Page 1

Instructions for use

WASHING MACHINE

NA

English, 1

FR

Français, 19

ARWXF 129 W

ES

Español, 37

Contents

Important safety instructions 2-3

Important safety instructions

Grounding Instructions

Safety

Installation instructions 4-5-6

Unpacking and leveling

Minimum Installation Spacing

Connecting Water Inlet

Drainage

Connecting the drain hose

Electrical

Under Sink Method

Technical data

Description of the washing machine

and starting a wash cycle 7-8

Control panel

Indicator lights

Starting a wash cycle

Wash cycles 9

Table of wash cycles

Special wash cycles

NA

Personalisation 10-11

Setting the temperature

Setting the spin speed

Functions

Detergents and laundry 12

Detergent dispenser drawer

Bleach cycle

Preparing the laundry

Garments requiring special care

Load balancing system

Helpful Hints

Care and maintenance instructions 13

Cutting off the water and electricity supplies

Cleaning the washing machine

Cleaning the detergent dispenser drawer

Caring for the door and drum of your appliance

Cleaning the pump

Checking the water inlet hose

RV/Marine Winterization

Troubleshooting 15

Service 16

Warranty, 17-18

1

Page 2

Important safety instructions

NA

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce the risk of fire, electrical shock, or

injury to persons when using your appliance, follow basic

precautions, including the following:

• Read all instructions before using the appliance.

• Do not wash articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline, dry

cleaning solvents, other flammable, or exlosive substances as they give off vapors that could ignite or explode.

• Do not allow children to play on or in the appliance. Close supervision of children is necessary when the appliance is used near children.

• Before the appliance is removed from service or discarded, remove the door to the washing compartment.

• Do not add gasoline, dry cleaning solvents, or other flammable or explosive substances to the wash water. These

substances give off vapors that could ignite or explode.

• Do not install or store this appliance where it will be

exposed to the weather.

• Do not tamper with controls.

• Under certain conditions Hydrogen gas may be produced in a hot water system that has not been used for 2

weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the

hot water system has not been used for such a period,

before using the appliance, turn on all hot water faucets

and let the water flow from each for several minutes.

This will release any accumulated hydrogen gas. As the

gas is flammable do not smoke or use an open flame

during this time.

• Turn off water faucets to relieve pressure on hoses and

valves and to minimize leakage if a break or rupture

occurs.

• Do not reach into the appliance if the tub or drum is

moving.

• Do not repair or replace any part of the appliance or

attempt any servicing unless specifically recommended

in the user-maintenance instructions or in published

user-repair instructions that you understand and have

the skills to carry out.

• Good, safe practices and caution MUST be applied

when installing, operating, and maintaining any appliance. Follow basic precaution.

• Disconnect power to the washer at the circuit breaker

or fuse box, or unplug the machine in an emergency or

when servicing required. Have the installer show you and

label the proper switch or fuse at the electrical disconnect box.

• The interior of the appliance should be cleaned periodically by qualified service personnel.

• Before loading the washer, make sure the drum is empty.

SAVE THESE INSTRUCTIONS

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistence for

electric current. This appliance is equipped with a cord having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with

all local codes and ordinances.

WARNING - Improper connection of the equipment-grounding conductor can result in a electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the appliance is properly gounded.

Do not modify the plug provided with the appliance: if it will

not fit outlet, have a proper outlet installed by a qualified

electrician.

2

Page 3

Safety

!

!

C

U

L

US LISTED

®

!

CAUTION RISK

OF ELECTRIC

SHOCK DO

NOT OPEN

CAUTION:

To reduce the risk of electric shock, DO NOT remove cover (or back)/no user servicable parts inside.

Refer for servicing to qualified services personnel.

The model number of this product may be found on the back of the unit; the serial number of the label affixed to the back of

the unit.

You should note the model and serial numbers of this unit in the space provided. Retain this booklet as a permanent record

of your purchase to aid in identification in the event of theft.

MODEL N.

SERIAL N.

WARNING:

TO PREVENT FIRE OR SHOCK HAZARD DO NOT EXPOSE THIS PRODUCT TO RAIN OR MOISTURE.

NA

The linghtning flash with arrowhead symbol, within an equilateral triagle, is intended to alert the user to the presen-

ce of uninsulated “dangerous voltage” within the product’s enclosure that may be of sufficient magnitude to constitu-

te a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of important opera-

ting and maintenance (servicing) instructions in the booklet.

Indesit Company offers to his customers products with the ENERGY STAR Label.

This appliance was tested by UL and conforms with both Canadian and U.S. UL safety requirements

and displays their Mark

3

Page 4

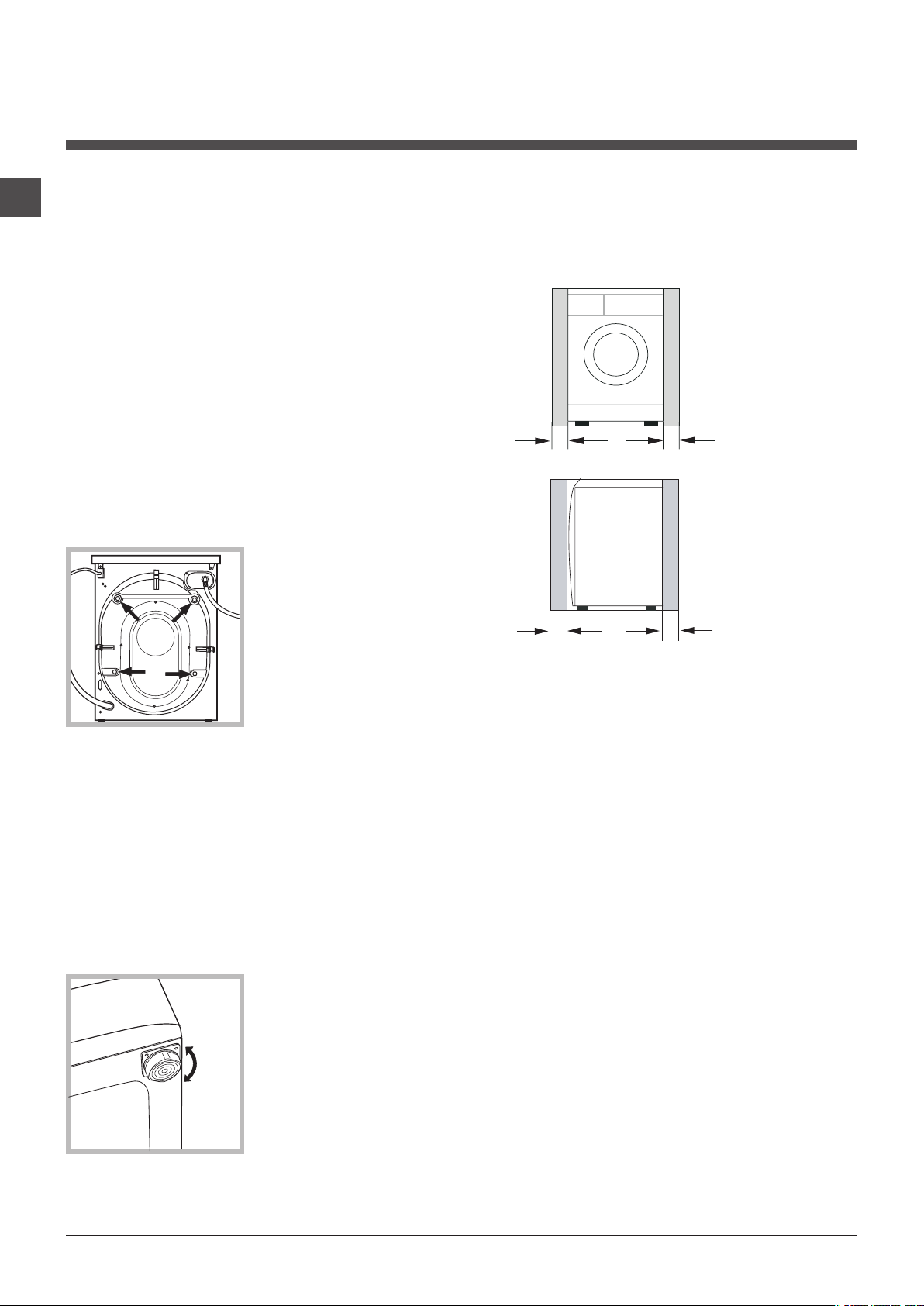

0" *

0" *

Recessed Front View

1" *

1"

Side View

Installation instructions

NA

! This instruction manual should be kept in a safe place

for future reference. If the washer is sold, transferred or

moved, make sure that the instruction manual remains with

the machine so that the new owner is able to familiarise

himself/herself with its operation and features.

! Read these instructions carefully: they contain vital infor-

mation relating to the safe installation and operation of the

appliance.

Unpacking and levelling

Unpacking

1. Remove the washer from its packaging.

2. Make sure that the washer has not been damaged

during the transportation process. If it has been damaged,

contact the retailer and do not proceed any further with the

installation process.

3. Remove the 4 protective

screws (used during transportation) and the rubber

washer with the corresponding spacer, located on the

rear part of the appliance

(see figure).

Levelling the machine correctly will provide it with stability,

help to avoid vibrations and excessive noise and prevent it

from shifting while it is operating.

Minimum Installation Spacing

This appliance may be installed in a recessed area, closet

or alcove. The installation spacing is in inches and is the

minimum acceptable.

4. Close off the holes using the plastic plugs provided.

5. Keep all the parts in a safe place: you will need them

again if the washer needs to be moved to another location.

! Packaging materials should not be used as toys for

children.

Levelling

1. Install the washer on a flat sturdy floor, without resting it

up against walls, furniture cabinets or anything else.

2. If the floor is not perfectly

level, compensate for any

unevenness by tightening

or loosening the adjustable

front feet (see figure); the an-

gle of inclination, measured

in relation to the worktop,

must not exceed 2°.

*Additional spacing should be considered for easy installation, servicing and compliance with local codes and

ordinances. Installations must conform with the minimum

dimensions indicated.

