Astor P2A Service Manual

ASTOR ELECTRONICS PTY. LTD.

D I V I S ION OF ELEC TR O N IC IN D UST R IE S L T D , B O X 183, P.O. SO UTH M ELBO UR NE

Reg . Office: Asto r H o u s e, 161-173 S turt St., South Melbourne. Date: 14 / 8 / 1 9 64

ASTOR MODEL “P2A”

9 TRANSISTOR FOUR BAND PORTABLE RECEIVER

File: Receivers Portable

Page: 1

TUNING RANGE:

Int e rmed ia te

Frequency:

Power Output:

Current

Consum ptio n:

Power Source: 9 volts DC.

ACCESS TO INTERIOR

Loosen the ex t er n a l ae ri a l and e a r th screws at re ar of cab in et .

Pull lower ed g e o f c a b in e t ba c k outw ard and downward from ca b i ne t body.

SERIAL NUMBER

Remove c a b in e t b a c k and r e m o v e batt er ies . N um b er is sta m pe d into me t a l chassis a d j a ce n t

to te le s c op i c whip ae r ia l .

Info rm a ti on co nt a in ed he re in mu st not be re pro duc ed w ith o ut prio r writ te n permi ssio n from

Astor Elec tron ics Pty. Ltd.

Broadcast Band

SW1 Band

SW2 Band

SW3 Band

455 Kil oc yc le s

500 M illi w atts

11 mA . , no signal

525 - 1605 K iloc yc les

I. 6 - 4 . 4 M e g ac y cle s

