Page 1

8G.51.10.00/10.05

INSTALLATION MANUAL

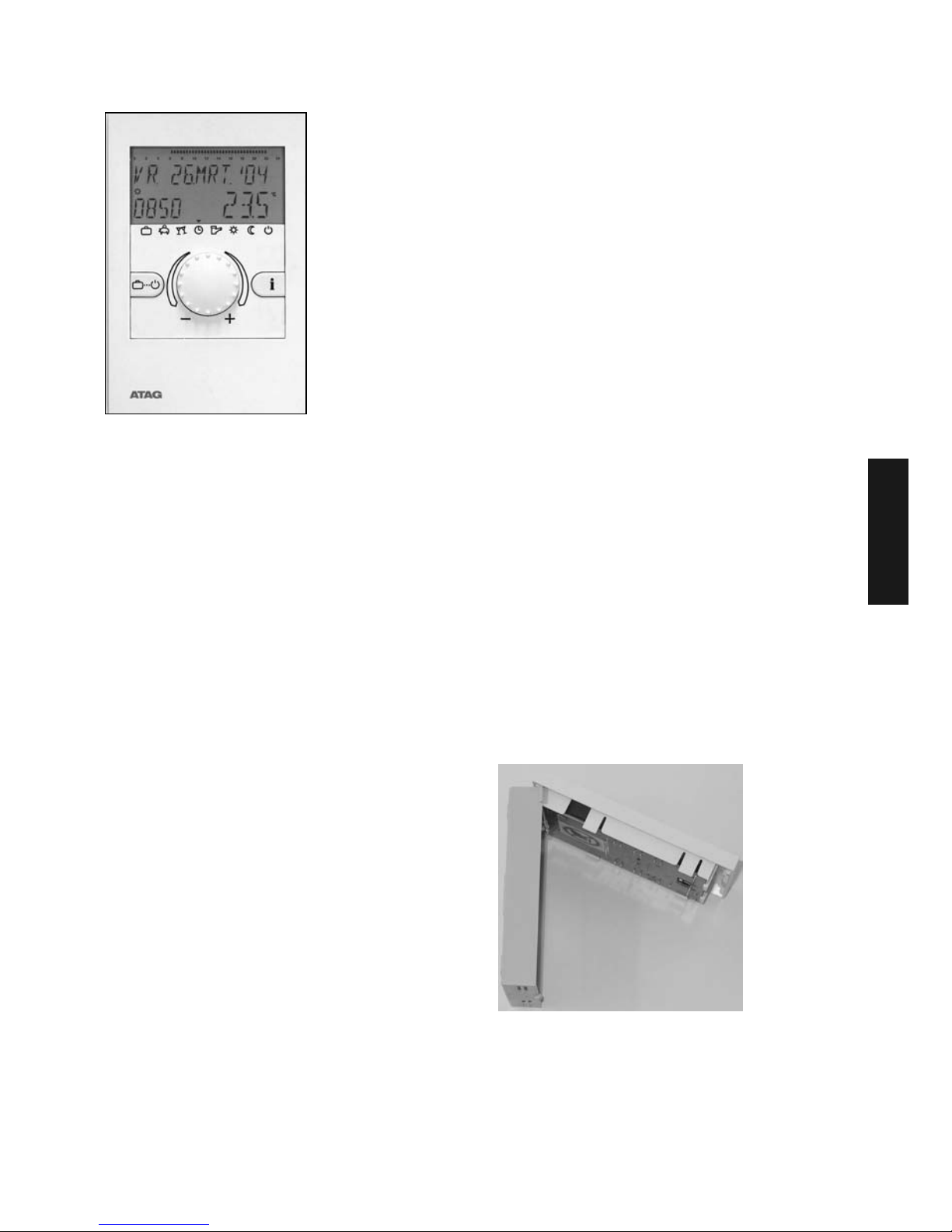

MadQ/2

MadQ/2 Controller

Page 2

GB English

Page 3

GB-3

Contents

General safety instructions..............................................................................GB-4

Safety measures for EMC - compliant installation.........................................GB-4

Installation of the control unit.........................................................................GB-6

Mounting instructions .................................................................................... GB-6

Electrical installation...................................................................................... GB-6

Electrical connection ..................................................................................... GB-7

Installation set MadQ .................................................................................... GB-8

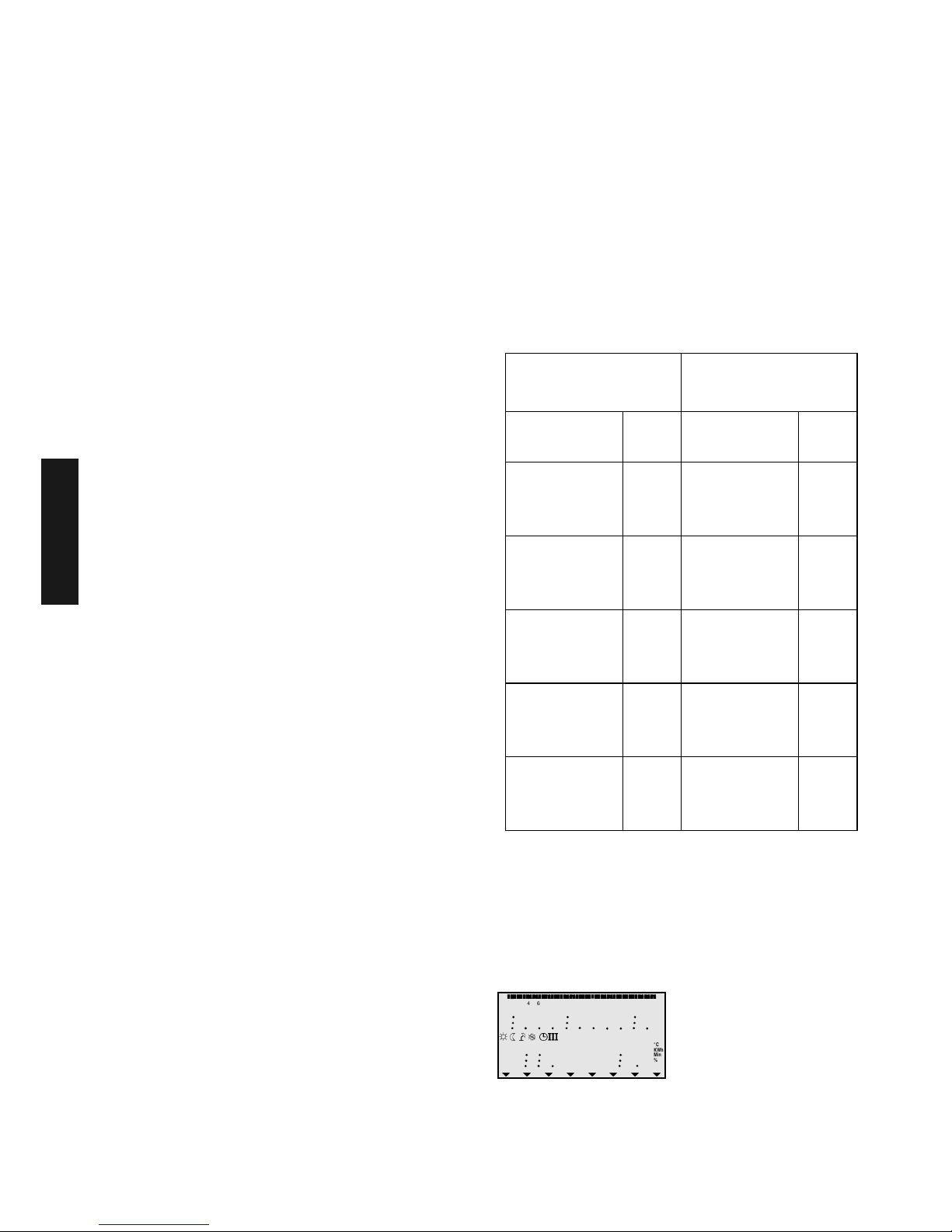

Wall-mounting case .......................................................................................GB-9

Assembly and electric installation .................................................................. GB-9

Electrical connections ................................................................................. GB-10

Thermostats (for remote- control) .............................................................. GB-11

Mounting Location....................................................................................... GB-11

Mounting instructions .................................................................................. GB-11

Electrical connection ................................................................................... GB-12

Electrical connection at control unit ............................................................ GB-12

Data bus allocation...................................................................................... GB-12

Accessories ..................................................................................................GB-14

Outdoor sensor ........................................................................................... GB-14

Tank sensor ................................................................................................ GB-15

Flow sensor................................................................................................. GB-15

Resistance values of sensors depending on temperature.......................... GB-16

Commissioning the control unit .................................................................GB-17

Code input................................................................................................... GB-17

Automatic setting function..........................................................................GB-18

Alarm messages...........................................................................................GB-19

Plant information ..........................................................................................GB-20

Parameter synoptic ......................................................................................GB-23

Overview of installer parameters and adjustment options.......................... GB-25

Appendix ................................................................................................................ I

GB

Page 4

GB-4

General safety instructions

All electrical connections and safety

measures have to be carried out by a

specialist in due consideration of valid

standards and VDE-guidelines as well as

the local regulations.

The electrical connection must be a

permanent connection in accordance with

VDE 0100).

The electrical connection must be in

compliance with the specifications of the

ATAG boiler.

Important!

Deenergize the boiler or wall-mounting

case before opening.

Unprofessional plugging attempts under

voltage may damage the control or

cause dangerous electrical shocks.

Safety measures for EMC compliant

installation

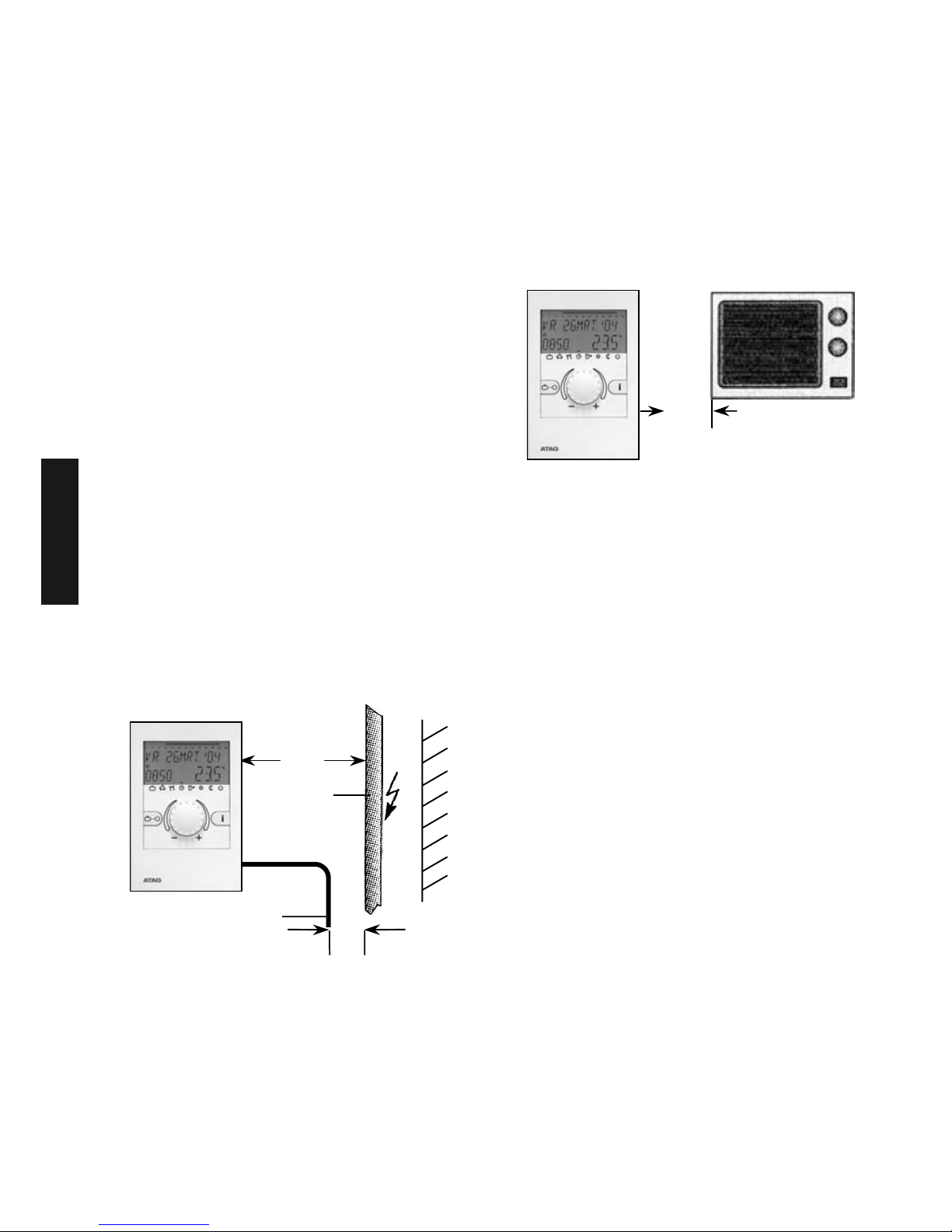

1. Cables with mains voltage must be

generally routed separately from

sensor lines and data bus cables.

A minimum distance of 2 cm between the

lines is mandatory. Crossing of lines is

permitted.

2. For control units with their own mains

connections, ensure the power-,

sensor- and bus lines are routed

separately. If cable ducts are in use,

they must be equipped with separators.

3. When installing the control units or

thermostats, a minimum distance of 40

cm must be maintained to other

electrical utilities with electromagnetic

emissions, such as radio`s, motors,

transformers, dimmer switches,

microwave ovens and televisions,

loudspeakers, computers, radiophones

etc.

4. A minimum distance of 40 cm between

the thermostats and control units is

mandatory. Several control units in a

data bus connection may be installed

directly side by side.

