LVB-2 INSTRUCTION SHEET

Leakage Current Verication Box

V 1.02 | 1.2018

DECLARATION OF CONFORMITY

Manufacturer: Associated Research, Inc.

Address: 13860 W. Laurel Dr.

Lake Forest, IL 60045, USA

Product Name: LLT Verication Box

Model Number: LVB-2

Conforms to the following Standards:

Safety: EN 61010-1:2010

EMC: E N 613 26 -1: 2 013

Supplementary Information

The product herewith complies with the requirements of the Low Voltage Directive 2014/35/EU

and the EMC Directive 2014/30/EU.

The technical le and other documentation are on le with Associated Research, Inc.

Joseph Guerriero

President

Associated Research, Inc.

Lake Forest, Illinois USA

November 20, 2015

© Ikonix USA 1

LVB-2 Instruction Sheet

LVB-2 Technical Specications

INPUT CONNECTOR TERMINAL

VO LTAGE 277V MAC through LLT Tester L, N, GND AC Socket

PROBE L, N, GND, PH, PL PH, PL Alden Connector

PROBE CONFIGURATION PROBE CONFIGURATION SWITCH

GND LINE ON/OFF by 10A power switch

PROBE HI LINE ON/OFF by 10A power switch

PROBE HI PROBE LO ON/OFF by 10A power switch

Note: Only one switch can be CLOSED at a time

RESISTOR RANGE SPECIFICATION RESISTOR RANGE SWITCH

7.5 K 300VAC / 20W / 2% +/- 100PPM

15K 300VAC / 10W / 2% +/- 100PPM

30K 300VAC / 5W / 2% +/- 100PPM

150 K 300VAC / 2W / 2% +/- 100PPM

350K 300VAC / 0.5W / 2% +/- 100PPM

1.47M 300VAC / 0.25W / 2% +/- 100PPM

2.97M 300VAC / 0.25W / 2% +/- 100PPM

6.37M 300VAC / 0.25W / 2% +/- 100PPM

Select by Rotary Switch

GENERAL

TEST POINTS TEST CONDITION SPECIFICATION

PASS 15k Ω 1. LLT: 132VAC, 10,000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 7.5k Ω 1. LLT: 132VAC, 10,000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 30kΩ 1. LLT: 132VAC, 6000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 15k Ω 1. LLT: 132VAC, 6000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 150 k Ω 1. LLT: 132VAC, 2000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

2%

2%

2%

2%

2%

© Ikonix USA 2

LVB-2 Instruction Sheet

GENERAL CONTINUED

TEST POINTS TEST CONDITION SPECIFICATION

FAIL 30kΩ 1. LLT: 132VAC, 2000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 350kΩ 1. LLT: 132VAC, 500uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 150k Ω 1. LLT: 132VAC, 500uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 1.47MΩ 1. LLT: 132VAC, 100uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 350kΩ 1. LLT: 132VAC, 100uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 2.97MΩ 1. LLT: 132VAC, 30uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 1.47MΩ 1. LLT: 132VAC, 30uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 30kΩ 1. LLT: 264VAC, 10,000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 15k Ω 1. LLT: 264VAC, 10,000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 150 k Ω 1. LLT: 264VAC, 6000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 30kΩ 1. LLT: 264VAC, 6000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 350kΩ 1. LLT: 264VAC, 2000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 150k Ω 1. LLT: 264VAC, 2000uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 1.47MΩ 1. LLT: 264VAC, 500uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 350kΩ 1. LLT: 264VAC, 500uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

2%

2%

2%

2%

2%

2%

2%

2%

2%

2%

2%

2%

2%

2%

2%

© Ikonix USA 3

LVB-2 Instruction Sheet

GENERAL CONTINUED

TEST POINTS TEST CONDITION SPECIFICATION

PASS 2.97MΩ 1. LLT: 264VAC, 100uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 1.47MΩ 1. LLT: 264VAC, 100uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

PASS 6.37MΩ 1. LLT: 264VAC, 30uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

FAIL 2.97MΩ 1. LLT: 264VAC, 30uA High Limit

2. Maximum Voltage 277VAC

3. Ground = Open, Neutral = Closed, Reverse = O

SAFETY CE

ENVIRONMENT 0° - 40° C

DIMENSIONS W X H X D 186mm x 75 x 146

WEIGHT 1.3 lbs.

STANDARD ACCESSORIES

POWER CORD 10A x1

2%

2%

2%

2%

© Ikonix USA 4

LVB-2 Instruction Sheet

MAINTENANCE:

To prevent electric shock do not remove the instrument cover. There are no user serviceable parts inside. Routine maintenance or

cleaning of internal parts is not necessary. Any external cleaning should be done with a clean dry or slightly damp cloth. Avoid the use

of cleaning agents or chemicals to prevent damage plastic parts or lettering.

ENTRETIEN:

Pour éviter les chocs électriques ne pas enlever le couvercle de l’instrument. Il n’y a aucune pièce reparable par l’utilisateur. L’entretien

de routine ou le nettoyage des pièces internes ne sont pas nécessaires. Tout nettoyage externe doit être fait avec un chion sec

ou légèrement humide. Éviter l’utilisation de produits de nettoyage ou des produits chimiques pour éviter d’eacer les lettres ou

d’abimer les pièces en plastique.

