Page 1

Symmetra

TM

User Manual

380V/400V/415V - 3:1

Frame Model: SYMSTRF3I

Page 2

Limited Warranty

American Power Conversion (APC) warrants its products to be free from defects in materials and workmanship

for a period of one year from the date of purchase. Its obligation under this warranty is limited to repairing or

replacing, at its own sole option, any such defective products. To obtain service under warranty you must obtain

a Returned Material Authorization (RMA) number from APC or an APC service center. Products must be returned to APC or an APC service center with transportation charges prepaid and must be accompanied by a brief

description of the problem encountered and proof of date and place of purchase. This warranty does not apply to

equipment which has been damaged by accident, negligence, or mis-application or has been altered or modified

in any way. This warranty applies only to the original purchaser who must have properly registered the product

within 10 days of purchase.

EXCEPT AS PROVIDED HEREIN, AMERICAN POWER CONVERSION MAKES NO WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. Some states do not permit limitation or exclusion of implied warranties; therefore, the aforesaid

limitation(s) or exclusion(s) may not apply to the purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL APC BE LIABLE FOR DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN

IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. Specifically, APC is not liable for any costs, such as

lost profits or revenue, loss of equipment, loss of use of equipment, loss of software, loss of data, costs of substitutes, claims by third parties, or otherwise. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state.

Life Support Policy

As a general policy, American Power Conversion (APC) does not recommend the use of any of its products in life

support applications where failure or malfunction of the APC product can be reasonably expected to cause failure

of the life support device or to significantly affect its safety or effectiveness. APC does not recommend the use of

any of its products in direct patient care. APC will not knowingly sell its products for use in such applications

unless it receives in writing assurances satisfactory to APC that (a) the risks of injury or damage have been minimized, (b) the customer assumes all such risks, and (c) the liability of American Power Conversion is adequately

protected under the circumstances.

Examples of devices considered to be life support devices are neonatal oxygen analyzers, nerve stimulators (whether

used for anesthesia, pain relief, or other purposes), autotransfusion devices, blood pumps, defibrillators, arrhythmia detectors and alarms, pacemakers, hemodialysis systems, peritoneal dialysis systems, neonatal ventilator incubators, ventilators for both adults and infants, anesthesia ventilators, infusion pumps, and any other device

designated as “critical” by the U.S.F.D.A.

Hospital grade wiring devices and leakage current may be ordered as options on many APC UPS systems. APC

does not claim that units with this modification are certified or listed as Hospital Grade by APC or any other

organization. Therefore these units do not meet the requirements for use in direct patient care.

Entire contents copyright © 1999 American Power Conversion. All rights reserved; reproduction in whole or in

part without permission is prohibited. Symmetra, Power Array, SmartSlot, SmartCell and SNMP Adapter are

trademarks of APC. PowerChute and PowerDoctor are registered trademarks of APC. All other trademarks are

the property of their respective owners.

SymmetraTM User Manual - Model SYMSTRF3I

English User Manual: # 990-7173A Rev. 2

Page 3

Safety Information

Safety Symbols

Safety Information

Radio Frequency Interference

Operation Symbols

Introduction

We l co m e

System Components

Model Specific Details

Basic Operation

Glossary of Symmetra

Site Requirements

Operating Space Requirements

Structural Requirements

Environmental Requirements

Heat Output

Short-Term Battery Module Storage

Electrical Requirements

Table of Contents

TM

Te r m s

Receiving and Unpacking

Receiving

Moving the SymmetraTM Frame and Modules

Unpacking The SymmetraTM Frame

Electrical Installation

Electrical Requirements

Wiring Overview

Wiring Procedures

Wiring Verification Procedure

Startup Procedure

Securing the Frame - Setting the Leveling Feet

Power Module Installation

Battery Module Installation

System Startup Procedure

Configuration and Advanced Operation

Advanced Monitoring Functions

Advanced Configuration Functions

Appendix A: PowerView Interface

Appendix B: Troubleshooting

Appendix C: Module Replacement

Appendix D: SymmetraTM Specifications

Page 4

Notes

Page 5

Safety Symbols

Safety Information

Warning!

Warning!

Caution!

Notice!

Indicates a hazard which, if not avoided, could result

in injury or death.

Indicates a hazard which, if not avoided, could result

in damage to the product or other property.

Read and pay attention to this important information.

Indicates the primary safety ground.

Safety Information

n The SymmetraTM contains an internal energy source. Hazardous voltage can be present even when discon-

nected from the utility power source.

n READ AND SAVE THIS USER’S MANUAL - This User's Manual provides safety, installation and operat-

ing instructions for optimal performance and service life from the Symmetra

list of technical support numbers are printed on the back cover. Record serial numbers on the back cover

before calling technical support.

n Before installing electrical connections -

this User Manual. All wiring connections must be made correctly by a qualified electrician.

n Where required, the electrician must attach the UPS warning tag to the input power distribution panel.

n Installation of the power and battery modules, and operation of the SymmetraTM to be performed by

personnel trained in electrical and mechanical hazards.

n Installation and replacement of the Main and Redundant Intelligence Modules (MIM & RIM) can be

performed by any untrained person.

n The protective earth conductor for the Symmetra

(computer equipment). Therefore, the size of the conductor must be at least as large as the wire required

by IEC 950. IEC 950 states the following nominal cross-sectional areas:

- 6 mm2 for rated current between 33 & 40 A

2

- 10 mm

- 16 mm

- 25 mm

n The 120V, 7.2 Ah battery module constitutes a risk of electrical shock and an energy hazard. Before

replacing battery modules, remove conductive jewelry such as chains, wrist watches and rings. High short

circuit current through conductive materials could cause severe burns.

for rated current between 41 & 63 A

2

for rated current between 64 & 80 A

2

for rated current between 81 & 100 A

Read, Study, and Understand the Electrical Installation Section of

TM

carries the leakage current from the load devices

TM

Power Array. A complete

990-7162-001

Safety Information - Page 1

Page 6

n Do not dispose of batteries or battery modules in a fire. The batteries may explode. Return all battery

modules to APC or to an appropriate recycling center.

n Do not open or mutilate battery modules or batteries. Released electrolyte is harmful to the skin and eyes.

It may be toxic.

n Battery modules are heavy (60 lb). Two people are required to handle battery modules.

n This product is intended for installation in a temperature controlled, clean, dry, indoor area that is free of

conductive contaminants. (0° to 40° C.)

n This product must be connected to an Emergency Power Off (EPO) switch.

Total Power Off Procedure

n

Remove all power from the SymmetraTM before opening any of the wiring panels:

1. Set system enable switch to the “stand by” position.

2. Set input circuit breaker to the “stand by” position.

3. Remove all battery modules from the Power Array.

TM

4. If an extended run battery cabinet is connected to the Symmetra

, disconnect the cabinet by

removing the power cable from the bottom rear connector of the SymmetraTM.

5. Disconnect the utility power source circuit breaker. Label it with a safety warning tag.

Radio Frequency Interference

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules and the Class A limits for radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with the Class A FCC limits.

Operation Symbols

On Position

Off Position

Stand By Position

Page 2 - Safety Information

Indicates that a switch or current protection device is in the “on” position. The

system enable switch, maintenance bypass switch and the input circuit breaker

can be placed in the “on” position.

Indicates that a switch is in the “off” position. The maintenance bypass switch is

the only switch that can be placed in the “off” position.

Indicates that a switch or current protection device is in the “stand by” position.

The system enable switch, and the input and output circuit breakers can be

placed in the “stand by” position.

990-7162-001

Page 7

Introduction

Welcome!

Congratulations for your purchase of a SymmetraTM Power Array! The SymmetraTM is a UPS system with

redundant and modular power, battery and intelligence components. It is the finest protection available to

safeguard a datacenter and important data against the unpredictability of power fluctuation and failure.

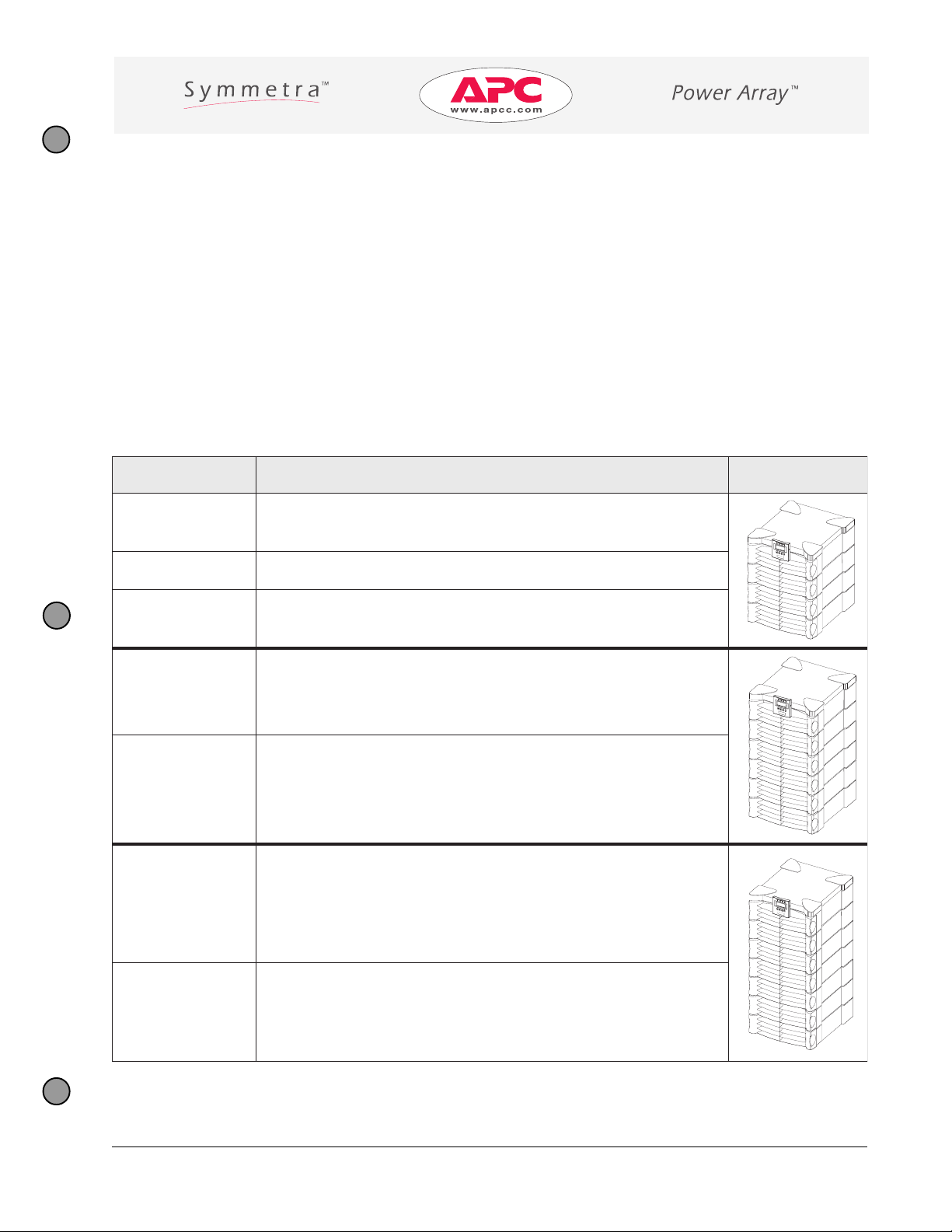

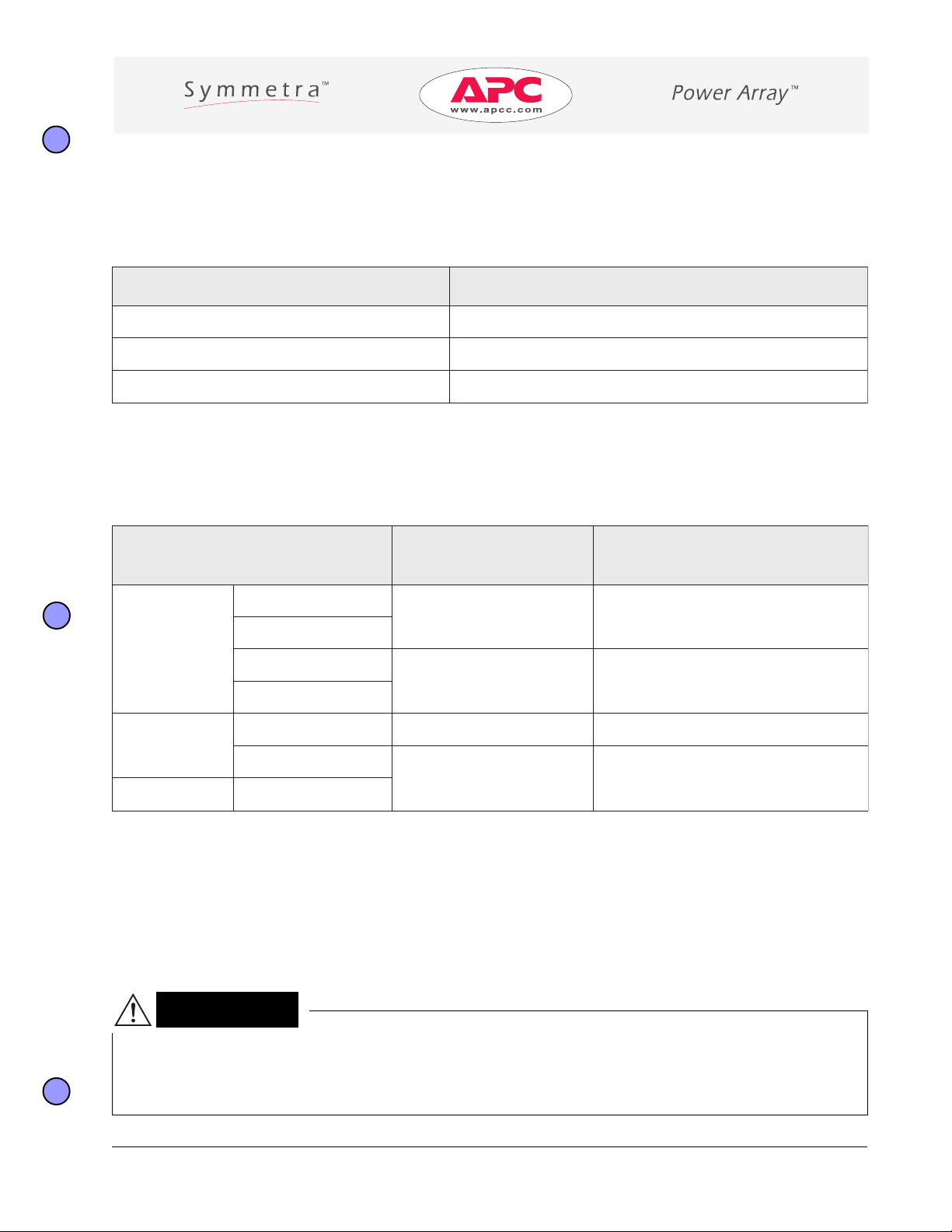

Models

SymmetraTM systems can be ordered in a variety of configurations. All of these are built around one of the

frames listed below. Refer to the packaging list or the frame name plate to determine the frame model.

