTION

(a) VEHICLE PROTECTION

(1) When welding, cover glass, seats, carpets, etc. with

heat resistant fireploof covers to protect them.

(b) SAFETY

(1) Never stand in the path of the chain when using a pull-

er on the body or frame, and be sure to attach a safety

cable.

WRONG

F33001

F33002

F33003

(2) If it is necessary to use a frame in the area of the fuel

tank, first remove the tank and plug the fuel line.

(c) SAFETY WORK CLOTHES

(1) In addition to the usual mechanic’s wear, cap and

safety shoes, the appropriate gloves, head protector,

welder’s glasses, ear plugs, face protector, dust

mask, etc. should be worn as the situation demands.

Code Name

A Dust mask

B Face protector

C Safety glasses

D Safety shoes

E Welder’s glasses

F Ear plugs

G Head protector

H Welder’s gloves

Page 25

INTRODUCTIONIN-6

2. PRECAUTIONS WHEN REPAIRING BODY FRAME PARTS

(INCLUDING CRUSH BOX)

(a) PROHIBITION OF HEAT REPAIR FOR BODY

FRAME PARTS

(1) Rustproof high strength steel sheets are used for the

body frame. Therefore, if these parts are heat repaired using an acetylene torch or equivalent, the

crystalline structure changes, causing the strength of

the steel sheets to decrease. Also, the zinc corting

which is used to protect the body from rust will be

damaged. This causes the surface of the steel sheets

F33014

(b) WHEN TO REPLACE FRAME PARTS

F33015

to become oxidized, which reduces their ability to resist rust.

NOTICE:

Replace frame parts that have kinks.

HINT:

What is kink?

A deformatision bon a steel sheet that cannot be returned

to its original shape by pulling or hammering due to the deformation angle being sharp.

Page 26

F33016

F33017

INTRODUCTION IN-7

(c) REPAIR OF DOOR SIDE IMPACT BEAM IS

PROHIBITED

(1) The impact beam is desined so that it performs at

100% in its original shape.

However, if the impact beam is repaired, its performance may not be the same as before the accident.

PARTS EHICH ARE PROHIBITED TO BE

REPAIRED: Door side impact beam

F30442

(d) REPAIR OF BUMPER REINFORCEMENT IS

PROHIBITED

(1) The bumper reinforcement is designed so that it par-

forms at 100% in uts original shape.

However, if the impact beam is repaired, its performance may not be the same as before the accident.

PARTS EHICH ARE PROHIBITED TO BE

REPAIRED: Bumper reinforcement

Page 27

IN-8

INTRODUCTION

3. PRECAUTIONS FOR CORRECT REPAIR

(a) REMOVAL OF ADJACENT COMPONENTS

(1) When removing adjacent components, apply protec-

tive tape to the surrounding body and your tools to

prevent damage.

NOTICE:

If the paint film is damaged, make sure to refinish

the paint.

F33007

(b) ANTI-RUST TREATMENT BEFORE WELDING

(1) Apply welding primer to the contact surfaces of the

welding areas to protect them from rust.

NOTICE:

Do not apply welding primer outside of the contact surfaces.

Puncher

Old Spot Locations

New Spot Locations

F33008

F33009

F33010

(c) MAKING HOLES FOR PLUG WELDING

(1) For areas where a spot welder cannot be used, use a

puncher or drill to make holes for plug welding.

Thickness of welded portion Diameter of plug hole

Under 10 mm (0.04 in.) Over 5 mm (0.20 in.)

1.0 to 1.6 mm (0.04 to 0.06 in.) Over 6.5 mm (0.26 in.)

1.7 to 2.3 mm (0.07 to 0.09 in.) Over 8 mm (0.31 in.)

Over 2.4 mm (0.09 in.) Over 10 mm (0.39 in.)

(d) WELDING PRECAUTIONS

(1) The number of welding spots should be as follows.

Spot weld: 1.3 X No. of manufacturer’s spots

Plug weld: More than No. of manufacturer’s plugs

(2) Spot weld locations

Avoid welding over previously welded areas.

Page 28

INTRODUCTION

8. PRECAUTIONS FOR RESIN PARTS

(a) PLASTIC PROPERTIES CHART

(1) When repairing, some parts may be deformed by the heat. Therefore, confirm the properties of

the platic parts, and remove parts beforehand as necessary.

Heat*

Code Material name

resistant

temperature

limit _C (_F)

alcohol or gasoline

Resistance to

IN-9

Notes

Acrylonitrile

ABS

AES

ASA

EPDM

PA

PBT

PC Polycarbonate

Butadiene

Styrene

Acrylonitrile

Ethylene Styrene

Acrylonitrile

Styrene

Acrylate

Ethylene

Propylene

Polyamide

(Nylon)

Polybutylene

Terephthalate

80

(176)

80

(176)

80

(176)

100

(212)

80

(176)

160

(320)

120

(248)

Alcohol is harmless if applied only

for short time in small amounts

(e.g., quick wiping to remove

grease).

Alcohol is harmless if applied only

for short time in small amounts

(e.g., quick wiping to remove

grease).

Alcohol is harmless if applied only

for short time in small amounts

(e.g., quick wiping to remove

grease).

Alcohol is harmless. Gasoline is

harmless if applied only for short

time in small amounts.

Alcohol and gasoline are harmless. Avoid battery acid.

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol is harmless.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline and organic

or aromatic solvents.

Most solvents are harmless

but avoid dipping in

gasoline,solvents, etc.

Avoid gasoline brake fluid,

wax, wax removers and

organic solvents.

Avoid alkali.

PE Polyethylene

PET

PMMA

PP Polypropylene

PVC

TPE

TPO

Polyethylene

Terephthalate

Polymethyl

Methacrylate

Polyvinylchloride

(Vinyl)

Thermoplastic

Elastomer

Thermoplastic

Olefine

80

(176)

75

(167)

80

(176)

80

(176)

80

(176)

80

(176)

80

(176)

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol and gasoline are harmless. Avoid dipping in water.

Alcohol is harmless if applied only

for short time in small amounts

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol and Gasoline are harmless.

if applied only for short time in small

amounts. (e.g., quick wiping to

remove grease).

Alcohol and Gasoline are harmless.

if applied only for short time in small

amounts. (e.g., quick wiping to

remove grease).

Alcohol and Gasoline are harmless.

if applied only for short time in small

amounts. (e.g., quick wiping to

remove grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Most solvents are harmless

but avoid dipping in

gasoline, solvents, etc.

Most solvents are harmless

but avoid dipping in

gasoline, solvents,

etc.TSOP

Page 29

IN-10

Code Material name

INTRODUCTION

Heat*

resistant

temperature

limit _C (_F)

Resistance to

alcohol or gasoline

Notes

TSOP

TOYOTA

Super Olefine

Polymer

80

(176)

Alcohol and gasoline are harmless. Most solvents are harmless.

* Temperatures higher than those listed here may result in material deformation during repair.

