Page 1

Operating Instructions

COOKER AND OVEN

GB

English,1

A6TMC2 C

(X)

AUS

Contents

GB

Warning, 2

Installation, 3-9

Positioning and levelling

Mounting a Power Supply Cable

Electrical connection

Gas connection

Adapting to different types of gas

Post Installation Checks

Technical specifications

Table of characteristics

Description of the appliance, 10

Overall view

Control panel

Start-up and use, 11-14

Using the hob

Using the oven

Using the cooking timer

Cooking modes

Oven cooking advice table

Precautions and tips, 15-16

General Appliance Warnings

Installation Warnings

Safety With The Cooktop

Maintenance Warnings

Gas And Electrical Safety

Respecting and conserving the environment

Care and maintenance, 17-18

Switching the appliance off

Cleaning the appliance

Replacing the oven light bulb

Cleaning The Cooktop

Gas tap maintenance

Assistance

Service information, 19

Page 2

WARNING

GB

WARNING: The appliance and its

accessible parts become hot

during use.

Care should be taken to avoid

touching heating elements.

Children less than 8 years of age

shall be kept away unless

continuously supervised.

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance in

a safe way and understand the

hazards involved. Children shall not

play with the appliance. Cleaning

and user maintenance shall not be

made by children without

supervision.

Do not close the glass cover (if

present) when the gas burners or

electric hotplates are still hot.

WARNING: Ensure that the

appliance is switched off before

replacing the lamp to avoid the

possibility of electric shock.

CAUTION: the use of inappropriate

hob guards can cause accidents.

! When you place the rack inside,

make sure that the stop is directed

upwards and in the back of the cavity.

WARNING: Unattended cooking on

a hob with fat or oil can be

dangerous and may result in fire.

NEVER try to extinguish a fire with

water, but switch off the appliance

and then cover flame e.g. with a lid

or a fire blanket.

Do not use harsh abrasive cleaners

or sharp metal scrapers to clean the

oven door glass since they can

scratch the surface, which may

result in shattering of the glass.

The internal surfaces of the

compartment (where present) may

become hot.

Never use steam cleaners or

pressure cleaners on the appliance.

Remove any liquid from the lid

before opening it.

2

Page 3

Installation

This appliance must be installed by an authorised person in accordance with this instruction manual AS/NZS 5601.1 – Gas installations

(installation and pipe sizing), local gas fitting regulations, local electrical regulations, Building Code of Australia and any other government authority.

! Before operating your new appliance please read

this instruction booklet carefully. It contains

important information concerning the safe installation

and operation of the appliance.

! Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualified

professional according to the instructions provided.

! This cooktop must be installed in accordance with

the requirements of local gas and electrical authorities,

as well as the latest published versions of the following

standards:

• AS/NZS 5601 Gas Installation code

• SAA Wiring Rules.

! Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

Adjacent room Room requiring ventilation

AB

A

Ventilation opening Increase in the gap between

for comburent air the door and the flooring

Room ventilationRoom ventilation

Room ventilation

Room ventilationRoom ventilation

Where the total input of all appliances exceeds 3

MJ/h for each cubic metre of the room or enclosure

volume, the space shall be ventilated by one of the

methods detailed below. For the purpose of

assessing the adequacy of ventilation, the space

that cannot be isolated by doors is the ‘volume of a

room’.

Natural ventilation direct from outsideNatural ventilation direct from outside

Natural ventilation direct from outside

Natural ventilation direct from outsideNatural ventilation direct from outside

Two permanent openings shall be provided directly

to outside. The openings shall be located to ensure

the distance between the top of the upper opening

and the ceiling of the room or enclosure, and the

distance between the bottom of the lower opening

and the floor of the room or enclosure does not

exceed 5% of the height of the room or enclosure.

The minimum free ventilation area provided by each

opening shall be calculated using the following

formula:

A = 3 × T, where

A = the minimum free ventilation area (cm

T = the total gas consumption of all appliances

(MJ/h)

The minimum vertical dimension of any free

ventilation opening shall be 6 mm.

When used in this Clause, the term When used in this Clause, the term

NOTE 1

‘directly to outside’ means any one of the‘directly to outside’ means any one of the

‘directly to outside’ means any one of the

‘directly to outside’ means any one of the‘directly to outside’ means any one of the

following options, provided that thefollowing options, provided that the

following options, provided that the

following options, provided that thefollowing options, provided that the

ventilation path is unobstructed by buildingventilation path is unobstructed by building

ventilation path is unobstructed by building

ventilation path is unobstructed by buildingventilation path is unobstructed by building

material or insulation:material or insulation:

material or insulation:

material or insulation:material or insulation:

(a) Directly through an outside wall (preferred

option).

(b) Through to an outside wall but offset.

(c) Into a cavity ventilated to outside.

(d) Into an underfloor space ventilated to outside.

(e) Into a roof space ventilated to outside.

NOTE 2

provided that the top and bottom of theprovided that the top and bottom of the

provided that the top and bottom of the

provided that the top and bottom of theprovided that the top and bottom of the

opening reach the limits set by this Clause.opening reach the limits set by this Clause.

opening reach the limits set by this Clause.

opening reach the limits set by this Clause.opening reach the limits set by this Clause.

Natural ventilation via adjacent roomNatural ventilation via adjacent room

Natural ventilation via adjacent room

Natural ventilation via adjacent roomNatural ventilation via adjacent room

Two permanent openings shall be provided in the

room or enclosure. The openings shall be located to

ensure the distance between the top of the upper

opening and the ceiling of the room or enclosure,

and the distance between the bottom of the lower

opening and the floor of the room or enclosure does

not exceed 5% of the height of the room or

enclosure.

The minimum free ventilation area provided by each

opening shall be calculated using the following

formula:

A = the minimum free ventilation area (cm

T = the total gas consumption of all appliances

(MJ/h)

These requirements shall apply to all subsequent

rooms until a room is ventilated to outside, in

accordance with the previous section, or the total

input of the appliances does not exceed 3 MJ/h for

each cubic metre of the total volume of the

enclosure and rooms.

The minimum vertical dimension of any free

ventilation opening shall be 6 mm.

NOTE

provided that the top and bottom of theprovided that the top and bottom of the

provided that the top and bottom of the

provided that the top and bottom of theprovided that the top and bottom of the

opening reach the limits set by this Clause.opening reach the limits set by this Clause.

opening reach the limits set by this Clause.

opening reach the limits set by this Clause.opening reach the limits set by this Clause.

When used in this Clause, the term

When used in this Clause, the term When used in this Clause, the term

The two openings may be combined The two openings may be combined

The two openings may be combined

The two openings may be combined The two openings may be combined

A = 6 × T, where

: The two openings may be combined: The two openings may be combined

: The two openings may be combined

: The two openings may be combined: The two openings may be combined

2

)

2

)

GB

3

Page 4

GB

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min. mm.

420

Min. mm.

