Aquacal Pool Pilot 75003 User Manual

PoolPilot®

Digital

Salt Chlorine Generator

By

Swimming Pool and Spa Purification System

Model # 75003

Owners Manual

(For Indoor or Outdoor Use)

Pool Owner - Save this manual for reference.

Installer - Leave this manual with pool owner.

IMPORTANT.

Read This Manual Before Installing & Operating

This manual covers the installation of the Digital Chlorine Generator with any of the following Cell/Manifold assemblies (sold separately); 94105, 94107, 94113, 941-15C

This manual also covers the installation, connection and programming of the optional #75001 Pool Chemistry Controller for the Pool Pilot Digital Total Control, and the #75004, 75005, 75006, or 75007 pH Acid Feed Pump and Tank Kit.

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed, including the following:

READ AND FOLLOW ALL INSTRUCTIONS

DANGER – RISK OF ELECTRICAL SHOCK - Disconnect all AC power when installing or servicing this system.

A bonding lug has been provided on the outside of the Control Unit. This lug permits the connection of a No. 8 AWG (8.4mm2) solid copper-bonding conductor. Make this connection between the Control Unit and all other electrical equipment and exposed metal within 5 feet (1.5m) of the Control Unit. All field-installed metal components such as rails, ladders, drains, etc. within 10 feet of the pool, spa or hot tub must be bonded to the equipment grounding bus with copper conductors not smaller than No. 8 AWG (8.4mm2).

WARNING – RISK OF ELECTRICAL SHOCK - Control units configured to 115 Vac must be installed at least 10 feet (3m) from the pool or spa wall. Control units configured to 230 Vac must be installed at least 5 feet (1.5m) from the pool or spa wall.

WARNING – RISK OF CHILD DROWNING OR INJURY - Children should never use this equipment, or a pool, spa or hot tub unless they are closely supervised at all times.

The AutoPilot chlorinator is equipped with an electronic flow switch that automatically turns the unit off in the event of a “low water flow” situation. Do not tamper in any way with this safety feature.

A disconnect device incorporated in the fixed wiring must be included in the supply circuit (such as a time clock, relay, or circuit breaker).

The proper residual chlorine level and water chemistry must be maintained.

The addition of certain pool maintenance chemicals can reduce the effectiveness of chlorine.

WARNING - The Control Unit must be mounted at least 1 foot (300mm) off the ground to allow for air circulation around it, and permanently installed over concrete.

The AutoPilot chlorinator must be installed and operated as specified. Failure to do so will void the AutoPilot warranty.

The SC-36, SC-48 and SC-60 SuperCells are designed for residential use only. Use in any other application will void the warranty. (The CC-15 cell may be used in commercial or residential applications.)

SAVE THESE

INSTRUCTIONS

ii

UNIT NUMBERS AND CONTACT INFORMATION

Please record the following information prior to installation:

......................................................Installer: |

...................................Date of Installation: |

Control Unit |

Control Unit |

Model Type: ............................................... |

Serial Number: ........................................... |

SuperCell |

SuperCell |

Model Type: ............................................... |

Serial Number: ........................................... |

Pool Volume in Gallons: ............................ |

Tri-Sensor |

(Pool Volume in Liters:) ............................. |

Serial Number: ........................................... |

|

|

Thank you for purchasing an AutoPilot Salt Chlorination System. You will enjoy the benefits of ownership for years to come. Please take a moment to read this manual before proceeding with the installation.

Questions?

Refer to www.AutoPilot.com for the latest manual revisions, additional information and helpful service.

You can also reach our factory direct customer assistance by calling 800.786.7751 or 727.832.5642,

by email at AutoPilotTechSupport@teamhorner.com, or by FAX at 727.824.0847

PoolPilot®

D i g i t a l

Manufactured by

AquaCal AutoPilot Inc.

2737 24th Street North

St Petersburg • Florida 33713 • U.S.A.

iii

TABLE OF CONTENTS |

|

IMPORTANT SAFETY INSTRUCTIONS ..................................................................................................... |

ii |

UNIT NUMBERS / AUTOPILOT CONTACT INFO.................................................................................... |

iii |

TABLE OF CONTENTS........................................................................................................................... |

iv - vi |

SYSTEM OVERVIEW .................................................................................................................................... |

1 |

CHLORINE GENERATION .................................................................................................................................................................. |

1 |

PH CONTROL M ODE ........................................................................................................................................................................ |

2 |

TOTAL CONTROL MODE .................................................................................................................................................................. |

2 |

TOTAL CONTROL PROTECTION ................................................................................................................................................. |

2 |

DEFINING ORP (ACTIVE CHLORINE) OPERATION ............................................................................................................... |

2 |

DEFINING PH OPERATION .................................................................................................................................................. |

2 |

CONTROL UNIT FEATURES................................................................................................................................. |

3 |

PATENTED TEMPERATURE COMPENSATION ..................................................................................................................................... |

3 |

PATENTED AUTOMATIC-FLOW BYPASS MANIFOLD ASSEMBLY....................................................................................................... |

3 |

SPECIFICATIONS........................................................................................................................................... |

4 |

FOR #75003 POOL PILOT DIGITAL CONTROL UNIT |

|

AC INPUT POWER ............................................................................................................................................................................ |

4 |

CHLORINE OUTPUT .......................................................................................................................................................................... |

4 |

MANIFOLD FLOW REQUIREMENTS ................................................................................................................................................... |

4 |

PUMP/AUXILIARY RELAY INPUT/OUTPUT........................................................................................................................................ |

4 |

AGENCY APPROVALS....................................................................................................................................................................... |

4 |

FOR #75001 POOL CHEMISTRY CONTROLLER UNIT |

|

PH ACID FEED PUMP AND TANK AC INPUT POWER ......................................................................................................................... |

4 |

Low Voltage Input Power ............................................................................................................................................................... |

4 |

Flow Cell......................................................................................................................................................................................... |

4 |

PREPARING THE POOL WATER................................................................................................................. |

5 |

CALCULATING POOL VOLUME ......................................................................................................................................................... |

5 |

TYPE OF SALT .................................................................................................................................................................................. |

5 |

HOW TO ADD SALT OR REMOVE SALT............................................................................................................................................. |

5 |

SALT LEVEL..................................................................................................................................................................................... |

5 |

SALT ADDITION CHART .................................................................................................................................................................. |

6 |

BASIC WATER CHEMISTRY .............................................................................................................................................................. |

7 |

SATURATION INDEX (SI).................................................................................................................................................................. |

8 |

INSTALLATION ............................................................................................................................................. |

9 |

BEFORE INSTALLING THE #75003 POOL PILOT DIGITAL SYSTEM ........................................................................................................ |

9 |

WHAT IS INCLUDED.......................................................................................................................................................................... |

9 |

WHAT IS NOT INCLUDED .................................................................................................................................................................. |

9 |

PLUMBING REQUIREMENTS............................................................................................................................................................ |

10 |

ELECTRICAL REQUIREMENTS......................................................................................................................................................... |

