Page 1

®

w w w

.apc.com

Power Inverter

Model BI800T and BI800F

Installation Guide and User’s Manual

990-1810A Copyright © 2004 American Power Conversion. All rights reserved.

APC is a registered trademark of American Power Conversion. All other trademarks are the property of their respective owners.

Page 2

CONTENTS

Page

Overview 1

Checklist 1

Section 1. Unpacking/Inspection (at reseller location) 2

Main Housing Chassis and Inverter 2

Battery Inspection 2

Unpack Battery 2

Inspect Battery 2

Clean battery 2

Remove Battery from Shipping Container 2

Check Battery Fluid Level 2

Check Battery Charge Level 3

Repackage Battery 3

Section 2. Unpacking/Inspection (at customer location) 3

Main Housing Chassis and Inverter 3

Battery Inspection 4

Unpack Battery 4

Inspect Battery 4

Clean Battery 4

Remove Battery from Shipping Containe 4

Check Battery Fluid Level 4

Check Battery Charge Level 4

Section 3. Installation 1

Main Housing Placement 4

Location Selection 4

Lock Wheels 4

Battery Installation 4

Main Housing Chassis Rear Panel Removal 4

Install a Battery 5

Battery Connections 6

Install Main Housing Chassis Rear Panel 6

Install Inverter 6

Install Wiring Management Kit 7

Section 4. Controls and Indicators 9

Inverter Controls 9

AWAY/HOME 9

TEST/MUTE 9

Circuit Breaker Switch 9

Inverter Indicators 9

Section 5. Troubleshooting 12

Manual Bypass 12

Preventative Maintenance 13

Specifications 14

Warranty 15

Contact Information 15

i

Page 3

CONTENTS - continued

FIGURES

Page

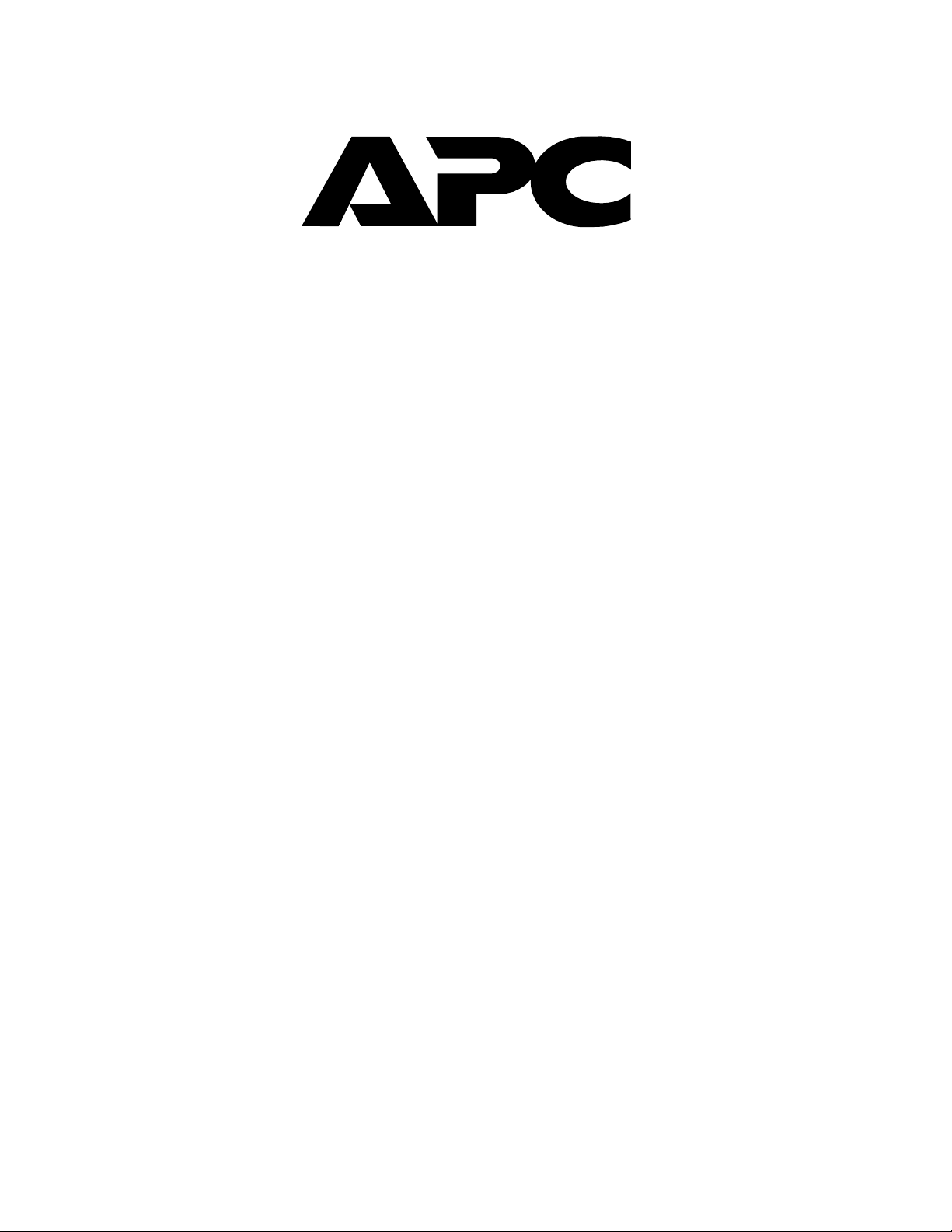

Figure 1. APC Power Inverter 1

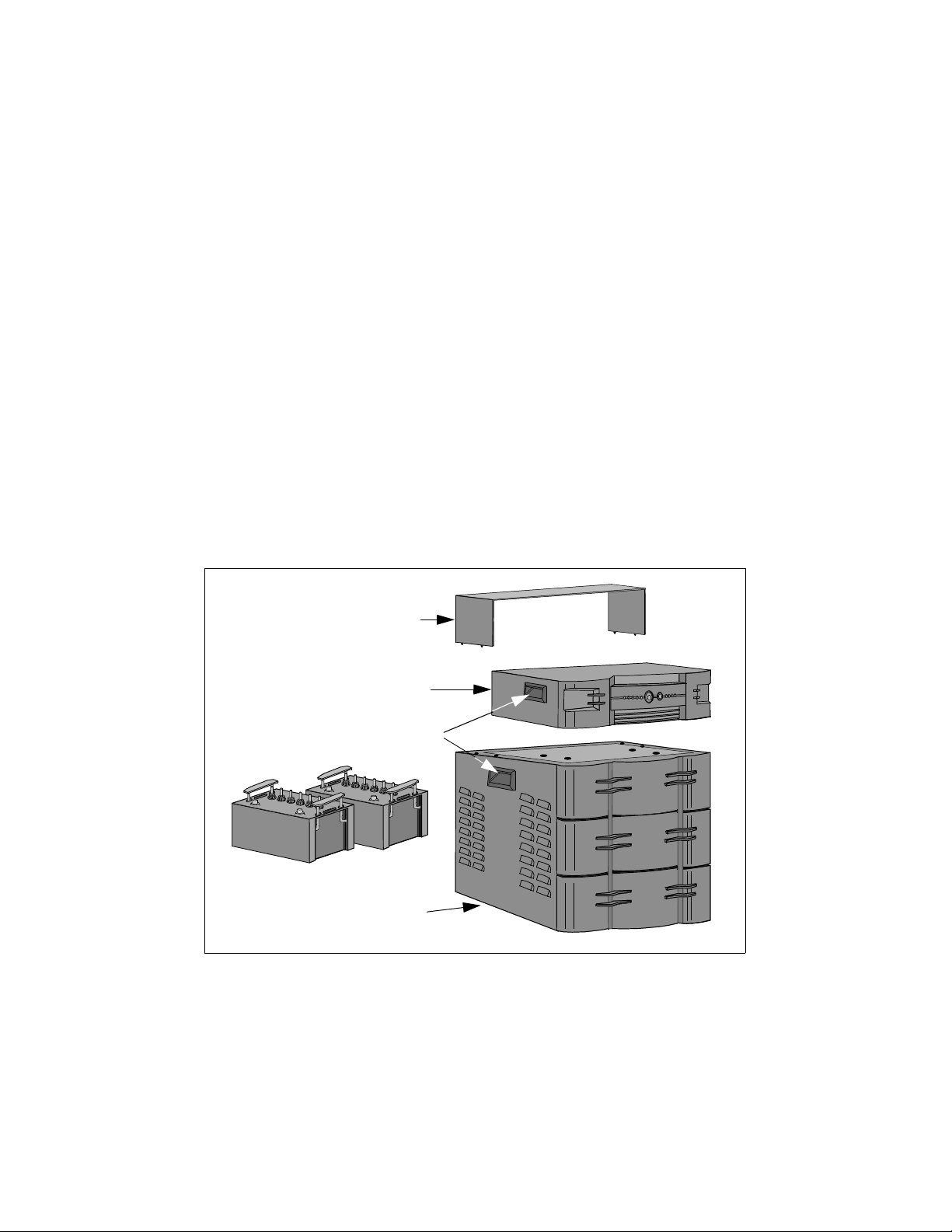

Figure 2. Battery Elements (tubular battery shown) 2

