Features

• Utilizes the AVR

• High-performance and Low-power 8-bit RISC Architecture

– 90 Powerful Instructions – Most Single Clock Cycle Execution

– 32 x 8 General Purpose Working Registers

– Up to 8 MIPS Throughput at 8 MHz

• Nonvolatile Program and Data Memory

– 1K Byte of Flash Program Memory

QuickFlash

In-System Programmab le (ATt iny12)

Endurance: 1,000 Write/Erase Cycles (ATtiny11/12)

– 64 Bytes of In-System Programmable EEPROM Data Memory (ATtiny12)

Endurance: 100,000 Write/Erase Cycles

– Programming Lock for Flash Program and EEPROM Data Security

• Peripheral Features

– Interrupt and Wake-up on Pin Change

– One 8-bit Timer/Counter with Separate Prescaler

– On-chip Analog Comparator

– Programmable Watchdog Timer with On-chip Oscillator

• Special Microcontroller Features

– Low-power Idle and Power-down Mode s

– External and Internal Interrupt Sources

– In-System Programmab le via SPI Port (A Ttiny12)

– Enhanced Power-on Reset Circuit (ATtiny12)

– Internal Calibrated RC Oscillator (ATtiny12)

• Specification

– Low-power, High-speed CMOS Process Technology

– Fully Static Operation

• Power Consumption at 4 MHz, 3V, 25°C

– Active: 2.2 mA

– Idle Mode: 0.5 mA

– Power-down Mode: <1 µA

• Packages

– 8-pin PDIP and SOIC

• ATtiny10 is the QuickFlash OTP Version of ATtiny11

• Operating Voltages

– 1.8 - 5.5V (ATtiny12V-1)

– 2.7 - 5.5V (A T t iny11L-2 and ATtiny12L-4)

– 4.0 - 5.5V (ATtiny11-6 and ATtiny12-8)

• Speed Grades

– 0 - 1 MHz (ATtiny12V-1)

– 0 - 2 MHz (ATtiny11L-2)

– 0 - 4 MHz (ATtiny12L-4)

– 0 - 6 MHz (ATtiny11-6)

– 0 - 8 MHz (ATtiny12-8)

®

RISC Architecture

™

One-time Programmable (ATtiny10)

8-bit

Microcontroller

with 1K Bytes

Flash

ATtiny10

ATtiny11

ATtiny12

Preliminary

Pin Configuration

ATtiny10/11

PDIP/SOIC

GND

1

2

3

4

(RESET) PB5

(XTAL1) PB3

(XTAL2) PB4

8

VCC

7

PB2 (T0)

6

PB1 (INT0/AIN1)

5

PB0 (AIN0)

(RESET) PB5

(XTAL1) PB3

(XTAL2) PB4

GND

ATtiny12

PDIP/SOIC

1

2

3

4

8

7

6

5

VCC

PB2 (SCK/T0)

PB1 (MISO/INT0/AIN1)

PB0 (MOSI/AIN0)

Rev. 1006B–10/99

1

Description

The ATtiny10/11/12 is a low- pow er CMO S 8-bi t micr oc on troll er based on the AVR RI SC arc hi tectur e. B y exec ut ing powe rful instructions in a single clock cycle, the ATtiny10/11/12 achieves throughputs approaching 1 MIPS per MHz, allowing the

system designer to optimize power consumption versus processing speed.

The AVR core combines a rich instruction set with 32 general-purpose working registers. All the 32 registers are directly

connected to the Arithmetic Logic Unit (ALU), allowing two independent registers to be accessed in one single instruction

executed in one clock cycle. The resulting architecture is more code efficient while achieving throughputs up to ten times

faster than conventional CISC microcontrollers.

