Arista DCS-7050QX-32S, DCS-7280SE-64, DCS-7050TX-72, DCS-7050SX-64, DCS-7050SX-72 Quick Start Manual

...

Quick Start Guide

7000 Series 1 RU – Gen 3

Data Center Switches

(Tool-less)

DCS-7050QX-32S DCS-7050TX-72

DCS-7050SX-64 DCS-7050TX-96

DCS-7050SX-72 DCS-7280SE-64

DCS-7050SX-96 DCS-7280SE-68

DCS-7050TX-48 DCS-7280SE-72

DCS-7050TX-64

Arista Networks

www.arista.com

PDOC-00041-07

Headquarters

Support

Sales

5453 Great America Parkway

Santa Clara, CA 95054

USA

408 547-5500

www.arista.com

408 547-5502

866 476-0000

support@arista.com

408 547-5501

866 497-0000

sales@arista.com

© Copyright 2015 Arista Networks, Inc. The information contained herein is subject to change without notice. Arista Networks

and the Arista logo are trademarks of Arista Networks, Inc in the United States and other countries. Other product or service names

may be trademarks or service marks of others.

Chapter 1: Overview

Chapter 1 Overview

1.1 Scope

This guide is intended for properly trained service personnel and technicians who need to install the

following Arista Networks Data Center Switches:

• DCS-7050QX-32S • DCS-7050TX-48 • DCS-7280SE-64

• DCS-7050SX-64 • DCS-7050TX-64 • DCS-7280SE-68

• DCS-7050SX-72 • DCS-7050TX-72 • DCS-7280SE-72

• DCS-7050SX-96 • DCS-7050TX-96

Important! Only qualified personnel should install, service, or replace this equipment.

1.2 Receiving and Inspecting the Equipment

Upon receiving the switch, inspect the shipping boxes and record any external damage. Retain packing

materials if you suspect that part of the shipment is damaged; the carrier may need to inspect them.

If the boxes were not damaged in transit, unpack them carefully. Ensure that you do not discard any

accessories that may be packaged in the same box as the main unit.

Inspect the packing list and confirm that you received all listed items. Compare the packing list with

your purchase order. Appendix B provides a list of components included with the switch.

1.3 Installation Process

The following tasks are required to install and use the switch:

Step 1 Select and prepare the installation site (Section 2.1).

Step 2 Assemble the installation tools listed in Section 2.2.

Step 3 Attach the mounting brackets and install the switch in an equipment rack (Chapter 3).

Step 4 Connect the switch to the power source and network devices (Chapter 4).

Step 5 Configure the switch (Chapter 5).

Important! Class 1 Laser Product: This product has provisions to install Class 1 laser transceivers which provide

optical coupling to the communication network. Once a Class 1 laser product is installed, the

equipment is a Class 1 Laser Product (Appareil à Laser de Classe 1). The customer is responsible for

selecting and installing the Class 1 laser transceiver and for insuring that the Class 1 AEL (Allowable

Emission Limit) per EN/IEC 6-825, CSA E60825-1, and Code of Federal Regulations 21 CFR 1040 is not

exceeded after the laser transceiver have been installed. Do not install laser products whose class rating

is greater than 1. Refer to all safety instructions that accompanied the transceiver prior to installation.

Only Class 1 laser devices, certified for use in the country of installation by the cognizant agency are to

be utilized in this product.

Important! Ultimate disposal of this product should be in accordance with all applicable laws and regulations.

1.4 Safety Information

Refer to the Arista Networks document Safety Information and Translated Safety Warnings available at:

http://www.arista.com/en/support/docs/eos

7000 Series 1 RU – Gen 3 Quick Start Guide PDOC-00041-06 3

1.5 Obtaining Technical Assistance

Any customer, partner, reseller or distributor holding a valid Arista Service Contract can obtain technical

support in any of the following ways:

• Email: support@arista.com. This is the easiest way to create a new service request.

Include a detailed description of the problem and the output of “show tech-support”.

Chapter 1: Overview

• Web: www.arista.com/en/support

.

A support case may be created through the support portal on our website. You may also download

the most current software and documentation, as well as view FAQs, Knowledge Base articles,

Security Advisories, and Field Notices.

