Page 1

NESLAB ThermoFlex™900

Recirculating Chiller

Delivers continuous cooling capacity

up to 900 watts

Product Specifications

Reliable, easy-to-use chillers

optimized for the most demanding

applications

Chilling Performance

Ideal for diverse applications

within the following markets:

• Analytical instrumentation

• Laser

• Medical equipment

• Packaging

• Research

• University

High Reliability

You can expect years of consistent operation

from the NESLAB ThermoFlex 900 recirculating

chiller. The unit features a robust refrigeration

system designed for continuous use in a

variety of installations. The recirculation

system incorporates highly reliable plumbing

connections to eliminate leaks. Integrated air

and fluid filters minimize wear to mechanical

parts, which lowers lifetime maintenance

costs and improves system reliability.

Superior Performance

ThermoFlex 900 chillers offer up to 10%

greater cooling capacity than comparable

units. The breadth of available options allows

you to optimize chiller performance based on

your application requirements. These chillers

also have improved noise quality ensuring a

pleasant work environment.

Easy to Use

The quick-start guide enables trouble-free

system start up. Snap in-and-out air and

fluid filters promote quick and simple

maintenance. The innovative recirculation

system includes an integrated funnel and

visual indicator for operator convenience. An

intuitive controller allows customer-defined

alarms to be set for various parameters,

ensuring your process is always in control.

Configurable to Meet Application Needs

The NESLAB ThermoFlex 900 recirculating

chiller can be configured with a variety of

plug & play options. The result is a reliable,

easy-to-maintain, high performance unit that

can be optimized for the most demanding

cooling applications.

Analyze • Detect • Measure • Control

TM

Page 2

NESLAB ThermoFlex™900 Specifications

Product Specfications

Setpoint Temperature Range 5°C - 40°C

Ambient Temperature Range 10°C - 40°C

Temperature Stability +/- 0.1°C

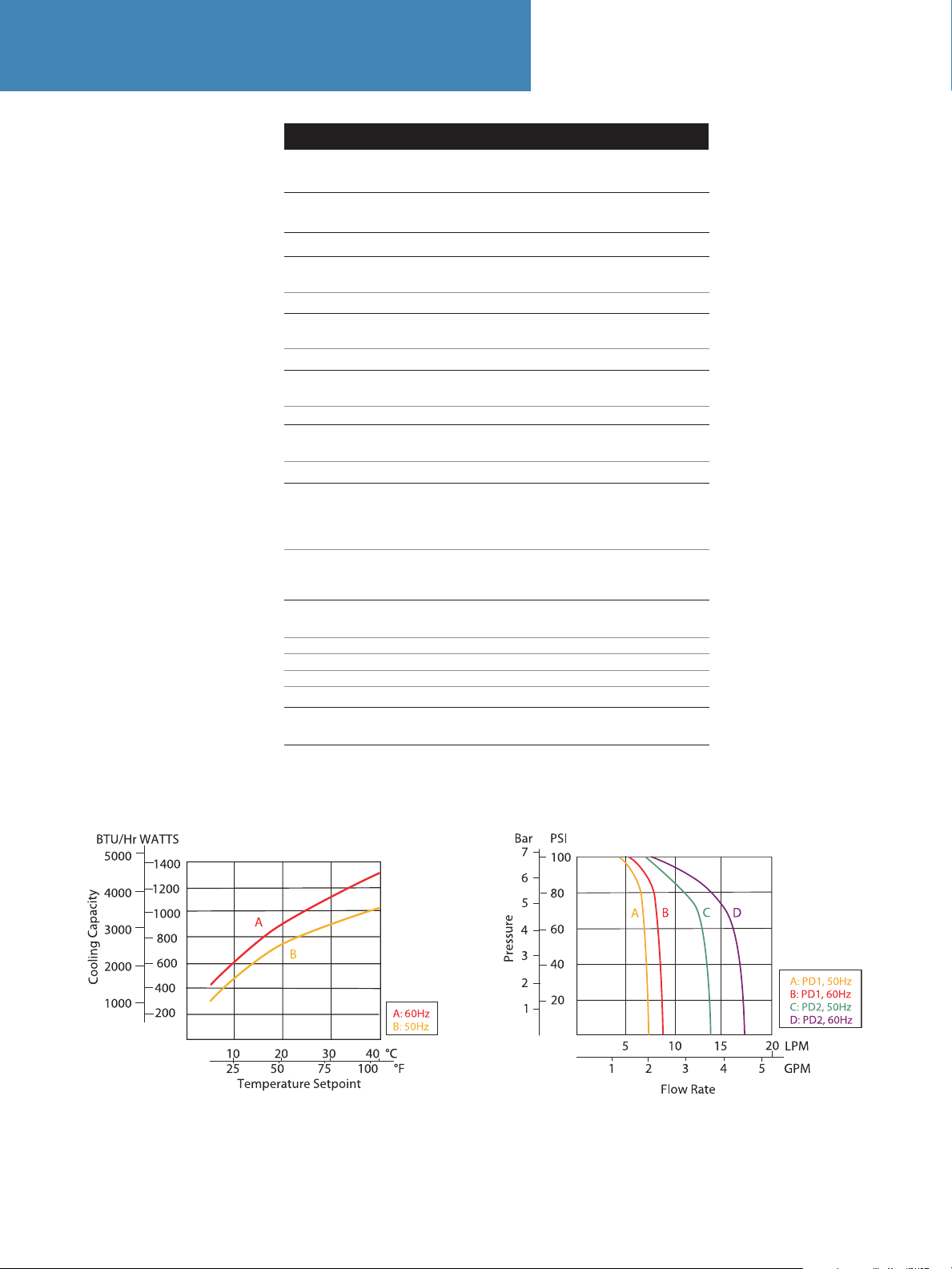

Setpoint Cooling Capacity at 20°C (see graph below for cooling curves)