10 |

INSTALLATION STEPS..................................................................................................................................................................... |

10 |

PLUMBING THE MANIFOLD ASSEMBLY ............................................................................................................ |

11 |

MOUNTING THE #75003 DIGITAL CONTROL UNIT ........................................................................................... |

12 |

ELECTRICAL CONNECTIONS ............................................................................................................................. |

13 |

GROUNDING AND BONDING ............................................................................................................................. |

13 |

HIGH VOLTAGE WIRING .................................................................................................................................. |

13 |

CONVERTING FROM 230 VAC TO 115VAC ................................................................................................................................... |

13 |

CONNECTING POWER TO THE POOL PILOT ..................................................................................................................................... |

14 |

CONNECTING POOL PILOT TO AN EXTERNAL TIMER OR CONTROLLER .......................................................................................... |

14 |

CONNECTING POOL PILOT TO ONE-SPEED PUMP OR ACID PUMP ................................................................................................... |

14 |

CONNECTING POOL PILOT TO TWO-SPEED PUMP........................................................................................................................... |

14 |

iv

TABLE OF CONTENTS |

|

LOW VOLTAGE WIRING .................................................................................................................................... |

15 |

CONNECTING THE SUPERCELL CABLE ........................................................................................................................................... |

15 |

CONNECTING THE TRI-SENSOR CABLE .......................................................................................................................................... |

15 |

INSTALLATION – POOL CHEMISTRY CONTROLLER AND PH CONTROL SYSTEM ..................... |

16 |

BEFORE INSTALLING THE #75001 POOL PILOT POOL CHEMISTRY CONTROLLER SYSTEM ............................... |

17 |

WHAT IS INCLUDED ....................................................................................................................................................................... |

17 |

WHAT IS NOT INCLUDED ................................................................................................................................................................ |

17 |

MOUNTING THE POOL CHEMISTRY CONTROLLER UNIT ................................................................ |

18 |

POOL CHEMISTRY CONTROLLER SENSORS AND INTERFACE CABLE ......................................... |

19 |

CONNECTING THE ORP AND PH CONNECTORS .............................................................................................................................. |

19 |

CONNECTING THE INTERFACE CABLE ............................................................................................................................................ |

19 |

PH INSTALLATION...................................................................................................................................... |

20 |

CONNECTING THE PH FEED PUMP.................................................................................................................................................. |

20 |

INTO THE DIGITAL CONTROL UNIT............................................................................................................................................ |

20 |

INTO THE #75008 AUXILIARY RELAY KIT.................................................................................................................................. |

20 |

POOL CHEMISTRY CONTROLLER FLOW CELL PLUMBING ............................................................. |

21 |

pH CONTROL PLUMBING.......................................................................................................................... |

22 |

CONNECTING THE #75003 DIGITAL TO ANY OTHER ORP CONTROLLER..................................... |

23 |

INSTALLING THE OPTIONAL #110-ORP RELAY KIT ................................................................................................................... |

23 |

CONNECTING THE #75003 DIGITAL TO AN ELECTRONIC CONTROLLER ..................................... |

24 |

MENU OVERVIEW ...................................................................................................................................... |

25 |

PROGRAMMING AND OPERATION......................................................................................................... |

27 |

CONTROL PANEL FEATURES AND FUNCTIONS.................................................................................................. |

26 |

CONTROL OPTIONS AND SYSTEM START UP...................................................................................................... |

27 |

PURIFIER MODE - QUICK PROGRAMMING ...................................................................................................................................... |

27 |

PH CONTROL MODE - QUICK PROGRAMMING ................................................................................................................................ |

28 |

TOTAL CONTROL (TC) MODE - QUICK PROGRAMMING ................................................................................................................. |

28 |

OPERATION OF BUTTONS ................................................................................................................................. |

29 |

ADJUSTING THE PURIFIER OUTPUT % ............................................................................................................................................ |

29 |

BOOST OR SUPERBOOST ................................................................................................................................................................ |

29 |

MENU BUTTON .............................................................................................................................................................................. |

29 |

SELECT BUTTON ............................................................................................................................................................................ |

29 |

PUMP BUTTON ............................................................................................................................................................................... |

30 |

TEST POOL PILOT PROGRAM............................................................................................................................ |

31 |

VIEW SETUP PROGRAM.................................................................................................................................... |

31 |

SELECT LANGUAGE PROGRAM......................................................................................................................... |

32 |

SELECT UNITS PROGRAM................................................................................................................................. |

32 |

SELECT TEMPERATURE PROGRAM ................................................................................................................... |

32 |

SELECT 12/24 HOUR CLOCK PROGRAM ............................................................................................................ |

32 |

SET TIME OF DAY PROGRAM ............................................................................................................................ |

32 |

PROGRAMMING PUMP OPERATING TIMES ........................................................................................................ |

32 |

ACTIVATING FORCE REVERSE.......................................................................................................................... |

33 |

PROGRAMMING REVERSE TIME ....................................................................................................................... |

33 |

ENABLE / DISABLE REMOTE ............................................................................................................................ |

33 |

REPLACE CELL (RESET AMPERE - HOUR COUNTER) ......................................................................................... |

33 |

SET PRIME PROTECT ........................................................................................................................................ |

33 |

v

TABLE OF CONTENTS |

|

SALT CALIBRATION.......................................................................................................................................... |

34 |

ADJUSTING TEMPERATURE DISPLAY ................................................................................................................. |

34 |

PROGRAMMING POOL VOLUME ....................................................................................................................... |

34 |

PROGRAMMING CELL TYPE ............................................................................................................................. |

34 |

PROGRAMMING CELL POWER .......................................................................................................................... |

34 |

PROGRAMMING SET RELAY 1 FUNCTION (PUMP CONTROL) ............................................................................ |

34 |

PROGRAMMING SELECT REMOTE (ELECTRONIC CONTROLLER INTERFACE) .................................................... |

35 |

PROGRAMMING SYSTEM MODE ....................................................................................................................... |

35 |

PH CONTROL AND TOTAL CONTROL MENUS ................................................................................................... |

35 |

BOOST ACID .................................................................................................................................................................................. |

35 |

PRIME ACID PUMP ......................................................................................................................................................................... |

35 |

RESET ACID METER ........................................................................................................................................................................ |

35 |

ENABLE / DISABLE ACID ................................................................................................................................................................. |

35 |

TOTAL CONTROL MENUS................................................................................................................................. |

36 |

SET PH OVERFEED.......................................................................................................................................................................... |

36 |

SET PH MIN ..................................................................................................................................................................................... |

36 |

SET PH MAX.................................................................................................................................................................................... |

36 |

CALIBRATING PH ............................................................................................................................................................................ |

36 |

ENABLE/DISABLE ORP ................................................................................................................................................................... |

36 |

SET ORP OVERFEED ....................................................................................................................................................................... |

36 |

ELECTRONIC CONTROLLER OPERATION........................................................................................................... |

