Page 1

DEFINITY

®

Enterprise Communications Server

Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

Comcode 108678699

Issue 1

April 2000

Page 2

Copyright 2000, Lucent Technologies

All Rights Reserved

Printed in U.S.A.

Notice

Every effort was made to ensure that the informa tion in thi s book was

complete and accurate at the time of printing. However, information is

subject to change.

Canadian Department of Communications (DOC)

Interference Information

This digital apparatus does no t exceed the Class A limits for radio

noise emissions set out in the radi o int er f erence regulations of the

Canadian Department of Com m unications.

Your Responsibility for Your System’s Security

Toll fraud is the unauthorized use of your tel ec ommunications system

by an unauthorized party, for example, persons other than your com-

pany’s employees, agents, subcontractors, or persons working on your

company’ s beh alf. Not e t hat t her e ma y be a ris k of toll f rau d ass oci at ed

with your telecommunications system and, if toll fraud occurs, it can

result in substantial additional charges for your telecommunications

services.

You and your system manager are responsible for the security of your

system, such as programming and confi guring your equipment to prevent unauthorized use. The system manager is also responsibl e for

reading all installation, instruc tion, and system administration doc uments provided with this pro duct in order to fully understand th e fe atures that can introduce risk of toll fraud and the steps that can be taken

to reduce that risk. Lucent Technologies does not warrant that this

product is immune fro m or will prevent unauthorized use of common-carrier telecommun ic ation services or facili ti es accessed through

or connected to it. Lucent Technologies will not be responsible for any

charges that result from such unauthorized use.

Lucent Technologies Fraud I n tervention

If you suspect that you are being victimized by toll fraud and you need

technical support or assistan ce , c al l Technical Service Cen ter Toll

Fraud Intervention Hotline at 1 800 643-2353 or contac t your local

Lucent repr esentative .

Federal Communica tions Commissi on S ta tement

Part 15: Class A Statement. This equipment has been tested and

found to comply with the limits for a Class A digital device, pursua nt

to Part 15 of the FCC Rules. These limits are design ed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio-frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct th e in te rfe re nce at his own expense.

Le Présent Appareil Nom

dépassant les limites applicables aux appareils numériques de la class

A préscrites dans le reglement sur le brouillage radioélectrique édicté

par le ministére des Communications du Canada.

Trademarks

See the preface of this docum e nt.

Ordering Information

Call: Lucent Technologies BCS Publications Center

Voice 1 800 457-1235 International Voice 317 322-6416

Fax 1 800 457-1764 International Fax 317 322-6699

Write: Lucent Technologies BCS Publications Center

2855 N. Franklin Road

Indianapolis, IN 46219

Order: Document No. 555-233-120

Comcode 10867869 9

1, April 2000

For additional documents, refer to the section in “About This Document” entitled “Related Resources.”

Y ou can be placed on a standing order list for this and other documents

you may need. Standing order will enable you to automatically receive

updated versions of individu al documents or document sets, billed to

account information that you provide. For more information on standing orders, or to be put on a list to receive future issues of this document, contact the Lucent Technologies Publications Ce nt er.

European Union Declaration of Conformity

The “CE” mark affixed to the DEFIN ITY® equipment described in

this book indicates that the e quipment conforms to the foll ow i ng European Union (EU) Directives:

• Electromagne tic Compatibility (89/336/EEC)

• Low Voltage (73/23/EEC)

• Telecommunications Terminal Equi p ment (TTE) i-CTR3 BRI

and i-CTR4 PRI

For more information on standards compliance, contact your local distributor.

érique n’é

met pas de bruits radioélectriques

Part 68: Network Registration Number. This equipment is registered

with the FCC in accordan ce with Part 68 of the FCC Rules. It is identified by FCC registration number AS593M-13283-MF-E.

Part 68: Answer-Supervision Signaling. Allowing this equipment to

be operated in a manner that does not provide proper answ e r-supervi sion signaling is in violation of Part 68 Rule s. This e qui pm e nt retu rns

answer-supervision signals to the public switched netw ork whe n:

• Answered b y the called station

• Answered by the attendant

• Routed to a recorded announcement that can be administered by

the CPE user

This equipment returns answer-supervision signals on all DID calls

forwarded back to the publi c swi tched telephone network. Permissible

exceptions are:

• A call is unanswered

• A busy tone is received

• A reorder tone is received

Comments

To comment on this document, re turn the comment ca rd at the front of

the document.

Acknowledgment

This document was prepared by Product Documentation Development,

Lucent Technologies, Denver, CO.