ledoMemarF noitpircseD noitartsullI

FINIMYS

DP-FINIMYS .selcatpecernoitubirtsidrewopsedulcnitubevobasaemaS

IFINIMYS

IFRTSMYS

I3FRTSMYS

FRTSMYS

zH06/esahPelgniS/mumixaMAVk8

V042/V802/V021:tuptuOV042roV802:tupnI

zH06rozH05/esahPelgniS/mumixaMAVk8

tupnisaemaS:tuptuOV042ro032roV022:tupnI

zH06rozH05/esahPelgniS/mumixaMAVk61

tupnisaemaS:tuptuOV042roV032roV022:tupnI

zH06rozH05/mumixaMAVk61

83

esahPeerhT:tupnI

V514roV004roV0

V042roV032roV022esahPelgniS:tuptuO

zH06/esahPelgniS/mumixaMAVk61

V042/V802/V021:tuptuOV042roV802:tupnI

990-7163-001

DP-FRTSMYS .selcatpecernoitubirtsidrewopsedulcnitubevobasaemaS

Introduction - Page 1

Page 8

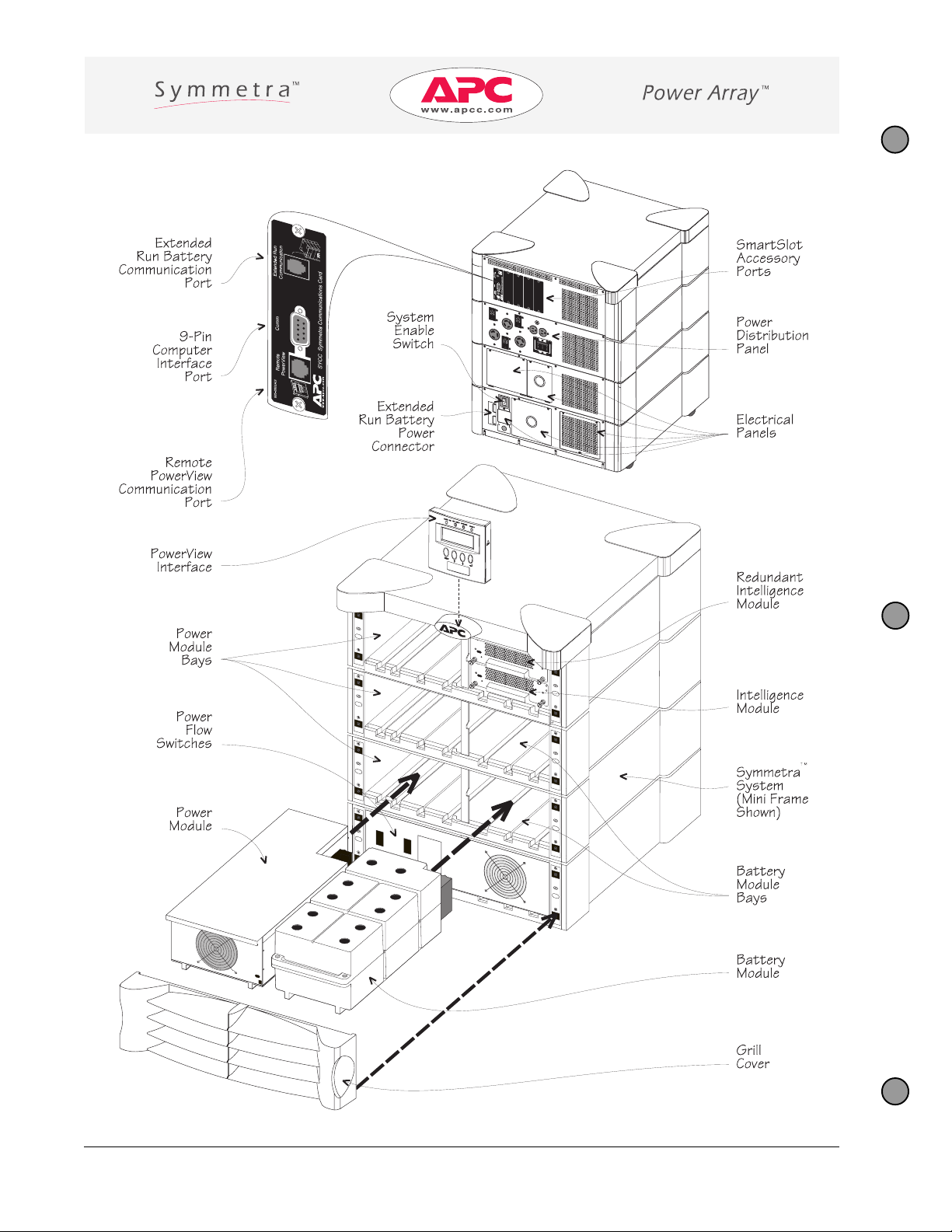

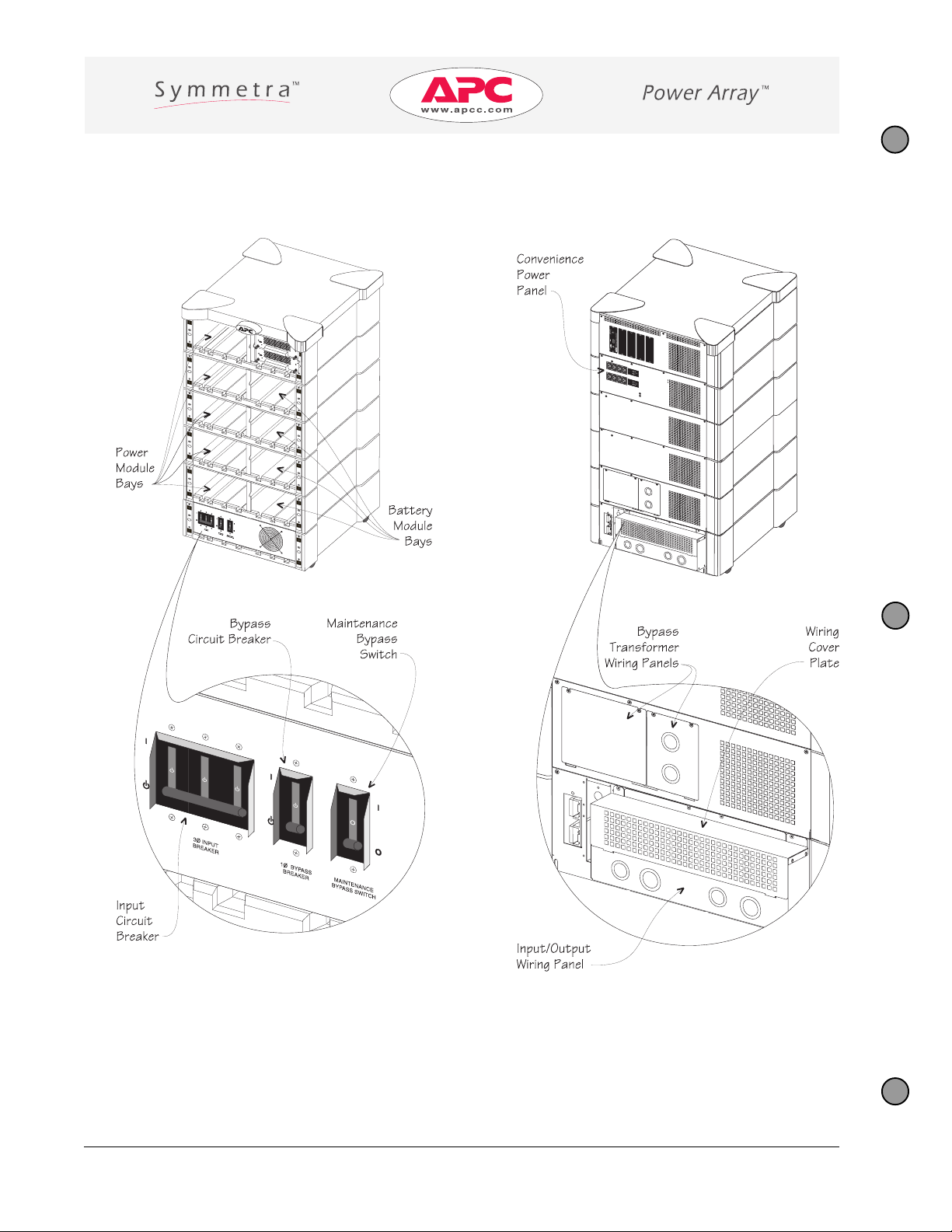

System Components

Page 2 - Introduction

990-7163-001

Page 9

MT

artemmyS

eludoMrewoP

tnenopmoC noitpircseD

.emarf

MT

artemmySehtotnisedilS.tinugnissecorprewoptnerrucgnitanretlaAVk4A

eludoMyrettaB

)MIM(eludoMecnegilletnIniaM

MT

artemmyS

MT

artemmySehtfoecnegilletniehT

.semarfyrettabnuRdednetxEemosdna,emarf

.snoitcnufnoitacinummoc

eludoMecnegilletnItnadnudeR

)MIR(

MT

MT

artemmyS

emarFmetsyS

artemmySehT

.metsys

sehctiwSwolFrewoP

)s(rekaerBtiucriCtupnI

hctiwSssapyBecnanetniaM

.sliated

revoCllirG

.wolfrewopSPUehtgnitpurretni

MT

artemmySehtotrewopetaluger)s(rekaerbtiucrictupniehT

artemmySehtsessapybhctiwSssapyBecnanetniaMeht,noitisop

MT

artemmySehtfotnorfehtotspanS

.emarf

aotnisedilS.erusolcnecitsalpaedisnidesuohgnirtsyrettabCDV021A

dnalortnoc,gnirotinomllasmrofreP.metsys

tuohtiwelbappaws-tohebotMIMehtswollA.MIMehtfonoisrevtnadnuderA

ehtfostnenopmocraludomehtrofesabehtsasevresemarf

MT

"no"ehtninehW.

stcennocdna

rofsmargaidledomcificepseeS.ecruosrewopytilituehtotyltceridtnempiuqedaol

n .ecafretniweiVrewoPetomeragnitcennocroftropA

stroPnoitacinummoC

n etuhcrewoPCPAroftropecafretniretupmocnip-9A sulP .erawtfos

n .sledomemarfyrettabnuRdednetxEemosroftropnoitacinummocA

stroPyrosseccAtolStramS

lenaPnoitubirtsiDrewoP

).elbacilppaerehW(

hctiwSelbanEmetsyS

MT

artemmyS

.emarf

daoleht nehW).weiVrewoPehtgnisuybdeussisidnammoc"nOdaoLnruT"ehT(.

lanoitporofdedivorperastropruoF tolStramS

MT

.seirossecca

ehtfokcabehtotnitnempiuqedaolgniggulproflenapnoitubirtsidrewoP

MT

artemmySeht,noitisop"no"ehtninehW

,yllanretnipusrewop rewoptonseodtub

.yllanretninwodsrewopmetsyseht,noitisop"ffo"ehtni

990-7163-001

rewoPyrettaBnuRdednetxE

rotcennoC

slenaPlacirtcelE

lenaPsseccAgniriWOPE

lenaPsseccAgniriWtupnI

.slenap

.sliatedrofsmargaidledomcificepseeS

.noitcennocrewopemarfyrettabnuRdednetxEnA

esehtdnihebsnoitcennoclanimrettuptuO/tupnIdnagniriwffOrewoPycnegremE

slenaPsseccAgniriWtuptuO

Introduction - Page 3

Page 10

Model Specific Details (SYMSTRF3I)

