Page 1

Version 1.0

Published April 2022

Copyright©2022 ASRock INC. All rights reserved.

Copyright Notice:

No part of this documentation may be reproduced, transcribed, transmitted, or

translated in any language, in any form or by any means, except duplication of

documentation by the purchaser for backup purpose, without written consent of

ASRock Inc.

Products and corporate names appearing in this documentation may or may not

be registered trademarks or copyrights of their respective companies, and are used

only for identication or explanation and to the owners’ benet, without intent to

infringe.

Disclaimer:

Specications and information contained in this documentation are furnished for

informational use only and subject to change without notice, and should not be

constructed as a commitment by ASRock. ASRock assumes no responsibility for

any errors or omissions that may appear in this documentation.

With respect to the contents of this documentation, ASRock does not provide

warranty of any kind, either expressed or implied, including but not limited to

the implied warranties or conditions of merchantability or tness for a particular

purpose.

In no event shall ASRock, its directors, ocers, employees, or agents be liable for

any indirect, special, incidental, or consequential damages (including damages for

loss of prots, loss of business, loss of data, interruption of business and the like),

even if ASRock has been advised of the possibility of such damages arising from any

defect or error in the documentation or product.

is device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

CALIFORNIA, USA ONLY

e Lithium battery adopted on this motherboard contains Perchlorate, a toxic substance

controlled in Perchlorate Best Management Practices (BMP) regulations passed by the

California Legislature. When you discard the Lithium battery in California, USA, please

follow the related regulations in advance.

“Perchlorate Material-special handling may apply, see www.dtsc.ca.gov/hazardouswaste/

perchlorate”

Page 2

e terms HDMI® and HDMI High-Denition Multimedia Interface, and the HDMI

logo are trademarks or registered trademarks of HDMI Licensing LLC in the United

States and other countries.

INTEL END USER SOFTWARE LICENSE AGREEMENT

IMPORTANT - READ BEFORE COPYING, INSTALLING OR USING.

LICENSE. Licensee has a license under Intel’s copyrights to reproduce Intel’s Soware

only in its unmodied and binary form, (with the accompanying documentation, the

“Soware”) for Licensee’s personal use only, and not commercial use, in connection with

Intel-based products for which the Soware has been provided, subject to the following

conditions:

(a) Licensee may not disclose, distribute or transfer any part of the Soware, and You agree

to prevent unauthorized copying of the Soware.

(b) Licensee may not reverse engineer, decompile, or disassemble the Soware.

(c) Licensee may not sublicense the Soware.

(d) e Soware may contain the soware and other intellectual property of third party

suppliers, some of which may be identied in, and licensed in accordance with, an enclosed

license.txt le or other text or le.

(e) Intel has no obligation to provide any support, technical assistance or updates for the

Soware.

OWNERSHIP OF SOFTWARE AND COPYRIGHTS. Title to all copies of the Soware

remains with Intel or its licensors or suppliers. e Soware is copyrighted and protected

by the laws of the United States and other countries, and international treaty provisions.

Licensee may not remove any copyright notices from the Soware. Except as otherwise

expressly provided above, Intel grants no express or implied right under Intel patents,

copyrights, trademarks, or other intellectual property rights. Transfer of the license terminates Licensee’s right to use the Soware.

DISCLAIMER OF WARRANTY. e Soware is provided “AS IS” without warranty of

any kind, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATION OF LIABILITY. NEITHER INTEL NOR ITS LICENSORS OR SUPPLIERS

WILL BE LIABLE FOR ANY LOSS OF PROFITS, LOSS OF USE, INTERRUPTION OF

BUSINESS, OR INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND WHETHER UNDER THIS AGREEMENT OR OTHERWISE, EVEN

IF INTEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

LICENSE TO USE COMMENTS AND SUGGESTIONS. is Agreement does NOT

obligate Licensee to provide Intel with comments or suggestions regarding the Soware.

However, if Licensee provides Intel with comments or suggestions for the modication,

correction, improvement or enhancement of (a) the Soware or (b) Intel products or

processes that work with the Soware, Licensee grants to Intel a non-exclusive, worldwide,

perpetual, irrevocable, transferable, royalty-free license, with the right to sublicense, under

Page 3

Licensee’s intellectual property rights, to incorporate or otherwise utilize those comments

and suggestions.

TERMINATION OF THIS LICENSE. Intel or the sublicensor may terminate this license

at any time if Licensee is in breach of any of its terms or conditions. Upon termination,

Licensee will immediately destroy or return to Intel all copies of the Soware.

THIRD PARTY BENEFICIARY. Intel is an intended beneciary of the End User License

Agreement and has the right to enforce all of its terms.

U.S. GOVERNMENT RESTRICTED RIGHTS. e Soware is a commercial item (as

dened in 48 C.F.R. 2.101) consisting of commercial computer soware and commercial

computer soware documentation (as those terms are used in 48 C.F.R. 12.212), consistent

with 48 C.F.R. 12.212 and 48 C.F.R 227.7202-1 through 227.7202-4. You will not provide

the Soware to the U.S. Government. Contractor or Manufacturer is Intel Corporation,

2200 Mission College Blvd., Santa Clara, CA 95054.

EXPORT LAWS. Licensee agrees that neither Licensee nor Licensee’s subsidiaries will

export/re-export the Soware, directly or indirectly, to any country for which the U.S.

Department of Commerce or any other agency or department of the U.S. Government

or the foreign government from where it is shipping requires an export license, or other

governmental approval, without rst obtaining any such required license or approval. In

the event the Soware is exported from the U.S.A. or re-exported from a foreign destination by Licensee, Licensee will ensure that the distribution and export/re-export or import

of the Soware complies with all laws, regulations, orders, or other restrictions of the U.S.

Export Administration Regulations and the appropriate foreign government.

APPLICABLE LAWS. is Agreement and any dispute arising out of or relating to it will

be governed by the laws of the U.S.A. and Delaware, without regard to conict of laws

principles. e Parties to this Agreement exclude the application of the United Nations

Convention on Contracts for the International Sale of Goods (1980). e state and federal

courts sitting in Delaware, U.S.A. will have exclusive jurisdiction over any dispute arising

out of or relating to this Agreement. e Parties consent to personal jurisdiction and venue

in those courts. A Party that obtains a judgment against the other Party in the courts identied in this section may enforce that judgment in any court that has jurisdiction over the

Parties.

Licensee’s specic rights may vary from country to country.

Page 4

AUSTRALIA ONLY

Our goods come with guarantees that cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for a major failure and compensation for

any other reasonably foreseeable loss or damage caused by our goods. You are also entitled

to have the goods repaired or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure. If you require assistance please call ASRock Tel

: +886-2-28965588 ext.123 (Standard International call charges apply)

ASRock INC. hereby declares that this device is in compliance with the essential requirements and other relevant provisions of related UKCA Directives. Full text of UKCA declaration of conformity is available at: http://www.asrock.com

ASRock INC. hereby declares that this device is in compliance with the essential requirements and other relevant provisions of related Directives. Full text of EU declaration of

conformity is available at: http://www.asrock.com

ASRock follows the green design concept to design and manufacture our products, and

makes sure that each stage of the product life cycle of ASRock product is in line with global

environmental regulations. In addition, ASRock disclose the relevant information based

on regulation requirements.

Please refer to https://www.asrock.com/general/about.asp?cat=Responsibility for information disclosure based on regulation requirements ASRock is complied with:

DO NOT throw the motherboard in municipal waste. is product has been

designed to enable proper reuse of parts and recycling. is symbol of the

crossed out wheeled bin indicates that the product (electrical and electronic

equipment) should not be placed in municipal waste. Check local regulations

for disposal of electronic products.

Page 5

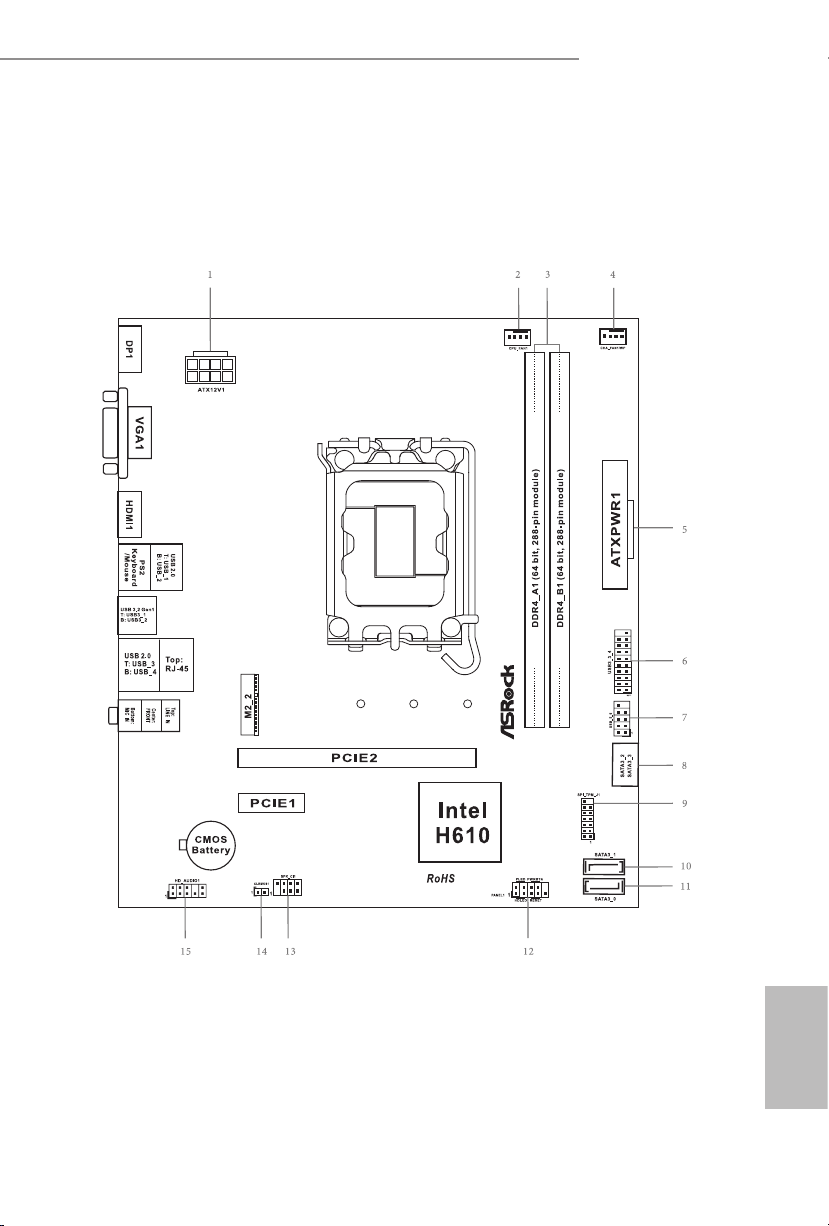

Motherboard Layout

H610M-HDV/M.2 R2.0:

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

English

1

Page 6

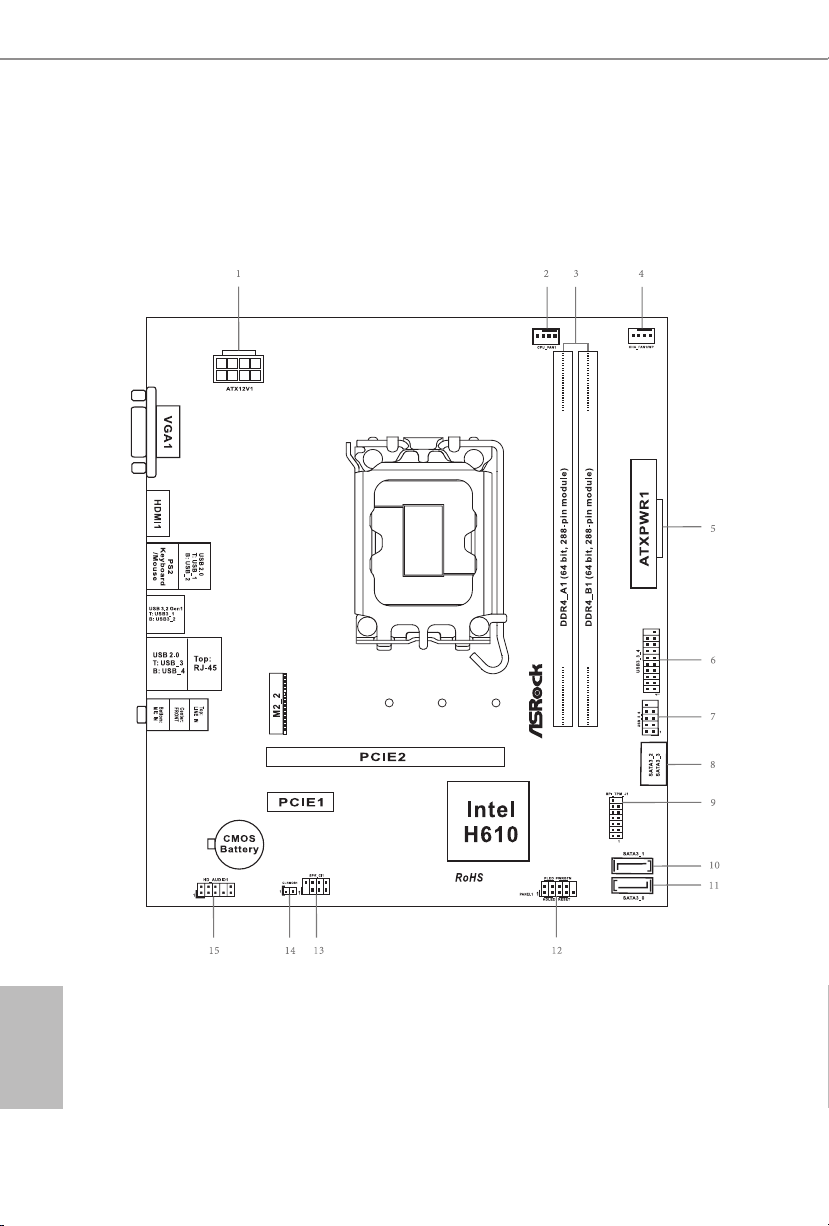

H610M-HVS/M.2 R2.0:

English

2

Page 7

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

No. Description

1 ATX 12V Power Connector (ATX12V1)

2 CPU Fan Connector (CPU_FAN1)

3 2 x 288-pin DDR4 DIMM Slots (DDR4_A1, DDR4_B1)

4 Chassis/Water Pump Fan Connector (CHA_FAN1/WP)

5 ATX Power Connector (ATXPWR1)

6 USB 3.2 Gen1 Header (USB3_3_4)

7 USB 2.0 Header (USB_5_6)

8 SATA3 Connector (SATA3_2) (Upper), SATA3 Connector (SATA3_3) (Lower)

9 SPI TPM Header (SPI_TPM_J1)

10 SATA3 Connector (SATA3_1)

11 SATA3 Connector (SATA3_0)

12 System Panel Header (PANEL1)

13 Chassis Intrusion and Speaker Header (SPK_CI1)

14 Clear CMOS Jumper (CLRMOS1)

15 Front Panel Audio Header (HD_AUDIO1)

English

3

Page 8

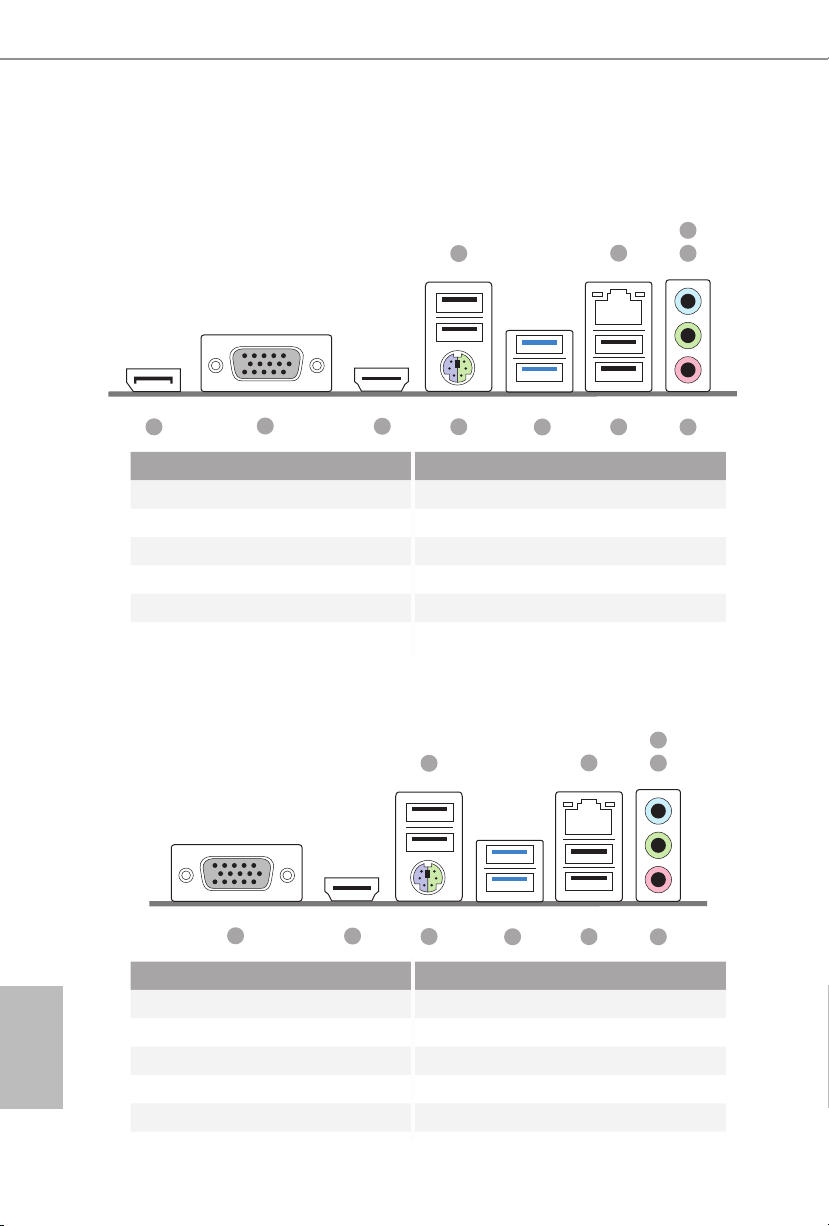

I/O Panel

H610M-HDV/M.2 R2.0:

3

1

2

4

English

11 6

No. Description No. Description

1 USB 2.0 Ports (USB_1_2) 7 USB 3.2 Gen1 Ports (USB3_1_2)

2 LAN RJ-45 Port* 8 PS/2 Mouse/Keyboard Port

3 Line In (Light Blue)** 9 HDMI Port

4 Front Speaker (Lime)** 10 D-Sub Port

5 Microphone (Pink)** 11 DisplayPort 1.4

6 USB 2.0 Ports (USB_3_4)

10

9

8

7

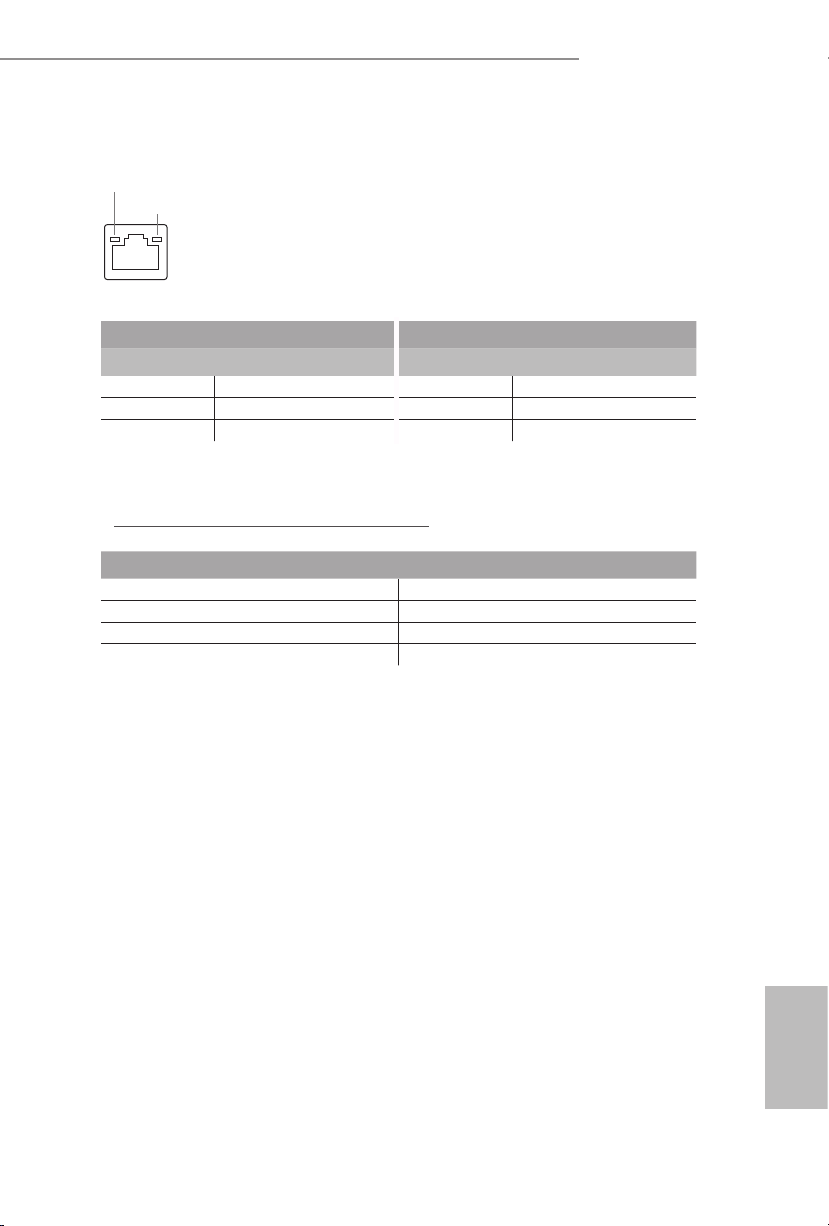

H610M-HVS/M.2 R2.0:

1

10

No. Description No. Description

1 USB 2.0 Ports (USB_1_2) 6 USB 2.0 Ports (USB_3_4)

2 LAN RJ-45 Port* 7 USB 3.2 Gen1 Ports (USB3_1_2)

3 Line In (Light Blue)** 8 PS/2 Mouse/Keyboard Port

4 Front Speaker (Lime)** 9 HDMI Port

5 Microphone (Pink)** 10 D-Sub Port

9

8

7

2

6

5

3

4

5

4

Page 9

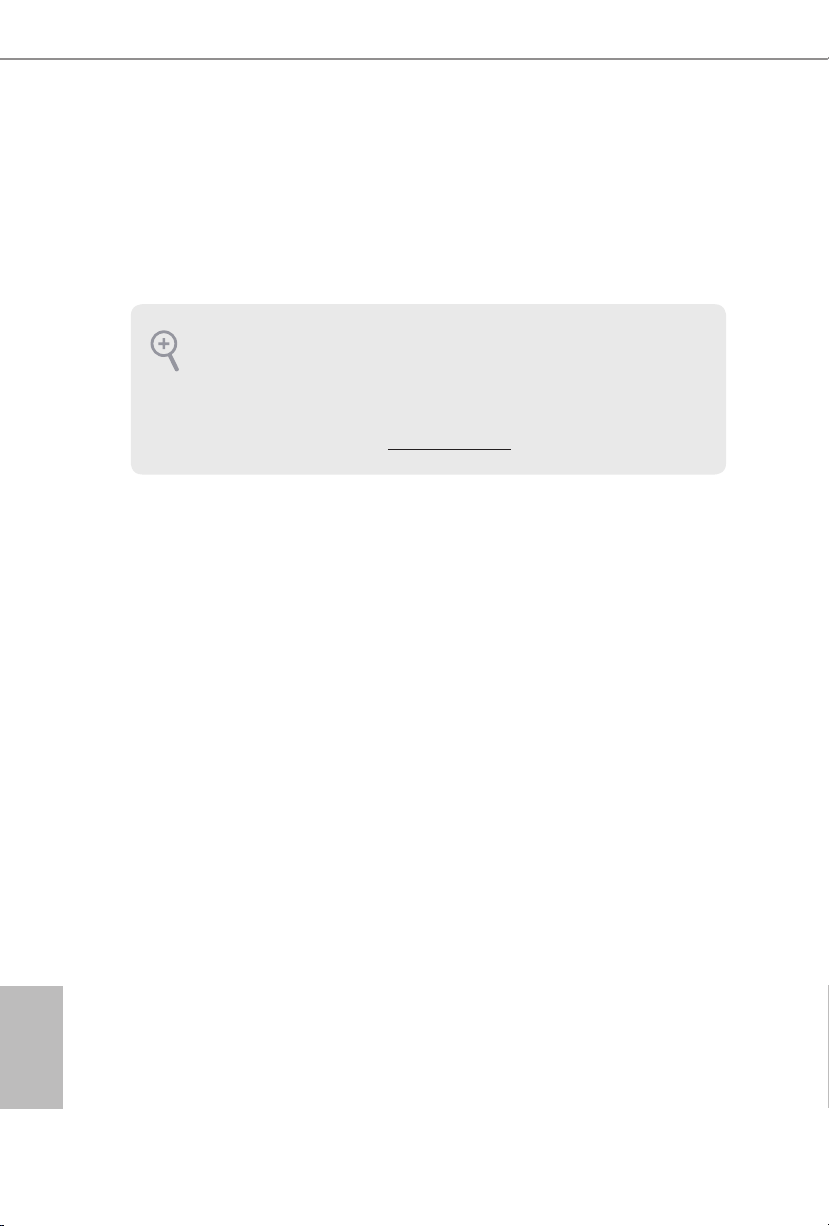

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

* ere are two LEDs on each LAN port. Please refer to the table below for the LAN port LED indications.

ACT/LINK L ED

SPEED LE D

LAN Por t

Activity / Link LED Speed LED

Status Description Status Description

O No Link O 10Mbps connection

Blinking Data Activity Orange 100Mbps connection

On Link Green 1Gbps connection

** Function of the Au dio Ports in 7.1-channel Con guration:

Port Function

Light Blue (Rear panel) Rear Speaker Out

Lime (Rear panel) Front Speaker Out

Pink (Rear panel) Central /Subwoofer Speaker Out

Lime (Front panel) Side Speaker Out

English

5

Page 10

Chapter 1 Introduction

ank you for purchasing ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2

R2.0 motherboard, a reliable motherboard produced under ASRock’s consistently

stringent quality control. It delivers excellent performance with robust design

conforming to ASRock’s commitment to quality and endurance.

Becau se the motherboard specications and the BIOS soware might be updated, the

content of this documentation will be subject to change without notice. In case any

modications of this documentation occur, the updated version will be available on

ASRock’s website without further notice. If you require technical support related to

this motherboard, please vi sit our website for s pecic information about the model

you are using. You may nd the l atest VGA cards and CPU suppor t list on ASRock’s

website a s well. ASRock website http://www.a srock.com.

1.1 Package Contents

ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 Motherboard (Micro ATX

•

Form Factor)

ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 Quick Installation Guide

•

ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 Support CD

•

2 x Serial ATA (SATA) Data Cables (Optional)

•

1 x Screw for M.2 Socket (Optional)

•

1 x I/O Panel Shield

•

English

6

Page 11

1.2 Specications

Platform

CPU

Chipset

Memory

* Please refer to Memory Support List on ASRock's website for

more information. (http://www.asrock.com/)

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

Micro ATX Form Factor

•

Solid Capacitor design

•

Supports 12th Gen Intel® CoreTM Processors (LGA1700)

•

7 Power Phase design

•

Supports Intel® Hybrid Technology

•

Supports Intel® Turbo Boost Max 3.0 Technology

•

Intel® H610

•

Dual Channel DDR4 Memory Technology

•

2 x DDR4 DIMM Slots

•

Supports DDR4 non-ECC, un-buered memory up to 3200*

•

Supports ECC UDIMM memory modules (operate in non-

•

ECC mode)

Max. capacity of system memory: 64GB

•

Supports Intel® Extreme Memory Prole (XMP) 2.0

•

Expansion

Slot

Graphics

CPU:

1 x PCIe 4.0 x16 Slot (PCIE2), supports x16 mode*

•

Chipset:

1 x PCIe 3.0 x1 Slot (PCIE1)*

•

* Supports NVMe SSD as boot disks

Intel® UHD Graphics Built-in Visuals and the VGA outputs

•

can be supported only with processors which are GPU

integrated.

Intel® Xe Graphics Architecture (Gen 12)

•

H610M-HDV/M.2 R2.0:

ree graphics output options: D-Sub, HDMI and

•

DisplayPort 1.4

Supports HDMI 2.1 TMDS Compatible with max. resolution

•

up to 4K x 2K (4096x2160) @ 60Hz

English

7

Page 12

Audio

LAN

Supports DisplayPort 1.4 with DSC (compressed) max.

•

resolution up to 8K (7680x4320) @ 60Hz / 5K (5120x3200) @

120Hz

Supports D-Sub with max. resolution up to 1920x1200 @

•

60Hz

Supports HDCP 2.3 with HDMI 2.1 TMDS Compatible and

•

DisplayPort 1.4 Ports

H610M-HVS/M.2 R2.0:

Dual graphics output: support HDMI and D-Sub ports by

•

independent display controllers

Supports HDMI 2.1 TMDS Compatible with max. resolution

•

up to 4K x 2K (4096x2160) @ 60Hz

Supports D-Sub with max. resolution up to 1920x1200 @

•

60Hz

Supports HDCP 2.3 with HDMI 2.1 TMDS Compatible Port

•

7.1 CH HD Audio (Realtek ALC897/887 Audio Codec)

•

Supports Surge Protection

•

PCIE x1 Gigabit LAN 10/100/1000 Mb/s

•

1 x Realtek RTL8111H

•

Supports Wake-On-LAN

•

Supports Lightning/ESD Protection

•

Supports Energy Ecient Ethernet 802.3az

•

Supports PXE

•

English

8

Rear Panel

I/O

1 x PS/2 Mouse/Keyboard Port

•

2 x USB 3.2 Gen1 Ports (Supports ESD Protection)

•

4 x USB 2.0 Ports (Supports ESD Protection)

•

1 x RJ-45 LAN Port with LED (ACT/LINK LED and SPEED

•

LED)

HD Audio Jacks: Line in / Front Speaker / Microphone

•

H610M-HDV/M.2 R2.0:

1 x D-Sub Port

•

1 x HDMI Port

•

1 x DisplayPort 1.4

•

H610M-HVS/M.2 R2.0:

1 x D-Sub Port

•

1 x HDMI Port

•

Page 13

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

Storage

Connector

Chipset:

1 x Ultra M.2 Socket (M2_2, Key M), supports type

•

2242/2260/2280 PCIe Gen3x4 (32 Gb/s) mode*

4 x SATA3 6.0 Gb/s Connectors

•

* Supports NVMe SSD as boot disks

* Supports ASRock U.2 Kit

1 x SPI TPM Header

•

1 x Chassis Intrusion and Speaker Header

•

1 x CPU Fan Connector (4-pin)

•

* e CPU Fan Connector supports the CPU fan of maximum

1A (12W) fan power.

1 x Chassis/Water Pump Fan Connector (4-pin) (Smart Fan

•

Speed Control)

* e Chassis/Water Pump Fan supports the water cooler fan of

maximum 2A (24W) fan power.

* CHA_FAN1/WP can auto detect if 3-pin or 4-pin fan is in use.

1 x 24 pin ATX Power Connector

•

1 x 8 pin 12V Power Connector

•

1 x Front Panel Audio Connector

•

1 x USB 2.0 Header (Supports 2 USB 2.0 ports) (Supports

•

ESD Protection)

1 x USB 3.2 Gen1 Header (Supports 2 USB 3.2 Gen1 ports)

•

(Supports ESD Protection)

BIOS

Feature

Hardware

Monitor

AMI UEFI Legal BIOS with multilingual GUI support

•

ACPI 6.0 Compliant wake up events

•

SMBIOS 2.7 Support

•

CPU Core/Cache, CPU Core/Cache Load-Line, CPU GT,

•

CPU GT Load-Line, DRAM, +0.82V PCH, +1.05V PCH,

VCCIN AUX, +1.8V PROC, +1.05V PROC Voltage Multi-

adjustment

Fan Tachometer: CPU, Chassis/Water Pump Fans

•

Quiet Fan (Auto adjust chassis fan speed by CPU tempera-

•

ture): CPU, Chassis/Water Pump Fans

Fan Multi-Speed Control: CPU, Chassis/Water Pump Fans

•

CASE OPEN detection

•

English

9

Page 14

Voltage monitoring: CPU Vcore, DRAM, +0.82V PCH,

•

+1.05V PCH, VCCIN AUX, VCCSA, +1.05V PROC, +12V,

+5V, +3.3V

Microso® Windows® 10 64-bit / 11 64-bit

OS

Certications

* For detailed product information, please visit our website: http://ww w.asrock.com

Please realize that the re is a certain risk involved with overclocking, including

adjusting the setting in the BIOS, applying Untied Overclocking Technology, or using

third-party overclocking tool s. Overclocking may aect your system’s stability, or

even cause damage to the components and devices of your system. It should be done

at your own risk and expense. We are not responsible for possible damage caused by

overclocking.

•

FCC, CE

•

ErP/EuP ready (ErP/EuP ready power supply is required)

•

English

10

Page 15

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

Chapter 2 Installation

is is a Micro ATX form factor motherboard. Before you install the motherboard,

study the conguration of your chassis to ensure that the motherboard ts into it.

Pre-installation Precautions

Take note of the following precautions before you install motherboard components

or change any motherboard settings.

Make sure to unplug the power cord before installing or removing the motherboard

•

components. Failure to do so may cause physical injuries and damages to motherboard

components.

In order to avoid damage from static electricity to the motherboard’s components,

•

NEVER place your motherboard directly on a carpet. Also remember to use a grounded

wrist strap or touch a safety grounded object before you handle the components.

