Page 1

Features

• High Performance, Low Power AVR

• Advanced RISC Architecture

– 120 Powerful Instructions – Most Single Clock Cycle Execution

– 32 x 8 General Purpose Working Registers

– Fully Static Operation

– Up to 20 MIPS Througput at 20 MHz

• High Endurance Non-volatile Memory segments

– 1K Bytes of In-System Self-programmable Flash program memory

– 64 Bytes EEPROM

– 64K Bytes Internal SRAM

– Write/Erase cyles: 10,000 Flash/100,000 EEPROM

– Data retention: 20 years at 85°C/100 years at 25°C

– Optional Boot Code Section with Independent Lock Bits

In-System Programming by On-chip Boot Program

True Read-While-Write Operation

– Programming Lock for Software Security

• Peripheral Features

– One 8-bit Timer/Counter with Prescaler and Two PWM Channels

– 4-channel, 10-bit ADC with Internal Voltage Reference

– Programmable Watchdog Timer with Separate On-chip Oscillator

– On-chip Analog Comparator

• Special Microcontroller Features

– debugWIRE On-chip Debug System

– In-System Programmable via SPI Port

– External and Internal Interrupt Sources

– Low Power Idle, ADC Noise Reduction, and Power-down Modes

– Enhanced Power-on Reset Circuit

– Programmable Brown-out Detection Circuit

– Internal Calibrated Oscillator

• I/O and Packages

– 8-pin PDIP/SOIC: Six Programmable I/O Lines

– 20-pad MLF: Six Programmable I/O Lines

• Operating Voltage:

– 1.8 - 5.5V for ATtiny13V

– 2.7 - 5.5V for ATtiny13

• Speed Grade

– ATtiny13V: 0 - 4 MHz @ 1.8 - 5.5V, 0 - 10 MHz @ 2.7 - 5.5V

– ATtiny13: 0 - 10 MHz @ 2.7 - 5.5V, 0 - 20 MHz @ 4.5 - 5.5V

• Industrial Temperatur e Ra nge

• Low Power Consumption

– Active Mode:

1 MHz, 1.8V: 240µA

– Power-down Mode:

< 0.1µA at 1.8V

®

8-Bit Microcontroller

(1)

8-bit

Microcontroller

with 1K Bytes

In-System

Programmable

Flash

ATtiny13V

ATtiny13

Summary

2535HS–AVR–10/07

Rev. 2535HS–AVR–10/07

Page 2

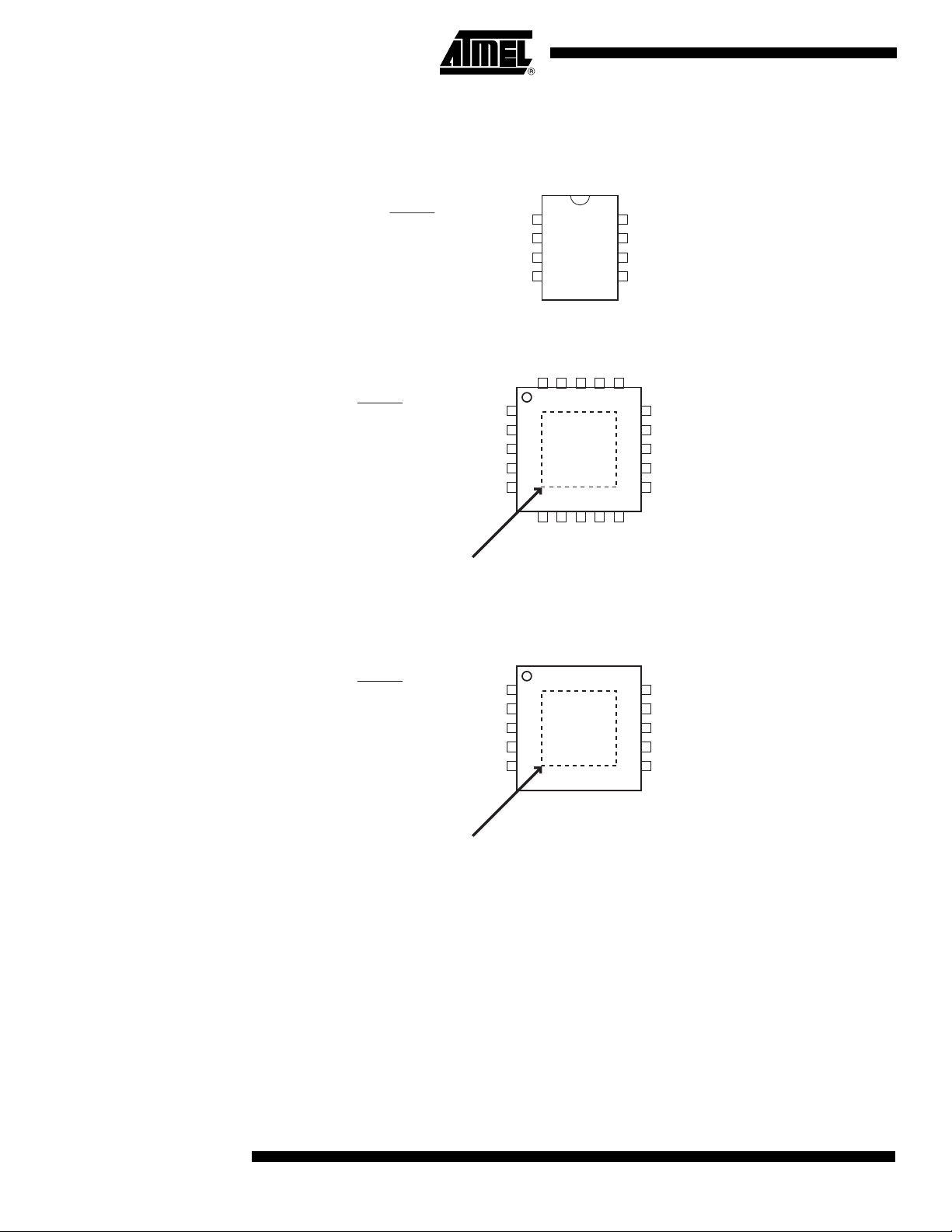

Pin Configurations Figure 1. Pinout ATtiny13

(PCINT5/RESET/ADC0/dW) PB5

(PCINT3/CLKI/ADC3) PB3

(PCINT4/ADC2) PB4

8-PDIP/SOIC

1

2

3

GND

4

20-QFN/MLF

NCNCNCNCNC

8

VCC

7

PB2 (SCK/ADC1/T0/PCINT2)

6

PB1 (MISO/AIN1/OC0B/INT0/PCINT1)

5

PB0 (MOSI/AIN0/OC0A/PCINT0)

(PCINT5/RESET/ADC0/dW) PB5

(PCINT3/CLKI/ADC3) PB3

NC

NC

(PCINT4/ADC2) PB4

NOTE: Bottom pad should be soldered to ground.

NC: Not Connect

(PCINT5/RESET/ADC0/dW) PB5

(PCINT3/CLKI/ADC3) PB3

NC

(PCINT4/ADC2) PB4

GND

NOTE: Bottom pad should be soldered to ground.

NC: Not Connect

2019181716

1

2

3

4

5

6

789

NC

NC

GND

10-QFN/MLF

1

2

3

4

5

NC

15

VCC

14

PB2 (SCK/ADC1/T0/PCINT2)

13

NC

12

PB1 (MISO/AIN1/OC0B/INT0/PCINT1)

11

PB0 (MOSI/AIN0/OC0A/PCINT0)

10

NC

10

VCC

9

PB2 (SCK/ADC1/T0/PCINT2)

8

NC

7

PB1 (MISO/AIN1/OC0B/INT0/PCINT1)

6

PB0 (MOSI/AIN0/OC0A/PCINT0)

Overview The ATtiny13 is a low-power CMOS 8-bit microcontroller based on the AVR enhanced

RISC architecture. By executing powerful instructions in a single clock cycle, the

ATtiny13 achieves throughputs approaching 1 MIPS per MHz allowing the system

designer to optimize power consumption versus processing speed.

