Page 1

Features

• Utilizes the AVR

• High-performance and Low-power 8-bit RISC Architecture

– 90 Powerful Instructions – Most Single Clock Cycle Execution

– 32 x 8 General Purpose Working Registers

– Up to 8 MIPS Throughput at 8 MHz

• Nonvolatile Program and Data Memory

– 1K Byte of Flash Program Memory

In-System Programmable (ATtiny12)

Endurance: 1,000 Write/Erase Cycles (ATtiny11/12)

– 64 Bytes of In-System Programmable EEPROM Data Memory for ATtiny12

Endurance: 100,000 Write/Erase Cycles

– Programming Lock for Flash Program and EEPROM Data Security

• Peripheral Features

– Interrupt and Wake-up on Pin Change

– One 8-bit Timer/Counter with Separate Prescaler

– On-chip Analog Comparator

– Programmable Watchdog Timer with On-chip Oscillator

• Special Microcontroller Features

– Low-power Idle and Power-down Modes

– External and Internal Interrupt Sources

– In-System Programmable via SPI Port (ATtiny12)

– Enhanced Power-on Reset Circuit (ATtiny12)

– Internal Calibrated RC Oscillator (ATtiny12)

• Specification

– Low-power, High-speed CMOS Process Technology

– Fully Static Operation

• Power Consumption at 4 MHz, 3V, 25°C

– Active: 2.2 mA

– Idle Mode: 0.5 mA

– Power-down Mode: <1 µA

• Packages

– 8-pin PDIP and SOIC

• Operating Voltages

– 1.8 - 5.5V for ATtiny12V-1

– 2.7 - 5.5V for ATtiny11L-2 and ATtiny12L-4

– 4.0 - 5.5V for ATtiny11-6 and ATtiny12-8

• Speed Grades

– 0 - 1.2 MHz (ATtiny12V-1)

– 0 - 2 MHz (ATtiny11L-2)

– 0 - 4 MHz (ATtiny12L-4)

– 0 - 6 MHz (ATtiny11-6)

– 0 - 8 MHz (ATtiny12-8)

®

RISC Architecture

8-bit

Microcontroller

with 1K Byte

Flash

ATtiny11

ATtiny12

Pin Configur a t ion

ATtiny11

PDIP/SOIC

(RESET) PB5

(XTAL1) PB3

(XTAL2) PB4

GND

1

2

3

4

8

7

6

5

VCC

PB2 (T0)

PB1 (INT0/AIN1)

PB0 (AIN0)

(RESET) PB5

(XTAL1) PB3

(XTAL2) PB4

GND

ATtiny12

PDIP/SOIC

1

2

3

4

8

7

6

5

VCC

PB2 (SCK/T0)

PB1 (MISO/INT0/AIN1)

PB0 (MOSI/AIN0)

1006D–AVR–0 7/ 03

Rev. 1006D–AVR–07/03

1

Page 2

Description The ATtiny11/12 is a low-power CMOS 8-bit microcontroller based on the AVR RISC

architecture. By executing powerful instructions in a single clock cycle, the ATtiny11/12

achieves throug hputs a pproac hing 1 MIPS pe r MHz, all owing the syst em de signer to

optimize power consumption versus processing speed.

The AVR c ore c omb ines a r ich ins tructi on se t wi th 3 2 ge neral -purp ose wo rking regi sters. All the 32 regis ters are directly co nnected to the Ari thmetic Logic U nit (ALU),

allowing two independent registers to be accessed in one single instruction executed in

one clock cycle. The resulting architecture is more code efficient while achieving

throughputs up to ten times faster than conventional CISC microcontrollers.

Table 1. Parts Description

Device Flash EEPROM Register Voltage Range Frequency

ATtiny11L 1K - 32 2.7 - 5.5V 0-2 MHz

ATtiny11 1K - 32 4.0 - 5.5V 0-6 MHz

ATtiny12V 1K 64 B 32 1.8 - 5.5V 0-1.2 MHz

ATtiny12L 1K 64 B 32 2.7 - 5.5V 0-4 MHz

ATtiny12 1K 64 B 32 4.0 - 5.5V 0-8 MHz

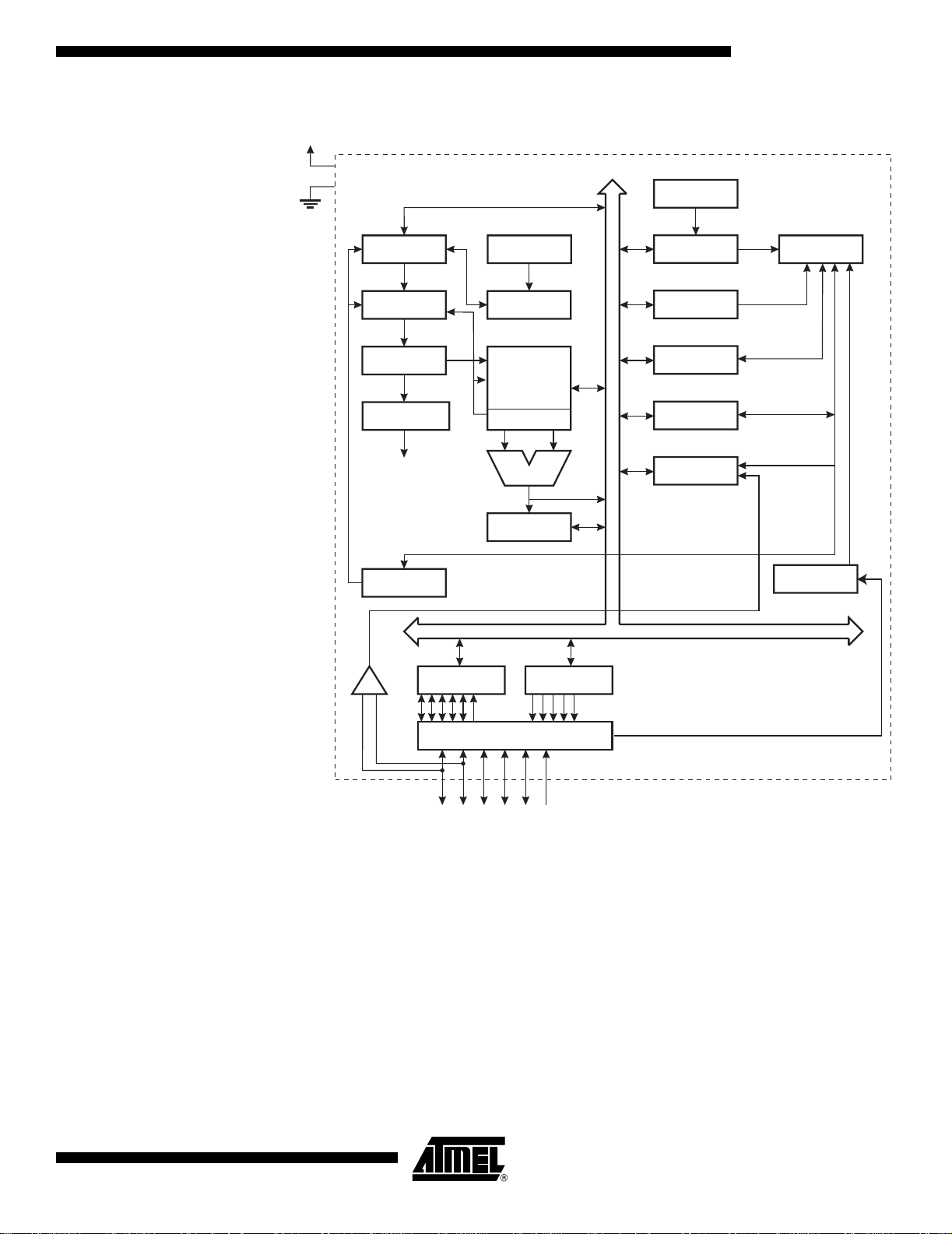

ATtiny11 Block Diagram The ATtiny11 provides the following features: 1K bytes of Flash, up to five general-pur-

pose I/O lines, on e input line, 32 ge neral-purpose work ing registers, an 8-bit

timer/counter, internal and external interrupts, programmable W atchdog Timer w ith

internal oscillator, and two software-selectable power-saving modes. The Idle Mode

stops the CPU while allowing the timer/counters and interrupt system to continue functioning. The Power-d own M ode s aves th e regist er conte nts but freezes the o scillator,

disabling all other chip functions until the next interrupt or hardware reset. The wake-up

or interrupt on pin change features enable the ATtiny11 to be highly responsive to external events, still f eaturi ng the l owest power c onsumpt ion while in the power-down modes .

The device is manufactured using Atmel’s high-density nonvolatile memory technology.

By combining an RISC 8-bit CPU with Flash on a monolithic chip, the Atmel ATtiny11 is

a powerful mic rocontro ller that provide s a highly-fl exible and cost -effec tive solution to

many embedded control applications.

The ATtiny11 AVR is supported with a full suite of program and system development

tools including: macro assemblers, progra m debugger/s imulators, in-circuit emulators,

and evaluation kits.

2

ATtiny11/12

1006D–AVR–07/03

Page 3

Figure 1. The ATtiny11 Block Diagram

VCC

GND

PROGRAM

COUNTER

STACK

POINTER

8-BIT DATABUS

INTERNAL

OSCILLATOR

WATCHDOG

TIMER

ATtiny11/12

TIMING AND

CONTROL

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

ANALOG

DATA REGISTER

ARATOR

COMP

+

PORTB

PORTB DRIVERS

HARDWARE

STACK

GENERALPURPOSE

REGISTERS

Z

ALU

STATUS

REGISTER

DATA DIR.