4

Page 5

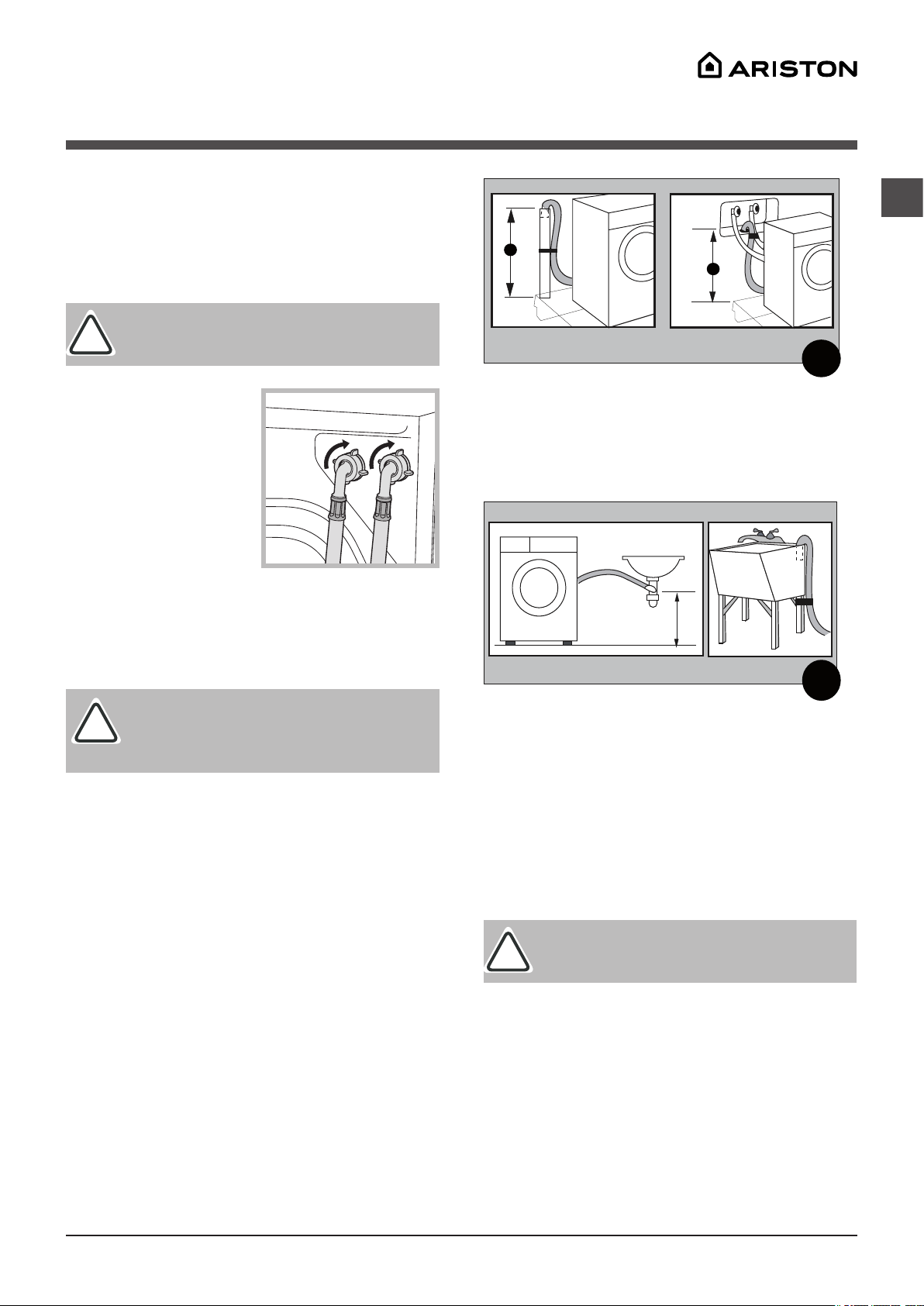

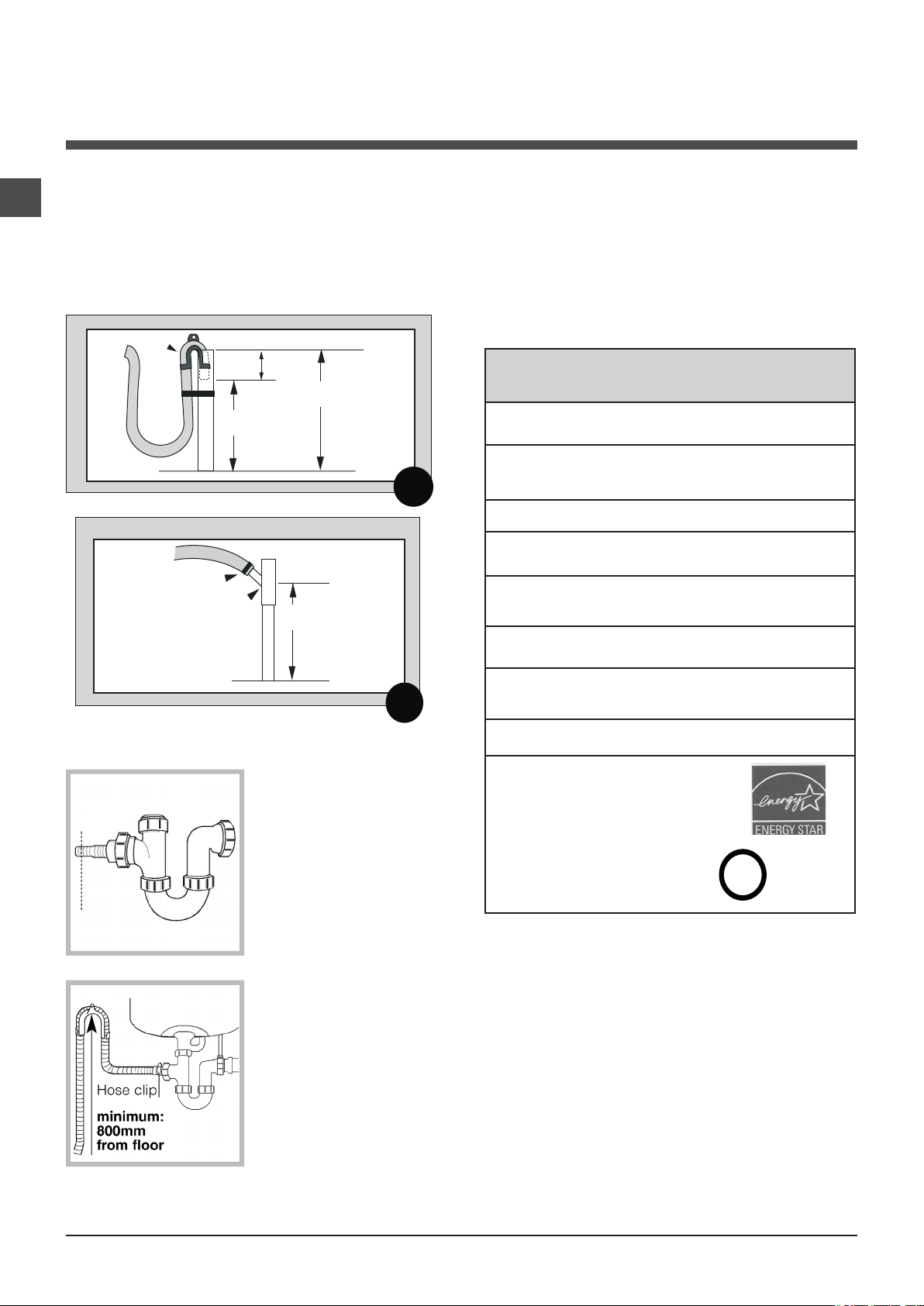

A & B = 25" (62 cm) min. / 34" (86 cm) max.

Floor Standpipe Wall Standpipe

A

B

Fig. 4

25" (62 cm) min.

with an air break

Laundry Sink Drain

Fig. 5

Sink Drain W/ "Y" Branch Tailpiece

!

H

C

Connecting Water Inlet

!

!

If the water pipes you will be connecting to are new or

unused, run the water until clear to remove any debris that

could clog the water valve screens or valves before connecting the machine. NOTE: Supply shut-off valves should

be easily accessible.

Important: Water pressure MUST range wi-

thin the values indicated on the “Technical Data”

chart.

NA

1. Screw the cold water fill

hose (C blue connector) onto

the cold water supply until

tight.

2. turn on the cold water

supply and check for leaks,

tighten if necessary.

3. Screw the hot water fill

hose (H red connector) onto

the hot water supply until tight.

4. Turn on the hot water supply and check for leaks,

tighten if necessary.

Important: Do not use excessive force. Da-

mage to the couplings can result. The couplings

should be tightened by hand; a tool should only

be used if a leak occurs.

Drainage

• Standpipe Diameter/Capacity - Needs a 1 ¼”

minimum diameter standpipe with a minimum carry-away

capacity of 7 gallons per minute.

• Top of Standpipe - Must be between 25” - 34” high

from the bottom of the machine.

• Outlet End of Drain Hose (provided with the unit)

- Must be at least 20” above the bottom of the washer-

dryer. An air break must be available at the standpipe to

avoid siphoning. No more than 6” of the drain hose should

be inserted into the drain pipe to prevent siphoning.

Connecting the drain hose

It is possible for the water to be discharged into a sink,

standpipe or drainpipe, but an air break must be available

at a min. 20” height to prevent the machine from siphoning

(Fig. 6).

Standpipe Drain System - Installations require a minimum

1 ¼” (3.2 cm) diameter standpipe with a minimum carry

away capacity of 7 gallons (26 liters) per minute.

Wall or Floor Standpipe Drain System - The top of the

standpipe must be between 25” (62 cm) - 34” (86 cm)

from the bottom of the washer (Fig. 4).

Sink Drainpipe System - Entry into the sink drain

system must be above the trap (Fig. 5). When routing the

drain hose through cabinets or walls, use a protective material such as electrical or duct tape to cover sharp edges

that could damage the drain hose. Use a suitable clamp

to secure the drain hose to the “Y” branch or the disposer.

With a sink drainpipe system, you may connect directly:

1) to a disposer by following the manufacturers attachment

method.

2) directly to a “Y” branch tail piece (available at most

hardware stores).

Important: Make sure that the drain hose is

not kinked and that water flow is not restricted.

3) Through the floor to a separate trap. The trap must be

vented to prevent siphoning. To provide proper venting,

install an Air Gap Kit (available at most hardware stores).

4) To the to the faucet using a Faucet Adapter Kit (available

separately).

• Use a U-Clamp (provided in your accessories packet)

or suitable item to secure the outlet end of the drain hose

(pre-installed on the back of your machine).

5

Page 6

NA

C

U

L

US LISTED

®

20" (62 cm) min.

34" (86 cm) max.

Standpipe

"Y" Tail Piece

This connection MUST be

before drain trap and at

least 20" (50.8 cm) above

the floor where washer will

be installed.

Cable tie

Floor Standpipe w/ "Y" Branch Tail Piece

Fig. 7

20" (50 cm) min.

with an air break

25" (62 cm) min.

34" (86 cm) max.

6" max.

Standpipe

Floor Standpipe

Fig. 6

U-Clamp

• Insert the outlet end of the drain hose into the standpipe,

wall or floor drain (Fig. 6). NOTE: The outlet end of the

drain hose MUST be at least 20” (50 cm) above the base

of the machine. No more than 6” of the drain hose should

be inserted into the drain pipe to prevent siphoning.

• Use a strap, cable tie, or similar item to hold the hose or

the U-Clamp in place.

Electrical

• Machine Voltage/Amperage - 120V, 60 Hz, 4 Amp.

• Connection - 3-prong plug with 6’ cord is provided with

the machine.

• Circuit/Protector - 3-wire single phase, 120V, 60 Hz, AC,

on a separate 15 Amp circuit.