Page 3

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

Contents

Contents

Contents iii

About This Book ix

■ Related Documents x

■ How to Order Documentation x

■ How to Comment on This Document xi

■ Trademarks xi

■ Standards Compliance xii

■ LASER Product xiii

■ Electromagnetic Compatibility Standards xiii

■ Security Issues xiv

■ Where to Call for Technical Support xv

■ Antistatic Protection xv

April 2000

iii

Issue 1

■ Remove/Install Circuit Packs xvi

■ Federal Communications Commission Statement xvi

1 Install and Connect the Cabinets 1-1

■ Check Circuit Packs 1-1

■ Check Customer’s Order 1-1

■ How to Correct Shipping Errors 1-2

■ Unpack and Inspect 1-2

■ Install Single-Carrier Cabinets 1-2

■ Approved Grounds 1-5

■ Connect Cabinet Grounds 1-6

■ Connect AC Power 1-13

■ Connect DC Power 1-14

■ Connect Battery Cabinet 1-18

■ Connect Optional Battery Leads 1-19

■ Connect AC Power to Stratum 3 Clock Cabinet 1-20

■ Connect DC Power and Ground to

Stratum 3 Clock Cabinet 1-20

■ Connect Time Division Multiplexing Bus Cables 1-21

■ Verify Port Cabinet Address Plugs 1-26

■ Install Re ar Panels 1-27

Page 4

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

Contents

■ Install Ground Plates 1-28

■ Connect System Cables 1-31

■ Install Earthquake Protection 1-37

2 Install Telecommunications Cabling 2-1

■ Equipment Room Hardware 2-1

■ Main Distribution Frame 2-4

■ Installation Requirements 2-5

■ Install Equipment and Cables 2-7

■ Install Sneak Fuse Panels 2-8

■ Install Coupled Bonding Conductor 2-11

■ Label the Main Distribution Frame 2-13

3 Accessing and Activating the System 3-1

■ Access the System 3-2

■ Activate the System 3-13

Issue 1

April 2000

iv

■ Screens and Commands 3-16

■ Administer the System 3-17

■ Administer the Circuit Packs 3-26

■ Set System Maintenance Parameters 3-29

■ Administer Attendant Consol e 3-30

■ Save Translations 3-30

■ Installation Completion 3-32

■ DEFINITY AUDIX System Power Procedures 3-33

4 Test the System 4-1

■ Check System Status for Each Cabinet 4-2

■ Check Circuit Pack Configuration 4-4

■ Test Time Division Multiplexing Bus

in Processor Port Network 4-5

■ Test Tone-Clock Boards 4-6

■ Test Expansion Interface Circuit Packs 4-7

■ Test Time Division Multiplexing Bus

for Each Expansion Port Network 4-8

■ Test Tone-Clock for Each Expansion Port Network 4-9

■ Test Tone-Clock Interchange for Each

Expansion Port Network 4-9

■ Test Expansion Interface Exchange for

Each Expansion Port Network 4-10

Page 5

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

Contents

■ Check Circuit Pack Configuration 4-11

■ Save Translations, if Required 4-11

■ Next Steps 4-12

5 Install and Wire Telephones and

Other Equipment 5-1

■ Voice and Data Terminals 5-1

■ Telephone Connection Example 5-1

■ Analog Station or 2-Wire Digital Station Example 5-4

■ Analog Tie Trunk Example 5-5

■ Digital Tie Trunk Example 5-6

■ DS1 Tie Trunk Example 5-7

■ Auxiliary Connector Outputs 5-9

■ Three-Pair and Four-Pair Modularity 5-11

■ Adjunct Power Connections 5-15

■ Attendant Console 5-17

April 2000

v

Issue 1

■ Install 26B1 Selector Console 5-18

■ Connect External Alarm Indicators 5-18

■ Install Remote Network Interface 5-19

■ Install Off-Premises Station Wiring 5-21

■ Install Off-Premises or Out-of-Building Stations 5-22

■ Install Emergency Transfer Units and

Associated Telepho nes 5-28

■ Install External Ringing 5-37

■ Install Queue Warning Indicator 5-37

■ Install Adjuncts and Peripherals 5-37

■ Install the 1145B Power Supply 5-38

■ 1151A1 and 1151A2 Power Supplies 5-47

■ CAMA/E911 Installation 5-5 0

■ Install the BRI Terminating Resistor 5-58

■ Install Multi-point Adapters 5-62

■ Connect Stratum 3 Clock 5-65

■ DEFINITY Wireless Business System 5-71

■ Cellular Business Sy st em 5-71

■ Forum PCM 5-71

■ Connect Modem to Telephone Network 5-72

■ Add Circuit Packs 5-75

Page 6

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

Contents

■ List of Circuit Packs 5-76

■ Add DCS Interface 5-81

■ Add ISDN — PRI 5-85

■ Add Packet Bus Support to R8si 5-87

■ Add CallVisor ASAI 5-93

■ Add ISDN—BRI 5-95

■ Add IP Interface Assembly 5-96

■ Installing an Integrated Channel

Service Unit (ICSU) Module 5-129

■ Installing a 3150/3170 Channel Service Unit 5-133

■ Connector and Cable Diagrams (Pinout Charts) 5-135

6 Test Telephones and Other Equipment 6-1

■ Make Test Calls 6-2

■ Test 302C Attendant Console 6-2

Issue 1

April 2000

vi

■ Test External Ringing 6-3

■ Test Queue Warning Indicator 6-3

■ Test Integrated Announcement 6-3

■ Test Music-on-Hold 6-4

■ Test Emergency Transfer 6-4

■ Test Remote Access Interface 6-4

■ Test Basic Rate Interface 6-5

■ Test C-LAN Board 6-5

A Option Switch Settings A-1

■ Data Module Option Switch Settings A-1

■ 7400D Data Module Option Settings A-3

■ Add Pooled Modem A-5

■ Printer Option Settings A-8

■ Call Detail Recording Option Settings A-11

■ AUDIX Interface Option Settings A-11

■ TN760D Tie Trunk Circuit Pack Option Settings A-12

■ TN464/2464 Option Settings A-15

Page 7

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

Contents

B Connecting and Handling Fiber Optic Cables B-1

■ LASER Product B-1

■ Optical Cross-Connect Hardware B-2

■ Labels for Fiber Optic Cables B-8

■ Cleaning Fiber Optic Cables B-8

C Connector and Cable Diagrams C-1

D Access Security Gateway D-1

■ Using the ASG Mobile D-2

E UPS Installation for SCC EPN

A-Carrier Cabinet E-1

■ Parts List E-2

■ Connect the UPS E-2

■ Wire the 700A8 Plug E-3

■ Make the Remaining Connections E-4

■ Administer the EDA E-8

Issue 1

April 2000

vii

■ Load Test and Verify Alarms E-9

GL Glossary and Abbreviations GL-1

IN Index IN-1

Page 8

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Contents

555-233-120

April 2000

viii

Issue 1

Page 9

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

About This Book

Issue 1

April 2000

ix

This document provides procedures and information for installing and initially

testing the DEFINITY

®

Release 8.2si and Release 8.2si with memory system

configurations. This document also provides information on power and

peripheral equipment that connects directly to a system.

This document covers information related to DEFINITY ECS Release 8.2. For

details about changes for Release 8.2, refer to

DEFINITY Enterprise

Communications Server Release 8.2, Change Description.

The following conventions describe the systems referred to in this document.

■ The word

system

, is a general term encompassing Release 8.2 and

includes references to the DEFINITY Enterprise Communications Server.

■ DEFINITY Systems are called: Release 8; Re lease 8si + memory; and

Release 8si.

■ All occurrences of Release 8si, and Release 8si + memory are called

Release 8si unless a specific configuration is required to differentiate

between product offerings.

■ Information in this document is applicable for Release 5 through Release

8, unless otherwise specified.

■ DEFINITY Enterprise Communications Server is abbreviated DEFINITY

ECS.

■ All physical dimensions in this book are in English (foot pound second)

(FP S) followed by metric (centimeter grams second) (CGS) in parenthesis.

Wire gauge measurements are in AWG followed by the diameter in

millimeters in parenthesis.

Page 10

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

Related Documents

The following documents are useful for system-related information:

■

DEFINIT Y E nterprise Communications Server Release 8 Administration for

Network Connectivity

■

DEFINITY Enterprise Communications Server Release 8 System

Description

■

DEFINITY Enterprise Communications Server Release 8 Maintenance for

R8r

■

DEFINITY Enterprise Communications Server Release 8 Maintenance for

R8si

■

AT&T Network and Data Connectivity Reference

■

BCS Product s Secur it y Handbook

■

DE FINITY Wireless Business System Users Guide

■

DEFINITY Wireless Business System Installation and Test Guide

Issue 1

April 2000

xRelated Documents

■

DEFINITY Wireless Business Systems System Interface

■

DEFINITY Enterprise Communications Server Release 8 Installation and

Test for Multicarrier Cabinets

■

DEFINITY Enterprise Communications Server Release 8 Administrator’s

Guide

■

DEFINITY Enterprise Communications Server Release 8 Upgrades and

Additions for R8si

■

DEFINITY Enterprise Communications Server Release 8 Upgrades and

Additions for R8r

■

DEFINITY Enterprise Communications Server Release 8 Installation for

Adjuncts and Peripherals

How to Order Documentation

In addition to this book, other description, installation and test, maintenance, and

administration documents are available. A complete list of DEFINITY documents

can be found in the

This document and any other DEFINITY documentation can be ordered directly

from the Lucent Technologies Business Communications System Publications

Fulfillment Center at 1-317-322-6791 or toll free at 1-800-457-1235.

Business Communications System Publications Catalog

.

Page 11

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

About This Book

How to Comment on This Document

Lucent Technologies welcomes your feedback. Please fill out the reader

comment card found at the front of this manual and return it. Your comments are

of great value and help improve our documentation.

If the reader comment card is missing, FA X your comments to 1-303-538-1741 or

to your Lucent Technologies representative, and mention this document’s name

and number,

and Test for Single-Carrier Cabinets

DEFINITY Enterprise Communication Server Release 8 Installation

.

Trademarks

This document contains references to the following Lucent Technologies

trad em arke d prod ucts:

■ ACCUNET

■ AUDIX

■ Callmaster

■ CallVisor

■ CONVERSANT

■ DEFINITY

■ FORUM

■ MEGACOM

■ SYSTIMAX

■ TRANSTALK

®

®

®

®

®

®

™

®

®

™

Issue 1

April 2000

xiHow to Comment on This Document

The following products are trademarked by their appropriate vendor:

■ Audichron

■ LINX

■ Music Mate

■ PagePac

®

is a registered trademark of Audichron Company.

™

is a trademark of Illinois Tool Works, Inc.

®

is a registered trademark of Harris Corporation.

®

is a registered trademark of Harris Corporation, Dracon

Division.

■ PORTA

■ Shockwatch

■ Styrofoam

■ Tiltwatch

■ Zone Mate

™

Systems is a trademark of PORTA Systems Corporation.

®

is a registered trademark of Media Recovery, Incorporated.

®

is a registered trademark of Styrofoam Corporation.

®

is a registered trademark of Media Recovery, Incorporated.

®

is a registered trademark of Harris Corporation.

Page 12

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

555-233-120

About This Book

Standards Compliance

The equipment presented in this document complies with the following standards

(as ap propriate):

■ ITU-T (Formerly CCITT)

■ ECMA

■ ETSI

■ IPNS

■ DPNSS

■ National ISDN-1

■ National ISDN-2

■ ISO-9000

■ ANSI

■ FCC Part 15

Issue 1

April 2000

xiiStandards Compliance

■ EN55022

■ EN50081

■ EN50082

■ CISPR22

■ Australia AS3548 (AS/NZ3548)

■ Australia AS3260

■ IEC 825

■ IEC 950

■ UL 1459

■ UL 1950

■ CSA C222 Number 225

■ TS001

Page 13

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

LASER Product

The DEFINITY ECS may contain a Class 1 LASER device if single-mode fiber

optic cable is connected to a remote Expansion Port Network (EPN). The LASER

device operates within the following parameters:

Maximum Power Output: -5 dBm

Wavelength: 1310 nm

Mode Field Diameter: 8.8 microns

CLASS 1 LASER PRODUCT

IEC 825 1993

!

CAUTION:

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Contact your Lucent Technologies representative for more information.

Issue 1

April 2000

xiiiLASER Product

Electromagnetic Compatibility Standards

This product complies with and conforms to the following EMC standards (as

appropriate):

■ Limits and Methods of Measurements of Radio Interference

Characteristics of Information Technology Equipment, EN55022

(CISPR22), 1993

■ EN50082-1, E uropean Generic Immunity Standard

■ FCC Parts 15 and 68

■ Australia AS3548

NOTE:

The system conforms to Class A (industrial) equipment. Voice

terminals meet Class B requirements.

■ Electrostatic Discharge (ESD) IEC 1000-4-2

■ Radiated radio frequency field IEC 1000-4-3

■ Electrical Fast Transient IEC 1000-4-4

■ Lightning effects IEC 1000-4-5

■ Conducted radio frequency IEC 1000-4-6

■ Mains frequency magnetic field IEC 1000-4-8

■ Low frequency mains disturbance IEC 1000-4-11

Page 14

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

European Union Standards

Lucent Technologies Business Communications Systems declares that the

DEFINITY equipment specified in this document bearing the “CE” mark conforms

to the European Union Electromagnetic Compatibility Directives.

The “CE” (Conformité Europeénne) mark indicates conformance to the European

Union Electromagnetic Compatibility Directive (89/336/EEC) Low Voltage

Directive (73/23/EEC) and Telecommunication Terminal Equipment (TTE).

Directive (91/263/EEC) and with i-CTR3 Basic Rate Interface (BRI) and i-CTR4

Primary Rate Interface (PRI) as applicable.

The “CE” mark is applied to the following Release 8 products:

■ Global AC powered Multi-Carrier Cabinet (MCC)

■ DC powered Multi-Carrier Cabinet (MCC) with 25 Hz ring generator

■ AC powered Single-Carrier Cabinet (SCC) with 25 Hz ring generator

■ AC powered Compact Single-Carrier Cabinet (CSCC) with 25 Hz ring

generator

Issue 1

April 2000

xivSecurity Issues

■ Enhanced DC Power System

Security Issues

To ensure the customer of the greatest security possible, Lucent Technologies

offers services that can reduce toll fraud liabilities. Contact your Lucent

Technologies representative for more security information.

Login security is an attribute of the DEFINITY Enterprise Communications Server

(ECS) software. Advise customers that their existing passwords expire 24 hours

after the upgrade. Also explain that the new passwords must conform to strict

requirements.

