Page 1

®

USER INSTRUCTION MANUAL

®

Single Shade and Variable Shade

Auto-Darkening Filters

4000V 5000V 6000VI4

iDF48

Products Which Improve

Quality, Productivity, Safety, &

Performance

85 Independence Drive, Taunton, MA 02780

TEL: (508) 884-9600 TOLL FREE: (800) 223-4685 FAX: (508) 884-9666

M-EUROALTADF-2003 REV J

Page 2

Table of Contents Page

Preparations for Use........................................................................................1

Technical Information / Use .............................................................................1

Limitations of Use ............................................................................................3

Care and Maintenance ....................................................................................4

Spatter Protection............................................................................................4

Parts Selection Guide......................................................................................5

Filter Specifications .........................................................................................8

Significance of markings:.................................................................................9

Shade Selection Guide..................................................................................10

Filter Removal Diagram.................................................................................10

Warranty and Service Information .................................................................11

Preparations for Use

WARNING, materials which may come in contact with the wearer’s skin may cause an allergic reaction to susceptible individuals.

Filters:

Before you begin welding always inspect your filter to ensure it is not damaged. Check to see if

the filter protection plates (cover plates) are clean, clear, undamaged, and securely attached to

the helmet and covering the auto-darkening filter both front and rear.

WARNING, never begin welding without first checking to see if the correct front and rear

protection plates are in place (See Part Selection Guide section for part numbers). Failure

to protect the welding filter may cause damage and become a safety hazard should the

UV/IR protection be compromised from spatter or cracks from impact. DAMAGE CAUSED

BY ABUSE SUCH AS EXCESSIVE TEMPERATURES, CRACKS FROM IMPACT, AND PITTING FROM SPATTER CAUSED BY POOR MAINTENANCE WILL VOID WARRANTY.

Warning, toughened mineral filter oculars shall only be used in conjunction with a suitable backing ocular.

Welding Helmets:

Before you begin welding make sure there is no damage to the helmet shell including, but not

limited to cracks, holes, and melting. Ensure that the springs holding the filter are not broken or

corroded. Do not use the helmet if any of these conditions exist and contact your distributor for

replacement parts. Use only replacement components as specified for each weldinghelmet in

accordance with this user manual.

WARNING, other safety precautions such as protective clothing, adequate ventilation,

breathing protection, such as a Clean Air Flow

for co-workers, should also be considered.

Technical Information / Use

Filters:

®

ArcOne

rays, both in the dark and light state. No matter what shade the filter is set to the UV/IR protection is always there. You can never burn your eyes due to optical radiation passing through the

filter.

Warning: Severe burns are possible with a damaged lens (cracks, pits, holes, etc.). Do not

use damaged lens. Optical radiation can possibly enter in from behind the helmet from

other welders welding in the immediate area.