2

ATtiny13

2535HS–AVR–10/07

Page 3

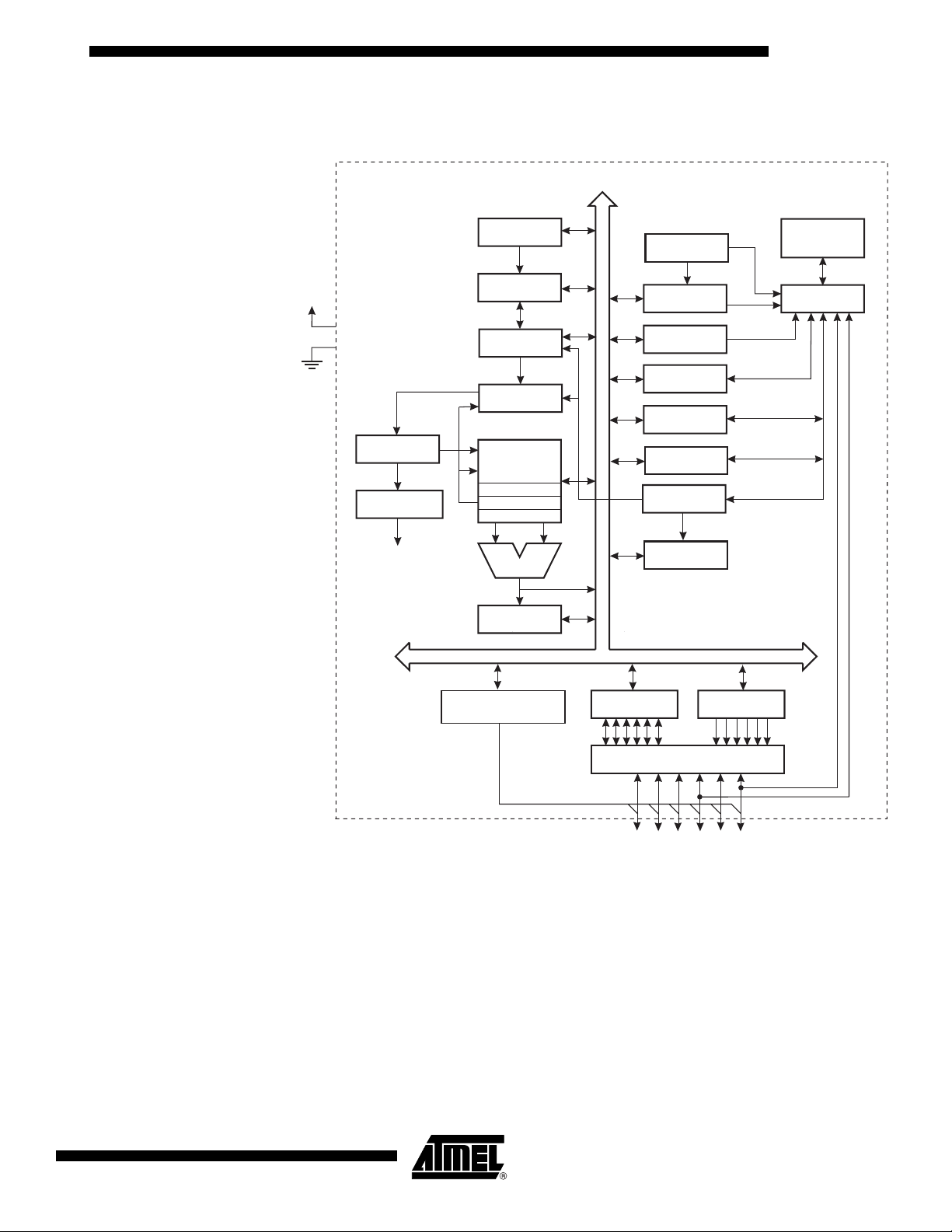

Block Diagram Figure 2. Block Diagram

ATtiny13

8-BIT DATABUS

VCC

GND

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

STACK

POINTER

SRAM

PROGRAM

COUNTER

PROGRAM

FLASH

GENERAL

PURPOSE

REGISTERS

X

Y

Z

ALU

STATUS

REGISTER

WATCHDOG

OSCILLATOR

WATCHDOG

TIMER

MCU CONTROL

REGISTER

MCU STATUS

REGISTER

TIMER/

COUNTER0

INTERRUPT

UNIT

PROGRAMMING

LOGIC

DATA

EEPROM

CALIBRATED

INTERNAL

TOR

OSCILLA

TIMING AND

CONTROL

ADC /

ANALOG COMPARATOR

DATA REGISTER

PORT B

PORT B DRIVERS

PB0-PB5

DATA DIR.

REG.PORT B

RESET

CLKI

The AVR core combines a rich instruction set with 32 general purpose working registers.

All the 32 registers are directly connected to the Arithmetic Logic Unit (ALU), allowing

two independent registers to be accessed in one single instruction executed in one clock

cycle. The resulting architecture is more code ef ficient while a chieving th roughputs up to

ten times faster than conventional CISC microcontrollers.

The ATtiny13 provides the following features: 1K byte of In-System Programmable

Flash, 64 bytes EEPROM, 64 bytes SRAM, 6 general purpose I/O line s, 32 ge neral pu rpose working registers, one 8-bit Timer/Counter with compare modes, Internal and

External Interrupts, a 4-channel, 10-bit ADC, a programmable Watchdog Timer with

internal Oscillator, and three software selectable power saving modes. The Idle mode

stops the CPU while allowing the SRAM, Timer/Counter, ADC, Analog Comparator, and

2535HS–AVR–10/07

3

Page 4

Interrupt system to continue functioning. The Power-down mode saves the register contents, disabling all chip functions until the next Interrupt or Hardware Reset. The ADC

Noise Reduction mode stops the CPU and all I/O modules except ADC, to minimize

switching noise during ADC conversions.

The device is manufactured using Atmel’s high density non-vo latile m emo ry te chno logy.

The On-chip ISP Flash allows the Program memory to be re-programmed In-System

through an SPI serial interface, by a conventional non-volatile memory programmer or

by an On-chip boot code running on the AVR core.

The ATtiny13 AVR is supported with a full suite of program and system development

tools including: C Compilers, Macro Assemblers, Program Debugger/Simulators, In-Circuit Emulators, and Evaluation kits.

Pin Descriptions

VCC Digital supply voltage. GND Ground. Port B (PB5..PB0) Port B is a 6-bit bi-directional I/O port with internal pull-up resistors (selected for each

bit). The Port B output buffers have symmetrical drive character istics with both high sink

and source capability. As inputs, Port B pins that are externally pulled low will source

current if the pull-up resistors are activated. The Port B pins are tri-stated when a reset

condition becomes active, even if the clock is not running.

Port B also serves the functions of various special features of the ATtiny13 as listed on

page 51.

RESET

Reset input. A low level on this pin for longer than the minimum pulse length will generate a reset, even if the clock is not running. The minimum pulse length is given in Table

12 on page 31. Shorter pulses are not guaranteed to generate a reset.

Note: 1.

Data Retention Reliability Qualification results show that the projected data retention failure rate is much

less than 1 PPM over 20 years at 85°C or 100 years at 25°C.

About Code Examples

This documentation contains simple code examples that briefl y show how to use various

parts of the device. These code examples assume that the part specific header file is

included before compilation. Be aware t hat not all C c ompiler vendors in clude bit de finitions in the header files and interrupt handling in C is compiler dependent. Please

confirm with the C compiler documentation for more details.