Page 15

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

Where to Call for Technical Support

Use the following telephone numbers for the region in which the system is being

installed:

Issue 1

April 2000

xvWhere to Call for Technical Support

Tel ep ho ne N um be r

DEFINITY Helpline (feature administration and system

applications)

Luc ent Tec hnologies Toll Fraud Intervention 1-800-643-2353

Lucent Technologies National Customer Care Center 1-800-242-2121

Lucent Technologies Corporate Security 1-800-822-9009

Streamlined Implementation (for missing equipment) 1-800-772-5409

USA/Canada Technical Service Center 1-800-248-1234

ITAC 1-303-804-3777

Luc ent Tec hnol ogies Center s of Excelle nce

Asia/Pacific Regional Support Center 65-872-8686

Western Europe/Middle East/South Africa 44-1252-77-4800

Central/Eastern Europe 361-345-4334

Central/Latin America Caribbean 1-303-804-3778

Australia 61-2-9352-9090

North America (INADS Database Administra tio n) 1-800-248-1111

1-800-225-7585

Antistatic Protection

!

CAUTION:

When handling circuit packs or any components of a DEF INITY System,

always wear an authorized wrist ground strap. Connect the strap to an

approved ground such as an unpainted metal surface on the DEFINITY

System.

Page 16

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

Remove/Install Circuit Packs

!

CAUTION:

The control circuit packs with white labels cannot be removed or installed

when the power is on. The port circuit packs with gray labels (older version

circuit packs had purple labels) can be removed or installed w hen the

power is on.

Federal Communications Commission Statement

Part 68: Statement

Part 68: Answer-Supervision S ignaling. Allowing this equipment to be operated in

a manner that does not provide proper answer-supervision signaling is in

violation of Part 68 rules. This equipment returns answer-supervision signals to

the public switched network when:

Issue 1

April 2000

xviRemove/Install Circuit Packs

■ Answered by the called station

■ Answered by the attendant

■ Routed to a recorded announcement that can be administered by the CPE

user

This equipment returns answer-supervision signals on all DID calls forwarded

back to the public switched telephone network. Permissible exceptions are:

■ A call is unanswered

■ A busy tone is received

■ A reorder tone is received

Lucent Technologies attests that this registered equipment is capable of

providing users access to interstate providers of operator services through the

use of access codes. Modification of this equipment by call aggregators to block

access dialing codes is a violation of the Telephone Operator Consumers Act of

1990.

This equipment complies with Part 68 of the FCC Rules. On the rear of this

equipment is a label that contains, among other information, the FCC registration

number and ringer equivalence number (REN) for this equipment. If requested,

this information must be provided to the telephone company.

Page 17

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

The REN is used to determine the quantity of devices which may be connected

to the telephone line. Excessive RE Ns on the telephone line may result in devices

not ringing in response to an incoming call. In most, but not all areas, the sum of

RENs should not exceed 5.0. To be certain of the number of devices that may be

connected to a line, as determined by the total RENs, contact the local telephone

company.

NOTE:

REN is not required for some types of analog or digital facilities.

Means of Connection

Connection of this equipment to the telephone network is shown in the following

table.

Issue 1

April 2000

xviiFederal Communications Commission Statement

Manufacturer’s Port

Identifier FIC Code

SOC/REN/

A.S. Code Network Jacks

Off/On Premises Station OL13C 9.0F RJ2GX,

RJ21X, RJ11C

DID Trunk 02RV2-T 0.0B RJ2GX, RJ21X

CO Trunk 02GS2 0.3A RJ21X

CO Trunk 02LS2 0.3A RJ21X

Tie Trunk TL31M 9.0F RJ2GX

1.544 Digital Interface 04DU9-B,C 6.0P RJ48C, RJ48M

1.544 Digital Interface 04DU9-BN,KN 6.0P RJ48C, RJ48M

120A2 Channel Service Unit 04DU9-DN 6.0P RJ48C

®

If the terminal equipment (DEFINITY

System) causes harm to the telephone

network, the telephone company will notify you in advance that temporary

discontinuance of service may be required. But if advance notice is not practical,

the telephone company will notify the customer as soon as possible. Also, you

will be advised of your right to file a complaint with the FCC if you believe it is

necessary.

The telephone company may make changes in its facilities, equipment,

operations or procedures that could affect the operation of the equipment. If this

happens, the telephone company will provide advance notice in order for you to

make necessary modifications to maintain uninterrupted service.

If trouble is experienced with this equipment, for repair or warranty information,

please contact the Technical Service Center at 1-800-248-1234. If the equipment

is causing harm to the telephone network, the telephone company may request

that you disconnect the equipment until the problem is resolved.

Page 18

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

About This Book

555-233-120

It is recommended that repairs be performed by Lucent Technologies certified

technicians.

The equipment cannot be used on public coin phone service provided by the

telephone company. Connection to party line service is subject to state tariffs.

Contact the state public utility commission, public service commission or

corporation commission for information.

This equipment, if it uses a telephone receiver, is hearing aid compatible.

Issue 1

April 2000

xviiiFederal Communications Commission Statement

Page 19

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Install and Connect the Cabinets

This chapter describes how to install the Release 8si Single-Carrier Cabinets.

Issue 1

April 2000

1-1Check Circuit Packs

1

Multicarrier Cabinet installation procedures are provided in

Communications Server Release 8 Installation and Test for Multicarrier Cabinets

Floor plans and equipment layouts for typical system installations are provided in

DEFINITY Enterprise Communications Server Release 8 System Description

Check Circuit Packs

Ensure all circuit packs are fully inserted into the proper slots according to the

Customer Service Document (CSD). Report any discrepancies in circuit pack

type or quantity to your Lucent Technologies representative. For detailed circuit

pack descriptions, r efer to

8 System Description

Release 8si systems contain a RISC-based TN790B Processor circuit pack.

.

Check Customer’s Order

Check the customer’s order and the shipping packing lists to confirm all

equipment is present. If any equipment is missing, report the information to your

Lucent Technologies representative. Check the system adjuncts for damage and

report all damage according to local shipping instructions.

DEFINITY Enterprise

.

.

DEFINITY Enterprise Communications Server Release

Page 20

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

How to Correct Shipping Errors

Defective equipment and over-shipped equipment must be red-tagged and

returned per the nearest Material Stocking Location (MSL) instructions.

Short-shipped reports must also be directed to the nearest Material Stocking

Location (MSL). Contact the appropriate location for specific instructions. For

Str eamlined Implementation in the United States, call 1-800-772-5409.

Unpack and Inspect

1. Unpack the cabinets from the shipping material and inspect for damage.

Report any shipping damage accordin g to local shipping instructions.

2. Open and remove the front door and rear panels from the cabinet.

3. Verify the label near the circuit breaker on the power supply toward the

rear of each cabinet corresponds to the local voltage type.

Issue 1

April 2000

1-2How to Correct Shipping Errors

!

DANGER:

If the label is different than the voltage type at the site, notify your

Lucent Technologies representative immediately for a replacement

power supply. Do

incorrect power supply to a power source.

not

Install Single-Carrier Cabinets

This section describes how to position and stack the cabinets for all reliability

configurations.

!

CAUTION:

Lifting the cabinet may require two people, as it may weigh as much as 130

pounds (60 kilograms). Use caution to avoid injury.

Before beginning the cabinet installation, check the location of the AC/DC power

receptacle. The receptacle must be on a separately fused circuit

by a wall switch. It must be located within 10 feet (3 meters) of the cabinet, and

should be located outside the Main Distribution Frame (MDF) area.

, under any circumstances, connect an

not

controlled

Page 21

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

Refer to the serial numbers and lettered designation strips in the Customer

Service Document (CSD) when stacking the cabinets. If earthquake protection is

required, skip to ‘‘Install Earthquake Protection’’

finished.

!

CAUTION:

555-233-120

System grounding must comply with the general rules for grounding

contained in Article 250 of the National Electrical Code (NEC), National Fire

Pr otection Agency (NFPA) 70, or the applicable electric code in the country

containing the equipment.

Position Cabinets (Standard Reliability)

One Cabinet Stack (Processor Port Network)

Issue 1

April 2000

1-3Install Single-Carrier Cabinets

. Return to this section when

Perform this step first for

1. Place Control Cabinet A (J58890L) on the floor in the position determined

when the room layout was planned.

2. Set Port Cabinet B (J58890H) on top of Control Cabinet A.

3. Set Port Cabinet C (J58890H) on top of Port Cabinet B.

4. Set Port Cabinet D (J58890H) on top of Port Cabinet C.

5. If additional cabinet stacks are being installed, continue to the next

section. If not, proceed to ‘‘Approved Grounds’’ on page 1-5

all

standard reliability cabinet installations.

Two Cabinet Stacks (Expansion Port Network)

1. Place the Expansion Control Cabinet (J58890N) on the floor next to

Control Cabinet A. See previous instru ctions.

2. Set Port Cabinet B (J58890H) on top of the Expansion Control Cabinet.

3. Set Port Cabinet C (J58890H) on top of Port Cabinet B.

4. Set Port Cabinet D (J58890H) on top of Port Cabinet C.

5. If three cabinet stacks are being installed, continue to the next section. If

not, proceed to ‘‘Approved Grounds’’ on page 1-5

Three Cabinet Stacks (Expansion Port Network)

.

.

1. Place the second Expansion Control Cabinet (J58890N) on the floor next

to the first Expansion Control Cabinet. See previous instructions.

2. Set Port Cabinet B (J58890H) on top of the Expansion Control Cabinet.

3. Set Port Cabinet C (J58890H) on top of Port Cabinet B.

4. Set Port Cabinet D (J58890H) on top of Port Cabinet C.

5. Proceed to ‘‘Approved Grounds’’ on page 1-5

.

Page 22

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Position Cabinets (High or Critical Reliability)

One Cabinet Stack (Processor Port Network)

Issue 1

April 2000

1-4Install Single-Carrier Cabinets

Perform this step first for

all

high or critical reliability cabinet installations.

1. Place Control Cabinet A (J58890L) on the floor in the position determined

when the room layout was planned.

2. Set Duplicate Control Cabinet B (J58890M) on top of Control Cabinet A.

3. Set Port Cabinet C (J58890H) on top of Duplicate Control Cabinet B.

4. Set Port Cabinet D (J58890H) on top of Port Cabinet C.

5. If additional cabinet stacks are being installed, continue to the next

section. If not, skip to ‘‘Approved Grounds’’

Two Cabinet Stacks (Expansion Port Network)

1. Place the Expansion Control Cabinet (J58890N) on the floor next to

Control Cabinet A See previous instructions.

