AquaPRO WIP100PRO, WIP150PRO User Manual

GARANTÍA LIMITADA

Durante 1 (uno) año a partir de la fecha de compra, Wayne Water Systems, cuyo nombre comercial es Aqua Pro Systems

(“AquaPro”), reparará o reemplazará para el comprador original, según lo que decida, cualquier pieza o piezas de su Juego

para estanque, Bombas de resumideros, Bombas de agua (“Producto”) que después de un examen Wayne encuentre que

tenían defectos en su material o mano de obra.

Sírvase llamar a AquaPro al 1-877-AQUASYS (1-877-278-2797) para obtener instrucciones. Esté listo para proporcionar

los números de modelo y de serie cuando ejerza el derecho a esta garantía limitada.

El comprador deberá pagar todos los cargos de transporte de los Productos o piezas enviadas para reparación o cambio.

Todos los cargos por servicios no incluidos en esta garantía corren por cuenta del comprador original. El no pago de los cargos

de servicios que no pertenecen a la garantía anularán esta Garantía limitada.

Esta Garantía Limitada no cubre productos que estén dañados debido a accidentes, congelación, abuso, uso indebido,

negligencia, instalación incorrecta, mantenimiento inadecuado, o no hacerlo funcionar según las instrucciones escritas

de Aqua Pro. Todo el mantenimiento y servicio deberá ser realizado por parte de agentes de servicio aprobados por AquaPro.

Cualquier modificación o reparación no autorizada anulará esta Garantía limitada.

NO EXISTE OTRA GARANTÍA EXPRESA. LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO AQUELLAS DE

COMERCIALIZACIÓN Y APTITUD PARA UN PROPÓSITO EN PARTICULAR, ESTÁN LIMITADAS A 1 (UN) AÑO A PARTIR

DE LA FECHA DE COMPRA. ÉSTE ES EL RECURSO EXCLUSIVO Y SE EXCLUYE CUALQUIER RESPONSABILIDAD POR

TODO Y CUALQUIER DAÑO INDIRECTO O CONSECUENTE O GASTOS AFINES.

Algunos estados no permiten limitaciones sobre la duración de las garantías implícitas o no permiten la exclusión ni la

limitación de daños incidentales o consecuentes, por lo tanto es posible que las limitaciones anteriores no se apliquen en su

caso. Esta garantía limitada le proporciona derechos legales específicos, y también puede tener otros derechos legales que

varían de un estado a otro.

Bajo ningún concepto, ya sea por incumplimiento del contrato de garantía, incumplimiento extracontractual (incluyendo

negligencia) u otro, AquaPro o sus proveedores serán responsables de ningún daño especial, consecuente, incidental o penal,

incluyendo, pero sin limitarse a pérdida de ganancias, pérdida de uso del producto o cualquier equipo asociado, daños al

equipo asociado, costo de capital, costo de productos sustitutos, instalaciones, poderes de servicio o reemplazo, costos de

inutilidad, o reclamos de clientes del comprador por dichos daños.

Usted DEBE conservar su recibo de compra junto con este formulario. En caso de que necesite hacer ejercicio de un reclamo

dentro de la garantía, DEBERÁ presentar una copia del recibo de compra en el momento del servicio. Sírvase llamar

a AquaPro Systems al 1-877-278-2797 para solicitar servicio o una autorización de devolución e instrucciones.

NO ENVÍE ESTE FORMULARIO POR CORREO A AQUAPRO. Utilice este formulario para mantener un registro.

MODELO Nº.________________ Nº DE SERIE _______________ FECHA DE INSTALACIÓN _______________

ANEXE SU RECIBO AQUI

Manual de Instrucciones de Operación y Piezas

Bombas para piscinas enterradas

16 Sp

Pool Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

© 2006

Operating Instructions and Parts Manual WIP100PRO, WIP150PRO

instructions could cause serious

bodily injury and/or property damage.

To reduce the risk

of injury, do not

permit children to use this product

unless they are closely supervised at

all times.

This pump is for

use with permanently installed pools. Do not use with

storable pools. A permanently installed

pool is constructed in or on the ground

or in a building such that it cannot be

readily disassembled for storage. A

storable pool is constructed so that it

may be readily disassembled for storage and reassembled to it’s original

integrity.

Pump

only clear water. Do not

pump flammable or explosive fluids such as gasoline,

fuel oil, kerosene, etc. Do not use in a

flammable and/or explosive atmosphere. Personal injury and/or property

damage could result.