Hold components by the edges and do not touch the ICs.

•

Whenever you uninstall any components, place them on a grounded anti-static pad or

•

in the bag that comes with the components.

When placing screws to secure the motherboard to the chassis, please do not over-

•

tighten the screws! Doing so may damage the motherboard.

11

English

Page 16

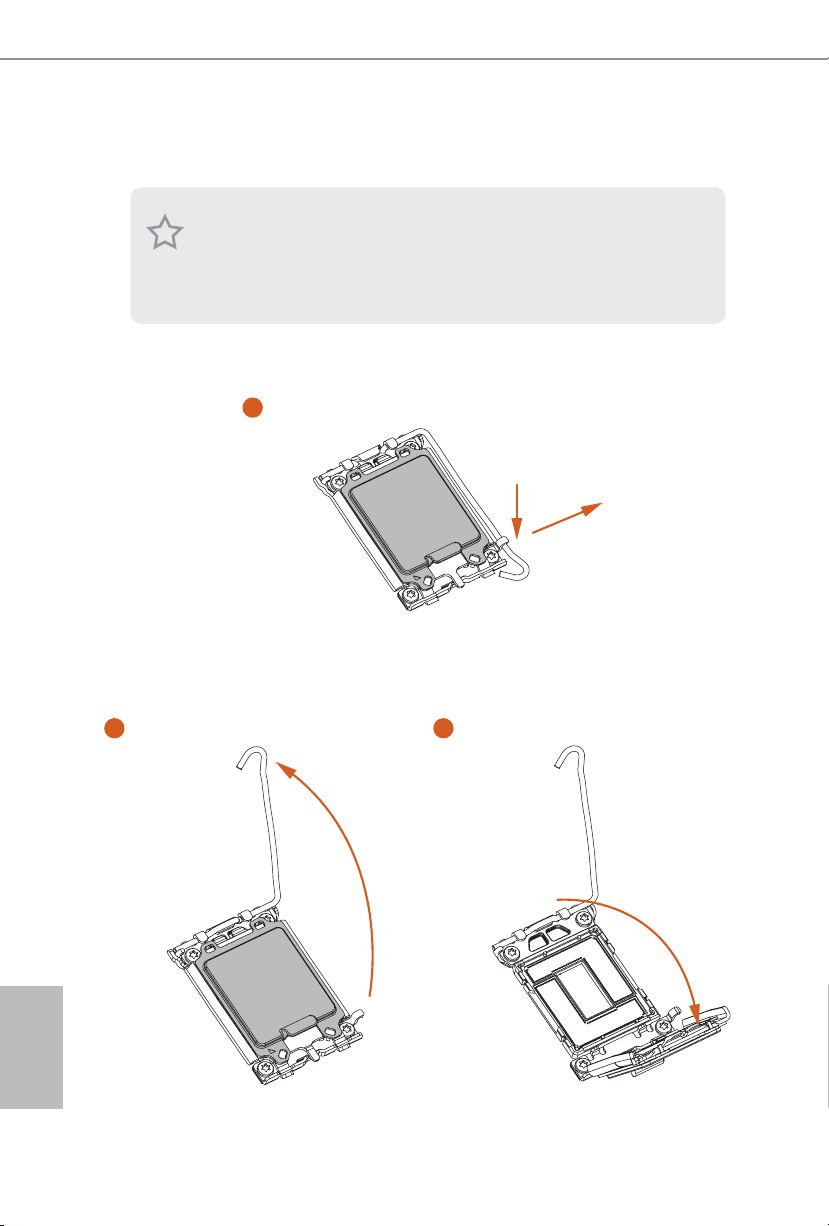

2.1 Installing the CPU

1. Before you insert the 1700-Pin CPU into the socket, please check if the P nP cap

is on the socket, if the CPU sur face is unclean, or if there are any b ent pins in the

socket. Do not force to insert the CPU into the socket if above situation is found.

Other wise, the CPU will be seriously d amaged.

2. Unplug all power cables be fore installing the CPU.

1

A

B

English

12

2 3

Page 17

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

4

76

5

13

English

Page 18

Please save and replace the cover if the processor i s removed. e cover must be

placed if you wish to return the motherboard for aer service.

English

14

Page 19

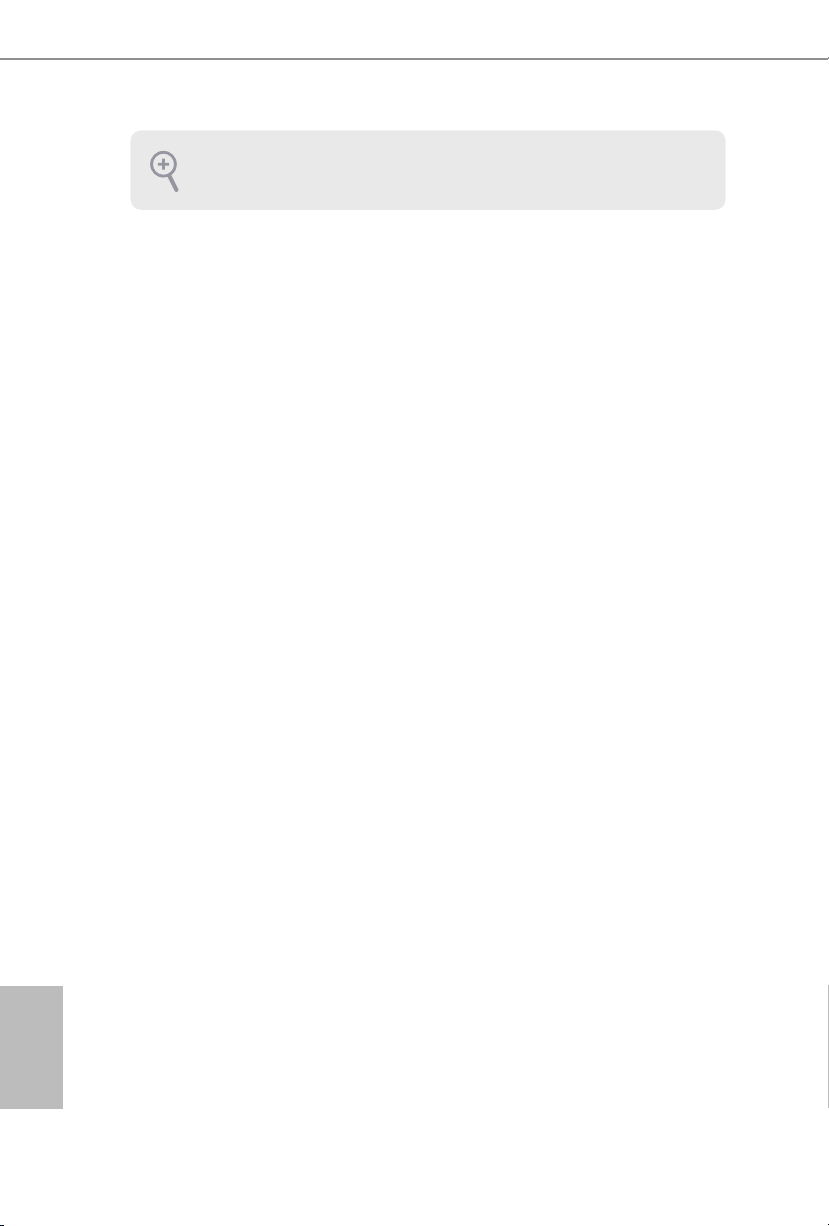

2.2 Installing the CPU Fan and Heatsink

1 2

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

CPU_FAN

English

15

Page 20

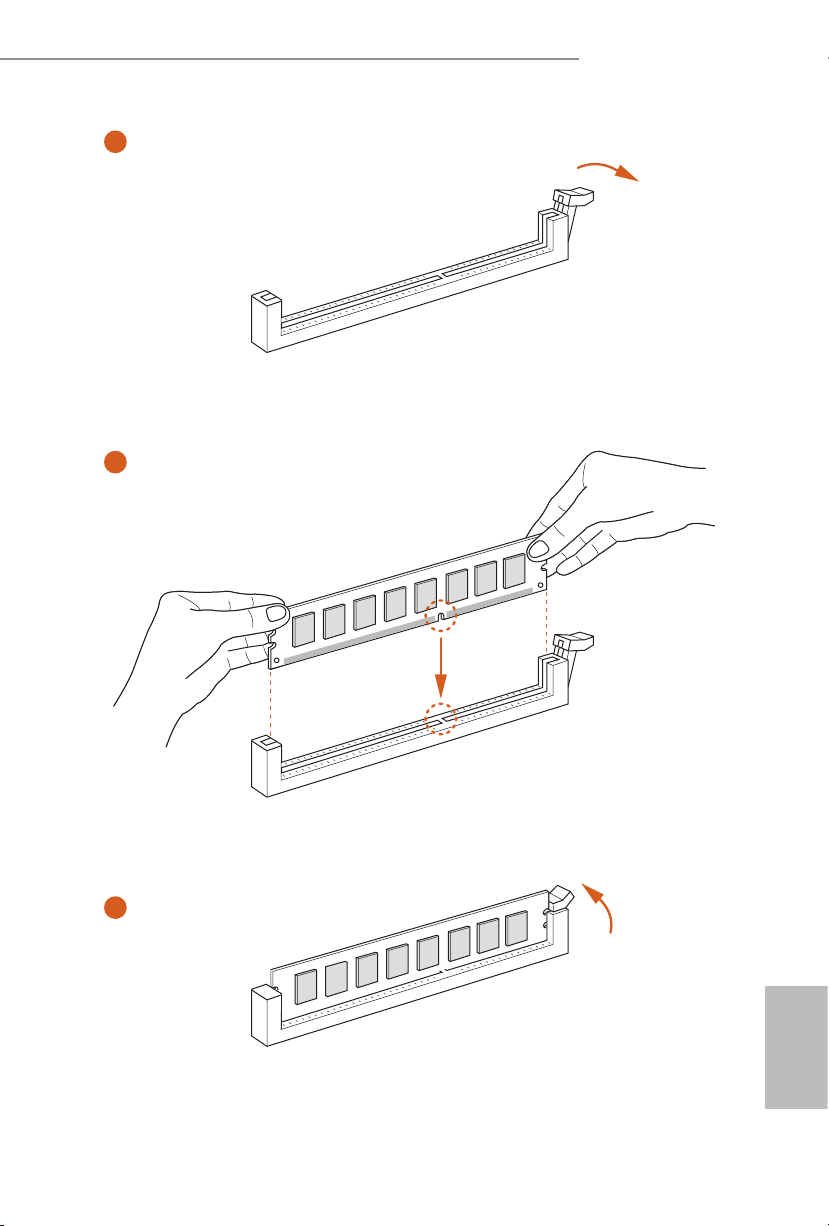

2.3 Installing Memory Modules (DIMM)

is motherboard provides two 288-pin DDR4 (Double Data Rate 4) DIMM slots,

and supports Dual Channel Memory Technology.

1. For dual channel conguration, you always need to install identical (the same

brand, speed , size and chip-type) DDR4 DIMM pairs.

2. It is unable to activate Dual Channel Memor y Technology with only one memory

module installed.

3. It is not allowed to install a DDR, DDR2 or DDR3 memory module into a DDR4

slot; otherwise, this motherboard and DIMM may be damaged.

e DIMM only ts in one correct orientation. It will cause permanent damage to

the mothe rboard and the DIMM if you force the DIMM into the slot at incor rect

orientation.

English

16

Page 21

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

1

2

3

English

17

Page 22

2.4 Expansion Slots (PCIe Slots)

ere are 2 PCIe slots on the motherboard.

Before installing an ex pansion card, please make sure that the power supply is

switched o or the power cord is unplugged. Plea se read the documentation of the

expan sion card and make necessary hardware settings for the card before you start

the installation.

PCIe slots:

PCIE1 (PCIe 3.0 x1 slot) is used for PCIe x1 lane width cards.

PCIE2 (PCIe 4.0 x16 slot) is used for PCIe x16 lane width graphics cards.

English

18

Page 23

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

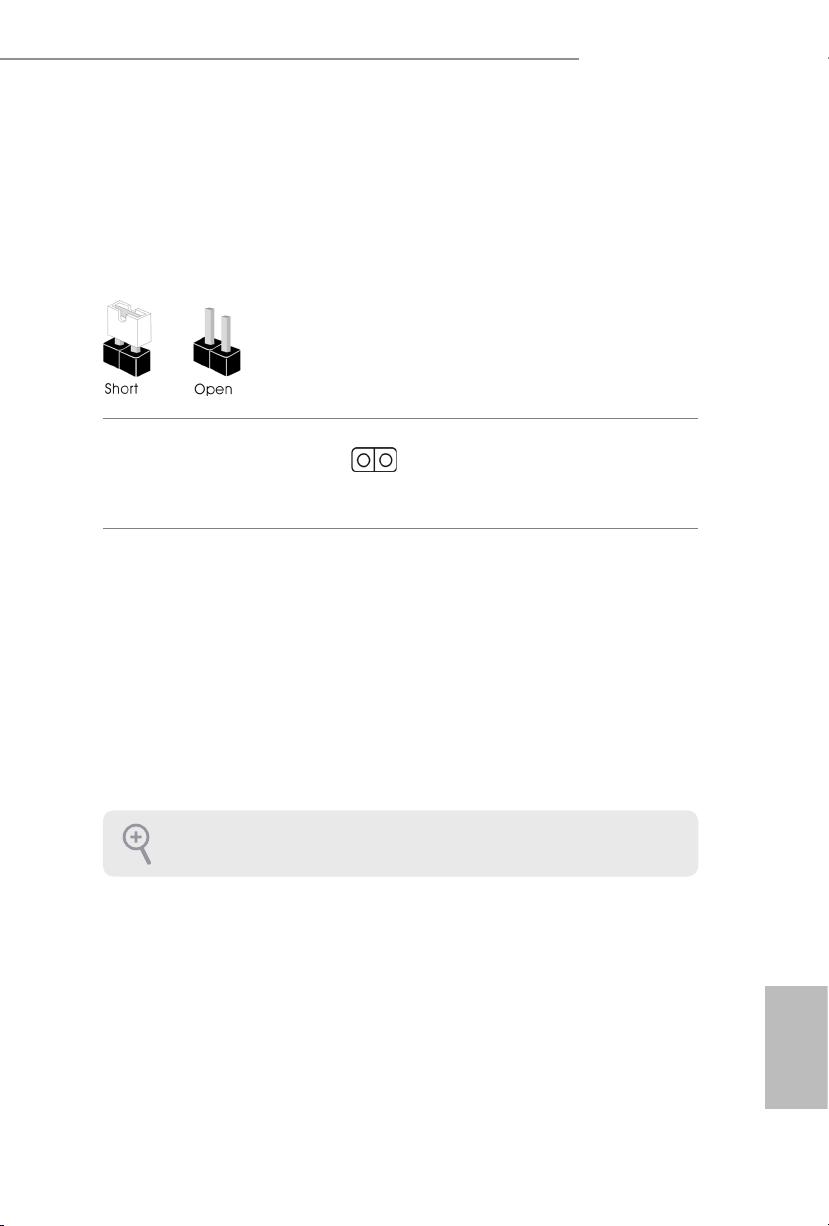

2.5 Jumpers Setup

e illustration shows how jumpers are setup. When the jumper cap is placed on

the pins, the jumper is “Short”. If no jumper cap is placed on the pins, the jumper is

“Open”.

Clear CMOS Jumper

(CLRMOS1)

(see p.1, 2, No. 14)

CLRMOS1 allows you to clear the data in CMOS. To clear and reset the system

parameters to default setup, please turn o the computer and unplug the power

cord from the power supply. Aer waiting for 15 seconds, use a jumper cap to

short the pins on CLRMOS1 for 5 seconds. However, please do not clear the

CMOS right aer you update the BIOS. If you need to clear the CMOS when you

just nish updating the BIOS, you must boot up the system rst, and then shut it

down before you do the clear-CMOS action. Please be noted that the password,

date, time, and user default prole will be cleared only if the CMOS battery is

removed. Please remember toremove the jumper cap aer clearing the CMOS.

2-pin Jumper

If you clear the CMOS, the case open may be detec ted. Please adjust the BIOS option

“Clear Status” to clear the record of previou s chassis intrusion status.

English

19

Page 24

2.6 Onboard Headers and Connectors

SPE AKE R

Onboard headers and connectors are NOT jumpers. Do NOT place jumper caps over

these headers and connectors. Placing jumper caps over the headers and connectors

will cause permanent damage to the motherboard.

System Panel Header

(9-pin PANEL1)

(see p.1, 2, No. 12)

PWRBTN (Power Button):

Connec t to the power button on the chassi s front panel. You may congure the way

to turn o your system using the powe r button.

RESET (Reset Button):

Connec t to the reset button on the chassi s front panel. Press the reset button to

restar t the computer if the computer freezes and fails to perform a nor mal restart.

PLED (Syste m Power LED):

Connec t to the power status indicator on the chassis front panel. e LED i s on when

the system is ope rating. e LED keeps blinking when the system i s in S1/S3 sleep

state. e LED is o when the system is in S4 sleep state or powered o (S5).