4

ATtiny13

2535HS–AVR–10/07

Page 5

ATtiny13

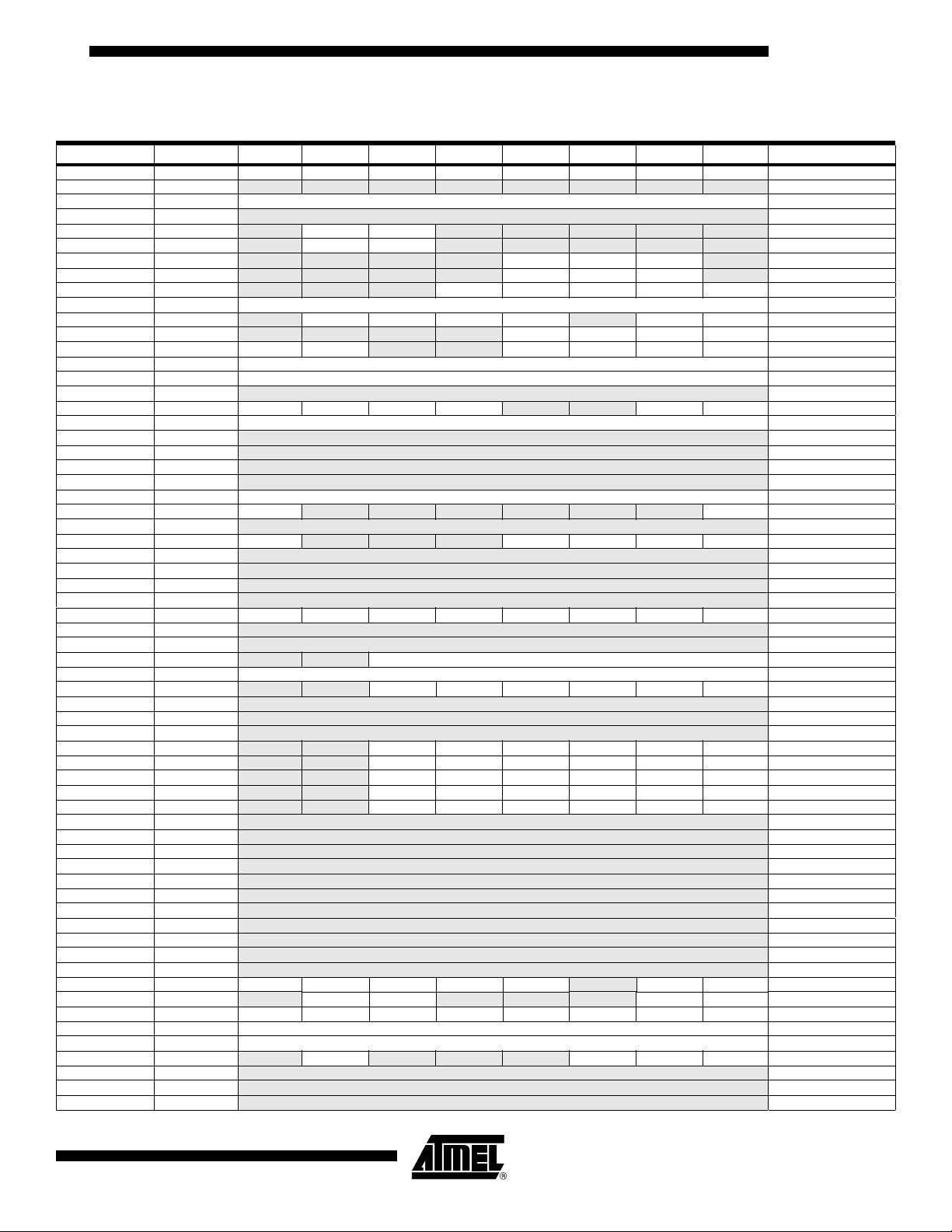

Register Summary

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Page

0x3F SREG I T H S V N Z C page 7

0x3E Reserved – – – – – – – –

0x3D SPL SP[7:0] page 9

0x3C Reserved –

0x3B GIMSK – INT0 PCIE – – – – – page 56

0x3A GIFR – INTF0 PCIF – – – – – page 56

0x39 TIMSK0 – – – – OCIE0B OCIE0A TOIE0 – page 73

0x38 TIFR0 – – – – OCF0B OCF0A TOV0 – page 74

0x37 SPMCSR – – – CTPB RFLB PGWRT PGERS

0x36 OCR0A Timer/Counter – Output Compare Register A page 73

0x35 MCUCR –PUDSESM1SM0– ISC01 ISC00 page 51

0x34 MCUSR – – – – WDRF BORF EXTRF PORF page 34

0x33 TCCR0B FOC0A FOC0B – – WGM02 CS02 CS 01 CS00 page 69

0x32 TCNT0 Timer/Counter (8-bit) page 73

0x31 OSCCAL Oscillator Calibration Register page 23

0x30 Reserved –

0x2F TCCR0A COM0A1 COM0A0 COM0B1 COM0B0 – – WGM01 WGM00 page 72

0x2E DWDR DWDR[7:0] page 97

0x2D Reserved –

0x2C Reserved –

0x2B Reserved –

0x2A Reserved –

0x29 OCR0B Timer/Counter – Output Compare Register B page 73

0x28 GTCCR TSM – – – – – – PSR10 page 76

0x27 Reserved –

0x26 CLKPR CLKPCE – – – CLKPS3 CLKPS2 CLKPS1 CLKPS0 page 25

0x25 Reserved –

0x24 Reserved –

0x23 Reserved –

0x22 Reserved –

0x21 WDTCR WDTIF WDTIE WDP3 WDCE WDE WDP2 WDP1 WDP0 page 39

0x20 Reserved –

0x1F Reserved –

0x1E EEARL – – EEPROM Address Register page 15

0x1D EEDR EEPROM Data Register page 15

0x1C EECR – – EEPM1 EEPM0 EERIE EEMPE EEPE EERE page 16

0x1B Reserved –

0x1A Reserved –

0x19 Reserved –

0x18 PORTB – – PORTB5 PORTB4 PORTB3 PORTB2 PORTB1 PORTB0 page 53

0x17 DDRB – – DDB5 DDB4 DDB3 DDB2 DDB1 D DB0 page 53

0x16 PINB

0x15 PCMSK – – PCINT5 PCINT4 PCINT3 PCINT2 PCINT1 PCINT0 page 57

0x14 DIDR0

0x13 Reserved

0x12 Reserved –

0x11 Reserved –

0x10 Reserved

0x0F Reserved

0x0E Reserved –

0x0D Reserved

0x0C Reserved

0x0B Reserved –

0x0A Reserved

0x09 Reserved

0x08 ACSR ACD ACBG

0x07 ADMUX – REFS0 ADLAR – – – MUX1 MUX0 page 91

0x06 ADCSRA ADEN ADSC

0x05 ADCH ADC Data Register High Byte page 93

0x04 ADCL ADC Data Register Low Byte page 93

0x03 ADCSRB –ACME– – – ADTS2 ADTS1 ADTS0 page 94

0x02 Reserved

0x01 Reserved

0x00 Reserved –

– – PINB5 PINB4 PINB3 PINB2 PINB1 PINB0 page 53

– – ADC0D ADC2D ADC3D ADC1D AIN1D AIN0D page 79, page 94

–

–

–

–

–

–

–

ACO ACI ACIE – ACIS1 ACIS0 page 77

ADATE ADIF ADIE ADPS2 ADPS1 ADPS0 page 92

–

–

SELFPRGEN

page 100

2535HS–AVR–10/07

5

Page 6

Note: 1. For compatibility with future devices, reserved bits should be written to zero if accessed. Reserved I/O memory addresses

should never be written.

2. I/O Registers within the address range 0x00 - 0x1F are directly bit-accessible using the SBI and CBI instructions. In these

registers, the value of single bits can be checked by using the SBIS and SBIC instructions.

3. Some of the Status Flags are cleared by writing a logica l one to them. Note that, unlike most other AVRs, the CBI and SBI

instructions will only operation the specified bit, and can therefore be used on registers containing such Status Flags. The

CBI and SBI instructions work with registers 0x00 to 0x1F only.

