Page 1

User's Manual

SYMINIF

SYMINIF-PD

SYMSTRF

SYMSTRF-PD

Page 2

Important Safety Instructions!Important Safety Instructions!

Important Safety Instructions!

Important Safety Instructions!Important Safety Instructions!

Please read this manual!

Veuillez lire ce manuel!

Bitte lesen Sie dieses Anleitungshandbuch!

¡Se ruega leer este manual de instrucciones!

This User's Manual provides safety, installation and operating instructions that will help you derive the fullest performance and

service life that the SymmetraTM Power Array has to offer.

PLEASE SAVE THIS USER'S MANUAL! It includes important instructions for the safe use of the SymmetraTM Power Array, and

for obtaining factory service should the proper operation of the system or the components come into question. Service or storage

issues may arise at a later date, and may require reference to this User's Manual, or to the technical support information that is

included in it.

CONSERVER CES INSTRUCTIONS! Cette notice contient des instructions importantes concernant la sécurité.

Radio Frequency Interference

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules and the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of

the Canadian Department of Communications. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with the Class A FCC limits.

WARNING: Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

Part #: 990-7770A

Revised 10/97

Page 3

Limited Warranty

American Power Conversion (APC) warrants its products to be free from defects in materials and workmanship for a period of

two years from the date of purchase. Its obligation under this warranty is limited to repairing or replacing, at its own sole option,

any such defective products. To obtain service under warranty you must obtain a Returned Material Authorization (RMA)

number from APC or an APC service center. Products must be returned to APC or an APC service center with transportation

charges prepaid and must be accompanied by a brief description of the problem encountered and proof of date and place of

purchase. This warranty does not apply to equipment which has been damaged by accident, negligence, or mis-application or has

been altered or modified in any way. This warranty applies only to the original purchaser who must have properly registered the

product within 10 days of purchase.

EXCEPT AS PROVIDED HEREIN, AMERICAN POWER CONVERSION MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Some states do not

permit limitation or exclusion of implied warranties; therefore, the aforesaid limitation(s) or exclusion(s) may not apply to the

purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL APC BE LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. Specifically, APC is not liable for any costs, such as lost profits or revenue, loss of equipment, loss

of use of equipment, loss of software, loss of data, costs of substitutes, claims by third parties, or otherwise. This warranty gives

you specific legal rights and you may also have other rights which vary from state to state.

Life Support Policy

As a general policy, American Power Conversion (APC) does not recommend the use of any of its products in life support applications where failure or malfunction of the APC product can be reasonably expected to cause failure of the life support device or

to significantly affect its safety or effectiveness. APC does not recommend the use of any of its products in direct patient care.

APC will not knowingly sell its products for use in such applications unless it receives in writing assurances satisfactory to APC

that (a) the risks of injury or damage have been minimized, (b) the customer assumes all such risks, and (c) the liability of

American Power Conversion is adequately protected under the circumstances.

Examples of devices considered to be life support devices are neonatal oxygen analyzers, nerve stimulators (whether used for

anesthesia, pain relief, or other purposes), autotransfusion devices, blood pumps, defibrillators, arrhythmia detectors and alarms,

pacemakers, hemodialysis systems, peritoneal dialysis systems, neonatal ventilator incubators, ventilators for both adults and

infants, anesthesia ventilators, infusion pumps, and any other device designated as “critical” by the U.S.F.D.A.

Hospital grade wiring devices and leakage current may be ordered as options on many APC UPS systems. APC does not claim that

units with this modification are certified or listed as Hospital Grade by APC or any other organization. Therefore these units do

not meet the requirements for use in direct patient care.

Entire contents copyright © 1997 American Power Conversion. All rights reserved; reproduction in whole or in part without

permission is prohibited. Symmetra, Power Array, SmartSlot, SmartCell and SNMP Adapter are trademarks of APC. Power-

Chute and PowerDoctor are registered trademarks of APC. All other trademarks are the property of their respective owners.

Page 4

Table of Contents

INTRODUCTION

Theory of Operation ................................................................................................................. i

Modes of Operation .................................................................................................................. iii

SAFETY INFORMATION

Symbols Used In This Manual ......................................................................................... safety-1

Important Safety Instructions .......................................................................................... safety-1

1. PHYSICAL REPRESENTATION

The Power Array Frame ............................................................................................................ 1-1

PowerView User Interface ......................................................................................................... 1-2

Louvered Cover Grills ............................................................................................................... 1-2

Power Modules .......................................................................................................................... 1-2

Battery Module .......................................................................................................................... 1-2

Main Intelligence Module (MIM) ........................................................................................... 1-3

Redundant Intelligence Module (RIM) ................................................................................... 1-3

Input Circuit Breaker ................................................................................................................ 1-3

Maintenance Bypass Switch ..................................................................................................... 1-3

Rear View of Power Array ......................................................................................................... 1-4

System Enable Switch ................................................................................................................ 1-4

Communication Interface Ports .............................................................................................. 1-4

SmartSlot Accessory Ports ........................................................................................................ 1-4

REPO/Input/Output Wiring Panels ........................................................................................ 1-4

Power Distribution Unit Panel................................................................................................. 1-4

Battery Extension Frame Connector ....................................................................................... 1-4

2. SITE PREPARATION

Space and Weight Considerations ........................................................................................... 2-1

Transporting Power Array to Installation Site ........................................................................ 2-1

Operating Conditions ............................................................................................................... 2-1

BTU Output ............................................................................................................................... 2-1

3. UNPACKING AND INSTALLING FRAME

Initial Inspection ....................................................................................................................... 3-1

Check For Damage .................................................................................................................... 3-1

Handling Considerations ......................................................................................................... 3-1

Tools Required For Setup ......................................................................................................... 3-1

Storage of Battery and Power Modules ................................................................................... 3-1

Moving the Frame ..................................................................................................................... 3-1

Removing Packing Materials .................................................................................................... 3-2

Remove the Frame from the Pallet .......................................................................................... 3-2

Moving Battery & Power Modules .......................................................................................... 3-2

Clean-Up .................................................................................................................................... 3-2

4. WIRING REQUIRMENTS & PROCEDURES

Wiring Overview ....................................................................................................................... 4-1

Input Wiring .............................................................................................................................. 4-2

Output Wiring ........................................................................................................................... 4-4

Remote Emergency Power Off Wiring .................................................................................... 4-7

Electrical Wiring Test/Checklist ............................................................................................... 4-8

Page 5

5. SETTING UP THE POWER ARRAY

Overview of Setup ..................................................................................................................... 5-1

Frame Leveling Procedure ........................................................................................................ 5-1

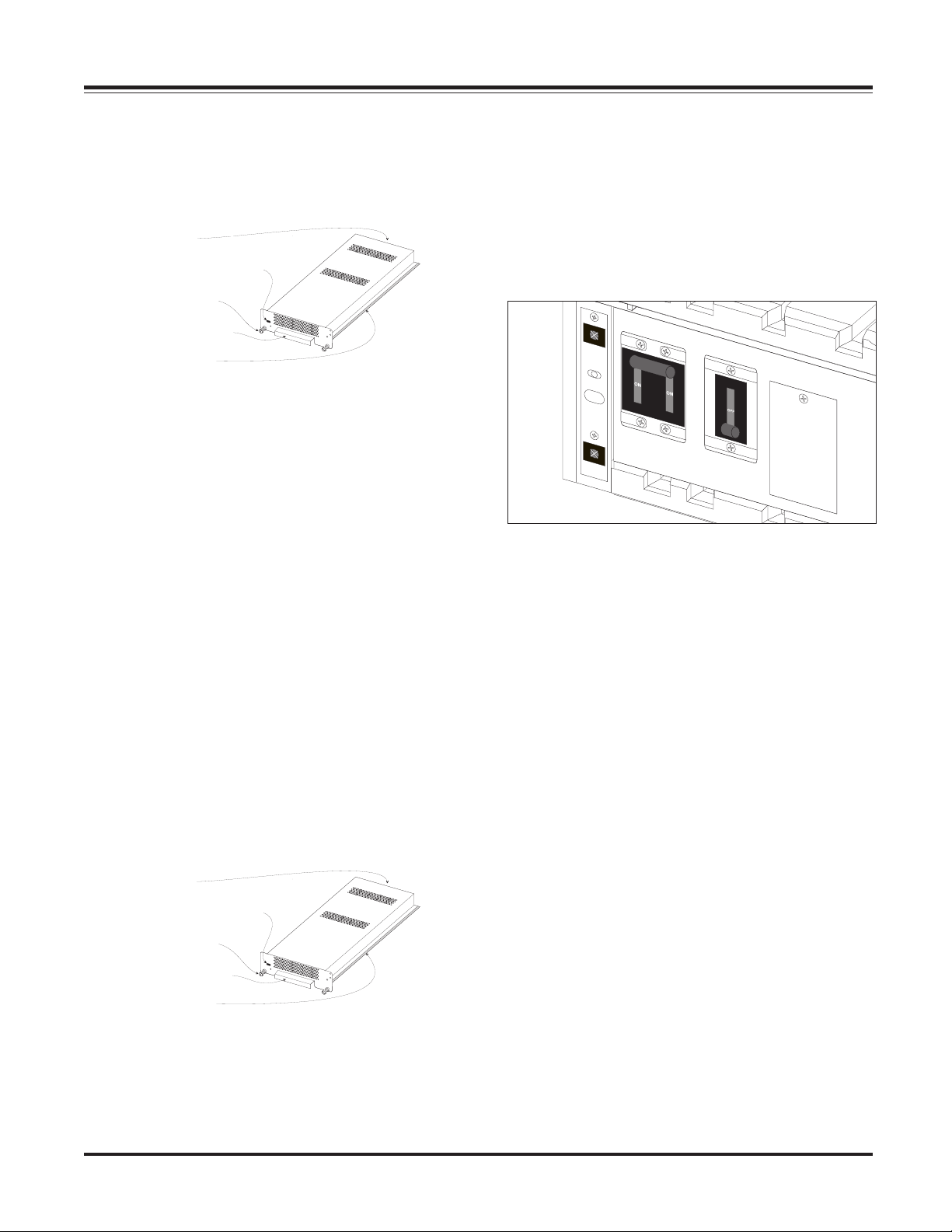

Installing Battery Modules ....................................................................................................... 5-2

Installing Power Modules ......................................................................................................... 5-3

Installing the Main Intelligence Module (MIM) .................................................................... 5-4

Installing the Redundant Intelligence Module (RIM) ........................................................... 5-4

Installing the PowerView Interface .......................................................................................... 5-5

SmartSlot Interface Accessories ............................................................................................... 5-6

Installation Test/Checklist ........................................................................................................ 5-7

6. THE POWERVIEW DISPLAY

Overview .................................................................................................................................... 6-1

PowerView Functions ............................................................................................................... 6-1

PowerView LED's ...................................................................................................................... 6-2

Navigation Keys ......................................................................................................................... 6-2

Startup Screen ............................................................................................................................ 6-3

Top level Menu Screen .............................................................................................................. 6-3

7. CONFIGURING & OPERATING THE SYMMETRA

Introduction .............................................................................................................................. 7-1

Powering the System ................................................................................................................. 7-1

Powering the Loads ................................................................................................................... 7-2

Review Status Conditions ......................................................................................................... 7-2

Perform a Self-Test .................................................................................................................... 7-4

Shutdown Parameters ............................................................................................................... 7-5

Configure Alarms ...................................................................................................................... 7-5

Review Diagnostics Menu ........................................................................................................ 7-6

Review Logging Menu............................................................................................................... 7-6

8. MODULE REPLACEMENT

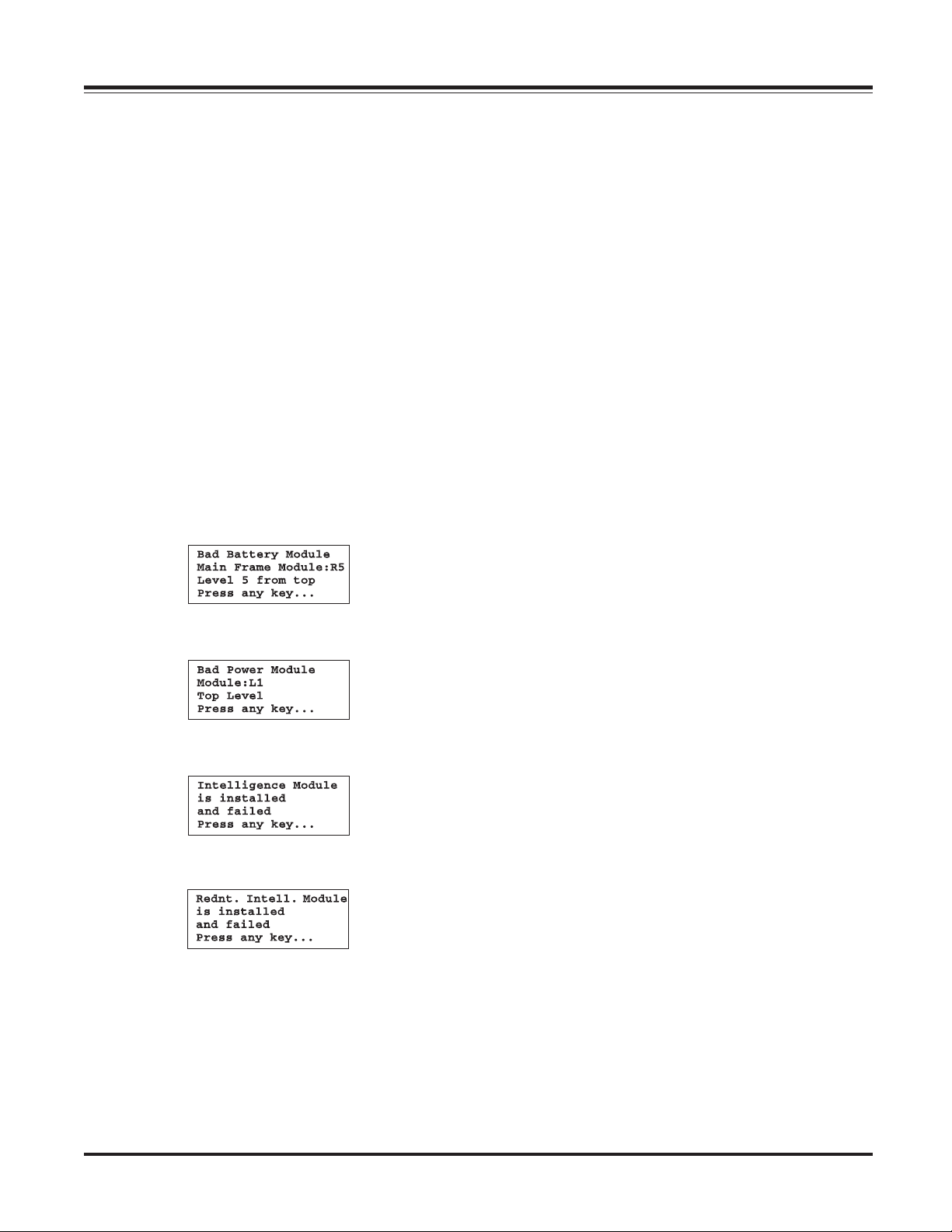

Module Failure Alarm Indicators .......................................................................................... 8-1

