AquaPRO PRO1300, PRO1100e TCE, PRO1300h-c, PRO1100e, PRO1300h-c TCE User Manual

...

HEAT PUMP POOL HEATER

BOMBA DE CALOR PARA PISCINAS

PRO1100, PRO1100e, PRO1300, PRO1300h/c, PRO1100e TCE, PRO1300 TCE, PRO1300h/c TCE

101 Production Drive, Harrison, OH 45030 877.278.2797 fax 877.289.2963

cs@aquaprosystems.com www.aquaprosystems.com

OWNER’S MANUAL MANUAL DEL USUARIO

.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions with owner for future reference.

Important Safety Instructions . . . . . . 1

Installation Procedures . . . . . . . . . 1 - 2

Unit Inspection . . . . . . . . . . . . . . . . 1

Unit Location . . . . . . . . . . . . . . . . . 2

Plumbing . . . . . . . . . . . . . . . . . . . . . 2

Basic Heat Pump Operation . . . . . 2 - 3

Electrical Connections . . . . . . . . 2 - 3

Electronic Temp. Controls . . . . . . . . 3

- Description . . . . . . . . . . . . . . . . . 3

- Buttons . . . . . . . . . . . . . . . . . . . . 3

- Water Temp. Set Point . . . . . . . . 3

Connecting to a Remote System. . .3

High Temperature Lock Out . . . . . . 3

SPECIFIC MODEL DETAILS

PRO1100 . . . . . . . . . . . . . . . . . . . . . 4

Wiring Diagram . . . . . . . . . . . . . . . . 4

Manual Temp. Controls . . . . . . . . . 4

PRO1300 & PRO1100e . . . . . . . . . 5

Wiring Diagram . . . . . . . . . . . . . . . . 5

PRO1300h/c . . . . . . . . . . . . . . . . 5 - 6

Wiring Diagram . . . . . . . . . . . . . . . . 5

Toggling Between Heat/

Cool Mode . . . . . . . . . . . . . . . . . . . 6

Defrost Cycle . . . . . . . . . . . . . . . . . . 6

PRO1300 TCE/ PRO1100e TCE. . . . 6 - 7

Selecting Functionality of Unit . . . . 6

TCE Operation . . . . . . . . . . . . . . . . . 6

TCO Operation . . . . . . . . . . . . . . 6 - 7

Wiring Diagram . . . . . . . . . . . . . . . . 7

PRO1300h/c TCE . . . . . . . . . . . . 8 - 9

Wiring Diagram . . . . . . . . . . . . . . . . 8

Toggling Between Heat/

Cool Mode . . . . . . . . . . . . . . . . . . . 8

Defrost Cycle . . . . . . . . . . . . . . . . . . 8

Selecting Functionality of Unit . . . . 8

TCE Operation . . . . . . . . . . . . . . 8 - 9

TCO Operation . . . . . . . . . . . . . . . . 9

Application Guidelines . . . . . . . . 9 - 10

Maintenance . . . . . . . . . . . . . . . . . . 9

Condensation . . . . . . . . . . . . . 9 - 10

Pool Blankets . . . . . . . . . . . . . . . . 10

Seasonal Shutdowns . . . . . . . . . . 10

Pool Openings . . . . . . . . . . . . . . . 10

Weather Conditions . . . . . . . . . . . 10

Troubleshooting Guide . . . . . . . 10 - 11

- Diagnostics . . . . . . . . . . . . . 10 - 11

Warranty . . . . . . . . . . . . . . . . . . . . . . 12

322902-013 2/08

© 2008 AquaPRO®Systems

For parts, product & service information

visit www.aquaprosystems.com

Important Safety

Instructions

READ AND FOLLOW ALL

INSTRUCTIONS.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Warning

indicates a

potentially hazardous situation which, if

not avoided, could result in death or

serious injury.

Caution

indicates a

potentially hazardous situation which, if

not avoided, may result in minor or

moderate injury.

Notice

indicates

important information, that if not

followed, may cause damage to

equipment.

CALIFORNIA PROPOSITION 65

This

product or

its power cord may contain chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

GENERAL SAFETY INFORMATION

• The water in a pool or tub should never

exceed 104ºF (40ºC). A water

temperature in excess of 104ºF is

considered unsafe for all persons. Lower

water temperatures are recommended

for extended use (exceeding 10 - 15

minutes) and young children.

• Excessive water temperatures have a

high potential for causing fetal damage

during the early months of pregnancy.

Pregnant or possibly pregnant women

should limit pool or tub water

temperatures to 100ºF (38ºC).

• Alcohol, drugs, or medication should

not be used before or during pool or

tub use since their use may lead to

unconsciousness with the possibility

of drowning.

• Obese persons and persons with a

medical history of heart disease, low or

high blood pressure, circulatory system

problems, or diabetes should consult a

physician before using a pool or tub.

• Persons using medication should

consult a physician before using a pool

or tub since some medication may

induce drowsiness while other

medication may affect heart rate,

blood pressure, and circulation.

• Prolonged immersion in hot water may

induce hyperthermia. Hyperthermia

occurs when the internal temperature

of the body reaches a level several

degrees above the normal body

temperature of 98.6ºF. The symptoms

of hyperthermia include dizziness,

fainting, drowsiness, lethargy, and an

increase in the internal temperature of

the body. The effects of hyperthermia

include: unawareness of impending

hazard; failure to perceive heat; failure

to recognize the need to exit pool or

tub; physical inability to exit pool or

tub; fetal damage in pregnant women;

and unconsciousness resulting in a

danger of drowning.

• Because the tolerance of water

temperature-regulating devices may

vary as much as ±5ºF (±3ºC), you

should measure the water

temperature at several locations

using an accurate thermometer

before entering a pool or tub.