37 |

ADJUSTING AND SUPERCHLORINATING THE POOL PILOT THROUGH THE ELECTRONIC CONTROLLER CONTROL PANEL.................. |

37 |

PROGRAMMING THE POOL PILOT DIGITAL FOR AN ELECTRONIC CONTROLLER ............................................................................. |

37 |

ELECTRONIC CONTROLLER DISPLAYS “CHECK POOL PILOT” ................................................................................................... |

37 |

SYSTEM MAINTENANCE .......................................................................................................................... |

38 |

WINTERIZING................................................................................................................................................................................. |

38 |

FREEZE PROTECTION PROGRAM .................................................................................................................................................... |

38 |

SPRING START-UP.......................................................................................................................................................................... |

38 |

FUSE LOCATIONS AND RATINGS .................................................................................................................................................... |

39 |

TRI-SENSOR ASSEMBLY................................................................................................................................... |

40 |

REMOVING/INSPECTING/CLEANING THE TRI-SENSOR..................................................................................................................... |

40 |

TESTING THE FLOW SWITCH, CLEANING THE FILTER SCREEN, AND CLEANING THE BYPASS VALVE ............................................ |

41 |

SUPERCELL...................................................................................................................................................... |

41 |

REMOVAL OF THE SUPERCELL ....................................................................................................................................................... |

41 |

VISUAL INSPECTION OF THE SUPERCELL ....................................................................................................................................... |

42 |

MANUAL CLEANING OF THE SUPERCELL ....................................................................................................................................... |

42 |

INSTALLATION OF THE SUPERCELL................................................................................................................................................ |

42 |

POOL CHEMISTRY CONTROL MAINTENANCE AND CLEANING..................................................... |

43 |

HELPFUL HINTS ............................................................................................................................................................................. |

43 |

REMOVAL ...................................................................................................................................................................................... |

43 |

CLEANING...................................................................................................................................................................................... |

43 |

TESTING THE FLOW CELL .............................................................................................................................................................. |

43 |

TROUBLESHOOTING GUIDE ............................................................................................................. |

44 - 49 |

STANDARD DISPLAYS ............................................................................................................................................................. |

44 - 47 |

OTHER CONDITIONS....................................................................................................................................................................... |

47 |

TOTAL CONTROL AND PH DISPLAYS....................................................................................................................................... |

48 - 49 |

vi

SYSTEM OVERVIEW

System Overview

Although the Pool Pilot is easy to use, it is important to read through the manual before attempting to operate the unit. The Pool Pilot Digital, #75003, is a salt chlorination system for pool or spa purification, which is designed to operate in the following configurations:

•Purifier – standard mode, manually adjusted purifier output. See pg. 27 for system operation and programming.

•Purifier and pH Control – optional mode – standard purifier mode operating in conjunction with the optional pH Acid Feed Pump and Tank System (#75004, #75005, #75006, #75007), which is manually programmed for daily pH control. This mode will require #75008 Auxiliary Relay Kit when using the Digital “Set Relay 1” to control the main circulation pump. See pg. 28 for system operation and programming.

•Total Control – optional mode - utilizing the optional #75001 Pool Chemistry Controller for automatic daily adjustments of purifier and pH, based upon user programmed settings. See pg. 28 for system operation and programming.

The Pool Pilot has a digital interface that allows the unit to be operated through a Jandy® Aqualink RS (versions I and K only), Polaris® EOS, or Pentair IntelliTouch® electronic remote panel located in your home (if so equipped), or through an external ORP controller. The Pool Pilot Digital can also be programmed to control the main circulation pump operating times or be controller by an external timer/switch/relay.

Dotted lines are

optionalElectronicconnections, equipment,Dotted linesschematics,are

Controller and componentsoptional

System

connection

schematics and components.

Circuit |

Timer |

#75003 |

#75001 |

#75008 |

Breaker |

|

Digital |

Pool |

|

|

|

Control |

Chemistry |

Auxiliary |

|

|

AUTOPILOT |

Control |

Relay Kit |

|

|

SYSTEMS |

|

|

|

|

INC |

|

|

pH Acid

Feed System #75004, #75005, #75006, #75007.

Chlorine Generation (Manual purifier control)

The system requires a low concentration of dissolved salt (sodium chloride) in the pool water. This level is normally below the taste threshold. The Pool Pilot automatically converts the salt into free chlorine, which keeps your pool sanitized and algae free. The chlorine reverts back to a salt after treating the water. Since the salt is constantly recycled, there is minimal loss during a swimming season. However, salt can be lost due to filter backwash, rain water overflow, leaks, or bather splashing/carryout, but not through evaporation.

The Pool Pilot Control Unit is designed to handle the purification needs of residential and commercial swimming pools. The cell must be properly sized according to the chlorine requirements. The amount of chlorine required for proper sanitization will vary based on the pool size and various factors such as water temperature, bather load, exposure to direct sunlight, special water features, and pump runtime, particularly in commercial applications.

1

SYSTEM OVERVIEW

pH Control Mode (Manual purifier and pH control)

Note: Requires option # 75004, 75005, 75006, or 75007 pH Acid Feed Pump and Tank System must be installed with the #75003 Digital Controller for this mode to function. Option # 75008 Auxiliary Relay Kit will be necessary if the Digital is used to control the main circulation pump.

This mode adds to the Purifier mode by using an Acid feed pump that is user programmed for manual feed of diluted muriatic acid. The Acid Feed Pump and Tank System come with AutoPilot and Stenner factory components. If the Stenner factory components are used for the installation, follow their installation instructions. Otherwise, follow the instructions in this manual.

Total Control Mode - Pool Chemistry Controller (Automated purifier and pH control)

Note: Option #75001 Pool Chemistry Controller and the pH Control System must both be installed with the #75003 Digital Controller for this mode to function.

These options activate the Total Control mode in which the purifier (ORP – defined below) and pH levels are monitored (using sensors) and controlled automatically, to maintain proper levels. The system automatically enters the Total Control configuration if it is able to communicate with the Pool Chemistry Controller. The system will display "Error purify off, Error acid off, Check OpEC" if it is not able to communicate with the Pool Chemistry Controller. OpEC is the acronym for “ORP pH Electronic Controller” and is the electronic control logic of the Pool Chemistry Controller. Under normal operating mode, the Total Control display cycles between the “ORP” screen, the “pH” screen, and the “Salt level” screen.

Total Control Protection

The Total Control system does not generate chlorine or dispense acid if:

•A one-speed or two speed pump is not running,

•Flow (at the Manifold Tri-sensor or Flow Cell flow switch) is not detected,

•Salt is below 2000 ppm,

•Communications with the #75001 Pool Chemistry Controller is lost,

•A sensor error is detected,

•An overfeed condition is detected (if set to detect pH or ORP overfeed),

•An extended period of high pH condition is detected.

Also:

•The Total Control system does not dispense acid until after flow has been detected a minimum of three (3) minutes after activation.

•The Total Control system does not generate chlorine or dispense acid one (1) minute prior to the Pump Program “Off” time, when programmed for a One speed pump.