Technical Support and Obtaining a Replacement Module.................................................. 8-1

Battery Module Replacement Procedure ............................................................................... 8-2

Power Module Replacement Procedure ................................................................................ 8-3

Main Intelligence Module Replacement Procedure ............................................................. 8-4

Redundant Intelligence Module Replacement Procedure ................................................... 8-4

9. POWERVIEW DISPLAY MESSAGES

Start-Up Messages ................................................................................................................... 9-1

General Status Messages ......................................................................................................... 9-2

Module Failure Messages ........................................................................................................ 9-3

Threshold Alarm Messages ..................................................................................................... 9-3

Bypass Messages ...................................................................................................................... 9-3

General Fault Messages ........................................................................................................... 9-4

INDEX

Page 6

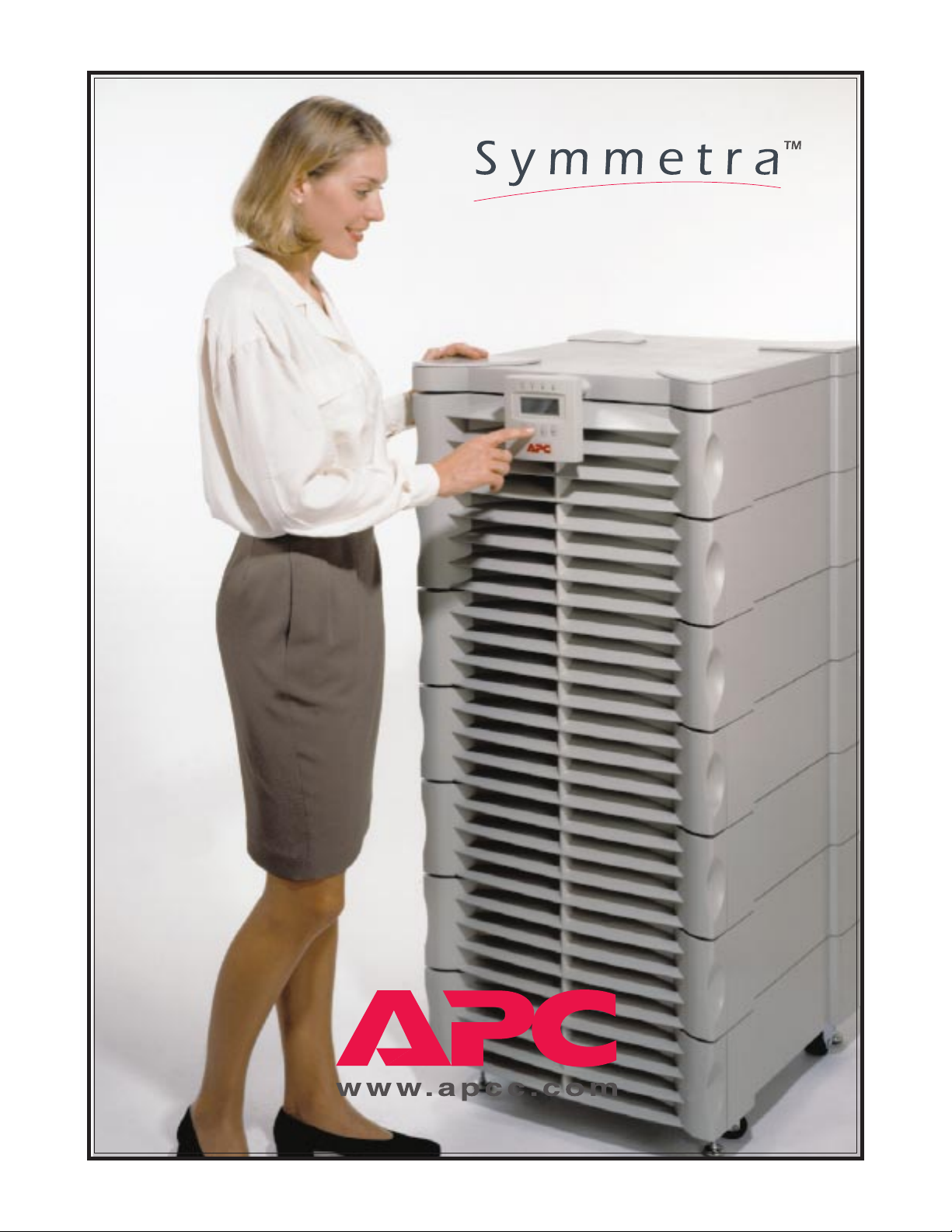

Introduction

The APC SymmetraTM Power Array is a

scalable, redundant power protection sys-

tem for multiple servers and business

critical applications. This is an introduction

to the SymmetraTM Power Array.

Page 7

Thank You!

Theory of Operation

Thank you for investing in the SymmetraTM Power Array. Please

read this User's Manual thoroughly prior to installing the sys-

tem. It provides important information about installing and

using the SymmetraTM safely and effectively.

SymmetraTM Overview

The SymmetraTM is a high-performance, uninterruptible

power “array” system, designed for large-scale loads. It provides conditioned, reliable AC power to load equipment, and

provides protection from power blackouts, brownouts, swells,

sags, surges and interference. The SymmetraTM Power Array

system is comprised of either a MiniFrame, or a MasterFrame,

and a variable set of modules. A MiniFrame system can be

configured to deliver a maximum output of 8kVA, and a

MasterFrame system, a maximum of 16kVA.

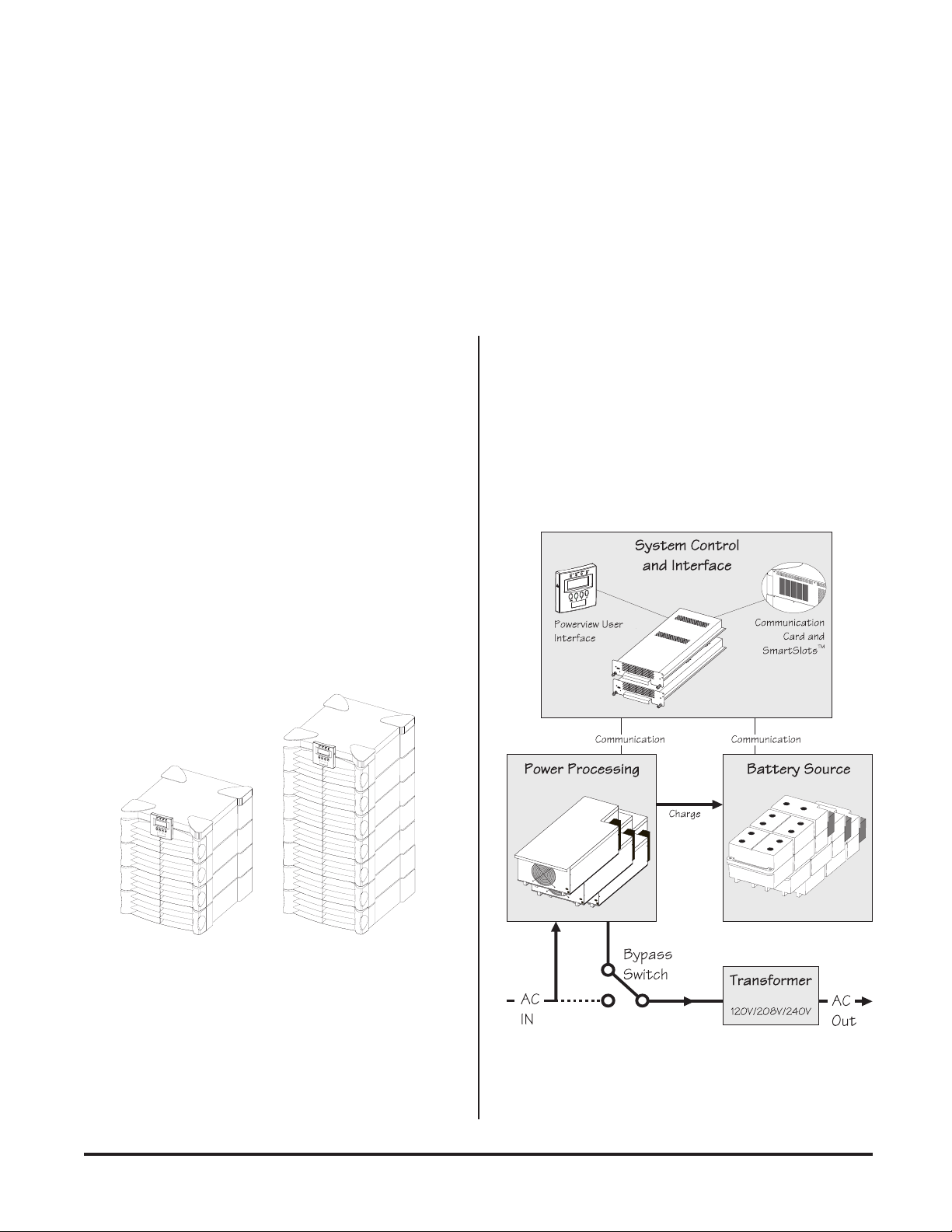

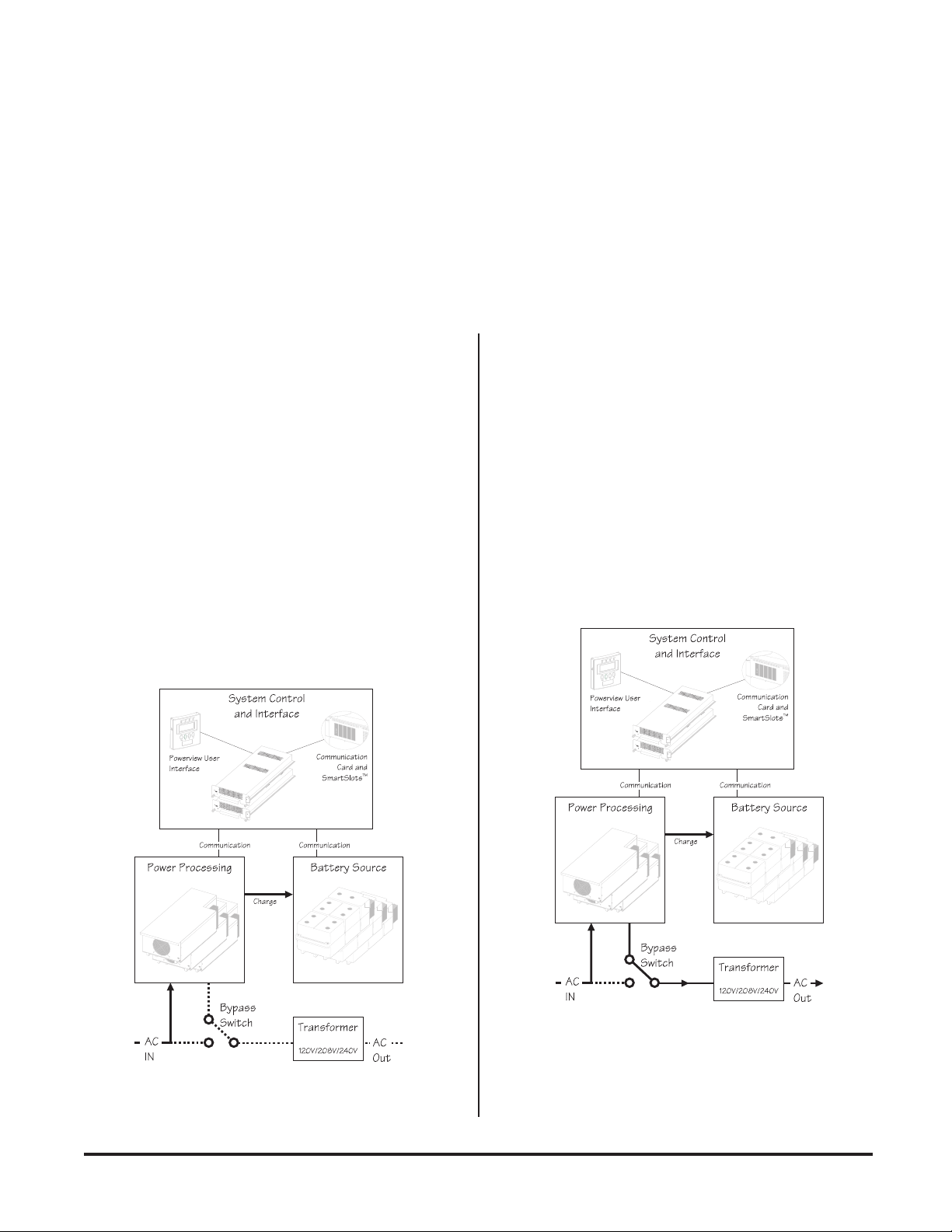

The SymmetraTM Power Array is comprised of three functional components: A power processing system, a battery

source, and a control/user interface system. Output power is

routed through a transformer prior to delivery to the load

equipment. See figure I-2. Each of the functional components

and the transformer are described in the following text.

