Page 1

Elgar TerraSAS

1kW-1MW

Programmable Solar Array Simulator

• Simulate dynamic irradiance and temperature

ranging from a clear day to cloud cover conditions

• Ramp the voltage, temperature or irradiance level

over a programmed time interval

• Readback of voltage, current, irradiance level and

temperature setting

• Tests for inverter Maximum Power Point Tracking

(MPPT)

• Provides programmable I-V curves for PV Inverter

testing

• Simulates different types of solar cell material

• Multi-Channel, Up to 1MW

Why power supply is critical for PV simulations

Many solar inverters generate AC ripple on their

DC input, which is connected to the photovoltaic

array. For single phase inverters, the frequency

of this ripple is twice the line frequency (120 Hz

for US models). The simulator’s power supplies

must not supress this ripple as a function of

their regulation loop. An increasing number

of inverters (and virtually all micro-inverters)

accurately measure amplitude and phase of the

ripple voltage and current to quickly track the

MPP of the array. This approach allows tracking

the MPP at a much higher speed when compared

to conventional dithering techniques (also called

perturbate-and-observe). Faster tracking of the

MPP results in a much higher overall efciency

in cloudy conditions, where the irradiance is

constantly changing. It is likely that all solar

inverters will use this approach in the near future,

since end users are very sensitive to the overall

efciency of their solar energy installations.

To satisfy this requirement, the PV simulator must

be capable of reproducing the voltage / current

behavior of a solar array at the ripple frequency.

Most standard switching power supplies employ

very large output capacitors and inductors in

their output circuits and are unable to deliver the

required performance - regardless of the response

speed of the I/V curve controller.

Elgar’s line of PV simulators are based on high

speed versions of our standard products, where

output capacitors and other speed-limiting

components have been adjusted. This results

in a speed improvement of 10 times or better.

Proprietary features built into the PV controller

hardware and rmware, combined with our

high speed power supplies, deliver the required

performance. This technology was extensively

tested on micro-inverters and is ready to test the

next generation of inverters.

Strengths of using DSP signal processing

Our technology avoids using linear ampliers,

which are fast but bulky and inefcient. The

required performance is delivered by high speed

switching power supplies and advanced DSP

signal processing techniques. Competitors data

sheets mentions that speed requirements may

not be met in some conditions, “...depending

also on the type of MPP tracking principles”. An

additional linear module is required to satisfy

the new requirements. Some competitor’s

power supplies specications say that it uses “...

innovative IGBT and transformer technology”.

Our power supplies use Power MOSFETs, which

typically switch ten times as fast as the most

recent IGBTs. Higher switching frequency

translates to smaller output capacitors and

inductors - which is the key to a successful high

speed power supply design.

Product Overview

The Elgar TerraSAS System, (TSAS) provides

an easily programmable means of simulating

the characteristic behavior of a PV array. The

system provides a turn-key approach to testing

the maximum peak power tracking (MPPT)

characteristics for grid-tied inverters and DC

charge controllers. The ability to simulate virtually

any ll factor or solar cell material allows the

customer to validate the MPPT algorithm with a

power source. Hardware control is accomplished

by an application running on the local controller

that communicates directly to the PV simulator

using RS422, which operate as a dedicated IV

curve generation processor. The local Graphical

User Interface (GUI) is accomplished via another

application that provides all of the user controls

to the TerraSAS system. Imbedded in the

application is the Ethernet (LAN) parser for

remote communication and control. All of the

80-1000 V

115 208 400

480

AMETEK

Programmable Power

9250 Brown Deer Road

San Diego, CA 92121-2267

USA

858.458.0223

sales@ProgrammablePower.com

1

Page 2

Elgar TerraSAS

functions available locally through the controller

are also available remotely.