2. Set Port Cabinet B (J58890H) on top of the Expansion Control Cabinet.

3. Set Port Cabinet C (J58890H) on top of Port Cabinet B.

4. Set Port Cabinet D (J58890H) on top of Port Cabinet C.

5. If additional cabinet stacks are being installed, continue to the next

section. If not, skip to ‘‘Approved Grounds’’

Three Cabinet Stacks (Expansion Port Network)

.

.

1. Place the second Expansion Control Cabinet (J58890N) on the floor next

to the first Expansion Control Cabinet. See previous instructions.

2. Set Port Cabinet B (J58890H) on top of the second Expansion Control

Cabinet.

3. Set Port Cabinet C (J58890H) on top of Port Cabinet B.

4. Set Port Cabinet D (J58890H) on top of Port Cabinet C.

5. Proceed to ‘‘Approved Grounds’’

.

Page 23

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Approved Grounds

An approved ground is the closest acceptable medium for grounding the

building entrance protector, entrance cable shield, or single-point ground of

electronic telephony equipment. If more than one type of approved ground is

available on the premises, the grounds must be bonded together as required in

Section 250-81 of the National Electrical Code.

Issue 1

April 2000

1-5Approved Grounds

Grounded Building Steel

— The metal frame of the building where it is

effectively grounded by one of the following grounds: acceptable metallic water

pipe, concrete encased ground, or a ground ring.

Acceptable Water Pipe

— A metal underground water pipe, at least 1/2-inch

(1.27 cm) in diameter, in direct contact with the earth for at least 10 feet (3 m).

The pipe must be electrically continuous (or made electrically continuous by

bonding around insulated joints, plastic pipe, or plastic water meters) to the point

where the protector ground wire is connected. A metallic underground water

pipe must be supplemented by the metal frame of the building, a concrete

encased ground, or a ground ring. If these grounds are not available, the water

pipe ground can be supplemented by one of the following types of grounds:

■ Other local metal underground systems or structures — Loc al

underground structures such as tanks and piping systems

■ Rod and pipe electrodes — A 5/8-inch (1.58 cm) (solid rod) or 3/4-inch

(1.9 cm) (conduit or pipe) electrode driven to a minimum depth of 8 feet

(2.43 m).

■ Plate electrodes — Must have a minimum of 2 square feet (0.185 square

m) of metallic surface exposed to the exterior soil

Concrete Encased Ground

— An electrode encased by at least 2 inches (5.08

cm) of concrete and located within and near the bottom of a concrete foundation

or footing in direct contact with the earth. The electrode must be at least 20 feet

(6.1 m) of one or more steel reinforcing bars or rods 1/2-inch (1.27 cm) in

diameter, or at least 20 feet (6.1 m) of bare, solid copper, 4 AWG (5.189 mm

2

)

wire.

Ground Ring

— A buried ground that encircles a building or structure at a depth

of at least 2.5 feet (0.76 m) below the earth’s surface. The ground ring must be at

least 20 feet (6.1 m) of 2 AWG (6.543 mm

2

), bare, copper wire.

Page 24

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

APPROVED FLOOR GROUNDS

Approved floor grounds are those grounds on each floor of a high-rise building

suitable for connection to the ground terminal in the riser closet and to the

cabinet equipment single-point ground terminal. Approved floor grounds may

include the following:

■ Building steel

■ The grounding conductor for the secondary side of the power transformer

feeding the floor

■ Metallic water pipes

■ Power feed metallic conduit supplying panel boards on the floor

■ A grounding point specifically provided in the building for the purpose

!

WARNING:

If the approved ground or approved floor ground can only be

accessed inside a dedicated power equipment room, then

connections to this ground should be made by a licensed electrician.

Issue 1

April 2000

1-6Connect Cabinet Grounds

Connect Cabinet Grounds

To connect the cabinet grounds on the J58890R DC Power Cabinet and the

Single-Carrier Cabinets, perform the following steps. To connect the cabinet

grounds on AC-powered cabinets, skip to ‘‘Grounding AC-Powered Cabinets

Only’’ on page 1-11.

DC-Powered Cabinets Only

!

CAUTION:

System grounding shall comply with the general rules for grounding

contained in Article 250 of the National Electrical Code (NEC), National Fire

Protection Agency (NFPA) 70, or the applicable code at the installation site.

NOTE:

Before connecting the cabinets to the approved ground, determine the

best method of grounding. Also, locate the approved ground as close to

the cabinets as possible.

NOTE:

The ground plates and cabinet clips are installed later in this chapter.

Page 25

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect DC Power Cabinet Ground

Issue 1

April 2000

1-7Connect Cabinet Grounds

3

2

1

dc_rect1 RBP 051396

Figure Notes

1. DC Power Cabinet

2. To Approved Ground

3. 1 AWG (#70) (7 mm

4. Ground Discharge Bar

Figure 1-1. DC Power Cabinet Grounding

1. At the DC Power Cabinet, connect a 1 AWG (#70) (7 mm

the GROUND DISCHARGE bar. Se e Figure 1-1

.

4

2

) Wire

2

) ground wire to

2. Route the ground wire out of the cabinet and terminate it on the approved

ground.

!

CAUTION:

The approved ground must be connected using the correct gauge

wire, terminated with a listed clamp, and identified with a grounding

tag (FORM 15657NR, or equivalent).

Page 26

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect DC Battery Cabinet Frame Ground

1

3

Issue 1

April 2000

1-8Connect Cabinet Grounds

2

dc_rect6 RBP 052996

Figure Notes

1. 6 AWG (#40) (4mm

2. DC Battery Cabinet

3. DC Power Cabinet

4. Grounding Hole in Top of Cabinets

2

) Wire

5. Terminal Lug (Part of D-18181895)

6. Pan Head Slotted Screw

7. Star Washer

8. Hex Nut

Figure 1-2. Frame Ground Wiring Between Power Cabinets

2

1. Cut a length of 6 AWG (#40) (4 mm

) wire long enough to reach between

the DC Power Cabinet and the DC Battery Cabinet. See Figure 1-2

2. Crimp a terminal lug on the each end of the wire. The terminal lugs are

furnished as part of D-181895, kit of parts.

3. At the DC Battery Cabinet, attach the 6 AWG (#40) (4 mm

2

) wire to the

frame ground mounting hole using a pan head slotted screw, star washer,

and hex nut. Tighten the screw securely.

4. Route the opposite end of the wire to the DC Power Cabinet.

5. Attach the 6 AW G (#40) (4 mm

2

) wire to the mounting hole in the top of the

cabinet. Use a pan head slotted screw, star washer, and hex nut. Tighten

the screw securely.

.

Page 27

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect DC Power Distribution Unit Ground

j58890r1 RBP 042296

Figure Notes

Issue 1

April 2000

1-9Connect Cabinet Grounds

1. DC Power Cabinet

2. DC Power Distribution Unit

3. Ground Discharge Bar

4. 6 AWG (#40) (4 mm

2

) Wire

5. GRD Connector Terminal on DC

Power Distribution Unit

6. To Additional DC Power Di stribution

Units (If Required)

Figure 1-3. DC Power Distribution Unit Ground

2

1. Measure and cut a length of 6 AW G (#40) (4 mm

) wire long enough to

reach between the GROUND DISCHARGE bar in the DC Power Cabinet

and the GRD connector on the DC Distribution Unit. See Figure 1-3

2. At the DC Power Cabinet, connect the 6 AWG (#40) (4 mm

2

) wire to the

GROUND DISCHARGE bar.

3. Route the opposite end of the wire to the DC Power Distribution Unit and

connect the wire to the GRD connector.

4. Repeat Steps 2 and 3 for each remaining DC Power Distribution Unit.

.

Page 28

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect Single-Carrier Cabinet Ground

On On

Off

Issue 1

April 2000

1-10Connect Cabinet Grounds

Off

5

6

1

2

1

4

On On

Off

Off

3

Figure Notes

1. 6 AWG (#40) (4 mm

2. Control Cabinet (Cabinet A)

3. Single-Point Ground Block

2

) Wire

4. To Additional Control Cabinets in Same

Room

5. DC Power Cabinet

6. Ground Discharge Bar

Figure 1-4. Single-Carrier Cabinet Ground

2

1. Cut a length of 6 AWG (#40) (4 mm

) wire long enough to reach between

the GROUND DISCHARGE bar on the DC Power Cabinet and the

single-point ground block on the Control Cabinet (bottom cabinet in Figure

1-4).

dc_rect4 RBP 032896

2. At the DC Power Cabinet, connect the wire to the GROUND DISCHARGE

bar.

3. Route the wire to Control Cabinet and connect to the single-point ground

block.

4. Repeat for each Control Cabinet in the system room (duplicated Control

Cabinet and Expansion Control Cabinet).

Page 29

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Grounding AC-Powered Cabinets Only

!

CAUTION:

System grounding shall comply with the general rules for grounding

contained in Article 250 of the National Electrical Code (NEC), National Fire

Pr otection Agency (NFPA) 70, or the applicable code at the installation site.

NOTE:

Before connecting the cabinets to the approved ground, determine the

best method of grounding. See ‘‘Approved Grounds’’ on page 1-5

locate the approved ground as close to the cabinets as possible.

NOTE:

The ground plates and cabinet clips are installed later in this chapter.

Issue 1

April 2000

1-11Connect Cabinet Grounds

. Also,

1. Measure and cut a length of 6 AW G (#40) (4 mm

2

) wire long enough to

reach between the cabinet stack single-point ground block and the

approved ground. See Figure 1-5

2. At the lower left rear of the Control Cabinet (Cabinet A), connect the

6 AWG (#40) (4 mm

2

) ground wire to the cabinet stack single-point ground

.

block.