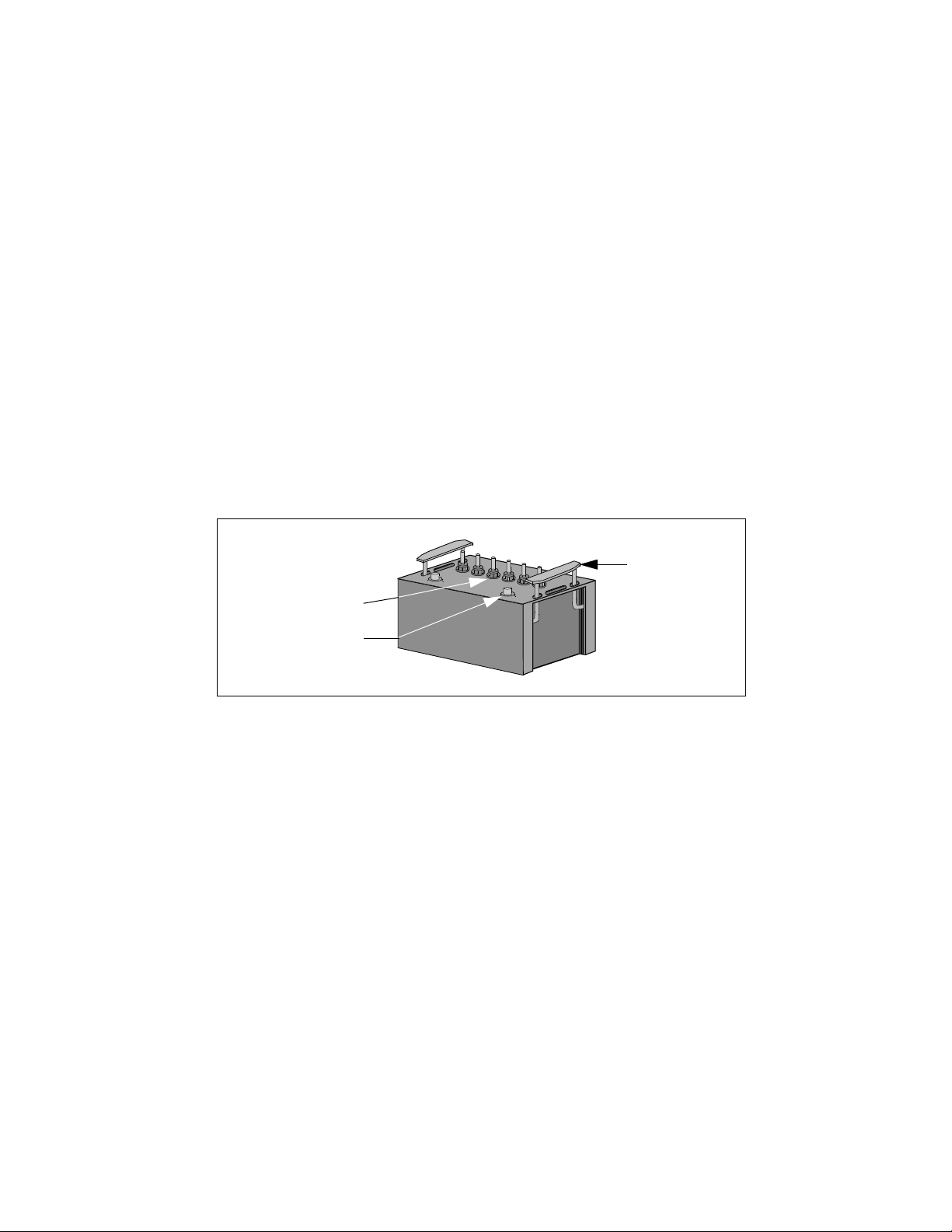

Figure 3. Battery Fill Cap Elements 3

Figure 4. Main Housing Chassis Rear Panel Removal 5

Figure 5. Battery Installations and Connections 6

Figure 6. Inverter Assembly Placement 7

Figure 7. Typical Home Wiring Before Inverter Installation 7

Figure 8. Typical Home Wiring After Inverter Installation 8

Figure 9. Power Inverter Connections 8

Figure 10. Wiring Management Kit Installation 9

Figure 11. Power Inverter Front Panel Controls and Indicators 10

Figure 12. Power Inverter Bypass Connection 13

TABLES

Table 1. Power Inverter Indicators 10

Table 2. Power Inverter Troubleshooting 12

Table 3. APC Power Inverter Technical Specifications 14

ii

Page 4

Thank you for purchasing APC’s Power Inverter. Please fill out the enclosed Warranty Registration Card, or register your purchase on-line

at: www.apc.com/support.

Overview

APC’s Power Inverter (Figure 1) is designed for years of trouble-free use. The Inverter is a sinewave back-up power supply intended to

serve house loads. It is rated for 800 VA/500W at 230 Vac, 50-Hz, and operates on a wide range of input voltages (100 - 265V). If the input

voltage goes out of range (less than 100V or more than 265V), the utility is isolated and the inverter supplies power to the load from the

internal batteries. The Inverter can serve inductive loads (flourescent lamps, ceiling and table fans), resistive loads (incandescent lamps),

and switched mode power supply (SMPS) loads (television). The typical backup time with the primary battery pack at full load is

approximately two (2) hours. Backup time can be further extended by connecting the optional external battery pack in parallel to the

existing battery pack.

