Page 1

RD104

DANA 30, 30 SPLINE, 3.73 & UP

INSTALLATION GUIDE

Copyright © 2002 by ARB Corporation Limited

Part No. 2102104

Revision Date 08/04/03

Page 2

No liability is assumed for damages resulting in the use of the information contained herein.

ARB Air Locker Air Operated Locking Differentials and Air Locker are trademarks of ARB Corporation Limited.

Other product names used herein are for identification purposes only and may be trademarks of their respective owners.

ARB 4x4 ACCESSORIES

Corporate Head Office

42-44 Garden St Tel: +61 (3) 9761 6622

Kilsyth, Victoria Fax: +61 (3) 9761 6807

AUSTRALIA

3137

Australian enquiries sales@arb.com.au

North and South American enquiries sales@arbusa.com

Other international enquiries exports@arb.com.au

www.arb.com.au

Page 3

Table of Contents:

1 Introduction 3

1.1

Pre-Installation Preparation 3

1.2

Tool-Kit Recommendations 4

1.3

2 Removing the Existing Differential 6

3 Installing the Air Locker 12

3.10

3.11

4 Installing the Air System 30

5 Mounting & Connecting the Electrical System 35

6 Testing & Final Assembly 40

Assembly Type Identification 5

2.1

Vehicle Support 6

2.2

Differential Fluid Drain 6

2.3

Disconnecting the Axles 7

2.4

Marking the Bearing Caps 8

2.5

Checking the Current Backlash Amount 9

2.6

Removing the Differential Center 10

3.1

Insuring Adequate Oil Drainage 12

3.2

Installing the Carrier Bearings 13

3.3

Approximate Backlash Shimming 14

3.4

Mounting the Ring Gear 16

3.5

Drilling and Tapping the Bulkhead Port 17

3.6

Assembling the Seal Housing 19

3.7

Pre-Load Shimming 20

3.8

Reinstalling the Bearing Caps 25

3.9

Checking the Backlash 26

Setting Up the Bulkhead Fitting 27

Profiling the Seal Housing Tube 29

4.1

Mounting the Solenoid 30

4.2

Running & Securing the Air Line 32

4.3

Connection to the Bulkhead Fitting 33

5.1

Mounting the Actuator Switch(es) 35

5.2

Wiring the Actuator System 36

6.1

Leak Testing 40

6.2

Reinstalling the Axles 40

6.3

Testing the Air Locker Actuation 41

6.4

Re-Sealing & Filling the Differential 41

6.5

Post-Installation Check List 42

7 Parts List 43

7.1

Exploded Assembly Diagram 43

7.2

Itemized Parts List 44

1

Page 4

2

Page 5

1 Introduction

IMPORTANT :

BEFORE ATTEMPTING TO DISMANTLE YOUR VEHICLE FOR THIS

INSTALLATION, PLEASE READ THIS INSTALLATION GUIDE IN ITS

ENTIRETY, AS WELL AS ALL APPLICABLE SECTIONS OF YOUR

VEHICLE MANUFACTURER’S SERVICE MANUAL.

1.1 Pre-Installation Preparation

This booklet is to be used in conjunction with your vehicle

manufacturer’s service manual. ARB endeavors to account for every

possible variation in vehicle model when publishing its installation

guides, and guides are updated regularly as new model information

becomes available, however, the rapid and globally varied release of

some vehicles makes it difficult to insure that your vehicle model has

been accurately accounted for. In the case of any technical

discrepancies between this guide and your service manual, we

strongly advise that you adhere to the specifications and techniques

as documented in your service manual.

Although your ARB Air Locker comes complete with all the step by

step instructions you will need to supplement your vehicle

manufacturer’s service manual and install your new differential, ARB

recommends that you have your Air Locker installed by a trained

professional. Many ARB distributors around the world have been fully

instructed in Air Locker installations by ARB, and have gained a wealth

of experience and skill from years of performing similar installations.

Once you begin this installation your vehicle will be immobile until all

steps of the installation are complete. Make sure your Air Locker kit is

the correct model for your vehicle and that it contains all of the parts

listed on back cover of this booklet. Also be sure you have

appropriately equipped yourself with all the necessary tools, parts, and

materials to complete this installation (see section 1.2 Tool-Kit

Recommendations), and that you have allowed for an appropriate

amount of vehicle down time.

HINT :

Place a mark inside each of the c symbols as

you complete each step. It is very important NOT to

miss any of the steps!

3

Page 6

1 Introduction

1.2 Tool-Kit Recommendations

Below is a list of tools and supplies you may need to complete this

installation. Requirements for your vehicle may vary. Please consult

your vehicle service manual for additional recommendations.

1.2.1 Tools

c Standard automotive sizes (metric and/or imperial) of sockets,

wrenches, Alan keys, and drills.

c A dial indicator or other suitable measuring tool for checking ring &

pinion backlash.

c A standard automotive feeler gauge.

c A razor knife to cut the nylon tubing.

c A differential housing spreader, to facilitate removal of the carrier.

(not required on aluminum housings)

c A torque wrench. (See vehicle service manual for required torque

range.)

c A lubricant drain reservoir.

c Suitable measuring tools to measure a differential for pre-load

and/or backlash shimming. (See Section 3.3)

c A 11.2mm [7/16”] drill and ¼” NPT tap for bulkhead fitting

installation.

c An automotive bearing puller (2 jawed is recommended) or a

differential carrier bearing puller.

c A bearing press or arbor press.

1.2.2 Supplies

c Thread lubricant/sealant compound for pressure fittings

(e.g., LOCTITE #567 Teflon paste)

c Thread locking compound (e.g., LOCTITE #272)

c Either a replacement gasket, or gasket sealant, for your differential

cover.

c A sufficient volume of differential oil to completely refill your

housing. (see the ARB Air Locker Operating and Service Manual

for recommended lubricants)

c A soap and water mixture to test for air leaks.

c Teflon paste.

4

Page 7

1 Introduction

A

B

1.3 Assembly Type Identification

IMPORTANT:

Sections 2 and 3 of this installation guide have been written to

accommodate two different Dana 30 applications:

A the Independent Front Suspension (IFS) type with an

aluminum housing (Refer to Fig.1.)

B the live axle Salisbury type with a cast iron housing.

(Refer to Fig.2.)

To eliminate confusion, you should identify which figure your vehicle

matches with. The section numbers within the guide that refer ONLY

to the IFS type have been suffixed with an ‘ A ’, and those that refer

ONLY to the live axle type have been suffixed with a ‘ B ’.

PLEASE IGNORE ALL SECTIONS WHICH

DO NOT APPLY TO YOUR APPLICATION

Figure 1.

