Atlantic VF 40, VF 60, VF 80, VF 100 Use & Maintenance Manual

ADDRESS: ATLANTIC BOILERS, PO BOX 11, ASHTON UNDER LYNE, OL6 7TR

WEB: WWW.ATLANTICBOILERS.COM EMAIL: INFO@ATLANTICBOILERS.COM

TEL: 0161 621 5960 FAX: 0161 621 5966

VF Model

USE & MAINTENANCE

WALL-MOUNTED GAS CONDENSING BOILER

40, 60, 80 & 100KW OUTPUT

MODULATING BURNERS

After sales service is guaranteed by Atlantic Boilers

The boilers conform to the following CE Directives

Directive 2006/95/CD - low voltage

Directive 2004/108/CEE - electromagnetic compatibility

Directive 92/42/CEE - efficiency

Directive 90/396/CEE - gas fired equipment

Summary

1. General characteristics .........................................................................................................3

1.1. Acceptable gas pressure .................................................................................................................3

1.2. Combustion conditions .....................................................................................................................3

1.3. Operating conditions .......................................................................................................................4

1.4. Electrical conditions .........................................................................................................................4

2. Boiler installation ...................................................................................................................5

3. Running the boiler .................................................................................................................5

4. Switching the boiler off..........................................................................................................5

5. Maintenance of the boiler......................................................................................................5

6. Frost protection......................................................................................................................5

7. Boiler control panel................................................................................................................6

7.1. Control panel fascia..........................................................................................................................6

7.2. Control panel display arrangement...................................................................................................6

7.3. Control panel functions.....................................................................................................................7

7.4. Adjustment of the settings.................................................................................................................9

7.5. Information on boiler condition........................................................................................................10

7.6. Adjust the settings...........................................................................................................................13

8. Function of the LMU64 060D168..........................................................................................14

9. Table of boiler settings for the Client..................................................................................15

page 3/17

1. General Characteristics

The V F boiler is set in the Factory to operate

on Natural Gas Group H with a supply pressure of 20mBar.

F

or higher gas pressure up to 300mBar, a filter and

a pressure regulator must precede the V

F gas valve.