ORP (Oxidation Reduction Potential - measured in millivolts, mV)

ORP is a measurement of the amount of active oxidizer (chlorine) in the water. This system controls ORP by generating chlorine when the ORP measurement falls below a user programmable set point, which should correspond with the desired free chlorine level. A one-minute timer prevents the chlorine generation circuit from cycling on/off unless an error condition exists.

The first line of the ORP screen displays the measured ORP, followed by the ORP set point in parenthesis (as shown below). The ORP screen contains the text “On” only if chlorine is being generated. The ORP display range is 200 to 900mV.

The second line of the ORP screen indicates if the ORP is high or low, relative to the set point. If the measured ORP is equal to the set point, a block █ with no text is displayed. If the measurement falls below the set point, the ▼ and Low are displayed and chlorine is generated. If the measurement exceeds the set point, the ▲ and High are displayed and no chlorine is generated.

|

ORP 200(650)On. |

ORP 650(650) |

ORP 900(650) |

pH |

█▼▼▼▼▼▼▼ Low |

█ |

High ▲▲▲▲▲▲▲▲█ |

|

|

|

The system controls pH by dispensing diluted mixture of water and muriatic acid (4:1 ratio recommended) when the pH rises above a user programmable set point, which should correspond with the desired pH level. To avoid overdosing, the system dispenses acid in low increments based on the difference between the set point and the measured pH.

The first line of the pH screen displays the measured pH, followed by the pH set point in parenthesis (as shown below). The pH screen contains the text “On” only if acid is being dispensed. The pH display range is 4.00 to 9.90.

The second line of the pH screen indicates if the pH is high or low, relative to the set point. If the measured pH is equal to the set point, a block █ with no text is displayed. If the measurement falls below the set point, the ▼ and Low are displayed and no acid is fed. If the measurement exceeds the set point, the ▲ and High are displayed and acid is fed until set point is reached.

pH 4.00(7.50) |

pH 7.50(7.50) |

pH 9.90(7.50) On |

█▼▼▼▼▼▼▼ Low |

█ |

High ▲▲▲▲▲▲▲▲█ |

2

SYSTEM OVERVIEW

Control Unit Features

The control unit has the following features:

•Patented temperature compensation for chlorine output

•Programmable Microprocessor Control

•Multi-language digital display – (English, Spanish, French & German)

•Digitally controlled power to the SuperCell

•Tri-sensor Circuitry to monitor water flow, water temperature, and salt level (and salt addition amounts to maintain 3000 ppm (3.0 g/l))

•Internal Relay for controlling an external pump or acid feeder

•On-board Diagnostic and Test programs

•Lithium battery (CR-2025) back up for clock and program settings

•ORP dry contact interface for connection to an external ORP controller.

•Electronic controller interface for Jandy® (Versions I, K, and newer), Polaris® EOS, or Pentair IntelliTouch® controllers.

BOOST MENU SELECT PUMP

Patented Temperature Compensation

The Tri-Sensor Assembly’s temperature sensor works in conjunction with the purifier % output to automatically adjust the chlorine output based upon changes in the water temperature between the range of 55°F – 95°F (13°C - 35°C). As temperatures fall lower than 75°F (24°C), the unit will activate a high purifier % lock out and may not allow purifier adjustments up to 100%. This prevents the unit from overdriving the cell under cold temperatures, which can cause premature cell wear. At 55°F (13°C) or colder, the unit will adjust to a fixed 1% output to prevent the over chlorination and premature cell failure during cooler temperatures. At 95°F (35°C) or warmer, the unit will adjust up to 100% of the normal purifier % setting to prevent under chlorination during warmer temperatures.

The Temperature Compensation feature is not needed and is therefore automatically disabled when the Pool Pilot Digital (model #75003) is installed as a part of the Digital TC Total Control System (in conjunction with AutoPilot’s Pool Chemistry Controller -

# 75001)

Patented Automatic-Flow Bypass Manifold Assembly

The manifold is connected into the pool plumbing. Water from the pool is circulated though the manifold by the circulation/filter pump. The manifold’s four key components are the strainer screen, Tri-Sensor, SuperCell, and bypass flow valve.

The strainer screen prevents debris in the water from entering the Tri-Sensor or SuperCell and requires periodic inspection and cleaning.

The Tri-Sensor provides data (from electronic sensors) to the Control Unit for monitoring water flow, water temperature, and salt level through the cell. The Control Unit will use this data to determine if the conditions are safe for the SuperCell to operate.

The SuperCell receives power from the Control Unit and converts the salt water to chlorine.

The Bypass Flow Valve allows water flow rate to be optimized through the SuperCell. The slower water flow through the SuperCell results in a more efficient “Super-Chlorination effect” in the cell that results in better overall sanitization results.

Tri-Sensor

SuperCell

Strainer Screen

Bypass Flow Valve

3

Specifications |

SPECIFICATIONS |

|

|

||

#75003 Pool Pilot Digital Control unit |

||

Input Power |

|

|

230 Vac |

1.5 amps |

(Normal input configuration shipped from the factory) |

115 Vac |

3 amps |

(Optional input configuration – jumper wire to convert included) |

Dry Contact |

5 mA typical Non-factory ORP input circuit (110Vac output require a Relay Kit – PN# 110-ORP) |

|

Chlorine Output |

|

|

SuperCell Type |

Maximum Chlorine Output (# 75003 Control unit set on Cell Power 3) |

|

SC-36 |

|

1.28 lbs/day (0.58 kg/day) |

SC-48 |

|

1.56 lbs/day (0.71 kg/day) |

SC-60 |

|

1.92 lbs/day (0.88 kg/day) |

CC-15 |

|

2.50 lbs/day (1.14 kg/day) – Commercial Cell |

Manifold Flow Requirements

Minimum Flow Rate |

20 gallons per minute (gpm) (76 liters/minute (L/m)) |

Maximum Flow Rate |

100 gallons per minute (gpm) (379 liters/minute (L/m)) |

Maximum Pressure |

85 psi (as tested by NSF) |

Pump/Auxiliary Relay Output

Voltage Input |

Amps / HP max |

115 Vac |

30 amps / 1 HP |

230 Vac |

30 amps / 2.5 HP |

Agency Approvals

•ETL tested to conform to the following UL specifications:

o UL1081 - Standard for Safety for Swimming Pool Pumps, Filters and Chlorinators

oUL 1563 - Standard for Safety for Electric Spas, Equipment Assemblies, and Associated Equipment.