Fig I-1 MiniFrame and MasterFrame

Fig I-2 Functional Diagram of a Symmetra

TM

i

Page 8

Power Processing System

Control/User Interface

The power processing system delivers conditioned AC output

power with a low distortion sinewave. Under normal operating conditions, power is received from the AC utility power

source, conditioned by the power processing system, and delivered to the load equipment. In the event of an AC utility

source failure, the power processing system receives power

from the battery source (battery modules), converts it to conditioned AC, and delivers it to the load equipment. When AC

utility power is present, the power processing system also

maintains the battery source at full charge.

The power processing system in SymmetraTM is comprised of

individual power module(s). Each power module contains

the electronics for a complete 4kVA UPS, including the rectifier,

charger and inverter. When two or more power modules are

present, they operate in parallel, sharing the load equally.

By configuring the system with at least one more power module than is required to power the load (a redundant power

module), SymmetraTM can sustain a power module failure,

and still deliver full power to the load equipment. The failed

module is identified by the control/user interface system, an

alarm is initiated to notify the user of the module failure, and

the hot-swappable module can be replaced by the user, without the need to power down the load equipment.

A SymmetraTM MiniFrame provides bays for up to three power

modules, and a MasterFrame provides bays for up to five.

This provides the full system capacity (8kVA and 16kVA respectively), plus one redundant power module.

Battery Source

The control/user interface system coordinates the operation

of the SymmetraTM and reports status conditions via several

user interface options. Functions performed by the control/

user interface component include module coordination and

state control, analysis and reporting of system status, and

reporting of alarm conditions.

Module Coordination & State Control - The Symmetra

incorporates a main intelligence module (MIM) that continuously monitors the system, and delivers data to both the

PowerView user interface, and to the communication ports.

The MIM coordinates the initial power up of the system, transfers it into and out of bypass mode, transfers the power source

between the utility AC power, and the battery source, and coordinates shutdown operations.

System Status Monitoring - The MIM gathers data about the

system components, and delivers it to both the PowerView

interface, and to the computer interface ports. System status

monitoring and reporting data include the current predicted

run time, the status of individual battery modules and power

modules, input & output voltage, input & output voltage frequency, and the size and status of the current output load.

Alarm Condition Detection - The control/user interface system monitors the SymmetraTM for alarm conditions. If an

alarm condition is detected, the PowerView user interface initiates an audible and visual alarm. Alarm conditions include

on-battery, low battery, module faults, overloads, loss of redundancy and a variety of other default and user defined events.

All possible alarm messages and the appropriate user responses

are provided in chapter 10.

TM

The battery source is comprised of parallel, hot-swappable,

120V battery modules. These are housed in the Symmetra

frame, and in an optional extension battery frame.

A SymmetraTM MiniFrame provides bays for up to two battery modules, and a MasterFrame provides bays for up to

four. Both of these frames can be connected to an extension

battery frame. Additional battery modules increase on-battery run time.

ii

TM

Transformer

The power processing system receives either 208V or 240V

input AC utility power, and delivers 240V power to an internal

transformer. The transformer delivers multiple output voltages (120V/208V/240V) to an output wiring terminal block

inside the SymmetraTM frame. Output wiring procedures are

provided in chapter 4.

Page 9

Modes of Operation

The Power Array functions in one of four modes of operation,

depending on user commands, the status of the AC utility

voltage, and the condition of the SymmetraTM itself. The four

modes are Load-Disconnect, On-Line, On-Battery, and Bypass. The PowerView interface reports the operating mode.

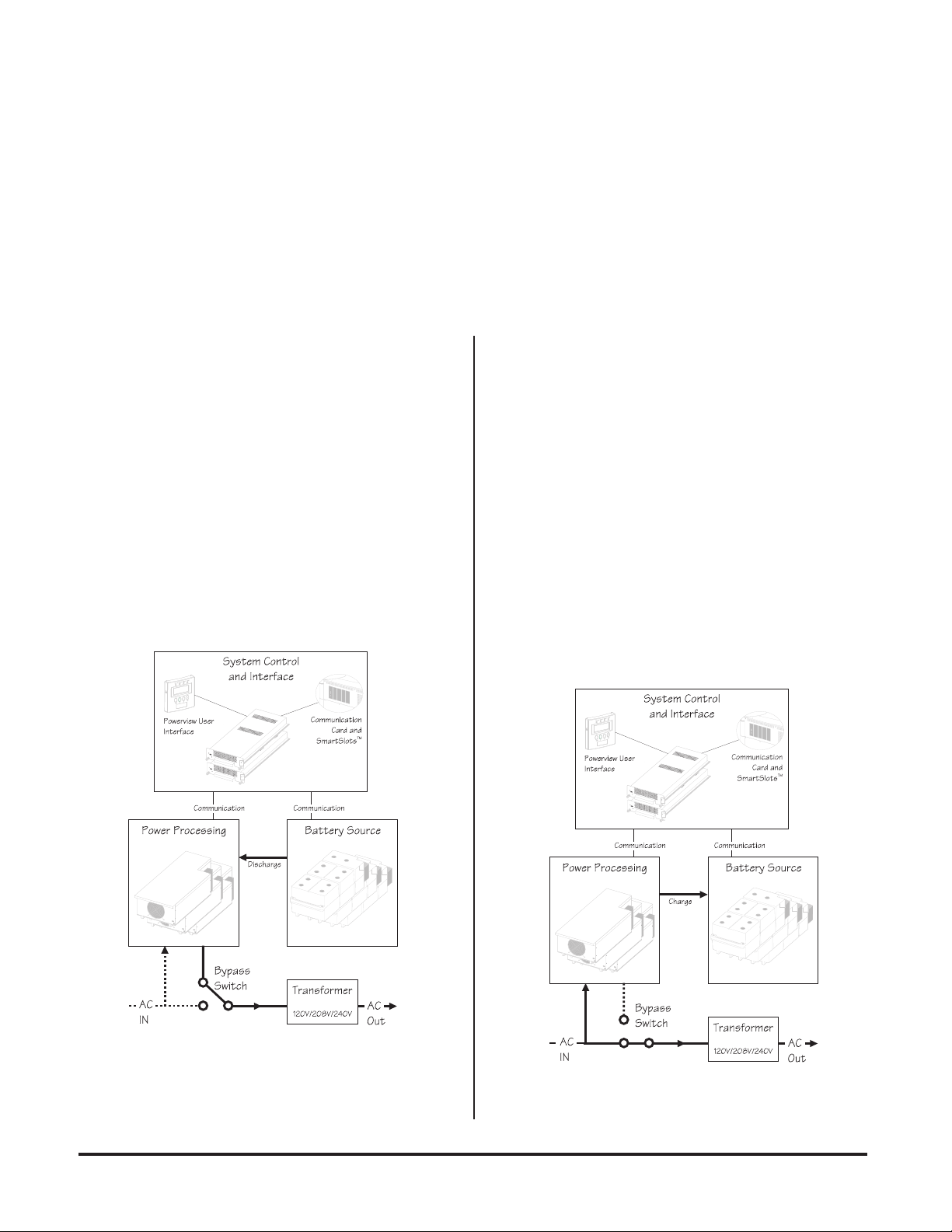

Load-Disconnect Mode

In the load-disconnect mode, incoming AC utility power is

present and the system is internally powered, but no output

power is delivered to the load equipment. The Symmetra

enters the load-disconnect mode at the initial power up, when

the system enable switch is switched to the “on” position. When

the system is operating on-line, and the “load off ” command

is entered in the PowerView interface, it returns to the loaddisconnect mode. Figure I-3 illustrates the power flow when

the system is operating in the load-disconnect mode.

TM

On-Line Operating Mode

The on-line operating mode is the “normal” operating mode.

When the system is in the on-line operating mode, the Power

Array receives power from the AC utility, and delivers conditioned power to the load equipment. The Power Array maintains proper battery charge, regulates the output voltage and

frequency, and protects the load from surges and electrical

noise. SymmetraTM will operate in this mode if it has been

commanded to turn the load on, the incoming utility voltage

is present and functioning properly, and there are no preventing abnormal conditions, such as an overload. See figure I-4

for a diagram of the power flow when the system is in the online operating mode.

Fig I-3 Load-Disconnect Operating Mode

Fig I-4 On-Line Operating Mode

iii

Page 10

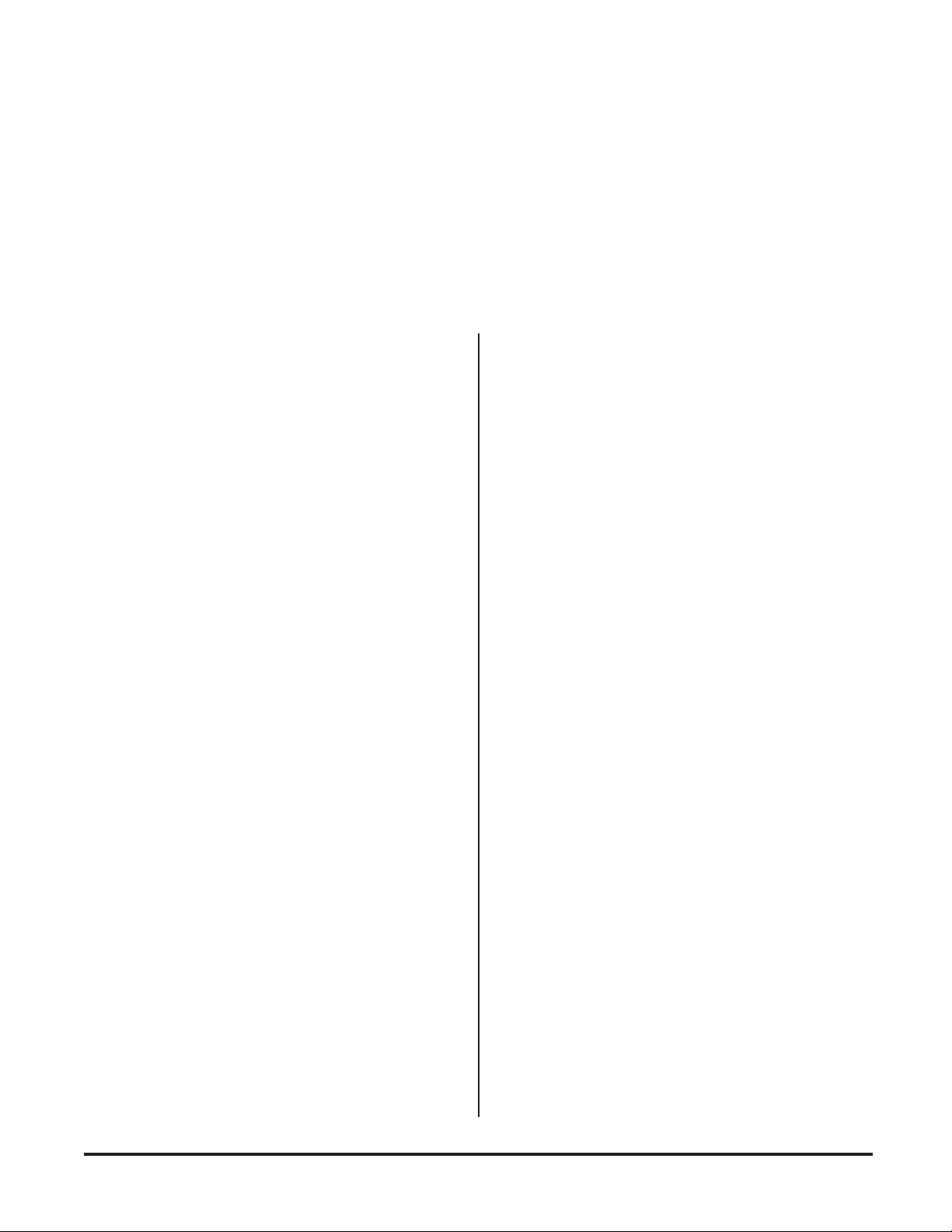

On-Battery Operating Mode

Bypass Operating Mode

When in the on-battery mode, the Power Array draws DC

power from the battery source, converts it to conditioned AC

power that is then delivered to the load equipment.

SymmetraTM typically enters this mode in the event of a utility

power failure. It will also operate in the on-battery mode

during a user initiated battery self test.

On-battery operation is limited in duration and is dependent

upon the number of battery modules, their state of charge,

and the size of the load. SymmetraTM will remain in the onbattery state until either the incoming utility power is restored,

or the batteries are depleted. See figure I-5 for a diagram of the

power flow when the system is in the on-battery mode.

When the SymmetraTM is in the bypass operating mode, the

system is bypassed, and utility power is delivered directly to

the load. SymmetraTM is equipped with an automatic bypass

function to allow the system to automatically go into bypass

mode, and a manual maintenance bypass switch to allow a

user to manually bypass the system. Either can be used to

place the Power Array into bypass operating mode.

The SymmetraTM will automatically transfer to the bypass

operating mode when AC utility power is present, but the load

cannot be powered by the inverter. Events which may cause

this include overloads, or failed non-redundant power modules. The SymmetraTM will automatically return to the on-line

mode when the triggering event clears. Figure I-6 illustrates

the power flow when the system is in the bypass mode.

Fig I-5 On-Battery Operating Mode

Fig I-6 Bypass Operating Mode

iv

Page 11

Definitions

Important Information

The following definitions are used in this manual and will be

helpful in understanding SymmetraTM.

Redundancy - Indicates the presence of one or more extra

modules, allowing the system to sustain a fault and continue

to provide full protection to the load. To be fully redundant,

the system should be configured with a redundant intelligence

module, and at least one redundant power module.

Note: The number of battery modules determines the length of

the run time. While it is prudent to use the maximum number

of battery modules possible, they are not considered redundant.

N+1 Redundancy - Refers to the level of redundancy, specifically related to power modules. “N” represents the number of

modules required to power the load, and “+1, +2, etc.” represents the number of extra power modules that are present.

For example, a 7.3 kVA load requires two power modules for

adequate protection. If the SymmetraTM is configured with

only two modules, it has an “N+0,” level of redundancy. (No

redundancy). If the system is configured with three power

modules, it has an “N+1” redundancy. Depending on the size

of the load, SymmetraTM can be configured with 2, 3 or even 4

extra power modules. Respectively, it would have an N+2,

N+3, or N+4 level of redundancy.