60 Hz 900W (3072 BTU)

50 Hz 750W (2560 BTU)

Reservoir Volume

Gallons 1.9

Liters 7.6

Footprint or dimensions (HxWxD)

Inches 27.4 x 14.2 x 24.7

cm 69.6 x 36.1 x 62.7

Unit Weight

lb 126

kg 57.2

Pumps (see graph below for performance curves)

PD 1 - Positive Displacement

60 Hz 2.1 gpm @ 60 psi

50 Hz 1.7 gpm @ 60 psi

PD 2 - Positive Displacement

60 Hz 4.1 gpm @ 60 psi

50 Hz 3.3 gpm @ 60 psi

Power options

Option 1 100V/50Hz/1 Phase 15A Circuit

Option 2 100V/60Hz/1 Phase 15A Circuit

Option 3 115V/60Hz/1 Phase 15A Circuit

Option 4 208-230V/60Hz/1 Phase 15A Circuit

Option 5 230V/50Hz/1 Phase Amp 16A Circuit

Compliance NRTL Certified to CSA and

41°F - 104°F

50°F - 104°F

UL Standards; CE-Marked

Cooling Capacity Pumping Capacity

Specifications obtained at sea level using water as the recirculating fluid, at a 20°C process setpoint, 25°C ambient condition, at nominal

operating voltage. Other fluids, fluid temperatures, ambient temperatures, altitude or operating voltages will affect performance. Thermo Electron

reserves the right to change specifications without notice. Pump performance results obtained with no restrictions on return to the system.

Page 3

Power Button

Controller Display

Circuit Breaker

Integrated Funnel

Level Indicator

Removable Grill

Integrated

Air Filter

Locking Casters

Options

Feature Benefit

Auxiliary Port

Process Fluid

Outlet

Process Fluid

Inlet

Unit Drain

Power

Receptacle

Auto refill Allows for self-filling of the chiller to ensure that the proper level in reservoir is maintained,

saving valuable time.

Anti-drainback Ensures reservoir does not overflow when chiller is shut down. This allows the chiller to be

installed more than 24 ft. below the application.

DI resistivity internal DI filtration internal to the chiller is used to maintain the resistivity level below 3 Mohm, with

an alarm at 1 Mohm. This minimizes footprint and eliminates downtime needed to change

the filter, while ensuring constant quality of DI water to your application.

Pressure relief Easily adjustable pressure relief valve allows for control of the outlet pressure from the

chiller to be regulated, ensuring your process performance requirements are met.

Flow Control Utilizes a 3-way valve that allows you to control the amount of flow to the application. The

process flow is measured on the return to the unit, ensuring the appropriate amount of flow

is provided to the application.

Pressure/Flow Control Allows you to control the pressure as well as the flow in your application. Utilizes a pressure

relief valve and monitors the flow through the process return and displays the reading on the

controller.

Accessories

Feature Details

Installation Kit Supply and return plumbing available in 25 and 50 ft lengths, suitable for temperatures up to

+80°C.

Fluid Quality Kit Complete fluid quality system includes algaecide and corrosion inhibitor to ensure your process

has optimal fluid quality.

Ethylene Glycol Laboratory-grade ethylene glycol allows circulation to temperatures down to -20°C in a 50/50

mixture with water. Available in a 5 gallon container.

Propylene Glycol Laboratory-grade propylene glycol allows circulation to temperatures down to -20°C in a 50/50

mixture with water. Available in a 5 gallon container.

Maintenance Kit Includes condenser air filters and in-line fluid filters for ease of maintenance.

Page 4

About Thermo

Thermo Electron Corporation has a well-established reputation in temperature control through its NESLAB and HAAKE product

lines. Formerly independent companies, NESLAB and HAAKE have joined forces within Thermo to provide proven temperature

control technology along with global service and support. With over 75 years of extensive industry experience, we have the

technical expertise and resources to support your specific application.

USA HEADQUARTERS

25 Nimble Hill Rd.

Newington, NH 03801

Tel. 800 258 0830

info.tc.us@thermo.com

Benelux

Takkebijsters 1

NL-4817 Breda

Tel. +31 (0) 76 5 87 98 88

info.tc.nl@thermo.com

China

Bldg 6, No. 27, Xin Jinqiao Rd

Jinqiao Export Zone, Pudong

Shanghai 201206

Tel. +86 (21) 68 65 45 88

info.china@thermo.com

France

16 Avenue du Québec - Silic 765

91963 Courtaboeuf Cedex

Tel. +33 (0) 1 60 92 48 00

info.tc.fr@thermo.com

www.thermo.com/thermoflex

Germany

Dieselstr. 4

76227 Karlsruhe

Tel. +49 (0) 721 4 09 44 44

info.tc.de@thermo.com

India

415 City Point

193 Dhole, Patil Road

Pune 411001

Tel +91 20 56 01 12 45

info.pid.in@thermo.com

United Kingdom

Unit 5, The Ringway Centre

Basingstoke, Hampshire

Rg21 6YH

Tel. +44 (0) 870 609 9254

info.tc.uk@thermo.com

© 2006 Thermo Electron Corporation. All rights reserved. Results may vary under different operating conditions. Specifications, terms and pricing

are subject to change. Not all products are available in all countries. Please consult your local sales representative for details. Thermo Electron

Corporation, Question everything, ThermoFlex, and Analyze. Detect. Measure. Control are trademarks of Thermo Electron Corporation.

PSTHERMOFLEX900V1.0E04/06TC

Loading...

Loading...