Note: APC offers tubular, as well as flat-plate batteries for use with the Power Inverter.

For the purposes of this manual, only the tubular batteries are shown.

Checklist:

Depending on what the customer has ordered, ensure the following items have been delivered:

• Inverter

• Batteries (2), Tubular Batteries Shown

• Main Housing

• Wiring Kit

• Fill Kit (rubber gloves and a funnel)

• Wire Management Kit

• Parallel Wiring Kit (if external battery pack was ordered - not shown)

Wire Management Kit

(Optional)

Inverter Assembly

Handles

(1 each side)

Batteries

Main Housing Chassis

(Wire Harness Not Shown)

Figure 1. APC Power Inverter

Page 1

Page 5

Section 1. Unpacking/Inspection (at reseller location)

Main Housing Chassis and Inverter

Warning: The Main Housing Chassis weighs 18 kg. Two-person lift required. Failure to

comply may result in personal injury.

!

Inspect the shipping containers for signs of obvious damage. If damage to either shipping container is extensive, notify the carrier

and return the unit to the factory. If there are no apparent signs of damage, carefully open the container, and remove the packing

materials (do not discard). To remove the Main Housing Chassis or Inverter Assembly from the shipping container, grasp the

handles located on each side of the housing or inverter (Figure 1), and remove the item from the container. Inspect each for: dents,

scratches, broken or missing wheels (housing only), warpage of the top cover, or other signs of damage. If either unit is damaged,

please notify the factory and obtain a Return Material Authorization number and return the unit as/if instructed. If there are no

obvious signs of damage, repackage the unit for shipment to the customer using the materials already removed from the shipping

container. Ship or otherwise deliver the unit to the customer location.

Battery Inspection

Unpack Battery - Inspect the battery shipping container for signs of obvious damage. Carefully inspect the container for signs

of a leaking battery. If the shipping container shows signs of leakage, the battery may be damaged. Contact the factory for

instructions to further inspect the battery inside the container, or for return instructions. Carefully open the shipping container

and remove the packing materials (do not discard).

Inspect Battery - If there are no obvious signs of damage or leakage, with the battery in the shipping container, inspect the

battery for leaks, cracks, broken wiring terminals, broken handles, and broken fill caps (Figure 2).

Battery Handle

(1 each side)

Battery Fill Cap (6)

Battery Terminal (2)

Figure 2. Battery Elements (tubular battery shown)

Clean battery - If the inspection shows signs of a leaking battery, put on rubber gloves and remove the battery fluid/residue

from the battery housing using a mixture of baking soda and distilled water. If cracks or other damage is noted after cleaning the

battery, contact the factory for return or disposal instructions.

Warning: Each battery weighs 28 kg. Two-person lift required. Failure to

comply may result in personal injury.

!

Remove Battery from Shipping Container - Remove the battery from the shipping container by grasping the handles (see

Figure 1) located at each end of the battery. Lift the battery straight up and out of the shipping container.

Check Battery Fluid Level - After cleaning and inspection for damage, check the battery fluid level of each cell (Figure 3). If

the fluid level of any cell is not within the specified range on the fill cap, put on rubber gloves (from Fill Kit), remove the

battery cell cap, and fill the cell with distilled water using the funnel provided in the Fill Kit. Install the cell cap on each cell.

Page 2

Page 6

Fluid Level

Tube

Fluid Level

Indicator

Battery Fill Cap

Float Device

Figure 3. Battery Fill Cap Elements

Check Battery Charge Level - After filling battery cells (if necessary), check the battery specific gravity using a hydrometer.

The battery specific gravity should be between 1230 and 1250. If battery specific gravity is below 1230, charge the battery

using a battery charger until the battery specific gravity is within the acceptable range.

Optimum

Fill Range

Warning: Each battery weighs 28 kg. Two-person lift required. Failure to

comply may result in personal injury.

!

Repackage Battery - Place the battery in the shipping container by grasping the handles located at each end of the battery. Lift

the battery straight upwards and place it in the shipping container. Install packaging materials. Seal the shipping container, and

ship the battery to the customer location.

Section 2. Unpacking/Inspection (at customer location)

Main Housing Chassis and Inverter

Note: The Inverter Assembly is shipped with two (one male and one female) IEC

connectors for use in installing home wiring to/from the Inverter.

Inspect the shipping containers for signs of obvious damage. If damage to either shipping container is extensive, notify the carrier

and return the unit to the factory. If there are no apparent signs of damage to the shipping container, carefully open the container,

and remove the packing materials (do not discard).

Warning: The Main Housing weighs 18 kg. Two-person lift required. Failure

to comply may result in personal injury.

!

To remove the Main Housing Chassis or Inverter from the shipping container, grasp the handles located on each side of the Housing

or Inverter (Figure 1), and remove the item from the shipping container. Inspect each for: dents, scratches, broken or missing wheels

(housing only), warpage of the top cover, or other signs of damage. If either unit is damaged, please notify the factory and obtain a

Return Material Authorization number and return the unit as/if instructed. If there are no obvious signs of damage, proceed with

Battery Inspection.

Page 3

Page 7

Battery Inspection

Unpack Battery - Inspect the battery shipping container for signs of obvious damage. Carefully inspect the container for signs

of damage due to a leaking battery. If the shipping container shows signs of leakage, the battery may be damaged. Contact the

factory for instructions to further inspect the battery inside the container, or for return instructions. Carefully open the shipping

container and remove the packing materials (do not discard).

Inspect Battery - If there are no obvious signs of damage or leakage, with the battery in the shipping container, inspect the

battery for leaks, cracks, broken wiring terminals, broken handles, and broken fill caps (Figure 2).

Clean Battery - If the inspection shows signs of a leaking battery, put on rubber gloves and remove the battery fluid from the

battery housing using a mixture of baking soda and distilled water. If cracks or other damage is noted after cleaning the battery,

contact the factory for return or disposal instructions.

Warning: Each battery weighs 28 kg. Two-person lift required. Failure to

comply may result in personal injury.

!

Remove Battery from Shipping Container - Remove the battery from the shipping container by grasping the handles (see

Figure 2) located at each end of the battery. Lift the battery straight upwards and out of the shipping container.

Check Battery Fluid Level - After cleaning and inspection for damage, check the battery fluid level of each cell (Figure 3). If

the fluid level of any cell is not within the specified range on the fill cap, put on rubber gloves, remove the fill cap, and fill the

cell with distilled water. Install the fill cap on each cell. If battery fluid is discharged from the battery during the filling process,

put on rubber gloves and remove the battery fluid from the battery housing using a mixture of baking soda and distilled water.

Check Battery Charge Level - Ufter filling battery cells (if necessary), check the battery specific gravity using a hydrometer.

The battery specific gravity should be between 1230 and 1250. If battery specific gravity is below 1230, charge the battery

using a battery charger until the battery specific gravity is within the acceptable range.