Page 30

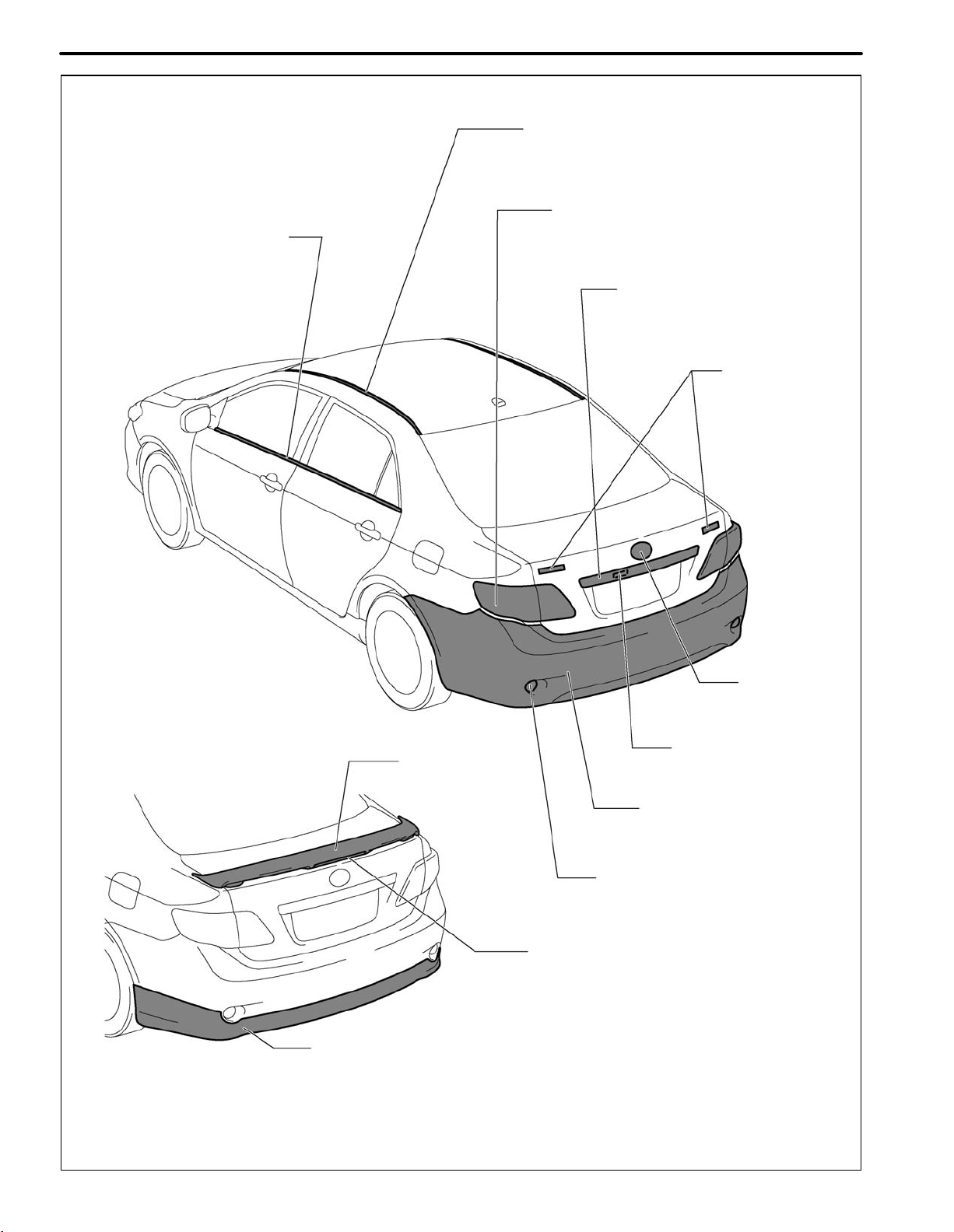

Headlight

(PC/PP)

INTRODUCTION

Cowl Top Ventilator Louver

(PE/PP/TSOP)

Front Wiper Blade

(PBT/PE)

IN-11

Front Piller Cover

(AES)

Antenna

(ABSSASA / PC)

Emblem

(AES/ABS)

Radiator Grille

(TSOP)

Front Bumper Cover

(TSOP)

Front Spoiler Cover

(PP)

Door Outside Handle

(PC/PBT)

Body Rocker Panel Moulding

(TSOPSPP)

Outer Rear View Mirror

(ASA/PBT/ABSSPA/ PE / PET / PBT)

Foglight

(ASA/PBT)

/ Made up of 2 or more kinds of materials.

S Resin material differs with model.

B0709140118B

Page 31

IN-12

Door Belt Moulding

(EPDM/PP)

INTRODUCTION

Roof Drip Side Finish Moulding

(TPE)

Rear Combination Light

(ASA/PMMA)

Luggage Compartment

Door Outside Garnish

(ABS)

Emblem

(ABS)

Rear Spoiler

(ABS)

Rear Under Spoiler

(TSOP)

Emblem

(ABS)

Licence Plate Light

(PA/ PC)

Rear Bumper Cover

(TSOP)

Reflex Refrector

(ABS/PMMA)

High Mount Stop Light

(ABS/PMMA)

/ Made up of 2 or more kinds of materials.

S Resin material differs with model.

B0709140120

Page 32

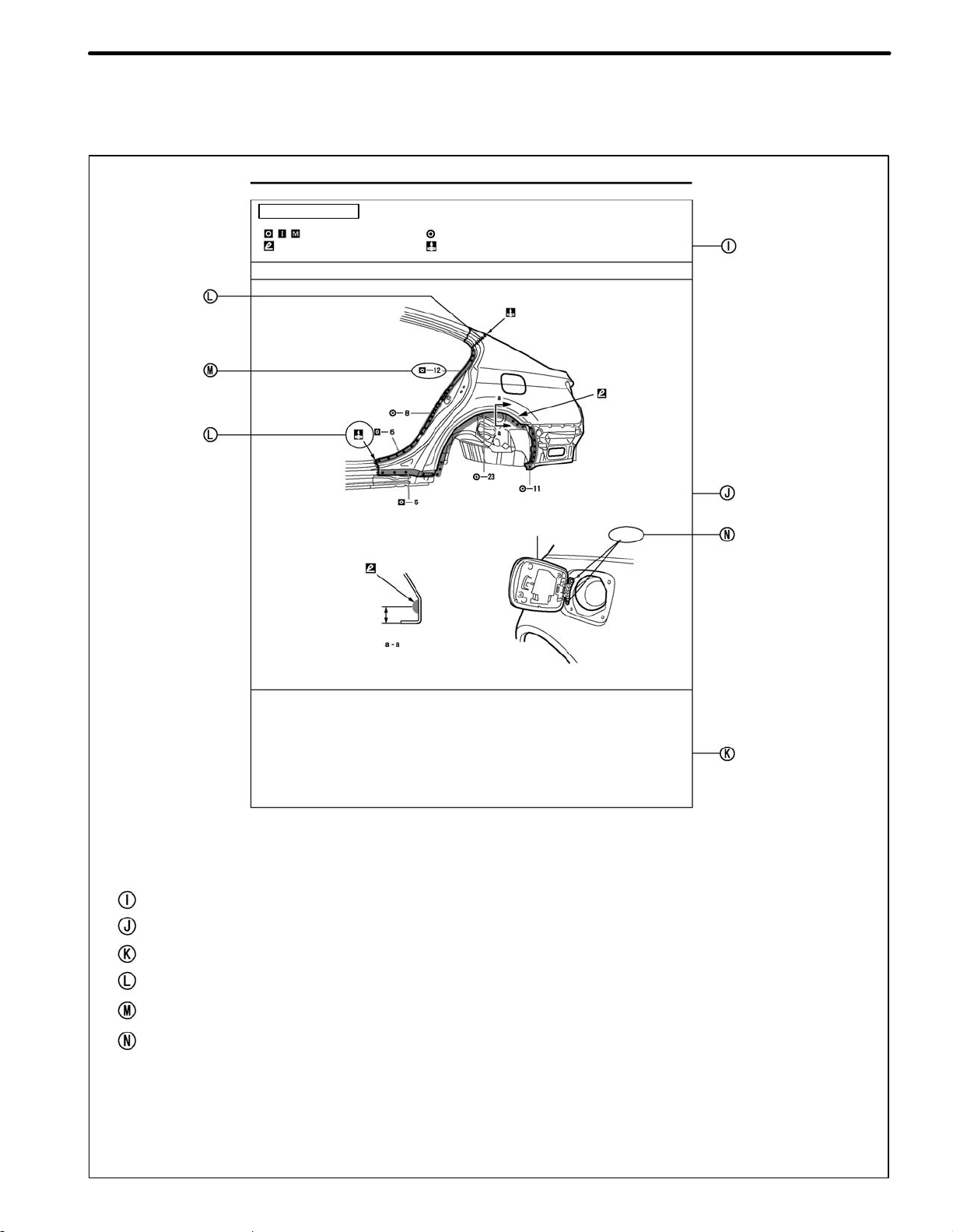

ABOUT THIS VEHICLE

1. STRUCTURAL OUTLINE

INTRODUCTION

IN-13

Adhesive Application Area

Laser Welding

. . .

Formed material application areas (refer to PC-8)

B0706260033

Page 33

IN-14

INTRODUCTION

. . .

980 MPa Ultra High stregth steel

. . .

590 MPa High stregth steel

. . .

440 MPa High stregth steel

. . .

370 MPa High stregth steel

. . .