• Phone: 866-476-0000 or 408-547-5502.

Important! No user serviceable parts inside. Refer all servicing to qualified service personnel.

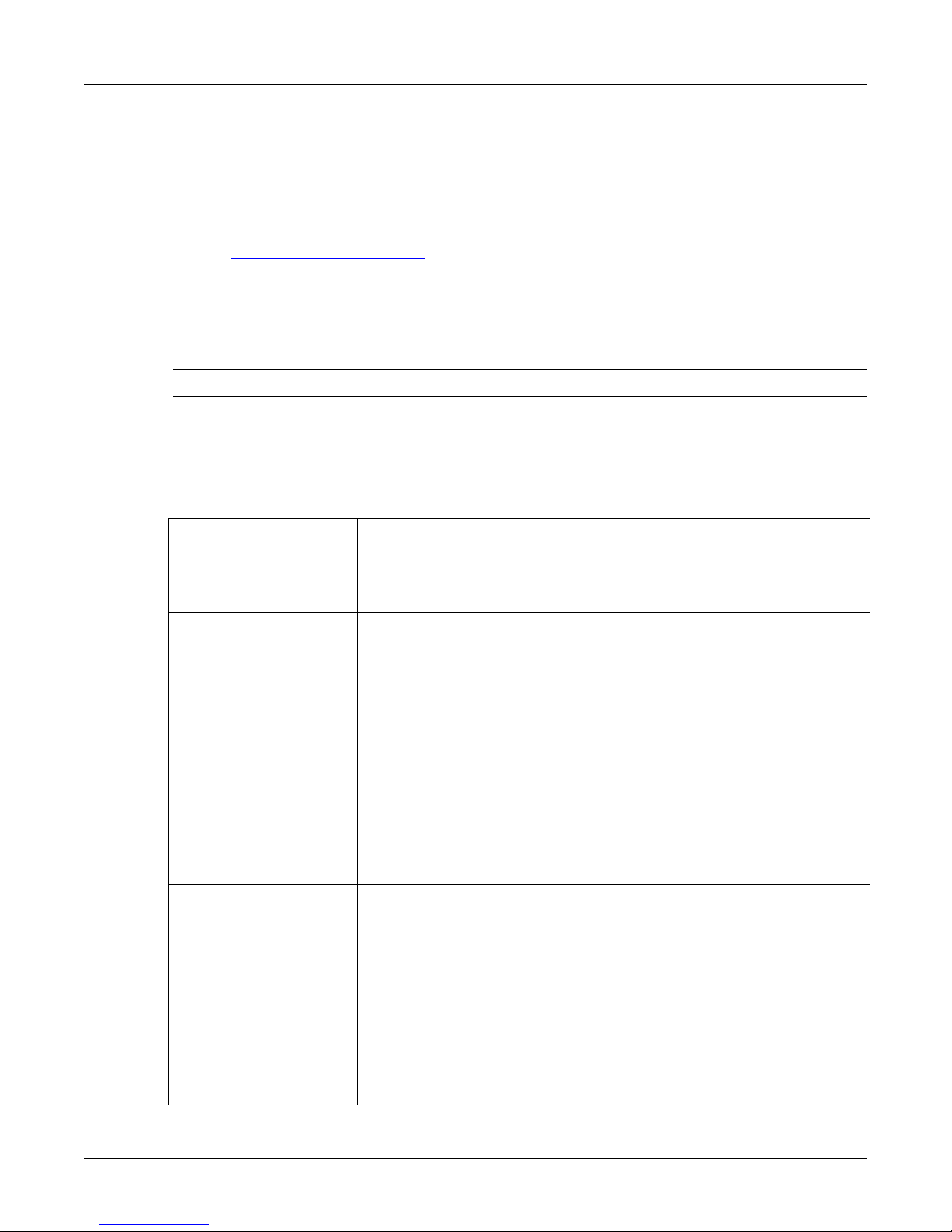

1.6 Specifications

Ta b l e 1 lists the specifications of Arista Data Center switches covered by this guide.