SAVE THESE INSTRUCTIONS.

Installation Procedures

Unit Inspection

Inspect your unit very carefully before

installing. Make sure there has been

no damage to the evaporator fins or

there are no punctures or oil-soaked

areas on the box. This would indicate

damage to the refrigeration system

and should be rejected immediately.

Contents

Heat Pump

Pool and Spa Heater

Operating Instructions

PRO1300, PRO1100e, PRO1300h/c, PRO1100,

PRO1300h/c TCE, PRO1300 TCE, PRO1100e TCE

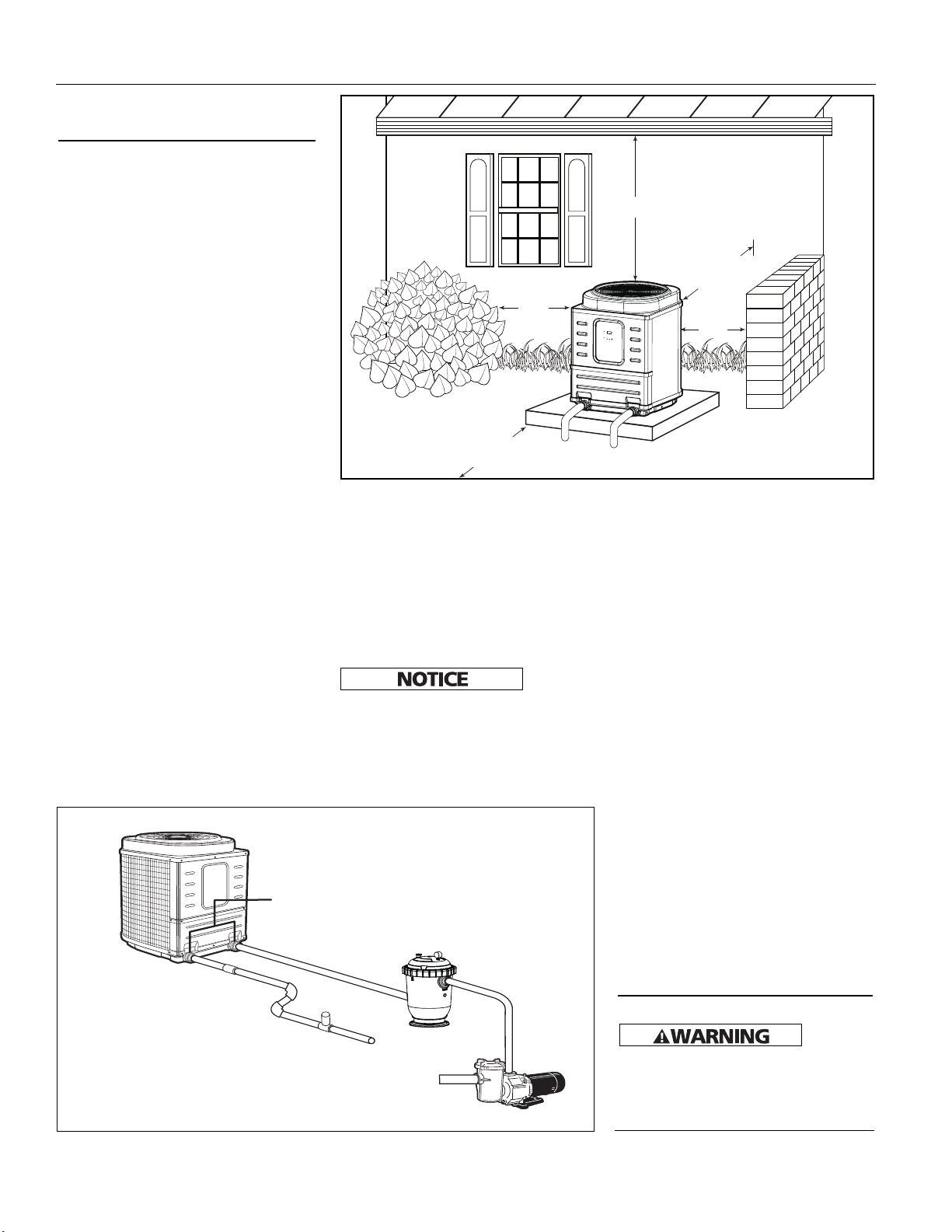

Figure 2 Recommended installation layout

POOL

HEATER

UNIONS

FILTER

POOL

PUMP

CHLORONATOR

WARM

WATER OUT

TO POOL

COLD WATER

IN FROM POOL

IN

OUT

CHECK

VALVE

THE UNIT MUST BE TRANSPORTED

IN THE UP-RIGHT POSITION AT ALL

TIMES AND MUST NOT BE DROPPED

OR TAILGATED. DAMAGE TO THE

UNIT DURING TRANSPORTATION IS

NOT THE RESPONSIBILITY OF THE

MANUFACTURER.

Unit Location

Once the unit has been inspected and

cleared of any transportation damage,

it is now time to locate the pool heater.

It is very important to understand the

location of the unit for the best

performance of operation. See Figure 1

for location recommendations. A

minimum of 18" of clearance between

the evaporator coils and shrubs, fences,

walls, etc. must be maintained for

adequate air intake. A minimum of 5' of

vertical clearance between the top of

the unit and any roof overhang or other

obstructions must be maintained in

order to prevent the re-circulation of

cold air back into the evaporator coils.

This is to maintain the efficiency of the

unit. A minimum of 36" of clearance

between the front of the unit (access

panel area) and any obstruction must

be maintained to allow maintenance on

the unit when necessary. The unit

should be located on a solid level

surface, a minimum of 36"x 36" for

proper drainage. Make sure any

sprinkler heads are not directly spraying

water on the unit. While heat pumps

are made for an outdoor environment,

they are not designed to have sprinkler

water constantly spraying them.