Section 3. Installation

Main Housing Placement

Note: Once the unit has been completely installed, it is not desireable to move it.

Location selection - unlock the wheels located at the bottom of the Main Housing Chassis, and roll it to the desired location.

Ensure the area where the unit is to be placed is not in direct sunlight (surfaces may become hot). Further ensure the unit is

placed in a dry area away from sources of liquids, and that the vents on each side have at least 15 cm (6 inches) of unobstructed

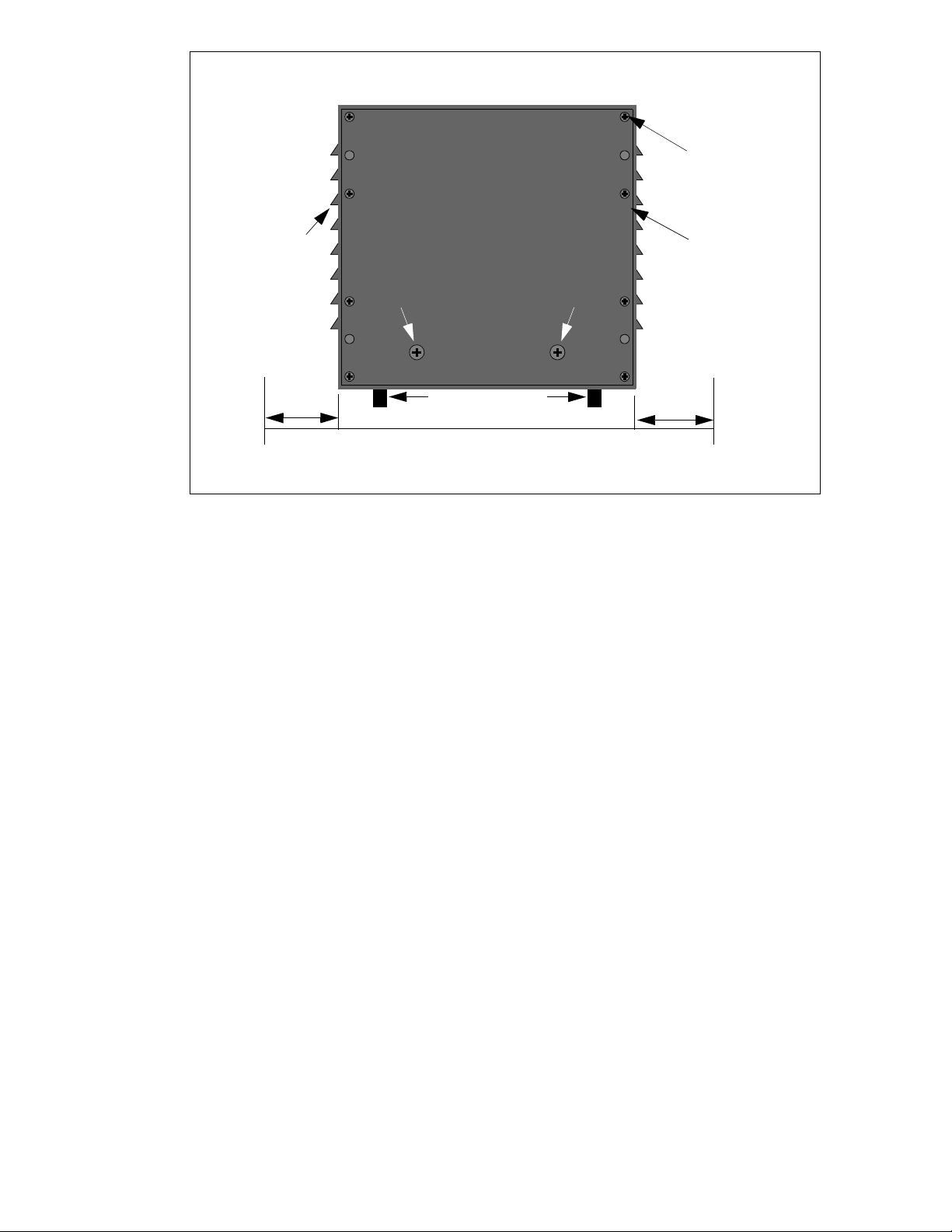

clearance (Figure 4).

Lock Wheels - Lock the wheels to restrict movement during battery installation.

Battery Installation

Main Housing Chassis Rear Panel Removal - Remove the four machine screws (Figure 4) that secure the Rear Panel to the Main

Housing Chassis. Remove the Rear Panel and set it aside.

Page 4

Page 8

Main Housing Chassis (Rear View -

Wire Harness not Shown)

Remove the 4 corner

screws only.

Air Vents

(Each Side)

Do Not Remove These Two Screws

15 cm

(6 inches)

Note: Allow 15 cm (6 inches) of unobstructed

Figure 4. Main Housing Chassis Rear Panel Removal

Note: Access through the top of the Main Housing Chassis is provided for connecting and topping

(filling) of the batteries only.

Warning: Each battery weighs 28 kg, and must be installed through the opening at

the rear of the Main Housing Chassis and not through the opening in the top of the

!

unit. Failure to comply may result in personal injury and/or equipment damage

Wheels (4).

clearance on each side.

(6 inches)

Rear Panel

15 cm

Install a Battery - Raise the top lid of the Main Housing Chassis to provide visual access to the interior of the chassis (Figure 5).

Note: The batteries are installed with the long side of the battery going across the length of

the front panel.

Caution: Installation of the Power Inverter Batteries must be performed by a licensed and

qualified electrician. Failure to comply may result in equipment damage, and may also

void the Warranty.

At the rear of the Main Housing Chassis, position the first battery to be installed through the rear opening so that the positive (+)

terminal is to the right. Position the second battery so that the positive (+) terminal is to the left. Grasp the battery using the handles

(Figure 2) located at each end of the battery. Carefully lift the battery and slide it into the Main Housing through the rear opening.

Slide the first battery as far forward as it will go into the Main Housing Chassis. Repeat this step for the second battery until it is up

against the second battery.

Page 5

Page 9

Main Housing Chassis

(top cover not shown)

Main Housing Chassis

(top cover shown)

Battery

Handle

Negative

(-)

Ter mina l

First

Battery

Battery

Handle

Second Battery

(rotated 180 degrees)

Battery

Handle

Positive

(+)

Term ina l

Negative

(-)

Terminal

Black

(-)

Wire

Battery

Handle

Positive

(+)

Terminal

Red (+)

Wire

Positive (+)

Term ina l

Black

Wire

Negative (-)

Term ina l

Main Housing Chassis

(rotated 180 degrees)

Battery Installation Battery Connections

Figure 5. Battery Installations and Connections

Battery Connections - Note: The batteries are charged and produce electric current. Small sparks by be noted during the

connection process. This is a normal condition and does not pose a threat of injury.