340 MPa High stregth steel

B0710190003

Page 34

INTRODUCTION

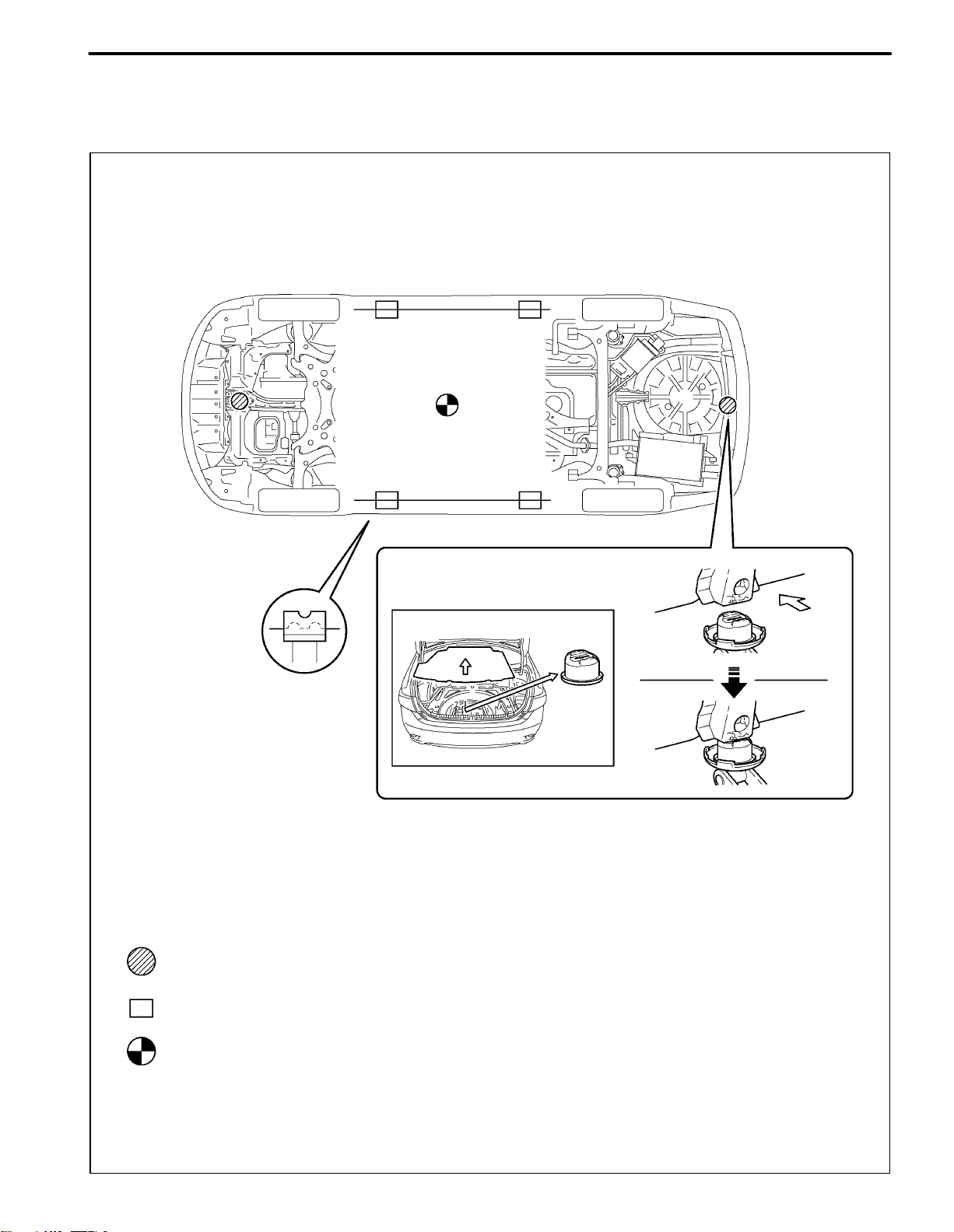

2. NOTICE ABOUT VEHICLE CONDITION WHEN JACKING UP

VEHICLE

(a) NOTICE FOR USING JACK AND SAFETY STAND

IN-15

Remove the jack attachment from the the spare tire cover in the

trunk, then, align the concave portion with the rear jack position and

jack up the vehicle.

NOTICE: Set the jack attachment with the arrow facing towards the

front of the vehicle.

: JACK POSITION

: SUPPORT POSITION, PANTOGRAPH JACK POSITION

: VEHICLE CENTER OF GRVITY (unloaded condition)

Front of

vehicle

B0709140118A

Page 35

IN-16

INTRODUCTION

(b) NOTICE FOR USING SWING ARM TYPE LIFT

Center of Lift

Rubber Attachment

: VEHICLE CENTER OF GRAVITY (unloaded condition)

B0701260007

Page 36

INTRODUCTION

(c) NOTICE FOR USING PLATE TYPE LIFT

IN-17

Attachment Dimensions

85 mm (3.35 in.)

100 mm

(3.94 in.)

Right and left set position

Front and rear set position

200 mm (7.87 in.)

Attachment

70 mm (2.76 in.)

S Place the vehicle over the center of the lift.

S Align the cushion ends of the plate with the

attachment lower ends (A and C).

S Align the attachment upper end (B) with the

rocker flange front side notch.

B0701260008

Page 37

IN-18

3. DAMAGE DIAGNOSIS

INTRODUCTION

Confirmation Point

Head-on Collision:

Front Bumper

Reinforcement

Side Collision:

Collision Direction

Front Body Pillar

Upper Reinforcement

Front Side Member

Collision Force Absorption Direction

Rocker Panel Reinforcement

Roof Reinforcement

Floor Cross Member

Center Pillar Reinforcement

B0706260035

Page 38

4. COMPONENTS

(a) Front bumper

FRONT BUMPER

SIDE SUPPORT RH

INTRODUCTION

IN-19

FRONT BUMPER

ENERGY ABSORBER

36 (367,27)

FRONT BUMPER REINFORCEMENT

SUB-ASSEMBLY

FRONT BUMPER

RADIATOR GRILLE

PROTECTOR

SIDE SUPPORT LH

FRONT BUMPER ASSEMBLY

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0710120001B

Page 39

IN-20

(b) Side Mudguard

INTRODUCTION

for Sport Package:

NO. 1 MOULDING TAPE

Non-reusable part

SIDE MUDGUARD

ROCKER PANEL REAR

MOULDING RETAINER

ROCKER PANEL FRONT

MOULDING RETAINER

NO. 2 MOULDING TAPE

SIDE MUDGUARD

B192955E01

Page 40

(c) Rear bumper

REAR BUMPER SIDE

SUPPORT LH

REAR BUMPER ARM

LH

36 (367, 27)

INTRODUCTION

REAR BUMPER SIDE

SUPPORT RH

REAR BUMPER ARM

RH

36 (367, 27)

IN-21

NO. 2 REAR BUMPER

SIDE SUPPORT RH

REAR UPPER BUMPER

RETAINER RH

NO. 1 REAR BUMPER

REINFORCEMENT

NO. 2 REAR BUMPER

SIDE SUPPORT LH

REAR UPPER BUMPER

RETAINER LH

w/ Rear Fender Mudguard:

36 (367, 27)

REAR BUMPER

ASSMBLY

REAR QUARTER

PANEL MUDGUARD LH

REAR BUMPER

ENERGY ABSORBER

REAR QUARTER

PANEL MUDGUARD RH

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0710120002

Page 41

IN-22

(d) Door

FRONT DOOR INNER

GLASS WEATHERSTRIP

INTRODUCTION

FRONT DOOR INSIDE

HANDLE BEZEL

FRONT DOOR TRIM

BOARD SUB-ASSEMBLY

FRONT DOOR INSIDE

HANDLE SUB-ASSEMBLY

w/o Power Window:

FRONT ARMREST UPPER

BASE PANEL

FRONT DOOR REGULATOR

INSIDE HANDLE PLATE

SNAP RING

FRONT DOOR WINDOW

REGULATOR HANDLE ASSEMBLY

w/ Power Window:

FRONT ARMREST

UPPER BASE PANEL

B0707100004A

Page 42

REAR DOOR INNER

GLASS WEATHERSTRIP

INTRODUCTION

IN-23

REAR DOOR INSIDE

HANDLE BEZEL

w/o Power Window:

REAR DOOR ARMREST

UPPER BASE PANEL

PLATE

REAR DOOR INSIDE

HANDLE SUB-ASSEMBLY

REAR DOOR TRIM

BOARD SUB-ASSEMBLY

w/ Power Window:

REAR DOOR ARMREST

UPPER BASE PANEL

SNAP RING

REAR DOOR WINDOW

REGULATOR HANDLE

ASSEMBLY

B0707100005A

Page 43

IN-24

INTRODUCTION

w/ Rear Spoiler:

REAR SPOILER

ASSEMBLY

LIGGAGE COMPARTMENT

DOOR COVER

B0707100006

Page 44

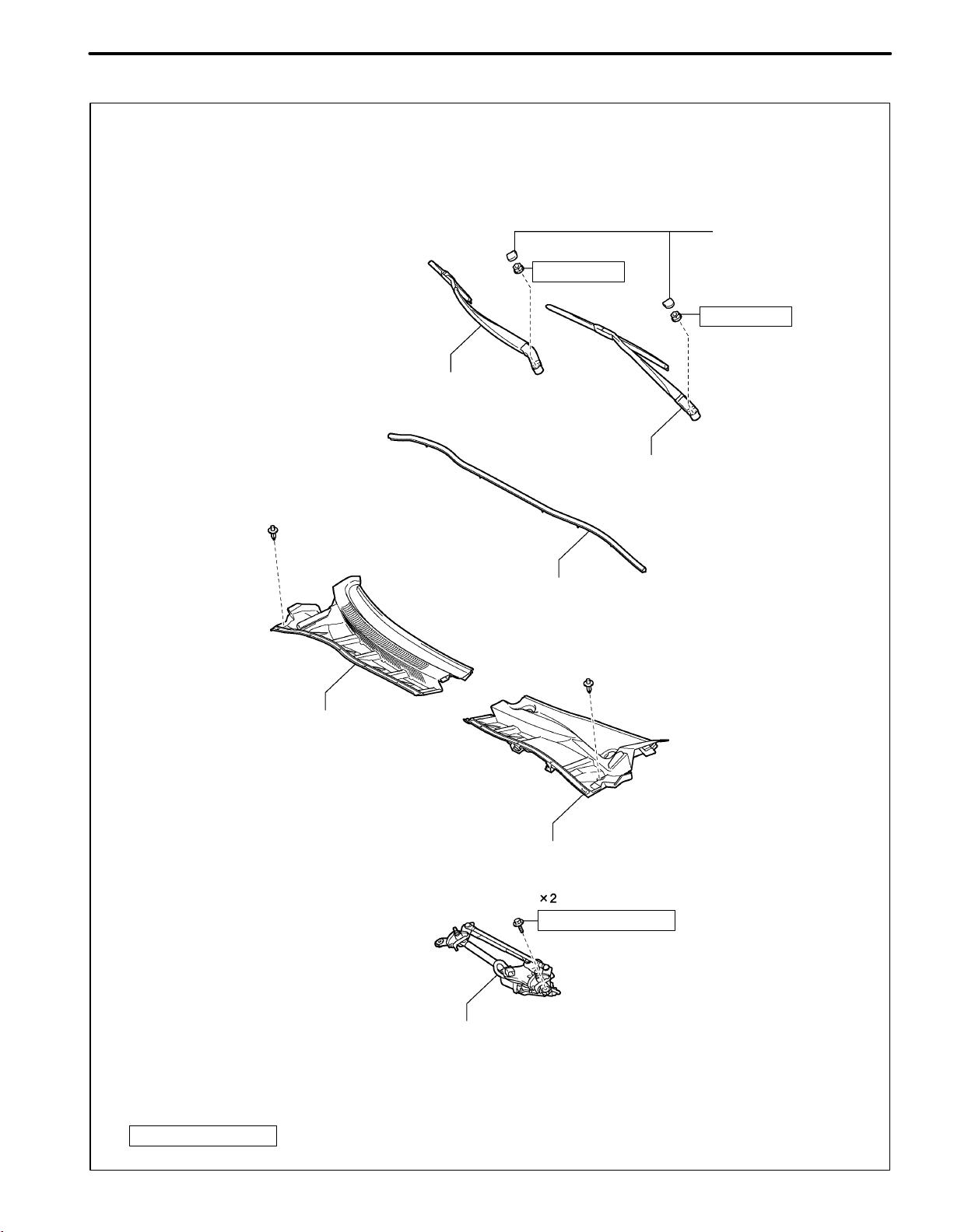

(e) Cowl Top Ventilator Louver

FRONT WIPER ARM AND

BLADE ASEMBLY RH

INTRODUCTION

IN-25

FRONT WIPER ARM

HEAD CAP

26 (265, 19)

26 (265, 19)

FRONT WIPER ARM AND

BLADE ASEMBLY LH

CENTER NO. 1 COWL TOP VENTILATOR LOUVER

COWL TOP VENTILATOR LOUVER LH

WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

HOOD TO COWL TOP SEAL

5.5 (56, 49 in.*lbf)

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0707100007

Page 45

IN-26

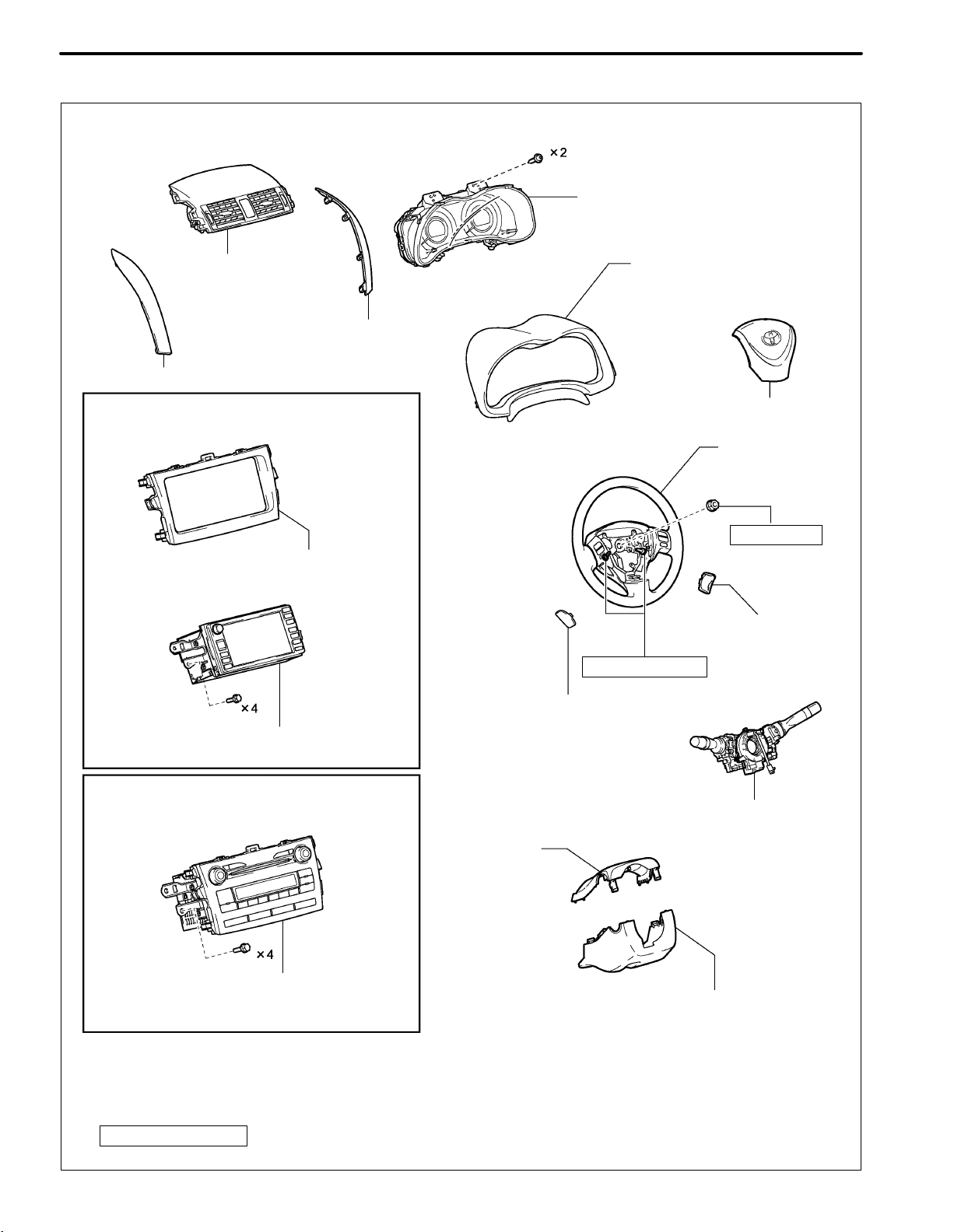

(f) Instrument panel

INTRODUCTION

COMBINATION METER ASSEMBLY

CENTER INSTRUMENT PANEL

REGISTER ASSEMBLY

INSTRUMENT PANEL FINISH

PANEL END RH

INSTRUMENT PANEL FINISH PANEL END LH

w/ Navigation System:

CENTER INSTRUMENT CLUSTER

FINISH PANEL SUB-ASSEMBLY

INSTRUMENT CLUSTER

FINISH PANEL ASSEMBLY

STEERING PAD

STEERING WHEEL

ASSEMBLY

50 (510, 37)

LOWER NO.2 STEERING

WHEEL COVER

8.8 (90, 78 in..ibf)

LOWER NO.3 STEERING WHEEL COVER

NAVIGATION RECEIVER WITH BRACKET

w/o Navigation System:

TURN SIGNAL SWITCH ASSEMBLY WITH

SPIRAL CABLE SUB-ASSEMBLY

UPPER STEERING

COLUMN COVER

RADIO RECEIVER WITH BRACKET

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

LOWER STEERING COLUMN COVER

B0710150022

Page 46

INTRODUCTION

w/ Curtain Shield Airbag:

IN-27

w/ Curtain Shield Airbag:

SIDE INSTRUMENT

PANEL LH

FRONT PILLAR

GARNISH CLIP

FRONT PILLAR

GARNISH CLIP

FRONT PILLAR GARNISH RH

FRONT PILLAR GARNISH LH

SIDE INSTRUMENT

PANEL RH

20 (204, 15)

UPPER INSTRUMENT

PANEL SUB-ASSEMBLY

NO. 2 INSTRUMENT PANEL

NO. 1 INSTRUMENT PANEL

REGISTER ASSEMBLY

REGISTER ASSEMBLY

LOWER INSTRUMENT PANEL

FINISH PANEL LH

LOWER INSTRUMENT PANEL

NO. 1 INSTRUMENT PANEL

BOX DOOR SUB-ASSEMBLY

FINISH PANEL RH

LOWER INSTRUMENT PANEL FINISH PANEL ASSEMBLY

GLOVE COMPARTMENT

DOOR ASSEMBLY

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

Non-reusable part

B0710150023

Page 47

IN-28

INTRODUCTION

INSTRUMENT PANEL

BOX ASSEMBLY

FRONT NO. 2 CONSOLE

BOX INSERT

for Automatic Transaxle:

SHIFT LEVER KNOB

SUB-ASSEMBLY

CENTER NO. 1 INSTRUMENT

CLUSTER FINISH PANEL

ASSEMBLY

for Manual Transaxle:

SHIFT LEVER KNOB

SUB-ASSEMBLY

CENTER NO. 1 INSTRUMENT

CLUSTER FINISH PANEL ASSEMBLY

FRONT NO. 1 CONSOLE BOX INSERT

for Automatic Transaxle:

CONSOLE BOX ASSEMBLY

CONSOLE BOX

CARPET

for Manual Transaxle:

CONSOLE BOX ASSEMBLY

UPPER CONSOLE PANEL

SUB-ASSEMBLY

B0710150026

Page 48

LOWER INSTRUMENT PANEL

SUB-ASSEMBLY

COWL SIDE TRIM

BOARD LH

FRONT DOOR

SCUFF PLATE LH

w/ Smart Key System:

INTRODUCTION

IN-29

COWL SIDE TRIM

BOARD RH

FRONT DOOR

SCUFF PLATE RH

NO. 1 SWITCH HOLE BASE

w/o Smart Key System:

NO. 1 SWITCH HOLE BASE

for Manual Air Conditioning System:

AIR CONDITIONING

CONTROL ASSEMBLY

LOWER INSTRUMENT PANEL

FINISH PANEL SUB-ASSEMBLY

w/ Instrument Panel Under Cover:

NO. 2 INSTRUMENT PANEL

UNDER COVER SUB-ASSEMBLY

NO. 1 INSTRUMENT PANEL

UNDER COVER SUB-ASSEMBLY

for Automatic Air Conditioning System:

INSTRUMENT PANEL

HOLE COVER

AIR CONDITIONING

PANEL ASSEMBLY

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0710150027

Page 49

IN-30

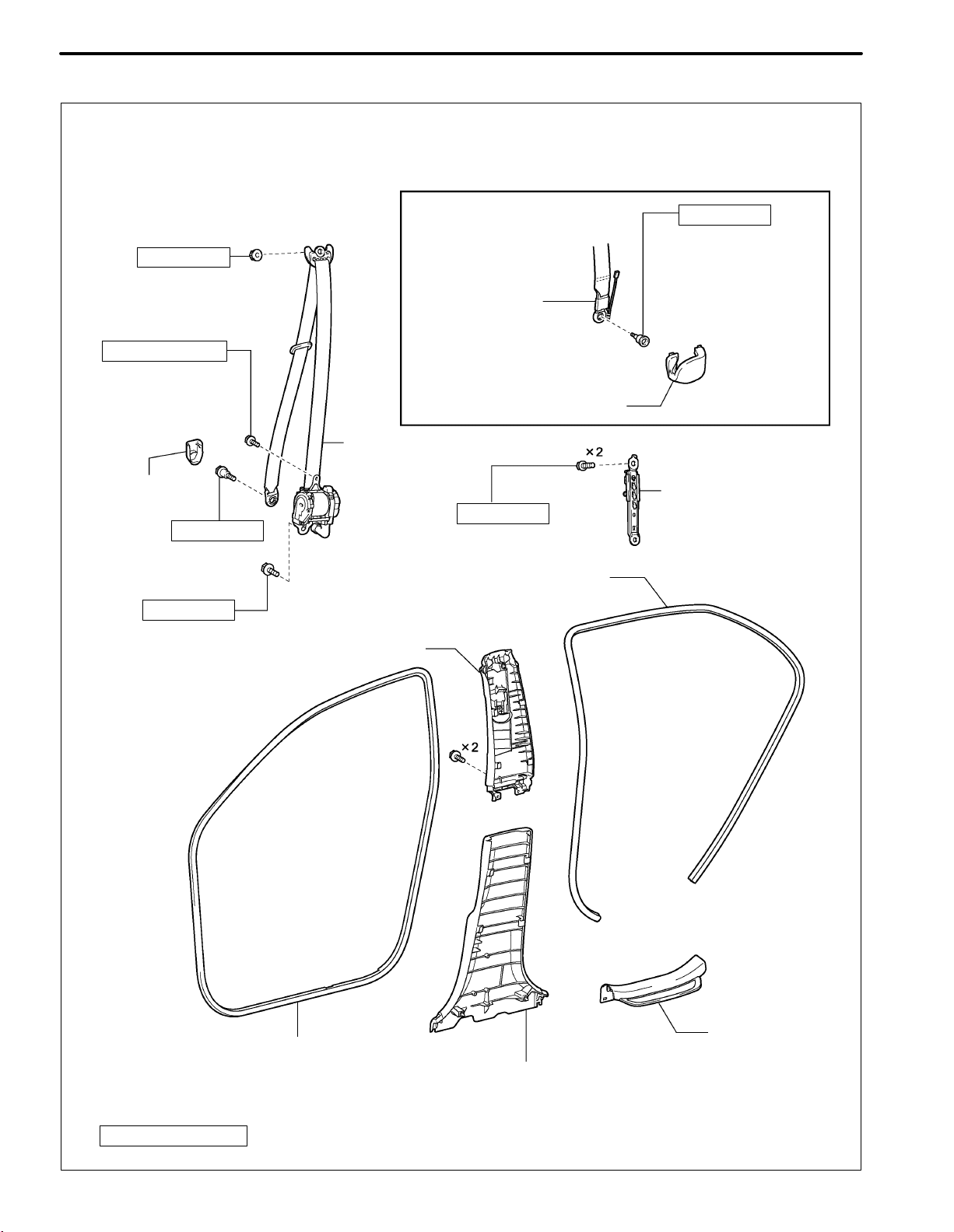

(g) Interior trim

INTRODUCTION

41 (420, 30)

5.0 (51, 44 in..ibf)

LAP BELT OUTER

ANCHOR COVER

41 (420, 30)

41 (420, 30)

UPPER CENTER PILLAR GARNISH

for Front Passenger Side:

FRONT SEAT

OUTER BELT

ASSEMBLY RH

FRONT SEAT OUTER

BELT ASSEMBLY

41 (420, 30)

REAR DOOR OPENING

TRIM WEATHERSTRIP

41 (420, 30)

FRONT SEAT BELT

ANCHOR BASE

LAP BELT OUTER

ANCHOR COVER

FRONT SHOULDER

BELT ANCHOR

ADJUSTER ASSEMBLY

REAR DOOR

FRONT DOOR OPENING

TRIM WEATHERSTRIP

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

LOWER CENTER

PILLAR GARNISH

SCUFF PLATE

B0710120003

Page 50

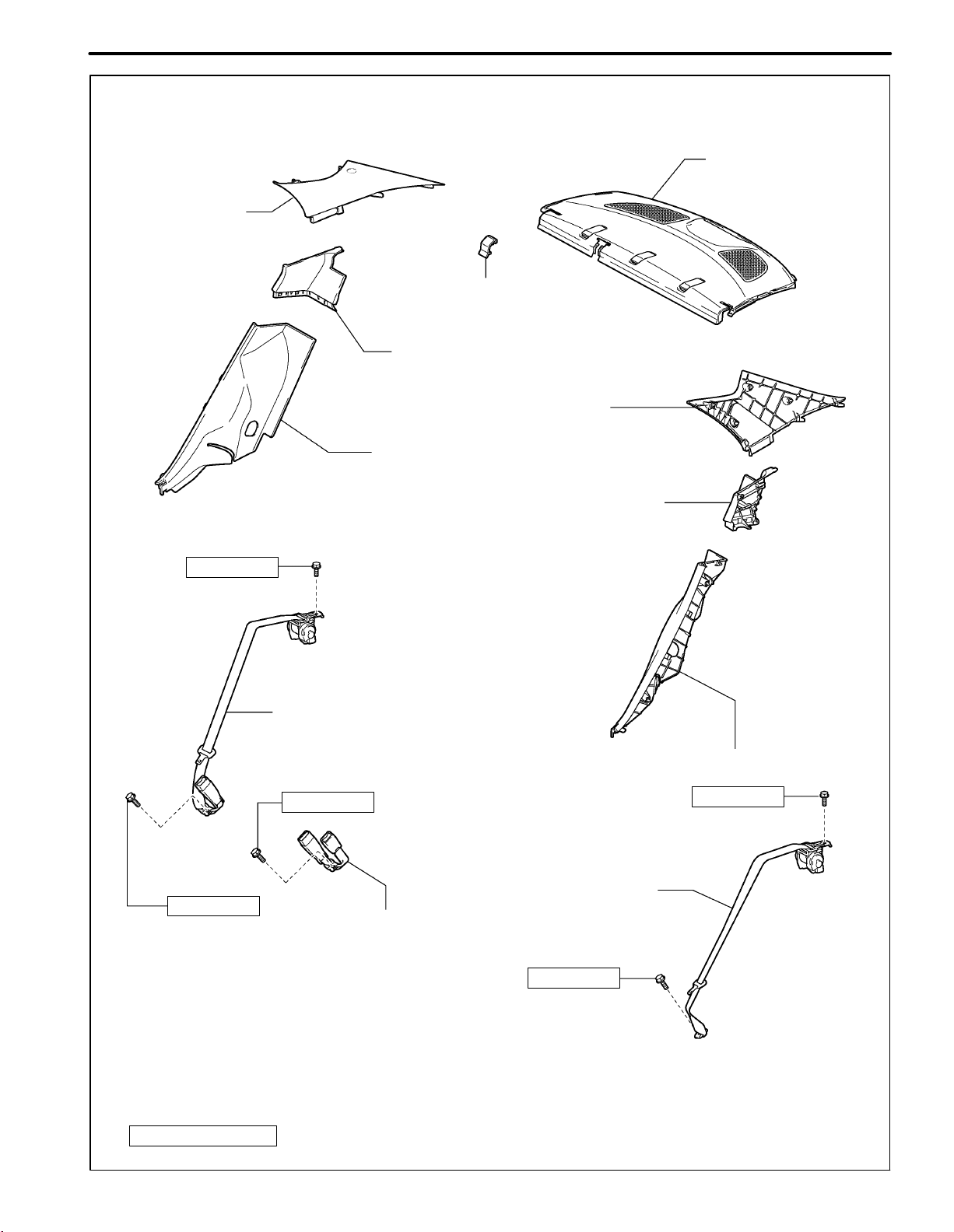

ROOF SIDE INNER

GARNISH ASSEMBLY RH

INTRODUCTION

PACKAGE TRAY TRIM

BELT HOLE COVER

ROOF SIDE INNER

GARNISH BOARD RH

ROOF SIDE INNER

GARNISH ASSEMBLY LH

REAR SEAT SIDE GARNISH RH

IN-31

PACKAGE TRAY TRIM

PANEL ASSEMBLY

41 (420, 30)