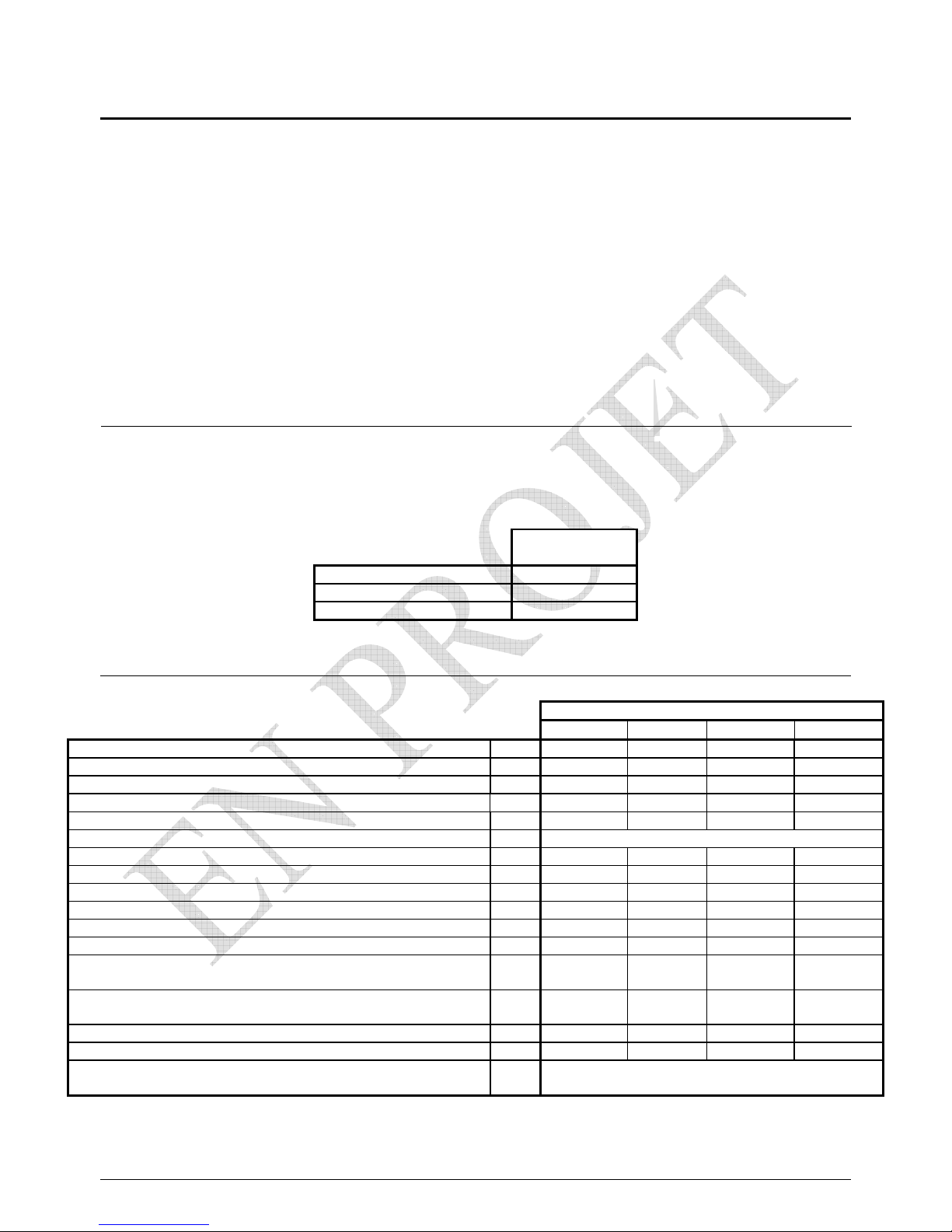

1.1. Acceptable gas pressure

Gaz naturel H

G20

Nominal (mbar)

20

Minimum (mbar)

17

Maximum (mbar)

25

1.2. Combustion conditions

VF

40 60 80 100

Nominal output Pn (80/60°C)

kW

56,5

92,6

Nominal condensing output P (50/30°C)

kW

61,8 100

Nominal heat outflow Qn

kW

58 95,1

Minimum heat outflow Qmin

kW

14,5 25,5

G20 gas flow rate at Pn

m

3

/h 6,1 10,1

Recommended CO2 values

% see chapter 6.2

Mass flow of flue gases Qn / Qmin (80/60°C)

g/s 27 / 6,1 44 / 12

Mass flow of flue gases Qn / Qmin (50/30°C)

g/s 25,3 / 5,7 39,6 / 10,4

Temperature of flue gases Qn / Qmin (80/60°C)

°C 70 / 55 76 / 60

Temperature of flue gases Qn / Qmin (50/30°C)

°C 46 / 32 56 / 32

Pressure loss for flue gas circuit Qn

Pa 75 74

Diameter of flue gas outlet mm 80 100

Maximum pressure at flue gas output (B23P)

Qn / Qmin (80/60°C) *

Pa 150 / 8 110 / 6

Maximum pressure at flue gas outlet (B23P)

Qn / Qmin (50/30°C) *

Pa 123 / 3 97 / 5

Combustion air at Qn

m

3

/h 76 124

NOx class to EN 483:2000 4 / 5 5 / 5

Types of flue gas and combustion air arrangements

B23, B23P, C13, C33, C53

page 4/17

1.3. Operating conditions

VF

60 100

Maximum flow water temperature °C 80

Temperature Limit thermostat °C 100

Maximum working pressure

hPa

(bar)

4000

(4,0)

Minimum working pressure

hPa

(bar)

1000

(1,0)

Minimum water flow rate :

primary / secondary circuits (P/20)