All

wiring must be performed

by a qualified electrician.

The pump must be installed

in compliance with all local codes and

the National Electrical Code.

2. Do not install within an outer

enclosure.

Pump suction is

hazardous and can

trap and drown or disembowel

bathers. Do not use or operate swim-

ming pools or spas if a suction outlet

cover is missing, broken, or loose. New

pools are being constructed with antientrapment devices and/or multiple

drains to prevent entrapment. If you

have any doubts about your pool, consult with your local ASPS/NSPI pool

professional about anti-entrapment

protection.

321700-013 3/06

Installation

LOCATION

Disconnect, tag and lock

out power source before

attempting to install, service, relocate or perform any maintenance.

Locate pump as close to pool/spa as

possible. Install the pump on a hard,

level surface that is dry, well ventilated

and away from direct sunlight. The surrounding area should provide protection from the elements and ample

room for maintenance and service.

Ensure the drainage will flow away

from the pump.

Inground pool pumps are self-priming. Mount pump below water level for

easy priming. If the pump must be

located above the filled water level,

keep the vertical distance to a minimum.

GENERAL PLUMBING

SOLVENT WELD CONNECTIONS

Use rigid or flexible PVC pipe. Ensure

pipe ends are clean and free of any

flash caused by the cutting operation.

Use the proper adhesive for the type of

pipe specified.

Description

This swimming pool pump is designed

for use with permanently installed

pools only.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or components are damaged, return the unit

to the place of purchase for replacement. Failure to do so could result in

serious injury or death.

Danger indicates

an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause

damage to equipment.

This manual contains information that

is very important to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the

following:

1. Read these rules and

instructions carefully.

Failure to follow these

READ &

FOLLOW ALL

INSTRUCTIONS

SAVE THESE

INSTRUCTIONS – DO

NOT DISCARD

IMPORTANT

SAFETY

INSTRUCTIONS

PVC - PVC Joint PVC - ABS Joint

Uni-Weld Uni-Weld

Pool-Tite 2000 Pool-Tite 2000

Suregard Flex 20 Suregard Weld

All No. 5

IPS Weld-On 705 IPS Weld-On 794

*

These recommendations are examples only

and are not intended to restrict brands

RECOMMENDED ADHESIVES*

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

!

WARNING

!

DANGER

!

WARNING

!