6

ATtiny13

2535HS–AVR–10/07

Page 7

ATtiny13

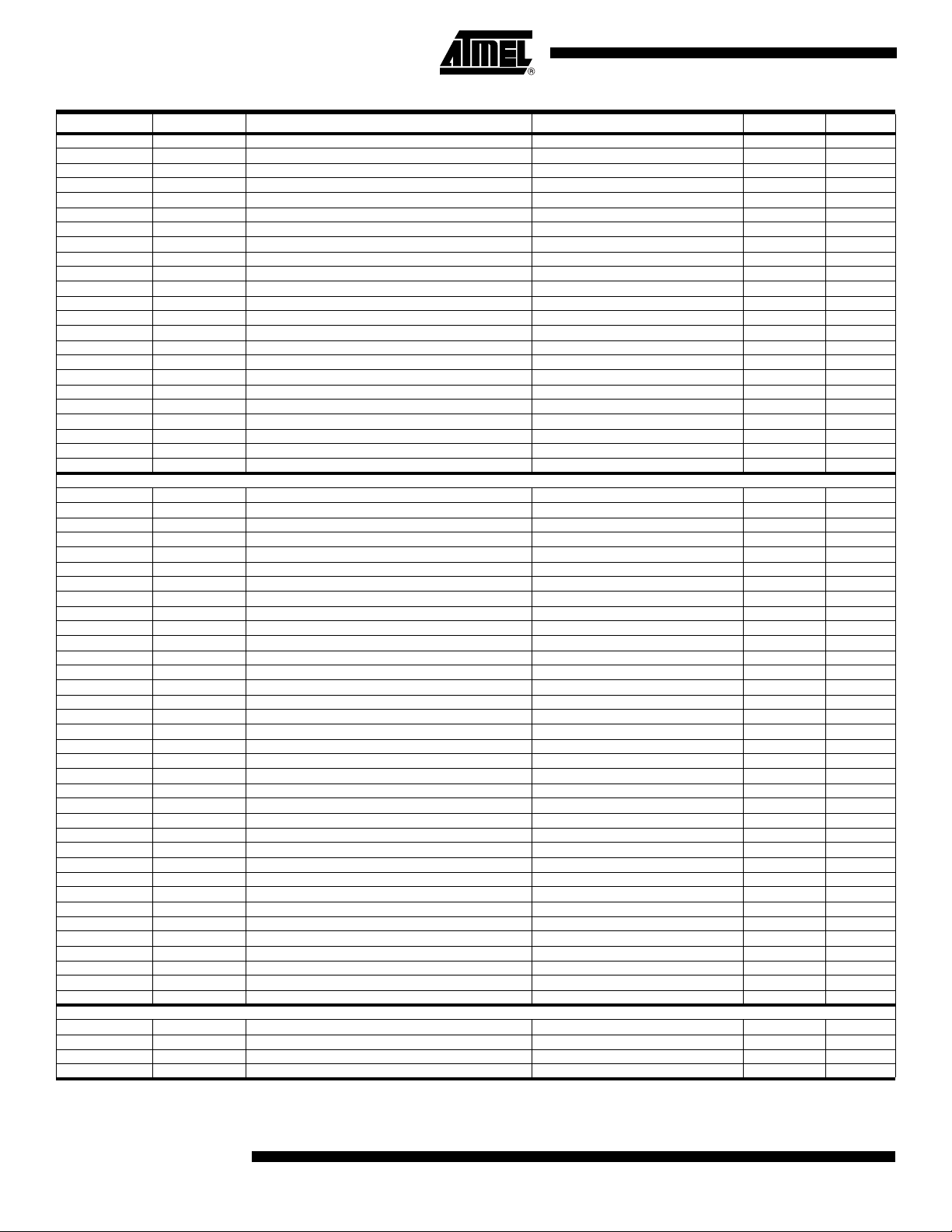

Instruction Set Summary

Mnemonics Operands Description Operation Flags #Clocks

ARITHMETIC AND LOGIC INSTRUCTIONS

ADD Rd, Rr Add two Registers Rd ← Rd + Rr Z,C,N,V,H 1

ADC Rd, Rr Add with Carry two Registers Rd ← Rd + Rr + C Z,C,N,V,H 1

ADIW Rdl,K Add Immediate to Word Rdh:Rdl ← Rdh:Rdl + K Z,C,N,V,S 2

SUB Rd, Rr Subtract two Registers Rd ← Rd - Rr Z,C,N,V,H 1

SUBI Rd, K Subtract Constant from Register Rd ← Rd - K Z,C,N,V,H 1

SBC Rd, Rr Subtract with Carry two Registers Rd ← Rd - Rr - C Z,C,N,V,H 1

SBCI Rd, K Subtract with Carry Constant from Reg. Rd ← Rd - K - C Z,C,N,V,H 1

SBIW Rdl,K Subtract Immediate from Word Rdh:Rdl ← Rdh:Rdl - K Z,C,N,V,S 2

AND Rd, Rr Logical AND Registers Rd ← Rd • Rr Z,N,V 1

ANDI Rd, K Logical AND Register and Constant Rd ← Rd • K Z,N,V 1

OR Rd, Rr Logical OR Registers Rd ← Rd v Rr Z,N,V 1

ORI Rd, K Logical OR Register and Constant Rd ← Rd v K Z,N,V 1

EOR Rd, Rr Exclusive OR Registers Rd ← Rd ⊕ Rr Z,N,V 1

COM Rd One’s Complement Rd ← 0xFF − Rd Z,C,N,V 1

NEG Rd Two’s Complement Rd ← 0x00 − Rd Z,C,N,V,H 1

SBR Rd,K Set Bit(s) in Register Rd ← Rd v K Z,N,V 1

CBR Rd,K Clear Bit(s) in Register Rd ← Rd • (0xFF - K) Z,N,V 1

INC Rd Increment Rd ← Rd + 1 Z,N,V 1

DEC Rd Decrement Rd ← Rd − 1 Z,N,V 1

TST Rd Test for Zero or Minus Rd ← Rd • Rd Z,N,V 1

CLR Rd Clear Register Rd ← Rd ⊕ Rd Z,N,V 1

SER Rd Set Register Rd ← 0xFF None 1

BRANCH INSTRUCTIONS

RJMP k Relative Jump PC ← PC + k + 1 None 2

IJMP Indirect Jump to (Z) PC ← Z None 2

RCALL k Relative Subroutine Call PC ← PC + k + 1 None 3

ICALL Indirect Call to (Z) PC ← ZNone3

RET Subroutine Return PC ← STACK None 4

RETI Interrupt Return PC ← STACK I 4

CPSE Rd,Rr Compare, Skip if Equal if (Rd = Rr) PC ← PC + 2 or 3 None 1/2/3

CP Rd,Rr Compare Rd − Rr Z, N,V,C,H 1

CPC Rd,Rr Compare with Carry Rd − Rr − C Z, N,V,C,H 1

CPI Rd,K Compare Register with Immediate Rd − K Z, N,V,C,H 1

SBRC Rr, b Skip if Bit in Register Cleared if (Rr(b)=0) PC ← PC + 2 or 3 None 1 / 2/3

SBRS Rr, b Skip if Bit in Register is Set if (Rr(b)=1) PC ← PC + 2 or 3 None 1 /2/3

SBIC P, b Skip if Bit in I/O Register Cleared if (P(b)=0) PC ← PC + 2 or 3 None 1/2/3

SBIS P, b Skip if Bit in I/O Register is Set if (P(b)=1) PC ← PC + 2 or 3 None 1/2/3

BRBS s, k Branch if Status Flag Set if (SREG(s) = 1) then PC←PC+k + 1 None 1/2

BRBC s, k Branch if Status Flag Cleared if (SREG(s) = 0) then PC←PC+k + 1 None 1/2

BREQ k Branch if Equal if (Z = 1) then PC ← PC + k + 1 None 1/2

BRNE k Branch if Not Equal if (Z = 0) then PC ← PC + k + 1 None 1/2

BRCS k Branch if Carry Set if (C = 1) then PC ← PC + k + 1 None 1/2

BRCC k Branch if Carry Cleared if (C = 0) then PC ← PC + k + 1 None 1/2

BRSH k Branch if Same or Higher if (C = 0) then PC ← PC + k + 1 None 1/2

BRLO k Branch if Lower if (C = 1) then PC ← PC + k + 1 None 1/2

BRMI k Branch if Minus if (N = 1) then PC ← PC + k + 1 None 1/2

BRPL k Branch if Plus if (N = 0) then PC ← PC + k + 1 None 1/2

BRGE k Branch if Greater or Equal, Signed if (N ⊕ V= 0) then PC ← PC + k + 1 None 1/2

BRLT k Branch if Less Than Zero, Signed if (N ⊕ V= 1) then PC ← PC + k + 1 None 1/2

BRHS k Branch if Half Carry Flag Set if (H = 1) then PC ← PC + k + 1 None 1/2

BRHC k Branch if Half Carry Flag Cleared if (H = 0) then PC ← PC + k + 1 None 1/2

BRTS k Branch if T Flag Set if (T = 1) then PC ← PC + k + 1 None 1/2

BRTC k Branch if T Flag Cleared if (T = 0) then PC ← PC + k + 1 None 1/2

BRVS k Branch if Overflow Flag is Set if (V = 1) then PC ← PC + k + 1 None 1/2

BRVC k Branch if Overflow Flag is Cleared if (V = 0) then PC ← PC + k + 1 None 1/2

BRIE k Branch if Interrupt Enabled if ( I = 1) then PC ← PC + k + 1 None 1/2

BRID k Branch if Interrupt Disabled if ( I = 0) then PC ← PC + k + 1 None 1/2

BIT AND BIT-TEST INSTRUCTIONS

SBI P,b Set Bit in I/O Register I/O(P,b) ← 1None2

CBI P,b Clear Bit in I/O Register I/O(P,b) ← 0None2

LSL Rd Logical Shift Left Rd(n+1) ← Rd(n), Rd(0)