Figure 2.

5

Page 8

2 Removing the Existing Differential

2.1 Vehicle Support

c Safely secure the vehicle on a hoist. We recommend supporting

the vehicle on a chassis hoist to keep the differential area at a

convenient working height and to leave the wheels and axles free

to be rotated and removed.

c Once supported off the ground, release the parking brake and

leave the vehicle in neutral. Chock the wheels if necessary.

2.2 Differential Fluid Drain

HINT : This is a good time to check for metal particles in

your oil, on your drain plug, or in the bottom of the

housing which may indicate a worn bearing or

differential component.

2.2.1 A IFS Fluid Drain

c Remove any skid plates covering the bottom of the front axle area

and position a fluid drain reservoir under the differential.

c Remove the threaded drain plug and completely drain all differential

oil from the housing.

c Finger-tighten the drain plug back in to prevent drips during the

removal of the axle assembly.

2.2.2 B Live Axle Fluid Drain

c Clean around the differential cover plate seal to prevent dirt from

entering the differential.

c Position a fluid drain reservoir under the differential and loosen all

differential cover plate retaining bolts.

c Gently pry the cover plate away from the differential housing to

completely drain all differential fluid.

c Once drained, remove the differential cover plate.

6

Page 9

2 Removing the Existing Differential

2.3 Disconnecting the Axles

2.3.1 A IFS CV Shafts

c Remove the wheels, and brakes according to your vehicle

manufacturer’s service manual.

c Disconnect the drive shaft from the differential drive flange.

c Disconnect the struts (shocks) from the lower control arms.

c Remove the forked strut mounts off of the bottoms of the strut

cylinders.

c Disconnect the upper and lower ball joints.

c Tap the CV shafts outward to disconnect the retaining clips, and

draw the knuckle joints outward until you can completely disengage

the spline of the CV shafts from the differential housing.

NOTE : The oil seals are delicate and can be easily damaged.

Support the weight of the CV shaft when drawing them

out of their sockets in the housing.

c Completely remove the differential assembly from the vehicle.

c Secure the differential assembly to a work bench.

c Remove the front access cover plate.

2.3.2 B Live Axle CV Shafts

IMPORTANT :

Collision damage or heavy off-road use of your vehicle in the past may

have resulted in some degree of bending in the axle. Any misalignment

of the axle tubes may result in excessive wear and/or failure of your

differential and axle shafts. ARB strongly recommends that you have

your axle assembly inspected for concentricity and straightness before

c Remove the wheels, and brakes according to your vehicle

manufacturer’s service manual.

installing your Air Locker.

c Disconnect the drive shaft from the differential drive flange.

c Disconnect the upper and lower ball joints.

c Draw the knuckle joints outward until you can completely disengage

the spline of the CV shafts from the differential housing.

NOTE : The oil seals are delicate and can be easily damaged.

Support the weight of the CV shaft when drawing them

out of their sockets in the housing.

7

Page 10

2 Removing the Existing Differential

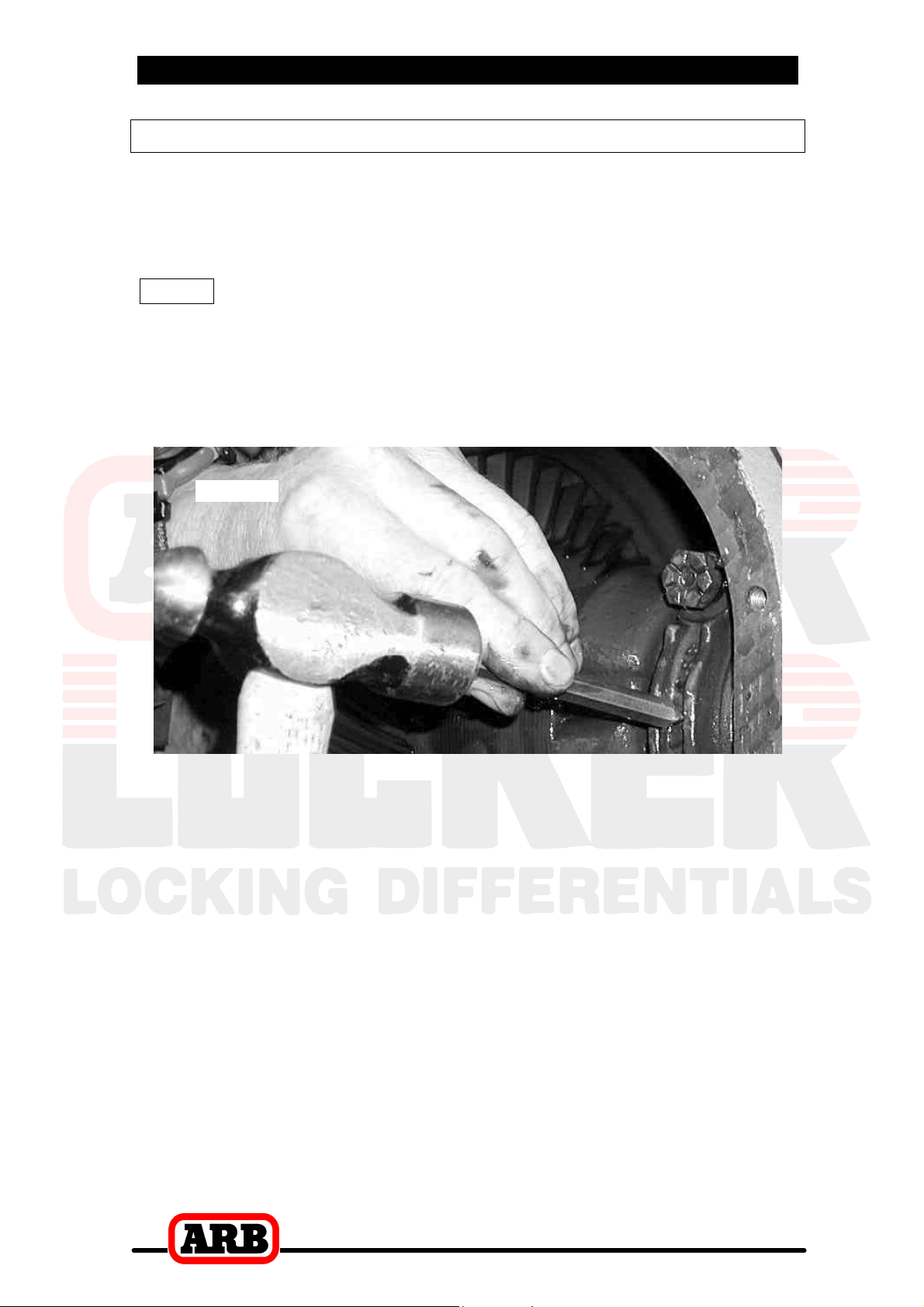

2.4 Marking the Bearing Caps

c Using a pointed center punch, gently mark the bearing caps in a

way that will enable you to know which cap is ‘LEFT’ and which cap

is ‘RIGHT’, which way is ‘UP’ and which way is ‘DOWN’. (Fig.3.)