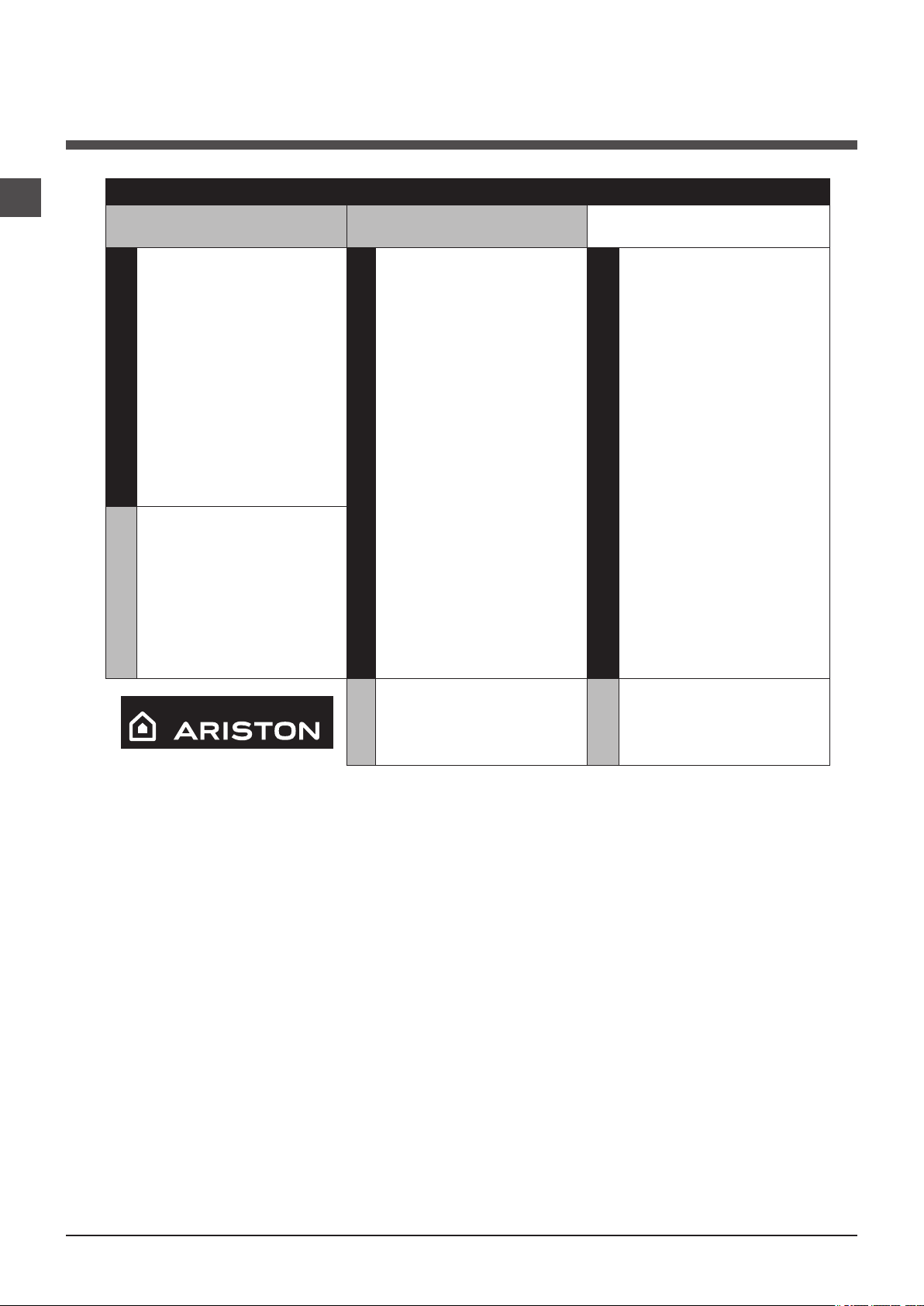

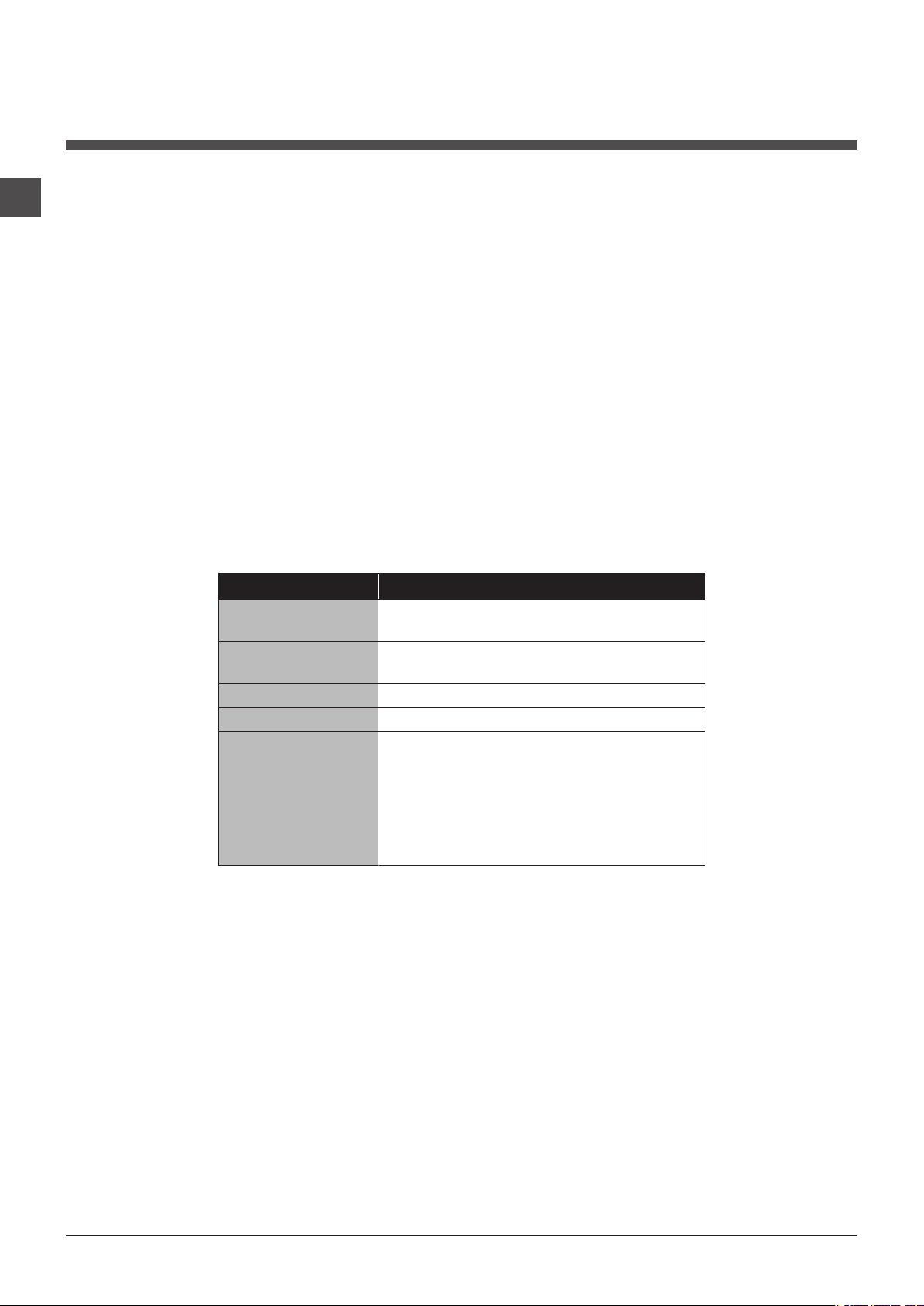

Technical Information

Technical data

Under Sink Method

1. Cut the blocked end of

the under sink drainage unit.

Model

Dimensions

Weight

Minimum Installa-

tion Clearances

Capacity

Electrical

connections

Water

connections

Max. Spin speed

Indesit Company offers to his customers

products with the ENERGY STAR Label.

This appliance was tested by UL and

conforms with both Canadian and U.S.

UL safety requirements and displays

their Mark.

ARWXF 129 W

width: 23.4”” (59.5 cm)

height: 33.24”” - 33.75”” (84.5 - 85.7 cm)

depth: 22”” (55.9) cm

148 lbs

Sides: 0””

Front / Back: 1””

Washing: 2 to 15 lbs. (1 to 7 kg)

Voltage: 120Volts, 4 A, 60 Hz

Max. Pressure: 0.69 MPa (6.9 bar), 100 psi

Min. Pressure: 0.05 MPa (0.5 bar), 7.2 psi

up to 1200 RPM

6

2. Fix the hooked end sup-

porta minimum of 620 mm

from the floor.

3. Use a hose clip clamp to

securely attach the grey drainage hose end to the under

sink drainage unit using a

hose. clamp

Page 7

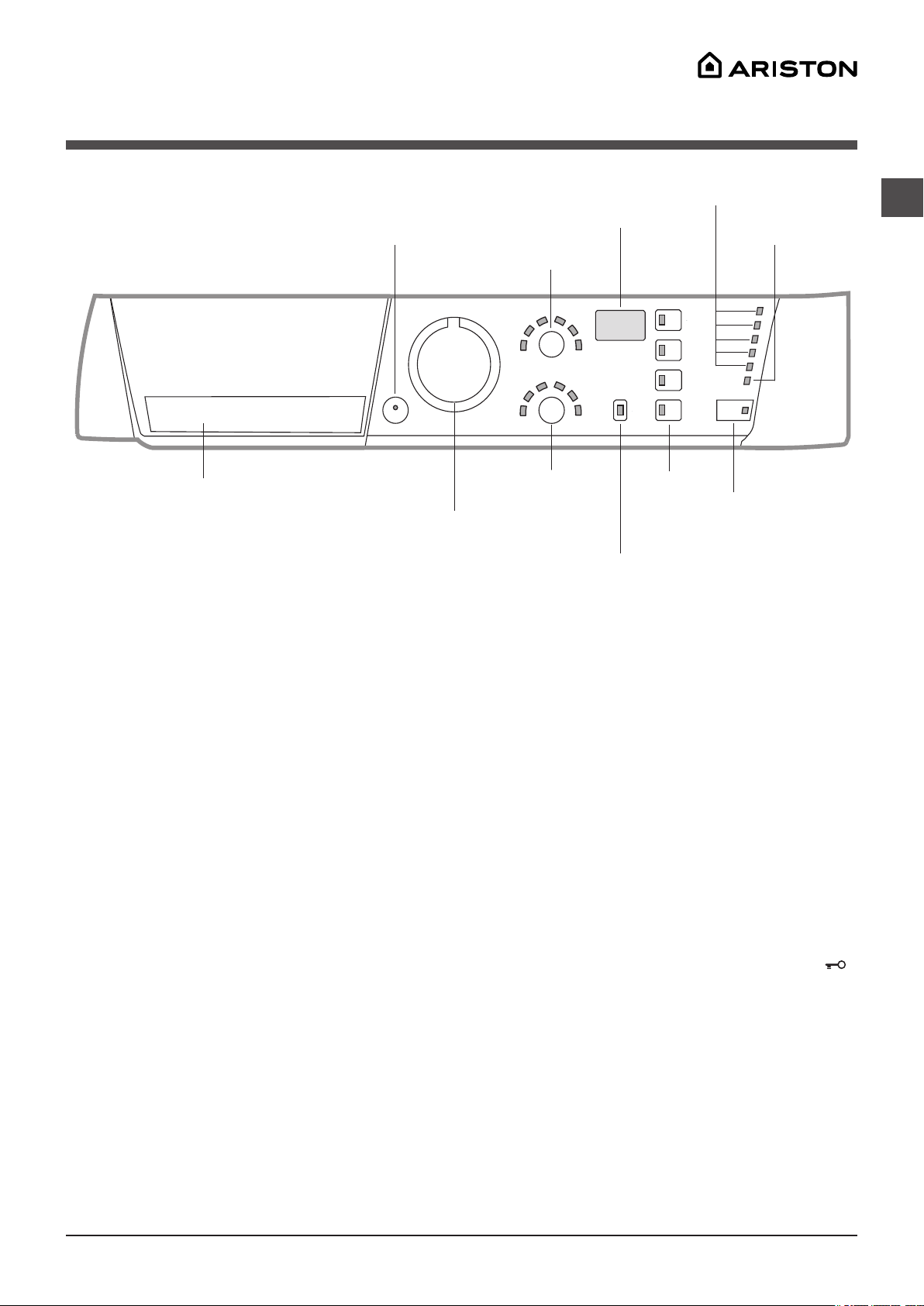

Description of the washing

machine and starting a wash cycle

Control panel

button with indicator

ON/OFF

light

Detergent dispenser drawer

WASH CYCLE

WASH CYCLE PROGRESS

DISPLAY

TEMPERATURE

button

SPIN SPEED

button

knob

CONTROL PANEL LOCK

button with indicator light

indicator lights

FUNCTION

buttons with

indicator lights

DOOR

LOCKED

indicator light

START/PAUSE

button with indicator

light

NA

WARNING: To reduce the risk of fire, electric shock, or

injury to persons, read the IMPORTANT SAFETY INSTRUCTIONS before operating this appliance.

Detergent dispenser drawer: used to dispense

detergents and washing additives (see “Detergents and

laundry”).

ON/OFF button with indicator light: switches the machine

on and off.

If the indicator light is illuminated, this indicates that the

machine is switched on.

WASH CYCLE knob: programmes the wash cycles. During

the wash cycle, the knob does not move.

SPIN SPEED button: sets the spin speed or exclude the

spin cycle completely (see “Personalisation”).

TEMPERATURE button: sets the temperature or the cold

wash cycle (see “Personalisation”).

The wash temperatures selections are uniformly distribuited.

DISPLAY: indicates the time remaining for the selected

wash cycle and, if a delayed start has been programmed,

the time remaining until the start of the wash cycle.

FUNCTION buttons with indicator light: used to select the

available functions. The indicator light corresponding to the

selected function will remain lit.

WASH CYCLE PROGRESS

monitor the progress of the wash cycle.

The illuminated indicator light shows which phase is in

progress.

DOOR LOCKED indicator light: indicates whether the

door may be opened or not (see next page).

START/PAUSE button with indicator light: starts or temporarily interrupts the wash cycles.

N.B. To pause the wash cycle in progress, press this

button; the corresponding indicator light will flash orange,

while the indicator light for the current wash cycle phase

will remain lit in a fixed manner. If the DOOR LOCKED

indicator light is switched off, the door may be opened.

To start the wash cycle from the point at which it was interrupted, press this button again.

indicator light

s: used to

CONTROL PANEL LOCK button with indicator light:

activates or deactivates the control panel lock.

7

Page 8

NA

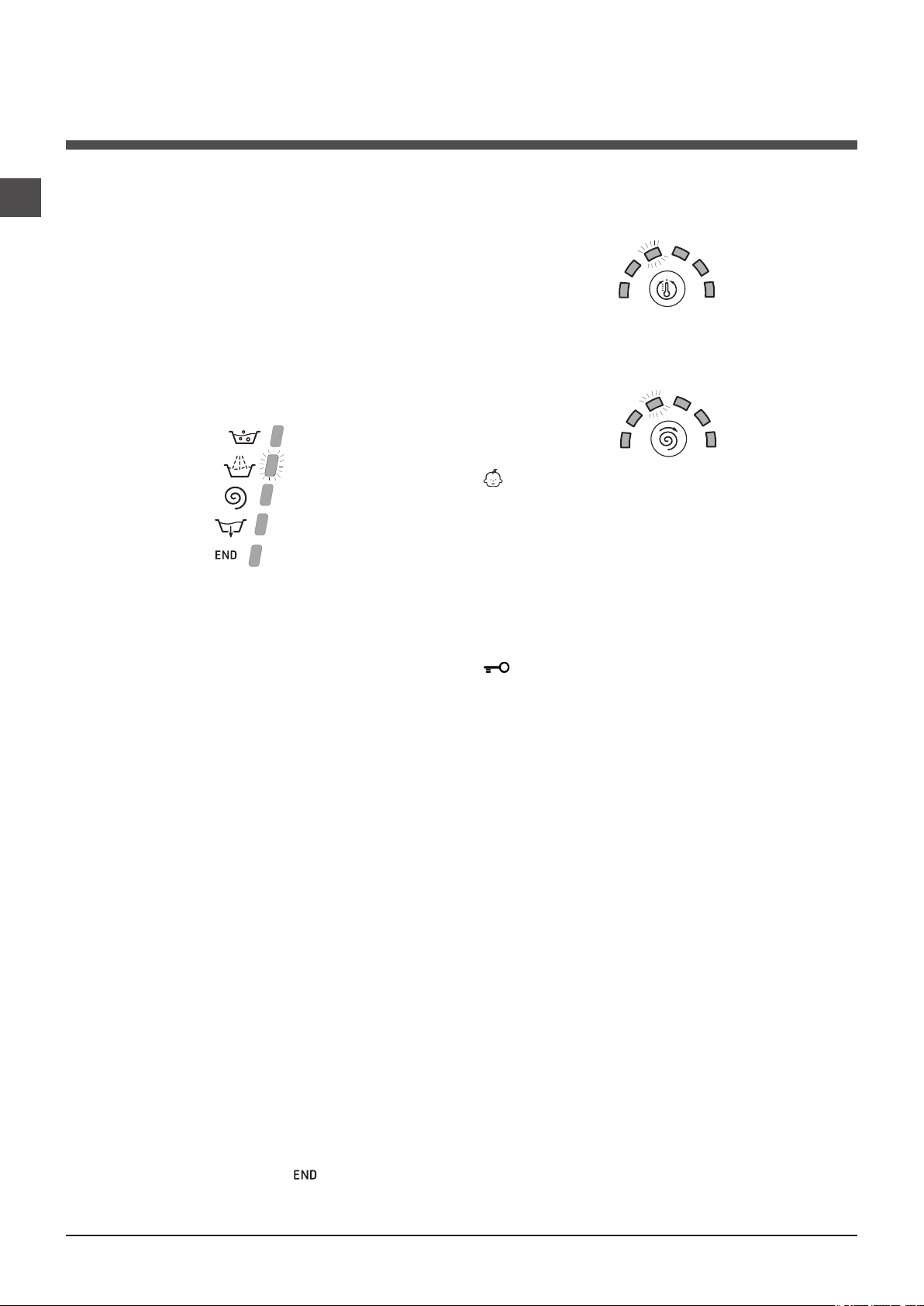

Indicator lights

The indicator lights provide important information.