LSR Rd Logical Shift Right Rd(n) ← Rd(n+1), Rd(7) ← 0 Z,C,N,V 1

ROL Rd Rotate Left Through Carry Rd(0)←C,Rd(n+1)← Rd(n),C←Rd(7) Z,C,N,V 1

← 0 Z,C,N,V 1

2535HS–AVR–10/07

7

Page 8

Mnemonics Operands Description Operation Flags #Clocks

ROR Rd Rotate Right Th rough Carry Rd(7)←C,Rd(n)← Rd(n+1),C←Rd(0) Z,C,N,V 1

ASR Rd Arithmetic Shift Right Rd(n) ← Rd(n+1), n=0..6 Z,C,N,V 1

SWAP Rd Swap Nibble s Rd(3..0)←Rd(7..4),Rd(7..4)←Rd(3..0) None 1

BSET s Flag Set SREG(s) ← 1 SREG(s) 1

BCLR s Flag Clear SREG(s) ← 0 SREG(s) 1

BST Rr, b Bit Store from Register to T T ← Rr(b) T 1

BLD Rd, b Bit load from T to Register Rd(b) ← TNone1

SEC Set Carry C ← 1C1

CLC Clear Carry C ← 0 C 1

SEN Set Negative Flag N ← 1N1

CLN Clear Negative Flag N ← 0 N 1

SEZ Set Zero Flag Z ← 1Z1

CLZ Clear Zero Flag Z ← 0 Z 1

SEI Globa l Inte rru pt Enable I ← 1I1

CLI Global Interrupt Disable I ← 0 I 1

SES Set Signed Test Flag S ← 1S1

CLS Clear Signed Test Flag S ← 0 S 1

SEV Set Twos Complement Overflow. V ← 1V1

CLV Clear Twos Complement Overflow V ← 0 V 1

SET Set T in SREG T ← 1T1

CLT Clear T in SREG T ← 0 T 1

SEH Set Half Carry Flag in SREG H ← 1H1

CLH Clear Half Carry Flag in SREG H ← 0 H

DATA TRANSFER INSTRUCTIONS

MOV Rd, Rr Move Between Registers Rd ← Rr None 1

MOVW Rd, Rr Copy Register Word

LDI Rd, K Load Immediate Rd ← KNone1

LD Rd, X Load Indirect Rd ← (X) None 2

LD Rd, X+ Load Indirect and Post-Inc. Rd ← (X), X ← X + 1 None 2

LD Rd, - X Load Indirect and Pre-Dec. X ← X - 1, Rd ← (X) None 2

LD Rd, Y Load Indirect Rd ← (Y) None 2

LD Rd, Y+ Load Indirect and Post-Inc. Rd ← (Y), Y ← Y + 1 None 2

LD Rd, - Y Load Indirect and Pre-Dec. Y ← Y - 1, Rd ← (Y) None 2

LDD Rd,Y+q Load Indirect with Displacement Rd ← (Y + q) None 2

LD Rd, Z Load Indirect Rd ← (Z) None 2

LD Rd, Z+ Load Indirect and Post-Inc. Rd ← (Z), Z ← Z+1 None 2

LD Rd, -Z Load Indirect and Pre-Dec. Z ← Z - 1, Rd ← (Z) None 2

LDD Rd, Z+q Load Indirect with Displacement Rd ← (Z + q) None 2

LDS Rd, k Load Direct from SRAM Rd ← (k) None 2

ST X, Rr Store Indirect (X) ← Rr None 2

ST X+, Rr Store Indirect and Post-Inc. (X) ← Rr, X ← X + 1 None 2

ST - X, Rr Store Indirect and Pre-Dec. X ← X - 1, (X) ← Rr None 2

ST Y, Rr Store Indirect (Y) ← Rr None 2

ST Y+, Rr Store Indirect and Post-Inc. (Y) ← Rr, Y ← Y + 1 None 2

ST - Y, Rr Store Indirect and Pre-Dec. Y ← Y - 1, (Y) ← Rr None 2

STD Y+q,Rr Store Indirect with Displacement (Y + q) ← Rr None 2

ST Z, Rr Store Indirect (Z) ← Rr None 2

ST Z+, Rr Store Indirect and Post-Inc. (Z) ← Rr, Z ← Z + 1 None 2

ST -Z, Rr Store Indirect and Pre-Dec. Z ← Z - 1, (Z) ← Rr None 2

STD Z+q,Rr Store Indirect with Displacement (Z + q) ← Rr None 2

STS k, Rr Store Direct to SRAM (k) ← Rr None 2

LPM Load Program Memory R0 ← (Z) None 3

LPM Rd, Z Load Program Memory Rd ← (Z) None 3

LPM Rd, Z+ Load Program Memory and Post-Inc Rd ← (Z), Z ← Z+1 None 3

SPM Store Program Memory (z) ← R1:R0 None

IN Rd, P In Port Rd ← PNone1

OUT P, Rr Out Port P ← Rr None 1

PUSH Rr Push Register on Stack STACK ← Rr None 2

POP Rd Pop Register from Stack Rd ← STACK None 2

MCU CONTROL INSTRUCTIONS

NOP No Operation None 1

SLEEP Sleep (see specific descr. for Sleep function) None 1

WDR Watchdog Reset (see specific descr. for WDR/Timer) None 1

BREAK Break For On-chip Debug Only None N/A

Rd+1:Rd ← Rr+1:Rr

None 1

1

8

ATtiny13

2535HS–AVR–10/07

Page 9

Ordering Information

Speed (MHz)

(3)

10 1.8 - 5.5

Power Supply Ordering Code Package

ATtiny13V-10PI

ATtiny13V-10PU

ATtiny13V-10SI

ATtiny13V-10SU

(2)

(2)

ATtiny13V-10SSI

ATtiny13V-10SSU

ATtiny13V-10MU

(2)

ATtiny13V-10MMU

(2)

I

(2)

8P3

8P3

8S2

8S2

S8S1

S8S1

20M1

10M1

ATtiny13

(1)

Operation Range

Industrial

(-40°C to 85°C)

8P3

8P3

8S2

8S2

S8S1

S8S1

20M1

10M1

Industrial

(-40°C to 85°C)

20 2.7 - 5.5

ATtiny13-20PI

ATtiny13-20PU

ATtiny13-20SI

ATtiny13-20SU

(2)

(2)

ATtiny13-20SSI

ATtiny13-20SSU

ATtiny13-20MU

ATtiny13-20MMU

(2)

(2)

(2)

Notes: 1. This device can also be supplied in wafer form. Please contact your local Atmel sales office for detailed ordering information

and minimum quantities.

2. Pb-free packaging alternative, complies to the European Directive for Restriction of Hazardous Substances (RoHS directive). Also Halide free and fully Green

3. For Speed vs. V

CC

, see

Maximum Speed vs. VCC on page 123

.

Package Type

8P3 8-lead, 0.300" Wide, Plastic Dual Inline Package (PDIP)

8S2 8-lead, 0.209" Wide, Plastic Small Outline Package (EIAJ SOIC)

S8S1 8-lead, 0.150" Wide, Plastic Gull-Wing Small Outline (JEDEC SOIC)

20M1

10M1

2535HS–AVR–10/07

20-pad, 4 x 4 x 0.8 mm Body, Lead Pitch 0.50 mm, Micro Lead Frame Package (MLF)

10-pad, 3 x 3 x 1 mm Body, Lead Pitch 0.50 mm, Micro Lead Frame Package (MLF)