HINT : Many installers choose to make one punch mark on

the left hand side of the left hand bearing cap and one

similar punch mark on the housing at close proximity to

the cap mark. The right hand side is then designated

with two punch marks on the right hand side of the cap

and two similar punch marks on the housing.

Figure 3.

8

Page 11

2 Removing the Existing Differential

2.5 Checking the Current Backlash Amount

IMPORTANT:

This step is a precautionary measure recommended by ARB due

to the fact that some after market ring and pinion sets have been

manufactured to run with different backlash settings than those

specified by your vehicle manufacturer. Although ARB must

recommend you set backlash according to your service manual

guidelines, we also advise that you compare the backlash

measurements taken here to the recommended backlash settings

in your vehicle service manual. Measurements found to be

outside of your service manual recommendations may indicate

the need to deviate from those settings in order to achieve quiet

running with a good contact mark.

Refer to your vehicle service manual or your local authorized

ARB installer for more information.

c Set a depth indicator on one of the ring gear teeth as in figure 4.

Figure 4.

c While supporting the pinion gear by holding the drive shaft flange,

rotate the differential in both directions while observing the

maximum variation in depth from the indicator (i.e., the highest

value minus the lowest value). This value is referred to as the ring

and pinion backlash.

c Rotate the differential center 90° and measure again for accuracy.

c Record the average of all measurements.

9

Page 12

2 Removing the Existing Differential

2.6 Removing the Differential Center

2.6.1 A Cast Aluminum Housings

IMPORTANT:

YOU MUST NOT SPREAD THE HOUSING ON

ALUMINUM IFS ASSEMBLIES.

IFS models like the Jeep Liberty (KJ) were made with an

aluminum differential housing (See Figure 1.) and therefore must

not be spread like a cast iron housing. Spreading an aluminum

housing could cause irreparable damage to the housing and is

therefore strongly advised against.

c Remove both bearing caps.

c Carefully remove the differential center by pulling or prying forward.

NOTE : Keep track of which shims came from which side as it

will be important to match them to their original

positions for measurements later.

NOTE : The differential center is heavy and quite difficult to

handle when covered in oil. Take care not to drop it.

2.6.2 B Cast Iron Housings

IMPORTANT:

YOU MUST SPREAD THE HOUSING ON CAST IRON MODELS

Spreading the differential housing with a differential case

spreader is a step which is critical to set up bearing pre-load on

cast iron differential housings (See Figure 2.). Improper pre-load

will result in undue bearing wear, increased stresses in the

differential center, increased running noise, and ultimately, ring

and pinion gear damage.

c Remove both bearing caps.

c Carefully spread the housing (Fig.5.) enough to remove the

differential center. (Refer to your vehicle’s service manual).

NOTE : Do not spread the housing more than 0.50mm [0.020”].

10

Page 13

2 Removing the Existing Differential

HINT : Be sure not to mix up the left and right hand bearing

cups. Later it will be necessary to know which cup

came from which side.

c Once the housing has been adequately spread, the differential may

be removed by pulling forward on the differential carrier.

Figure 5.

NOTE : The differential center is heavy and quite difficult to

handle when covered in oil. Take care not to drop it.

c Relieve any tension on the spreader immediately after the

differential has been removed.

