Page 1

InRoom™

Precision Air Conditioner

Technical Data

ACPDX21-86, ACPCW40-150

Page 2

American Power Conversion Legal Disclaimer

The information presented in this manual is not warranted by the American Power Conversion Corporation

to be authoritative, error free, or complete. This publication is not meant to be a substitute for a detailed

operational and site specific development plan. Therefore, American Power Conversion Corporation

assumes no liability for damages, violations of codes, improper installation, system failures, or any other

problems that could arise based on the use of this Publication.

The information contained in this Publication is provided as is and has been prepared solely for the purpose

of evaluating data center design and construction. This Publication has been compiled in good faith by

American Power Conversion Corporation. However, no representation is made or warranty given, either

express or implied, as to the completeness or accuracy of the information this Publication contains.

IN NO EVENT SHALL AMERICAN POWER CONVERSION CORPORATION BE LIABLE FOR

ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL, OR INCIDENTAL

DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS,

CONTRACT, REVENUE, DATA, INFORMATION, OR BUSINESS INTERRUPTION)

RESULTING FROM, ARISING OUT, OR IN CONNECTION WITH THE USE OF, OR

INABILITY TO USE THIS PUBLICATION OR THE CONTENT, EVEN IF AMERICAN POWER

CONVERSION CORPORATION HAS BEEN EXPRESSLY ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. AMERICAN POWER CONVERSION CORPORATION RESERVES THE

RIGHT TO MAKE CHANGES OR UPDATES WITH RESPECT TO OR IN THE CONTENT OF

THE PUBLICATION OR THE FORMAT THEREOF AT ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights in the content (including but not limited to software,

audio, video, text, and photographs) rests with American Power Conversion Corporation or its licensors.

All rights in the content not expressly granted herein are reserved. No rights of any kind are licensed or

assigned or shall otherwise pass to persons accessing this information.

This Publication shall not be for resale in whole or in part.

Page 3

Contents

Overview ..................................................................................................... 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Scalable Solution for Critical Environments . . . . . . . . . . . . . . . . . . . . . . . . .2

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Optional Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Display Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

InRoom Model Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

InRoom Cooling Unit Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

60Hz Performance Specifications .......................................................... 23

Chilled Water (CW) – 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Air Cooled (DX) System – 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

MultiCool – Air Cooled (DX) with CW – 60Hz. . . . . . . . . . . . . . . . . . . . . . . .27

Fluid Cooled (Glycol 40%) – 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Fluid Cooled (Glycol 0%) – 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Fluid Cooled (Glycol 0%) with CW – 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . .34

Fluid Cooled (Glycol 40%) with CW – 60Hz . . . . . . . . . . . . . . . . . . . . . . . . .37

Fluid Cooled (Glycol 40%) with Economizer - 60Hz . . . . . . . . . . . . . . . . . .40

60Hz InRoom Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

50Hz Performance Specifications .......................................................... 45

Chilled Water (CW) - 50Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Air Cooled (DX) System - 50Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

MultiCool - Air Cooled (DX) with CW - 50Hz . . . . . . . . . . . . . . . . . . . . . . . .49

Fluid Cooling (Glycol 40%) – 50Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Fluid Cooled (Glycol 0%) – 50Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fluid Cooled (Glycol 40%) with CW - 50Hz . . . . . . . . . . . . . . . . . . . . . . . . .56

Fluid Cooled (Glycol 40%) with Economizer - 50Hz . . . . . . . . . . . . . . . . . .59

50Hz InRoom Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

General Specifications ............................................................................ 63

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Transporting and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Guidelines for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Piping Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

InRoom Guide Specifications ................................................................. 74

Warranty ................................................................................................... 84

InRoom Precision AC Tech Data Manual i

Page 4

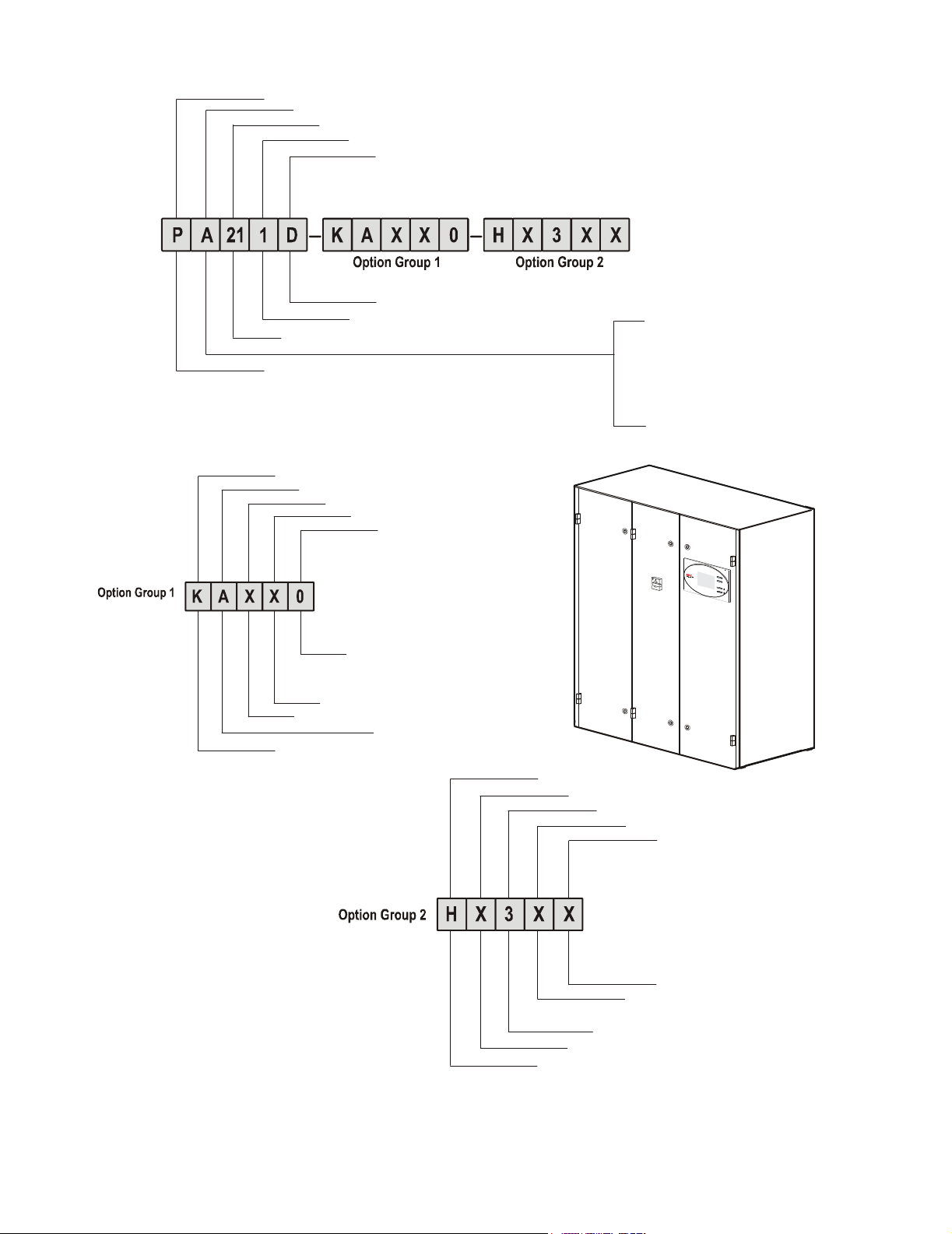

InRoom Nomenclature

Vol ta ge

B: 208-230V

G: 380-415V

K: 460-480V

M: 575-600V

Z: 400V

Phase/Hertz

A: 3/60

B: 3/50

Reheat

Humidification

Mains Input Selection

0 - Standard Disconnect,

na2868a

H: R407C

Chilled Water Valve

Hot Gas By-pass Valve

H - HGPV

Placeholder

X - Reserved for Future Use

P = Perimeter unit

Cooling System

Model Size

0, 1, 2

Number of Refrigeration Circuits

D - Downflow, U - Upflow

Airflow Pattern

A: Air-cooled

G: Glycol-cooled

A

CW: Chilled Water

1 - Dual Power with ATS *,

2 - Dual Power without ATS **,

X - None

X: None

* Dual Power with ATS - Base Cooling Units without Heat and Humidifier with two Disconnects.