Description

As shown in the rack drawing, the TerraSAS

consists of programmable DC power supplies,

a rack mounted controller, keyboard and LCD

display with control software and GUI interface,

output isolation and polarity reversing relays and

a unique PV simulation engine that controls the

power supply. This combination of hardware

allows the TerraSAS to simulate most test

protocols or combination of events that a solar

installation will be subjected to. Power supplies

are available in 1-15KW increments to simulate

arrays up to 1MW.

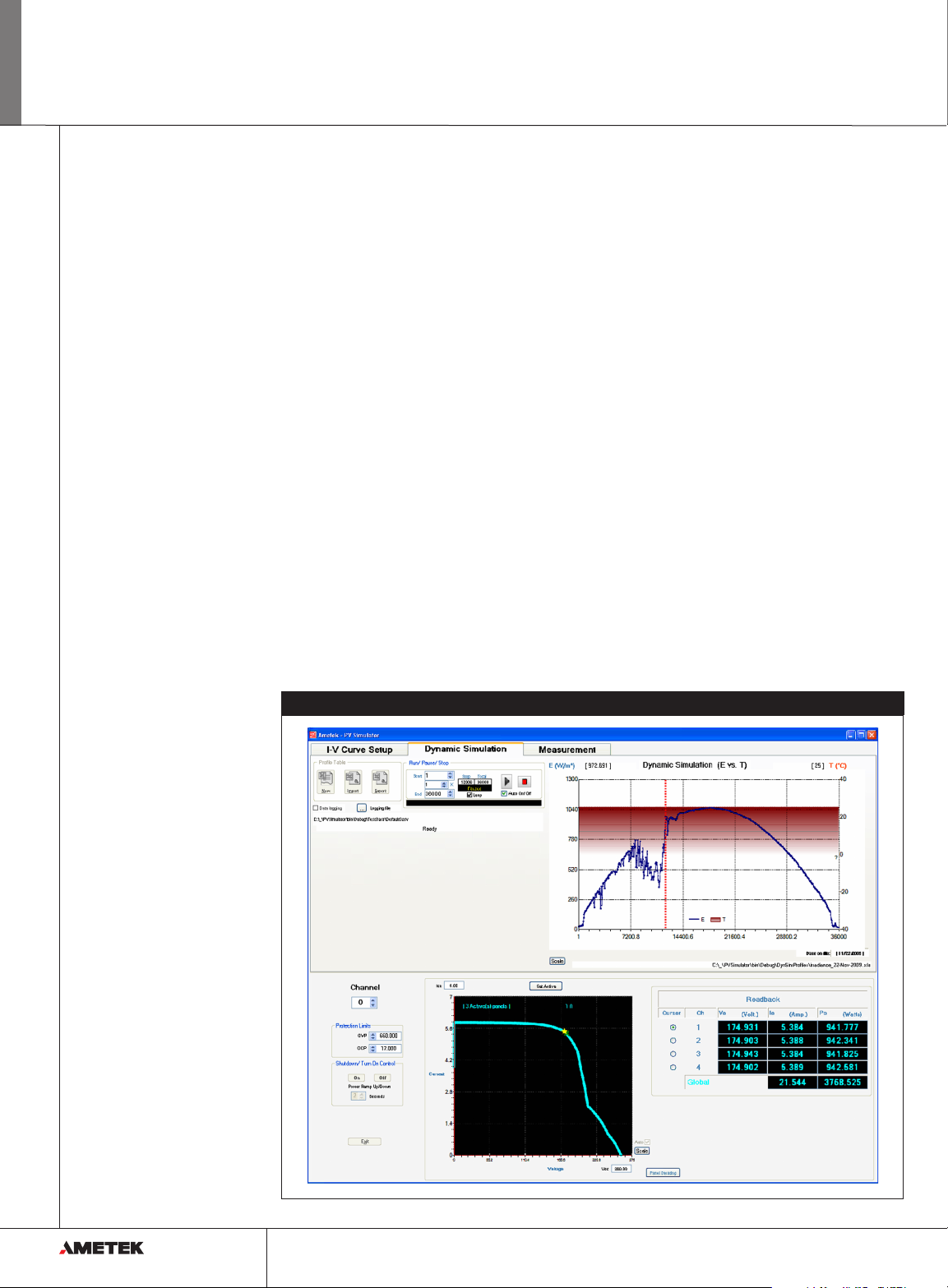

The included software, as displayed below, allows

modeling of a PV panel without an extensive

knowledge of solar array parameters. The only

parameters required for a simulation are the open

circuit voltage and short circuit current. The slope

of the VI curve can then be modied by the peak

power parameters, Vmpp and Impp. Changes to

these parameters will allow the shape of the VI

curve to be adapted to any ll factor between

0.5 and 1. Once an IV curve has been generated,

changes to the irradiation level or temperature

can be changed on the y so that the behavior

of a grid tied inverter can be tested under realistic

conditions for cloud shadowing and panel

temperature rise. Long term weather simulations

can be run to determine the amount of energy

delivered in a given situation. Inverters can be

optimized for real MPP search modes, because

shadowing and temperature changes can be

simulated realistically.

The PV simulation software allows denition of

key parameters like Voc, Isc, Vmpp and Isc at 25

°C and 1000W/m2, so that the resulting VI curve

is calculated according to a standard solar cell

model.

The PV simulator has the ability to simulate

ideal IV curves as well as irregular characteristics

for peak power tracking that result when solar

panels with different output characteristics are

paralleled as shown on the following two graphs

below. With the simulator programmed for

different values of irradiance or temperature,

the characteristic “multiple hump” IV curve will

result. By programming the changes in irradiance

and temperature in a table, dynamic simulation

of compressed time proles of a 24 hour day can

be run in a loop to simulate the day and night

periods for extended periods of time.

Dynamic simulation showing changes in Irradiance and Temperature over time

2