11

Page 14

3 Installing the Air Locker

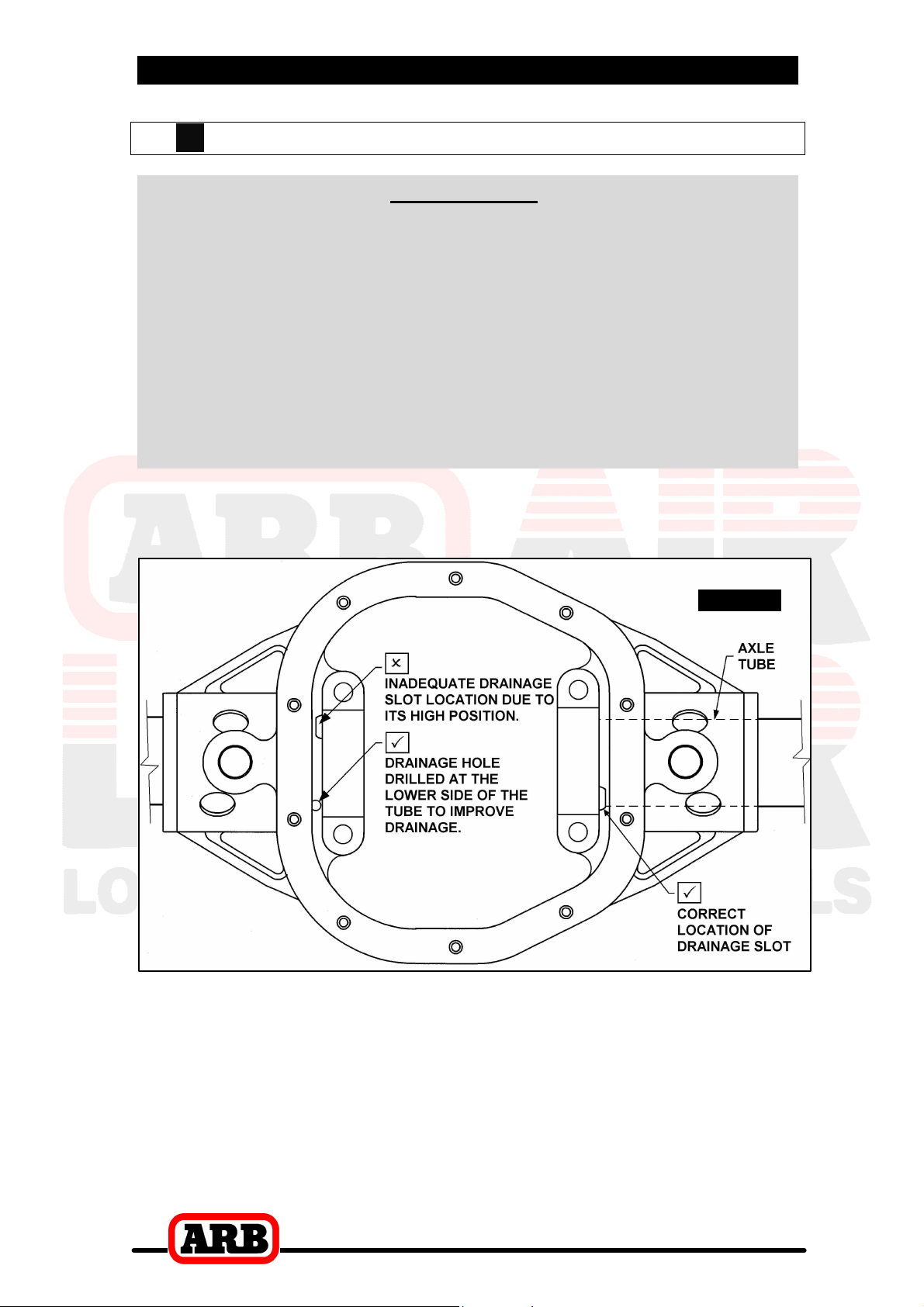

3.1 B Insuring Adequate Oil Drainage

IMPORTANT:

Some Salisbury axles were manufactured with poor oil drainage

between the axle tubes and the differential housing. This can

often result in one of the axle tubes filling up with differential oil

while running. In most cases this will result in a blocked air vent

which will cause the differential housing to pressurize and expel

oil from the axle seals at the wheels or force oil into the air

system of the Air Locker, eventually expelling oil at the solenoid

valve. This is a design flaw which was corrected by most

automakers in the later releases of their axle assemblies. If no

lower drainage point is present in the differential housing then it

is critical that you modify the housing to include one.

c Inspect the differential housing for the presence of adequate

drainage in both axle tubes (refer to Fig.6.).

Figure 6.

c If no drainage slot is present at the left-hand side (refer to Fig.6.) of

the housing at all, then a slot will have to be created as clearance

for the seal housing tube (Refer to Section 3.8 Reinstalling the

Bearing Caps).

c If drainage exists but is inadequate then a slot or hole should be cut

into the housing on the lower side of the tube(s) to allow oil out of

the axle tube area.

12

Page 15

3 Installing the Air Locker

NOTE : Make sure any grinding dust, filings or drill chips left

behind by cutting the drainage slots is completely

cleaned out of the housing.

c Check that the axle air vents are clear and working correctly.

3.2 Installing the Carrier Bearings

c Apply a thin film of high pressure grease to both bearing journals of

the Air Locker to prevent seizing.

c Using a bearing press or arbor press, press one of the bearing

cones (supplied with the Air Locker kit) onto one bearing journal of

the Air Locker (refer to Figure 7.) until the bearing seats firmly

against the bearing journal shoulder.

Figure 7.

c Invert the Air Locker and press the other tapered roller bearing

cone onto the opposite bearing journal of the differential carrier until

the bearing seats firmly against the bearing journal shoulder.

NOTE : Do not add any shims between the bearings and the

bearing seat. Shimming of the Air Locker will be

performed with the supplied shim kits and/or the

original master shims (if any) on the outside of the

carrier bearings.

13

Page 16

3 Installing the Air Locker

3.3 Approximate Backlash Shimming

In order to reproduce a similar pre-load and ring and pinion backlash

in your Air Locker to that of your original differential, measurements

need to be taken so that a shim thickness can be calculated.

c Secure the original differential to a work bench.

c Remove the bolts that hold the ring gear in place.

c Using a plastic or copper hammer, tap in a circle around the ring

gear to separate it from the differential carrier.

Figure 8.

c Assemble the original bearing cup onto the cone of the right-hand

side of the original differential carrier.

c Using a caliper or similarly accurate measurement method

(i.e., able to take accurate measurements within 0.04mm [0.0015”]),

measure the distance from the shoulder of the outer face of the

bearing cup to the ring gear mounting face (shown as ‘A’ in Figure

8.) and record this measurement as ‘A’.

NOTE : Be sure to measure using the bearing cup that

originally came off of the right-hand side.

14

Page 17

3 Installing the Air Locker

c Assemble the new bearing cup and master shim (supplied with your

Air Locker kit) onto the right-hand side of the Air Locker (as shown

in Fig. 9.) and measure the total distance ‘C’.

NOTE : The shim pack ‘B’ should not be installed at this time.

Figure 9.

c Record this measurement as ‘C’.

The thickness of the shim pack ‘B’ should make the distance ‘C’ on the

Air Locker closely match the distance ‘A’ on the existing differential

(within 0.1mm [0.004”] ).

c Use the following calculation to find the desired thickness of ‘B’:

A – C = B (Replacement Shim Pack)

HINT : If your calculations are correct then the following

equation will also be true:

A – B – C = ZERO

15

Page 18

3 Installing the Air Locker

c Select shims from the shim kit supplied with your Air Locker to

make the thickness ‘B’ as determined above.

c Place this shim pack between the master shim and the bearing cup.

c Re-measure the new distance ‘C’ from the Air Locker (now

including the shim pack ‘B’) to make sure that it matches ‘A’ on the

original differential.

NOTE : NEVER machine the Air Locker.

3.4 Mounting the Ring Gear

c Apply a thin film of high pressure grease to the ring gear shoulder

of the Air Locker to prevent seizing.

c Thoroughly clean any thread locking compound or other foreign

matter from the holes of the ring gear, the threads of the ring gear

bolts, and the mating surfaces between the ring gear and the Air

Locker flange.

HINT : Stoning the ring gear mounting face before

installation will remove any high spots around the

threads.

c Heat the ring gear to between 80 and 100°C [175 - 212°F] in hot

water or in an oven to slightly expand the gear and facilitate

assembly.

NOTE : NEVER HEAT GEARS WITH A FLAME! This could

damage the hardened surface of the gear and result

in premature wear or failure.

c Dry the gear and bolt holes with compressed air (if wet).

c Install the ring gear onto the Air Locker by aligning the bolt holes

and then gently tapping it around in a circle with a soft mallet.

Avoid using the bolts to pull down the ring gear as this puts excess

strain on the bolts and the differential flange.

c Apply a thread locking compound to the thread of each ring gear

bolt before inserting it. Do not apply threading compound directly

into the threaded hole as this could prevent the bolt from reaching

its full depth.

c Tighten the ring gear bolts in a star pattern with a torque wrench

according to your vehicle manufacturer’s specified torque.

16

Page 19

3 Installing the Air Locker

3.5 Drilling and Tapping the Bulkhead Port

An airline port must be drilled and tapped through the differential

housing to mount the bulkhead fitting into.

