Aprilaire 6508KV, 6510KV Installation Manual

Model 6508KV and 6510KV

Make-Up Air Damper Kit

Installation Instructions

WARNING

Significant depressurization of the home can lead to back drafting

of combustion appliances or chimneys which can cause build-up

of dangerous levels of chemicals inside the home and lead to

asphyxiation. The make-up air system design must be done by a

qualified design professional.

The Model 65##KV Make-Up Air Kit provides components that are to

be used for the installation of a make-up air duct which can be used

to prevent home depressurization that occurs when larger kitchen

range hoods (generally those that exhaust greater than 400 cfm) are

operating. The negative pressure caused by the range hood, will draw

some make-up air in through openings in the home; this quantity of air

can be significant, and should be measured using a blower door test

or similar procedure to determine how much additional make-up air is

needed. The additional make-up air is drawn in through the installed

make-up air duct; the goal is to achieve proper pressure balance. If

the make-up air duct is connected to the return ductwork of the HVAC

system (see FIGURE 3), additional negative pressure can be made

available to draw in even more air when the make-up air system is

interlocked with the HVAC system.

Excessive negative pressures in the home can result in improper

venting of combustion appliances and fireplaces and thus the design

of the make-up air system must be done by a qualified professional

with knowledge of all relevant local building codes and equipment

manufacturer specifications to determine:

1. if make-up air is required

2. how much make-up air is needed

3. what must be done to install the system safely

4. whether or not the make-up air needs heating, cooling or moisture

control

INCLUDED IN THE KIT

(1) Model 65## Normally Closed 24VAC Damper

• 6508 = 8" diameter damper

• 6510 = 10" diameter damper

(1) Model 50 Current Sensing Relay

(1) Part No. 4010 Transformer

AIRFLOW SPECIFICATIONS

CAUTION

Improper duct sizing can lead to insucient make-up airflow and

reduced performance. Use the airflow specifications provided as a

guide to select the correct size(s) of make-up air duct/damper.

TABLE 1 – TYPICAL AIRFLOW THROUGH MAKE-UP AIR DUCT (FIGURE 1)

Available Negative Pressure Make Up Airflow (CFM)

"w.c. Pa 6508KV (8") 6510KV (10")