Please read this User's Manual thoroughly, before proceeding

with the installation of the SymmetraTM Power Array system.

It provides important information about installing and using

the SymmetraTM safely and effectively. Pay close attention to

text that is accompanied by a danger, or caution symbol. For

technical support, contact APC at:

1-888-809-TECH

Capacity - The maximum amount of output power that a

SymmetraTM system can deliver. The capacity is limited by the

lesser of the frame size, or the capacity of the installed power

modules.

For example, a MiniFrame (8kVA) with one power module

installed (4kVA) has a system capacity of 4kVA. A MasterFrame

(16kVA) with five power modules (20kVA) has a system capacity of 16kVA.

Hot-swappable - The modules are “hot-swappable” means

they can be replaced safely by a user or service provider while

the load is still powered and fully protected.

v

Page 12

Safety Information

Important Safety Information

Read this safety information in its entirety,

before proceeding with the installation &

operation of the SymmetraTM Power Array.

Page 13

Safety

Symbols Used In This Manual

The following symbols appear in this User's Manual:

CAUTION/DANGER - Caution indicates risk of

bodily harm. Danger indicates that a risk of electrical shock is present and the associated procedures should be followed carefully.

“STAND BY MODE” - The system enable switch,

and the input circuit breaker use the “stand by”

mode. When either of these are switched to “stand

by,” the Power Array is disconnected from utility

input voltage. In this mode, the system appears to

be off, although the utility power is still connected

to the system. For this reason, the standby mode

is unsafe for servicing the system. Always follow the

five step Total Power Off procedure before servicing the Power Array. (See procedure at right.)

“OFF POSITION” - The maintenance bypass

switch is the only switch that can be placed in the

“off” position. When switched to the “off” position, the Power Array functions normally, receiving power from the utility source, and delivering

conditioned power to the load equipment.

“ON POSITION” - All three switches (The system enable switch, the maintenance bypass switch

and the input circuit breaker) can be placed in the

“on” position. See the description for each of these

switches in chapter 1.

SAFETY EARTH GROUND - Indicates the primary safety ground.

IMPORTANT SAFETY INSTRUCTIONS

n SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation and maintenance of the Power Array, and for

installation or replacement of the battery and power modules.

CONSERVER CES INSTRUCTIONS. CETTE NOTICE

CONTIENT DES INSTUCTIONS IMPORTANTES

CONCERNANT LA SÉCURITÉ.

n Connection to the branch circuit (mains) must be per-

formed by a licensed electician.

n Installation of the power and battery modules can be per-

formed by any individual with no previous technical experience.

n Operation of the equipment can be performed by any

individual with no previous technical experience.

n The protective earth conductor for the SymmetraTM car-

ries the leakage current from the load devices (computer

equipment). Therefore, the size of the conductor must be

at least as large as the wire required by IEC 950. IEC 950

states the following nominal cross-sectional areas:

- 2.5 mm2 for rated current between 17 & 25 A

- 6 mm2 for rated current between 33 & 40 A

- 10 mm2 for rated current between 41 & 63 A

- 16 mm2 for rated current between 64 & 80 A

n FIVE STEP TOTAL POWER OFF PROCEDURE

To remove all power from the Power Array (Total Power

Off), the following series of events must occur in the order listed:

1. Set system enable switch to the “stand by” position.

2. Set input circuit breaker to the “stand by” position.

3. Remove all battery modules from the Power Array.

4. Disconnect external battery cabinet (if present).

5. Disconnect the mains/branch circuit breaker.

Safety-1

Page 14

Safety

n CAUTION: Risk of Electrical Shock and Energy Hazard,

120V, 7.2 Ah battery module. Before replacing battery

modules, remove conductive jewelry such as chains, wrist

watches and rings. High short circuit current through

conductive materials could cause severe burns.

n CAUTION: Do not dispose of batteries or battery mod-

ules in a fire. The batteries may explode.

n CAUTION: Do not open or mutilate battery modules or

batteries. Released electrolyte is harmful to the skin and

eyes. It may be toxic.

n While battery modules are user replaceable, servicing of

the battery modules themselves should be performed or

supervised by personnel knowledgeable of batteries and

the required precautions. Keep unauthorized personnel

away from batteries.

n When replacing or adding battery modules to the Power

Array system, use only the “SYBATT SymmetraTM Battery Module.” Contact APC for technical support, for

additional, or for replacement battery modules at:

1-888-809-TECH

Safety-2

Page 15

Chapter One

Physical Representation

This chapter provides an illustrated descrip-

tion of the SymmetraTM Power Array sys-

tem, and each of the modular components.

Before proceeding, examine the illustration

below. It depicts a MasterFrame (16kVA)

Power Array as it appears during normal

operating conditions. The grill covers are

correctly installed, and the Powerview

Interface is mounted on the frame.

Page 16

Chapter 1 - Physical Representation

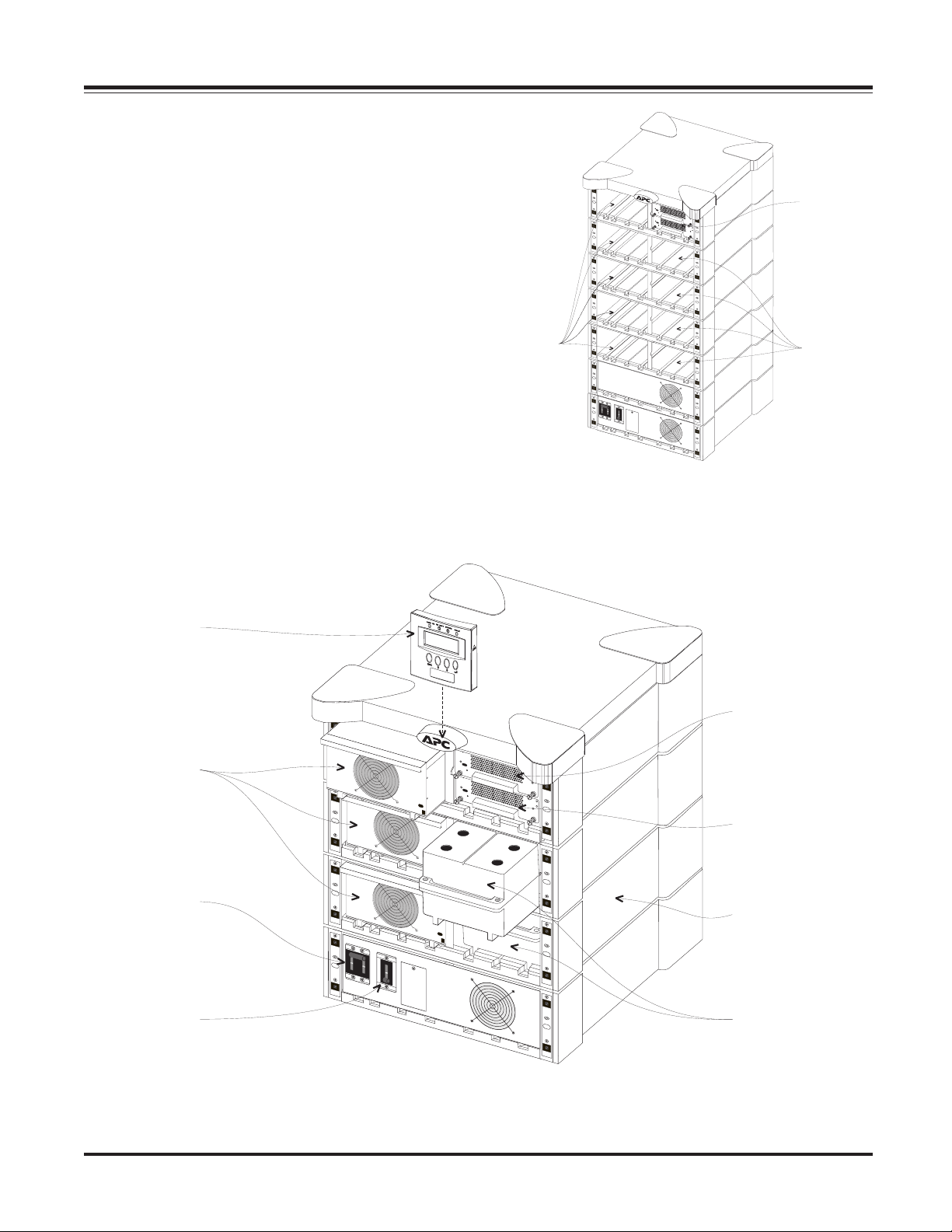

The Power Array Frame

The SymmetraTM Power Array frame serves as the base for the

modular components of the system. The MiniFrame provides bays for three power modules, and two battery modules. The MasterFrame provides bays for five power modules, and four battery modules. Both frames provide one bay

at the top right that houses the main intelligence module (MIM)

and redundant intelligence module (RIM).

The bottom of both frames contain wiring input/output access panels and terminal blocks. A system enable switch, input

circuit breaker and maintenance bypass switch are also located at the bottom of the frame. The output voltage transformer is located inside the bottom of the frame. A fully loaded

MiniFrame is depicted in figure 1-1. A MasterFrame with

factory installed MIM and RIM, and empty power and battery module bays is depicted in figure 1-2.

Five

Power

Module

Bays

Fig 1-2 An Empty MasterFrame (grill covers removed)

Main

Intelligence

and

Redundant

Intelligence

Modules

Four

Battery

Module

Bays

Powerview

Interface

Power

Modules

Input

Circuit

Breaker

Maintenance

Bypass

Switch

Redundant

Intelligence

Module

Main

Intelligence

Module

MiniFrame

Battery

Modules

Fig 1-1 A Fully Loaded MiniFrame (grill covers removed)