NOTE : Higher ratio gearing uses deeper (thicker) ring gears

with teeth that extend much further. Make sure the

intended hole location is far enough away from the

ring gear teeth that the air line will not be at risk of

contact with the current or future ring gears.

3.5.1 A Port Location on the IFS KJ Housing

c Mark a spot on the top of the outside shell of the differential

housing on the thick section of the large external rib of the housing

as shown in Figure 10.

Figure 10.

c Cover the drive pinion and axle tube areas with a rag to protect

them from metal filings.

c Drill through the housing square to the outside surface using a

11.2mm [7/16”] drill.

c Tap the hole from the outside using a ¼” NPT pipe tap.

c Remove any sharp edges from the hole that may chip-off and fall

into the housing.

c Carefully remove the rags and inspect with a service light inside the

housing to insure no metal filings are left behind.

17

Page 20

3 Installing the Air Locker

3.5.2 B Port Location on the Live Axle Housing

c Mark a spot on the top of the outside shell of the differential

housing that will be clear of the ring gear position once the seal

housing tube has been installed. Figures 10. and 12. show how the

tube will port through the differential housing.

Figure 11.

c Cover the drive pinion and axle tube areas with a rag to protect

them from metal filings.

c Drill through the housing square to the outside surface using a

11.2mm [7/16”] drill.

c Tap the hole from the outside using a ¼” NPT pipe tap. (Figure 12.)

Figure 12.

c Remove any sharp edges from the hole that may chip-off and fall

into the housing.

c Carefully remove the rags and inspect with a service light inside the

housing to insure no metal filings are left behind.

18

Page 21

3 Installing the Air Locker

3.6 Assembling the Seal Housing

Figure 13.

c Make sure the grooves and airway of the seal housing are clean

and free from any contaminants (e.g. water, dirt, metal filings, etc.).

c Inspect the seal housing O-rings (supplied) for dirt, damage or

other conditions which might cause leaks.

c Generously lubricate the O-rings with oil prior to assembly, then

insert them into the grooves of the seal housing.

NOTE : When assembling the O-rings, be careful not to leave

them twisted when seated in the grooves as this could

cause excessive wear and leakage.

c Lubricate the seal housing running surface on the Air Locker carrier

with oil. Assemble the bearing cup onto the left-hand side of the Air

Locker.

c Assemble one of the two master shims (included with the Air

Locker shim kit) onto the stepped face of the seal housing with the

rounded edge of the shim facing out.

NOTE : No shims other than the single master shim should be

assembled onto the seal housing at this time.

c Carefully install the seal housing (master shim towards the

center) by sliding it all of the way onto the bearing journal with a

gentle twisting motion. This will allow the O-rings to engage gently.

19

Page 22

3 Installing the Air Locker

3.7 Pre-Load Shimming

In order to pre-load the tapered roller bearings in your Air Locker,

measurements need to be taken so that a value can be calculated for

the shim thickness ‘D’ in Figure 13.

3.7.1 A Pre-Loading an Aluminum Housing

c Grind or cut a notch into the left-hand factory shim as clearance for

the seal housing tube at final assembly. Figure 14. shows the

desired size of the notch.

Figure 14.

c Remove any sharp or protruding edges from around the notch.

c While holding the right-hand bearing cup in place, insert and hold

the Air Locker into the differential housing.

c Insert one of the two master shims from the Air Locker shim kit

between the right-hand bearing cup and the bearing seat of the

axle housing with the rounded edge of the master shim facing away

from the center.

c Insert the shim pack determined earlier as ‘B’ between the bearing

cup (right-hand side) and the master shim.

c Insert the original factory shims in their original positions on both

sides.

c Push (or lightly pry) the Air Locker hard across to the right-hand

side, and measure the maximum gap (also called the ‘end float’)

between the left-hand factory shim and the seal housing with an

automotive feeler gauge. (Fig.15.)

20

Page 23

3 Installing the Air Locker

Figure 15.

c Consult your vehicle manufacturer’s service manual to determine

the carrier bearing pre-load amount specified for your vehicle.

c Add the specified pre-load amount to the measurement taken with

the feeler gauge to determine a shim amount for ‘D’ in Figure 13.

PRE-LOAD + END FLOAT = SHIM PACK

c Create a shim pack ‘D’ from the shims supplied with your Air

Locker.

NOTE : Do not add shims between the bearing cone and the

bearing seat of the Air Locker and NEVER machine

the Air Locker.

c Remove the factory shim from the left-hand side.

c Install the shim pack ‘D’ between the master shim and the seal

housing as shown in Figure 13.

c Rotate the seal housing until the tube is positioned in the center of

the oil drainage notch of the aluminum housing. (Fig.16.)

21

Page 24

3 Installing the Air Locker

Figure 16.

c Tap the factory shim into place between the seal housing and the

aluminum housing with the notch lined up with the notch in the seal

housing and the notch in the aluminum differential housing.

(Fig.17.)

Figure 17.

NOTE : Do not spread the housing on the aluminum models.

c Check that some clearance exists between the bearing cap and the

seal housing tube. If not, the bearing cap should be removed and

the tube re-bent for adequate clearance.

c Check that some backlash can be felt between the ring and pinion

gears. No backlash would be an early indication of incorrect shim

thickness.

22

Page 25

3 Installing the Air Locker

3.7.2 B Pre-Loading a Live Axle Housing

c Insert and hold the Air Locker into the differential housing.

c Insert the remaining master shim from the Air Locker shim kit

between the right-hand bearing cup and the bearing seat of the

axle housing with the rounded edge of the master shim facing away

from the center.

c Insert the shim pack determined earlier as ‘B’ between the bearing

cup (right-hand side) and the master shim.

c Push (or lightly pry) the Air Locker hard across to the right-hand

side, and measure the maximum gap (also called the ‘end float’)

between the outside of the seal housing and the inside face of the

axle housing with an automotive feeler gauge. (Fig.18.)

Figure 18.

c Consult your vehicle manufacturer’s service manual to determine

the carrier bearing pre-load amount specified for your vehicle.

c Add the specified pre-load amount to the measurement taken with

the feeler gauge to determine a shim amount for ‘D’ in Figure 13.

PRE-LOAD + END FLOAT = SHIM PACK

c Create a shim pack ‘D’ from the shims supplied with your Air

Locker.

NOTE : Do not add shims between the bearing cone and the

bearing seat and NEVER machine the Air Locker.

c Remove the Air Locker from the axle housing.

23

Page 26

3 Installing the Air Locker

c Install the shim pack ‘D’ between the master shim and the seal

housing as shown in Figure 13.

c Spread the differential housing again (Refer to Section 2.6).

c Re-install the Air Locker into the axle housing.