REG. PORTB

MCU CONTROL

REGISTER

MCU STATUS

REGISTER

TIMER/

COUNTER

INTERRUPT

UNIT

OSCILLATORS

1006D–AVR–07/03

PB0-PB5

3

Page 4

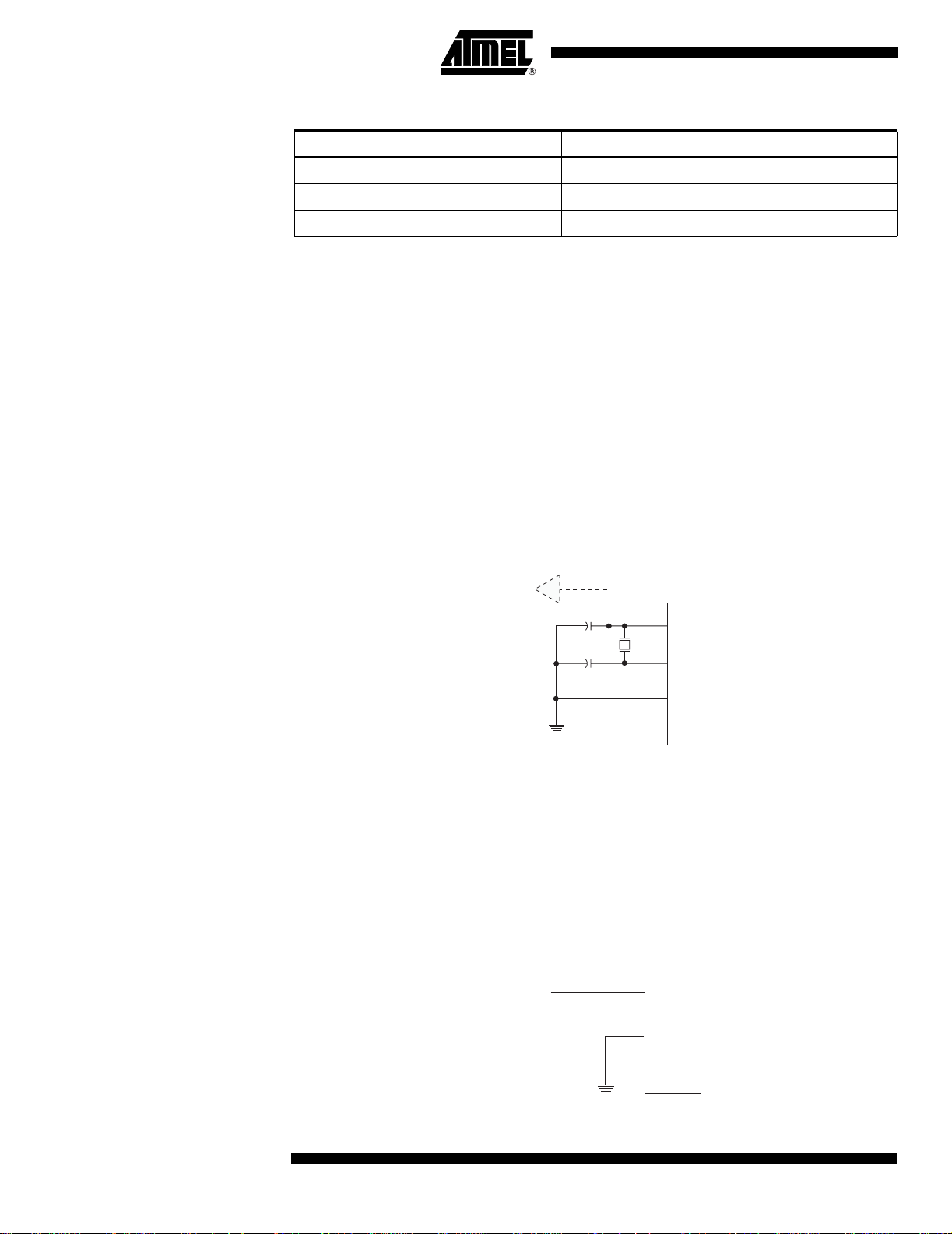

ATtiny12 Block Diagram Figure 2. The ATtiny12 Block Diagram

VCC

GND

PROGRAM

COUNTER

STACK

POINTER

8-BIT DATA BUS

INTERNAL

OSCILLATOR

WATCHDOG

TIMER

INTERNAL

CALIBRATED

OSCILLATOR

TIMING AND

CONTROL

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

ANALOG

DATA REGISTER

ARATOR

COMP

+

PORTB

PORTB DRIVERS

HARDWARE

STACK

GENERALPURPOSE

REGISTERS

Z

ALU

STATUS

REGISTER

SPI

DATA DIR.

REG. PORTB

MCU CONTROL

REGISTER

MCU STATUS

REGISTER

TIMER/

COUNTER

INTERRUPT

UNIT

EEPROM

OSCILLATORS

PB0-PB5

The ATtiny12 provides the following features: 1K bytes of Flash, 64 bytes EEPROM, up

to six general-purpose I/O lines, 32 general-purpose working registers, an 8-bit

timer/counter, internal and external interrupts, programmable W atchdog Timer w ith

internal oscillator, and two software-selectable power-saving modes. The Idle Mode

stops the CPU while allowing the timer/counters and interrupt system to continue functioning. The Power-d own M ode s aves th e regist er conte nts but freezes the o scillator,

disabling all other chip functions until the next interrupt or hardware reset. The wake-up

or interrupt on pin change features enable the ATtiny12 to be highly responsive to external events, still feat uring the lowest power consumpt ion while i n the power- down modes .

The device is manufactured using Atmel’s high-density nonvolatile memory technology.

By combining an RISC 8-bit CPU with Flash on a monolithic chip, the Atmel ATtiny12 is

a powerful mic rocontro ller that provide s a highly-fl exible and cost -effec tive solution to

many embedded control applications.

4

ATtiny11/12

1006D–AVR–07/03

Page 5

ATtiny11/12

The ATtiny12 AVR is supported with a full suite of program and system development

tools including: macro assemblers, progra m debugger/s imulators, in-circuit emulators,

and evaluation kits.

Pin Descriptions

VCC Supply voltage pin. GND Ground pin. Port B (PB5..PB0) Port B is a 6-bit I/O port. PB4..0 are I/O pins that can provide internal pull-ups (selected

for each bit). On ATtiny11, PB5 is input onl y. On ATtiny12, PB 5 is input or open-drain

output. The port p ins are t ri-stated w hen a res et con dition be comes a ctive, even if the

clock is not running. The use of pins PB5..3 as input or I/O pins is limited, depending on

reset and clock settings, as shown below.

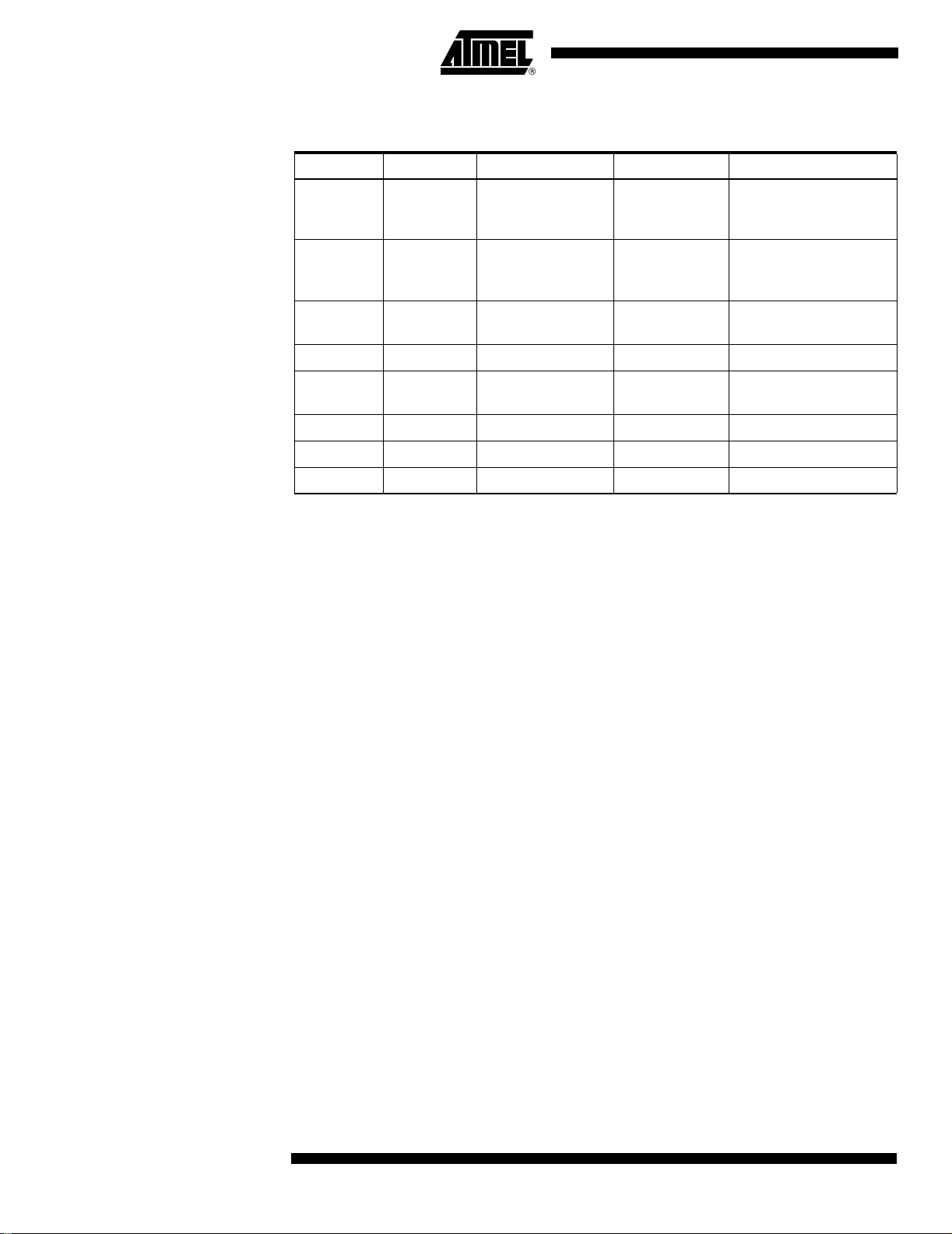

Table 2. PB5..PB3 Functionality vs. Device Clocking Options

Device Clocking Option PB5 PB4 PB3

External Reset Enabled Used

External Reset Disabled Input

External Crystal - Used Used

(1)

(3)

(4)

/I/O

(2)

-

--

-

External Low-frequency Crystal - Used Used

External Ceramic Resonator - Used Used

External RC Oscillator - I/O

External Clock - I/O Used

Internal RC Oscillator - I/O I/O

Notes: 1. “Used” means the pin is used for reset or clock purposes.

2. “-” means the pin function is unaffected by the option.

3. Input means the pin is a port input pin.

4. On ATtiny11, PB5 is input only. On ATtiny12, PB5 is input or open-drain output.

5. I/O means the pin is a port input/output pin.

(5)

Used

XTAL1 Input to the inverting oscillator amplifier and input to the internal clock operating circuit. XTAL2 Output from the inverting oscillat or amplifier.

RESET

Reset input. An external reset is generated by a low level on the RESET pin. Reset

pulses longer than 50 ns will generate a reset, even if the clock is not running. Shorter

pulses are not guaranteed to generat e a reset.

Clock Options The device has the f ollowing clock source op tions, selectable by Flash fuse bit s as

shown:

Table 3. Device Clocking Options Select

1006D–AVR–07/03

Device Clocking Option ATtiny11 CKSEL2..0 ATtiny12 CKSEL3..0

External Crystal/Ceramic Resonator 111 1111 - 1010

External Low-frequency Crystal 110 1001 - 1000

External RC Oscillator 101 0111 - 0101

5

Page 6

Table 3. Device Clocking Options Select (Continued)

Device Clocking Option ATtiny11 CKSEL2..0 ATtiny12 CKSEL3..0

Internal RC Oscillator 100 0100 - 0010

External Clock 000 0001 - 0000

Reserved Other Options -

Note: “1” means unprogrammed, “0” means programmed.

The various choices for ea ch clocking op tion give different start-u p times as shown in

Table 7 on page 18 and Table 9 on page 20.

Internal RC Oscillator The internal RC oscillator option is an on-chip oscil lat or running at a f ixed frequency of 1

MHz in ATtiny11 and 1.2 MHz in ATtiny12. If selected, the device can operate with no

external components. The device is shipped with this option selected. On ATtiny11, the

Watchdog Oscillator is used as a clock, while ATtiny12 uses a separate calibrated

oscillator.

Crystal Oscillator XTAL1 and XTAL2 are input and o utput , respectively, of an inverting amplifier which can

be configured for use as an on-chip oscillator, as shown in Figure 3. Either a quartz

crystal or a ceramic resonator may be used. Maximum frequency for crystal and resonators is 4 MHz. Minimum voltage for running on a low-frequency crystal is 2.5V.

Figure 3. Oscillator Connections

MAX 1 HC BUFFER

HC

C2

C1

Note: When using the MCU Oscillator as a clock for an external device, an HC buffer should be

connected as indicated in the figure.

XTAL2

XTAL1

GND

External Clock To drive the device from an external clock source, XTAL1 should be driven as shown in

Figure 4.