NOTE: This type of constant

watering directly on the unit can

void your warranty.

Condensation drain holes are provided

in all units for adequate removal of

condensation and rainwater. ALL

UNITS WILL HAVE CONDENSATION.

THIS SHOULD NOT BE MISTAKEN

FOR A LEAK IN THE UNIT.

Plumbing

Where freezing weather is encountered,

the detachable connection/union

(provided) must be installed

immediately adjacent to the heater to

facilitate servicing and draining of the

heat exchanger. Draining is necessary

Phone: (877)-278-2797

2

Operating Instructions

to prevent damage to the

condenser shell and coil due to the

expansion of freezing water.

The minimum water circulation

capacity flowing through the pool

heater is 25 gallons per minute and

the maximum capacity is 80 gallons

per minute.

Do not install a water shutoff valve in

the piping from the outlet of the pool

heater to the pool or tub. However, a

check valve that does not include a

shut-off feature may be installed for

convenience during servicing.

A check valve or Hartford Loop is

recommended between the unit and a

chlorinator. The chlorinator must be

downstream of the heat pump. Failure

to do so may void the warranty.

If you have an in-floor cleaning

system, please take note of any special

plumbing requirements to operate all

units effectively.

Figure 2 shows the recommended

installation layout.

Basic Heat Pump

Operation

Electrical Connections

All

wiring

and electrical connections must be

performed by a qualified electrician.

Installations must be in accordance with

local and national codes.

www.aquaprosystems.com

5' Minimum

18" Min.

18"

Min.

36"Min.

18"

Min.

Figure 1 Unit Location

Installation Procedures

(continued)

36” clearance

18“ min

5 feet

(minimum)

18“ min

18“ min

www.aquaprosystems.com

Overheating, short-circuiting and fire

damage will result from inadequate

wiring.

All units are equipped with an

electrical wiring schematic inside the

electrical panel. If this is missing,

please contact the factory at 1-877278-2797 to obtain one.

All units are to be wired for 230 VAC, 1

phase. These units require a dedicated

50-amp breaker or time delay fuse.

Pool Heater is to be installed in

accordance with Article 680 of the

National Electrical Code (NEC), NFPA

70, and within the requirements of all

local codes having jurisdiction.

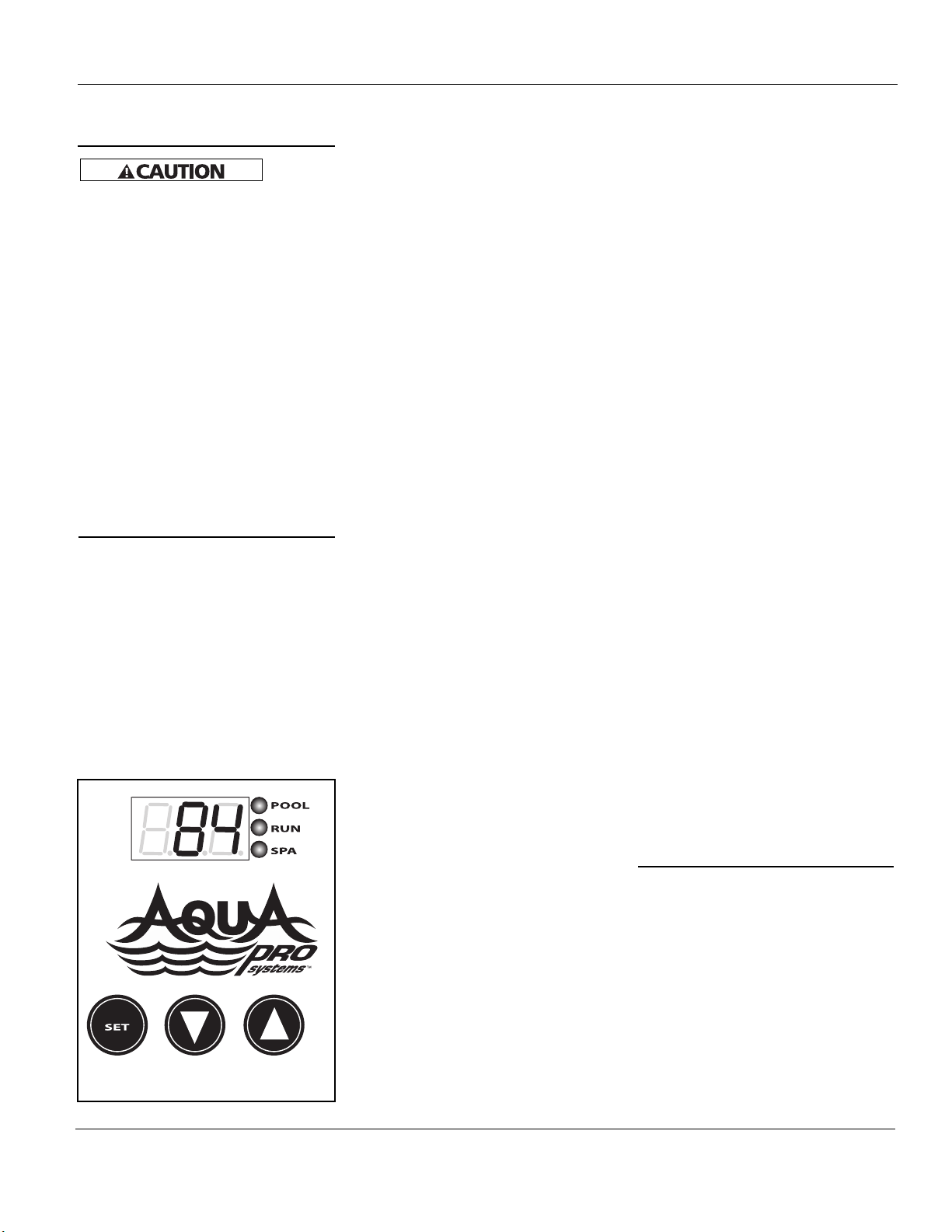

Electronic Temp.