1-1

Page 17

Chapter 1 - Physical Representation

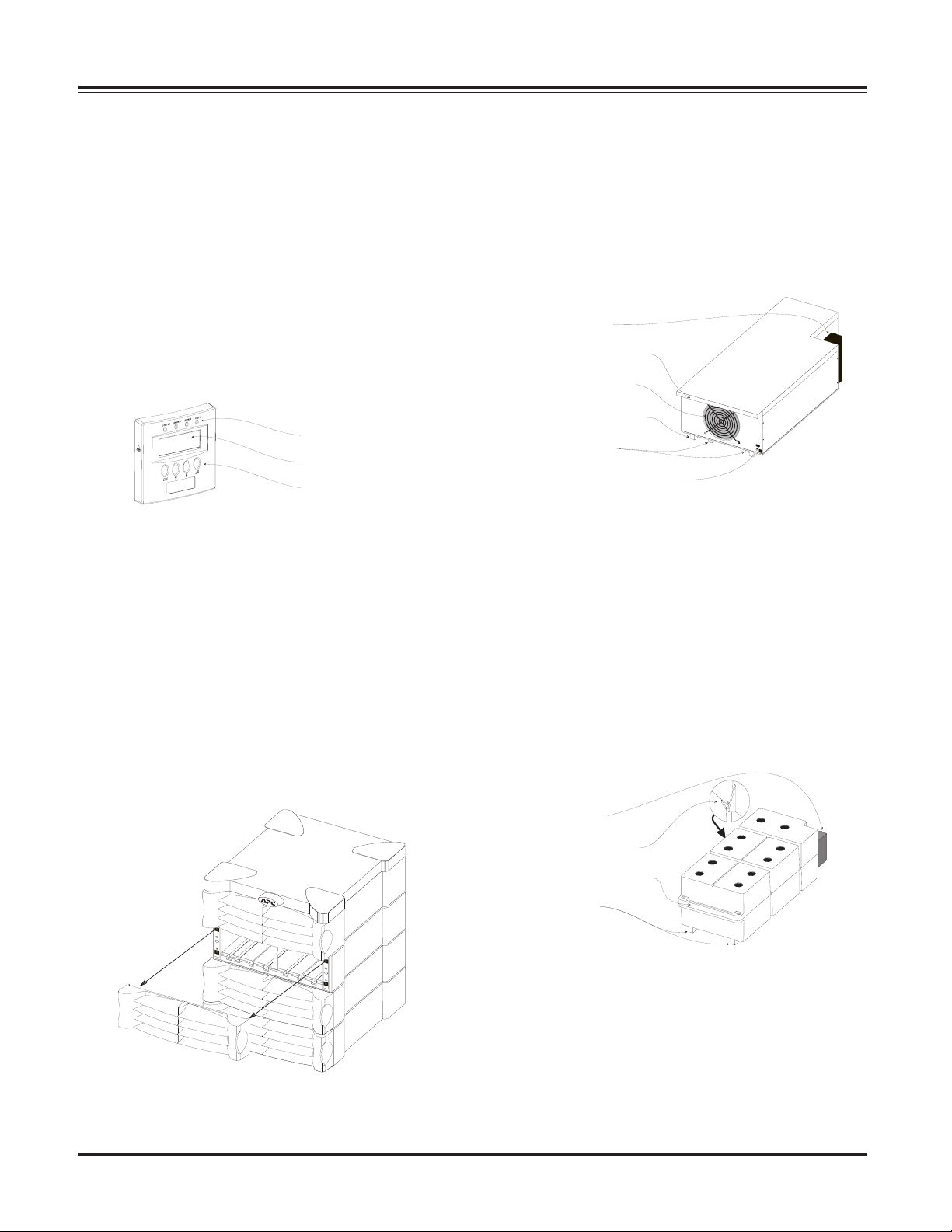

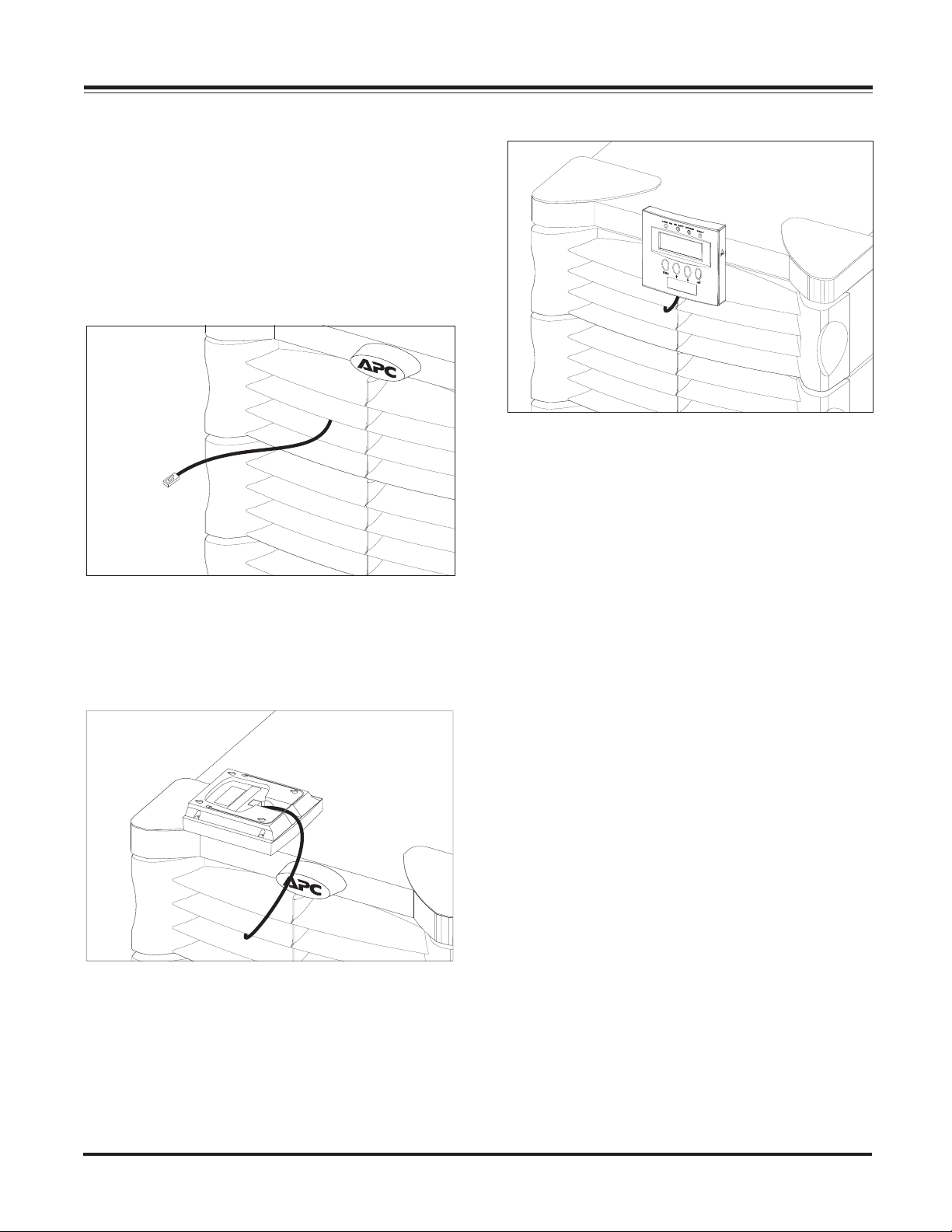

Powerview User Interface

The Powerview incorporates a 4 x 20 alphanumeric LCD screen

with four navigation keys, four LED status indicators, and an

audible alarm beeper. The display communicates with the

Power Array via a local RJ45 connector cable that is hardwired

into the top power module bay. It can be mounted on the

front of the frame, stand on top of the frame, or it can be

installed at a remote location. (A 20’ RJ45 cable is provided,

and plugs into a communication port at the rear of the frame.)

The alphanumeric LCD screen displays system status, fault

reporting and module diagnostics information. The navigation keys are used to scroll through an elaborate menu. Chapter 6 provides detailed information about the Powerview.

LED Status Indicators

LCD Screen

Navigation Keys

Fig 1-3 Powerview User Interface

Alarm thresholds and parameters are set with the Powerview.

In the event of an alarm condition, the Powerview emits both

audible and visual alarm indicators.

Power Module

The power module is a self-contained, 4kVA UPS (without

batteries) housed inside a metal enclosure. A blind mating

connector at the rear of the module engages with a connector

inside the frame, and powers the unit. Power modules are

installed in the vertical column of bays at the left of the frame.

These bays are labelled L1, L2, L3, etc.

Blind Mating

Connector

Positioning Handle

Cooling Fan Grill

Alignment Runner

Seating Tabs

Flip Latch Micro Switch

Fig 1-4 Power Module

In the event of a power module failure, the Powerview initiates

an audible alarm, and displays an error message. The power

module is hot-swappable. Instructions for module replacement are provided in chapter 8.

Louvered Grill Covers

Each level of the frame is equipped with a louvered grill cover.

These covers are interchangable, and snap securely onto the

frame. When removing, temporarily storing, and replacing

grill covers, use care to prevent them from being marred or

scratched.

Fig 1-3 Front Grill Cover Removal and Replacement

Battery Module

The battery module is comprised of a series of ten 12V batteries housed inside a plastic enclosure. A blind mating connector at the rear of the module engages with a connector inside

the frame.

Blind Mating

Connector

Retaining Flange

Positioning Handle

Runners

Fig 1-5 Battery Module

Battery modules are installed in the vertical column of bays at

the right of the frame. These are labelled R2, R3, R4, etc. (The

top right bay houses the intelligence modules.) The condition

and charge of each battery module is reported on the

PowerView. If a battery module fails, an alarm is initiated.

Battery modules are hot-swappable, and user replaceable.

1-2

Page 18

Chapter 1 - Physical Representation

Main Intelligence Module (MIM)

The MIM is the onboard computer for the Power Array system. It gathers and processes data, including monitoring the

condition of each of the modules.

Blind Mating

Connector

Flip Latch Micro Switch

Retaining Screw

Positioning Handle

Installation Rail

Fig 1-6 Main Intelligence Module

The PowerView functions as the user interface for the MIM,

and is used to access data, and to configure the system. When

a redundant intelligence module is installed and functioning,

the main intelligence module can be replaced without placing

the load at risk. The main intelligence module also communicates to an external battery frame (if present). The main intelligence module and the redundant intelligence module are factory installed into custom racks that are built into the bay at

the upper right of the frame.

Important: The MIM is always installed in the bottom rack, and

the RIM is always installed in the top rack.

Redundant Intelligence Module

(RIM)

The redundant intelligence module is a back-up version of the

main intelligence module. It provides redundancy in the event

of a MIM failure, or while a MIM is being replaced. If a functioning MIM is present, the RIM can be removed and replaced

without placing the load at risk. The condition of the RIM can

be determined with the PowerView.

Input Circuit Breaker

The input circuit breaker protects the Power Array from extreme overloads. When switched to “stand by” the Power

Array is disconnected from incoming utility voltage. When

switched to the “on” position, power flows from the utility

source into the Power Array. Under normal operating conditions, the input circuit breaker always remains in the “on” position.

Fig 1-8 Input Circuit Breaker & Maintenance Bypass Switch

Maintenance Bypass Switch

When switched to the “on” position, the maintenance bypass

switch bypasses the Power Array, and causes the load equipment to be powered directly from utility power. When it is

switched to the “off ” position, utility power flows into the

Power Array, and conditioned power is delivered to the load

equipment. The load equipment is unprotected when the main-

tenance bypass switch is in the “on” position. Under normal

operating conditions, the maintenace bypass switch always

remains in the “off” position.

Blind Mating

Connector

Flip Latch Micro Switch

Retaining Screw

Positioning Handle

Installation Rail

Fig 1-7 Redundant Intelligence Module

1-3

Page 19

Chapter 1 - Physical Representation

Rear View of a Power Array

The rear of a MiniFrame system is displayed below. The rear

of a MasterFrame is similar. Each of the components are

described in a section that follows:

System Enable Switch

The system enable switch regulates internal power to the Power

Array. It does not power the load. When switched to the “on”

position, the Power Array enters the load-disconnect operating mode. When switched to “stand by” the Power Array is

disconnected from incoming utility voltage. The load is not

powered until the “power the load” command is entered into

the PowerView interface.

Communication Interface Ports

The following three communication ports are provided: A

remote PowerView cable port; an APC PowerChute Plus software interface port, and two battery extension frame communication ports. A 20’ RJ45 cable is provided with the Power

Array for remote installation of the PowerView.

TM

Smart Slots

APC manufactures a set of auxillary user interface accessories,

called SmartSlot

are provided. SmartSlotTM interface options include:

Accessory Ports

TM

devices. Four SmartSlotTM installation ports

n Protection and safe shutdown of multiple servers

n SNMP adaptor for accessing data via a network

n CallUPSTM - Initiates telephone notification of power event

n MeasureUPSTM - monitoring environmental conditions

n Control and monitor via modem

Note: Use only SmartSlot

TM

devices labelled “Symmetra

TM

compatible.”

REPO/Input/Output Wiring Access Panels

Wiring terminal blocks for input and output wiring, and for

remote emergency power off (REPO) switch intallations are

accessed through these panels. For use by a licensed electrian.

Power Distribution Unit Panel (Optional)

An optional power distribution unit provides output power

receptacles and corresponding circuit breakers. The MiniFrame

PDU provides one L6-30R receptacle (208V), two 5-15R receptacles (120V), and two L14-30R receptacles (120V/240V). The

MasterFrame PDU provides three L6-30R receptacles, four 515R receptacles, and three L14-30R receptacles. The PDU panel

for both frame sizes are equipped with a panel circuit breaker.

Battery Extension Frame Connector

An optional Battery Extension Frame can be connected to the

Power Array using this coupler. See the User’s Manual inluded

with the Battery Extension Frame.

Communication

Interface

Ports

Power Distribution

Unit (Optional)

System

Enable

Switch

Battery

Extension

Frame

Connector

REPO Wiring

Access Panels

SmartSlot

Accessory

Ports

MiniFrame

Output

Wiring

Access

Panels

Input

Wiring

Access

Panels

TM

1-4

Fig 1-8 Rear View of a Mini Frame SymmetraTM Power Array System

Page 20

Chapter Two

Site Preparation

This chapter provides the site requirements

for a SymmetraTM Power Array system.

Included are structural and environmental

requirements, weights, dimensions and the

heat output of a functioning system.

Page 21

Chapter 2 - Site Preparation

Space and Weight Considerations

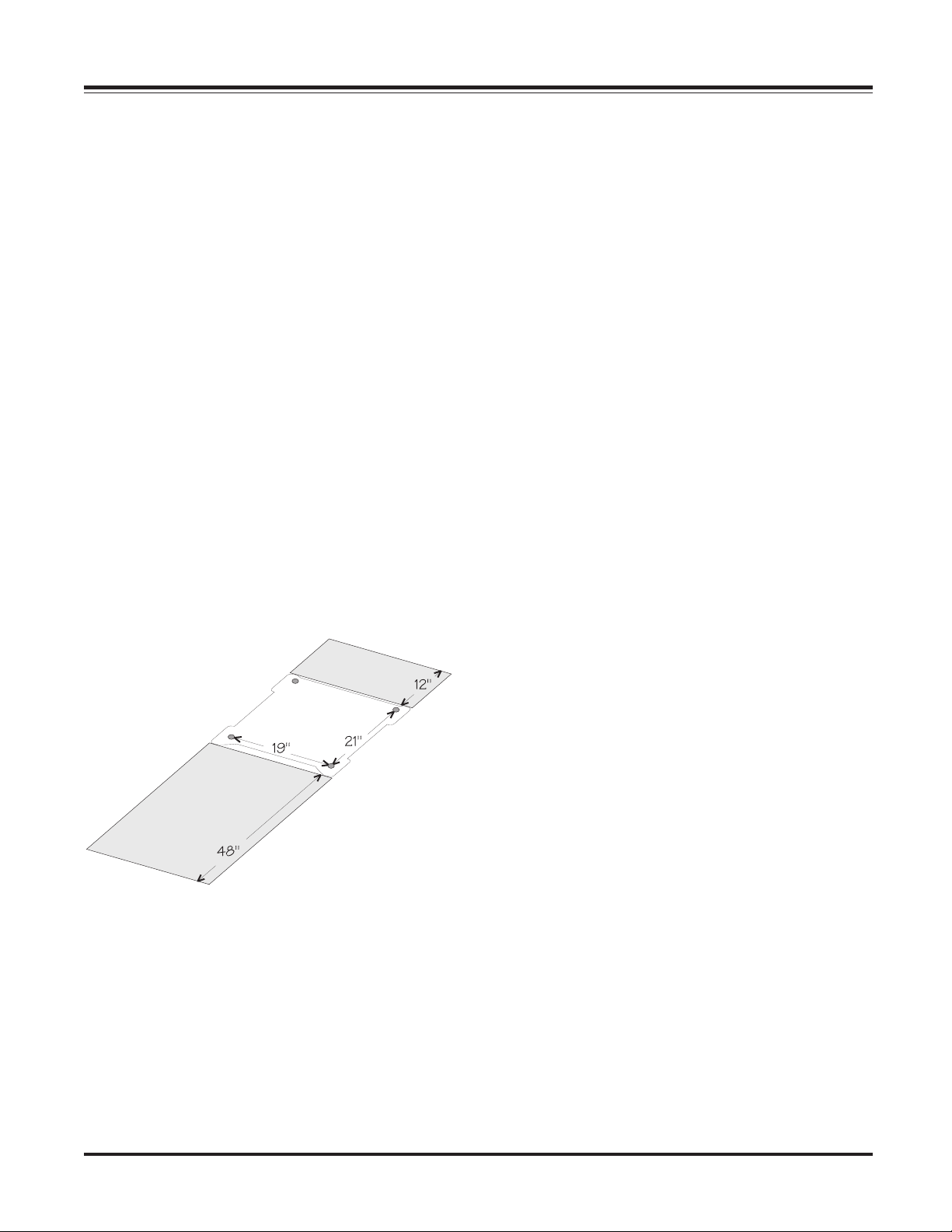

All Power Array frames are 24” wide and 27” deep. Refer to

table 4-1 for dimensions and weights of fully loaded systems.