3. Run the ground wire to the approved ground and attach securely.

4. Repeat Steps 1-3 for each Expansion Control Cabinet.

NOTE:

If the Expansion Control Cabinet is remotely located from Cabinet A

(in a separate room or building), run the 6 AWG (#40) (4 mm

2

)

cabinet ground wire to an approved protective ground.

5. At Cabinet A, connect a 10 AWG (#25) (2.5 mm

ground block. The 10 AWG (#25) (2.5 mm

2

) wire to the single-point

2

) wire must be long enough to

reach the telecommunications cables at the rear of the system cabinets,

follow these cables to the Main Distribution Frame (MDF), and to terminate

at the Coupled Bonding Conductor (CBC).

The Coupled Bonding Conductor (CBC) wires are installed and terminated in

Chapter 2, ‘‘Install Telecommunications Cabling’’

.

Page 30

DEFINITY Enterprise Communication Server Release 8.2

bCJL030896

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Single-Carrier Cabinet Ground

1

Issue 1

April 2000

1-12Connect Cabinet Grounds

2

3

4

7

On

OffOnOff

5

8

Figure Notes

1. Cabinet Stack 1 Control Cabinet A

2. Circuit Breaker

3. AC Power Receptacle

4. Cabinet Stack Single-Point Ground

Block

5. 8-Foot (2.5 Meters) Power Cord

6

r781851

6. National Electrical Manufacturers

Association (NEMA) 5-15 or 5-20

Receptacle or Equivalent

2

7. 6 AWG (#40) (4 mm

) Ground Wire

to Approved Ground

8. 10 AWG (#25) (2.5 mm

2

) Wire to

Coupled Bonding Conductor

Figure 1-5. Typical AC Power and Ground Layout — Rear

Page 31

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect AC Power

Set the Ringer Frequency

The default ringer frequency setting on the 1217A power supply for North

America is 20 Hz and the international setting can be either 20 Hz or 25 Hz. To

set the ringer frequency on the 1217A power supply:

!

CAUTION:

When adding or replacing any hardware, be sure to ground yourself against

electrostatic discharge (ESD) by wearing a grounded wrist strap.

1. Power down AUDIX and any other circuit pack that might be running an

application.

2. Power down the cabinet.

3. Release both latches on the power supply and slide the unit out of the

cabinet.

Issue 1

April 2000

1-13Connect AC Power

4. Observe the ring frequency switch label on the side of the power supply

and locate the switch on the bottom.

5. Set the ring frequency select switch to the appropriate frequency setting.

6. Slide the power supply back into the slot and ensure that both latches

snap closed.

Connect the Power Cord into the Power Receptacle

1. Provide one receptacle per Single-Carrier Cabinet.

2. Verify the circuit breakers are OFF.

3. Plug the cabinet AC power cord into the AC power receptacle on the rear

of each cabinet.

4. Plug the opposite end of each AC power cord into the appropriate AC

power receptacle in the equipment room.

NOTE:

Loop the excess cord and tie wrap it to the back cover to prevent

accidental unplugging.

Page 32

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect DC Power

The following procedures apply to both the Processor Port Networks (PPN) and

Expansion Port Networks (EPN).

DC Power Connections

A 30 foot (9 m) cable connects to each cabinet. A special connector on one end

of the cable is plugged into the cabinet power connector. The cable must be cut

to length and terminated inside the J58890R DC Power Cabinet.

Each rectifier assembly can supply up to 50 Amps of DC current. A minimum of

two rectifiers are installed in each DC Power Cabinet to supply a total of 100

Amps. A third rectifier assembly can be installed and is used as a backup (N+1).

Each Single-Carrier Cabinet can pull up to 18 Amps. Up to three DC Power

Cabinets can be stacked to supply power to Single-Carrier Cabinet stacks.

Issue 1

April 2000

1-14Connect DC Power

Figure 1-6

without a J58890CG DC Power Distribution Unit. The J58890CG is required if the

distance between the DC Power Cabinet(s) is greater than 30 feet (9 m). Figure

1-7 shows a typical power and ground layout for a DC-powered system

containing a DC power distribution unit.

shows a typical power and ground layout for a DC-powered system

Connect AC Power to DC Power Cabinet

1. Ensure the associated circuit breakers at the AC power panel are OFF.

2. Have an electrician connect AC power leads to the rectifiers using the

instructions provided with the rectifiers in the DC Power Cabinet. Each

rectifier should have its own branch circuit. Terminate leads on the AC

INPUT terminal block of each rectifier.

!

CAUTION:

Power is present in the cabinet even if the AC power cable is

unplugged. Turn off the main circuit breaker on the front of the

cabinet when procedures require ALL power to be removed from the

cabinet.

Page 33

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

DC Power Connections

Issue 1

April 2000

1-15Connect DC Power

Figure Notes

1. System Cabinet Stack

2. DC Power Cabinet

3. White Wires

4. Green Ground Wires and Black

Wires Connect to the -48 VDC

Return Bus

5. -48 VDC Bus

6. Connect White Wires to Circuit

Breakers

7. DC Power Cable (H600-436, G1) to

Power Connector on Each Cabinet. Cut

to Length and Crimp a Ring Terminal

Onto Each Wire

8. 30 Feet (9 m) Maximum

9. Route Cables Through Sliding Door

10. Circuit Breaker

11. Supplied #10-32 Screw, #10 S tar

Washer, and #10-32 Hex Nut

12. Inset Showing DC Power Connector

(Male)

Figure 1-6. Typical DC Power Connections

Page 34

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

DC Power Connections with DC Distribution Unit

A 10 foot (3 meter) power cord is equipped with the appropriate connectors. In

the configuration shown in Figure 1-7

Distribution Unit associated with it.

, each cabinet stack has a DC Power

Issue 1

April 2000

1-16Connect DC Power

Figure Notes

1. System Cabinet Stack

2. DC Power Cabinet

3. DC Power Distribution Unit (Position

to the Right of the Cabinet Stack)

4. White Wire (Connect to Circuit

Breaker). See Inset.

5. Green Ground Wire and Black Wire

Connect to the -48 VDC Return Bus

6. -48 VDC Bus

7. Inset

8. 12 Inches (30.5 cm) From Floor to

9. DC Power Cable to Power

Connector on Each Cabinet

10. DC Power Distribution Unit Power

Cord (Route to Rear of DC Power

Cabinet)

11. Route P ower Cord Through Sliding

Door

12. Circ uit Breaker

13. Supplied #10-32 Screw, #10 Star

Washer, and #10-32 Hex Nut

14. Inset Showing DC Power Connector

(Male)

DC Power Distribution Unit

Figure 1-7. Connections Using DC Power Distribution Unit

Page 35

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Stacking DC Power Cabinets

Up to three DC P ower Cabinets can be stacked to supply power to Single-Carrier

Cabi net sta cks. See Figure 1-8

.

Issue 1

April 2000

1-17Connect DC Power

Figure Notes

1. DC Power Cabinet Stack

2. DC Power Cables Daisy Chained

Between DC Power Cabinets

3. Connect to -48 VDC Bus

4. Connect to -48 VDC Return Bus

5. Inset Applies to -48 VDC and -48

VDC Return Buses in All Three DC

Power Cabinets

Figure 1-8. DC Power Cabinet Stack — Rear

pwrdist4RBP 052896

Page 36

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect Battery Cabinet

Figure 1-9 shows typical connections from the DC Battery Cabinet to the DC

Power Cabinet.

Issue 1

April 2000

1-18Connect Battery Cabinet

pwrdist5 RBP 052896

Figure Notes

1. DC Power Cabinet

2. Connect Red DC Power Cable to

-48 VDC Return Bus

3. Connect Black DC Power Cable to

4. Inset Applies to -48 VDC Buses an d

-48 VDC Return Buses

5. Battery Cabinet

6. DC Power Cables (Red and Black)

-48 VDC Bus

Figure 1-9. DC Battery to DC Power Cabinet Connections

!

CAUTION:

Power is present in the cabinet even if the AC power cable is unplugged.

Turn off the main circuit breaker on the front of the cabinet when procedures

require ALL power to be removed from the cabinet.

Page 37

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect Optional Battery Leads

To prevent the internal batteries from discharging, the Control Cabinet is shipped

with the battery leads disconnected.

1

2

Issue 1

April 2000

1-19Connect Optional Battery Leads

3

4

4_3 LJK 031096

Figure Notes

1. Battery

2. Battery Lead Connector

3. Circuit Breakers (Located Between

Plates)

4. Cabinet Single-Point Ground Block

Figure 1-10. Control Cabinet Battery Location — Right Side

1. Set the circuit breakers OFF. See Figure 1-10

.

2. Connect the battery leads. The battery is near the top of the carrier toward

the front-right. The battery leads are located next to the battery and are

accessible from the front of the cabinet.

Page 38

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect AC Power to Stratum 3 Clock Cabinet

The clock cabinet requires a 120 VAC, 15 Amp receptacle. The green wire

ground provided by the receptacle is sufficient. The clock cabinet does not

require a ground connection back to the single-point ground.

Check and Connect Commercial AC Power

Before powering up the system, check the AC power using a KS-20599 digital

voltmeter (DVM) (or equivalent).

1. Set the DVM to the 250 volt range.

2. Carefully measure the voltage between the hot and neutral side of the

receptacle. The neutral wire is white, the hot wire is black.

3. Verify the meter reads 106 to 128 V AC. If not, have a qualified electrician

correct the problem.

Issue 1

April 2000

1-20Connect AC Power to Stratum 3 Clock Cabinet

4. Measure the voltage between the neutral and ground side of the

receptacle. The ground wire is green.

5. Verify the meter reads 0 VAC. If not, have a qualified electrician correct the

problem.

6. Set all cabinet power modules OFF. Plug the AC power cable into the

receptacle.