•CAN/CSA-E335-1 - Safety of Household and Similar Electrical Appliances

#75001 Pool Pilot Pool Chemistry Control unit

pH Acid Feed Pump and Tank AC Input Power

#75004 |

120 Vac |

1.7 amps |

#75005 |

220 Vac |

0.9 amps |

#75006 |

230 Vac |

0.9 amps |

#75007 |

250 Vac |

0.9 amps |

#75008 Auxiliary Relay Kit |

115 / 230 Vac Relay |

30 amps max |

Low Voltage Input Power

PCC Communication |

Factory Low Voltage Interface Cable provided with #75001 |

#75008 pH Auxiliary Relay Kit |

(Optional) Dedicated Factory Low Voltage Terminal |

Flow Cell

Flow Sensor |

Fail – Safe status |

Maximum working pressure |

50 psi |

4

PREPARING THE POOL WATER

Calculating Pool Volume (needed to determine proper balance chemical additions)

Average Depth = (depth of deep end +depth of shallow end) 2

Pool Shape |

Gallons (pool size measured in feet) |

Liters (pool size measured in meters) |

Rectangular |

Length x Width x Average Depth x 7.5 |

Length x Width x Average Depth x 1000 |

Round |

Diameter x Diameter x Average Depth x 5.9 |

Diameter x Diameter x Average Depth x 785 |

Oval |

Length x Width x Average Depth x 5.9 |

Length x Width x Average Depth x 785 |

Your calculated pool volume is ____________. Enter this number for reference on the information section, pg. iii.

Type of Salt

It is important to use Sodium Chloride (NaCl) salt that is greater than 99% pure. Common types of salt include granular food grade, water softener pellets, or solar salt flakes. These are usually available in 25 lb to 80 lb bags at a local pool or building supply store. Water softener and solar salt will have a slower dissolve rate than food grade salt. Rock salt and Granular Salt with Iodine or Rust Preventatives should not be used as they contain high levels of impurities that will cause staining.

Note: Granular salt with anti-caking additives such as YPS (Yellow Prussiate of Soda) or Sodium Ferrocyanide can be used but may cause a localized tint to the water or yellow staining on the pool finish if not mixed and dissolved immediately.

How to Add or Remove Salt

The filter pump should be turned on and run continuously for 24 hours after salt is added to the pool to allow for proper dissolving and circulation throughout the pool. The filter pump should be run continually for up to 24 hours. The salt should be added directly to the pool and over the bottom main drain if so equipped. If there is no main drain, a vacuum head can be used to circulate the salt. Vacuum the salt, brush it around to agitate, or brush into the main drain (if applicable) to speed up the dissolving process.

Caution: Do not use a pool cleaner or vacuum head with wheels as they can leave track marks on newly plastered pools. Do not allow Granular salt to pile up in one location without brushing as staining may occur.

If the salt level in the pool becomes undesirably high, the only way to remove excess salt is to partially drain the pool and refill with fresh water.

Salt Level

Your Pool Pilot requires that the size of your pool be entered into the microprocessor so that it can automatically measure the amount of salt in your pool and indicate how many pounds (kgs) to add when the salt level falls low. To program your pool size, see “Set Pool Volume” on pg. 34. To calculate the number of gallons (liters) of water in your pool, see Calculating Pool Volume above. The salt chart on the following page can also be used to calculate how much salt, in pounds (kgs) should be added to reach the recommended level of 3000 ppm (3.0 g/l).

The ideal salt range is 2500 – 3500 PPM (parts per million) (2.5 – 3.5 g/l). However, the Pool Pilot can operate with salt levels in excess of 35,000 PPM (35.0 g/l), if so desired. High salt levels above 6000 PPM are not normally recommended as this may cause corrosion to metallic objects such as light fixtures, ladders, handrails, heaters, and pumps. Low salt levels below 2400ppm will reduce the efficiency of the Pool Pilot and result in low chlorine production. Extremely low salt levels below 1900 ppm will activate the low salt safety cut-off and halt chlorine production until salt is replenished to proper salt levels.

The salt is constantly recycled during normal operation. The loss of salt during a swimming season should be minimal. Filter backwashing, draining due to rain water overflow, splashing and bathing suit drag out, and leaks (excessive salt loss in a short span of time) are typical ways the salt is lost. Salt does not evaporate from the pool when the water evaporates.

5

PREPARING THE POOL WATER

Salt Addition Chart

The following salt chart is included for reference only. Once your Pool Pilot Digital is properly programmed to the pool water volume, it will automatically indicate how much salt is needed. To use this chart:

1.Find your current salt level (ppm or g/l) in the left column. (This can be obtained from your Pool Pilot display or by testing your water.)

2.Find your pool/spa volume in the second row (Gallons or Liters).

3.Find the amount of salt needed to bring your pool to the ideal level by finding the intersection of the row and column. For volumes other than what is shown, use combinations of various columns.

For example, for an 11,000 gallon (41,646 liter) pool with a salt level of 500 ppm (5 mg/l), the column value for 1000 gallons (4,000 liters) (21 pounds (9 kg)) is added to the column value for 10,000 gallons (38,000 liters) (209 pounds (95 kg)) which gives a total of 230 pounds (104 kg) of salt needed to bring your pool salt level up to the ideal level of 3000 ppm (3.0 g/l).

Pounds (kilograms) of Salt needed to attain 3000 ppm (3.0 g/l)

Current |

|

|

|

Pool/Spa Volume in Gallons (Liters) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