HDLED (Ha rd Drive Activity LED):

Connec t to the hard drive activity LED on the chassis front panel. e LED is on

when the hard drive i s reading or writing data.

e front panel design may dier by chassis. A front panel module mainly consists

of power button, reset button, power LED, hard drive activity LED, speaker and etc.

When connecting your chassis front panel module to this head er, make sure the wire

assig nments and the pin assig nments are matched correctly.

1

PLE D+

PLE D-

HDL ED-

HDL ED+

PWR BTN #

GND

RES ET#

GND

GND

Connect the power button,

reset button and system

status indicator on the

chassis to this header

according to the pin

assignments below. Note the

positive and negative pins

before connecting the cables.

English

20

Chassis Intrusion and

Speaker Header

(7-pin SPK_CI1)

(see p.1, 2, No. 13)

DUM MY

+5V

1

SIG NAL

DUM MY

GND

DUM MY

Please connect the

chassis intrusion and the

chassis speaker to this

header.

Page 25

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

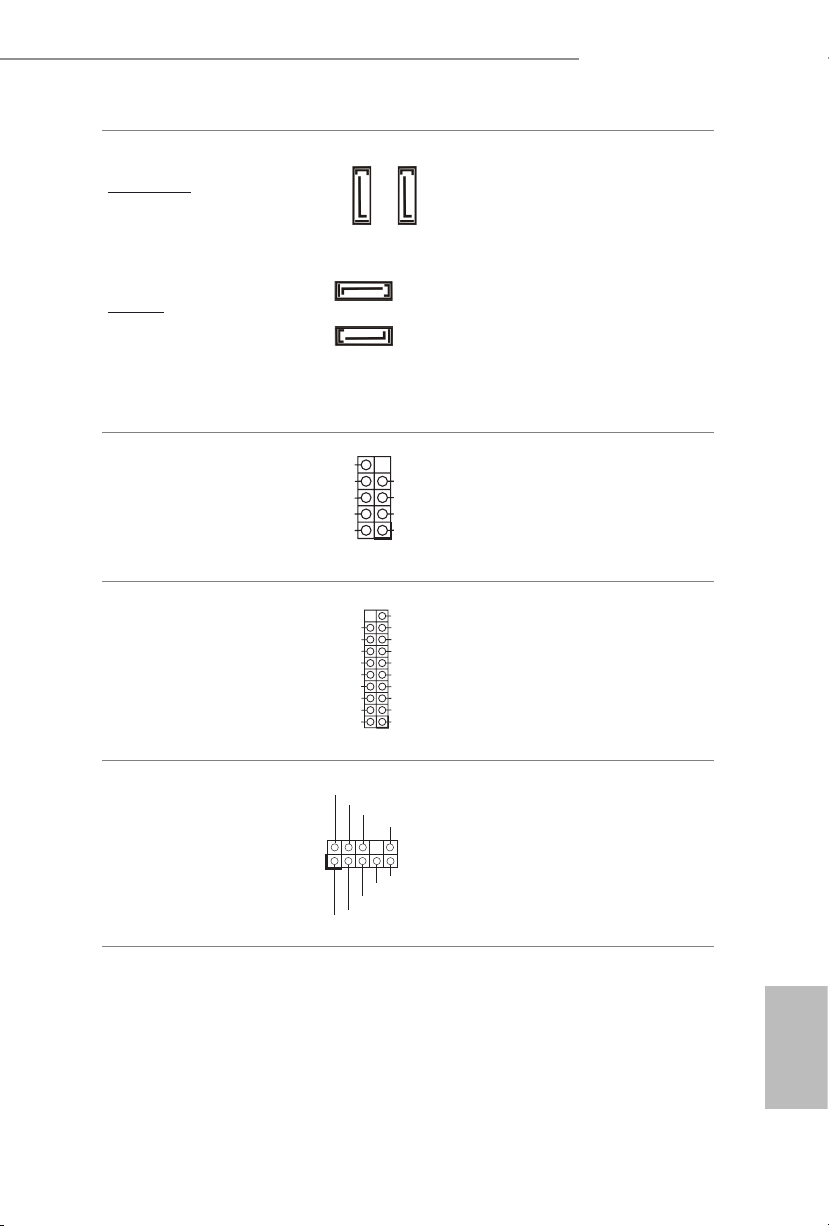

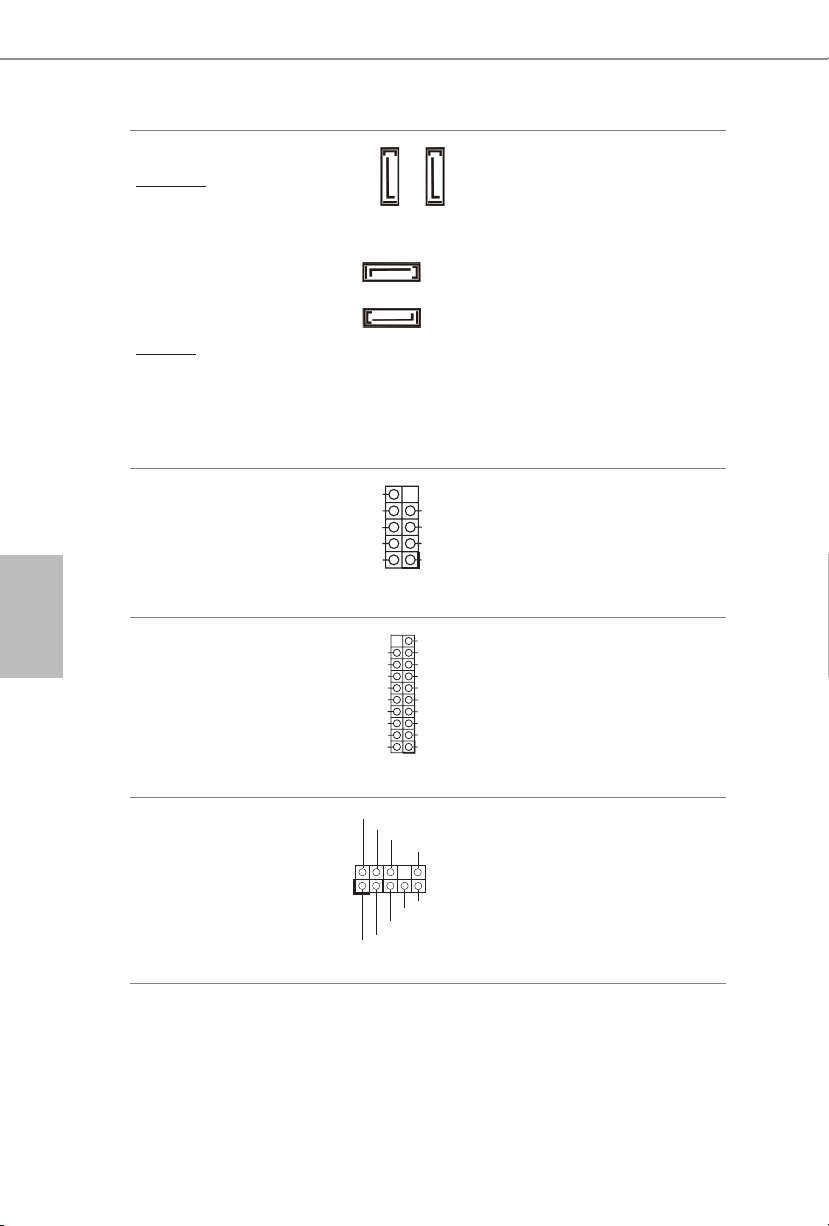

Serial ATA3 Connectors

Right Angle:

(SATA3_2:

see p.1, 2, No. 8) (Upper)

(SATA3_3:

see p.1, 2, No. 8) (Lower)

Vertical:

(SATA3_0:

see p.1, 2, No. 11)

(SATA3_1:

see p.1, 2, No. 10)

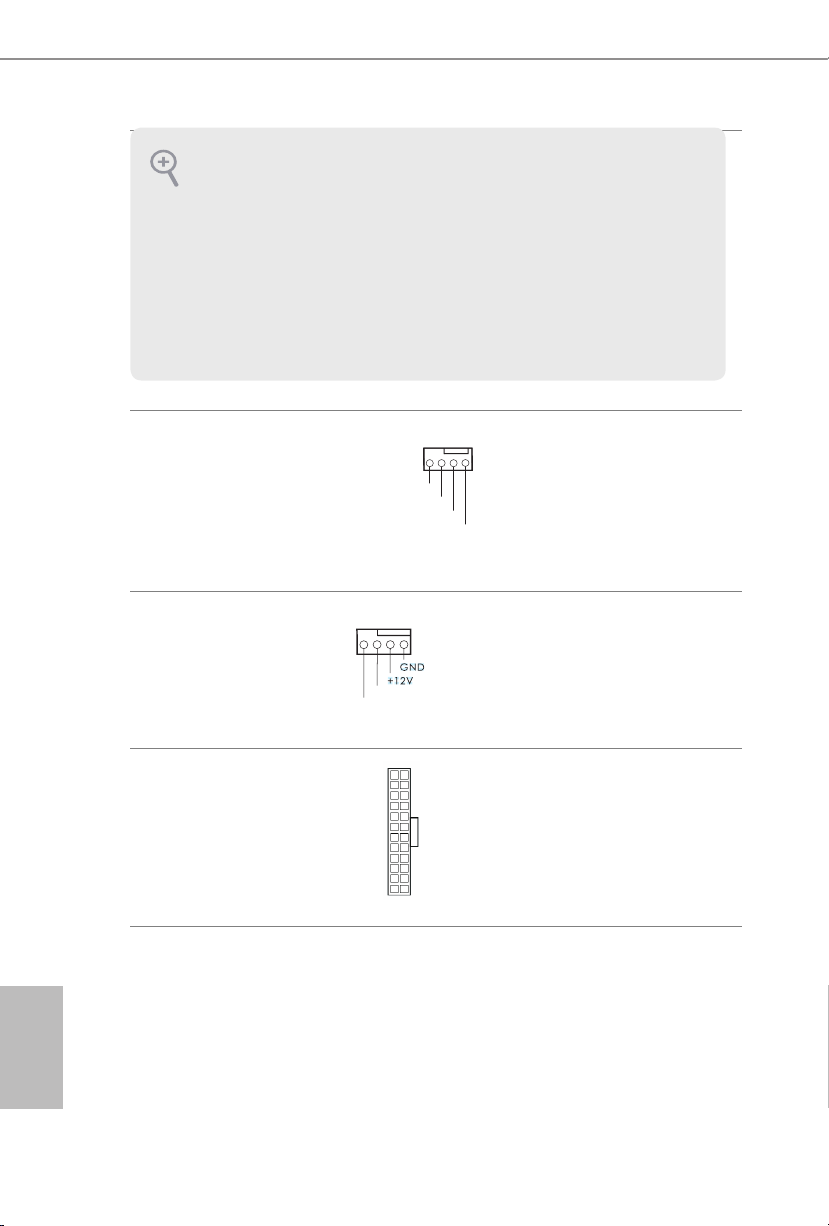

USB 2.0 Header

(9-pin USB_5_6)

(see p.1, 2, No. 7)

USB 3.2 Gen1 Header

(19-pin USB3_3_4)

(see p.1, 2, No. 6)

SATA3_2

SATA3_1

SATA3_0

DUM MY

GND GND

+B

-B

USB _PW R

Vbus

IntA _PA_S SRX-

IntA _PA_S SRX+

GND

IntA _PA_S STX-

IntA _PA_S STX+

GND

IntA _PA_D -

IntA _PA_D +

SATA3_3

+A

-A

USB _PW R

1

VbusVbus

IntA _PB_ SSRX -

IntA _PB_ SSRX +

GND

IntA _PB_ SSTX -

IntA _PB_ SSTX +

GND

IntA _PB_ D-

IntA _PB_ D+

Dumm y

1

ese four SATA3

connectors support SATA

data cables for internal

storage devices with up to 6.0

Gb/s data transfer rate.

ere is one header on this

motherboard. is USB

2.0 header can support two

ports.

ere is one header on this

motherboard. is USB 3.2

Gen1 header can support

two ports.

Front Panel Audio Header

(9-pin HD_AUDIO1)

(see p.1, 2, No. 15)

1

GND

PRE SEN CE#

MIC 2_R

MIC 2_L

MIC _RE T

J_S ENS E

OUT 2_R

OUT _RE T

OUT 2_L

is header is for connecting

audio devices to the front

audio panel.

English

21

Page 26

CPU_ FAN_SP EED

FAN_S PEED_ CONTR OL

4 3 2 1

1. High Denition Audio supports Jack Sensing, but the panel wire on the chassis

must support HDA to function correctly. Please follow the instructions in our

manual and chassis manual to install your system.

2. If you use an AC’97 audio panel, please install it to the front panel audio heade r by

the steps below:

A. Connect Mic_IN (MIC) to MIC2_ L.

B. Conne ct Audio_R (RIN) to OUT2_R and Audio_ L (LIN) to OUT2_ L.

C. Connect Ground (GND) to Ground (GND).

D. MIC_ RET and OUT_RET are for the HD audio panel only. You don’t need to

connect them for the AC’97 audio panel.

E. To activate the front mic, go to the “FrontMic” Tab in the Realtek Control panel

and adju st “Recording Volume”.