Controls

All Units Except PRO1100

Description

• The control located on the front of

your heat pump has a large threecharacter display for the water

temperature, set points, and

diagnostics (see figure 3 for front

panel appearance). The three button

keypad includes SET, UP arrow, and

DOWN arrow buttons. LED indicators

next to the display show if the heat

pump is in the pool mode or in the

spa mode and if the unit is running.

Buttons

Press the SET button to change

between modes and use the up and

down arrows to change the selected

mode’s settings.

Modes available are:

POL - allows you to change the pool

water temperature set point

SPA - allows you to change the spa

water temperature set point

P-S - changes between pool and spa

settings. LED’s on front panel will

indicate current mode selected.

F-C - display temperature in

Fahrenheit or Celsius

TCE UNITS ONLY:

FIL - used to set system run time.

H/C UNITS ONLY:

H-C - change between heating and

cooling mode.

Water Temperature Set

Point

Temperature set point range is OFF, and

61°F to 95°F for POL mode. For SPA

mode, set point range is OFF, and 61°F to

104°F. Pushing the UP arrow or DOWN

arrow buttons will prompt the control to

display the current set point. Continuing

to press the UP or DOWN buttons will

allow the set point values to scroll until

the desired set point is reached. Once the

new set point has been reached, stop

pressing the UP or DOWN buttons. Once

the unit toggles back to the current

water temperature display, the set point

is entered. The controls have a feature

called “Set Point Memory Retention”. If

the power is removed from the unit, it

retains the last set point displayed.

Connecting to a Remote

System: All Units Except

Pro1100

This Pool Heater is compatible with all

known remote systems in the industry.

The following models’ diagrams show

how to connect all of the remote

systems to the Electronic Temp.

Controller.

For 2 wire remotes

1. Bring up “POL” setting and arrow

temperature down until pool setting

reads “off”.

2. Bring up “SPA” setting and arrow

temperature up until spa setting

reads 104.

3. Set unit to the “POL” mode.

4. Connect remote system with 2 wires

to the P/S terminal on control board

(see specific model wiring diagram).

For 3 wire remotes

1. Bring up “POL” setting and use

arrows to select desired pool

temperature.

2. Bring up “SPA” setting and use the

arrows to select the desired spa

temperature.

3. Set unit to the “POL” mode.

4. Connect the common and high (or

spa) wires to the “P/S” terminals on

control board (see specific model

diagram). Low or pool wire does not

get connected.

Note: For heat/ cool units, the remote

will not work in the cooling mode.

Connecting to Remote

Systems: PRO1100

This Pool Heater is compatible with 2wire remote systems only, and is not

compatible with 3 wire remote

systems. Figure 4 shows where to

connect the remote systems to the

Temperature Controller.

Connection to AquaLink, Compool,

Hayward, AquaLogic or any other 2

wire remote system with their own

thermostat:

• Remove gray jumper from terminals

1 and 2 on TB1.

• Bring the two wires from the remote

system to terminals 1 & 2 on Terminal

Block 1 (TB1).

• The Temperature Control knob must

be turned clockwise (highest temp.

setting) for the remote system to

operate the Pool Heater properly.

High Temperature Lock Out:

All Units Except PRO1100

Your heat pump includes a special

feature to “lock” the high

temperature settings. This eliminates

the need for a thermostat lock-box.

This prevents unauthorized persons

from adjusting the heat pump above

these desired limits. To activate this

feature, please call AquaPRO

®

Systems

at 877-AQUA-SYS (877-278-2797)

during business hours 8 AM to 5 PM

EDT Monday through Friday and we

will be glad to assist in setting up this

feature.

PRO1300, PRO1100e, PRO1300h/c, PRO1100,

PRO1300h/c TCE, PRO1300 TCE, PRO1100e TCE

Phone: (877)-278-2797

3

Figure 3 - Front Panel

Basic Heat Pump

Operation (continued)

Operating Instructions

www.aquaprosystems.com

Manual Temperature

Controls

Description

• The manual Temperature Control is

designed to regulate pool and spa

water temperature.

• There are two indicator lights on the

control panel to display the current

status of the unit.

• The thermostat knob may be

adjusted to maintain the desired

water temperature.

Indicator Lights

• There are two indicator lights on the

front panel that display unit status. The

GREEN light indicates that power to the

unit is on. The RED light indicates that

the unit is in heating mode.