Page 4 - Introduction

990-7163-001

Page 11

MT

artemmyS

stnenopmoC

:ledoMoTcificepS

noitpircseD

I3FRTSMYS

:etoN .ylnoI3FRTSMYSledomotseilppaelbatsihT

rekaerBtiucriCtupnI

.edomenilnoehtninehwsdaolrevoemertxe

slenaPgniriWtuptuO/tupnI

slenaPgniriWremrofsnarTssapyB

lenaPrewoPecneinevnoC

.slenapesehtdniheb

.stuptuomumixampmA01otdetcetorp,sgulpruof

rekaerBtiucriCssapyB

hctiwSsssapyBecnanetniaM

.tnempiuqedaoleht

tsniagametsysehtstcetorP.ecruosrewopytilituehtotartemmySstcennoC

ehthtiwxobseirosseccaehtnideppihseraetalprevocdnalenapgniriwehT

.artemmySehtgniriwnehwesehtsllatsninaicirtceleehT.launamresu

detacolkcolbnoitcennoclanimretaotderiwsiremrofsnartssapyblanoitponA

fostesowtnidegnarrA.)V042-V022(steltuorewopepyt31C023CEIthgiE

metsysehtstcetorP.dellatsnisinoitporemrofsnartssapybonnehwdesuylnO

siremrofsnartssapybafI.edomssapybninehwsdaolrevoemertxetsniaga

.hctiwssihtrevodellatsniebtsumetalprevoca,metsysehthtiwdedulcni

hctiwsssapybecnanetniamehtnehW.noitcnufssapybehtfolortnoclaunaM

otecruosrewopytilitumorfyltceriddereviledsirewop,noitisop"no"ehtnisi

990-7163-001

Introduction - Page 5

Page 12

Basic Operation

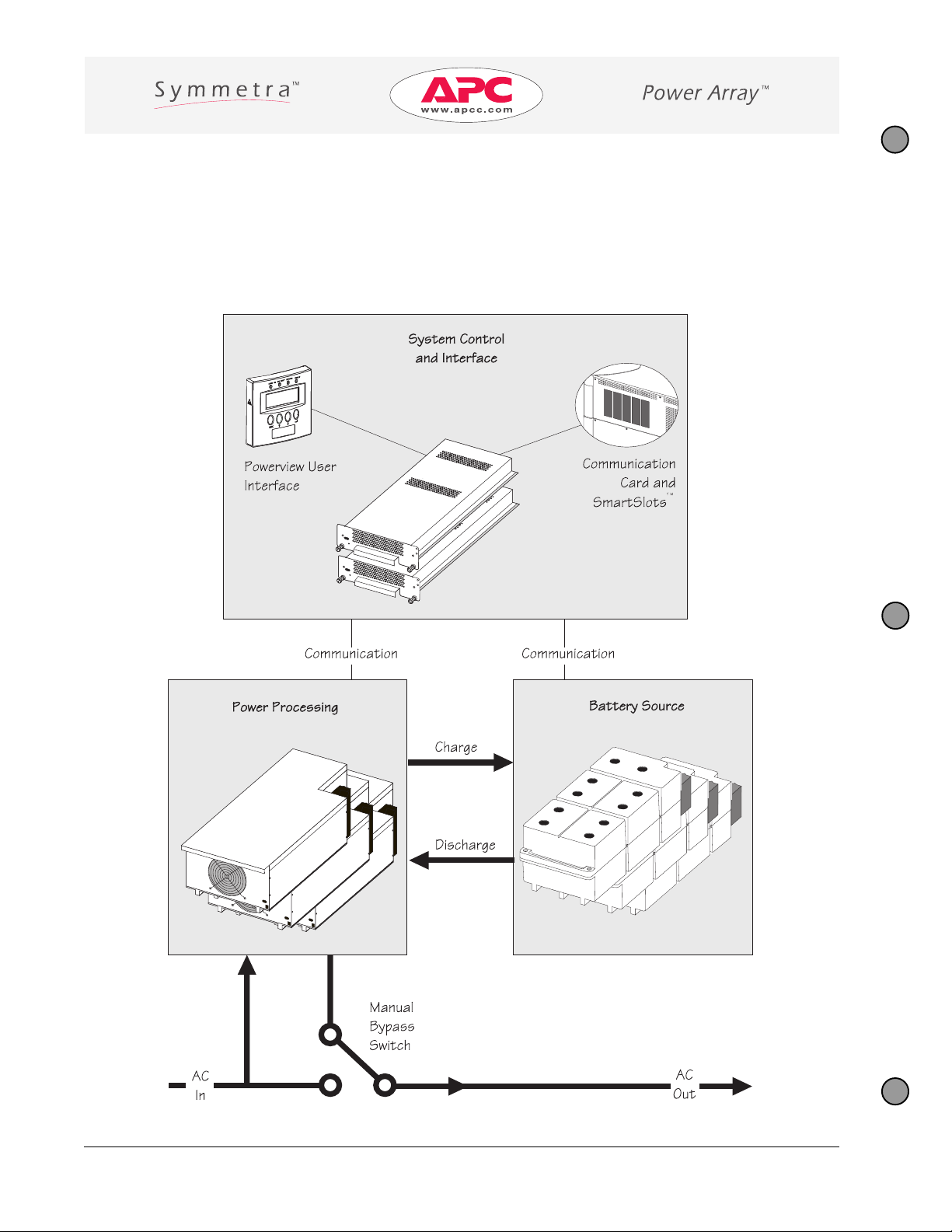

The internal architecture of the SymmetraTM system is comprised of a control and interface system (intelligence

modules and several user interface options) that monitors and controls a power processing system (power

modules) and a battery source (battery modules). The relationship between these functional components is

illustrated below.

Page 6 - Introduction

990-7163-001

Page 13

Glossary of SymmetraTM Terms

Extended Run Battery Frame - An accessory that increases the battery capacity of a system. Multiple

Extended Run frames can be connected to a single SymmetraTM to significantly increase run time.

Hot-Swappable - Modules are “hot-swappable” when they can be replaced safely while the load equipment is

still powered and the Symmetra

TM

is fully functional.

N+1 - Refers to the level of power module redundancy. “N” represents the number of power modules required

to power the load, and “+1, +2, etc.” represents the number of extra power modules that are installed. For

example, a 7.3 kVA load requires two power modules for adequate protection. If the Symmetra

TM

is configured

with only two modules, it has an “N+0” level of redundancy, or no redundancy. If the system is configured with

three power modules, it has an “N+1” redundancy. Depending on the the load requirements, SymmetraTM can

be configured with 2, 3 or even 4 extra power modules, giving it an N+2, N+3, or N+4 level of redundancy.

Redundancy - Refers specifically to power modules. If at least one “extra” power module is installed, the

system can sustain a fault condition and still provide protection to the load equipment. To be fully redundant,

the system should be configured with at least one redundant power module, and a minimum of two battery

modules. (When two or more battery modules are present, one of them can fail and the system will still have a

battery power source. The total number of battery modules determines the length of on-battery run time.)

Scalability - The modular architecture allows the user to increase power capacity as load requirements increase. Scalability is limited by the size of the frame, and the number of available power module bays.

SmartSlot

cards. Before installing any SmartSlot

n Share-UPS

n PowerNet

n Measure-UPS

n Call-UPS

TM

Accessories - SmartSlotTM bays at the rear of the frame accommodate up to four accessory

TM

- Provides automatic shutdown of up to two additional servers.

TM

SNMP - Provides network UPS management.

TM

II - Provides environmental information such as ambient temperature and humidity.

TM

- Works with an external modem to provide out-of-band UPS management.

TM

accessory, ensure it is a compatible “Symmetra

TM

OK” model.

System Capacity - The maximum output power that a Symmetra

TM

system can deliver. System capacity is

limited by the lesser of the frame size, or the capacity of the installed power modules.

n A Mini Frame (8kVA) with one power module installed (4kVA) has a system capacity of 4kVA.

n A Master Frame (16kVA) with five power modules (20kVA) has a system capacity of 16kVA.

990-7163-001

Introduction - Page 7

Page 14

Page 8 - Introduction

990-7163-001

Page 15

Site Requirements

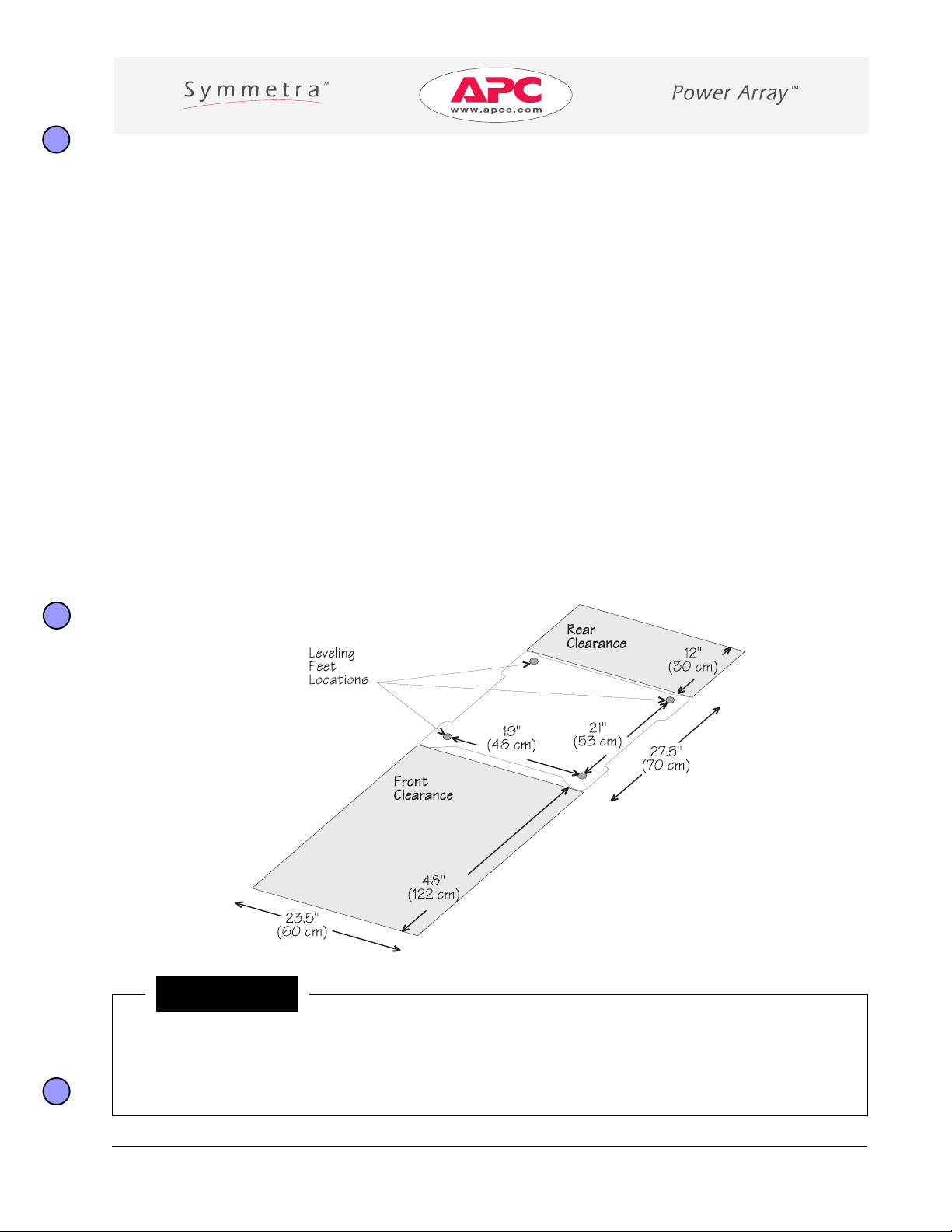

Operating Space Requirements

The SymmetraTM is 23.5” (60cm) wide, and 27.5” (70cm) deep. No space is required on the sides of the

SymmetraTM frame.

Rear Clearance

n A minimum of 12" (30 cm) of clearance is required behind the frame for adequate airflow.

n The system enable switch must remain accessible.

n The back of the Symmetra

Front Clearance

n A minimum of 48" (122 cm) of clearance is required in front of the frame.

n The PowerView interface must remain accessible.

n The front of the Symmetra

TM

must be accessible for the electrician to install wiring.

TM

must be accessible to install and replace power and battery modules.

Notice!

n The voltage transformer in the SYMINIF and SYMSTRF models emits an electro magnetic field (EMF)

that can interfere with the normal function of a computer monitor. Do not install these models in

close proximity to a computer monitor. The EMF is not of sufficient magnitude to cause interference

with other equipment.