4 . 4 - 11 . 4 M eg ac yc le s

II .4 - 1 8 . 2 M eg ac y cle s

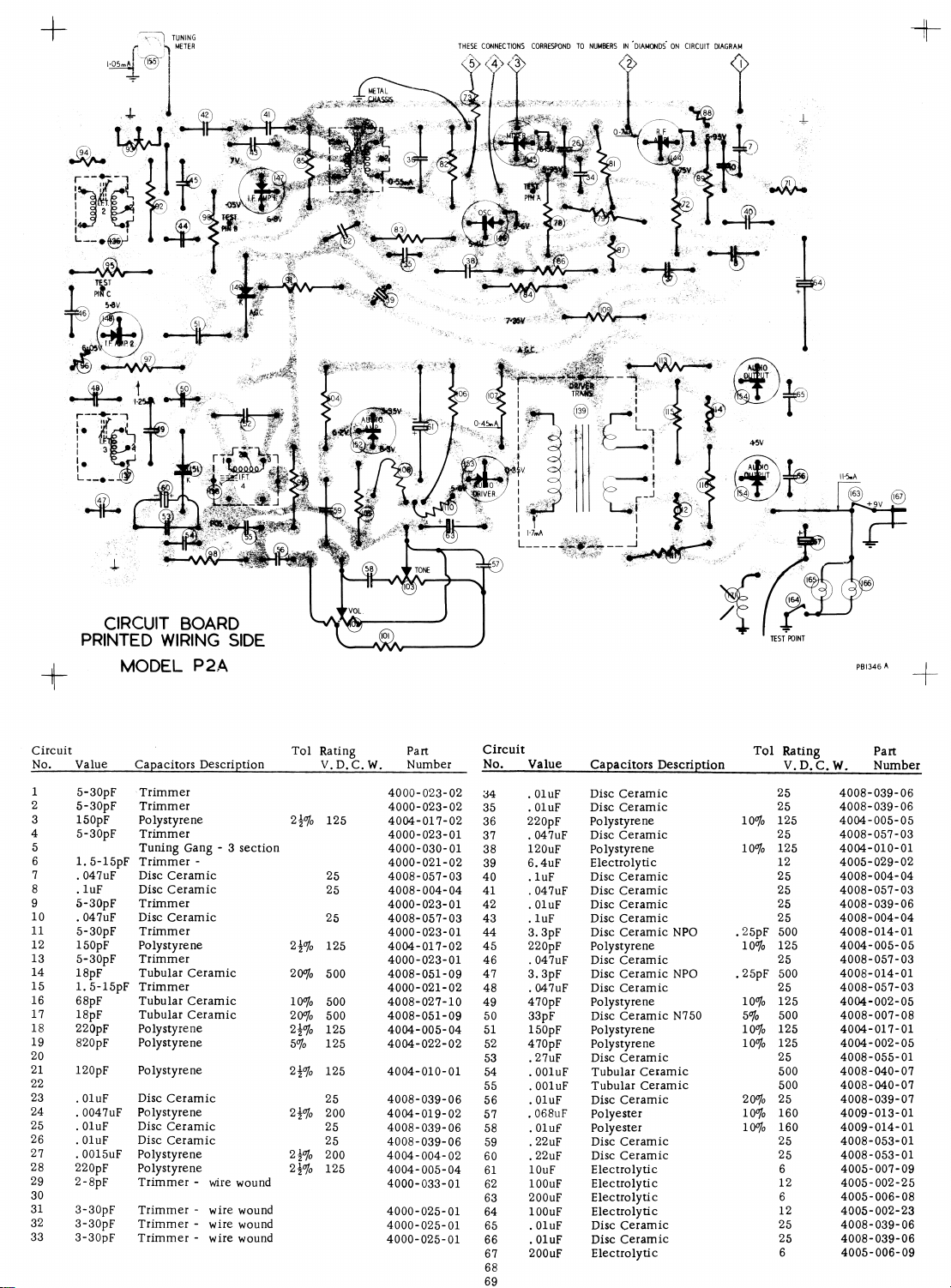

THESE CONNECTIONS CORR ESPOND TO NUMBERS IN DIAMONDS ON CIRC UIT DIAGRAM

,-X Λ

CI RCUI T BOAR D

PRINT ED WI RING SI DE

MODE L P2A

+

Circ u it

Value

No.

1

5-30pF Tri mme r

2

5-30pF T r imme r

3

150pF

4

5-30pF

5

6

1. 5-15pF

7

. 047uF

8

. lu F

9 5-30pF

10

. 047uF Disc Ceramic

11

5-30pF

12

150pF

13

5-30pF

14

18pF

15

1. 5-15pF Trimmer

16

68pF Tubular Cer amic

17

18pF Tubular Cer a mic

18

220pF

19

820pF

20

21

120pF

22

23

. OluF Disc Ce r amic

24

. 0047uF

25

.Olu F Disc Cera m i c

26

. OluF

27

. 0015uF

28

220pF

29

2-8pF Tri mme r - wire wound

30

31

3-30pF

32

3-30pF Tr i mmer - wir e wound

33

3-30pF

Capacito rs Descr ipti on

Polystyren e

Tri mmer

Tuning Gang - 3 se ctio n

Tri mme r -

Disc Cera mic

Disc Cera mic

Tr i mmer

Tr imme r

Polystyrene

Tri mme r

Tubular Cer a mic

Polystyren e

Polystyrene

Polystyrene

Polystyren e

Disc Cer a mic

Polystyren e

Polystyre ne

Tri mmer - wir e wound

Tri mmer - wir e wound

Rating

Tol

V.D.C . W.