Product Range

DX: 21, 31, 45, 61, 86 CW: 40, 66, 90, 110, 150

X - None, E - Immersed Electrode

X - None, E - Electric

Refrigerant

Head Pressure Control Valve

CW: Air-cooled with MultiCool

GCW: Glycol-cooled with MultiCool

GE: Glycol-cooled with Economizer

** Dual Power without ATS - Units with Heat and Humidifier with one Disconnect.

ii InRoom Precision AC Tech Data Manual

X - None, 2 - 2-way, 3 - 3-way

X - None, 2 - 2-way, 3 - 3-way

Page 5

Overview

C

General

The InRoom product family is an

assemble to order (ATO) line of

perimeter air conditioning

systems that provide precision

cooling for data centers and

server rooms.

Precision environmental close

control requirements now reach

far beyond the confines of the

traditional data center or

computer room to encompass a

larger suite of applications,

referred to as technology rooms.

Critical environment applications

include:

• Computer rooms

• Telecommunication facilities

• Clean rooms

• Power equipment

• Medical equipment rooms

• Archives

• LAN/WAN environments

A worldwide network of APC

representatives is fully qualified

to provide engineering, sales,

installation and service for our

products.

APC warrants all parts for 1 year.

Models

The InRoom precision air

conditioning unit is available in

five sizes. The system is available

in both chilled water and direct

expansion for a combination of

six heat rejection methods.

Select from ACPDX21-86 and

ACPCW40-150.

Room Air Distribution

The InRoom downflow system

draws warm exhaust air in

through the top of the unit and

cools it. The cool air is distributed

back into the room through a

raised floor plenum. These

systems are ideal for areas with

raised floors greater than 305 mm

(10 in) high. Upflow systems

draw warm exhaust air in through

the front of the unit. The warm

exhaust air is then cooled and

discharged back into the room

through a plenum or ductwork.

Upflow systems are ideal for

areas without a raised floor, but

can also be used in a raised floor

environment.

The InRoom precision air

conditioner delivers high volume

airflow to help eliminate hot spots

in densely populated

environments.

Configurations

• Air Cooled

• Air Cooled with Chilled

Water Coil (MultiCool)

• Chilled Water Coil

• Fluid Cooled (Glycol)

• Fluid Cooled (Glycol) with

Economizer Cooling Coil

• Fluid Cooled (Glycol) with

Chilled Water Coil

Compliance Approval

1. ETL/CETL

2. NTRL Listed

3. Electrical Systems comply

with NEC and UL 1995/

CSA22.2 No.236

US

Standard Features

1. Insulated Cabinet

2. Direct Drive Fans

3. Electrical Panel

4. Main Power Disconnect

Switch

5. Refrigeration System with

Scroll Compressor and

Crankcase Heater (DX only)

6. Redundant Group Control

7. Network Management Card

8. Electronic Expansion Valve

(DX only)

9. Duct Flange (Upflow only)

10. 30% ASHRAE Air Filters

11. Brazed plate condenser

12. 2 or 3 Way Fluid Regulating

Valves (Glycol models)

13. 2 or 3 Way Fluid Regulating

Valves (CW only)

14. Discrete Input/Output

Interface

15. Resettable Circuit Breakers

16. Microprocessor Controller

17. Graphical User Interface

18. Electrically Commutated

(EC) Fans

19. Stainless Steel Condensate

Pan

20. Automatic Transfer Switches

Optional Features

1. Plenum

2. Sub-base Plenum

3. Floorstand

4. Seismic Floorstand

5. Immersed Electrode

Humidifier

6. Condensate Pump

7. Electric Heat

8. Spot Water Detector(s)

9. Cable Water Detector(s)

(60 Hz only)

10. Smoke Detector

11. Hot Gas Bypass Valve

1InRoom Precision AC Tech Data Manual

Page 6

Scalable Solution for Critical Environments

Temperature and Humidity Design Conditions

Maintenance of temperature and

humidity design conditions is

critical to the smooth operation of

a technology room. Based on

ASHRAE TC9.9, the

recommended design conditions

for class one and class two

environments should be 20–25°C

(68–77°F) and 40–55% relative

humidity (R.H.). Precision air

conditioning is designed to

maintain temperature at ±2°F and

humidity at ±3–5% R.H. 24 hours

a day, 365 days a year. Vapor

barriers and sealed rooms are

required to maintain these

tolerances. In contrast, comfort

systems are designed to maintain

±5°F from the temperature

setpoint. There is usually no

dedicated humidity control and

the simple controllers cannot

maintain the setpoint tolerance

required for temperature,

allowing potentially harmful

temperature and humidity swings

to occur. This is not acceptable for

sensitive electronic equipment.

Air Quality

Precision air conditioners provide

a high volume of air flow, around

600 CFM/ton (286 L/m, 150

CFM/kW). This high CFM moves

more air through the space

improving air distribution and

reducing the chance of localized

hot spots. It also allows more air

to move through filters, ensuring

a cleaner environment. This

requires a moderate-to highefficiency filter bank to minimize

airborne particles.

Low Humidity

Low humidity greatly increases

the possibility of static electric

discharges. Static discharges can

corrupt data and damage

hardware.

High Humidity

High humidity can result in tape

surface deterioration, head

crashes, condensation, corrosion,

paper handling problems and gold

and silver migration leading to

component and board failure.

High & Low Temperature

A high or low temperature or

rapid temperature swings can

corrupt data processing and shut

down an entire system.

Temperature variations can alter

the electrical and physical

characteristics of electronic chips

and other board components

causing faulty operation or

failure. These problems may be

transient or may last for days.

Transient problems can be very

difficult to diagnose and repair.

Efficiency and Reliability

The use of energy efficient, direct

drive fans along with fewer

moving internal parts eliminate

most potentials for failure. Scroll

compressor technology provides

unparalleled efficiency and constant, reliable operation with an

ability to withstand liquid

refrigerant ‘slugging’ which is a

major cause of compressor failure. The compressor is also

equipped with an internal high

pressure sensor which opens a

bypass valve in case of high

pressure. This ensures internal

pressure compensation takes

place and damage to the

compressor is avoided.

APC InRoom The Right Solution

The APC InRoom cooling unit

provides the maximum amount of

precision cooling in a compact

footprint with the lowest

operating cost and noise level.