Figure 4. External Clock Drive Configurati on

PB4 (XTAL2)

EXTERNAL

OSCILLATOR

XTAL1

SIGNAL

GND

6

ATtiny11/12

1006D–AVR–07/03

Page 7

ATtiny11/12

External RC Oscillator For timing insensitive applications, the external RC configuration shown in Figure 5 can

be used. For details on how to choose R and C, see Table 29 on page 59. The external

RC oscillator is sensitive to noise from neigh boring pins, and to avoid proble ms, PB5

(RESET

put pin.

Figure 5. External RC Configuration

) should be used as an output or reset pin, and PB4 should be used as an out-

VCC

R

C

PB4 (XTAL2)

XTAL1

GND

1006D–AVR–07/03

7

Page 8

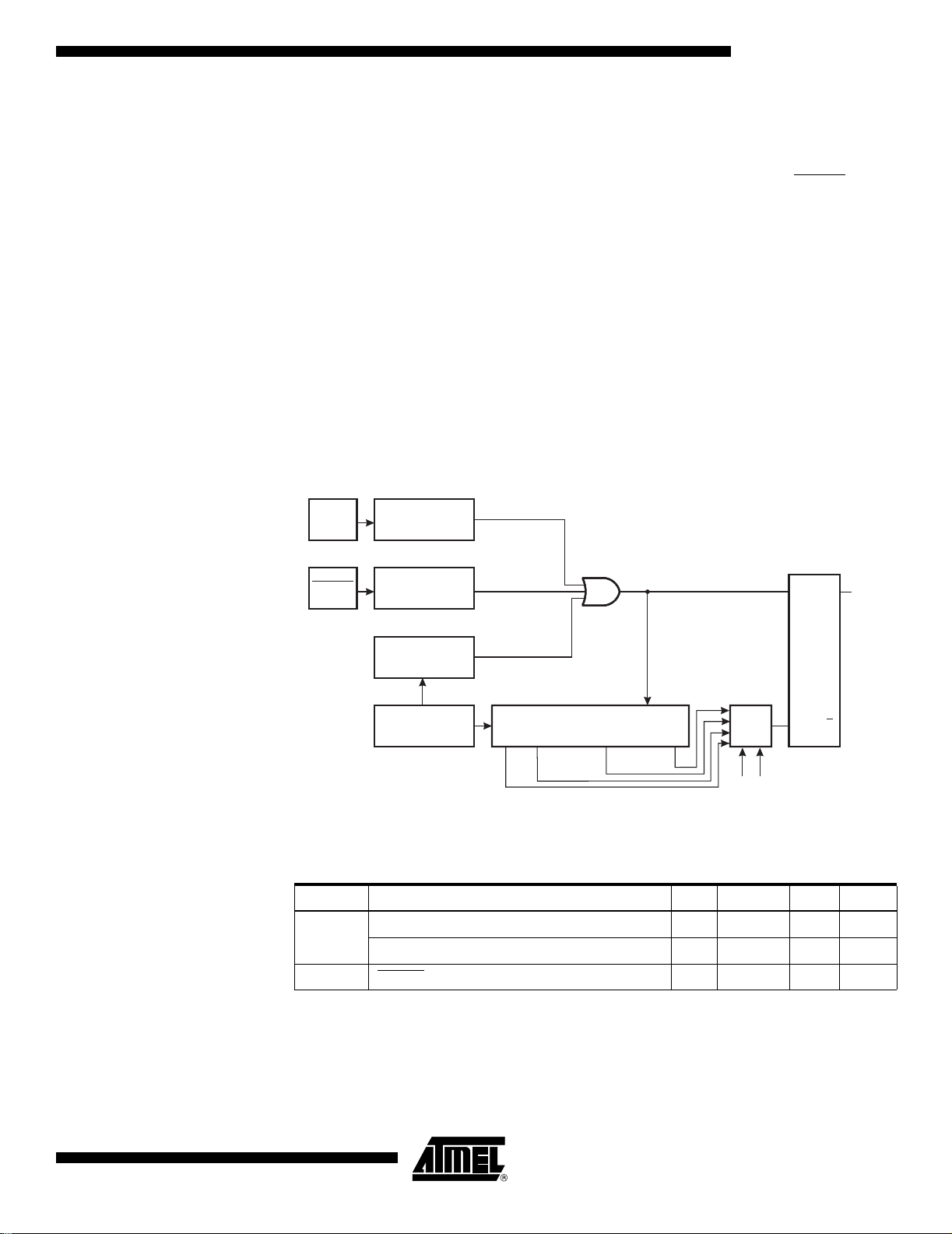

Architectural Overview

The fast-access register file concept contains 32 x 8-bit general-purpose working registers with a single-clock-cycle access time. This means that du ring one sing le clock

cycle, one ALU (Arithmetic Logic Unit) operation is executed. Two operands are output

from the register file, the operation is executed, and the result is stored back in the register file – in one clock cycle.

Two of the 32 registers can be used as a 16-bit pointer for indirect memory access. This

pointer is called the Z-pointer, and can address the register file and the Flash program

memory.

The ALU supp orts arithm etic and log ic fun ctions betwe en reg isters or b etween a co nstant and a register. Sin gle-register operati ons are also e xecuted in the A LU. Figure 2

shows the AT tiny1 1/12 AVR RISC mic rocont roller arc hitectu re. The A VR use s a Harvard architecture concept with separate memori es and buses for progra m and data

memories. The program memory is accessed with a two-stage pipelining. While one

instruction is being executed, the next instruction is pre-fetched from the program memory. This concept enables instructions to be executed in every clock cycle. The program

memory is reprogrammable Flash memory.

With the relative jump and relative call instructions, the whole 512 address space is

directly accessed. All A VR instructio ns have a single 16-bit word f ormat, mea ning that

every program memory address contains a single 16-bit instruction .

During interrupts and subroutine calls, the return address program counter (PC) is

stored on the stack . Th e stack i s a 3 -level-deep hardware stack de dicated for subroutines and interrupts.

The I/O memory space con tains 64 addresses f or CPU peri pheral functions as cont rol

registers, timer/counters, and other I/O functions. The memory spaces i n the AVR architecture are all linear and regular memory maps.

8

ATtiny11/12

1006D–AVR–07/03

Page 9

Figure 6. The ATtiny11/12 AVR RISC Architecture

8-bit Data Bus

ATtiny11/12

512 x 16

Program

Flash

Instruction

Register

Instruction

Decoder

Control Lines

Program

Counter

Direct Addressing

Status

and Test

32 x 8

General-

purpose

Registers

ALU

64 x 8 EEPROM

(ATtiny12 only)

Control

Registers

Interrupt

Unit

SPI Unit

(ATtiny12 only)

8-bit

Timer/Counter

Watchdog

Timer

Analog

Comparator

6

I/O Lines

A flexible inte rrupt modu le has its con trol regist ers in the I/O space with an additio nal

global interrupt enable bit in the status register. All the different interrupts have a separate interrupt vector in the interrupt vector tab le at the beginning of the

program memory. The different interrupts have priority in accordance with their interrupt

vector position. The lower the interrupt vector address, the higher the priority.

General-purpose Register File

1006D–AVR–07/03

Figure 7 shows the structure of the 32 general-purpose registers in the CPU.

Figure 7. AVR CPU General-purpose Working Registers

70

R0

R1

R2

General- …

purpose …

Working R28

Registers R29

R30 (Z-register low byte)

R31 (Z-r egister high byte)

All the register operating instructions in the instruction set have direct- and single-cycle

access to a ll regist ers. The only excepti on is the five c onstan t arithm etic an d logic

instructions SBCI, SUBI, CPI, ANDI, and ORI between a constant and a register and the

LDI instruction for load-immediate constant data. These instructions apply t o the second

half of the registe rs in the register f ile – R16..R 31. The genera l SBC, SU B, CP, AND,

9

Page 10

OR and all o ther op eration s bet ween two re gisters or on a si ngle reg ister apply to the

entire register file.

Registers 30 and 31 form a 16-bit pointer (the Z-pointer) which is used for indirect Flash

memory and register fil e access. When the register file is accessed, t he contents of R31

are discarded by the CPU.

ALU – Arithmetic Logic Unit

The high-performance AVR ALU operat es in d irect con nection with all the 32 gene ralpurpose working registers. Wit hin a sing le clock cycle , ALU op erations be tween registers in the register file are executed. The ALU operations are divided into three main

categories – arithmetic, logic and bit-functions. Some microcontrollers in the AVR product family feature a hardware multiplier in the arithmetic part of the ALU.

Flash Program Memory The ATtiny11/12 contain s 1K bytes on-chip Flash me mory for program storag e. Since

all instructions are single 16-bit words, the F lash is organized as 5 12 x 16 words. T he

Flash memory has an endurance of at least 1000 write/er ase cycles.

The ATtiny11/12 Program Counter is 9 bits wide, thus addressing the 512 words Flash

program memory.

See page 46 for a detailed description on Flash memory programming.

Program and Data Addressing Modes

Register Direct, Single Register Rd

The ATtiny11/12 AVR RISC Microcontroller supports powerful and efficient addressing

modes. This se ction describes the different addressin g modes supported i n the

ATtiny11/12. In the figures, OP means the ope ration code part of the instruction word.

To simplify, not all figure s show the exact location of the addressing bits.

Figure 8. Direct Single-register Addressing

10

The operand is contained in regist er d (Rd).

ATtiny11/12

1006D–AVR–07/03

Page 11

Register Indirect Figure 9. Indirect Register Addressing

ATtiny11/12

REGISTER FILE

0

The register accessed is the one pointed to by th e Z-register (R31, R30).

Register Direct, Two Registers

Figure 10. Direct Register Addressing, Two Registers

Rd and Rr

Operands are contained in register r (Rr) and d (Rd). The result is store d in regi ster d

(Rd).

I/O Direct Figure 11. I/O Direct Addressing

Z-register

30

31

1006D–AVR–07/03

Operand addres s is con taine d in 6 bit s of the instruc tion wor d. n is the desti natio n or

source register address.

11

Page 12

Relative Program Addr essing, RJMP and RCALL

Figure 12. Relative Program Memor y Addressing

+1

Program execution continues at address PC + k + 1. The relative address k is -2048 to

2047.

Constant Addressing Using the LPM Instruction

Subroutine and Interrupt Hardware Stack

Figure 13. Code Memory Constant Addressing

PROGRAM MEMORY

15 1 0

Z-REGISTER

$000

$1FF

Constant byte address is specified by the Z-register contents. The 15 MSBs select word

address (0 - 511) , the LSB sel ects low byte i f cleare d (LSB = 0) or hi gh byte if set

(LSB = 1).

The ATtiny11/12 uses a 3-level -deep hardwar e st ack for subr outin es and inter rupts. The

hardware stack is 9 bits wide and stores the program counter (PC) return address while

subroutines and inter rupt s are executed.

RCALL instructi ons an d int errupts pu sh th e PC return a ddress o nto stack l evel 0, a nd

the data in the other stack levels 1-2 are pushed one level deeper in the stack. When a

RET or RETI instruction is executed the returning PC is fetched from stack level 0, and

the data in the other stack level s 1-2 are popped one level in the stack.

12

If more than three subsequent subroutine calls or interrupts are executed, the first values written to the stack are overwritten. Pushing four return addresses A1, A2, A3, and

A4, followed by four subroutine or interrupt returns, will pop A4, A3, A2, and once more

A2 from the hardware stack.