125

2i %

25

25 400 8 -00 4 -0 4 41

25 4008 -0 5 7- 0 3 43 . luF

125

2

20%

500

500

10%

20% 500

125

2i %

5%

125

125 4004-0 10 -0 1

2i %

25

to

200

25

25

200

2i %

125

2i %

Part

Number

4000 -0 2 3- 02

4000 -0 23 -0 2

4004 -0 1 7- 02

4000-02 3 -0 1

4000-03 0 -0 1

4000 -0 21 -0 2

4008 -0 57 -0 3

4000-02 3-0 1

4000-0 23-0 1

4004- 01 7 -0 2 45 220pF

4000-02 3-0 1 46 . 047uF

4008 -0 51 -0 9

4000 -0 2 1 -0 2

4008 -0 2 7-1 0

4008 -0 51 -0 9

4004 -0 0 5- 0 4

4004 -0 22 -0 2

4008 -0 39 -0 6

4004 -0 1 9- 02

4008 -03 9 -0 6

4008 -0 39 -0 6

4004 -0 0 4- 0 2

4004 -0 05 -0 4

4000-033 -0 1

4000-0 25 -0 1 64 lOOuF

4000- 025 -01

4000-02 5-0 1

Ci r c uit

Va l u e

No .

34

. OluF

. OluF

35

36

220pF

. 047uF

37

38

120uF

6 . 4uF

39

40 . luF

. 047uF

42

.Olu F

44

3. 3pF

47

3. 3pF

48 . 047uF

470pF

49

50 33pF

51 150pF

52

470pF

. 27uF

53

54

. OOluF

55 . OOluF

56 .Ol u F

. 068uF

57

.Olu F

58

. 22uF

59

. 22uF

60

lOuF

61

62

lOOuF

200uF

63

. OluF

65

.Olu F

66

200uF

67

68

Ratin g

Cap a c it o r s D e s cr i p ti o n

Disc C e r amic

Disc Ceramic

Polystyren e

Disc Ceramic 25

Polystyrene

Elec t r o lytic

Disc Cera m i c

Disc Ceram i c 25

Disc Ceramic

Disc Ceramic 25

Disc Cera m i c NPO . 25pF

Polystyrene

Disc Ceramic 25

Disc C e r a mic NPO . 25pF 500

