Page 1

THERMONICS

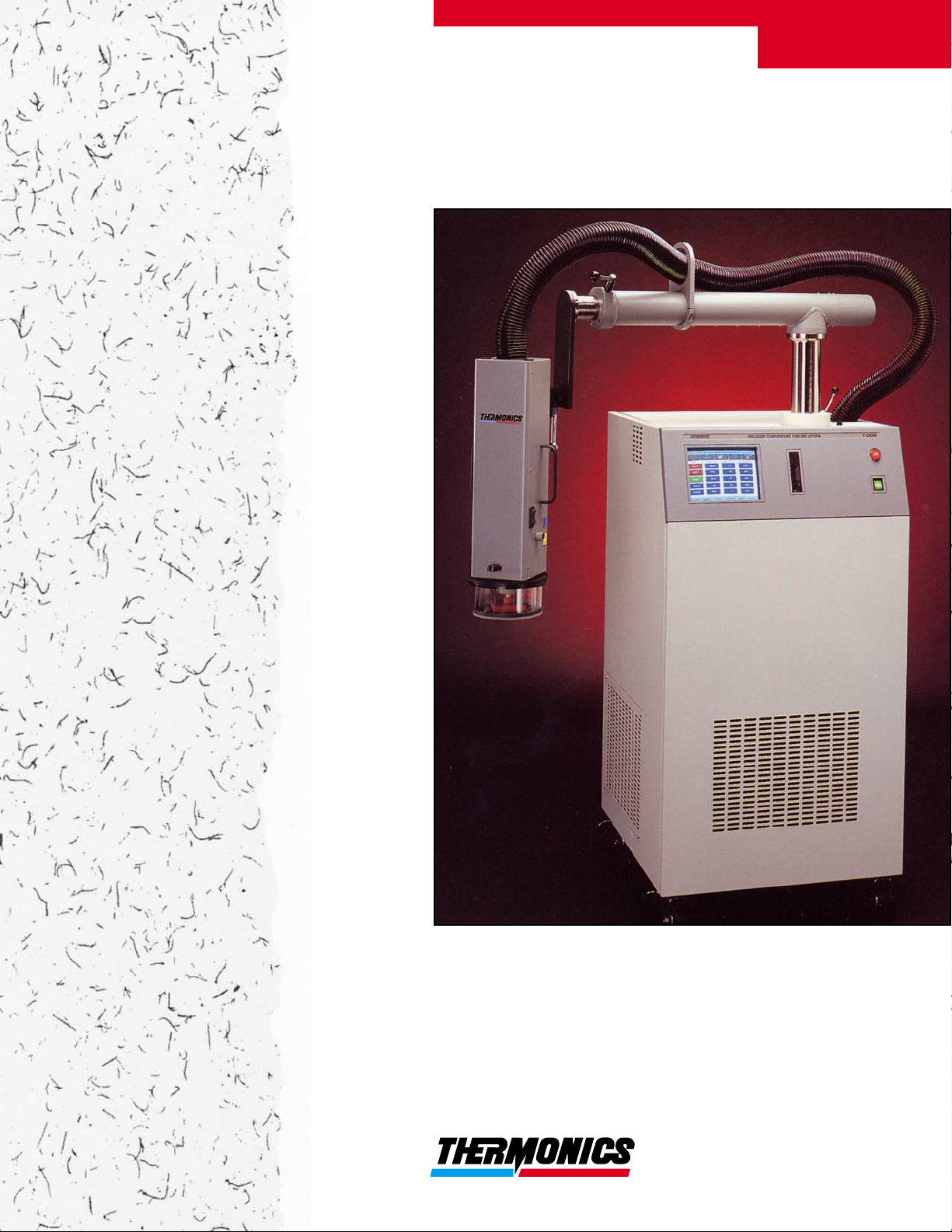

T-2500SE

PRECISION

TEMPERATURE

FORCING

SYSTEM

A Test Enterprises Company

Page 2

FAST

Aleader in temperature testing technology, Thermonics, sets a higher standard for performance and

ACCURATE

RELIABLE

TEMPERATURE

TESTING

value with the T-2500SE precision temperature forcing system. Designed with speed, accuracy and reliability as

essential design criteria, the T-2500SE provides the most advanced temperature testing capability available.

The system transitions air temperature between +125C and -55C in as little as 4 seconds and has a wide

temperature range of -90C to +225C; encompassing the requirements of both production and engineering

environments. Field-proven, single-stage mechanical refrigeration eliminates the need for liquid nitrogen or any

other consumable refrigerants.

