Page 1

PUMP PROTECTOR

Operating Manual

1-877-80-PONDS

www.atlanticwatergardens.com

Page 2

Product: Pump Protector

Model: TWPP14

Features:

• Pump motor is protected from operating when system is dry

• Provides pump protection from certain cavitations due to

decreased water ow

• Protection from excessive line currents

• 14 amp / 1HP maximum at 120 VAC operation

• Reset/calibration push button for fast commissioning

• Works with existing ground fault circuits

• No wiring; just plug in the unit and pump

Description:

The Pump Protector is an electronic control module designed to help protect pump

motor damage due to sudden restriction in water ow or when system is dry. The

product monitors subtle line power changes that are created by the pump during

changing load conditions, and therefore does not need level

sensors which can plug during operation.

When line current changes exceed the product’s internal threshold, the power to the

pump is switched off until the user pushes the reset button. The product also has

calibration means to set the lower and upper current threshold specic to each pump

size to protect during abnormal power changes.

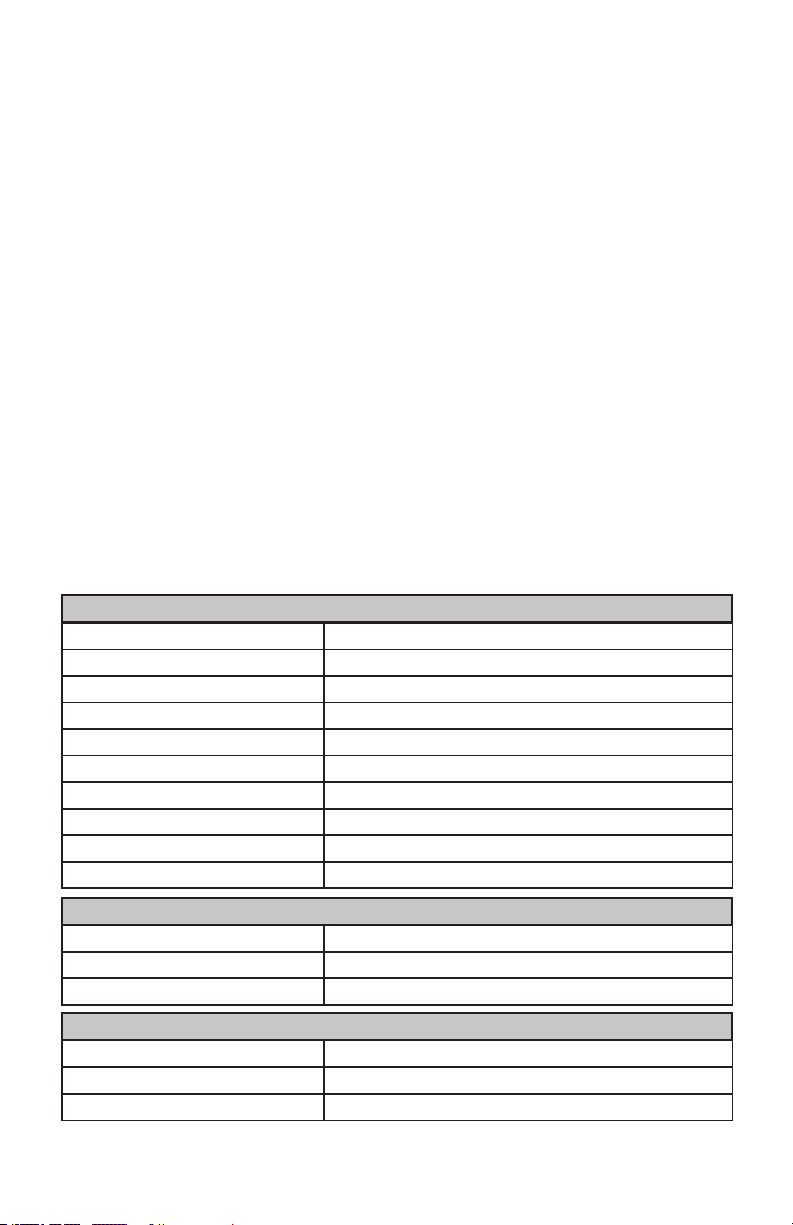

ELECTRICAL

Supply Voltage 105-132 AC

Supply Voltage Frequency 50Hz, 60Hz

Burden Current <12mA

Output Type Relay Form A

Output Current (Maximum) 14 Amp AC, 1 HP

Over Current Circuit Protection 125% of Programmed Current, < 10 sec response time