990-7164-001

Site Requirements - Page 1

Page 16

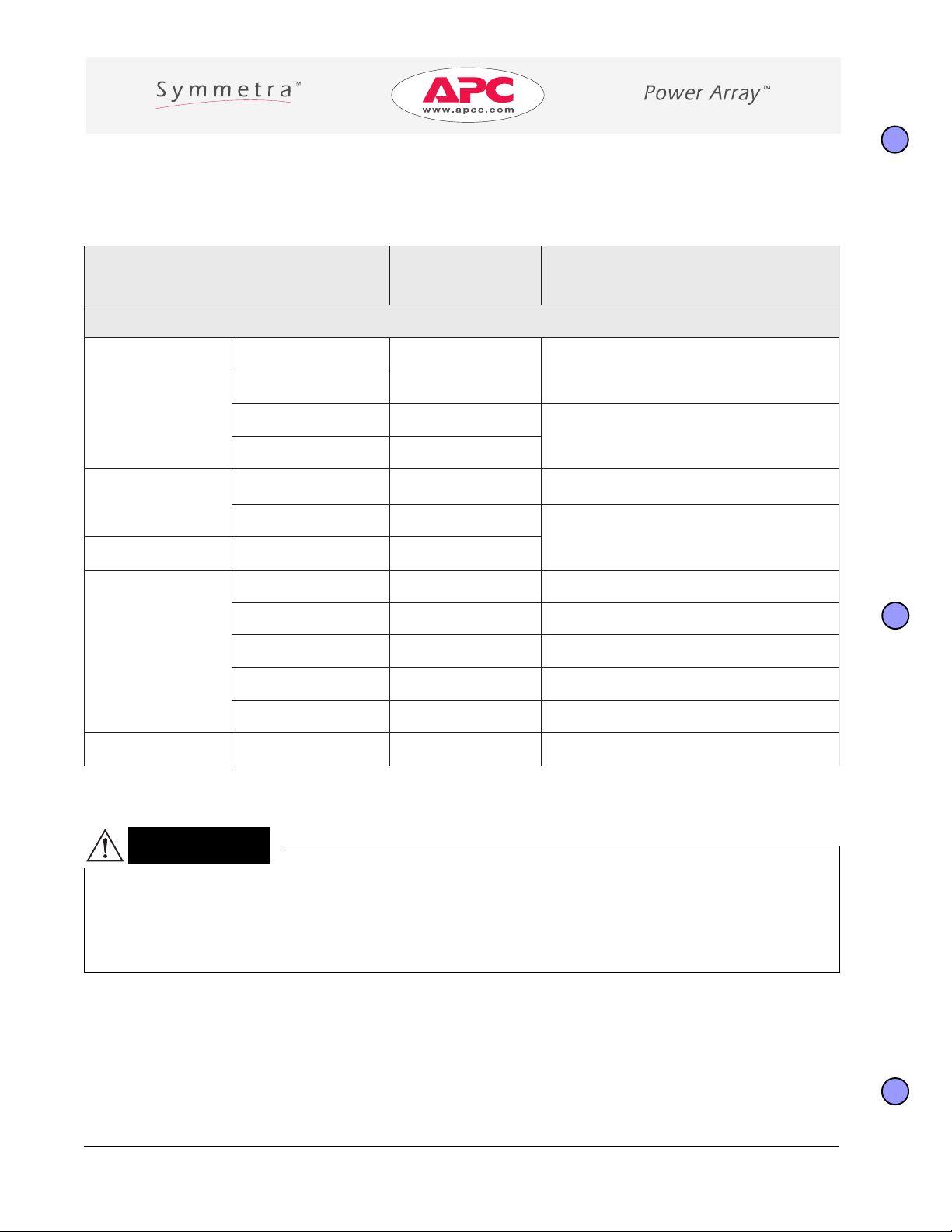

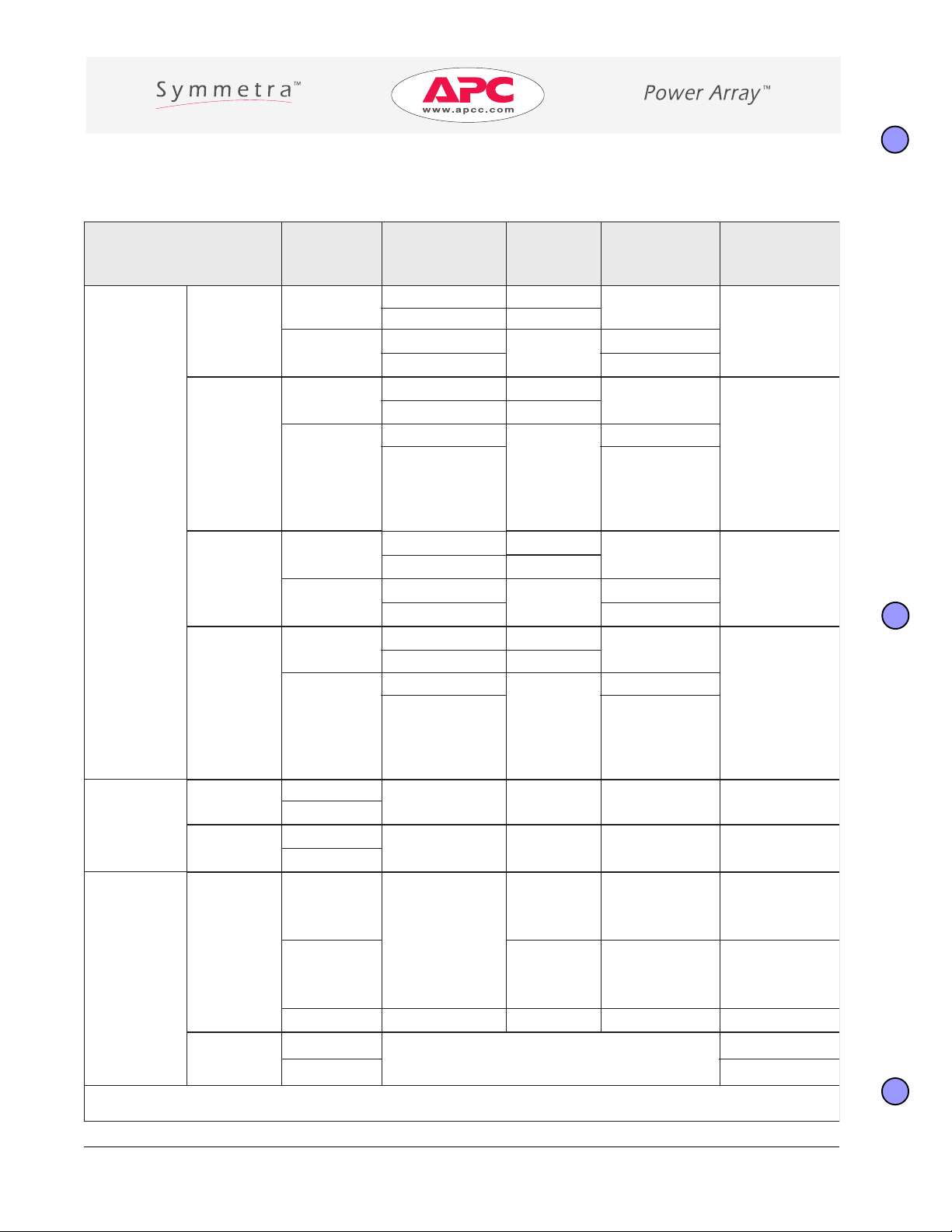

Structural Requirements

SymmetraTM components are heavy. Use this table to determine the total weight of the system.

MT

artemmyS

tnenopmoC

thgieW

)gk(bl

snoisnemiDtcudorP

)mc(sehcniHxDxW

:etoN .seludomhtiwdedaolyllufsemarfroferanwohssthgieW

FINIMYS)gk922(bl094

5.72x"5.32)68x07x06("43x"

naciremAhtroN

sledoM

DP-FINIMYSbl594gk522()

FRTSMYS)gk414(bl019

)041x07x06("55x"5.72x"5.32

DP-FRTSMYS)gk024(bl529

lanoitanretnI

sledoM1:1

IFINIMYSbl063gk461() 5.72x"5.32)68x07x06("43x"

IFRTSMYSbl056gk592()

5.72x"5.32)221x07x06("84x"

ledoM1:3

I3FRTSMYSbl556gk892()

4RXYSMB-1(bl023gk54) "5.72x"5.32)15x07x06("02x

dednetxE

yrettaBnuR

emarF

snoitpO

21RXYSMB-bl039gk324() 5.72x"5.32)221x07x06("84x"

1CBRXYSbl068gk193() )901x48x16("34x"33x"42

2CBRXYSbl0651gk907() )901x48x201("34x"33x"04

3CBRXYSbl003,2gk540,1() )251x48x201("06x"33x"04

snoitpOrehtO

RMFXPB-YSbl002gk19() )46x46x64("52x"52x"81

Caution!

n The weight of the SymmetraTM frames rest on four 1.5" (3.8 cm) diameter leveling feet. Ensure the floor

and subfloor is structurally sound to support the weight of the SymmetraTM frame(s) when concentrated on the leveling feet. Also, make sure the structure can support the total weight of all Symmetra

frames, extended run battery frames, and all other options.

Page 2 - Site Requirements

TM

990-7164-001

Page 17

Environmental Requirements

Install SymmetraTM in a temperature controlled, clean, dry, and protected indoor area that is free of conductive

contaminants. The environment must have adequate airflow, and be free of corrosive fumes.

noitidnoClatnemnorivnE egnaRelbatpeccA

erutarepmeT)C°04-C°0(F°401-F°23

ytidimuHevitaleRgnisnednoc-non%59-0

noitavelE )m840,3ot0(levelaesnaemevobateef000,01ot0

Heat Output

Heat output of the SymmetraTM is significantly increased when batteries are charging. Battery recharge periods

are relatively infrequent.

MT

artemmyS

htroN

naciremA

sledoM

lanoitanretnI

sledoM1:1

ledoM1:3

tnenopmoC

FINIMYS

DP-FINIMYS

FRTSMYS

DP-FRTSMYS

IFINIMYS123,2875,7

IFRTSMYS

I3FRTSMYS

tuptuOUTB

)degrahCseirettaB(

314,3076,8

628,6046,51

246,4654,31

tuptuOUTB

)gnigrahCseirettaB(

Short-Term Battery Module Storage Requirements

Battery modules must be temporarily stored until the electrical wiring is connected and the SymmetraTM is

ready to be powered.

n Batteries should be stored at 0°F to 77°F (-18°C to 25°C) to preserve battery life.

n Storage environment can be within 0 to 100% relative humidity , non-condensing.

Note: Condensation will cause corrosion of electronic and chassis parts.

Caution!

n Installing battery modules in a SymmetraTM that is not powered will discharge the batteries and could

damage them permanently. Do not install battery modules into the SymmetraTM frame until after the

electrical wiring connections have been made, and the system is ready to be powered.

990-7164-001

Site Requirements - Page 3

Page 18

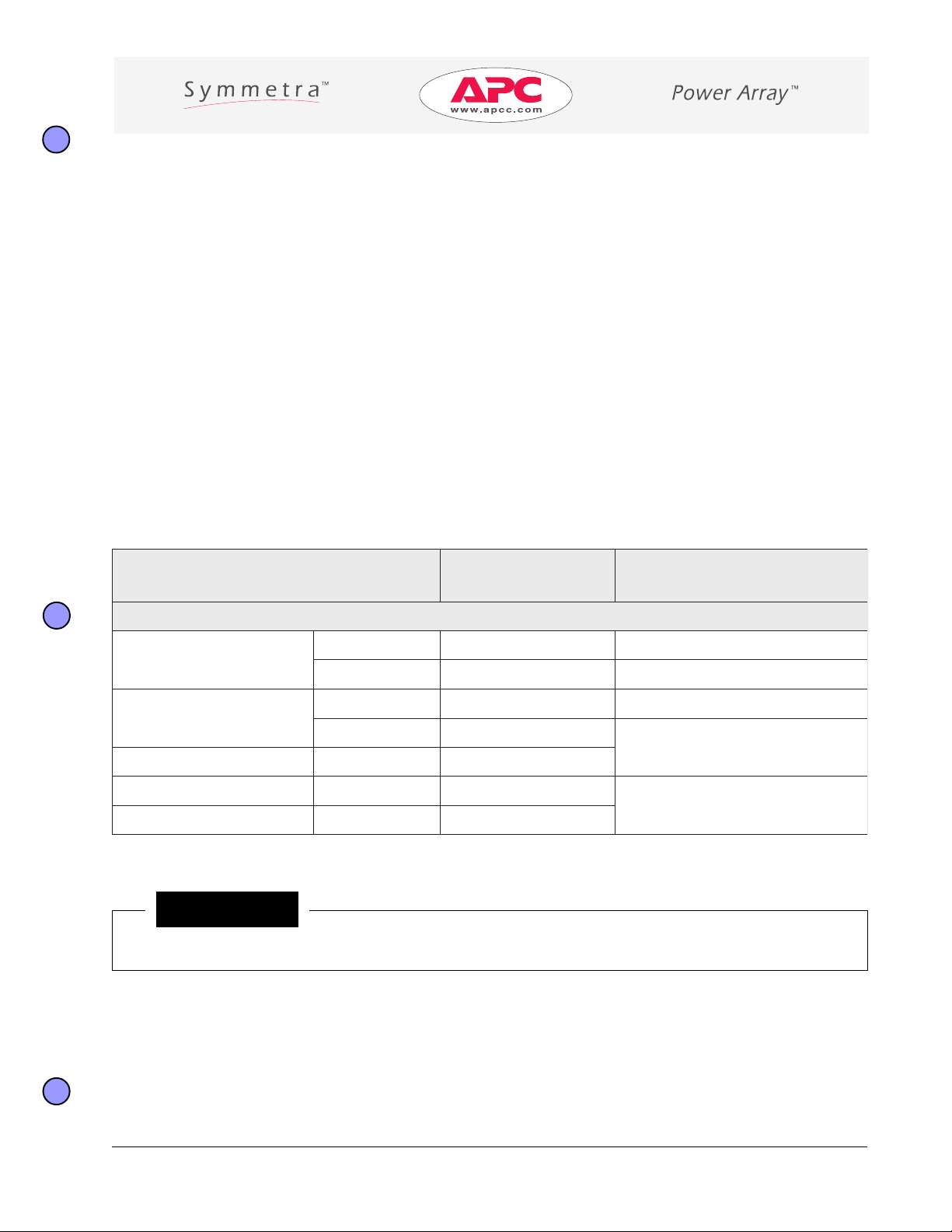

Electrical Requirements - Input/Output

MT

artemmyS

tnenopmoC

gniriW

tupnI

FINIMYS

tuptuO

tupnI

egatloV

)CAV(

V802A04

V042A53

V042/V021

V042/V802/V021eloP-3pmA05

V802A04

V042A53

tnerruC

daoLlluF

A04

V042/V021

DP-FINIMYS

tuptuO

V042/V802/V021

A04

htroN

naciremA

sledoM

FRTSMYS

DP-FRTSMYS

tupnI

tuptuO

tupnI

tuptuO

V802A08

V042A07

V042/V021

V042/V802/V021eloP-3pmA001

V802A08

V042A07

V042/V021

V042/V802/V021

A08

A08

tnerrucrevO

noitcetorP

)lanretxE(

muminiM

eziSeriW

eloP-1pmA05

2

mm01(GWA8#

eloP-2pmA05

)