English

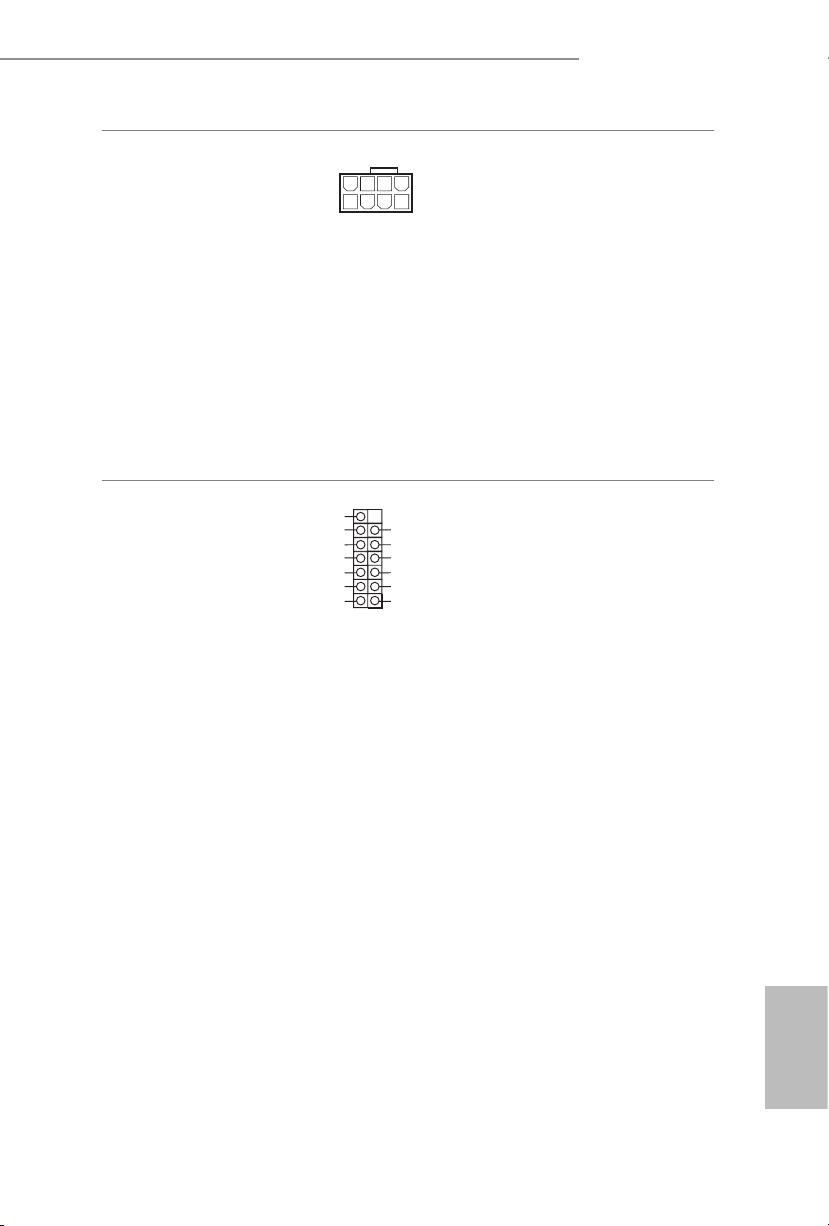

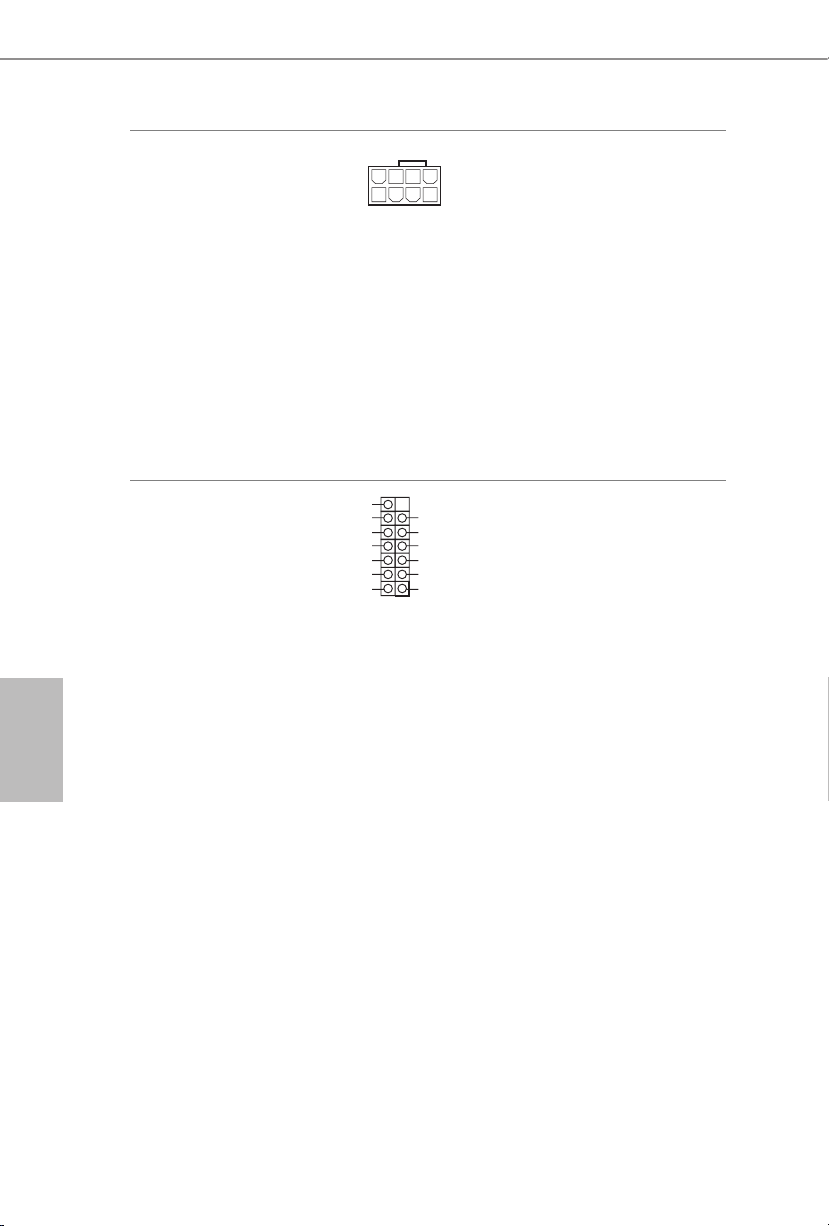

Chassis/Water Pump Fan

Connector

(4-pin CHA_FAN1/WP)

(see p.1, 2, No. 4)

CPU Fan Connector

(4-pin CPU_FAN1)

(see p.1, 2, No. 2)

ATX Power Connector

(24-pin ATXPWR1)

(see p.1, 2, No. 5)

FAN _SP EED _CO NTR OL

CHA _FA N_S PEE D

FAN _VO LTA GE

12

1

4 3 2 1

24

13

is motherboard provides

a 4-Pin water cooling chassis

fan connector. If you plan to

connect a 3-Pin chassis water

GND

cooler fan, please connect it

to Pin 1-3.

is motherboard provides

a 4-Pin CPU fan (Quiet Fan)

connector. If you plan to

connect a 3-Pin CPU fan,

please connect it to Pin 1-3.

is motherboard provides

a 24-pin ATX power connector. To use a 20-pin ATX

power supply, please plug it

along Pin 1 and Pin 13.

22

Page 27

H610M-HDV/M.2 R2.0

8 5

H610M-HVS/M.2 R2.0

ATX 12V Power

Connector

(8-pin ATX12V1)

(see p.1, 2, No. 1)

SPI TPM Header

(13-pin SPI_TPM_J1)

(see p.1, 2, No. 9)

TPM _ PIR Q

RST #

SPI _ MOS I

CLK

Dum m y

SPI _ PWR

SPI _ DQ3

4

SPI _ TPM _CS #

GND

RSM R ST#

SPI _ MIS O

SPI _ CS0

SPI _ DQ2

1

is motherboard

provides a 8-pin ATX 12V

1

power connector. To use a

4-pin ATX power supply,

please plug it along Pin 1 and

Pin 5.

*Warning: Please make

sure that the power cable

connected is for the CPU

and not the graphics card.

Do not plug the PCIe power

cable to this

connector.

is connector supports SPI

Trusted Platform Module (TPM)

system, which can securely store

keys, digital certicates, passwords,

and data. A TPM system also helps

enhance network security, protects

digital identities, and ensures

platform integrity.

English

23

Page 28

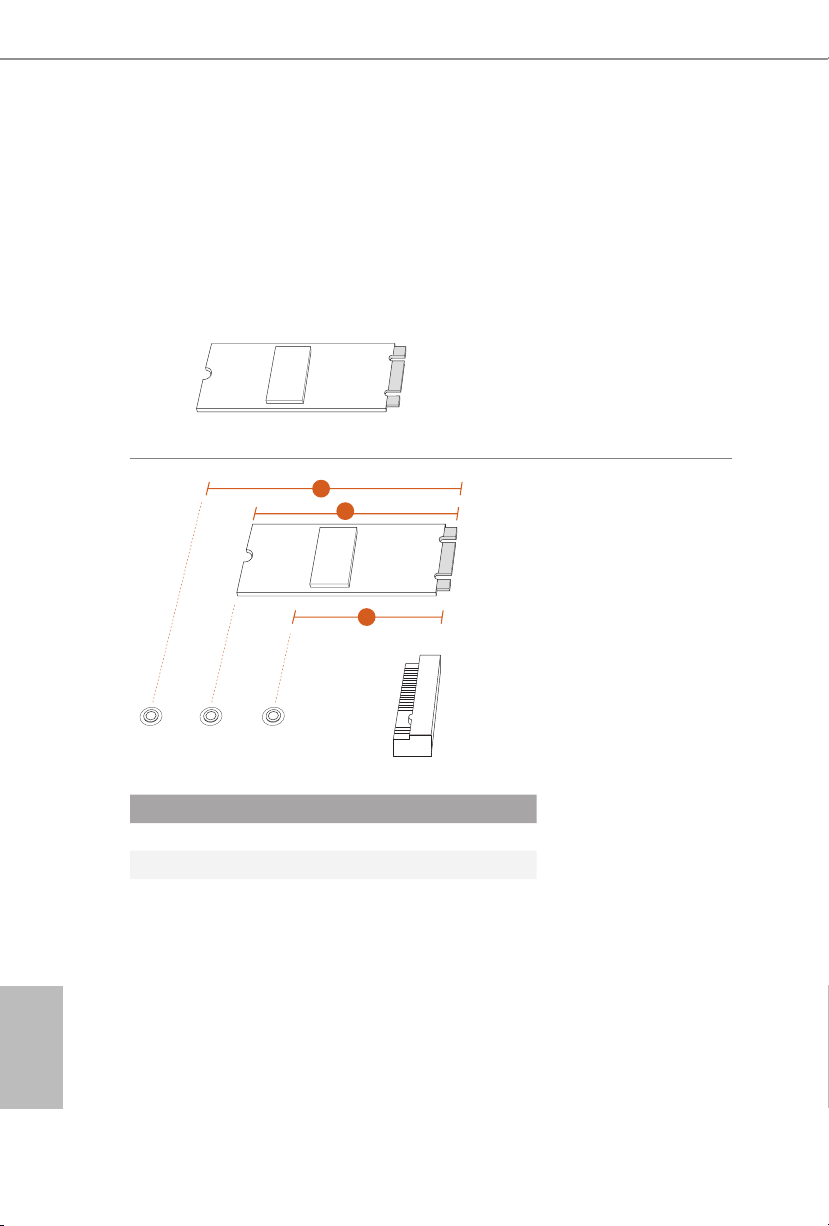

2.7 M.2_SSD (NGFF) Module Installation Guide (M2_2)

e M.2, also known as the Next Generation Form Factor (NGFF), is a small size and

versatile card edge connector that aims to replace mPCIe and mSATA. e Ultra M.2

Socket (M2_2, Key M) supports type 2242/2260/2280 PCIe Gen3x4 (32 Gb/s) mode.

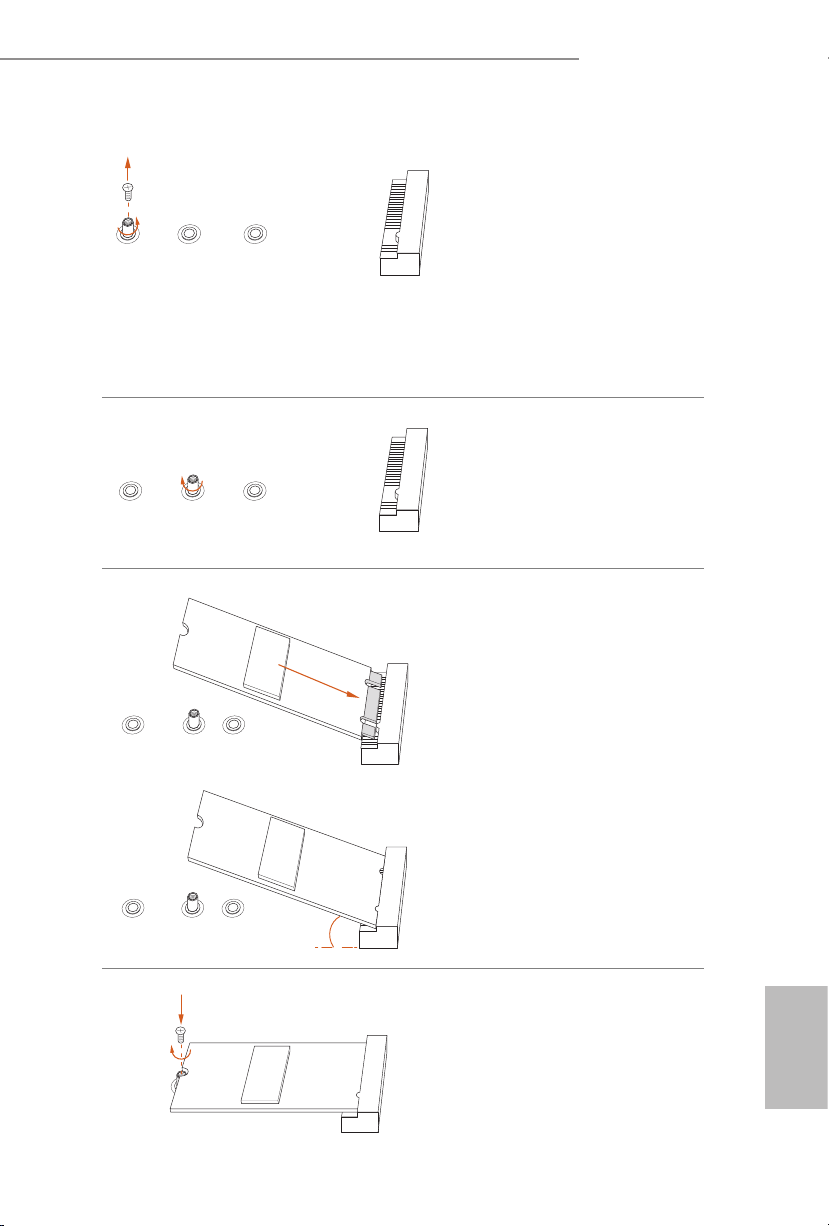

Installing the M.2_SSD (NGFF) Module

Step 1

Prepare a M.2_SSD (NGFF) module

and the screw.

English

3

2

1

ABC

No. 1 2 3

Nut Location A B C

PCB Length 4.2cm 6cm 8cm

Module Type Type2242 Type2260 Type 2280

Step 2

Depending on the PCB type and

length of your M.2_SSD (NGFF)

module, nd the corresponding nut

location to be used.

24

Page 29

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

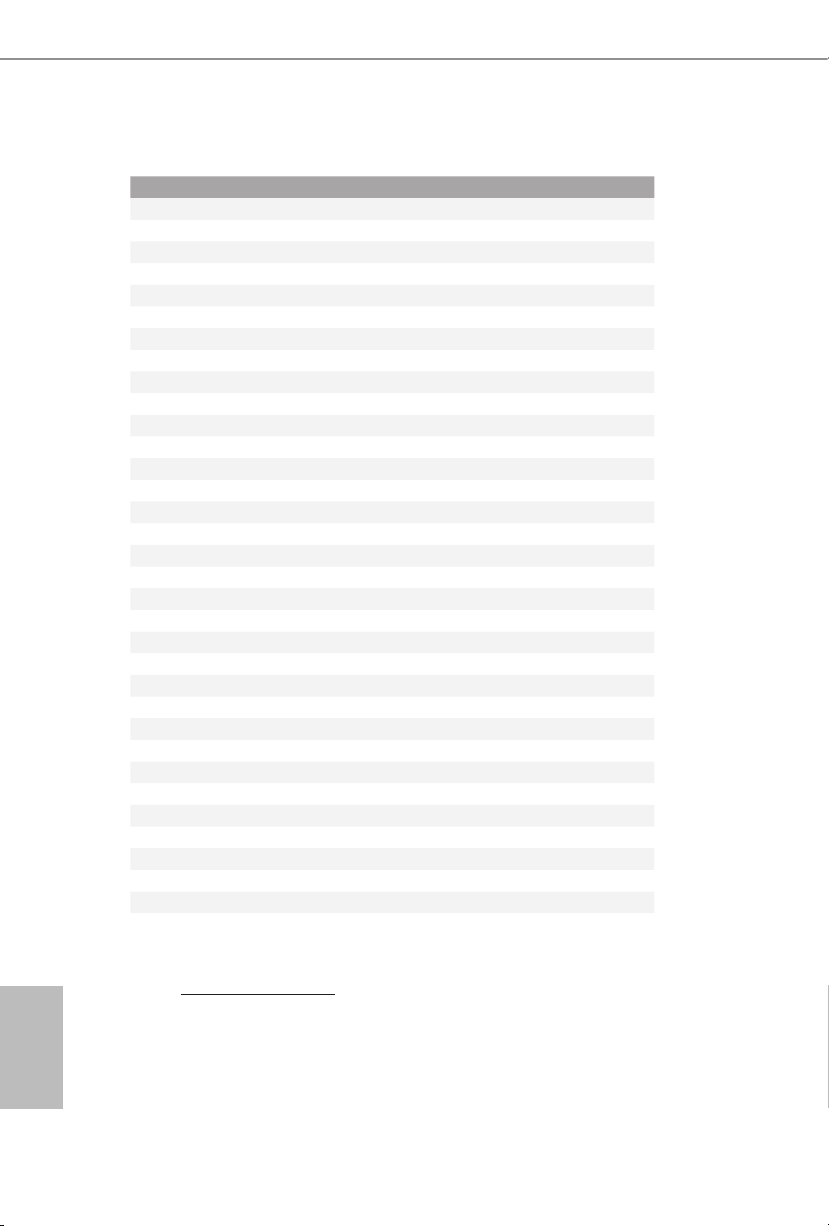

Step 3

Move the stando based on the

module type and length.

ABC

ABC

e stando is placed at the nut

location C by default. Skip Step 3 and

4 and go straight to Step 5 if you are

going to use the default nut.

Otherwise, release the stando by

hand.

Step 4

Peel o the yellow protective lm on

the nut to be used. Hand tighten the

stando into the desired nut location

on the motherboard.

Step 5

Gently insert the M.2 (NGFF) SSD

module into the M.2 slot. Please

be aware that the M.2 (NGFF) SSD

module only ts in one orientation.

ABC

ABC

o

20

Step 6

Tighten the screw with a screwdriver

to secure the module into place.

Please do not overtighten the screw as

NUT1NUT2

this might damage the module.