Phone: (877)-278-2797

4

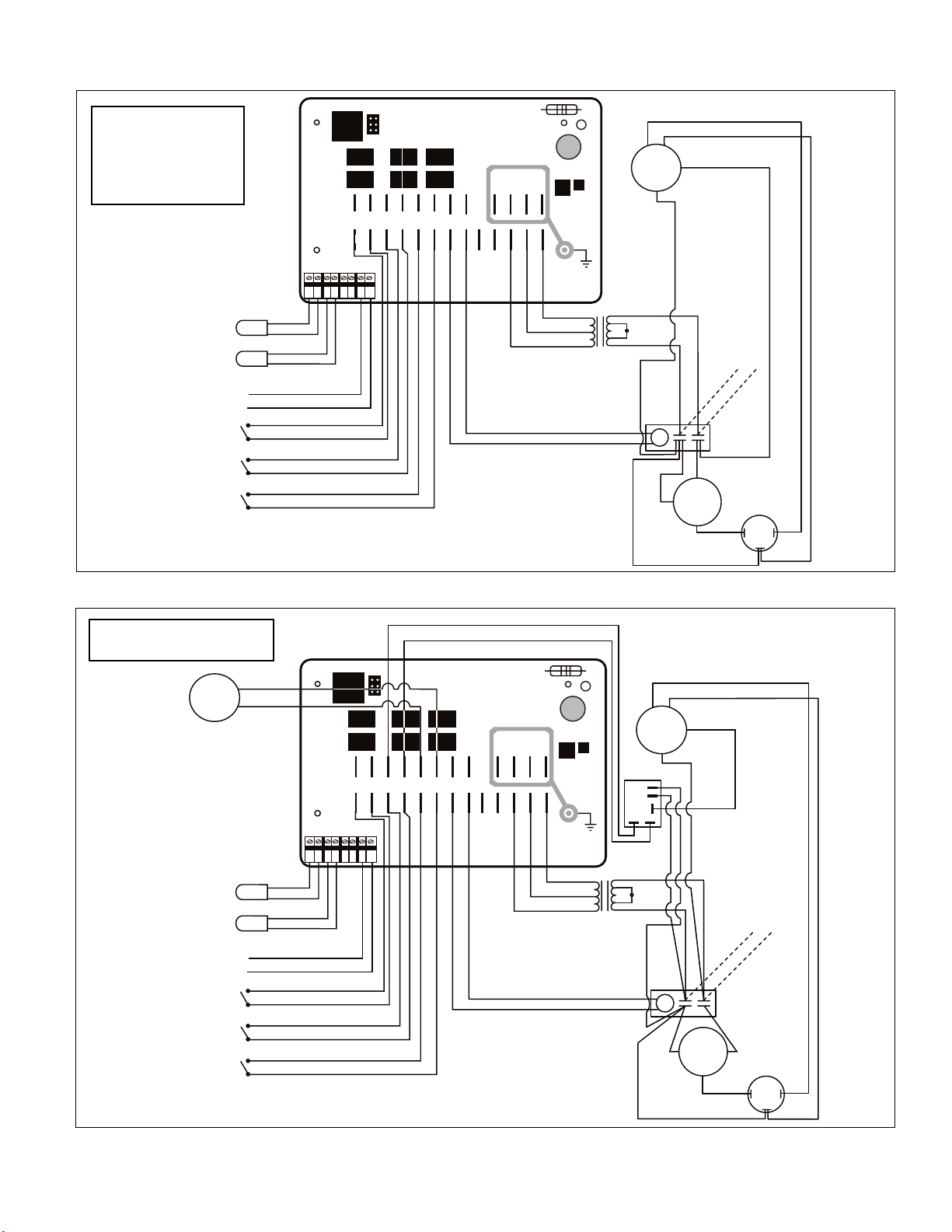

Figure 4 - PRO1100 wiring diagram

PRO1100

• The RED light may become

illuminated prior to heater start up.

The RED light will become lit when

the thermostat knob is set at or

above the water temperature.

• The unit has a built in time delay.

Every time the unit turns off there is a

five-minute time delay until the unit

may be restarted. The HEAT light may

turn on during this delay cycle. Do not

rotate the thermostat knob during this

time delay. Rotating the knob during

this cycle may reset the time delay,

causing the unit to wait an additional

five minutes prior to startup.

Water Temperature Set Point

• Temperature set point range is 45°F

to 107°F. Rotating the thermostat

knob clockwise will increase the

temperature set point, while rotating

counterclockwise will decrease the

temperature set point.

• A floating thermometer may be

placed in the pool or spa to monitor

water temperature.

• To initially calibrate the thermostat to

the desired set point, turn the

thermostat knob fully clockwise. The

unit will turn on and begin heating

after a possible five minute time delay.

Allow the unit to run until pool or spa

water reaches the desired temperature.

Slowly turn thermostat knob counterclockwise until the unit turns off. The

unit will now maintain this water

temperature, providing the circulation

pump is running.