Fig. 1: Minimum distances during electrical

installation

Fig. 2: Minimum distance to other electric

instruments

40 cm

15 cm

Mains

230 V~

Data bus line 12 V

2c

m

GB

Page 5

GB-5

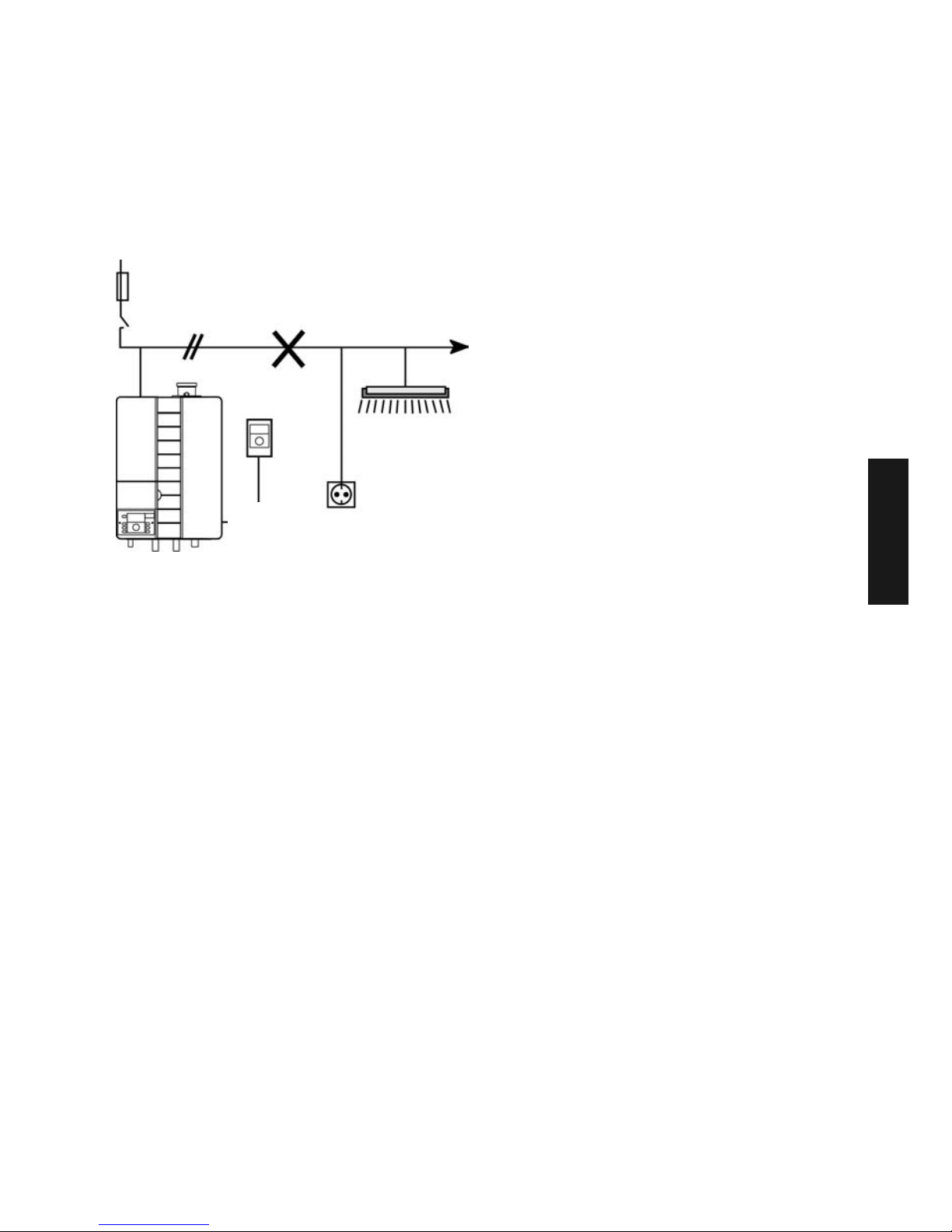

5. The main connection for the heating

system (i.e. boiler control panel control unit) must be designed as an

independent electrical circuit. There

should no fluorescent lamps or other

machines, which may be sources of

disturbance, be connected and even

the possibility of such connections

should be ruled out.

6. The outside sensor may not be

installed close to transmitting or

receiving equipment (on garage walls

close to receivers for radio-controlled

garage door openers, amateur radio

antennas, radio controlled alert

systems or close to large scale radio

transmission equipment).

Recommended cable cross-sections

and maximum permitted cable lengths:

For all cables with mains voltage (power

supply, burner, pumps, actuators)

1.5 mm

2

Maximum length:

Unlimited cable length within house

installation.

All low voltage cables (sensors, external

switches due to demands via contact

points, modem connection cables,

analogue signal cables etc.): 0.5 mm

2

Maximum length:

100 m (duplicate wire)

Longer connecting cables should be

avoided in order to reduce the risk of

interfering radiation.

Data bus line: 0.6 mm Ø

Maximum length:

50 m (duplicate wire)

Longer connecting cables should be

avoided in order to reduce the risk of

interfering radiation.

Fuse 16 A

Heating room emergency switch

Only connect heating

room lighting and

sockets on separate

power circuit!

Thermostat(s

)

ATAG - burner

Fig. 3: Electric routing in heating room

GB

Page 6

GB-6

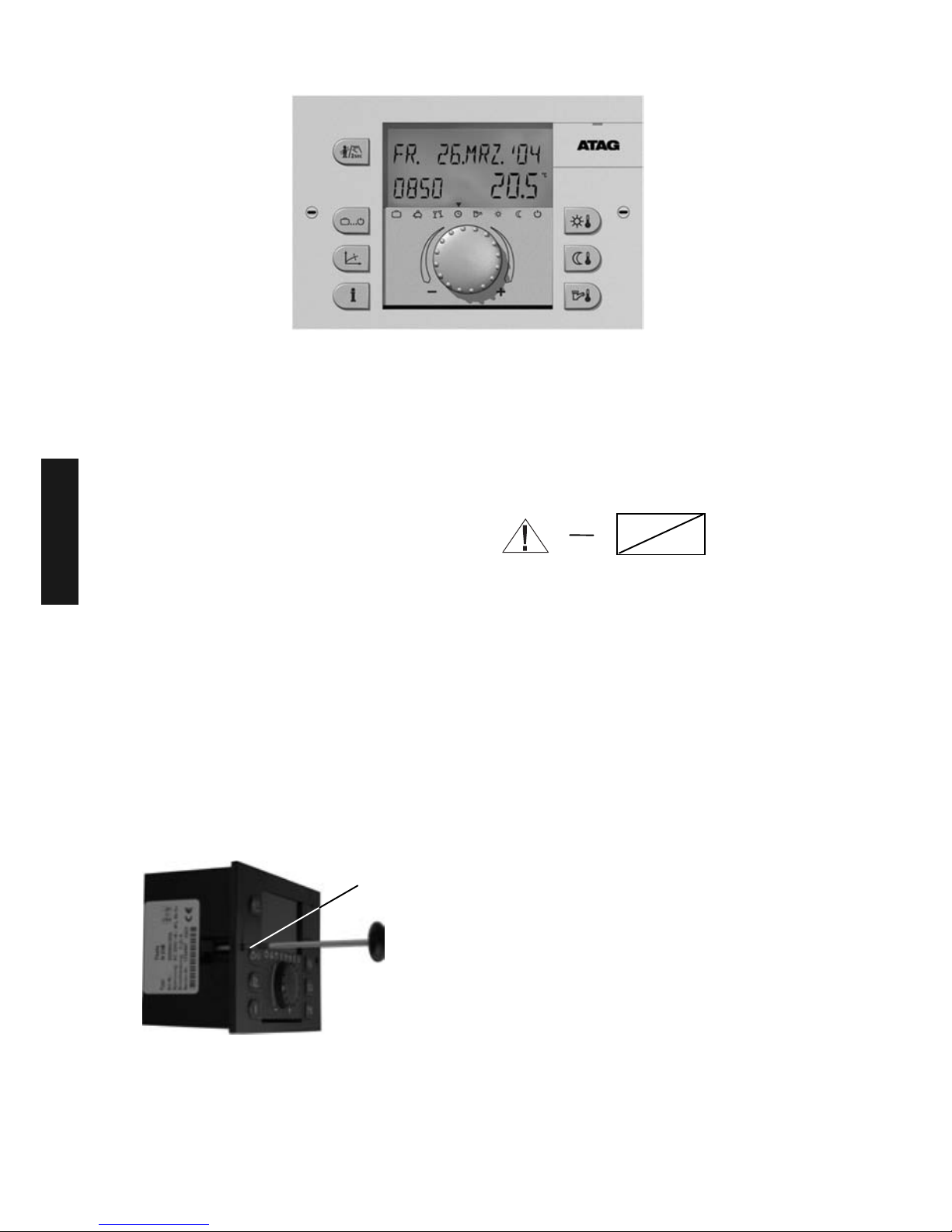

Installation of the control unit

Mounting instructions

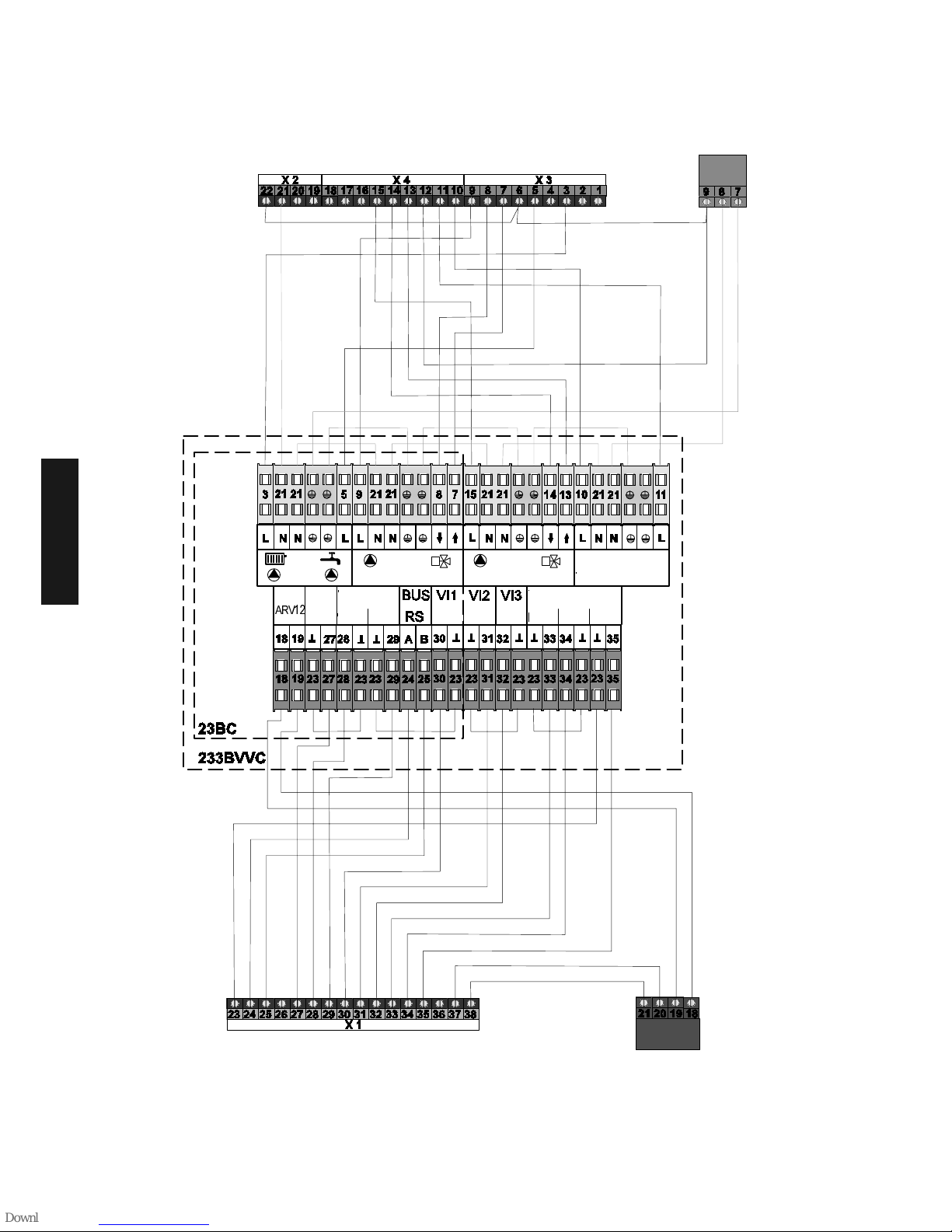

Parts necessary for the installation into the

boiler control unit:

- MadQ control unit 23BC or 233BVVC

- MadQ installation set for 23BC or

233BVVC

Parts necessary for the installation into the

wall-mounting case:

- MadQ control unit 23BC or 233BVVC

- MadQ wall-mounting case

All control units can be built into the

corresponding ATAG boiler control unit or

wall-mounting case after the electrical

connections have been made.

They should be fastened with quickclamping devices (1) by turning them

clockwise.

The removal is done in reverse order. See

the assembly instructions that belong to

the MadQ installation set and the MadQ

wall-mounting case.

