Astor P5D Service Manual

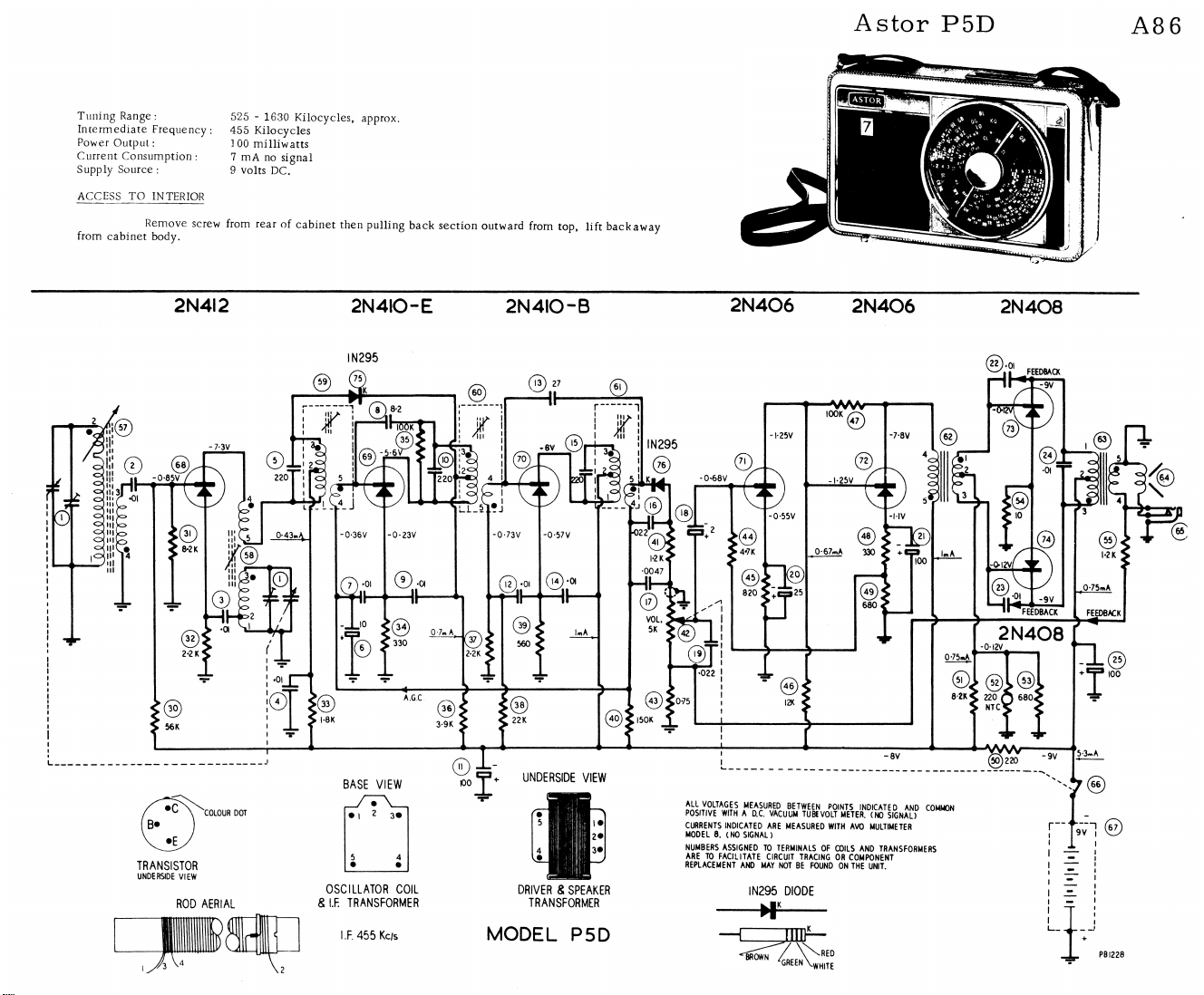

Asto r P5D

A86

Tuning Range:

Intermediate Frequency:

Power Outp ut:

Current Consumption :

Supply Source :

ACCESS TO INTERIOR

from cabinet body.

Remove screw from rear o f cabinet then pulling back section outward from top, lift back away

2N4I2

525 - 1630 Kilocycles, approx.

455 Kilocyc les

1 00 milliw atts

7 mA no signal

9 volts DC.

2N4IO-E 2N4IO-B

2N406

2N406

2N4Q8

©

TRANS IS TOR

UNDERSIDE VIEW

ROD AERIAL

I

COLOUR DOT

• 1 2 3 ·

5 4

• ·

OS CILLATOR COIL

& I.F. TRANS FORMER

I.F. 455 Kc/s

r n H n

4 Η · !· 3*

,· nuniiiii ,

DRIVER & SPEAKER

TRANSFORMER

MODEL P5D

CURRENTS INDICATED ARE MEASURED WITH AVO MULTIMETER

MODEL 8. (NO SIGNAL)

NUMBERS ASSIGNED TO TERMINALS OF COILS AND TRANSFORMERS

ARE TO FACILITATE CIRCUIT TRACING OR COMPONENT

REPLACEMENT AND MAY NOT BE FOUND ON THE UNIT.