This is what they can tell you:

Wash cycle phase indicator lights

As the WASH CYCLE knob is rotated, the indicator lights

illuminate, indicating the stages which will be performed by

the machine in accordance with the selected wash cycle.

Once the desired wash cycle has been selected and has

begun, the indicator lights switch on one by one to indicate

which phase of the cycle is currently in progress.

Wash

Temperature indicator light

When a temperature value is selected, the corresponding

indicator light will illuminate.

Spin indicator light

When a spin value is selected, the corresponding indicator

light will illuminate.

Rinse

Spin

Drain

End of wash cycle

Function buttons and corresponding indicator

lights

When a function is selected, the corresponding indicator

light will illuminate.

If the selected function is not compatible with the programmed wash cycle, the corresponding indicator light will

flash, a sound signal will be emitted and the function will

not be activated.

If a function which is incompatible with another function

selected previously, only the most recent selection will

remain active.

Starting a wash cycle

Control panel lock indicator light

To activate the control panel lock, press and hold the

button for approximately 2 seconds. When the indicator

light is illuminated, the control panel is locked. This means

it is possible to prevent wash cycles from being modified

accidentally, especially where there are children in the

home.

To deactivate the control panel lock, press and hold the

button for approximately 2 seconds.

Door locked indicator light

If this indicator light is on, the appliance door is locked to

prevent it from being opened accidentally; to avoid any

damage, wait for the indicator light to switch off before you

open the appliance door.

N.B. If the DELAY TIMER function is activated, the door

cannot be opened; pause the machine by pressing the

START/PAUSE button if you wish to open it.

! If the START/PAUSE indicator light (orange) flashes

rapidly at the same time as the function indicator light, this

indicates a problem has occurred (see “Troubleshooting”).

1. Switch the washing machine on by pressing the ON/OFF button. All indicator lights will switch on for a few seconds, then

they will switch off and the START/PAUSE indicator light will pulse.

2. Load the laundry and close the door.

3. Set the WASH CYCLE knob to the desired programme.

4. Set the washing temperature (see “Personalisation”).

5. Set the spin speed (see “Personalisation”).

6. Measure out the detergent and washing additives (see “Detergents and laundry”).

7. Select the desired functions.

8. Start the wash cycle by pressing the START/PAUSE button and the corresponding indicator light will remain lit in a fixed

manner, in green.

To cancel the set wash cycle, pause the machine by pressing the START/PAUSE button and select a new cycle.

9. At the end of the wash cycle the ( ) indicator light will switch on. The DOOR LOCKED indicator light will switch off, in-

dicating that the door may be opened. Take out your laundry and leave the appliance door ajar to make sure the drum dries

completely. Switch the washing machine off by pressing the ON/OFF button.

8

Page 9

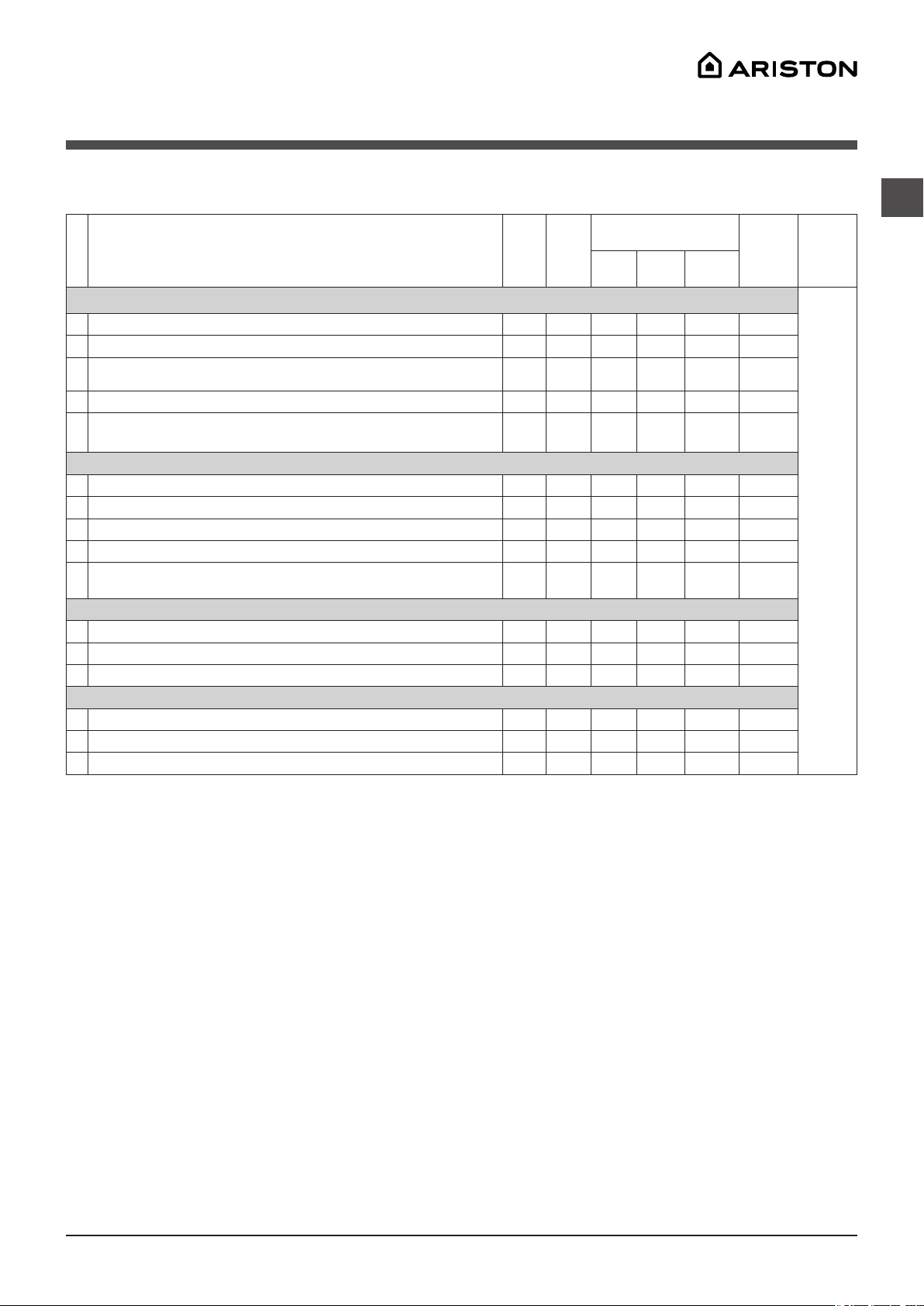

Wash cycles

Table of wash cycles

Max.

Description of the wash cycle

Wash

cycles

Essentials cycles

1

Cottons Regular: Heavily soiled whites and resistant colours. Hot Max -

2

Cottons Colored: Lightly soiled whites and delicate colours. Warm Max -

Permanent Press: Normally soiled synthetics or permanent press labelled

3

garments.

4

Quick Wash

Mixed Load 30 min.:To refresh lightly soiled garments quickly (not suitable

5

for wool, silk and clothes which require washing by hand).

Special wash cycles

6

Bright White: Heavily soiled whites and resistant colours. Warm Max

7

Jeans

8

Active Wear

9

Infant Wear: Heavily soiled delicate colours Warm 800 -

Lightly Soiled 15 min.: To refresh lightly soiled garments quickly

10

(not suitable for wool, silk and clothes which require washing by hand)

Delicates

11

Delicate: Lightly soiled delicates colours. Warm 800 -

12

Silk/Curtains

13

Wool: for wool, cashmere, etc. Warm 600 -

Partials wash cycles

A

Rinse

B

Spin

C

Drain

temp.

Warm 800 -

Warm Max -

Warm 800 -

Warm 800 -

Warm 600 -

Warm 800 -

Warm 0 -

Max.

speed

(°C)

(rpm)

- Max - -

- Max - - - Max

- - - - - Max

Detergents

Bleach Wash

Fabric

softener

Max load

(lb)

Max

Max

6.6

2.20

6.6

Max

6.6

6.6

4.4

3.30

6.6

2.20

3.30

Max

NA

Cycle

duration

The duration of the wash cycles can be checked on the display.

Special wash cycles

Permanent press (wash cycle 3) this cycle has less mechanical agitation and spinnig speed designed to reduce wrinkles.

Mixed Load (wash cycle 5) this wash cycle was designed to wash lightly soiled garments quickly: it lasts just 30 minu-

tes and therefore saves both energy and time. By selecting this wash cycle (5 at WARM temperature), it is possible to

wash different fabrics together (except for wool and silk items), with a maximum load of 6.6 lb - (3 kg).

Bright White (wash cycle 6) Use this cycle when bleaching with hypoclorite based products.

Pour the bleach, the detergent and the additives into the relevant compartments (see paragraph entitled “Detergent

dispenser drawer”).

Active wear (wash cycle 8) is for washing lightly soiled sports clothing fabrics (tracksuits, shorts, etc.); for best results,

we recommend not exceeding the maximum load indicated in the “Table of wash cycles”.

Infant Wear (wash cycle 9). This wash cycle can be used to remove the soiling typically caused by babies, while ensuring

that all detergent is removed from nappies in order to prevent the delicate skin of babies from suffering allergies. The cycle

has been designed to reduce the amount of bacteria by using a greater quantity of water and optimising the effect of special

disinfecting additives added to the detergent.

At the end of the wash cycle, the machine will slowly rotate the drum to prevent the formation of creases; to end the cycle

press the START/PAUSE button.

Lightly Soiled 15 min. (wash cycle 10) this wash cycle was designed to wash lightly soiled garments quickly: it lasts

just 15 minutes and therefore saves both energy and time. By selecting this wash cycle (10 at WARM temperature), it is

possible to wash different fabrics together (except for wool and silk items), with a maximum load of 3.30 lb - (1.5 kg).

For this cycle we recommend pretreating stains, shirt necks and wrists with specific antistain products.

9

Page 10

Personalisation

NA

Setting the temperature

By pressing the TEMPERATURE button to set the wash temperature. (See Table of wash cycles) Wash temperature can be

set selecting , “Cold”, “Warm”, “Hot” or 2 in-between positions which correspond to intermediate levels of water temperature (example: the position between “cold” and “warm” is lukewarm). See below for the indication in °C and °F for each

temperature position.

The available selections are:

• Tap water

• Cold 15 °C/ 59 °F

• 30 °C/ 86 °F

• Warm 40 °C/ 104 °F

• 50 °C / 122 °F

• Hot 57°C / 134 °F

Setting the spin speed

By pressing the SPIN SPEED button to set the spin speed for the selected wash cycle.

The maximum spin speeds available for each wash cycle are as follows:

Wash cycles Maximum spin speed

Cottons 1200 rpm only

Synthetics 800 rpm

Wool 600 rpm

Silk drain only

The spin speed may be lowered, or the spin cycle can be excluded altogether by selecting the symbol .

The washing machine will automatically prevent you from selecting a spin speed which is higher than the maximum speed

set for each wash cycle.

Note 1: During the (Cotton) cycles 1 and 2, it is not possible to eliminate the spin cycle or reduce the pre determined spin speed.”

Note 2: For the first two Programmes (Cottons Regular and Cottons Colored) the garments will be spun at maximum speed.

This allows to get the most from the spinning phase and reduce time and energy needed for the drying.

Functions

The various wash functions available with this washing machine will help to achieve the desired results, every time.

To activate the functions:

1. Press the button corresponding to the desired function;

2. the function is enabled when the corresponding indicator light is illuminated.

Note: If the indicator light flashes rapidly, this signals that this particular function may not be selected in conjunction with the

selected wash cycle.

Delay timer

To set a delayed start for the selected wash cycle, press the button repeatedly until the desired delay time is displayed (this

may be between 1 hour and 24 hours).

To disable the function press the button until the text is displayed.

N.B. Once you have pressed the START/PAUSE button, the delay time may only be decreased if you wish to modify it.

! This option is enabled with all programmes.

Super Wash

Because a greater quantity of water is used in the initial phase of the cycle, and because of the increased cycle duration, this

function offers a high-performance wash.

! This function may not be used in conjunction with wash cycles 4, 5, 7, 10, 12, 13, A, B, C.

Extra rinse

By selecting this function, the efficiency of the rinse is increased and optimal detergent removal is guaranteed. It is particularly

useful for sensitive skin.

! This function may not be used in conjunction with wash cycles 5, 10, B, C.