NOTE : If the Air Locker is too tight to fully install then the

spreader tension may need to be increased. Do not

spread the housing more than 0.50mm [0.020”].

c Rotate the seal housing until the tube is positioned in the center of

the oil drainage notch of the axle housing. (Fig.19.)

Figure 19.

c Release all spreader tension.

c Check that some backlash can be felt between the ring and pinion

gears. No backlash would be an early indication of incorrect shim

thickness.

24

Page 27

3 Installing the Air Locker

3.8 Reinstalling the Bearing Caps

IMPORTANT:

The Air Locker master shim must be assembled between the

stepped side of the seal housing and the bearing cup.

NOT HAVING THE MASTER SHIM IN PLACE

HERE WILL CAUSE BEARING FAILURE.

c Using a soft instrument such as the wooden handle of a hammer,

bend the seal housing tube outward and away from the position of

the bearing cap. (Fig.20.)

Figure 20.

DANA30 IFS PICTURED

NOTE : The seal housing tube should lay as low in the seal

housing groove as possible.

c Install the bearing caps oriented as they were marked before they

were removed, and tighten the bearing cap bolts. It is not

necessary to torque them down at this time.

c Check that some clearance exists between the bearing cap and the

seal housing tube. If not, the bearing cap should be removed and

the tube re-bent for adequate clearance.

c Tighten all bearing cap bolts with a torque wrench to the torque

specified in your vehicle manufacturer’s service manual.

NOTE : Aluminum housings require a smaller torque amount

than a cast iron housing. Make sure you use the

correct torque for your vehicle.

25

Page 28

3 Installing the Air Locker

3.9 Checking the Backlash

c Set a depth indicator on one of the ring gear teeth as in

Figure 21.

c While supporting the pinion gear by holding the drive shaft, rotate

the differential in both directions while observing the maximum

variation in depth from the indicator (i.e., the highest value minus

the lowest value). This value is referred to as the ring and pinion

backlash.

c Rotate the differential center 90° and measure again for accuracy.

Figure 21.

c Refer to your vehicle service manual for the specified maximum

and minimum amounts of backlash. If the backlash is not within the

specifications then the differential will have to be removed and reshimmed.

26

Page 29

3 Installing the Air Locker

3.9.1 Re-Shimming the Backlash

NOTE : This step is only necessary when adjusting for

incorrect backlash.

c Remove the bearing caps.

c Remove the differential as before.

NOTE : Never spread the housing on the aluminum models.

c To decrease the amount of backlash, reduce the shim thickness ‘B’

(Fig.9.) and increase the shim thickness ‘D’ (Fig.13.) by the same

amount. Reverse this step to increase the backlash.

c Remount the differential as before.

c Release spreader tension (if applicable).

c Check backlash again as before.

3.10 Setting Up the Bulkhead Fitting

c Apply thread sealant to the threads of the bulkhead body.

c Screw the bulkhead body into the tapped hole, and tighten.

c Wipe the area clean of any excess thread sealant (inside and

outside of the housing).

c Insert the free end of the seal housing tube into the bulkhead fitting

until it protrudes approximately 8mm [5/16”] through the other side.

c From the outside of the housing, assemble the small O-ring over

the top of the short length of seal housing protruding through the

bulkhead fitting.

c While still holding the seal housing tube into the bulkhead fitting,

insert the small drilled end of the center compression nut over the

extended tube as shown in the assembly diagram (Fig.22.), and

screw it into the bulkhead body, and lightly tighten.

NOTE : Be sure to insert the correct end of the center

compression nut into the bulkhead body. The thread

has been partially relieved on the bulkhead side of the

center compression nut to visually identify its

orientation. (Fig.22.)

27

Page 30

3 Installing the Air Locker

Figure 22.

NOTE : Excessive tightening of the center compression nut is

not necessary to form a good seal around the tube

and may damage the O-ring or the threads of the

compression nut.

NOTE : Make sure the seal housing tube is all of the way into

the center compression nut while you are tightening

it.

28

Page 31

3 Installing the Air Locker

3.11 Profiling the Seal Housing Tube

c Completely remove the differential spreader (if applicable).

c Without using sharp, jagged tools such as pliers (usually your

hands are the best tool for this job), gently bend the seal housing

tube so that it runs along the inside of the differential housing as

shown in Figure 23.

Figure 23.

NOTE : It is also a good idea to keep the tube away from the

bearing caps or any other part of the differential

casting as any contact due to vibration or shock may

wear the tube and eventually cause a leak.

29

Page 32

4 Installing the Air System

4.1 Mounting the Solenoid

4.1.1 Connection to an ARB Air Compressor (Fig.24.)

c Remove one of the 1/8” BSP plugs from its port in the compressor

tank.

c Apply Teflon paste to the nipple (1/8” X 1/8” BSP) and insert it into

the port and tighten.

c Apply Teflon paste to the free end of the nipple.

c Assemble the inlet port side of the solenoid (stamped with a ‘1’)

onto the nipple and tighten. The solenoid should be rotated into a

position that does not obstruct any other ports on the compressor

tank.

NOTE : The solenoid exhausts compressed air through the

center of the black retaining cap when the Air Locker

is disengaged. Make sure this orifice cannot be

obstructed.

c Apply Teflon paste to the threads of the 5mm push-in fitting and

assemble it into the solenoid outlet port (stamped “2”) and tighten.

ARB

Air Compressor

Figure 24.

30

Page 33

4 Installing the Air System

4.1.2 Connection to an Alternate Air Source

For ease of installation, quality of air supply, and a high level of

dependability from your Air Locker(s), ARB strongly recommends use

of a genuine ARB Air Compressor, however, the Air Locker air system

can be operated on any alternate air source that meets each of the

following guidelines:

c Must supply a minimum of 85PSI [586kPa].

c The supply must never exceed 105PSI [724kPa].

c The Air source should have a tank capacity that enables it to

actuate the Air Locker(s) in one charge so that no hesitation

is experienced when locking one or two differentials.

HINT : A good way to insure that you have the necessary

capacity is to make sure you can engage, disengage,

and then reengage your Air Locker(s) without the air

source having to regenerate (e.g., without the

compressor turning on to refill the tank).

c Must supply clean air, free of rust, dirt, water, or other foreign

matter.

c Must match the 1/8” BSP porting of the Air Locker solenoid.

c Mount solenoid within close proximity of the air supply and secure it

from the effects of vibration and shock.

c Connect the air supply to the 1/8” BSP inlet port of the solenoid

(stamped “1” on the solenoid body) using thread sealant.