Disc Ceramic 25

Polystyrene

Disc C e r a mic N750

Polystyrene

Polystyrene 10% 125

Disc C eram i c

Tubular Ceramic

Tubular Cer a mic

Disc Ceramic

Polyester

Polyester 10% 160

Disc Cera mic 25

Disc Ceramic

Elec t r o ly t ic

Elec t r o lytic

Elec t r o lytic

Ele ct r o ly t ic

Disc C e r a mic

Disc C e r a mic

Ele c tr o l y t ic

T o l

V.D .C. W . Numb e r

25

25

125 4004 -0 0 5- 0 5

10 %

125

10%

12

25

25

500

125

10%

125

10%

500 4008 -00 7 -0 8

5%

125

10%

25

500 4008 -0 40 -0 7

500

25

20%

10% 160

25

6

12

6 4005 -0 06 -0 8

12

25

25

6

Part

4008 -0 39 -0 6

4008 -0 39 -0 6

4008 -0 5 7-0 3

4004-0 10 -0 1

4005 -0 29 -0 2

4008 -00 4 -0 4

4008 - 05 7- 03

4008 -0 3 9- 0 6

4008 -0 0 4 -0 4

4008-0 14-0 1

4004 - 00 5 -0 5

4008 -05 7 -0 3

4008-01 4 -0 1

4008 -05 7 -0 3

4004 -00 2 -0 5

4004-0 17 -0 1

4004 -0 0 2-0 5

4008-0 55-0 1

4008 -04 0 -0 7

4008- 03 9- 07

4009- 013 -01

4009- 014 -01

4008-0 53 -0 1

4008-0 53-0 1

4005-0 07 -0 9

4005 -0 02 -2 5

4005- 00 2- 23

4008 -0 39 -0 6

4008 -03 9 -0 6

4005 -00 6 -0 9

ι" I

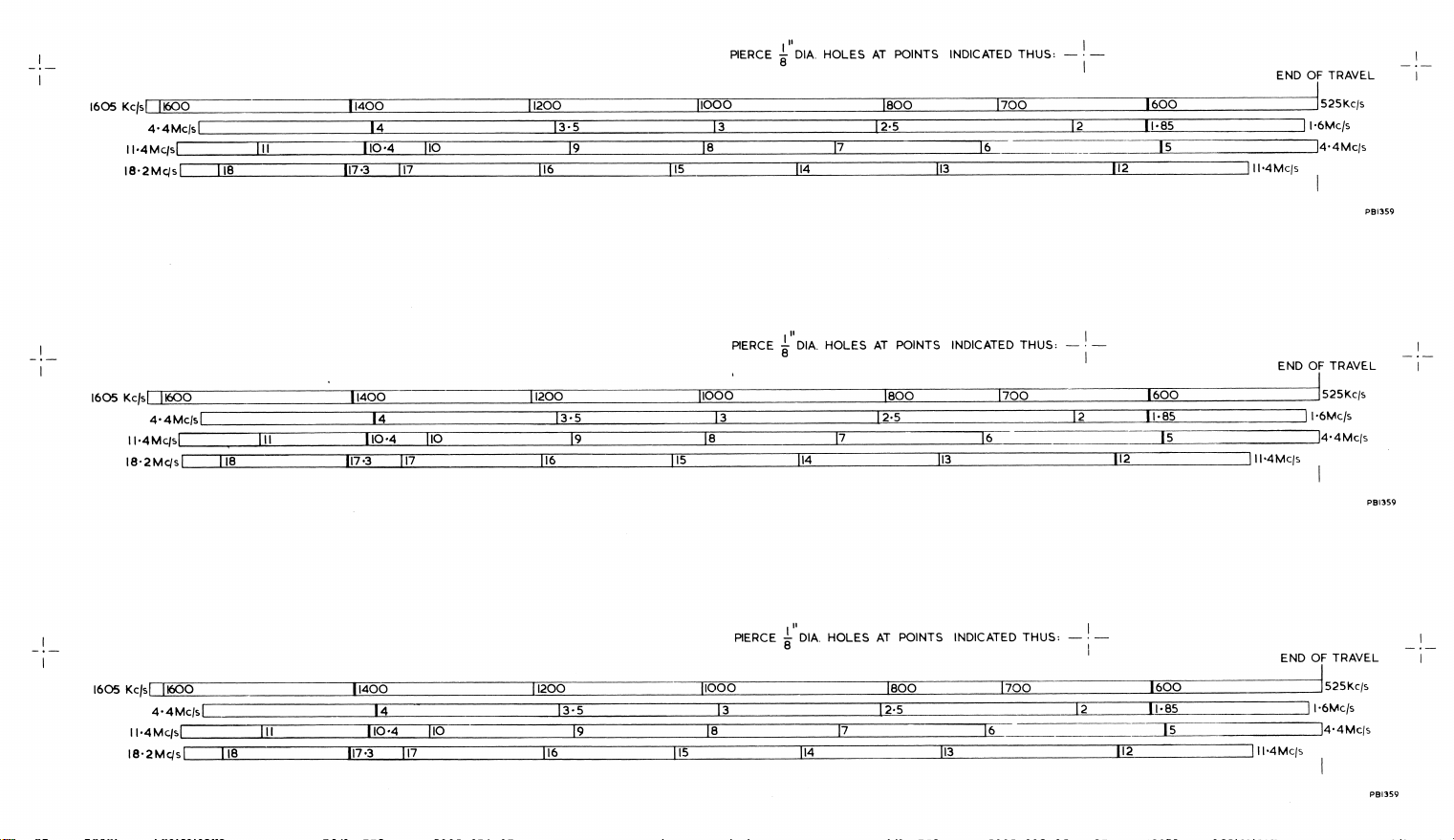

PIERCE ± D|A- HOLES AT POINTS INDICATED THUS; — · —

8 I

1605 Kc/sl 11600 |l4QO 11200 IIOOO 1800 1700 |6QO _ ] 525Kc/s

4-4Mcfsl 14 13-5 |3 12-5 12 ..lhgS

ll’4M c/ sl

l8-2Mc/s |

..i l l"

li e

f lO *4 h o

11 7-3 117

.