Table 2-1 Power Array Dimensions and Weights (Fully

Loaded with Modules)

Make sure there is adequate space and structural integrity to

support the fully loaded frame. Refer to figure 2-1 below. The

weight of the Power Array rests on four 1.5” diameter leveling

feet. Positions of the leveling feet are shown. When installing

the frame, allow 12” of clearance behind the frame for adequate airflow. (The fans on the system pull air in through the

front of the frame, and blows it out the back.) Allow 48” of

clearance in the front of the SymmetraTM to access the

PowerView interface, and for installation and replacement of

modules.

Rear

Clearance

Operating Conditions

The Power Array is intended for installation in a temperaturecontrolled, indoor area, free of conductive contaminants. The

operating evironment must be clean, dry and protected. The

atmosphere must be free of dust and corrosive fumes. Adequate airflow must be provided for the operation of the system. Make sure environmental conditions where the

SymmetraTM is to be installed are within the following parameters:

n Operating Relative Humidity: The Power Array will op-

erate within a relative humidity range of 0 to 95%, noncondensing.

n Operating Temperature: The Power Array will operate

within a temperature range of 32°F to 104°F (0°C to 40°C).

n Operating Elevation: The Power Array will operate at

elevations within a range of 0ft to 10,000ft (0m to 3,048m).

n Electro-Static Discharge (ESD) Susceptibility: The Power

Array and all modules are capable of withstanding

“through air” electro-static discharges up to an amplitude of +/-15kV and “direct discharge” electro-static discharges up to an amplitude of +/-8kV without failure,

abnormal operation or degradation in performance. ESD

test methods conform to IEC 801-2.

BTU Output

Footprint and

Feet Positions

Front Clearance

Fig 2-1 System Footprint and Required Clearance

Transporting Power Array to Installation Site

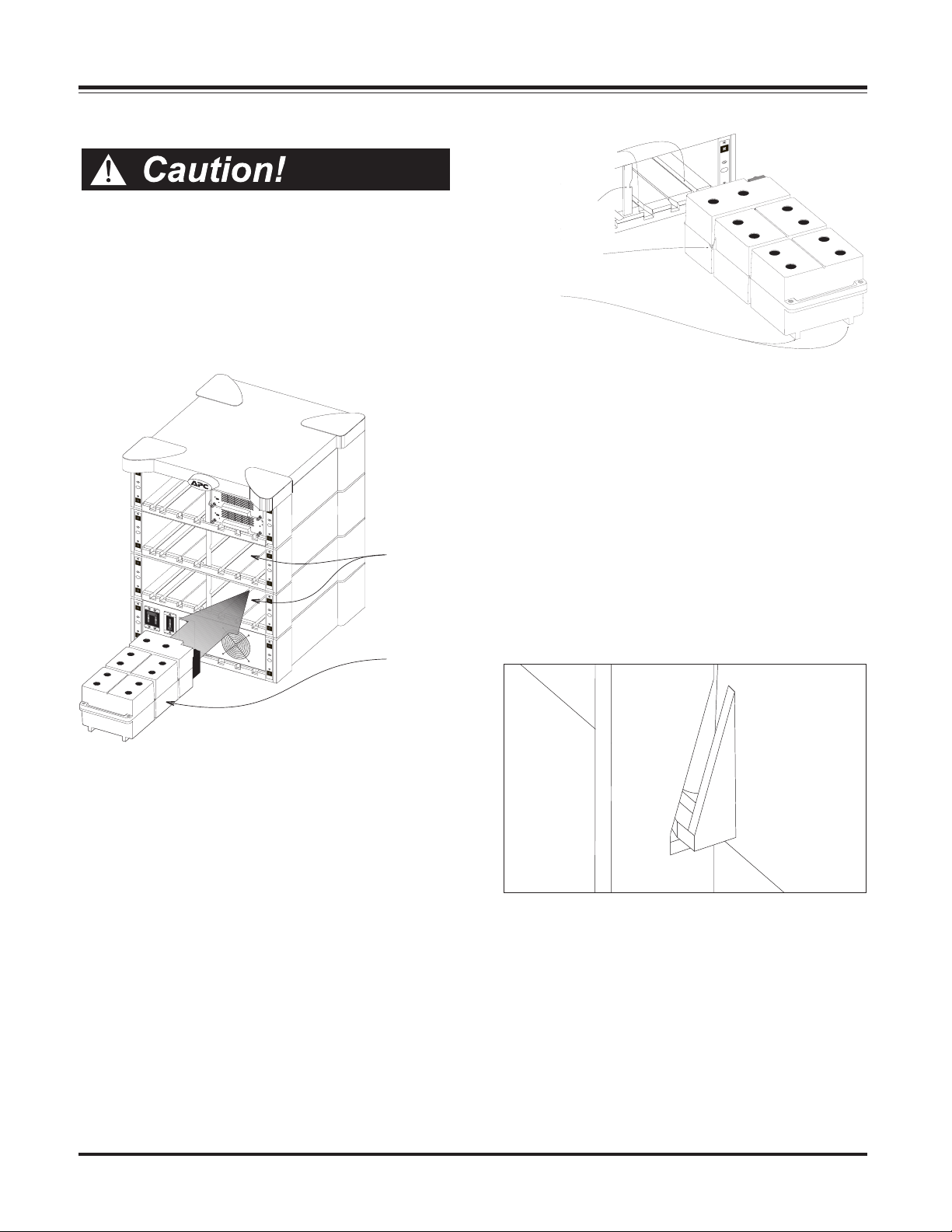

When it is shipped, the Power Array frame is bolted to a custom-designed pallet. The modules are stacked on either one

or two additional pallets. It is recommended that these pallets

be moved from the receiving dock to the installation area with

a pallet jack. Make sure there is enough space and structural

integrity to move these pallets.

Refer to table 2-2 for BTU output of a fully loaded, and functioning Power Array system. The BTU output is significantly

higher while the batteries are charging. Under normal operating conditions, battery recharge periods are relatively infrequent.

Table 2-2 BTU Output

Temporary Storage of Modules

The battery and power modules must be temporarily stored

until the frame is permanently installed. To preserve battery

life, always store batteries in a cool, dry place.

2-1

Page 22

Chapter 2 - Site Preparation

2-2

Page 23

Chapter Three

Unpacking and Installing Frame

Because the installation process begins on

the loading dock, this chapter provides the

procedures for inspecting the Symmetra

Power Array frame and modular components

when they arrive. It includes procedures for

moving the frame to the installation site,

removing it from the pallet, and preparing the

frame and the modules for installation.

TM

Page 24

Chapter 3 - Unpacking and Installing Frame

Initial Inspection

The SymmetraTM Power Array system is shipped on pallets.

The system frame is bolted to one pallet, and the modules are

boxed, and stacked on one or two additional pallets.

Check For Damage

1. Inspect the Packaging - for damage or signs of mishandling before moving the pallets. If damage is detected, note it

on the Bill of Lading.

2. If Any Damage Is Detected - file a damage claim with the

shipping agency within 24 hours. Contact APC Customer

Service at 1-800-800-APCC to inform them of the damage

claim, and the condition of the equipment.

3. System Administrator- make sure the system administrator participates in the initial inspection.

Tools Required for Setup

The following tools are required to move the pallets into place,

remove packaging materials, install the ramp on the frame

pallet, and to remove the frame from the pallet.

1. Large Philips screwdriver

2. Adjustable, open-end wrench

3. Heavy duty shears

4. Sharp utility knife

5. Pallet jack

Storage of Battery and Power

Modules

The modules must be temporarily set aside, while the frame is

installed and wired. To preserve battery life, always store battery modules in a cool, dry place.

Moving the Frame

1. Plan the Route - Make sure all passages are large enough to

accomodate the frame, and the pallet jack. Check to see that

the floor has sufficient strength. See Table 3-1 for weights and

dimensions. Check doorways, elevators, ramps, etc, to insure

there are no non-negotiable corners, step-ups, or offsets. Select a route that provides the smoothest possible floor surface.

2. Staging Area - A smooth, level floor surface is required to

position the frame pallet, remove the packaging materials, install the ramp, and for two people to carefully roll the frame

down the ramp, and onto the floor. See Figure 3-1 below for

staging area dimensions.

Table 3-1 Dimensions and Weights

Handling Considerations

1. The Frame Pallet - See Table 3-1 for frame pallet weight and

dimensions. Before removing shipping materials, the frame

and pallet should be positioned as close as possible to the

installation site. The frame is bolted to a specially designed

pallet, and is removed from the pallet using a ramp that is

included. Use a pallet jack to position the frame pallet.

Note: Do not attempt to move the frame with a hand dolley.

2. The Modules Pallet - If possible, it is recommended that the

module pallet(s) be positioned as close as possible to the final

installation site with the pallet jack. If this is not possible,

remove the outer packaging materials from the module cartons, and carry each individual, boxed module to the installation site. See Table 3-1 for module weights.

Fig 3-1 Staging Area

3. Using a Pallet Jack - Carefully move the frame to the staging area.

3-1

Page 25

Chapter 3 - Unpacking and Installing Frame

Remove Packing Materials

Note: It is recommended that all packaging materials be removed, and temporarily stored, in case any of the system components must be returned to the factory.

1. Remove the Shipping Bands - Using appropriate precautions, carefully cut the plastic shipping bands.

2. Removing the Plastic Wrap - Using care to not damage the

surface of the Power Array, cut off the plastic wrap by running

the tip of a sharp utility knife along the surface of one of the

cardboard corner supports. Remove the plastic wrap from

the frame.

3. The Pallet Ramp - The pallet ramp is shipped under the

cardboard cap, on top of the frame. It will sometimes become

wedged inside the cardboard cap. Use caution removing this

cap from the frame. Remove the ramp from the top of the

frame.

4. Corner Supports - When the cardboard cap is removed,

the four corner supports will fall away. Remove them, and

place to one side.

5. Remove the Cover Grills - Remove the grill covers from the

frame. Grasp each grill cover by the side finger hold that is

molded into them. Pull straight forward. Set the covers to one

side. Be careful not to scratch them.

6. Leveling Feet - Fully retract each of the four leveling feet

located near the casters on the bottom of the frame.

3. Install the Ramp - Position the ramp so that the installation

bolts line up with the ramp bolt holes on the pallet. Install the

ramp onto the pallet as shown in Figure 3-3.

Fig 3-3 Frame Pallet Ramp

4. Roll the Frame from the Pallet - The following operation

requires two people. Holding the frame near the center, care-

fully roll it down the ramp, and onto the floor. (The frame is

equipped with casters.)

5. Roll the Frame to the Installation Site - Carefully roll the

frame from the staging area to the final installation site.

6. Shipping Material Storage - Gather all shipping materials

together, and store it temporarily, in case any system component must be returned to the factory.

Fig 3-2 Frame Restraint and Ramp Holes

Remove the Frame from the Pallet

1. Loosen Rear Bracket Screws - Loosen the two phillipshead screws securing the brackets at the rear of the frame.

2. Remove Two Pallet Restraint Screws - See Figure 3-2. Remove the two phillips-head, pallet restraint screws. Use the

cloth handle to remove the frame restraint from the pallet.

Place the frame restraint and two screws to one side.

Moving Battery & Power Modules

1. Moving All Modules On Pallet - Using the pallet jack, move

the modules pallet(s) to the installation site. If necessary, the

modules can be moved one at a time. Remove all outer packaging materials from pallet, and carry each boxed module to

the final installation site.

3. Stack Modules - Carefully stack the battery and power

modules near the installation site. Leave enough room for the

electrican to install the wiring to the frame.

Clean-UP

1. Packaging Materials - Remove all packaging materials from

the installation site. Store it temporarily, so that it will be

available if any components must be returned to the factory.

2. Final Inspection - Check the module bays of the frame to

make sure they are clear of debris.

3-2

Page 26

Chapter Four

Wiring Requirements & Procedures

This chapter is addressed to the licensed

electrican who will install the input, output

and remote emergency power off hardwiring

connections. Circuit requirements and

minimum wire gauges are included.

Page 27

Chapter 4 - Electrical Requirements and Procedures

SymmetraTM Wiring

n All power and control wiring must be installed by a

licensed electrician only. All input, output and emergency power off wiring must comply with the National

Electric Code (NEC) and applicable local codes.

n It is highly recommended that flexible metal conduit

be used when hardwiring the Power Array. This will

provide for ease of service and maintenance of the system.

There are four categories of hardwiring installation procedures for the SymmetraTM Power Array. These are; input

wiring, output wiring, remote emergency power off switch

wiring, and installing an optional local grounding electrode.

Input Wiring

The Power Array requires a single phase 208V or 240V incoming AC utility power source. Incoming power is wired

directly to a terminal block inside the Power Array. Specifications and installation procedures are provided.

REPO Switch Wiring

The SymmetraTM Power Array can be connected to either a

dry contact, or a 24Vdc remote emergency power off (REPO)

switch. The wiring terminal connections for the REPO are

physically isolated from the primary circuitry of the Power

Array. Specifications and installation procedures for REPO

wiring are provided.

Local Grounding Electrode

A 1/2” knockout is provided on the output wiring access panel

for those sites where NEC code 250-26 requires a local

grounding electrode. This grounding electrode is installed in

addition to the equipment safety ground that is run with the

input hardwiring connection. The local grounding electrode

is connected from the output terminal block to the nearest

effective ground, such as building steel, a metal water pipe,

or other appropriate grounding structure. The procedure

for installing a local grounding electrode is included in the

output wiring procedures.

Note: The local grounding electrode must meet National Electric Code standards, as per NEC Table 310-16.

Output Wiring

Power is distributed to the load equipment via hardwired

connections to an output terminal block inside the frame,

and by plugging the load equipment into an optional power

distribution panel. The Power Array delivers 120V/208V/

240V power to the output terminal block. Configurations

for hardwiring 120/240V and 120/208/240V output voltages

are provied in this chapter. Specifications and installation

procedures are provided.

4-1

Page 28

Chapter 4 - Electrical Requirements and Procedures

Input Wiring

n Verify that all incoming line voltage (utility power)

and low voltage (control) circuits are de-energized, and

locked out before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Always verify that all battery modules are removed

and all battery extension frames are disconnected from

the Power Array before installing any wiring to the

Power Array.

n Read this chapter completely before installing any wir-

ing to the Power Array.