eloP-1pmA05

eloP-2pmA05

2

)

tnerrucrevO

mm01(GWA8#

tliubsinoitcetorp

rewopehtotni

lenapnoitubirtsid

.tuptuollarof

eloP-1pmA001

2

mm52(GWA3#

eloP-2pmA001

)

eloP-1pmA001

eloP-2pmA001

2

)

tnerrucrevO

mm52(GWA3#

tliubsinoitcetorp

rewopehtotni

lenapnoitubirtsid

.tuptuollarof

lanoitanretnI

IFINIMYS

sledoM1:1

IFRTSMYS

tuptuO

tupnI

tuptuO

tupnI

ssapyBhtiw

remrofsnarT

tupnI

I3FRTSMYS

lanoitanretnI

ledoM1:3

tupnI

ssapyBtuohtiw

remrofsnarT

tuptuOV042roV032,V022A08eloP-1pmA001mm52(GWA3#

ssapyB

gnicnalaB

remrofsnarT

tupnI

tuptuO mm52(GWA3#

,V022

V042roV032

,V022

V042roV032

A04eloP-1pmA05mm01(GWA8#

A08eloP-1pmA001mm52(GWA3#

2

)

2

)

esahP/A62

,enilnonehw

dna1LnoA05

,V083

V514roV004

ssapybni2L

esahP/A62

,enilnonehw

1LnoA08

eloP-3pmA06mm01(GWA8#

eloP-3pmA001mm52(GWA3#

2

)

2

)

ssapybni

2

)

2

mm01(GWA8#

.emarfmetsysybdellortnoC

MT

artemmySehtmorf)m51('05nahtrehtrufonremrofsnartgnicnalabssapybehtllatsnI*

.

*)

2

*)

.eguageriwgnitcelesnehwpordegatlovnirotcaf,deriuqersiecnatsidretaergafI

Page 4 - Site Requirements

990-7164-001

Page 19

Electrical Requirements - EPO Switch

The SymmetraTM Power Array can be connected to either a dry contact or 24Vdc Emergency Power Off switch.

The terminal connections for the EPO switch are physically isolated from the primary circuitry of the Power

Array system.

EPO Specifications

The EPO circuit is considered a Class 2 and SELV circuit.

SELV is an acronym for “Safety Extra Low Voltage.” SELV is a common term in Europe and IEC standards. A

SELV circuit is isolated from primary circuitry through an isolating transformer and designed so that under

normal conditions, the voltage is limited to 42.4 Vpeak or 60 Vdc.

A Class 2 Circuit is a common term in North America and in UL and CSA standards. It is defined in the

Canadian Electrical Code (C22.1, Section 16) and in the National Electrical Code (NFPA 70, Article 725).

SELV and Class 2 circuits must be isolated from all primary circuitry. Do not connect any circuit to the EPO

terminal block unless it can be confirmed that the circuit is SELV or Class 2. If there is a question, use a contact

closure switch. Use one of the following cable types to connect the Symmetra

CL2 - Class 2 cable for general purpose use.

CL2P - Plenum cable for use in ducts, plenums, and other space used for environmental air.

CL2R - Riser cable for use in a vertical run in a shaft or from floor to floor.

CL2X - Limited Use cable for use in dwellings and for use in raceway.

For installation in Canada, the cable should be CSA Certified, type ELC (Extra-Low-Voltage Control Cable).

TM

to the REPO switch:

990-7164-001

Site Requirements - Page 5

Page 20

Electrical Wiring Overview

Page 6 - Site Requirements

990-7164-001

Page 21

Receiving and Unpacking

Receiving the Symmetra

The SymmetraTM Power Array frame and modular components are shipped on a number of pallets, dependant on

the configuration ordered. Verify that labeled boxes match the purchase order. Consider the system component

shipping weights and dimensions before moving them. If power modules are missing, check the frame. The

power modules may have been pre-installed at the factory.

TM

Inspect Packaging

Inspect packaging for signs of mishandling. If damage is detected:

1. Note the damage on the Bill of Lading.

2. File a damage claim with the shipping agent within 24 hours.

3. Notify APC of the damage claim, and condition of the equipment.

MT

artemmyS

:etoN S

naciremAhtroN

sledoM

lanoitanretnI

sledoM1:1

ledoM1:3

tnenopmoC

FINIMYS)gk251(bl533)701x67x48("24x"03x"33

FRTSMYS)gk462(bl085)061x67x48("36x"03x"33

IFINIMYS)gk39(bl502)701x67x48("24x"03x"33

IFRTSMYS)gk341(bl513

I3FRTSMYS)gk541(bl023

)gk(bl

thgieWgnippihS

.seludomonhtiwsemarfroferanwohssthgiewgnippih

snoisnemiDgnippihS

)mc(sehcniHxDxW

)241x67x48("65x"03x"33

eludoMyrettaB

eludoMrewoP

TTABYSbl07gk23()

MPYS)gk81(bl04

Notice!

n If power modules were pre-installed, add their weight to the SymmetraTM frame weight.

990-7165-001

Receiving and Unpacking - Page 1

1x"13x"3134x97x33("7)

Page 22

Moving The SymmetraTM Frame and Modules

The frame (bolted to the pallet), should be positioned with a pallet jack or a fork lift. Leave enough space to

unpack the frame, install the ramp, and for two people to roll it onto the floor. The SymmetraTM frame can be

moved over a flat, smooth floor surface by rolling it on the frame casters. The individually boxed power and

battery modules should be stacked close to the installation site.

Caution!

n Do not install battery modules into the SymmetraTM frame until after electrical wiring connections have

been made, and the system is ready to be powered.

n If battery modules are to be stored for an extended time, store them in a dry, cool environment.

n Battery modules are heavy (70 lb). Two people are required to carry, move and install them.

Page 2 - Receiving and Unpacking

990-7165-001

Page 23

Unpacking the SymmetraTM Frame

1. Remove packaging materials and the grill covers. Use care to prevent scratching the surface of the frame.

2. Locate the pallet ramp that is shipped beneath the top corrogated shipping cover.

3. Follow the steps below to remove the frame from the pallet. After unpacking, carefully roll the Symmetra

the installation site. It is now ready to be wired.

TM

to

Caution!

n Two people are required to remove the frame from the pallet.

TM

n All four leveling feet at the base of the Symmetra

from the pallet.

n If rolling the frame on the casters over objects such as door thresholds or floor irregularities, be careful to

prevent the frame from tipping.

990-7165-001

frame must be fully retracted before rolling the frame

Receiving and Unpacking - Page 3

Page 24

Page 4 - Receiving and Unpacking

990-7165-001

Page 25

Electrical Installation

Model: SYMSTRF3I

The following procedures must be performed by a qualified electrician!

Wiring the three phase SYMSTRF3I SymmetraTM includes:

1. Connecting 380V, 400V, or 415V three phase input wiring from a dedicated circuit

2. Connecting 220V, 230V, or 240V single phase output wiring to load equipment via a distribution panel

3. Connecting an Emergency Power Off (EPO) switch

4. Connecting an optional Bypass Balancing Transformer

Notice!

n All power and control wiring must be installed by a qualified electrician.

n Input, Output, Emergency Power Off , and Bypass Transformer wiring must comply with all applicable

local and country codes.

n It is recommended that input electricity for the Symmetra

source. (There are no other circuits on the line.)

n It is recommended that flexible metal conduit be used for all wiring connections. Place the Symmetra

in the final operating position when determining the length of flexible conduit.

n Read this section

completely before installing any wiring to the SymmetraTM frame.

TM

be provided from a dedicated utility power

TM

Warning!

n Verify that all incoming line voltage (utility power) and low voltage (control) circuits are de-energized,

and locked out, before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Verify that all battery modules are removed from the frame, and all Extended Run battery frames are

disconnected from the Power Array before making any wiring connections to the Symmetra

n Always follow the Total Power Off Procedure before making wiring connections to or from a function-

ing Symmetra

990-7166-001

TM

Power Array. (See the Safety Information section.)

Electrical Installation - Page 1

TM

.

Page 26

Electrical Requirements

MT

artemmyS

tnenopmoC

I3FRTSMYS

lanoitanretnI

gniriW

tupnI

ssapyBhtiw

remrofsnarT

tupnI

ssapyBtuohtiw

remrofsnarT

ledoM1:3

tuptuO

ssapyB

gnicnalaB

remrofsnarT

tupnI

tuptuO mm52(GWA3#

egatloV

)CAV(

,V004,V083

V514ro

,V032,V022

V042ro

tnerruC

daoLlluF

nehwesahP/A62

noA05,enilno

ni2Ldna1L

ssapyb

nehwesahP/A62

noA08,enilno

ssapybni1L

A08eloP-1pmA001mm52(GWA3#

.emarfmetsysybdellortnoC

noitcetorP

eloP-3pmA06mm01(GWA8#

artemmySehtmorf)m51('05nahtrehtrufonremrofsnartgnicnalabssapybehtllatsnI*

.eguageriwgnitcelesnehwpordegatlovnirotcaf,deriuqersiecnatsidretaergafI

tnerrucrevO

)lanretxE(

eloP-3pmA001mm52(GWA3#

MT

.

muminiM

eziSeriW

2

)

2

)

2

)

2

mm01(GWA8#

2

EPO Switch Wiring (Required)

The SymmetraTM Power Array is to be connected to either a dry contact or 24Vdc Emergency Power Off (EPO)

switch. The terminal connections for the EPO switch are physically isolated from the primary circuitry of the

Power Array system.

*)

*)

EPO Specifications

The EPO circuit is considered a Class 2 and SELV circuit.

SELV is an acronym for “Safety Extra Low Voltage.” SELV is a common term in Europe and IEC standards. A

SELV circuit is isolated from primary circuitry through an isolating transformer and designed so that under

normal conditions, the voltage is limited to 42.4 Vpeak or 60 Vdc.

A Class 2 Circuit is a common term in North America and in UL and CSA standards. It is defined in the Canadian

Electrical Code (C22.1, Section 16) and in the National Electrical Code (NFPA 70, Article 725).

SELV and Class 2 circuits must be isolated from all primary circuitry. Do not connect any circuit to the EPO

terminal block unless it can be confirmed that the circuit is SELV or Class 2. If there is a question, use a contact

closure switch. Use one of the following cable types to connect the Symmetra

CL2 - Class 2 cable for general purpose use.

CL2P - Plenum cable for use in ducts, plenums, and other space used for environmental air.

CL2R - Riser cable for use in a vertical run in a shaft or from floor to floor.

CL2X - Limited Use cable for use in dwellings and for use in raceway.

For installation in Canada, the cable should be CSA Certified, type ELC (Extra-Low-Voltage Control Cable).

Page 2 - Electrical Installation

TM

to the EPO switch:

990-7166-001

Page 27

Electrical Wiring Overview

990-7166-001

Electrical Installation - Page 3

Page 28

Input/Output Wiring

I/O Wiring Schematic

Page 4 - Electrical Installation

990-7166-001

Page 29

Input/Output Wiring Procedure

1. Mount the Input/Output Wiring Panel to the lower rear frame panel.

Note: The I/O wiring panel and the cover plate are shipped in the frame accessory package located in the upper

TM

right module bay of the frame. Remove the four mounting screws from the rear of the Symmetra

frame, and use

them to install the panel. Place the cover plate aside.

2. Attach flexible metal conduit to the wiring panel.

Note: If the pre-installed knock-outs do not fit your strain relief hardware, use existing knock-out as a pilot to

create a new hole.

3. Pull the wire through the conduit. Leave enough wire extending from the conduit strain relief to reach

terminal blocks.

4. Strip approximately 1/2” (13 mm) of insulation from the end of each wire.

5. Connect the ground wires to the green/yellow grounding terminal block connections.

Note: Both input and output grounds attach to the same terminal block. Make sure to wire them correctly.

6. Connect the neutral wires to terminal block connections marked “N” in blue.

Caution!

n Tighten screws to ensure good electrical connection.

7. Connect remaining power wires to terminal block connections.

8. Inspect wiring for proper connections.

Note: Do not mount the wiring cover plate until the wiring verification procedure is complete.