CAUTION

NOTICE

MANUAL

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

DANGER

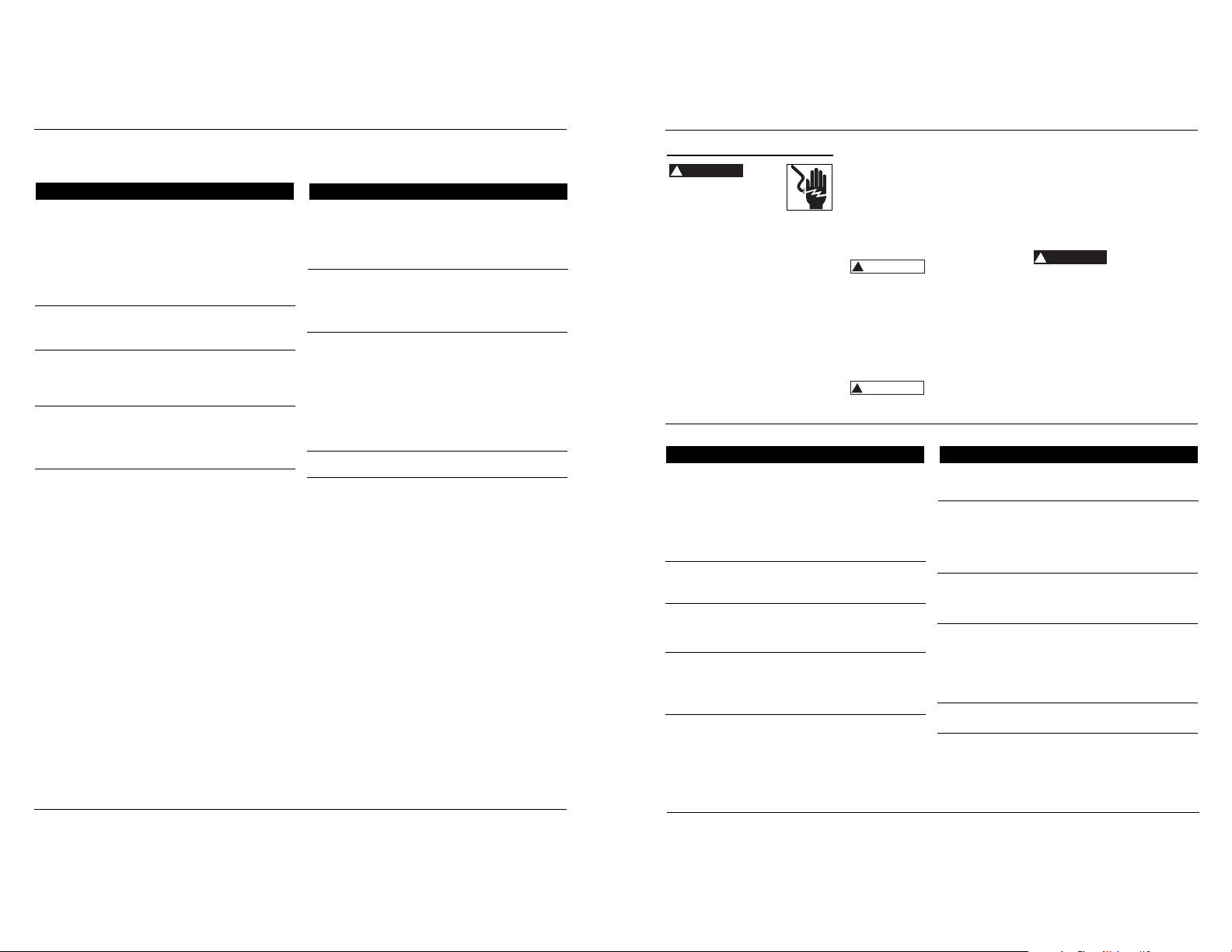

Manual de Instrucciones de Operación y Piezas

Para Piezas de Repuestos, Llame al 1-877-278-2797

Sírvase proporcionar la suguiente información:

- Número de modelo

- Número de serie (si tiene)

- Descripción y número de repuesto como se muestra

en la lista de repuestos

Envíe su solicitud de repuestos a la siguiente direccion:

AquaPro Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

3

2

1

1 Juego de la bomba 69004-001 69005-001 1

2 Juego del sello del eje 21009-001 21009-001 1

3 Juego del motor 69000-001 69001-001 1

4 Tapa del cuerpo

de la bomba 28563-001 28564-001 1

5 Cesta filtrante

(no se muestra) 28565-001 28566-001 1

No. de

Ref. Descripción WIP100PRO WIP150PRO Ctd.

4

Notas

15 Sp

2

Operating Instructions and Parts Manual

Installation (Continued)

NOTE: Use an adhesive primer to

ensure adhesive joints are secure.

Suregard P-3000 has a purple tracer to

qualify in areas where codes specify a

primer must be used.

Consider climatic conditions when

applying adhesives. Atmospheric conditions with high humidity will make the

adhesive action of certain glues less

effective. Follow the manufacturer’s

instructions.

THREADED CONNECTIONS

Use only Teflon

®

tape or equivalent on

threaded plumbing connections. Other

pipe compounds may damage threads.

Do not use silicone or petroleum based

compounds. Do not overtighten. Hand

tightening plus 1/2 turn is sufficient.

PUMP PLUMBING

Suction pipe should be as large or larger

than discharge pipe. Avoid using a suction pipe smaller than pump connection.

1. Keep the piping as straight and

short as possible, and of suitable

size.

2. Do not connect an elbow directly

into the pump inlet. A length of

straight pipe will allow proper entry

of the water to the pump.

3. Slope horizontal runs upward to the

pump to prevent trapping air.

4. Use independent piping supports to

alleviate strain on the pump.

5. Keep as much of the suction line as

possible below the water level to

reduce priming time.

6. Install valves and unions in the

pump suction and return lines to

facilitate servicing. Valves will throttle the pump discharge. Valves are

also essential for pump maintenance if the system is installed

below deck level.

7. Use a check valve in the suction pipe

for inground pumps at or below the

water level if the suction lift is more

than 5 feet or the dry suction is

more than 10 feet long. Keep the

valve in the suction line fully open

during operation.

WIRING

All

wiring must be performed

by a qualified electrician.

The pump must be installed

in compliance with all local codes and

the National Electrical Code.

When motor installation is within 5 ft.