10

Page 11

Reduced Wrinkles

By selecting this function, the wash and spin cycles will be modified in order to reduce the formation of creases. At the end

of the cycle the washing machine will perform slow rotations of the drum; the REDUCED WRINKLES indicator light will switch

on and the START/PAUSE indicator light will flash in an orange colour and the phase END will remain lit in a fixed manner.

To end the cycle, press the START/PAUSE button or the REDUCED WRINKLES button.

For the Silk/Curtains cycle, the machine will end the cycle while the laundry is soaking and the REDUCED WRINKLES indicator light will flash. To drain the water so that the laundry may be removed, press the START/PAUSE button or the REDUCED WRINKLES button.

! It may not be used with the 5, 8, 9, 10, 13, B, C.

NA

11

Page 12

Detergents and laundry

M

AX

1

3

2

NA

Detergent dispenser drawer

Good washing results also depend on the correct dose of

detergent: adding too much detergent will not necessarily result in a more efficient wash, and may in fact cause

build up on the inside of your appliance and contribute to

environmental pollution.

! Do not use hand washing detergents because these

create too much foam.

Open the detergent dispenser drawer and pour

in the detergent or washing

additive, as follows.

compartment 1: Detergent for the wash cycle

(powder or liquid)

Liquid detergent should only

be poured in immediately prior

to the start of wash cycle.

compartment 2: Additives (fabric softeners, etc.)

The fabric softener should not overflow the grid.

extra compartment 3: Bleach

Bleach cycle

Bleaching may only be performed in conjunction with wash

cycles 6. Pour the bleach into extra compartment 3; pour

the detergent and softener into the corresponding compartments, then select one of the abovementioned wash cycles.

This option is recommended only for very soiled cotton

garments.

! At the end of the cycle, there may be water standing in the

bleach or other compartments, this is NORMAL. The Bleach

compartment can be removed when not in use.

Preparing the laundry

• Divide the laundry according to:

- the type of fabric/the symbol on the label.

- the colours: separate coloured garments from whites

• Empty all garment pockets and check the buttons.

• Do not exceed the listed values, which refer to the weight

of the laundry when dry:

Durable fabrics: max. 15 lb - (7 kg)

Synthetic fabrics: max. 6.6 lb - (3 kg)

Delicate fabrics: max. 4.4 lb - (2 kg)

Wool: max. 3.30 lb - (1,5 kg)

How much does your laundry weigh?

1 sheet 14-17 oz - (400-500 g)

1 pillow case 5-7 oz - (150-200 g)

1 tablecloth 14-17 oz - (400-500 g)

1 bathrobe 31-42 oz - (900-1200 g)

1 towel 5-8 oz - (150-250 g)

Garments requiring special care

Jeans: Turn garments inside-out before washing and use a

liquid detergent. Use programme 7.

Silk: use special wash cycle 12 to wash all silk garments.

We recommend the use of special detergent which has

been designed to wash delicate clothes.

Curtains: fold curtains and place them in a pillow case or

mesh bag. Use wash cycle 12.

Wool: Ariston is the only washer manufacturer to have been

awarded the prestigious Woolmark Platinum Care endorsement

(M.0508) by the Woolmark Company, which means that all

woollen garments may be washed in the washer, even those

which state “hand wash only” on the label. Wash cycle 13

therefore offers complete peace of mind when washing woollen

garments in the washer (max. load 3.30 lb - 1,5 kg) and guarantees optimal performance.

Load balancing system

Before every spin cycle, to avoid excessive vibrations and

to distribute the load in a uniform manner, the drum rotates

continuously at a speed which is slightly greater than the

washing rotation speed. If, after several attempts, the load is

not balanced correctly, the machine spins at a reduced spin

speed. If the load is excessively unbalanced, the washerperforms the distribution process instead of spinning. To

encourage improved load distribution and balance, we

recommend small and large garments are mixed in the load.

Helpful Hints

Your washer features three different speeds during the wash

cycle. During the Cotton cycle the drum spins at 1,200 or 800

rpm. During Permanent Press the drum spins at 850 rpm.

During delicates, the drum spins at 500 rpm.

Use Liquid Fabric Softener. Fill the softener compartment

up to the level marked. Using fabric softner fluffs out clothes

immediately after tha wash cycle. This helps speed drying

time and reduce wrinkles.

Use Low sudsing Detergent. This is recommended for

all front loading washers. It ensures there is no over sudsing,

which may reduce the performance of your machine. Also,

this prevents damage to your machine which may be caused

by excess suds. We recommend using Splendide All-Natural

Premium HE Laundry Powder (Part No. 1005). It softens fabrics naturally and does not require the use of fabric softener.

When sorting laundry always take into consideration

the quantity and type of fabric contained in the load. Highly

absorbent fabrics such as those used in towels or jeans will

abosorb more water and become very heavy when saturated.

If you notice that your clothes are taking longer than usual to

dry may be overloading the machine, or washing too many

highly absorbent articles for a single load.

12

Page 13

Care and maintenance

1

2

instructions

Cutting off the water and electricity

supplies

• Turn off the water tap after every wash cycle. This will

limit wear on the hydraulic system inside the washing

machine and help to prevent leaks.

• Unplug the washing machine when cleaning it and during all maintenance work.

Cleaning the washing machine

The outer parts and rubber components of the appliance

can be cleaned using a soft cloth soaked in lukewarm

soapy water. Do not use solvents or abrasives.

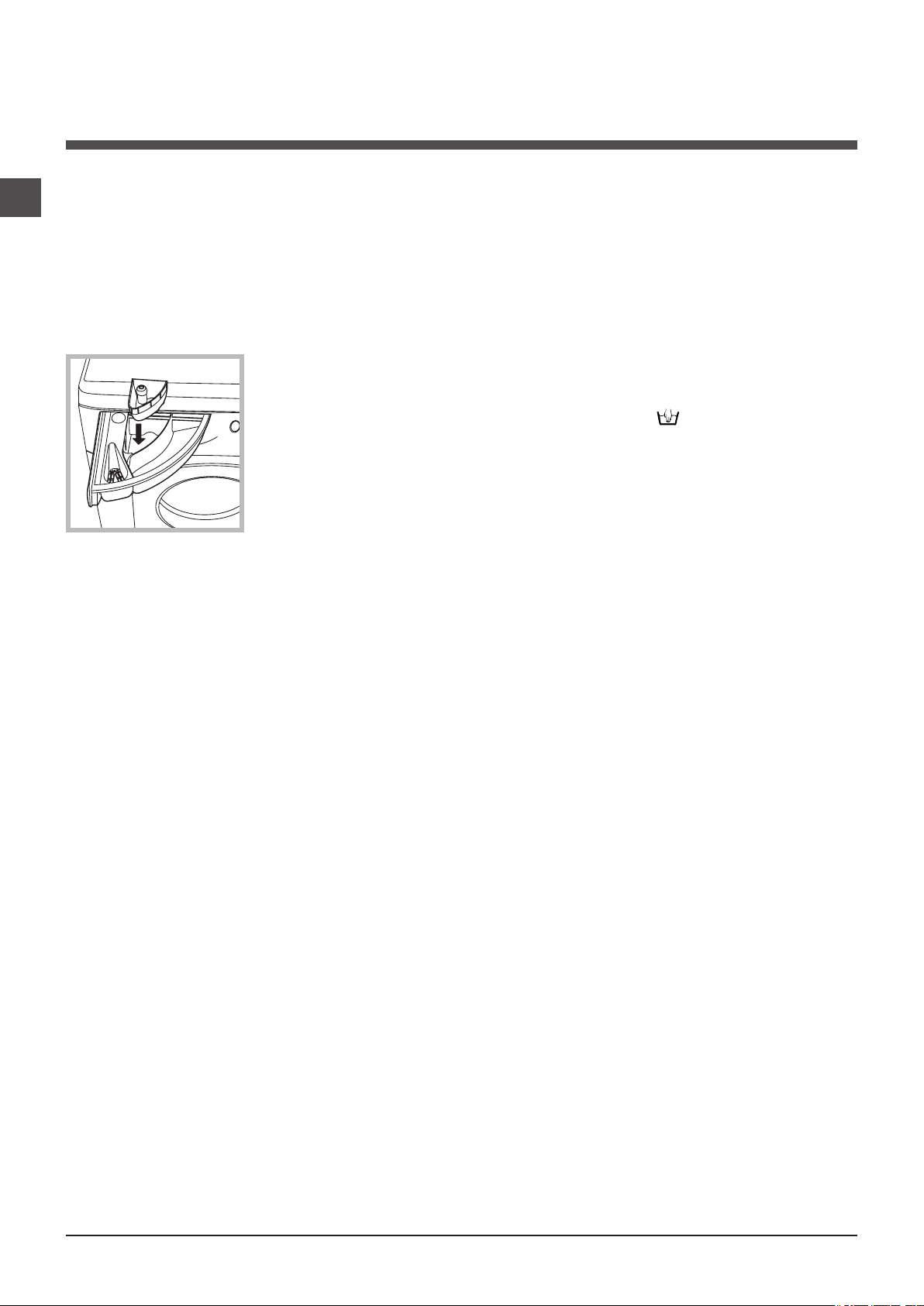

Cleaning the detergent dispenser drawer

Remove the dispenser by

raising it and pulling it out

(see figure).

Wash it under running water; this operation should be

repeated frequently.

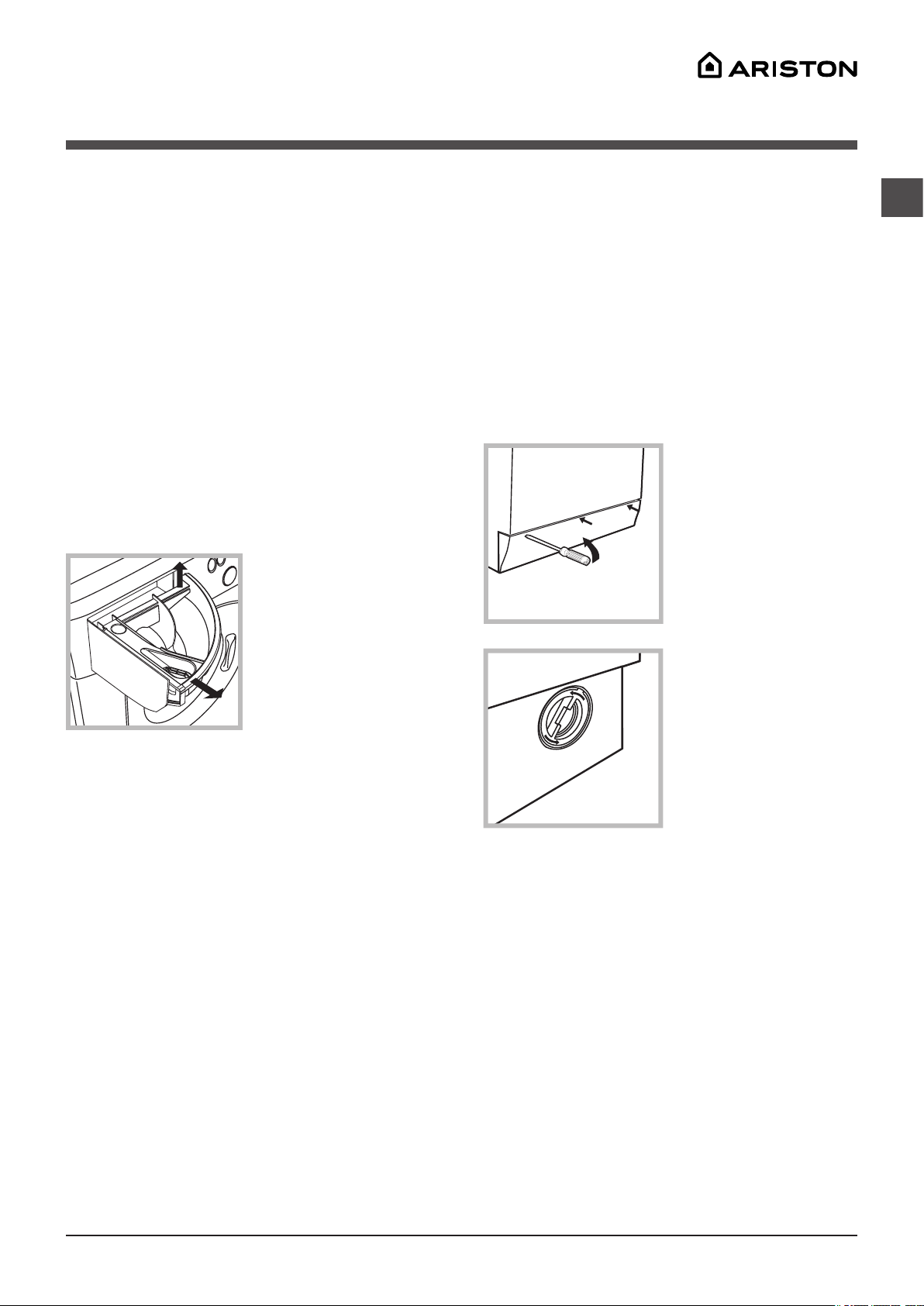

Cleaning the pump

The washing machine is fitted with a self-cleaning pump

which does not require any maintenance. Sometimes,

small items (such as coins or buttons) may fall into the prechamber which protects the pump, situated in its bottom

part.