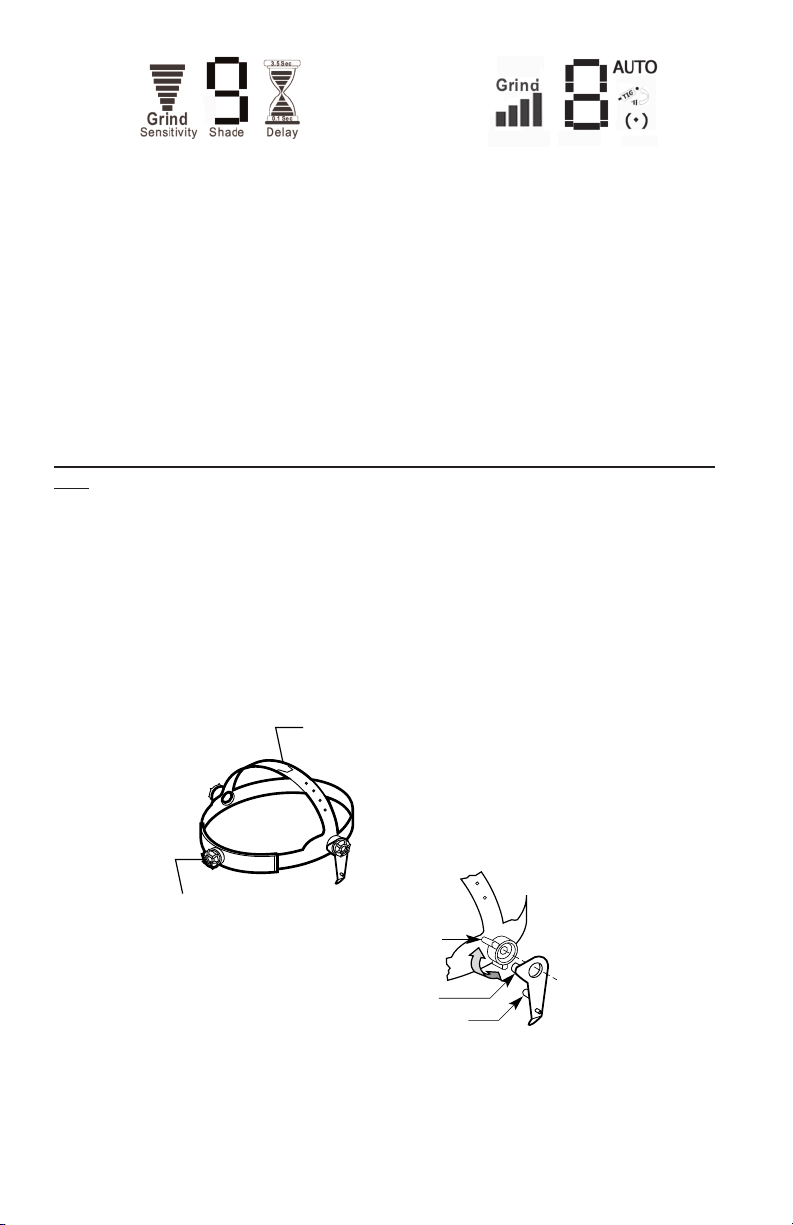

Shade Adjustment (refer to Fig. 1 through 4)

See CE Shade Selection Guide (Table 3) for recommended shades for arc welding applications.

See Filter Specification section for filter specifications.

auto-darkening filters protect the user against harmful ultra-violet and infrared UV/IR

®

or equal, fire extinguisher, and protection

- 1-

Page 3

Single Shade Filters: Shade is fixed; no adjustment.

Analog and Digital LCD Controlled Variable Filters (Fig. 2): manually control dark shade with

the shade knob located on the outside of the helmet. Digital LCD users, number will change on

the LCD (Fig. 3 & 4) as the user turns the knob up or down.

Sensitivity Adjustment

Analog Controlled Filters: Models with external control turn the knob to change the sensitivity,

increasing or decreasing it. Some Digital LCD models will display the level of sensitivity (Fig. 3),

where more bars equals increased sensitivity.

Digitally Controlled Filters: Briefly press the Select button (Fig. 1), an LED will indicate the

current setting. Press and hold the button to change the setting.

Figure 1: Digital Controls

Delay Adjustment and Grind Mode (not on all models)

Digital Controlled Filters: Change the Delay by pressing; do not hold down, the Delay/Grind

button. Activate Grind mode by pressing and holding the Delay/Grind or Grind button (depends

on model) down until the filter flashes. Deactivate Grind mode by pressing, do not hold down

,

the Delay/Grind or Grind button (**Note: the filter will not flash). Some models (Fig 3), will display

GRIND to indicate the Grind mode is active.

Analog Controlled Filters: Applicable model(s) only, turn the Sensitivity switch until it clicks

and the LCD displays GRIND (Fig. 4).

Intelligent Darkening Filter (IDF) Modes

To switch from one mode to another Press AND Hold down the Mode button for two seconds. To

cycle through modes continue depressing the Mode button. (***NOTE: Modes will not switch

when in Grind Mode)

Low Shade Mode: Dark Shades 5-8 available in this mode. Arc detection to 10 Amps.

Auto-Variable Mode: LCD displays “AUTO” (Fig. 4). Filter automatically responds to the inten-

sity of the welding arc and sets the filter to the appropriate dark shade. The Auto-Variable mode

Figure 2: Analog Controls

Shade

Adjusment

Sensitivity Adjustment

(where applicable)

- 2-

Page 4

$GMXVW+HLJKW6QDS2XW

6OLGH6QDS,Q

$GMXVW)LW3XVK,Q7XUQ5HOHDVH

7DE R Q +HD G J H D U V K R Z Q

EHWZHHQ,QQHU7DEDQG

8SSHU6WRS

8SSHU6WRS

,QQHU7DE

+HDGJHDU7DE

Fig. 3: LCD Readout

(4000V & 5000V)