The appliance may only be installed in permanentlyventilated rooms, in accordance with current national

legislation. The room in which the appliance is

installed must be ventilated adequately so as to

provide as much air as is needed by the normal gas

combustion process (the flow of air must not be

lower than 2 m

3

/h per kW of installed power).

The air inlets, protected by grilles, should have a

duct with an inner cross section of at least 100 cm

2

and should be positioned so that they are not liable

to even partial obstruction (

see figure A

).

These inlets should be enlarged by 100% - with a

minimum of 200 cm2 - whenever the surface of the

hob is not equipped with a flame failure safety

device. When the flow of air is provided in an

indirect manner from adjacent rooms (

see figure B

),

provided that these are not communal parts of a

building, areas with increased fire hazards or

bedrooms, the inlets should be fitted with a

ventilation duct leading outside, as described

above.

! After prolonged use of the appliance, it is

advisable to open a window or increase the speed of

any fans used.

! The liquefied petroleum gases are heavier than air

and collect by the floor, therefore all rooms containing

LPG cylinders must have openings leading outside

so that any leaked gas can escape easily.

LPG cylinders, therefore, whether partially or

completely full, must not be installed or stored in

rooms or storage areas that are below ground level

(cellars, etc.). Only the cylinder being used should

be stored in the room; this should also be kept well

away from sources of heat (ovens, chimneys,

stoves) that may cause the temperature of the

cylinder to rise above 50°C.

• If the cooker is installed

underneath a wall

cabinet, there must be

a minimum distance of

420 mm between this

cabinet and the top of

the hob.

This distance should be

increased to 700 mm if

the wall cabinets are

flammable (

see figure

).

The following minimum clearances to combustible

materials must be observed:

• Minimum clearance from edge of burner to side

wall must be 200 mm.

• Minimum clearance from edge of burner to rear

wall must be 200 mm.

• Do not position blinds behind the cooker or less

than 200 mm away from its sides.

Range hoods

Range hoods and overhead exhaust fans must be

installed according to manufacturers’ instructions but

in no case shall clearance from hob burners be less

than 600 mm for range hoods and 750 mm for

overhead exhaust fans.

If the hood is installed below a wall cabinet, the

latter must be at least 700 mm (millimetres) above

the surface of the hob.

Positioning and levelling

! It is possible to install the appliance alongside

cupboards whose height does not exceed that of the

hob surface.

! Make sure that the wall in contact with the back of

the appliance is made from a non-flammable, heatresistant material (T 90°C).

To install the appliance correctly:

• Place it in the kitchen, the dining room or the bedsit (not in the bathroom).

• If the top of the hob is higher than the cupboards,

the appliance must be installed at least 600 mm

away from them.

4

Page 5

NL

GREEN &

YELLOW

BROWN

BLUE

13 amp fuse

CROSS-BAR

CORD GRIP

a washer should be used. Concrete wall requires the

screw of at least 8mm of diameter, and 60mm of length.

Ensure that the chain is fixed to the rear wall of the cooker

and to the wall, as shown in figure, so that after installation

it is tensioned and parallel to the ground level.

Levelling

If it is necessary to level the

appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (

figure

).

see

The legs* fit into the slots on

the underside of the base of

the cooker.

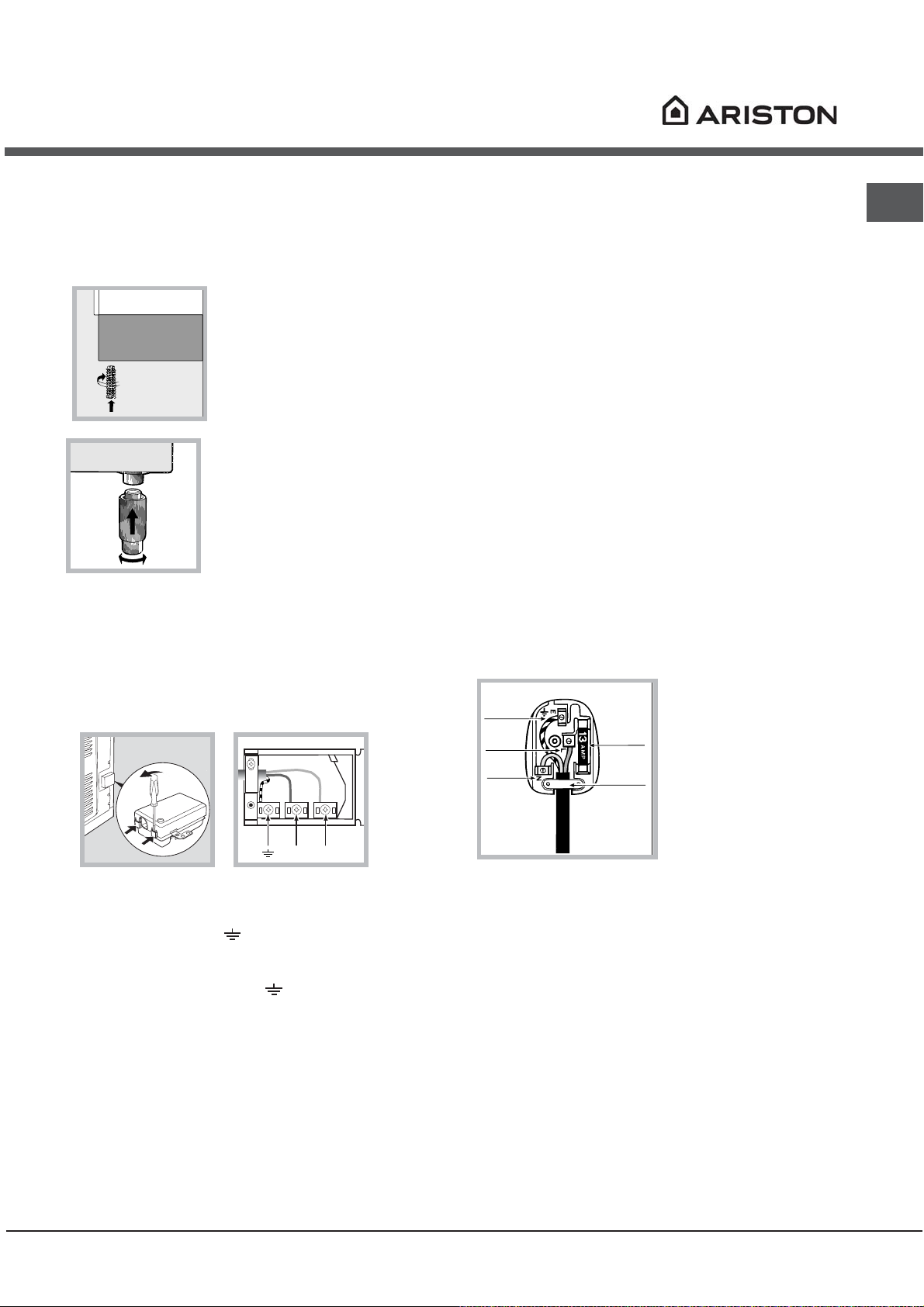

Mounting a Power Supply Cable

Connecting the power supply cable to the mains.