IN295 DIODE

—HP

---

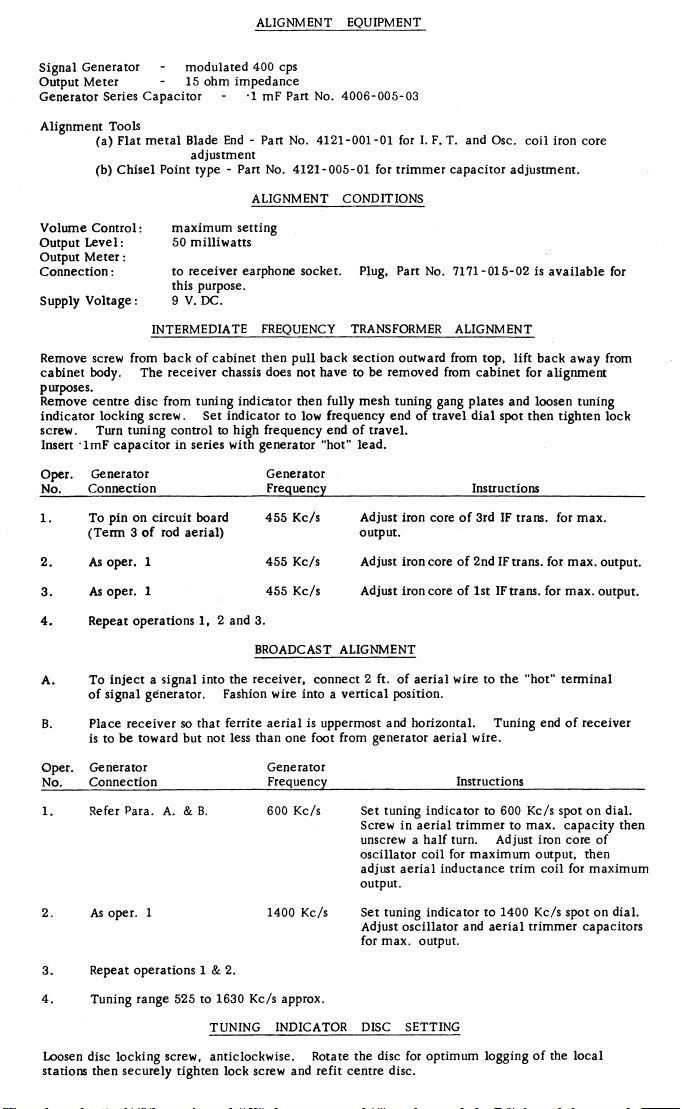

ALIGNMENT EQUIPMENT

Signal Generator - modulated 400 cps

Out put Meter - 15 ohm impedance

Generator Series Capac itor - ·1 mF Part No. 4006-005-03

Al ignment Tool s

(a ) Fla t m etal Blade End - Part No. 4121 -001-01 for I. F. T. and Osc. c oil iron co re

(b) Chisel Point type - Part No. 412 1-005-01 for t rimmer capacitor adjustment.

Volume Control:

Output Level:

Out put M eter:

C o nne cti o n :

Supply Vo lta g e:

Remove screw from back of cabinet then pull back se ctio n outwar d from top, lift back away from

cabinet body. The receiv er chassis does not have to be removed from cabinet for alignment

purposes.

Remove centre disc fro m tuning indicator then fully mesh tun ing gang plates and loo sen tuning

indicator locking screw . Set indicator to low frequency end o f travel dial sp ot then tighten loc k

scre w. Tur n tuning control to high frequency end of travel .

Insert lm F capacitor in series with generator "hot" lead.

Oper. Genera tor

No. Connection

To pin on c ircuit board

(T erm 3 o f rod aerial)

As oper. 1 455 Kc/s

2.

As oper. 1 455 Kc/s

3.

Rep eat operations 1, 2 and 3.

4.

To inject a signal into the receiver, connect 2 ft. of aeri al wire to th e "hot" ter m inal

A.

of si gnal generat or. Fashion wire into a vertical position.

Place receiver so that ferrite aeri al is uppermost and hori zontal. Tuni ng end o f receiver

is to be toward but not less than one foot from gene rator aerial wire.

Genera tor

Oper.

Connection

No.

Refer Para. A. & B.

As oper. 1

Repeat ope rations 1 & 2.

Tun ing range 525 to 1630 Kc/s approx.

Loosen disc locking screw, anticlockwise. Rotate the disc for optimum logging of the local

sta tions the n sec urel y tighten lock screw and refit centre disc .

adjustment

ALIGNMENT CONDITIONS

m axim um setting

50 milliwat ts

to receiver earphone socket. Plug, Part No. 7171-01 5-02 is avai lable for

this purpose.

9 V. DC.

INTERMEDIATE FREQUENCY TRANSFORMER ALIGNMENT

Generator

Frequency Instr uctions

455 Kc/s

BROADCAST ALIGNMENT

Generator

Freq uency Instruction s

600 Kc/s Set tuning indicat or to 600 Kc/s spot on dial.

1400 Kc/s Set tuning indica tor to 1400 Kc/s spot o n dial.

TUNING INDICATOR DISC SETTING

Adju st iron core o f 3rd IF trans. for max.

output.

Adjust ir on core of 2n d IF trans. for max. output.

Adjust iron core of 1st IF trans. for max. output.

Screw in aerial trimmer to max. capacity then

unscrew a h alf turn. Adjust iron core o f

oscillator coil for maxim um output , then

adj ust a erial inductance trim coil for maxi m um

ou tput.

Adjust oscillator and a erial trim mer capacitors

for ma x. output.

Loading...

Loading...