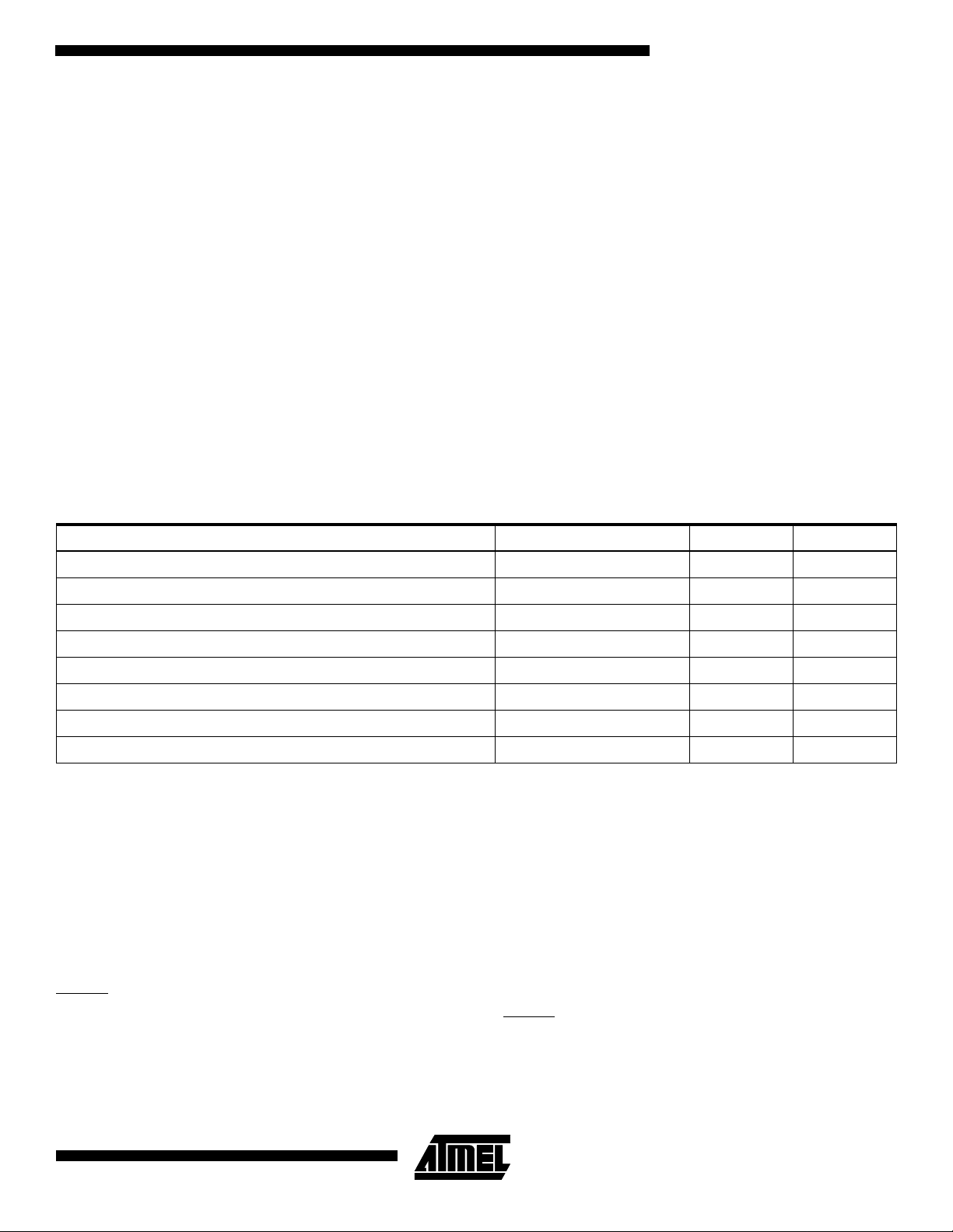

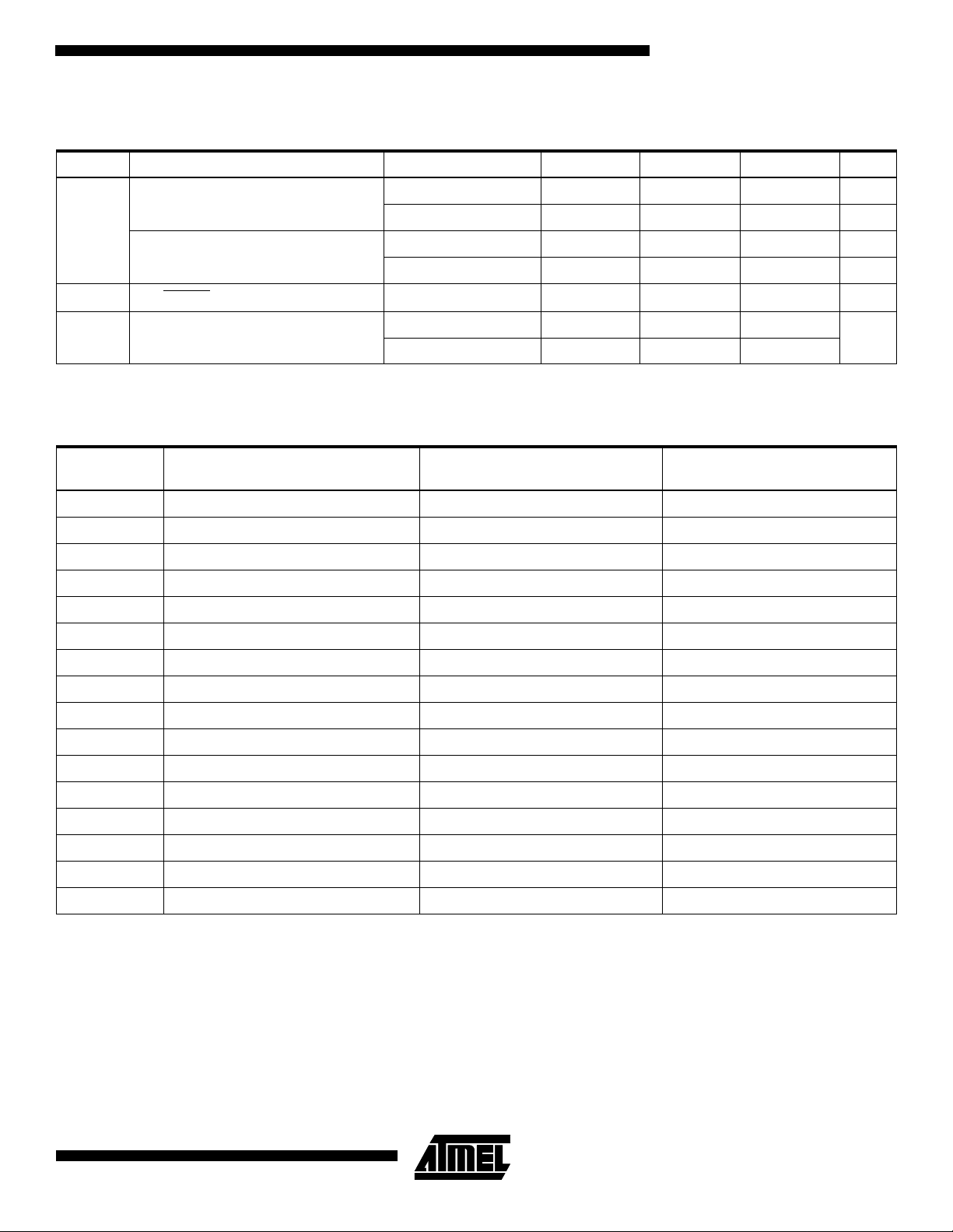

Table 1. Parts Description

Device Flash EEPROM Register Voltage Range Frequency

ATtiny10/11L 1K - 32 2.7 - 5.5V 0-2 MHz

ATtiny10/11 1K - 32 4.0 - 5.5V 0-6 MHz

ATtiny12V 1K 64 B 32 1.8 - 5.5V 0-1 MHz

ATtiny12L 1K 64 B 32 2.7 - 5.5V 0-4 MHz

ATtiny12 1K 64 B 32 4.0 - 5.5V 0-8 MHz

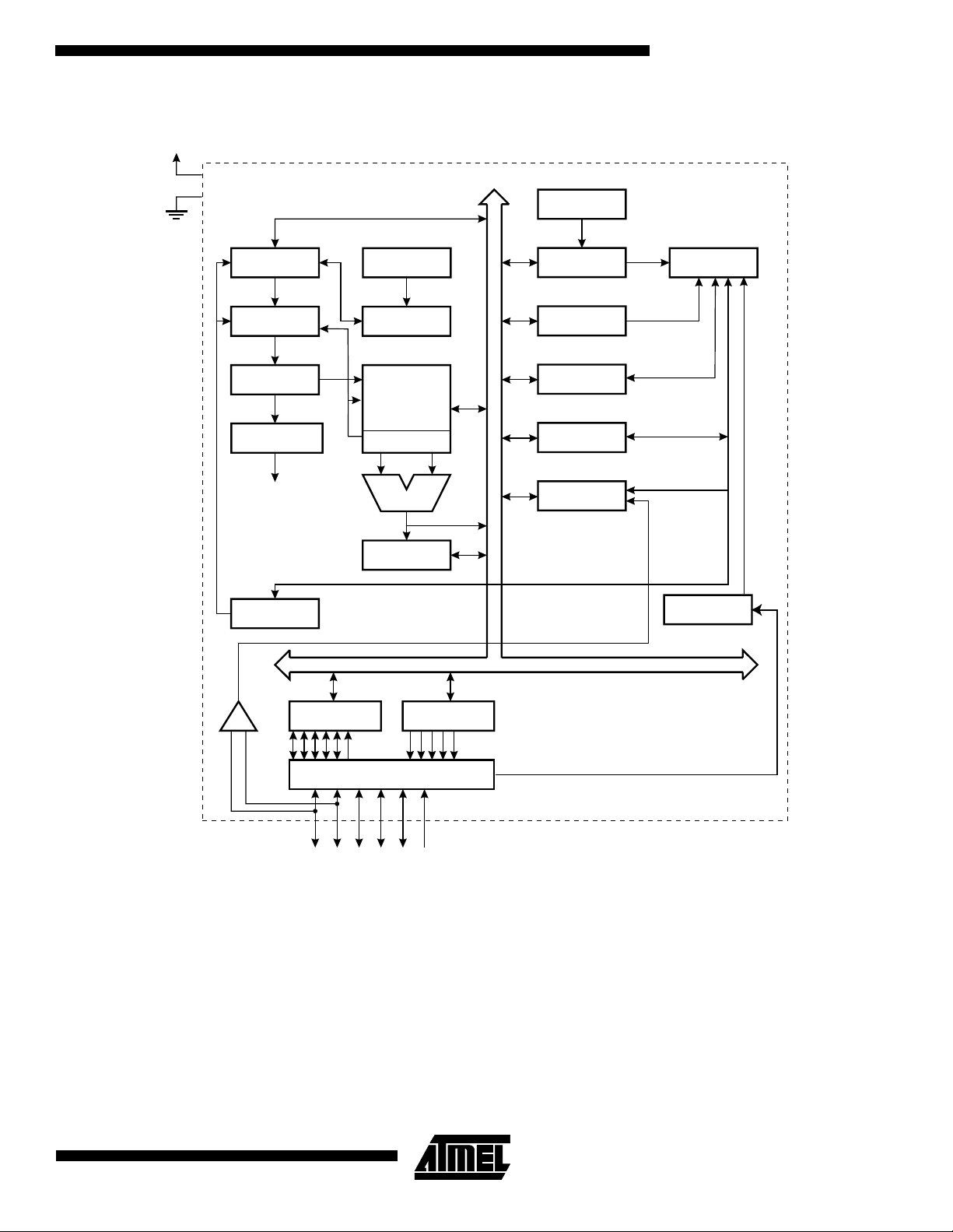

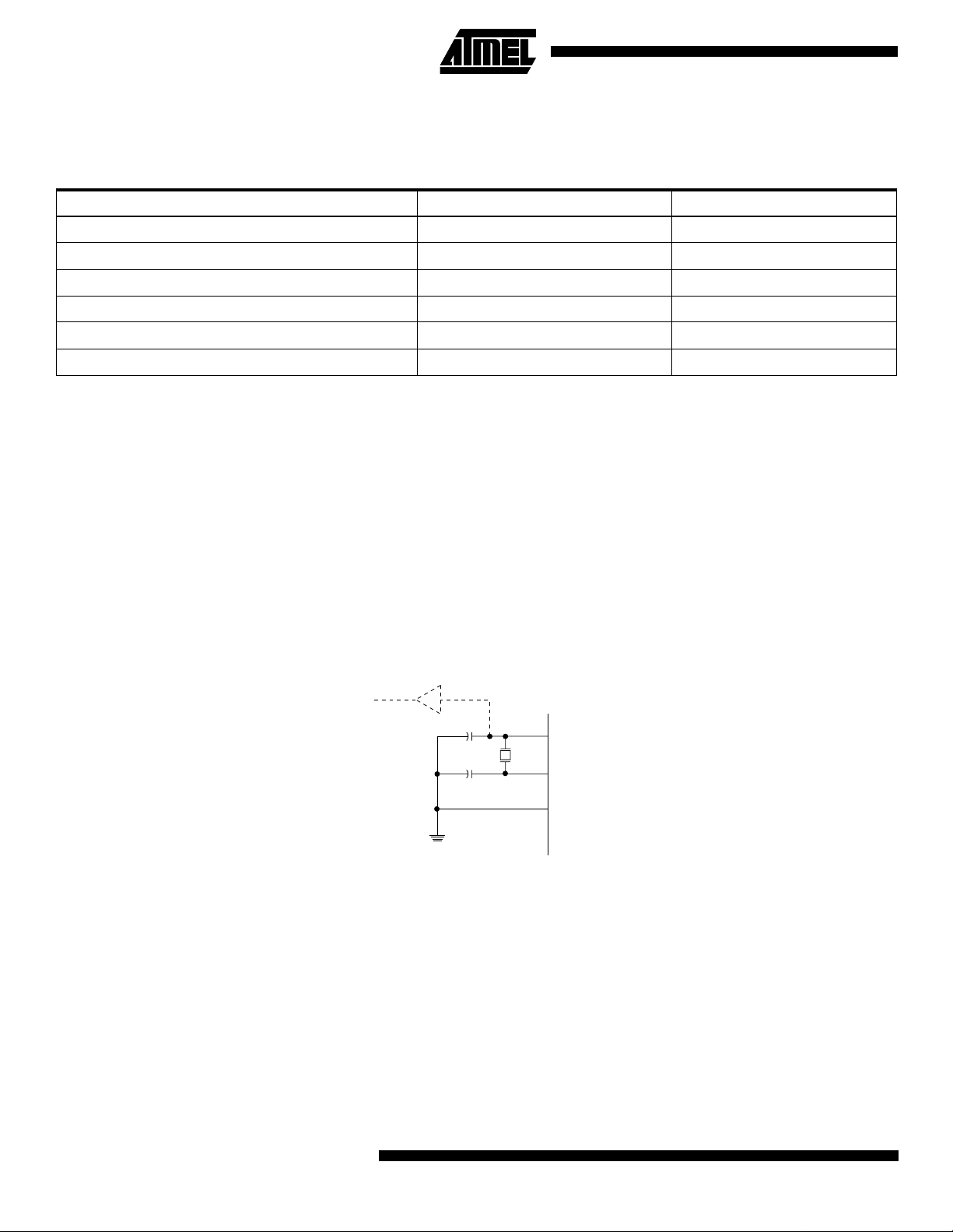

ATtiny10/11 Block Diagram

The ATtiny10/11 provides the foll owing features : 1K bytes o f Flash, up to five general-purpos e I/O lines, one input line,

32 general-purpose w orking regi sters, an 8-bit ti mer/counter , inter nal and ext ernal inter rupts, programma ble Watchdo g

Timer with internal oscillator, and two software-selectable power-saving modes. The Idle Mode stops the CPU while allowing the timer/counters and interrupt system to continue functioning. The Power-down Mode saves the register contents but

freezes the oscill ator, disa bling al l other chip fu nctions until the nex t interru pt or hardwa re reset. The wake-u p or interrup t

on pin change featu res enabl e the ATtiny10 /11 to be highly resp onsive to ex ternal ev ents, st ill featu ring the low est power

consumption while in the power-down modes.

The device is manufactured using Atmel’s high-density no nvolatil e memory tec hnology. By combining an RISC 8-bit CP U

with Flash on a monolithic chip, the Atmel ATtiny10/11 is a powerful microcontroller that provides a highly-flexible and costeffective solution to many embedded control applications.

The ATtiny10/11 AVR is supported with a full suite of program and system development tools including: macro assemblers,

program debugger/simulators, in-circuit emulators, and evaluation kits.

2

ATtiny10/11/12

Figure 1. The ATtiny10/11 Block Diagram

VCC

GND

8-BIT DATABUS

INTERNAL

OSCILLATOR

ATtiny10/11/12

PROGRAM

COUNTER

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

STACK

POINTER

HARDWARE

STACK

GENERALPURPOSE

REGISTERS

Z

ALU

STATUS

REGISTER

WATCHDOG

TIMER

MCU CONTROL

REGISTER

MCU STATUS

REGISTER

TIMER/

COUNTER

INTERRUPT

UNIT

TIMING AND

CONTROL

OSCILLATORS

DATA REGISTER

ARATOR

COMP

PORTB

PORTB DRIVERS

PB0-PB5

+

ANALOG

DATA DIR.

REG. PORTB

3

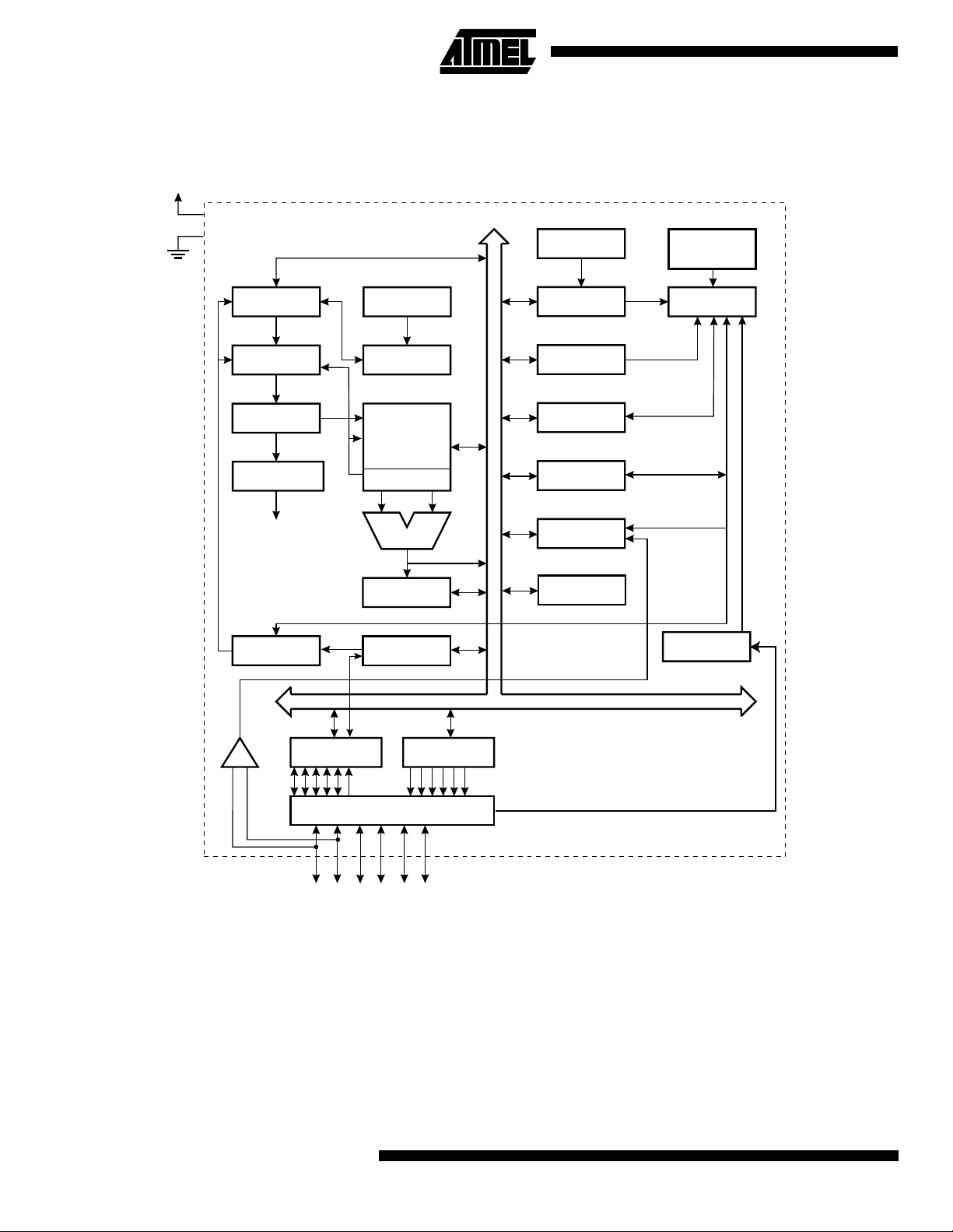

ATtiny12 Block Diagram

Figure 2. The ATtiny12 Block Diagram

VCC

GND

8-BIT DATA BUS

INTERNAL

OSCILLATOR

INTERNAL

CALIBRATED

OSCILLATOR

PROGRAM

COUNTER

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

ANALOG

DATA REGISTER

ARATOR

COMP

+

PORTB

PORTB DRIVERS

STACK

POINTER

HARDWARE

STACK

GENERALPURPOSE

REGISTERS

Z

ALU

STATUS

REGISTER

SPI

DATA DIR.

REG. PORTB

WATCHDOG

TIMER

MCU CONTROL

REGISTER

MCU STATUS

REGISTER

TIMER/

COUNTER

INTERRUPT

UNIT

EEPROM

TIMING AND

CONTROL

OSCILLATORS

PB0-PB5

The ATtiny12 provides the following features: 1K bytes of Flash, 64 bytes EEPROM, up to six general-purpose I/O lines,

32 general-purpose w orking regi sters, an 8-bit ti mer/counter , inter nal and ext ernal inter rupts, programma ble Watchdo g

Timer with internal oscillator, and two software-selectable power-saving modes. The Idle Mode stops the CPU while allowing the timer/counters and interrupt system to continue functioning. The Power-down Mode saves the register contents but

freezes the oscill ator, disa bling al l other chip fu nctions until the nex t interru pt or hardwa re reset. The wake-u p or interrup t

on pin change feature s enable the ATt iny12 to be highl y responsi ve to external eve nts, still feat uring the lowes t power

consumption while in the power-down modes.

4

ATtiny10/11/12

ATtiny10/11/12

The device is manufactured using Atmel’s high-density no nvolati le memory tec hnology. By combining an RISC 8-b it CPU

with Flash on a monolithic chip, the Atmel ATtiny12 is a powerful microcontroller that provides a highly-flexible and costeffective solution to many embedded control applications.

The ATtiny12 AVR is supported with a full suite of program and system development tools including: macro assemblers,

program debugger/simulators, in-circuit emulators, and evaluation kits.

Pin Descriptions

VCC

Supply voltage pin.

GND

Ground pin.

Port B (PB5..PB0)

Port B is a 6-bit I/O port. PB4..0 are I/O pins that can provide internal pull-ups (selected for each bit). On ATtiny10/11, PB5

is input only. On ATtiny12, PB5 is input or open-dr ain output. The port pi ns are tri-st ated when a reset con dition beco mes

active, even if the c lock is no t runn in g. T he us e of pi ns PB5..3 as input or I/O pins is lim ited , de pen din g on r es et a nd c lock

settings, as shown below.

Table 2. PB5..PB3 Functionality vs. Device Clocking Options

Device Clocking Option PB5 PB4 PB3

External Reset Enabled Used

External Reset Disabled Input

External Crystal - Used Used

External Low-frequency Crystal - Used Used

External Ceramic Resonator - Used Used

External RC Oscillator - I/O

External Clock - I/O Used

Internal RC Oscillator - I/O I/O

Notes: 1. “Used” means the pin is used for reset or clock purposes.

2. “-” means the pin function is unaffected by the option.

3. Input means the pin is a port input pin.

4. On ATtiny10/11, PB5 is input only. On ATtiny12, PB5 is input or open-drain output.

5. I/O means the pin is a port input/output pin.

(1)

(3)

(4)

/I/O

(2)

-

--

(5)

Used

XTAL1

Input to the inverting oscillator amplifier and input to the internal clock operating circuit.

XTAL2

Output from the inverting oscillator amplifier.

-

RESET

Reset input. An exter nal res et is gen er ate d by a lo w le ve l o n th e RE S ET p in. Reset p ul se s lon ger th an 50 ns will generate

a reset, even if the clock is not running. Shorter pulses are not guaranteed to generate a reset.

5

Clock Options

The device has the following clock source options, selectable by Flash fuse bits as shown:

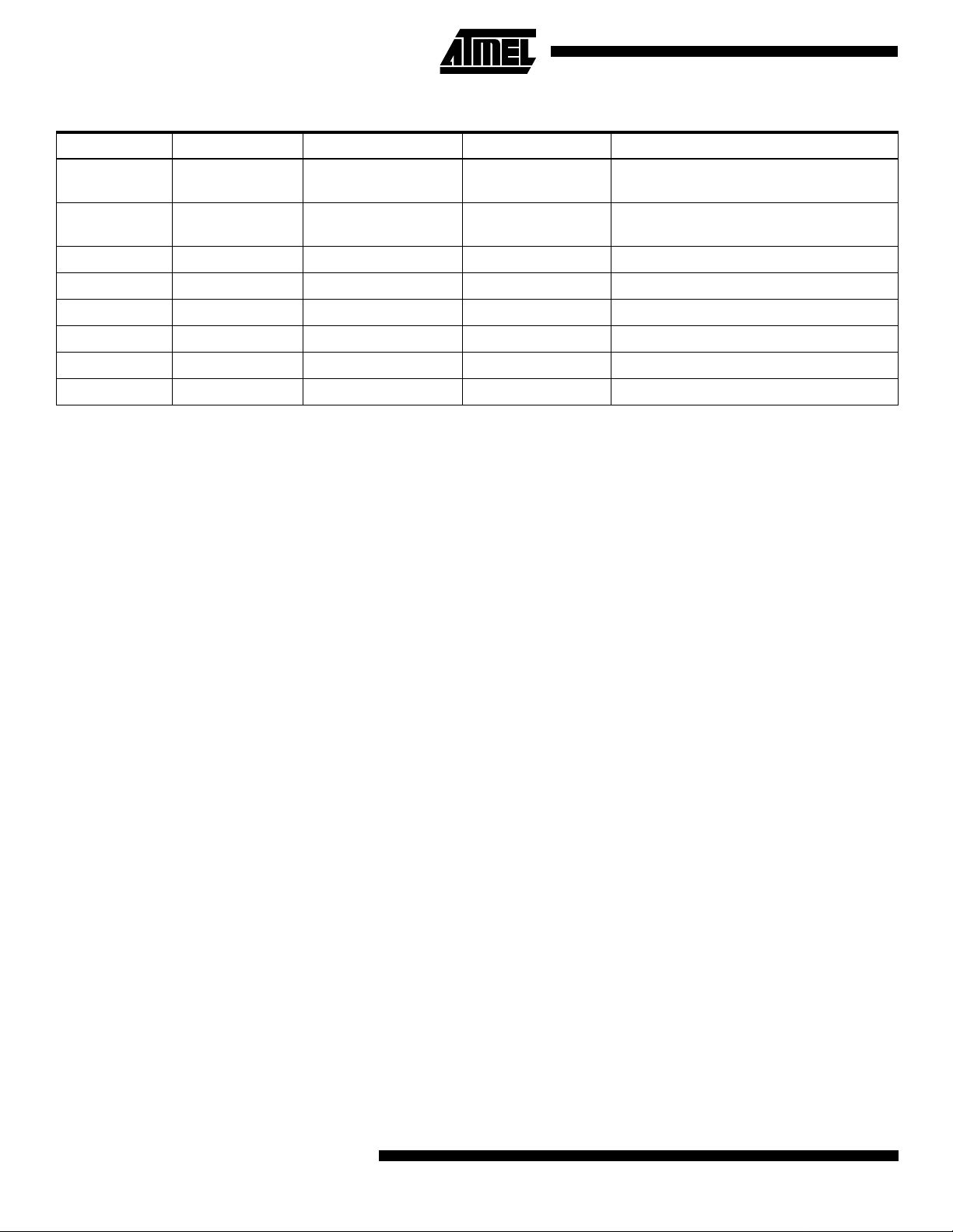

Table 3. Device Clocking Options Select

Device Clocking Option ATtiny10/11 CKSEL2..0 ATtiny12 CKSEL3..0

External Crystal/Ceramic Resonator 111 1111 - 1010

External Low-frequency Crystal 110 1001 - 1000

External RC Oscillator 101 0111 - 0101

Internal RC Oscillator 100 0100 - 0010

External Clock 000 0001 - 0000

Reserved Other Options -

Note: “1” means unprogrammed, “0” means programmed.