(1.5 m) of the pool’s interior walls, a

solid copper bonding conductor (minimum size No. 8 AWG/8.4 mm

2

) should

be connected from the accessible wire

connector on the motor.

• to all metal parts of the swimming

pool

• to all electrical equipment

• to metal conduit

• to metal piping within 5 ft. (1.5 m)

of the pool’s interior walls

Refer to information on motor nameplate for electrical service data. Install

motors with a fused disconnect switch

or dedicated circuit breaker. Be sure

wire size is sufficient for pump HP and

distance from power source. Install a

ground fault circuit interrupter for

maximum safety.

Disconnect, tag,

and lock out power

source before attempting to install, service, relocate, or perform any maintenance.

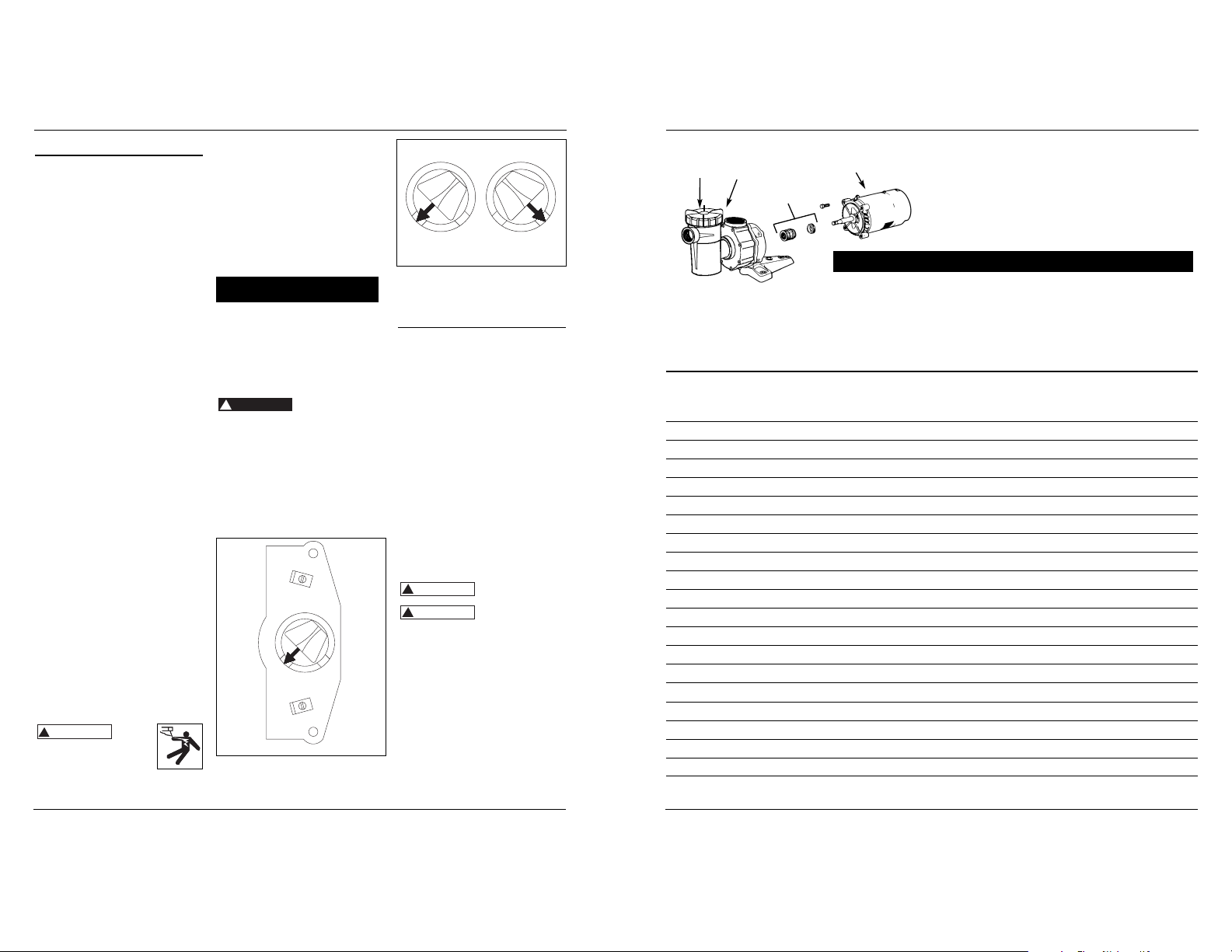

VOLTAGE SELECTOR

This pump is factory wired for 230 volts.