Table 1: Switch Specifications

Size (W x H x D) DCS-7050QX-32S

DCS-7050SX-64, -72. -96

DCS-7050TX-48, -64

DCS-7050TX -72, -96

DCS-7280SE-64, -68, -72

Weight DCS-7050QX-32S

DCS-7050SX-64

DCS-7050SX-72

DCS-7050SX-96

DCS-7050TX-48

DCS-7050TX-64

DCS-7050TX-72

DCS-7050TX-96

DCS-7280SE-64

DCS-7280SE-68

DCS-7280SE-72

Operating Temperature

Storage Temperature

Operating Altitude

Relative Humidity

Power Input (AC Power) all switches 100 - 240 VAC, 6.5 - 3.0 A, 50/60 Hz

Power Draw

(Typical / Maximum)

all switches

all switches

all switches

all switches

DCS-7050QX-32S

DCS-7050SX-64

DCS-7050SX-72

DCS-7050SX-96

DCS-7050TX-48

DCS-7050TX-64

DCS-7050TX-72

DCS-7050TX-96

DCS-7280SE-64

DCS-7280SE-68

DCS-7280SE-72

44.5 x 4.4 x 40.6 cm (19 x 1.75 x 16 inches)

44.5 x 4.4 x 40.6 cm (19 x 1.75 x 16 inches)

44.5 x 4.4 x 40.6 cm (19 x 1.75 x 16 inches)

44.5 x 4.4 x 52.3 cm (19 x 1.75 x 20.6 inches)

44.5 x 4.4 x 52.3 cm (19 x 1.75 x 20.6 inches)

9.1 kg (20 pounds)

8.6 kg (19 pounds)

8.6 kg (19 pounds)

9.1 kg (20 pounds)

7.7 kg (17 pounds)

8.6 kg (19 pounds)

10.0 kg (22 pounds)

10.5 kg (22 pounds)

10.0 kg (22 pounds)

10.1 kg (22 pounds)

10.2 kg (22 pounds)

0° to 40° C (32° to 104° F)

-25° to 70° C (-13° to 158° F)

0 to 3,000 meters (0 to 10,000 feet)

5 to 90%

150 W / 300 W

140 W / 220 W

144 W / 276 W

159 W / 290 W

305 W / 367 W

315 W / 387 W

349 W / 440 W

355 W / 455 W

263 W / 381 W

313 W / 405 W

262 W / 399 W

4 Arista Networks Copyright 2014

Chapter 2: Preparation

MAC ADDRESS

II

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

I

SERIAL NUMBER

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

ASSEMBLY NUMBER

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

Fan Module

Handle

Module 1

Airflow Direction

Power Supply

Module 1

Airflow Direction

Power Supply

Module 2

Fan Module

Handle

Module 2

Fan Module

Handle

Module 3

Fan Module

Handle

Module 4

Chapter 2 Preparation

2.1 Site Selection

The following criteria should be considered when selecting a site to install the switch:

• Temperature and Ventilation: For proper ventilation, install the switch where there is ample airflow

to the front and back of the switch. The ambient temperature should not go below 0° or exceed 40° C.

Important! To prevent the switch from overheating, do not operate it in an area where the ambient temperature

exceeds 40°C (104°F).

• Airflow Orientation: Determine airflow direction of the four fan modules and two power supply

modules on the rear panel. Fan and power supply module handles indicate airflow direction:

— Blue Handle: Air Inlet module.

— Red Handle: Air Exit module.

Figure 1 displays fan and power supply module locations on the rear panel. Their red handles

indicate that they are air exit modules. Verify that each module has the same airflow direction. Base

the switch orientation on the airflow direction of the modules to assure the air inlet is always

oriented toward the cool aisle:

— Air Exit modules: orient the rear panel toward the hot aisle.

— Air Inlet modules: orient the rear panel toward the cool aisle.

If the airflow direction is not compatible with the installation site, contact your sales representative

to obtain modules that circulate air in the opposite direction.

Figure 1: Airflow Direction Labels

• Rack Space: Install the switch in a 19" rack or cabinet. The switch height is 1 RU. The accessory kit

provides mounting brackets for two-post and four-post racks.

When mounting the switch in a partially filled rack, load the rack from bottom to top, with the

heaviest equipment at the bottom. Load the switch at the bottom if it is the only item in the rack.