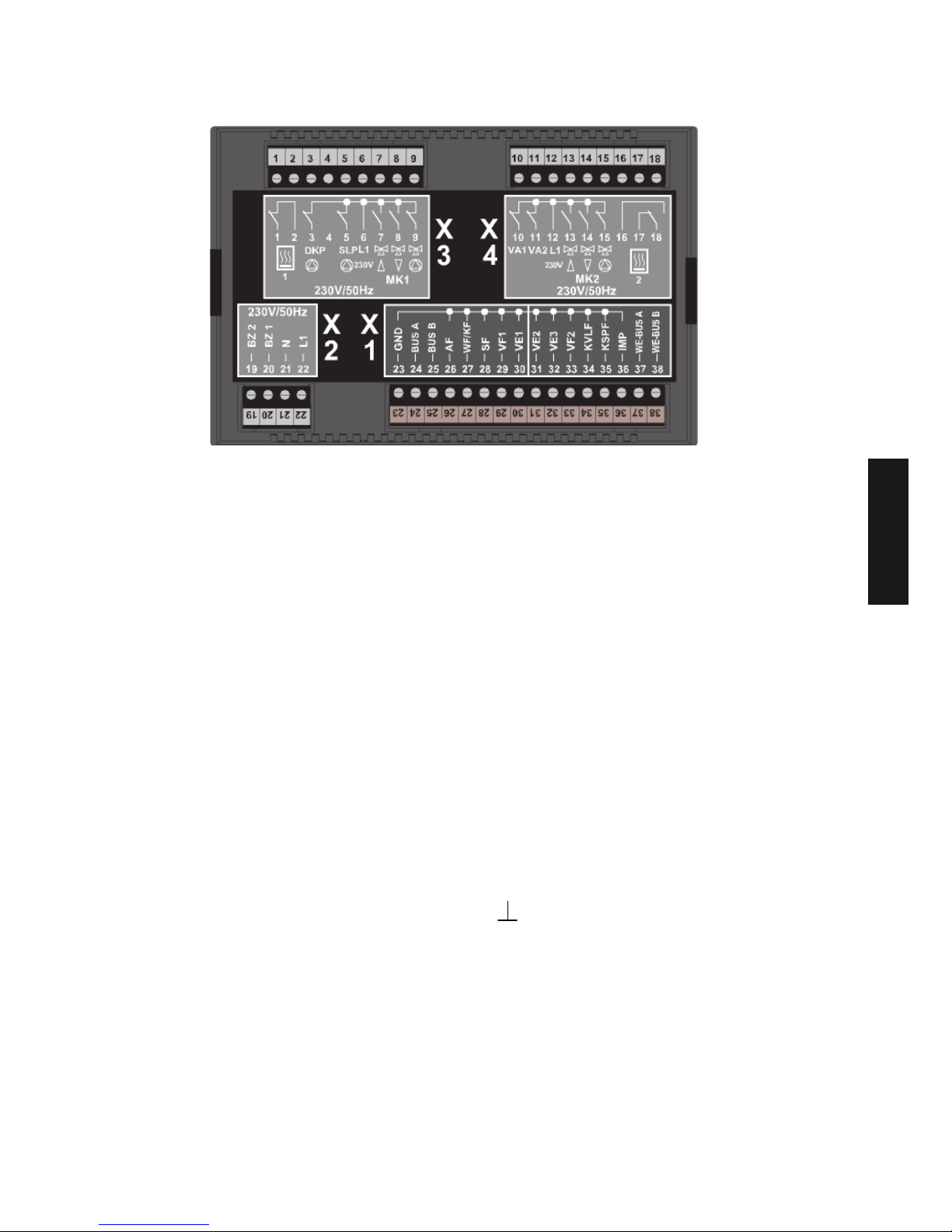

Electrical installation

The electrical connection and the further

routing to the control units is done on the

back of the unit with the four

terminal strips X1, X2, X3 and X4 in the

boiler control unit, corresponding to the

designations in the coloured terminal

fields.

The routing in the wall-mounting case is

prepared in the factory.

All terminal clamps inside the blue

fields (X1) carry low voltage and may

not get into contact with the mains

voltage! Ignoring this will inevitably

lead to the destruction of the control

unit and to the loss of the basis for

warranty claims!

The terminal clamps in the red fields

(X2...X4), depending on the operation

mode, generally carry mains voltage.

Terminal occupation, see next page.

Note:

When routing the unit, ensure that sensor, data bus- and mains lines are routed

separately. Mutual routing inside one

cable is prohibited. Sensor- and data bus

lines may not be routed with mains lines

that supply electrical units that are not

interference suppressed according to EN

60555-2.

230 V~

GB

Page 7

GB-7

Electrical connection

Mains connection

1 - Do not use

2 - Do not use

3 - Unmixed circuit pump

4 - Do not use

5 - Charge pump

6 - L 1 / 230 V

7 - Mixing valve 1 OPEN

8 - Mixing valve 1 CLOS

9 - Mixed circuit pump 1

10 - Variable output 1

11 - Variable output 2

12 - L 1 / 230 V

13 - Mixing valve 2 OPEN

14 - Mixing valve 2 CLOS

15 - Mixed circuit pump 2

16 - Do not use

17 - Do not use

18 - Do not use

19 - Do not use

20 - Do not use

21 - N / 230 V

22 - L 1 / 230 V

Sensor-/data bus connection

23 - GND for sensor

24 - Data bus connection A

25 - Data bus connection B

26 - Outside sensor ARV20 Mad

27 - Do not use

28 - Tank sensor

29 - Flow sensor mixed circuit 1

30 - Variable input 1

31 - Variable input 2

32 - Variable input 3

33 - Flow sensor mixed circuit 2

34 - Do not use

35 - Do not use

36 - Impulse input

37 - Boiler control unit-data bus A

38 - Boiler control unit-data bus B

GND for sensor

} Mains connection

GB

When building in a MadQ controller into a boiler a data bus connection is made between the

boiler and the controller through the cable loom. In case of a Cascade installation the

positions 20 and 21 of the connection block of each boiler have to be connected to each

other. Adjust Parameter 89 of each boiler to their individual bus address: Boiler 1 = 00, boiler

2 = 01, etc. See also example 17 on page XXXIV.

Page 8

GB-8

Installation set MadQ

GB

Cable harness for the installation of a control unit in the boiler control unit

MC-1 MC-2

MC-1

MC-2

Sensor

Sensor

DHW

VO1 VO2

USPSPS

OS

ARV12

Page 9

GB-9

Wall-mounting case

Application:

The wall-mounting case serves as a case

for the control unit.

Design

The wall-mounting case is only suitable for

use as a case and for the connections of

the control unit.

The control unit is ready for use after it

has been fastened to the motherboard

and after the output cables have been

routed.

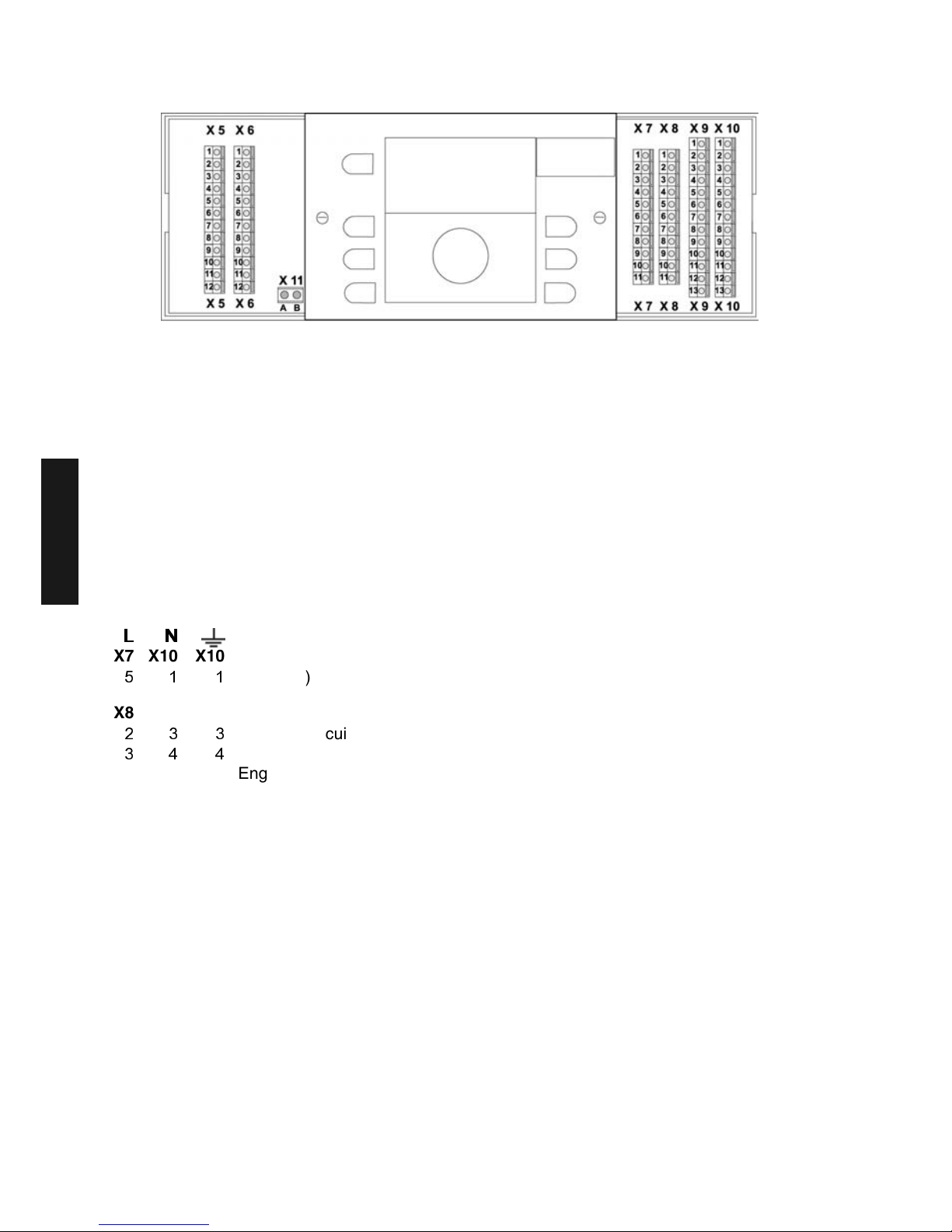

Assembly and electric installation

1- Push out the cable inlets at the pre-

stamped locations at the top or bottom

according to the size and number of

the cable ducts.

Note:

If no cable duct is used, a suitable

strain relief for the cables must be

ensured during installation.

2- Place locking bolts (1) horizontally and

pull off the connection covers (2) to

one side.

3- Install the wall-mounting case with the

supplied bolts and dowel pins on a flat

surface without distorting it. Use the

enclosed drilling jig.

4- Carry out the electric routing according

to the unit version and the connection

diagram (see reverse).

The terminal clamps of the terminal

blocks X5 and X6 in the left

connection

area carry low voltage and may not

come into contact with the mains

voltage! Ignoring this will inevitably

lead to the destruction of the control

unit and to the loss of the basis for

warranty claims!

The terminal clamps of the terminal

blocks X7 to X10 in the right

connection area carry mains voltage,

depending on the operation mode.

When connecting the electric cables,

the cables with a solid core can be

placed directly into the clamp. The

twisted core must carefully be lead in

by pressing the locking device

5- Slide clamp covers onto the wall-

mounting case and fasten them.

6- Slide the control unit into the wall-

mounting unit and let it engage under

evenly distributed pressure. The

electric connection is made via the

socket strip on the motherboard.

Tighten the control unit and both quickclamping devices clockwise.

Note:

When routing the control unit, ensure that

sensor-, data bus- and mains lines are

routed separately. Mutual routing inside

one cable is prohibited. Use cable ducts

equipped with separators, if necessary.

230 V~

1

2

GB

Page 10

GB-10

Electrical connections

X5 X6 Sensor- and data bus lines (X5-X6)

1 1 B – Data bus - A (T2B)

2 2 Outdoor sensor ARV20 Mad

3 3 Do not use

4 4 Tank sensor

5 5 Flow sensor mixed circuit 1

6 6 Variable input 1

7 7 Variable input 2

8 8 Variable input 3

9 9 Flow sensor mixed circuit 2

10 10 Do not use

11 11 Do not use

12 12 Do not use

////1

11

1

X7 X10 X10 Mains connections (X7)

L1 (230V)

X8 X9 X10 Pumps and mixing valve engines (X8, X9, X10)

Unmixed circuit pump

Charge pump

4 5 5 Engine mixing valve 1 (OPEN)

5 Engine mixing valve (CLOS)

6 7 7 Mixed circuit pump 1

7 8 8 Variable output 1

8 9 9 Variable output 2

9 10 10 Engine mixing valve 2 (OPEN)

10 Engine mixing valve 2 (CLOS)

11 12 12 Mixed circuit pump 2

X11 Data bus boiler control unit (X11)

A

Data bus boiler control unit A

B Data bus boiler control unit B

Here, only connect the first MadQ of the data bus connection!

Only connect the A-B data bus boiler control unit (RS485) of the boiler control unit after the first MadQ

control unit from position 20-21 in the boiler to position A-B on X11 in the wall-mounting case. Every

following MadQ control unit (up to 5) must be connected to the A-B data bus (T2B) from position 1 to

X6 and X5.

GB

Page 11

GB-11

Thermostats (for remotecontrol)

Mounting Location

a – for applications without room sensor

If the internal room sensor is not to be

activated the unit may be mounted at

any location indoors.

b – for applications with room sensor

The activated room sensor should be

fixed at a height of approx.1.20 – 1.50

m at a place most representative of all

rooms. It is recommended to chose a

partition wall in the coolest day room.

In order to ensure sufficient air

circulation at the room station, it must be

mounted to the wall with a gap

inbetween.

The thermostat must not be mounted:

– at locations subjected to direct solar

radiation (consider the position of the

sun during winter).

– close to heat-generating appliances,

such as televisions, refrigerators, wall

lamps, radiators etc.

– on walls with heating or domestic hot

water pipes or chimneys behind.

– on non-insulated outside walls

– in corners or wall recesses, shelves or

behind curtains (insufficient ventilation)

– close to doors of unheated rooms

(influence of low temperatures)

– on unsealed flush-type boxes

(influence of external low temperatures

due to the chimney effect of installation

tubes)

– in rooms with radiators controlled by

thermostatic valves (mutual influence).

Mounting instructions

After removing the front panel by pressing

the locating lug the wall mounting base

can be taken off and mounted at the

desired location using the enclosed dowel

pins and screws. The data bus line must

thereby be routed through the bottom

cable gland.

Recommended connecting cable:

2x0.6 max. cable length: 50 m.