Connect the red battery terminal lead (protrudes from the lid) to the positive (+) terminal of the battery (Figure 5) closest to the rear

of the Main Housing Chassis (second battery installed). Connect the black battery terminal lead (protrudes from the lid) to the

negative (-) terminal of the first battery installed. Connect the black battery cable attached to the left side of the Main Housing

Chassis to the positive (+) terminal of the first battery, and to the negative (-) terminal of the second battery. Ensure battery

connections are tight by grasping each connector at the terminal and try to move it. If the terminal lead has movement on the

terminal, tighten the connection until no movement is evident. Install battery terminal covers.

Install Rear Panel - Align the Rear Panel with the mounting holes at the rear of the Main Housing Chassis. Install the four machine

screws which secure the Rear Panel to the chassis.

Install Inverter

Caution: Installation of the Power Inverter must be performed by a licensed and qualified

electrician. Failure to comply may result in equipment damage, and may also void the

Warranty.

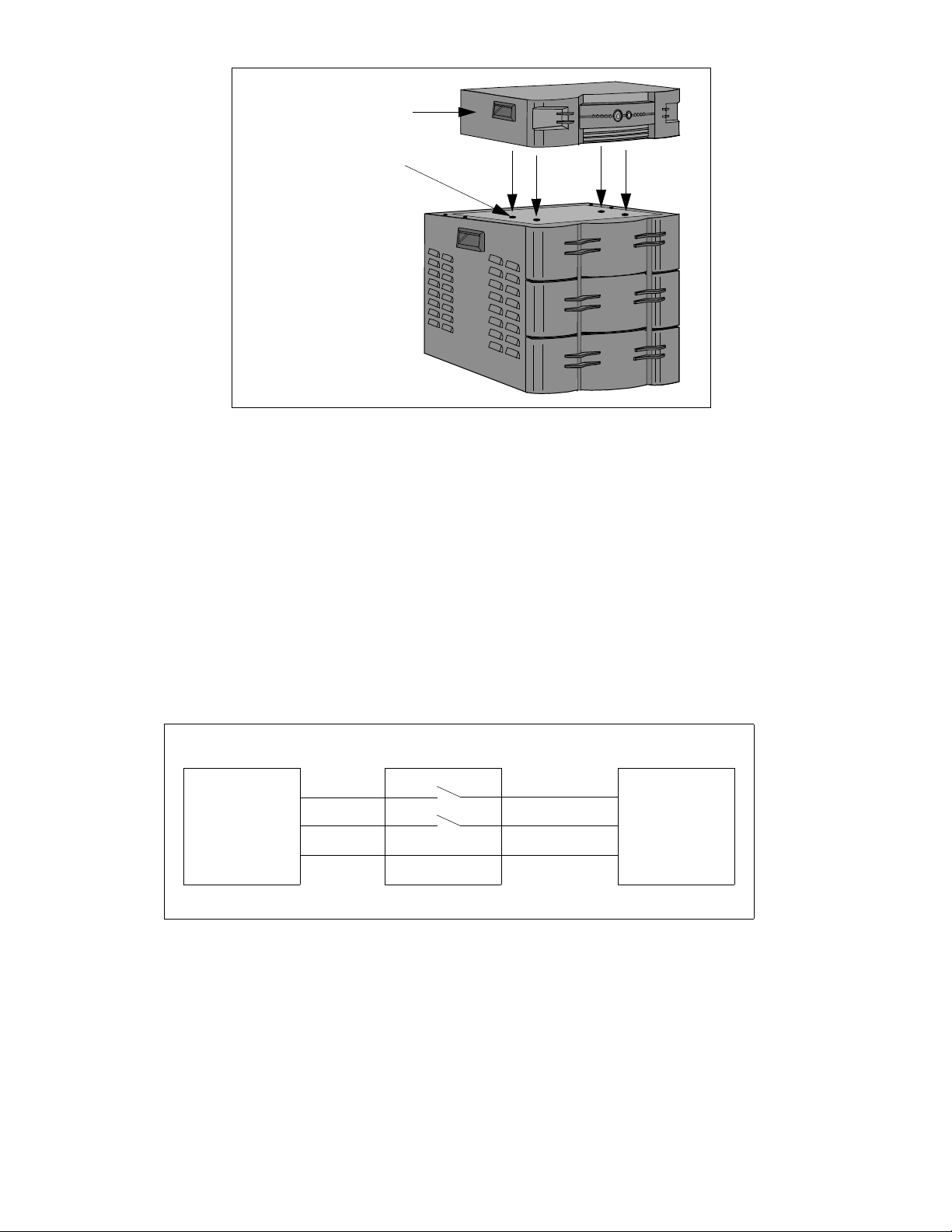

Place the Inverter Assembly on top of the Main Housing Chassis with the Inverter facing forward, and the Inverter “feet” in the

indents provided on the Main Housing Chassis top cover.

Page 6

Page 10

Inverter Assembly

(“feet” not shown)

Indents (4 places)

(Wire Harness not

Shown)

Figure 6. Inverter Assembly Placement

Remove power at the electricity board meter (circuit breaker panel) of the home.

Figure 7 shows a diagram of a typical home wiring scenario. Figure 8 shows a typical home wiring scenario after installation of the

Inverter Assembly wiring.

Note: The Power Inverter can serve inductive loads (flourescent lamps, ceiling and table fans), resistive loads (incandescent lamps),

and SMPS loads (television). The typical backup time with the primary battery pack at full load is approximately two (2) hours.

Caution: Connecting the Power Inverter to a branch circuit that exceeds 16 amps may

result in equipment damage.

Note: Home wiring to power the desired loads should be routed and connected to a single

branch circuit providing a maximum of 16 amps to the circuit, Wiring must be in

accordance with local electric codes and standards. Connected loads must not exceed 500

watts when the Inverter is On Battery.

Double-Pole

Switch

Electricity

Board

Meter

L

N

E

Existing Wiring

Figure 7. Typical Home Wiring Before Inverter Installation

N

L

Load

E

Page 7

Page 11

Electricity

Board

Meter

E

N

L

Double-Pole

Switch Lighting

Circuit

E

N

L

Load

Input

Output

Wiring for Power Inverter

Figure 8. Typical Home Wiring After Inverter Installation

Connect one end of the electrical cable from the double-pole switch lighting circuit in accordance with local electric codes and

standards. Connect the other end of the electrical cable to the provided IEC connector, and then to the rear panel Input connector on

the Inverter Assembly (Figures 8 and 9).

Connect one end of the electrical cable from the load in accordance with local electric codes and standards. Connect the other end of

the electrical cable to the provided IEC connector, and then to the rear panel Output connector on the Inverter Assembly (Figures 8

and 9).

Connect the wiring harness (protrudes out of the top of the Main Housing Chassis top cover) from the batteries to the rear panel

input connector of the Inverter (Figure 9) marked 24V Battery. Once the home wiring is complete and the batteries are connected

to the Inverter Assembly, turn on power at the Electricity Board Meter then at the Double-Pole Switch Lighting Circuit. The

Inverter will automatically turn on.

24V Battery

Push to Reset

INPUT

N

OUTPUT

LN

L

Page 8

Battery Wiring Output Harness

(Red and Black Wires from

Main Housing Chassis - Top)

These connectors are provided

with the Inverter Assembly

and must be installed

on to the wiring.