GB

Fit a normalized plug to the cable, which

corresponds to the load indicated on the data plate;

if the cooker is connected directly to the mains, an

omnipolar circuit-breaker with a minimum opening of

3 mm between the contacts, suitable for the load

indicated and complying with current directives,

must be installed between the appliance and the

mains (the earthing wire must not be interrupted by

the circuit-breaker). The power supply cable must be

positioned so that it does not exceed room

temperature by 50°C at any point of its length.

Before making the connection check that:

• the limiter valve and the home system can

support appliance load (see data plate);

• the power supply system has an efficient earthing

connection which complies with the provisions of

current regulations and the law;

• there is easy access to the socket or the

omnipolar circuit-breaker once the cooker has

been installed.

! Do not use reducers, adapters or shunts as these

could cause heating or burning.

Opening the terminal board:

••

• Using a screwdriver, prise on the side tabs of the

••

terminal board cover;

••

• Pull open the cover of the terminal board.

••

To install the cable, proceed as follows:

••

• Remove the wire clamp screw and the three

••

contact screws L-N-

• Fasten the wires beneath the heads of the screws

using the following color scheme : Blue (N)

Brown (L) Yellow-Green

• Fasten the supply cable in place with the clamp

and close the cover of the terminal board.

Electrical connection

Ovens with a three-pole power supply cable are

designed to operate with alternated current at the

supply frequency and voltage indicated on the data

plate (at the bottom of the oven dashboard). The

earthing conductor of the cable is the yellow-green

conductor.

How to connect an alternative plug

The wires in this mains

lead are coloured in

accordance with the

following code:

BLUE “NEUTRAL”BLUE “NEUTRAL”

BLUE “NEUTRAL”

BLUE “NEUTRAL”BLUE “NEUTRAL”

(N)(N)

(N)

(N)(N)

BROWNBROWN

BROWN

BROWNBROWN

GREEN AND YELLOWGREEN AND YELLOW

GREEN AND YELLOW

GREEN AND YELLOWGREEN AND YELLOW

“EARTH” (E)“EARTH” (E)

“EARTH” (E)

“EARTH” (E)“EARTH” (E)

“LIVE” (L)“LIVE” (L)

“LIVE” (L)

“LIVE” (L)“LIVE” (L)

! Once the appliance has been installed, the power

supply cable and the electrical socket must be

easily accessible.

! The cable must not be bent or compressed.

! The cable must be checked regularly and replaced

by authorised technicians only.

Disconnecting the cable

Ensure that the means for disconnection of the

power cable is incorporated into the fixed wiring in

accordance with local wiring rules.

(New Zealand statutory warning): The cooker must

be connected to the electricity supply by a cable

fitted with an appropriately rated plug that is

compatible with the socket-outlet fitted to the final

subcircuit in the fixed wiring that is intended to

supply this cooker.

5

Page 6

GB

L

! The manufacturer declines any liability should

these safety measures not be observed.

right gas connection, the cap should be inverted

and the seal supplied with the appliance should be

replaced when changing the connection.

Gas connection

This appliance is suitable for use withThis appliance is suitable for use with

This appliance is suitable for use with

!

This appliance is suitable for use withThis appliance is suitable for use with

either a flexible connection or rigid coppereither a flexible connection or rigid copper

either a flexible connection or rigid copper

either a flexible connection or rigid coppereither a flexible connection or rigid copper

connection.connection.

connection.

connection.connection.

Check The Gas Type

WARNING: Before installation, check that the gas

type (natural gas or LPG/

suitable for the gas type available to the installation.

It is extremely dangerous to use the wrong gas type

with any appliance, as fire or serious injury can

result.

This cooker is supplied from the factory already set

for Natural Gas. To convert the cooker to LPG (or

back to Natural Gas from LPG), follow the directions

later in this section.

Fit regulator supplied for Natural Gas (if applicable)

at rear of appliance, and as close as practicable to

the appliance.

It is recommended that an isolating valve and union

be fitted, to enable simple disconnection for

servicing. These are to be in an accessible location.

! Check that the pressure of the gas supply is

consistent with the values indicated in the “Technical

specifications”, p6. This will ensure the safe

operation and durability of your appliance while

maintaining efficient energy consumption.

Natural gas test point is located on the regulator

ULPG test point adaptor is supplied and must be fitted to

the inlet connection.

Gas connection using a flexible rubber hose

and a seal "G" is fitted at the end "L" of the pipe to

be connected to the gas mains. This fitting should

not be removed. When the connection pipe (flexible

or rigid) is dismounted, the fitting "R" should be

locked in place using a spanner before unscrewing

the metal pipe bolt. This is to prevent the fitting "R"

from slipping and so as not to cause any leaks from

sleeve "L". If the appliance is designed for left and

Universal

of the cooker is

Make the connection

using a gas hose that

complies with

requirements set forth

by the current National

Regulations. The

appliance is factory set

for connection to a

natural gas supply. A

fitting "R" with a conical

thread ISO7-1 (1/2 gas)

If a flexible hose is used, it should be as short as

possible with a maximum length of 1.2metres;

• the flexible connection must be approved to class

B or D of AS/NZS1869 as a minimum.

• it should not be bent, kinked or compressed;

• it should not be in contact with the rear wall of the

appliance or in any case with parts which may

reach a temperature of 50°C;

• it should not come into contact with pointed parts

or sharp corners;

• it should not be subject to any pulling or twisting

forces;

• it should be easy to inspect along its entire length

in order to be able to check its condition.

• The supply connection point must be accessible

with the appliance installed.

• The inner diameters of the pipe are as follows:

8 mm for LPG; 13 mm for Natural Gas.

Upon completion of installation, check the gas

circuit, the internal connections and the taps for

leaks using a soapy solution (never a flame). Also

check that the connecting pipe cannot come into

contact with moving parts which could damage or

crush it. Make sure that the natural gas pipe is

adequate for a sufficient supply to the appliance

when all the burners are lit

Connecting a flexible jointless stainless steel

pipe to a threaded attachment

Make sure that the hose and gaskets comply with

current national legislation.

To begin using the hose, remove the hose holder on

the appliance (the gas supply inlet on the appliance

is a cylindrical threaded 1/2 gas male attachment).

! Perform the connection in such a way that the hose

length does not exceed a maximum of 1.2 metres,

making sure that the hose is not compressed and

does not come into contact with moving parts.

Checking the tightness of the connection

Upon completion of installation, check the gas

circuit, the internal connections and the taps for

leaks using a soapy solution (never a flame). Also

check that the connecting pipe cannot come into

contact with moving parts which could damage or

crush it. Make sure that the natural gas pipe is

adequate for a sufficient supply to the appliance

when all the burners are lit.

6

Page 7

Duplicate Data Plate

Where the data plate is obscured by cabinetry when

the cooker is in the installed position, place a

duplicate data plate on a surface of the cabinetry

adjacent to the cooker.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to “regulators for channelled gas”.