1

2

3

A

B

C

D

E

990-7166-001

gniriW lobmyS noitpircseD

dnuorGtuptuO

!dnoceSllatsnI

lartueNtuptuO

!htruoFllatsnI

esahPtuptuO

dnuorGtupnI

N

1L

!tsriFllatsnI

lartueNtupnI

!drihTllatsnI

esahPtupnI

tupnIesahP

tupnIesahP

N

3L

2L

1L

muminiM

eziSeriW

)wolleY/neerG(dnuorGytefaS

2

mm52(GWA3#

)eulB(nruteRtuptuO

rewoPtuptuO

)wolleY/neerG(dnuorGytefaSyramirP

)eulB(nruteRtupnI

rewoPtupnI

rewoPtupnI

rewoPtupnI

Electrical Installation - Page 5

.dellatsni

)

2

afi)

mm01(GWA8#

siremrofsnartssapyb

2

mm52(GWA3#

afi)

siremrofsnartssapyb

.dellatsniton

Page 30

Emergency Power Off Switch Wiring (Required)

EPO Wiring Schematic

12

Page 6 - Electrical Installation

990-7166-001

Page 31

Emergency Power Off Switch Wiring Procedure

1. Remove EPO wiring access panel.

2. Determine the type of EPO switch to be used: A contact closure or 24V dc. If a 24V dc EPO switch will be

used, remove the factory installed jumper.

4. Attach flexible conduit, or appropriate wire/strain relief to panel.

5. Pull the wire through the conduit. Leave enough wire extending from the conduit strain relief to reach

terminal blocks.

6. Strip approximately 1/2” (13 mm) of insulation from both wires. Secure a wire terminal to each wire.

Note: It is recommended that ring terminals (crimped) be used to ensure good electrical connection.

7. Connect wires as shown according to switch type.

8. Inspect wiring to ensure proper connections. Carefully fold wiring into the entry compartment and remount

the access panel.

990-7166-001

Electrical Installation - Page 7

Page 32

Bypass Balancing Transformer Wiring (Optional)

Balancing Transformer Wiring Schematic

Page 8 - Electrical Installation

990-7166-001

Page 33

Bypass Balance Transformer Wiring Procedure (Optional)

1. Remove the transformer wiring panels on the SymmetraTM frame, and on the back of the transformer.

2. Move the jumper bar on the frame terminal block up one position. See illustration.

3. Pull the wire through the conduit. Leave enough wire extending from the conduit strain relief to reach

terminal blocks.

Note: The input wires must

4. Attach flexible metal conduit to the Symmetra

wiring panel onto the Symmetra

not be in the same conduit as the output wires. See wiring schematic.

TM

TM

frame.

wiring panel and to the transformer frame . Remount the

5. Strip approximately 1/2” (13 mm) of insulation from the end of each wire.

6. Connect the ground wire to the green/yellow grounding terminal block connection.

7. Connect the neutral wires to terminal block connections marked “N” in blue.

8. Connect remaining power wires to terminal block connections.

9. Inspect wiring to ensure proper connections.

Caution!

n Fasten connection screws to ensure good electrical connection.

10. Remount the wiring panels onto the

TM

Symmetra

11. Switch the bypass circuit breaker to the on

(I) position and install the cover plate over it.

See illustration.

Note: Installing the bypass transformer option

removes the bypass circuit breaker from the

power path.

frame and the transformer.

1

2

3

A

B

990-7166-001

gniriW lobmyS noitpircseD

esahPtuptuOrewoPtuptuO

lartueNtuptuO

dnuorGytefaS)wolleY/neerG(dnuorGytefaS

tupnIesahP

tupnIesahP

3

N

2L

1L

muminiM

eguaGeriW

2

mm52(GWA3#

)eulB(nruteRtuptuO

rewoPtupnI

rewoPtupnI

Electrical Installation - Page 9

)

2

mm01(GWA8#

)

Page 34

Wiring Verification Procedure

The following procedure will ensure that the SymmetraTM has been wired properly. The electrician who performed this electrical installation should complete this checklist and deliver it to the system operator.

Caution!

n Ensure all switches (system enable, maintenance bypass , input circuit breaker, and bypass circuit breaker)

are in the “off ” or “stand by” position. Ensure all load equipment is turned off or is unplugged from the

Power Array.

Note: If a bypass transformer was installed, disregard the bypass circuit breaker.

q 1. Apply power to the system input, and measure voltage at the input terminal block. Record measured

voltages below:

L1-Neutral: ______________________

L2-Neutral: ______________________

L3-Neutral: ______________________

Caution!

n Measured voltage must be between 184V and 265V. If it is not, STOP! Verify correct wiring from the

power source to the input wiring connections. Repeat step 1.

q 2. Connect the PowerView display as shown below:

q 3. Switch the input circuit breaker and bypass breaker on, then switch the system enable switch on.

Note: The system will make some clicking sounds as it powers up, and may display fault messages on the PowerView

display. Disregard these messages at this time.

Page 10 - Electrical Installation

990-7166-001

Page 35

q 4. Press the “Escape” key on the display until the top level menu screen appears. Select “Status.” Pressing the

enter key opens the voltage status screen as illustrated below.

Note: The fault light on the display may remain on. Disregard this visual indicator at this time.

q 5. Record input voltages below, and compare with measured voltages from step 1. If the two measurements

are significantly different, contact APC Symmetra

Vin1: ______________________

Vin2: ______________________

Vin3: ______________________

TM

technical support.

q 6. Switch the maintenance bypass switch on.

Note: Disregard any LED indicator or fault messages on the PowerView.

Record output voltage below, and compare with Vin1 from step 5. If the two measurements are significantly

TM

different, contact APC Symmetra

technical support.

Reported Output Voltage: Out:____________V_________Hz

q 7. Test the EPO switch. The system enable switch should physically move to the “stand by” position, and the

system should shut down completely. If this does not occur, check the connections and the EPO switch to

ensure they are installed and functioning properly.

q 8. Successful completion of steps 1 through 7 indicate that the system wiring is properly installed. Turn off

breakers and switches and shut down input power to the system. Reinstall all wiring access panels on the

frame.

Electrical Installation Completed by:__________________________________________

__________________________________________

__________________________________________

990-7166-001

Electrical Installation - Page 11

Page 36

APC Worldwide Technical Support Telephone Numbers:

APC Headquarters, US

Tel:800-800-4272

APC Argentina

Tel:0800-9-2722

APC Australia

Tel:+612-9955-9366

Fax: +612-9955-2844

Freephone:1 800 652 725

APC Austria

Tel: 0800 296480

APC Belgium

Tel:0800 15063

APC Brazil

Tel: 0800-127221

APC China

Tel:+86-10-8529-9888

Fax: +86-10-8529-9158

APC Czech Republic

Tel:0800 102063

APC Denmark

Tel:800 18 153

APC Finland

Tel:9800 13 374

APC France

Tel:0800 906 483

APC Germany

Tel:0800 1801227

APC Greece

Tel:00800 353 12206

APC Hungary

Tel: 06800 12221

APC India, Nepal,

Sri Lanka, Bangladesh,

and Maldives

Tel: +91-44-433-1124

Fax: +91-44-434-1464

APC Indonesia

Tel: +62-21-650-0813

Fax: +62-21-60-7427

APC Ireland

Tel: 1-800-702000 x2045

APC Israel

Tel: 177 353 2206

APC Italy

Tel: 800 874731

APC Japan

Tel: +813-5434-2021

Fax: +813-5434-2022

APC Korea

Tel: +82-2-501-6492

Fax: +82-2-501-6369

APC Luxembourg

Tel: 0800 2091

APC Malaysia

Tel: +603-756-8786

Fax: +603-756-8780

APC Norway

Tel: 800 11 632

APC Philippines

Tel: +63-2-813-2662

Fax: +63-2-892-2448

APC Poland

Tel:00800 353 1202

APC Portugal

Tel:0800 853 182

APC Russia

Tel:+7 095 916 7166

APC Singapore, Thailand,

Vietnam

Tel:+65-398-1000

Fax:+65-398-1010

APC South Africa

Tel: 0800 994206

APC Spain

Tel:900 95 35 33

APC Sweden

Tel: 020 795 419

APC Switzerland

Tel: 0800 556177

APC Taiwan

Tel: +886-2-2755-1945

Fax: +866-2-2755-1946

APC Turkey

Tel: 0800 353 90275

APC United Kingdom

Tel: 0800 132990

Latin America, toll free to

APC Corporate, USA:

Antigua

Tel: 800-326-0640

Bahamas

Tel: 800-788-9688

Barbados

Tel: 800-534-0631

Bermuda

Tel: 800-623-0717

Brazil

Tel: 0800-127221

Chile

Tel: 123-0-020-0254

Tel: 00-020-3255

Colombia

Tel: 980153947

Mexico

Tel: 95-800-804-4283

Tel: 001-800-788-2208

Peru

Tel: 001-800-804-4383

Uruguay

Tel: 000-413-598-2139

Tel: 1 800-788-9688

Venezuela

Tel: 8001-2856

Tel: 800-1-3506

APC Holland

Tel:0800 0224655

Page 12 - Electrical Installation

990-7166-001

Page 37

Startup Procedure

After the electrical wiring connections are verified, power and battery modules can be installed and the Symmetra

can begin to deliver conditioned power to the output power panel(s).

Securing The Frame - Setting The Leveling Feet

1. Locate the frame in its final operating position.

Note: Leave a minimum of 12” (30 cm) of clearance at the rear of the frame for adequate airflow. Make sure the

system enable switch remains accessible.

2. Hand turn all four leveling feet until the pads make contact with the floor.

3. Use a wrench to extend each leveling foot by turning the hex nut two complete turns.

4. Adjust the leveling feet until the frame is level front to back and side to side.

TM

Lower all four leveling feet

Notice!

n After the leveling feet are lowered, attempting to move the frame may bend them.

990-7167-001

Start-Up Procedure - Page 1

Page 38

Power Module Installation

1. Align the runners of a power module with the alignment grooves in the bottom module bay. Firmly slide the

power module into the frame until the “drop-lock” engages.

2. Swing the flip latch up and fasten the screw to the power module. Do not overtighten.

3. Follow this procedure to install all power modules.

Notice!

n Power modules are installed on the left, battery modules are installed on the right.

n Always install power modules into the lowest available bay.

n If the power modules were installed at the factory, remove each of the shipping retainers that secured the

modules during shipping. Secure the flip latches.

Page 2 - Start-Up Procedure

990-7167-001

Page 39

Battery Module Installation

1. With one person on each side of a battery module, align the runners of a battery module with the alignment

grooves in the bottom module bay. Carefully slide the battery module into the frame until the retaining

flange passes through the frame notch.

2. One person can now firmly push the battery module into the frame until the “drop-lock” engages.

3. Follow this procedure to install all battery modules.

Warning!

n The 120V, 7.2 Ah battery module constitutes a risk of electrical shock and an energy hazard. High short

circuit current through conductive materials could cause severe burns. Before handling battery modules, remove conductive jewelry such as chains, wrist watches and rings.

n Battery modules weigh approx. 60 lb (27 kg). Two people are required to handle battery modules.

n Always install battery modules in the lowest available bay. When removing modules, start from the

highest level and work down.

990-7167-001

Start-Up Procedure - Page 3

Page 40

System Startup Procedure

Notice!

n Refer to Appendix A for information about the PowerView Interface.

n At least one power module, one battery module, and the main intelligence module must be installed

before the system will start.

n Load equipment can be left connected during this start-up procedure, but it should be switched off

until startup is complete.

n The PowerView can be configured to display French, Italian, German or Spanish. (Appendix A, page 3.)

1. Apply input power to the system from the utility power source.

2. Switch the input circuit breaker(s) and the system enable switch on.

3. Wait approximately 15 seconds to allow the system intelligence module to boot up and complete a startup

sequence.

4. Open the top-level menu screen on the PowerView display. (See Appendix A, page 4.)

Note: The PowerView may display some “configuration change” messages because the system was configured at

the factory with a different number of power or battery modules than are now installed. Disregard these messages,

and press the escape key to close them.

5. Verify that all power, battery and intelligence modules are detected by the system and are functioning properly by reviewing all status screens on the PowerView. (From the Status menu, open status screens for battery,

power, main intelligence, and redundant intelligence modules. See Appendix A, page 5.)

Note: If a problem is reported, ensure the system component in question is properly installed. If the problem

persists, refer to the troubleshooting information in Appendix B.

6. Turn load on. (From the Control menu, click Turn Load On. See Appendix A, page 5.)

7. Replace all front grill covers. Make sure all wiring panels are firmly secured to the frame.

TM

8. The Symmetra

power needs.

system is now ready to support the load equipment and be configured to meet specific

Page 4 - Start-Up Procedure

990-7167-001

Page 41

Configuration and

Advanced Operation

Notice!

n The following information should be considered when configuring the Symmetra Power Array to pro-

vide optimal power protection for your specific requirements. For detailed settings and programming

sequences, refer to The PowerView Interface - Appendix A.

Configuration

Display Settings

n The PowerView display date/time should be set to ensure an accurate set of records in the event log. The

beeper volume and screen contrast can be adjusted to meet your particular site needs.

n A password can be used to prevent unauthorized access to configuration settings. Once a password is in-

voked, changes can be made only after entering the password.

n The Startup Screen can be customized to display information that is most important to you.