ATtiny11/12

1006D–AVR–07/03

Page 13

ATtiny11/12

EEPROM Data Memory The ATtiny12 contains 64 bytes of data EEPROM memory. It is organized as a separate

data space, in which single bytes can be read and written. The EEPROM has an endurance of at least 100,000 write/erase cycles. The access between the EEPROM and the

CPU is described on page 38, specifying the EEPROM Address Register, the EEPROM

Data Register, and the EEPROM Control Register.

For SPI data downloading, see “Memory Programming” on page 46 for a detailed

description.

Memory Access and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and

internal memory access.

The AVR CPU is driven by the System Clock Ø, directly generated from the external

clock crystal for the chip. No internal clock division is used.

Figure 14 shows the parallel instruction fet ches and instruction e xecutions enab led by

the Harvard architecture and the fast-access register file concept. This is the basi c pipelining concept to obtain up to 1 MIPS per MHz with the corresponding unique results for

functions per cost, functions per clocks, and functions per po wer-unit.

Figure 14. The Parallel Instruc ti on Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

Figure 15 shows the internal timing concept for the register file. In a single clock cycle,

an ALU operation using two register operands is executed and the result is stored back

to the destination regis ter.

1006D–AVR–07/03

Figure 15. Single-cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

13

Page 14

I/O Memory The I/O space definition of the ATtiny11/12 is shown in the following table:

Table 4. ATtiny11/12 I/O Space

Address Hex Name Device Function

$3F SREG ATtiny11/12 Status Register

$3B GIMSK ATtiny11/12 General Interrupt Mask Register

$3A GIFR ATtiny11/12 General Interrupt Flag Register

$39 TIMSK ATtiny11/12 Timer/Counter Interrupt Mask Register

$38 TIFR ATtiny11/12 Timer/Counter Interrupt Flag Register

$35 M CUCR ATtiny11/12 MCU Control Register

$34 MCUSR ATtiny11/12 MCU Status Register

$33 T CCR0 ATtiny11/12 Timer/Counter0 Control Register

$32 TCNT0 ATtiny11/12 Timer/Counter0 (8-bit)

$31 OSCCAL ATtiny12 Oscillator Calibration Register

$21 WDTCR ATtiny11/12 Watchdog Timer Control Register

$1E EEAR ATtiny12 EEPROM Address Register

$1D EEDR ATtiny12 EEPROM Data Register

$1C EECR ATtiny12 EEPROM Control Register

$18 PORTB ATtiny11/12 Data Register, Port B

$17 DDRB ATtiny11/12 Data Direction Register, Port B

$16 PINB ATtiny11/12 Input Pins, Port B

$08 ACSR ATtiny11/12 Analog Comparator Control and Status Register

Note: Reserved and unused locations are not shown in the table.

All the different ATtiny11/12 I/O and peripherals are placed in the I/O space. The different I/O locations are acce ssed by the I N and OUT instruc tions t ransfer ring data bet ween

the 32 general-purpose working registers and the I/O space. I/O registers within the

address range $00 - $1F are directly bit-accessible using the SBI and CBI instructions.

In these registers, the value of single bits can be checked by using the SBIS and SBIC

instructions. Refer to the Instruction Set Summary for more details.

For compatibility wit h future devices, rese rved bits should be writte n to zero if accessed.

Reserved I/O memory addressed should never be written.

The different I/O and peripherals control regi sters are explained in t he following

sections.

Status Register – SREG The AVR status register (SREG) at I/O space location $3F is defi ned as:

Bit 76543210

$3F ITHSVNZCSREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value00000000

14

• Bit 7 - I: Globa l Int e rrupt Ena ble

The global interru pt enable bit must be set (one) for the interru pts to be ena bled. The

individual interrupt enable control is then performed in separate control registers. If the

ATtiny11/12

1006D–AVR–07/03

Page 15

ATtiny11/12

global interrupt enab le regi ster i s cleared (zero), none of the i nterr upt s are enable d independent of the individual interrupt enable settings. The I-bit is cleared by hardware after

an interrupt has occurre d, and is set by the RETI instruc tion to enable subs equent

interrupts.

• Bit 6 - T: Bit Copy Storage

The bit copy instructio ns BLD (B it LoaD) and BST (Bit STore) use the T-bit as source

and destination for t he oper ated bi t. A bit from a register i n the r egister fil e can be copi ed

into T by the BST instruction, and a bit i n T can be copied into a b it in a reg ister in the

register file by the BLD instruction.

• Bit 5 - H: Half Carry Flag

The half carry flag H indicates a half-carry in some arithmetic operations. See the

Instruction Set descri p ti on for detailed information.

• Bit 4 - S: Sign Bit, S = N ⊕ V

The S-bit is always an exclusive or between the negative flag N and the two’s complement overflow flag V. See the Instruction Set description for detailed information.

• Bit 3 - V: Two’s Complement Overflow Flag

Reset and Interrupt Handling

The two’s complem ent overflow flag V sup ports tw o’s co mplemen t arit hmetic. See t he

Instruction Set descri p ti on for detailed information.

• Bit 2 - N: Negative Flag

The negative flag N indicates a negative result from an arithmetical or logical operation.

See the Instruction Set description for detailed information.

• Bit 1 - Z: Zero Flag

The zero flag Z indicates a zero result from an arithmetical or logical operation. See the

Instruction Set descri p ti on for detailed information.

• Bit 0 - C: Carry Flag

The carry flag C ind icates a carry in an arithmet ical or logical operat ion. See the Instruction Set description for detailed information.

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from an interrupt routine. This must be handled by

software.

The ATtiny11 provi des four differe nt interrupt sou rces and the AT tiny12 prov ides five.

These interrupts and the separate reset vector each have a separate program vector in

the program memory space. All the interrupts are assigned individual enable bits which

must be set (one) together with the I-bit in the status register in order to enable the

interrupt.

1006D–AVR–07/03

The lowest addresse s in the program me mory space are au tomaticall y defined as the

Reset and Interrupt vectors. The complete list of vectors is shown in Table 5. The list

also determines the priority levels of the different interrupts. The lower the address, the

higher the priority level. RESET has the highest priority, and next is INT0 – the External

Interrupt Request 0, etc.

15

Page 16

Table 5. Reset and Interrupt Vectors

Vector No. Device Program Address Source Inte r rupt Definition

External Pin, Power-on

1 ATtiny11 $000 RESET

1 ATtiny12 $000 RESET

Reset and Watchdog

Reset

External Pin, Power-on

Reset, Brown-out Reset

and Watchdog Reset

2 ATtiny11/12 $001 INT0

External Interrupt

Request 0

3 ATtiny11/12 $002 I/O Pins Pin Change Interrupt

4 ATtiny11/12 $003 TIMER0, OVF0

Timer/Counter0

Overflow

5 ATtiny11 $004 ANA_COMP Analog Comp arator

5 ATtiny12 $004 EE_RDY EEPROM Ready

6 ATtiny12 $005 ANA_COMP Analog Comp arator

The most typical and general program setup for the reset and i nterru pt vector address es

for the ATtiny11 are:

Address Labels Code Comments

$000 rjmp RESET ; Reset handler

$001 rjmp EXT_INT0 ; IRQ0 handler

$002 rjmp PIN_CHANGE ; Pin change handler

$003 rjmp TIM0_OVF ; Timer0 overflow handler

$004 rjmp ANA_COMP ; Analog Comparat or handler

;

$005 MAIN: <instr> xxx ; Main program start

… … … …

The most typical and general program setup for the reset and i nterru pt vector address es

for the ATtiny12 are:

Address Labels Code Comments

$000 rjmp RESET ; Reset handler

$001 rjmp EXT_INT0 ; IRQ0 handler

$002 rjmp PIN_CHANGE ; Pin change handler

$003 rjmp TIM0_OVF ; Timer0 overflow handler

$004 rjmp EE_RDY ; EEPROM Ready handler

$005 rjmp ANA_COMP ; Analog Comparat or handler

;

$006 MAIN: <instr> xxx ; Main program start

… … … …

16

ATtiny11/12

1006D–AVR–07/03

Page 17

Reset Sources The ATtiny11/12 provides three or four sources of reset:

• Power-on Reset. The MCU is reset when the supply voltage is below the power-on

reset threshold (V

POT

).

• External Reset. The MCU is reset when a low level is present on the RESET

more than 50 ns.

• Watchdog Reset. The MCU is reset when the Watchdog timer period expires and

the Watchdog is enabled.

• Brown-out Reset. The MCU is reset when the supply voltage V

certain voltage (ATtiny12 only).

During reset, all I/O registers are then set to their initial values, and the program starts

execution from address $000. The instruction placed in address $000 mu st be an RJMP

– relative jump – instruction to the reset handling routine. If the program never enables

an interrupt source, the interrupt vectors are not used, and regular program code can be

placed at these locations. The circuit diagram in Figure 16 shows the reset logic for the

ATtiny11. Figure 17 shows the reset logic for the ATt iny12. Table 6 defines the electrical

parameters of the reset circui try fo r ATtiny1 1. Table 8 shows t he para meters of t he reset

circuitry for ATtiny12.

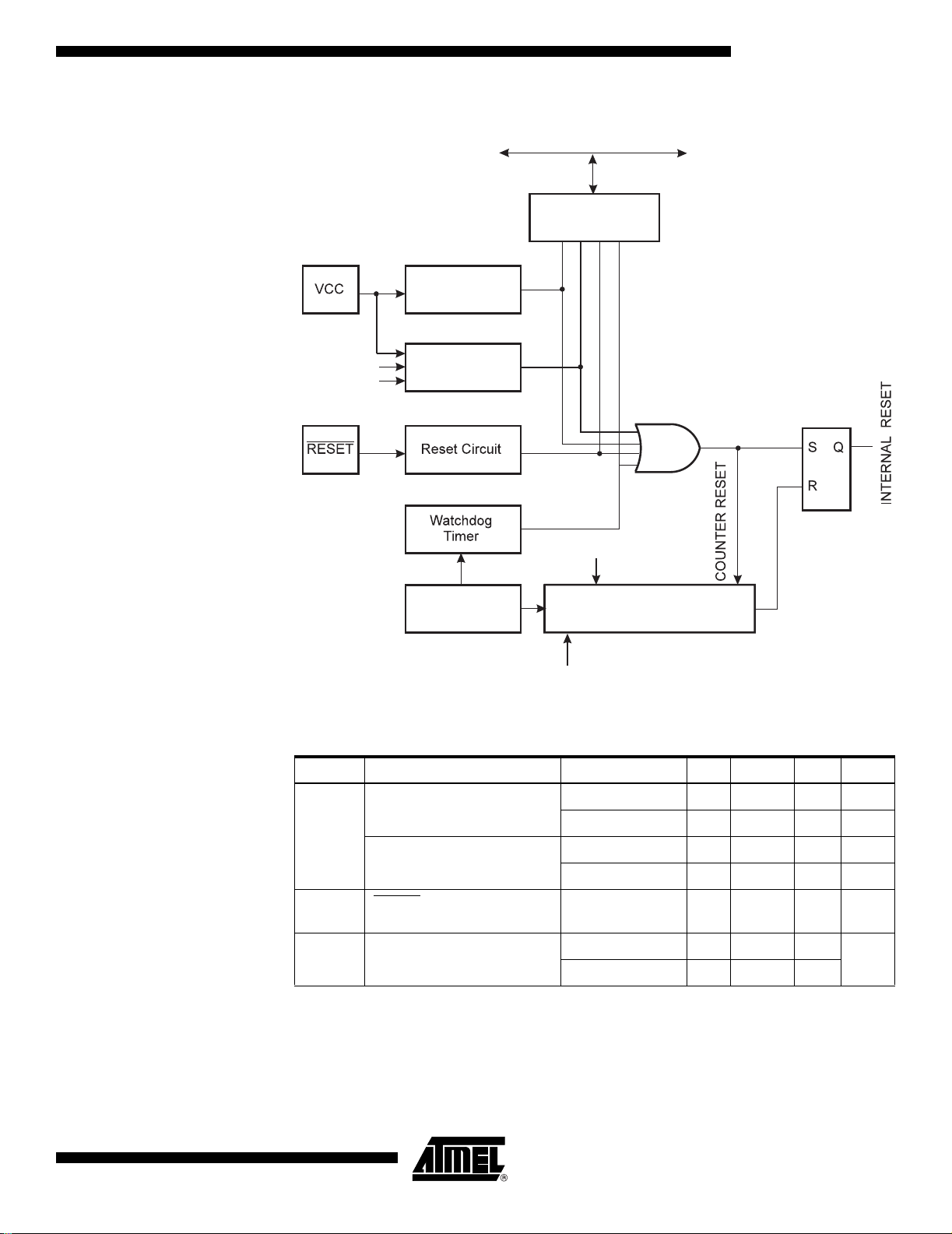

Figure 16. Reset Logic for the ATtiny11

VCC

Power-on Reset

Circuit

POR

ATtiny11/12

pin for

falls belo w a

CC

RESET

Reset Circuit

Watchdog

Timer

On-chip

RC Oscillator

COUNTER RESET

20-stage Ripple Counter

Q3 Q19

Q9

Q13

CKSEL

FSTRT

QS

Q

R

Table 6. Reset Characteristics for the ATtiny11

Symbol Parameter Min Typ Max Units

Power-on Reset Threshold Voltage (rising) 1.0 1.4 1.8 V

(1)