To change the voltage to 115 volts follow the steps below:

1. Disconnect the pump from power.

2. Remove cover from back of motor

to find voltage selector (Figure 1a).

3. Pull selector knob out.

4. Rotate selector knob to correct volt-

age setting (Figure 1b).

5. Push selector knob back in place.

6. Reinstall cover to back of motor.

Operation

Prime pump before attempting to operate. To prime pumps located above water

level, remove strainer cover, fill strainer

body with water then replace cover. If

pump and all piping is located below

water level, the pump will self prime.

After pump has been primed, open all

suction and discharge line valves and

energize motor. If no flow is observed

in five minutes, stop the motor and

reprime. If the pump fails to operate,

check for air leaks. Refer to troubleshooting section.

After about 10 minutes of operation,

check the return fittings for air bubbles.

A continuous flow of air indicates leaks

in the suction line. Locate and correct

any leaks immediately.

CONTROLLING PUMP DISCHARGE

Keep the gate valve in the suction line

fully open during operation. To control

the discharge, use a valve in the return

line.

Do not retighten lid

during operation.

Do not operate

pump with closed

suction or discharge valve.

WATER CHEMISTRY

Proper and consistent use of chemicals

is necessary to manage a water system.

Chlorine is the most commonly used

chemical to provide clean, sanitary

water. Daily administration of dry or

liquid chlorine (calcium or sodium

hypochlorite) is essential.

IMPORTANT: Maintain the correct

level of acidity or alkalinity of the pool

water. Readings above pH 7.0 are alkaline. A pH 7.0 is neutral. Readings

below pH 7.0 are acidic. A desirable

range is 7.2 to 7.4.

IMPORTANT: Use copper

conductors only.

Figure 1a

LO

Volt

HI

115 Volts

115 Volts

230 Volts

Volt

LO

HI

Figure 1b

230 Volts

!

WARNING

!

DANGER

L1

LO

L2

HI

Volt

LO

Volt

HI

LO

Volt

HI

!

CAUTION

!

CAUTION

14 Sp

Manual de Instrucciones de Operación y Piezas

Guía de Diagnóstico de Averías

Problema Posible(s) Causa(s)

El motor no

enciende

El motor no llega a

la máxima velocidad

El motor se

recalienta

(el protector

se acciona)

La bomba no

entrega agua

Baja capacidad de la

bomba

1. Desconecte el interruptor o disyuntor

en la posición de apagado (OFF)

2. Hay fusibles quemados o sobrecarga

térmica abierta

3. El eje del motor está bloqueado

4. El bobinado del motor está quemado

5. El interruptor de arranque dentro del

motor monofásico está defectuoso

6. El cableado está desconectado o

defectuoso

7. Bajo voltaje

1. Bajo voltaje

2. El bobinado del motor está conectado

para el voltaje incorrecto en el modelo

de doble voltaje

1. Bajo voltaje

2. El bobinado del motor está conectado

para el voltaje incorrecto en el modelo

de doble voltaje

3. Ventilación inadecuada

1. La bomba no está cebada

2. La válvula de la línea de succión

o descarga está cerrada

3. Hay una pérdida o aire en el sistema

de succión

4. El impulsor está obstruido

1. La válvula en la línea de succión

o descarga está parcialmente cerrada

2. La línea de succión o descarga está

conectada parcialmente

3, La línea de succión o descarga es

demasiado pequeña

4. La bomba funciona a una velocidad

reducida (ver anterior)

5. Cesta tapada en el recolector de

residuos o pelo y pelusa en el filtro

6. El filtro está sucio

7. El impulsor está obstruido

1. La bomba funciona a una velocidad

reducida (ver anterior)

2. Rotación equivocada (sólo modelos

trifásicos)

3. La válvula de descarga o las

conexiones de entrada están

demasiado abiertas

1. La válvula de descarga o las

conexiones de entrada están

demasiado cerradas

2. Las líneas de retorno son demasiado

pequeñas

3. El filtro está sucio

1. Cesta tapada en el recolector de

residuos o pelo en el filtro de pelusa

2. Los rodamientos del motor están

gastados

3. La válvula en la línea de succión está

parcialmente cerrada

4. La línea de succión está conectada

parcialmente

5. La manguera de vacío está conectada

o es demasiado pequeña

6. La bomba no está sostenida

adecuadamente

Se debe reemplazar el sello del eje

1. Hay una pérdida de aire en la línea de

succión en las conexiones o vástago de

la válvula

2. Debe limpiar la junta de la cubierta

alrededor del filtro de pelo y pelusa

3. Hay una restricción en la línea de

succión

4. El nivel de agua en la piscina es bajo

Baja presión de la

bomba

Alta presión de la

bomba

Bomba y motor

ruidosos

Pérdida de agua en

el eje

Burbujas de aire en

las conexiones de

entrada

Problema Posible(s) Causa(s)

plumbing lines as this can cause an

explosion.