1,000 |

2,000 |

5,000 |

10,000 |

15,000 |

20,000 |

25,000 |

|

30,000 |

35,000 |

40,000 |

||

salt level |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

ppm (g/l) |

(4,000) |

(8,000) |

(18,000) |

(38,000) |

(56,000) |

(76,000) |

(94,000) |

|

(114,000) |

(132,000) |

(152,000) |

|

0 |

25 |

50 |

125 |

250 |

376 |

501 |

626 |

|

751 |

876 |

1,002 |

|

(11) |

(23) |

(57) |

(114) |

(170) |

(227) |

(284) |

|

(341) |

(398) |

(454) |

||

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

250 |

23 |

46 |

115 |

230 |

344 |

459 |

574 |

|

689 |

803 |

918 |

|

(0.25) |

(10) |

(21) |

(52) |

(104) |

(156) |

(208) |

(260) |

|

(312) |

(364) |

(416) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

500 |

21 |

42 |

104 |

209 |

313 |

417 |

522 |

|

626 |

730 |

835 |

|

(0.50) |

(9) |

(19) |

(47) |

(95) |

(142) |

(189) |

(237) |

|

(284) |

(331) |

(379) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

750 |

19 |

38 |

94 |

188 |

282 |

376 |

470 |

|

563 |

657 |

751 |

|

(0.75) |

(9) |

(17) |

(43) |

(85) |

(128) |

(170) |

(213) |

|

(256) |

(298) |

(341) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1,000 |

17 |

33 |

83 |

167 |

250 |

334 |

417 |

|

501 |

584 |

668 |

|

(1.0) |

(8) |

(15) |

(38) |

(76) |

(114) |

(151) |

(189) |

|

(227) |

(265) |

(303) |

|

1,250 |

15 |

29 |

73 |

146 |

219 |

292 |

365 |

|

438 |

511 |

584 |

|

(1.25) |

(7) |

(13) |

(33) |

(66) |

(99) |

(133) |

(166) |

|

(199) |

(232) |

(265) |

|

1,500 |

13 |

25 |

63 |

125 |

188 |

250 |

313 |

|

376 |

438 |

501 |

|

(1.5) |

(6) |

(11) |

(28) |

(57) |

(85) |

(114) |

(142) |

|

(170) |

(199) |

(227) |

|

1,750 |

10 |

21 |

52 |

104 |

157 |

209 |

261 |

|

313 |

365 |

417 |

|

(1.75) |

(5) |

(9) |

(24) |

(47) |

(71) |

(95) |

(118) |

|

(142) |

(166) |

(189) |

|

2,000 |

8 |

17 |

42 |

83 |

125 |

167 |

209 |

|

250 |

292 |

334 |

|

(2.0) |

(4) |

(8) |

(19) |

(38) |

(57) |

(76) |

(95) |

|

(114) |

(133) |

(151) |

|

2,250 |

6 |

13 |

31 |

63 |

94 |

125 |

157 |

|

188 |

219 |

250 |

|

(2.25) |

(3) |

(6) |

(14) |

(28) |

(43) |

(57) |

(71) |

|

(85) |

(99) |

(114) |

|

2,500 |

4 |

8 |

21 |

42 |

63 |

83 |

104 |

|

125 |

146 |

167 |

|

(2.5) |

(2) |

(4) |

(9) |

(19) |

(28) |

(38) |

(47) |

|

(57) |

(66) |

(76) |

|

3,000 |

|

|

|

|

Ideal |

|

|

|

|

|

||

(3.0) |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

3,500 |

OK for Pool Pilot Operation – (This is typically the maximum salt level desired by most pool |

|||||||||||

(3.5) |

|

owners/operators since most people can taste salt levels above this.) |

|

|||||||||

Greater |

OK for Pool Pilot Operation but greater than 6000 ppm can cause corrosion to metallic |

|||||||||||

than |

||||||||||||

objects- (If lower salt level is desired, partially drain and refill with fresh water.) |

||||||||||||

3,500 |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

6

PREPARING THE POOL WATER

Basic Water Chemistry

Your Pool Pilot Digital is designed to produce chlorine on a daily basis. To monitor your system’s efficiency, the water chemistry ranges and schedule of periodic checks outlined below should be followed.

CHEMICAL |

IDEAL RANGE |

IDEAL TEST |

EFFECT OF LOW/HIGH LEVELS |

CORRECTIVE ACTIONS |

|||||||

|

|

|

|

|

|

|

SCHEDULE |

|

|

|

|

Free Chlorine |

1.0 To 3.0 |

ppm |

Weekly |

Low free chlorine: Not enough residual |

Low free chlorine: Check for |

||||||

|

|

|

|

|

|

|

|

chlorine to safely sanitize pool water. |

combined chlorine level and shock as |

||

|

|

|

|

|

|

|

|

High free chlorine: Corrosive to metallic |

necessary. Increase purifier output to |

||

|

|

|

|

|

|

|

|

fixtures in pool water. Can bleach |

maintain a 1-3 ppm residual reading. |

||

|

|

|

|

|

|

|

|

swimwear and hair. |

High free chlorine: Decrease purifier |

||

|

|

|

|

|

|

|

|

|

output. Let chlorine dissipate |

||

|

|

|

|

|

|

|

|

|

normally until 1-3 ppm is achieved. |

||

|

|

|

|

|

|

|

|

|

In extreme cases, pool water can be |

||

|

|

|

|

|

|

|

|

|

diluted with fresh water or a chlorine |

||

|

|

|

|

|

|

|

|

|

neutralizer added. (Diluting will |

||

|

|

|

|

|

|

|

|

|

reduce salt and CYA. Check and |

||

|

|

|

|

|

|

|

|

|

adjust as needed.) |

||

pH |

7.2 To 7.8 |

|

Weekly |

Low pH: (acidic) Equipment corrosion, |

Low pH: Add sodium carbonate or |

||||||

|

|

|

|

|

|

|

|

eye/skin irritation, plaster etching, rapid |

soda ash |

||

|

|

|

|

|

|

|

|

chlorine consumption |

|

|

|

|

|

|

|

|

|

|

|

High pH: (basic) Scale formation, |

High pH: Add muriatic acid or |

||

|

|

|

|

|

|

|

|

cloudy water, eye/skin irritation, poor |

sodium bisulfate. |

||

|

|

|

|

|

|

|

|

chlorine effectiveness |

|

|

|

Total |

80 To 120 |

ppm |

Monthly |

Low TA: Eye irritation, pH “bounce”, |

Low TA: Add sodium bicarbonate. |

||||||

Alkalinity |

|

|

|

|

stained/etched plaster and metal |

High TA: Add muriatic acid often, a |

|||||

|

|

|

|

|

|

|

|

corrosion. |

little at a time (may take a week or |

||

|

|

|

|

|

|

|

|

High TA: Constant acid demand, |

more to lower the TA). Aerate by |

||

|

|

|

|

|

|

|

|

difficulty in maintaining pH, and |

pointing return jets toward the |

||

|

|

|

|

|

|

|

|

contributes to scale formation or cloudy |

surface. |

||

|

|

|

|

|

|

|

|

water conditions. |

|

|

|

Salt |

2500 To 3500 ppm |

Monthly |

Low Salt: Below 2,400 ppm causes |

Low Salt: Add salt according to |

|||||||

|

|

|

|

|

|

|

|

premature cell failure and reduces |

digital display on Pool Pilot unit or |

||

|

|

|

|

|

|

|

|

chlorine production |

salt chart. |

||

|

|

|

|

|

|

|

|

High Salt: Above 6,000 ppm can cause |

High Salt: If undesirably high, |

||

|

|

|

|

|

|

|

|

corrosion of metallic fixtures and will |

partially drain and refill the pool with |

||

|

|

|

|

|

|

|

|

taste salty. Note: AutoPilot can safely |

fresh water. (Diluting will reduce |

||

|

|

|

|

|

|

|

|

operate with salt levels up to 35,000. |

CYA. Check and adjust as needed.) |

||

Calcium |

200 To 400 |

ppm |

Monthly |

Low CH: Etching of plaster, equipment |

Low CH: Add calcium chloride |

||||||

Hardness |

|

|

|

|

corrosion |

flakes. |

|||||

|

|

|

|

|

|

|

|

High CH: Scale formation, cloudy |

High CH: Partially drain and refill |

||

|

|

|

|

|

|

|

|

water. Rapid buildup of scale may |

pool with fresh water to dilute. |

||

|

|

|

|

|

|

|

|

exceed the system’s self-cleaning |

(Diluting will reduce salt and CYA. |

||

|

|

|

|

|

|

|

|

capability and require manual cleaning |

Check and adjust as needed.) |

||

|

|

|

|

|

|

|

|

of the SuperCell. |

|

|

|

Cyanuric Acid |

60 To 80 |

ppm |

Monthly |

Low CYA: destruction of chlorine by |

Low CYA: Add cyanuric acid |

||||||

(CYA or |

|

|

|

|

the UV rays from the sun. |

(1 lb/5000 gallons increases CYA 25 |

|||||

Stabilizer) |

|

|

|

|

High CYA: Requires more chlorine to |

ppm) |

|||||

|

|

|

|

|

|

|

|

maintain proper sanitizer levels. |

High CYA: Partially drain and refill |

||

|

|

|

|

|

|

|

|

Note: CYA not needed for indoor or |

pool with fresh water to dilute. |

||

|

|

|

|

|

|

|

|

bromine pools. |

(Diluting will reduce salt. Check and |

||

|

|

|

|

30 To 50 |

ppm |

|

CYA can be reduced to 30 – 50 ppm for |

adjust as needed.) |

|||

|

|

|

|

|

|

|

|

Pool Pilot Digital TC/ORP or colder |

|

|

|

|

|

|

|

|

|

|

|

climate regions. |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

! WARNING |

|

Excessively high chlorine levels can cause premature cell failure and corrosion |