V

POT

V

RST

Note: 1. The Power-on Reset will not work unless the supply voltage has been below V

Power-on Reset Threshold Voltage (falling) 0.4 0.6 0.8 V

RESET Pin Threshold Voltage 0.6 V

CC

(falling).

V

INTERNAL

RESET

POT

1006D–AVR–07/03

17

Page 18

Power-on Reset for the ATtiny11

A Power-on Reset (POR) circuit ensures that the device is reset from power-on. As

shown in Figure 16, an in ternal timer is clocked from the watchdog timer. This t imer prevents the MCU from starting a certain period after V

Threshold Voltage – V

period – t

. The FSTRT fuse bit in the Flash can be programmed to give a shorter

TOUT

. See Figure 18. The total reset period is the Delay Tim e-out

POT

has reached the Power-on

CC

start-up time.The start-up times for the different clock options are shown in the following

table. The Watchdog Oscillator is used for timing the start-up time, and this oscillator is

voltage dependent as shown in the section “A Ttiny11 Typical Charact eristics” on page

60.

Table 7. Start-up Times for the ATtiny11 (V

Selected Clock Opti on

External Crystal 67 ms 4.2 ms

External Ceramic Resonator 67 ms 4.2 ms

External Low-frequency Crystal 4.2 s 4.2 s

External RC Oscillator 4.2 ms 67 µs

Internal RC Oscillator 4.2 ms 67 µs

External Clock 4.2 ms

FSTRT Unprogrammed FSTRT Programmed

If the built-in start-up delay is sufficient, RESET

an external pull-up resistor. By holding the RESET

= 2.7V)

CC

Start-up Time t

TOUT

5 clocks from reset,

2 clocks from power-down

can be connected to VCC directly or via

pin low for a period after VCC has

been applied, the Power-on Reset period can be extended. Refer to Figure 19 for a timing example on this.

18

ATtiny11/12

1006D–AVR–07/03

Page 19

Figure 17. Reset Logic for the ATtiny12

DATA BUS

MCU Status

Register (MCUSR)

Power-on Reset

Circuit

PORF

BORF

EXTRF

ATtiny11/12

WDRF

BODEN

BODLEVEL

Brown-out

Reset Circuit

CKSEL[3:0]

On-chip

RC Oscillator

Delay Counters

Full

CK

Table 8. Reset Characteristics for the ATtiny12

Symbol Parameter Condition Min Typ Max Units

Power-on Reset Threshold

V ol tage (risin g)

(1)

V

POT

Power-on Reset Threshold

V oltage (falling)

BOD disabled 1.0 1.4 1.8 V

BOD enabled 0.6 1.2 1.8 V

BOD disabled 0.4 0.6 0.8 V

BOD enabled 0.6 1.2 1.8 V

1006D–AVR–07/03

V

V

RST

BOT

RESET Pin Threshold

Voltage

Brown-out Re set Threshold

Voltage

0.6V

CC

(BODLEVEL = 1) 1.5 1.8 1.9

(BODLEVEL = 0) 2.3 2.7 2.8

V

V

Note: 1. The Power-on Reset will not work unless the supply voltage has been below V

(falling).

POT

19

Page 20

Table 9. ATtiny12 Clock Options and Start-up Times

Start- up Time,

VCC = 1.8V,

BODLEVEL

CKSEL3..0 Clock Source

1111 Ext. Crystal/Ceramic Resonator

1110 Ext. Crystal/Ceramic Resonator

1101 Ext. Crystal/Ceramic Resonator

1100 Ext. Crystal/Ceramic Resonator 16K CK 16K CK

1011 Ext. Crystal/Ceramic Resonator 3.6 ms + 16K CK 4.2 ms + 16K CK

1010 Ext. Crystal/Ceramic Resonator 57 ms + 16K CK 67 ms + 16K CK

1001 Ext. Low-frequency Crystal 57 ms + 1K CK 67 ms + 1K CK

1000 Ext. Low-frequency Crystal 57 ms + 32K CK 67 ms + 32K CK

0111 Ext. RC Oscillator 6 CK 6 CK

0110 Ext. RC Oscillator 3.6 ms + 6 CK 4.2 ms + 6 CK

0101 Ext. RC Oscillator 57 ms + 6 CK 67 ms + 6 CK

0100 Int. RC Oscillator 6 CK 6 CK

0011 Int. RC Oscillator 3.6 ms + 6 CK 4.2 ms + 6 CK

0010 Int. RC Oscillator 57 ms + 6 CK 67 ms + 6 CK

0001 Ext. Clock 6 CK 6 CK

Unprogrammed

(1)

1K CK 1K CK

(1)

3.6 ms + 1K CK 4.2 ms + 1K CK

(1)

57 ms 1K CK 67 ms + 1K CK

Start-up Time,

VCC = 2.7V,

BODLEVEL

Programmed

0000 Ext. Clock 3.6 ms + 6 CK 4.2 ms + 6 CK

Note: 1. Due to the limited number of clock cycles in the start-up period, it is recommended

that Ceramic Resonator be used.

This table shows the start-up times from reset. From sleep, only the clock counting part

of the start-up time is used. The Watchdog oscillator is used for timing the real-time part

of the start-up time. The number of WDT oscillator cycles used for each time-out is

shown in Table 10.

Table 10. Number of Watchdog Oscillator Cycl es

BODLEVEL Time-out Number of Cycles

Unprogrammed 3.6 ms (at Vcc = 1.8V) 256

Unprogrammed 57 ms (at Vcc = 1.8V) 4K

Programmed 4.2 ms (at Vcc = 2.7V) 1 K

Programmed 67 ms (at Vcc = 2.7V) 16K

The frequency of the watchdog oscillator is voltage dependent as shown in the section

“ATtiny11 Typical Characteristics” on page 60.

Note that the BODL EVEL fuse can be used to select start-up times even if the Brownout Detection is disabled (by leaving the BODEN fuse unprogrammed).

The device is shipped with CKSEL3..0 = 0010.

20

ATtiny11/12

1006D–AVR–07/03

Page 21

ATtiny11/12

Power-on Reset for the ATtiny12

A Power-on Reset (POR) pulse is generated by an on-chip detection circuit. The detection level is nominally 1.4V. The POR is activated whenever V

is below the detection

CC

level. The POR circuit can be used to trigger the start-up reset, as well as detect a failure in supply voltage.

The Power-on Rese t (POR) circuit en sures that th e device is reset from pow er-on.

Reaching the Power-on Reset threshold voltage i nvokes a delay cou nter, which determines the delay for which the device is kept in Reset after V

rise. The time-out period

CC

of the delay counter can be defined by the user through the CKSEL fuses. The different

selections for the del ay period are pre sented i n Table 9 . The Reset signa l is act ivated

again, without any delay, when the V

If the built-in start-up delay is sufficient, RESET

an external pull-up resistor. See Figure 18. B y holding t he RESET

after V

has been applied, the Power-on Reset period can be extended. Refer to Fig-

CC

decreases below detection level.

CC

can be connected to VCC directly or via

pin low for a period

ure 19 for a timing example on this.

t

TOUT

Tied to VCC.

Figure 18. MCU Start-up, RESET

V

V

CC

RESET

TIME-OUT

POT

V

RST

INTERNAL

RESET

Figure 19. MCU Start-up, RESET

V

V

RESET

TIME-OUT

INTERNAL

RESET

CC

POT

Extended Externally

V

RST

t

TOUT

External Reset An external reset is generated by a low level on the RESET

than 50 ns will generate a reset, even if the clock is not running. Shorter pulses are not

guaranteed to generate a reset. When the applied signal reaches the Rese t Threshold

Voltage – V

period (t

– on its positive edge, the delay timer starts the MCU after the Time-out

RST

) has expired.

TOUT

pin. Reset pulses longer

1006D–AVR–07/03

21

Page 22

Figure 20. External Reset during Op eration

V

CC

Brown-out Detection (ATtiny12)

RESET

TIME-OUT

INTERNAL

RESET

ATtiny12 has an on-chip brown-out detection (BOD) circuit for monitoring the V

V

RST

t

TOUT

level

CC

during the operation. The BOD circuit can be enabled/disabled by the fuse BODEN.

When BODEN is enabled (BODEN programmed), and V

level, the brown-out reset is immediately activated. When V

decreases below the trigger

CC

increases above the trig-

CC

ger level, the b rown-out reset is dea ctivated after a delay. T he delay i s defined by the

user in the sa me w ay a s t he de lay of P OR s ignal , in Tab le 5. The trig ger l evel for the

BOD can be selected by the fuse BODLEVEL to be 1.8V (BODLEVEL unprogrammed),

or 2.7V (BODLEVEL programmed). The trigger level has a hysteresis of 50 mV to

ensure spike-free bro wn -out detection.

The BOD circuit will only detect a drop in V

if the voltage stays below the trigger level

CC

for longer than 7 µs for trigger level 2.7V, 24 µs for trigger level 1.8V (typical values).

Figure 21. Brown-out Reset during Operation (ATtiny12)

V

CC

RESET

TIME-OUT

INTERNAL

RESET

Note: The hysteresis on V

BOT

: V

V

BOT-

BOT +

= V

+ 25 mV, V

BOT

BOT-

= V

V

BOT

BOT+

t

TOUT

- 25 mV.

22

ATtiny11/12

1006D–AVR–07/03

Page 23

ATtiny11/12

Watchdog Reset When the Watchdog times out, it will generate a short reset pulse of 1 CK cycle dura-

tion. On the falling edge of this puls e, the delay timer start s countin g the Time-out period

). Refer to page 36 for details on operation of the Watc hdog.

(t

TOUT

Figure 22. Watchdog Reset during Operation

V

CC

CK

MCU Status Register – MCUSR of the ATtiny11

The MCU Status Register provides information on which reset source caused an M CU

reset.