www.ProgrammablePower.com

Page 3

TerraSAS

IV Curve Control Interface : Parameters are programmable through sliding scale or direct input of value

Control Displays

The graphic above shows the GUI interface

displays. The entered set of IV curves is displayed

as soon as the parameters are entered. The actual

measured data is then overlaid on the screen so

that the operating point can be viewed in real

time. The display times can be set from minutes

to days to allow for long term testing.

Programmable Parameters

Set a specied irradiance level

Set a specied temperature value

Set a specied voltage level

Set a specied current level

Set a specied temperature coefcient

Ramp of voltage, temperature or irradiance level

over a programmed time interval Readback of

voltage, current, irradiance level, and temperature

setting Programmable calibration of system

Curve Formula

The PV curves for the simulator are derived from

the formula shown below.

Io as a function of Vo:

Io=Isc (1-C1 (exp (V/(C2 x Voc))-1))

C1=(1-(Imp/Isc)) (exp(-Vmp/(C2 x Voc)))

C2=((Vmp/Voc)-1)/(ln(1-Imp/Isc))

Where the Reference Irradiance conditions for the

simulated arrays is 1000W/m2 and the Reference

Array Temperature is 25°C

The simulated PV arrays are provided in terms of

array ll factor, Maximum Power Point Voltage

and Maximum Power Point Power. The curves

generated are based on the Sandia Labs simplied

PV Array model dening the relationship between

these values and other parameters as provided

below:

Where:

858.458.0223

sales@ProgrammablePower.com

3

Page 4

TerraSAS - Specications

1kW-1MW

Where:

β Array temperature Coefcient, %/°C

T= Cell temperature, °C

V= Voltage, V

I= Current, A

FF= Fill Factor

Subscripts:

Ref= Reference (i.e., at reference or rated

conditions)

MP= Maximum Power

OC= Open Circuit

SC= Short Circuit

DC Output Connections

The output connections will use nger safe,

pressure type connectors or terminal blocks of

suitable ampacity on the rear I/O panel depending

on output current requirements.

Characteristic “multiple hump” IV curve results when three PV proles are added

“Multiple Hump” IV Curve

Utilizing data gathered from the Solar Advisor

Model (SAM) data base, the TerraSAS allows

the user to model systems made up of two or

more subsystems. For example, a PV system that

consists of three arrays with different orientations,

thus creating a “Multiple Hump” as shown below.