Note: For new installations use a

flush-mounting switch box to

ensure perfect routing of

cable.

↑ Locating lug

GB

Page 12

GB-12

Electrical connection

The 2-strand data bus cable is connected

to terminals A and B of the 2-pole terminal

strip on the bottom plate. The connections

are not interchangeable and must be

connected in compliance with the

identification A/B on the base. If the two

connecting lines are mixed up by mistake

the display will be out of function.

Once the electrical connection is

completed the thermostat is hooked in

flush at the top and folded down, as

shown in the picture, until it audibly

engages into the wall-mounting base.

Electrical connection at control unit

See assembly instructions of the controll

unit.

Data bus allocation

The connection of one or more

thermostats to the control unit occurs via a

two-core data bus line. Because this

connection is always carried out parallel in

the same line, a separate bus address

must be allocated to every thermostat.

Likewise, a separate bus address must be

allocated to every control unit (if there is

more than one, e.g. when the heating

circuit is extended).

Bus address (control unit)

If there is only one control unit, it should

have bus address 10. If there is more than

one control unit in the network (max.: five),

the leading control unit that controls the

boiler control unit, has bus address 10, the

others are allocated in sequence with bus

addresses 20, 30, 40 and 50.

Setting the bus address in the control

unit

The setting of the bus address is carried

out after entering the installer code in the

data bus level of the corresponding control

unit (see commissioning of the control

unit).

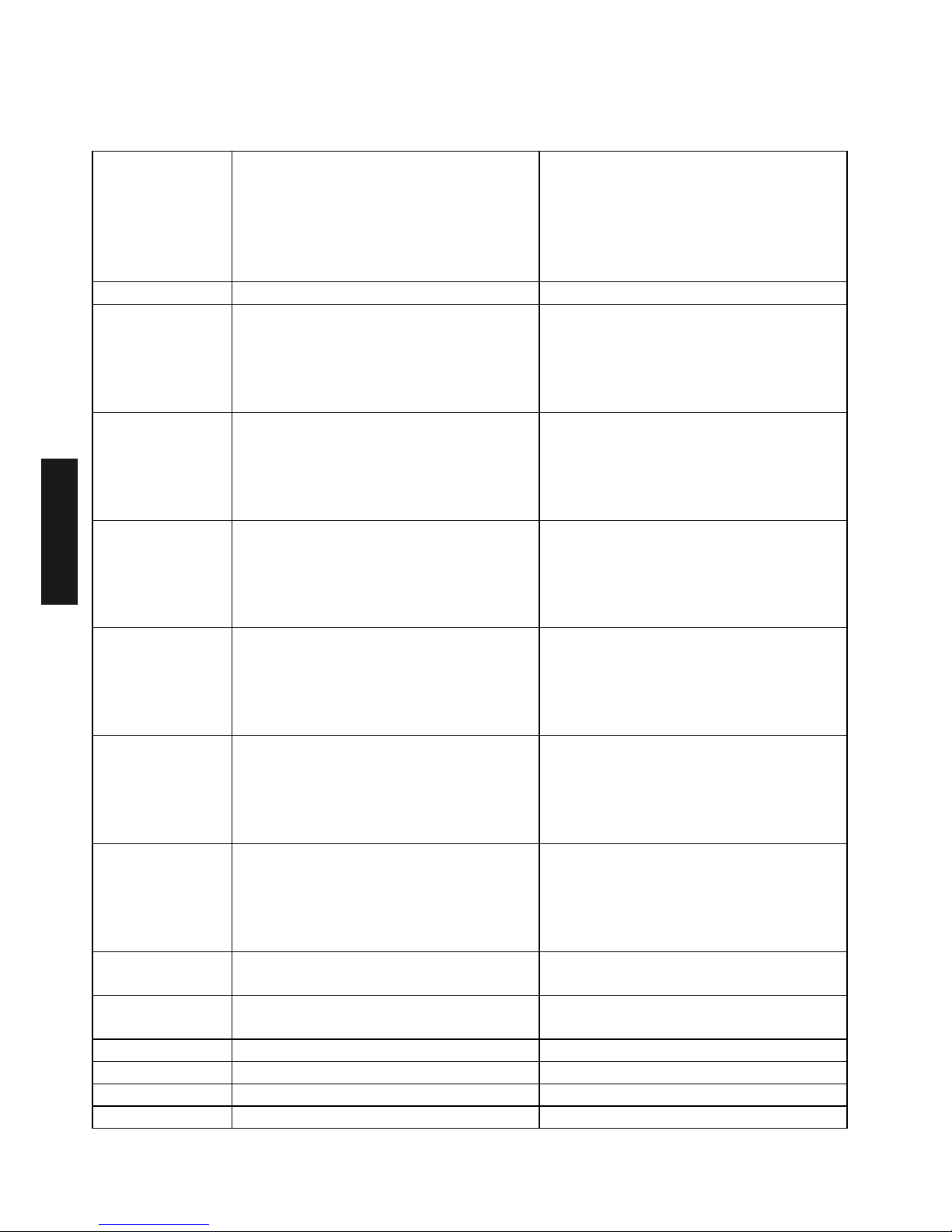

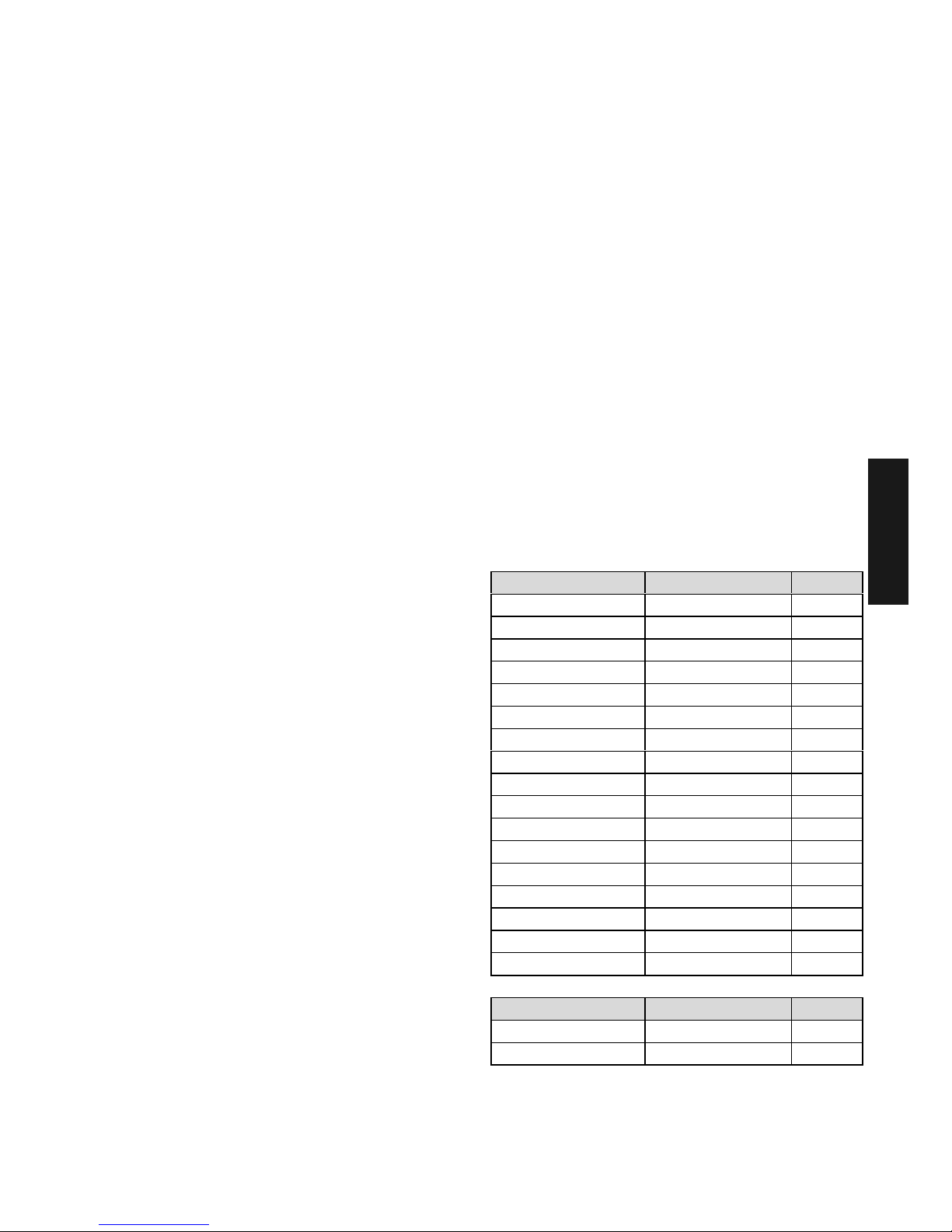

Bus address (thermostat)

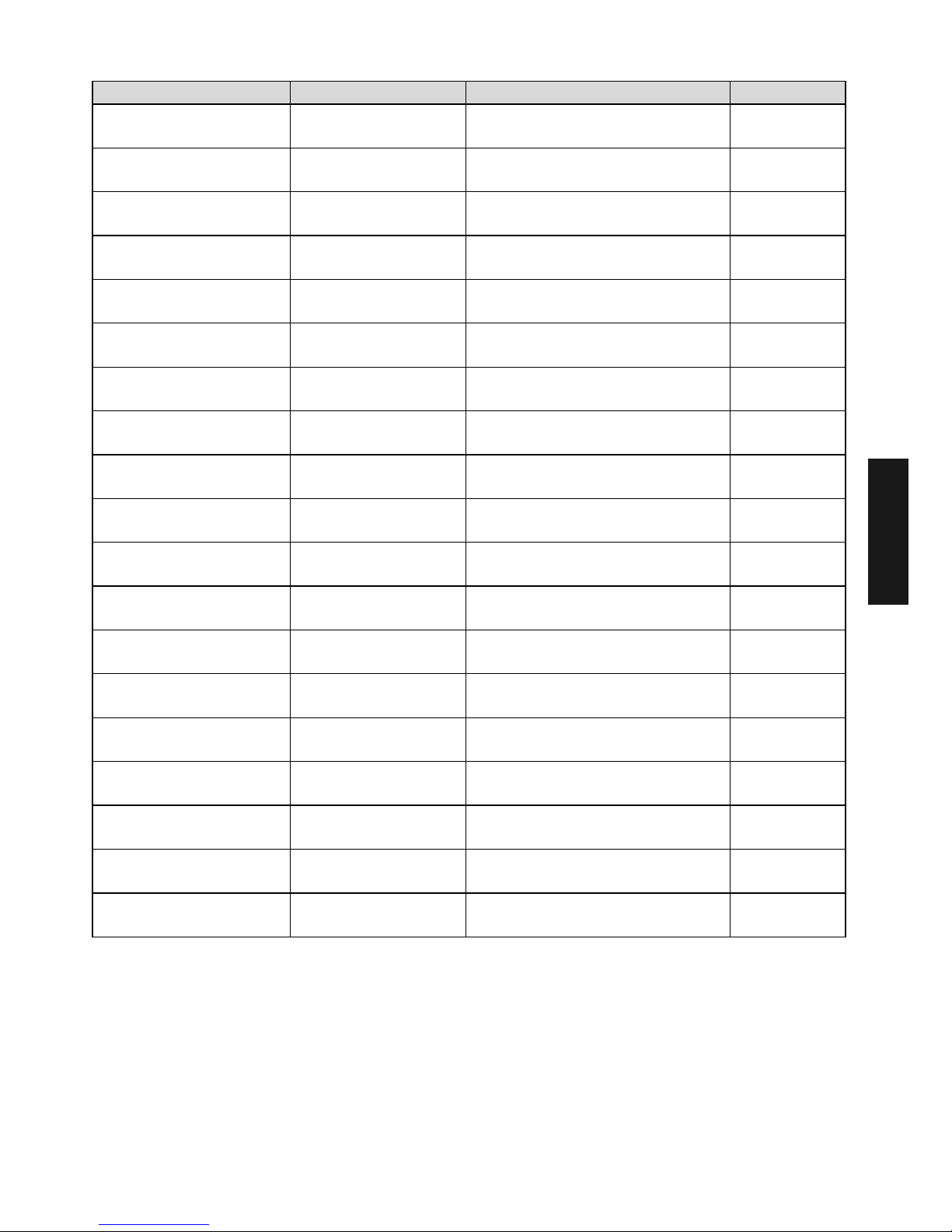

The allocation of the bus addresses of the

control units and the bus addresses of the

thermostats must be carried out according

to the enclosed table.

Setting the bus address in the thermostat

A- Commissioning

After completing the electrical installation

and commissioning the plant, all available

segments appear in the display.

Control unit Thermostat

Function

Bus

address

Heating circuit

Bus

address

Control unit 1 10

Unmixed circ.

Mixed circ. 1

Mixed circ. 2

11

12

13

Control unit 2 20

Unmixed circ.

Mixed circ. 1

Mixed circ. 2

21

22

23

Control unit 3 30

Unmixed circ.

Mixed circ. 1

Mixed circ. 2

31

32

33

Control unit 4 40

Unmixed circ.

Mixed circ. 1

Mixed circ. 2

41

42

43

Control unit 5 50

Unmixed circ.