Fan

Motor

Green

Light

Red

Llight

240V-24V

Transformer

Capacitor

Compressor

Thermostat

Time

Delay

Water

Pressure

Low

Pressure

High

Pressure

Black

Black

Black

Black

Black

White

Brown/ White

Brown

Blue

Blue

Blue

Blue

Blue

Yellow

Yellow

Gray

Gray

Gray

Gray

Red

Red

Orange

Nuet Hot In Out

T2 T1

Contractor

L2 L1

Line Line

Temp

1 2

TB1

3 4

C

F H

C

R

S

PRO1100

PRO1300, PRO1100e, PRO1300h/c, PRO1100,

PRO1300h/c TCE, PRO1300 TCE, PRO1100e TCE

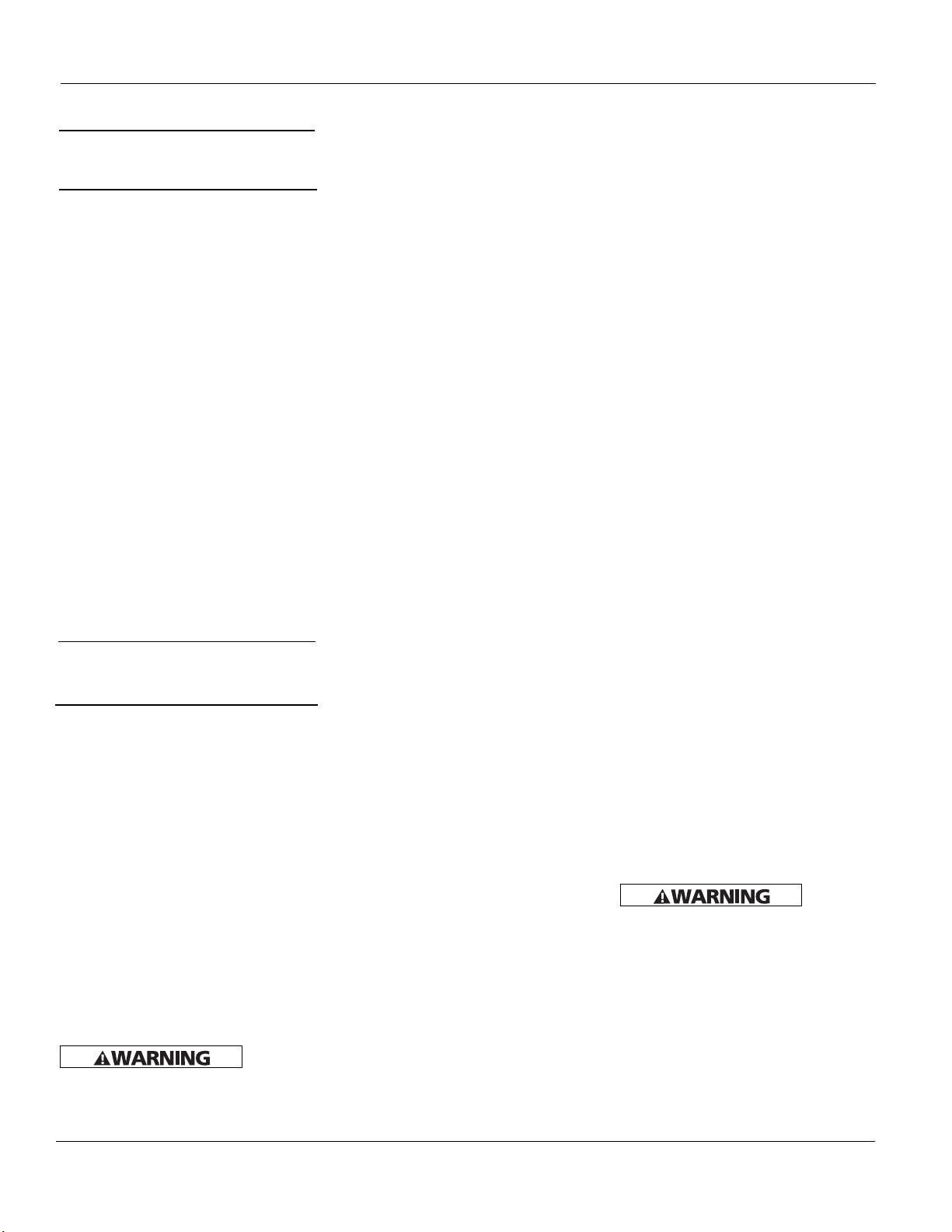

Figure 5 - PRO1100e & PRO1300 wiring diagram

Water Sensor

Defrost Sensor

High Pressure Switch

Closed = OK

Opened = High Pressure

Low Pressure Switch

Closed = OK

Opened = Low Pressure

Flow Switch

Closed = Flow

Opened = No Flow

MY-TECH PH-111A

Brown

Brown & White

SPR1

SPR2

REVR

JANDY

HP

LP FLO

COMP

PUMP

12 ~8 ~12

AC F1 F2 F3

WS

DSASP/S

Black

Black

Blue

Orange

Blue

Orange

Blue

Gray

12 VAC

Blue

Red

Blue

12 / 24 VAC

Transformer

Black

Yellow

Yellow

24

Vac

COMPRESSOR

R

S

C

24 VAC

Compressor

Contactor

Coil

Run Cap

L1

L2

Black

Black

Yellow

Black

Black

Red

H

C

F

Red

Blue

FAN

Black

Black

White

PRO1100e

and

PRO1300

Phone: (877)-278-2797

5

www.aquaprosystems.com

To Remote System

(If Applicable)

Figure 6 - PRO1300h/c wiring diagram

Water Sensor

Defrost Sensor

High Pressure Switch

Closed = OK

Opened = High Pressure

Low Pressure Switch

Closed = OK

Opened = Low Pressure

Flow Switch

Closed = Flow

Opened = No Flow

Red

Black

MY-TECH PH-111A

Brown

Brown & White

FAN

SPR1

SPR2

REVR

JANDY

HP

LP FLO

COMP

PUMP

12

~0 ~12

AC F1 F2

F3

WS

DSASP/S

White

White

Black

Black

Yellow

Orange

Yellow

Orange

Blue

Gray

12 VAC

Blue

Red

Blue

12 / 24 VAC

Transformer

Black

Yellow

Yellow

Yellow

24

Vac

COMPRESSOR

R

S

C

24 VAC

Compressor

Contactor Coil

Run Cap

L1L2

REVERSING

VALVE

Black

Black

NC

NO

COM

Black

Black

White

Yellow

Black

Orange

H

C

F

To Remote System

(If Applicable)

PRO1300h/c

Operating Instructions

Phone: (877)-278-2797

6

www.aquaprosystems.com

PRO1300h/c

Electronic Temp.

Controls

Toggling Between Heating

and Cooling Mode

The unit will default to the heating

mode. If the cooling mode is desired,

press the SET button until the H-C screen

is displayed. Then press the arrow

buttons until “COL” is displayed on the

screen. This puts the unit into cooling

mode. The water temperature set point

will now be the water temperature that

the unit is cooling the water to. When

the unit is in cooling mode, the screen

will flash between the current water

temperature and “COL” to remind the

user that cooling mode is activated.

Defrost Cycle

Your AquaPRO®h/c unit is capable of

keeping your pool warm in very cool

temperatures. Most pool heaters will

not operate below 50°F. Your h/c unit

will work down to 38°F by utilizing a

“defrost cycle”. It does this

automatically by sensing the coolant

temperature and reversing operation

for 2 minutes to defrost the evaporator

coil and will resume heating function

after defrosting the evaporator coil.