English

25

Page 30

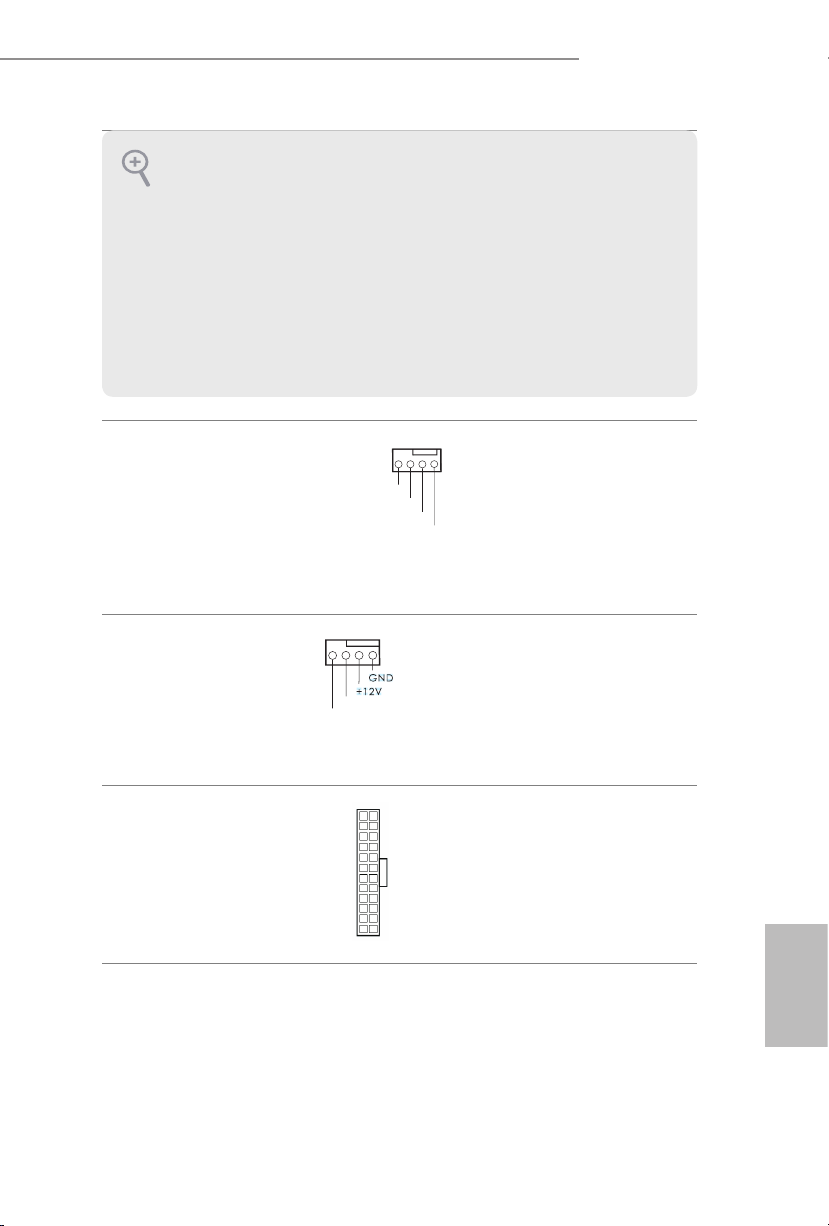

M.2_SSD (NGFF) Module Support List

Vendor Interface P/N

ADATA PCIe3 x4 ASX7000NP-128GT-C

ADATA PCIe3 x4 ASX8000NP-256GM-C

ADATA PCIe3 x4 ASX7000NP-256GT-C

ADATA PCIe3 x4 ASX8000NP-512GM-C

ADATA PCIe3 x4 ASX7000NP-512GT-C

Apacer PCIe3 x4 AP240GZ280

Corsair PCIe3 x4 CSSD-F240GBMP500

Intel PCIe3 x4 SSDPEKKF256G7

Intel PCIe3 x4 SSDPEKKF512G7

Kingston PCIe3 x4 SKC1000/480G

Kingston PCIe2 x4 SH2280S3/480G

OCZ PCIe3 x4 RVD400 -M2280-512G (NVME)

PATRIOT PCIe3 x4 PH240GPM280SSDR NVME

Plextor PCIe3 x4 PX-128M8PeG

Plextor PCIe3 x4 PX-1TM8PeG

Plextor PCIe3 x4 PX-256M8PeG

Plextor PCIe3 x4 PX-512M8PeG

Plextor PCIe PX-G256M6e

Plextor PCIe PX-G512M6e

Samsung PCIe3 x4 SM961 MZVPW128HEGM (NVM)

Samsung PCIe3 x4 PM961 MZVLW128HEGR (NVME)

Samsung PCIe3 x4 960 EVO (MZ-V6E250) (NVME)

Samsung PCIe3 x4 960 EVO (MZ-V6E250BW) (NVME)

Samsung PCIe3 x4 SM951 (NVME)

Samsung PCIe3 x4 SM951 (MZHPV256HDGL)

Samsung PCIe3 x4 SM951 (MZHPV512HDGL)

Samsung PCIe3 x4 SM951 (NVME)

Samsung PCIe x4 XP941-512G (MZHPU512HCGL)

SanDisk PCIe SD6PP4M-128G

SanDisk PCIe SD6PP4M-256G

TEAM PCIe3 x4 TM8FP2240G0C101

TEAM PCIe3 x4 TM8FP2480GC110

WD PCIe3 x4 WDS256G1X0C-00ENX0 (NVME)

WD PCIe3 x4 WDS512G1X0C-00ENX0 (NVME)

English

26

For the latest updates of M.2_SSD (NFGG) module support list, please visit our website for

details: http://www.asrock.com

Page 31

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

1 Einleitung

Vielen Dank, dass Sie sich für das H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 von

ASRock entschieden haben – ein zuverlässiges Motherboard, das konsequent unter der

strengen Qualitätskontrolle von ASRock hergestellt wurde. Es liefert ausgezeichnete Leistung

mit robustem Design, das ASRock Streben nach Qualität und Beständigkeit erfüllt.

Da die technischen Daten des Motherboards sowie die BIOS-Soware aktualisiert werden

können, kann der Inhalt dieser Dokumentation ohne Ankündigung geändert werden.

Falls diese Dokumentation irgendwelchen Änderungen unterliegt, wird die aktualisierte

Version ohne weitere Hinweise auf der ASRock-Webseite zur Verfügung gestellt. Sollten Sie

technische Hilfe in Bezug auf dieses Motherboard benötigen, erhalten Sie auf unserer Webseite

spezischen Informationen über das von Ihnen verwendete Modell. Auch nden Sie eine

aktuelle Liste unterstützter VGA-Karten und Prozessoren auf der ASRock-Webseite. ASRockWebseite http://www.asrock.com.

1.1 Lieferumfang

•

ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 Motherboard (Micro-ATXFormfaktor)

•

ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0-Schnellinstallationsanleitung

•

ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0-Support-CD

•

2 x Serial-ATA- (SATA) Datenkabel (optional)

•

1 x Schraube für M.2-Sockel (optional)

•

1 x E/A-Blendenabschirmung

27

Deutsch

Page 32

1.2 Technische Daten

•

Plattform

Prozessor

Chipsatz

Speicher

Micro-ATX-Formfaktor

•

Feststoondensator-Design

•

Unterstützt Intel® CoreTM-Prozessoren der 12. Gen. (LGA1700)

•

7-Leistungsphasendesign

•

Unterstützt Intel® Hybrid-Technologie

•

Unterstützt Intel® Turbo Boost Max Technology 3.0

•

Intel® H610

•

Dualkanal-DDR4-Speichertechnologie

•

2 x DDR4-DIMM-Steckplätze

•

Unterstützt ungepuerten DDR4-Non-ECC-Speicher bis 3200*

* Weitere Informationen nden Sie in der Speicherkompatibilitätsliste

auf der ASRock-Webseite. (http://www.asrock.com/)

•

Unterstützt ECC-UDIMM-Speichermodule (Betrieb im non-ECC-

Modus)

•

Systemspeicher, max. Kapazität: 64GB

•

Unterstützt Intel® Extreme Memory Prole (XMP) 2.0

Deutsch

28

Erweiterungssteckplatz

Grakkarte

CPU:

•

1 x PCIe 4.0 x16-Steckplätze (PCIE2), unterstützt x16-Modus*

Chipsatz:

•

1 x PCIe-3.0-x1-Steckplätze (PCIE1)*

* Unterstützt NVMe-SSD als Bootplatte

•

Integrierte Intel® UHD Graphics-Visualisierung und VGA-

Ausgänge können nur mit Prozessoren unterstützt werden, die

GPU-integriert sind.

•

Intel® Xe-Grakarchitektur (12. Gen.)

H610M-HDV/M.2 R2.0:

•

Drei Grakkarten-Ausgangsoptionen: D-Sub, HDMI und

DisplayPort 1.4

•

Unterstützt HDMI 2.1 TMDS-kompatiblen mit max. Auösung bis

4K x 2K (4096x2160) bei 60 Hz

Page 33

Audio

LAN

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

•

Unterstützt DisplayPort 1.4 mit DSC (komprimiert) max.

Auösung bis 8K (7680x4320) bei 60 Hz / 5K (5120x3200) bei

120 Hz

•

Unterstützt D-Sub mit maximaler Auösung von 1920x1200 bei

60 Hz

•

Unterstützt HDCP 2.3 mit TMDS-kompatiblen HDMI-2.1- und

DisplayPort-1.4-Ports

H610M-HVS/M.2 R2.0:

•

Dualer Grakkartenausgang: Unterstützt HDMI- und D-Sub-Ports

durch unabhängige Monitor-Controller

•

Unterstützt HDMI 2.1 TMDS-kompatiblen mit max. Auösung bis

4K x 2K (4096x2160) bei 60 Hz

•

Unterstützt D-Sub mit maximaler Auösung von 1920x1200 bei

60 Hz

•

Unterstützt HDCP 2.3 mit TMDS-kompatiblen HDMI-2.1-Port

•

7.1-Kanal-HD-Audio (Realtek ALC897/887-Audiocodec)

•

Unterstützt Überspannungsschutz

•

PCIE-x1-Gigabit-LAN 10/100/1000 Mb/s

•

1 x Realtek RTL8111H

•

Unterstützt Wake-On-LAN

•

Unterstützt Schutz gegen Blitzschlag/elektrostatische Entladung

•

Unterstützt energieezientes Ethernet 802.3az

•

Unterstützt PXE

Rückblende,

E/A

•

1 x PS/2-Maus-/Tastaturanschluss

•

2 x USB-3.2-Gen1-Ports (unterstützt Schutz gegen elektrostatische

Entladung)

•

4 x USB-2.0-Ports (unterstützt Schutz gegen elektrostatische

Entladung)

•

1 x RJ-45-LAN-Port mit LED (Aktivität/Verbindung-LED und

Geschwindigkeit-LED)

•

HD-Audioanschlüsse: Line-in / Vorderer Lautsprecher / Mikrofon

H610M-HDV/M.2 R2.0:

•

1 x D-Sub-Port

•

1 x HDMI-Port

•

1 x DisplayPort 1.4

H610M-HVS/M.2 R2.0:

•

1 x D-Sub-Port

•

1 x HDMI-Port

Deutsch

29

Page 34

Speicher

Anschluss

Chipsatz:

•

1 x Ultra-M.2-Steckplatz (M2_2, Key M), unterstützt Type-

2242/2260/2280-PCIe-Gen3x4-(32 Gb/s) Modus*

•

4 x SATA-III-6,0-Gb/s-Anschlüsse

* Unterstützt NVMe-SSD als Bootplatte

* Unterstützt ASRock U.2-Kit

•

1 x SPI-TPM-Stileiste

•

1 x Gehäuseeingri- und Lautsprecher-Stileiste

•

1 x CPU-Lüeranschluss (4-polig)

* Der CPU-Lüeranschluss unterstützt einen CPU-Lüer mit einer

maximalen Lüerleistung von 1 A (12 W).

•

1 x Anschluss Gehäuse/Wasserpumpenlüer (4-polig)

(intelligente Lüergeschwindigkeitssteuerung)

* Der Gehäuse-/Wasserpumpenlüer unterstützt einen

Wasserkühlerlüer mit einer maximalen Lüerleistung von 2 A

(24 W).

* CHA_FAN1/WP können automatisch erkennen, ob ein 3- oder

4-poliger Lüer verwendet wird.

•

1 x 24-poliger ATX-Netzanschluss

•

1 x 8-poliger 12-V-Netzanschluss

•

1 x Audioanschluss an Frontblende

•

1 x USB 2.0-Stileiste (unterstützt zwei USB 2.0-Ports) (unterstützt

Schutz gegen elektrostatische Entladung)

•

1 x USB 3.2 Gen1-Stileiste (unterstützt zwei USB 3.2 Gen1-Ports)

(unterstützt Schutz gegen elektrostatische Entladung)

Deutsch

30

BIOSFunktion

Hardwareüberwachung

•

AMI-UEFI-Legal-BIOS mit Unterstützung mehrsprachiger

grascher Benutzerschnittstellen

•

ACPI 6.0-konforme Aufweckereignisse

•

SMBIOS 2.7-Unterstützung

•

CPU-Kern/Cache, CPU-Kern/Cache Load-Line, CPU GT, CPU

GT Load-Line, DRAM, +0,82V PCH, +1,05V PCH, VCCIN AUX,

+1,8V PROC, +1,05V PROC Mehrfachspannungsanpassung

•

Lüertachometer: CPU-, Gehäuse-/Wasserpumpen-Lüer

•

Lautloser Lüer (automatische Anpassung der

Gehäuselüergeschwindigkeit durch CPU-Temperatur): CPU-,

Gehäuse-/Wasserpumpen-Lüer

•

Mehrfachgeschwindigkeitssteuerung: CPU-, Gehäuse-/

Wasserpumpen-Lüer

•

Gehäuse-oen-Erkennung

Page 35

•

Spannungsüberwachung: CPU Vcore, DRAM, +0,82 V PCH,

+1,05 V PROC, VCCIN AUX, VCCSA, +1,05 V PROC, +12 V,

+5 V, +3,3 V

•

Betriebs-

Microso® Windows® 10 64 Bit / 11 64 Bit

system

•

Zertizierungen

* Detaillierte Produktinformationen nden Sie auf unserer Webseite: http://www.asrock.com

Bitte beachten Sie, dass mit einer Übertaktung, zu der die Anpassung von BIOS-Einstellungen,

die Anwendung der Untied Overclocking Technology oder die Nutzung von

Übertaktungswerkzeugen von Drittanbietern zählen, bestimmte Risiken verbunden sind. Eine

Übertaktung kann sich auf die Stabilität Ihres Systems auswirken und sogar Komponenten

und Geräte Ihres Systems beschädigen. Sie sollte auf eigene Gefahr und eigene Kosten

durchgeführt werden. Wir übernehmen keine Verantwortung für mögliche Schäden, die durch

eine Übertaktung verursacht wurden.

FCC, CE

•

ErP/EuP ready (ErP/EuP ready-Netzteil erforderlich)

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

31

Deutsch

Page 36

1.3 Jumpereinstellung

Die Abbildung zeigt, wie die Jumper eingestellt werden. Wenn die Jumper-Kappe auf den

Kontakten angebracht ist, ist der Jumper „kurzgeschlossen“. Wenn keine Jumper-Kappe auf

den Kontakten angebracht ist, ist der Jumper „oen“.

CMOS-löschen-Jumper

(CLRMOS1)

(siehe S. 1, 2, Nr. 14)

CLRMOS1 ermöglicht Ihnen die Löschung der Daten im CMOS. Zum Löschen und

Rücksetzen der Systemparameter auf die Standardeinrichtung schalten Sie den Computer

bitte ab und ziehen das Netzkabel aus der Steckdose. Warten Sie 15 Sekunde, schließen

Sie dann die Kontakte an CLRMOS1 5 Sekunden lang mit einer Jumper-Kappe kurz.

Löschen Sie den CMOS jedoch nicht direkt nach der BIOS-Aktualisierung. Falls Sie den

CMOS direkt nach Abschluss der BIOS-Aktualisierung löschen müssen, starten Sie das

System zunächst; fahren Sie es dann vor der CMOS-Löschung herunter. Bitte beachten Sie,

dass Kennwort, Datum, Zeit und Benutzerstandardprol nur gelöscht werden, wenn die

CMOS-Batterie entfernt wird. Bitte denken Sie daran, die Jumper-Kappe nach der CMOSLöschung zu entfernen.

2-poliger Jumper

Deutsch

32

Falls Sie den CMOS löschen, wird möglicherweise ein Gehäuseeingri erkannt. Bitte passen

Sie die BIOS-Option „Status löschen“ zur Löschung der Aufzeichnung des vorherigen

Gehäuseeingristatus an.

Page 37

1.4 Integrierte Stiftleisten und Anschlüsse

Integrierte Stileisten und Anschlüsse sind KEINE Jumper. Bringen Sie KEINE Jumper-Kappen

an diesen Stileisten und Anschlüssen an. Durch Anbringen von Jumper-Kappen an diesen

Stileisten und Anschlüssen können Sie das Motherboard dauerha beschädigen.

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

Systemblende-Stileiste

(9-polig, PANEL1)

(siehe S. 1, 2, Nr. 12)

PWRBTN (Ein-/Austaste):

Mit der Ein-/Austaste an der Frontblende des Gehäuses verbinden. Sie können die Abschaltung

Ihres Systems über die Ein-/Austaste kongurieren.

RESET (Reset-Taste):

Mit der Reset-Taste an der Frontblende des Gehäuses verbinden. Starten Sie den Computer

über die Reset-Taste neu, wenn er abstürzt oder sich nicht normal neu starten lässt.

PLED (Systembetriebs-LED):

Mit der Betriebsstatusanzeige an der Frontblende des Gehäuses verbinden. Die LED leuchtet,

wenn das System läu. Die LED blinkt, wenn sich das System im S1/S3-Ruhezustand bendet.

Die LED ist aus, wenn sich das System im S4-Ruhezustand bendet oder ausgeschaltet ist (S5).

HDLED (Festplattenaktivitäts-LED):

Mit der Festplattenaktivitäts-LED an der Frontblende des Gehäuses verbinden. Die LED

leuchtet, wenn die Festplatte Daten liest oder schreibt.