GB

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

Adapting the hob

Replacing the nozzles for the hob burners:

1. Remove the hob grids and slide the burners off

their seats.

2. Unscrew the nozzles using

a 7 mm socket spanner (

figure

), and replace them with

nozzles suited to the new type

of gas

3. Replace all the

components by following the

above instructions in reverse.

Adjusting the hob burners’ minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory

screw, which is positioned inside or next to the tap

pin, until the flame is small but steady.

! If the appliance is connected to a liquid gas

supply, the regulatory screw must be fastened as

tightly as possible:

3. While the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame is not

extinguished.

! The hob burners do not require primary air adjustment.

! After adjusting the appliance so it may be used with a

different type of gas, replace the old rating label with a

new one that corresponds to the new type of gas (these

labels are available from Authorised Technical Assistance

Centres).

see

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of

their housing. The burner consists of two separate

parts (see pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The two

nozzles have the same hole diameter.

3. Replace all the components by completing the above

operations in reverse order.

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the adjustment screw,

which is positioned in or next to the tap pin, until the

flame is small but steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax

! If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

! Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).

7

Page 8

GB

Post Installation Checks

Perform post installation checks and ensure proper

and safe operation before leaving. Test all burners

individually and in combination.

For other minor adjustments or if the appliance does not

perform correctly: contact Arisit Pty Ltd 1300 762 219

Leak Check

• Ensure all gas control knobs are in the Off

position.

• Ensure the gas supply is switched on.

• Spray a solution of soapy water onto all gas joints

as well as the full length of any flexible hoses.

UNDER NO CIRCUMSTANCES USE A NAKED

FLAME IN CHECKING FOR LEAKS.

If bubbles appear anywhere, turn the gas supply off,

check all connections and retest. If satisfactory

operation cannot be achieved, contact place of

purchase or their appointed agent for service.

Flame check

Turn each burner on, and ensure that the flame is

blue with minimal yellow tipping. If there is

significant yellow tipping, flame lift off or excessive

noise, check pressure and adjust at the regulator if

necessary.

If satisfactory operation cannot be achieved, contact

place of purchase or their appointed agent for

service.

Anti-tilt Wall Bracket

! In order to prevent accidental

tipping of the appliance, for

example by a child climbing onto

the oven door, the supplied "antitilt bracket" MUST be installed!

To install the Anti-Tilt Wall Bracket:To install the Anti-Tilt Wall Bracket:To install the Anti-Tilt Wall Bracket:

1. Fit the cooker between the cabinets and adjust the

height of the appliance (if necessary) by means of

adjustable feet.

2. Take out the lower compartment.

3. On the wall behind the cooker draw a line along

the horizontal edge A and then along the vertical edge

B so that the lines cross (see figures below).

Igniter operation

Check that the igniter for each burner successfully

ignites the gas.

If an igniter fails to work, first remove the plug from

the electrical power outlet, and then check that all

the electrical connections are in place.

If satisfactory operation cannot be achieved, contact

place of purchase or their appointed agent for

service.

Low flame setting

Check the low flame setting for each hob burner to

ensure that the minimum flame will not be

extinguished by air draughts.

• Light the burner.

• Turn the control until it engages in the minimum

position.

•Table of burner and nozzle specifications Ensure

the flame is stable and will not be extinguished by

air draughts.

To adjust the minimum flame:

Follow the procedure described in the gas conversion

instruction.

DO NOT MODIFY THIS APPLIANCE IN ANY WAY,

OTHER THAN AS DESCRIBED IN THESE

INSTRUCTIONS.

4. Pull the cooker out of the space between cabinets

and attach the Anti-tilt Bracket with (its shorter arm

to the wall) in the position shown in the picture below:

37 mm left and 5 mm up from the crossing of the lines

A and B, inserting two bolts of 6mm diameter in the

holes: x and y.

x

y

5. Place the cooker back between the cabinets so that

the Anti-Tilt Wall Bracket fits inside the appliance.

6. Reinsert the lower compartment.

! The Anti-Tilt Wall Bracket may be installed both on the

! The Anti-Tilt Wall Bracket may be installed both on the

! The Anti-Tilt Wall Bracket may be installed both on the

left and on the right handside of the cooker.

left and on the right handside of the cooker.

left and on the right handside of the cooker.

8

Page 9

p

y

Technical specifications

The product was tested in accordance with AS4551 standard

Gas Consumption

Auxiliary Burner

Semi Rapid Burne r

Rapid Burner

Wok BurnerWok Burner

Total

Natural Gas (1.0 kPa) ULPG (2.75 kPa)

Injector

Diameter

Gas Input Injecto r

Diameter

0.85 mm 3.5 MJ/h 0.55 mm 3.7 MJ/h

5

1.10 mm 6.0 MJ/h 0.

5

2

1.

mm 8.2 MJ/h 0.80 mm 8.5 MJ /h

1.19 mm 13.5 MJ/h 0.70 mm 13.0 MJ/h

(x2)

3

1.2

MJ/h 30.7 MJ/h

6

Connections

Gas Inlet Fitting 1/2” BSP (male) thread

Location of ga s inlet

at rear of cooker

185 mm from top of cooker

85 mm from left e dge of cooker

GB

Gas Input

mm 5.5 MJ /h

(x2)

S

R

A

TC

A6TMC2C/AUS

TECHNICAL DATA

Appliance

dimensions

(HxWxD)

Oven dimensions

(HxWxD)

Volume

Useful

measurements

relati ng to the oven

compartmen t

Burners

Voltage and

frequenc

93x59.5x59. 5 cm

32x42x40 cm

60 l

width 42 cm

depth 44 cm

height 8.5 cm

may be adapted for use with any

type of gas shown on the data

late

see data plate

EC Directives: 2006/95/EEC

dated 12/12/06 (Low Voltage)

and subsequent amendments 2004/108/EC dated 15/12/04

(Electromagnetic Compatibility)

and subsequent amendments 90/369/EEC dated 29/06/90 (Gas)

and subsequent amendments 93/68/EEC dated 22/07/93 and

subsequent amendments 2002/96/EC.

9

Page 10

Description

of the appliance

GB

Overall view

Control panel

Gas burner

Hob grid

Control panel

GRILL rack

DRIPPING PAN rack

Adjustable foot

Containment surface

for spills

GUIDE RAILS

for the sliding racks

position 5

position 4

position 3

position 2

position 1

Adjustable foot

SELECTOR knob

OVEN

OPERATION

indicator light

THERMOSTAT indicator light

THERMOSTAT knob

COOKING TIMER knob

Hob BURNER

control knobs

10

Page 11

Start-up and use

Using the hob

Lighting the burners

For each BURNER knob there is a complete ring

showing the strength of the flame for the relevant burner.

To light one of the burners on the hob:

1. Bring a flame or gas lighter close to the burner.

2. Press the BURNER knob and turn it in an

anticlockwise direction so that it is pointing to the

maximum flame setting .