This section allows you to run the heat

pump at set intervals during the day. If

you have a time clock, and would like to

use it please refer to the Time Clock

Override section.

For the TCE feature to work, your pool

pump must be wired to the heat pump

See figure 7 for wiring the TCE feature

•

This unit is prepared at the factory

with the TCE feature installed, but

set to the “off” position in the “FIL”

mode. You will need to set the

hours of run time for the pump and

filter system. See “activating and

setting system run time” below.

•

The function of the TCE is done through

a timing sequence of 6 periods per

24 hours. You select the hours for your

required filter pump run time, and the

heater takes care of the rest. It does this

by dividing the system run time equally

over the 6 periods, turning the pump on

for 1/6th of the specified run time and

off the remainder of the period unless

additional heating is required. The

heater will always operate the system

on a daily basis for the amount of run

time you have selected. The timing

sequence begins at the initial start up.

•

If your pool is at or above the desired

operating temperature, the heater will

run the system the desired hours each

day and spread the time out evenly

between the 6 periods. This makes for

better filter operation and allows the

heater to update the water

temperature 6 times per day.

•

If your pool needs heat, the heater will

continue to run the system until the

desired temperature is met. If the

amount of run time exceeds a period’s

run time, the excess time will be

subtracted from the next run period(s).

Please note that on cold and / or windy

days, the unit could run for long times

to generate and maintain the desired

pool temperature. Please see the

“application” section about “pool

blankets” to help maintain your pool’s

temperature.

•

The timing function built into the TCE

will always run the heat pump for

15 minutes every 4 hours to determine if

more heat is needed to maintain the

pool’s desired temperature - even if all

of the available run time was used in

previous cycles. This provides a couple of

added benefits. Pools will lose most of

their heat at night if left uncovered,

however, since the unit is checking for

and adding heat when needed, it

prevents long recovery times when

compared to non-TCE units. The other

benefit is that some states and electric

utility companies offer a discount for

off-peak usage of electricity. Please

contact your electricity provider if you

have questions.

•

Example of TCE operation – you require

the system to run for 12 hours to meet

your pool filtering needs. This means for

each of the 6 periods, the heater will

run the system for 2 hours and then

turn off for 2 hours. If the system

needed to run for 3 hours in one of the

periods to reach the desired pool

temperature, the next period would be

1 hour on and 3 hours off unless

additional heating is needed. The cycle

continues for 6 periods and renews at

the end of each 24 hours. Please call

AquaPRO

®

Systems at 1-877-AQUA-SYS

(1-877-278-2797) if you need further

clarification of this feature’s operation.

Activating and Setting System Run

Time - TCE Operation

•

To set the run time of the system, push

the “SET” button repeatedly until “FIL”

displays. Then using the “up” and

“down” arrows, you can select how

many total hours a day you want the

system to run for your pump and

filtration needs. The range of hours is

“off” to 2, 3, 4,… up to 23 hours to

“on”. As described before, the run time

will then be calculated and spread out

over the 6 time periods for 24 hours.

Selecting the “on” position will run the

pump and filter system continuously.

The unit leaves the factory with the

“FIL” mode set to “OFF”.

Time Clock Override

(TCO) Operation

All wiring

and

electrical connections must be performed

by a qualified electrician. Installation

must be in accordance with local and

national codes.

This section allows you the option of

using an existing time clock with the

heat pump. If you do not have a time

clock, please refer back to the Time Clock

Eliminator section.

The pump must be connected to the heat

pump and also the time clock for the Time

Clock Override feature to work correctly.

See figure 8 for the optional TCO wiring

schematic and electrical connections.

PRO1100e TCE

and PRO1300 TCE

Selecting

Functionality of Unit

This unit is capable of operating as a Time

Clock Override (TCO) or as the Time Clock

Eliminator (TCE). If you already have a

time clock on your swimming pool and

would like to maintain its normal

operation with the added benefit of a

heat pump time clock override – please

review the section for the Time Clock

Override. If you do not own a time clock

for your pool system - please review the

section for the Time Clock Eliminator.

Time Clock Eliminator

(TCE) Operation

Please read the functions of this feature

carefully.

All wiring

and

electrical connections must be performed

by a qualified electrician. Installation

must be in accordance with local and

national codes.

Figure 7 - PRO1100e TCE & PRO1300 TCE wiring diagram

Water Sensor

Defrost Sensor

High Pressure Switch

Closed = OK

Opened = High Pressure

Low Pressure Switch

Closed = OK

Opened = Low Pressure

Flow Switch

Closed = Flow

Opened = No Flow

MY-TECH PH-111A

Brown

Brown & White

SPR1

SPR2

REVR

JANDY

HP

LP FLO

COMP

PUMP

12 ~8 ~12

AC F1 F2 F3

WS

DS

AS

P/S

Black

Black

Blue

Orange

Blue

Orange

Blue

Gray

12 VAC

Blue

Red

Blue

12 / 24 VAC Transformer

Black

Yellow

Yellow

24

Vac

COMPRESSOR

R

S

C

24 VAC

Compressor

Contactor Coil

Run Cap

L1

L2

Black

Black

Yellow

Black

Black

Red

H

C

F

Red

Blue

FAN

Black

Black

White

24 VAC

pool pump

contactor coil

L4

Pool Pump

L3

PRO1300, PRO1100e, PRO1300h/c, PRO1100,

PRO1300h/c TCE, PRO1300 TCE, PRO1100e TCE

Phone: (877)-278-2797

7

www.aquaprosystems.com

To Remote System

(If Applicable)

•

This unit is prepared at the factory with

the “FIL” mode set to the “off” position.