7000 Series 1 RU – Gen 3 Quick Start Guide PDOC-00041-06 5

Chapter 2: Preparation

• Power Requirements: Power requirements vary by switch and power supply model. Refer to

Ta b l e 1 for information regarding your specific system.

Two circuits provide redundancy protection. Section 4.2 describes power cable requirements.

Important! The power input plug-socket combination must be accessible at all times; it provides the primary

method of disconnecting power from the system.

• Other Requirements: Select a site where liquids or objects cannot fall onto the equipment and

foreign objects are not drawn into the ventilation holes. Verify these guidelines are met:

— Clearance areas to the front and rear panels allow for unrestricted cabling.

— All front and rear panel indicators can be easily read.

— Power cords can reach from the power outlet to the connector on the rear panel.

Important! All power connections must be removed to de-energize the unit.

2.2 Tools Required for Installation

Each switch provides an accessory kit that contains parts that are required to install the switch. In

addition to the accessory kit, the following tools and equipment are required to install the switch:

Two - Po st R ac k

• Screws or rack mounting nuts and bolts.

• Screwdriver

Four-Post Rack (Toolless)

No additional equipment required.

Four-Post Rack (Conventional)

• Screws or rack mounting nuts and bolts.

• Screwdriver

Accessory kit does not include screws for attaching the switch to the equipment rack. When installing

the switch into an equipment rack with unthreaded post holes, nuts are also required to secure the

switch to the rack posts.

2.3 Electrostatic Discharge (ESD) Precautions

Observe these guidelines to avoid ESD damage when installing or servicing the switch.

• Assemble or disassemble equipment only in a static-free work area.

• Use a conductive work surface (such as an antistatic mat) to dissipate static charge.

• Wear a conductive wrist strap to dissipate static charge accumulation.

• Minimize handling of assemblies and components.

• Keep replacement parts in their original static-free packaging.

• Remove all plastic, foam, vinyl, paper, and other static-generating materials from the work area.

• Use tools that do not create ESD.