3. Adjust the intensity of the flame to the desired level

by turning the BURNER knob in an anticlockwise

direction. This may be the minimum setting , the

maximum setting or any position in between the two.

If the appliance is fitted with

an electronic lighting device*

(

see figure

BURNER knob and turn it in

an anticlockwise direction,

towards the maximum flame

setting, until the burner is lit.

The burner may be

extinguished when the knob is released. If this

occurs, repeat the operation, holding the knob down

for a longer period of time.

! If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight it.

), press the

to replicate the flame intensity and to identify

easily the preferred level for different cooking

operations.

NOTE: Failure to follow these lighting andNOTE: Failure to follow these lighting and

NOTE: Failure to follow these lighting and

NOTE: Failure to follow these lighting andNOTE: Failure to follow these lighting and

shut down procedures might lead to ashut down procedures might lead to a

shut down procedures might lead to a

shut down procedures might lead to ashut down procedures might lead to a

hazardous conditionhazardous condition

hazardous condition

hazardous conditionhazardous condition

Lighting the burners for the first time

If the appliance is being used for the first time,

or if it has not been used for a long period of

time, it may be necessary to purge the gas lines

of excess air before you can successfully light

the burners.

To do this, turn each burner to High for 10-15

seconds and press the ignition button several

times. If the burner does not light, repeat this

procedure twice more. Wait 1-2 minutes for any

gas build up to disperse before allowing any further gas flow.

Practical advice on using the burners

For the burners to work in the most efficient way

possible and to save on the amount of gas

consumed, it is recommended that only pans that

have a lid and a flat base are used. They should

also be suited to the size of the burner:

Burner ř Cookware Diameter (cm)

GB

If the appliance is equipped with a flame failure

safety device*, press and hold the BURNER knob

for approximately3-7 seconds to keep the flame

alight and to activate the device.

Check that the gas has been lit. If the burner fails to

ignite try again. If the burner fails to ignite after 3 attempts,

wait a few minutes for the gas to disperse before making

any further attempts.

If the burner still fails to ignite, a match or lighting device

can be used, but care must be taken. If the problem

persists, contact place of purchase or their appointed

agent for service.

If the flame has excessive yellowing, or appears to lift

off the burner ports, or makes a loud noise, turn the burner

off and call your service agent.

To switch the burner off, turn the knob until it

reaches the stop position •.

Flame adjustment according to levels

the burner flame intensity can be adjusted with the

knob according to 6 power levels, from maximum

to minimum with 4 intermediate positions:

a click will indicate the change from one level to

another when turning the knob. The system

guarantees a more precise adjustment, allows

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

Triple Crown (TC) 24 - 26

To identify the type of burner, please refer to the

diagrams contained in the “Technical

specifications”.

! For models equipped with a reducer grid, the latter

must be used only for the auxiliary burner, when

pans with a diameter of less than 12 cm are used.

Always use cookware with a flat base. Do not

use pans which are unstable or which have a

warped or damaged base.

Ensure the pot sits securely on the trivet and is

centred above the burner.

Using the oven

! The first time you use your appliance, heat the empty

oven with its door closed at its maximum temperature

for at least half an hour. Ensure that the room is well

ventilated before switching the oven off and opening

the oven door. The appliance may emit a slightly

unpleasant odour caused by protective substances

used during the manufacturing process burning away.

11

Page 12

GB

! Never put objects directly on the bottom of the oven;

this will avoid the enamel coating being damaged.

1. Select the desired cooking mode by turning the

SELECTOR knob.

2. Select the recommended temperature for the

cooking mode or the desired temperature by turning

the THERMOSTAT knob.

A list detailing cooking modes and suggested

cooking temperatures can be found in the relevant

table (

see Oven cooking advice table

During cooking it is always possible to:

• Change the cooking mode by turning the

SELECTOR knob.

• Change the temperature by turning the

THERMOSTAT knob.

• Stop cooking by turning the SELECTOR knob to

the “0” position.

! Always place cookware on the rack(s) provided.

).

! To use the oven manually, in other words when you

do not wish to use the end of cooking timer, turn the

COOKING TIMER knob until it reaches the

symbol.

Cooking modes

! A temperature value can be set for all cooking modes

between 60°C and Max, except for the following modes

• GRILL (recommended: set only to MAX power level)

• GRATIN (recommended: do not exceed 200°C).

Both the top and bottom heating elements will come on.

When using this traditional cooking mode, it is best to use

one cooking rack only. If more than one rack is used, the

heat will be distributed in an uneven manner.

TRADITIONAL OVEN mode

THERMOSTAT indicator light

When this is illuminated, the oven is generating heat.

It switches off when the inside of the oven reaches

the selected temperature. At this point the light

illuminates and switches off alternately, indicating

that the thermostat is working and is All If

maintaining the temperature at a constant level.

OPERATION indicator light

When this is illuminated, the oven is generating heat.

Oven light

This is switched on by turning the SELECTOR knob

to any position other than “0”. It remains lit as long

as the oven is operating. By selecting

knob, the light is switched on without any of the

heating elements being activated.

Installing the shelves

When inserting the shelves onto the guide rails,

ensure the raised section is towards the rear of

the oven. This prevents food from falling off the

back of the tray.

with the

Using the cooking timer

BAKING mode

The rear heating element and the fan are switched on,

thus guaranteeing the distribution of heat in a delicate and

uniform manner throughout the entire oven. This mode is

ideal for baking and cooking temperature sensitive foods

(such as cakes that need to rise) and for the preparation

of pastries on 3 shelves simultaneously.

FAST COOKING mode

The heating elements and the fan come on, guaranteeing

the distribution of heat consistently and uniformly

throughout the oven.

Preheating is not necessary for this cooking mode. This

mode is particularly suitable for cooking pre-packed

food quickly (frozen or pre-cooked). The best results are

achieved using one cooking rack only.

MULTI-COOKING mode

All the heating elements (top, bottom and circular) switch

on and the fan begins to operate. Since the heat remains

constant throughout the oven, the air cooks and browns

food in a uniform manner. A maximum of two racks may

be used at the same time.

1. To set the buzzer, turn the COOKING TIMER knob

clockwise almost one complete revolution.

2. Turn the knob anticlockwise to set the desired

time: align the minutes shown on the COOKING

TIMER knob with the indicator on the control panel.

3. When the selected time has elapsed, a buzzer

sounds and the oven turns off.

4. When the oven is off the cooking timer can be used

as a normal timer.

12

PIZZA mode

The circular heating elements and the elements at

the bottom of the oven are switched on and the fan is

activated. This combination heats the oven rapidly by

producing a considerable amount of heat, particularly

from the element at the bottom. If you use more than one

rack at a time, switch the position of the dishes halfway

through the cooking process.

Page 13

The central part of the top heating element is switched

on. The high and direct temperature of the grill is

recommended for food that requires a high surface

temperature (veal and beef steaks, fillet steak and

entrecôte). This cooking mode uses a limited amount of

energy and is ideal for grilling small dishes. Place the food

in the centre of the rack, as it will not be cooked properly

if it is placed in the corners.