Under Current Circuit Protection 75% of Programmed Current, <10 sec response time

Overload Current Protection 15 amp +/- 20%, <10 AC cycles

Cavitations Current Protection Adaptive, <10 sec response

Pump Dry Shut down < 10 seconds

ENVIRONMENTAL

Sealing IP64, Dust protection and water spray

Shock 10G

Temperature -25° to 50°C

MECHANICAL

Package Material ASA, Black

Dimensions (LxWxD) L 5.18”, Q 3.25”, H 2.12” w/o base plate

Mounting Holes 2 x 0.125”

2

Page 3

Installation Instructions:

1. Attach the mounting plate to the back of the Pump Protector with

the four screws provided.

2. Choose a spot near the GFCI outlet to mount the Pump Protector.

3. Attach the Pump Protector to a post or structure using two exterior

screws (not included).

Note: Make sure that the Pump Protector is high enough that the Pump Power Supply

Cord ( gure 1) is not lying on the ground. The Pump Protector can either be mounted

horizontally or vertically.

Controller Unit

Reset Button

Pump Power

Supply Cord

Controller Unit

Power Supply Cord

FIGURE 1

To Improve The Reliability of Your Pump Protecting System:

1. Provide adequate wiring to the Pump Protector to ensure that load

switching from other appliances do not change line voltatge more

than 10% during abrupt load changes.

2. Calibrate the Pump Protector only after verication that the pump

liquid ow is adequate.

3. Connect only one pump to the Pump Protector.

4. Regularly check the conveyance system for slow build up of

deposits that can affect water ow over time.

5. Some pumps inherently have cavitation due to pump design and

may intermittently shut down.

Page 4

Instructions - Quick Set Up:

1. Connect pump motor to the pump power supply cord. (See gure 1.)

2. Plug the controller power supply cord into GFCI protected outlet. The pump

should start and buzzer will sound. (See gure 1.)

3. Ensure water ow is adequate in the conveyance lines and wait until the

buzzer stops.

4. Press the reset button once – the internal buzzer will pulse.

5. During the time between buzzer pulse 2 and pulse 5, press the reset button

once – this auto calibrates the unit to a power change range of plus or minus

10%. These settings will be permanently stored.

NOTE: Some pumps require a wider power change. Push the reset button

twice for a range of plus or minus 15%.

6. The buzzer will increase in tone frequency to acknowledge button depression.

7. The above process can be repeated if pump is changed or operating

conditions change.

Application Summary

The Pump Protector is designed to help reduce damage to water pumps like

those used in outdoor ponds and pond-free water features. Pumps need water

owing through the chamber in order to cool the motor windings. If water ow

is impeded, the pump can overheat, resulting in permanent damage. Water also

lubricates moving parts and therefore a loss of water ow can also damage these

internal parts.

Excessive water bubbles or a quick reduction in water ow creates small

changes in the line current to the pump. Additionally, a blockage from debris on

either the inlet or outlet side also causes small line current changes. The Pump

Protector control module is designed to detect these small changes and take action to help protect the pump. Upon fault detection the control circuit will switch

off the power to the pump to protect it from over heating. Once tripped, the

user needs to inspect the water system to ensure adequate water ow is

established to the pump. Pressing the reset button on the control module once

will restart the pump.

The Pump Protector also has a calibration feature, which sets a high and low

protection threshold for each pump. To implement this feature, press the reset

button once and the buzzer will beep. Then press the button once between the

second and fth beep from the buzzer. The unit will acknowledge by increasing

the tone of the buzzer. The control module is now calibrated to your pump. It is

critical that the water ow is checked for adequate movement before calibrating

the system to ensure that trip thresholds are set to normal operating conditions.

Some motors have thermal protection built in to help protect the pump. The

thermal protection will turn off the pump when hot but after cooling the pump

will automatically restart. Therefore the pump can get into a continuous on-off

cycle, which can result in permanent pump damage. The control circuit will detect

a thermal shutdown as a low current fault and switch off the pump to

eliminate cycling.

4

Loading...

Loading...