! Make sure the wash cycle has finished and unplug the

appliance.

To access the pre-chamber:

1. using a screwdriver,

remove the cover panel

on the lower front part of

the washing machine (see

figure);

2. unscrew the lid by rotating it anti-clockwise (see

figure): a little water may

trickle out. This is perfectly

normal;

NA

Caring for the door and drum of your

appliance

• Always leave the porthole door ajar in order to prevent

unpleasant odours from forming.

3. clean the inside thoroughly;

4. screw the lid back on;

5. reposition the panel, making sure the hooks are securely

in place before you push it onto the appliance.

Checking the water inlet hose

Check the inlet hose at least once a year. If there are any

cracks, it should be replaced immediately: during the wash

cycles, water pressure is very strong and a cracked hose

could easily split open.

! Never use second-hand hoses.

13

Page 14

RV/Marine Winterization

NA

SPECIAL WINTERIZATION INSTRUCTIONS FOR RV/MARINE INSTALLATIONS:

To winterize your ARWXF129W

washer,

1. With washing machine po-

wer OFF, pour ½ quart of RVtype antifreeze into washer

drum;

2. Close door. Advance Cycle

Selector to ‘B’;

3. Press ON/OFF button, then

press START. let the washing

WINTERIZE

machine run for 1 to 2 minutes;

4. Press ON/OFF button to

turn power OFF.

5. Unplug washing machine

from electrical outlet (or disconnect power);

6. Turn water supply faucets

OFF. Disconnect inlet hoses

END

from faucets;

7. Drain remaining water from

the hoses. FINISHED.

To use your washer again, Optional Winterization

Instructions

1. Reconnect water inlet hoses

to corresponding HOT/COLD

faucets. Turn faucets ON.

NOTE: Check water inlet hoses and pump periodically (see

Users Guide);

2. Plug washing machine into

appropriate electrical outlet (see

Users Guide) - OR reconnect

power supply;

3. With washing machine power OFF, pour 1/2 TBSP. of

WINTERIZE

powder detergent (or liquid

equiv.) into compartment ‘2’

inside Dispenser Drawer;

4. Advance Cycle Selector to

position ‘4’;

5. Press ON/OFF button, then

press START.

6. Allow machine to run through

the complete cycle to clean out

any remaining antifreeze.

END

FINISHED.

If you’re currently pumping antifreeze through your fresh water

system, you can follow these

steps to winterize your washing

machine:

1. With machine power OFF,

advance Cycle Selector to

position ‘3’;

2. Press ON/OFF button, set

water temperature to WARM,

then press START. Let machi-

ne fill until the drum turns (could

take up to 1 to 2 minutes);

Winterization Option

3. Press ON/OFF button to

turn power OFF;

4. Advance Cycle Selector

to ‘B’;

5. Press ON/OFF button, then

press START.

6. After letting antifreeze drain

completely from drum, press

the ON/OFF button to turn po-

END

wer OFF. FINISHED.

IMPORTANT! DO NOT DISCARD!

Keep this page with your owners manual for future reference

14

Page 15

Troubleshooting

Your washing machine could fail to work. Before contacting the Technical Assistance Centre (see “Assistance”), make sure

that the problem cannot be not solved easily using the following list.

Problem:

The washing machine does not

switch on.

The wash cycle does not start.

The washing machine does not

take in water (the indicator light for

the first wash cycle stage flashes

rapidly).

The washing machine continuously

takes in and drains water.

Possible causes / Solutions:

• The appliance is not plugged into the socket fully, or is not making contact.

• There is no power in the house.

• The washing machine door is not closed properly.

• The ON/OFF button has not been pressed.

• The START/PAUSE button has not been pressed.

• The water tap has not been opened.

• A delayed start has been set (using the Delay Timer, see “Personalisation”).

• The water inlet hose is not connected to the tap.

• The hose is bent.

• The water tap has not been opened.

• There is no water supply in the house.

• The pressure is too low.

• The START/PAUSE button has not been pressed.

• The drain hose is not fitted at a height between 65 and 100 cm from the floor

(see “Installation”).

• The free end of the hose is under water (see “Installation”).

• The wall drainage system is not fitted with a breather pipe.

If the problem persists even after these checks, turn off the water tap, switch

the appliance off and contact the Assistance Service. If the dwelling is on one of

the upper floors of a building, there may be problems relating to water drainage,

causing the washing machine to fill with water and drain continuously. Special

anti-draining valves are available in shops and help to avoid this inconvenience.

NA

The washing machine does not

drain or spin.

The washing machine vibrates a lot

during the spin cycle.

The washing machine leaks.

The START/PAUSE indicator light

(orange) and the function indicator

lights flash rapidly.

There is too much foam.

• The wash cycle does not include draining: some wash cycles require the drain

phase to be started manually.

• The REDUCED WRINKLES function has been activated: To complete the

wash cycle, press the START/PAUSE button (“Personalisation”).

• The drain hose is bent (see “Installation”).

• The drainage duct is clogged.

• Pump is obstructed.

• The drum was not unlocked correctly during installation (see “Installation”).

• The washing machine is not level (see “Installation”).

• The washing machine is trapped between cabinets and walls (see “Installation”).

• The water inlet hose is not screwed on properly (see “Installation”).

• The detergent dispenser drawer is blocked (for cleaning instructions, see

“Care and maintenance”).

• The drain hose is not fixed properly (see “Installation”).

• Switch off the machine and unplug it, wait for approximately 1 minute and

then switch it back on again.

If the problem persists, contact the Technical Assistance Service.

• The detergent is not suitable for machine washing (it should display the text

“for washing machines” or “hand and machine wash”, or the like).

• Too much detergent was used.

15

Page 16

Service

NA

Before calling for Assistance:

• Check whether you can solve the problem alone (see “Troubleshooting”);

• Restart the programme to check whether the problem has been solved;

• If this is not the case, contact an authorised Technical Assistance Centre using the telephone number provided on the

guarantee certificate.

! Always request the assistance of authorised technicians.

Have the following information to hand:

• the type of problem;

• the appliance model (Mod.);

• the serial number (S/N).

This information can be found on the data plate applied to the rear of the washing machine, and can also be found on the

front of the appliance by opening the door.

If You Have You’ll Need to Buy

No access to Hot/

Cold water hookups

Water damage

Concerns

Floor drain

Disposer drain

Shifting Concerns

(RV and Marine Installations)

Ariston Faucet Adapter kit, Part No.

154187104A (8ft, 2.4m)

Ariston Drain-A-Way™ Pan, Part No. PI-22,

PI-24 (or similar)

Siphon break kit (sold at most hardware stores)

“Y” connector (sold at most hardware stores)

Ariston SecureFit™ installation Brackets,

Part No. MK01.

Keeps washer in place during the travel to prevent:

• Kinked inlet hoses

• Blocked dispenser drawer

• Knobs rubbing against closed doors

• Scuffed cabinet woodwork

16

All Ariston parts are available direct From Westland

Sales: 1-800-356-0766

Page 17

Warranty

ARISTON ONE-YEAR LIMITED WARRANTY

(USA & CANADA ONLY)

WHO IS COVERED BY THIS WARRANTY

This limited one-year warranty (“Warranty”) is given only

to the original end-use/retail purchaser (the “First Using

Purchaser”) of the accompanying Ariston product(s) (the

“Ariston Product”).

If you purchased this Ariston Product from someone other

than an authorized Ariston reseller/dealer in the United States

or Canada, or if the Ariston Product was used (including but

not limited to floor models or refurbished products) prior to

your purchase, then you are not the First Using Purchaser

and the Ariston Product that you purchased is not covered

by this Warranty. This Warranty is not transferable.

WHAT IS COVERED BY THIS WARRANTY

Ariston will repair or replace any part of the Ariston Product

which fails due to a defect in materials or workmanship when

used under normal home-use conditions. Ariston will also

provide, free of charge, all labor and related services to repair

or replace the defective part.

This Warranty applies only to Ariston Products purchased

and used in the United States or Canada. Subject to the

exclusions below, for Ariston Products purchased in, but

used outside, the United States or Canada, this Warranty

covers only warranty service within the United States or

Canada (and does not include shipping outside the United

States or Canada).

LENGTH OF THE WARRANTY

This Warranty runs for a period of one (1) year from the date

of the original purchase by the First Using Purchaser. Please

note that a copy of your original purchase receipt showing

the purchase date and the vendor’s name and address are

required to obtain service under this Warranty. For the purposes of determining the applicable warranty period, please

note that any and all replaced or repaired parts shall assume

the identity of the original.

WHAT IS NOT COVERED BY THE WARRANTY

(EXCLUSIONS)

This Warranty does not cover:

1. Improper installation, delivery, maintenance and/or im-

proper operation of the Ariston Product.

2. Damage caused if the Ariston Product has not been used

in compliance with the electricity or gas supply specifications

printed on the rating plate.

3. Failure of or damage to the Ariston Product if it is altered,

abused, misused, or used for other than the intended purpose, or if it is used commercially.

4. Service trips to your home to provide instructions on the

use of your Ariston Product.

NA

5. Replacement of house fuses or correction of the plumbing

or electric wiring in your home.

6. Damage caused by neglect, accident, fire, floods or acts

of God.

7. Physical Damage to the appearance of your Ariston

Product including, without limitation, scratches, rust, dents,

warping, peeling and the like.

8. Damage caused by transportation.

9. Replacement of any consumable or degradable item or

accessory including, but not limited to: plugs, cables, batteries, light bulbs, fluorescent tubes and starters, covers

and filters, or replacement of any removable parts made of

glass or plastic.

10. Damage caused after delivery.

11. Water damage of any kind.

12. An Ariston Product not accessible to provide required

service.

13. Problems arising from other than defects in materials or

workmanship.

14. Travel time when installed in a recreational vehicle or

marine application.

This Warranty is void if the Ariston Product is altered, serviced, maintained, dismantled, or otherwise interfered with

by any person who is not authorized by Ariston.

15. Non-standard labor when installed in a marine application.

16. Water leaks of any kind.

TO THE EXTENT PERMITTED BY LAW, THIS WARRANTY

IS IN LIEU OF ALL OTHER WARRANTIES, WRITTEN

OR ORAL, WHETHER EXPRESSED BY AFFIRMATION,

PROMISE, DESCRIPTION, DRAWING, MODEL OR

SAMPLE. ANY AND ALL WARRANTIES OTHER THAN

THIS ONE, WHETHER EXPRESS OR IMPLIED, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY

DISCLAIMED. IMPLIED WARRANTIES INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS THAT CANNOT BE

EXCLUDED BY LAW, SHALL BE LIMITED TO THE SAME

DURATION AS THIS WARRANTY. EXCEPT FOR THAT

REPAIR OR REPLACEMENT AS DESCRIBED ABOVE,

ARISTON SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR SPECIFIC RELIEF.

Some States and Provinces do not allow the exclusion or

limitation of incidental or consequential damages and/or

implied warranties, so the above limitations or exclusions

may not apply to you. This Warranty gives you specific legal

rights and you may also have other legal rights which vary

from State to State or Province to Province.

17

Page 18

NA

WHAT YOU SHOULD DO TO OBTAIN WARRANTY

SERVICE

All repairs or warranty service must by provided by Ariston

or an Authorized Ariston Service Center.

To schedule warranty service please call 1-800-356-0766,

email service@westlandsales.com. Please remember to

provide us with your Ariston Product’s model number and

serial number.

Please note that a copy of your original purchase receipt

showing the purchase date and the vendor’s name and address are required to obtain service under this Warranty. If

the Ariston Product is located in an area where service by an

Authorized Ariston Service Center is not available, you may

be responsible for a trip charge or you may be required to

bring the Ariston Product to an Authorized Ariston Service

Center for service.

The foregoing are your sole (i.e., only) and exclusive remedies under this Warranty. This Warranty is the only warranty that Ariston is giving for this Ariston Product. This

Warranty replaces all other agreements and understandings that you may have with Ariston or its representatives.

18

Page 19

Manuel d'utilisation

LAVE-LINGE

FR

Français

ARWXF 129 W

Table des matières

Consignes de sécurité importantes, 20-21

Consignes de sécurité importantes

Consignes de mise à la terre

Sécurité

Instructions pour l'installation, 22-23-24

Déballage et mise de niveau

Encombrement minimum

Raccordement de l'arrivée d'eau

Évacuation

Raccordement de la décharge

Raccordements électriques

Pose sous évier

Caractéristiques techniques

Description du lave-linge et démarrage

d'un cycle de lavage, 25-26

Tableau de commande

Témoins

Démarrage d'un cycle de lavage

Cycles de lavage, 27

Tableau des cycles de lavage

Cycles de lavage spéciaux

FR

Personnalisation, 28-29

Réglage de la température

Réglage de la vitesse d'essorage

Fonctions

Produits lessiviels et linge, 30

Distributeur de produits lessiviels

Cycle à l'eau de Javel

Préparation du linge

Vêtements nécessitant des soins particuliers

Système d'équilibrage des charges

Conseils utiles

Consignes pour l'entretien et le nettoyage, 31

Coupure de l'arrivée d'eau et de l'électricité

Nettoyage du lave-linge

Nettoyage du distributeur de produits lessiviels

Entretien du hublot et du tambour de votre machine

Nettoyage de la pompe

Contrôle du tuyau d'arrivée d'eau

Hivernage des lave-linge installés dans

des véhicules de plaisance/bateaux 32

Dépannage, 33

Entretien, 34

Garantie, 35-36

19

Page 20

Consignes de sécurité importantes

FR

CONSIGNES DE SÉCURITÉ IMPORTANTES

AVERTISSEMENT : Tpour limiter le risque d'incendie,

d'électrocution ou de blessure lors de l'utilisation de la

machine, suivez les consignes de base suivantes :

• Lisez le manuel dans son intégralité avant d'utiliser la

machine.