Connect DC Power and Ground to Stratum 3 Clock Cabinet

The clock cabinet should be powered from the same DC power plant as the

DEFINITY System. The clock cabinet must be grounded to the DC power plant.

Connect Clock Cabinet Grounding

1. Measure and cut a 6 AWG (#40) (4 mm2) wire long enough to reach from

the clock cabinet to the ground discharge bar in the DC power plant.

2. Insert one end of the wire into the ground lug on the clock cabinet and

tighten the screw.

3. Attach the lug to the receptacle cover. Be sure the lug and cabinet ground

wires connect to separate screws on the receptacle cover.

4. Route the ground wire to the DC power plant and connect to DISCH GRD

in the cabinet.

Page 39

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect Stratum 3 Clock DC Power

1. Set the clock cabinet circuit breaker at the DC power plant OFF.

2. At the clock cabinet, connect a 6 AWG (#40) (4 mm

-48V terminal on the terminal strip.

3. At the clock cabinet, connect a 6 AWG (#40) (4 mm

terminal on the terminal strip.

4. Route the wires out of the cabinet and to the DC power plant.

5. At the DC power plant, connect the -48V wire to the DC OUTPUT circuit

breaker.

6. At the DC power plant, connect the -48VRTN wire to the DISCH GRD bar.

Connect Time Division Multiplexing Bus Cables

If the cabinet stack contains only one Single-Carrier Cabinet, skip this section

and proceed to ‘‘Verify Port Cabinet Address Plugs’’ on page 1-26

Issue 1

April 2000

2

) ground wire to the

2

) wire to the -48VRTN

.

1-21Connect Time Division Multiplexing Bus Cables

Locate the white fabric-covered Time Division Multiplexing (TDM) bus cable on

the rear of the cabinets.

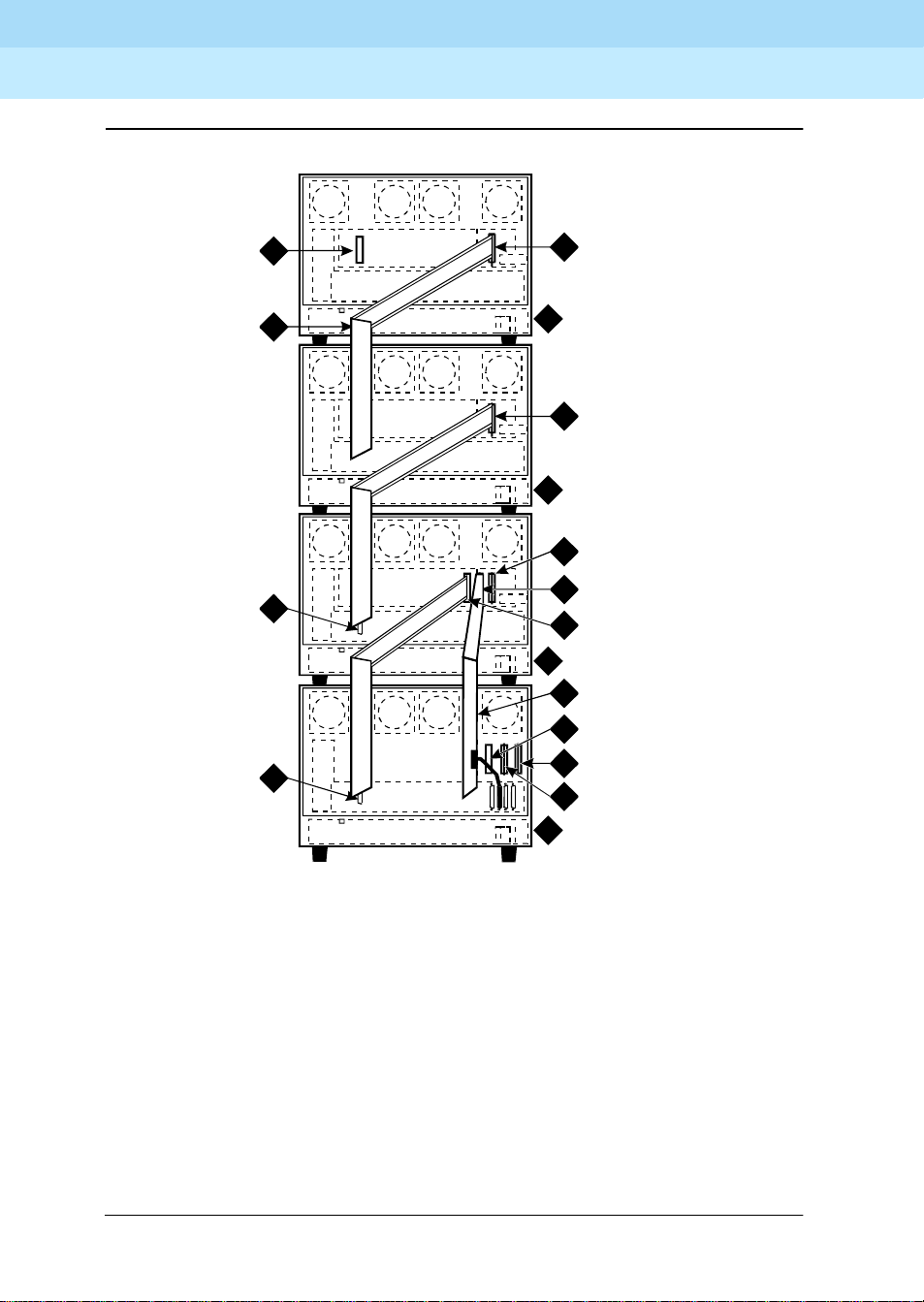

Standard Reliability Processor Port Network

One cabinet stack:

1. Remove the Time Division Multiplexing (TDM) Bus Terminator (AHF110)

from Slot 18 of the Control Cabinet (Processor Port Network (PPN)) and

move it to Slot 17 on the top Port Cabinet. See Figure 1-11

2. Connect the supplied Time Division Multiplexing (TDM) Bus Cables

(WP-91716 L3) as shown in Figure 1-11

.

.

Page 40

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

High or Critical Reliability Processor Port Network

Two cabinet stacks:

1. Remove the Time Division Multiplexing (TDM) Bus Terminator from Slot 18

of Control Cabinet A (Pr ocessor Port Network (PP N)) and move it to Slot 18

of Control Cabinet B. See Figure 1-12

2. Connect the supplied Time Division Multiplexing (TDM) Bus Cables

(WP-91716 L3) from Cabinet A to Cabinet B as shown.

High or Critical Reliability Processor Port Network

Three cabinet stacks:

1. Remove the Time Division Multiplexing (TDM) Bus Terminator from Slot 18

of Control Cabinet A (Pr ocessor Port Network (PP N)) and move it to Slot 17

on the top port cabinet. See Figure 1-13

Issue 1

April 2000

1-22Connect Time Division Multiplexing Bus Cables

.

.

2. Connect the supplied TDM Bus Cables (WP-91716 L3) as shown.

Expansion Port Network (All Reliability Options)

1. Remove the TDM Bus Terminator from Slot 18 of Control Cabinet A (PPN)

and move it to Slot 17 on the top port cabinet. See Figure 1-12

2. Connect the supplied TDM Bus Cables (WP-91716 L3) as shown.

.

Page 41

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Issue 1

April 2000

1-23Connect Time Division Multiplexing Bus Cables

1

3

3

3

7

2

4

2

4

2

4

6

5

tdm_cab2 CJ L 030696

Figure Notes

1. AHF110 TDM Bus Terminator (Slot

17)

2. TDM/Local Area Network

(TDM/LAN) Pinfield (Slot 00)

3. TDM Bus Cable WP-91716 L3

4. Port Cabinet (Standard Reliability)

5. Control Cabinet A Position

6. AHF110 TDM Bus Terminator (Slot

03)

7. Slot 18

Figure 1-11. Connections for Standard Reliability Systems

Page 42

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Issue 1

April 2000

1-24Connect Time Division Multiplexing Bus Cables

1

3

7

7

2

4

2

4

9

10

2

11

8

6

9

10

5

tdm_cab3 CJL 053096

Figure Notes

1. AHF110 TDM Bus Terminator (Slot 17)

2. TDM/Local Area Network (TDM/LAN)

Pinfield (Slot 00)

3. TDM bus Cable (WP-91716 L3)

4. Port Cabinet

5. Control Cabinet A Position

6. AHF110 TDM Bus Terminator (Slot 01)

7. Slot 18

8. Inter-Cabinet Cables (ICC) A, B

and C (H600-248-G1)

9. Inter-Cabinet Cable (ICC) A

10. Inter-Cabinet Cable (ICC) B

11. Duplicated Control Cabinet B

Position

Figure 1-12. Connections for High or Critical Reliability Systems

Page 43

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Issue 1

April 2000

1-25Connect Time Division Multiplexing Bus Cables

1

3

3

3

7

2

4

2

4

8

2

9

5

8

6

tdm_cab4 CJL 053096

Figure Notes

1. AHF110 TDM Bus Terminator (Slot

17)

2. TDM/Local Area Network

(TDM/LAN) Pinfield (Slot 00)

3. TDM bus Cable (WP-91716 L3)

4. Port Cabinet

5. Control Cabinet A Position

6. AHF110 TDM Bus Terminator (Slot

03)

7. Slot 18

8. Inter-Cabinet Cables (ICC) B and C

(H600-259-G1)