||||||

|

|

|

|

damage to pool fixtures and equipment. |

|

|

|

||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

! WARNING |

|

Always follow the instructions on the manufacturer’s label whenever adding |

|||||||

|

|

|

chemicals to your pool. |

|

|

|

|||||

|

|

|

|

|

|

||||||

7

PREPARING THE POOL WATER

Saturation Index (SI)

The Saturation Index is a formula used to predict the calcium carbonate saturation of water, that is, whether your water will precipitate, dissolve, or be in equilibrium with calcium carbonate. Your water is properly balanced if the SI is 0 ± 0.3. If your SI is greater than 0.3, scaling and staining will occur. If your SI is less than -0.3, then the water is corrosive to metallic fixtures and aggressive to plaster surfaces and vinyl liners. A high or low SI can cause premature damage to the cell, equipment or pool finish. As a general rule, higher concentrations of calcium, total dissolved solids, pH, and alkalinity all promote a greater tendency for scale. Scaling potential also increases with increasing temperature.

Use the chart below to determine your overall water balance. Test your water for pH, water temperature, Calcium Hardness, Total Alkalinity and Salt Level and use the equivalent Factors (TF, CF, AF, Constant) from the chart below to determine your Saturation Index. Adjust your chemicals to maintain balanced water.

pH + TF + CF + AF – SC = SI

Temperature |

|

TF |

|

|

Calcium |

|

CF |

|

|

Total |

|

AF |

|

|

Salt Level |

|

SC |

|

|

|

|

|

Hardness |

|

|

|

Alkalinity |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

60oF |

15.6oC |

0.4 |

|

|

150 ppm |

1.8 |

|

|

75 ppm |

1.9 |

|

|

0 – 1000 ppm |

12.1 |

|

||||

66oF |

18.9oC |

0.5 |

|

|

200 ppm |

1.9 |

|

|

100 ppm |

2.0 |

|

|

1001 - 2000 ppm |

12.2 |

|

||||

76oF |

24.4oC |

0.6 |

|

|

250 ppm |

2.0 |

|

|

125 ppm |

2.1 |

|

|

2001 - 3000 ppm |

12.3 |

|

||||

84oF |

28.9oC |

0.7 |

|

|

300 ppm |

2.1 |

|

|

150 ppm |

2.2 |

|

|

3001 - 4000 ppm |

12.4 |

|

||||

94oF |

34.4oC |

0.8 |

|

|

400 ppm |

2.2 |

|

|

200 ppm |

2.3 |

|

|

4001 - 5000 ppm |

12.5 |

|

||||

103oF |

39.4oC |

0.9 |

|

|

600 ppm |

2.4 |

|

|

250 ppm |

2.4 |

|

|

5001 - 6000 ppm |

12.6 |

|

||||

|

|

-.3 |

-.2 |

-.1 |

0 |

.1 |

.2 |

.3 |

|

|

Corrosive to |

|

|

|

|

|

|

|

|

|

Scaling, |

metals, etches |

|

|

|

|

|

|

|

|

|

staining, and |

plaster |

|

|

|

|

|

|

|

|

|

cloudy water |

finishes, and |

|

|

|

|

|

|

|

|

|

conditions |

irritates skin |

|

|

|

|

OK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Examples

Water test results #1: |

|

Total Alkalinity = 125 ppm |

=> AF = 2.1 |

Calcium Hardness = 400 ppm |

=> CF = 2.2 |

pH = 7.4 |

=> pH = 7.4 |

Water Temperature = 84 F |

=> TF = 0.7 |

Salt Level = 3000 ppm |

=> SC = 12.4 |

|

7.4 + 0.7 + 2.2 + 2.1 – 12.4 = 0 (Water is perfectly balanced) |

Water test results #2: |

|

Total Alkalinity = 200 ppm |

=> AF = 2.3 |

Calcium Hardness = 600 ppm |

=> CF = 2.4 |

pH = 7.8 |

=> pH = 7.8 |

Water Temperature = 84 F |

=> TF = 0.7 |

Salt Level = 3000 ppm |

=> SC = 12.4 |

|

7.8 + 0.7 + 2.4 + 2.3 – 12.4 = 0.8 (Water is scale forming) |

8

INSTALLATION

Before Installing the # 75003 Pool Pilot Digital System

•Determine that everything needed for installation is on hand

•Determine where the Manifold Assembly will be plumbed

•Find a suitable mounting location for the Control Unit within proper cord length to the manifold

•Plan cord runs for SuperCell Cable and Tri-Sensor Cable

•For optional TC or pH control systems, plan for flow cell water feed tubes and acid feed tube and electrical connections

•Plan wire runs and wiring connections for source power and optional connections if any;

o Determine where input power for the Pool Pilot will originatedirectly from a circuit breaker

|

from an external Timer or |

Pool Pilot is to be wired to the same location as the main filter pump |

|

from an electronic controller |

so that it only activated when the pump is energized. |

o Determine whether the input voltage for the Pool Pilot is 230Vac (factory configured) or 115Vac o Determine whether the Pool Pilot will be used to control a single speed pump or a dual speed pump o Determine whether the Pool Pilot will be controlled by an ORP controller (or TCC Option)

o Determine whether the Pool Pilot will be controlled by an Electronic Controller system.

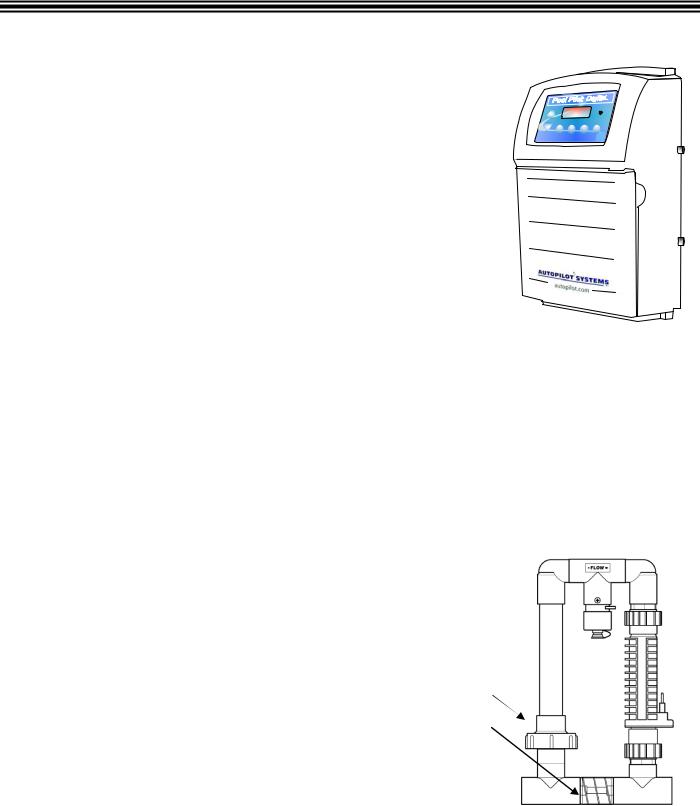

What is included?