OPERATING ENVIRONMENT:

This instrument may be operated in environments with the following limits:

- Indoor Use Only

- Altitude: 2000 m

- Temperature: 0ºC to 40ºC

- Humidity: Maximum 80% RH at 31ºC decreasing to 50% RH at 40ºC

- Pollution Degree: 2

Symbols Explanation:

Please refer to the instruction manual for specic warning or caution information to avoid personal injury or damage to the

product.

S’il vous plaît se référer au manuel d’instructions de mise en garde ou information sur la prudence pour éviter des blessures

ou des dommages au produit

To indicate hazardous voltages may be present.

Avertissement des tensions dangereuses qui peuvent être présentes

Note: pay close attention to the maximum voltage and duty cycle limitations of each resistor. Applying voltages that are

higher than the recommended maximum setting or duty cycles greater than indicated can cause damage to the LVB-2.

Note: attention à la tension maximale et les limites du cycle de travail de chaque résistance. L’application de tensions

plus élevées que le réglage maximum recommandé ou cycles de travail supérieures à celles indiquées peut causer des

dommages à la LVB-2

WARNING

The LVB-2 works with test voltages and currents which can cause harmful or fatal electric shock. To prevent accidental injury

or death, these safety procedures must be strictly observed when handling and using the test instrument.

Les tensions et les courants qui peuvent causer des chocs électriques dangereux ou fatal. Pour éviter les blessures

accidentelles ou la mort, ces procédures de sécurité doivent être strictement observées lors de la manipulation et

l’utilisation de l’instrument de test

© Ikonix USA 5

LVB-2 Instruction Sheet

Not rated for measurements within MEASUREMENT CATEGORIES II, III, or IV

N’est pas classé pour les catégories de surtension II, III ou IV

DO NOT TOUCH WHEN TESTING OR AFTER A MALFUNCTION HAS OCCURRED.

NE TOUCHEZ PAS LORS DE L’ESSAI OU APRÈS UN DYSFONCTIONNEMENT DU PRODUIT.

CAUTION: Never connect LVB-2 to any mains circuit directly

ATTENTION: Ne jamais connecter directement le LVB-2 à un circuit d’alimentation.

General Information

The LVB-2 is a load box used for the following applications:

• Verifying that the failure detectors for a leakage current test sequence of your Ikonix USA electrical safety testing instrument are

functioning properly.

• Verifying failure limit thresholds for a leakage current test.

• Verifying the three probe congurations of the instrument (G-L, PH-L and PH-PL) are functioning properly.

The LVB-2 consists of loads based on the 132V/264V test voltages and failure limits listed in the IEC60601-1 test standard for dierent

types of leakage tests.

Note: The LVB-2 is not intended to comply with any specic safety agency standard.

Note: The trip setting may vary up to 10% of the set value based on the combined tolerances of the instrument and the components

used in the LVB-2.

Using the LVB-2

The LVB-2 can be used with the following Ikonix USA instrument models:

Model Capability

OMNIA 2 8206 GB/GC, ACW, DCW, IR, RUN, LLT

OMNIA 2 8207 GB/GC, ACW, DCW, IR, RUN, LLT, Built-in

500VA AC Source

OMNIA 2 8256 GB/GC, ACW(500VA), DCW, IR, RUN, LLT

OMNIA 2 8257 GB/GC, ACW(500VA), DCW, IR, RUN, LLT,

Built-in 500VA AC Source

LINECHEK II 620L LLT, RUN

SCI 6330 GB, ACW, DCW, IR, RUN, LLT

© Ikonix USA 6

LVB-2 Instruction Sheet

The LVB-2 load box consists of resistors designed to induce a PASS or FAIL condition:

• The Check Point knob position determines which

resistor is set in the LVB-2

• Each check point has a PASS and FAIL condition.

• For a list of all PASS and FAIL condition test settings,

refer to the LVB-2 Technical Specications table.

• There is no PASS condition for the 7.5kΩ check point.

• There is no FAIL condition for the 6.37MΩ check point

The Probe Conguration switch can be set to two dierent positions depending on the verication type.

Figure 2 shows the two dierent settings of the switch. This setting should match with the Probe Conguration setting on the Leakage

Current test instrument.

An example of the Probe Conguration setting on the instrument is shown in Figure 3 along with the corresponding leakage test type.

On the test instrument the Probe Conguration is programmed depending on the type of leakage test needed to be performed.