9

Page 10

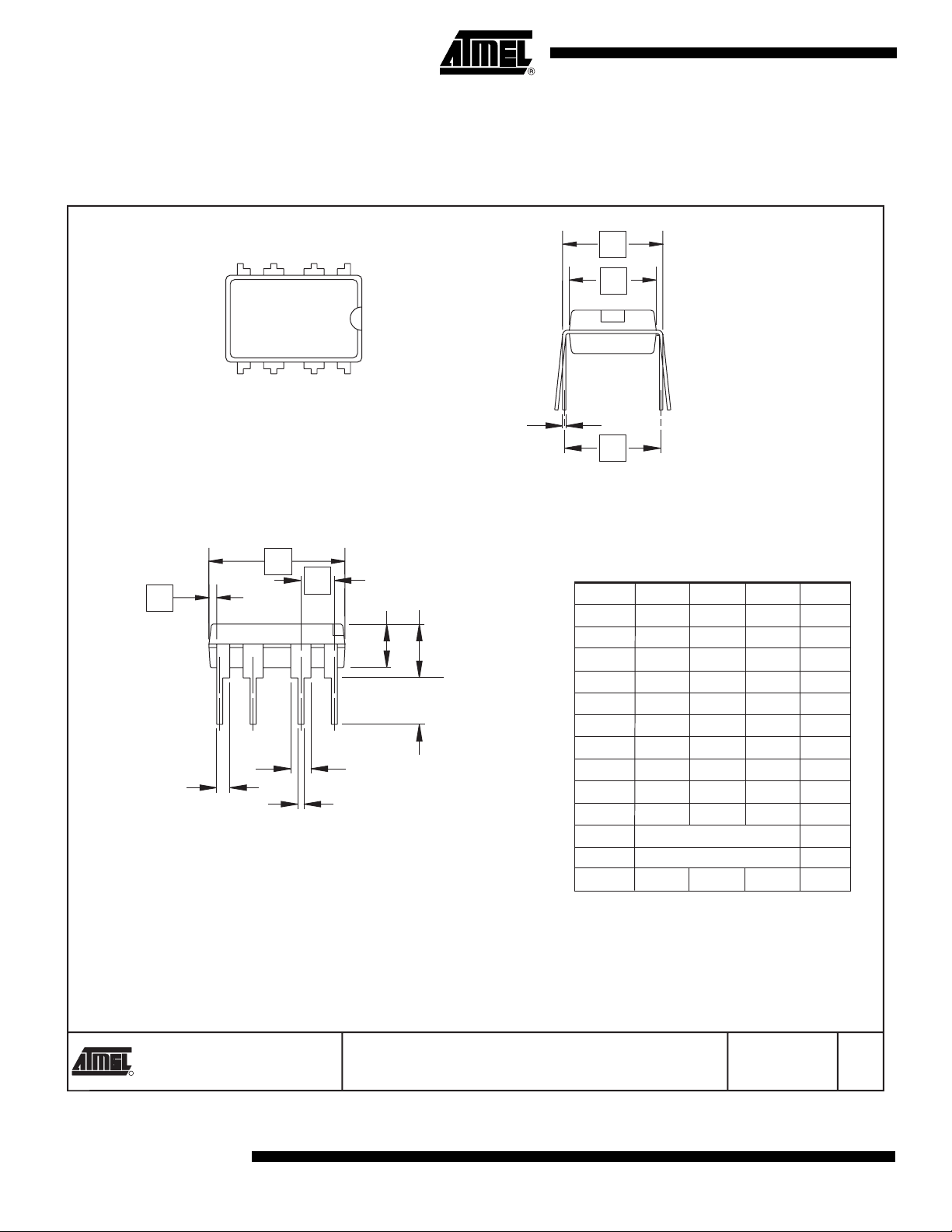

Packaging Information

8P3

D1

b3

4 PLCS

Top View

D

e

Side View

1

E

E1

N

c

eA

End View

COMMON DIMENSIONS

(Unit of Measure = inches)

b

b2

A2 A

SYMBOL

A 0.210 2

A2 0.115 0.130 0.195

b 0.014 0.018 0.022 5

b2 0.045 0.060 0.070 6

b3 0.030 0.039 0.045 6

c 0.008 0.010 0.014

D 0.355 0.365 0.400 3

L

D1 0.005 3

E 0.300 0.310 0.325 4

E1 0.240 0.250 0.2803

e 0.100 BSC

eA 0.300 BSC 4

L 0.115 0.130 0.150 2

MIN

NOM

MAX

NOTE

Notes: 1. This drawing is for general information only; refer to JEDEC Drawing MS-001, Variation BA for additional information.

10

2. Dimensions A and L are measured with the package seated in JEDEC seating plane Gauge GS-3.

3. D, D1 and E1 dimensions do not include mold Flash or protrusions. Mold Flash or protrusions shall not exceed 0.010 inch.

4. E and eA measured with the leads constrained to be perpendicular to datum.

5. Pointed or rounded lead tips are preferred to ease insertion.

6. b2 and b3 maximum dimensions do not include Dambar protrusions. Dambar protrusions shall not exceed 0.010 (0.25 mm).

TITLE

2325 Orchard Parkway

R

San Jose, CA 95131

8P3, 8-lead, 0.300" Wide Body, Plastic Dual

In-line Package (PDIP)

ATtiny13

DRAWING NO.

8P3

2535HS–AVR–10/07

01/09/02

REV.

B

Page 11

8S2

θ

1

N

E

TOP VIEW

C

E1

END VIEW

A

b

L

A1

e

D

SIDE VIEW

ATtiny13

C

1

TOP VIEW

E

N

θ

E1

L

END VIEW

e

D

SIDE VIEW

Notes: 1. This drawing is for general information only; refer to EIAJ Drawing EDR-7320 for additional information.

2. Mismatch of the upper and lower dies and resin burrs are not included.

3. It is recommended that upper and lower cavities be equal. If they are different, the larger dimension shall be regarded.

4. Determines the true geometric position.

5. Values b,C apply to plated terminal. The standard thickness of the plating layer shall measure between 0.007 to .021 mm.

b

A

SYMBOL

A1

A 1.70 2.16

A1 0.05 0.25

b 0.35 0.48 5

C 0.15 0.35 5

D 5.13 5.35

E1 5.18 5.40 2, 3

E 7.70 8.26

L 0.51 0.85

θ 0° 8°

e 1.27 BSC 4

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

NOM

MAX

NOTE

4/7/06

2325 Orchard Parkway

R

San Jose, CA 95131

2535HS–AVR–10/07

TITLE

8S2, 8-lead, 0.209" Body, Plastic Small

Outline Package (EIAJ)

DRAWING NO.

8S2 D

REV.

11

Page 12

S8S1

3

Top View

1

2

H

N

e

B

A

D

Side View

SYMBOL

A – – 1.75

A2

C

L

E

End View

Note:

This drawing is for general information only. Refer to JEDEC Drawing MS-012 for proper dimensions, tolerances, datums, etc.

B – – 0.51

C – – 0.25

D – – 5.00

E – – 4.00

e 1.27 BSC

H – – 6.20

L – – 1.27

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

NOM

MAX

NOTE

12

2325 Orchard Parkway

R

San Jose, CA 95131

ATtiny13

TITLE

8S1, 8-lead (0.150" Wide Body), Plastic Gull Wing

Small Outline (JEDEC SOIC)

DRAWING NO.

8S1 A

2535HS–AVR–10/07

10/10/01

REV.