I1 6

___ _

|I5 ..

|8

. ._

19

. .

" ” I T I : —

11 4.. ...

.. [ 6

113

..

1 (2

__________

1 5

....

..

END OF TRAVEL

_______

1 1 l*4Mc / s

I l-6Mc/s

l4-4M cls

PBI359

1605 Kc/sl 11600

4-4Mc/sl

1 l-4Mc/sl

l8*2Mc/s |

1605 Kc/sl 11600

4-4Mc/sl

ll-4Mcfsl III

l8-2Mc/sl 118

.

........

....

ΤΊΓ ■

.118 __________

.....

.......

11400

...

“ 1 4

.........

110*4 |IO

117-3 117

11400

14

ό

1 17-3 117

..........

- "

.......

O

........

.. _ |3-5

....

..

11200

M6

1120 0

116

13 · 5

..........

1.9

9

....

l"

^ DIA . HOLES AT POINTS

PIERCE

IIOOO

........

_.13_ ..........

|8

115 _

PIERCE ± DIA. HOLES AT POINT S INDICATED THUS: — · —

liooo 1800 1700

13

18 7

ii5 _

... _

114

ι" 1

8 1

114

......

17

----------

leoo

12-5

12 *5

INDICATED THUS: — ·* —

.................................

....

_

113

1

.112

112 ....

1600

n-85

Z I5 _

1600

15

_ _

1700

_12_.

|6

12 11-85

16

END OF TRAVEL

______________

1 ll-4Mc|s

END OF TRAVEL

..