Figure 2 – Probe Conguration Switch Positions

Figure 3 - Instrument Probe Conguration Setup

© Ikonix USA 7

LVB-2 Instruction Sheet

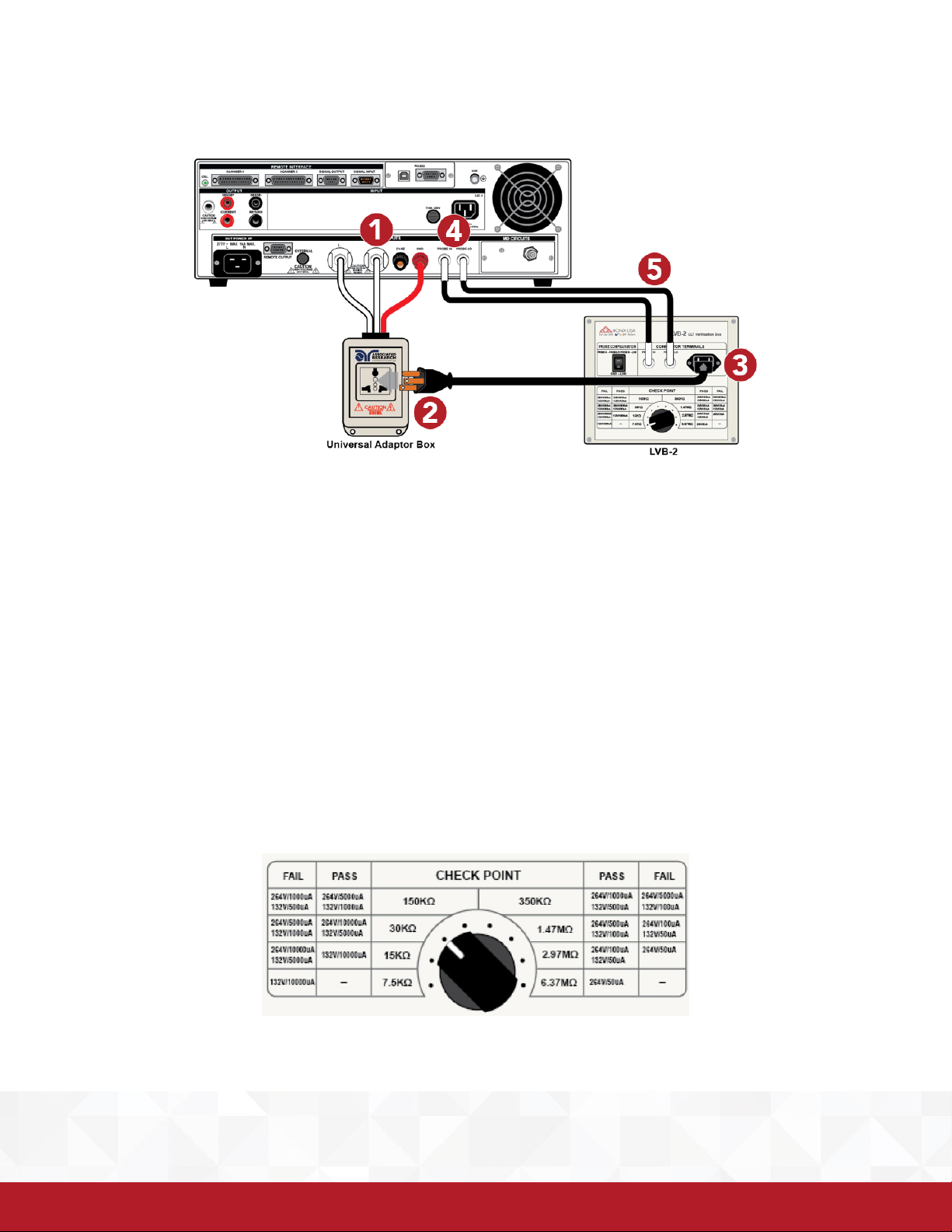

Instrument Connections

The diagram below shows all the connections needed to be made between the instrument and the LVB-2:

1. DUT Output connections - Line, Neutral and Ground of the DUT outputs connect to the DUT adapter box.

2. DUT Adapter box – DUT adapter box for connection of Line, Neutral and Ground to the LVB-2 connector terminal.

3. L, N and G connections – This is the socket for the standard IEC320 connector. The line cord from the DUT adapter

box connects these ports for making the Line, Neutral and Ground connections to the LVB-2 box.

4. Probe connections (Instrument) – Probe Hi and Probe Lo ports on the instrument.

5. Probe connections (LVB-2) – Probe Hi and Probe Lo connections on the LVB-2.

Test Setup

To setup a test, connect the DUT outputs (L, N and G) of the leakage instrument to the line cord connector on the LVB-2. The two probe

connections will also need to be made between the instrument and the LVB-2 for the verication of additional leakage test types

Program a test sequence based on the parameters listed on the test box for each load type. Select the appropriate Probe Conguration

on the LVB-2 using the Probe Confguration switch.

Refer to the specications table and use the rotary switch to select the appropriate Check Point by rotating it clockwise or counterclockwise:

Ensure that the settings on your electrical safety tester are less than or equal to the maximum recommended voltage, current and

duty cycle settings of the LVB-2. For each Check Point a PASS test and a FAIL test will be needed to programmed into the leakage test

instrument for the pass/fail verifcation. When all connections have been made and the appropriate test programmed in the instrument,

press the TEST button to begin the test. With the correct settings entered into the leakage test instrument, the leakage test instrument

should record a failure for the FAIL settings and a pass for the PASS settings.

© Ikonix USA 8

Loading...

Loading...