ASTRO

AstroJet 2000

High-Speed Inkjet Printer

Installation, Operating, and Parts Manual

REQUIREMENTS

1. An IBM or Compatible Pentium 100 Megahertz PC or better.

2. Windows 95 or 98 installed.

3. A minimum of 10 Megabytes of free hard disk space.

4. At least 16 Megabytes of RAM.

5. A 2X CD ROM or better.

6. An 800 X 600 SVGA Monitor or better.

7. Parallel (Centronics) printer cable, no longer than 6 feet.

8. The Parallel Port must be set to the EPP (Enhanced Parallel Port) setting in the

CMOS of the computer.

SAFETY PRECAUTIONS

THIS EQUIPMENT PRESENTS NO PROBLEM WHEN USED PROPERLY. HOWEVER, CERTAIN SAFETY

RULES SHOULD BE OBSERVED WHEN OPERATING THE ASTROJET 2000 SYSTEM.

BEFORE USING THE PRINTER, YOU SHOULD READ THIS MANUAL CAREFULLY AND FOLLOW THE

RECOMMENDED PROCEDURES, SAFETY WARNINGS, AND INSTRUCTIONS:

1. Keep hands, hair, and clothing clear of rollers and other moving parts.

2. Always turn off the machine before making adjustments, cleaning the machine, or performing any

maintenance not covered in this manual.

3. Turn power off, including conveyor when not in use.

4. Keep this manual with the printer for future reference.

5. If you have any questions contact your local Astro Machine Corporation Distributor.

CAUTION

THIS EQUIPMENT MUST BE CONNECTED TO

A PROPERLY GROUNDED OUTLET. FAILURE

TO DO SO CAN CAUSE ELECTRICAL SHOCK!

This manual is intended solely for the use and information of Astro Machine Corporation, its designated agents,

customers, and their employees. The information in this guide was obtained from several different sources that

are deemed reliable by all industry standards. To the best of our knowledge, that information is accurate in all

respects. However, neither Astro Machine Corporation nor any of its agents or employees shall be responsible

for any inac curacies contained herein.

Hewlett-Packard is a registered trademark of Hewlett-Packard Corporation.

Windows 95 and Windows 98 are registered trademarks of Microsoft Corporation.

IBM is a registered trademark of International Business Machines.

All other TradeMarks are the property of their respective holders.

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying, recording, or any information storage and retrieval system, without permission in writing from the Publisher.

TABLE OF CONTENTS

Section 1 – Introduction 1

Section 2 – Getting Acquainted 3

Components 3

Feeder Section 4

Printer Section 4

Key Pad Definitions 5

Operator Display Screen and Menu 7

Section 3 – Installation and Setup 9

Choose a Location 9

Install the Inkjet Cartridge 9

Plug in the AstroJet 2000 10

Setting up the AstroJet 2000 10

Install Software on the Computer 11

Section 4 – Operating the AstroJet 2000 13

Software Tutorial 13

Bundle and Bag Break 25

Running a Job 26

Printing Tips 28

Databases 29

Section 5 – Maintenance 33

The Inkjet Cartridge 33

Jams in the AstroJet 2000 Printer 36

Cleaning 36

Section 6 – Trouble Shooting Guide 39

Inkjet Cartridges 39

AstroJet 2000 Printer 40

AstroJet 2000 Software 41

Appendices 43

Specifications 43

Supplies and Optional Hardware 44

i

Notes

ii

Section 1 – Introduction

Section 1, Introduction, describes how this manual is arranged. The manual covers the

AstroJet 2000.

Section 2, Getting Acquainted, introduces the AstroJet 2000 System and describes the

major components, controls, indicators, and important areas with which the user or operator

should be familiar.

Section 3, Installation and Setup, describes how to install the software and get the

AstroJet 2000 System ready for printing.

Section 4, Operating the AstroJet 2000, describes how to set up the AstroJet 2000

System and Software to run a particular addressing job.

Section 5, Operator Maintenance, shows how to replace inkjet cartridges, how to safely

and quickly clear paper jams, and how to care for your AstroJet 2000. Also, covered in this

section are tips and suggestions that will help you increase efficiency and avoid problems.

Section 6, Trouble Shooting Guide; gives advice on how to remedy problems that may

occur during use of the AstroJet 2000.

Appendices, is where important but infrequently used information is presented. The

appendices are arranged as follows:

Appendix A, Specifications, lists the more important AstroJet 2000 characteristics,

e.g., electrical, physical, et c.

Appendix B, Supplies and Optional Hardware, presents a list of supplies for the

AstroJet 2000 System and optional equipment which will further enhance the

operation of the AstroJet 2000.

1

Notes

2

Section 2 – Getting Acquainted

The AstroJet 2000 is a high -speed printing and addressing systems that can print

addresses, bar code, return addresses, bitmapped graphics, and special messages using

TrueType scaleable fonts simultaneously on up to 30,000 postcard (3.5 X 5.5 inch) mail

pieces per hour. The AstroJet 2000 has its own built in top loading feeder.

Before getting into the operation of the AstroJet 2000, there is some basic information

necessary for its efficient and problem-free use.

To understand and operate the trouble free AstroJet 2000 System lets look at the two main

areas on the printer.

1. Components

2. Operator Display Screen and Menu

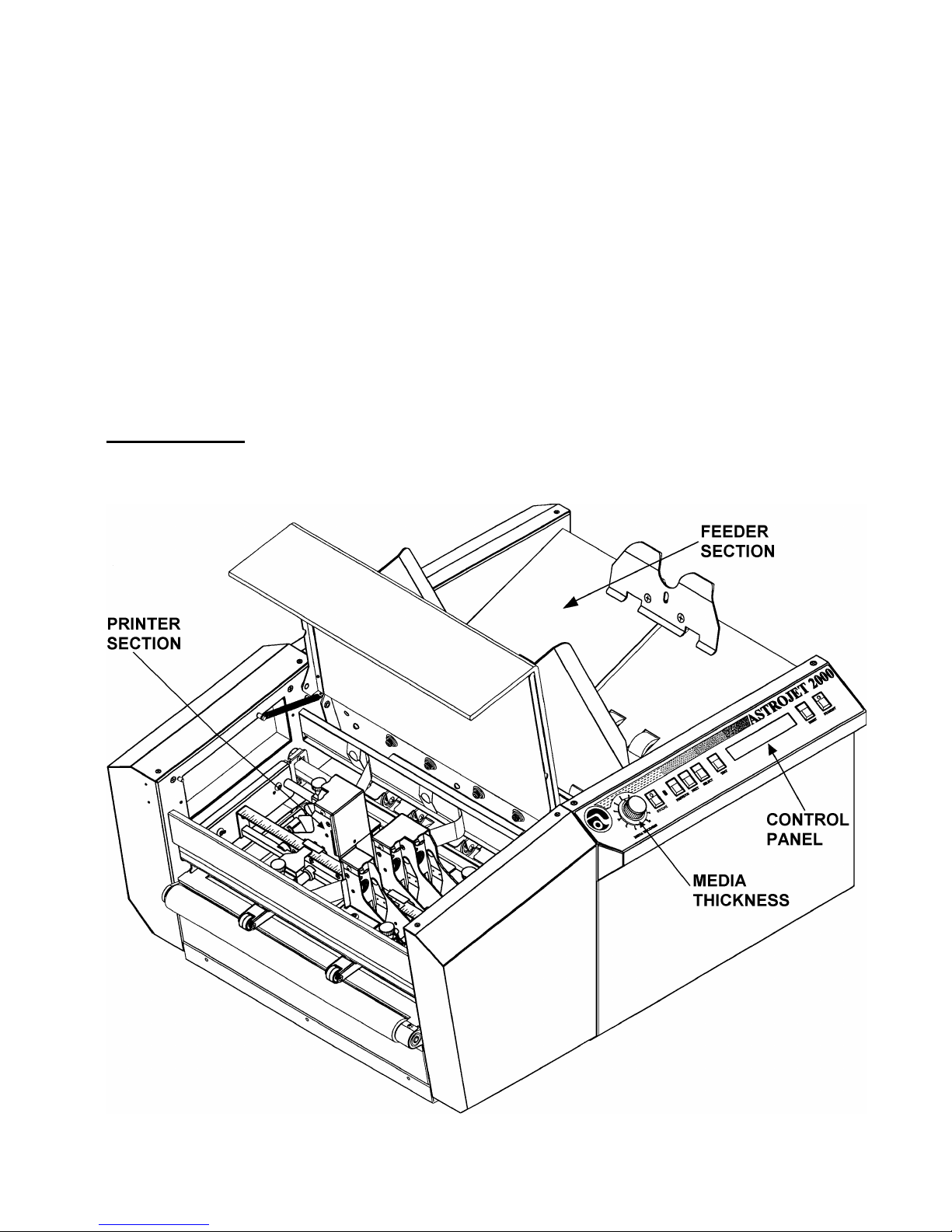

Components

The main areas of the AstroJet 2000 printer are shown in the following drawing. These

areas are described in the paragraphs that follow.

3

Feeder Section

The media to be printed and addressed is loaded into the feeder section of the AstroJet

2000. It is fed into the printer section as required at the speed selected by the operator from

the AstroJet 2000 Software Control Panel. The feeder is adjustable for a wide variety of

media.

Printer Section

The Printer is the most important part of the AstroJet 2000. It is here that the address and

other information are printed on the media. Two important features of the printer that you

should become familiar with are:

• The Control Panel

• The Medial Thickness Adjustment

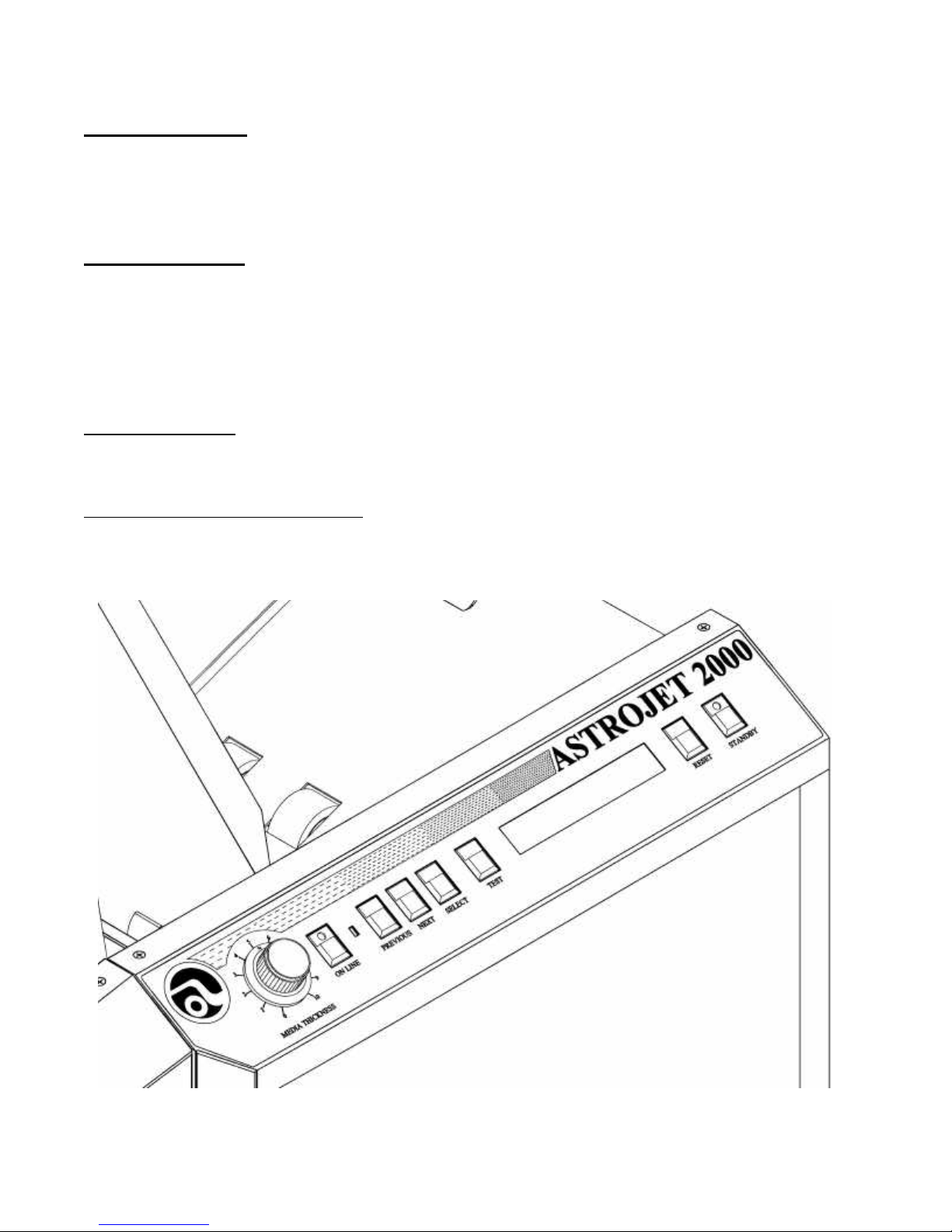

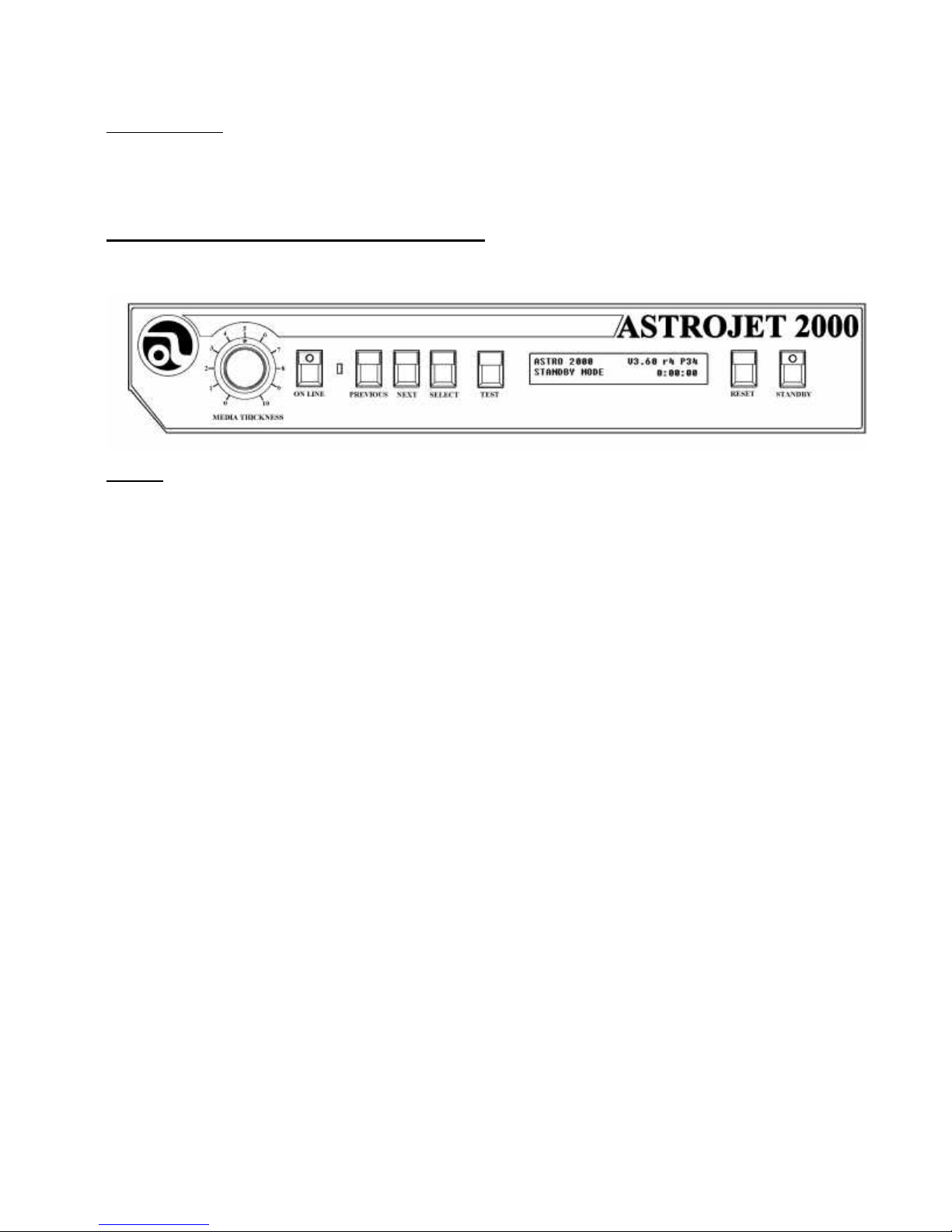

The Control Panel

The control panel is on the front of the printer and contains the controls and indicators

(described in the following table) used to set up and operate the AstroJet 2000.

The Media Thickness Adjustment

The Media Thickness Adjustment is to the left of the ON LINE button on the control panel. It

adjusts for media thickness and is turned counterclockwise for thin media, and clockwise for

thick media.

4

Keypad Definitions

CONTROL / INDICATOR DESCRIPTION

OPERATOR DISPLAY Indicates AstroJet 2000 status including menus

ON LINE When this indicator button is lit, the AstroJet 2000

PREVIOUS When in menu mode, will scroll to the previous

NEXT When in menu mode, will scroll to the previous

SELECT/FEED Locks and unlocks selection when in the menu

and error messages. Any display readout

indicates that the unit is ON.

is ready to accept data from your computer and

begin printing. Turns the printer on and off line.

selection. When in select mode, will scroll

through choices.

selection. When in select mode, will scroll

through choices.

mode. In the operational mode it starts and stops

the feeder.

TEST NON FUNCTIONING.

RESET NON FUNCTIONING.

STANDBY Toggles the printer between the ON LINE and

STANDBY modes.

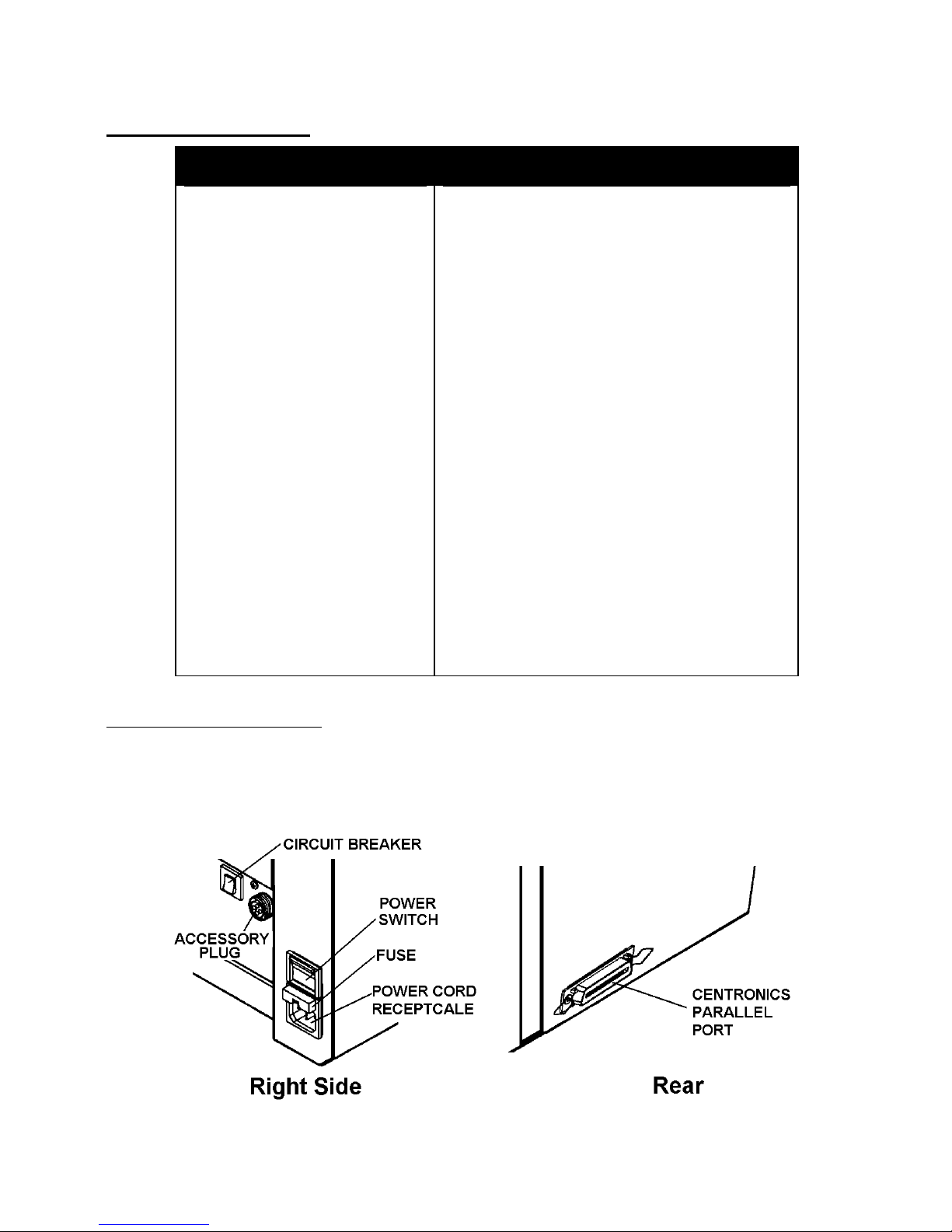

Interface and Power Panel

While facing the control panel of the AstroJet 2000, the power panel can be found on the

right of the machine. It contains the main power switch, fuse, power cord receptacle, circuit

breaker, an d accessory plug. At the rear of the printer you will find the Centronics parallel

port.

5

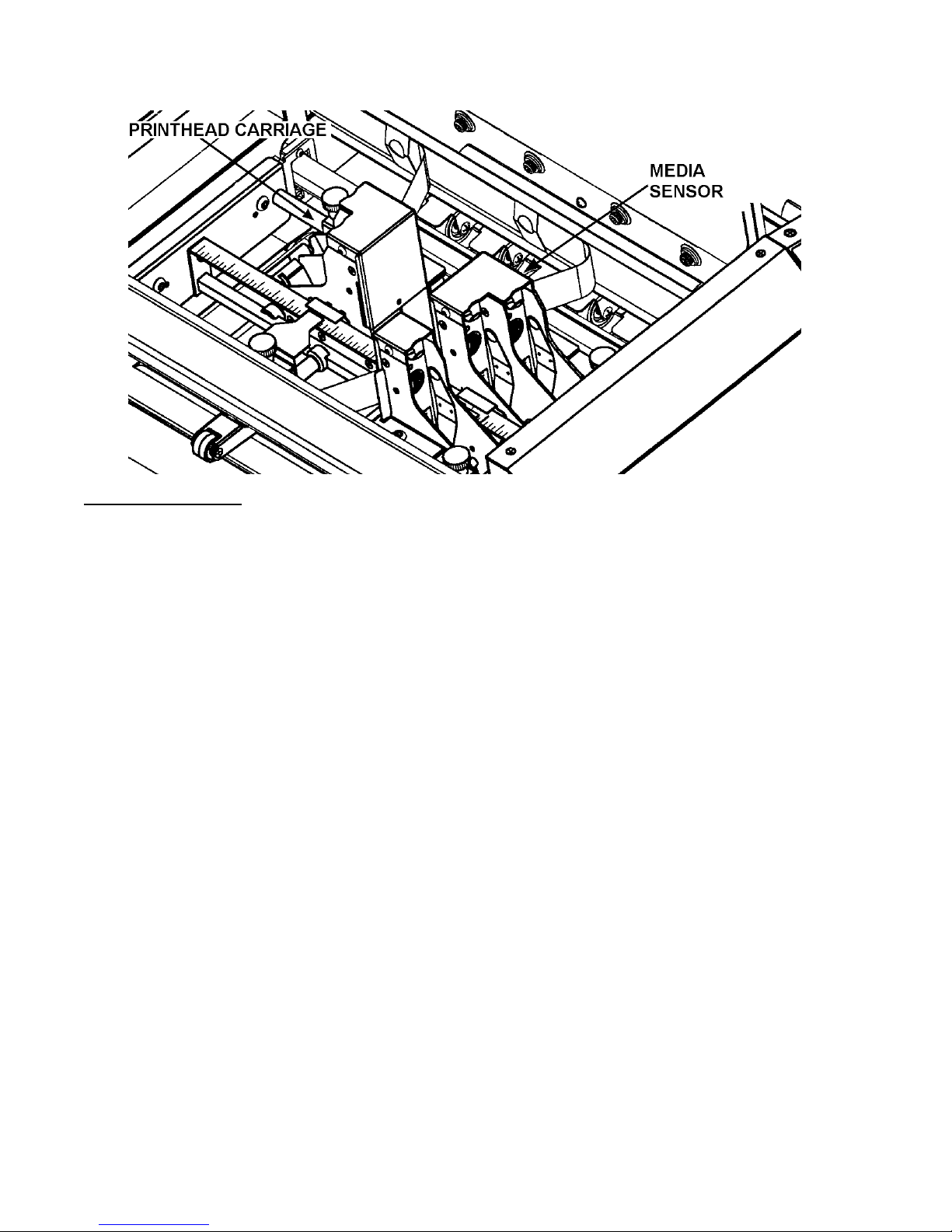

Printhead Carriage

The AstroJet 2000 has five printheads. The heads are arranged in the following

configuration:

Head 1 is on a separate rail and can be positioned between the other two banks of heads.