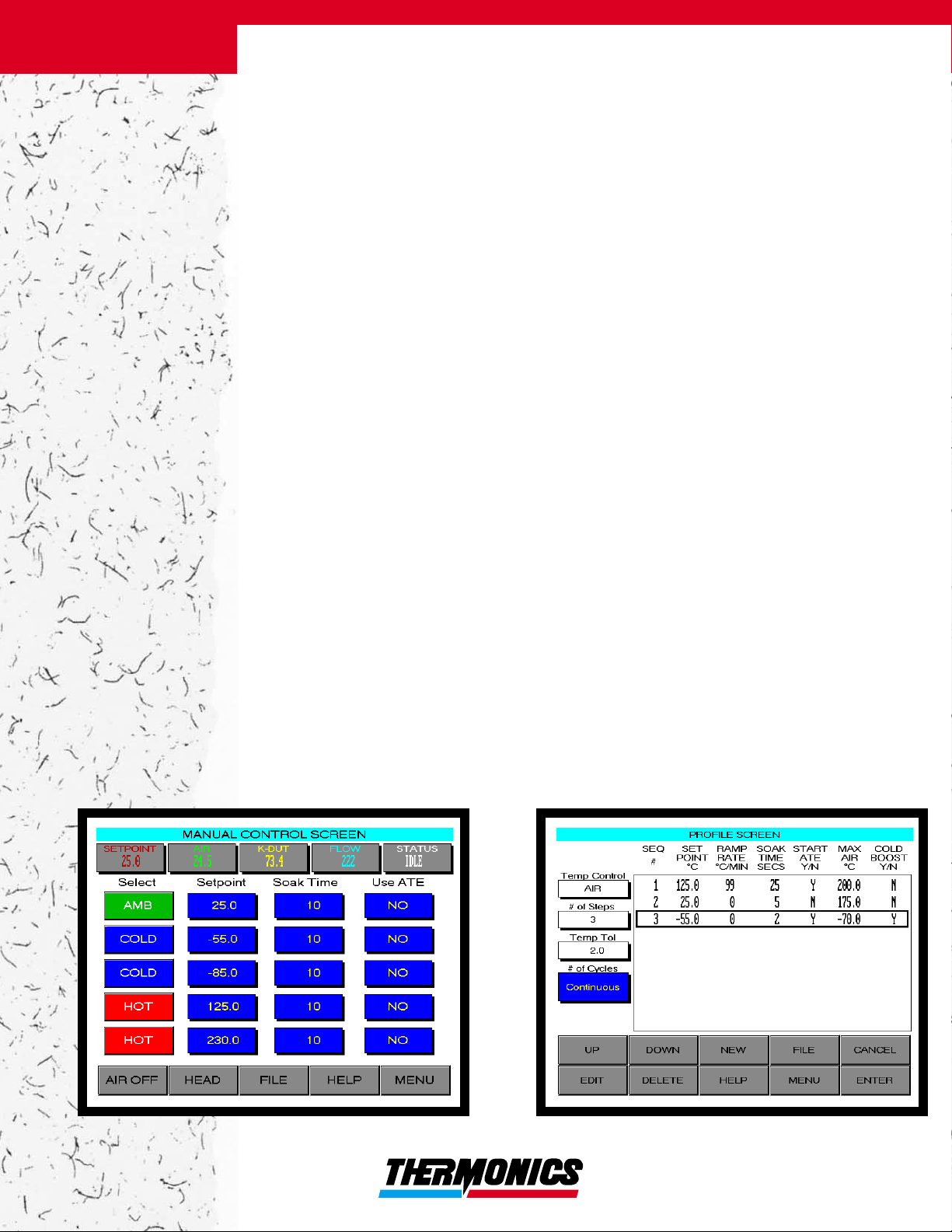

Intelligent Touch-Screen Interface

An intelligently designed, multi-color touchscreen makes the system easy to set up and

operate. The temperature setpoint, air temperature, DUT (device under test) temperature, airflow rate, and current system status

display continuously facilitating instant statusing. A variety of menus enable the operator to change parameters by touching the

desired selections. In addition, a password

protection feature makes it possible for the

test engineer to determine operator accessibility to key software segments.

Sophisticated Temperature Cycling

Complex temperature profiles are easily set up

on the touch screen. Temperature profiles can

be saved and recalled for use or exported to

3.5" diskette. Data entered can be as simple as

two temperatures and soak times, or as complex as a 99-step cycle - each with a unique

temperature, soak time, or ramp rate. The

T-2500SE may be used for temperature cycling

per MIL STD-883C for thermal stressing of

semiconductor devices.