IMPORTANT :

ARB cannot warrant your Air Locker(s) against damage caused

as a result of using an alternate air supply. If you have any

doubts as to the suitability of your air system to use in an Air

Locker system, consult your ARB distributor.

31

Page 34

4 Installing the Air System

4.2 Running and Securing the Air Line

The path taken by the air line from your air source (i.e., compressor) to

your Air Locker is unique to your vehicle and the position of your air

source. Plan ahead carefully when running the air line and always

follow these guidelines:

c Account for axle travel when running the line from the axle to a

fixed point on the vehicle. Leave enough slack in the air line to

allow for maximum suspension travel in both directions.

(Not necessary on IFS installations)

c Avoid leaving large lengths of air line hanging underneath the

vehicle where they may get tangled on rocks, sticks, etc.

HINT : Cable tying the air line to one of your flexible brake

lines will account for axle travel and should help keep

your line from getting snagged.

c Run the air line all the way from the compressor to the differential

before trimming either end of the line to length. This will save

complications that may arise if the air line has to be removed.

c Make sure the line does not contact sharp edges or abrasive

surfaces that may damage the air line over time.

c Do not run the air line around tight bends which may kink the air

line and restrict or block the air flow.

c Keep the air line well away from your vehicle’s exhaust

components. Air lines will melt if subjected to extreme heat.

c Do not run more air line than necessary. Excess line volume

created when coiling the left over hose, using unusually large

diameter hose, etc., will increase drain on the compressor tank

resulting in the compressor running more often than needed.

c Support the air line by tying it back with cable ties wherever

possible.

c At the solenoid end of the air line, always trim the line to length with

a sharp knife to avoid distorting the tube where it plugs into the

push-in fitting.

NOTE : To remove the air line from the push-in fitting; while

holding the flange of the fitting out, push the air line

into the fitting as far as possible, then press the flange

inward, then pull the air line free of the fitting.

32

Page 35

4 Installing the Air System

c To attach the air line to the push-in fitting of the solenoid; insert the

line firmly into the fitting, pull outward on the flange of the fitting

while holding the line as far into the fitting as possible, and then

gently pull outward on the air line to clamp the line in place.

4.3 Connection to the Bulkhead Fitting

c In the case of an IFS axle assembly or in the case that the axle

assembly has been completely removed from the vehicle, the

assembly will have to be remounted in order to position the

bulkhead fitting in its correct location for air line access.

c Trim the air line to length using a sharp knife.

c Insert the support spring over the end of the air line - small end first.

(Fig.25.)

c Insert the outer compression nut over the air line.

c Insert the 5mm [0.197”] ferrule over the end of the air line. Leave

approx. 5mm of tubing between the ferrule and the end of the tube.

Figure 25.

c Insert the support tube all the way into the end of the air line.

33

Page 36

4 Installing the Air System

HINT : If the support tube is too difficult to insert, place the

end of the air line into a cup of boiled water to soften

the tubing.

c Insert the tube end all the way into the center compression nut.

c Screw on the outer compression nut and tighten. The ferrule and

support tube are now permanently attached.

c Assemble the support spring over the outside of the outer

compression nut.

c Secure any loose sections of tube with a cable tie.

34

Page 37

5 Mounting & Connecting the Electrical System

5.1 Mounting the Actuator Switch(es)

Air Locker actuator switch(es) can be easily panel mounted inside the

vehicle in a 21mm x 36.5mm [0.83” x 1.44”] rectangular cutout.

NOTE : Only attach the cover plate to the face of the switch

once the switch has been mounted and wired correctly

as the cover plates are designed to be difficult to

remove.

For reasons of safety and for ease of operation, the Air Locker

actuator switch(es) should be mounted in a location picked to best suit

the operator. Make sure you have taken the following points into

consideration:

c Switch(es) MUST be mounted and should never be allowed to

simply dangle from the wiring loom during vehicle use.

c Switch(es) should be within easy reach of the driver. Ideally, any

Air Locker switch should be able to be operated without physical

effort or distraction to the driver.

c Switch(es) should be mounted within the line of sight of the driver

so that switch position (‘ON’ or ‘OFF’) can be visually determined

by the rocker position and the illumination state.

c The position of the switch(es) should best eliminate any possibility

of accidental operation by the driver or one of the passengers.

c Switch cutout position(s) must be located in an area with a

minimum of 50mm [2”] of clearance behind the face of the cutout.

c Switch(es) should not be mounted where they will be exposed to

water (e.g., in the lower section of an inner door panel).

c ARB recommends that you apply the Air Locker Warning Sticker

(ARB part # 210101) within close visual proximity of the switch

location.

NOTE : If no adequate position can be found on existing

dashboard panels, a surface mounted bracket

(Fig. 26.) may be purchased from your ARB Air Locker

distributor to suit 1, 2, or 3 switches.

35

Page 38

5 Mounting & Connecting the Electrical System

Figure 26.

5.2 Wiring the Actuator System

5.2.1 Connection to an ARB Air Compressor

When wiring the Air Locker actuator switch(es) and solenoid(s) to an

ARB Air Compressor, all connections can easily be set up directly from

the supplied wiring loom. (Fig. 27.)

NOTE : Refer to your ARB Air Compressor Installation Guide

for details on configuring your installation.

36

Page 39

5 Mounting & Connecting the Electrical System

IDENTIFICATION

ARB AIR COMPRESSOR WIRING LOOM

Figure 27.

SWITCH

TERMINAL

Figure 28.

UP

37

Page 40

5 Mounting & Connecting the Electrical System

5.2.2 Connection to an Alternate Air Source

When connecting the actuation switch to an alternate air source, the

switch(es) should be wired according to figures 29. and 30., depending

on whether one or two Air Lockers will be installed in the vehicle.

5.2.2.1 Single Air Locker System

c If only one Air Locker is to be installed in the system, the switch and

solenoid should be wired according to figure 29. regardless of

whether the Air Locker has been installed in the front or rear axle of

the vehicle.

c Attach the appropriate switch cover (i.e., ‘FRONT’ or ‘REAR’) to

the switch.

NOTE : Refer to Figure 28. for the correct switch terminal

identification and switch orientation.

SINGLE Air Locker SYSTEM

Figure 29.

38

Page 41

5 Mounting & Connecting the Electrical System

DUAL

SYSTEM

5.2.2.2 Dual Air Locker System

c If two Air Lockers are to be installed in the system, ARB

recommends that the switches and solenoids be wired according to

figure 30. For safety reasons, this configuration allows SOLENOID

2 to be actuated only if SOLENOID 1 is already on.

c Attach the “REAR AIR LOCKER” switch cover to SWITCH 1, and

the “FRONT AIR LOCKER” switch cover to SWITCH 2.