Mixed circ. 1

Mixed circ. 2

51

52

53

¾ ¿ À Á Ä

°C

KWh

Min

%

°C

KWh

Min

%

0 2 4 6 8 10 12 14 16 18 20 22 24

Fffff

ffff

Segment test

GB

Page 13

GB-13

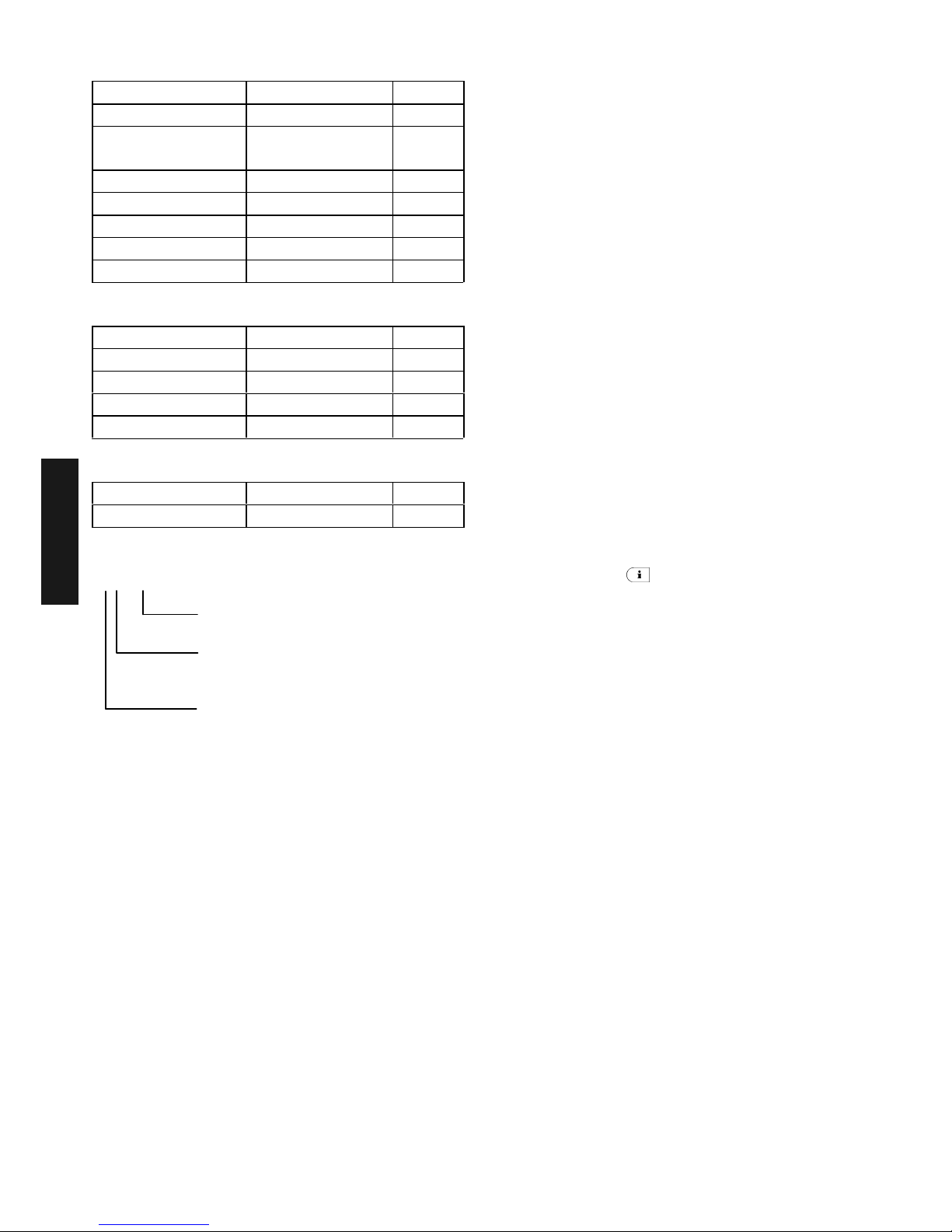

Subsequently, the unit identification and

the data bus address will appear.

After setting the bus address using the

rotary pushbutton and confirming this by

pressing it, the allocation determined by the

address will appear automatically.

Attention:

Double allocation of bus addresses is not

permitted and inevitably lead to faults in

data transfer and therefore to faulty control

of the heating system.

B - Changing bus addresses

If a bus address has to be changed

afterwards, then carry out the following

procedure:

1 - By pressing the bottom locking device,

remove the thermostat from the

ground board (the bus is

disconnected).

2 - Place the thermostat again while

keeping the rotary pushbutton

depressed until the address setting

appears.

3 - Set and confirm a new bus address.

RS-2

15.05.

V1.2

BUS ADDRES

11

Instrument identification

Device type

Software date

Software version

Address settings

see table above

BUS

HC

AU-1

Data bus address

Unmixed circ.

MadQ control unit 1

(=AU1),

MadQ control unit 2

(=AU2), etc.

GB

Page 14

GB-14

Accessories

Outdoor sensor

Mounting Location

The outdoor sensor should be mounted on

the most exposed and coldest side of the

building (north or north-east) at a height of

min. 2 m above ground.

Exception: If the preferential living

area is facing another

direction, the

corresponding side of

the building should be

chosen.

When mounting the sensor mind external

heat sources (heated chimneys, war hot

air from air shafts, installation on black

surfaces, thermal bridges in the wall, etc.)

which could falsify the measuring value.

The cable outlet must always be directed

downwards in order to avoid the

penetration of moisture.

The outside sensor may not be installed

close to transmitting or receiving

equipment (on garage walls close to

receivers for garage door openers,

amateur radio antennas, radio controlled

alarm systems or close to large scale

radio transmission equipment etc.).

Electrical connection

For the electrical installation preferably

use a 2-strand cable with a minimum

cross-section of 0,6mm

2

. The connection

is made at the 2 screw terminals inside the

sensor case and may be interchanged.

Mounting instructions

1– Route the sensor cable to the

mounting location

2– Loosen lid screws from sensor case

and remove top

3– Mount sensor base with enclosed

central fastening screw.

Use sealing ring! Cable outlet must be

directed downwards!

4– Insert the sensor cable so that the

cable jacket is fully enclosed by the

sealing lip.

5– Electrical connection on terminal block

boiler control unit position 18-19.

6– Attach the lid again an and screw it

firmly onto the base. Ensure correct fit

of sealing ring.

In situations when the control unit has to

be controlled via its own outside sensor,

ARV20 (white) must be used. Connection

to the control unit.

Outside sensor

ARV12

GB

Page 15

GB-15

Tank sensor

Versions:

AVB06 Cable length 5 m

Application: Tank sensor (for nearby hot

water generators, buffer

tanks etc.)

Mounting location:

In the designated immersion sleeve of the

corresponding application.

Mounting in DHW- or buffer tanks

Bend the pressing spring towards the

sensor tip and slide the sensor into the dry

immersion sleeve of the corresponding

tank.

Electrical connection

Clamp the sensor to the appropriate

terminal clamps of the respective control

unit (see corresponding connection

diagram). The two-strand connection is

interchangeable.

Flow sensor

Flow sensor VF20

Versions:

VF 20 Cable length 4 m

S4363400

Application: As a flow sensor for unmixed

circuits and mixed circuits of

heating circuits

Mounting location:

Behind the mixer pump at a distance of at

least 50 cm.

Mounting:

Polish the flow pipe and apply heat

conductive paste.

Fasten the sensor to the contact location with

a tensioning belt so that it is flush with the

pipe's surface.

Ensure a tight fitting!

Electrical connection

Clamp the sensor to the appropriate terminal

clamps of the respective control unit (see

corresponding connection diagram). The twostrand connection is interchangeable.

Tank sensor AVB06

GB

Page 16

GB-16

Resistance values of sensors

depending on temperature

temperature

°°°°Celsius

PTC 2K

(2kΩΩΩΩ/25°°°°C)

Flow sensor VF20

Outside sensor ARV20

Tank sensor AVB06

NTC 12K

(12kΩΩΩΩ/25°°°°C)