System Settings (Setup)

n Shutdown and return parameters can be set to best fit your specific power environment. Consider the time

required to gracefully shut down your equipment in the event that a power outage drains the SymmetraTM to

battery exhaustion. Also consider how and when power to the load equipment should be restored after the

utility power returns.

n Output frequency can be controlled. Full Range Tracking (default) offers the widest available range. If your

equipment requires tighter limits, consider the output frequency tolerance setting and bypass control.

n Alarm thresholds can be set to protect your selected system limits. The Symmetra will constantly self moni-

tor load output and alert you with an audible alarm and an error message displayed on the PowerView screen

if a violation occurs.

n Other settings include system self test scheduling, UPS Identification setting, output voltage, and output

voltage reporting.

Logging Control

n A log of the last 64 system events is recorded and stored in the PowerView. The log function can be configured

to record only those events important to you. The event log is especially valuable for diagnosing configuration problems.

990-7168-001

Configuration and Advanced Operation - Page 1

Page 42

Advanced Operation

Control Functions

Symmetra requires you to use the “power load on/off” function to deliver power to the load equipment. Other

control functions allow you to conduct a system self test, test/control external communications by simulating a

power failure, and command the system to go into and out of bypass mode. These functions are primarily used

during configuration changes or system maintainance.

Diagnostic Information

Symmetra constantly monitors itself for internal problems. If an error is detected, the display fault indicator will

light, and an error message will appear on the PowerView screen. Use this diagnostic information to determine

the source of the fault.

Status Review

The status of each modular component in the system - battery, power, and intelligence modules - can be individually reviewed using the PowerView. System settings can also be reviewed.

Load/Capacity changes

Over time, it is possible there will be an increased power demand placed on the Symmetra. As the power demand

increases, system capacity is decreased. Symmetra monitors this relationship and will initiate an audible alarm if

the user-defined parameters are violated. This can be rectified by the following methods:

a.) Increase system capacity by adding Power and Battery Modules.

b.) Change alarm settings to eliminate the violation.

c.) Reduce the load by disconnecting equipment.

Note: System capacity is limited by the lesser of the frame size, or the total capacity of the installed power modules.

Runtime Calibration

To ensure the Symmetra is accurately reporting the battery runtime. A Runtime Calibration test should be conducted at least once a year. The runtime calibration exercises the battery system to 50% discharge, and helps

maintain optimal battery function.

Accessories

The PowerView will communicate with SmartSlot accessories only when an auxilary power cable connects the

PowerView to the computer interface port at the rear of the Symmetra. Contact APC Technical Support for

information about this function.

Page 2 - Configuration and Advanced Operation

990-7168-001

Page 43

Appendix A

The PowerView Interface

It is easy to use the PowerView to command, monitor and configure the SymmetraTM Power Array system. The

interface is so intuitive that even first-time users get up to speed quickly.

Notice!

n The PowerView default language is English. It can be configured to display French, Italian, German or

Spanish. See page 3.

n The PowerView can be connected or disconnected without interrupting the UPS function of the

Symmetra

990-7169-001

TM

.

Appendix A - The PowerView Interface - Page 1

Page 44

PowerView Components

342

1

5

12

11

10

6

9

8

7

tnenopmoCweiVrewoP noitpircseD

1

)neerg(DELNODAOL

.rewopgniviecersitnempiuqedaolehT

2

3

4

5

6

7

8

9

01

11

21

)wolley(DELYRETTABNO

)wolley(DELSSAPYB

)der(DELTLUAF

yalpsiDDCL

dnatSpotelbaT

yeKepacsE

yeKpUllorcS

yeKnwoDllorcS

yeKretnE

mralAoiduA

pihCMORPEegaugnaL

.seludom

MT

artemmySehT

MT

artemmySehT

.mrala"peeb"astimeweiVrewoPehT

.tiucricehtmorfdessapybylevitceffesi

).BxidneppAeeS(.yalpsidciremunahplaehtnosraeppa

.yalpsidlatsyrcdiuqilciremunahplaretcarahc02x4A

.ecafrustalfanoweiVrewoPehttesotliaberiwehttuolluP

.neercssuoiverpehtotsnruteR.neercstnerrucehtstixE

.tsilahguorhtpusllorcsro,puworranoitcelesehtsevoM

.tsilahguorhtnwodsllorcsro,nwodworranoitcelesehtsevoM

.tsilnoitcelesasneporo,dnammocunemdetcelesehtsnepO

).hsilgnEsitluafeD(.hsinapSronamreG,nailatI,hcnerF,hsilgnE

yrettabehtmorfdeilppusgniebsirewoP.derruccosaheruliafrewoptupninA

.ecruosrewopytilituehtmorfyltceriddeilppusgniebsidaolehtotrewoP

egassemmralanA.noitidnoctluaflanretninadetcetedsah

Page 2 - The PowerView Interface - Appendix A

990-7169-001

Page 45

Language Configuration

To change the PowerView display language, an internal EPROM chip must be replaced.

Caution!

n The internal circuitry of the PowerView and the language EPROM chip are sensitive to static electricity.

Use all necessary precautions to eliminate static electricity from yourself and all tools before replacing

the chip. Do not remove the chip from the protective case until ready to install it in the PowerView.

n The PowerView cable must be disconnected from the PowerView before proceeding.

Language Chip Replacement Procedure

1. Remove four screws to separate the rear cover from the PowerView.

2. Locate the language EPROM chip. It is adjacent to a larger 40-pin chip. There is a semicircular notch at one end

of the language chip. The replacement chip must be oriented so that the semicircular notch is in the same position.

3. Insert a small flathead screwdriver between the language chip and the socket. Gently twist the blade to lift the

chip. Proceed with caution and patience to avoid bent pins.

4. Position the replacement language chip on the socket with the semicircular notch in the same orientation as

the original. Carefully ensure that all pins are properly aligned with the socket. Apply even pressure with fingers

to the top of the EPROM until it is fully seated in the socket. Replace the rear cover.

990-7169-001

Language

EPROM Chip

Appendix A - The PowerView Interface - Page 3

Page 46

The Startup Screen

The factory default startup screen is opened by pressing the escape key. It displays the following information:

n Fuel Percentage - the percentage of battery capacity (fuel) that is presently available.

n Load Percentage - the percentage of system capacity that is being used to supply conditioned power to

the load equipment.

n Voltage and Frequency - the input/output voltage, and the ouput frequency.

n Run Time - the run time that can be expected, based on the amount of power required by the load

equipment, and the power capacity of all battery modules connected to the Symmetra

Note: The PowerView interface will “time out” after ten minutes of inactivity, and the LCD display will go blank. The

screen display will reappear when any key is touched.

Note: The startup screen for the international single phase models is depicted. Your startup screen may vary.

TM

Power Array.

Top-Level Menu Screen

Press the escape key to open the “Top-Level Menu” screen. This screen is the “launching pad” to monitor, command and configure the system. Refer to the following tables for all PowerView commands and controls.

Note: The selection arrow in the illustration below is used to select a command. Pressing the up or down key moves the

selection arrow to the desired command, and then pressing the enter key opens it.

Page 4 - The PowerView Interface - Appendix A

990-7169-001

Page 47

lortnoC

noitcnuF

ffO/nOdaoLnruT

tseTfleSoD

eruliaFrewoPetalumiS

.tneve

.deyalpsideblliwegassemrorrena,detceted

toobeRlufecarG

.syaledemitesehttesotnwodtuhS>puteS

nO/ffOnruTlufecarG

.syaledemiteseht

noitarbilaCemitnuRtratS

ssapyBfOtuO/otnISPU

sutatS

noitcnuF

.tnempiuqedaolotecruosytilitu

neercSsutatStnerruC/egatloV

.tnempiuqedetcennocotrewoptuptuofoyreviledroflortnocmetsysehT

simelborpafI.scitsongaid-flesllahguorhtsnuR.tsetflesmetsysasetaitinI

sihtsezingocerrevresehtfitsetotdesU.nruter/eruliafrewopasetalumiS

asetaitinI.erawtfosetuhCrewoPotdetcennocebotartemmySehtseriuqeR

yrettaB-woL"denifed-resuehtretfA.nwodtuhsotrevresehtroflangis

-resuehtfonoitarudehtrofffodehctiwssirewoptuptuoeht",noitaruD

eeS.niaganodehctiwssirewoptuptuoehtnehT".yaleDnruteR"denifed

asetaitinI.erawtfosetuhCrewoPotdetcennocebotartemmySehtseriuqeR

yrettaB-woL"denifed-resuehtretfA.nwodtuhsotrevresehtroflangis

tesotnwodtuhS>puteSeeS.ffodehctiwssirewoptuptuoeht",noitaruD

tuptuodaolsrevileD.tnemerusaememitnuryrettabetaruccanasetaluclaC

.yticapacriehtfo%05otyrettabsegrahcsiD.ecruosyrettabmorfrewop

morfyltceriddereviledsirewoP.noitcnufssapybehtfolortnocmetsysehT

.noitamrofnitnerructuptuodna,egatlovtuptuo,egatlovtupnisyalpsiD

ycnadnudeRoN-daoLegatnecreP

htiW-daoLegatnecreP

ycnadnudeR

seicneuqerFtuptuOdnatupnI

neercSsutatSyrettaB

neercSsutatSeludoMrewoP

neercSsutatSsdlohserhTmralA

neercSsutatSsuoenallecsiM

tsTfleS.tsetflesfotluseryrammussyalpsiD

rfxtsL .refsnartmetsystsalehtrofnosaerehtfoyrammusasyalpsiD

sutatS .).cte,ssapyb,ttabno,enilno,.e.i(edomgnitarepotnerrucehtsyalpsiD

MIR/MI .seludomecnegilletnItnadnudeRdnaecnegilletnIfosutatsehtsyalpsiD

.seludomrewopllafoyticapaclatotehtotdaoltnerrucehtserapmoC

tpecxeseludomrewopllafoyticapaclatotehtotdaoltnerrucehtserapmoC

.dlohserhtmrala"ecnareloTtluaF"ehtybedisateseratahtseludomrewopeht

ecnarelottluafehtdna,dellatsniseludomrewopruoferaerehtfi,elpmaxeroF

rewop3ylnosesudaolfoegatnecrepsiht",1"ottessidlohserhtmrala

ehttesotsdlohserhTmralA>puteSeeS.noitaluclacehtrofseludom

.levelycnadnuder

seicneuqerftuptuodnatupniderusaemehtsyalpsiD

sutatsdna,emitnur,yticapac,egatlovecruoseludomyrettabsyalpsiD

.noitamrofni

.noitamrofnisutatsdna,ecnarelottluaf,yticapacecruoseludomrewopsyalpsiD

mralaesehttesotsmralA>puteSeeS.sgnittesmraladenifed-resuehtsyalpsiD

.sdlohserht

990-7169-001

Appendix A - The PowerView Interface - Page 5

Page 48

PowerView Commands

(continued)

puteS

nwodtuhS

ruDttaBwoL

ylDnwodtuhS

ylDnruteR

paCtaBnruteR

tluafeD

s

qerFtuptuO

smralA

ycnadnudeR

daoL .timilsihtsdeecxedaolehtnehwdnuoslliwmralaelbiduanA

noitcnuF snoitpO

.noitsuahxeyrettaboteudnwodstuhsartemmyS

dnammocnwodtuhsehtseussitahtretupmocehtfidesU

.nwodflestituhsyllufecargotemitnurlanoitiddaseriuqer

ehterofebezilibatsotrewopytilituwollaotlavretniyaled

.enilnokcabseogmetsys

a,eruliafrewopytilitudednetxenamorfgninruternehW

.daolehtgnirewopererofebyticapacyrettabmuminim

stluafedyrotcafotsgnittesllateS

.egnar

.sdlohserhtmralaehtsteS

.level

.eruliafrewopytilituafotneveehtnisretemarapnwodtuhsehtsteS

ehterofebsetunimforebmunsihtdnuoslliwmralaelbiduanA

sdnoces

a,eruliafrewopytilituaretfaderotsersirewopytilitunehW

sdnoces

sihtnihtiwtupniehtotkcolesahplliwtuptuoartemmySehT

sihtwolebsllafycnadnuderehtfidnuoslliwmralaelbiduanA

2ro1,0

)emarFiniM(

setunim01ro,7,5,2

006ro003,081,02

003ro081,06,0

%09ro,05,51,0

,zH1.-/+zH06ro05

,zH3-/+zH06ro05

gnikcarTegnaRlluF

reveN,AVk8otAVk1

reveN,AVk6otAVk1

)emarFretsaM(

emitnuR

ssapyB

ypoC

rehtO

tseTfleS

DISPU.metsysaotgnirtstxetretcarahc-nevesasngissA

tuptuO

gnitropeRtuoV

Page 6 - The PowerView Interface - Appendix A

).ylnosmetsys

).ylnosnoisrev

.muminimsihthtaeneb

MT

artemmySehthtobtahttneveylekilnuehtnI

:snoitpoesehtfoenoesoohc

.artemmyShtiwdesutoN

.sgnittesdenifed-resugniniameR

.lavretnicidoirepdeificeps

sllafemitnurelbaliavaehtfidnuoslliwmralaelbiduanA

reven

ehtdna,sliaf

,egnarlamronfoedistuosiycneuqerfenilroegatlovtupni

-resusihttaflestitsetyllacitamotuanacartemmySehT

lanoitanretnI(.egatlovtupnifosseldrageregatlovtuptuosteS

naciremAhtroN(.egatlovtuptuotnacifingistsomehtstropeR

daoLporD

54ro,03,51,01,5

,5,4,3,2,1,setunim

ro,sruoh8ro,7,6

rossapyBotoG

,syad7,nOrewoPtA

delbasiDro,syad41

V042roV032,V022

otuAro,V042,V802

990-7169-001

Page 49

PowerView Commands

seirosseccA

SPUerusaeMehtsrotinoM tolStramS .yrosseccA

(continued)