Bit 76543210

$34 ------EXTRFPORFMCUSR

Read/WriteRRRRRRR/WR/W

Initial Value000000See bit description

• Bit 7..2 - Res: Reserved Bits

These bits are reserved bit s in t he ATtiny11 and always read as zero.

• Bit 1 - EXTRF: EXT ernal Reset Flag

After a power-on reset, this bit is undefined (X). It will be set by an external reset. A

watchdog reset will leave this bit unchan ged.

• Bit 0 - PORF: Power-on Reset Flag

This bit is set by a power-on reset. A watchdog reset or an external reset will leave this

bit unchanged.

To summarize, the follow ing table show s the value o f these two bits a fter the three

modes of reset.

Table 11. PORF and EXTRF Values afte r Re set

Reset Source EXTRF PORF

1006D–AVR–07/03

Power-on Undefined 1

External Reset 1 Unchanged

Watchdog Reset Unchanged Unchanged

To identify a reset condition, the user software should clear both the PORF and EXTRF

bits as early as possible in the program. Checking the PORF and EXTRF values is done

23

Page 24

before the bits are cleared. If the bit is cleared before an external or watchdog reset

occurs, the source of reset can be found by using the following truth table:

Table 12. Reset Source Identification

EXTRF PORF Reset Source

0 0 Watchdog Reset

1 0 External Reset

0 1 Power-on Reset

1 1 Power-on Reset

MCU Status Register – MCUSR for the ATtiny12

The MCU Status Register provides information on which reset source caused an M CU

reset.

Bit 76543210

$34 ----WDRFBORFEXTRFPORFMCUSR

Read/Write R R R R R/W R/W R/W R/W

Initial Valu e 0 0 0 0 See Bit Descri p tion

• Bit 7..4 - Res: Reserved Bits

These bits are reserved bit s in t he ATtiny12 and always read as zero.

• Bit 3 - WDRF: Watchdog Reset Flag

This bit is set if a watchdog reset occurs. The bit is reset by a power-on reset, or by writing a logic zero to the flag.

• Bit 2 - BORF: Brown-out Reset Flag

This bit is set if a brown-out reset occurs . The bit is reset by a power-on reset , or by writ ing a logic zero to the flag.

• Bit 1 - EXTRF: EXT ernal Reset Flag

This bit is set if an external reset occurs. The bit is reset by a power-on reset, or by writing a logic zero to the flag.

ATtiny12 Internal Vo ltage Reference

Voltage Reference Enable Signals and Start-up Time

24

ATtiny11/12

• Bit 0 - PORF: Power-on Reset Flag

This bit is set if a pow er-on reset occu rs. The bit is reset b y writing a logic zero to the

flag.

To use the reset flags to identify a reset condition, the user should read and then reset

the MCUSR as early as possib le i n the program. If the re gister is cleared before another

reset occurs, the source of the reset can be found by examining the reset flags.

ATtiny12 fea tures an intern al voltag e referenc e with a n ominal vo ltage of 1 .22V. T his

reference is used for Brown-out Detection, and it can be used as an input to the Analog

Comparator.

The voltage reference has a start-up time that may influence the way it should be used.

The maximum start-up time is 10µs. To save power, the reference is not always turned

on. The reference is on during the follo wing situations:

1006D–AVR–07/03

Page 25

ATtiny11/12

1. When BOD is enabled (by programming the BODEN fuse)

2. When the bandgap refere nce is conn ected to the Analog Comp arato r (by setting

the AINBG bit in ACSR)

Thus, when BOD is not enabled, after setti ng the AINBG bit, the user must always allow

the reference to start up before the output from the Analog Comparator is used. The

bandgap reference uses approximately 10 µA, and to reduce power consumption in

Power-down mode, the user can turn off the reference when entering this mode.

Interrupt Handling The ATtiny11/12 has two 8-bit Interrupt Mask control registers; GIMSK – General Inter-

rupt Mask register and TIMSK – Timer/Counter Interrupt Mask register.

When an interrupt occ urs, the Global Interrupt Enable I-bit is cleared (zero) and all inter-

rupts are disabled. The user software can set (one) the I-bit to enable nested interrupts.

The I-bit is set (one) when a Return from Interrupt instruction – RETI – is executed.

When the Program Counter is vectored to the actual interrupt vector in order to execute

the interrupt handling rou ti ne, hardwar e clears the corre sponding f lag that generated t he

interrupt. Some of t he inter rupt f lags can also be cl eared by wri ting a logic o ne to the flag

bit position(s) to be cl eared.

If an interrupt con dition oc curs when the corres ponding i nterrupt ena ble bit is cleared

(zero), the interrupt flag will be set and remembered until the interrupt is enabled, or the

flag is cleared by software.

If one or more interrupt conditions occur when the global interrupt enable bit is cleared

(zero), the corresponding interrupt flag(s) will be set and remembered until the global

interrupt enable bit is set (one), and will be executed by order of pr iority.

Note that external level interrupt does not have a flag, and will only be remembered for

as long as the interrupt condit ion is active.

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from an interrupt routine. This must be handled by

software.

Interrupt Response Time The interrupt execution response for all the enabled AVR interrupts is 4 clock cycles

minimum. After the 4 clock cycles, the program vector address for the actual interrupt

handling routine is executed. D uring this 4-clock-cycle period, the Prog ram Counter (9

bits) is pushed onto the Stack. The vec tor is normall y a relative j ump to the interru pt rou tine, and this jump takes 2 clock cycles. If an interrupt occurs during execution of a

multi-cycle instruction, this instruction is completed before the interrupt is served. In

ATtiny12, if an interrupt occurs when the MCU is in Sleep mode, the interrupt response

time is increased by 4 clock cycles.

A return from an interrupt handling routine takes 4 clock cycles. During these 4 clock

cycles, the Program Counter (9 bits) is popped back from the Stack, and the I-flag in

SREG is set. When AVR exits from an interrupt, it will always ret urn to the main program

and execute one more instruction bef ore any pending interrupt is served.

General Interrupt Mask Register – GIMSK

Bit 7 6 5 4 3 2 1 0

$3B - INT0 PCIE - - - - - GIMSK

Read/Write R R/W R/W R R R R R

Initial Valu e 0 0 0 0 0 0 0 0

1006D–AVR–07/03

25

Page 26

General Interrupt Flag Register – GIFR

• Bit 7 - Res: Reserved Bit

This bit is a reserved bit in the ATtiny11/12 and always reads as zero.

• Bit 6 - INT0: E x te r n al In te r ru p t Request 0 E n a ble

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one),

the external pin interrupt is enabled. The Interrupt Se nse Control0 bi ts 1/0 (ISC01 and

ISC00) in the MCU general Control Register (MCU CR) define whether the ext ernal

interrupt is activa ted on risin g or fallin g edge, on pin chang e, or low le vel of the INT0 pin .

Activity on the pin will ca use an inter rupt re quest even i f INT0 is co nfigur ed as an output .

The corresponding interrupt of External In terrupt Request 0 is executed from progra m

memory address $001. See also “External Interrupts.”

• Bit 5 - PCIE: Pi n Ch a n g e In te r ru p t Enable

When the PCIE bit is set (one) and the I-bit in the Status Register (SREG) is set (one),

the interrupt on pin change is enabled. Any change on any input or I/O pin will cause an

interrupt. The corresponding interrupt of Pin Change Interrupt Request is executed from

program memory address $002. See also “Pin Change Interrupt.”

• Bits 4..0 - Res: Reserved Bits

These bits are reserved bits in the ATtiny11/12 and always read as zero.

Bit 7 6 5 4 3 2 1 0

$3A - INTF0 PCIF - - - - - GIFR

Read/Write R R/W R/W R R R R R

Initial Valu e 0 0 0 0 0 0 0 0

Timer/Counter Interrupt Mask Register – TIMSK

• Bit 7 - Res: Reserved Bit

This bit is a reserved bit in the ATtiny11/12 and always reads as zero.

• Bit 6 - INTF0 : E x te rnal Interrupt Flag 0

When an edge on the INT0 pin triggers an interrupt request, the corresponding interrupt

flag, INTF0 becomes set (one). If the I-bit in SREG and th e corresponding interrupt

enable bit, INT0 bit in G IMSK, are set (on e), the MCU will jum p to the interrupt ve ctor.

The flag is cleared when the interrupt routine is executed. Alternatively, the flag can be

cleared by writing a logical one to it. The flag is always cleared when INT0 is configur ed

as level inte r ru p t.

• Bit 5 - PCIF: Pin Change Interrupt Flag

When an event on any input or I/O pin triggers an interrupt request, PCIF becomes set

(one). If the I-bit in SREG and the PCIE bit in GIMSK are set (one), the MCU will jump to

the interrupt vector at address $002. The flag is cleared when the interrupt routine is

executed. Alternatively, the flag can be cleared by writing a logical one to it.

• Bits 4..0 - Res: Reserved Bits

These bits are reserved bits in the ATtiny11/12 and always read as zero.

Bit 7 6 5 4 3 2 1 0

26

ATtiny11/12

1006D–AVR–07/03

Page 27

Timer/Counter Interrupt Flag Register – TIFR

ATtiny11/12

$39 - - - - - - TOIE0 - TIMSK

Read/Write R R R R R R R/W R

Initial Valu e 0 0 0 0 0 0 0 0

• Bit 7..2 - Res: Reserved Bits

These bits are reserved bits in the ATtiny11/12 and always read as zero.

• Bit 1 - TOIE0: Timer/Counter0 Overflow Interrupt Enable

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the

Timer/Counter0 Overflow interrupt is enabled. The corresponding interrupt (at vector

$003) is executed if an overflow in Timer/Counter0 occurs, i.e., when the Overflow Flag

(Timer0) is set (one) in the Timer/Counter Interrupt Flag Register – TIFR.

• Bit 0 - Res: Reserved Bit

This bit is a reserved bit in the ATtiny11/12 and always reads as zero.

Bit 7 6 5 4 3 2 1 0

$38 -- ----TOV0-TIFR

Read/Write R R R R R R R/W R

Initial Valu e 0 0 0 0 0 0 0 0

• Bits 7..2 - Res: Reserved Bits

These bits are reserved bits in the ATtiny11/12 and always read as zero.

• Bit 1 - TOV0: Timer/Counter0 Overflow Flag

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared

by hardware when executing the corresponding interrupt handling vector. Alternatively,

TOV0 is cleared by writing a logical one to the flag. When the SREG I-bit, TOIE0

(Timer/Counter0 Overflow Interrupt Enable), and TOV0 are set (one), the

Timer/Counter0 Overflow interrupt is executed.

• Bit 0 - Res: Reserved bit

This bit is a reserved bit in the ATtiny11/12 and always reads as zero.

External Interrupt The external interrupt is trigg ered by the INT0 pin. Observe that, if enabled, the in terrupt

will trigger even if the INT 0 pin is configu red as an output . This featur e prov ides a way of

generating a software interr upt. The ext ernal i nterr upt can be tr iggered by a f alli ng or ris ing edge, a pin change, or a low level. This is set up as indicated in the specification for

the MCU Control Register – MCUCR. When the external interrupt is enabled and is configured as level triggered, the interrupt will trigger as long as the pin is held low.

The external interrupt is set up as described in the specification for the MCU Control

Register – MCUCR.

Pin Change Interrupt The pin change interrupt is triggered by any change on any input or I/O pin. Change on

pins PB2..0 will a lways cause an in terrupt. Cha nge on pins PB 5..3 w ill cause an interrupt if the pin is c onfi gured as input or I/O, as descr ibed in the section “Pin Descriptions”

on page 5. Observe that, if enabled, the interrupt will trigger even if the changing pin is

configured as an output. This feature provides a way of generating a software interrupt.