9. Duplicated Control Cabinet B

Position

Figure 1-13. Connections for High or Critical Reliability Systems

Page 44

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

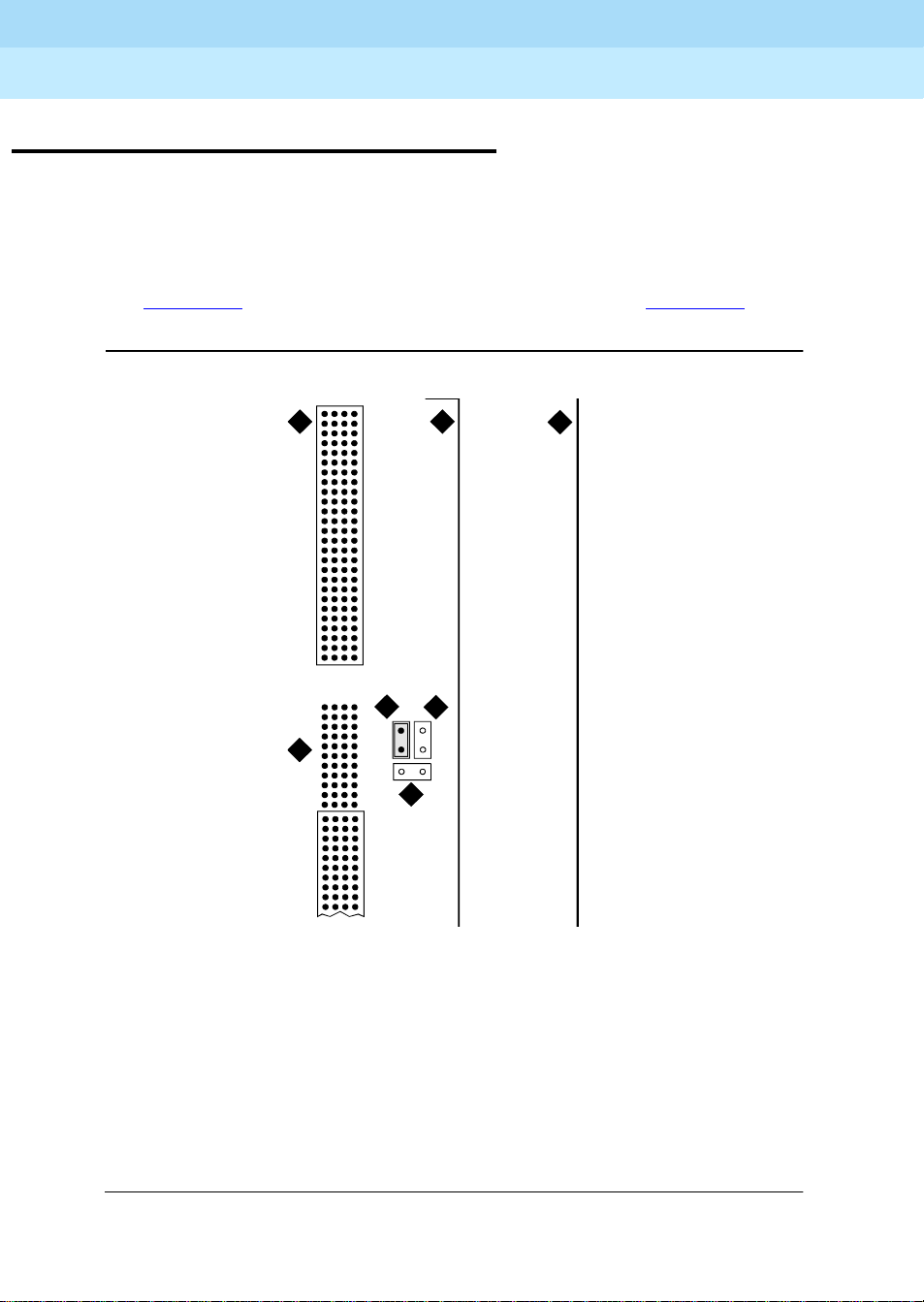

Verify Port Cabinet Address Plugs

The address plug is a jumper field on port cabi nets only. The address plug is

located on the far right hand side of the backplane, to the right of slot 00.

A group of six pins is labeled for the cabinet (carrier) jumper connections. V erify

the address plug for

See Figure 1-14

each

port carrier is in the correct location for that carrier.

. The factory default setting is “B” (Callout 2 in Figure 1-14).

Issue 1

April 2000

1-26Verify Port Cabinet Address Plugs

6

7

4

1

2

3

add_plug CJL 050906

5

Figure Notes

1. Address Plug (Shown Set to Carrier D)

2. Carrier B Jumper Location (Default)

3. Carrier C Ju mper Location

5. Right Edge of Cabinet

6. Backplane Slot 00

7. To Connector Panel

4. Right Edge of Backplane

Figure 1-14. Port Cabinet Address Plug Location — Cabinet Rear

Page 45

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

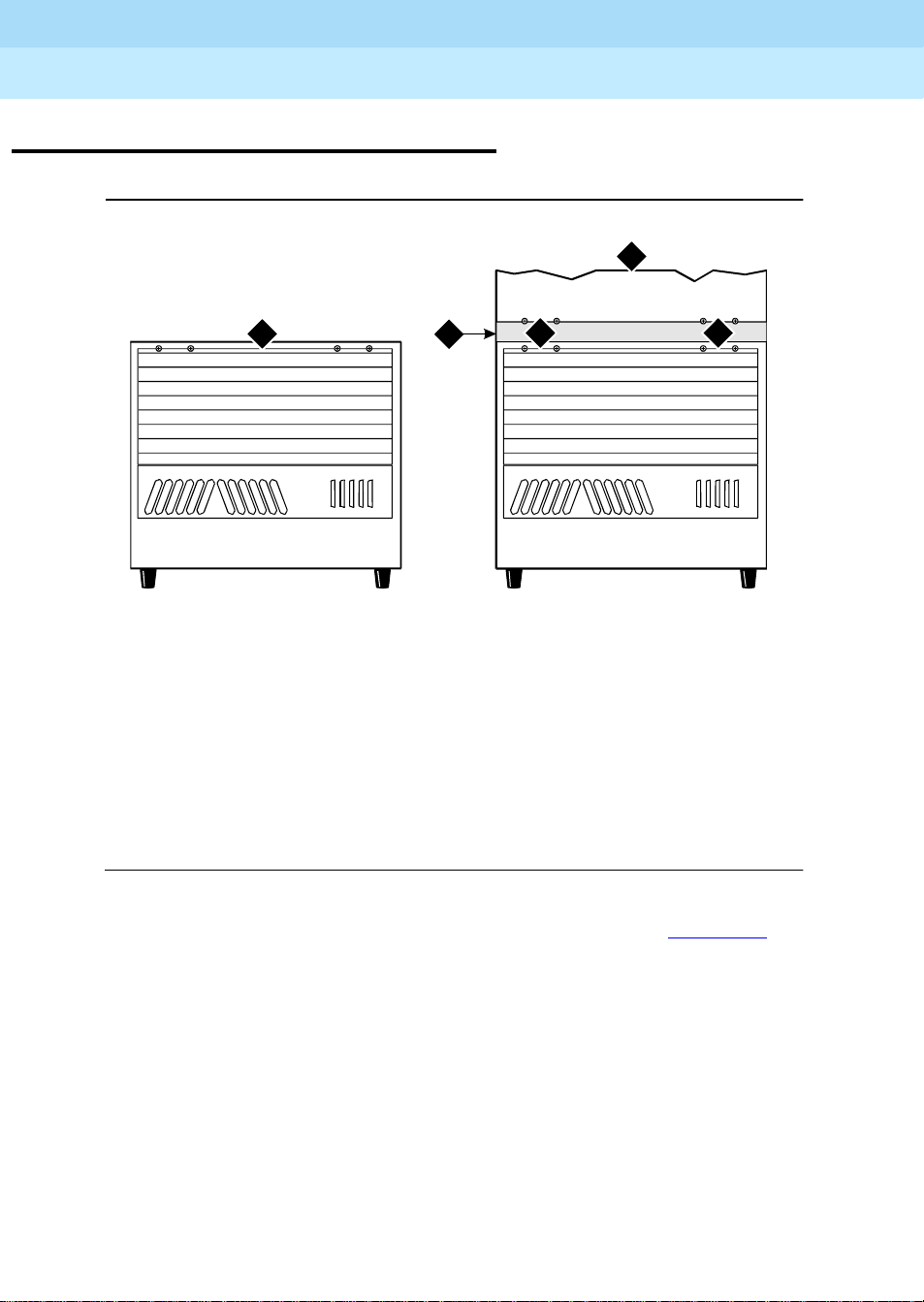

Install Rear Panels

Issue 1

April 2000

1-27Install Rear Panels

3

1

2

Figure Notes

1. Cabinet in A Position (No Ground Plate is

Installed on an Unstacked Cabinet)

2. Rear Ground Plate (Attached Between Stacked

Cabinets)

Figure 1-15. Rear Panel Screw Locations

4 4

grnd_plt CJL 030696

3. Cabinet in B Position

4. Screws to Loosen

1. Install the rear panels and loosely thread each screw. See Figure 1-15

2. For

unstacked

For a

cabinets, tighten the screws securely.

stack

of cabinets, allo w the screws labeled Callout 4 to r emain loose .

These screws are tightened when the ground plates are installed.

3. Be sure the Time Division Multiplexing (TDM) bus cables and the

Inter-Cabinet Cables (ICC) are not pinched by the panels. Also be sure

the cables are routed through the channels provided on the rear panels.

.

Page 46

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Install Ground Plates

Ground plates are installed between stacked cabinets, provide the ground

connection between cabinets, provide radio frequency (RF) radiation protection,

and help stabilize the cabinets.

Install Rear Ground Plates (Systems with Earthquake Protection)

1. Loosen the four screws at the bottom of the top cabinet and at the top of

the cabinet underneath the top cabinet. See Figure 1-15

2. Align the mounting holes in the rear ground plate over the bottom screws

in the top cabinet. See Figure 1-16

3. Align the mounting holes in the ground plate with the four holes at the top

of the cabinet below the top cabinet. Slide the mounting plate down to

seat on the screws.

4. Check all Time Division Multiplexing (TDM) bus cables and the Inter

Cabinet Cables (ICC) to be sure they are not pinched by the plates.