41 (420, 30)

REAR SEAT INNER WITH

CENTER BELT ASEMBLY RH

41 (420, 30)

REAR SEAT OUTER BELT ASSEMBLY

REAR SEAT INNER WITH

CENTER BELT ASEMBLY LH

ROOF SIDE INNER

GARNISH BOARD LH

REAR SEAT SIDE GARNISH LH

41 (420, 30)

41 (420, 30)

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0710120006

Page 51

IN-32

INTRODUCTION

(h) Seat

for Manual Seat:

FRONT SEAT HEADREST

ASSEMBLY

INNER SEAT

TRACK COVER

OUTER SEAT TRACK

COVER

FRONT SEAT ASSEMBLY

for Power Seat:

FRONT SEAT HEADREST ASSEMBLY

37 (377, 27)

37 (377, 27)

INNER SEAT

TRACK COVER

OUTER SEAT TRACK

COVER

FRONT SEAT ASSEMBLY

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0707100014A

Page 52

INTRODUCTION

IN-33

REAR SEAT HEADREST

ASSEMBLY RH

REAR SEAT CENTER HEADREST

ASSEMBLY

REAR SEATBACK

ASSEMBLY RH

REAR SEAT HEADREST

ASSEMBLY LH

18 (184, 13)

REAR SEATBACK

ASSEMBLY LH

18 (184, 13)

REAR SEAT CUSHION

ASSEMBLY

CAUTION:

The bolts must be tightened to the torque specification, as they are related to vehicle safety during a collision.

N.m (kgf.cm, ft..lbf)

: Specified torque

B0710120007

Page 53

IN-34

INTRODUCTION

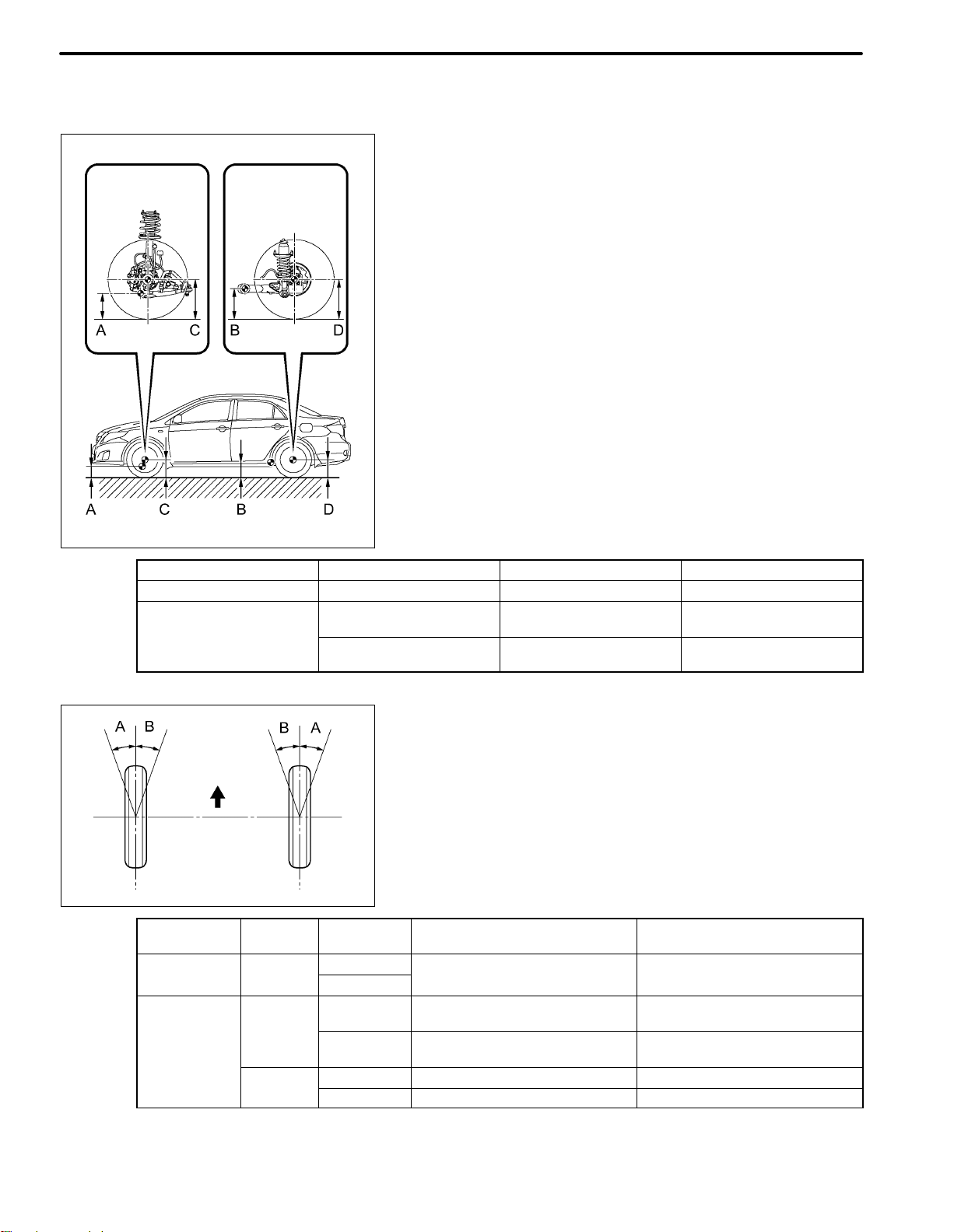

5. WHEEL ALIGNMENT STANDARD

(a) FRONT WHEEL ALIGNMENT

(1) Vehicle Height (Unloaded Vehicle)

NOTICE:

S Before inspecting the wheel alignment, adjust

S Be sure to perform measurement on a level

S If it is necessary to go under the vehicle for

Measuring points:

A: No. 1 lower suspension arm bushing set bolt

B: Rear axle beam set bolt ground clearance

C: Front wheel center ground clearance

D: Rear wheel center ground clearance

the vehicle height to the specified value.

surface.

measurement, confirm that the parking brake

is applied and the vehicle is secured with

chocks.

ground clearance

C178672E02

– Engine Front C – A Rear D – B

for TMC Made 2ZR-FE 92 mm (3.62 in.) 45 mm (1.77 in.)

except TMC Made

2ZR-FE

2AZ-FE

92 mm (3.62 in.)

80 mm (3.15 in.)*

96 mm (3.78 in.)

81 mm (3.19 in.)*

45 mm (1.77 in.)

32 mm (1.26 in.)*

51 mm (2.01 in.)

36 mm (1.42 in.)*

*for vehicle height for Mexico, add 15 mm (0.591 in.)

(2) Wheel Angle (Unloaded Vehicle)

Front

A: Inside

B: Outside

C132439E01

– Engine Tire Size Inside Wheel

for TMC Made 2ZR-FE

except TMC

Made

2ZR-FE

2AZ-FE

195/65R15

205/55R16

195/65R15

205/55R16

205/55R16* 37_19’ +/-2_ (37.32_ +/-2_)* 32_18’ (32.30_)*

215/45R17 36_59’ +/-2_ (36.98_ +/-2_) 32_01’ (32.02_)

38_13’ +/-2_ (38.22_ +/-2_) 32_50’ (32.83_)

38_13’ +/-2_ (38.22_ +/-2_)

38_29’ +/-2_ (38.48_ +/-2_)*

38_13’ +/-2_ (38.22_ +/-2_)

38_31’ +/-2_ (38.52_ +/-2_)*

Outside Wheel

Reference

32_50’ (32.83_)

33_04’ (33.07_)*

32_50’ (32.83_)

33_04’ (33.07_)*

*for vehicle height for Mexico, add 15 mm (0.591 in.)

If the angles are not as specified, check and adjust the

right and left rack end lengths.

Page 54

INTRODUCTION

(3) Camber (Unloaded Vehicle)

IN-35

Alignment

Tester

Gauge

C132440E07

– Engine Tire Size Camber Inclination Right-Left Difference

for TMC Made 2ZR-FE

2ZR-FE

except TMC

Made

2AZ-FE

195/65R15

205/55R16

195/65R15

205/55R16

205/55R16* -0_27’ (-0.62_)*

215/45R17 -0_37’ (-0.62_)

-0_35’ (-0.58_)

-0_34’ (-0.57_)

-0_26’ (-0.43_)*

-0_35’ (-0.58_)

-0_26’ (-0.43_)*

45’ (0.75_) or less

* for vehicle height for Mexico, add 15 mm (0.591 in.)

(4) Caster (Unloaded Vehicle)

– Engine Tire Size Camber Inclination Right-Left Difference

for TMC Made 2ZR-FE

2ZR-FE

except TMC

Made

2AZ-FE

195/65R15 2_50’ +/-45’ (2.83_ +/-0.75_)

205/55R16 2_51’ +/-45’ (2.85_ +/-0.75_)

195/65R15

205/55R16

205/55R16* 2_45’ +/-45’ (2.75_ +/-0.75_)*

215/45R17 2_55’ +/-45’ (2.92_ +/-0.75_)

2_50’ +/-45’ (2.83_ +/-0.75_)

2_40’ +/-45’ (2.67_ +/-0.75_)*

2_50’ +/-45’ (2.83_ +/-0.75_)

2_41’ +/-45’ (2.68_ +/-0.75_)*

45’ (0.75_) or less

* for vehicle height for Mexico, add 15 mm (0.591 in.)