From Electricity Board Meter

(through Double-Pole

Switch Lighting Circuit)

Figure 9. Power Inverter Connections

To Lo ad

Input : 230V, 5A, 50Hz

Output : 230V, 5A, 50HZ

Page 12

Install Wiring Management Kit

Installation of the Wiring Management Kit consists of unpacking and inspecting the kit for signs of obvious damage, and return or

replace as necessary, and placement of the unit on the Main Housing Chassis. Secure the kit to the chassis by placing the alignment

pins (Figure 10) with the holes provided in the top of the Main Housing Chassis, and pushing straight downward until all four

retaining pins are fully seated.

Wiring Management

Kit

Holes (4 places)

Figure 10. Wiring Management Kit Installation

Alignment Pins

(4 places)

Section 4. Controls and Indicators

Please review this section thoroughly before applying power to the Power Inverter.

Inverter Controls - Controls provided on the Power Inverter consist of the holiday mode switch marked AWAY/HOME, and the

Te st / Mu t e switch, as well as a rear panel Push to Reset circuit breaker, and are defined in the following:

AWAY/HOME - (also known as the holiday mode switch) - In the HOME position, this two-position rocker switch (Figure 11) sets

the Inverter so that it will switch to battery output when there is a utility power outage.

In the AWAY position, the Inverter goes into standby mode and will not switch to battery power in the event of a power outtage.

This is to conserve the batteries. However, in this position, the Inverter will charge the batteries until a utility power failure occurs.

TEST/MUTE - In TEST mode, when ON MAINS LED is lit, on pressing this push button, the unit will do self test to determine

the state of the system. During On Battery self test it will also show the load status which can be used to find out the load capacity.

In the MUTE position (push in for 5 seconds), this push button switch silences the low battery buzzer.

Circuit Breaker Switch (Rear Panel) - When in ON MAINS mode, if the system draws more than 10A, circuit breaker will trip. To

reset the circuit breaker switch, push the switch fully inward.

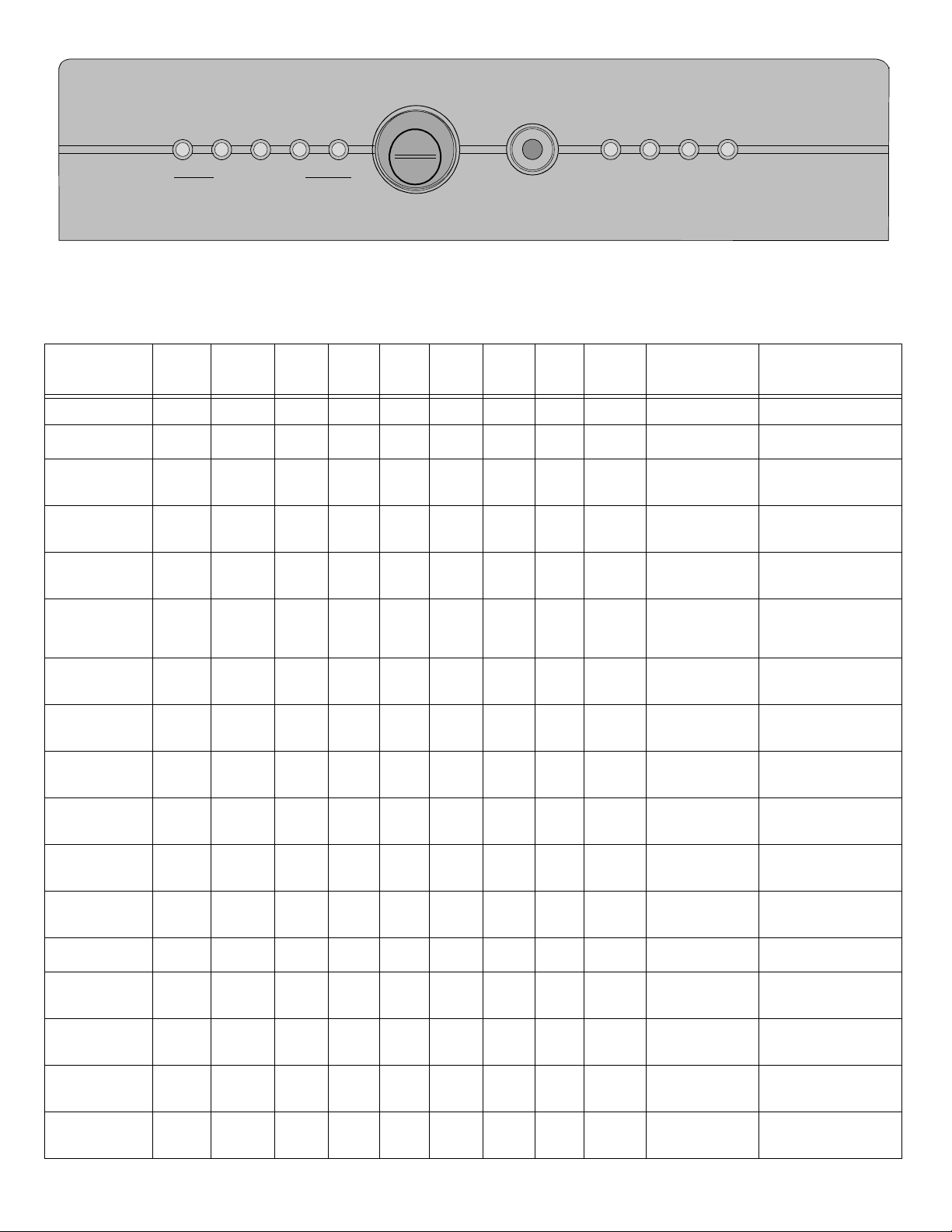

Inverter Indicators - The Inverter provides light emitting diode (LED) indicators (Figure 11) to show the operational condition of

the Inverter and batteries. Indicators consist of Inverter Load Status (25%, 50%, 75%, 100%, and OVER LOAD). Other

indicators consist of: INVERTER DISABLE, ON MAINS, ON BATTERY, and FAULT). Using Table 1, determine the condition

of the Inverter and batteries.