Dedicated Dehumidification Cycle

A dedicated dehumidification

cycle allows the system to

increase latent capacity without

boosting compressor capacity,

and also lowers the requirement

for reheat. To achieve

dehumidification, the electronic

expansion valve is first partially

closed. The reduction of the

refrigerant mass flow makes the

evaporation temperature drop,

which lets the surface temperature

in a part of the evaporator fall

below the dew point of the air,

causing dehumidification. For

increased dehumidification, the

fan speed is reduced. With a

constant cooling capacity, the

temperature of the air which

flows through the heat exchanger

coil passes below the dew point.

The moisture contained in the air

condenses on the heat exchanger,

gathers in the condensate pan, and

is carried away by the drain. To

achieve humidification for the

DX units with cabinet size 1 and

all CW units, the fan speed is

reduced. For the DX units with

cabinet size 2–5, approximately

one third of the evaporator is

isolated from the refrigerant flow

by a solenoid valve to achieve

dehumidification by lowering the

evaporator temperature below the

dew point.

InRoom Precision AC Tech Data Manual2

Page 7

Standard Features

Insulated Panels

The frame is constructed of 16

gauge steel sheet metal for

maximum strength. All exterior

panels and corner posts on the

frame are powder coated for

durability and an attractive finish.

The side panels are double wall

construction (inner and outer

panels) with insulation between.

The insulation is 12 mm (1/2 in)

thick fiberglass. The walls isolate

the insulation from the air stream

and further reduce sound levels.

Panels are hinged and removable

for easy access. The cabinet is

serviceable from the front of the

unit.

Electronically Commutated (EC) Fans

Each unit is equipped with

electronically commutated (EC)

fan modules. This technology

increases fan efficiency by up to

30% while reducing operating

costs. Each fan module has an

anti-vibration mounting to isolate

it from the unit structure.

Electrical Panel

The electrical panel contains the

contactors, starters, overload

protection devices, and input

power disconnects.

Main Power Disconnect Switch

A main power disconnect switch

disconnects all high voltage

power to the unit if necessary.

The disconnect switch is

accessible without removing the

electric box cover.

Network Management Card

Permits multi-level access to

monitoring, control, and event

notification features over the

building management network.

Refrigeration System and Compressor

The refrigeration system operates

under a master controller for

greater efficiency and accuracy.

Suction and discharge pressures

(DX models) are monitored and

electronically controlled. The

scroll compressors are designed

for year-round operation with a

15-year life expectancy. The

controller microprocessor

provides real-time suction and

discharge pressure readings

reported by transducers installed

on the refrigeration system.

For compressor protection, the

InRoom precision air conditioner

utilizes charge isolation and crank

case heaters during off cycles

(DX only). This eliminates the

threat of liquid refrigerant

migration that could lead to

compressor slugging and

lubrication issues.

Mains Automatic Transfer Switches

Mains automatic transfer switches

allow two power sources to be

connected to the cooling unit. A

secondary power source

(generator or UPS) can be

automatically transferred in the

event of a failure of the main

power source to maintain cooling.

Programmable switches are

voltage adjustable with On and

Off delay which can be adjusted

from 0 to 20 seconds. The Off

delay should be set to 3 seconds.

Contact customer support for

assistance to determine your

requirements.

Duct Flange

A 25 mm (1 in) duct flange is

included for the upflow units to

provide convenient connection to

external ductwork for either

supply or return air as needed.

Evaporative Freeze Protection

Suction pressure is actively

monitored by two individual

sensors and controlled by the

microprocessor controller to

calculate the opening of the

electronic expansion valve,

eliminating the risk of condensate

freeze-up on the evaporator coil.

Redundant Group Control

Allows up to 16 units to

communicate with each other for

redundancy, demand fighting

prevention, and mode assist.

Global sharing of certain settings

requires a twisted pair shielded

wiring interconnection.

30% ASHRAE 52.1 Filters

The filtration of conditioned air is

extremely vital to maintaining the

clean, particle-free environment

required by electrical equipment.

The system uses 30% (100

micron) filters, with full depth

filter pleats. Deeper filters

produce a lower pressure drop,

requiring less energy during

normal operation. Filters are

replaceable through the front of

the upflow unit and through the

top of the downflow unit.

Condenser (Direct Expansion units only)

Standard air cooled condensers

are suitable for cooling up to the

maximum ambient temperature of

either 35°C (95°F) or 46.1°C

(115°F) depending on the

requirement. These condensers

have variable fan speed controls

to allow operation down to

-28.9°C (-20°F).

3InRoom Precision AC Tech Data Manual

Page 8

Optional Features

Humidifier

The humidifier utilizes a pure

steam generator specifically

designed for precision

environmental close control. The

pure steam eliminates

contaminating mineral deposits,

potentially harmful bacteria,

white dust, and excessive

humidity. The humidifier requires

little scheduled maintenance. The

humidifier is proportionally

controlled to meet the

humidification demands of the

conditioned space. Humidifier

canisters are replaceable.

Electric Reheat

Electric reheat elements are low

watt density, wired for 3-phase

and loaded equally on all three

phases, SCR controlled, and

electrically and thermally

protected by both automatic and

manual reset thermal cut outs.

Reheat coils are stainless steel,

tubular fin construction.

Spot Water Detector

The solid-state spot water

detector is available for both 50

and 60 Hz cooling units. The spot

water detector activates an

audible alarm on the controller

when moisture is detected.

Smoke Detector

The factory-installed smoke

detector is designed to sense

smoke in the return air stream.

Upon detection of smoke, an

audible and visual alarm on the

microprocessor controller will be

activated and the unit will be shut

down immediately.

Hot Gas Bypass Valve

The hot gas bypass valve

(HGBV) adjusts the flow of

compressor discharge gas to the

evaporator coil at low load

conditions to protect the coil from

freezing and the compressor from

excessive cycling. 60 Hz cooling

units use a mechanical HGBV.

50 Hz cooling units use an

electronically controlled HGBV.

On 50 Hz cooling units, the

HGBV option requires the analog

extension board EAIO.

Cable Leak Detector (60 Hz only)

The optional 6 m (20 ft) leak

detection sensing cable (APC part

number ACAC75105) is available

for 60 Hz cooling units only. The

cable leak detector is placed on

the floor or subfloor around all

possible leak sources. If water or

other conductive liquids contact

the cable anywhere along its

length, the master controller

visually and audibly announces

the leak.

Floorstand

The floorstand raises the unit

above the subfloor to match the

height of the raised floor. Heights

are available from 254 mm (10

in) to 610 mm (24 in) in 76.2 mm

(3 in) increments and are

adjustable +/– 38.1 mm (1.5 in).

Adjustment is provided by

threaded pedestals. Vibrationabsorbing pads are included. The

floorstand, pedestal, and pads

ship loose. In areas where

earthquakes are a concern,

seismic floorstands are available

in 305 mm (12 in), 457 mm (18

in), and 610 mm (24 in) heights.

Plenums

Discharge plenums are available

on upflow configurations. This

application is recommended in

rooms where raised floors are not

available for air distribution.

Discharge air should be ducted

down cold aisles.

Base Plenum

Insulated base plenums are

available for downflow cooling

units where raised floors are not

available for air distribution. Four

front-discharge configurations are

available equipped with dampers,

grilles, flexible ductwork or open.