(5) Steering Axis Inclination (Unloaded Vehicle)

except TMC Made:

– Engine Tire Size Steering Axis Inclination

for TMC Made 2ZR-FE

2ZR-FE

except TMC

Made

2AZ-FE

195/65R15

205/55R16

195/65R15

205/55R16

205/55R16* 12_16’ (12.27_)*

215/45R17 12_37’ (12.62_)

12_32’ (12.53_)

12_32’ (12.53_)

12_13’ (12.22_)*

* for vehicle height for Mexico, add 15 mm (0.591 in.)

Page 55

IN-36

INTRODUCTION

Tread Center

Mark

Front

Dimension A

Dimension B

C125225E04

Front

C162810E01

(6) Toe-in

HINT:

S Measure “B - A” only when “C + D” cannot be

measured.

S If toe-in is not within the specified range, adjust it

at the rack ends.

Specified Condition

C + D: 0_00’ +/-0_12’ (0_ +/-0.2_)

B - A: 0 +/-2.0 mm (0 +/-0.08 in.)

Page 56

(b) REAR WHEEL ALIGNMENT

Front

C132438E08

– Grade Specified Condition Right-Left Difference

for TMC Made except XRS

except XRS

except TMC

Made

for XRS

C + D: 0_16’ +/-0_15’ (0.27_ +/-0.25_) 45’ (0.75_) or less

B - A: 2.5 +/- 2.5 mm (0.098 +/-0.098 in.) –

C + D: 0_16’ +/-0_15’ (0.27_ +/-0.25_)

C + D: 0_16’ +/-0_15’ (0.27_ +/-0.25_)*

B - A: 2.6 +/-2.5 mm (0.102 +/-0.098 in.)

B - A: 2.0 +/-2.5 mm (0.0787 +/-0.098 in.)*

C + D: 0_16’ +/-0_15’ (0.27_ +/-0.25_)

C + D: 0_16’ +/-0_15’ (0.27_ +/-0.25_)*

B - A: 3.1 +/-2.5 mm (0.102 +/-0.098 in.)

B - A: 2.2 +/-2.5 mm (0.0866 +/-0.098 in.)*

INTRODUCTION

(6) Toe-in (Unloaded Vehicle)

S Measure “B - A” only when “C + D” cannot be

measured.

IN-37

45’ (0.75_) or less

–

45’ (0.75_) or less

–

* for vehicle height for Mexico, add 15 mm (0.591

in.) If the toe-in is not within the specified range,

inspect the suspension parts and replace them if

necessary.

(2) Camber (Unloaded Vehicle)

HINT:

Camber is not adjustable. If the measurement is not

within the specified range, inspect the suspension

parts for damage and/or wear, and replace them if

necessary.

– Grade Specified Condition Right-Left Difference

for TMC Made except XRS

except TMC

Made

except XRS

for XRS

-1_28’ +/-30’ (-1.47_ +/-0.50_)

30’ (0.50_) or less

-1_27’ +/-30’ (-1.45_ +/-0.50_)

30’ (0.50_) or less

-1_28’ +/-30’ (-1.47_ +/-0.50_)

30’ (0.50_) or less

30’ (0.50_) or less

Page 57

IN-38

INTRODUCTION

HOW TO USE THIS MANUAL

1. BODY PANEL REPLACEMENT IN THIS MANUAL

REMOVAL

BODY PANEL REPLACEMENT

QUARTER PANEL (CUT)

@ With the body lower back panel removed.

Symbol meaning

: Remove Weld Points

: Cut and Join Location

: Cut Location for Supply Parts

Fuel Filler Opening Lid

BP-34

150 (5.91)

REMOVAL POINT

1 Remove the Fuel Filler Opening Lid at the same time.

REPLACEMENT PART

QUARTER PANEL (CUT)

Replacement method

(ASSY) ...Assembly replacement

(CUT) ...Major cutting (less than 1 /2 of part used)

(CUT-H) ...Half cutting (about 1/ 2 of part used)

(CUT-P) ...Partial cutting (most of part used)

Replacement part

PART LOCATION

REMOVAL AND INSTALLATION CONDITIONS

SYMBOL MEANING

REMOVAL DIAGRAM

REMOVAL GUIDE

40

(1.57)

150 (5.91)

mm (in.)

WELDING EXPLANATION (See page IN-46)

SYMBOLS (See page IN-44)

B0608210134

Page 58

INTRODUCTION

IN-39

BP-38

Symbol meaning

: Mig Plug Weld

: Body Sealer

INSTALLATION

BODY PANEL REPLACEMENT

: Spot Weld

: Butt Weld

Fuel Filler Opening Lid

5

(0.20)

Rivets

INSTALLATION POINT

1 Before temporarily installing the new parts, apply body sealer to the wheel arch.

HINT:

1) Apply body sealer evenly about 5 mm (0.20 in.) from the flange, avoiding any oozing.

2) Apply sealer evenly, about 3 − 4 mm (0.12 − 0.16 in.) in diameter.

2 Temporarily install the new parts and measure each part of the new parts in accordance with

the body dimension diagram. (See the body dimension diagram)

3 After welding, apply body sealer and undercoating to the corresponding parts.

SYMBOLS

INSTALLATION DIAGRAM

INSTALLATION GUIDE

SYMBOLS (See page IN-44)

INSTALLATION OF WELD POINTS (See page IN-46)

PART NAME

mm (in.)

B0608210135

Page 59

2. SYMBOLS

INTRODUCTIONIN-40

REPAIR AREA

INDICATOR SYMBOLS

CUT

BRAZE

REPAIR METHOD

INDICATOR SYMBOLS

CUT AND JOIN

LOCATION

(Saw Cut)

CUT AND JOIN

LOCATION

(Cut Location for

Supply Parts)

CUT LOCATION

CUT WITH DISC

SANDER ETC.

BRAZING OR

ARC BRAZING

FOR REMOVAL

ILLUSTRATION

BRAZE

WELD

POINTS

WELDING

SEALER

BRAZE

SPOT WELD OR

PLUG WELD

(refer to

“ILLUSTRATION

OF WELD POINT

SYMBOLS”)

BUTT WELD

FILLET WELD

BODY SEALER

B0608210136

Page 60

INTRODUCTION

IN-41

REPAIR AREA

INDICATOR SYMBOLS

ASSEMBLY

MARK

BODY

SEALER

REPAIR METHOD

INDICATOR SYMBOLS

STANDARD HOLE

FOR INSTALLATION

FLAT FINISHING

NO FLAT FINISHING

ILLUSTRATION

B0608210137

Page 61

IN-42

INTRODUCTION

3. ILLUSTRATION OF WELD POINT SYMBOLS

REMOVAL INSTALLATION

Weld points

Position of panels that are removed

SYMBOLS

MEANING ILLUSTRATION

Remove Weld

Points

Position of Panel

Being Replaced is

on Outside

Position of Panel

Being Replaced is

in Center

Weld points

Welding method and panel position

SYMBOLS

MEANING

Spot Welding

Plug Welding

ILLUSTRATION

Position of Panel

Being Replaced is

on Inside

Spot MIG Welding

B0608210138

Page 62

PAINT S COATING

PC-1

BODY PANEL SEALING AREAS

Be sure to apply body sealer to the body panel joints and door edges (tip of outer panel folded part), etc., to waterproof and rustproof them.

HINT:

1) Apply degreasing agent to a clean cloth and clean the sealer application areas.

2) After removing the applied spot sealer from the sealer application areas using thinner or equivalent, rustproof the areas by applying primer or equivalent. Then apply body sealer.

3) If sealer is unnecessarily applied to an area, apply degreasing agent to a clean cloth and clean off the

sealer immediately.

Flat Finishing No Flat Finishing

1. ENGINE COMPARTMENT

[LH]