l/s 0.67 / 0.67 1.11 / 1.11

Water content

l 6,1 9,4

Dry weight

kg 73 88

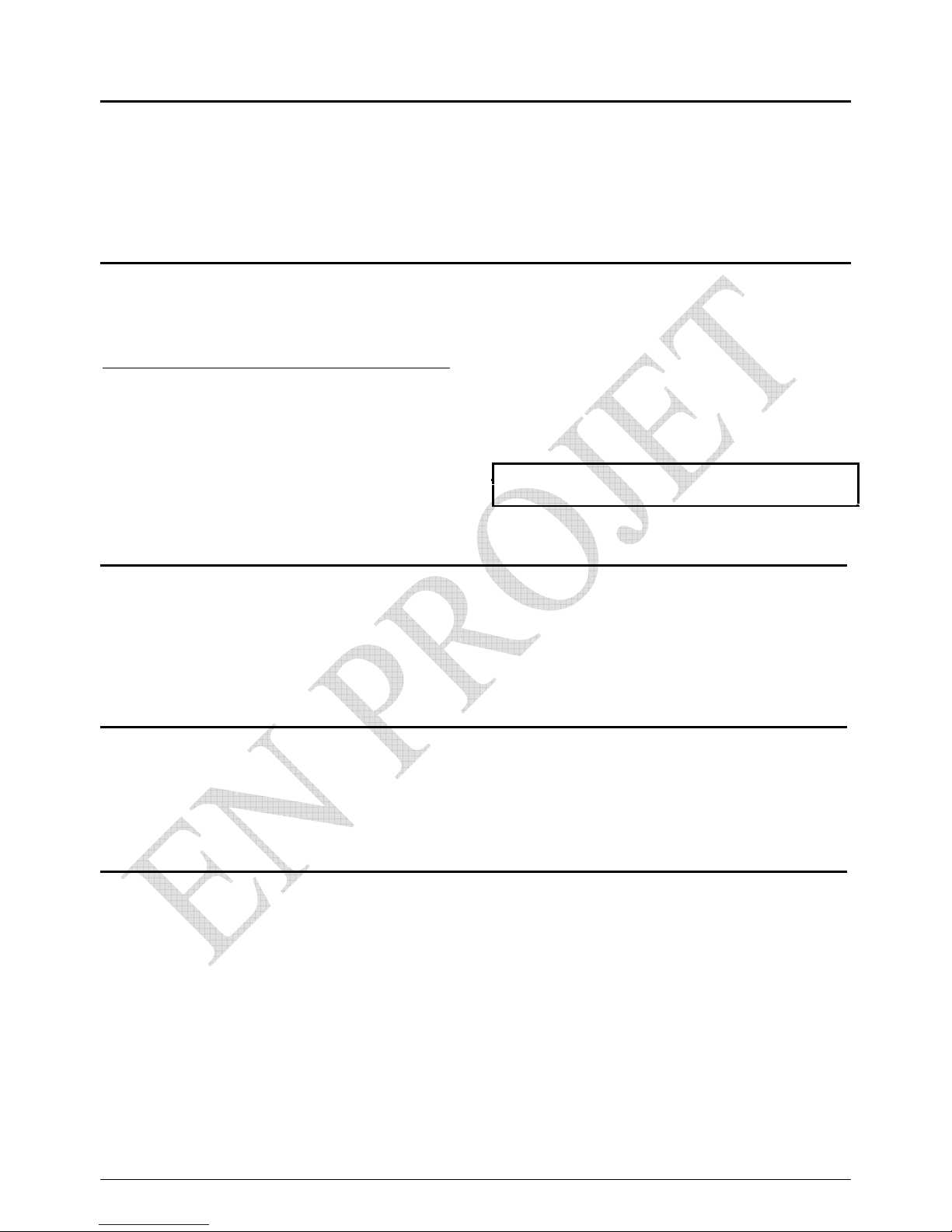

1.4. Electrical conditions

VF

60 100

Electrical supply

V 230 V AC (+10% -15%), 50Hz

Requirement at Qn

W 190 300

Requirement at standing load

W 7

Maximum length for sensor cables

m

domestic hot watersensor : 10

external sensor : 40

room thermostat : 40

room sensor : 50

Control panel requirement

V

A

230V AC (+10%, -15%)

5 mA à 1 A

Temperature °C

Ohm resistance

flow/return sensor QAK36.095/109

flue gas sensor QAK36.670/109

NTC 10 KΩ at 25°C

0°C

32 555 Ω

10°C

19 873 Ω

20°C

12 488 Ω

25°C

10 000 Ω

30°C

8 059 Ω

40°C

5 330 Ω

50°C

3 605 Ω

60°C

2 490 Ω

70°C

1 753 Ω

80°C

1 256 Ω

90°C

915 Ω

100°C

677 Ω

110°C

508 Ω

120°C

387 Ω

page 5/17

2. Boiler installation

Installation and maintenance of the installation shoukd be carried by a qualified

engineer according to the recommendations of the relevant codes of practice

and of the boiler manufacturer

The boiler must be installed in an appropriately ventilated compartment

…………………………………………………………….