All configurations are 450 mm

(17.7 in) high and sit beneath the

InRoom cooling unit.

Water Regulating Valves

Water and fluid cooled systems

utilize two- or three-way valves to

regulate the amount of water or

glycol supplied to the condenser

in response to refrigerant

discharge pressure. The standard

valve pressure rating is 28 kPa

(400 psi).

Extreme Low Temperature Kit (Direct Expansion units only)

Extreme Low Temperature Kits

for air cooled condensers are

available for operation below

–34.4°C (–30°F). The optional

kit consists of pressure control

valves and receivers for the liquid

return side of the refrigerant

piping.

InRoom Precision AC Tech Data Manual4

Page 9

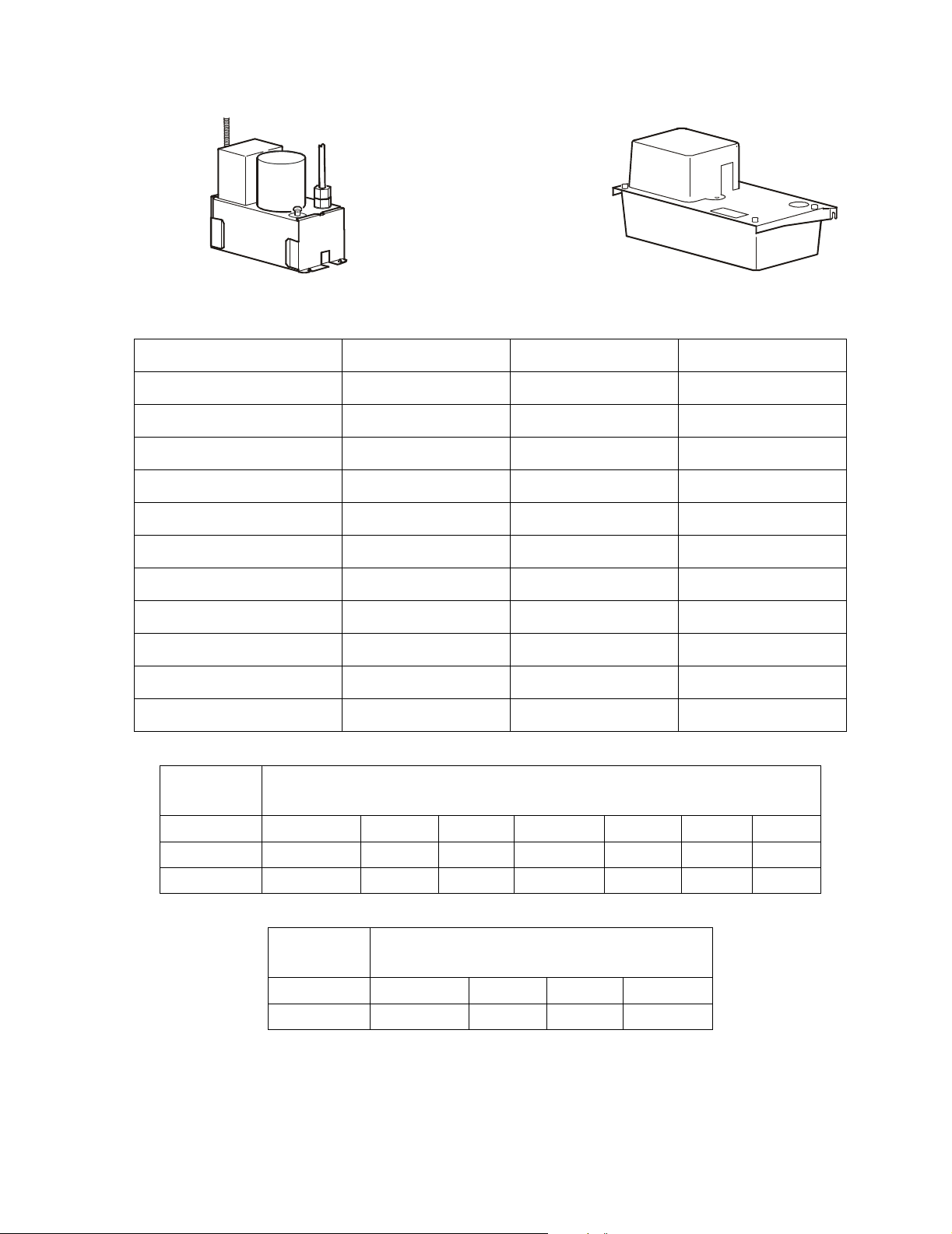

Condensate Pump

na28 57a

60 Hz

50 Hz

Model # ACAC75107 ACAC75107 ACAC76106

Hz 60 60 50

Height mm (in) 259 (10 1/8) 259 (10 1/8) 210 (8 1/4)

Width mm (in) 152 (6) 152 (6) 132 (5 1/4)

Length 304 (12) 304 (12) 295 (11 1/2)

Outlet mm (in) 13 (1/2) 13 (1/2) 6 (1/4)

na2867a

Vol ts 230 460 400

Amps 1.9 0.8 0.125

Watts 360 360 30

Weight Kg (Lb) Ea

5.8 (13) 5.8 (13) 3 (6.6)

HP (motor only) 1/5 1/5 1/20

Tank Capacity Ltr (Gal) 3.785 (1) 3.785 (1) 1.4 (1/3)

Liters (Gallons) per hour at 60 Hz/Rated Voltage

Model

Flow rate per pressure drop

1 ft 5 ft 10 ft 15 ft 20 ft 30 ft 40 ft

ACAC75107 1839 (486) 1714 (453) 1559 (412) 1407 (372) 1275 (337) 942 (249) 635 (168)

ACAC75108 1589 (420) 1438 (380) 1343 (355) 1248 (330) 1173 (310) 908 (240) 548 (145)

Liters (Gallons) per hour at 50 Hz/Rated

Model

Voltage - Flow rate per pressure drop

1 m 2 m 3 m 4 m

ACAC76106 135 (35.5) 100 (26.4) 60 (15.8) 20 (5.3)