Das Design der Frontblende kann je nach Gehäuse variieren. Ein Frontblendenmodul

besteht hauptsächlich aus Ein-/Austaste, Reset-Taste, Betrieb-LED, Festplattenaktivität-LED,

Lautsprecher etc. Stellen Sie beim Anschließen Ihres Frontblendenmoduls an diese Stileiste

sicher, dass Kabel- und Pinbelegung richtig abgestimmt sind.

1

PLE D+

PLE D-

HDL ED-

HDL ED+

PWR BTN #

GND

RES ET#

GND

GND

Verbinden Sie Ein-/Austaste,

Reset-Taste und

Systemstatusanzeige am Gehäuse

entsprechend der nachstehenden

Pinbelegung mit dieser Stileiste.

Beachten Sie vor Anschließen der

Kabel die positiven und negativen

Kontakte.

Gehäuseeingris- und

Lautsprecher-Stileiste

(7-polig, SPK_CI1)

(siehe S. 1, 2, Nr. 13)

DUM MY

+5V

1

SIG NAL

SPE AKE R

DUM MY

GND

DUM MY

Bitte verbinden Sie

Gehäuseeingrisvorrichtung und

den Gehäuselautsprecher mit

dieser Stileiste.

Deutsch

33

Page 38

Serial-ATA-III-Anschlüsse

Winkel rechts:

(SATA3_2:

siehe S. 1, 2, Nr. 8) (obere)

(SATA3_3:

siehe S. 1, 2, Nr. 8) (untere)

Vertikal:

(SATA3_0:

siehe S. 1, 2, Nr. 11)

(SATA3_1:

siehe S. 1, 2, Nr. 10)

SATA3_2

SATA3_1

SATA3_0

SATA3_3

Diese vier SATA-III-Anschlüsse

unterstützen SATA-Datenkabel

für interne Speichergeräte mit

einer Datenübertragungsgeschwin

digkeit bis 6,0 Gb/s.

Deutsch

USB 2.0-Stileiste

(9-polig, USB_5_6)

(siehe S. 1, 2, Nr. 7)

USB 3.2 Gen1-Stileiste

(19-polig, USB3_3_4)

(siehe S. 1, 2, Nr. 6)

Audiostileiste

Frontblende

(9-polig, HD_AUDIO1)

(siehe S. 1, 2, Nr. 15)

DUM MY

GND GND

+B

USB _PW R

Vbus

IntA _PA_S SRX-

IntA _PA_S SRX+

GND

IntA _PA_S STX-

IntA _PA_S STX+

GND

IntA _PA_D -

IntA _PA_D +

GND

1

MIC 2_L

-B

PRE SEN CE#

MIC _RE T

OUT 2_R

MIC 2_R

+A

-A

USB _PW R

1

VbusVbus

IntA _PB_ SSRX -

IntA _PB_ SSRX +

GND

IntA _PB_ SSTX -

IntA _PB_ SSTX +

GND

IntA _PB_ D-

IntA _PB_ D+

Dumm y

1

OUT _RE T

OUT 2_L

J_S ENS E

Es gibt eine Stileiste an diesem

Motherboard. Diese USB 2.0Stileiste unterstützt zwei Ports.

Es gibt eine Stileiste an diesem

Motherboard. Diese USB-3.2Gen1-Stileiste kann zwei Ports

unterstützen.

Diese Stileiste dient dem

Anschließen von Audiogeräten an

der Frontblende.

34

Page 39

H610M-HDV/M.2 R2.0

CPU_ FAN_SP EED

FAN_S PEED_ CONTR OL

4 3 2 1

H610M-HVS/M.2 R2.0

1. High Denition Audio unterstützt Anschlusserkennung, der Draht am Gehäuse muss dazu

jedoch HDA unterstützt. Bitte befolgen Sie zum Installieren Ihres Systems die Anweisungen

in unserer Anleitung und der Anleitung zum Gehäuse.

2. Bei Nutzung eines AC’97-Audiopanels dieses bitte anhand folgender Schritte an der

Audiostileiste der Frontblende installieren:

A. Mic_IN (Mikrofon) mit MIC2_L verbinden.

B. Audio_R (RIN) mit OUT2_R und Audio_L (LIN) mit OUT2_L verbinden.

C. Erde (GND) mit Erde (GND) verbinden.

D. MIC_RET und OUT_RET sind nur für das HD-Audiopanel vorgesehen. Sie müssen sie

nicht für das AC’97-Audiopanel verbinden.

E. Rufen Sie zum Aktivieren des vorderen Mikrofons das „FrontMic (Vorderes Mikrofon)“Register in der Realtek-Systemsteuerung auf und passen „Recording Volume

(Aufnahmelautstärke)“ an.

Gehäuse-/WasserpumpenLüeranschlusse

(4-polig, CHA_FAN1/WP)

(siehe S. 1, Nr. 4)

CPU-Lüeranschluss

(4-polig, CPU_FAN1)

(siehe S. 1, Nr. 2)

ATX-Netzanschluss

(24-polig, ATXPWR1)

(siehe S. 1, 2, Nr. 5)

FAN _SP EED _CO NTR OL

CHA _FA N_S PEE D

FAN _VO LTA GE

12 124

4 3 2 1

13

Dieses Motherboard bietet

einen 4-poligen WasserkühlungGehäuselüeranschluss. Falls

Sie einen 3-poligen Gehäuse-

GND

Wasserkühlerlüer anschließen

möchten, verbinden Sie ihn bitte

mit Kontakt 1 bis 3.

Dieses Motherboard bietet einen

4-poligen CPU-Lüeranschluss

(lautloser Lüer). Falls Sie einen

3-poligen CPU-Lüer anschließen

möchten, verbinden Sie ihn bitte

mit Kontakt 1 bis 3.

Dieses Motherboard bietet einen

24-poligen ATX-Netzanschluss.

Bitte schließen Sie es zur Nutzung

eines 20-poligen ATX-Netzteils

entlang Kontakt 1 und Kontakt 13

an.

Deutsch

35

Page 40

ATX-12-V-Netzanschluss

8 5

(8-polig, ATX12V1)

(siehe S. 1, 2, Nr. 1)

4

Dieses Motherboard bietet

einen 8-poligen ATX-12-V-

1

Netzanschluss. Bitte schließen Sie

es zur Nutzung eines 4-poligen

ATX-Netzteils entlang Kontakt 1

und Kontakt 5 an.

*Warnung: Bitte stellen Sie

sicher, dass das Stromkabel

der CPU und nicht das der

Grakkarte angeschlossen

ist. Schließen Sie das PCIe-

Stromkabel nicht an diesen

Anschluss an.

Deutsch

SPI-TPM-Stileiste

(13-polig, SPI_TPM_J1)

(siehe S. 1, 2, Nr. 9)

TPM _ PIR Q

RST #

SPI _ MOS I

Dum m y

SPI _ PWR

SPI _ DQ3

CLK

1

SPI _ TPM _CS #

GND

RSM R ST#

SPI _ MIS O

SPI _ CS0

SPI _ DQ2

Dieser Anschluss unterstützt

das SPI Trusted Platform

Module- (TPM) System, das

Schlüssel, digitale Zertikate,

Kennwörter und Daten sicher

auewahren kann. Ein TPMSystem hil zudem bei der

Stärkung der Netzwerksicherheit,

schützt digitale Identitäten

und gewährleistet die

Plattformintegrität.

36

Page 41

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

1 Introduction

Nous vous remercions d’avoir acheté cette carte mère ASRock H610M-HDV/M.2 R2.0 /

H610M-HVS/M.2 R2.0, une carte mère able fabriquée conformément au contrôle de qualité

rigoureux et constant appliqué par ASRock. Fidèle à son engagement de qualité et de

durabilité, ASRock vous garantit une carte mère de conception robuste aux performances

élevées.

Les spécications de la carte mère et du logiciel BIOS pouvant être mises à jour, le contenu

de ce document est soumis à modication sans préavis. En cas de modications du présent

document, la version mise à jour sera disponible sur le site Internet ASRock sans notication

préalable. Si vous avez besoin d’une assistance technique pour votre carte mère, veuillez visiter

notre site Internet pour plus de détails sur le modèle que vous utilisez. La liste la plus récente

des cartes VGA et des processeurs pris en charge est également disponible sur le site Internet de

ASRock. Site Internet ASRock http://www.asrock.com.

1.1 Contenu de l’emballage

•

Carte mère ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 (facteur de forme

Micro ATX)

•

Guide d’installation rapide ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0

•

CD d’assistance ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0

•

2 x câbles de données Serial ATA (SATA) (Optionnel)

•

1 x vis pour socket M.2 (Optionnel)

•

1 x panneau de protection E/S

37

Français

Page 42

1.2 Spécications

•

Plateforme

Facteur de forme Micro ATX

•

Conception à condensateurs solides

Processeur

Chipset

Mémoire

Fente

d’expansion

•

Prend en charge les processeurs 12

(LGA1700)

•

Alimentation à 7 phases

•

Prend en charge Intel® Hybrid Technology

•

Prend en charge la technologie Intel® Turbo Boost Max 3.0

•

Intel® H610

•

Technologie mémoire double canal DDR4

•

2 x fentes DIMM DDR4

•

Prise en charge des mémoires DDR4 non-ECC, sans tampon et

jusqu'à 3200*

* Veuillez consulter la liste de prise en charge des mémoires sur le site

Web d'ASRock pour de plus amples informations.

(http://www.asrock.com/)

•

Prend en charge les modules mémoire UDIMM ECC (fonctionne

en mode non-ECC)

•

Capacité max. de la mémoire système : 64GO

•

Prend en charge Intel® Extreme Memory Prole (XMP) 2.0

Processeur:

•

1 x Fente PCIe 4.0 x16 (PCIE2), prend en charge le mode x16*

Chipset:

•

1 x Fent PCIe 3.0 x1 (PCIE1)*

ème

génération Intel® CoreTM

Français

38

Graphiques

* Prend en charge les SSD NVMe comme disques de démarrage

•

La technologie Intel® UHD Graphics Built-in Visuals et les sorties

VGA sont uniquement prises en charge par les processeurs

intégrant un contrôleur graphique.

•

Architecture graphique Intel® Xe (Gen 12)

H610M-HDV/M.2 R2.0:

•

Trois options de sortie graphique : D-Sub, HDMI et DisplayPort 1.4

•

Prend en charge la technologie HDMI 2.1 TMDS Compatible avec

résolution maximale de 4K x 2K (4096x2160) @ 60Hz

Page 43

Audio

Réseau

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

•

Prend en charge DisplayPort 1.4 avec résolution max. DSC

(compressée) jusqu’à 8K (7680x4320) @ 60 Hz / 5K (5120x3200) @

120Hz

•

Prend en charge le mode D-Sub avec une résolution maximale de

1920x1200 @ 60Hz

•

Prend en charge HDCP 2.3 avec ports HDMI 2.1 compatibles

TMDS et DisplayPort 1.4

H610M-HVS/M.2 R2.0:

•

Double sortie graphique: Prend en charge les ports D-Sub et

HDMI via contrôleurs d’achage indépendants

•

Prend en charge la technologie HDMI 2.1 TMDS Compatible avec

résolution maximale de 4K x 2K (4096x2160) @ 60Hz

•

Prend en charge le mode D-Sub avec une résolution maximale de

1920x1200 @ 60Hz

•

Prend en charge HDCP 2.3 via port HDMI 2.1 TMDS Compatible

•

Audio 7.1 CH HD (Codec audio Realtek ALC897/887)

•

Prend en charge la protection contre les surtensions

•

PCIE x1 Gigabit LAN 10/100/1000 Mo/s

•

1 x Realtek RTL8111H

•

Prend en charge la fonction Wake-On-LAN

•

Prend en charge la protection contre la foudre/les décharges

électrostatiques

•

Prend en charge la fonction d’économie d’énergie Ethernet 802.3az

•

Prend en charge PXE

Connectique

du panneau

arrière

•

1 x port souris/clavier PS/2

•

2 x ports USB 3.2 Gen1 (Protection contre les décharges

électrostatiques)

•

4 x ports USB 2.0 (Protection contre les décharges électrostatiques)

•

1 x port RJ-45 LAN avec LED (LED ACT/LIEN et LED VITESSE)

•

Connecteurs jack audio HD : Entrée ligne / haut-parleur avant /

microphone

H610M-HDV/M.2 R2.0:

•

1 x port D-Sub

•

1 x port HDMI

•

1 x DisplayPort 1.4

H610M-HVS/M.2 R2.0:

•

1 x port D-Sub

•

1 x port HDMI

Français

39

Page 44

Stockage

Connecteur

Chipset:

•

1 x socket Ultra M.2 (M2_2, Key M), prend en charge le mode PCIe

Gen3x4 (32 Gb/s) type 2242/2260/2280*.

•

4 x connecteur SATA3 6,0 Go/s

* Prend en charge les SSD NVMe comme disques de démarrage

* Prend en charge le kit ASRock U.2

•

1 x embase SPI TPM

•

1 x prise LED d’alimentation et emplacement sur châssis

•

1 x connecteur pour ventilateur de CPU (4 broches)

* Le connecteur pour ventilateur de CPU prend en charge un

ventilateur de CPU d'une puissance maximale de 1 A (12 W).

•

1 x connecteur pour ventilateur de châssis /pompe à eau

(4 broches) (contrôle de vitesse de ventilateur intelligent)

* Le ventilateur de châssis /pompe à eau prend en charge un ventilateur

de refroidisseur d'eau d'une puissance maximale de 2 A (24 W).

* CHA_FAN1/WP peuvent détecter automatiquement si un ventilateur

3 broches ou 4 broches est utilisé.

•

1 x connecteur d’alimentation ATX 24 broches

•

1 x connecteur d’alimentation 12V 8 broches

•

1 x connecteur audio panneau frontal

•

1 x embase USB 2.0 (2 ports USB 2.0 pris en charge) (Protection

contre les décharges électrostatiques)

•

1 x embase USB 3.2 Gen1 (2 ports USB 3.2 Gen1 pris en charge)

(Protection contre les décharges électrostatiques)

Français

40

Caractéristiques du

BIOS

Surveillance

du matériel

•

BIOS UEFI AMI avec prise en charge d’interface graphique

multilingue

•

Compatible ACPI 6.0 Wake Up Events

•

Compatible SMBIOS 2.7

•

Réglage de la tension CPU Core/Cache, CPU Core/Cache Load-

Line, CPU GT, CPU GT Load-Line, DRAM, +0,82V PCH, +1,05V

PCH, VCCIN AUX, +1,8V PROC, +1,05V PROC

•

Tachymètre de ventilateur : Ventilateurs de CPU / châssis / pompe

à eau

•

Ventilateur silencieux (réglage automatique de la vitesse du

ventilateur du châssis d’après la température du CPU) : Ventilateurs

de CPU / châssis / pompe à eau

•

Contrôle simultané des vitesses du ventilateur : Ventilateurs de

CPU / châssis / pompe à eau

•

Détection CHÂSSIS OUVERT

Page 45

•

Surveillance de la tension d’alimentation : CPU Vcore, DRAM,

+0,82V PCH, +1,05V PCH, VCCIN AUX, VCCSA, +1,05V PROC,

+12V, +5V, +3,3V

•

Système

Microso® Windows® 10 64-bits / 11 64-bits

d’exploitation

•

Certications

* pour des informations détaillées de nos produits, veuillez visiter notre site: http://www.asrock.com

Il est important de signaler que l’overclocking présente certains risques, incluant des

modications du BIOS, l’application d’une technologie d’overclocking déliée et l’utilisation

d’outils d’overclocking développés par des tiers. La stabilité de votre système peut être aectée

par ces pratiques, voire provoquer des dommages aux composants et aux périphériques du

système. L’overclocking se fait à vos risques et périls. Nous ne pourrons en aucun cas être tenus

pour responsables des dommages éventuels provoqués par l’overclocking.

FCC, CE

•

ErP/EuP Ready (alimentation ErP/EuP ready requise)

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

41

Français

Page 46

1.3 Conguration des cavaliers (jumpers)

L’illustration ci-dessous vous renseigne sur la conguration des cavaliers (jumpers). Lorsque

le capuchon du cavalier est installé sur les broches, le cavalier est «court-circuité». Si le

capuchon du cavalier n’est pas installé sur les broches, le cavalier est «ouvert».

Cavalier Clear CMOS

(CLRMOS1)

(voir p.1 ou 2, No. 14)

CLRMOS1 vous permet d’eacer les donnés de la CMOS. Pour eacer les paramètres du

système et rétablir les valeurs par défaut, veuillez éteindre votre ordinateur et débrancher

son cordon d’alimentation. Patientez 15 secondes, puis utilisez un capuchon de cavalier

pour court-circuiter les broches sur CLRMOS1 pendant 5 secondes. Toutefois, n’eacez

pas la CMOS immédiatement après avoir mis à jour le BIOS. Si vous avez besoin d’eacer

les données CMOS après une mise à jour du BIOS, vous devez tout d’abord redémarrer le

système, puis l’éteindre avant de procéder à l’eacement de la CMOS. Veuillez noter que les

paramètres mot de passe, date, heure et prol de l’utilisateur seront uniquement eacés en

cas de retrait de la pile de la CMOS. N’oubliez pas de retirer le capuchon du cavalier une

fois les données CMOS eacées.