The various choice s for each clo cking optio n give diff erent start -up times as shown in Tab le 7 on page 18 and Tabl e 9 on

page 19.

Internal RC Oscillator

The internal RC o scill ator option is an on -chip oscil lator r unnin g at a fix ed freq uen cy of 1 M Hz. If sel ected, the d evice can

operate with no external components. The device is shipped with this option selected. On ATtiny10/11, the Watchdog

Oscillator is used as a clock, while ATtiny12 uses a separate calibrated oscillator.

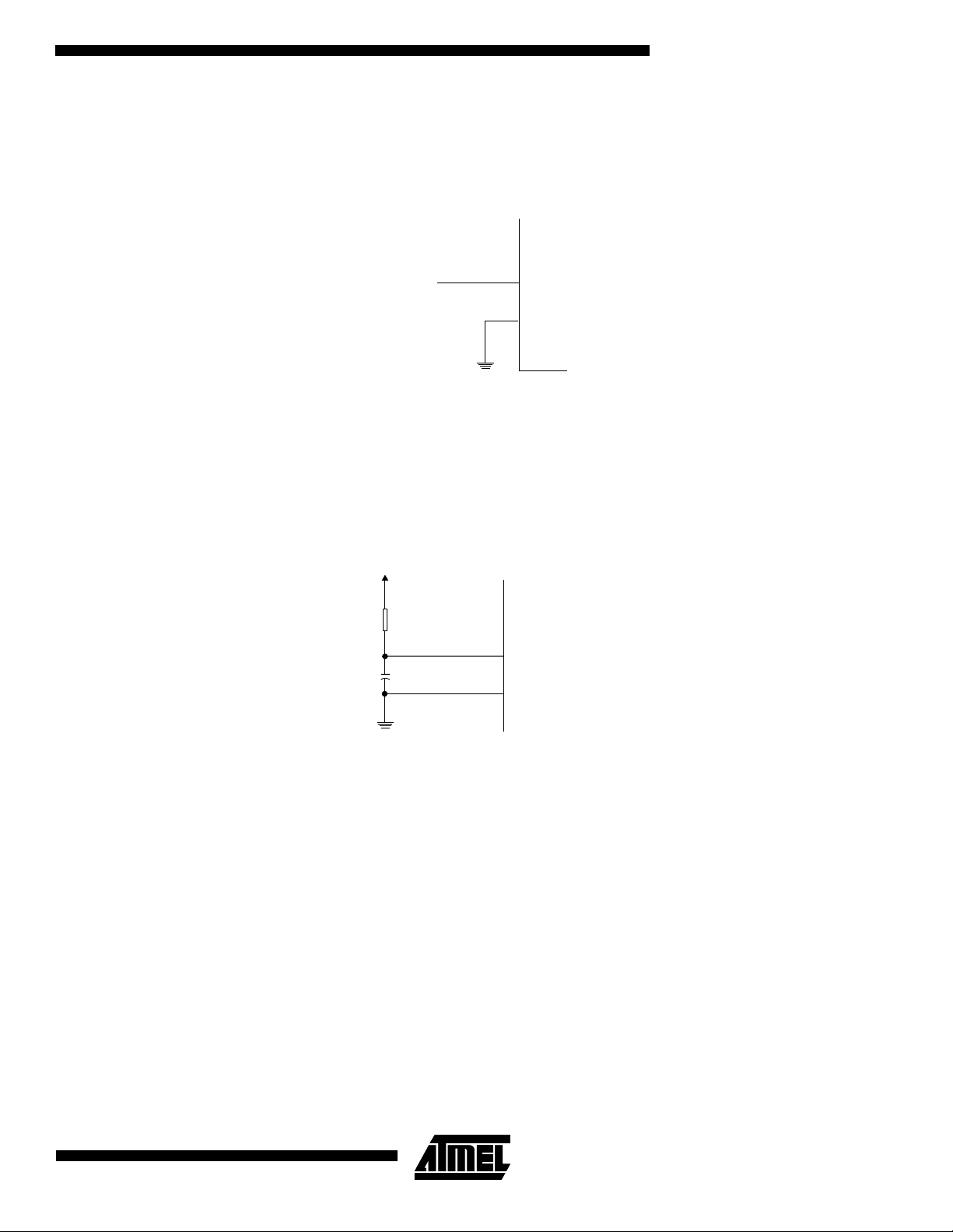

Crystal Oscillator

XTAL1 and XTAL2 are input and output, respectively, of an inverting amplifier which can be configured for use as an

on-chip oscillator, as shown in Figure 3. Either a quartz crystal or a ceramic resonator may be used.

Figure 3. Oscillator Connections

MAX 1 HC BUFFER

HC

C2

C1

Note: When using the MCU Oscillator as a clock for an external device, an HC buffer should be connected as indicated in the figure.

XTAL2

XTAL1

GND

6

ATtiny10/11/12

ATtiny10/11/12

External Clock

To drive the device from an external clock source, XTAL1 should be driven as shown in Figure 4.

Figure 4. External Clock Drive Configuration

PB4 (XTAL2)

EXTERNAL

OSCILLATOR

SIGNAL

External RC Oscillator

For timing insensitive applicati ons, the exter nal RC conf iguration sho wn in Figur e 5 can be used. For details on how to

choose R and C, see Table 29 on page 53.

XTAL1

GND

Figure 5. External RC Configuration

VCC

R

C

PB4 (XTAL2)

XTAL1

GND

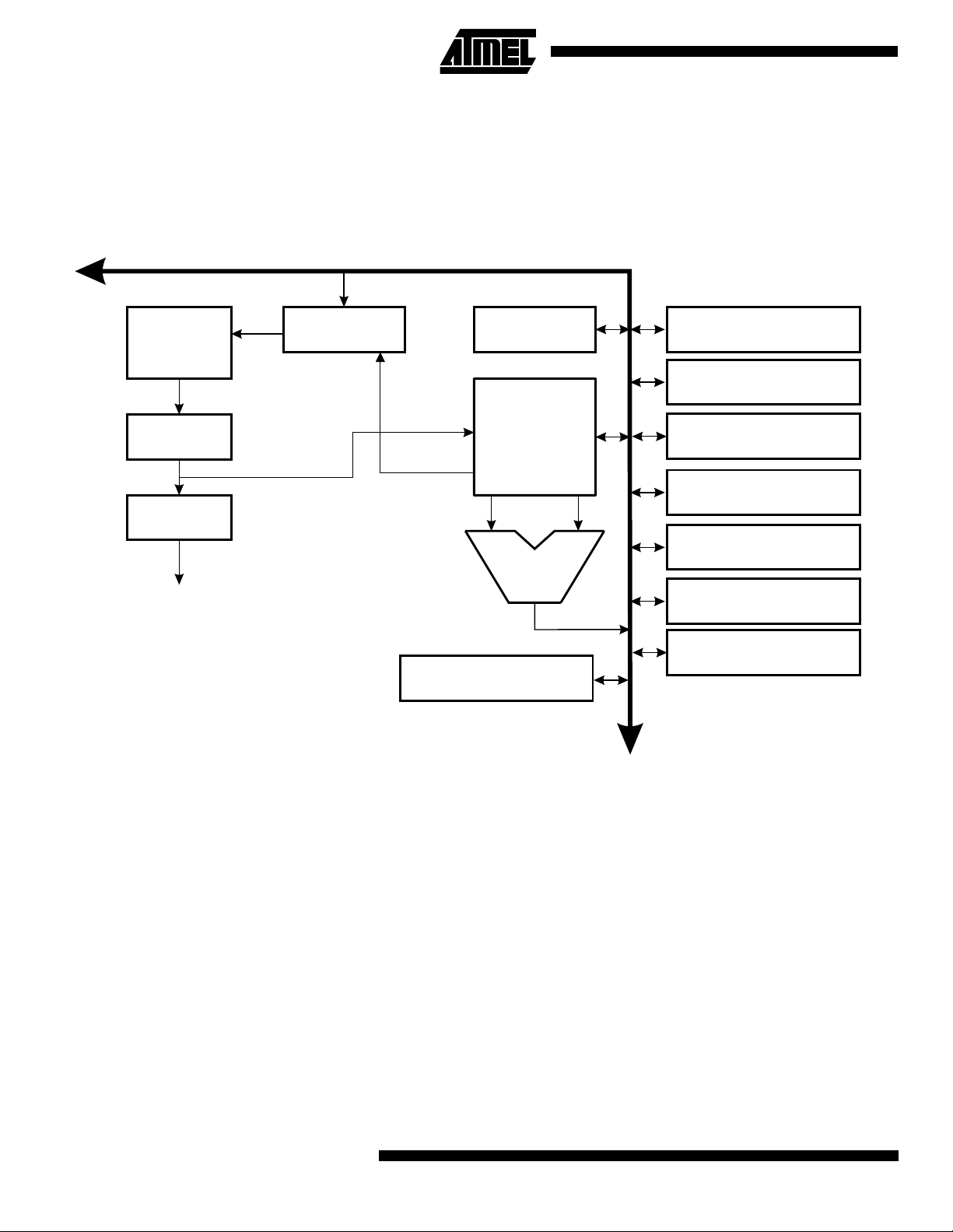

Architectural Overview

The fast-access register file concept contains 32 x 8-bit general-purpose working registers with a single-clock-cycle access

time. This means th at d urin g on e s in gl e cloc k cyc le, one ALU (Arithmetic Logic Uni t) op erati on i s exec ute d. T wo ope ra nds

are output from the register file, the operation is executed, and the result is stored back in the register file – in one clock

cycle.

Two of the 32 registers can be used as a 16-bit pointer for indirect memory access. This pointer is called the Z-pointer, and

can address the register file and the Flash program memory.

The ALU supports arithmetic and logic functions between registers or between a constant and a register. Single-register

operations are als o executed in the ALU. F igure 2 sh ows the ATtiny 10/11/1 2 AVR RISC microco ntroller ar chitect ure. The

AVR uses a Harvard architecture concept with separate memories and buses for program and data memories. The program memory is a ccesse d with a two-sta ge pipeli ning. Wh ile o ne ins truc tion i s being exec uted, the next instr uction is pr efetched from the program memory. This con cept enables ins tructions to be exec uted in every clock cycle. The progr am

memory is reprogrammable Flash memory.

With the relative jump and relative call instructions, the whole 512 address space is directly accessed. All AVR instructions

have a single 16-bit word format, meaning that every program memory address contains a single 16-bit instruction.

7

During interrupts and subroutine calls, the return address program counter (PC) is stored on the stack. The stack is a

3-level-deep hardware stack dedicated for subroutines and interrupts.

The I/O memory space c ontain s 64 add resses for CPU per iphe ral func tions a s con trol reg isters , timer /count ers, a nd other

I/O functions. The memory spaces in the AVR architecture are all linear and regular memory maps.

Figure 6. The ATtiny10/11/12 AVR RISC Architecture

8-bit Data Bus

512 x 16

Program

Flash

Instruction

Register

Instruction

Decoder

Control Lines

Program

Counter

Direct Addressing

Status

and Test

32 x 8

General-

purpose

Registers

ALU

64 x 8 EEPROM

(ATtiny12 only)

Control

Registers

Interrupt

Unit

SPI Unit

(ATtiny12 only)

8-bit

Timer/Counter

Watchdog

Timer

Analog

Comparator

6

I/O Lines

A flexible interrupt module has its control registers in the I/O space with an additional global interrupt enable bit in the status

register. All the different interrupts have a separate interrupt vector in the interrupt vector table at the beginning of the

program memory. The di fferent interrup ts hav e prior ity in acco rdance with th eir inte rrupt v ector p osition. The lower the

interrupt vector address, the higher the priority.

8

ATtiny10/11/12

General-purpose Register File

Figure 7 shows the structure of the 32 general-purpose registers in the CPU.

ATtiny10/11/12

Figure 7. AVR

CPU General-purpose Working Registers

70

R0

R1

R2

General- …

purpose …

Working R28

Registers R29

R30 (Z-register low byte)

R31 (Z-register high byte)

All the register operating instructions in the instruction set have direct- and single-cycle access to all registers. The only

exception is the f iv e con sta nt ar ith meti c an d logi c in st ru cti on s SB CI, SUB I, CPI, ANDI, and ORI between a constant and a

register and the LDI instructi on for load- immediat e constant data. Th ese instruc tions apply to the se cond half of the r egisters in the register file – R16..R31. The general SBC, SUB, CP, AND, OR and all other operations between two registers or

on a single register apply to the entire register file.

Registers 30 and 31 form a 16-bi t pointer (th e Z-pointer ) which is used fo r indirect Flash mem ory and regist er file acces s.

When the register file is accessed, the contents of R31 are discarded by the CPU.

ALU – Arithmetic Logic Unit

The high-performan ce AVR AL U operat es in direct con nectio n with all the 32 general- purpose working r egisters. W ithin a

single clock cy cl e, AL U ope r atio ns be tween r egi ster s in the re gis te r f ile ar e ex ec uted . The ALU operations are divi ded in to

three main categories – arithmetic, logic and bit-functions. Some microcontrollers in the AVR product family feature a hardware multiplier in the arithmetic part of the ALU.

Flash Program Memory

The ATtiny10/11/12 contains 1K bytes on-chip Flash memory for program storage. Since all instructions are single 16-bit

words, the Flash is organized as 512 x 16 words. The Flash memory has an endurance of at least 1000 write/erase cycles.

The ATtiny10/11/12 Program Counter is 9 bits wide, thus addressing the 512 words Flash program memory.

See page 39 for a detailed description on Flash memory programming.

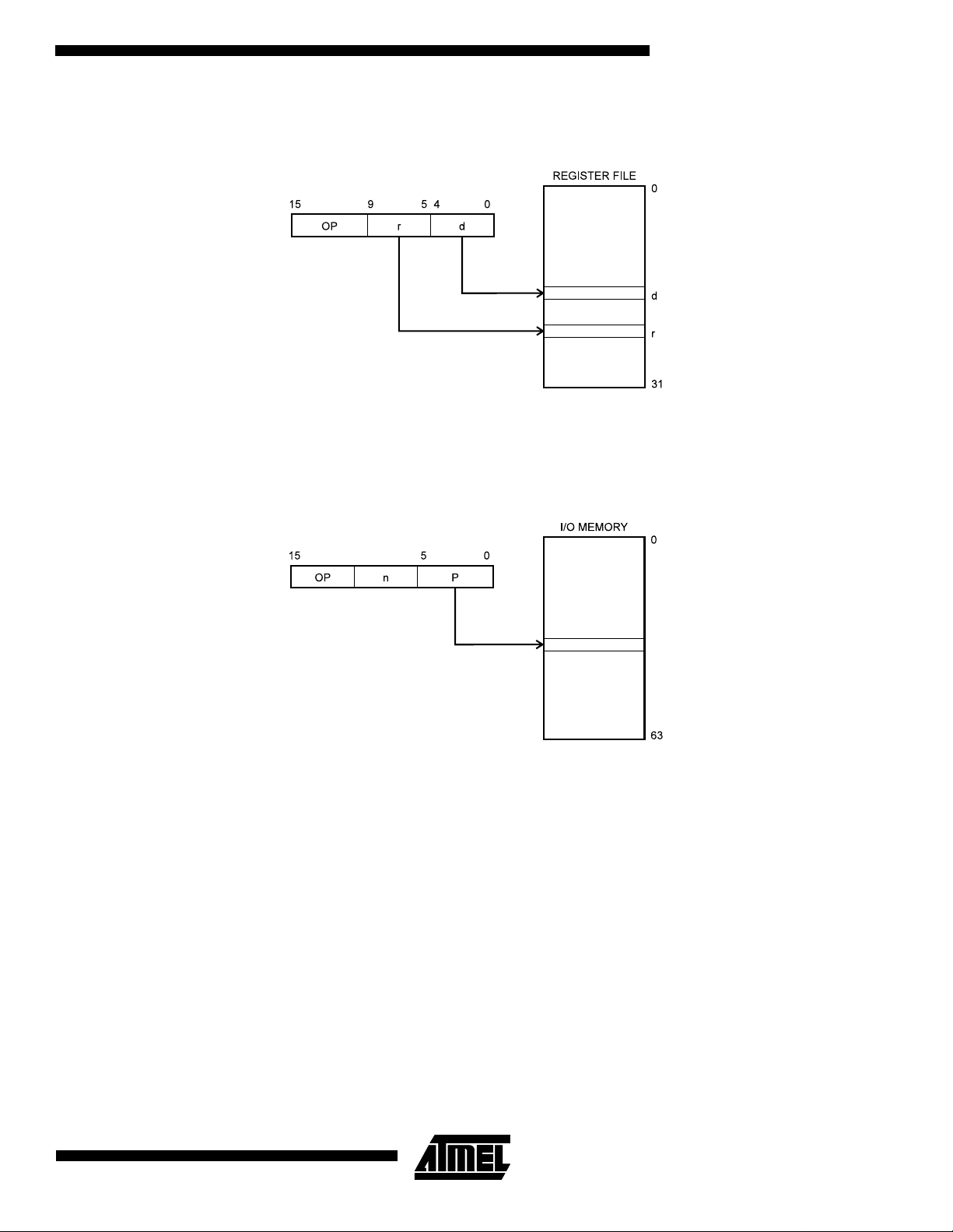

Program and Data Addressing Modes

The ATtiny10/11/12 AVR RISC Microcontroller supports powerful and efficient addressing modes. This section describes

the different addressing modes supported in the ATtiny10/11/12. In the figures, OP means the operation code part of the

instruction word. To simplify, not all figures show the exact location of the addressing bits.