The top heating element and the rotisserie (where

present) are activated and the fan begins to operate.

This combination of features increases the effectiveness

of the unidirectional thermal radiation provided by the

heating elements through forced circulation of the air

throughout the oven. This helps prevent food from burning

on the surface and allows the heat to penetrate right into

the food.

! The GRILL and GRATIN cooking modes must be

performed with the oven door shut.

GRILL mode

GRATIN

mode

! In the GRILL cooking mode, place the dripping pan in

position 1 to collect cooking residues (fat and/or grease).

GRILL

• Insert the rack in position 3 or 4. Place the food in the

centre of the rack.

• We recommend that the power level is set to maximum.

The top heating element is regulated by a thermostat

and may not always operate constantly.

PIZZA

• Use a light aluminium pizza pan. Place it on the rack

provided.

For a crispy crust, do not use the dripping pan as it

prevents the crust from forming by extending the total

cooking time.

• If the pizza has a lot of toppings, we recommend

adding the mozzarella cheese on top of the pizza

halfway through the cooking process.

GB

DEFROSTING mode

The fan located on the bottom of the oven makes the air

circulate at room temperature around the food. This is

recommended for the defrosting of all types of food, but in

particular for delicate types of food which do not require

heat, such as for example: ice cream cakes, cream or

custard desserts, fruit cakes. By using the fan, the

defrosting time is approximately halved. In the case of

meat, fish and bread, it is possible to accelerate the

process using the “multi-cooking” mode and setting the

temperature to 80° - 100°C.

BOTTOM VENTILATED mode

The bottom heating element and the fan is activated,

which allows for the heat distribution within the whole

cavity of the oven. This combination is useful for light

cooking of vegetables and fish.

BOTTOM mode :

The lower heating element is activated. This position

is recommended for perfecting the cooking of dishes

(in baking trays) which are already cooked on the

surface but require further cooking in the centre, or

for desserts with a covering of fruit or jam, which only

require moderate colouring on the surface. It should

be noted that this function does not allow the maximum

temperature to be reached inside the oven (250°C)

and it is therefore not recommended that foods are

cooked using only this setting, unless you are baking

cakes (which should be baked at a temperature of

180°C or lower).

WARNING! The oven is

provided with a stop system to extract the racks

and prevent them from

coming out of the oven.(1)

As shown in the drawing,

to extract them completely, simply lift the racks,

holding them on the front

part, and pull (2).

13

Page 14

GB

Oven cooking advice table

Cooking

modes

Traditional

Oven

Baking

Mode

Fast

cooking

Multi-

cooking

Pizza Mode

Grill

Gratin

Foods Weight

(in kg)

Rack Position Pre-heating

time

(minutes)

Duck

Roast veal or beef

Pork roast

Biscuits (short pastry)

Tarts

Tarts

Fruit cakes

Plum cake

Sponge cake

Stuffed pancakes (on 2 racks)

Small cakes (on 2 racks)

Cheese puffs (on 2 racks)

Cream puffs (on 3 racks)

Biscuits (on 3 racks)

Meringues (on 3 racks)

Frozen food

Pizza

Courgette and prawn pie

Country style spinach pie

Turnovers

Lasagne

Golden Rolls

Chicken morsels

Pre-cooked food

Golden chicken wings

Fresh Food

Biscuits (short pastry)

Plum cake

Cheese puffs

Pizza (on 2 racks)

Lasagne

Lamb

Roast chicken + potatoes

Mackerel

Plum cake

Cream puffs (on 2 racks)

Biscuits (on 2 racks)

Sponge cake (on 1 rack)

Sponge cake (on 2 racks)

Savoury pies

Pizza

Roast veal or beef

Chicken

Soles and cuttlefish

Squid and prawn kebabs

Cuttlefish

Cod filet

Grilled vegetables

Veal steak

Sausages

Hamburgers

Mackerels

Toasted sandwiches (or toast)

Grilled chicken

Cuttlefish

1

1

1

-

1

0.5

1

0.7

0.5

1.2

0.6

0.4

0.7

0.7

0.5

0.3

0.4

0.5

0.3

0.5

0.4

0.4

0.4

0.3

0.6

0.2

1

1

1

1+1

1

1

0.5

0.5

0.5

1

1.5

0.5

1

1

0.7

0.6

0.6

0.8

0.4

0.8

0.6

0.6

1

4 and 6

1.5

1.5

3

3

3

3

3

3

2 or 3

3

3

2 and 4

2 and 4

2 and 4

1 and 3 and 5

1 and 3 and 5

1 and 3 and 5

2

2

2

2

2

2

2

2

2

2

2

2 and 4

3

2

2 and 4

2

2

2 and 4

2 and 4

2

2 and 4

3

3

2

2 or 3

4

4

4

4

3 or 4

4

4

4

4

4

2

2

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

10

10

15

10

10

10

10

10

10

15

15

10

10

10

10

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Recommended

temperature

200

200

200

180

180

180

180

180

160

200

190

210

180

180

90

250

200

220

200

200

180

220

200

200

180

210

230

180

180

200

180

170

190

180

170

170

200

220

220

180

Max

Max

Max

Max

Max

Max

Max

Max

Max

Max

200

200

Cooking

time

(minutes)

65-75

70-75

70-80

15-20

30-35

20-30

40-45

40-50

25-30

30-35

20-25

15-20

20-25

20-25

180

12

20

30-35

25

35

25-30

15-20

20-25

15-18

45

10-12

15-20

30-35

40-45

60-70

30-35

40-50

20-25

10-15

15-20

20-25

25-30

15-20

25-30

60-70

10-12

8-10

10-15

10-15

15-20

15-20

15-20

10-12

15-20

3-5

55-60

30-35

Bottom

Bottom

Ventilated

Ventilated

Bottom

Bottom

14

For perfecting cooking

Page 15

Precautions and tips

! This appliance has been designed and manufactured in

compliance with international safety standards.

The following warnings are provided for safety reasons and

must be read carefully.

General Appliance Warnings

• Read the recommendations in this instruction

booklet carefully, as they give important advice

regarding safe installation, use and maintenance.

Keep this booklet in a safe place for further

reference when required.

• This appliance is not suitable for marine craft,

caravans or recreational vehicles.

• This appliance has been designed for private,

nonprofessional use in normal dwellings.

• This appliance is not intended for use by persons

(including children) with reduced physical,

sensory or mental capabilities, or lack of

experience and knowledge, unless they have

been given supervision or instruction concerning

the use of the appliance by a person responsible

for their safety.

• Children should be supervised to ensure they do

not play with this appliance.

• Always make sure the knobs are in the OFF

position when the appliance is not in use.

• The openings used for ventilation and dispersion

of heat must never be covered.

• During operation, the oven glass door, adjacent

parts of the appliance and the internal sections of

the appliance become hot. Care should be taken

to avoid touching any of these parts.