Outside sensor ARV12

-20 1.387 98.900

-18

-16

-14

-12

-10

1.413

1.438

1.463

1.488

1.513

98.950

80.100

72.200

65.150

58.900

-8

-6

-4

-2

0

1.540

1.566

1.593

1.619

1.646

53.300

48.250

43.750

39.750

36.150

2

4

6

8

10

1.673

1.700

1.728

1.756

1.783

32.900

29.950

27.350

24.950

22.800

12

14

16

18

20

1.812

1.841

1.869

1.898

1.927

20.850

19.100

17.500

16.100

14.750

22

24

26

28

30

1.957

1.986

2.016

2.046

2.077

13.600

12.500

11.500

10.600

9.800

32

34

36

38

40

2.107

2.128

2.169

2.200

2.232

9.100

8.350

7.750

7.200

6.650

45

50

2.311

2.393

5.525

4.600

55

60

2.475

2.559

3.850

3.250

70 2.732 2.325

80 2.910 1.700

90 3.093 1.275

100 3.283 950

GB

Page 17

GB-17

Commissioning the control unit

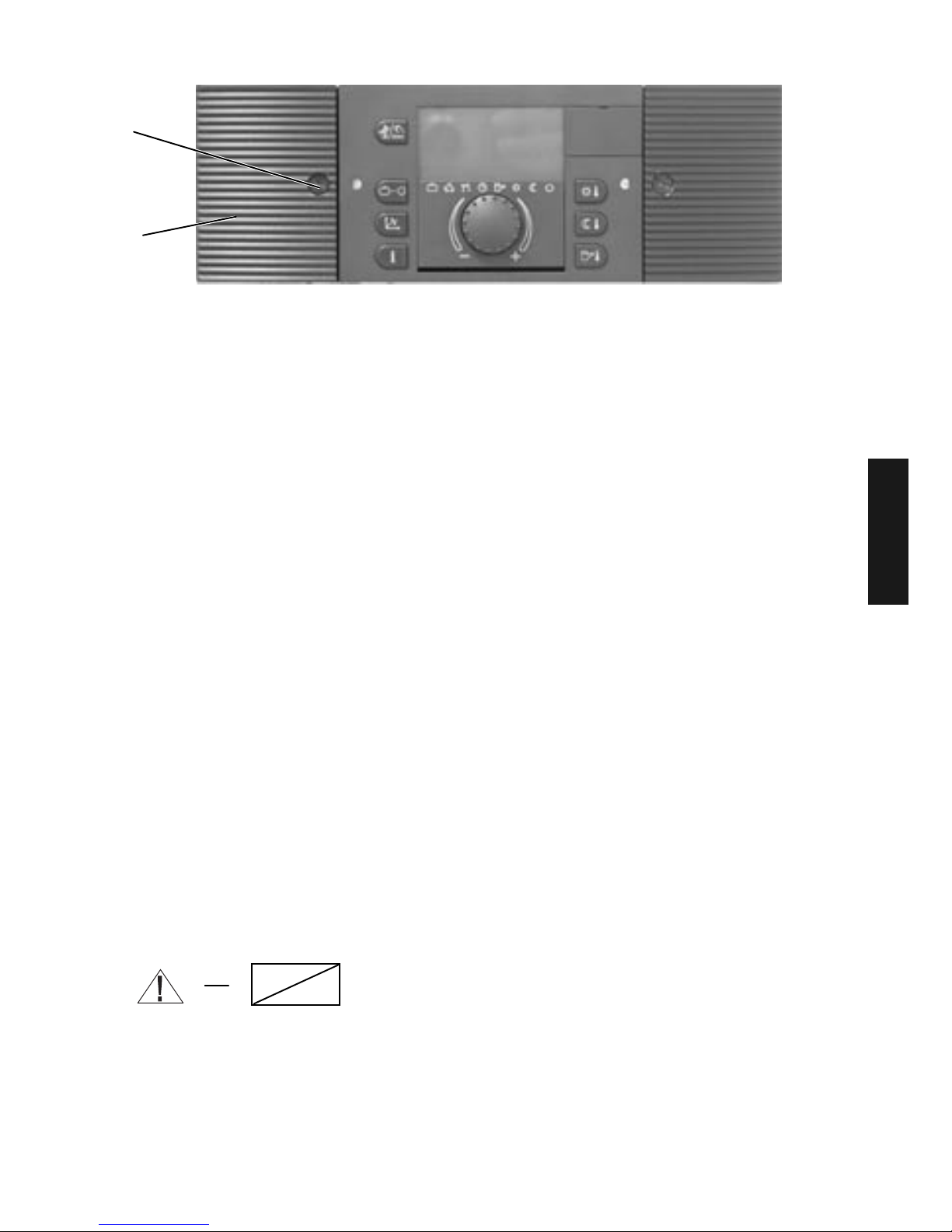

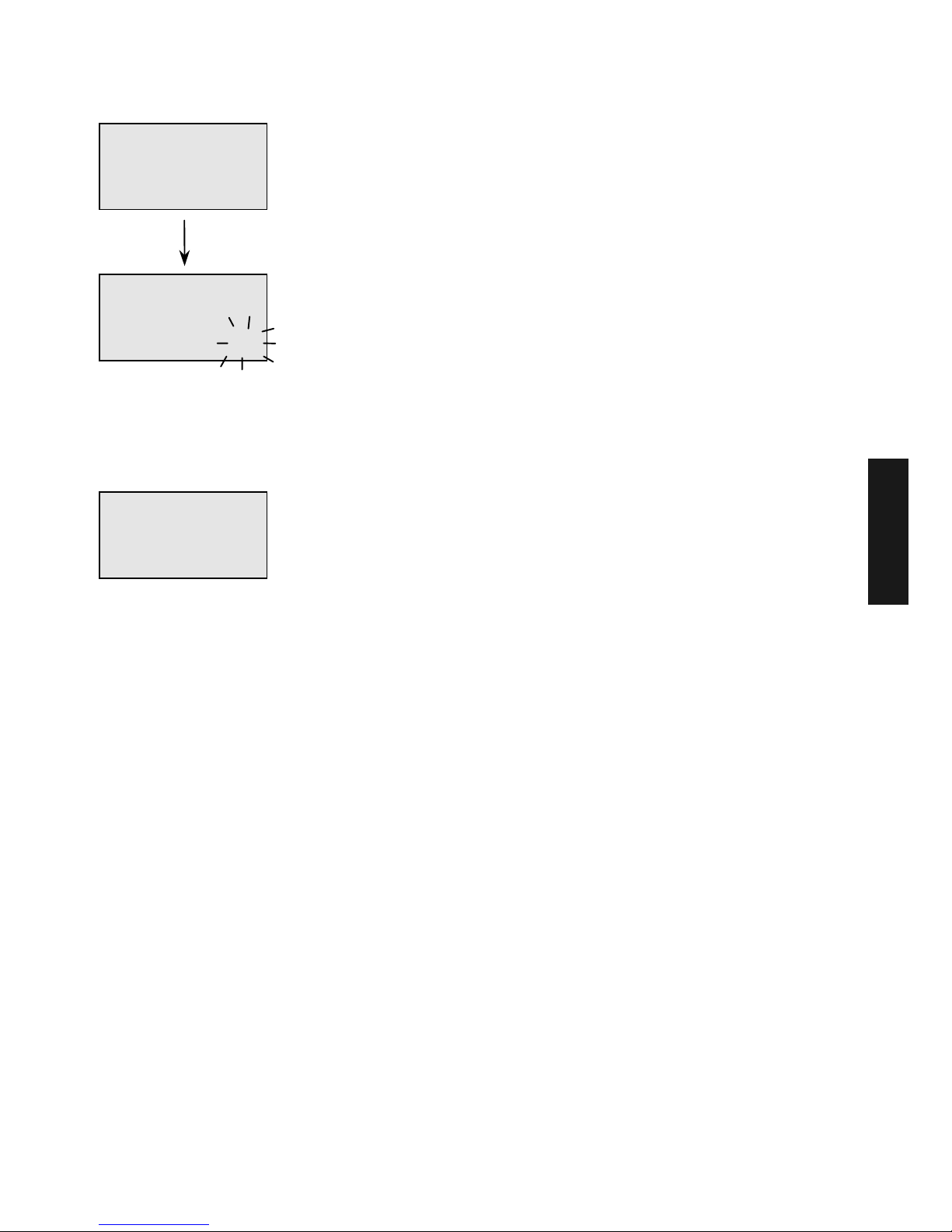

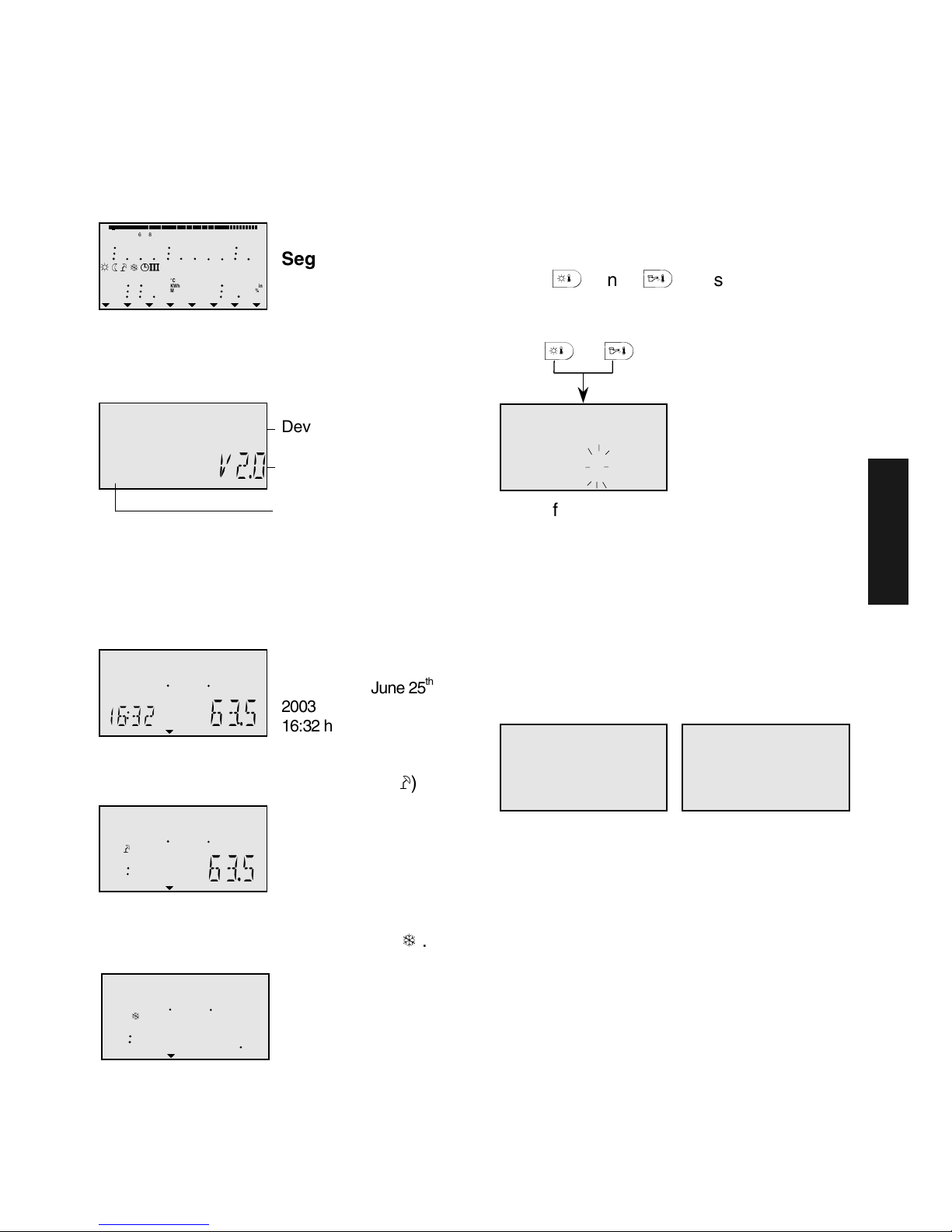

Segment test and identification

During the first activation of the control

unit or with each return of voltage after a

power failure all segments available in

display will appear:

This is followed by the equipment version

with type code and current version number

of software status

If there is no alarm at present, the

standard display with date, time and

current flow temperature will appear

afterwards.

An active summer switch-off is

represented by a sunshade symbol (À).

An active frost protection function is

represented by a ice crystal symbol (Á).

Code input

Installer code

After entering the installer code all

parameters determined for the heating

specialist are released and can be edited

in accordance with the syst version.

Code input

In order to enter the installer code, the

keys

¥

and

§

must be pressed

simultaneously for approx. three seconds,

until the code input appears in the display.

¥

+

§

Each flashing digit is set by using the

rotary pushbutton in accordance with the

code number and is confirmed by pressing

the button. All other digits are edited in the

same way.

After the code has been entered correctly,

the acknowledgement INSTALLER OK will

appear upon confirmation of the last digit,

after a wrong entry, the message CODE

ERROR will appear.

The factory set consumer code is: 1 2 3 4

The factory set installer code is : 0 1 2 3

Note: If the code is not accepted, you

should consult the supplier!

Attention: Enabled installer parameters will

be blocked again if no further

action takes place over a period of

ten minutes. In this case the

installer code must be entered

again.

¾ ¿ À Á Ä

°C

KWh

Min

%

°C

KWh

Min

%

0 2 4 6 8 10 12 14 16 18 20 22 24

Fffff

ffff

À

°C

;

1632

63.5

°C

;

1632

63.5

Segment test

Standard displa

y

Wednesday, June 25

th

2003

16:32 hrs Temp. 63.5°C

Summer shutdown

active

Á

°C

;

1632

635

Plant frost

protection

active

N

VV

18

V2.0

Device type

Version number

Type code

CODE

0

000

I

OK

GB

Page 18

GB-18

Automatic setting function

This function can switch off control circuits

that are not needed or are only needed later.

The control circuits are registered

automatically when their corresponding

sensors are connected and transfer

permitted measuring values. Control circuits

without sensor circuits are automatically

switched off without displaying an alarm.

The AUTO-SET function is activated every

time the mains voltage is switched on.

Automatic activation

If the AUTO-SET function is switched on by

parameter 14 in the SYSTEM level and the

commissioning date has not yet been saved,

then the sensors that are connected or

clamped off are registered automatically

every time the control unit is switched on.

During this period, the error messages of the

sensors (short circuit interruption) are

suppressed.

If the commissioning date was saved, a

changed sensor configuration can only be

confirmed via manual activation.

Manual activation

The AUTO-SET function can be activated

manually at any time. To do this, press the

rotary pushbutton when switching on the

control unit while the version is being

displayed. Keep the button depressed until

the AUTO-SET function in the display is quit.

The AUTO-SET function serves the following

sensor inputs:

– Outdoor sensor

– Flow sensor 1

– Flow sensor 2

– Tank sensor

Apart from that, the AUTO-SET function is

only carried out if the circuits in the following

levels that are allocated to the sensors were

parameterised accordingly.

For the tank sensor:

HYDRAULIC Level

Parameter 2 - DHW-charge pump function

set value OFF or 1 (DHW-charge pump)

For flow sensor 1:

HYDRAULIC Level

Parameter 3 – mixed circuit function 1 set

value OFF or 3 (mixed circuit)

For flow sensor 2:

HYDRAULIC Level

Parameter 4 – mixed circuit function 2 set

value OFF or 3 (mixed circuit)

Because a parameter setting is not changed

by the AUTO-SET function, the current

settings are checked beforehand. A change is

only made if one of the settings above is

changed. This means that the deeper system

configuration can never be changed by the

AUTO-SET function.

N

VV

18

V2.0

T

T

Standard display

GB

Page 19

GB-19

Alarm messages

In order to be able to perform an exact

diagnose in case of a problem the control

system is equipped with a comprehensive

fault alarm system. An alarm is thereby

always displayed and saved on the

corresponding control unit.

There are five different categories of error

messages:

1 - Sensor error messages

Sensor measuring values that are not

inside the measuring range are valued as

errors. They appear with an error message

according to their use.

2 - Error messages of the boiler control

unit

These error messages evaluate the

respective control status. They appear with

the corresponding error message,

depending on the version and allocation.

3 - Logical error messages

The error messages evaluate the expected

control result. They appear with the

corresponding error message, depending

on the version and allocation.

4 - Bus error messages

These error messages relate to address

errors such as double allocation or

unrecognised address settings inside the

data bus. They appear with the

corresponding error message, depending

on the version and allocation.

5 - Alarms from the boiler control

These error messages come from the

boiler control and are divided into

permanent faults (permanent locking) with

error code E-XX (MCBA-code) or

temporary faults (self-eliminating locking)

with fault code B-XX (MCBA-code).

The display and further processing of logical

error messages can be suppressed by a

corresponding parameter setting (see

parameter 13 – SYSTEM level – logical error

message)

Further processing of errors:

– Errors appear in the standard display of the

control

– System errors appear in the info-level at the

corresponding info-value

– If necessary, errors are transferred into the

error message level (see description below)

– At the corresponding parameter settings,

errors activate an error notification output

for connecting an optical or acoustic signal

transmitter.

– Errors are transferred to the corresponding

gateways via the data bus.

Table of error messages:

Sensors and variable inputs:

Designation Error type Code

Outdoor sensor Interruption 10-0

Outdoor sensor Short circuit 10-1

Flow sensor 1 Interruption 12-0

Flow sensor 1 Short circuit 12-1

Tank sensor Interruption 13-0

Tank sensor Short circuit 13-1

VI 2 Interruption 14-0

VI 2 Short circuit 14-1

VI 2 Error message 14-7

VI 3 Interruption 15-0

VI 3 Short circuit 15-1

VI 3 Error message 15-7

VI 1 Interruption 16-0

VI 1 Short circuit 16-1

VI 1 Error message 16-7

Buffer sensor Interruption 17-0

Buffer sensor Short circuit 17-1

Designation Error type Code

Flow sensor 2 Interruption 18-0

Flow sensor 2 Short circuit 18-1

GB

Page 20

GB-20

Temperatures:

Heat generator Not reached 50-4

Heat generator Exceeded 50-5

Domestic hot

water

Not reached 51-4

Flow MC1 Not reached 52-4

Flow MC2 Not reached 53-4

Room HC Not reached 54-4

ROOM MC1 Not reached 55-4

ROOM MC2 Not reached 56-4

Data bus error

Address Address conflict 70-0

Activity No T2B-signal 70-1

EEPROM 71-0

EEPROM defective 71-1

Bus error Bus error 70-6

Fault in boiler control

Error Locking En: XX

Error Blockage Bn: XX

Explanation fault in boiler control:

En: XX

Alarm message register

The control unit is provided with an error

message level, which is able to hold up to five

alarms. The alarms are displayed with date,

time, and nature of fault (error number), the

errors are polled in the sequence of their

occurrence in the level

ALARM

.

The latest (= up-to-date) alarm is prioritized at

first position, alarms that have arrived before

appear in the order of their occurrence. Upon

arrival of a new alarm the fifth alarm will be

deleted.

The alarm messages of the MCBA are a

special case. Because they are external

errors, they are not saved in the internal error

message register of the control unit.

Plant information

Plants and system temperatures

After accessing the information level using the

information key ¤ , all available plant- and

system temperatures can be requested one

by one by turning the rotary pushbutton

clockwise.

If

set value

is displayed in the following table

in the category "display value", it will appear

when the rotary pushbutton is pushed.

The following displays only appear under the

specified display conditions. Some of the

displays are not available for certain unit

versions and are therefore skipped.

GB

Boiler error codes

(see boiler documentation)

Boiler

0 = Boiler 1

1 to 7 = Boiler 2 to 8 (Cascade)

E = Error

(B =Boiler blocking code)

Page 21

GB-21

INFORMATION Display value Comments Application

Outside (1)

Mean value/

current value

Outside (1)

Min./max. value

(0.00 to 24.00 h)

Outside 2

Mean value/

current value

Outside sensor 2 to var. input

Outside 2

Min./max. value

(0.00 to 24.00 h)

Outside sensor 2 to var. input

External blockage

Blocked status

ON/OFF

Ext. blockage to VI

Tank (1)

Set value/actual

value

If there is a tank (..B..)

Tank 2

Set value/actual

value

Tank sensor 2 to var. input (..B..)