B0709250158

Page 63

PC-2

2. INSIDE

PAINT S COATING

B0709260006

Page 64

3. OUTSIDE

PAINT S COATING

PC-3

B0709250159

Page 65

PC-4

PAINT S COATING

B0709250160

Page 66

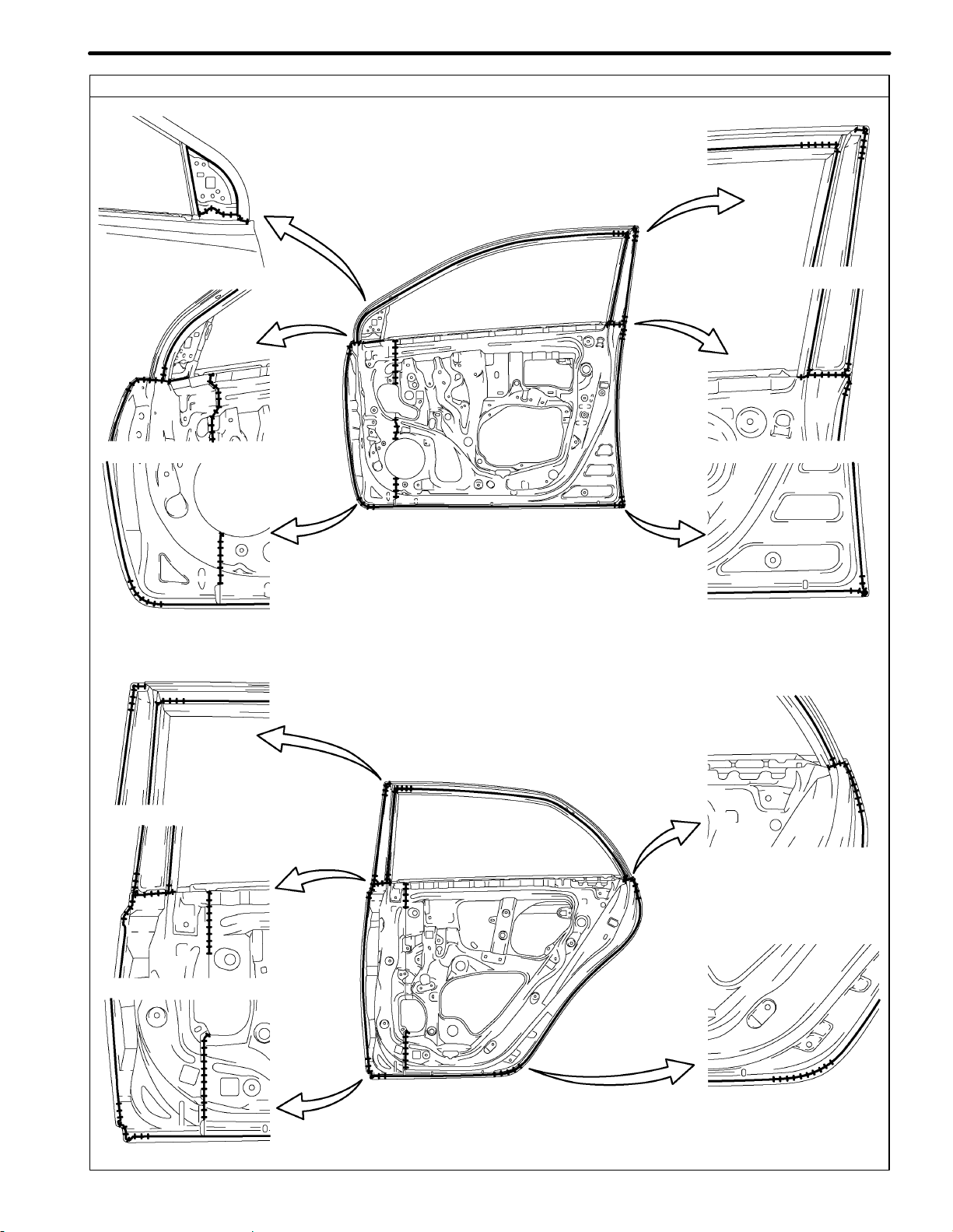

4. DOOR PARTS

PAINT S COATING

PC-5

B0709250161

Page 67

PC-6

PAINT S COATING

B0709250162

Page 68

PAINT S COATING

PC-7

BODY PANEL UNDERCOATING AREAS

Apply PASTAR UWE or PASTAR UC to the chassis, floor underside, sheet metal fitting weld points of the body, and

inside of the wheel house to prevent rust and noise, as well as protect the body from flying rocks.

HINT:

1) Work must be performed while wearing the appropriate protective gear and in a well-ventilated area.

2) Apply degreasing agent to a clean cloth and clean any dirt and oil from the application areas.

3) Cover the surrounding areas of the application areas with masking paper to avoid coating unnecessary

areas.

4) Do not coat high temperature areas, such as the tailpipe, or moving parts, such as the driveshaft.

5) Do not leave any gaps between the panel joints.

6) Apply sealer to the panel joints in advance.

HINT:

1) Parts coated using the PASTAR UWE should be left until dry to the touch in a 25_C environment for 60 to

75 minutes. Parts coated using PASTAR UC should be left until dry to the touch in a 25_C environment

for 15 to 30 minutes.

2) If using a PASTAR gun, one spray applies a 0.5 mm thick coating.

3) PASTAR UWE: Part number V9240-0025 PASTAR UC: Spray type :Part number V9240-0008

Aerosol type: Part number V9240-0021

Front

Rear

Rear

Front

B0710040023

REFERENCE

The undercoating should be applied according to the specifications for your country while referring to the notes

above.

Page 69

PC-8

PAINT S COATING

FOAMED MATERIAL APPLICATION AREAS

If an increase in temperature or other condition damages the foamed material when repairing or replacing the panel,

fill in the insufficient areas with urethane foam. The following illustration shows the areas for one side, but the

foamed material must be applied equally to both the left and right sides.

HINT:

1) Work must be performed while wearing the appropriate protective gear and in a will-ventilated area.

2) Apply tape or equivalent to any holes, nuts, etc., near the areas to be filled.

B0709250165

Page 70

PAINT S COATING

PC-9

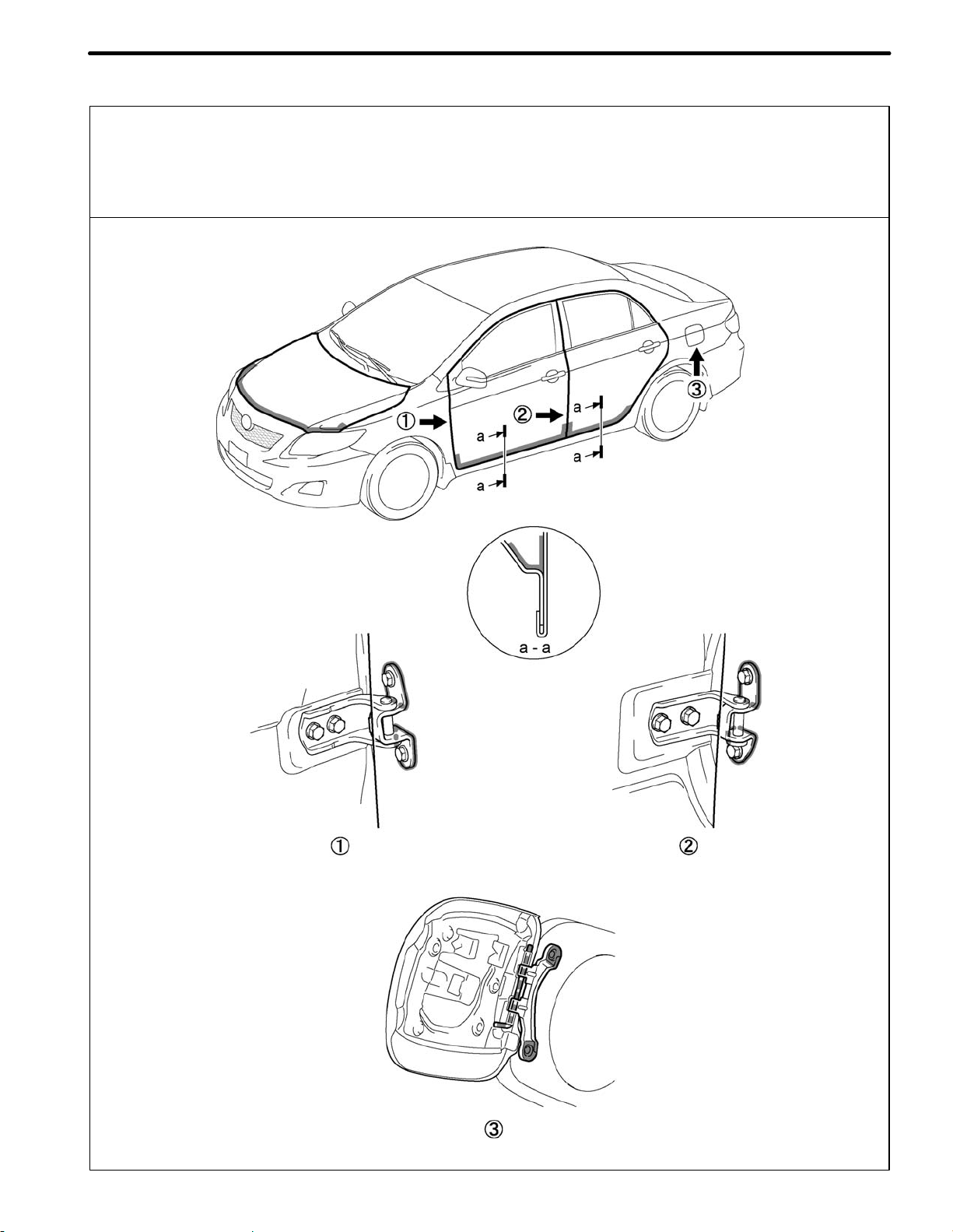

BODY PANEL ANTI-RUST AGENT (WAX) APPLICATION AREAS

Apply RUSTOP W to the doors and hood edges (tips of outer panel folded parts) and undersides, areas around

hinges, etc.to prevent rust. Coat the undersides of the edges using a nozzle and air gun, and coat the areas around

the hinges using a brush.

HINT:

1) If RUSTOP is unnecessarily applied to an area, apply degreasing agent to a clean cloth and clean off the

RUSTOP immediately.

B0709250166A

Page 71

PAINT S COATINGPC-10

SILENCER SHEET INSTALLATION AREAS

Substitute silencer sheets for the laminate coat application areas.

Thicknee of Silencer Sheet mm (in.)

. . .

1.5 (0.06)

. . .

2.0 (0.08)

. . .

3.0 (0.12)

B0710040024

Loading...

Loading...