NOTE : Refer to Figure 28. for the correct switch terminal

identification and switch orientation.

c Configure SOLENOID 1 as the air line leading to the rear axle Air

Locker, and SOLENOID 2 as the air line leading to the front axle Air

Locker.

Air Locker

Figure 30.

39

Page 42

6 Testing & Final Assembly

6.1 Leak Testing

c With the vehicle parked and the engine off, turn the compressor on

and wait until the air system is fully charged.

NOTE : With the Air Locker(s) disengaged, the air source (i.e.,

compressor) should not have to recharge over time.

Intermittent recharging without Air Locker use usually

indicates a leak at the solenoid fittings or at the

c Actuate the Air Locker(s).

c The compressor should not come on again for a period of at least

15min. Air system recharging within that time period would indicate

that a leak is present in the system.

NOTE : If an alternate air source (e.g., an air cylinder or a belt

c If a leak is found to be present, spray a soap and water mixture

onto all air fittings in the system while the compressor is fully

charged. Bubbles should appear at any leak points.

compressor tank O-ring seal.

driven air pump) is used instead of a compressor, the

air system will have to be leak tested with a pressure

gauge and a shut-off valve in series before the

solenoid input.

c Check that leaky fittings have been adequately tightened.

c Disassemble, clean threads, and reapply thread sealant if leaking

persists.

6.2 Reinstalling the Axles

c Insert both axles fully into the housing and gently tap them inward.

NOTE : Be careful not to damage the axle oil seals with the

spline of the axle.

c Reconnect the drive shaft to the differential drive flange.

c Reassemble the remainder of the differential assembly

(e.g., hubs, brakes, wheels, etc.) to the vehicle according to your

vehicle’s service manual.

40

Page 43

6 Testing & Final Assembly

6.3 Testing the Air Locker Actuation

To test that your air system, electrical system, and your Air Locker

differential is functioning correctly:

c Support the vehicle such that the wheels are free to rotate (e.g., on

axle stands, a chassis hoist, etc.)

c Leave the parking brake off, the transmission in neutral, and the Air

Locker switch ‘OFF’.

c Turn the ignition to the ‘ON’ position (leaving the motor off). The

large illuminating symbol on the Air Locker switch cover should be

‘OFF’.

c Turn the compressor (or alternate air source) on to charge the air

supply up to its maximum pressure.

c While supporting the drive shaft flange, rotate one wheel by hand.

c The wheel should rotate freely and the opposite wheel should be

turning in the opposite direction without any resistance or

mechanical noise from within the differential.

c Turn the Air Locker switch to the ‘ON’ position. The illuminated

symbol on the switch cover should light up.

c Rotate the same wheel again.

c Both wheels should rotate together.

c Turn the switch off again.

c Rotate the same wheel.

c The wheels should again rotate in opposite directions.

6.4 Re-Sealing & Filling the Differential

NOTE : Consult the ARB Air Locker Operating & Service

Manual for recommendations on differential lubricant

specifications.

c Replace the differential cover using gasket sealant or a new

standard differential cover gasket for your make of vehicle.

c Refill the differential until level with the filler hole.

c Rotate the differential center 2 full turns.

c Check the oil level and add oil if necessary.

c Replace filler plug (apply thread sealant to filler plug before

inserting if it is a threaded type plug).

c Wipe differential housing clean of any oil or grease which may

collect dirt or other abrasive particles.

41

Page 44

6 Testing & Final Assembly

6.5 Post-Installation Check List

Now that the Air Locker installation has been completed, ARB

recommends that you take the time to complete the following check list

just to insure that you haven’t missed any of the vital steps.

c The air system has been leak tested.

c Thread locking compound was used on the ring gear bolts.

c All torque settings comply with the vehicle manufacturer’s specs

and were set with an accurate torque wrench.

c Differential fluid complies with ARB recommendations and has

been filled to the correct level.

c All air lines and wiring have been securely cable tied to resist

snagging.

c Switch(es) have been securely mounted within operator reach, yet

well away from danger of accidental engagement.

c Switch(es) function properly and illuminate to indicate that Air

Locker(s) are engaged.

c All operators who are to use the Air Locker have read, and fully

understand the ARB Air Locker Operating & Service Manual.

c The Air Locker Warning Sticker has been located within close

proximity of the actuator switch(es).

INSTALLATION PERFORMED BY:

DATE OF INSTALLATION:

ODOMETER READING:

ARB AIR LOCKER SERIAL No:

___________________________

___________________________

___________________________

___________________________

42

Page 45

7 Parts List

7.1 Exploded Assembly Diagram

(See itemized parts list overleaf)

Figure 31.

43

Page 46

7 Parts List

7.2 Itemized Parts List

(See exploded diagram figure 31.)

AIR LOCKER MODEL No. : RD104

ITEM # QTY

01 2 SEAL HOUSING O-RING 160235

02 1 SEAL HOUSING ASSEMBLY 081801

03 2 SHIM KIT SHK003

04 1 BONDED SEAL 160701

05 1 CLUTCH GEAR 050803

06 1 SPIDER BLOCK 070503

07 1 LONG CROSS SHAFT 061302

08 1 SIDE GEAR 131503H

09 2 COUNTERSUNK SCREW 200213

10 3 CROSS SHAFT RETAINING PIN 120601

11 2 TAPERED ROLLER BEARING 160109

12 1 FLANGE CAP ASSEMBLY 023502

13 8 RETURN SPRING 150107

14 1 SPLINED SIDE GEAR 131603H

15 2 SHORT CROSS SHAFT 061402

16 4 PINION GEAR 140801H

17 4 PINION THRUST WASHER 151112

18 2 SIDE GEAR THRUST WASHER 151011

19 1 DIFFERENTIAL CASE 013102

* 1 BULKHEAD KIT,O-RING TYPE,3.5-5mm 170105

* 1 PUSH-IN FITTING,5mm (R1 5 1/8”) 170201

* 1 AIR LINE (5mm DIA X 6m LONG) 170301

* 1 NIPPLE, 1/8” BSP,MALE TO MALE 170501

* 1 SOLENOID VALVE 180103

* 1 ACTUATOR SWITCH 180209

* 1 SWITCH COVER (FRONT) 180210

* 10 CABLE TIE 180301

* 1 WARNING LABEL 210101

* 1 BUMPER STICKER 210102

* 1 OPERATION & SERVICE MANUAL 210200

* 1 INSTALLATION GUIDE 2102104

* Not illustrated in exploded view.

DESCRIPTION PART #

44

Loading...

Loading...