Input Wiring Specifications

The Power Array requires either a single phase 208V, 50/60Hz,

or a 240V, 50/60Hz incoming utility power source. A 3-conductor cable (2 live, 1 ground) is to be brought to the input

wiring terminal block inside an adequate length of flexible

metal conduit. To minimize disturbances caused by other

loads in the building, input wiring should be supplied directly from the service entrance (a dedicated power feeder).

All electrical service, both input and output, must be sized in

accordance with the NEC and any local building codes. The

circuit for input power must be adequate to carry the full

load of the system and the load equipment. The 3-conductor input cable should be sized for no more than 3% voltage

drop. A 3/4” knockout in the input wiring access panel provides access to the terminal block.

See table 4-1 for input wiring specifications.

Input Wiring Procedures

An input voltage jumper must be manually set before input

wiring can be installed. Follow the procedure below:

Voltage Jumper Procedure

1. Refer to figure 4-1. Remove the screw that secures the

voltage select access panel to the frame. Place the screw and

access panel aside temporarily.

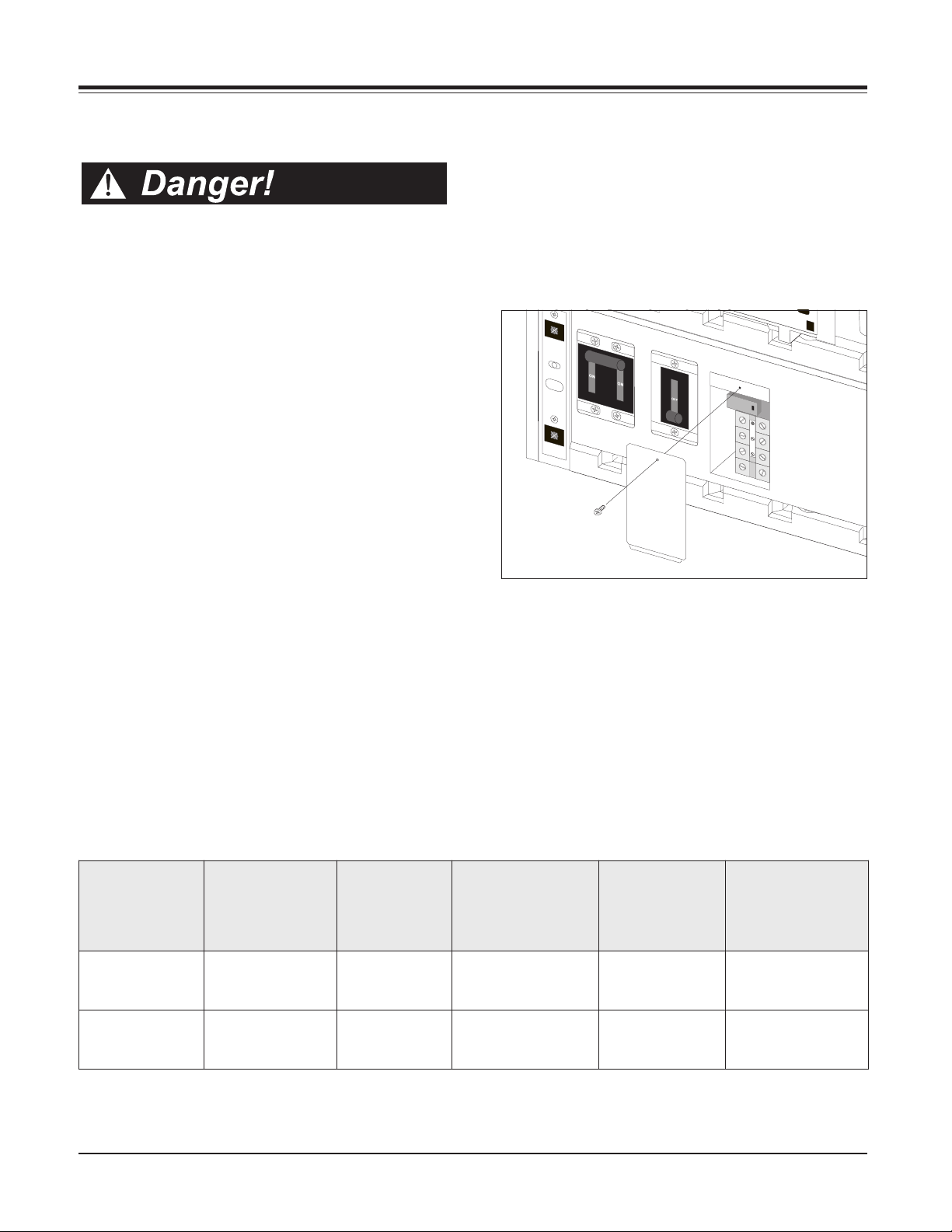

Fig 4-1 Voltage Select Access Panel

2. Use a small, flat head screwdriver to position the input

voltage jumper to the correct voltage setting. See figure 4-2.

Do not overtighten screws.

Note: When the input voltage jumper is in the 240V position,

the jumper bar activates a micro switch at the top of the terminal block. In the 208V position, the micro switch is not activated.

4-2

tupnI

egatloV

sulperiw-2(

)dnuorg

caV802

caV042

emarF

eziS

AVk.xaM(

)gnitaR

)AVk8(iniM

)AVk61(retsaM

)AVk8(iniM

)AVk61(retsaM

Table 4-1 Input Wiring Specifications

lluFtupnI

daoL

egarepmA

pmA04

pmA08

pmA53

pmA07

tupnI

tnerrucrevO

noitcetorP

)lanretxE(

pmA05

pmA001

pmA05

pmA001

muminiM

eriWtupnI

eguaG

eguaG8#

eguaG3#

eguaG8#

eguaG3#

muminiM

eriWdnuorG

eguaG

eguaG8#

eguaG3#

eguaG8#

eguaG3#

Page 29

3. After the electrical wiring test/checklist is completed (end

of this chapter), replace the voltage select access panel.

240V

208V

Chapter 4 - Electrical Requirements and Procedures

Fig 4-4 Input Wiring Pathway

Fig 4-2 Input Voltage Jumper

Input Wiring Procedure

1. Refer to figure 4-3. Locate the input wiring entry and

input wiring inspection panels.

2. Remove the four screws securing the panels to the frame.

Remove only the screws indicated in the illustration. Place

the screws and panels to one side.

Fig 4-3 Removal of Input Hardwiring Panels

2. Pull the three input wires through conduit, leaving about

20” of wiring extending from the end. Install a flexible metal

conduit connector to the end of the conduit. Using appropriate tools, remove the knockout in the entry panel. Feed

the wires through the entry panel, and attach the flexible metal

conduit connector to the panel. Strip 1/2” of insulation from

the end of each of the incoming wires.

3. Feed wire into the entry compartment through the wiring

pathway hole between the input wiring entry compartment

and the input wiring compartment. See figure 4-4 for the

input wiring pathway.

4. Connect input wires to the input terminal block connections labelled L1, L2/N and Ground as shown in figure 4-5.

Make sure there are no loose strands and that the terminal

connection screws are sufficiently tightened. Connections

are the same for 208V or 240V incoming voltages.

Note: In North America, L2/N is a phase (hot) connection. In

Europe, L2/N indicates a neutral connector.

Fig 4-5 Input Hardwiring Configuration

5. Carefully fold the excess wiring into the entry compartment. After the electrical wiring test/checklist is completed

(end of this chapter), replace the input wiring panels.

4-3

Page 30

Chapter 4 - Electrical Requirements and Procedures

Output Wiring

Output voltage is delivered to the load equipment via

hardwired connections and/or via receptacles on an optional

power distribution unit (PDU). To facilitate maintenance

and service of the Power Array, it is recomended that flexible

metal conduit be used for all hardwiring connections.

See table 4-2 for output wiring specifications.

Output Wiring Configurations

The Power Array is typically wired to deliver either120V/240V,

or 120V/208V/240V output voltages. The internal wiring to

the output terminal block is depicted in figure 4-6. Note the

neutral ground bond in figure 4-7. Wiring configurations

for installations with a power panel are provided in figures

4-8 and 4-9. If wiring is to be connected directly to the load

equipment, refer to table 4-3 for the correct terminal connections.

Note: Use only the connections shown in table 4-3. All others

will yield voltages other than normal utility voltages.

egatloV *snoitcennoC

V021 8-6ro8-2

V042 6-2

V802 6-4

rehtollA.snoitcennocesehtylnoesU*

nahtrehtosegatlovdleiylliwsnoitanibmoc

.segatlovytilitulamron

Table 4-3 Terminal Block Voltage Combinations

Fig 4-6 Voltages Delivered to the Output Terminal Block

Neutral

Ground

Bond

.

Fig 4-7 Output Wiring Neutral Ground Bond

Output Overcurrent Protection

SymmetraTM requires output voltage overcurrent protection

in accordance with the ratings in table 4-2. If an optional

PDU is installed on the Power Array, the panel circuit breaker

acts as the overcurrent protection for the PDU receptacles

and the hardwired connections. See figure 4-11 and 4-12. If a

PDU panel is not installed, circuit breakers must be installed

in the power panels as shown in figures 4-8 and 4-9.

4-4

tuptuO

egatloV

caV042/021

)dnuorg+seriw-2(

caV042/802/021

)dnuorg+seriw-3(

emarF

eziS

AVk.xaM(

)gnitaR

)AVk8(iniM

)AVk61(retsaM

)AVk8(iniM

)AVk61(retsaM

Table 4-2 Output Wiring Specifications

mumixaM

rePtuptuO

rotcudnoC

pmA04

pmA08

pmA04

pmA08

tuptuO

tnerrucrevO

noitcetorP

)lanretxE(

)elop-2(pmA05

)elop-2(pmA09

)elop-3(pmA05

)elop-3(pmA09

muminiM

tuptuO

eriW

eguaG

eguaG8#

eguaG3#

eguaG8#

eguaG3#

muminiM

dnuorG

eriW

eguaG

eguaG8#

eguaG3#

eguaG8#

eguaG3#

Page 31

Chapter 4 - Electrical Requirements and Procedures

Fig 4-8 Output Wiring Configuration for 120V/240V Output Voltages

Fig 4-9 Output Wiring Configuration for 120V/208V/240V Output Voltages

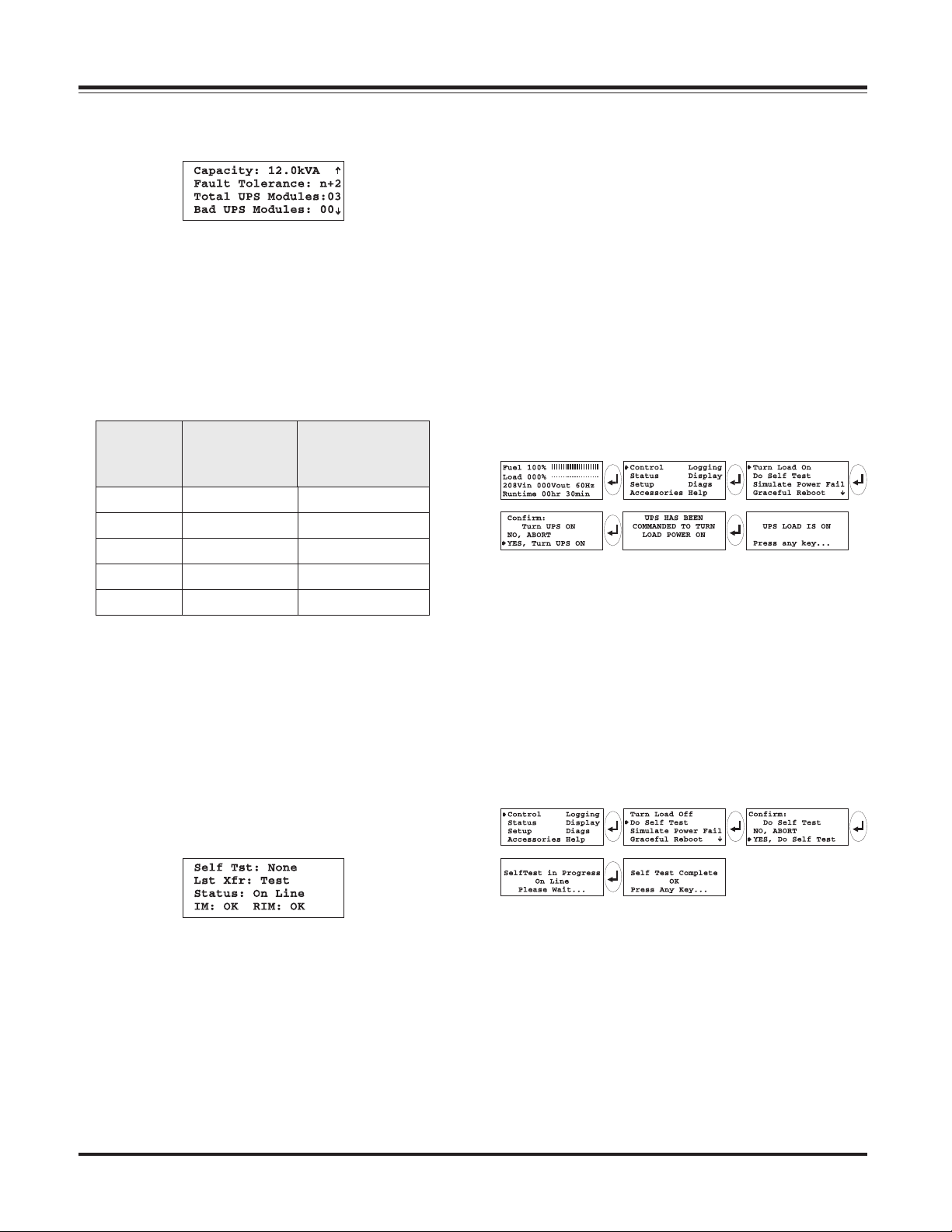

4-5

Page 32

Chapter 4 - Electrical Requirements and Procedures

Output Wiring Installation

n Verify that all incoming line voltage (utility power)

and low voltage (control) circuits are de-energized, and

locked out before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Always verify that all battery modules are removed

and all battery extension frames are disconnected from

the Power Array before installing any wiring to the

Power Array.

n Read this chapter completely before installing any wir-

ing to the Power Array.