Although the manifold assembly may be sold separately, both a manifold and a Pool Pilot Digital Control unit are required for a complete installation and start-up. The standard cell/manifold assembly is available with the following cells: SC-36, SC-48, SC60 (residential cells), or the CC-15 (commercial cell). Before attempting the installation, check that the following items have been included with the Pool Pilot Pool Pilot Digital Control unit:

DIGITAL CONTROLLER

Quantity |

Item Description |

|

1 |

# 75003 Pool Pilot Digital Control Unit |

BOOST MENU SELECT PUMP |

|

AC jumper for 115 Vac configuration |

|

1 |

Tri-Sensor Cable |

|

1 |

SuperCell Cable |

|

1 |

Mounting Template |

|

4 |

Plastic Anchors |

|

4 |

Mounting Screws |

|

*2 |

68mm x 2” metric adapters (#19059) |

|

* European Systems only

What is not included

Some of the additional equipment that may be needed to complete the installation:

For any installation

•Appropriate gauge electrical wire

•½”liquidtite (non-metallic flex) conduit

•½” conduit connector for service to the Pool Pilot

•Drill

•¼” masonry drill bit

For installations using optional equipment

•Appropriate gauge electrical wire

•½” liquidtite (non-metallic flex) conduit

•½” conduit connector for filter pump

•Cable for connection for ORP interface (PN # 315-AC)

•4-Conductor cable for connection to Electronic Controller option

MOUNTING TEMPLATE

Drill (4) ¼

cations.

Drill o

Sean Assam

9

INSTALLATION

Plumbing Requirements

The Manifold Assembly is 2” Schedule 40 and is typically plumbed into the pool return line and, if applicable, after the heater and spa return diverter valve.

Electrical Requirements

Power must be shut off at the circuit breaker before performing any wiring. All local and NEC electrical codes should be followed.

The Pool Pilot Digital has been factory configured for 230Vac operation. If it needs to be reconfigured for 115Vac operation, then see Converting from 230 Vac to 115Vac on pg. 13.

Installation Steps

Details on each step of the installation process are presented on the following pages:

1.Plumbing the Manifold Assembly (pg. 11)

2.Mounting the Pool Pilot Digital (pg. 12)

3.Electrical connections (pgs. 13 - 15)

a.Grounding and bonding

b.High voltage wiring

i.Pool Pilot Digital to an external timer or controller

ii.Pool Pilot Digital relay for a One-speed pump or pH acid feed pump (optional)

iii.Pool Pilot Digital relay for a Two speed pump output (optional)

iv.Pool Pilot Digital relay for acid feeder (optional)

c.Low voltage wiring

i.SuperCell cable

ii.Tri-Sensor cable

4.#75001 Pool Chemistry Controller Configuration – optional (pgs. 16 - 23)

5.Electronic Control Configuration – optional (pg. 24)

6.Menu Overview (pg. 25)

7.System Startup and programming (pgs. 26 - 37)

10

INSTALLATION

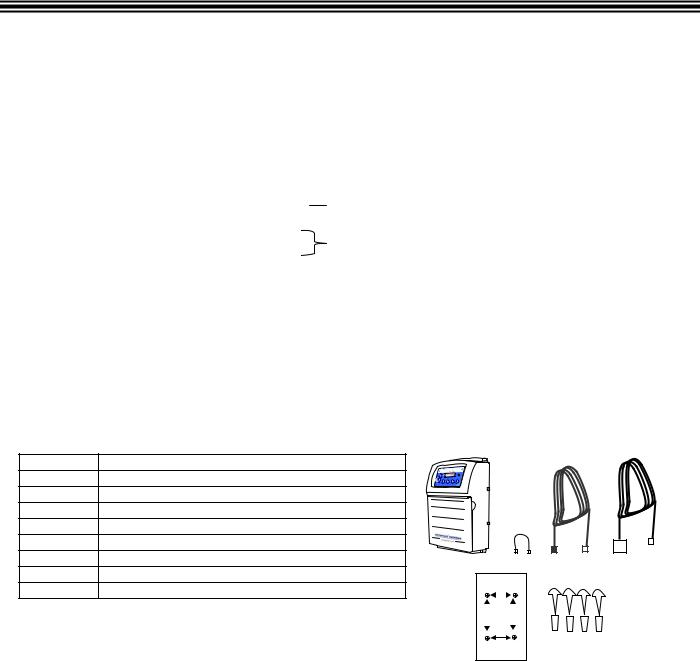

Plumbing the Manifold Assembly

Step 1: Select the location for installing the manifold:

The manifold is designed for a flow rate of 20 to 100 gpm (76 to 379 L/m).

•It is recommended that the manifold be installed prior to installation of the control unit. The Control Unit will need to be installed close enough to the Manifold Assembly so that the Tri-Sensor and SuperCell Cables (12’ long) will have enough slack so that the cables can be serviced easily.

•The manifold/cell should be installed in a vertical orientation as illustrated in the picture below. This orientation prevents hazardous gas buildup in the system if the flow switch should fail to detect insufficient flow.

•The direction of the water flow through the manifold must be as indicated for the system to work properly.

•For a Pool/Spa combination, the manifold must be located as the last component in the POOL RETURN LINE to avoid oversanitization of the SPA.

For flow rates within the normal range:

•The manifold can be directly plumbed into the system as shown in the diagram to the right.

•If the flow rate for the system is less than 20 gpm (76 L/m),

a larger pump must be installed.

Note: Ensure that flow rates for a two-

speed pump can provide sufficient flow at low speed.

For flow rates greater than 100 gpm (379 L/m):

• A 5 lb spring bypass check valve must be plumbed in parallel with the manifold as shown in the diagram to the right.

Main Flow |

To Pool Return |

5 lb bypass valve

Step 2: Install the cell into the manifold with the cell cable terminals at the bottom of the manifold as illustrated in the picture. Tighten the unions by hand for a watertight seal. The manifold will accept the SC-36, SC-48, SC-60 residential cells, or the CC-15 commercial cell.

|

! WARNING |

|

If the cell is improperly installed upside down, water from rain or other sources may enter |

|

|

the cable contacts and result in failure of the SuperCell and void your warranty. |

|

|

|

11

Loading...

Loading...