Fig. 4: LCD Readout

(iDF48)

is dependent upon light intensity of the arc and distance from the filter to the arc. The user can

further adjust the dark shade up or down one shade number for comfort while the “(٠)” icon is

flashing. This mode has one memory position for each shade in the dark state; i.e. 9, 10, 11, 12,

and 13. (NOTE: Shade 13 cannot be set higher than 13. This mode only works on split range;

i.e. 5-9/9-13 filters in the higher shade range.) To reset all memory slots press and hold both

iTIG Mode: Upon entering iTIG mode, where LCD displays “TIG” icon and flashing “(٠)” (Fig. 4)

user first sets lower desired shade while the “(٠)” flashes. After approximately 5 seconds of not

turning the shade knob the flashing stops and the user can then set the desired upper shade.

The lowest possible shade is fixed according to the standard in which the filter is tested to (example: iDF48, iTIG in 9-13 range goes 9 lowest, 13 highest, in 5-9 range 7 lowest 9 highest).

Welding Helmets:

Welding helmets are designed to provide protection against UV/IR radiation around the user's

face. ArcOne®welding helmets meet/exceed face coverage defined by CE standards. ArcOne

welding helmets are suitable for arc welding. Refer to any or all of the following standards for

more specifications: ANSI Z87, CAN/CSA Z94.3, and CE EN 166 & 175.

Welding helmets made of a durable, modern material for use in a variety of environments.

Limitations of Use

Filters:

®

ArcOne

applications. Arc detection may be impaired due to amperage, distance from the arc, welding

current frequency, electrode type, shielding gasses, and lighting conditions.

Do not weld with filter in the light state. If the filter fails to turn dark immediately stop use and

welding filters are not designed for oxy-acetylene, laser, or very low amperage welding

®

Fig 5: Headgear Adjustments

contact a service provider for help.

Welding Helmets:

Not meant to Protect against Severe Impact, explosives, fragments from grinding wheels, and

abrasive discs, and hazardous fluids.

- 3-

Page 5

Do not use this helmet without proper training from a certified welder or welding instructor.

Do not use this helmet in an excessive heat environment where the operation of the filter becomes non-functional due to exceeding the temperature ratings of the electronic components.

ANSI defines all welding helmets as secondary eye protection from optical radiation and

impact. For complete safety, primary protection, such as spectacles or goggles, should

be used in conjunction with welding helmets. Protective clothing and accessories such

as leather bibs attached to the welding helmet will protect the user from spatter and optical radiation indirectly entering from areas behind the helmet.

ACGIH (American Conference of Governmental Industrial Hygienists) has established a

TLV-TWA of 5mg/m3 for welding fumes. Welding fumes cannot be classified simply. The

composition and quantity of both are dependent on the alloy being welded and the

process and electrodes used.

Care and Maintenance

NOTE: Replacement components must be used in accordance with these instructions.

Failure to use ArcOne replacement components in accordance with these instructions voids

certification of this product.

Filters:

Filters require virtually no maintenance other than periodic cleaning when the lens, solar panel,

and/or sensor(s) become dirty or clouded from smoke. Clean your filter by using window cleaner

or a mild soapy solution and a soft cloth or paper towel (do not immerse in water or solution).

Change the cover plates frequently. Storage Temperature -10 - 38°C (14 - 100°F)

Models with a replaceable battery will need the battery changed periodically when the Low Bat

LED/LCD indicates.

Welding Helmets:

Welding helmets require virtually no maintenance other than periodic cleaning when dirty. Clean

your helmet by using a mild soapy solution and a soft cloth or paper towel (do not immerse in

water or solution).

Do not throw or abuse the helmet. Doing so may crack the helmet shell and compromise the

protection.

Polycarbonate Protection (Cover) Plates:

Change cover plates when they lose flexibility and/or become bowed or distorted. Clean with

mild soapy solution including any build-up from the area where the cover plate is retained. Discard if cleaning fails to improve visibility or cracks, scratches, etc. impair visibility.

Spatter Protection

SPATTER DAMAGE IS NOT COVERED BY WARRANTY

The Legend and Cobra welding helmets have been designed to accept an additional protective

lens. This additional lens installs immediately in front of the auto-darkening filter or behind the

outer cover plate, thus adding an even greater level of spatter protection.

Users with excessive spatter applications can rely on the greater protection provided by

this option.

All helmets use 1 mm thick cover plates.