Manual Control Screen

A Test Enterprises Company

Profile Setup Screen

Page 3

T-2500SE on

Autotester

Load Board

Precise Temperature Control

A patented, proprietary temperature control algorithm provides the most accelerated and precise temperature control of any available temperature forcing system. Physical integration to the DUT is accomplished with the interface kit which includes thermal

caps and a shroud assembly. Coupled with the system’s high airflow - and cold boost feature, test temperatures are achieved efficiently and economically; making the T-2500SE the optimal system for testing semiconductor packages, hybrids, modules, MCMs,

PCBs, and small subassemblies. Examples of typical semiconductor packages that the system can accommodate include PLCC,

DIP, LCC, PGA, SOP, QFP, and others. Custom thermal fixtures are available to provide a controlled temperature environment for

testing larger modules.

Full ATE Compatibility

Remote operation of the system is accomplished with RS-232C and IEEE-488.2 interfaces. A library of remote communication

commands enable easy configuration, monitoring, and actuation of critical setup and operating parameters; such as temperature set points

and soak times; from any remote computer or

terminal. A standard ATE interface providing

start test, end of test, and class signals is provided to assure full ATE compatibility which

includes the ability to communicate with all

main ATE and Rack and Stack test systems.

Easy PM and Calibration

Thermonics’ Precision Temperature Forcing Systems

are field proven for durability, performance and reliability. The system can be relied upon for use in

around-the-clock production environments.

Maximum up time is achieved with a modular design

that promotes quick and easy implementation of preventive maintenance activities. Calibration of the system is facilitated by a series of software screens that

guide you through the procedure in a systematic

manner. In addition, diagnostics screens that report

system malfunctions in an easy to understand format

assist with servicing of the system.

A Test Enterprises Company

Page 4

A Test Enterprises Company

Optional Systems

T-2500E provides a lower cost solution with an

economical, easily-adjusted arm. The system

has a temperature range of -80C to +225C, and

air temperature transitions between +125C and

-55C in 10 seconds. Vertical motion of the arm

is motorized and horizontal motion is manual.

T-2500BE replaces the arm with a basic output hose. This system is ideal for use in applications that incorporate the use of custom test

fixtures.

Models T-2500IX and T-2500IX/M, which can

achieve cold temperatures of -100C and -130C,

respectively, are ideal for test applications that

require extremely low temperatures.

The T-2500IX/M uses uses liquid nitrogen to

facilitate cooling and is an optimal solution for

large power dissipating devices in the 50 to

100W range.

Efficient Air Dryer

To ensure the use of clean, dry air a built-in air

dryer removes water vapor and particles from

the compressed air source. This heatless air

dryer lowers the dew point of the source air to

approximately -80C.

World-Wide Service and Support

Service is available around the world. Whether

you’re the U.S.A., Asia, or Europe, your system

can be serviced quickly and efficiently by a

qualified technician. Telephone support is

always available from the factory.

CE Certification

For use in Europe, CE certification is provided.

Conductive Thermal Caps

High Productivity

The wide temperature range of -90C to +225C,

in conjunction with the rapid transition rate,

can quickly and accurately bring devices to test

temperature.

Optional LN

injection can further increase

2

productivity when testing large devices at

extreme low temperatures.

DUT Sensor

The case temperature of the DUT can be determined with the use of the DUT sensor (K-type

or T-type). This feature makes it possible to control the temperature of the DUT to within

±

1C

of the desired temperature setpoint. In addition,

an advanced temperature control algorithm

assures the DUT is stabilized at temperature

quickly.

Thorough Documentation

Comprehensive, easy to read Users and

Maintenance Manuals are provided with the

T-2500SE. These manuals provide information

on operation of the system, routine preventive

maintenance, and service.

Further Information

For additional information on this new product,

call a Thermonics Sales Representative today!

(408) 542-5900

Page 5

Fully-Motorized Arm

ESD Protection

Grounding of all surfaces and air pathways prevents the development

of electro-static discharge (ESD) which can damage sensitive semiconductor components.

Integrated Thermal Test Head and

Motorized Arm

Provides a strong support for adapting the

thermal test head to the DUT. The positive

action, quick adjust arm has several degrees of

freedom that enable it to be positioned in a

wide range of horizontal and vertical positions.

The combination of electro-mechanical and

pneumatic action of this assembly ensures precise, stable and repeatable placement of the

thermal fixture over the DUT. Heated purge air

is provided to keep the test interface free of

frost or moisture when operating at cold temperatures. Ambient purge air prevents overheating of test electronics when testing at hot temperatures.