• Ne lavez les vêtements préalablement lavés avec de

l'essence, imbibés ou tachés d'essence, de solvants

pour le nettoyage à sec, d'autres produits inflammables

ou de substances explosives car ils sont susceptibles de

produire des vapeurs inflammables.

• Interdisez aux enfants de jouer sur ou dans la machine.

Gardez les enfants sous étroite surveillance lorsqu'ils se

trouvent à proximité de la machine.

• Avant l'enlèvement de la machine pour l'entretien ou

pour sa mise au rebut, retirez la porte permettant l'accès

au compartiment de lavage.

• N'ajoutez pas d'essence, de solvants utilisés pour le

nettoyage à sec ou d'autres substances inflammables

ou explosives dans l'eau de lavage. Ces substances

libèrent des vapeurs inflammables.

• N'installez ni ne stockez la machine dans un endroit

exposé aux intempéries.

• Veillez à ne pas endommager les commandes.

• Dans certains cas, de l'hydrogène peut être produit

dans le circuit d'eau chaude s'il n'a pas été utilisé

pendant 2 semaines ou plus. L'HYDROGÈNE EST UN

GAZ EXPLOSIF. Si le circuit d'eau chaude n'a pas été

utilisé pendant cette période, avant d'utiliser la machine,

ouvrez tous les robinets d'eau chaude et laissez l'eau

s'écouler pendant plusieurs minutes. Cela permettra de

libérer l'hydrogène accumulé. Le gaz étant inflammable,

évitez de fumer ou d'approcher une flamme vive pendant

cette période.

• Coupez les robinets d'eau chaude pour libérer la

pression sur les tuyaux et les vannes. Vous pourrez ainsi

contenir les fuites en cas de rupture éventuelle.

• Évitez toute manipulation à l'intérieur de la machine

lorsque la cuve ou le tambour est en mouvement.

• Ne tentez pas de réparer ou de remplacer un

quelconque élément de la machine ni d'effectuer

une quelconque réparation sauf si la marche à suivre

est clairement expliquée dans le manuel d'entretien

de l'utilisateur ou dans le manuel de réparation de

l'utilisateur. Assurez-vous au préalable de disposer des

compétences nécessaires pour prendre en charge ces

opérations.

• Veillez à faire preuve de la prudence nécessaire lors de

l'installation, l'utilisation et la maintenance de la machine.

Respectez les précautions de base.

• Coupez l'alimentation du lave-linge au niveau du

disjoncteur ou de la boîte à fusibles ou débranchez la

machine en cas d'urgence ou lors d'une réparation.

Faites en sorte que l'installateur vous montre et signale

le commutateur ou le fusible correspondant au niveau du

tableau.

• L'intérieur de la machine doit faire l'objet d'un nettoyage

périodique par un technicien qualifié.

• Avant de charger le lave-linge, vérifiez si le tambour est

bien vide.

CONSERVEZ CE MANUEL

CONSIGNES POUR LA MISE À LA

TERRE

Cet appareil doit être mis à la terre. En cas de

dysfonctionnement ou de panne, la mise à la terre permet

de limiter le risque d'électrocution offrant une résistance

inférieure au courant électrique. L'appareil est équipé d'un

câble doté d'un conducteur de terre et d'une prise de

mise à la terre. La fiche doit être branchée dans la prise

adéquate, laquelle devra être correctement installée et

mise à la terre conformément aux règlements locaux en

vigueur.

AVERTISSEMENT - Tout raccordement inadéquat du

conducteur de terre peut provoquer une électrocution.

Vérifiez auprès d'un électricien, d'un technicien ou du

personnel qualifié en cas de doute quant à la mise à la

terre de l'appareil.

Ne modifiez pas la fiche fournie avec l'appareil : si elle ne

rentre pas dans la prise, demandez à un électricien qualifié

d'en installer une nouvelle.

20

Page 21

Sécurité

!

!

!

C

U

L

US LISTED

®

ATTENTION : RISQUE

D'ELECTROCUTION.

NE PAS OUVRIR

AVERTISSEMENT :

Pour réduire le risque d'électrocution, N'enlevez PAS le capot (ou le dos) de l'appareil. Aucune pièce

protégée par ces éléments ne peut être remplacée par l'utilisateur.

Faites appel à un technicien qualifié le cas échéant.

La référence du modèle et le numéro de série se trouvent à l'arrière de l'appareil.

Notez le modèle et le numéro de série dans l'espace indiqué. Conservez ce manuel comme preuve d'achat. Il permettra

l'identification de la machine en cas de vol.

N° DE MODÈLE

N° DE SÉRIE

AVERTISSEMENT :

POUR ÉVITER TOUT RISQUE D'INCENDIE OU D'ÉLECTROCUTION, PROTÉGEZ L'APPAREIL CONTRE

LES INTEMPÉRIES ET L'HUMIDITÉ.

FR

Le symbole représentant une flèche en forme d'éclair encadré d'un triangle équilatéral signale la présence d'une

tension non isolée à l'intérieur du bâti d'une intensité suffisante pour causer une électrocution.

Le point d'exclamation encadré d'un triangle équilatéral signale à l'utilisateur la présence de consignes d'utilisation et

d'entretien importantes dans le manuel.

La Société Indesit propose à ses clients des produits marqués par le label ENERGY STAR.

Cet appareil a été testé par UL. Il a été déclaré conformé aux normes de sécurité UL pour le Canada

et les États-Unis, comme l'indique le symbole.

21

Page 22

Consignes d'installation

0" *

0" *

Recessed Front View

0" *

0" *

Recessed Front View

FR

! Conservez ce manuel en vue d'une consultation

ultérieure. En cas de vente du lave-linge, si celui-ci

est déplacé ou déménagé, veillez à ce que le manuel

accompagne la machine de sorte que le nouveau

propriétaire puisse se familiariser avec son fonctionnement

et ses caractéristiques.

! Lisez attentivement ces instructions : elles contiennent

des informations essentielles quant à l'installation et à

l'utilisation en toute sécurité de la machine.

Déballage et mise de niveau

Déballage

1. Déballez le lave-linge.

2. Vérifiez si le lave-linge n'a pas été endommagé pendant

le transport. S'il a été endommagé, contactez le vendeur

et attendez avant de continuer l'installation.

3. Retirez les 4 vis de

protection (utilisées pendant

le transport), la rondelle en

caoutchouc et l'entretoise

sur la face arrière de la

machine (voir figure).

4. Bouchez les trous à

l'aide des pastilles en plastique fournies.

5. Conservez toutes les pièces en lieu sûr : vous en aurez

besoin si le lave-linge doit à nouveau être déplacé.

! Les emballages ne sont pas des jouets. Ils doivent être

conservés hors de portée des enfants.

Cela permet également d'éviter le déplacement de la

machine pendant son fonctionnement.

Encombrement minimum

La machine peut être installée dans un espace confiné,

dans un placard ou une alcôve. Les espaces sont

exprimés en pouces et représentent le minimum

acceptable.

*Prévoyez un espace supplémentaire pour une installation

et un entretien facile. Veillez également à respecter les

règlements locaux en vigueur. L'installation doit respecter

les dimensions minimum indiquées.

Mise de niveau

1. Installez le lave-linge sur une surface résistante sans

toutefois l'appuyer contre les parois, le mobilier ou tout

autre élément à proximité.

2. Si le sol n'est pas parfaitement de niveau, compensez

les écarts en serrant ou desserrant les pieds avant

réglables (voir figure).

L'angle d'inclinaison,

mesuré au niveau du plan

de travail, ne peut pas

dépasser 2°.

22

Mettez correctement la

machine de niveau pour

assurer sa stabilité, éviter

les vibrations et les bruits

excessifs.

Page 23

!

Raccordement de l'arrivée d'eau

!

!

A & B = 25" (62 cm) min. / 34" (86 cm) max.

Floor Standpipe Wall Standpipe

A

B

Fig. 4

25" (62 cm) min.

with an air break

Laundry Sink Drain

Fig. 5

Sink Drain W/ "Y" Branch Tailpiece

H

C

Si les canalisations prévues pour le raccordement sont

neuves ou n'ont jamais été utilisées, faites couler l'eau

pour évacuer les débris susceptibles de boucher les

filtres ou les vannes avant de raccorder la machine.

REMARQUE : les vannes d'arrêt fournies doivent être

facilement accessibles.

Important : la pression de l'eau doit être

comprise entre les valeurs figurant dans les

Caractéristiques techniques.

FR

1. Raccordez le robinet

d'eau froide (raccord bleu

C) à l'arrivée d'eau froide.

Serrez bien.

2. Ouvrez l'arrivée d'eau

froide et vérifiez l'absence de

fuites. Serrez davantage si

nécessaire.

3. Raccordez le robinet

d'eau chaude (raccord rouge H) à l'arrivée d'eau chaude.

Serrez bien.

4. Ouvrez l'arrivée d'eau froide et vérifiez l'absence de

fuites. Serrez davantage si nécessaire.

Important : Do not use excessive force.

Damage to the couplings can result. Les raccords

doivent être serrés à la main. N'utilisez un outil

qu'en cas de fuite.

Évacuation

• Diamètre/capacité de la conduite verticale : une

conduite verticale d'au moins 1 ¼” et dotée d'une capacité

de 26,50 litres/minutes est nécessaire.

• Sommet de la conduite verticale : doit se trouver

à une distance comprise entre 64 et 86 cm du bas de la

machine.

• Extrémité du tuyau de décharge (fourni avec la

machine) : doit se trouver à au moins 50 cm au-dessus

du fond du lave-linge/sèche-linge. Une prise d'air doit

être prévue au niveau du tuyau de décharge afin d'éviter

le siphonnage. Veillez à introduire le tuyau d'évacuation

sur 6” (15 cm) maximum dans la décharge pour éviter le

siphonnage.

Raccordement de la décharge

L'eau peut être évacuée vers un lavabo, une conduite

verticale ou un tuyau d'écoulement. Une prise d'air doit

être prévue à au moins 50 cm pour éviter le siphonnage

(Fig. 6).

Conduite verticale : l'installation nécessite une colonne

montante de 1 ¼” (3,2 cm) d'une capacité de 26 litres par

minute.

Canalisation encastrée dans le sol ou dans le mur : le haut de

la canalisation doit être compris entre 25” (62 cm) et 34” (86

cm) par rapport au fond du lave-linge (Fig. 4).

Décharge sous évier : le raccordement au système

d'évacuation du bac doit se trouver au-dessus du siphon

(Fig. 5). Lorsque la décharge est encastrée dans des

parois ou des murs, utilisez un matériau de protection

(ruban isolant ou adhésif en toile) pour couvrir les bords

tranchants susceptibles d'endommager la conduite.

Utilisez un système de fixation adapté pour raccorder

la décharge à la bifurcation ou au broyeur. En présence

d'une décharge sous évier, vous pouvez effectuer le

raccordement directement aux éléments suivants :

1) à un broyeur en respectant les techniques de fixation

prévues par le fabricant.

2) directement à un about de bifurcation (disponible dans

la plupart des quincailleries).

Important : veillez à ce que la décharge ne

soit pas pincée et que l'eau s'écoule librement.

3) par le plancher vers un siphon distinct. Le siphon doit

être doté d'une prise d'air pour éviter le siphonnage.

Pour garantir l'aération du système, installez un reniflard

(disponible dans la plupart des quincailleries).

4) Au robinet à l'aide d'un adaptateur (disponible

séparément).

• Utilisez la bride ouverte (fournie avec les accessoires) ou

un élément adéquat pour fixer l'extrémité de la décharge

(préinstallée à l'arrière de votre machine).

23

Page 24

FR

C

U

L

US LISTED

®

20" (62 cm) min.

34" (86 cm) max.

Standpipe

"Y" Tail Piece

This connection MUST be

before drain trap and at

least 20" (50.8 cm) above

the floor where washer will

be installed.

Cable tie

Floor Standpipe w/ "Y" Branch Tail Piece

Fig. 7

20" (50 cm) min.

with an air break

25" (62 cm) min.

34" (86 cm) max.

6" max.

Standpipe

Floor Standpipe

Fig. 6

U-Clamp

• Introduisez l'extrémité de la décharge dans la conduite

verticale ou la décharge encastrée dans le mur ou le sol

(Fig. 6). REMARQUE : l'extrémité de la décharge DOIT

se trouver à au moins 20” (50 cm) au-dessus de la base

de la machine. Veillez à introduire le tuyau d'évacuation

sur 6” (15 cm) maximum dans la décharge pour éviter le

siphonnage.