• Accessible parts may become hot during use. To

avoid burns young children should be kept away.

• The appliance was designed for domestic use

inside the home and is not intended for

commercial or industrial use.

• Make sure that power supply cables of other

electrical appliances do not come into contact

with hot parts of this appliance.

• Always use oven gloves when placing or

removing cookware into or out of the oven.

• Do not place flammable material in the lower

storage compartment or in the oven itself. If the

appliance is accidentally switched on, these

materials could catch fire.

provided, and should be used for the purpose for

which it was designed. Any other purpose (for

example, heating the room) constitutes improper

use of the cooker and is dangerous. The

manufacturer shall not be held responsible for any

harm caused to persons or animals or for any

damage to property resulting from incorrect

installation, or caused as a result of improper,

incorrect or unreasonable use of the appliance.

• The electrical safety of this appliance is only

guaranteed when it has been correctly connected

to an efficient earthed electricity supply in

compliance with current electrical safety

regulations. This is a fundamental safety

requirement that must be checked and, if there is

any doubt, you should ask a professionally

qualified technician to carry out a thorough check

of the supply system. The manufacturer may not

be held responsible for any damage caused by a

mains supply that has not been earthed correctly.

• Before connecting the appliance, make sure its

rating (which can be found on the appliance itself

and/or on the packaging) corresponds to the gas

and electrical power supply.

• Make sure that the mains supply and the

electrical sockets can withstand the maximum

power of the appliance, which is indicated on the

serial number plate. If there is any doubt, contact

a professionally qualified technician.

• Some parts are covered with a removable scratchproof film. Before using the appliance the film

should be removed and the underlying part

cleaned with a cloth and a non-abrasive

household cleaning product. When switching on

for the first time, it is advisable to heat the empty

oven at maximum temperature for about 30

minutes to eliminate any residue from

manufacture.

• In order to prevent accidental tipping of the

appliance, for example by a child climbing onto

the open oven door, the supplied safety chain

must be installed. Refer to the installation section

of this manual for details.

• Do not lean or rest heavy objects on the open

door.

Safety With The Cooktop

GB

Installation Warnings

• The appliance must not be installed outdoors,

even in covered areas. It is extremely dangerous

toleave the appliance exposed to weather.

• The appliance must be installed by a qualified

person in compliance with the instructions

• Never leave cooking food unattended. Do not

allow the liquid to boil dry

• Do not use asbestos mats or heat diffusers, as

these trap the heat and can cause damage to the

cooktop from overheating.

• Don’t wear loose clothing while cooking, as garments

may catch utensil handles or catch fire.

15

Page 16

GB

• Use dry utensil holders. Wet pot holders can

build up steam. Do not use towels or other large

pieces of cloth to pick up cooking utensils, as

these may touch the heating element and catch

fire.

• Do not allow pot handles to overhang other

burners that are in use, as this will cause

scorching of the handle, and potential handling

burns.

• Always make sure that pan handles are turned

towards the centre of the hob in order to avoid

accidental burns.

Maintenance Warnings

• DO NOT MODIFY THIS APPLIANCE.

• When you have removed the packing, check that

the appliance is not damaged. If you have any

doubts, do not use the appliance and contact

your nearest Ariston Service Centre.

• There are no user serviceable parts within this

appliance. For any service, contact the place of

purchase or the nominated service agent. Do not

attempt repairs yourself.

• Do not touch hot surfaces. Allow hob to cool

before wiping spillage.

• Do not attempt to replace the power supply cable

yourself. If the cable is damaged or needs

replacing, contact a technical assistance centre

that has been authorised by the manufacturer.

• Always disconnect the appliance from the mains

supply (either by unplugging it or by shutting off

the switch) before cleaning it or carrying out any

maintenance work.

• Before disposing of the appliance, make it

unusable by unplugging it and cutting off the

power supply cable. It is also advisable to

remove any potentially hazardous parts,

especially with regard to children who may use

the old appliance as a toy.

• Periodically check the condition of the gas

connection pipe and have it replaced by a

qualified technician as soon as it shows any

signs of wear or damage.

Gas And Electrical Safety

• If you are using small domestic appliances near

the hob, ensure that their power supply cables do

not come into contact with the hot parts of the

surface.

• DO NOT SPRAY AEROSOLS IN THE VICINITY OF

THIS APPLIANCE WHILE IT IS IN OPERATION.

• DO NOT USE OR STORE FLAMMABLE

MATERIALS IN THE APPLIANCE STORAGE

DRAWER OR NEAR THIS APPLIANCE.

Not suitable for operation with aftermarket lids or covers

•

fitted.

16

• Gas appliances require a regular air supply to

maintain efficient operation. Always ensure that

the kitchen is adequately ventilated whilst the

appliance is in use.

Respecting and conserving the

environment

• You can help to reduce the peak load of the electricity

supply network companies by using the oven in the hours

between late afternoon and the early hours of the morning.

• Always keep the oven door closed when using the TOP

OVEN, GRILL and GRATIN modes: This will achieve

improved results while saving energy (approximately 10%).

• Check the door seals regularly and wipe them clean to

ensure they are free of debris so that they adhere properly

to the door, thus avoiding heat dispersion.

Assembling the sliding rack kit

To assemble the sliding racks:

1. Remove the two

frames, lifting them

away from the spacers

A (

see figure

2. Choose which shelf

to use with the sliding

rack. Paying attention to

Left

guide rail

A

Right guide

rail

the direction in which

B

Direct

C

of

e

i

on

x

tracti

on

the sliding rack is to be

extracted, position joint

B and then joint C on

the frame.

3. Secure the two frames

with the guide rails using

the holes provided on

the oven walls (

diagram

the left frame are

D

situated at the top, while

the holes for the right

frame are at the bottom.

4. Finally, fit the frames on the spacers A.

Do not place the sliding racks in position 5.

!

).

see

). The holes for

Page 17

Care and maintenance

Switching the appliance off

Disconnect your appliance from the electricity

supply before carrying out any work on it.

DO NOT TOUCH HOT SURFACES. ALLOW

COOKTOP AND ALL OVEN SURFACES TO COOL

COMPLETELY BEFORE CLEANING

Cleaning the appliance

! Never use steam cleaners or pressure cleaners on

the appliance.

• The stainless steel or enamel-coated external

parts and the rubber seals may be cleaned using

a sponge that has been soaked in lukewarm water

and neutral soap. Use specialised products for

the removal of stubborn stains. After cleaning,

rinse well and dry thoroughly. Do not use abrasive

powders or corrosive substances.

• The hob grids, burner caps, flame spreader rings

and burners may be removed to make cleaning

easier; wash them in hot water and non-abrasive

detergent, making sure all burnt-on residue is

removed before drying them thoroughly.

• Clean the terminal part of the flame failure safety

devices* frequently.

• The inside of the oven should ideally be cleaned

after each use, while it is still lukewarm. Use hot

water and detergent, then rinse well and dry with

a soft cloth. Do not use abrasive products.