Issue 1

April 2000

1-28Install Ground Plates

.

.

5. Repeat Steps 1-3 until the rear ground plates are installed between all

stacked cabinets.

6. Do not tighten the screws yet.

Install Front Ground Plates (Systems with Radiation Shielding and Earthquake Protection)

Use the front ground plate instead of the cabinet clip to attach the cabinets to

each other. Use one front ground plate between two

1. At the front of the cabinets, align the holes in the top of the front ground

plate with the holes at the bottom of the upper cabinet, and insert the four

screws. Do not tighten the screws yet. See Figure 1-16

2. At the front of the cabinets, align the holes in the bottom of the front

ground plate with the holes at the top of the lower cabinet. Insert the four

supplied #12-24 x 1/2-inch (1.27 cm) thread-forming screws. Do not

tighten the screws yet.

3. Repeat Steps 1 and 2 until all stacked cabinets are fastened together.

4. Tighten all screws securely.

stacked

cabinets.

.

Page 47

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Issue 1

April 2000

1-29Install Ground Plates

1

2

Figure Notes

1. Front Ground Plate or Cabinet Clip

2. Battery

3

grdpltec LJK 031096

3. Rear Ground Plate

Figure 1-16. Rear Ground Plate and Front Plate or Cabinet Clip — Side View

Page 48

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

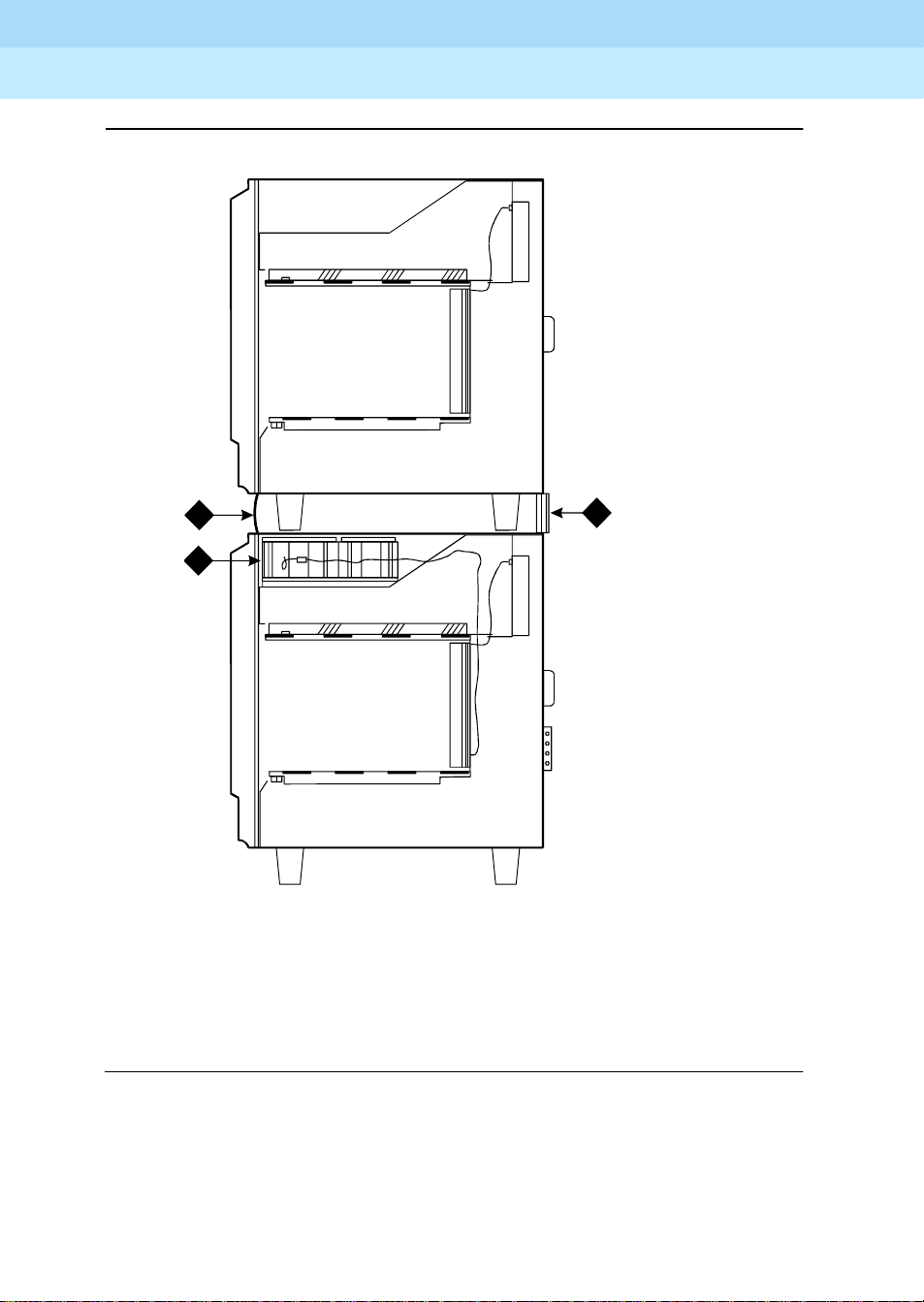

Install Cabinet Clips (Systems without Earthquake Protection)

A cabinet clip is required between each pair of stacked cabinets.

At the front of the cabinets, install a cabinet clip between each pair of cabinets

by hooking the clip into the slot of the upper cabinet and snapping the straight

leg of the clip into the slot on the lower cabinet. See Figure 1-17

Issue 1

April 2000

1-30Install Ground Plates

.

Figure Notes

1. Control Cabinet

2. Port Cabinet or Duplicated Control Cabinet

3. Port Cabinet

Figure 1-17. Location of Cabinet Clips

4. Port Cabinet

5. Cabinet Clips

Page 49

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Connect System Cables

Inter-Cabinet Cables (High or Critical Reliability)

1. Connect the cables for critical reliability Expansion Port Networks (EPNs)

as shown in Figure 1-12

2. Connect the cables for high or critical reliability Processor Port Networks

(PPNs) as shown in Figure 1-13

Table 1-1. Inter-Cabinet Cable Connections

Cabinet Carrier Connection Carrier Connection

Processor Port

Network (PPN)

Expansion Port

Network (EPN)

J58890L (ICC) B J58890M (ICC) B

J58890N (ICC) A J58890H (ICC) A

and in Table 1-1 below.

.

From Cabinet A To Cabinet B

(ICC) C (ICC) C

(ICC) B (ICC) B

Issue 1

April 2000

1-31Connect System Cables

Fiber Optic Cables

The fiber optic cables are connected to the Main Distribution Frame (MDF) in

Chapter 2, ‘‘Install Telecommunications Cabling’’

‘‘Connecting and Handling Fiber Optic Cables’’ for information about connecting

to optical cross-connect hardware and routing through lightguide equipment.

The DEFINITY ECS may contain a Class 1 LASER device if single-mode fiber

optic cable is connected to a remote Expansion Port Network (EPN). The LASER

device operates within the following parameters:

Maximum Power Output: -5 dBm

Wavelength: 1310 nm

Mode Field Diameter: 8.8 microns

CLASS 1 LASER PRODUCT

IEC 825 1993

!

CAUTION:

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Contact your Lucent Technologies representative for more information.

. Refer to Appendix B,

Page 50

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Fiber Optic Cable Connections

The Customer Service Document (CSD) provides an “Inter-Cabinet Cable

Running List.” Each row on the list represents a cable connection. Use the

running list to determine where to connect each fiber optic cable.

Multi-Mode Fiber Optic Connections

The following components are used in multi-mode fiber optic connections:

■ Expansion Interface (EI) circuit packs in port slots in cabinet carriers

■ Cables from each interface circuit pack to each port slot connector

■ The 9823A lightwave transceiver transmits up to 4,900 feet (1.5 km). The

9823B lightwave transceiver transmits up to 25,000 feet (7.6 km).

■ Multi-mode fiber optic cable consists of two separate 62.5 micron

diameter fiber optic cables or 50 micron diameter fiber optic cables.

Single-Mode Fiber Optic Connections

The following components are used in single-mode fiber optic connections:

Issue 1

April 2000

1-32Connect System Cables

■ Expansion Interface (EI) circuit packs in port slots in cabinet carriers

■ Cables from each interface circuit pack to each port slot connector

■ The 300A lightwave transceivers transmits light up to 115,000 feet (35

km). Fiber loss must be less than 17dB. Saturation may occur if distances

are short; attenuators may be required if the total loss on the fiber link is

less than 10dBm. An Optical Time Domain Reflectometer (OTDR) test is

recommended to determine specific fiber op t ic hardware requirements .

■ Single-mode fiber optic cable consists of two separate 8 to 10 micron core

cables.

NOTE:

5 and 10dB attenuators are available. Contact your Lucent

Technologies representative for more information.

Page 51

DEFINITY Enterprise Communication Server Release 8.2

Installation and Test for Single-Carrier Cabinets

Install and Connect the Cabinets

1

555-233-120

Recommended Cable Routing

1. Route the fiber op t ic cable up toward the top of the cabinet. The exces s

cable should be looped and draped from the B25A cable clamp on the

top ground plate in the stack. See Figure 1-18

2. Dress the cable by tie wrapping it to the outside of the B25A cable clamp.

!

CAUTION:

Do not route fiber optic cables and the B25A cables together.

4 4

2

Issue 1

April 2000

1-33Connect System Cables

.

1

4 4

4 4

5 5

Figure Notes

1.Supplied B25A Cables

2. Loop and Drape Excess Fiber

Optic Cable

3

3. Fiber Optic Cable Sheath

4. Port Cabinet

5. Control Cabinet

Figure 1-18. Single-Carrier Cabinet Fiber Routing

Page 52

DEFINITY Enterprise Communication Server Release 8.2