Heads 2 and 3 are banked together as are heads 4 and 5. These heads share the same

rail assembly.

The AstroJet 2000 Layout software shows the position of the heads and how they are

banked together. For more information on this feature, please check Section 4 Operating

the AstroJet 2000 or the AstroJet 2000 software help program.

You can move the various printing banks from side to side to position the information

properly on the media with the following restrictions:

Head 1 prints a band 1/2” wide and may be positioned anywhere within a range of 9-3/8” on

the media. It can be positioned next to and stitched to Head 2 or Head 4 to form a printing

band 1-1/2” wide. It should not be positioned next to Head 3 or Head 5, as the exit rollers

will cause tracking on the printing from those respective heads.

Heads 2 and 3 and Heads 4 and 5 form a continuous printing bank of 1” each. The

maximum distance that these two banks can be placed apart is 9-3/8”. The minimum

distance they can be placed with respect to each other is 1-3/4”. When the banks are

placed that distance from each other Head 1 can be placed between them. It is

recommended that Head 1 be placed as close to Head 4 under these circumstances if a 11/2” prin ting width is required.

A minimum of a 1/4” margin should be left at the top and bottom of the media to insure good

feeding and print quality. In addition a 1/4” margin should be left at the leading and trailing

edges of the media.

6

Media Sensor

The media sensor is located behind the front feed plate just before the printhead carriage. It

senses the leading edge of the media and communicates this to the software. It is very

important that the media sensor be kept clean.

Operator Display Screen and Menu

When you first turn on the AstroJet 2000, you see the AstroJet 2000 welcome screen, and

the STANDBY key is lit.

MENU

To access the Menu press the STANDBY key to put the printer in the on line mode and then

press the ON LINE key to take the print off line. This action will place the AstroJet 2000 in

the MENU mode and permit access to the following settings and adjustments:

• Left Margin Setting

• Purge

• Counter

• Print Speed

7

Notes

8

Section 3 – Installation and Setup

Before using the AstroJet 2000 Printer for the first time, the following procedures must be

performed:

• Choose a location for the AstroJet 2000 Printer

• Install the inkjet cartridges

• Plug in the AstroJet 2000

• Set up the AstroJet 2000

• Install the AstroJet 2000 software

• Set up the transport

• Adjust for media thickness

• Position the printed output on the media

Choose a Location

Ø The AstroJet 2000 should be attached to the computer with a parallel printer

cable not more than 6 feet in length.

Ø Use a grounded electrical outlet. DO NOT USE AN ADA PTER PLUG!

Ø Do not use outlets that are controlled by wall switches.

Ø Do not use an outlet that shares the same circuit with large electrical machines

or appliances.

Ø Protect the AstroJet 2000 from excessive heat, dust, and moisture – avoid

placing it in direct sunlight.

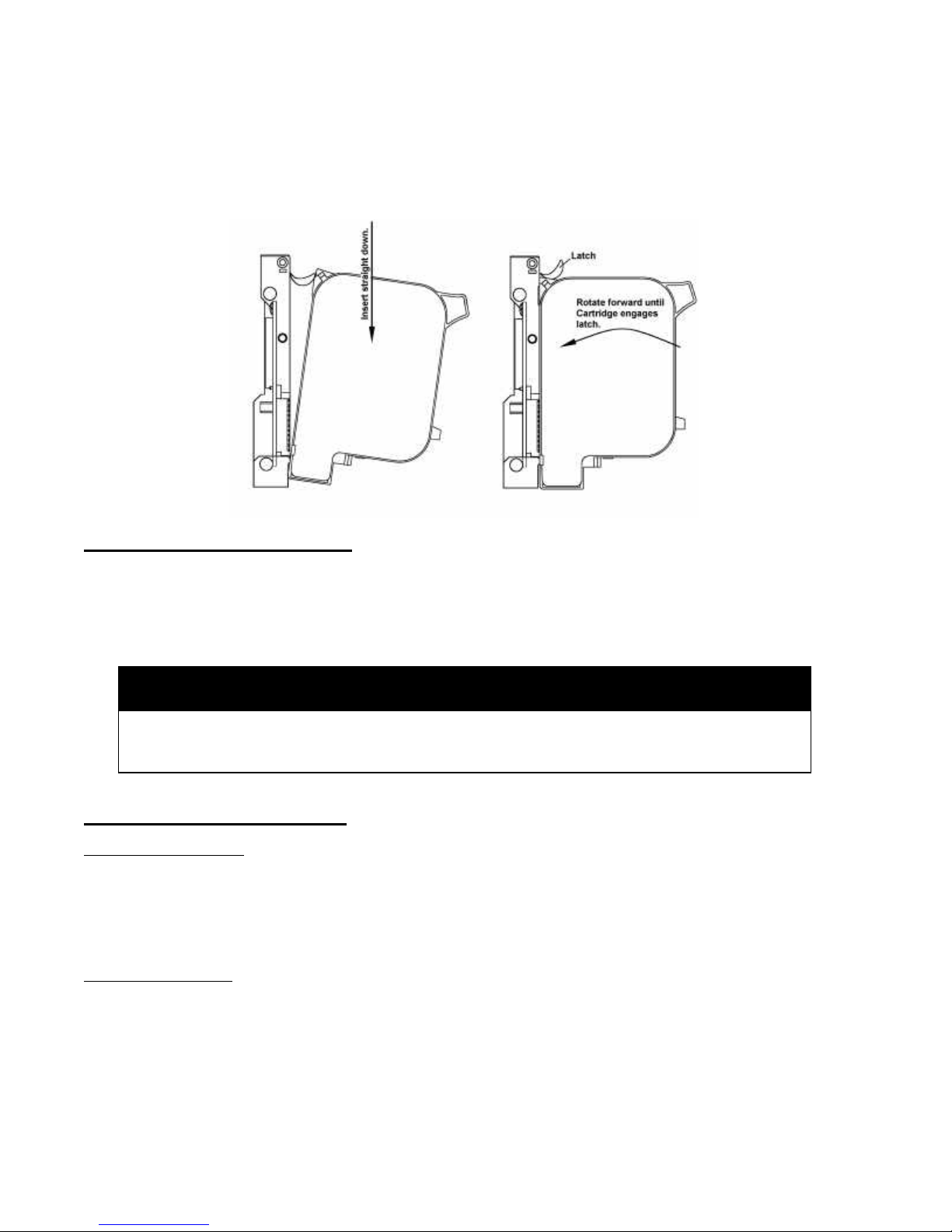

Install the Inkjet Cartridges

NOTE: For optimum image quality during the run, refer to Cleaning the Printhead on page

34.

HP 51645A Inkjet Cartridges

The AstroJet 2000 can be equipped with 5 inkjet cartridges to give a total printing area of 2

1/2 inches. The cartridges are installed as follows:

• Remove the inkjet cartridge from its packaging, taking care not to touch the

copper contacts, the metal plate, or the gold printhead. Remove the protective

tape from the printhead.

• The cartridges are held in place by vertical brackets mounted on the inkjet

cartridge holder.

• With the cartridge’s gold printhead pointing toward the rear of the unit and while

holding it vertically, slide the bottom edge of the cartridge down along the front of

the bracket until it slides partly into place.

9

• At this point press the upper part of the cartridge toward the bracket until it clicks

completely into place under the metal spring secured to the bracket. (See the

diagram below.)

• Repeat the above for the remaining cartridges.

Plug in the AstroJet 2000

Make sure that the main power switch of the AstroJet 2000 Printer is in the OFF position.

1. Connect one end of the power cord to the rear of the AstroJet 2000 in the

corresponding receptacle.

2. Plug the other end into a 120-Volt AC, 60 Hz. Grounded outlet.

CAUTION

DO NOT USE AN ADAPTER PLUG OR EXTENSION CORD TO CONNECT

THE ASTROJET 2000 PRINTER TO THE WALL RECEPTACLE!

Set up the AstroJet 2000

Connect the Printer

In order for your computer and the AstroJet 2000 to work toget her, you will need to connect

them with a parallel cable. The cable is connected between the parallel port on the

computer and the printer. The cable used to connect the AstroJet 2000 to the computer

must not exceed 6 feet long.

Set up the Feeder

NOTE: The AstroJet 2000 is supplied with two types of sheet separators. A soft tip which is

installed on the unit when you receive it is for use with standard 20 # paper and a hard tip

for thicker media. Refer to the drawing below for the location of the separator tips. To

change them release the separator-locking lever on the left side of the feeder and lower the

separators. Remove the screw attaching the tip to the separator. Remove the existing

10

separator and install the new one. Take care not to loose the mounting screw in the

machine.

The following steps will assist you in setting the feeder portion of the AstroJet 2000:

1. Place one piece of media on the feeder table move the side guides out to their extreme

open position. Release the separator-locking lever located on the left side of the feeder

and raise the separators to their up and locked position.

2. There are four separators on the feeder. Use the two center separators for narrow

media and the two end separators for wide media. Place the media under the

separators and lower the separators so that they rest on the media.

3. Move the locking lever up to lock the separators in place.

4. Adjust the side guides to the width of the media and set the back guide so that it just

touches the back of the media.

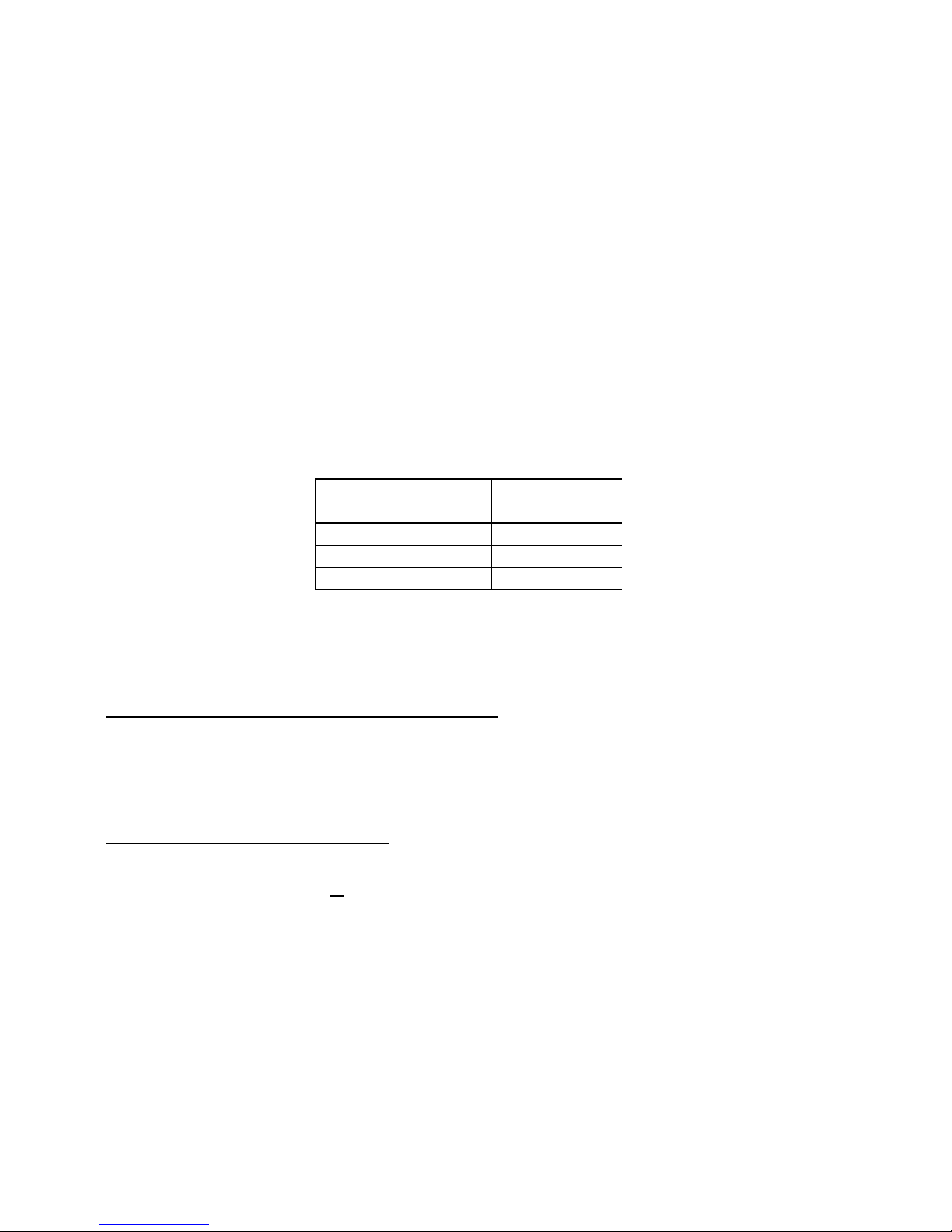

5. Turn the AstroJet 2000 on and then turn the media thickness knob to set the initial print

head height as follows:

Media Thickness Dial Setting

.004” to 1/32” 0 to 2

1/32” to 1/16” 2 to 3

1/16” to 1/8” 3 to 7

1/8” to 1/4” 7 to 10

NOTE: These are initial settings to check the media feed. It may be necessary to adjust

the MEDIA THICKNESS control to optimize the print quality

6. Press the STAND BY switch then press the SELECT/FEED switch, to test feed media.

Install the Software on the Computer

The computer that is supplied with your AstroJet 2000 System is optimized for efficient,

trouble free operation. It is equipped with a network card (10-base T) to enable you to

connect the AstroJet 2000 System to your existing network. Contact your system manager

or deal er for installation

AstroJet 2000 Software Installation

1. Install the CD in the computer. The CD should start automatically. If it does not click on

Start button, then select Run. Type “D:\Setup.exe” (where D is the CD drive) and click

OK.

2. The AstroJet Setup Menu will appear on your screen. It contains five options.

Install Printer Software

Read the Manuals

Browse this CD

Install Adobe Acrobat – This is version 4.0 of Adobe Acrobat for reading and printing

the Operator Manuals.

11

www.astromachine.com – This is a link to our web site if you are connected to the

Internet.

3. Click on “Install Printer Software” and then click on the AstroJet Printer model you wish

to install. Follow the instructions on screen. Use default settings only.

Note: If the message “Setup Can Not Execute the Following Program:

C:\ProgramFiles\Astrojet III\DeReg.exe” or ”The following file is in use and can not be

updated” appears, click on Cancel button and continue with the installation.

4. If this is a new printer installation (not a software update) skip #6. Your software and

firmware are installed and configured.

5. If this is software and firmware update you must download new bios to the printer.

Connect printer to the computer and turn it on. Open AstroJet Control Panel and click on

Advanced… button then Update BIOS button. Follow instructions on screen.

6. Be sure to fill out and mail registration sheet to insure that you will be notified of all

updates to the software and firmware.

12

Section 4 – Operating the AstroJet 2000

Once the AstroJet 2000 software has been installed on the computer and the AstroJet 2000

printer has been supplied with media and ink cartridges, it is ready to print. Using your

existing database, you create a Layout and Job files with the AstroJet 2000 software. The

computer sends the job to the AstroJet 2000 printer. The AstroJet 2000 then prints the Job

with both the addresses and other information you input in the layout.

This section explains how the AstroJet 2000 System is used and is divided into five main

categories:

• Software Tutorial

• Starting Up

• Preparing a Job

• Running a Job

• Printing Tips

Software Tutorial

Description of the Software

The following is a brief tutorial on how to use the AstroJet Printer Software. A more detailed

description of the various parts of the software may be found in the AstroJet “Help” menu

that accompanies the software. It is assumed that you have experience in navigating

through Windows. If you are new to computers or are not familiar with Windows many

books are available that can hel p you.

The software is divided into two parts, The AstroJet Layout Editor and the AstroJet Control

Panel. When the AstroJet Printer Software was loaded on the computer, the two icons

shown below were placed on the desktop.

The AstroJet III folder was placed in your Program Files. This is the place where all of the

AstroJet software resides. The AstroJet Layout Editor, AstroJet Control Panel and Help files

are located in this folder along with the AccuJet Data folder. The AccuJet Data folder

contains several additional folders. These folders contain all of the information required by

the AstroJet Printer Software to create and run the job. The file structure is illustrated below:

13

1 AstroJet III

1 AccuJet Data

0 Bios

0 Databases

0 Fonts

0 Jobs

0 Logos

0 Projects

The latest version of the system Bios is stored here.

This folder is used to store your databases.

When a job is printed from the AstroJet Control Panel

the fonts and logos used for that job are rendered in a

format that the AstroJet Image Bl aster Printer can use.

These rendered fonts and logos are stored in this folder

for future use when the job is run again.

The Jobs folder shows information about the job such as

total number of records, the template used to layout the

job, resolution, and last record processed.

The Logos folder can be used to store any logos in

Windows .BMP format that are used with the job.

This folder stores all of the information necessary for the

software to format and run the job.

The AstroJet Layout Editor is used to create the job. The AstroJet Control Panel is used to

send the job you created to the AstroJet Printer. All jobs are designed in the AstroJet Layout

Editor. This is where we will begin with this tutorial.

Starting the Software

Double click on the AstroJet Layout Editor icon to open the program and we will begin.

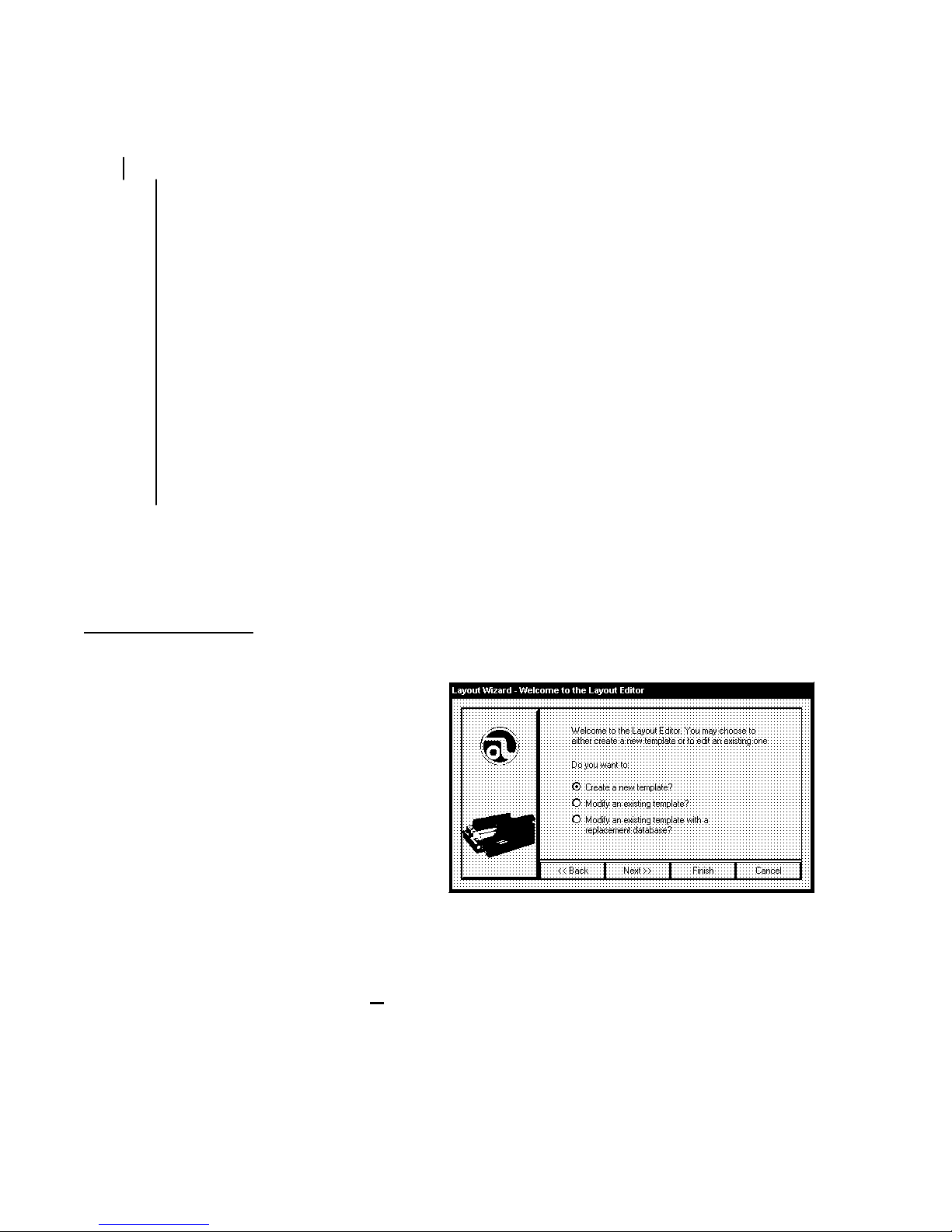

The first screen that appears is the

“Welcome to the AstroJet Layout Editor”

screen. There are three choices,

"Create a new template?", "Modify an

existing template?”, and “Modify an

existing template with a replacement

database?”. Click on the “Create a new

template?” and then click on the Next>>

button.

The “Layout Wizard – Select Database”

screen will appear. Click Next>> to

continue. The “Open” window is used to search and select the database. The

11 Databases folder in the AstroJet software is the default. You should store your

databases in this folder. Select the database type from the drop down menu. Next, select

the appropriate database and click Open to open the database. For more information on

databases and how to prepare them for the AstroJet refer to DATABASES at the end of this

section.

14

Move 1 Backward Move 1 Forward

Record Position Record Number

The Wizard will switch to the “Database View – (file name)”. The first record of the

database will be displayed. There is a series of arrows just below the record. These can be

used to step through the records as follows:

Move 10 Backward Move 10 Forward

Move 10X Backward Move 10X Forward

Move to First Record Move to Last Record

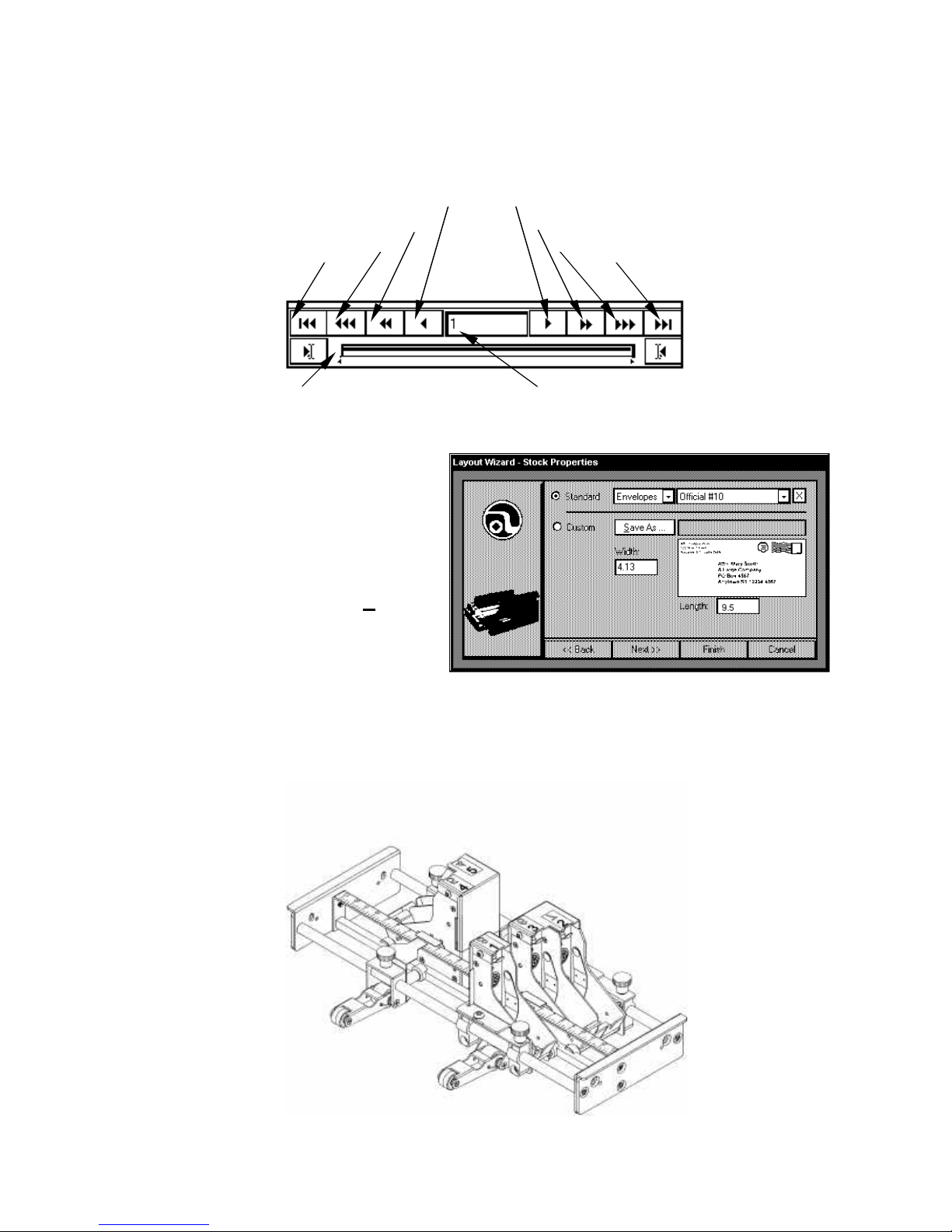

Click Next>> and the “Layout Wizard – Stock Properties” window will open. Select the size

and/or type of stock that y ou will be

printing on. There are many standard

envelopes available. Select one by

using the drop down menu next to

Standard or select Custom and enter

the Width and Length of the piece.

You may save the custom size by

giving it a name and clicking on Save

As…. When you have completed this

step, click Finish. The “Layout Editor

– Untitled” screen will appear.

When the software was installed on the computer, the printing banks were set up according

to the AstroJet 2000’s configuration. The white lines in the display represent the print

cartridges and how they are positioned in the printer. The AstroJet 2000 has five print

cartridges. The print cartridges are arranged on two sets of rails as follows:

15

Printhead 1 may be connected in the software to either to head 4 or head 2. This will permit

you to print up to 1.5 inch wide on the media. There are some restrictions as to the

placement of printhead 1, however due to the guide rollers in the printing section. If in doubt

run a test before beginning the job.

Before continuing, spend a little time exploring the “Layout Editor – Untitled” screen.

The AstroJet 2000 uses five

print heads. To eliminate the

unused heads, click on Setup,

then Print head. Click on the

boxes in the window for the

head positions that are not

used (heads 6, 7, and 8) and

de-select them. Then click OK.

The bands in the layout that

are remaining represent the

print heads on your particular

model of AstroJet Printer and

are properly banked together.

In the top line of the display, you see the following items:

File View Fields Setup Tools Help

16

Each of these controls a drop down menu that permit choices that perform the tasks

required to set up the job. The second line contains icons that represent those tasks. The

drop down menus duplicates the function of some of the icons. It really depends on how

you wish to use the software. For the purpose of this tutorial, we will use the icon buttons to

set up a sample job.

Setting up the Job

When you first opened the job you set the size of the piece. The piece size may be

changed at any time during or after the setup of the job by clicking on Setup and then

Envelope Size or by clicking on the Envelope Size icon on the menu bar.

Click on this icon and the Envelope Properties window will open. Select either

Standard or Custom. Press the OK button. If you choose Custom you may use any

number or fraction from 3 inches up to 15 inches in width and from 5 inches up to 17 inches

in length. When you press the OK button, the Layout screen will adjust the view of the

media to the size selected automatically. If you intend to use the Custom size again, save it

by giving it a name and clicking on Save As next to Custom. You must enter a name for

this feature to work.

Refer to the screen image on page 18. The corresponding print banks will show on the

screen in white. These banks can be moved together or separately in sets in the same way

that they can be changed on the printer. The maximum printing area on the Image Blaster

with 6 heads is 3 inches.

To the right of the template image are numbers. These correspond to the printheads and

are marked with the same numbers on the AstroJet Printer. Also, to the right is a line. This

guideline can be moved to any point on the layout to assist you in lining up the fields or

information that you will be adding. To get all of the information to line up on a particular

bank move the line close to the position desired for the lines and right click on the mouse

while the guideline is selected with the mouse pointer.

The next step is to build the job on the layout. When you click on the “Text Field

Properties” icon the “Layout Editor – Text Field Properties” window will open. This window

permits you to enable up to 24 lines of information and data with up to 4000 characters per

Text Field. Enable one button for each

line of type style in the layout. If you wish

to make additions, deletions, changes in

the style of type, or the number of lines,

you can click on this icon anytime during

the setup or before you run the job to

make changes. For the purposes of this

tutorial, we are going to enable the first 4

lines and set them up according to the

picture. Line 1 will be for the database

address. Line 2 will be for the company

name in the return address. Line 3 will be

for the rest of the return address. Line 4

will be for an additional message on the media.

17

After enabling the lines, select the style of font, size of type, and whether the type should be

bold, italicized, underlined or struck through . The down

arrow will permit you to access the other sixteen lines of

data that are available for use. Click OK to continue.

The software returns to the Layout Editor screen and the

data selected will be displayed at the bottom right hand

corner of the media layout called the blotter area. Use the

mouse to move each line into the general area of the

layout where they will be finally positioned. Once you

have done this, place the cursor on the field that will

contain the variable address from y our database and

double click on the left mouse button.

The following window will appear on the screen. This window allows you to layout the

variable address fields in their proper order.

Use the drop down box in the upper right hand corner of the window to add fields from your

database in their appropriate position in the layout. Click on the icon to eliminate blank

lines in the database. The icon will disable all the information in the layout. The

icon selects the standard barcode font and displays the information using a fixed default

font. The database may be setup in any format that conforms to a standard address.

Database fields may be combined on a particular line and punctuation and spaces may be

added. When finished click OK.

NOTE: The database Field may be edited at any time by double clicking on it.

To add a fixed return address to the media double click on the first line in the return

address. The following window will appear. Type the information as shown in that window.

Each line that uses a different type or style of type is entered by means of an Text Filed

Editor window. When you have completed the entry below click OK.

18

The next step is to enter the rest of the return address. Double click on the second line in

the return address area in the layout and enter the following in the “Text Field Editor – Field

3” window:

Once you click the OK button, the second line will appear as you typed it in the “Layout

Editor” window. To the right of the media

layout is a vertical lin e, you can drag this line

to the position where you want the

information from the two edits to line up and

then right click on the line. The lines will

then line up with each other.

The AstroJet Software has the flexibility to

allow you to add additional information to your layout in any position on it. For the purpose

of this tutorial, we will add the following line at the bottom of the layout:

19

You may add as many messages to the layout in any position on the media by simply

enabling an Address Line in the “Text Field

Properties” window and dragging the line

from the blotter area to the position you

would like to have it appear on the media.

Then double click on the line and enter the

information in the “Text Field Editor” window.

The Logo icon is used to add logos and graphics in .BMP format to your design.

When you click on the “Logo” icon or access it from the Fields drop box, under Logos, the

“Layout Editor-Logo Properties” window appears. You may add up to eight logos to the

layout. Each logo is selected by first

activating one of the Logo Enable

buttons and then typing in the file name

and location. You can also click on the

folder icon and browse for the desired

file. The default is the logo folder

located in the AstroJet software. Use

this folder to store logos.

The AstroJet is a 600-dpi printer. When

creating graphics or logos for use on the

AstroJet, 1” is equal to 600 pixels. A

logo or graphics that is 300 pixels tall will

print the width of a single print head or 1/2” high. If you wish to print a logo or graphic that

would span two or more banked printheads it

has to be taller than 300 pixels.

Once you have found the logo you wish to use,

click OK. The screen will return to the Layout

Editor and the logo will appear in the lower right

hand corner to the right of the media layout in

the blotter area. Use your mouse to place the

20

logo or graphic on the layout as illustrated. The logo can be edited with Windows paint by

double clicking on it.

Press this button to add the USPS bar code to the address. Press the number 1

Enable button and then select the Field where the bar code is located in the database.

Then press OK. The bar code

will appear in the lower right

hand corner of your screen just

below the layout in the blotter

area. Click and drag the bar

code to its position under the

address as shown.

IMPORTANT NOTE: The bar

code displayed in the Layout

Editor view is a representation of

the positioning of the bar code

on your layout. If you use the data base view

function in the Layout Editor, the bar code will

appear the same for each record. When the

record is printed on the AstroJet Printer the bar

code will be the correct one for each zip code in

the database.

You may also add a barcode with the “Layout

Editor”. This is used when the barcode

appears as a five plus four in one data field and a separate two-digit delivery point in

another field. Click on the Text Field Properties icon and Enable a font. Click OK. Drag

the field to a position under or over the address and double click on it. When the “Text Field

Editor” window opens, click on the barcode icon to select the “Astro USPS” font. Then

select the fields that contain the barcode information from the drop down box and combine

them on the same line without any spaces. Click OK and position the resulting image on

the layout.

The image will appear as follows: | ~FIELD_4~ | | ~FIELD_5~ | When in database view the

actual barcode for each address will display.

The actual database records can be viewed by clicking on the Template/Database View

icon. A set of arrow buttons will appear below the icons that will permit you to step through

the records or search for specific records..

Saving the Template

Now that you have designed the template using the layout editor, it is time to save it.

Click on File and select either Save Template or Save Template As… and the “Save As”

window will appear. You must give the template file a unique name with the extension

“.AJPJT” then click Save. The Template will be saved in the AstroJet Data 1Projects

folder.

21

Saving the Job

IMPORTANT: Before exiting the “Layout Editor” you must create a job so that the data

base and the layout can be

output on your printer. To

do this select, File and

then select New Job. The

“Layout Wizard – Select

Print Range” window will

appear. Click Next>> to

select “Database View –

(database name)“. At this

point, it is possible to

select a specific range of

records to be output. To

set the range select the

starting record that you

wish to use by using the database advance buttons. Click on the left (44 É) to choose the

starting record. Use the same buttons to step to the last record you wish to print and click

on the right button (É33 ) to set the end of the job.

Selection of specific records to print can be done anytime by following this procedure.

Always save the job to make the range changes permanent.

If you wish to print all of the database records then skip this step and click on Next>>. The

“Save As” window will appear. The default is the layout file name is displayed. Click save

to save it or enter a unique name for the job with the “.AJJOB” extension and click Save.

The template and the job that have been created are now ready to be printed. Close the

layout window by clicking File and then Exit.

Running the Job

Before running the job make sure that the AstroJet Printer is turned on and properly

connected to the computer.

There are two ways that a job can be selected to be run. One is from the AstroJet Control

Panel button in the “Layout Editor”. The other is from the “AstroJet Control Panel”

icon on the desktop of the computer.

For the purpose of this tutorial, double click on the “AstroJet Control Panel” icon on the

desktop. The following window will appear:

22

By clicking on the Open Folder 1 icon, the Load Job window will open. Choose the job you

just created and then click Load Job.

The database information will now display in the Control Panel. The arrows below the

database information can be used to step through the data. In addition, a Search ,

Search next , and Jump buttons are available to help you find a specific record

23

in the database. Simply click on the search or jump button and fill in the requested

information. The following is a list and description of each search variable:

Variable Default Description

Search For Must be filled

in.