• Clean the glass part of the oven door using a

sponge and a non-abrasive cleaning product,

then dry thoroughly with a soft cloth. Do not use

rough abrasive material or sharp metal scrapers

as these could scratch the surface and cause the

glass to crack.

• The accessories can be washed like everyday

crockery, and are even dishwasher safe.

• Do not use harsh abrasive cleaners or materials,

or metal scrapers to clean the oven door glass

since these can scratch the surface, which may

result in shattering of the glass.

• Never use steam cleaners or pressure cleaners

on the appliance.

Replacing the oven light bulb

1. After disconnecting the oven

from the electricity mains,

remove the glass lid covering

the lamp socket (

2. Remove the light bulb and

replace it with a similar one:

voltage 230 V, wattage 25 W,

cap E 14.

3. Replace the lid and reconnect the oven to the

electricity supply.

! Do not use the oven lamp as/ for ambient

lighting.

see figure

).

Cleaning The Cooktop

• Always wipe spills up when they occur. Do not

leave spills to dry onto the surface of the hob.

• It is usually enough to wash the hob with a damp

sponge and dry it with absorbent kitchen roll.

• NOTE: Do not put hot components in cold water.

The sudden temperature shock could cause the

component to crack.

• Do not use abrasive or corrosive detergents such

as stain removers, anti-rust products, powder

detergents or sponges with abrasive surfaces:

these may scratch the surface beyond repair.

Burners

• Wait for the cooktop to cool completely. Remove

the burner cap and check the gas outlet holes for

blockages. Clean with a soft bristle brush and

warm soapy water.

• The removable parts of the burners should be

washed frequently with warm water and soap and

any burnt-on substances removed.

• Dry the burner parts thoroughly before replacing.

Ignitors

• The terminal part of the electronic instant lighting

devices and flame failure probes should be

cleaned frequently,

GB

Inspecting the oven seals

Check the door seals around the oven regularly. If

the seals are damaged, please contact your nearest

Authorised After-sales Service Centre. We

recommend that the oven is not used until the seals

have been replaced.

Enamelled parts (trivets)

• Never use abrasives, scouring pads or sharp

objects. This will cause irreparable damage to the

enamel.

• Clean the enamelled parts with soapy water when

*Only available in certain models

17

Page 18

GB

cold and wipe off with a clean, dry cloth. The

enamel could dull if cleaned while still hot.

Stainless steel and chromed parts

• Stainless steel can be marked by hard water that

has been left on the surface for a long time, or by

aggressive detergents containing phosphorus.

After cleaning, rinse and dry any remaining drops

of water.

• Use commercial products designed for cleaning

stainless steel and chromed steel, and follow the

maker’s instructions. Care should be taken when

cleaning around graphics.

• Never use steam cleaners or pressure cleaners on

the appliance.

Removing and fitting the oven door:

1.Open the door

2.Make the hinge clamps of the oven door rotate

backwards completely (see photo)

Grill Plate

• We recommend that the grill plate be cleaned

while it is still hot, using the knobs provided to

move it from the cooking rack to the sink. Wash

the grill plate with hot water and non-abrasive

detergent.

Gas tap maintenance

Over time, the taps may become jammed or difficult

to turn. If this occurs, the tap must be replaced.

!

!

This procedure must be performed by a

This procedure must be performed by a

qualified technician authorised by the

qualified technician authorised by the

manufacturer.

manufacturer.

Assistance

! Never use the services of an unauthorised

technician.

Please have the following information to hand:

3.Close the door until the clamps stop (the door will

remain open for 40° approx.) (see photo)

40°

4.Press the two buttons on the upper profile and

extract the profile (see photo)

• The type of problem encountered.

• The appliance model (Mod.).

• The serial number (S/N).

The latter two pieces of information can be found on

the data plate located on the appliance.

To keep your cooker running smoothly, we

recommend that you have your cooker serviced

every 5 years by an authorised service agent.

18

5.Remove the glass sheet and do the cleaning as

indicated in chapter: "Care and maintenance".

Page 19

6.Replace the glass.

WARNING! Oven must not be operated with inner

door glass removed!

Steam-Assisted Oven Cleaning

GB

This method of cleaning is recommended especially after

cooking very fatty (roasted)meats.

WARNING! When reassembling the inner door

glass insert the glass panel correctly so that the

text written on the panel is not reversed and

can be easily legible.

7.Replace the profile, a click will indicate that the

part is positioned correctly.

8.Open the door completely.

9.Close the supports (see photo).

10.Now the door can be completely closed and the

oven can be started for normal use.

This cleaning process allows to facilitate the removal of

dirt of the walls of the oven by the generation of steam

that is created inside the oven cavity for easier cleaning.

! Important! Before you start steam -cleaning:

-Remove any food residue and grease from the bottom

of the oven.

- Remove any oven accessories (grids and drip pans).

Perform the above operations according to the following

procedure:

1. pour 300ml of water into the baking tray in the oven,

placing it in the bottom shelf. In the models where the

drip pan is not present, use a baking sheet and place it

on the grill at the bottom shelf;

2. select the function of the oven

and set the temperature to 100 ° C;

3. keep it in the oven for 15min;

4. turn off the oven;

5. Once cooled the oven, you can open the door to

complete the cleaning with water and a damp cloth;

6. eliminate any residual water from the cavity after

finishing cleaning

When the steam –cleaning is done, after cooking

especially fatty foods, or when grease is difficult to

remove, you may need to complete the cleaning with the

traditional method, described in the previous paragraph.

BOTTOM

! Perform cleaning only in the cold oven!

19

Page 20

GB

ARISTON PRIORITY SERVICEARISTON PRIORITY SERVICE

ARISTON PRIORITY SERVICE

ARISTON PRIORITY SERVICEARISTON PRIORITY SERVICE

If you are not completely satisfied with your

appliance or require service call:

Australia

Phone: 1300 815 589

New Zealand

Phone: (09) 306 1020

GENUINE ACCESSORIES & SPARE

PARTS

A wide range of genuine accessories are available

for your appliance call:

Australia

Phone: 03 9768 0888

New Zealand

Phone: (09) 306 1020

07/2013 - 195116247.01

XEROX FABRIANO

AUSTRALIA

ARISIT PTY LIMITEDARISIT PTY LIMITED

ARISIT PTY LIMITED

ARISIT PTY LIMITEDARISIT PTY LIMITED

40-44 Mark Anthony Drive, Dandenong South,

VIC 3175, Australia

Fax: Service & Sales (03) 9768 0838

Email:

NEW ZEALAND

ARISIT PTY LIMITEDARISIT PTY LIMITED

ARISIT PTY LIMITED

ARISIT PTY LIMITEDARISIT PTY LIMITED

PO Box 68-140 Newton, Auckland

1145, New Zealand

Fax: (09) 302 0077 Email: sales@aristonappliances.co.nz

consumer.care@arisit.com

20

Loading...

Loading...