-0.02 -5 55 115

-0.04 -10 75 160

-0.06 -15 95 195

-0.08 -20 110 235

-0.10 -25 125 265

-0.20 -50 185 390

-0.30 -75 225 490

-0.40 -100 260 565

-0.50 -125 295 640

-0.60 -150 320 705

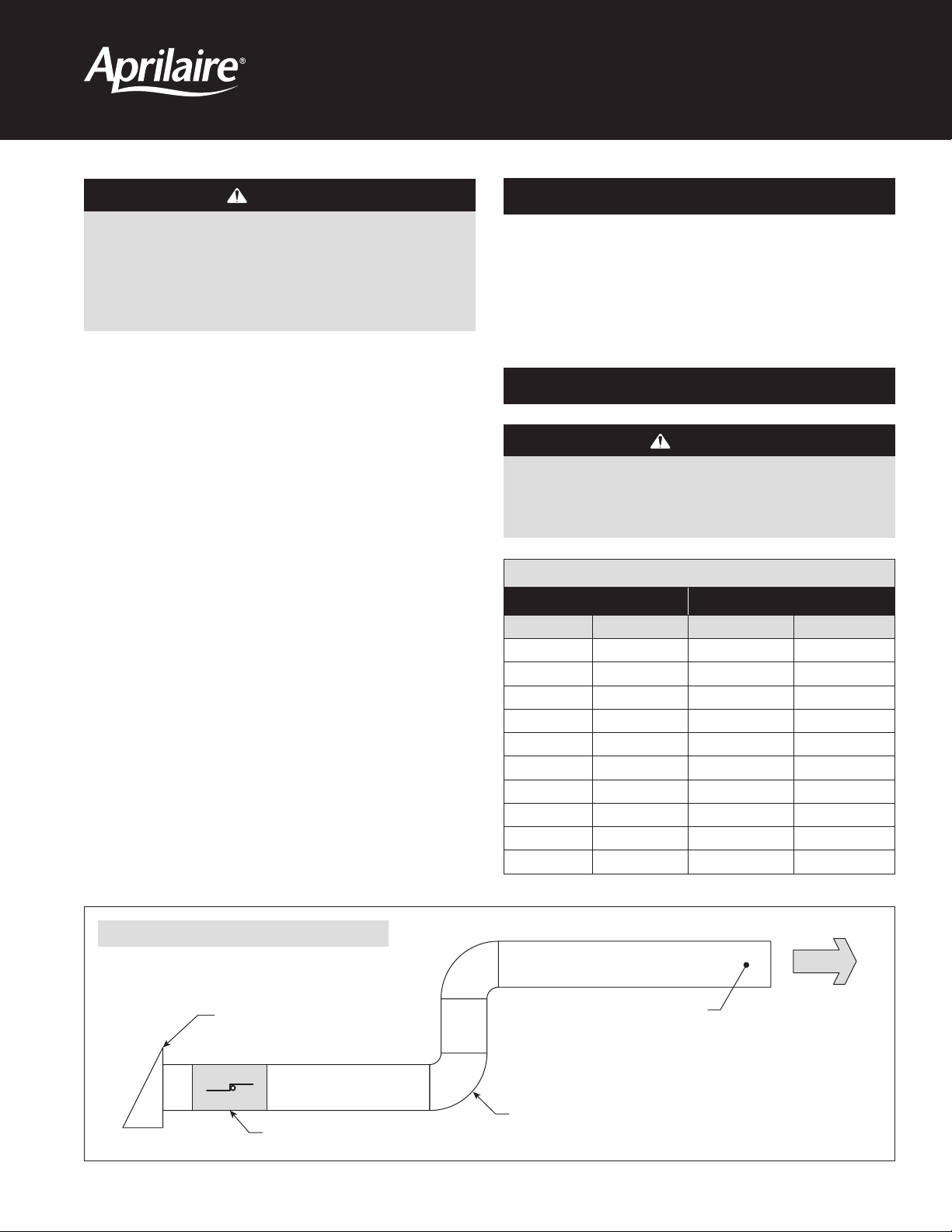

FIGURE 1 – MAKE-UP AIR DUCT TEST CONFIGURATION

INTAKE HOOD WITH 1/4" BIRD SCREEN

DAMPER

PRESSURE

TOTAL 25 FT. INSULATED FLEX DUCT WITH TWO 90° BENDS

AIRFLOW

1

TYPICAL DUCT INSTALLATION

WARNING

Sharp edges may cause injury from cuts. Wear appropriate hand/

eye protection when cutting or handling ductwork.

DIRECT DUCTING

Use this method when there is no existing duct system or access to the

existing duct system is not practical (see FIGURE 2).

1. Install a register(s) with the desired neck diameter at the desired

location in the kitchen so that the air is directed toward the range

hood.

2. Install an intake hood of the desired diameter and with a bird

screen at an appropriate location in an outside wall. Make sure the

intake hood is not located near any exhaust hoods or other sources

of contaminants, and that the hood is mounted higher than any

expected snow drift line.

3. Run a duct between the register and intake hood. Insulated

ductwork is required to prevent condensation.

4. Install the properly sized, normally closed damper in the duct as

close to the intake hood as possible. Insulate the damper to prevent

condensation.