DHW-thermostat

Charge status

ON/OFF

Instead of tank sensor (..B..)

Demand via

contact point (VI-1)

Demand ON/OFF Contact to var. input

Demand via

contact point (VI-2)

Demand ON/OFF Contact to var. input

Demand via

contact point (VI-3)

Demand ON/OFF Contact to var. input

Flow

Mixed circ. 1

Set value/actual

value

(..3..)

Flow

Mixed circ. 2

Set value/actual

value

(..33..)

Room temperature

Unmixed circ.

Set value/actual

value

Control unit required (..2..)

Room temperature

Mixed circ. 1

Set value/actual

value

Control unit required (..3..)

Room temperature

Mixed circ. 2

Set value/actual

value

Control unit required (..33..)

Thermostat function

Unmixed circ.

THERMOSTAT HC

Room thermostat function active

OFF = no room limit

(..2..)

Thermostat function

Mixed circ. 1

THERMOSTAT

MC-1

Room thermostat function active

OFF = no room limit

(..3..)

Thermostat function

Mixed circ. 2

THERMOSTAT

MC-2

Room thermostat function active

OFF = no room limit

(..33..)

GB

Page 22

GB-22

Operation modes

After entering the information level using the

information key ¤ all available operating

states and usage data

such as counter readings, specified

performance data etc. can be requested one

by one by turning the rotary pushbutton anticlockwise.

Information

Example of

display

Function Application

Status

Unmixed circ.

AUTO-P1 ECO

HC ON

Program/3-program/mode

status of heating pump

(..2..)

Status

Mixed circ. 1

AUTO-P1 ECO

MC-1 ON

(..3..)

Status

of

mixing valve

Mixed circ. 1

ACTUATOR-1

OPEN

Display of set direction

OPEN-STOP-CLOS

(..3..)

Status

Mixed circ. 2

AUTO-P1 ECO

MC-2 ON

Program/3-program/mode

status of heating pump

(..33..)

Status

of

mixing valve

Mixed circ. 2

ACTUATOR-2

STOP

Display of set direction

OPEN-STOP-CLOS

(..33..)

Status of boiler

control unit stage 2

HEAT GENER.

ST-2 OFF

Switching condition

of boiler control unit

Stage 2

(..22..)

Status of boiler

control unit

(mod.)

MODULATION

57% 60%

Modulating, continuously

variable boiler control unit,

display of set and actual value

(..VV..)

Status

Tank circuit

AUTO-P1 ECO

DHW ON

Program/3-program/mode

Status of heating pump

(..B..)

Function and status

Unmixed circuit

pump

OUTPUT HC-P

EO ON

Information on the allocated

function and switching condition

of the pump

(..2..)

Function and status

Variable output 1

OUTPUT VO-1

SOP OFF

Information on the allocated

function and switching condition

of the var. output 1

(..VV..)

Function and status

Variable output 2

OUTPUT VO-2

SOP OFF

Information on the allocated

function and switching condition

of the var. output 2

(..VV..)

Explanation of the type designation

- MadQ 23BC

- MadQ 233BVVC

Application:

(2...) an unmixed circuit

(..3..) with one mixed circuit

(..33..) with two mixed circuits

(..B..) domestic hot water circuit

(..VV..) with two variable outputs

(....C) in combination with ATAG boiler control unit with an RS-485 bus.

GB

Page 23

GB-23

Parameter synoptic

Entry into the time program level: Hold rotary push-button depressed for 3 seconds - automatic call-up of time program level

Select required level with rotary pushbutton and confirm, if necessary enter code beforehand

Without colour: Directly accessible

Light gray background: accessible with code 1234

Dark gray background: accessible with code 0123

Programming Configuration Parameter settings (heating circuits, control intervals)

Parame

ter no.

Time-

Date

Time

pro-

grams

Hydrau-

lic

System

para-

meters

Domes-

tic hot

water

Unmixed

circ.

(..2..)

Mixed

circ. 1

(..3..)

Mixed

circ. 2

(..33..)

Heating

unit

(..2..)

1

TIME

(min/h)

Heat. selection

HC,MC1/2,

DHW

Installation

diagram

Language

DHW economy

temperature

Reduced

operation

Reduced

operation

Reduced

operation

Type

2 Year

Select program

P1...P3

Domestic hot

water

supply

Time

programs

Legionella

protection

(week-day)

Exponent

heating curve

Heating

system

Heating

system

3

Day-

month

Week-day

Mo...Su

Heat. cycle

(1...3)

Function MC1

Enabling

separated mode

Legionella

protection

(time)

Room sensor

display

Room sensor Room sensor

Minimum

temperature

4

Su-Wi-

timer

Switching-on

time

Function MC 2

Temperature

ECO

Legionella

protection

(temperature)

Room sensor

function

Room sensor

function

Room sensor

function

Maximum

temperature

5 Switch-off time Function HC

System frost

protection

Signal source

Heating curve

adaptation

Heating curve

adaptation

Heating curve

adaptation

6

Room / dhw

temperature

Function VO1

Heat demand

VI-1

DHW-

maximum limit

Inrush

optimization

Inrush

optimization

Inrush

optimization

7 Function VO 2

Heat demand

VI-2

DHW

programs

8 Function VI -1

Heat demand

VI-3

Cool down

protection

Room frost

protection

temperat ure

Room frost

protection

temperat ure

Room frost

protection

temperat ure

9 Function VI 2 Climate zone DHW-Tset

Exceeding

room

temperature

Exceeding

room

temperature

Exceeding

room

temperature

10 Function VI 3

Type of

building

DHW-

switching

difference

Allocation

outside sensor

Allocation

outside sensor

Allocation

outside sensor

11

minimu m

boiler return flow

temperature

Back to

standard

display

DHW-charge

pump

Constant

control

Constant

control

Constant

control

12 Forced control

Program charge

pump

Minimum flow

temperature

Minimum flow

temperature

Minimum flow

temperature

13

Logical error

messages

Economy interval

charge pump

Maximum flow

temperature

Maximum flow

temperature

Maximum flow

temperature

14 Auto SET Cycle AUP Temp. rise Tset Temp. rise Tset Temp. rise Tset

15

Reset to

factory values

Pump after-run

(HCP)

Pump after-run

(MC1-P)

Pump after-run

(MC2-P)

16

DHW basic

temperature

Screed

function

Screed

function

Screed

function

17

Maximum

return flow

temperature

Maximum

return flow

temperature

18

19

20

21

22

23

24

25

Set

temperature

day

Set

temperature

day

Set

temperature

day

26

Set

temperature

night

Set

temperature

night

Set

temperature

night

27

Heating curve

slope

Heating curve

slope

Heating curve

slope

28

GB

Page 24

GB-24

Parameter settings

Communication

Service

Buffer tank

(..VV..)

Cascade

Data bus

Relay test

Error

Sensor

adjustment

Parameter

no.

Minimum temperature Switching difference AU- Bus address Unit Alarm 1 Outdoor sensor 1

Maximum

temperature

Inrush

delay

Bus rights

RS HC

Pump

Unmixed circ.

Alarm 2 Boiler sensor 2

Temperature rise

Tset

Switch off delay

Bus rights

RS MC-1

Pump

Mixed circ. 1

Alarm 3 Tank sensor 3

Switching difference

Maximum capacity for

connection

Bus rights

RS MC-2

dwk-engine

Mixed circ. 1

Alarm 4

Flow sensor mixed

circuit 1

4

Heat dissipation Boiler order

Pump

Mixed circ. 2

Alarm 5

Flow sensor mixed

circuit 2

5

Switching on

difference

Leading boiler

dwk-engine

Mixed circ. 2

6

Switching off

difference

DHW

Charge pump

7

Starting protection Output VO-1 Sensor VI-1 8

Discharge protection Output VO-2 Sensor VI-2 9

op. mode Sensor VI-3 10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

GB

Page 25

GB-25

Overview of installer parameters and adjustment options

HYDRAULIC Level

The parameters of this level refer to the general hydraulic system of the heating plant as

well as to the functionality and configuration of the programmable inputs and outputs for

the corresponding plant components.

PARA-

METER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From

code

01 Installation diagram 0000, .... 9999 0 0123

02 Function assignment of

domestic hot water supply

OFF Off

1On

4 DHW-circulation pump

5 No function

1 0123

03 Function of output

mixed circuit 1

(Type ..3..)

OFF Off

2 Unmixed circ.

3 Mixed circuit

6 Constant temperature

7 No function

8 No function

3 0123

04 Function of output

mixed circuit 2

(Type .0,33..)

Setting range and allocation as for parameter

03 3 0123

05 Function of unmixed circuit OFF Off

2 Unmixed circuit pump

4 DHW-circulation pump

5 No function

6 Constant control

10 Transport pump

11 Boiler pump 1

12 Boiler pump 2

13 Error output

14 Timer

15 No function

2 0123

06 Function of variable output 1

(Type ..VV..)

OFF Off

4 DHW-circulation pump

5 No function

9 Bypass pump

10 Transport pump

11 Boiler pump 1

12 Boiler pump 2

13 Error output

15 No function

16 No function

17 No function

18 No function

19 No function

20 No function

OFF 0123

07 Function of variable output 2

(Type ..VV..)

Setting range and allocation as for parameter

06

OFF 0123

08 Function of variable input 1 OFF Off

1 Outside sensor 2

2 No function

3 Tank sensor 2

4 No function

5 On/Off-contact

6 No function

7 No function

8 No function

9 No function

10 No function

11 No function

12 No function

13 Common flow sensor

14 No function

15 No function

16 No function

17 No function

18 No function

19 No function

OFF 0123

GB

Note:No function = in preparation

Page 26

GB-26

09

Function of variable

input 2

(Type ..VV.. )

Setting range and allocation as for parameter

08 OFF 0123

10

Function of variable input 3

(Type ..VV.. )

Setting range and allocation as for parameter

08

OFF 0123

11 Minimum boiler return flow

temperature

OFF, ON

OFF 0123

SYSTEM Level

The parameters in this level refer to the general limiting parameters and setting values in

the heating system to be used.

PARA-

METER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From

code

01

Language NL Dutch

GB English

F French

I Italian

NL 1234

02

Time programs P1 a time program is enabled

P1-P3 Three time programs enabled

P1 1234

03

Enabling of separate control

mode setting

1 Common adjustment for DHW-

/burner-circuits

2 Separate setting for each

individual heating circuit

1 1234

04 Summer shutdown OFF no function

10-30 °C

20 °C 1234

05 System frost protection OFF no function

-20...+10 °C

3 °C 0123

06 Heat demand on VI1 1 Mixed circ. 1

2 Mixed circ. 2

3 Unmixed circ.

1 0123

07 Heat demand on VI2 (Type

..VV..)

Settings see parameter 06

1 0123

08 Heat demand on VI3 (Type

..VV..)

Settings see parameter 06

1 0123

09 Climate zone -20.0.000.0°C -12 °C 0123

10 Type of building 1 light construction

2 medium construction

3 heavy construction

2 0123

11 Time for automatic exit OFF no

0,5...5 after set time

min Return to standard display

2 min 1234

12 24h cycle pump three way

valve

ON active

OFF inactive

ON 0123

13 Logical error messages OFF no display

ON Display active

OFF 0123

14 Automatic setting function OFF automatic error allocation

deactivated

ON automatic error allocation

activated

ON 0123

PARA

RESET

Resetting the parameter

settings

in dependence on access code only to

released parameters

GB

Page 27

GB-27

DHW level

This level contains all parameters which are necessary to program the DHW circuit with the

exception of the DHW time programs.

PARA-

METER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From

code

01

DHW economy temperature 10 °C ... DHW – normal temperature

20 °C

1234

02

DHW legionella protection day

OFF No legionella protection

Mo...Su Legionella protection on the specified

weekday

ALL Legionella protection every weekday

Mo

1234

03 DHW legionella protection -

time

00:00...23:50 o'clock

02:00

0123

04 DHW legionella protection -

temperature

10 °C ... DHW maximum temperature

65 °C

0123

05 DHW – signal source

1 DHW-sensor

2 DHW-thermostat (on/off)

1

0123

06 DHW- maximum temperature

limit

20 °C ... Heat generator temperature

65 °C 0123

07

DHW programs 1 Parallel operation

2 Priority operation

3 Limited priority

4 Weather dependent parallel

operation

5 Priority operation with intermediate

heating

6 Operation with circulation valve

(priority)

7 External operation

2

0123

08

DHW tank

cool down protection (only for

charge pump)

OFF - No cool down protection

ON - Cool down protection

activated

ON

0123

09

DHW-Tset temperature rise 0 ... 50 K;

Difference between DHW-Tset temperature

and DHW set temperature

15 K

0123

10

DHW Differential 2 ... 20 K;

Value of DHW differential, symmetrical to the

DHW set temperature

5 K

0123

11

DHW-charge pump 0 ... 60 min

5 min 0123

12

Program charge pump AUTO - Active DHW-time program

1 - Action with P1, unmixed circuit

2 - Active P2, unmixed circuit

3 - Active P3, unmixed circuit

4 - Active P1, mixed circuit 1

5 - Active P2, mixed circuit 1

6 - Active P3, mixed circuit 1

7 - Active P1, mixed circuit 2

8 - Active P2, mixed circuit 2

9 - Active P3, mixed circuit 2

10 - Active P1, DHW circuit

11 - Active P2, DHW circuit

12 - Active P3, DHW circuit

AUTO

0123

13

Charge pump-economy

interval (pause)

0 min ... Setting parameter 14;

duration of shutdown time of charge

pump)

5 min

0123

14

Charge pump-economy

interval (duration)

10... 60 min

Duration = shutdown time + operating time

20 min

0123

16

DHW basis temperature +10 – DHW max. °C

63

1234

GB

Page 28

GB-28

Level UNMIXED CIRC

MIXED CIRC 1

MIXED CIRC 2

This level contains all necessary parameters for the programming of the heating circuits (mixed or

unmixed) with the exception of the time programs.