Case Sensitive 0 Specifies whether upper and lower case characters should be

Search direction All 0 Specifies a search the entire database. Non-zero value forces

Search Direction

Forward

Look In (All Fields) Specifies the field the search will look in to. The value string

Limit search to: 0 Specifies the maximum number of records to search. “0” is

0 Specifies the direction of the search, either forward or

This field specifies the criteria the search must find. It can be

a complete or partial, word or phrase. If it is Case Sensitive ,

check the box in the Options and make sure that the Search

For is precise. If the criteria are in a specific field in the

database it can be specified in the Look In box.

treated as identical in searches. Non-zero value specifies

searches are sensitive to the case of letters. 0 calls for case

insensitive searches.

searches of the entire database in the forward direction,

proceeding from the first record to the last. A “0” value in the

Limit causes a directional search from the current position

base on Search Forward, and Search Limit.

backward. A number in Limit specifies forward searches, “0”

specifies backward. Not used when Search All is set to a nonzero value.

must be a valid field name for the database in use, or (All

Fields). If the Look In value doesn’t match a valid field name

(All Fields) is used instead.

implied to mean the number of records from the current

position to the end of the database in the specified direction.

Not used Search All is set to a non-zero value.

Template “ ” The last search template specified. This is the default pattern

to be searched for.

NOTE: The icon is used to search for the next record. The arrow in the icon shows

the direction that the search is moving through the database. When the last record is found

that meets the criteria in the search the “Control Panel – Search” window will reappear.

24

1 2 3 4 5 6 7 8 9 10 11 12

A description of the Control Panel controls follows:

13 14 15 16 17 18 19 20

1. Name of the Job file. 11. This button will print one piece for setup.

2. Current database record. 12. This button will open the Layout Editor.

3. These buttons and the ones to the right are

used to step through the database.

4. Search is used to find a record that contains

specific information.

5. Continue searching for the same specific

information.

6. Jump to a specific record by number. 16. The total number of records in the current

7. The 11 is used to open the job file to be used. 17. The status of the printer is displayed here.

8. The üü verifies the integrity of the database. 18. This is the number of the first record in the

9. STOP will pause the printing process 19. This is the number of the last record in the

10. GO is used to start printing the job 20. These buttons control the resolution of the

13. This area shows the status of the download

process.

14. The number of the current record is displayed

here.

15. The number of records in the printer buffer is

displayed here.

database is displayed here.

database selected for printing.

database selected for printing.

printed image.

25

NOTE: When the job is running the display in the lower right hand corner of the Control

Panel will tell you the speed of the printer in Inches Per Second (ips) and the approximate

number of pieces being processed per hour. This only displays when the Printer is

connected and printing pieces.

Bundle and Bag Breaks

A Bundle and a Bag Break feature are available in the AstroJet Control Panel Software.

This feature will permit you to stop the AstroJet printer in order to separate the pieces

according to USPS regulations. The various mail management software available for

presorting have the ability to prepare your database to conform to Post Office regulations.

We will not go into this part of the presorting, but we do suggest that you become familiar

with the software you are using to presort your database. The USPS provides a wealth of

information on their presorting regulations. Some of these are:

1. “Domestic Mail Manual” (DMM), published by the USPS and available by

subscription by calling (202) 783-3238.

2. “Postal Bulletin” which provides corrections and additions to the DMM on a

regular basis. You can subscribe to this by calling (202) 512-1800.

3. There are also several informative, free booklets available from your local Post

Office and the USPS on the subject of preparation of presorted mail.

4. Much useful information can also be obtained from the USPS web site at

www.usps.com.

The bundle and bag break windows can be found under the Advanced… button on the

Control Panel. When you click on this button the “Control Panel – Advanced Settings”

window will appear. At the bottom of the window there are two buttons, Bag Break and

Bundle Break. The functions of these buttons are similar. They are provided to permit you

to separate bags of mail and bundles in the same job. You can use either or both of these

to separate the pieces.

To use this feature you must first put a non -alpha or numeric character in your database,

either in one of the existing fields or create a field for the character. You may use any

character except the tilde (~). All presorting software is capable of preparing your database

in this way. For example we used (*) for bag break and (##) for bundle break.

26

Once you have loaded your job in the control panel, select Advanced…, then select Bag

Break, the above window will appear. You can enable these functions by clicking on the

Enable Breaks to select it.

Select the field where the break character was placed in the database. If you used a

character other than the (*) place that in the Break Sequence block, then select pieces for

the break in the Break Delay block. The printer will stop at the break. Then click OK.

If you require a Bundle Break repeat the above sequence, but use a different character or

field to designate this function. Remember you can not use any alpha or numeric character

or the tilde (~) for this function.

Start the printing process by clicking the GO button. When the AstroJet Control Panel

software reaches a break character the printer will stop feeding. To restart the printing

process press SELECT on the control panel.

Running a Job

Setting up the Feeder

The following steps will assist you in setting the feeder portion of the AstroJet 2000:

1. Place one piece of media on the feeder table. Move the side guides out to their extreme

open position. Release the separator-locking lever located on the left side of the feeder

and raise the separators to their up and locked position.

2. There are four separators on the feeder. Use the two center separators for narrow

media and the two end separators for wide media. Place the media under the

separators and lower the separators so that they rest on the media.

NOTE: Two types of separator tips are packaged with the AstroJet 2000. The set that is

installed on the unit was designed for all types of media from single sheets of paper to

booklets and carries the part number 90-103-09S. The second set is made from a

harder material and can be used for all media except single sheets of paper. It has a

part number of 90-103-09,

3. Move the locking lever up to lock the separators.

4. Adjust the side guides to the width of the media and set the back guide so that it just

touches the back of the media.

5. Turn the AstroJet 2000 on and then turn the medial thickness knob to set the initial print

head height as follows:

Media Thickness Dial Setting

.004” to 1/32” 0 to 2

1/32” to 1/16” 2 to 3

1/16” to 1/8” 3 to 7

1/8” to 1/4” 7 to 10

Starting Up the AstroJet 2000

It is a good idea to Purge the printheads before beginning to run a job. This can be done

from the AstroJet 2000 LCD Display Panel. Press STANDBY, then ON LINE to put the

AstroJet 2000 in the menu mode. Then using the NEXT or PREVIOUS buttons scroll to

27

PURGE: then press the SELECT button. Allow the AstroJet 2000 to run a few pieces then

press SELECT again to stop the purge. Check that the pattern run on the media is even,

without any blank areas or white streaks. If the pattern is OK, then return the AstroJet to the

standby mode by pressing the STANDBY button. Anytime the AstroJet 2000 sits idle for a

while the purge routine should be run before running the job.

Printing the Job

Click on the GO button to begin the job. The AstroJet 2000 will begin by rendering the fonts

and logos and storing them in the Fonts folder. Depending on the complexity of the page

this process takes only a few minutes. Once a font or logo is rendered, the AstroJet 2000

can call it up from this folder for reuse the next time a job that uses that particular type or

type style is run.

Monitoring the Job

The AstroJet 2000 can be stopped by pressing the SELECT/PRINT key or by clicking on

STOP in the Control Panel software without affecting the job. The printer will resume

printing at exactly the same point when it is back on -line.

NOTE: THE ASTROJET 2000 MUST BE OFF-LINE FOR THE FOLLOWING SETTINGS

TO BE CHANGED.

Checking the Piece Counter

To check the number of pieces run proceed as follows:

1. Turn the printer off-line.

2. Use the PREVIOUS or NEXT key to bring COUNTERS to the top line.

3. Press the SELECT key, the asterisk will disappear and MACH CYCLES with a number

will appear.

4. To reset this to “0” turn the machine off and then on.

5. To continue press the SELECT the asterisks will reappear.

Setting Print Resolution

To set or change the Print Speed:

1. Turn the Printer off-line.

2. Use the PREVIOUS or NEXT button to bring PRINT SPEED to the top line in the display.

3. Press the SELECT key, the asterisk will disappear.

4. Use the PREVIOUS or NEXT key to select the desired speed LOW, MEDIUM, or HIGH.

NOTE: If Standard resolution is selected there will be two speed choices available STD and

HIGH. If Draft resolution is selected three speed choices will be available: LOW, STD, and

HIGH. In the HIGH-resolution mode only the LOW speed is available.

5. Press the SELECT key to lock in the selection. The asterisk will reappear.

28

Purge the Printheads

It is necessary to Purge the printheads, especially when the AstroJet 2000 has been idle for

a period of time:

1. Turn the printer off-line.

2. Load media into the feeder on the AstroJet 2000.

3. Use the PREVIOUS or NEXT key to bring PURGE to the top line of the display.

4. Press the SELECT key. The asterisk will disappear and the AstroJet 2000 will start to

feed media and purge the print heads.

5. Press SELECT again to stop the purge and return the AstroJet 2000 to STAND BY.

6. Check that there is a consistent pattern printed on the media. If not, repeat Step 4 and 5

until the pattern is consistent.

Setting Left Margin

To increase the gap at the lead edge of the piece:

1. Turn the printer off-line.

2. Use the PREVIOUS or NEXT key to bring LEFT MARGIN to the top line.

3. Press the SELECT key. The asterisk will disappear.

4. Use the PREVIOUS or NEXT key to select the desired left margin in 0.1-inch

increments.

5. Press the SELECT key to lock in the selection. The asterisk will reappear.

Printing Tips

Types of Media

The AstroJet 2000 will print on many types of mailing media, but some restrictions apply.

As with any other printing process, the texture of the media has a direct effect on both the

print quality and the ink drying time. It is best to test each new type of media to determine

performance level s before beginning the Job.

Since coated and plastic types of paper do not easily absorb ink, smearing may occur. Print

may appear fuzzy on very porous paper. Another cause of fuzzy printouts is excessive

buildup of dust within the machine, or a printhead is too far away from the media. Be aware,

that when printing in the High Quality mode, drying time for the ink is longer than in the

other modes. In addition, when humidity is high, drying time is increased.

Media Thickness

The AstroJet 2000 will handl e pieces up to 1/4” thick (0.250”). All folds must be crisp and

even.

29

CAUTION

DO NOT use stapled pieces in the AstroJet 2000.

DO NOT use paper- clipped pieces in the AstroJet 2000.

These methods of binding the mail piece will damage the printheads, affect print

quality, and may seriously damage your printer. The Astro Warranty Policy will

not cover components damaged through improper use.

The USPS does not accept this type of mail for its automated equipment.

Databases

The AstroJet 2000 System is capable of handling many types of databases. There are,

however, some limitations. To avoid problems we offer the following suggestions to help

you improve the operation of your AstroJet 2000 System.

Large ODBC Databases

Random accessed ODBC databases are not indexed on the first column. As a result the

performance of the printer may get slower and even stop when using very large databases.

To prevent this from occurring, the following actions can be taken before the database is

loaded into the AstroJet 2000 software:

1. The user can convert the ODBC database to a text database (*.CSV file) with the

Layout Editor, and then subsequently open the project with that alternate database.

The Layout Editor explicitly indexes text databases, so performance is not an issue

for these files. Note: the Layout Editor retains ODBC field names in the first record of

the *.CSV file, so when you select it later, you should check off that the “first record

contains field names”.

2. The ODBC database vendor should be encouraged to index their database (on the

first column ascending). The index may be packaged as part of the database file, or

as a separate index file – depending on the format of the database.

3. The users can index the database themselves. To do this, you will need a database

management program for the database type you have. For example to index an

Access database (*.mdb files) require Microsoft Access, and to index dbase III, IV

and V (*.dbf) use Microsoft FoxPro.

4. Use sufficiently small ODBC databases that this effect doesn’t affect printing.

If the database has been saved in the ODBC format there are additional safeguards that

have been added to the layout Editor and Control Panel to warn you and offer a means of

changing the database and improving the performance of the system. The following

solutions have been programmed into the AstroJet 2000 software:

1. The Layout Wizard generates a warning when an ODBC database has been

selected. There is no way for the Layout Editor to determine if the database is

30

indexed, so the user is warned of the potential consequences of selecting an ODBC

database.

2. The ODBC to CSV converter was added to the Layout Editor, so users have a viable

alternative to using ODBC databases directly.

3. A timer has been placed in the Control Panel that mon itors ODBC reads. When

reading of a record exceeds a threshold, the Control Panel stops the job with a

timeout error.

Converting ODBC Databases to *.CSV (Comma Separated Value Format)

To convert an ODBC database to a Comma Separated Value file, use the fol lowing

procedure:

1. Create a new project, or open an existing project in the Layout Editor that uses the

ODBC database you wish to convert. For purposes of this discussion, the example

will be “MY SAMPLE.DBF”.