5InRoom Precision AC Tech Data Manual

Page 10

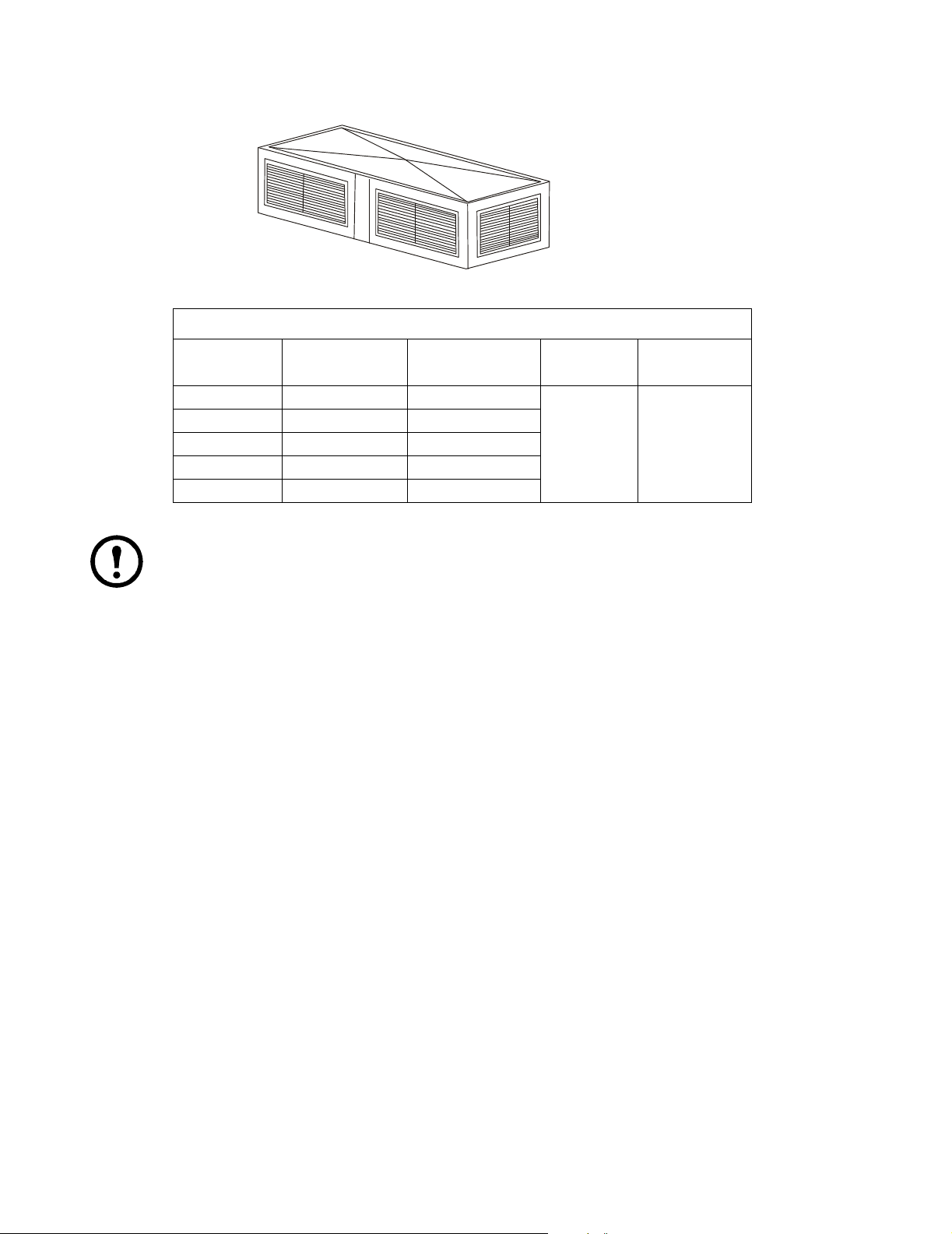

Upflow Discharge Plenums for 50 Hz and 60 Hz InRoom Cooling Units

na2874 a

Upflow discharge plenums

Width

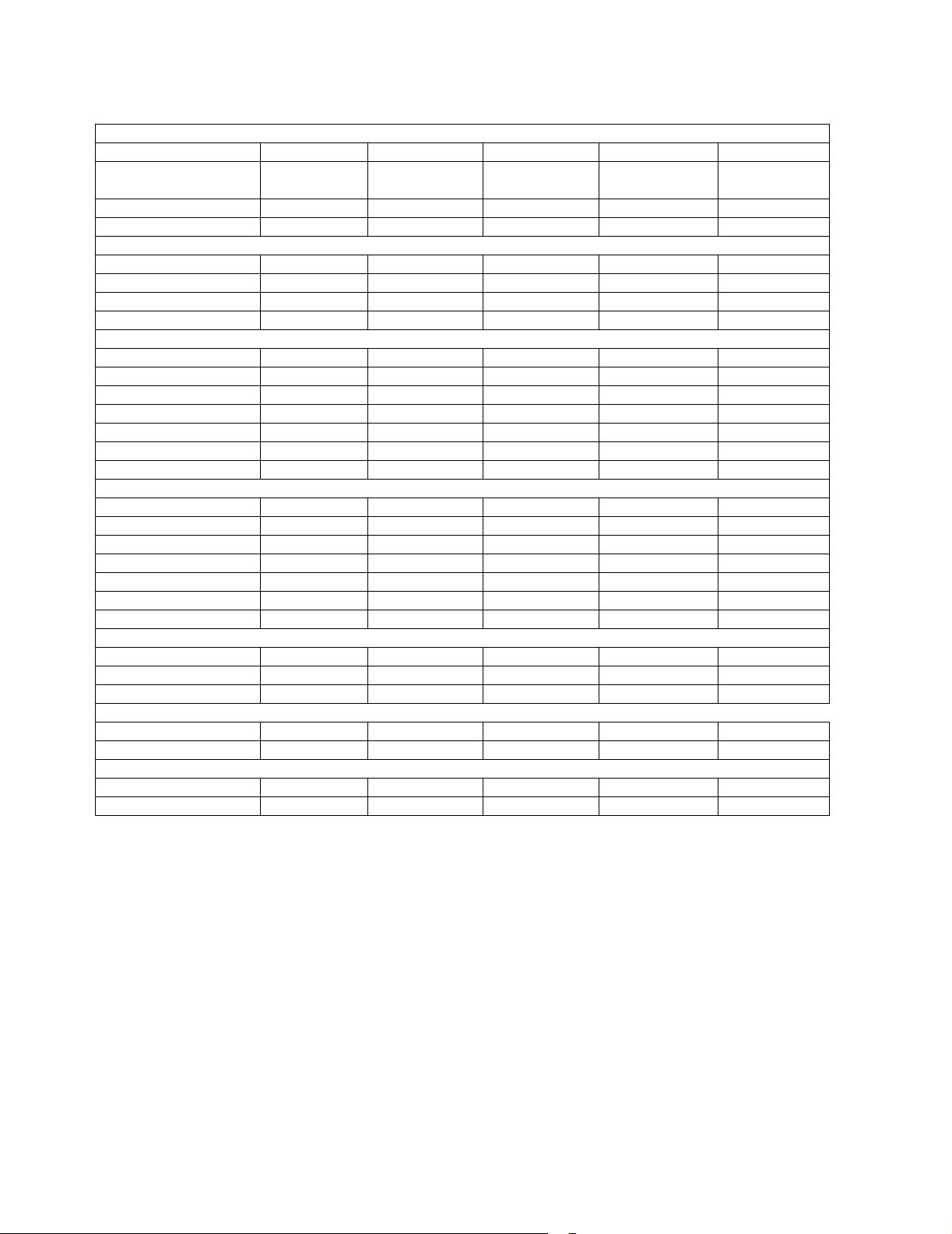

Cabinet size SKU

mm (in)

1 ACPL75100 1000 (39.37)

2 ACPL75101 1400 (55.11)

3 ACPL75102 1750 (68.90)

4 ACPL75103 2150 (84.65)

5 ACPL75104 2550 (100.39)

Note: Plenums are delivered completely assembled.