9

Register Direct, Single Register Rd

Figure 8. Direct Single-register Addressing

The operand is contained in register d (Rd).

Register Indirect

Figure 9. Indirect Register Addressing

REGISTER FILE

Z-register

The register accessed is the one pointed to by the Z-register (R31, R30).

0

30

31

10

ATtiny10/11/12

ATtiny10/11/12

Register Direct, Two Registers Rd and Rr

Figure 10. Direct Register Addressing, Two Registers

Operands are contained in register r (Rr) and d (Rd). The result is stored in register d (Rd).

I/O Direct

Figure 11. I/O Direct Addressing

Operand address is contained in 6 bits of the instruction word. n is the destination or source register address.

11

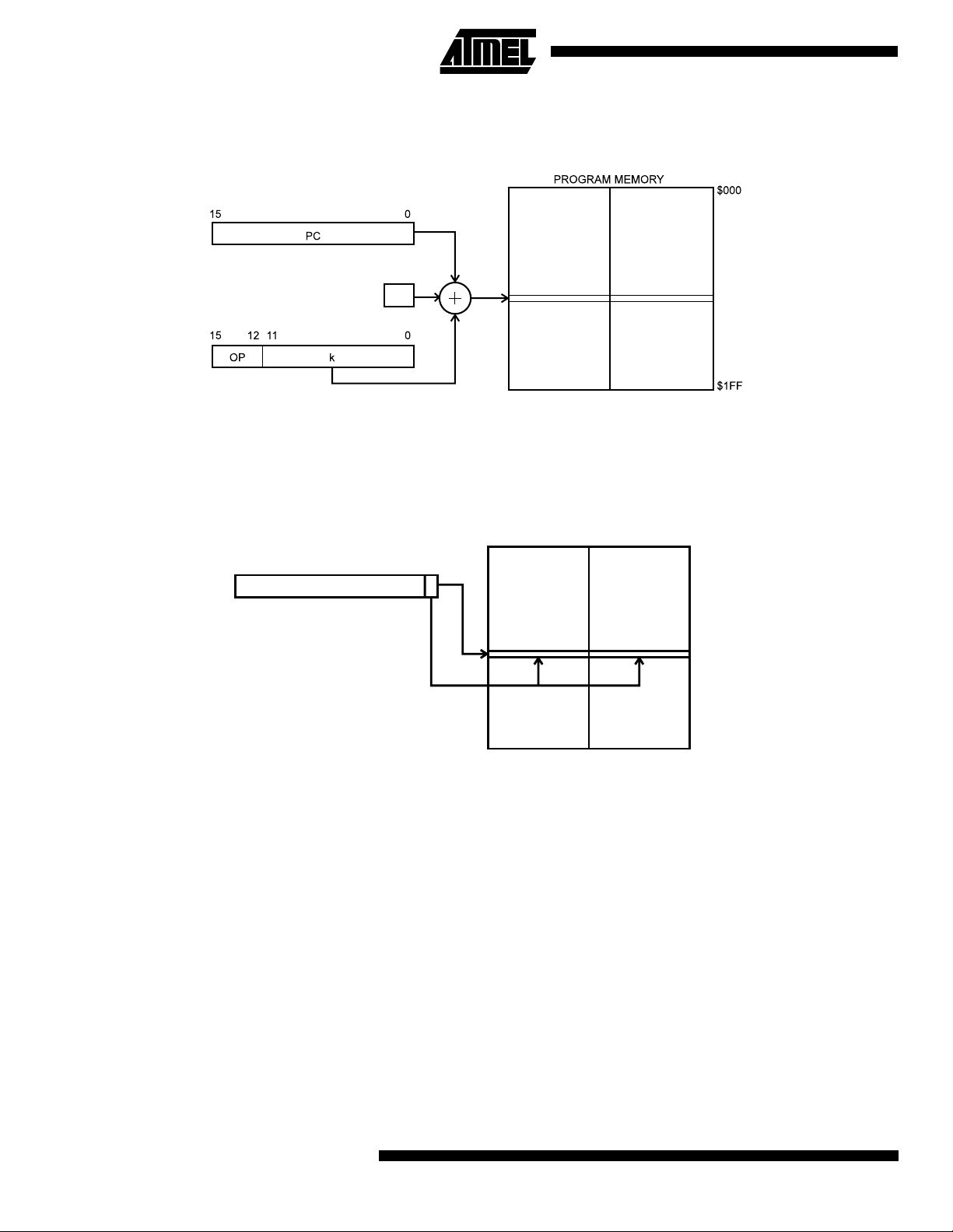

Relative Program Addressing, RJMP and RCALL

Figure 12. Relative Program Memory Addressing

+1

Program execution continues at address PC + k + 1. The relative address k is -2048 to 2047.

Constant Addressing Using the LPM Instruction

Figure 13. Code Memory Constant Addressing

PROGRAM MEMORY

15 1 0

Z-REGISTER

$000

$1FF

Constant byte address is specified by the Z-register contents. The 15 MSBs select word address (0 - 511), the LSB selects

low byte if cleared (LSB = 0) or high byte if set (LSB = 1).

Subroutine and Interrupt Hardware Stack

The ATtiny10/11 /12 uses a 3 -le vel-d eep hardw are stac k f or su brou tines and inter rup ts. The ha rdwa re sta ck is 9 bi ts w ide

and stores the program counter (PC) return address while subroutines and interrupts are executed.

RCALL instructions and interrupts push the PC return address onto stack level 0, and the data in the other stack levels 1-2

are pushed one level deeper in the stack. When a RET or RETI instruction is executed the returning PC is fetched from

stack level 0, and the data in the other stack levels 1-2 are popped one level in the stack.

If more than three subsequent su brouti ne calls or interrupt s are exec uted, the fi rst valu es written to the stack are overwr itten. Pushing four ret urn ad dr es ses A 1, A 2, A3 a nd A 4, fo ll owed by fou r sub ro utine or interrupt returns, will pop A 4, A3, A 2

and once more A2 from the hardware stack.

12

ATtiny10/11/12

ATtiny10/11/12

EEPROM Data Memory

The ATtiny12 contains 64 b yte s o f data EE PRO M m emo ry . It is o rg ani ze d as a sepa ra te da ta sp ac e, i n whi ch singl e by tes

can be read and written. The EEPROM has an endur ance of at least 100, 000 write /erase cy cles. The acces s betwee n the

EEPROM and the CPU is de scrib ed on pag e 33, sp ecifyin g the EE PROM Addres s Regis ter, th e EEPRO M Data Reg ister ,

and the EEPROM Control Register.

For SPI data downloading, see “Memory Programming ” on page 39 for a detailed description.

Memory Access and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and internal memory access.

The AVR CPU is driven by the System Clock Ø, directly generated from the external clock c rystal for the c hip. No interna l

clock division is used.

Figure 14 shows the parallel instruction fetches and instructio n executions enabled by the Harvard architecture and the

fast-access register file concept. This is the basic pipelining concept to obtain up to 1 MIPS per MHz with the corresponding

unique results for functions per cost, functions per clocks, and functions per power-unit.

Figure 14. The Parallel Instruction Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

Figure 15 shows the internal timing concept for the register file. In a single clock cycle, an ALU operation using two register

operands is executed and the result is stored back to the destination register.

Figure 15. Single-cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

13

I/O Memory

The I/O space definition of the ATtiny10/11/12 is shown in the following table:

Table 4. ATtiny10/11/12 I/O Space

Address Hex Name Device Function

$3F SREG ATtiny10/11/12 Status Register

$3B GIMSK ATtiny10/11/12 General Interrupt Mask Register

$3A GIFR ATtiny10/11/12 General Interrupt Flag Register

$39 TIMSK ATtiny10/11/12 Timer/Counter Interrupt Mask Register

$38 TIFR ATtiny10/11/12 Timer/Counter Interrupt Flag Register

$35 MCUCR ATtiny10/11/12 MCU Control Register

$34 MCUSR ATtiny10/11/12 MCU Status Register

$33 TCCR0 ATtiny10/11/12 Timer/Counter0 Control Register

$32 TCNT0 ATtiny10/11/12 Timer/Counter0 (8-bit)

$31 OSCCAL ATtiny12 Oscillator Calibration Register

$21 WDTCR ATtiny10/11/12 Watchdog Timer Control Register

$1E EEAR ATtiny12 EEPROM Address Register

$1D EEDR ATtiny12 EEPROM Data Register

$1C EECR ATtiny12 EEPROM Control Register

$18 PORTB ATtiny10/11/12 Data Register, Port B

$17 DDRB ATtiny10/11/12 Data Direction Register, Port B

$16 PINB ATtiny10/11/12 Input Pins, Port B

$08 ACSR ATtiny10/11/12 Analog Comparator Control and Status Register

Note: Reserved and unused locations are not shown in the table.

All the different ATtiny10/11/12 I/O and peripherals are placed in the I/O space. The different I/O locations are accessed by

the IN and OUT instructions transferring data between the 32 general-purpose working registers and the I/O space. I/O registers within the addr ess ran ge $00 - $1F ar e direc tly b it-acces sible us ing th e SBI and CBI instruc tions . In these regis ters,

the value of sing le bits can be checked by using the SBIS and SBIC inst ruct ions. Refer to the Instruct ion Se t S umm ar y for

more details.

For compatibility wi th fu tur e de vi ce s, re se rv ed bit s s ho uld be wr i tten to z ero i f ac ce ss ed . Res er v ed I/ O m emo ry ad dr es se d

should never be written.

The different I/O and peripherals control registers are explained in the following sections.

Status Register – SREG

The AVR status register (SREG) at I/O space location $3F is defined as:

Bit 76543210

$3F I T H S V N Z C SREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 - I: Global Interrupt Enable

•

The global interrup t enable bit must be set (one) for the interrup ts to be enable d. The indivi dual inter rupt enab le control is

then performed in sep arate contr ol registe rs. If the gl obal interru pt enable r egister is cleared (ze ro), none of the interrupts

14

ATtiny10/11/12

ATtiny10/11/12

are enabled independent of the individual interrupt enable settings. The I-bit is cleared by hardware after an interrupt has

occurred, and is set by the RETI instruction to enable subsequent interrupts.

Bit 6 - T: Bit Copy Storage

•

The bit copy instruc tions B LD (Bit L oaD) a nd BST (Bit ST ore) u se the T-bit a s sour ce and destinati on for the op erated bi t.

A bit from a register in the registe r file ca n be co pied into T by the BST instruction, and a bit in T can be cop ied into a bi t in

a register in the register file by the BLD instruction.

Bit 5 - H: Half Carry Flag

•

The half carry flag H indicates a half-carry in some arithmetic operations. See the Instruction Set description for detailed

information.

Bit 4 - S: Sign Bit, S = N ⊕ V

•

The S-bit is always an exclusive or between the negative flag N and the two’s complement overflow flag V. See the Instruction Set description for detailed information.

•

Bit 3 - V: Two’s Complement Overflow Flag

The two’s complement overflow flag V supports two’s com plement arithmetic. S ee the Instruction S et description for

detailed information.

•

Bit 2 - N: Negative Flag

The negative flag N indicates a negative result from an arithmetical or logical operation. See the Instruction Set description

for detailed information.

Bit 1 - Z: Zero Flag

•

The zero flag Z indicates a zero result from an arithmetical or logical operation. See the Instruction Set description for

detailed information.

Bit 0 - C: Carry Flag

•

The carry flag C indicates a carry in an a rithmetical or logical ope ration. See the Ins truction Set des cription for d etailed

information.

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from

an interrupt routine. This must be handled by software.

Reset and Interrupt Handling

The ATtiny10/11 provides four different interrupt sources and the ATtiny12 provides five. These interrupts and the separate

reset vector each hav e a se par at e pr ogram vector in the program memory spac e. A ll t he in terr upts are as si gn ed in div i dua l

enable bits which must be set (one) together with the I-bit in the status register in order to enable the interrupt.

The lowest addresses i n the pro gram memo ry space are automatica lly defined a s the Rese t and Inter rupt vector s. The

complete list of vectors is shown in Table 5. The list also determines the priority levels of the different interrupts. The lower

the address, the higher the priority level. RESET has the highest priority, and next is INT0 – the External Interrupt Request

0, etc.