2. From the “File” menu select “Convert Database”.

3. A wizard is started which tells you the conversion is about to occur, and that it may

take awhile. It also tells you the converted database will be stored in your databases

folder, under the current name with .CSV tacked on the end. In example the output

would be “MY SAMPLE.DBF.CSV”.

4. Press “Next” to start the conversion, or “Cancel” to quit. If you start the conversion,

you will not be able to interrupt it – the process will continue until the conversion is

complete.

5. Exit and restart the Layout Editor. From the Startup Wizard select “Modify an existing

project with a replacement database”. Work through the wizard and select the

converted database, in this case “MY SAMPLE.DBF.CSV”.

6. You can ignore the warning about database structure, because in this case the

structure will be identical.

7. The wizard will ask about # of fields per record – leave it at 0, is the “First record is

used to record field names” – check this box, and delimiter information – leave the

defaults. Press “Next” or “Finish”.

Your project is now associated with the converted database. Access to any record in the

database should be almost instantaneous and the Control Panel should always provide

individual page information faster than the printer can supply stock.

Indexing a Microsoft Access *.MDB file

To index an Access database file for use with the Layout Editor and Control Panel you will

need Microsoft Access ’97 (or 2000). This should be installed on the target system to ensure

the same leave of ODBC is available to Access and the Layout Editor and Control Panel.

Then follow this procedure:

1. Start ACCESS and open the database file, (for example: “MY SAMPLE.MDB”.

2. Select the table to be used - here it is “MY SAMPLE”.

31

3. Click the “Design” button. A window displaying the characteristics of each field

(column) in the database is drawn.

4. Select the first row by clicking in the blank gray square to its left. This selects the

characteristics of first column.

5. At the bottom left click in the cell to the right of the heading “Allow Zero Length” to

display a drop down arrow, from which you will select “yes”.

6. Click the cell to the right of the heading “Indexed” to display a drop down arrow, from

which you select “Yes (Duplicates OK)”

7. Exit Access.

Indexing a dBase III, IV, V, FoxPro (*.DBF) File

To index a dBase file for use with the Layout Editor and Control Panel you will need

Microsoft FoxPro. This should be installed on the target system to ensure the same leave of

ODBC is available to Access and the Layout Editor and Control Panel. Then follow this

procedure:

1. Start FoxPro and open the database file, (for example: “SAMPLE.DBF”.

2. Select the table to be used - here it is “SAMPLE”.

3. If you are asked about the character set to use, select 1252 – Windows ANSI.

4. From the “View” menu select “Table Designer”. A tabbed dialog wills popup.

5. Select the “Fields” tab. Note the name of the first field. Select the Indexes tab.

6. In the cell under Name, type the name for your index. In this case “SAMPLE”.

7. Once this is entered other fields become available. Fill in the following fields:

A. Order – click to show an up arrow (ascending)

B. Type – select regular

C. Expression – enter the field name you noted above

D. Filter – leave blank

8. Click “Okay” and “Yes” to make structures permanent.

9. Exit FoxPro.

32

Section 5 – Maintenance

This section show s you how to care for and replace inkjet cartridges, clear paper jams, and

perform routine operator maintenance to the AstroJet 2000 Printer. Other problems such as

not printing, poor print quality, etc., are also covered. Special tips and suggestions to help

you increase efficiency and avoid problems are also included.

The Inkjet Cartridge

The AstroJet 2000 inkjet cartridges must be replaced when out of ink, when print quality is

poor, or when purging and cleaning have not helped the image quality.

The Approximate life of the HP 51645A Inkjet cartridges based on three lines of 20

characters at 10-point size per address is:

High Quality 50,000 addresses

Standard Quality 100,000 addresses

Draft Quality 200,000 addresses

NOTE: These figures can vary depending on the font selected.

To Replace the HP 51645A Inkjet Cartridge:

1. Remove the cartridge by pulling the top toward you until the cartridge is free from

the retaining latch. Lift the cartridge up and out of the holder.

2. Remove a new print cartridge from its packaging, taking care not to touch the

copper contacts, the metal plate, or the gold printhead. Remove the protective

tape from the printhead.

3. With the gold printhead pointing toward the rear of the unit, slide the bottom edge

of the cartridge down along the front of the bracket until it slides partly into place.

4. Press the upper part of the cartridge toward the bracket until it clicks into place

under the retaining clip of the bracket.

5. Repeat this procedure for each cartridge.

CAUTION

Never shake, drop, or hit the cartridge against the palm of your hand or any

other hard surface. Shaking the print cartridge does not “mix” the ink and

hitting the cartridge against a hard surface does not clear the nozzles Both of

these actions actually hurt the print quality because they allow bubbles to

form near the ink firing chambers. These bubbles prevent the nozzles from

firing causing white streaks in the print image.

Storage

Short-term storage is defined as less than 2 days or less than 1 day in a hot and dry

environment. Long-term storage is defined as more than 2 days or more than 1 day in a hot

and dry environment.

33

Short-term Storage

Long-term Storage

Disposal

Leave the cartridge in the AstroJet 2000 for short periods of time, 2 days or

less.

The next time that the AstroJet 2000 is used, the printhead may have to be

cleaned per the cleaning instructions, below.

HP 51645A

Keep the printhead in an area that is relatively free of dust and paper particles

that is not too dry

Place the cartridges in a Tupperware container with a damp sponge or towel

to maintain humidity and prevent the printhead from drying out.

When the cartridges are ready to be used again, the printhead will need to be

cleaned.

The cartridge may be disposed of in normal manner.

If there should be an ink spill, use soap and water to clean up any problem

areas. Abrasive soap also works well to get the ink off of hands.

Cleaning the Printhead

In order to achieve good print output; maintenance of the printhead is required. Paper fibers

and dust can build up on the printhead degrading the print quality. Proper printhead

maintenance will allow the cartridge to produce good print quality its whole life. A cotton

Tex Wipe® and distilled water is one of the best ways to wipe ink and other build-up off of

the printhead. A Tex Wipe® is 100% cotton, high -density cloth with no chemical additives.

Something comparable is adequate to wipe the nozzles. A good choice of wipe would have

the following qualities:

Soft

Fiberless

No chemical additives

Moist with distilled water

A cloth should NOT be:

Abrasive

Dry

Made of small fibers that can be left behind on the cartridge’s nozzle plate

Never use the following to wipe the printhead:

Industrial paper towels – these cloths usually contain a high recycle content and are

abrasive

34

Toilet paper – this is usually not fiberless

Sponge – particles from the sponge can be left behind on the nozzle plate

The cloth must be soft so that it does not scratch the printhead. It should be fiberless

because small fibers on the cloth can be left behind and block the nozzles of the cartridge.

The cloth must be moist or it will scratch the printhead. Scratches on the printhead prevent

the ink from coming out of the nozzle straight. If the ink drops do not come out of the

nozzles straight they will not land on the paper in the proper place causing fuzzy text.

Distilled water is better than tap water because tap water contains an unmonitored amount

of minerals. During wiping, the water cleans out the nozzles and the fir ing chambers. A

small amount of water mixes with the ink in the chambers. Over time, the minerals in tap

water can leave behind deposits in the chambers that block it completely. A blocked

chamber will show up as a white streak in text or graphics.

The direction and force of the wipe is also important to note. During wiping, harmful

particles on the top of the printhead can be wiped into the nozzles if you are not careful.

The cartridges need to be wiped in a certain way to obtain optimal print quality .

It is important to wipe the cartridge nozzles in the direction of the nozzle rows for optimum

print quality. See below:

Purging the Nozzles

If the printhead sits inactive for a period of time, ink may dry in the nozzles. Printing may

not remove these “ink plugs” from the nozzles. White streaks will then show up in the

printed text or graphic. In order to obtain better print quality, this ink plugs need to be forced

out or purged. A Purge routine is built into the AstroJet 2000 Printer. It can be accessed

from the LCD panel on the AstroJet 2000 Printer. Refer to Section 4 – Operating the

AstroJet 2000, under Running a Job; Purge the Printheads. If this does not solve the

problem then proceed as follows:

1. Wipe the printhead with a wet cloth as described in Cleaning the Printhead above.

2. Perform the Purge routine from the AstroJet 2000 Printer LCD Display panel.

3. Wipe the printhead again with a moist cloth.

HP 51645A

35

NOTE: For more information refer to the Troubleshooting Print Heads in Section 6 –

Trouble Shoot ing Guide.

Jams in the AstroJet 2000 Printer

If a jam occurs, TURN THE ASTROJET 2000 OFF LINE. The missed addresses can be

recovered at the computer from the control panel by stepping back to the place in the job

where the jam occurred. No data will be lost.

Some possible reasons for jamming are:

1. Multiple pieces of media pass at once.

2. Damaged media, such a dog-eared (turn down corners).

3. Media that is not stiff enough may not be usable. Media that meets Postal

stiffness requirements for automated feeding is acceptable in the AstroJet 2000.

4. Envelopes that are caught under the flap of another envelope or stuck to one

another may cause jamming.

Removing Jammed Media

1. It may be necessary to move one or more of the printheads to gain access to the

jammed media. Take care in removing jammed media to prevent damage to the print

heads. All pieces of the jammed media must be removed from the feed path.

2. Use the control panel in the AstroJet 2000 Software to recover any lost addresses.

3. Restart the job by putting the AstroJet 2000 back ON LINE and resume printing by using

the GO button on the AstroJet 2000 Software Control Panel.

Cleaning

WARNING

THE ASTROJET 2000 PRINTER IS A PRECISION MACHINE THAT

SHOULD BE CLEANED REGULARLY TO INSURE MANY YEARS OF

SERVICE. BEFORE PERFORMING ANY MAINTENANCE DISCONNECT

THE MACHINE FROM ITS POWER SOURCE!

The AstroJet 2000 must be regularly cleaned of accumulated paper dust and ink.

Depending on the types of media that are run, paper dust may accumulate within the printer

and on the transport. To properly clean the AstroJet 2000, unplug it from the power

receptacle and remove the covers. Refer to the parts manual for this.

The internal areas are best cleaned with a vacuum that has a soft brush attachment to help

loosen the dust particles. Take care not to damage the PC Boards or electrical wiring.

The exterior of the machine may be cleaned with any standard household cleaner which is

non -abrasive and does not contain plastic harming solvents.

36

irectly on or into the AstroJet 2000 Printer.

CAUTION

Never spray or pour cleaners d

Excess liquid could harm electronic parts. Always dampen a rag with the

cleaner and apply it to the parts to be cleaned.

Cleaning the Media Sensor

Periodically check the media sensor located in the print carriage area of the printer section.

The sensor should be clean and free of accumulated paper dust. Use a vacuum with a soft

brush attachment or dry compressed air to remove the dust.

37

Notes

38

Section 6 – Trouble Shooting Guide

The follow ing trouble shooting guides are provided to assist you in solving any problems

that might occur with the AstroJet 2000 Printer or its software. We have tried to make them

as complete as possible. The best advice we can offer is to make sure that the system is

setup properly, plugged in, that it has an adequate supply of ink before attempting to trouble

shoot any problem.

Inkjet Cartridges

HP 51645A Print Cartridges

CONDITION PROBLEM SOLUTION

Cartridge will not print Sheet is blank even after it has

gone underneath cartridge(s).

White streaks in text or graphics

Black streaks around text

• Check to make sure the tape

is off the printhead

• Remove and reinsert the

cartridge into the carriage

holder

• Install a new print cartridge

• Re-insert the cartridge into

the carriage

• Wet wipe and purge the

cartridge (There are clogged

nozzles.)

• Clean interconnects

• Insert a new Print Cartridge

• Wet Wipe the cartridge

(There is ink buildup).

39

AstroJet 2000 Printer

PROBLEM REASON REMEDY

No communication Improper cabling

Unit not receiving power

Improper output (address information out of order, misfeeding,

etc.)

Extra lines; losing data Data base problem Check data in data base program

Not printing on media Media not positioned properly 1. Adjust print band vertically

Print too light or missing

character dots

Media jams Double feeding

Wrong interface settings

Static electricity

Dirty media sensor

Clogged or dirty printheads

Running out of ink

Media is curled or bent

Media is too thin

Use Proper cable (see Sect. 3)

Check plug connections, on/off

switch and fuse on back panel (see

Sect. 2)

Check software or data base on PC

Turn AstroJet 2000 of and on

Clean media sensor

2. Adjust media margin setting on

AstroJet 2000

Either purge or clean cartridges

Replace inkjet cartridges

Adjust feeder

Uncurl media

Media must be at least 0.008”

WARNING

DO NOT REMOVE THE SIDE COVERS OF THE ASTROJET 2000 PRINTER

THERE ARE HIGH VOLTAGES PRESENT BEHIND THE COVERS!