Depth

mm (in)

Height

mm (in)

900 (35) 500 (19.7)

InRoom Precision AC Tech Data Manual6

Page 11

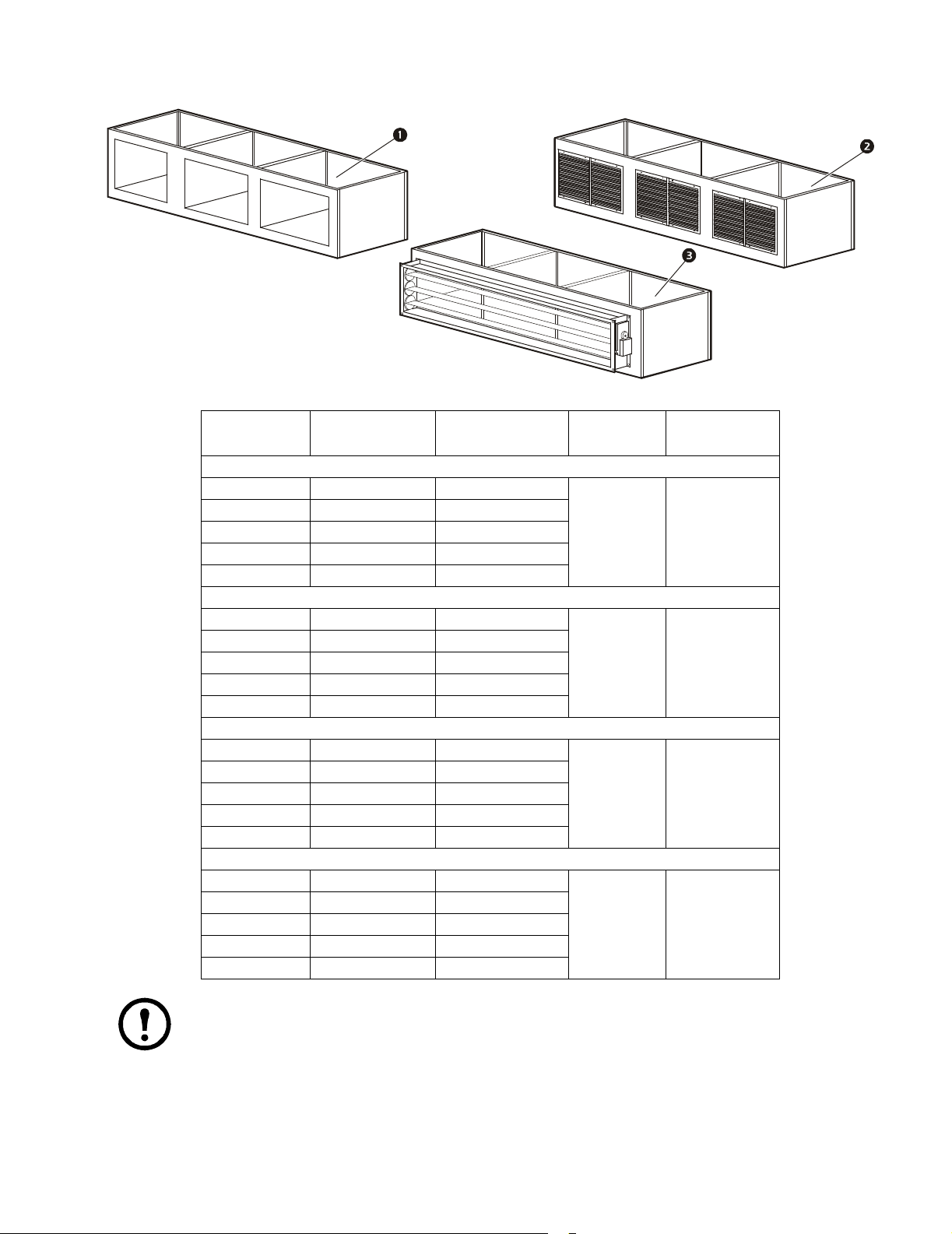

Downflow Discharge Plenums for 50 Hz InRoom Cooling Units

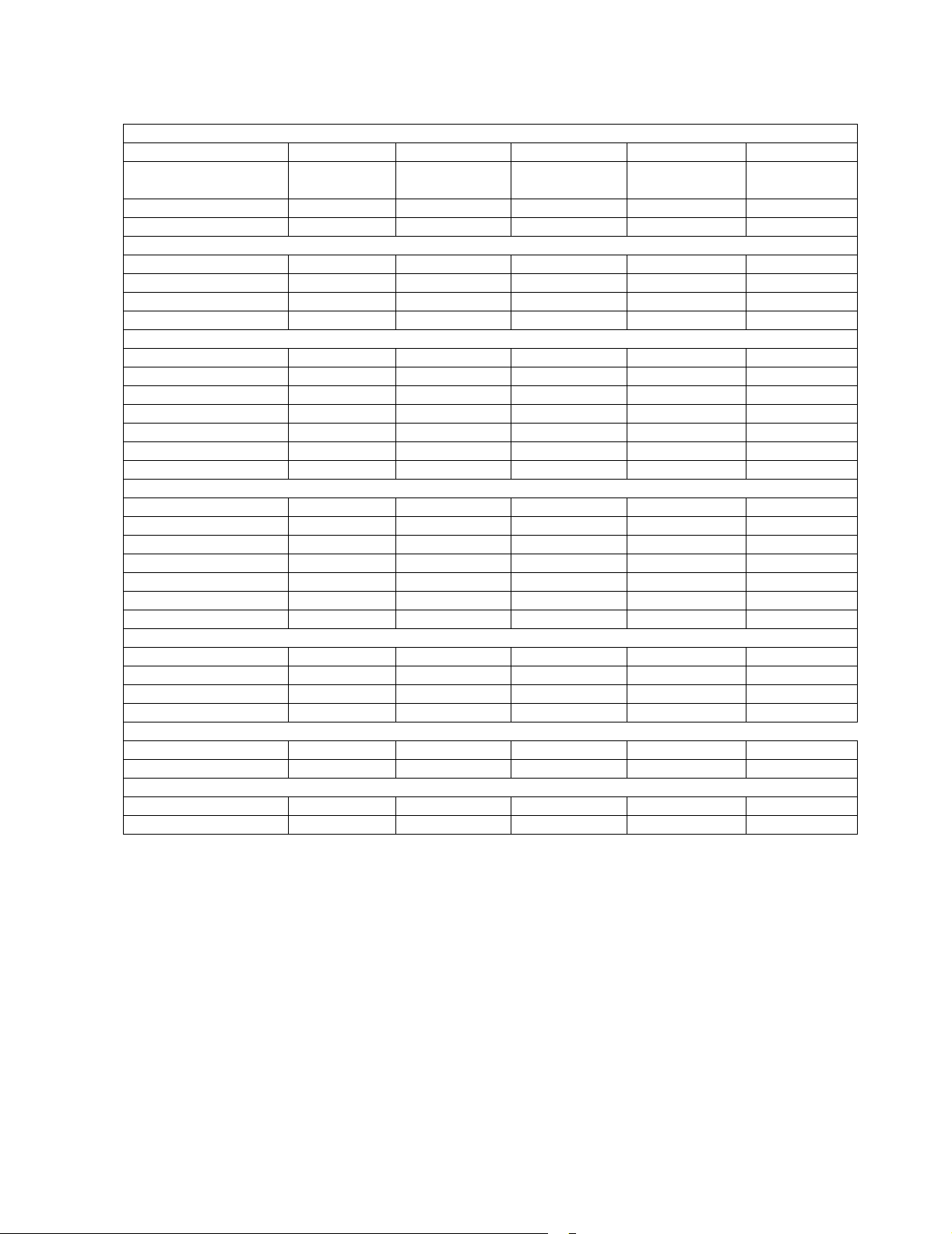

na3026a

Cabinet size SKU

Width

mm (in)