Output Wiring Procedure

1. Refer to Fig 4-10. Remove the four screws holding the

output wiring entry panels to the rear of the Power Array.

Remove only the screws indicated in the illustration. Set the

screws and both panels aside temporarily.

output wiring to the output terminal connections. Make sure

there are no loose strands and that the terminal connection

screws are sufficiently tightened.

Grounding Electrode (Optional)

If installing an optional grounding electrode, use the 1/2”

knockout in the output wiring panel, and attach the grounding electrode to the output terminal block ground connection. (Use a strain relief clamp, or a flexible metal conduit

connector.) Connect the local grounding electrode to the

nearest effective ground, such as building steel, a metal water

pipe, or other appropriate grounding structure.

See NEC code 250-26 and Table 310-16.

4. Carefully fold excess output wiring into the terminal compartment. After the electrical wiring test/checklist is completed (end of this chapter), replace the output wiring access

panels.

Power Distribution Units (Optional)

An optional power distribution unit provides output power

receptacles and corresponding circuit breakers. The

MiniFrame PDU provides one L6-30R receptacle (208V), two

5-15R receptacles (120V), and two L14-30R receptacles

(120V/240V). The MasterFrame PDU provides three L6-30R

receptacles, four 5-15R receptacles, and three L14-30R receptacles. The PDU panel for both frame sizes are equipped

with a panel circuit breaker.

Fig. 4-10 Removal of Output Hardwiring Panels

2. Pull wire through conduit, leaving about 20” of wiring

extending from the end. Install a flexible metal conduit connector to the end of the conduit. Using appropriate tools,

remove the knockout in the entry panel. Feed the wires

through the entry panel, and attach the flexible metal conduit connector to the panel. Strip 1/2” of insulation from

the end of each of the incoming wires.

3. Use the output wiring configuration that corresponds to

the output load voltage. See figures 4-8 and 4-9. Connect

L14-30R

Receptacles

L6-30R

Receptacles

L14-30R

Receptacles

L6-30R

Receptacles

5-15R

Receptacles

Panel Circuit

Breaker

Fig. 4-11 MiniFrame PDU Panel

5-15R

Receptacles

Panel

Circuit

Breaker

Fig. 4-12 MasterFrame PDU Panel

4-6

Page 33

Chapter 4 - Electrical Requirements and Procedures

Remote Emergency Power

Off Switch

The Power Array can be de-energized with a remote emergency power off (REPO) switch. REPO switches are common in computer rooms where, for safety reasons, power to

the loads must be quickly disconnected. The REPO switch

physically flips the system enable switch to “stand by” mode.

This cuts all power to the Power Array, and to the load equipment. The system enable switch must be physically reset.

The REPO can be connected to either a switched, 24Vdc circuit, or a simple, contact closure.

REPO Specifications

The REPO circuit is considered a Class 2 and SELV circuit.

SELV is an acronym for “Safety Extra Low Voltage.” SELV is

a common term in Europe and IEC standards. A SELV circuit is isolated from primary circuitry through an isolating

transformer and designed so that under normal conditions,

the voltage is limited to 42.4 Vpeak or 60 Vdc.

A Class 2 Circuit is a common term in North America and in

UL and CSA standards. It is defined in the Canadian Electrical Code (C22.1, Section 16), and the National Electrical Code

(NFPA 70, Article 725).

SELV and Class 2 circuits must be isolated from all primary

circuitry. Do not connect any circuit to the EPO terminal

block unless it can be confirmed that the circuit is SELV or

Class 2. If there is a question, use a contact closure switch.

REPO Switch Installation

n Verify that all incoming line voltage (utility power)

and low voltage (control) circuits are de-energized, and

locked out before installing cables or making connections, whether in the junction box or to the

SymmetraTM Power Array.

n Always verify that all battery modules are removed

and all battery extension frames are disconnected from

the Power Array before installing any wiring to the

Power Array.

n Read this chapter completely before installing any

hardwiring connections to the Power Array.

REPO Wiring Procedures

Remove the REPO wiring access panel to access the terminal

connections.

1. Refer to figure 4-13. Remove the screw holding the two

piece access panel at the rear of the Power Array. Remove the

panel. Set the screw and the panel aside temporarily.

Cable Specifications

The cable that connects SymmetraTM to the Emergency Power

Off switch should be UL Listed, type:

CL2 - Class 2 cable for general purpose use; or

CL2P - Plenum cable for use in ducts, plenums and other

space used for environmental air; or

CL2R - Riser cable for use in a vertical run in a shaft or from

floor to floor; or

CL2X - Limited Use cable for use in dwellings and for use in

raceway.

For installation in Canada, the cable should be CSA Certi-

fied, type ELC (Extra-Low-Voltage Control Cable).

Fig 4-13 Removal of REPO Wiring Panels

2. Refer to figures 4-14 and 4-15. Select the configuration

that matches the type of REPO switch that is to be installed.

Note: An existing jumper must be removed from the terminal

block if a 24Vdc REPO switch (Figure 4-15) is to be installed.

3. Extend the wiring from the switch to the Power Array. Strip

1/2” of insulation from the end of each of the incoming wires.

4. Feed the wires through the knockout in the access panel,

and install a strain relief (Romex) connector.

4-7

Page 34

Chapter 4 - Electrical Requirements and Procedures

5. Make sure there are no loose strands and that the terminal

connection screws are sufficiently tightened.

6. After the electrical wiring test/checklist is completed (end

of this chapter), replace the REPO access panel.

Contact Closure REPO Switch Connection

Connect the contact closure REPO wiring to the terminal

block as illustrated in figure 4-14 below.

Note: The factory installed jumper remains as shown.

Jumper Installed

Fig 4-14 Dry Contact Switch

24 Vdc REPO Switch Connection

Connect the 24Vdc REPO wiring to the terminal block as

illustrated in figure 4-15 below.

Note: The factory installed jumper must be removed.

Electrical Wiring Test

The following test procedure will ensure the Power Array has

been correctly hardwired. It is intended that the licenced

electrician who installed Power Array will perform this test.

A true RMS voltmeter is required for this procedure.

Before this test can be conducted, the main intelligence module (MIM) must be installed, and the PowerView display must

be connected to the Power Array. Refer to chapter 5 for procedures to install the MIM and the PowerView. The power

and battery modules need not be installed to perform this

test.

Note: This test is intended to verify the electrical connection to

the Power Array, not to verify it’s operation or explain it’s usage. In this procedure, you will be instructed to ignore

PowerView messages, etc. Refer to chapters 6 & 7 for detailed

information about the operation of the Power Array.

Electrical Wiring Test/Checklist

q 1. Make sure all three switches - system enable, mainte-

nance bypass, and input circuit breaker are in the “off ”

or “stand by” position. Make sure all load equipment is

either turned off, or is unplugged from the Power Array.

q 2. Use a true RMS voltmeter to measure the input AC

voltage at the terminal connections at the rear of the

frame (bottom level).

Note: If input voltage is less than 156Vrms or greater than

276Vrms, check input wiring for errors. DO NOT PROCEED UNTIL THE INPUT VOLTAGE IS WITHIN THIS

RANGE.

4-8

Fig 4-15 24Vdc EPO Switch

24Vdc

Power

Source

Record the input voltage here: ____________________

q 3. Check for proper ground installation. If available, a

ground ohmmeter should be used. Otherwise, check

for continuity to building ground.

q 4. Switch the input circuit breaker to the “on” position.

q 5. Switch the system enable switch to the “on” position.

Note: The Power Array may make a series of clicking sounds

as it runs through an initial self test.

Page 35

Chapter 4 - Electrical Requirements and Procedures

q 6. Using the PowerView display, read and record the re-

ported input voltage from the startup screen. (“122Vin”

in figure 4-16 indicates that the input voltage is 122V.)

Note: The PowerView may display one or more messages

such as “Number of Battery Modules Changed.” Press the

ESC key until the startup screen appears.

Record the PowerView reported

input voltage here: ______________________________

Fig 4-16 Startup Screen

q 7. Compare the RMS input voltage measurement (Step

#2) with the input voltage as reported by the PowerView.

If the reported input voltage is not within +/-5% of the

recorded input voltage, check the wiring, and measure

the input voltage again. If the two measurements are

still outside of the acceptable range, contact APC

SymmetraTM technical support at 1-888-809-TECH.

these messages by pressing the ESC navigation key on

the PowerView display, until the startup screen reappears.

See figure 4-16. Read and record the output voltage that

is indicated on the PowerView. (“000Vout” in figure 416 indicates that the output voltage is 000V.)

Note: The reported output voltage should be approximately 208V or 240V, depending on how the system is configured.

Record the PowerView reported

output voltage here: _____________________________

q 9. Measure the output AC voltage at the output wiring

terminal block connections as specified in table 4-4 below. Record the measured values in the table. The measured values should correspond to the nominal values

listed in the table. If the input voltage varies from 208V

or 240V, the output voltages vary accordingly. In this

case, use the multipliers in table 4-4 to calculate the expected output voltages. If these voltages still vary, contact SymmetraTM technical support at 1-888-809-TECH.

q 10. Successful completion of steps 1 through 9 indicate

that Power Array is correctly wired to the utility power

source, and that the correct output voltage is available at

the output terminal block. Load equipment voltage requirements and external wiring voltages can be checked

and verified at this time.

q 8. Switch the maintenance bypass switch to the “on”

position. The Power Array will go into the manual bypass mode, and voltage should now be present at the

output terminal connections. The bypass LED on the

PowerView display will glow, and an audible alarm may

sound, and one or more messages may appear. Ignore

slanimreT

6&2caV04251.110.1

6&4caV8020.1668.

8&2caV021675.5.

8&6caV021675.5.

01&8caV0stloV0stloV0

lanimoN

egatloV

Table 4-4 Input/Output Measured Voltage Multipliers

q 11. Shut down the Power Array by switching the input

circuit breaker and the system enable switch to the “off ”

position. Replace all wiring access panels on the Power

Array frame. The electrical connections have now been

properly installed and checked. The Power Array is now

ready for the setup procedure in chapter 5.

nodesaB(sreilpitluM

derusaeM

)noitisoPrepmuJegatloV

eulaV

noitisoPV802 noitisoPV042

reilpitlum*)derusaem(niV=)derusaem(tuOV

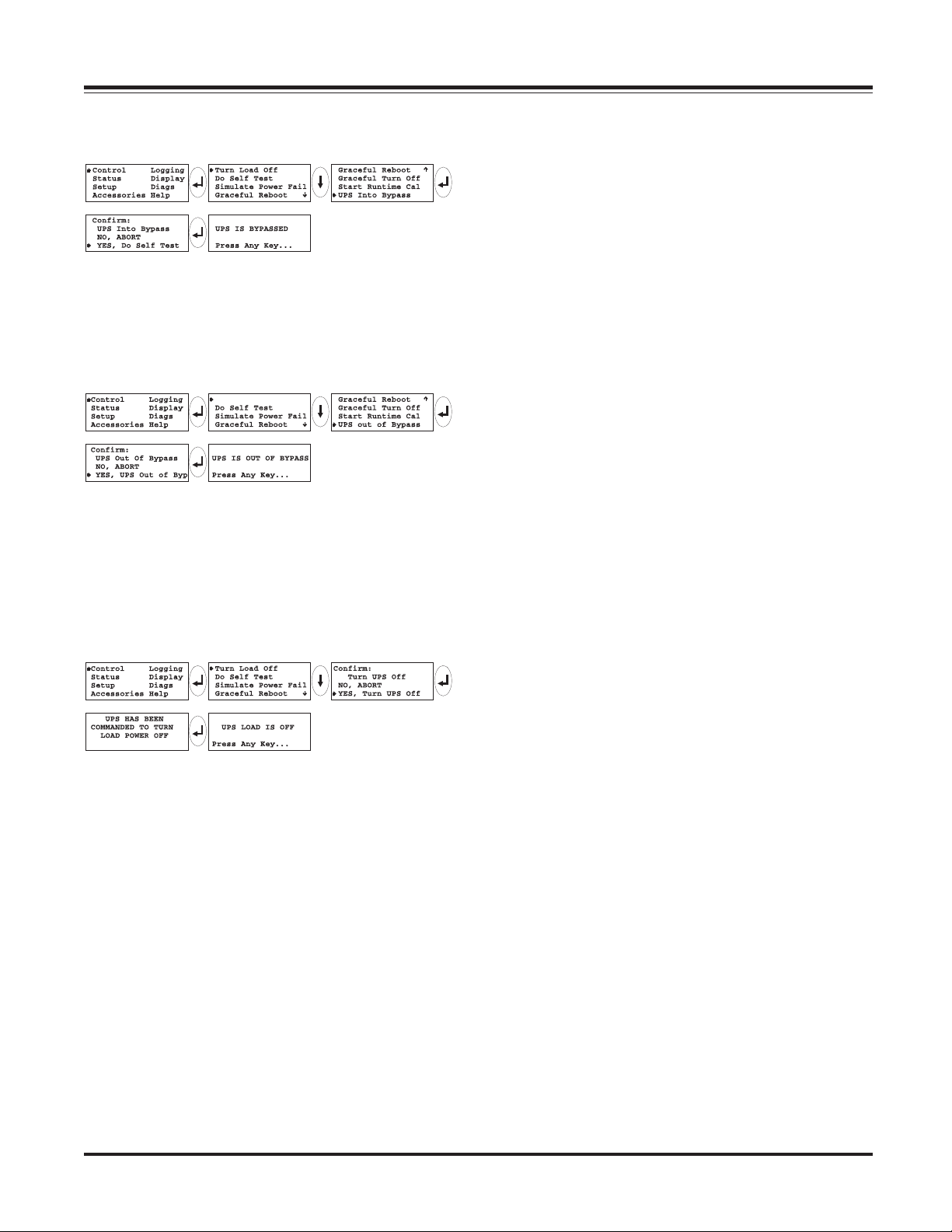

4-9