6 Arista Networks Copyright 2014

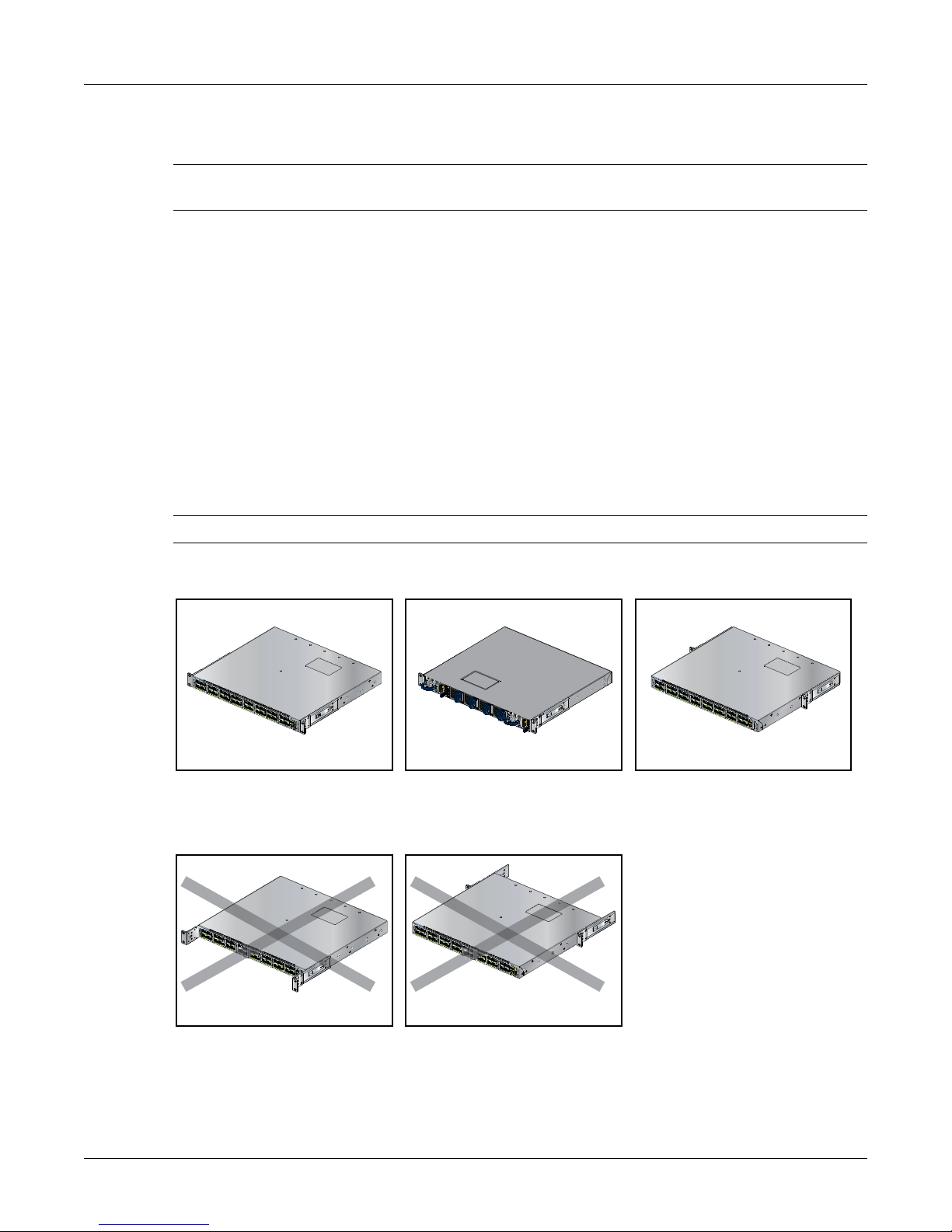

Chapter 3: Rack Mounting the Switch

Rear mount

Front mount

Center mount

Front bracket hole does not lock into pin

Rear bracket hole does not lock into pin

Chapter 3 Rack Mounting the Switch

Important! The rack mounting procedure is identical for all switches covered by this guide. Illustrations in this

chapter depict the mounting of a DCS-7050QX-32S switch.

• Section 3.1 provides instructions for mounting the switch in a two-post rack.

• Section 3.2 provides instructions for mounting the switch in a four-post rack.

After completing the instructions for your rack type, proceed to Chapter 4: Cabling the Switch.

3.1 Two-Post Rack Mount

To mount the switch onto a two-post rack, assemble the mounting brackets to the chassis, then attach

the brackets to the rack posts. Two-post accessory kits include the following two-post mounting parts:

• 2 three-hole mounting brackets

Each chassis side has attachment pins that align with bracket holes. Pin orientation is symmetric and

equidistant, supporing bracket placements where the flange is flush the front switch panel, flush with

the rear panel, or not flush with either panel. Each bracket hole includes a key-opening for placing the

bracket flush with the chassis and then locking it into place.

Important! Attachment pins must be lock all three upper bracket holes.

Figure 2 displays proper bracket mount configuration examples.

Figure 2: Bracket Mount Examples for Two-Post Rack Mount

Figure 3 displays improper bracket mount configuration examples.