• Utilisez du ruban adhésif, un serre-câbles ou tout autre

élément analogue pour maintenir le tuyau ou la bride

ouverte en place.

Raccordements électriques

• Tension/intensité de la machine : 120V, 60 Hz, 4 Amp.

• Raccordement : prise à trois broches et cordon de 1m80

fournis

• Circuit/parafoudre : monophasé à trois fils, 120 V, 60 Hz,

CA, sur circuit de 15 Amp séparé.

Données techniques

Caractéristiques techniques

Pose sous évier

1. Coupez l'extrémité

fermée de la décharge sous

l'évier.

Modèle

Dimensions

Poids

Encombrement

minimum

Capacité

Raccords

électriques

Raccordements

en eau

Vitesse

d’essorage max.

La Société Indesit propose à ses clients

des produits marqués par le label

ENERGY STAR.

Cet appareil a été testé par UL.

Il a été déclaré conformé aux

normes de sécurité UL pour le

Canada et les États-Unis,

comme l’indique le symbole.

ARWXF 129 W

largeur : 23.4” (59,5 cm)

hauteur : 33.24” - 33.75”

(84,5 - 85,7 cm)

profondeur : 22” (55,9) cm

148 lbs (68 kg)

Côtés : 0”

Avant / arrière : 1”

Lavage : 2 à 15 lbs. (1 à 7 kg)

Tension : 120 Volts, 4 A, 60 Hz

Pression maximale : 0,69 Mpa (6,9 bar),

100 psi

Pression minimale : 0,05 Mpa (0,5 bar),

7,2 psi

jusqu’à 1200 tr/min

24

2. Fixez le support pour le

raccord à au moins 620 mm

du sol.

3. Utilisez un collier de

serrage pour raccorder

l'extrémité de la conduite

d'évacuation grise à la

décharge sous l'évier.

Page 25

Description du lave-linge et

démarrage d'un cycle de lavage

Tableau de commande

Distributeur de produits lessiviels

Bouton

ON/OFF

avec témoin

Bouton

CYCLE DE

LAVAGE :

Témoins de

Bouton

TEMPERATURE

Bouton

VITESSE

D'ESSORAGE

Bouton

VERROU PANNEAU DE COMMANDE

avec témoin

PROGRESSION DU

CYCLE DE LAVAGE

ECRAN

Boutons de

FONCTION

avec témoin :

Témoin

VERROUILLEE

Bouton START/

PAUSE

avec témoin

lumineux

FR

PORTE

AVERTISSEMENT : pour limiter les risques d'incendie,

d'électrocution ou de blessures, lisez les CONSIGNES

DE SÉCURITÉ IMPORTANTES avant d'utiliser

l'appareil.

Distributeur de produits lessiviels : utilisé pour la

distribution des produits lessiviels et des compléments de

lavage (voir « Produits lessiviels et linge »).

Bouton ON/OFF avec témoin : permet de mettre la

machine sous/hors tension.

Si le témoin est allumé, cela indique que la machine est

sous tension.

Bouton CYCLE DE LAVAGE : permet de programmer

les cycles de lavage. Pendant le cycle de lavage, le bouton

reste immobile.

Bouton VITESSE D'ESSORAGE : permet de définir la

vitesse d'essorage ou d'exclure totalement l'essorage (voir

"Personnalisation").

Bouton TEMPERATURE : permet de régler la

température ou le cycle de lavage à froid (voir

"Personnalisation").

Les sélections pour les températures de lavage sont

distribuées de manière uniforme.

Bouton VERROU PANNEAU DE COMMANDE avec

témoin : active ou désactive le verrou du panneau de

commande.

Boutons de FONCTION avec témoin : permettent

la sélection des fonctions disponibles. Le témoin

correspondant à la fonction sélectionnée restera allumé.

Témoins de PROGRESSION DU CYCLE DE LAVAGE :

permettent de contrôler la progression du cycle de lavage.

Le témoin affiche la phase en cours.

Témoin PORTE VERROUILLEE : indique si le hublot

peut être ouvert ou non (voir page suivante).

Bouton START/PAUSE avec témoin lumineux : démarre

ou interrompt momentanément les cycles de lavage.

Remarque : pour interrompre un cycle de lavage, appuyez

sur ce bouton. Le témoin correspondant clignotera en

orange alors que le témoin indiquant la phase de lavage

restera fixe. Si le témoin PORTE VERROUILLEE est

éteint, la porte peut être ouverte.

Pour redémarrer le cycle de lavage à l'endroit où il a été

interrompu, appuyez à nouveau sur ce bouton.

ECRAN : indique le temps restant pour le cycle de lavage

sélectionné. En cas de départ différé, le temps restant

avant le démarrage du cycle de lavage s'affiche.

25

Page 26

FR

Témoins

Le témoin fournit des informations importantes.

A savoir :

Témoins d'indication de phase de lavage

Lorsque vous tournez le bouton CYCLE DE LAVAGE, les

témoins s'illuminent et indiquent les étapes qui seront

effectuées par la machine selon le cycle de lavage

sélectionné.

Une fois que le cycle de lavage sélectionné a commencé,

les témoins s'allument au fur et à mesure pour indiquer la

phase en cours.

Lavage

Rinçage

Essorage

Vidange

Fin du cycle de lavage

Boutons de fonction et témoins correspondants

Lorsqu'une fonction est sélectionnée, le témoin

correspondant s'allume.

Si la fonction désirée n'est pas compatible avec le cycle de

lavage programmé, le témoin correspondant clignotera, un

signal sonore sera émis et la fonction ne sera pas activée.

Si une fonction est incompatible avec une autre fonction

active, seule la dernière sélection restera active.

Témoin de température

Lorsqu'une température est sélectionnée, le témoin

correspondant s'allume.

Témoin d'essorage

Lorsqu'une vitesse d'essorage est sélectionnée, le témoin

correspondant s'allume.

Témoin de verrouillage du tableau de

commande

Pour activer le verrouillage du tableau de commande,

appuyez sur ce bouton et maintenez-le enfoncé pendant

2 secondes environ. Lorsque le témoin est allumé, le

tableau de commande est bloqué. Les cycles de lavage ne

peuvent donc pas être modifiés par accident, surtout en

présence d'enfants dans la maison.

Pour désactiver le verrouillage du tableau de commande,

appuyez sur ce bouton et maintenez-le enfoncé pendant 2

secondes environ.

Témoin de porte verrouillée

Si ce témoin est allumé, la porte de la machine est

verrouillée afin d'éviter toute ouverture accidentelle. Pour

éviter tout dommage à l'appareil, attendez que le témoin

s'éteigne avant d'ouvrir la porte.

Remarque : si la fonction DÉPART DIFFÉRÉ est active,

la porte ne peut pas être ouverte. Mettez la machine en

pause en appuyant sur le bouton START/PAUSE si vous

souhaitez l'ouvrir.

! Si le témoin START/PAUSE (orange) clignote rapidement

en même temps que le témoin indiquant la fonction, c'est

qu'un problème s'est produit (voir "Dépannage").

Démarrage d'un cycle de lavage

1. Éteignez le lave-linge en appuyant sur le bouton ON/OFF. Tous les témoins s'allumeront pendant quelques secondes. Ils

s'éteindront ensuite et le témoin START/PAUSE clignotera.

2. Chargez le linge et fermez le hublot.

3. Programmez le cycle de lavage à l'aide du bouton CYCLE DE LAVAGE.

4. Réglez la température (voir Personnalisation").

5. Réglez le cycle d'essorage si nécessaire (voir "Personnalisation").

6. Ajoutez la dose de produit lessiviel et les compléments de lavage (voir "Produits lessiviels et linge").

7. Sélectionnez les fonctions désirées.

8. Lancez le cycle de lavage en appuyant sur le bouton START/PAUSE. Le témoin correspondant restera fixe (vert).

Pour annuler le cycle programmé, mettez la machine en pause en appuyant sur le bouton START/PAUSE et en sélectionnant

un nouveau cycle.

9. Au terme du cycle de lavage, le témoin ( ) s'allumera. Le témoin PORTE VERROUILLE s'allumera pour signaler

que l'ouverture du hublot est possible. Retirez le linge et laissez le hublot ouvert pour que le tambour puisse sécher

complètement. Éteignez le lave-linge en appuyant sur le bouton ON/OFF.

26

Page 27

Cycles de lavage

Tableau des cycles de lavage

Tem-

Vitesse

Description du cycle de lavage

lavage

Cycles de

Cycles de base

1

Coton standard : vêtements blancs et colorés résistants très sales.

2

Coton couleur : vêtements blancs et colorés délicats peu sales. Chaud Max -

3

Permanent : vêtements synthétiques ou sans repassage normaux. Chaud 800 -

4

Lavage rapide

Volume mixte - 30 min : pour rafraîchir rapidement les vêtements peu

5

sales (ne convient pas pour la laine, la soie et les vêtements nécessitant

un lavage à la main).

Cycles de lavage spéciaux

6

Blanc éclatant : vêtements blancs et colorés résistants très sales. Chaud Max

7

Jeans

8

Vêtements de sport

9

Vêtements d’enfant : couleurs délicates très sales. Chaud 800 -

Peu de taches - 15 min : pour rafraîchir rapidement les vêtements peu

10

sales (ne convient pas pour la laine, la soie et les vêtements nécessitant

un lavage à la main).

Délicats

11

Délicat : couleurs délicates peu sales. Chaud 800 -

12

Soie/Tentures

13

Laine : laine, cashmere, etc. Chaud 600 -

Cycles de lavage partiels

A

Rinçage

B

Essorage

C

Vidange

pérature

chaud

Chaud Max -

Chaud 800 -

Chaud 800 -

Chaud 600 -

Chaud 800 -

Chaud 0 -

maxi-

maxi-

male (tr/

male

(°C)

Très

- Max - -

- Max - - - Max

- - - - - Max

Javel Lessive

min)

Max -

Produits lessiviels

Adoucis-

sant

FR

Volume

maximal

(lb)

Max

Max

6.6

2.20

6.6

Max

6.6

6.6

4.4

3.30

6.6

2.20

3.30

Max

Durée du

cycle

La durée des cycles de lavage s’affiche à l’écran.

Cycles de lavage spéciaux

Sans repassage (cycle 3) Ce cycle se caractérise par un lavage et un essorage plus lents afin de réduire le

froissement des vêtements.

Charge mixte (cycle 5) ce cycle de lavage est prévu pour le lavage rapide des vêtements peu sales : il ne dure que

30 minutes, ce qui permet d'économiser à la fois de l'énergie et du temps. Si vous sélectionnez ce cycle de lavage (5

avec température CHAUD), vous pourrez laver différents tissus en une seule machine (sauf la laine et la soie) pour une

lessive de maximum 6.6 lb - (3 kg).

Blanc éclatant (cycle 6) : utilisez ce cycle lorsque vous lavez à l'aide de produits à base d'hypochlorite.

Versez l'eau de Javel, la lessive et les compléments dans les compartiments prévus à cet effet (voir "Distributeur de

produits lessiviels").

Vêtements de sport (cycle 8) : permet de laver les vêtements de sport peu sales (survêtements, shorts, etc.). Pour

obtenir de meilleurs résultats, il est conseillé de ne pas dépasser la charge maximale indiquée dans le Tableau des

cycles de lavage.

Vêtements d'enfants (cycle de lavage 9). Ce cycle de lavage peut être utilisé pour nettoyer les taches causées

généralement par les enfants. Il permet également de rincer parfaitement les produits lessiviels lors du lavage des couches

afin de préserver la peau sensible des enfants en évitant les allergies. Ce cycle a été programmé pour réduire le volume de

bactéries grâce à l'usage d'une grande quantité d'eau et l'optimisation des désinfectants spéciaux ajoutés à la lessive. A la

fin du cycle de lavage, le tambour tournera lentement pour éviter la formation de plis. Pour mettre fin au cycle, appuyez sur le

bouton START/PAUSE.

Peu de taches - 15 min. (cycle 10) : ce cycle de lavage est prévu pour le lavage rapide des vêtements peu sales : il

ne dure que 15 minutes, ce qui permet d'économiser à la fois de l'énergie et du temps. Si vous sélectionnez ce cycle

de lavage (10 avec température CHAUD), vous pourrez laver différents tissus en une seule machine (sauf la laine et la

soie) pour une lessive de maximum 1,50 kg - (1,5 kg).

Pour ce cycle, il est conseillé de traiter au préalable les taches, les cols et les manchettes de chemise à l'aide d'un

détachant adapté.

27

Page 28

Personnalisation

FR

Réglage de la température

Appuyez sur le bouton TEMPERATURE pour régler la température de lavage. (Voir Tableau des cycles de lavage) La température de lavage peut être définie à l'aide des boutons , "Froid", "Chaud", "Très chaud" ou les deux positions intermédiaires

(par exemple : la position comprise entre "froid" et "chaud" équivaut donc à tiède). Voir ci-dessous pour les valeurs en °C et °F

correspondant à chaque température.

Les choix disponibles sont les suivants :

• L’ eau du robinet

• Froid (cold) 15 °C/ 59 °F

• 30 °C/ 86 °C

• Chaud (warm) 40 °C/ 104 °C

• 50 °C / 122 °F

• Très chaud (hot) 57 °C / 134 °F

Réglage de la vitesse d'essorage