40

AstroJet 2000 Software

ERROR MESSAGE PROBLEM SOLUTION

Template File is Corrupt The AstroJet 2000 Control Panel

can not open the related .ajpjt

file.

Job Loading Failure A problem arises loading the job

file.

Re-open AstroJet 2000 Layout

Editor and attempt to open the

file.

Re-save the file and attempt to

open the AstroJet 2000 Control

Panel again.

If the file still will not open in the

AstroJet 2000 Layout editor,

restart the computer and try

again.

Try a backup or older copy of the

.ajpjt file

Click on Remove Job, if you

know the file is out of date and

no longer in use.

Click on Recreate Job to reopen the Layout Editor, then click

on the File Menu and select New

Job, select the print range and

Click on Next>> to continue.

Click Next>> again and then

save the job with a new name.

Click on Cancel to return to the

Control Panel and select another

job file.

Template View Warning Due to the design of the

database management software,

it is not possible to display

records simultaneously in the

Layout Editor and Control Panel.

New Fields missing from layout

screen

Fields not visible in blotter area

on Layout Screen.

41

When you click OK the Layout

Editor will switch automatically to

the Template View.

Caution: If an attempt is made

to switch to Database View in

the Layout Editor, a fatal error

will occur and any unsaved

information will be lost.

The line may be piled up on top

of each other. Click and drag the

first line into the appropriate

Printhead Area.

Open the Address Field property

sheet by right clicking on one of

the existing address lines or by

selecting Address from the Fields

Menu. Select OK. The fields

should re-appear in the blotter

area.

Software continued…

ERROR MESSAGE PROBLEM SOLUTION

New Fields missing from layout

screen. Continued…

Printing in Wrong Location on the

mailing piece

Printing Too High or Low Check image on layout screen.

Fields not visible in blotter area

on Layout Screen.

Printing too far to the Left or

Right.

Right click on one of the fields

that has already been positioned

and click OK on the field property

sheet an they should re-appear

Right click on one of the fields

that has already been positioned

and click OK on the field property

sheet an they should re-appear

Make sure that the size of the

mailing piece entered in the

Setup Menu is correct.

Make sure that the piece on the

Layout Screen looks EXACTLY

the way you want your piece to

look. Use the rulers to verify that

the fields are located the proper

number of inches form the

edges.

Adjust the left margin setting.

Check the product detection

sensor to verify that it is properly

aligned.

Adjust the paper guide, or

individual printheads on their

mounting brackets to adjust how

far from the bottom edge of a

piece the fields are printed.

42

Appendices

APPENDIX A – ASTROJET 2000 Specifications

The information (electrical and physical dimensions, etc.) on the AstroJet 2000 is presented

here for your reference. Specifications are subject to change without notice.

PRINT QUALITY

(Dots Per Inch)

PRINT SPEED

(Inches Per Second)

IMAGE AREA Total of 2 1/2 inches using five printheads

MEDIA SIZES Maximum 17” long x 13 1/2” wide up to 1/4“ thick

PRINT MECHANISM HP 51645A Inkjet Cartridge

NUMBER OF

CARTRIDGES

INKJET CARTRIDGE LIFE

(approximate)

GRAPHICS AND LOGOS Allows printing of Bitmapped graphics, logos, and pictures

High Quality 600 x 600 dpi

Standard Quality 600 x 300 dpi

Draft Quality 600 x 150 dpi

High Quality 20 ips

Standard Quality 35 ips

Draft Quality 60 ips

Minimum 5” long x 3” wide up to 1/4” thick

5 cartridges

Addressing: High Quality 1,050,000 characters

Standard Quality 2,100,000 characters

Draft Quality 4,200,000 characters

(five line address labels only, logos and other printing not included in

the above)

SOFTWARE AND FONTS Windows 98

All Windows True-Type fonts

PRINT COLORS Black , Fast Drying Black, Yellow, Red, Green, Blue

INK Water based requiring drying assistance for coated stock

OPERATOR DISPLAY

OPTIONS (LCD)

PC INTERFACE Centronics Parallel Cable

DIMENSIONS 17” H x 26” L x 21” W

ELECTRICAL 120 VAC, 60 Hz @ 0.75 Amps

WEIGHT 76 lbs. (34.6 kg.)

Counter, Print Resolution, Purge, Left Margin, BIOS Version

43

APPENDIX B - Supplies and Optional Hardware

The following supply items and optional hardware are available from your Astro Machine

Distributor:

Supplies

Black Inkjet Cartridge HP 51645A

Fast Drying Black Inkjet Cartridge HP 6195A

Yellow Inkjet Cartridge HPC6173A

Red Inkjet Cartridge HPC6168A

Green Inkjet Cartridge HPC6169A

Blue Inkjet Cartridge HPC6170A

Optional Hardware

Various Conveyors Available

44

ASTROJET 2000

PARTS CATALOG

45

46

Group 1 - Covers

47

KEY# PART NO DESCRIPTION QTY

1. 21-100-14 COVER, R/H 1

2. 21-100-20 P/H COVER WELDMENT & DECAL 1

3. 21-100-19 CLOSURE, REAR 1

4. 21-100-18 COVER, L/H 1

5. 21-100-26 COVER WELD, L/H 1

6. 21-108-01 COVER, TOP ASSY. 1

7. 97-100-65 CABLE BRACKET 1

8. 123-0928 SCREW, 4-40 1/2 PH BIND HD 2

9. 123-1323 SCREW, TRUSS HD 4-40 X 3/16 SS 8

10. 123-1158 SCREW, 4-40 X 3/16 UNDRCT SS 8

11. 123-0017 SCREW, 10-32 X 1/4 PH TRUSS HD 2

12. 21-108-08 SPACER 2

13. 123-0390 KNOB, SPEED CONTROL 1

14. 123-0612 SCREW, 6-32 X 1/4 PAN HD 6

15. 80-120-25 SPRING, JOGGER ROD 2

Group 1 Covers

48

Group 2 – Mechanical

49

KEY# PART NO DESCRIPTION QTY KEY# PART NO DESCRIPTION QTY

1. 21-100-05 FRAME, L/H SIDE 1 42. 21-130-06 ARM ASSY., R/H 1

2. 21-500-04 POWER INLET-GROUND 1 43. 21-132-01 ASSY., INTERMEDIATE ROLLER 1

3. 21-100-37 BRACKET, MOTOR 1 44. 21-130-08 BELT, CONVEYOR ENDLESS 10

4. 123-1332 TIMING BELT 40DP 250 GR 5/16" KEVLAR 1 45. 123-1331 TIMING BELT 40DP 75 GR 3/16" KEVLAR 2

5. 21-149-12 SHAFT, ECCENTRIC 2 46. 94-109-03 PULLEY, 26 GR 1

6. 94-123-15 PULLEY, 34 GROOVES 2 47. 123-0994 PULLEY, 40 DP 1

7. 21-100-29 BRACKET 2 48. 21-131-02 ASSY., DRIVE ROLLER 1

8. 94-124-14 ECCENTRIC CAM 4 49. 21-115-00 ASSY., PULL OUT ROLLER 1

9. 94-124-08 ECCENTRIC BLOCK SUB-ASSY. 4 50. 21-114-00 ASSY., FRONT FEED SHAFT 1

10. 123-1175 SCREW, SET 10-32x5/8 W/INSERT 4 51. 123-0873 BELT, 160XL037 BLACK 1

11. 123-0050 NUT, 10-32x5/16 HEX ZINC 4 52. 94-105-04 PULLEY ASSY., 16 GROOVES 1

12. 123-0701 SCREW, 10-32x3/16 PH TRUSS HD 4 53. 63-105-15 WASHER,.505ID,.703OD,.030THICK 1

13. 123-0275 SCREW, 6-32x1/4 OVAL CSK PH ZINC 28 54. 123-0934 BELT, 90XL037 BLACK NEOPRENE 2

14. 90-103-52 ASSY., BALL BEARING 14 55. 21-113-00 ASSY., MIDDLE FEED SHAFT 1

15. 123-0017 SCREW, 10-32x1/4 PH TRUSS HD 23 56. 21-113-03 ASSY, PULLEY 17 GR 1

16. 21-100-11 COVER, INSIDE 2 57. 123-0277 BELT, TIMING 110XL031U 1

17. 21-100-04 FRAME, R/H SIDE 1 58. 123-0573 BELT, 130XL043 BLACK 1

18. 123-0494 SCREW, 10-32x1/4 BTN HD SOC CAP 2 59. 21-111-00 ASSY., CLUTCH SHAFT 1

19. 123-0461 SCREW, 6-32x3/16 PH RND HD ZINC 13 60. 65-300-43 STUD, BRAKE 1

20. 123-1323 SCREW, TRUSS HD 4-40x3/16 SS 9 61. 123-0081 C-CLIP #5133-25 1

21. 123-0620 FOOT, RUBBER 4 62. 123-1340 SCREW, TRUSS HD 4-40x1/8 SS 1

22. 123-0612 SCREW, 6-32x1/4 PAN HD 16 63. 65-303-01 MOTOR PULLEY, 14 GROOVES ASSY. 1

23. 21-149-08 BAR, CROSS 1 64. 123-0298 SCREW, SET 10-24x3/16 SOC PT 1

24. 21-149-05 COVER, SENSOR 1 65. 21-112-00 ASSY., REAR FEED SHAFT 1

25. 123-1023 SCREW, 4-40x5/16 PANHEAD PH 6 66. 123-0064 WASHER, LOCK 1/4 MED SPLIT 7

26. 21-133-13 ENCODER BRACKET, WELDMENT 1 67. 123-0524 SCREW, 1/4-20x1/2 SOC CAP 7

27. 123-1135 SCREW, 6-32 X 1/4 PH TRUSS HD SS 4 68. 123-0063 WASHER, 1/4" PLAIN MOTOR & PUMP ZINC 3

28. 123-0127 SCREW, 6-32x1/8 PH PAN HD 2 69. 123-0706 PIN, DRIVE LOCK - 3/16x1/2 2

29. 123-0446 SCREW, 8-32x5/16 PH UNDRCUT SS 2 70. 21-500-14 ENCODER ASSY. 1

30. 21-100-06 BASE, MOTOR 1 71. 123-1111 PIN, GROOVE 5/32 x 3/8 4

31. 21-100-25 CLOSURE 1 72. 123-0036 ROLL PIN, 3/32 X 5/8 STEEL 1

32. 21-100-43 BRACKET, SENSOR 1 73. 123-0137 TIMING BELT, 70XL031 1

33. 123-1204 SCREW, 6-32x1/4 BTN HD SOC CAP 4 74. 123-0567A WASHER, 5/16 IDx.7ODx1/16 THICK ZINC 1

34. 123-0674 SCREW, 6-32x1/4 SOC HD BLK OXIDE 4 75. 21-112-05 PULLEY ASSY., 14 GR 1

35. 21-103-01 BELT SIDE GUIDE ASSY. 1 76. 71-122-06 PULLEY, 12XL GROOVES 1

36. 21-130-05 ARM ASSY., R/H 1 77. 21-116-00 MOTOR BRACKET ASSY. 1

37. 21-130-03 SUPPORT, BELT 1 78. 56-101-02 RUBBER FEED ROLLER ASSY. 8

38. 21-130-01 CENTER PLATE (SMALL) 1 79. 90-102-21 FEED ROLLER ASSY. 4

39. 123-0675 SCREW, 6-32x3/16 PH FH UNDRCUT SS 2 80. 90-102-21B FEED ROLLER ASSY. 4

40. 21-130-04 COVER 1 81. 123-0322 SCREW, SET 8-32 X 1/4 8

41. 21-133-01 ASSY., EXIT ROLLER 1 * ONLY FOR FIRST 20 UNITS

Group 2 – Mechanical

50

Group 3 – Feed Table

51

KEY# PART NO

DESCRIPTION

QTY

1. 21-100-07 CENTER PLATE WLED. 1

2. 21-100-32 SLIDER 1

3. 21-100-31 SLIDER 1

4. 123-1335 CURVED DISC SPRING GR1074 HC

1