3. Running the boiler

The boiler must be supplied with G20 natural gas

to bring the boiler into service

1. switch on the electrical supply

2. use the controls to set up a heating demand

3. when the boiler fires, check the gas line for soundness

and measure the combustion efficiency using

a flue gas analyser

4. Set up the controls to the programme required

by the Client

breaking any Factory equipment seals

invalidates the Boiler guarantee

4. Switching the boiler off

1. switch off the electricity supply

2. close the gas supply

5. Maintenance of the boiler

It is essential to service the boiler every year

Be ensure to employ a qualified engineer

6. Frost protection

If the boiler plant is not in use and there

is a risk of freezing, then anti-freeze should be

introduced to the system

In addition the boiler can be drained as follows

• switch off the electricity supply

• close the gas supply valve

• close the heating system isolating valve

• use the safety valve to release water pressure in the boiler

• release the automatic air vent to allow air to enter the boiler

• open the boiler drain valve to release

water from the boiler

page 6/17

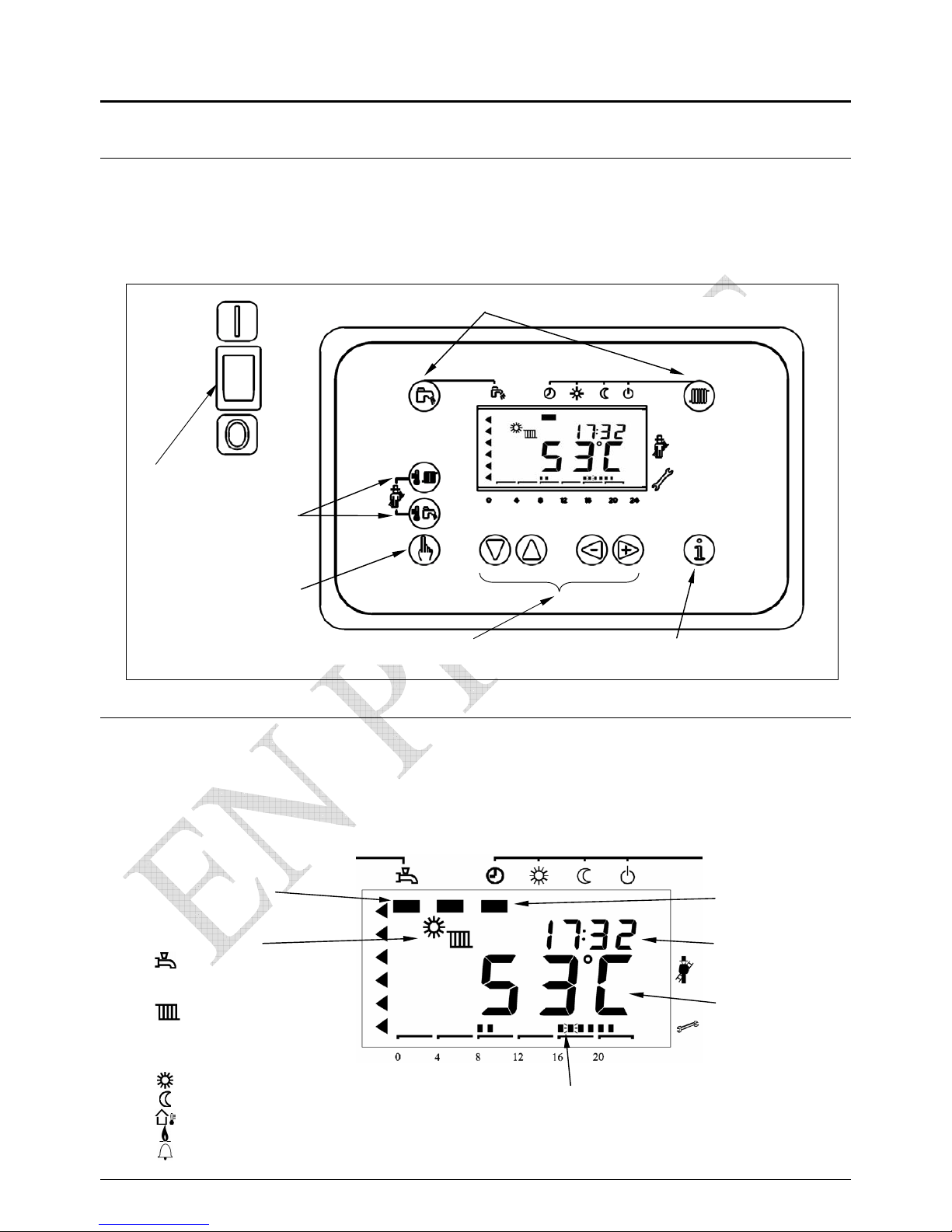

7. Boiler Control Panel

7.1. Control panel fascia

7.2. Display

The screen supplies boiler function, time, hourly programme,

temperature, burner, condition and defect

Hourly programme

Space heating

requirement

Time

Boiler

temperature

DHW requirement

Symbols :

DHW in progress

Space heating

in progress

Comfort requirement

Set back requirement

Outside temperature

Flame established

Defect

Touch requirement

Touch programme Touch information

boiIer isolator

Touch

signals

Touch

re-set

Loading...

Loading...