15

Table 5. Reset and Interrupt Vectors

Vector No. Device Program Address Source Interrupt Definition

1 ATtiny10/11 $000 RESET

External Pin, Power-on Reset and

Watchdog Reset

1 ATtiny12 $000 RESET

External Pin, Power-on Reset, Brown-out

Reset and Watchdog Reset

2 ATtiny10/11/12 $001 INT0 External Interrupt Request 0

3 ATtiny10/11/12 $002 I/O Pins Pin Change Interrupt

4 ATtiny10/11/12 $003 TIMER0, OVF0 Timer/Counter0 Overflow

5 ATtiny10/11 $004 ANA_COMP Analog Comparator

5 ATtiny12 $004 EE_RDY EEPROM Ready

6 ATtiny12 $005 ANA_COMP Analog Comparator

The most typical and general program setup for the reset and interrupt vector addresses for the ATtiny10/11 are:

Address Labels Code Comments

$000 rjmp RESET ; Reset handler

$001 rjmp EXT_INT0 ; IRQ0 handler

$002 rjmp PIN_CHANGE ; Pin change handler

$003 rjmp TIM0_OVF ; Timer0 overflow handler

$004 rjmp ANA_COMP ; Analog Comparator handler

;

$005 MAIN: <instr> xxx ; Main program start

… … … …

The most typical and general program setup for the reset and interrupt vector addresses for the ATtiny12 are:

Address Labels Code Comments

$000 rjmp RESET ; Reset handler

$001 rjmp EXT_INT0 ; IRQ0 handler

$002 rjmp PIN_CHANGE ; Pin change handler

$003 rjmp TIM0_OVF ; Timer0 overflow handler

$004 rjmp EE_RDY ; EEPROM Ready handler

$005 rjmp ANA_COMP ; Analog Comparator handler

;

$006 MAIN: <instr> xxx ; Main program start

… … … …

16

ATtiny10/11/12

ATtiny10/11/12

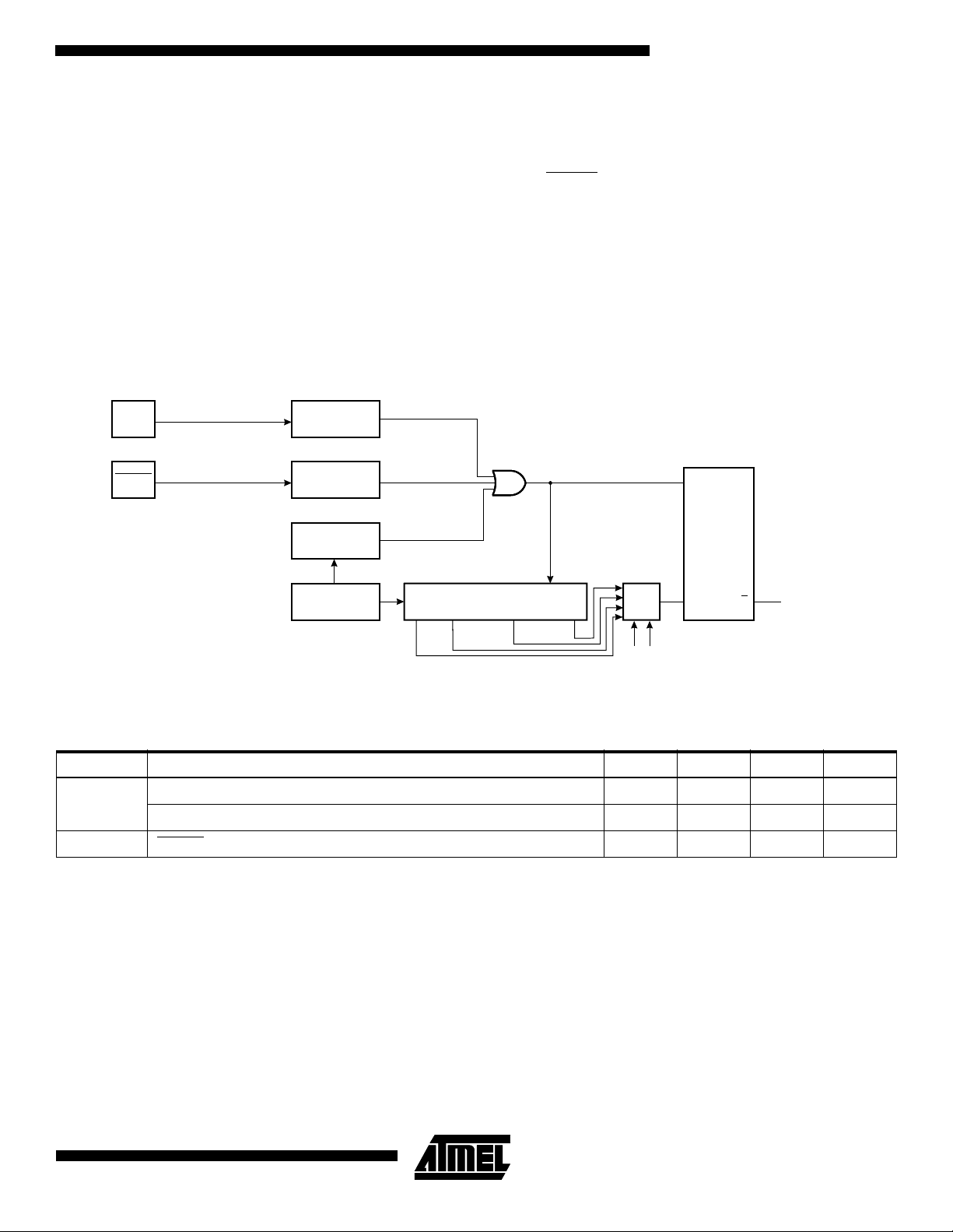

Reset Sources

The ATtiny10/11/12 provides three or four sources of reset:

• Power-on Reset. The MCU is reset when the supply voltage is below the power-on reset threshold (V

• External Reset. The MCU is reset when a low level is present on the RESET pin for more than 50 ns.

• Watchdog Reset. The MCU is reset when the Watchdog timer period expires and the Watchdog is enabled.

• Brown-out Reset. The MCU is reset when the supply voltage V

falls below a certain voltage (ATtiny12 only).

CC

During reset, all I/O regist ers are the n set to their ini tial valu es, and the pro gram starts execution from address $000. The

instruction pla ced in addr ess $000 m ust be an RJM P – relat ive ju mp – ins tructi on to the rese t han dling routi ne. If the program never enables an interrupt sour ce, the interrupt v ectors are not used, a nd regular progr am code can be pl aced at

these locations. The circuit diagram in Figure 16 shows the reset logic for the ATtiny10/11. Figure 17 shows the reset logic

for the ATtiny12. Table 6 def ine s th e el ec tric al param eter s of the reset circuitry for ATtiny10/11. T ab le 8 sh ows the p ar ameters of the reset circuitry for ATtiny12.

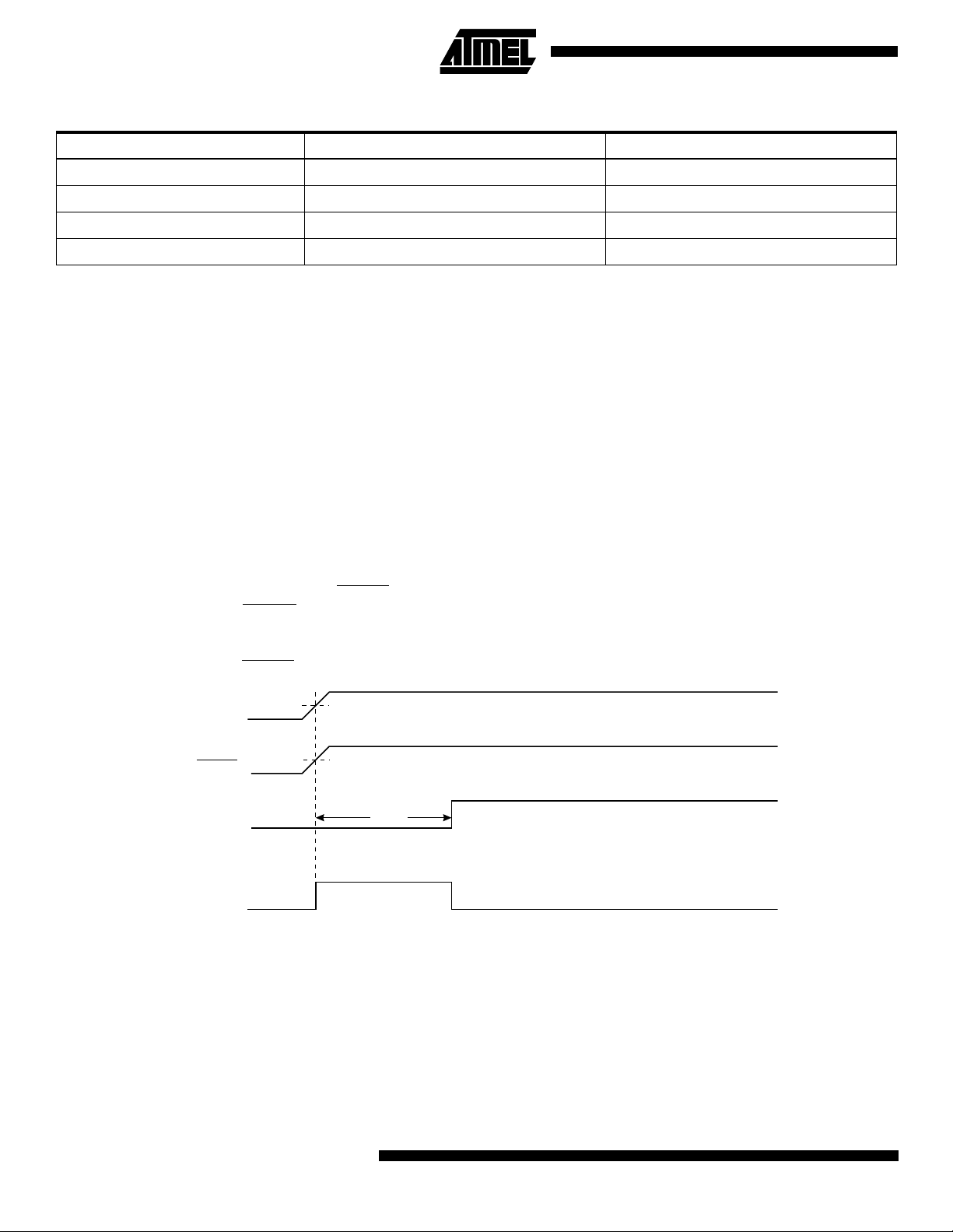

Figure 16. Reset Logic for the ATtiny10/11

VCC

Power-on Reset

Circuit

POR

POT

).

RESET

Reset Circuit

Watchdog

Timer

On-chip

RC Oscillator

COUNTER RESET

20-stage Ripple Counter

Q3 Q19

Q9

Q13

CKSEL

FSTRT

QS

INTERNAL

R

Q

RESET

Table 6. Reset Characteristics for the ATtiny10/11

Symbol Parameter Min Typ Max Units

(1)

V

POT

V

RST

Note: 1. The Power-on Reset will not work unless the supply voltage has been below V

Power-on Reset Threshold Voltage (rising) 1.0 1.4 1.8 V

Power-on Reset Threshold Voltage (falling) 0.4 0.6 0.8 V

RESET Pin Threshold Voltage 0.6 V

(falling).

POT

CC

V

17

Power-on Reset for the ATtiny10/11

A Power-on Reset (POR) circuit ensures that the device is reset from power-on. As shown in Figure 16, an internal timer is

clocked from the watchdog timer. Thi s timer prevents the MCU from starting a cer tain period after V

Power-on Threshold Voltage – V

. See Figure 18. The total reset period is the Delay Time-out period – t

POT

has reached the

CC

. The FSTRT

TOUT

fuse bit in the Flash can be programmed to give a shorter start-up time.The start-up times for the different clock options are

shown in the follo wing ta ble. T he Wa tchdog Oscill ator i s used for t iming the st art-up time, a nd t his osc illator is voltag e

dependent as shown in the section “ATtiny11 Typical Characteristics” on page 54.

Table 7. Start-up Times for the ATtiny10/11 (V

Selected Clock Option

= 2.7V)

CC

Start-up Time t

TOUT

FSTRT Unprogrammed FSTRT Programmed

External Crystal 67 ms 4.2 ms

External Ceramic Resonator 67 ms 4.2 ms

External Low-frequency Crystal 4.2 s 4.2 s

External RC Oscillator 4.2 ms 67 µs

Internal RC Oscillator 4.2 ms 67 µs

External Clock 4.2 ms

If the built-in start-up delay is sufficient, RESET

ing the RESET

pin low for a period after VCC has been applied, the Power-on Reset period can be extended. Refer to

can be connected to VCC directly or via an external pull-up resistor. By hold-

5 clocks from reset,

2 clocks from powe r-down

Figure 19 for a timing example on this.

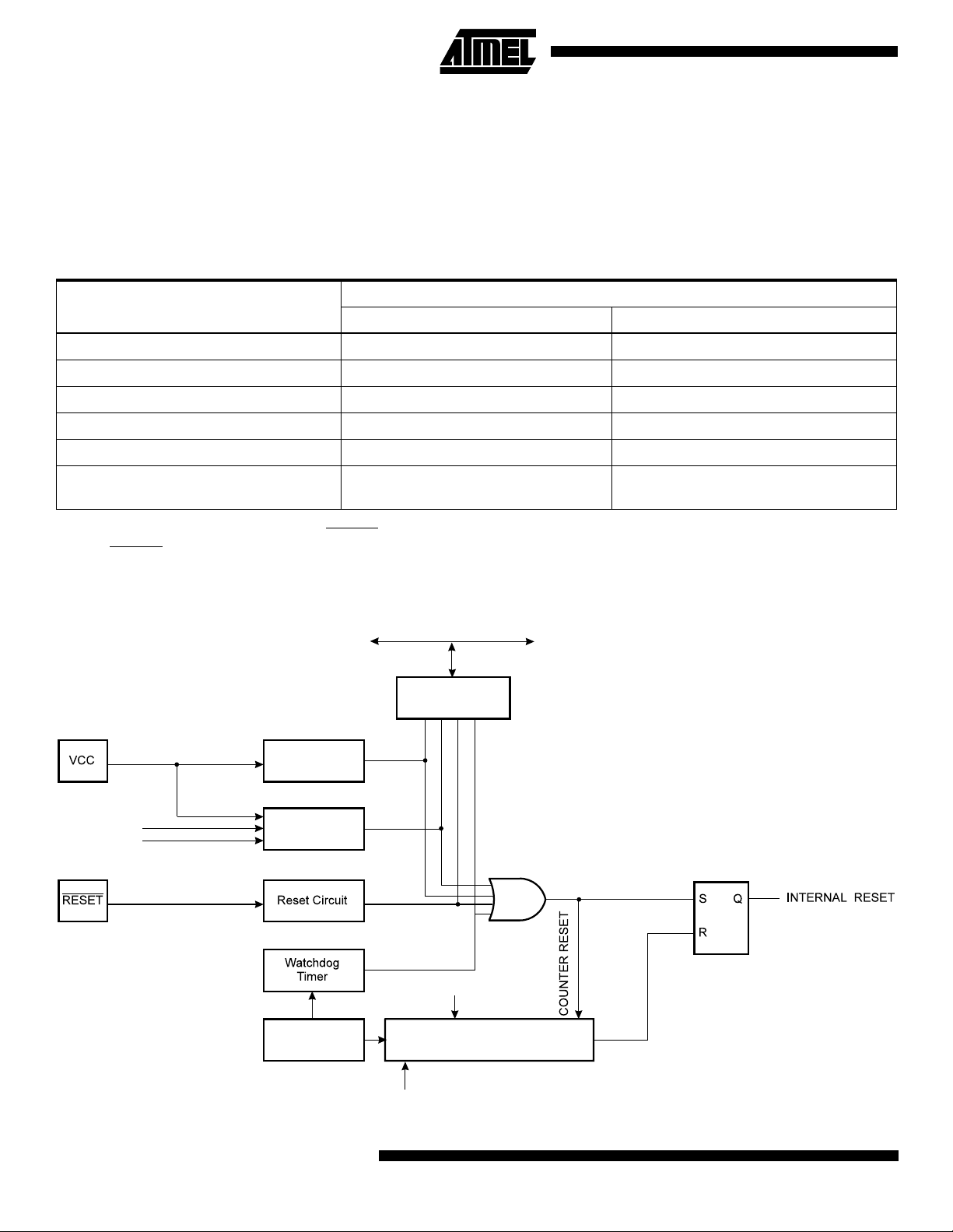

Figure 17. Reset Logic for the ATtiny12

DATA BUS

MCU Status

Register (MCUSR)

BODEN

BODLEVEL

18

Power-on Reset

Circuit

Brown-out

Reset Circuit

On-chip

RC Oscillator

ATtiny10/11/12

CK

BORF

PORF

CKSEL[3:0]

WDRF

EXTRF

Delay Counters

Full

ATtiny10/11/12

Table 8. Reset Characteristics for the ATtiny12

Symbol Parameter Condition Min Typ Max Units

Power-on Reset Threshold Voltage

(1)

V

POT

(rising)

Power-on Reset Threshold Voltage

(falling)

BOD disabled 1.0 1.4 1.8 V

BOD enabled 0.6 1.2 1.8 V

BOD disabled 0.4 0.6 0.8 V

BOD enabled 0.6 1.2 1.8 V

V

RST

RESET Pin Threshold Voltage 0.6V

CC

(BODLEVEL = 1) 1.7 1.8 1.9

V

BOT

Note: 1. The Power-on Reset will not work unless the supply voltage has been below V

Brown-out Reset Threshold Voltage

(BODLEVEL = 0) 2.6 2.7 2.8

(falling).