- 4-

Page 6

Parts Selection Guide

2XWVLGH3RO\FDUERQDWH

3LYRW$UP

$GMXVWPHQW+ROH

+HDGJHDU6ORW

+HOPHW6KHOO

3RWHQWLRPHWHU.QRE

0RGHOVZLWK

9DU LDE OH &RQ WU R O

,QVLGH3RO\FDUERQDWH

5DWFKHW.QRE

$XWR'DUNHQLQJ)LOWHU

,QVLGH3RO\FDUERQDWH

6ZHDWEDQG

+HDGJHDU$VVHPEO\

*

COBRA 90 x 110

***

06-HG

Sweatband

06-HG

Headgear Assembly

VISION 90 x 110

¹04-OP/03-OP

Inside Polycarbonate

V-911-S

Vision 90 x 110 Shell

Auto-Darkening

Filter

- 5-

Outside Polycarbonate

¹Depends on installed Auto-Darkening Filter

04-OP

Page 7

Cover Shell

Outer Cover Plate

Helmet Shell

Inside Cover Plate

Sweatband

A-D Filter

Headgear Assembly

***

VIPER 90 x 110

- 6-

Page 8

***

06-HG

Sweatband

06-HG

Headgear

Assembly

PYTHON 90 x 110

¹04-OP/03-OP

nside Polycarbonate

I

Auto-Darkening Filter

YTHON-911-S

P

Python 90 X 110 Shell

PYTHON01-911-CP

Python 90 X 110 Cover Plate

PYTHON01-911-CS

Python 90 x 110 Center Section

Slots

Guide Clip

Polycarbonate

COVER PLATE INSTRUCTIONS:

With notches facing up, slide one side

of polycarbonate into guide clip. Align

notches and push other side of polycarbonate into guide clip. Polycarbonate

will click into place.

Bottom

Catch

CENTER SECTION INSTRUCTIONS:

Slide A-D filter and Inside Polycarbonate

into Filter Holder. Slide notches on top of

Filter Holder into slots on helmet. Line up

Filter Holder with Centering Pin on helmet,

squeeze tabs on Filter Holder and push into

tab slots. Release tabs into bottom catches.

- 7-

Centering

Pin

Page 9

Filter Specifications (Table 1)

2500V 4500V 5500V 4000V 5000V iDF48 6000VI4

Viewing

Area

4608 mm

7.1 sq. in)

(

2

3291 mm

5.2 sq. in.)

(

2

4608 mm

7.1 sq. in)

(

2

3293 mm2

5.2 sq. in.)

(

4608 mm

7.1 sq. in)

(

2

4609 mm

7.1 sq. in)

(

2

8100 mm

12.5 sq. in)

(

90 x 110mm90 X 110mm90 X 110mm90 X 110mm90 X 110mm90 X 110mm90 X 110

Filter Size

ARC

Sensing

Two

sensors

Two

sensors

Two

sensors

Sensitivity

Control Fixed Fixed Fixed

Switching

Time

(seconds)

1/10,000

(0.5 milliseconds)

1/10,000

(0.1 milliseconds)

1/10,000

(0.1 milliseconds)

Two

sensors

Digital:

Variable

1/10,000

(0.1 milliseconds)

Two

sensors

Digital:

Variable

1/10,000

(0.1 milliseconds)

Two

Sensors

Digital:

Variable

1/10,000

(0.1 milliseconds)

mm

Four

Sensors

Analog:

High-Low

1/10,000

(0.1 milli-

seconds)

Replaceable AAA

Primary

Power Solar Cells Solar Cells Solar Cells Solar Cells Solar Cells

Back-up

Power

Operating

Temp.

Storage

Temp.

UV / IR

Protection

Dark to

Light Delay

Lithium

Battery

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1-2

seconds

Lithium

Battery

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1 -3.5

seconds

Lithium

Battery

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1-3.5

seconds

Lithium

Battery

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1-3.5

seconds

Lithium

Battery

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1-3.5

seconds

Battery,

Solar Cells

Lithium

Battery None

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1-3.5

seconds

Lithium

Battery

-10 – 55C

(14 – 131F )

-10 – 38C

(14 – 100F )