NOTE: For a skimmer, take care to

drain and make sure that water does

not accumulate and freeze inside the

skimmer.

Add Pool Antifreeze to the plumbing

lines and then cap the line at the fill

point.

Do not use

automotive or any

other non-pool approved antifreezes as

these are toxic. They may damage your

pool equipment also.

Pour in winterizing chemicals to

remaining pool water according to

chemical manufacturer’s recommendations. Cover pool. If you have any

questions, consult with your local

APSP/NSPI pool professional or call

AquaPro Systems at 1-877-278-2797.

3

Operating Instructions and Parts Manual

Maintenance

Disconnect, tag and lock

out power source before

attempting to install, service, relocate or perform any maintenance.

1. Motors are self-lubricating - no

additional lubrication is required.

2. Clean pool pump strainer of hair

and lint.

3. Visually inspect motor for blockage

of air vents on motor shell. Remove

any debris after shutting off breaker.

4. Replace worn shaft seals.

HAIR AND LINT STRAINER

1. Switch off the power.

2. Close the valves in the suction and

return line.

3. Turn lid counter-clockwise and

remove.

4. Lift strainer basket away from the

pump.

5. Clean and reposition the basket

into the pump. Take care to seat

the basket properly.

6. Clean the o-ring and relubricate

with petroleum jelly if necessary.

7. Clean o-ring seats on the cover and

strainer.

8. Refit the lid; hand tighten only.

9. Open the valves to return pump to

operation.

Do not retighten lid

during operation.

WINTERIZING

To prevent stains, clean pool of all dirt

and debris. Drain pool two to three

inches below the return lines. Drain filter, pump, heater, and any other pool

accessories according to their owner’s

manual instructions. Blow all of the

water out of the plumbing lines and

“cap” the lines at the pool.

Do not use air

pressure greater

than 10 psi to blow water out of the

Troubleshooting Chart

Symptom Possible Cause(s)

Motor does not

start

Motor does not

reach full speed

Motor overheats

(protector trips)

Pump does not

deliver water

Low pump capacity

1. Disconnect switch or circuit breaker

in OFF position

2. Fuses blown or thermal overload open

3. Locked motor shaft

4. Motor windings burned out

5. Defective starting switch inside single-phase motor

6. Disconnected or defective wiring

7. Low voltage

1. Low voltage

2. Motor windings connected for wrong

voltage on dual voltage model

1. Low voltage

2. Motor windings connected for wrong

voltage on dual voltage model

3. Inadequate ventilation

1. Pump is not primed

2. Closed valve in suction or discharge

line

3. Leakage or air into suction system

4. Impeller clogged

1. Valve in suction or discharge line

partly closed

2. Suction or discharge line partly plugged

3, Suction or discharge line too small

4. Pump running at reduced speed (see

previous)

5. Plugged basket in skimmer or hair

and lint strainer

6. Dirty filter

7. Impeller clogged

1. Pump running at reduced speed (see

previous)

2. Wrong rotation (three phase models

only)

3. Discharge valve or inlet fittings

open too wide

1. Discharge valve or inlet fittings

closed too much

2. Return lines too small

3. Dirty filter

1. Plugged basket in skimmer or hair in

lint strainer

2. Worn motor bearings

3. Valve in suction line partly closed

4. Suction line partly plugged

5. Vacuum hose plugged or too small

6. Pump not supported properly

Shaft seal requires replacement

1. Leakage of air into suction line at

connections or valve stem

2. Cover gasket around hair and lint

strainer needs cleaning

3. Restriction in suction line

4. Low water level in pool

Low pump capacity

(continued)

Low pump pressure

High pump pressure

Noisy pump and

motor

Leakage of water

at shaft

Air bubbles at inlet

fittings

Symptom Possible Cause(s)

!

DANGER

!

CAUTION

!

WARNING

!

DANGER

Loading...

Loading...