Page 9

Page 13

25% 50% 75% 100%

OVER

LOAD

AWAY

TEST

INVERTER

DISABLEONMAINSONBATTERY FAULT

INVERTER LOAD

MUTE

HOME

Figure 11. Power Inverter Front Panel Controls and Indicators

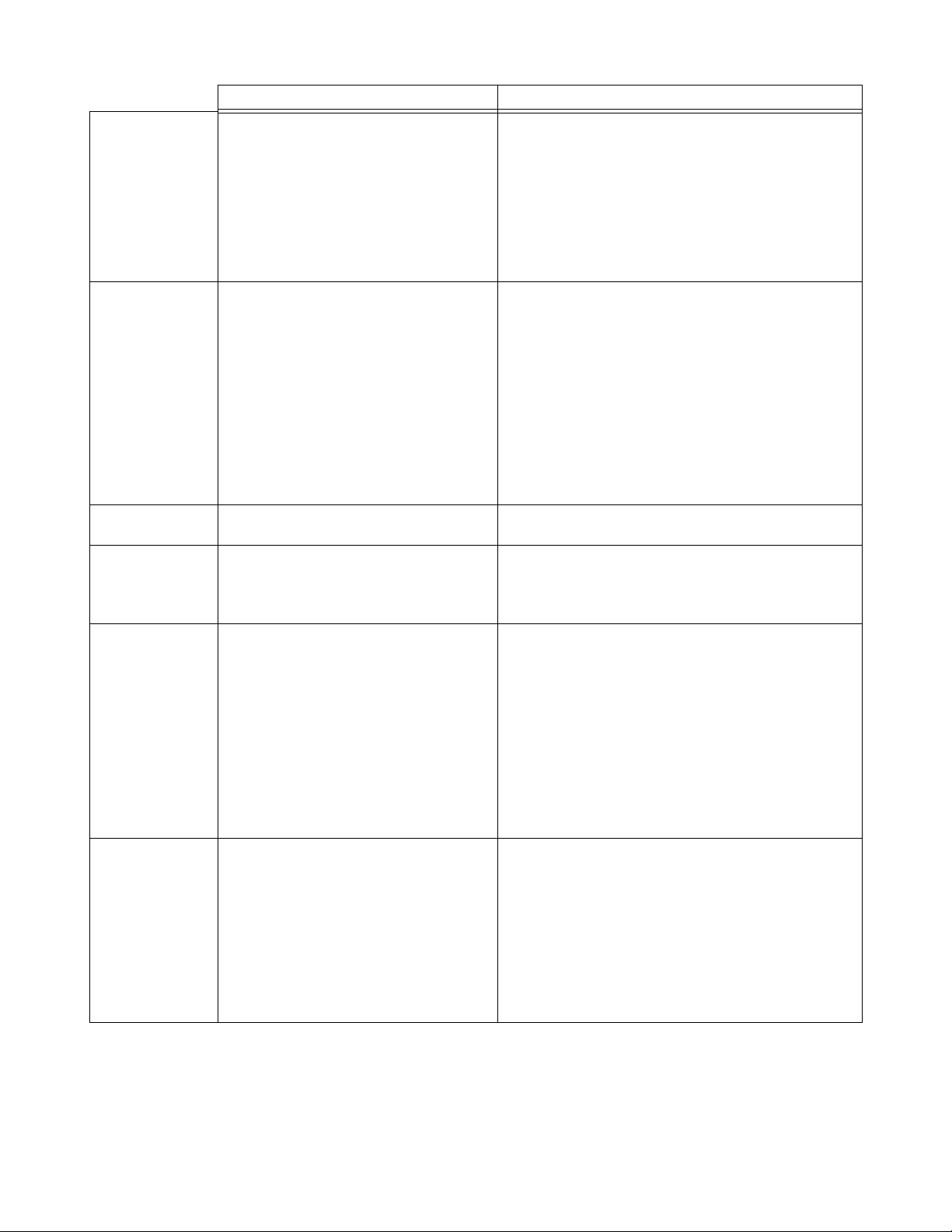

Table 1. Power Inverter Indicators

Mode

ON LINE On Off Off Off Off Off Off Off Off Off The unit is ON-LINE.

ON LINE SELF TEST Flashing Off Off Off Off Off Off Off Off Off The unit is in ON-LINE Self-

ON BATTERY SELF

TEST

ON BATTERY Off On Off Off On Off Off Off Off 4 beeps every 22

STANDBY ENABLE Off Off Off Off Off Off Off Off Off Short beep every 5

STANDBY Off Off Off Off Off Off Off Off Off Off The unit is in STANDBY

FAULT - Off Off Off Off On On On On On Off Iverter load capacity has

FAU LT- Flashing Flashing Flashing Off Off Off Off Off Off Off The unit is in FAULT mode,

FAU LT- Off Off On Off Off Off Off Off Off Continuously On The unit is in FAULT mode,

On Mains

(green)

Flashing On Off Off On Off Off Off Off Off The unit is in ON-BATTERY

Flashing On Off Off On On Off Off Off Off The unit is in ON-BATTERY

Flashing On Off Off On On On Off Off Off The unit is in ON BATTERY

Flashing On Off Off On On On On Off Off The unit is in ON-BATTERY

Flashing On Off Off On On On On On Continuous beep for

On Battery

(yellow)

Off On Off Off On On Off Off Off 4 beeps every 22

Off On Off Off On On On Off Off 4 beeps every 22

Off On Off Off On On On On Off 4 beeps every 22

Off On Off Off On On On On On Continuous beep for

Fault

(red)

INV

Disable

(red)

25%

(green)

50%

(green)

75%

(green)

100%

(green)

Overload

(red)

Buzzer Description

Tes t mod e.

Self-Test mode, and the load

is less than 25%.

Self-Test mode, and the load

is between 25% - 50%.

Self-Test mode, and the load

is between 50% - 75%.

Self-Test mode, and the load

is more than 75% but less

than oveload limit.

first 30 seconds for a

fresh overload.

minutes

minutes

minutes

minutes

first 30 seconds of a

new overload.

seconds

The unit is in ON-BATTERY

Self-Test mode, and is in an

overload condition.

The unit is in ON-BATTERY

mode, and the load is less

than 25%.

The unit is in ON-BATTERY

mde, and the load is between

25% and 50%.

The unit is in ON-BATTERY

mode, and the load is

between 50% and 75%.

The unit is in ON BATTERY

mode; the load is between

75% and the overload limit.

The unit is in ON-BATTERY

mode, and is in overload

condition (see NOTE below).

The unit is shut down due to a

LOW BATTERY.

mode, and is not powering

the load.

been exceeded (see NOTE

below).

contact APC Technical

Support.

contact APC Technical

Support.

Page 10

Page 14

Mode

FAU LT- On Flashing Flashing Off Off Off Off Off Off Chirps every 2.5

BATTERY

DISCONNECTED

OVER TEMP ONBATTERY

OVER TEMP ONLINE

ON LINE On Off Off On Off Off Off Off Off Off The unit is in ON-LINE, but

ON LINE SELF TEST Flashing Off Off On Off Off Off Off Off Off The unit is in ON-LINE Self-

ON BATTERY SELF

TEST

ON BATTERY Low

Battery Warning

ON BATTERY Low

Battery Warning

ON BATTERY Low

Battery Warning

ON BATTERY Low

Battery Warning

ON BATTERY Low

Battery Warning

On Mains

(green)

Flashing On Off On On Off Off Off Off Off The unit is ON-BATTERY-

On Battery

(yellow)

On Off Flashing Off Off Off Off Off Off Chirp every 2 seconds The unit is ON-LINE mode;

Off Off 4 flashes

On Off 4 flashes

Off On Off Off On Off Off Off Off Constant Beeping,

Off On Off Off On On Off Off Off Constant Beeping,

Off On Off Off On On On Off Off Constant Beeping,

Off On Off Off On On On On Off Constant Beeping,

Off On Off Off On On On On On Constant Beeping,

Fault

(red)

every 2

second

every 2

second

INV

Disable

(red)

25%

(green)

Off Off Off Off Off Off Continuously On The unit is in FAULT mode

Off Off Off Off Off Off Off The unit is in ON-LINE mode,

50%

(green)

75%

(green)

100%

(green)

Overload

(red)

Buzzer Description

seconds; sound is

mutable through the

front panel TEST/

MUTE push button.