POT

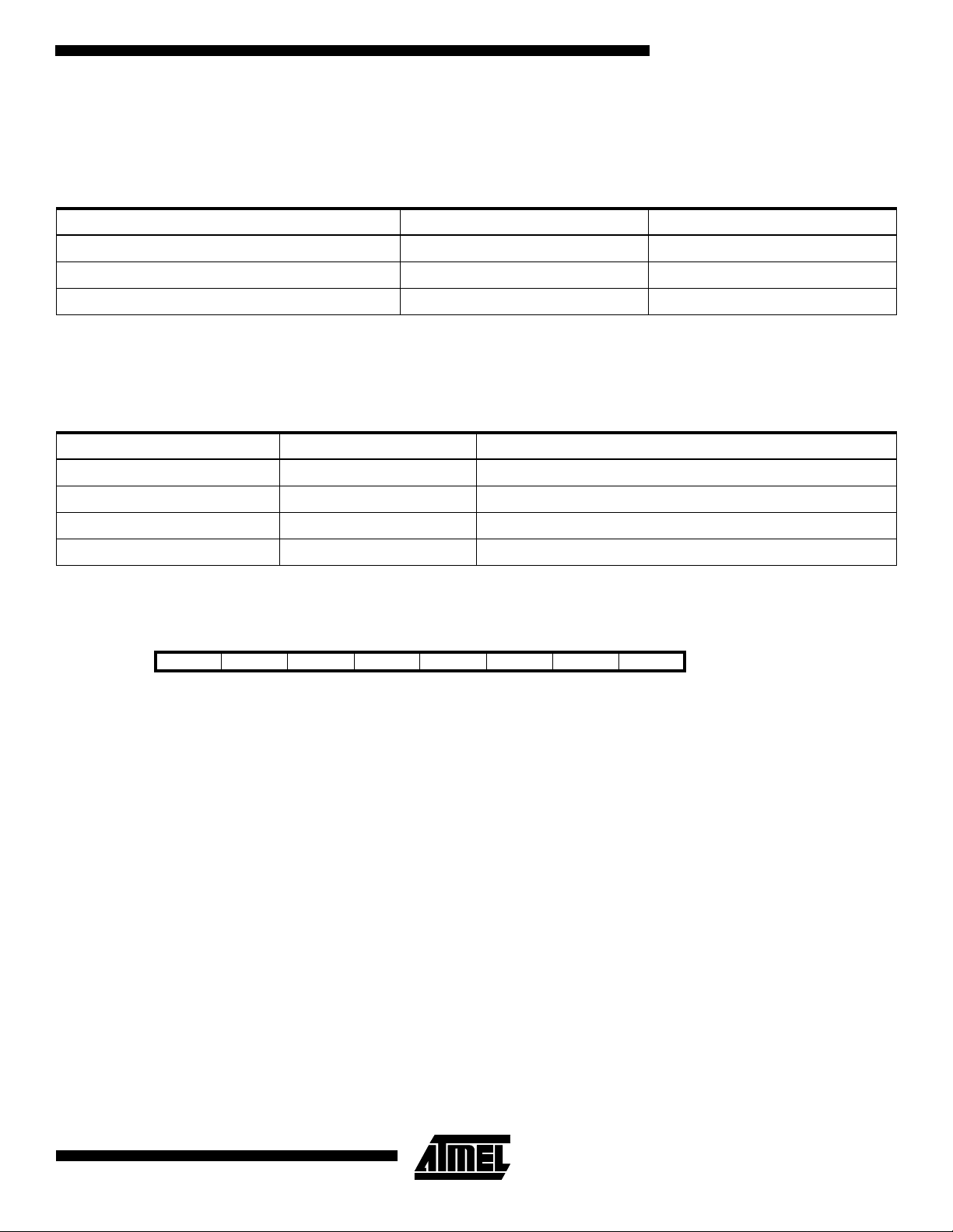

Table 9. ATtiny12 Clock Options and Start-up Times

Start-up Time, V

CKSEL3..0 Clock Source

1111 Ext. Crystal/Ceramic Resonator

1110 Ext. Crystal/Ceramic Resonator

1101 Ext. Crystal/Ceramic Resonator

(1)

(1)

(1)

BODLEVEL Unprogrammed

3.6 ms + 1K CK 4.2 ms + 1K CK

1100 Ext. Crystal/Ceramic Resonator 16K CK 16K CK

1011 Ext. Crystal/Ceramic Resonator 3.6 ms + 16K CK 4.2 ms + 16K CK

1010 Ext. Crystal/Ceramic Resonator 57 ms + 16K CK 67 ms + 16K CK

1001 Ext. Low-frequency Crystal 57 ms + 1K CK 67 ms + 1K CK

1000 Ext. Low-frequency Crystal 57 ms + 32K CK 67 ms + 32K CK

0111 Ext. RC Oscillator 6 CK 6 CK

0110 Ext. RC Oscillator 3.6 ms + 6 CK 4.2 ms + 6 CK

= 1.8V,

CC

Start-up Time, VCC = 2.7V,

BODLEVEL Programmed

1K CK 1K CK

57 ms 1K CK 67 ms + 1K CK

V

V

0101 Ext. RC Oscillator 57 ms + 6 CK 67 ms + 6 CK

0100 Int. RC Oscillator 6 CK 6 CK

0011 Int. RC Oscillator 3.6 ms + 6 CK 4.2 ms + 6 CK

0010 Int. RC Oscillator 57 ms + 6 CK 67 ms + 6 CK

0001 Ext. Clock 6 CK 6 CK

0000 Ext. Clock 3.6 ms + 6 CK 4.2 ms + 6 CK

Note: 1. Due to the limited number of clock cycles in the start-up period, it is recommended that Ceramic Resonator be used.

This table shows the start-up times from reset. From sleep, only the clock counting part of the start-up time is used. The

Watchdog oscillator is used for ti min g th e r eal -tim e part of the start-up time. Th e nu mbe r of WD T os ci ll ato r cy c les us ed for

each time-out is shown in Table 10.

19

Table 10. Number of Watchdog Oscillator Cycles

BODLEVEL Time-out Number of Cycles

Unprogrammed 3.6 ms (at V

Unprogrammed 57 ms (at V

Programmed 4.2 ms (at V

= 1.8V) 256

cc

= 1.8V) 4K

cc

= 2.7V) 1K

cc

Programmed 67 ms (at Vcc = 2.7V) 16K

The frequency of the watch dog osc illator is voltag e depe ndent as shown in the sect ion “A Ttiny 11 T ypic al Chara cter ist ics”

on page 54.

Note that the BODLEVEL fuse c an be us ed to s elec t st ar t- up times ev en i f the Brown- o ut Dete ct ion is dis ab led (by l eav in g

the BODEN fuse unprogrammed).

The device is shipped with CKSEL3..0 = 0010.

Power-on Reset for the ATtiny12

A Power-on Reset (POR) pulse is generated by an on-ch ip detection circuit. The de tection level is nominally 1.4V. The

POR is activated whenever V

is below the detection level. The POR circuit can be used to trigger the start-up reset, as

CC

well as detect a failure in supply voltage.

The Power-on Reset (POR) circuit ensures that the device is reset from power-on. Reaching the Power-on Reset threshold

voltage invokes a de la y c oun ter , wh ic h de ter mi nes the delay for which the device is ke pt i n Re set after V

rise. The time-

CC

out period of the del ay cou nter can be defined by the user t hr ough the CKS EL fuses . T he dif fer ent se lec ti ons for th e de lay

period are presented in Table 9. The Reset signal is activated again, without any delay, when the V

decreases below

CC

detection level.

If the built-in start-up delay is sufficient, RESET

Figure 18. By holding the RESET

pin low for a period after VCC has been applied, the Power-on Reset period can be

can be connected to VCC directly or via an external pull-up resistor. See

extended. Refer to Figure 19 for a timing example on this.

Figure 18. MCU Start-up, RESET

V

CC

RESET

TIME-OUT

INTERNAL

RESET

Tied to VCC.

V

POT

V

RST

t

TOUT

20

ATtiny10/11/12

ATtiny10/11/12

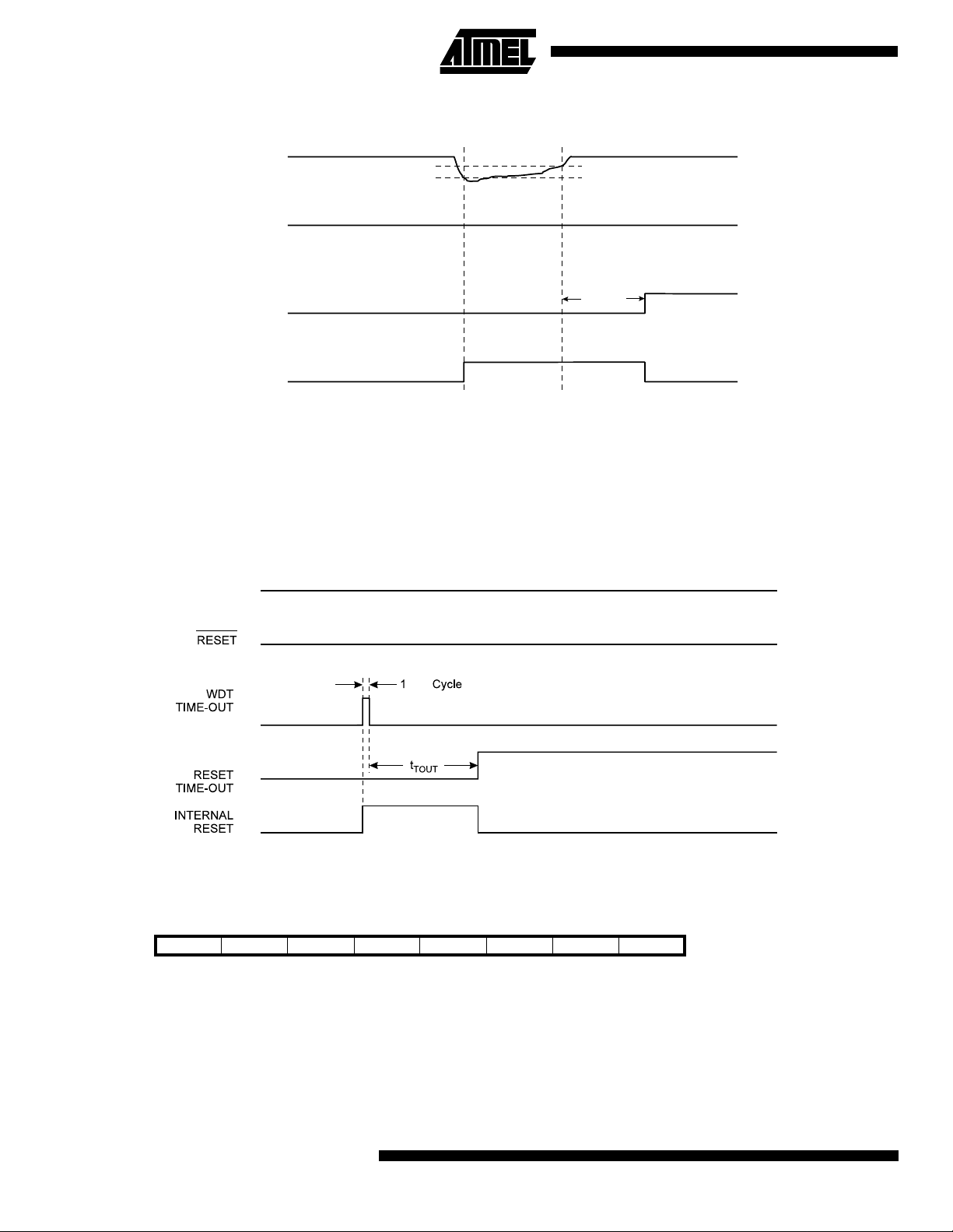

Figure 19. MCU Start-up, RESET

V

CC

RESET

TIME-OUT

INTERNAL

RESET

Extended Externally

V

POT

V

RST

t

TOUT

External Reset

An external reset is generated by a low level on the RESET

pin. Reset pulses longer than 50 ns will generate a reset, even

if the clock is no t running. Shorter pu lses are n ot guarante ed to gener ate a re set. When the applied s ignal reac hes the

Reset Threshold Voltage – V

– on its positive edge, the delay timer starts the MCU after the Time-out period (t

RST

TOUT

) has

expired.

Figure 20. External Reset during Operation

V

CC

RESET

TIME-OUT

INTERNAL

RESET

V

RST

t

TOUT

Brown-out Detection (ATtiny12)

ATtiny12 has an on-chi p brown-out dete ction (BOD ) circuit for monit oring the V

circuit can be enabled/disabled by the fuse BODEN. When BODEN is enabled (BODEN programmed), and V

below the trigger level, the brown-out reset is immediately activated. When V

level during the opera tion. The BOD

CC

increases above the trigger level, the

CC

decreases

CC

brown-out reset is de ac tiv ate d af ter a d el ay. T he d el ay is de fin ed b y the u se r in the sa me w ay as the del ay of PO R sig nal ,

in Table 5. The trigger level for the BOD can be selected by the fuse BODLEVEL to be 1.8V (BODLEVEL unprogrammed),

or 2.7V (BODLEVEL programmed). The trigger level has a hysteresis of 50 mV to ensure spike-free brown-out detection.

The BOD circuit will only detect a drop in V

if the voltage stays below the trigger level for longer than 7 µs for trigger level

CC

2.7V, 24 µs for trigge r level 1.8V (typical values).

21

Figure 21. Brown-out Reset during Operation (ATtiny12)

V

CC

V

BOT-

V

BOT+

RESET

t

TIME-OUT

TOUT

INTERNAL

RESET

Note: The hy steresis on V

BOT

: V

BOT +

= V

+ 25 mV, V

BOT

BOT-

= V

BOT

- 25 mV.

Watchdog Rese t

When the Watchdog tim es out , it wil l gene rate a s hor t res et pul se of 1 CK cy c le dur at ion . O n th e fa ll ing ed ge o f thi s pul s e,

the delay timer starts counting the Time-out period (t

). Refer to page 31 for details on operation of the Watchdog.

TOUT

Figure 22. Watchdog Reset during Operatio n

V

CC

CK

MCU Status Register – MCUSR of the ATtiny10/11

The MCU Status Register provides information on which reset source caused an MCU reset.

Bit 76543210

$34 ------EXTRFPORFMCUSR

Read/Write R R R R R R R/W R/W

Initial value 0 0 0 0 0 0 See bit description

Bit 7..2 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny10/11 and always read as zero.

Bit 1 - EXTRF: EXTernal Reset Flag

•

After a power-on reset, this bit is undefined (X). It will be set by an external reset. A watchdog reset will leave this bit

unchanged.

22

ATtiny10/11/12

ATtiny10/11/12

Bit 0 - PORF: Power-on Reset Flag

•

This bit is set by a power-on reset. A watchdog reset or an external reset will leave this bit unchanged.

To summarize, the following table shows the value of these two bits after the three modes of reset.

Table 11. PORF and EXTRF Values after Reset

Reset Source EXTRF PORF

Power-on undefined 1

External Reset 1 unchanged

Watchdog Reset unchanged unchanged

To identify a reset condition, the user software should clear both the PORF and EXTRF bits as early as possible in the program. Checking the PORF and EXTRF values is done before the bits are cleared. If the bit is cleared before an external or

watchdog reset occurs, the source of reset can be found by using the following truth table:

Table 12. Reset Source Identification

EXTRF PORF Reset Source

0 0 Watchdog Re set

1 0 External Reset

0 1 Power-on Reset

1 1 Power-on Reset

MCU Status Register – MCUSR for the ATtiny12

The MCU Status Register provides information on which reset source caused an MCU reset.

Bit 76543210

$34 - - - - WDRF BORF EXTRF PORF MCUSR

Read/Write R R R R R/W R/W R/W R/W

Initial value 0 0 0 0 See bit description

Bit 7..4 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny12 and always read as zero.

Bit 3 - WDRF: Watchdog Reset Flag

•

This bit is set if a watchdog reset occurs. The bit is reset by a power-on reset, or by writing a logic zero to the flag.

Bit 2 - BORF: Brown-out Reset Flag

•

This bit is set if a brown-out reset occurs. The bit is reset by a power-on reset, or by writing a logic zero to the flag.

•

Bit 1 - EXTRF: EXTernal Reset Flag

This bit is set if an external reset occurs. The bit is reset by a power-on reset, or by writing a logic zero to the flag.

Bit 0 - PORF: Power-on Reset Flag

•

This bit is set if a power-on reset occurs. The bit is reset by writing a logic zero to the flag.