Depth

mm (in)

Unit Sub Base Plenum with no Grills

1 ACSB76100 960 (37.8)

2 ACSB76101 1360 (53.5)

3 ACSB76102 1710 (67.3)

865 (34) 450 (17.7)

4 ACSB76103 2110 (83.1)

5 ACSB76104 2510 (98.8)

Unit Sub Base Plenum with Grills

1 ACSB76110 960 (37.8)

2 ACSB76111 1360 (53.5)

3 ACSB76112 1710 (67.3)

865 (34) 450 (17.7)

4 ACSB76113 2110 (83.1)

5 ACSB76114 2510 (98.8)

Unit Sub Base Plenum with Damper (50Hz only)

1 ACSB76120 960 (37.8)

2 ACSB76121 1360 (53.5)

3 ACSB76122 1710 (67.3)

865 (34) 450 (17.7)

4 ACSB76123 2110 (83.1)

5 ACSB76124 2510 (98.8)

Unit Sub Base Plenum with Flex Connector (not shown)

1 ACSB76130 960 (37.8)

2 ACSB76131 1360 (53.5)

3 ACSB76132 1710 (67.3)

865 (34) 450 (17.7)

4 ACSB76133 2110 (83.1)

5 ACSB76134 2510 (98.8)

Height

mm (in)

Note:

• All three sub-base plenum models are attached to the cooling unit with 4x M10 screws.

• Sub-base plenums with grills are equipped with adjustable horizontal fins to direct exiting air.

• The plenums can be installed with the opening to the front or with the opening to the rear.