Figure 3: Improper Bracket Mount Examples for Two-Post Rack Mount

7000 Series 1 RU – Gen 3 Quick Start Guide PDOC-00041-06 7

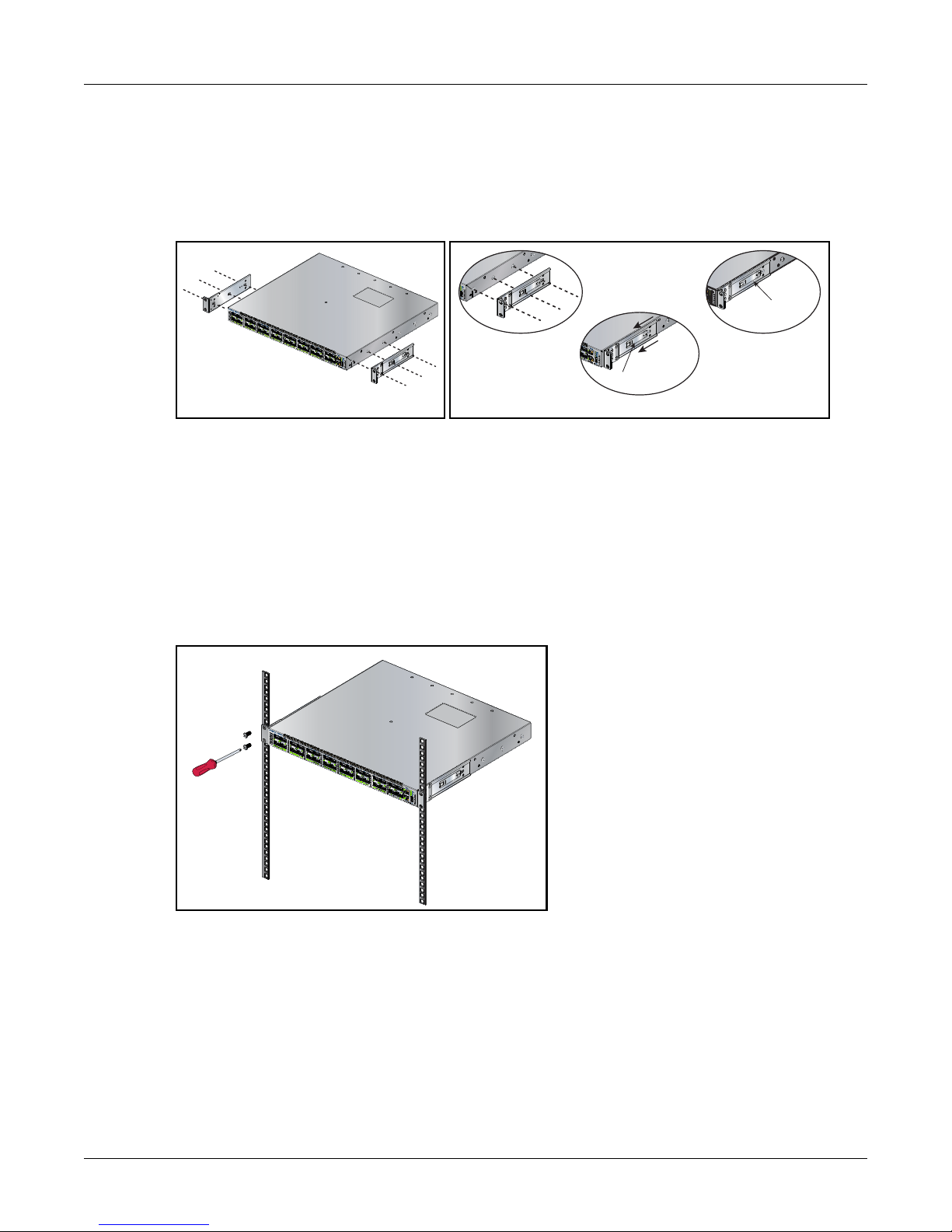

3.1.1 Attaching Mounting Brackets to the Chassis

Attaching the brackets: Front mount

Bracket Clip

Step 3

Bracket Clip

Step 2

Step 1

This procedure attaches mounting brackets to the switch chassis (Figure 4).

Step 1 Align the mounting brackets with the attachment pins to obtain the desired mounting position.

Step 2 Place the bracket flush on the chassis with attachment pins protruding through key-openings.

Step 3 Slide the bracket toward the front flange until the bracket clip locks with an audible click.

Figure 4: Attaching the Mounting Brackets to the Switch Chassis

To remove the mounting bracket from the chassis, lift the front edge of the mounting bracket clip with

a flathead screwdriver and slide the bracket away from the front flange (opposite from the installation

direction).

Chapter 3: Rack Mounting the Switch

3.1.2 Inserting the Switch into the Rack

This procedure attaches the switch to the rack (Figure 5).

Step 1 Lift the chassis into the rack. Position the flanges against the rack posts.

Figure 5: Inserting the Switch into the Rack

Step 2 Select mounting screws that fit your equipment rack.

Step 3 Attach the bracket flanges to the rack posts.

After completing the two-post rack mount, proceed to Chapter 4: Cabling the Switch.

8 Arista Networks Copyright 2014

Loading...

Loading...