Can be muted through

fron panel TEST/

MUTE push button.

Can be muted through

front panel TEST/

MUTE push button.

Can be muted through

front panel TEST/

MUTE push button.

Can be muted through

front panel TEST/

MUTE push button.

Can be muted through

front panel push

TEST/MUTE button.

The unit is in FAULT mode,

contact APC Technical

Support.

battery is disconnected.

due to over- temperature

condition.

but the charger is switched off

due to over- temperature.

the inverter is disabled and

the unit will not go ON

BATTERY during a power

failure.

Test mode, but the inverter is

disabled and the unit will not

go ON-BATTERY during a

power failure.

Self-Test but the inverter is

disabled and the unit will not

go ON-BATTERY during a

power failure.

Load is less than 25%.

Load is between 25% and

50%.

Load is between 50% and

75%.

Load is between 75% and

Overload limit.

Load is more than overlaod

limit.

NOTE: In the case of a sustained overload, the Inverter will be turned off automatically after one

minute, and will wait in the fault state for a minute. After that, it will restart again. If the overload

still persists, the Inverter will be turned off again after one minute, and will wait in fault state for one

minute and restart again. In the same way, it will try for three restarts. If the overload still persists, it

will stay in fault state permanently until the unit is restarted with push button. If the time interval

between two consecutive overloads is more than 5 mins, then the latest overload is considered as a

fresh overload and three restart cycle will begin again.

Page 11

Page 15

Section 5. Troubleshooting

Note: If the Power Inverter causes interference with a television while ON-BATTERY,

move the television at least 3 feet away from the Inverter.

Use the information provided in Tables 1 and 2 to diagnos Power Inverter problems. If the problem cannot be resolved using the

information provided in this manual, contact APC Technical Support.

Table 2. Power Inverter Troubleshooting

Problem Cause Corrective Action

Inverter fails to operate when

mains power is turned on, or

during a utility power failure.

Computer load reboots when

inverter switches to ON

BATTERY.

Inverter faults. Inverter drops the load.

Disconnected battery.

Power is off at the Mains.

Inverter HOME/AWAY switch in

the AWAY position.

Dead batteries.

Inverter rear panel Push to Reset

circuit breaker has tripped.

Improper wiring installation or

loose connection.

Inverter transfer time too slow for

computer load.

Ensure batteries are connected as defined in this

manual.

Turn on power at the Mains.

Set switch to the HOME position.

Inverter failed to charge batteries, or batteries were

allowed to completely discharge. Replace batteries. If

replacing the batteries does not fix the problem,

contact APC Technical Support.

Reset the circuit breaker by pushing it fully inward

until it stops; release the circuit breaker.

Ensure wiring is as described earlier in this manual,

and that all connections are secure.

For computer-type loads, a separate battery back-up

(UPS) should be used, as the 60 millisecond transfer

time is inadequate, and will cause the computer to

reboot.

Inverter may have an internal failure. If this happens,

the unit can be disconnected from the mains by

completion of a Manual Bypass (see Manual

Bypass).

Inverter is overloaded.

Manual Bypass - In the event of an Inverter failure or dead battery condition, the Inverter can be disconnected from the mains and

power restored to the circuit by completing a Manual Bypass (Figure 12) of the Inverter, as follows:

Remove the Wiring Management Kit from the Inverter. Disconnect all wires connected at the Inverter rear panel. Connect the wire

from the Input socket to the wire from the Output socket.

Turn off some loads connected to the Inverter until

the OVER LOAD LED is no longer lit

Page 12

Page 16

Push to Reset

INPUT

N

OUTPUT

LN

L

Input : 230V, 5A, 50Hz

Output : 230V, 5A, 50HZ

Disconnect from

Inverter

Connect Both Wires

Completed Bypass Connection

Figure 12. Power Inverter Bypass Connection

Preventative Maintenance - Preventative maintenance consists of inspecting the batteries for cracks and/or leakage, and checking battery fluid levels and

filling the batteries (every 120 days), using the criteria and methods as defined earlier in this manual. Dust the unit with a dry cloth. Do not use liquids

when cleaning.

Page 13

Page 17

Specifications

Input

Characteristics

Output

Characteristics

Surge

Protection

Environmental Ambient Operating Temperature 0-45 degrees C

Physical Input Line IEC socket

Batteries Type Two 12 V, 70 Amp-Hour

Table 3. APC Power Inverter Technical Specifications

Item Specification

Nominal Voltage 230 V

Rated Voltage 230 V

Frequency 47-53 Hz

Nominal Rated Current 3.47 A

Input Circuit Breaker Rating 10 A

Input Voltage Window for Utility Operation 100 - 265 VAC

Voltage (on Mains) 100 - 265 VAC

Voltage (on battery) 210 - 240 VAC

Rated VA 800 VA

Rated Watts 500 W

Nominal Rated Current 3.47 A

Overload Indicated ON BATTERY >100%

Shutdown due to OVERLOAD > 100% after 60 seconds (see Table 1 and following note)

Frequency (ON BATTERY) 50 Hz +/- 1%

Built-in Surge Protection Protects the load from surges and spikes..

Humidity 95 % Relative humidity, non-condensing

Altitude 3000 m

Outlet Receptacles IEC socket

Dimensions - Unit (h) x (w) x (d) Main Housing Chassis: 51.2 x 47.5 x 43.0 cm

Weight Main Housing Chassis: 18 kg

Shipping Weight Main Housing Chassis: 20.5 kg

Typical Runtime Approximately 120 minutes

Typical Load Set Up Set-up A = 5 fans, 4 tube lights

Runtime at 500 W Approximately 120 minutes

Typical Recharge Time (for a 90% Charge

Following a 50% Discharge)

AC Input Voltage Range for Charging 100 - 265 V

Inverter Assembly: 13.0 x 50.6 x 29.3 cm

Battery: 27.94 x 17.78 x 41.27 cm

Inverter Assembly: 13.5 kg

Battery: 28 kg

Inverter Assembly: 14.5 kg

Battery: XX kg (each)

Set-up B = 4 fans, 4 tube lights, and 1 TV

8-10 Hours

Page 14

Page 18

Warranty

APC warrants its products to be free from defects in materials and workmanship under normal use and service for 2 years for the Inverter,

and 2 years for the Batteries to the original purchaser. Its obligation under this warranty is limited to repairing or replacing, at its sole

option, any such defective products. To obtain service under warranty you must obtain a Return Material Authorization (RMA) number

from APC Technical Support or an APC Service Center. The defective unit must be returned with an RMA number, with transportation

charges prepaid and it must be accompanied by a brief description of the problem and proof of date and place of purchase. This warranty

applies only to the original purchaser.

Contact Information

APC Corporate Office

132 Fairgrounds Road

West Kingston, RI 02892, USA

Tel: 401-789-0204

APC Corporate Office (India)

27 Lavelle Road

Bangalore 560 001

www.apc.com

Toll Free Helpline: 1600 444 272 and 1600 444 877

email: indiainfo@apc.com

Technical Webchat: www.apc.com/in

Page 15/Page 16 blank

Loading...

Loading...