Cavalier (jumper) à

2 broches

Français

Si vous eacez la CMOS, l’alerte de châssis ouvert peut se déclencher. Veuillez régler l’option du

BIOS sur «Eacer » pour supprimer l’historique des intrusions de châssis précédentes.

42

Page 47

1.4 Embases et connecteurs de la carte mère

SPE AKE R

Les embases et connecteurs situés sur la carte NE SONT PAS des cavaliers. Ne placez JAMAIS

de capuchons de cavaliers sur ces embases ou connecteurs. Placer un capuchon de cavalier sur

ces embases ou connecteurs endommagera irrémédiablement votre carte mère.

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

Embase du panneau

système

(PANNEAU1 à 9 broches)

(voir p.1 ou 2, No. 12)

PWRBTN (bouton d’alimentation) :

pour brancher le bouton d’alimentation du panneau frontal du châssis. Vous pouvez congurer

la façon dont votre système doit s’arrêter à l’aide du bouton d'alimentation.

RESET (bouton de réinitialisation) :

pour brancher le bouton de réinitialisation du panneau frontal du châssis. Appuyez

sur le bouton de réinitialisation pour redémarrer l’ordinateur en cas de plantage ou de

dysfonctionnement au démarrage.

PLED (LED d’alimentation du système) :

pour brancher le témoin d’état de l’alimentation du panneau frontal du châssis. Le LED est

allumé lorsque le système fonctionne. Le LED clignote lorsque le système se trouve en mode

veille S1/S3. Le LED est éteint lorsque le système se trouve en mode veille S4 ou hors tension (S5).

HDLED (LED d’activité du disque dur) :

pour brancher le témoin LED d’activité du disque dur du panneau frontal du châssis. Le LED

est allumé lorsque le disque dur lit ou écrit des données.

La conception du panneau frontal peut varier en fonction du châssis. Un module de panneau

frontal est principalement composé d’un bouton d'alimentation, d'un bouton de réinitialisation,

d'un témoin LED d’alimentation, d'un témoin LED d’activité du disque dur, d'un haut-parleur

etc. Lorsque vous reliez le module du panneau frontal de votre châssis sur cette embase, veillez

à parfaitement faire correspondre les ls et les broches.

1

PLE D+

PLE D-

HDL ED-

HDL ED+

PWR BTN #

GND

RES ET#

GND

GND

Branchez le bouton de mise

en marche, le bouton de

réinitialisation et le témoin d’état

du système présents sur le châssis

sur cette embase en respectant la

conguration des broches illustrée

ci-dessous. Repérez les broches

positive et négative avant de

brancher les câbles.

Prise LED d’alimentation et

emplacement sur châssis

(SPK_CI1 à 7 broches)

(voir p.1 ou 2, No. 13)

DUM MY

+5V

1

SIG NAL

DUM MY

GND

DUM MY

Français

Veuillez brancher l'emplacement

sur le châssis et le haut-parleur du

châssis sur ce connecteur.

43

Page 48

Connecteurs Serial ATA3

Angle droit:

(SATA3_2:

voir p.1, 2, No. 8)

(Supérieur)

(SATA3_3:

voir p.1, 2, No. 8)

(Inférieur)

Vertical:

(SATA3_0:

voir p.1, 2, No. 11)

(SATA3_1:

voir p.1, 2, No. 10)

SATA3_2

SATA3_1

SATA3_0

SATA3_3

Ces quatre connecteurs SATA3

sont compatibles avec les câbles de

données SATA pour les appareils

de stockage internes avec un taux

de transfert maximal de 6,0 Go/s.

Français

Embase USB 2.0

(USB_5_6 à 9 broches)

(voir p.1 ou 2, No. 7)

Embase USB 3.2 Gen1

(USB3_3_4 à 19 broches)

(voir p.1 ou 2, No. 6)

Embase audio du panneau

frontal

(HD_AUDIO1 à

9 broches)

(voir p.1 ou 2, No. 15)

DUM MY

GND GND

+B

USB _PW R

Vbus

IntA _PA_S SRX-

IntA _PA_S SRX+

GND

IntA _PA_S STX-

IntA _PA_S STX+

GND

IntA _PA_D -

IntA _PA_D +

GND

1

MIC 2_L

-B

PRE SEN CE#

MIC _RE T

OUT 2_R

MIC 2_R

+A

-A

USB _PW R

1

VbusVbus

IntA _PB_ SSRX -

IntA _PB_ SSRX +

GND

IntA _PB_ SSTX -

IntA _PB_ SSTX +

GND

IntA _PB_ D-

IntA _PB_ D+

Dumm y

1

OUT _RE T

OUT 2_L

J_S ENS E

Cette carte mère comprend un

connecteur. Cette embase USB

2.0 peut prendre en charge deux

ports.

Cette carte mère comprend un

connecteur. Cette embase USB 3.2

Gen1 peut prendre en charge deux

ports.

Cette embase sert au branchement

des appareils audio au panneau

audio frontal.

44

Page 49

H610M-HDV/M.2 R2.0

CPU_ FAN_SP EED

FAN_S PEED_ CONTR OL

4 3 2 1

H610M-HVS/M.2 R2.0

1. L’audio haute dénition prend en charge la technologie Jack Sensing (détection de la che),

mais le panneau grillagé du châssis doit être compatible avec la HDA pour fonctionner

correctement. Veuillez suivre les instructions gurant dans notre manuel et dans le manuel

du châssis pour installer votre système.

2. Si vous utilisez un panneau audio AC’97, veuillez le brancher sur l’embase audio du

panneau frontal en procédant comme suit :

A. branchez Mic_IN (MIC) sur MIC2_L.

B. branchez Audio_R (RIN) sur OUT2_R et Audio_L (LIN) sur OUT2_L.

C. branchez la mise à terre (GND) sur mise à terre (GND).

D. MIC_RET et OUT_RET sont exclusivement réservés au panneau audio HD. Il est

inutile de les brancher avec le panneau audio AC’97.

E. Pour activer le micro frontal, sélectionnez l’onglet «FrontMic» du panneau de

contrôle Realtek et réglez le paramètre «Volume d’enregistrement».

Connecteurs du

ventilateur de châssis/

pompe à eau

(CHA_FAN1/WP à

4 broches)

(voir p.1 ou 2, No. 4)

Connecteur du ventilateur

du processeur

(CPU_FAN1 à 4 broches)

(voir p.1 ou 2, No. 2)

Connecteur d’alimentation

ATX

(ATXPWR1 à 24 broches)

(voir p.1 ou 2, No. 5)

FAN _SP EED _CO NTR OL

CHA _FA N_S PEE D

FAN _VO LTA GE

12 124

4 3 2 1

13

Cette carte mère est dotée d’un

connecteur pour ventilateur de

châssis à refroidissement par eau

à 4 broches. Si vous envisagez

GND

de connecter un ventilateur de

refroidisseur d'eau pour châssis à

3 broches, veuillez le brancher sur

la Broche 1-3.

Cette carte mère est dotée d’un

connecteur pour ventilateur de

processeur (Quiet Fan) à

4 broches. Si vous envisagez

de connecter un ventilateur de

processeur à 3 broches, veuillez le

brancher sur la broche 1-3.

Cette carte mère est dotée d’un

connecteur d’alimentation ATX

à 24 broches. Pour utiliser une

alimentation ATX à 20 broches,

veuillez eectuer les branchements

sur la Broche 1 et la Broche 13.

Français

45

Page 50

Connecteur d’alimentation

8 5

ATX 12 V

(ATX12V1 à 8 broches)

(voir p.1 ou 2, No. 1)

4

Cette carte mère est dotée d’un

connecteur d’alimentation ATX

1

12 V à 8 broches. Pour utiliser une

alimentation ATX à 4 broches,

veuillez eectuer les branchements

sur la Broche 1 et la Broche 5.

*Avertissement : Veuillez vérier

que le câble d'alimentation

connecté est pour l'unité

centrale et non pour la carte

graphique. Ne branchez pas le

câble d'alimentation PCIe sur ce

connecteur.

Français

Embase SPI TPM

(SPI_TPM_J1 à

13 broches)

(voir p.1 ou 2, No. 9)

TPM _ PIR Q

RST #

SPI _ MOS I

Dum m y

SPI _ PWR

SPI _ DQ3

CLK

1

SPI _ TPM _CS #

GND

RSM R ST#

SPI _ MIS O

SPI _ CS0

SPI _ DQ2

Ce connecteur prend en charge

un module SPI TPM (Trusted

Platform Module – Module de

plateforme sécurisée), qui permet

de sauvegarder clés, certicats

numériques, mots de passe et

données en toute sécurité. Le

système TPM permet également

de renforcer la sécurité du

réseau, de protéger les identités

numériques et de préserver

l’intégrité de la plateforme.

46

Page 51

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

1 Introduzione

Congratulazioni per l’acquisto della scheda madre ASRock H610M-HDV/M.2 R2.0 /

H610M-HVS/M.2 R2.0, una scheda madre adabile prodotta secondo i severissimi controlli

di qualità ASRock. La scheda madre ore eccellenti prestazioni con un design robusto che si

adatta all'impegno di ASRock di orire sempre qualità e durata.

Dato che le speciche della scheda madre e del soware BIOS possono essere aggiornate, il

contenuto di questa documentazione sarà soggetto a variazioni senza preavviso. Nel caso di

eventuali modiche della presente documentazione, la versione aggiornata sarà disponibile sul

sito Web di ASRock senza ulteriore preavviso. Per il supporto tecnico correlato a questa scheda

madre, visitare il nostro sito Web per informazioni speciche relative al modello attualmente

in uso. È possibile trovare l'elenco di schede VGA più recenti e di supporto di CPU anche sul

sito Web di ASRock. Sito Web di ASRock http://www.asrock.com.

1.1 Contenuto della confezione

•

Scheda madre H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0 ASRock (fattore di forma

micro ATX)

•

Guida all'installazione rapida di ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2

R2.0

•

CD di supporto ASRock H610M-HDV/M.2 R2.0 / H610M-HVS/M.2 R2.0

•

2 x cavi dati Serial ATA (SATA) (opzionali)

•

1 x viti per Socket M.2 (opzionali)

•

1 x mascherina metallica posteriore I/O

47

Italiano

Page 52

1.2 Speciche

Piattaforma

CPU

Chipset

Memoria

•

Fattore di forma Micro ATX

•

Design condensatore solido

•

Supporta processori 12th Generation Intel® CoreTM (LGA1700)

•

Potenza a 7 fasi

•

Supporta la tecnologia Intel® Hybrid

•

Supporta la tecnologia Intel® Turbo Boost Max 3.0

•

Intel® H610

•

Tecnologia memoria DDR4 Dual Channel

•

2 x alloggi DIMM DDR4

•

Supporta memoria DDR4 non ECC, senza buer no a 3200*

* Per maggiori informazioni fare riferimento all'elenco dei supporti di

memoria sul sito di ASRock. (http://www.asrock.com/)

•

Supporta moduli di memoria ECC UDIMM (funziona in modalità

non ECC)

•

Capacità max. della memoria di sistema: 64GB

•

Supporto di XMP (Extreme Memory Prole) Intel® 2.0

Italiano

48

Alloggio

d’espansione

Graca

CPU:

•

1 x PCIe 4.0 x16 Slot (PCIE2), supporta la modalità x16*

Chipset:

•

1 x PCIe 3.0 x1 Slot (PCIE1)*

* Supporto di SSD NVMe come disco d’avvio

•

La videograca integrata della scheda video UHD Intel® e le uscite

VGA possono essere supportate soltanto con processori con GPU

integrata.

•

Architettura graca Intel® Xe (Gen 12)

H610M-HDV/M.2 R2.0:

•

Tre opzioni di output graco: D-Sub, HDMI e DisplayPort 1.4

•

Supporta HDMI 2.1 compatibile TMDS con risoluzione massima

no a 4K x 2K (4096 x 2160) a 60Hz

Page 53

Audio

LAN

H610M-HDV/M.2 R2.0

H610M-HVS/M.2 R2.0

•

Supporta DisplayPort 1.4 con DSC (compresso) risoluzione max.

no a 8K (7680 x 4320) a 60 Hz / 5K (5120 x 3200) a 120 Hz

•

Supporta D-Sub con una risoluzione max. no a 1920 x 1200 a

60 Hz

•

Supporta HDCP 2.3 con HDMI 2.1 compatibile TMDS e porte

DisplayPort 1.4

H610M-HVS/M.2 R2.0:

•

Doppia uscita graca: Supporto di porte HDMI e D-Sub tramite

controller display indipendenti

•

Supporta HDMI 2.1 compatibile TMDS con risoluzione massima

no a 4K x 2K (4096 x 2160) a 60 Hz

•

Supporta D-Sub con una risoluzione max. no a 1920 x 1200 a

60 Hz

•

Supporta HDCP 2.3 con HDMI 2.1 compatibile TMDS porte

•

Audio HD 7.1 CH (codec audio Realtek ALC897/887)

•

Supporta protezione da sovratensione

•

1 x PCIE LAN Gigabit 10/100/1000 Mb/s

•

1 x Realtek RTL8111H

•

Supporto WOL (Wake-On-LAN)

•

Supporta protezione da fulmini/scariche elettrostatiche

•

Supporto Energy Ecient Ethernet 802.3az

•

Supporto PXE

I/O pannello

posteriore

•

1 x porta mouse/tastiera PS/2

•

2 x porte USB 3.2 Gen1 (supporto protezione da scariche

elettrostatiche)

•

4 x porte USB 2.0 (supporto protezione da scariche elettrostatiche)

•

1 x porta LAN RJ-45 con LED (ACT/LINK LED e SPEED LED)

•

Connettori audio HD: Ingresso linea / altoparlante frontale /

microfono

H610M-HDV/M.2 R2.0:

•

1 x porta D-Sub

•

1 x porta HDMI

•

1 x DisplayPort 1.4

H610M-HVS/M.2 R2.0:

•

1 x porta D-Sub

•

1 x porta HDMI

Italiano

49

Page 54

Archiviazione

Connettore

Chipset:

•

1 x socket Ultra M.2 (M2_2, Key M), supporta la modalità tipo

2242/2260/2280 PCIe Gen3x4 (32 Gb/s)*

•

4 x Connettori SATA3 6,0 Gb/s

* Supporto di SSD NVMe come disco d’avvio

* Supporta kit ASRock U.2

•

1 x connettore SPI TPM

•

1 x collegamento altoparlante e intrusione telaio

•

1 x connettore ventola CPU (4-pin)

* Il connettore ventola CPU supporta ventole CPU con potenza

massima di 1 A (12 W).

•

1 x connettore ventola chassis/ventola pompa dell’acqua (4 pin)

(Controllo intelligente della velocità della ventola)

* La ventola Chassis/ventola pompa dell’acqua supporta ventole di

sistemi di rareddamento ad acqua di potenza massima di 2 A (24W).

* CHA_FAN1/WP sono in grado di rilevare se è in uso una ventola a

3 pin o 4 a pin.

•

1 x connettore alimentazione ATX 24-pin

•

1 x connettore alimentazione 12 V 8-pin

•

1 x connettore audio pannello frontale

•

1 x connettore USB 2.0 (supporto di 2 porte USB 2.0) (supporto

protezione da scariche elettrostatiche)

•

1 x connettore USB 3.2 Gen1 (supporto di 2 porte USB 3.2 Gen1)

(supporto protezione da scariche elettrostatiche)

Italiano

50

Funzionalità

BIOS

Hardware

Monitor

•

AMI UEFI Legal BIOS con interfaccia di supporto multilingue

•

Eventi di riattivazione conformi a ACPI 6.0

•

Supporto di SMBIOS 2.7

•

Regolazione multipla tension CPU Core/Cache, CPU Core/Cache

Load-Line, CPU GT, CPU GT Load-Line, DRAM, +0,82V PCH,

+1,05V PCH, VCCIN AUX, +1,8V PROC, +1,05V PROC

•

Tachimetro ventola: Ventole CPU, chassis, pompa dell’acqua

•

Ventola silenziosa (regolazione automatica velocità in base alla

temperatura della CPU): Ventole CPU, chassis, pompa dell’acqua

•

Controllo velocità ventola: Ventole CPU, chassis, pompa dell’acqua

•

Rilevamento CASE OPEN

Page 55

•

Monitoraggio tensione: CPU Vcore, DRAM, + 0,82 V PCH,

+1,05 V PCH, VCCIN AUX, VCCSA, +1,05 V PROC, +12 V,

+ 5 V, + 3,3 V

•

SO

Certicazioni

* Per informazioni dettagliate sul prodotto, visitare il nostro sito Web: http://www.asrock.com

Prestare attenzione al potenziale rischio previsto nella pratica di overclocking, inclusa la

regolazione delle impostazioni nel BIOS, l'applicazione di tecnologia di Untied Overclocking o

l'utilizzo di strumenti di overclocking di terze parti. L'overclocking può inuenzare la stabilità