Also observe that the pin change interrupt will trigger even if the pin activity triggers

1006D–AVR–07/03

27

Page 28

another interrupt, for example, the external interrupt. This impli es that one external

event might cause several inter rupt s.

The values on t he p ins are s ample d befo re detecti ng e dges. If p in c hange int errupt is

enabled, pulses that last longer than one C PU cloc k period will g enerate an interrupt.

Shorter pulses are not guaranteed to generate an interrupt.

28

ATtiny11/12

1006D–AVR–07/03

Page 29

ATtiny11/12

MCU Control Register – MCUCR

The MCU Control Register contains control bits for general MCU functions.

Bit 76543210

$35 - (PUD) SE SM - - ISC01 ISC00 MCUCR

Read/Write R R(/W) R/W R/W R R R/W R/W

Initial Value00000000

Note: The Pull-up Disable (PUD) bit is only available in ATtiny12.

• Bit 7 - Res: Reserved Bit

This bit is a reserved bit in the ATtiny11/12 and always reads as zero.

• Bit 6 - Res: Reserved Bit in ATtiny11

This bit is a reserved bit in the ATtin y11 and always reads as zero.

• Bit 6 - PUD: Pu ll-up Disa ble in ATtiny12

Setting this bit, disables all pull-ups on p ort B. If this bit is cleared , the pull-ups can be

individually enable d as described in section “I/O Port B” on page 43.

• Bit 5 - SE: Sleep Enable

The SE bit must be set (one) to make the MCU enter the Sleep Mode when the SLEEP

instruction is executed. To avoid the MCU entering the Sleep Mode unless it is the programmer’s purpose, it is recommended to set the Sleep Enable SE bit just before the

execution of the SLEEP instruction.

• Bit 4 - SM: Sleep Mode

This bit selects between the two available sleep modes. When SM is cleared (zero), Idle

Mode is selected as Sleep Mode. When SM is set (one), Power-down Mode is selected

as Sleep Mode. For details, refer to the paragraph “Sleep Modes” below.

• Bits 3, 2 - Res: Reserved Bits

These bits are reserved bits in the ATtiny11/12 and always read as zero.

• Bits 1, 0 - ISC01, ISC00: Interrupt Sense Control0 Bit 1 and Bit 0

The External Interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the

corresponding interrupt mask are set. The following table shows how to set the ISC bits

to generate an external interrupt:

Table 13. Interrupt 0 Sense Control

ISC01 ISC00 Description

0 0 The low level of INT0 generates an interrupt request.

0 1 Any change on INT0 generates an interrupt request

1 0 The falling edge of INT0 generates an interrupt request.

1 1 The rising edge of INT0 generates an interrupt request.

The value on the INT0 pin is sampled before detecting edges. If edge interrupt is

selected, pulses that la st longer than one C PU clock pe rio d will g enerate an interr upt.

Shorter pulses are not guaranteed to generate an interrupt. If low-level interrupt is

selected, the low level must be held until the completion of the currently executing

1006D–AVR–07/03

29

Page 30

instruction to generate an interr up t. If en abled, a level-triggered interr upt will g enerate

an interrupt request as long as the pin is held low.

30

ATtiny11/12

1006D–AVR–07/03

Page 31

ATtiny11/12

Sleep Modes for the ATtiny11

Idle Mode When the SM bit is clea red (zero), the SLEEP instru ction forces the MCU into the Idl e

Power-down Mode When the SM bit is set (one), the SLEEP instruction forces the MCU into the Power-

To enter the sleep modes, t he SE bit in MCUCR must be set (o ne) and a SLEEP i nstruc tion must be executed. The SM bit in the MCUCR register selects which sleep mode

(Idle or Power-down) will be activated by the SLEEP instruction. If an enabled interrupt

occurs while the MCU is in a sleep mode, the MCU awakes, executes the interrupt routine, and resumes execution from the instruction following SLEEP. On wake-up from

Power Down M ode on pin ch ange, t wo instructi on cycle s are execu ted befo re the pin

change interrupt flag is updated. During these cycles, the prosessor executes intructions, but the interrupt condition is not readable, and the interrupt routine has not startet

yet. The content s of the register file and I/O memory are unaltered. If a reset occurs dur ing Sleep Mode, the MCU wakes up and executes from the Reset vector.

Mode, stopping the CPU but allowing Timer/Counters, Watchdog and the interrupt system to continue operating. This enables the MCU to wake up from external triggered

interrupts as well as internal ones like Timer Overflow interrupt and Watchdog Reset. If

wake-up from the Analog Co mparator interrupt is not requi red, the analog comp arator

can be powered down by setting the ACD-bit in the Analog Comparat or Control and Status register – ACSR. This will reduce power consumption in Idle Mode. When the MCU

wakes up from Idle mode, the CPU starts program executio n immediately.

down Mode. In this mode, the external oscillator is stopped, while the external interrupts

and the Watchdog (if enabled) contin ue operating . Only a n external reset, a watch dog

reset (if enabled), an external level interrupt, or an pin change interr upt can wake up the

MCU.

Note that if a level-triggered or pin change interrupt is used for wake-up from powerdown, the ch anged lev el mus t be h eld for a t ime longer than the re set delay p eriod of

. Otherwise , the MCU will fail to wake up.

t

TOUT

Sleep Modes for the ATtiny12

Idle Mode When the SM bit is clea red (zero), the SLEEP instru ction forces the MCU into the Idl e

Power-down Mode When the SM bit is set (one), the SLEEP instruction forces the MCU into the Power-

To enter the sleep modes, t he SE bit in MCUCR must be set (o ne) and a SLEEP i nstruc tion must be executed. The SM bit in the MCUCR register selects which sleep mode

(Idle or Power-down) will be activated by the SLEEP instruction. If an enabled interrupt

occurs while the MCU is in a sleep mode, the MCU awakes. The CPU is then halted for

four cycles, it executes the interrupt routine, and resumes execution from the instruction

following SLEEP. The contents of the register file and I/O memory are unaltered. If a

reset occurs during sleep mode, the MCU wakes up and executes from the Reset

vector.

Mode stopping the CPU but allowing Ti mer/Counters, Watchdog and the interrupt system to continue operating. This enables the MCU to wake up from external triggered

interrupts as well as internal ones like Timer Overflow interrupt and Watchdog Reset. If

wake-up from the Analog Co mparator interrupt is not requi red, the analog comp arator

can be powered down by setting the ACD-bit in the Analog Comparat or Control and Status Register – ACSR. This will reduce power consumption in Idle Mode.

down Mode. In this mode, the external oscillator is stopped, while the external interrupts

and the Watchdog (if enabled) contin ue operating . Only a n external reset, a watch dog

reset (if enabled), an external level interrupt, or a pin change interrupt can wake up the

MCU.

1006D–AVR–07/03

31

Page 32

Note that if a level triggered or pin change interrupt is used for wake-up from Powerdown Mode, the changed level must be h eld for a time to wake up the MCU. This mak es

the MCU less sensitive to noise. The wake-up period is equal to the clock-counting part

of the reset period (See Table 9). The MCU will wake up from the power-down if the

input has the required level for two watchdog oscillator cycles. If the wake-up period is

shorter than two watchdog oscillator cycles, th e MCU will wake up if the input has the

required level for the duration of the wake-up period. If the wake-up condition disappears before the wake-up period has expired, the MCU will wake up from po wer-down

without executing the corresponding interrupt. The period of the watchd og oscillator is

2.7 µs (nominal) at 3.0V and 25°C. The frequency of the watchdog oscillator is voltage

dependent as shown in the section “ATtiny11 Typical Characteristics” on page 60.

When waking up from Power-down Mode, there is a delay from the wake -up con dition

occurs until the wake-up becomes effective. Thi s allows the clock to restart and become

stable after having been stopp ed. The wake-u p p eriod is defined b y th e same CKS EL

fuses that define the reset time-out period.

ATtiny12 Calibrated Internal RC Oscillator

Oscillator Calibrat ion Register – OSCCAL

In ATtiny12, the calib rat ed internal oscillator provi des a fixed 1.2 MHz (nominal) clock at

5V and 25°C. This clock may be u sed as the system cloc k. See the section “Clock

Options” on page 5 for information on how to select this clock as the system clock. This

oscillator can be calibrat ed by writing the cal ibrat ion byte to the OSCCAL register. When

this oscillator is used as the chip clock, the Watchdog Oscillator will still be used for the

Watchdog Ti mer and for the reset time-out. Fo r details on ho w to use the pre -programmed calibration val ue, see t he secti on “Calibr ation By te in ATt iny12” on page 47. At

5V and 25

o

C, the pre-programmed calibration byte gives a frequency within ± 1% of the

nominal frequency.

Bit 76543210

$31 CAL7 CAL6 CAL5 CAL4 CAL3 CAL2 CAL1 CAL0 OSCCAL

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value00000000

• Bits 7..0 - CAL7..0: Oscillator Calibration V alue

Writing the calibration byte to this address will trim the internal oscillator to remove process variations from the oscillator frequency. When O SCCAL is zero, the lowest

available frequency is chosen. Writing non-zero values to this register will increase the

frequency of the inte rnal oscill ator. Writi ng $FF to t he re gister gives t he highes t avail able

frequency. The calibrated oscillator is used to time EEPROM access. If EEPROM is

written, do not calibrate to more than 10% above the nominal frequency. Otherwise, the

EEPROM write may fail. Table 14 shows the range for OSCCAL. Note that the oscill ator

is intended for calibration to 1.2 MHz, thus tuning to other values is not guaranteed.

32

Table 14. Internal RC Oscillator Frequency Range

OSCCAL Value Min Frequency Max Frequency

$00 0.6 MHz 1.2 MHz

$7F 0.8 MHz 1.7 MHz

$FF 1.2 MHz 2.5 MHz

ATtiny11/12

1006D–AVR–07/03

Page 33

ATtiny11/12

Timer/Counter0 The ATtiny11/12 provides one general-purpose 8-bit Time r/Counter – Timer/ Counter0.

The Timer/Counter0 has prescaling selection from the 10-bit prescaling timer. The

Timer/Counter0 can either be used as a timer with an internal clock timebase or as a

counter with an external pin connection that triggers the counting.

Timer/Counter Prescaler Figure 23 shows the Timer/Counter prescaler.

Figure 23. Timer/Counter0 Pres caler

CK

T0

CS00

CS01

CS02

10-BIT T/C PRESCALER

CK/8

0

TIMER/COUNTER0 CLOCK SOURCE

TCK0

CK/64

CK/256

CK/1024

The four differen t pres caled sel ections are: C K/8, C K/64, C K/256 a nd CK/1024 where

CK is the oscillator clock. CK , external source and stop, can also be select ed as clock

sources.

Figure 24 shows the block diagram for Timer/Counter0.

The 8-bit Timer/Counter0 can select clock source from CK, prescal ed CK, or an external

pin. In addition , it can be stopp ed as described in t he specification for t he

Timer/Counter0 Control Register – TC CR0. The overflow st atus flag is found in the

Timer/Counter Interrupt Flag Register – TIFR. Control signals are found in the

Timer/Counter0 Control Register – TCCR0. The interrupt enable/disable settings for

Timer/Counter0 are found in the Timer/Counter Interrupt Mask Register – TIMSK.