Page 13

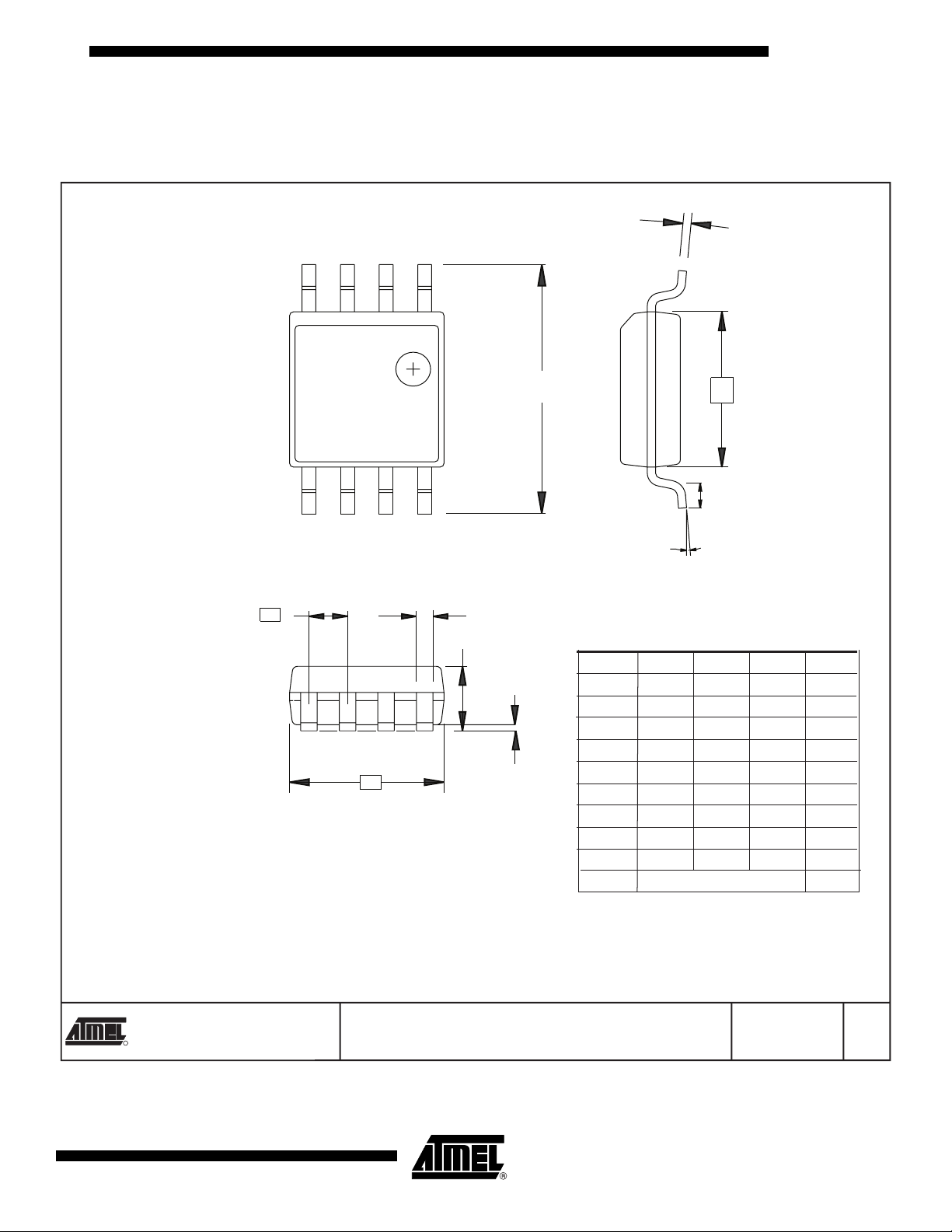

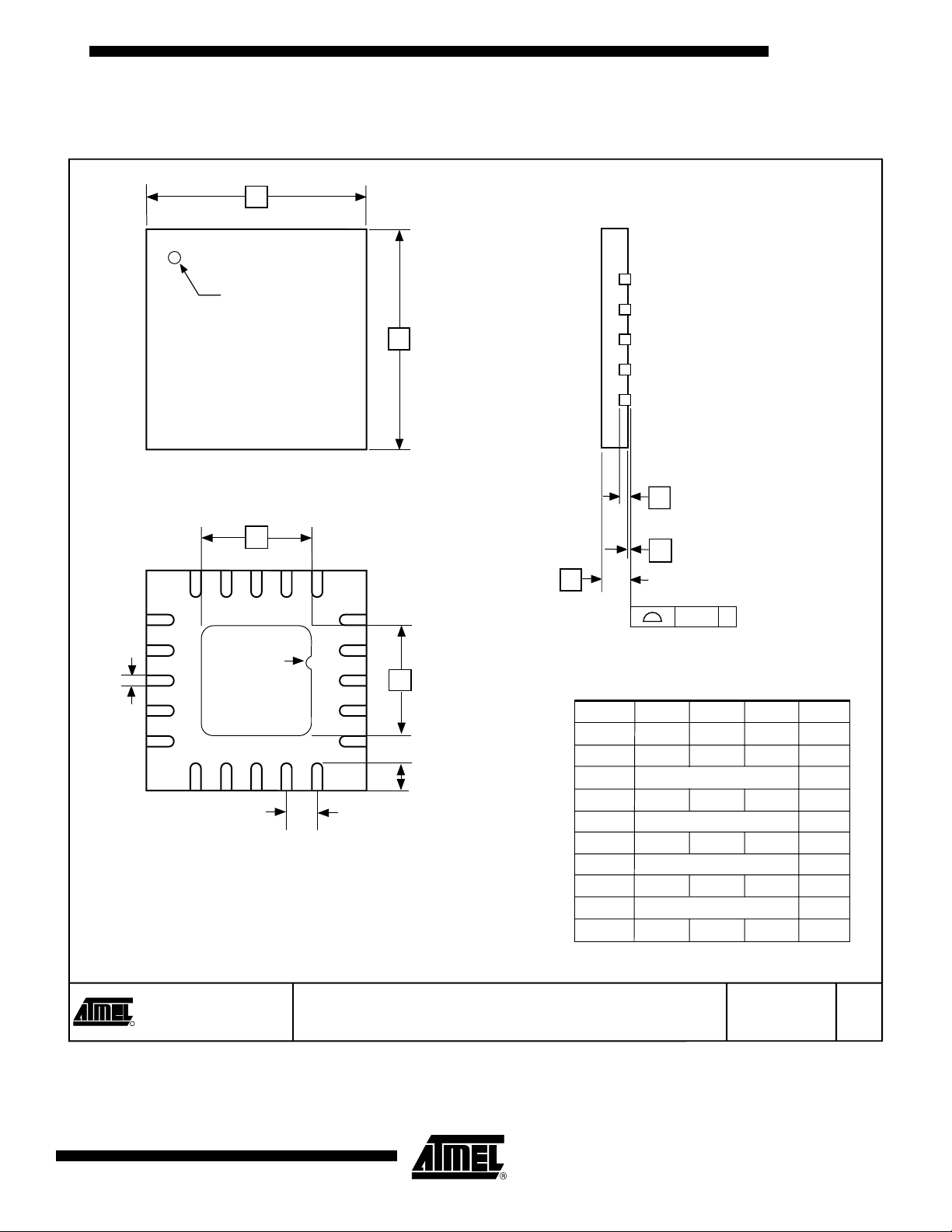

20M1

ATtiny13

D

1

Pin 1 ID

2

3

E

TOP VIEW

D2

1

Pin #1

Notch

(0.20 R)

2

3

E2

b

L

e

BOTTOM VIE W

Reference JEDEC Standard MO-220, Fig. 1 (SAW Singulation) WGGD-5.

Note:

SIDE VIEW

A2

A1

A

0.08

C

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A 0.70 0.75 0.80

A1 – 0.01 0.05

A2 0.20 REF

b 0.18 0.23 0.30

D 4.00 BSC

D2 2.45 2.60 2.75

E 4.00 BSC

E2 2.45 2.60 2.75

e 0.50 BSC

L 0.35 0.40 0.55

MIN

NOM

MAX

NOTE

2325 Orchard Parkway

R

San Jose, CA 95131

2535HS–AVR–10/07

TITLE

20M1, 20-pad, 4 x 4 x 0.8 mm Body, Lead Pitch 0.50 mm,

2.6 mm Exposed Pad, Micro Lead Frame Package (MLF)

DRAWING NO.

20M1

10/27/04

REV.

A

13

Page 14

10M1

D

E

E1

Pin 1 ID

y

SIDE VIEW

TOP VIEW

A

D1

L

BOTTOM VIEW

K

1

2

b

e

SYMBOL

A 0.80 0.90 1.00

A1 0.00 0.02 0.05

b 0.18 0.25 0.30

D 2.90 3.00 3.10

D1 1.40 – 1.75

E 2.90 3.00 3.10

E1 2.20 – 2.70

e 0.50

L 0.30 – 0.50

y – – 0.08

K 0.20 – –

A1

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

NOM

MAX

NOTE

14

Notes: 1. This package conforms to JEDEC reference MO-229C, Variation VEED-5.

2. The terminal #1 ID is a Lasser-marked Feature.

TITLE

2325 Orchard Parkway

R

San Jose, CA 95131

10M1, 10-pad, 3 x 3 x 1.0 mm Body, Lead Pitch 0.50 mm,

1.64 x 2.60 mm Exposed Pad, Micro Lead Frame Package

ATtiny13

DRAWING NO.

10M1

2535HS–AVR–10/07

7/7/06

REV.

A

Page 15

ATtiny13

Errata The revision letter in this section refers to the revision of the ATtiny13 device.

ATtiny13 Rev. D • EEPROM can not be written below 1.9 Volt

1. EEPROM can not be written below 1.9 Volt

Writing the EEPROM at V

Problem Fix/Workaround

Do not write the EEPROM when V

ATtiny13 Rev. B • Wrong values read after Erase Only operation

• High Voltage Serial Programming Flash, EEPROM, Fuse and Lock Bits may fail

• Device may lock for further programming

• debugWIRE communication not blocked by lock-bits

• Watchdog Timer Interrupt disabled

• EEPROM can not be written below 1.9 Volt

1. Wrong values read after Erase Only operation

At supply voltages below 2.7 V, an EEPROM location that is erased by the Erase

Only operation may read as programmed (0x00).