Unmixed circuit (..2..) Mixed circuit 1 (..3..) Mixed circuit 2 (.0,33..)

PARA-

METER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From

code

01

Reduced operation ECO - Nightly shutdown

RED - Nightly set back

RED

1234

02

Heating curve exponent

1,00 ... 10,00

HC =1,30

MC =1,10

0123

03

Room sensor display OFF Temperature display

1 Room sensor display activated

2 Room sensor display activated,

thermostat operation blocked

3 Like OFF - with room

temperature display

1

1234

04

Room factor OFF 100% weather-dependent

10...500% Room factor (RS)

RC PI-room control + influence

Outside temperature (RS)

RC

1234

05

Heating curve adaptation OFF, ON

ON

1234

06

Inrush optimization OFF, 1 ... 8 h

1

1234

08

Room frost protection temperat

ure

5 ... 30 °C

10 °C

0123

09

Exceeding room temperature OFF, 1 ... 5 K

1

0123

10

Outside sensor allocation

(only for extra Mad outside

sensor)

0 Control according to mean value

BU 1 + BU 2

1 Control according to BU 1

2 Control according to BU 2

0

0123

11

Constant temperature 10 ... 95 °C;

Only if output is set to constant control

20 °C

0123

12

Minimum flow temperature 10 °C ... Set value maximum temperature

(parameter 13)

20 °C

0123

13

Maximum flow temperature Set value minimum temperature

(parameter 12) ... 95 °C

HC=85°C

MC=70° C

0123

14

Temperature rise

Tset

heating circuits

0 ... 20 K

HC=0

MC=4

0123

15

Pump after-run 0 ... 60 min

5 min

0123

16

Screed function

(only possible when DHW-supply

is switched off)

OFF switched off

1 heating: 3 days at 25°C, then 4

days at maximum flow

temperature

2 Heating: 1st day at 25°C, then

5K/day more up to max. flow

temperature, then 5K/day less

until 25°C

3 Heat as for 2 except 10 days

constantly on max. flow

temperature.

OFF

0123

17

1)

Maximum return flow

tempertaure Mad (..F..)

10 ... 90 °C

90 °C

0123

25

Set day temperature 5-30°C

21

1234

26

Set temperature night 5-30°C

16

1234

27

Heating curve slope

0,2 - 3,5

HC 1,75

MC1.5

1234

1)

only for mixed circuits

GB

Page 29

GB-29

DHW level (..2.. and no ..F..)

The parameters in this level refer to the mode of the corresponding heat generator and the

corresponding specific control functions.

PARA-

METER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From

code

01

Version of boiler type

OFF without heat generator

Stand-alone control unit

1 Oil/gas single stage

2 Oil/gas two-stage (..22..)

3 Oil/gas 2x single stage (..22..)

5 ATAG boiler control units

(..C..)

5

0123

03

Minimum temperature

5 °C

... Maximum temperature

5 °C 0123

04

Maximum temperature

Minimum temperature ... 95 °C

80 °C 0123

BUFFER level (..VV..)

The parameters in this level refer to the special settings for buffer control. The enabling

only occurs after a correpsonding activation in the HYDRAULIC level.

PARA-

METER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From code

01 Minimum temperature 5 °C ... Maximum temperature

20 °C

0123

02 Maximum temperature Minimum temperature ... 95 °C

80 °C

0123

03 Temperature rise Tset 0 ... 20 K 8 K 0123

04 Switching difference 1 ... 20 K 2 K 0123

05 Heat dissipation OFF

1 In extra buffer

2 In heating circuits

OFF 0123

06 Switching on difference (Switching off difference + 2 K) ... 30 K 10 K 0123

07 Switching off difference 1 K ... (Switching on difference -2 K) 5 K 0123

08 Starting protection OFF no starting protection

ON Starting protection active

ON 0123

09 Discharge protection OFF no discharge protection

ON Discharge protection active

ON 0123

10 Buffer program 1 Charging control for HC and DHW

2 Charging control for HC without

DHW

3 Discharging control for HC and

DHW

4 Discharging control for HC without

DHW

5 Charging control with changeover

DHW

6 Discharging control to the unit

1 0123

GB

Page 30

GB-30

CASCADE Level

The parameters in this level refer to cascaded boiler control unit in the network (e.g.

multiple boiler plants) and are only accessible in the first central control unit with bus

address 10.

PARAMETER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From code

01

Switching difference 6.0...30.0 K 8 K

0123

02

Switch-on delay 0..0.60 min

0 min

0123

03

Switch off delay 0..0.60 min

0 min

0123

04

Maximum capacity for

connection

10...100%

40%

0123

05

Boiler order OFF, 1...240 h 250

0123

06

Leading boiler 1...n

1

0123

DATA BUS Level

The parameters in this level exclusively refer to the parameters that are conntected tot he

data bus.

PARAMETER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From code

01

Bus address MadQ control

unit

10, 20, 30, 40, 50

10

0123

02 Bus rights RS HC

1 Janitor status

2 Tenent status

2

0123

03 Bus rights RS MC-1

3 Janitor status

4 Tenent status

2

0123

04 Bus rights RS MC-2

1 Janitor status

2 Tenent status

2

0123

RELAY TEST Level

In this level, the relays inside the control unit can be selected and their function checked

using the rotary pushbutton.

PARAMETER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From code

01 Test unit

On/Off

OFF

0123

02 Test pump unmixed circuit

OFF-ON-OFF-...

OFF

0123

03 Test mixed circuit pump 1

OFF-ON-OFF-...

OFF

0123

04 Test dwk-engine

mixed circuit 1

STOP-OPEN-STOP-CLOS-STOP...

STOP

0123

05

Test mixed circuit pump 2

OFF-ON-OFF-...

OFF

0123

06

Test dwk-engine

mixed circuit 2

STOP-OPEN-STOP-CLOS-STOP...

STOP

0123

07 Test charge pump OFF-ON-OFF-...

OFF

0123

08 Test variable output1 OFF-ON-OFF-...

OFF

0123

09 Test variable output 2 OFF-ON-OFF-...

OFF

0123

GB

Page 31

GB-31

ALARM MESSAGE Level

In this level up to five alarm messages can be stored, these are permanently updated.

PARAMETER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From code

01 Alarm 1 Last alarm message 0123

02 Alarm 2 Alarm message before last 0123

03 Alarm 3 Third to last alarm message 0123

04 Alarm 4 Fourth to last alarm message 0123

05

Alarm 5 Fifth to last alarm message 0123

SENSOR CALIBRATION Level

In this level all sensors connected to the central control unit can be corrected by ± 5 K with

respect to the factory settings.

PARAMETER

Designation Setting range / Setting values

Factory

setting

Individual

setting

From code

01 Outside temperature

adaptation

- 5 K ... +5 K

0

0123

02 No function

03 Compensation tank sensor

- 5 K ... +5 K

0

0123

04 Compensation flow sensor 1

- 5 K ... +5 K

0

0123

05

Compensation flow sensor 2 - 5 K ... +5 K

0

0123

06

No function

07

No function

08

Compensation variable input 1 - 5 K ... +5 K

0

0123

09

Compensation variable input 2 - 5 K ... +5 K

0

0123

10

Compensation variable input 3 - 5 K ... +5 K

0

0123

GB

Page 32

GB-32

Notes

GB

Page 33

I

Appendix

Appendix

Appendice

Appendice

Page 34

II

Voorbeeld 1

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 1

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 1

Important!

This is only a basic schematic – Do not use for installation!

Esempio 1

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 35

III

Regeling met MadQ 23BC inbouw met

1 Directe groep weersafhankelijk

1 Menggroep weersafhankelijk

A

Toestel

4

Buitenvoeler9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

C

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

1 unmixed circuit, weather controlled

1 mixed circuit, weather controlled

A

Unit

4

Outdoor sensor9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

C

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 36

IV

Voorbeeld 2

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 2

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 2

Important!

This is only a basic schematic – Do not use for installation!

Esempio 2

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 37

V

Regeling met MadQ 23BC inbouw met

Open verdeler

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

C

1

Ruimteregelaar6Pomp

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

Open distributor

1 unmixed circuit with room control

1 mixed circuit, weather controlled

A

Unit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

C

1

Room control unit6Pump

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 38

VI

Voorbeeld 3

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 3

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 3

Important!

This is only a basic schematic – Do not use for installation!

Esempio 3

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 39

VII

Regeling met MadQ 23BC inbouw met

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

1 Boiler

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

B3

Boilervoeler5Drieweg(meng)klep

C1

Ruimteregelaar

D1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

1 unmixed circuit with room control

1 mixed circuit, weather controlled

1 tank

AUnit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

B3

Tank sensor5Threeway (mix) valve

C1

Room control unit

D1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pumpe

Page 40

VIII

Voorbeeld 4

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 4

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 4

Important!

This is only a basic schematic – Do not use for installation!

Esempio 4

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 41

IX

Regeling met MadQ 23BC inbouw met

Open verdeler

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

1 Boiler

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

B

3

Boilervoeler5Drieweg(meng)klep

C

1

Ruimteregelaar6Pomp

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

Open distributor

1 unmixed circuit with room control

1 mixed circuit, weather controlled

1 tank

A

Unit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

B

3

Tank sensor5Threeway (mix) valve

C

1

Room control unit6Pump

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 42

X

Voorbeeld 5

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 5

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 5

Important!

This is only a basic schematic – Do not use for installation!

Esempio 5

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 43

XI

Regeling met MadQ 23BC inbouw met

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

1 Boiler

A

Toestel

0

Contactstrip4Buitenvoeler5Drieweg(meng)klep9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

B

3

Boilervoeler

C

1

Ruimteregelaar

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

1 unmixed circuit with room control

1 mixed circuit, weather controlled

1 tank

A

Unit

0

Terminal strip4Outdoor sensor5Threeway (mix) valve9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

B

3

Tank sensor

C

1

Room control unit

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 44

XII

Voorbeeld 6

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 6

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 6

Important!

This is only a basic schematic – Do not use for installation!

Esempio 6

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 45

XIII

Regeling met MadQ 23BC inbouw met

Open verdeler

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

1 Boiler

A

Toestel

0

Contactstrip4Buitenvoeler5Drieweg(meng)klep9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

B3

Boilervoeler

C1

Ruimteregelaar6Pomp

D1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

Open distributor

1 unmixed circuit with room control

1 mixed circuit, weather controlled

1 tank

A

Unit

0

Terminal strip4Outdoor sensor5Threeway (mix) valve9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

B3

Tank sensor

C1

Room control unit6Pump

D1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 46

XIV

Voorbeeld 7

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 7

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 7

Important!

This is only a basic schematic – Do not use for installation!

Esempio 7

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 47

XV

Regeling met MadQ 23BC inbouw met

Open verdeler

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

1 Boilerpomp

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar10Kabelboom C/M-regelaar

B

3

Boilervoeler6Pomp

C

1

Ruimteregelaar6Pomp

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with built-in Mad Q 23BC with

Open distributor

1 unmixed circuit with room control

1 mixed circuit, weather controlled

1 heating pump

A

Unit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit10Cable harness C/M-control unit

B

3

Tank sensor6Pump

C

1

Room control unit6Pump

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 48

XVI

Voorbeeld 8

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 8

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 8

Important!

This is only a basic schematic – Do not use for installation!

Esempio 8

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 49

XVII

Regeling met MadQ 23BC wandopbouw met

1 Directe groep weersafhankelijk

1 Menggroep weersafhankelijk

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar11Wandopbouwkast C/M-regelaar

C

1

Ruimteregelaar

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with Mad Q 23BC (wall-mounting) with

1 unmixed circuit, weather controlled

1 mixed circuit, weather controlled

A

Unit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit11Wall-mounting case C/M-control unit

C

1

Room control unit

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 50

XVIII

Voorbeeld 9

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 9

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 9

Important!

This is only a basic schematic – Do not use for installation!

Esempio 9

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 51

XIX

Regeling met MadQ 23BC wandopbouw met

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar11Wandopbouwkast C/M-regelaar

C

1

Ruimteregelaar

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with Mad Q 23BC (wall-mounting) with

1 unmixed circuit with room control

1 mixed circuit, weather controlled

A

Unit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit11Wall-mounting case C/M-control unit

C

1

Room control unit

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 52

XX

Voorbeeld 10

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 10

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 10

Important!

This is only a basic schematic – Do not use for installation!

Esempio 10

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 53

XXI

Regeling met MadQ 23BC wandopbouw met

Open verdeler

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

A

Toestel

0

Contactstrip4Buitenvoeler9Cascade-/menggroepregelaar11Wandopbouwkast C/M-regelaar

C

1

Ruimteregelaar6Pomp

D

1

Ruimteregelaar (optie)2Aanvoervoeler5Drieweg(meng)klep6Pomp

Control unit with Mad Q 23BC (wall-mounting) with

Open distributor

1 unmixed circuit with room control

1 mixed circuit, weather controlled

A

Unit

0

Terminal strip4Outdoor sensor9Cascade-/mixed circuit control unit11Wall-mounting case C/M-control unit

C

1

Room control unit6Pump

D

1

Room control unit (optional)2Flow sensor5Threeway (mix) valve6Pump

Page 54

XXII

Voorbeeld 11

Opgelet!

Alleen principiële schema – geen uitvoeringsplan!

Exemple 11

Attention !

Seulement schéma de principe -Pas de plan d'exécution !

Example 11

Important!

This is only a basic schematic – Do not use for installation!

Esempio 11

Attenzione!

Solo schema di massima - non è il disegno di esecuzione!

Page 55

XXIII

Regeling met MadQ 23BC wandopbouw met

Open verdeler

1 Directe groep met ruimteregeling

1 Menggroep weersafhankelijk

1 Boiler

A

Toestel

0

Contactstrip4Buitenvoeler5Drieweg(meng)klep9Cascade-/menggroepregelaar11Wandopbouwkast C/M-regelaar

B

3

Boilervoeler

C

1

Ruimteregelaar6Pomp

D

1