Safety

The system includes a shutdown function that

will disable the output with an open interlock

contact. In the event of an open interlock, the

PV simulator chassis will program down the DC

output and open the output relays, and provides

complete qalvamic isolation

The benet of simulators is simply that they offer

the ability to test and invert without reliance on

a real array and can simulate PV behaviors that a

real array cannot be easily manipulated to do.

This assumes that the PV simulator can behave

like a real panel of course.

4

www.ProgrammablePower.com

Page 5

TerraSAS - Specications

Specications

AC Power AC Input Voltage: 115V (for DCS) 208VAC three phase Std, 400VAC and 480VAC three phase are optional

DC Output Open circuit voltage, Voc: 0 - 1000VDC

Programmable Parameters Irradiance level: 0 to 2000 W/m²

Accuracy Voltage Readback: 0.2% of rated max voltage

Programming Interface Ethernet with RJ-45 connector / LAN

AC Input Connections Finger safe, pressure type connectors three phase AC four wire plus safety ground stud AC input circuit breaker

DC Output Connections Finger safe, pressure type connectors positive and negative

Safety The output isolation relay operates as a disconnect relay in the event of a malfunction or an open interlock contact

Output Voltage and Current Ranges

Power (MPP) 1 kW 5 kW 10 kW 15 kW RMS P-P DC Leakage Current

Voc

80V Isc=12.5 Isc=83A Isc=167A Isc=250A 20 mV 100 mV

600Voc Isc=1.6A Isc=8A Isc=16A Isc=25A 60 mV 350 mV 335mA

1000Voc N/A Isc=5A Isc=10A N/A <1mA

MMPT

Scalable (MPPT) 1000W to 1.0MW

Response to MPPT Up to 120Hz

Current Slew Rate 3msec/A

Control Loop Sampling Rate 1usec / 10kHz

Static and Dynamic Programmable PV Array Parameters

Irradiance Level 0-2,000W/m2

Temperature -100 to +100*C

Voltage Level 0-600/1,000V 80V - Consult factory for other voltages

Current level to rated output current 0-Rated Output (see MPP Chart)

Voltage Temperature Coefcient 0 to -2% / *C

Arbitrary VI Curve Up to 4096 data points

Programmable Setpoints

Voc 0-Rated output voltage

Fill Factor 0.5 to 0.95

Vmp 0-Voc

Imp 0-Isc

ISC 0-Rated output current

Over Voltage Protection (OVP) 0.1% to 110% of Voc Max

VI Curve Set Point Accuracy

Voltage <0.1%, FS

Current <0.5%, FS

Programming Resolution

Programming Resolution <0.002% of FS

Voltage / Current <0.002% of FS

(Input current depends on power rating)

Short circuit current, Isc: 0 – 1000A

Maximum output power at MPP: 1MW

(Lower voltage ranges will provide proportionately higher currents) 1-6 channel output, consult factory for additional channels.

Temperature: -40 to 90°C

Temperature Coefcient: 0 to -65,000 mV/°C

Simulation Times: 0 to 65,000 seconds

Isolation relay and polarity relay closure

Current Readback: 0.5% of max current

858.458.0223

sales@ProgrammablePower.com

5

Page 6

TerraSAS

VI Curve Readback Accuracy

Voltage <0.1%, FS

Current <0.5%, FS

Output Sampling Rate 100usec

IV Curve Update Rate 1sec

IV Curve Interpolation rate 7.8msec

Stability

CC 0.05

Temperature Coefcient

CC 0.03

Misc

Simulation PV Array Channels 1-250

Preloaded Formula LUFT

SAM Database Over 100 pre-loaded PV Panels, Series & Parallel capability

Over 100 pre-loaded PV Panels, Series & Parallel capability

1kW-1MW

6

www.ProgrammablePower.com

Loading...

Loading...