Problem Fix/Workaround

If it is necessary to read an EEPROM location after Erase Only, use an Atomic Write

operation with 0xFF as data in order to erase a location. In any case, the Write Only

operation can be used as intended. Thus no special considerations are needed as

long as the erased location is not read before it is programmed.

below 1.9 volts might fail.

CC

is below 1.9 volts.

CC

2. High Voltage Serial Programming Flash, EEPROM, Fuse and Lock Bits may

fail

Writing to any of these locations and bits may in some occasions fail.

Problem Fix/Workaround

After a writing has been initiated, always observe the RDY/BSY

should fail, rewrite until the RDY/BSY

revision D.

3. Device may lock for further programming

Special combinations of fuse bits will lock the device for further programming effectively turning it into an OTP device. The following combinations of settings/fuse bits

will cause this effect:

– 128 kHz internal oscillator (CKSEL[1..0] = 11), shortest start-up time

(SUT[1..0] = 00), Debugwire enabled (DWEN = 0) or Reset disabled

RSTDISBL = 0.

– 9.6 MHz internal oscillator (CKSEL[1..0] = 10), shortest start-up time

(SUT[1..0] = 00), Debugwire enabled (DWEN = 0) or Reset disabled

RSTDISBL = 0.

– 4.8 MHz internal oscillator (CKSEL[1..0] = 01), shortest start-up time

(SUT[1..0] = 00), Debugwire enabled (DWEN = 0) or Reset disabled

RSTDISBL = 0.

Problem fix/ Workaround

Avoid the above fuse combinations. Selecting longer start-up time will eliminate the

problem.

verifies a correct writing. This will be fixed in

signal. If the writing

2535HS–AVR–10/07

15

Page 16

4. debugWIRE communication not blocked by lock-bits

When debugWIRE on-chip debug is enabled (DWEN = 0), the contents of program

memory and EEPROM data memory can be read even if the lock-bits are set to

block further reading of the device.

Problem fix/ Workaround

Do not ship products with on-chip debug of the tiny13 enabled.

5. Watchdog Timer Interrupt disabled

If the watchdog timer interrupt flag is not cleared before a new timeout occurs, the

watchdog will be disabled, and the interrupt flag will automatically be cleared. This is

only applicable in interrupt only mode. If the Watchdog is configured to reset the

device in the watchdog time-out following an interrupt, the device works correctly.

Problem fix / Workaround

Make sure there is enough time to always service the first timeout event before a

new watchdog timeout occurs. This is done by selecting a long enough time-out

period.

6. EEPROM can not be written below 1.9 Volt

Writing the EEPROM at V

Problem Fix/Workaround

Do not write the EEPROM when V

below 1.9 volts might fail.

CC

is below 1.9 volts.

CC

ATtiny13 Rev. A Revision A has not been sampled.

16

ATtiny13

2535HS–AVR–10/07

Page 17

ATtiny13

Datasheet Revision History

Changes from Rev. 2535G-01/07 to Rev. 2535H-10/07

Please note that the referring page numbers in this section are referring to this document. The referring revision in this section are referring to the document revision.

1. Updated Features o n page 1.

2. Updated Pin Configurations on page 2.

3. Added Data Retention on page 4.

4. Updated Assembly Code Exam ple

5. Updated Table 21 in Alternate Functions of Port B on page 51.

6. Updated Bit 5 description in General Interrupt Mask Register – GIMSK on

page 56.

7. Updated ADC Voltage Reference on page 87.

8. Updated Calibration Byte on page 106.

9. Updated Read Calibration Byte on page 110.

10. Updated Table 51 in Serial Programming Characteristics on page 111.

11. Updated Algorithm in Enter High-voltage Serial Programming Mode on

page 113.

12. Updated Read Calibration Byte on page 118.

13. Updated values in External Clock Drive on page 122.

14. Updated Ordering Information on page 9.

15. Updated Packaging Information on page 10.

(1)

on page 37.

Changes from Rev. 2535F-04/06 to Rev. 2535G-01/07

Changes from Rev. 2535E-10/04 to Rev. 2535F-04/06

Changes from Rev. 2535D-04/04 to Rev. 2535E-10/04

1. Removed Preliminary.

2. Updated Table 12 on page 31, Table 16 on page 39,Table 51 on page 111.

3. Removed Note from Table 15 on pag e 35.

4. Updated Bit 6 – ACBG: An alog Comparator Bandgap Select on page 78.

5. Updated Prescaling and Conversion Timing on page 83.

6. Updated Figure 56 on page 111.

7. Updated DC Characteristics on page 120.

8. Updated Ordering Information on page 9.

9. Updated Packaging Information on page 10.

1. Revision not published.

1. Bits EEMWE/EEWE changed to EEMPE/EEPE in document.

2. Updated Pinout ATtiny13 on page 2.

3. Updated “Write Fuse Low Bit s” in Ta ble 55 o n page 117 , Ta ble 57 on page

122.

2. Added Pin Change Interrupt Timing on page 54.

4. Updated General Interrupt Mask Register – GIMSK on page 56.

5. Updated Pin Change Mask Register – PCMSK on page 57.

6. Updated item 4 in Serial Programming Algorithm on page 108.

2535HS–AVR–10/07

17

Page 18

Changes from Rev. 2535C-02/04 to Rev. 2535D-04/04

Changes from Rev. 2535B-01/04 to Rev. 2535C-02/04

7. Updated Enter High-voltage Serial Programming Mode on page 113.

8. Updated DC Characteristics on page 120.

9. Updated Typical Characteristics on page 125.

10. Updated Ordering Information on page 9.

11. Updated Packaging Information on page 10.

12. Updated Errata on page 15.

1. Maximum Speed Grades changed

- 12MHz to 10MHz

- 24MHz to 20MHz

2. Updated Serial Programming Instruction Set on page 110.

3. Updated Maximum Speed vs. V

4. Updated Ordering Information on page 9

1. C-code examples updated to use legal IAR syntax.

2. Replaced occurrences of WDIF with WDTIF and WDIE with WDTIE.

3. Updated Stack Pointer on page 9.

4. Updated Calibrated Internal RC Oscillator on page 23.

5. Updated Oscillator Calibration Register – OSCCAL on page 23.

6. Updated typo in introduction on Watchdog Timer on page 36.

7. Updated ADC Conversion Time on page 85.

8. Updated Serial Downloading on page 107.

9. Updated Electrical Characteristics on page 120.

10. Updated Ordering Information on page 9.

11. Removed rev. C from Errata on page 15.

on page 123

CC

Changes from Rev. 2535A-06/03 to Rev. 2535B-01/04

18

ATtiny13

1. Updated Figure 2 on page 3.

2. Updated Table 12 on page 31, Table 17 on page 41, Table 37 on page 92

and Table 57 on page 122.

3. Updated Calibrated Internal RC Oscillator on page 23.

4. Updated the whole Watchdog Timer on page 36.

5. Updated Figure 54 on page 10 7 and Figure 57 on page 112.

6. Updated registers MCU Control Register – MCUCR on page 51,

Timer/Counter Control Register B – TCCR0B on page 72 and Digital Input

Disable Register 0 – DIDR0 on page 79.

7. Updated Absolute Maximum Ratings and DC Characteristics in Electrical

Characteristics on page 120.

8. Added Maximum Speed vs. V

9. Updated ADC Characteristics on page 124.

10. Updated Typical Characteristics on page 125.

11. Updated Ordering Information on page 9.

12. Updated Packaging Information on page 10.

13. Updated Errata on page 15.

14. Changed instances of EEAR to EEARL.

on page 123

CC

2535HS–AVR–10/07

Page 19

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard

warranty which is detailed in Atmel’s Terms and Condition s located on the Compa ny’s web site. The Company assumes no responsibility for any

errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without notice, and

does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are

granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are not authorized for use

as critical components in life support devices or systems.

© 2007 Atmel Corporation. All rights reserved. Atmel®, logo and combinations thereof, AVR®, AVR Studio®, and Everywhere You Are® are

registered trademarks of Atmel Corporation or its subsidiaries. Other terms and prod uct names may be trademarks of others.

2535HS–AVR–10/07

Page 20

20

ATtiny13

2535HS–AVR–10/07

Loading...

Loading...