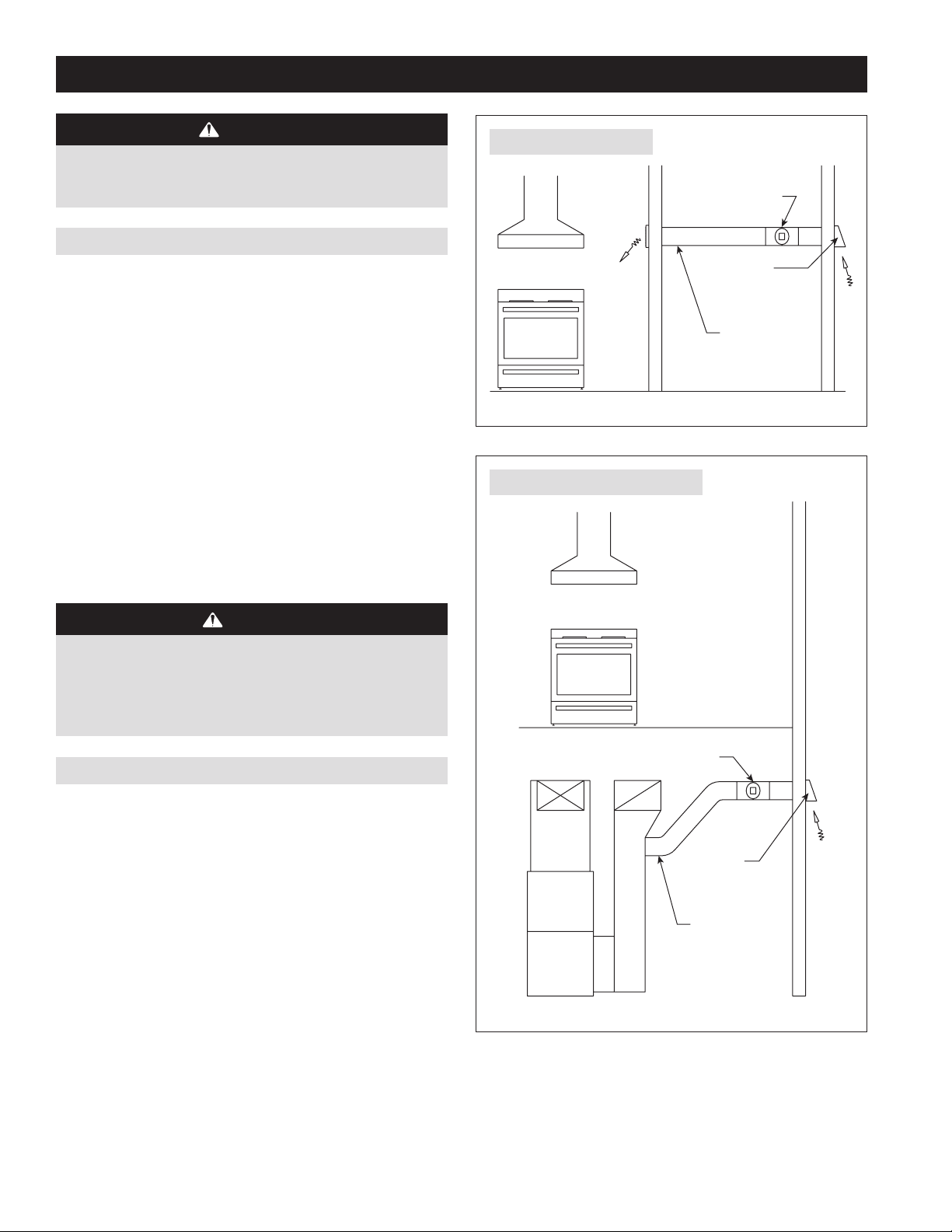

FIGURE 2 – DIRECT DUCTING

RANGE

HOOD

RANGE

FIGURE 3 – DUCTING TO HVAC SYSTEM

RANGE

HOOD

NORMALLY CLOSED

DAMPER – INSULATE

FRESH AIR

INTAKE HOOD

WITH BIRD SCREEN

INSULATED DUCT

90-2047

CAUTION

Keep air temperatures entering the HVAC equipment within

manufacturer recommendations to prevent voiding equipment

warranty. Make-up air system design is to be done by a qualified

HVAC professional.

DUCTING TO THE HVAC SYSTEM

Use this method when there is an existing duct system and it is

accessible (see FIGURE 3).

1. Install an intake hood of the desired diameter and with a bird

screen at an appropriate location in an outside wall. Make sure the

intake hood is not located near any exhaust hoods or other sources

of contaminants, and that the hood is mounted higher than any

expected snow drift line.

2. Run a duct between the intake hood and the return plenum of the

HVAC system. Locating the return duct connection close to the HVAC

system maximizes the negative pressure available for drawing in

outside air when the HVAC system is running. Insulated ductwork is

required to prevent condensation.

3. Install the properly sized, normally closed damper in the duct as

close to the intake hood as possible. Insulate the damper to prevent

condensation.

RANGE

NORMALLY CLOSED DAMPER – INSULATE

FRESH AIR

INTAKE HOOD

WITH BIRD SCREEN

INSULATED DUCT

90-2047

2

Loading...

Loading...