MT

artemmySehtfokcabehttatropecafretniretupmocehtotdetcennocsiweiVrewoPehtnehwdesuylnO

.emarf

gniggoL

goLweiV

scitsitatSweiV

noitcnuF

yekretneehtsserpdnayrtnenaottnioP.stneve46tnecertsomehtskcarT

.tnevetahtnonoitamrofnieromrof

nodna,stluaf,yrettabwol,yrettabotsrefsnartforebmunlatotehtsdroceR

.stneveemitnuryrettab

gniggoLerugifnoC

ffO/nO:stnevErewoP

ffO/nO:slortnoCSPU

ffO/nO:stluaFSPU

ffO/nO:ytivitcAresU

.golehtnidedrocereratahtstnevefoepytehtsteS

spuorGtnevEtsiL

stnevErewoP

stnevElortnoCSPU

seitivitcAresU

stnevEtluaFSPU

stnevESPUerusaeM

.gnitsiltnevecificepsrofswollA

990-7169-001

goLraelC

seoD.golweivehtsraelCton.stsiltneveevitcaehtraelc

Appendix A - The PowerView Interface - Page 7

Page 50

PowerView Commands

(continued)

yalpsiD

emiT/etaD

drowssaP

drowssaP.drowssapasteS dne='_',9-0,Z-A

tuoemiT.remitytivitcaninA ,setunim03ro,01,5,2,1

etadilavnI otsegnahcdezirohtuanustneverP.tceffeotnidrowssapstuP

noitcnuF snoitpO

.etaddnaemittcerrocehtteS dna)raey:htnom:yad(yy:mm:dd

.segnahcnoitarugifnocdezirohtuanutsniagastcetorP

.noitarugifnocartemmySeht

noitamrofnI

repeeB

SPUtA.artemmySehthtiwdesutoN

yalpsiDtA.weiVrewoPehtnimralaelbiduaehtrofsretemarapsteS 03+eruliaFrewoP,eruliaFrewoP

emuloVemulovmralaelbiduasteS iH,muideM,woL,ffO

kcilC.snottubyalpsidgnisserpnehwdnuoskcilcteSffO,nO

tsartnoC

tsartnocneercsDCLteS 7,6,5,4,3,2,1,0

.airetirc)repeeb(mralaelbiduasteS

)etunim:ruoh(mm:hh

.reveroFro,sruoH4ro,2,1

.noitamrofninoisiverdnaerutcafunamfoetad,rebmunlaires,rebmunledomweiVrewoPsyalpsiD

.reveN,yrettaBwoL,sdnoces

erugifnoC

Page 8 - The PowerView Interface - Appendix A

noitamrofnideyalpsidneercsputratsehtserugifnocmotsuC yrotcafesuotdednemmocersitI

tluafed

990-7169-001

Page 51

PowerView Commands

(continued)

)scitson(gaiD

scitsongaiDdnatluaF

eludoMecnegilletnI

eludoMletnItnadnudeR

P

rw

ttaB

s

seludoM

noitcnuF

.tluaftahtfonoitamrofnicitsongaiddnatluafmetsystnerrucyalpsiD

.noitamrofnidnasutatseludomecnegilletnideliatedsyalpsiD

.noitamrofnidnasutatseludomecnegilletnitnadnuderdeliatedsyalpsiD

.noitamrofnidnasutatseludomrewopdeliatedsyalpsiD

.noitamrofnidnasutatseludomyrettabdeliatedsyalpsiD

pleH

otylsuoenatlumissyek"nwoDllorcS"dna"pUllorcS"ehtsserP.yalpsidweiVrewoPehtotnitliuberasneercsplehenilnO

.plehevitisnestxetnocssecca

990-7169-001

Appendix A - The PowerView Interface - Page 9

Page 52

n The PowerV ew cable must be d sconnected from the PowerV ew before proceed ng.

Wall Mounting the PowerView

Use the template below to install the PowerView on a wall:

1. Note the four mounting slots molded into the back of the PowerView.

2. Secure four large screws on a clean dry wall surface.

3. Leave each screw extending 5/16" (8mm) out from the surface of the wall.

4. Connect the 20’ PowerView remote cable (provided) to the PowerView and to the PowerView communication

port at the rear of the Symmetra

5. Position the PowerView onto the screws.

TM

frame.

9cm (3 1/2")

Cut Here

Up

8cm (3 1/8")

Page 10 - The PowerView Interface - Appendix A

10.3cm (4")

990-7169-001

Page 53

Appendix B

Troubleshooting

The PowerView reports various messages on the display, including alarm status and changes in system configuration. This section lists all PowerView display messages, what each means, and an appropriate corrective action.

Note: More than one of these messages may occur at one time. If this happens, be sure to review all of the messages for

a better understanding of the system condition.

weiVrewoP

egasseM

pU-tratS

.NOtsalecnis

.NOtsal

ssapybrofton

degnahcseludomrwP#

MT

artemmyS

ecnisdegnahcseirettaB#

MT

artemmyS

tnadnudeRoN

.eludoMecnegilletnI

nahtsselyticapacttaB

paCttaBnruteR

edistuoqerFtupnI

egnarderugifnoc

tubSPUrofetauqedaCA

MT

artemmyS

MT

artemmyS

.elbaliava

MT

artemmySehT

gninaeM noitcAevitcerroC

neebsaheludomrewopenotsaeltA

ehtmorfdevomerro,dedda

ehtemittsalehtecnis

.deussisawdnammocNOrwP

neebsaheludomyrettabenotsaeltA

ehtmorfdevomerro,dedda

ehtemittsalehtecnis

.deussisawdnammocNOrwP

.dellatsniMIRonsierehTehttrobaro,putratsehthtiwdeecorP

:etoN ereht,MIRgninoitcnufatuohtiW

ehtfoyticapacyrettabehT

resuehtnahtsselsi

yticapacyrettabmuminimdeificeps

.daolehtnonrutotderiuqer

ehtotycneuqerftupniehT

derugifnocehtedistuosi

lliwycneuqerftuptuoehT.egnar

tupniehthtiwezinorhcnyston

tonsissapyblamroN.ycneuqerf

enilnonoitcnuflliw

ehtnitub,egatlovtupniehthtiw

eht,deriuqersissapybtahttneve

otetauqedatonsiegatlovtupni

.tnempiuqedaolehtrewop

noitpO2# lamroN.putratshtiwdeecorP:

deecorP.yrassecennoitcaevitcerrocoN

.putratsehthtiw

deecorP.yrassecennoitcaevitcerrocoN

.putratsehthtiw

.MIRallatsnidna,putrats

MIMafotneveehtniycnadnuderonsi

.eruliaf

1#noitpO wolladna,putratsehttrobA:

.egrahcerotseirettab

2#noitpO sselhtiw,putratseunitnoC:

.yticapacyrettabmuminimnaht

1#noitpO ehtfoycneuqerfehtevorpmI:

.egatlovgnimocni

2#noitpO ehtfoegnarehtnediW:

ehthtiwycneuqerfgnimocnielbatpecca

-qerFtuptuO-puteS-putratS(.weiVrewoP

).tceleS

3#noitpO lamroN.putratshtiwdeecorP:

.elbaliavatonsissapyb

1#noitpO gnimocniehtevorpmI:

.egatlov

.elbaliavatonsissapyb

990-7170-001

,tupniCAoN/woL

yrettabnoputrats

MT

artemmySeht

MT

artemmyS

.yrettab

tratsotetauqedatonsiegatlovtupnI

,sdeecorpputratsfI.

morfnoitcnuflliw

1#noitpO elbatpeccalitnuputratstrobA:

.tneserpsiegatlovtupni

2#noitpO yrettaB.putratshtiwdeecorP:

.degrahcsideblliw

Appendix B - Troubleshooting - Page 1

Page 54

weiVrewoP

egasseM

gninaeM noitcAevitcerroC

lareneG

sutatS

.desaercniseirettabfo#

.desaercedseirettabfo#

.desaercniseludoMrwPfo#

.desaercedseludoMrwPfo#

.detresnieludoMecnegilletnI

devomereludoMecnegilletnI

ecnegilletnItnadnudeR

.detresnieludoM

ecnegilletnItnadnudeR

.devomereludoM

MT

artemmyS

MT

artemmyS

MT

artemmyS

MT

artemmyS

.metsysehtotdedda

.metsysehtmorfdevomer

.metsysehtotdedda

.metsysehtmorfdevomer

.

.

.

.

stenibaCyrettaBlanretxEfo#

.desaercni

neebsaheludomyrettabenotsaeltA

neebsaheludomyrettabenotsaeltA

neebsaheludomrewopenotsaeltA

neebsaheludomrewopenotsaeltA

ehtotnidellatsnineebsahMIMA

ehtmorfdevomerneebsahMIMA

ehtotnidellatsnineebsahMIRA

ehtmorfdevomerneebsahMIRA

sahtenibacyrettablanretxeenotsaeltA

.emarfehtotdetcennocneeb

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.yrassecennoitcaevitcerrocoN

.desaerced

derotseRycnadnudeR

dlohserhT

.derotseremitnuRniM

Page 2 - Troubleshooting - Appendix B

stenibaCyrettaBlanretxEfo#

sahtenibacyrettablanretxeenotsaeltA

MT

.

artemmySehtmorfdetcennocsidneeb

.yrassecennoitcaevitcerrocoN

ycnadnudereludomrewopfossolA

rehtiE.derotserneebsahdna,derrucco

,dellatsnineebevahseludomlanoitidda

.yrassecennoitcaevitcerrocoN

.decuderneebsahdaolehtro

mraladaolehtdedeecxedahdaolehT

mralAevobaregnoLoNsidaoL

neebsahnoitautisehT.dlohserht

daolehtesuacebrehtiedetcerroc

.yrassecennoitcaevitcerrocoN

sawdlohserhtehtro,desaerced

.desaercni

wolebdepporddahemitnurmetsysehT

neebsahdna,muminimderugifnoceht

yrettablanoitiddarehtiE.derotser

gnitsixeeht,dellatsnierewseludom

.yrassecennoitcaevitcerrocoN

sawdaoleht,degrahcerseludomyrettab

.desiarsawdlohserhtehtro,decuder

990-7170-001

Page 55

weiVrewoP

egasseM

gninaeM noitcAevitcerroC

eludoM

eruliaF

deliaf

dlohserhT

mralA

dlohserht

.dlohserht

eludoMyrettaBdaB

eludoMrewoPdaB

sieludoMecnegilletnI

deliafdnadellatsni

ecnegilletnItnadnudeR

dnadellatsnisieludoM

mralaAVkevobasidaoL

MT

artemmyS

.tsolneebsahycnadnudeR

mralawolebsiycnadnudeR

.tnemecalperseriuqer

.tnemecalperseriuqer

.desaercnisahdaol

dna,deliafsaheludomyrettabA

.erudecorptnemecalper

dna,deliafsaheludomrewopA

.erudecorptnemecalper

saheludomecnegilletniniamehT

.tnemecalperseriuqerdna,deliaf

eludomecnegilletnitnadnuderehT

.tnemecalperseriuqerdna,deliafsah

resuehtdedeecxesahdaolehT

.dlohserhtmraladaoldeificeps

stcetedregnolon

.seludomrewoptnadnuder

,deliafevah)s(eludomrewoprehtiE

.desaercnisahdaolehtro

ycnadnudereludomrewoplautcA

deificepsresuehtwolebnellafsah

rehtiE.dlohserhtmralaycnadnuder

ehtro,deliafevah)s(eludomrewop

1#noitpO .daolehtecudeR:

2#noitpO otweiVrewoPehtesU:

1#noitpO llatsni,elbissopfI:

2#noitpO .daolehtesaerceD:

3#noitpO ycnadnuderehtelbasiD:

oreztceles).

1#noitpO llatsni,elbissopfI:

2#noitpO .daolehtesaerceD:

3#noitpO otweiVrewoPehtesU:

(.dlohserht-smralA-puteS-putratS

.erudecorptnemecalper

.erudecorptnemecalper

tceles-ycnadnudeR).

eludomrofCxidneppAotrefeR

eludomrofCxidneppAotrefeR

eludomrofCxidneppAotrefeR

eludomrofCxidneppAotrefeR

.dlohserhtmralaehtesiar

.seludomrewoplanoitidda

.orezotycnadnudergnittesybmrala

-ycnadnudeR-smralA-puteS-putratS(

.seludomrewoplanoitidda

mralaycnadnuderehtesaerced

990-7170-001

1#noitpO yrettabehtwollA:

.egrahcerotseludom

nahtrewolsiemitnurdetciderpehT

mralawolebsiemitnuR

.dlohserht

.desaercnisah

ssapyB

egnarnitonsissapyB

)egatlovroqerfrehtie(

fielbaliavaebtonyamedom

.deriuqer

nikcutsrotcatnocssapyB

.noitisopssapyb

MT

artemmyS

emitnurmuminimdeificepsresueht

yrettabehtrehtiE.dlohserhtmrala

daolehtro,desaercedsahyticapac

tuosiegatlovro/dnaycneuqerfehT

sihT.ssapybrofegnarelbatpeccafo

MT

artemmySnehwsruccoegassem

si