You will need to set the heat pump’s

hours of run time in the “FIL” mode to

“2” hours. See “activating and setting

system run time” below to set the run

time. Leave your time clock set to the

desired pump and filter operation time.

This will enable the heat pump and filter

system to run the desired hours of the

day and also provide the benefit of

checking if heat is needed every 4 hours.

It will do this by running the pump and

filter system for 15 minutes. If heat is

needed, it will continue to run until the

pool has reached the set temperature. If

no heat is needed, the system will turn

off and continue checking for heat every

4 hours. This provides a couple of added

benefits. Pools will lose most of their

heat at night if left uncovered, however,

since the unit is checking for and adding

heat when needed, it prevents long

recovery times when compared to nonTCO units. The other benefit is that some

states and electric utility companies offer

a discount for off-peak usage of

electricity. Please contact your electricity

provider if you have questions.

Activating and Setting System Run

Time – TCO Operation

•

To set the run time of the system,

push the “SET” button repeatedly

until “FIL” displays. Then using the

“up” and “down” arrows, set the

hours to “2”. The range of hours is

“off” to 2, 3, 4,… up to 23 hours to

“on”. By selecting “2” the heat pump

will run every 4 hours for 20 minutes,

checking if heat is needed. The unit

leaves the factory with the “FIL”

mode set to “OFF”.

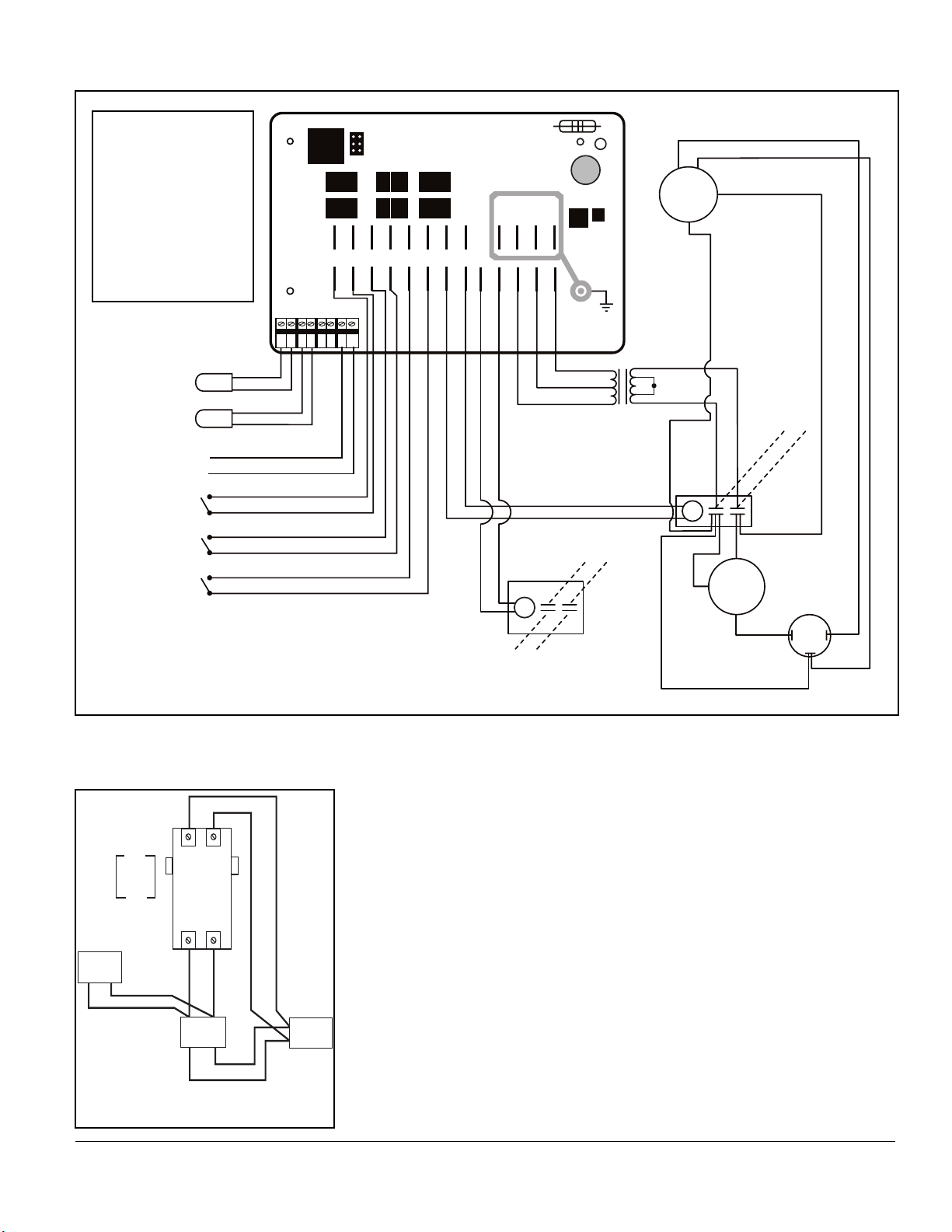

Time Clock Override

(TCO) Operation (cont.)

INSIDE

HEAT

PUMP

CONTACTOR

FOR THE

TIME CLOCK

OVERRIDE

TIME

CLOCK

FILTER

PUMP

BREAKER

Figure 8 - TCO wiring diagram

(optional)

PRO1100e

TCE

and

PRO1300

TCE

INSIDE

HEAT

PUMP

T2 T1

CONTACTOR

FOR THE

TIME

CLOCK

OVERRIDE

L3 L4

BREAKER

TIME

CLOCK

FILTER

PUMP

Loading...

Loading...