Optional Air Ionizer

ESD protection can be further enhanced by inclusion of the optional

air ionizer. The ionizer provides an ion balance that prevents a charge

from developing in the air stream and removes charges from non-conductive surfaces. Conductive silicon rubber thermal caps and insulation sheets are also available.

On-Screen Graphics

Numerical representations of the DUT, air and

set-point temperatures continuously display. A

screen that presents the data in graphical form

similar to a chart recorder is provided at the

touch of a key. Logged data can be stored and

recalled.

Numeric Keypad

Scrolling Graph Screen

Page 6

T-2500SE SPECIFICATIONS

The model T-2500SE PTFS is designed to comply with the following

specifications. The system has been factory tested to verify conformance.*

FEATURES

Fast temperature response time

·

Temperature range of -90C to +225C

·

Environmentally safe

·

Fully grounded

·

Small footprint

·

Fast DUT temperature stabilization time

·

Color LCD display with touch-screen, operator interface

·

Flexible ATE communications

·

Sophisticated system self diagnostics

·

±

±

1C accuracy with 0.1C readout

·

Motorized support arm

·

High air flow rate

·

Frost free operation

·

Graphical display of temperature response

·

GENERAL DESCRIPTION

Method of Cooling: Forced air with single-stage mechanical

refrigeration and multi-stage self-cooling heat exchanger. Non-CFC

based refrigerants are used - environmentally safe.

Method of Heating: Forced air with in-line air heaters.

Operator Interface: Color LCD display, menu-driven touch-screen

with software menu selections. Software contains system self

diagnostics. Uses graphical software to select system menus such as

operating mode, and to set system parameters such as temperature

setpoint or flow rate.

Data Communications: Interfaces to ATE systems. Contains IEEE-

488.2, RS-232C, Standard Tester Interface, and Printer ports. Software

communication parameters are configurable to accommodate varying

systems.

TEMPERATURE PERFORMANCE

Range Accuracy Stability Displayed Transition

(°C) (°C) (°C) Resolution Time

T-2500E -80–225±1.0

T-2500SE -90–225±1.0

T-2500BE -80–225±1.0

T-2500IX -100–225±1.0

T-2500IX/M -130–225±1.0

Maximum cold specifications are for room ambient temperature of 77°F (25°C), or lower, using 60Hz

power. Cold temperature specifications are degraded 5° C for 50Hz operation.

between +125°C and -55°C; air temperature measured at air output nozzle. Measured in temperature

cycle mode after system stabilization with a 10-second soak time, or less, at each temperature.

±

0.3 0.1 10

±

0.3 0.1 4

±

0.3 0.1 120

±

0.3 0.1 4

±

0.3 0.1 10

(°C) (sec)

††

††

Transition time is

ENVIRONMENTAL REQUIREMENTS

Ambient Temperature Range: 15°C to 28°C

Relative Humidity: 20 - 65%

POWER REQUIREMENTS

Volts Hertz Phases Amps

208–230 50/60 1

ø

20

AIR INPUT REQUIREMENTS

Pressure: 80-110 PSIG (5.7 - 7.8 Kg/Cm2)

Flow Rate: 18 SCFM (8.6 liters/sec)

Dew Point: Less than 10C at 80 PSIG (5.7 Kg/Cm2)

Quality: Clean air; free of oil, moisture and particles

AIR FLOW

200 to 900 SCFH (1.6 to 7.6 liters/sec.). Flow is under software

control.

PHYSICAL CHARACTERISTICS

Height Width Depth Weight

(in/cm) (in/cm) (in/cm) (lbs/kgm)

55/139 25/63 28/71 350/160

SYSTEM FEATURES

Temperature sensor: Device Under Test (DUT), K-type and T-Type

thermocouples. Also, K-type thermocouple for air temperature.

Controller: An 80X86, MS-DOS based microcomputer.

Fail safes: Snap-disc thermostats, air flow sensors and

thermocouples. Over-temperature limit of 245C.

1288 Reamwood Ave.

Sunnyvale, California 94089-2233

Phone: (408) 542-5900

Fax: (408) 542-5910

E-Mail: info@thermonics.com

URL: http://www.thermonics.com

*Specifications subject to change without notice.

' 4/2005 Thermonics Inc.

Printed in U.S.A.

A Test Enterpises Company

Min Max

(in/cm) (in/cm)

X 27/69 44/112

R 34/86 48/122

Loading...

Loading...