...1

111 -4MC/S

1

|525Kc/s

1 l*6Mc/s

|4-4Mc|s

|525Kc/s

I l-6Mc/s

l4*4Mcls

PBI359

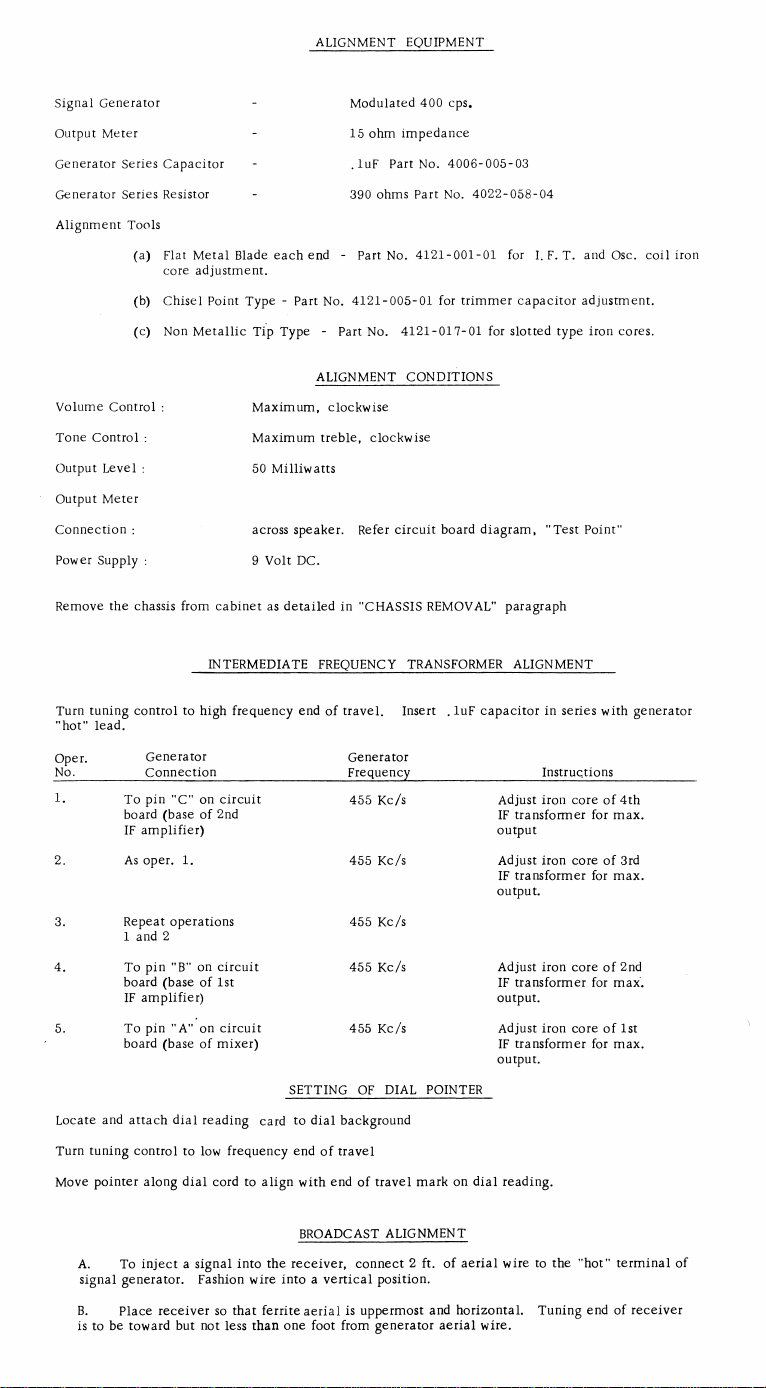

ALIGNMENT EQUIPMENT

Signal Generator

Output Meter

Generator Series Capacitor

Generator Series Resistor

Alignment Tools

(a) Flat Metal Blade each end - Part No. 4121-001-01 for I. F. T. and Osc. co i l iron

core adjustment.

(b) Chisel Point Ty pe - Part No. 4121-005-01 for trimmer capacitor adjustment.

(c) Non M e ta ll ic Tip Type - Part No. 4121-017-01 for slotted type iron cores.

Volume Control :

Tone Control :

Output Lev el :

Output Meter

Connection :

Power Supply :

Remove the chassis from cabinet as detailed in "CHASSIS REMOVAL" paragraph

Maximum, clockwise

Maximum treble, clockwise

50 Milliwatts

across speaker. Refer circuit board diagram, "Te s t Point"

9 Volt DC.

INTERMEDIATE FREQUENCY TRANSFORMER ALIGNMENT

Modulated 400 cps.

15 ohm impedance

. luF Part No. 4006-005-03

390 ohms Part No. 4022-058-04

ALIGNMENT CONDI TIO NS

Turn tuning control to high frequency end of travel. Insert . luF capacitor in series with generator

"hot" lead.

Oper.

No.

Locate and attach dial reading card to dia l background

Turn tuning control to low frequency end of travel

Move pointer along dia l cord to al ign with end of travel mark on dial reading.

A. To inject a signal into the receiv er, connect 2 ft. of aerial wire to the "hot" terminal of

signal generator. Fashion wire into a ver tic al position.

B. Place rec eive r so that ferrite aerial is uppermost and horizontal. Tuning end o f receiver

is to be toward but not less than one foot from generator aerial wire.

Generator

Connection

To pin "C " on circuit

board (base of 2nd

IF am p lifie r)

As oper. 1.

Repeat operations

1 and 2

To pin "B” on circuit

board (base of 1st

IF amp lif ier)

To pin "A" on circuit

board (base of m ixer )

Generator

Frequency Instructions

455 Kc/s

455 Kc/s

455 Kc/s

455 Kc/s

455 Kc/s

SETTING OF DIAL POINTER

BROADCAST A LIG NM EN T

Adjust iron core of 4th

IF transformer for max.

output

Adjust iron core of 3rd

IF transformer for max.

output.

Adjust iron core of 2nd

IF transformer for max.

output.

Adjust iron core of 1st

IF transformer for max.

output.

Loading...

Loading...