To use the reset flags to iden tify a res et c ondi ti on, th e user sho ul d read an d the n re se t the MC USR as early as possible in

the program. If the re gister is c leared bef ore anot her reset oc curs, the source of th e reset ca n be found by examinin g the

reset flags.

ATtiny12 Interna l Voltage Reference

ATtiny12 features an internal voltage reference with a nominal voltage of 1.22V. This reference is used for Brown-out

Detection, and it can be used as an input to the Analog Comparator.

23

Voltage Reference Enable Signals and Start-up Time

The voltage reference has a start-up time that may influence the way it should be used. The maximum start-up time is TBD.

To save power, the reference is not always turned on. The reference is on during the following situations:

1. When BOD is enabled (by programming the BODEN fuse)

2. When the bandgap reference is connected to the Analog Comparator (by setting the AINBG bit in ACSR)

Thus, when BOD is not enabled, after setting the AINBG bit, the user must always allow the reference to start up before the

output from the Analog Compara tor is used. The bandgap refe rence use s approxi matel y 10 µA, and to reduc e power consumption in Power-down mode, the user can turn off the reference when entering this mode.

Interrupt Handling

The ATtiny10/11/12 h as two 8-bi t Interr upt Ma sk cont rol regist ers; G IMSK – Gene ral Interrup t Ma sk reg ister and TIMSK –

Timer/Counter Interrupt Mask register.

When an interrupt occurs, the Global Interrupt Enable I-bit is cleared (zero) and all interrupts are disabled. The user software can set (one) the I-bit to enabl e nested interrupts. The I-bit is set (one) when a Return from Interrupt instruction –

RETI – is executed.

When the Program Counter is vectored to the actual interrupt vector in order to execute the interrupt handling routine, hardware clears the corresponding flag that generated the interrupt. Some of the interrupt flags can also be cleared by writing a

logic one to the flag bit position(s) to be cleared.

If an interrupt condition occurs when the corresponding interrupt enable bit is cleared (zero), the interrupt flag will be set

and remembered until the interrupt is enabled, or the flag is cleared by software.

If one or more interrupt condi tions occu r when the global interrupt ena ble bit is clea red (zero), th e correspondi ng interrup t

flag(s) will be set and remembered until the global interrupt enable bit is set (one), and will be executed by order of priority.

Note that external level interrupt does not have a flag, and will only be remembered for as long as the interrupt condition is

active.

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from

an interrupt routine. This must be handled by software.

Interrupt Response Time

The interrupt execution response for all the enabled AVR interrupts is 4 clock cycles minimum. After the 4 clock cycles, the

program vector addr ess fo r the actual i nte rrup t ha ndl in g r ou tin e i s exec ute d. Du r ing thi s 4- c lock -cy cle period, the Program

Counter (9 bits) is pushed onto the Stack. The vector is normally a relative jump to the interrupt routine, and this jump takes

2 clock cycles. If an interrupt occurs during execution of a multi-cycle instruction, this instruction is completed before the

interrupt is served. In ATtiny12, if an interrupt occurs when the MCU is in Sleep mode, the interrupt response time is

increased by 4 clock cycles.

A return from an in terrupt h andli ng rou tine ta kes 4 cloc k cyc les. Du ring the se 4 c lock c ycles, the Pr ogram Co unte r (9 bits)

is popped back from th e St ac k, a nd th e I-fla g in SREG is se t. W hen AV R ex its fr om an i nterr upt , it wi ll al ways r et urn to the

main program and execute one more instruction before any pending interrupt is served.

General Interrupt Mask Register – GIMSK

Bit 7 6 5 4 3 2 1 0

$3B - INT0 PCIE - - - - - GIMSK

Read/Write R R/W R/W R R R R R

Initial value 0 0 0 0 0 0 0 0

Bit 7 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny10/11/12 and always reads as zero.

Bit 6 - INT0: External Interrupt Request 0 Enable

•

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the external pin interrupt is enabled.

The Interrupt Sense Control0 bits 1/0 (ISC01 and ISC00) in the MCU general Control Register (MCUCR) define whether

the external interrupt is activated on rising or falling edge, on pin change, or low level of the INT0 pin. Activity on the pin will

24

ATtiny10/11/12

ATtiny10/11/12

cause an interrupt req uest even if INT0 is configured a s an output. The c orresponding in terrupt of External Interrupt

Request 0 is executed from program memory address $001. See also “External Inte rrup ts. ”

Bit 5 - PCIE: Pin Change Interrupt Enable

•

When the PCIE bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the interrupt on pin change is

enabled. Any change on any input or I/O pin will cause an interrupt. The corresponding interrupt of Pin Change Interrupt

Request is executed from program memory address $002. See also “Pin Change Interrupt.”

Bits 4..0 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny10/11/12 and always read as zero.

General Interrupt Flag Register – GIFR

Bit 7 6 5 4 3 2 1 0

$3A - INTF0 PCIF - - - - - GIFR

Read/Write R R/W R/W R R R R R

Initial value 0 0 0 0 0 0 0 0

Bit 7 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny10/11/12 and always reads as zero.

Bit 6 - INTF0: External Interrupt Flag0

•

When an event on the INT0 pin triggers an interrupt request, INTF0 becomes set (one). If the I-bit in SREG and the INT0 bit

in GIMSK are set (one), the MCU will jump to the interrupt vector at address $001. The flag is cleared when the interrupt

routine is executed. Alternatively, the flag can be cleared by writing a logical one to it. The flag is always cleared when INT0

is configured as level interrupt.

Bit 5 - PCIF: Pin Change Interrupt Flag

•

When an event on a ny inp ut or I/O pin trigge rs an inter rup t reque st , PCIF beco mes set (one ). If the I-bit in SRE G a nd th e

PCIE bit in GIMSK are set (one), the MCU will jump to the interrupt vector at address $002. The flag is cleared when the

interrupt routine is executed. Alternatively, the flag can be cleared by writing a logical one to it.

Bits 4..0 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny10/11/12 and always read as zero.

Timer/Counter Interrupt Mask Register – TIMSK

Bit 7 6 5 4 3 2 1 0

$39 ----- -TOIE0-TIMSK

Read/Write R R R R R R R/W R

Initial value 0 0 0 0 0 0 0 0

Bit 7..2 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny10/11/12 and always read as zero.

•

Bit 1 - TOIE0: Timer/Counter0 Overflow Interrupt Enable

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter0 Overflow interrupt is

enabled. The corresponding interrupt (at vector $003) is executed if an overflow in Timer/Counter0 occurs, i.e., when the

Overflow Flag (Timer0) is set (one) in the Timer/Counter Interrupt Flag Register – TIFR.

Bit 0 - Res: Reserved bit

•

This bit is a reserved bit in the ATtiny10/11/12 and always reads as zero.

Timer/Counter Interrupt Flag Register – TIFR

Bit 7 6 5 4 3 2 1 0

$38 -- ----TOV0-TIFR

Read/Write R R R R R R R/W R

Initial value 0 0 0 0 0 0 0 0

Bits 7..2 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny10/11/12 and always read as zero.

25

Bit 1 - TOV0: Timer/Counter0 Overflow Flag

•

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared by hardware when executing the

corresponding interrupt handling vector. Alternatively, TOV0 is cleared by writing a logical one to the flag. When the SREG

I-bit, TOIE0 (Timer/Counter0 Overflow Interrupt Enable), and TOV0 are set (one), the Timer/Counter0 Overflow interrupt is

executed.

Bit 0 - Res: Reserved bit

•

This bit is a reserved bit in the ATtiny10/11/12 and always reads as zero.

External Interrupt

The external interrupt is trigger ed by th e INT0 pin. Obs erve tha t, if enabl ed, the i nterrup t will trig ger even if the INT0 pi n is

configured as an o utput. Th is fe ature provid es a way of generati ng a s oftware int errupt. The ext ernal i nterrupt can be triggered by a falling or rising edge, a pin change, or a low level. This is set up as indicated in the specification for the MCU

Control Register – MCUCR. When the external interrupt is enabled and is configured as level triggered, the interrupt will

trigger as long as the pin is held low.

The external interrupt is set up as described in the specification for the MCU Control Register – MCUCR.

Pin Change Interrupt

The pin change interrupt is triggered by any change on any input or I/O pin. Change on pins PB2..0 will always cause an

interrupt. Change on pins PB 5..3 will caus e an interr upt if the p in is con figured as i nput o r I/O, as de scrib ed in the s ectio n

“Pin Descriptions” on page 5. Observe that, if enabled, the interrupt will tr igg er even if the cha nging pin is co nfi gured as an

output. This feature provides a way of generating a software interrupt. Also observe that the pin change interrupt will trigger

even if the pin activity triggers another interrupt, for example, the external interrupt. This implies that one external event

might cause several inter rupts .

The values on the pins are sa mpl ed b efor e d etec ting ed ges . If pi n c han ge i nterr upt is enab le d, pul s es that las t lon ger tha n

one CPU clock period will generate an interrupt. Shorter pulses are not guaranteed to generate an interrupt.

MCU Control Register – MCUCR

The MCU Control Register contains control bits for general MCU functions.

Bit 76543210

$35 - (PUD) SE SM - - ISC01 ISC00 MCUCR

Read/Write R R(/W) R/W R/W R R R/W R/W

Initial value 0 0 0 0 0 0 0 0

Note: The Pull-up Disable (PUD) bit is only available in ATtiny12.

• Bit 7 - Res: Reserved bit

This bit is a reserved bit in the ATtiny10/11/12 and always reads as zero.

Bit 6 - Res: Reserved bit in ATtiny10/11

•

This bit is a reserved bit in the ATtiny10/11 and always reads as zero.

Bit 6 - PUD: Pull-up Disable in ATtiny12

•

Setting this bit, d isab les a ll pull- up s on p or t B . If thi s b it is clea re d, t he p ul l-ups c an be ind iv id ual ly en abl ed as de sc r ibe d i n

section “I/O Port B” on page 36.

•

Bit 5 - SE: Sleep Enable

The SE bit must be set (one) to make the MCU enter the Sleep Mode when the SLEEP instruction is executed. To avoid

the MCU entering the Sleep Mode unless it is the programmer’s purpose, it is recommended to set the Sleep Enable SE bit

just before the execution of the SLEEP instruction.

Bit 4 - SM: Sleep Mode

•

This bit selects between the two ava ilabl e sl eep mode s. When SM is cl ea red (z ero) , Idl e Mod e is selec ted as Sl ee p Mod e.

When SM is set (one), Power-down Mode is selected as Sleep Mode. For details, refer to the paragraph “Sleep Modes”

below.

26

ATtiny10/11/12

ATtiny10/11/12

Bits 3, 2 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny10/11/12 and always read as zero.

•

Bits 1, 0 - ISC01, ISC00: Interrupt Sense Control0 bit 1 and bit 0

The External Interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the corresponding interrupt mask are

set. The following table shows how to set the ISC bits to generate an external interrupt:

Table 13. Interrupt 0 Sense Control

ISC01 ISC00 Description

0 0 The low level of INT0 generates an interrupt request.

0 1 Any change on INT0 generates an interrupt request

1 0 The falling edge of INT0 generates an interrupt request.

1 1 The rising edge of INT0 generates an interrupt request.

Note: When changing the ISC01/ISC00 bits, INT0 must be disabled by clearing its Interrupt Enable bit in the GIMSK Register.

Otherwise, an interrupt can occur when the bits are changed.

The value on the INT0 pin is sampled before detecting edges. If edge interrupt is selected, pulses that last longer than one

CPU clock period will generate an interrupt. Shorter pulses are not guaranteed to generate an interrupt. If low-level interrupt is selec ted, the l ow level must be held unti l the com pletion o f the curr ently executing instr uction to g enerate an

interrupt. If enabled, a level-triggered interrupt will generate an interrupt request as long as the pin is held low.

Sleep Modes for the ATtiny10/11

To enter the sleep modes, the SE bit in MCUCR must be set (one) and a SLEEP instruction must be executed. The SM bit

in the MCUCR register selects which sleep mode (Idle or Power -down) will be activated by the S LEEP instruction . If an

enabled interrupt occur s while t he MCU is in a sleep mode, the MCU awak es , exec utes the int er rupt r out ine , and re su mes

execution from the instruction following SLEEP. On wake-up from Power-down Mode on pin change, the two instructions

following SLEEP are executed before the pin change interrupt routine. The contents of the register file and I/O memory are

unaltered. If a reset occurs during Sleep Mode, the MCU wakes up and executes from the Reset vector.

Idle Mode

When the SM bit is cleared (zero), the SLEEP instruction forces the MCU into the Idle Mode, stopping the CPU but allowing

Timer/Counters, Watchdog and the interrupt system to continue operating. This enables the MCU to wake up from external

triggered interrupts as well as inte rnal one s li ke Ti mer Over fl ow inte r rupt and W atc hdo g Rese t. If wake-up from the Analog

Comparator interrupt is not required, the analog comparator can be powered down by setting the ACD-bit in the Analog

Comparator Control and Status register – ACSR . This wil l reduc e pow er cons um pti on in Idle Mod e. Wh en the MCU wak es

up from Idle mode, the CPU starts program execution immediately.

Power-down Mode

When the SM bit is set (one), the SLEEP instruction forces the MCU into the Power-down Mode. In this mode, the external

oscillator is stopped, while the external interrupts and the Watchdog (if enabled) continue operating. Only an external reset,

a watchdog reset (if enabled), an external level interrupt, or an pin change interrupt can wake up the MCU.

Note that if a level-triggered or pin change interrupt is used for wake-up from power-down, the changed level must be held

for a time longer than the reset delay period of t

. Otherwise, the MCU will fail to wake up.

TOUT

27

Sleep Modes for the ATtiny12

To enter the sleep modes, the SE bit in MCUCR must be set (one) and a SLEEP instruction must be executed. The SM bit

in the MCUCR register selects which sleep mode (Idle or Power -down) will be activated by the S LEEP instruction . If an

enabled interrupt occurs while the MCU is in a sleep mode, the MCU awakes. The CPU is then halted for four cycles, it

executes the interrupt routine, and resumes execution from the instruction following SLEEP. The contents of the register

file and I/O memory are unaltered. If a reset occurs during sleep mode, the MCU wakes up and executes from the Reset

vector.

Idle Mode

When the SM bit is cleared (zero), the SLEEP instruction forces the MCU into the Idle Mode stopping the CPU but allowing

Timer/Counters, Watchdog and the interrupt system to continue operating. This enables the MCU to wake up from external

triggered interrupts as well as inte rnal one s li ke Ti mer Over fl ow inte r rupt and W atc hdo g Rese t. If wake-up from the Analog

Comparator interrupt is not required, the analog comparator can be powered down by setting the ACD-bit in the Analog

Comparator Control and Status Register – ACSR. This will reduce power consumption in Idle Mode.

Power-down Mode

When the SM bit is set (one), the SLEEP instruction forces the MCU into the Power-down Mode. In this mode, the external

oscillator is stopped, while the external interrupts and the Watchdog (if enabled) continue operating. Only an external reset,

a watchdog reset (if enabled), an external level interrupt, or a pin change interrupt can wake up the MCU.

Note that if a level triggered or pin change interrupt is used for wake-up from Power-down Mode, the changed level must be

held for a time to wake up the MCU. This makes the MCU less sensitive to noise. The wake-up period is equal to the clockcounting par t of the re set per iod (Se e Tabl e 9). The M CU wi ll wake u p from the powe r-dow n if the in put has the re quired

level for two wa tchdog oscil lator c ycles. If the wak e-up period is sho rter than t wo watc hdog o scilla tor cy cles, th e MCU w ill

wake up if the input has the required level for the duration of the wake-up period. If the wake-up condition disappears

before the wake-up period has expired, the MCU will wake up from power-down without executing the corresponding interrupt. The period of the watchdog oscillator is 2.7 µs (nominal) at 3.0V and 25

voltage dependent as shown in the section “ATtiny11 Typical Characteristics” on page 54.

When waking up from Power-down Mode, there is a delay from the wake-up condition occurs until the wake-up becomes

effective. This a llows the clo ck to r estart a nd bec ome s table after havi ng bee n stop ped. The wake- up pe riod is defi ned by

the same CKSEL fuses that define the reset time-out period.