Up to

Shade 16

0.1 or 2

seconds

Light Shade 4 3 4 4 4 4 4

Dark Shade 9-13 11 9 to 13 9-13 9-13 5-8/9-13 9 to 13

Grind Mode No No No Yes Yes Yes Yes

Intelligent

Auto-Shade

Mode

No No No No No Yes No

Intelligent

TIG Mode No No No No No Yes No

Enclosure

Integrity

Standards

Dust /

Water

Resistant

*CE

EN379

Dust /

Water

Resistant

*CE

EN379

Dust /

Water

Resistant

*CE

EN379

Dust /

Water

Resistant

**CE

EN379

Dust /

Water

Resistant

**CE

EN379

Dust /

Water

Resistant

**CE

EN379

Dust /

Water

Resistant

*CE

EN379

Optical

Class 1 1 1 1 1 1 1

Diffusion of

Light Class 2 1 1 1 1 1 2

Variation in

Luminous

Transmittance Class 1 1 1 1 1 1 1

Angle Dependency

Class 3 2 2 2 2 2 1

- 8-

2

Page 10

Significance of markings:

Welding Filters:

Example: 4 / 5-8/9<13 AR M 1/1/1/2 EN379

4 – Light Shade number

5-8 – Dark Shade range 1

9<13 – Dark Shade range 2 (Auto-Variable mode)

AR – Manufacturers mark

M - Auto Variable

1 – Optical Class

1 – Diffusion of Light Class

1 – Variation in Luminous Transmittance class

2 – Angle Dependency class (This is a new classification of EN379. This marking may not be in-

dicated on older models)

Welding Helmets:

Significance of CE Markings:

Example: AR EN 175 –F CE

AR - Company Identification Mark,

EN 175 - CE Welding Helmet Standard,

-F – Impact Class (Low Energy),

CE – European Mark

Significance of Other Markings:

Example: AR Z87

AR - Company Identification Mark

Z87 - ANSI Standard for Eye and Face Protectors

Example: CAN/CSA Z94.3 Labs

CAN/CSA Z94.3 – CSA Standard for Eye and Face Protectors

Labs – CAN/CSA Certified Lab

Product Certification Bodies

*This model has been certified by: Certottica SCARL

Zona Industriale Villanova

32013 Longarone (BL), Italy

Notified Body Number: 0530

**This model has been certified by: ECS GmbH

Obere BahnstraBe 25

73431 Aelen - Germany

Notified Body Number: 1883

***This model has been certified by: INSPEC International

56 Leslie Hough Way

Salford

Greater Manchester

M6 6AJ, England

Notified Body Number: 0194

- 9-

Page 11

SER

I

A

L N

U

M

B

ER

Serial Number is located

on the top of the filter.

Slide A-D Filter out from

under Retention Spring.

Serial Number

SERIAL NUMBER

Shade Selection Guide

CE Shade selection Guide (Table 1)

Filter Removal Diagram

- 10 -

Page 12

®

LIMITED WARRANTY

®

ArcOne

ing from materials or workmanship for a period of 2 years from the date of purchase. Proof of purchase

e

m

tion to repair, replace or refund (not to exceed the purchase price). This limited warranty is not

transferable from the original purchaser to a secondary owner.

s

this product. This limited warranty is exclusive and is in lieu of any other warranty implied either oral or

written. Please read the instruction manual carefully to avoid certain situations which may void this limited warranty.

In the unlikely event that the auto-darkening filter malfunctions, the following procedures are to be

used to receive efficient service and repair: Determine if the product is damaged from abuse or misuse. Any pitted marks on the filter possibly from spatter, chips, dents, or cracks, etc., are some indications of operator abuse. In the case of operator abuse the warranty is void.

If you need to return your filter, follow the Return procedure below.

warrants all auto-darkening filters listed in this manual against all manufacturing defects result-

stablishing the date of sale and filter serial number must be provided, should a warranty claim be sub-

itted. The purchaser’s only remedy under this limited warranty shall be limited to

®

ArcOne

shall in no event be liable or re-

rcOne

A

®

ole opera-

s

ponsible for any injury, damage or loss resulting either directly or indirectly from the use or misuse of

RETURN PROCEDURE

Please do not contact the distributor or retailer from whom you purchased the filter

1. Remove the Auto-Darkening filter from the helmet. Record the model number and serial

number which are located on the filter edge or back. Also record the date of purchase from

your sales receipt.

2. Contact

ArcOne

®

Customer Service (800-223-4685) for a Return Tag Number.Note.

ArcOne®is a Division of A.C.E. International Company

85 Independence Drive, Taunton, MA 02780

TEL: (508) 884-9600 • TOLL FREE: (800) 223-4685 • FAX: (508) 884-9666

WEB: www.arc1weldsafe.com

Loading...

Loading...