1006D–AVR–07/03

When Timer/Counter0 is externally clocked, the external signal is synchronized with the

oscillator frequency of the CPU. To ensure prope r sampling of the external clock, the

minimum time between two external clock transitions must be at least one internal CPU

clock period. Th e external clock signal is sampled on the rising edge of the internal CPU

clock.

The 8-bit Timer/Counter0 features both a high-resolution and a high-accuracy usage

with the lower prescaling oppo rtunities. Similarly, the high-p rescaling opportuni ties

make the Timer/Count er0 useful for lower-speed functions or exact-timing functions with

infrequent actions.

33

Page 34

Timer/Counter0 Control Register – TCCR0

Figure 24. Timer/Counter0 Block Diagr am

T0

Bit 76 5 4 3 210

$33 - - - - - CS02 CS01 CS00 TCCR0

Read/Write R R R R R R/W R/W R/W

Initial Valu e 0 0 0 0 0 0 0 0

• Bits 7..3 - Res: Reserved Bits

These bits are reserved bits in the ATtiny11/12 and always read as zero.

• Bits 2,1,0 - CS02, CS01, CS00: Clock Select0, Bit 2,1 and 0

The Clock Select0 bits 2,1 and 0 define the prescali ng source of Timer0.

Table 15. Clock 0 Prescale Select

CS02 CS01 CS00 Description

0 0 0 Stop, the Timer/Counter0 is stopped.

001CK

010CK/8

011CK/64

100CK/256

101CK/1024

1 1 0 External Pin T0, falling edge

1 1 1 External Pin T0, rising edge

34

ATtiny11/12

1006D–AVR–07/03

Page 35

Timer Counter 0 – TCNT0

ATtiny11/12

The Stop condition provides a Timer Enable/Disable function. The CK down-divided

modes are scaled directly from the CK oscillator clock. If the external pin modes are

used for Timer/Counter0, transitions on PB2/(T0) will clock the counter even if the pin is

configured as an output. This feature can give the user SW control of the counting.

Bit 76543210

$32 MSB LSB TCNT0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value00000000

The Timer/Counter0 is implemented as an up-counter with read and write access. If the

Timer/Counter0 is written and a clock source is present, the Timer/Counter0 continues

counting in the timer clock cyc le following the write operation.

1006D–AVR–07/03

35

Page 36

Watchdog Timer The Watchdo g Tim er is clock ed fro m a separa te o n-chip oscilla tor. By co ntrolling the

Watchdog Timer prescaler, the Watchdog reset interval can be adjusted as shown in

Table 16. See charact erization da ta for typica l values at othe r V

Watchdog Reset – instruction resets the Watchdog Timer. Eight different clock cycle

periods can be selected to determine the reset period. If the reset period expi res withou t

another Watchdog reset, the ATti ny11/12 re set s and executes f rom the reset vecto r. For

timing details on the Watchdog rese t, refer to page 23.

To prevent unintentional disabling of the watchdog, a special turn-off sequence must be

followed when the watchdog i s disabled. Refer to the d escription of the Watchdog Ti mer

Control Register for details.

Figure 25. Watchdog Timer

Oscillator

levels. The WDR –

CC

Watchdog Timer Control Register – WDTCR

1 MHz at V

350 kHz at V

110 kHz at V

Bit 76543210

$21

Read/Write R R R R/W R/W R/W R/W R/W

Initial Value00000000

- - - WDTOE WDE WDP2 WDP1 WDP0 WDTCR

CC

CC

CC

= 5V

= 3V

= 2V

• Bits 7..5 - Res: Reserved Bits

These bits are reserved bit s in t he ATtiny11/12 and will always read as ze r o .

36

• Bit 4 - WDTOE: Watchdog Turn-off Enable

This bit must be set (one) when the WDE bit is cleared. Otherwise, the watc hdog will not

be disabled. Once set, hardwar e will clear this bit to zero after four clock cycles. Refer to

the description of the WDE bit for a watchdog dis able procedure.

• Bit 3 - WDE: Watchdog Enable

When the WDE is set (one) the Watchdog Timer is enabled, and if the WDE is cleared

(zero) the Watchdog Timer function is disabled. WDE can be cleared only when the

WDTOE bit is set(one). To disable an enabled watchdog timer, the following procedure

must be followed:

ATtiny11/12

1006D–AVR–07/03

Page 37

ATtiny11/12

1. In the same operation, write a logical one to WDTOE and WDE. A logical one

must be written to WDE even though it is set to one before the disable operation

starts.

2. Within the next four clock cycles, write a logical 0 to WDE. This disables the

watchdog.

• Bits 2..0 - WDP2, WDP1, WDP0: Watchdog Timer Prescaler 2, 1 and 0

The WDP2, WDP1 and WDP0 bits determine the Watchdog Timer prescaling when the

Watchdog Timer is enabled. The different prescaling values and their corresponding

time-out periods are shown in Table 16.

Table 16. Watchdog Timer Prescale Select

Typical

Number of WDT

WDP2 WDP1 WDP0

0 0 0 16K cycles 0.15s 47 ms 15 ms

0 0 1 32K cycles 0.30s 94 ms 30 ms

0 1 0 64K cycles 0.60s 0.19 s 60 ms

0 1 1 128K cycles 1.2s 0.38 s 0.12 s

1 0 0 256K cycles 2.4s 0.75 s 0.24 s

1 0 1 512K cycles 4.8s 1.5 s 0.49 s

1 1 0 1,024K cycles 9.6s 3.0 s 0.97 s

1 1 1 2,048K cycles 19s 6.0 s 1.9 s

Note: The frequency of the Wa tchdog Oscillator is voltage dependent as shown in the section

“ATtiny11 Typical Characteristics” on page 60.

The WDR – Watchdog Reset – instruction should always be executed before the Watchdog Timer is enabled. This ensures that the reset period will be in accordance with the

Watchdog Timer prescale settings. If the Watchdog Timer is enabled without reset, the

Watchdog Timer may not start counting from zero.

To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.

Oscillator cycles

Time-out at

V

= 2.0V

CC

Typical

Time-out at

V

= 3.0V

CC

Typical

Time-out at

V

= 5.0V

CC

1006D–AVR–07/03

37

Page 38

ATtiny12 EEPROM Read/Write Access

EEPROM Address Register – EEAR

The EEPROM access registers are accessible in the I/O space.

The write access time is in the range of 3.1 - 6.8 ms, depending on the frequency of the

calibrated RC oscillator. See Table 17 for details. A self-timing function lets the user

software detect when the next byte can be written. A special EEPROM Ready interrupt

can be set to trigger when the EEPROM is ready to accept new data. The minimum voltage for writing to the EEPROM is 2.2V.

In order to prevent unintentional EEPROM writes, a tw o-state write procedure must be

followed. Refer to the description of the EEPROM Control Regist er for details on this.

When the EEPROM is written, the CP U is halted for two clo ck cycles befo re the next

instruction is executed. When the EEPROM is read, the CPU is halted for four clock

cycles before the next instr u ction is executed.

Bit 76543210

$1E - - EEAR5 EEAR4 EEAR3 EEAR2 EEAR1 EEAR0 EEAR

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial Valu e 0 0 X X X X X X

The EEPROM Address Register – EEAR specifies the EEPROM address in the 64-byte

EEPROM sp ace. T he E EPRO M d ata by tes are ad dresse d lin early betwe en 0 and 63.

During reset, the EEAR register is not clear ed. I nstead, the data in the register is kept.

EEPROM Data Register – EEDR

EEPROM Control Register – EECR

Bit 76543210

$1D MSB LSB EEDR

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value00000000

• Bits 7..0 - EEDR7.0: EEPROM Data

For the EEPROM write operation, t he EEDR register contains the data to b e written to

the EEPROM in the address given by the EEAR register. For the EEPROM read operation, the EE DR co ntains the data read out fr om th e EEP ROM at the ad dres s given by

EEAR.

Bit 76543210

$1C - - - - EERIE EEMWE EEWE EERE EECR

Read/Write R R R R R/W R/W R/W R/W

Initial Valu e 0 0 0 0 0 0 X 0

• Bit 7..4 - Res: Reserved Bits

These bits are reserved bit s in t he ATtiny12 and will always read as zero.

• Bit 3 - EERIE: EEPROM Ready Interrupt Enable

When the I-bit in SREG and EERIE are set (one), the EEPROM Ready interrupt is

enabled. When cleared (zero), the interrupt is disabled. The EEPRO M Ready int errupt

generates a constant interrupt when EEWE is cleared (zero).

38

ATtiny11/12

1006D–AVR–07/03

Page 39

ATtiny11/12

• Bit 2 - EEMWE: EEPROM Master Write Enable

The EEMWE bit determines wh ether setting E EWE to one causes the EEP ROM to be

written. When EEMWE is set (one), setting EEWE will write data to the EEPROM at the

selected address. If EEMWE is zero, setting EEWE will have no effect. When EEMWE

has been set (one) by software, hardware clears the bit to zero after four clock cycles.

See the description of the EEWE bit for a EEPROM write procedure.

• Bit 1 - EEWE: EEPROM Write Enable

The EEPROM Write Enable Signal EEWE is the write strobe to the EEPROM. When

address and data are correctly set up, the EEWE bit must be set to write the value into

the EEPROM. The EEM WE bit must be set when the log ical one is written to EEWE,

otherwise no EEPR OM w rite tak es pl ace. The foll owing p roced ure shou ld b e follow ed

when writing the EEPROM (the order of steps 2 and 3 is unessential):

1. Wait until EEWE become s zero.

2. Write new EEPROM address to EEAR (optional).

3. Write new EEPROM data to EEDR (optional).

4. Write a logical one to the EEMWE bit in EECR (to be able to write a logical one

to the EEMWE bit, the EEWE bit must be written to zero in the same cycle).

5. Within four clock cycles after setting EEMWE, write a logical one to EEWE.

Caution: An interrupt between step 4 and step 5 will make the write cycle fail, since the

EEPROM Master Write Enable will time-out. If an interrupt routine accessing the

EEPROM is interrupting another EEPROM access, the EEAR or EED R register will be

modified, causing th e inte rrupted E EPROM acce ss to fa il. It is recom mended to ha ve

the global interrupt flag cl eared during the four last steps to avoid these problems.

When the write access time has elaps ed, the EEW E bit is cleared (zero) by hardware.

The user software can poll this bit and wait for a zero before writing the next byte. When

EEWE has been set, the CPU is halted for two cycles before the n ext instruction is

executed.

• Bit 0 - EERE: EEPROM Read Enable

The EEPROM Read Enable Signal EERE is the read strobe to the EEPROM. When the

correct address is set up in the EEAR register, the EERE bit must be set. When the

EERE bit is cleared (zero) by hardware, requested d ata is foun d in the EEDR regi ster.

The EEPROM read access takes one instruction and there is no need to poll the EERE

bit. When EERE has been set, the CPU is halted for four cycles before the next instruction is executed.

The user should poll the EEWE bit be fore st artin g the read oper ation. If a wri te opera tion

is in progress when new data or address is written to the EEPROM I/O registers, the

write operation will be interrupte d , and the result is undefined.

The calibrated oscillator is used to time EEPROM. In Table 17 the typical programming

time is listed for EEPROM access from the CPU.

1006D–AVR–07/03

Table 17. Typical EEPROM Programming Times

Number of Calibrated

Parameter

EEPROM write

(from CPU) 4096 3.1 ms 6.8 ms

RC Oscillator Cycles

Min Programming

Time

Max Programm ing

Time

39

Page 40

Prevent EEPROM Corruption

During periods of low VCC, the EEPROM data can be corrupted because the supply voltage is too low for the CPU and the EEPROM to operate properly. These issues are the