°C. The frequency of the watchdog oscillator is

ATtiny12 Calibrated Internal RC Oscillator

In ATtiny12, the calibrated internal oscillator provides a fixed 1 MHz ( nominal) clock at 5V and 25 °C. This clock may be

used as the system clock. See the section “Clock Options” on page 6 for information on how to select this clock as the system clock. This oscillator can be calibrated by writing the calibration byte to the OSCCAL register. When this oscillator is

used as the chip clock, the Watchdog Oscillator will still be used for the W atchdog Timer and for the reset time-out.

details on how to use the pre-programmed calibration value, see the section “Calibration Byte in ATtiny12” on page 40.

Oscillator Calibration Register – OSCCAL

Bit 76543210

$31 CAL7 CAL6 CAL5 CAL4 CAL3 CAL2 CAL1 CAL0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..0 - CAL7..0: Oscillator Calibration Value

•

Writing the calibration byte to this address will trim the internal oscillator to remove process variations from the oscillator

frequency. When OSCCAL is zero, the lowest available frequency is chosen. Writing non-zero values to this register will

increase the frequen cy of t he i nter na l os cil la tor . Wri tin g $F F to t he r eg is ter gi ve s the highest available frequenc y . The c al ibrated oscillator is used to time EEP ROM access. If EE PROM is writte n, do not calibrate to more than 10% ab ove the

28

ATtiny10/11/12

For

ATtiny10/11/12

nominal frequency. Otherwise, the EEPROM write may fail. Table 14 shows the range for OSCCAL. Note that the oscillator

is intended for calibration to 1.0 MHz, thus tuning to other values is not guaranteed.

Table 14. Internal RC Oscillator Frequency Range

OSCCAL Value Min Frequency Max Frequency

$00 0.5 MHz 1.0 MHz

$7F 0.7 MHz 1.5 MHz

$FF 1.0 MHz 2.0 MHz

Timer/Counter0

The ATtiny10/11/12 provides one general-purpose 8-bit Timer/Counter – Timer/Counter0. The Timer/Counter0 has prescaling selection from the 10-bit pr escali ng time r. The Tim er/Cou nter0 ca n either be used as a tim er with an i ntern al clock

timebase or as a counter with an external pin connection that triggers the counting.

Timer/Counter Prescaler

Figure 23 shows the Timer/ Counter pres caler.

Figure 23. Timer/Counter0 Prescaler

CK

T0

CS00

CS01

CS02

10-BIT T/C PRESCALER

CK/8

0

TIMER/COUNTER0 CLOCK SOURCE

TCK0

CK/64

CK/256

CK/1024

The four different prescaled selections ar e: CK/8, CK/64, CK/256 and CK/1024 where CK is the oscillator clo ck. CK,

external source and stop, can also be selected as clock sources.

Figure 24 shows the block diagram for Timer/Counter0.

The 8-bit Timer/Counter0 ca n se lec t c lock sou rce from CK , pr es ca led CK, or an ex ter na l pin. In add ition, it can be stopped

as described in the specification for the Timer/Counter0 Control Register – TCCR0. The overflow status flag is found in the

Timer/Counter Interrupt Flag Register – TIFR. Control signals are fo und in th e T i mer/Co unt er 0 Co ntrol Re gis ter – TCCR 0.

The interrupt enable/disable settings for Timer/Counter0 are found in the Timer/Counter Interrupt Mask Register – TIMSK.

When Timer/Counter0 is externally clocked, the external signal is synchronized with the oscillator frequency of the CPU. To

ensure proper sampling of the external clock, the minimum time between two external clock transitions must be at least one

internal CPU clock period. The external clock signal is sampled on the rising edge of the internal CPU clock.

29

The 8-bit Time r/Coun ter0 fe ature s both a hi gh-re soluti on and a high-ac curac y usag e with th e lower p resca ling o pport unities. Similarly, the hi gh-p rescal ing opp ortuniti es make th e Tim er/Counte r0 us eful for l ower-speed functi ons or ex act-ti ming

functions with infrequent actions.

Figure 24. Timer/Counter0 Block Diagram

T0

Timer/Counter0 Control Register – TCCR0

Bit 76 5 4 3 210

$33 - - - - - CS02 CS01 CS00 TCCR0

Read/Write R R R R R R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..3 - Res: Reserved bits:

•

These bits are reserved bits in the ATtiny10/11/12 and always read as zero.

•

Bits 2,1,0 - CS02, CS01, CS00: Clock Select0, bit 2,1 and 0:

The Clock Select0 bits 2,1 and 0 define the prescaling source of Timer0.

Table 15. Clock 0 Prescale Select

CS02 CS01 CS00 Description

0 0 0 Stop, the Timer/Counter0 is stopped.

001CK

010CK/8

011CK/64

100CK/256

101CK/1024

1 1 0 External Pin T0, falling edge

1 1 1 External Pin T0, rising edge

30

ATtiny10/11/12

ATtiny10/11/12

The Stop condition provides a Timer Enable/Disable function. The CK down-divided modes are scaled directly from the CK

oscillator clock. If the external pin modes are used for Timer/Counter0, transitions on PB2/(T0) will clock the counter even if

the pin is configured as an output. This feature can give the user SW control of the counting.

Timer Counter 0 – TCNT0

Bit 76543210

$32 MSB LSB TCNT0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

The Timer/Counter0 is implemented as an up-counter with read and write access. If the Timer/Counter0 is written and a

clock source is present, the Timer/Counter0 continues counting in the timer clock cycle following the write operation.

Watchdog Timer

The Watchdog Timer is clocked from a separate on-chip oscill ator. By controlling the Watchdog Timer pres caler, the

Watchdog reset interval can be adjusted as shown in Table 16. See characterization data for typical values at other V

levels. The WDR – Watchdog Reset – instruction resets the Watchdog Timer. Eight different clock cycle periods can be

selected to d etermine t he re set per iod. If the re set peri od expi res wi thout a nother W atchdog reset, the A Ttiny10 /11/12

resets and executes from the reset vector. For timing details on the Watchdog reset, refer to page 22.

To prevent unintentional disabling of the watchdog, a special tur n-off sequence must be followed when the watchdog is

disabled. Refer to the description of the Watchdog Timer Control Register for details.

CC

Figure 25. Watchdog Timer

Oscillator

1 MHz at V

350 kHz at V

110 kHz at V

CC

CC

CC

= 5V

= 3V

= 2V

31

Watchdog Timer Control Register – WDTCR

Bit 76543210

$21 - - - WDTOE WDE WDP2 WDP1 WDP0 WDTCR

Read/Write R R R R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..5 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny10/11/12 and will always read as zero.

•

Bit 4 - WDTOE: Watchdog Turn-off Enable

This bit must be set (one) when the WDE bit is clear ed. Oth erwise, the watch dog will not be dis able d. Once set, hardwar e

will clear this bit to zero after four clock cycles. Refer to the description of the WDE bit for a watchdog disable procedure.

Bit 3 - WDE: Watchdog Enable

•

When the WDE is set (one) the Watchdog Timer is enabled, and if the WDE is cleared (zero) the Watchdog Timer function

is disabled. WDE can be cle ared only whe n the WDTO E bit is set(on e). To disab le an enabled watchdog timer, the

following procedure must be followed:

1. In the same operation, write a logical one to WDTOE and WDE. A logical one must be written to WDE even though

it is set to one before the disable operation starts.

2. Within the next four clock cycles, write a logical 0 to WDE. This disables the watchdog.

Bits 2..0 - WDP2, WDP1, WDP0: Watchdog Timer Prescaler 2, 1 and 0

•

The WDP2, WDP1 and WDP0 bits determine the Watchdog Timer prescaling when the Watchdog Timer is enabled. The

different prescaling values and their corresponding time-out periods are shown in Table 16.

Table 16. Watchdog Timer Prescale Select

Number of WDT

WDP2 WDP1 WDP0

0 0 0 16K cycles 0.15s 47 ms 15 ms

0 0 1 32K cycles 0.30s 94 ms 30 ms

0 1 0 64K cycles 0.60s 0.19 s 60 ms

0 1 1 128K cycles 1.2s 0.38 s 0.12 s

1 0 0 256K cycles 2.4s 0.75 s 0.24 s

1 0 1 512K cycles 4.8s 1.5 s 0.49 s

1 1 0 1,024K cycles 9.6s 3.0 s 0.97 s

1 1 1 2,048K cycles 19s 6.0 s 1.9 s

Note: The frequency of the Watchdog Oscillator is voltage dependent as shown in the section “ATtiny11 Typical Characteristics” on

page 54.

The WDR – Watchdog Reset – instruction sho uld alw a y s be e x ecute d before the Watchdog Timer is enabled. This ensur es that

the reset period will be in accordance with the Watchdog Timer prescale settings. If the Watchdog Timer is enabled without

reset, the Watchdog Timer may not start counting from zero.

Oscillator cycles

Typical Time-out

at VCC = 2.0V

Typical Time-out

at VCC = 3.0V

Typical Time-out

at VCC = 5.0V

32

ATtiny10/11/12

ATtiny10/11/12

ATtiny12 EEPROM Read/Write Access

The EEPROM access registers are accessible in the I/O space.

The write access time is in the range of 1.9 - 3.4 ms, depending on the frequency of the calibrated RC oscillator. See Table

17 for details. A self-timing function lets the user software detect when the next byte can be written. A special EEPROM

Ready interrupt can be set to trigger when the EEPROM is ready to accept new data.

In order to prevent unintentional EEPROM writes, a two-state write procedure must be followed. Refer to the description of

the EEPROM Control Register for details on this.

When the EEPROM is written , the CPU is halted for two clock cycles b efore the next ins truction is ex ecuted. When the

EEPROM is read, the CPU is halted for four clock cycles before the next instruction is executed.

EEPROM Address Register – EEAR

Bit 76543210

$1E - - EEAR5 EEAR4 EEAR3 EEAR2 EEAR1 EEAR0 EEAR

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial value 0 0 X X X X X X

The EEPROM Address Register – EEAR specifies the EEPROM address in the 64-byte EEPROM space. The EEPROM

data bytes are addressed linearly between 0 and 63. During reset, the EEAR register is not cleared. Instead, the data in the

register is kept.

EEPROM Data Register – EEDR

Bit 76543210

$1D MSB LSB EEDR

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..0 - EEDR7.0: EEPROM Data

•

For the EEPROM wr ite o peration , th e EEDR r egist er co ntains the data to be writ ten to the EEPRO M in the ad dres s give n

by the EEAR register. For the EEPROM read operation, the EEDR contains the data read out from the EEPROM at the

address given by EEAR.

EEPROM Control Register – EECR

Bit 76543210

$1C - - - - EERIE EEMWE EEWE EERE EECR

Read/Write R R R R R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 X 0

Bit 7..4 - Res: Reserved bits

•

These bits are reserved bits in the ATtiny12 and will always read as zero.

Bit 3 - EERIE: EEPROM Ready Interrupt Enable

•

When the I-bit in SREG and EERIE are set (one), the EEPROM Ready interrupt is enabled. When cleared (zero), the interrupt is disabled. The EEPROM Ready interrupt generates a constant interrupt when EEWE is cleared (zero).

•

Bit 2 - EEMWE: EEPROM Master Write Enable

The EEMWE bit determin es whet her se tti ng E EWE to one causes the EEPROM to be written. W he n EEMW E i s s et (one) ,

setting EEWE will write data to the EEPROM at the selected address. If EEMWE is zero, setting EEWE will have no effect.

When EEMWE has been set (o ne) by softwa re, hardwa re cle ars the bit to zer o after four cl ock cyc les. See the descrip tion

of the EEWE bit for a EEPROM write procedure.

33

Bit 1 - EEWE: EEPROM Write Enable

•

The EEPROM Write Enable Signal EEWE is the write strobe to the EEPROM. When address and data are correctly set up,

the EEWE bit must be set to write the value into the EEPROM. The EEMWE bit must be set when the logical one is written

to EEWE, otherwise no EEP ROM write takes place. T he following procedure s hould be followed whe n writing the

EEPROM (the order of steps 2 and 3 is unessential):

1. Wait until EEWE becomes zero.

2. Write new EEPROM address to EEAR (optional).

3. Write new EEPROM data to EEDR (optional).

4. Write a logical one to the EEMWE bit in EECR.

5. Within four clock cycles after setting EEMWE, write a logical one to EEWE.

Caution: An interrupt between step 4 and step 5 will make the write cycle fail, since the EEPROM Master Write Enable will

time-out. If an interrupt routine accessing the EEPROM is interrupting another EEPROM access, the EEAR or EEDR register will be modified, causing the interrupted EEPROM access to fail. It is r ecommended to have the global i nterrupt flag

cleared during the four last steps to avoid these problems.

When the write access time has elapsed, the EEWE bit is cleared (zero) by hardware. The user software can poll this bit

and wait for a zero before writing the next byte. When EEWE has been set, the CPU is halted for two cycles before the next

instruction is execute d.

Bit 0 - EERE: EEPROM Read Enable

•

The EEPROM Read Enable Signal EERE is the read strobe to the EEPROM. When the correct address is set up in the

EEAR register, the EERE bit must be set. When the EERE bit is cleared (zero) by hardware, requested data is found in the

EEDR register. The EEPROM read access takes one instruction and there is no need to poll the EERE bit. When EERE

has been set, the CPU is halted for two cycles before the next instruction is executed.

The user should pol l the E EWE bi t before sta rting th e read operati on. If a write operati on is in prog ress when new data or

address is written to the EEPROM I/O registers, the write operation will be interrupted, and the result is undefined.

The calibrated oscilla tor is us ed to tim e EEP ROM. In T able 17 the typic al pr ogrammi ng time is liste d for EEP ROM ac cess

from the CPU.

Table 17. Typical EEPROM Programming Times

Number of Calibrated RC

Parameter

EEPROM write (from CPU) 2048 1.9 ms 3.4 ms

Oscillator Cycles Min Programming Time Max Programming Time

Prevent EEPROM Corruption

During periods of lo w VCC, the EEPROM data can be corrupted because the su ppl y v ol tag e is to o low for the CPU and the

EEPROM to operate properly. These issues are the same as for board-level systems using the EEPROM, and the same

design solutions should be applied.

An EEPROM data cor rup tion c an be cause d by two s ituati ons w hen the volta ge is too l ow. Fir st, a reg ular write s equenc e

to the EEPROM requi res a minim um vo ltage to opera te corr ectly. S econd ly, th e CPU it self c an ex ecute ins truc tions inco rrectly if the supply voltage for executing instructions is too low.

EEPROM data corruption can easily be avoided by following these design recommendations (one is sufficient):

1. K eep the AVR RESET active (low) during periods of insufficient power supply voltage. This can be done by enabling

the internal Brown-out Detector (BOD) if the operating speed matches the detection level. If not, an external low V

Reset Protection circuit can be applied.

2. Keep the A VR co re in Power-down Sleep Mode during p eriods of lo w V

. This will prevent the CPU from attempting

CC

to decode and execute instructions, effectively protecting the EEPROM registers from unintentional writes.

3. Store constants in Flash memory if the ability to change memory contents from software is not required. Flash

memory can not be updated by the CPU, and will not be subject to corruption.

CC

34

ATtiny10/11/12

ATtiny10/11/12

Analog Comparator

The Analog Comparator compares the input values on the positive input PB0 (AIN0) and negative input PB1 (AIN1). When

the voltage on the pos it iv e i npu t PB 0 (AI N0) is higher than the voltage on the nega tive i np ut P B1 ( A IN1), th e A nal og C omparator Output (ACO) is set (one). The comparator’s output can trigge r a separate interrupt, exclusive to the Analog

Comparator. The user can s elect interru pt trig gerin g on com parator output ris e, fall or toggle. A bloc k diag ram of the c omparator and its surrounding logic is shown in Figure 26.

Figure 26. Analog Comparator Block Diagram.

INTERNAL

VOLTAGE

REFERENCE

(ATtiny12 ONLY)

AINBG

MUX

Analog Comparator Control and Status Register – ACSR

Bit 76543210

$08 ACD (AINBG) ACO ACI ACIE - ACIS1 ACIS0 ACSR