7InRoom Precision AC Tech Data Manual

Page 12

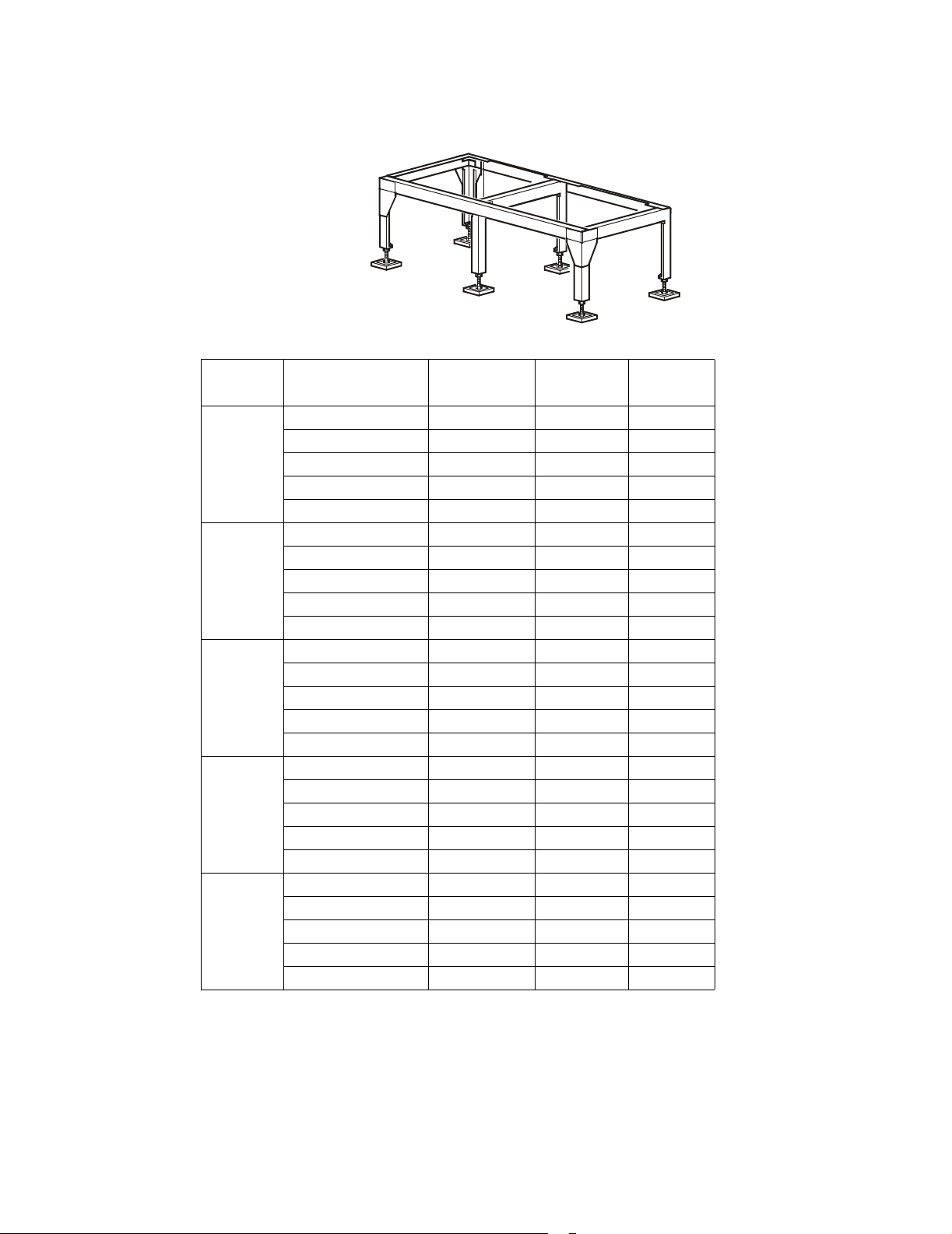

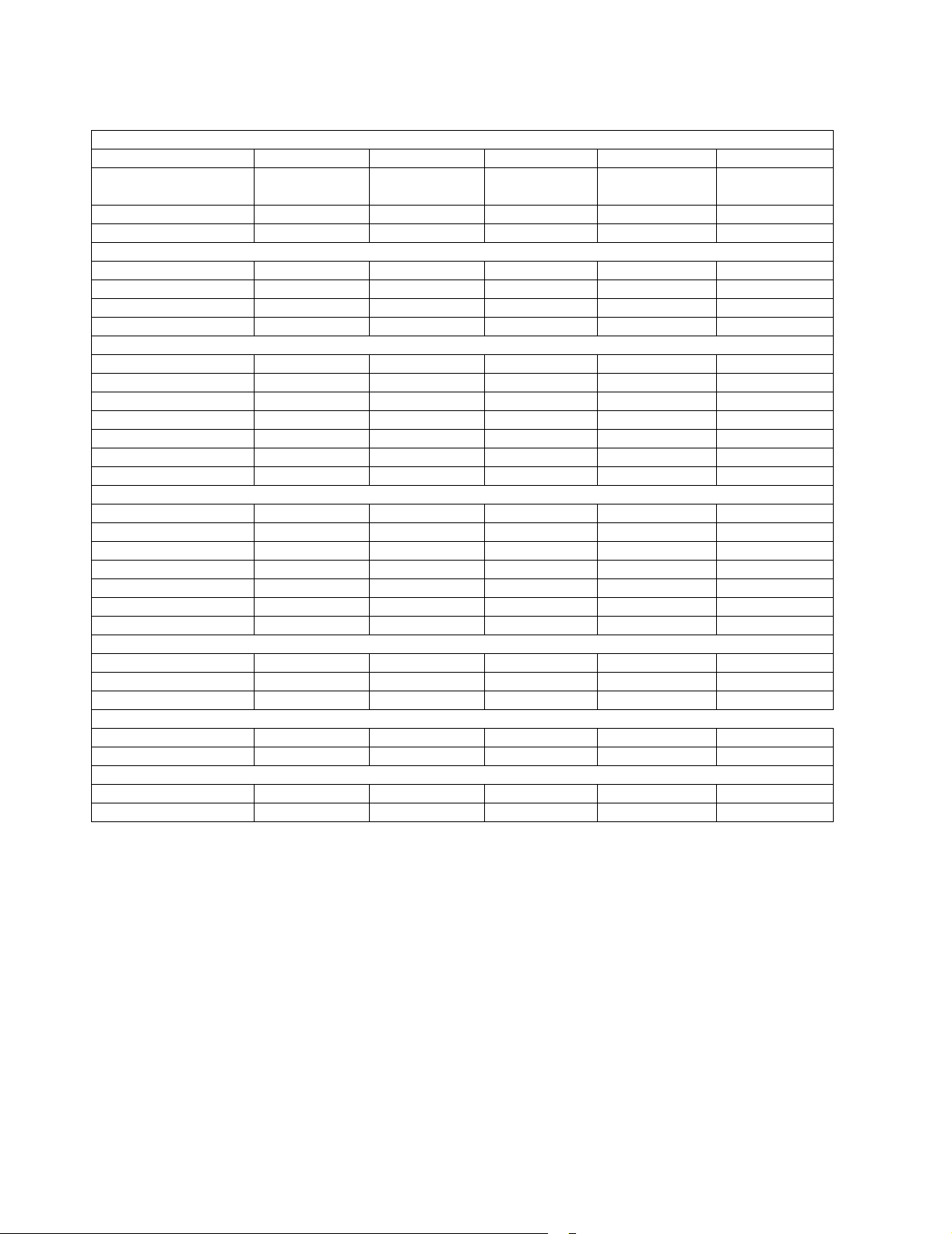

Standard Floorstands for InRoom 60Hz Cooling Units

na2834a

Cabinet

size Model

ACFS76000 254 (10) 960 (37.8) 864 (34)

ACFS76001 305 (12)

1

ACFS76002 381 (15)

ACFS76003 457 (18)

ACFS76004 609 (24)

ACFS76005 254 (10) 1359 (53.5) 864 (34)

ACFS76006 305 (12)

2

ACFS76007 381 (15)

ACFS76008 457 (18)

ACFS76009 609 (24)

ACFS76010 254 (10) 1712 (67.4) 864 (34)

ACFS76011 305 (12)

3

ACFS76012 381 (15)

ACFS76013 457 (18)

ACFS76014 609 (24)

ACFS76015 254 (10) 2108 (83.0) 864 (34)

ACFS76016 305 (12)

4

ACFS76017 381 (15)

ACFS76018 457 (18)

ACFS76019 609 (24)

ACFS76020 254 (10) 2512 (98.9) 864 (34)

ACFS76021 305 (12)

5

ACFS76022 381 (15)

ACFS76023 457 (18)

ACFS76024 609 (24)

Height

mm (in)

Width

mm (in)

Depth

mm (in)

InRoom Precision AC Tech Data Manual8

Page 13

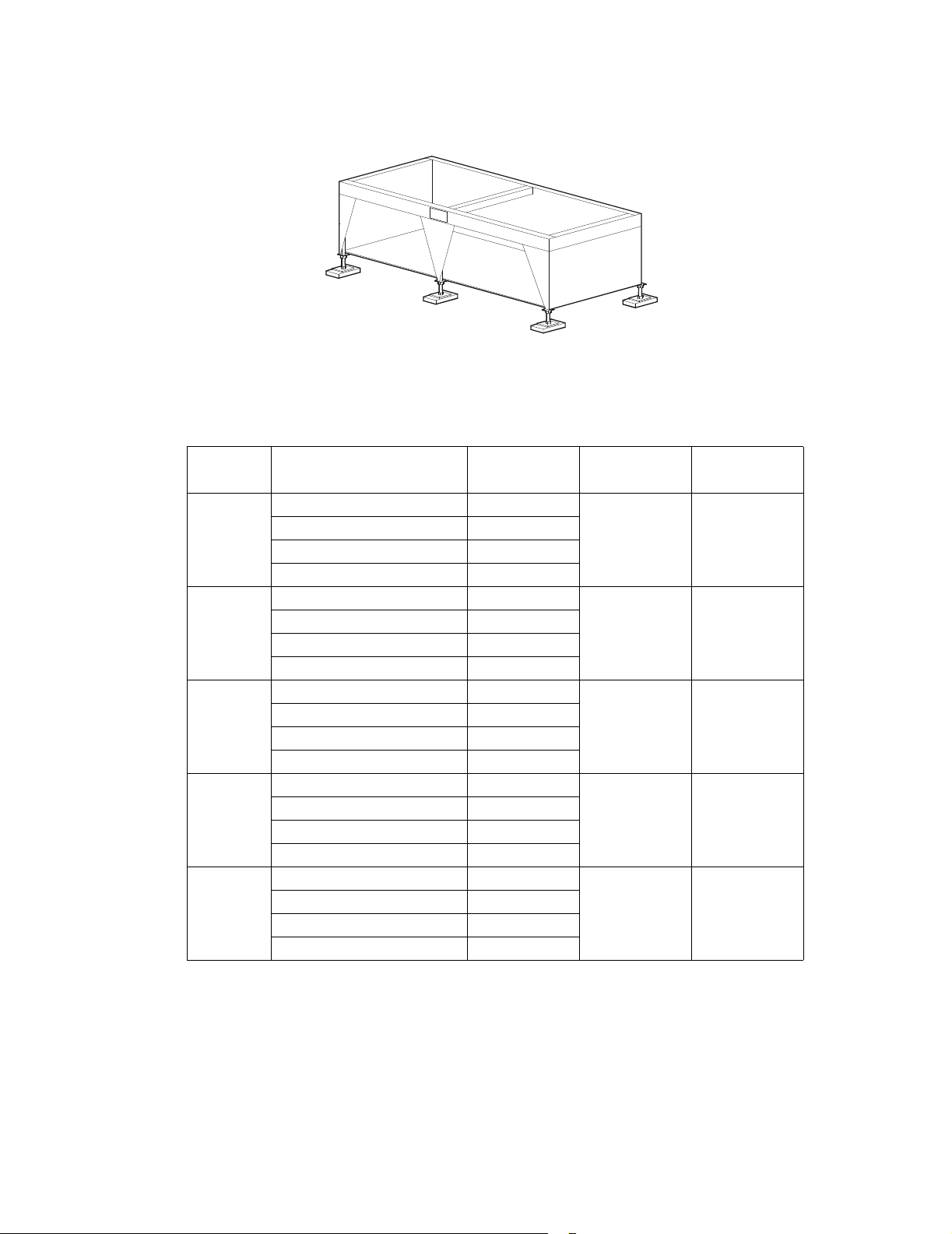

Bowling Alley Floorstands for InRoom 60Hz Cooling Units

na3053a

Cabinet

size Model

ACFS76033 305 (12)

1

ACFS76032 381 (15)

ACFS76031 457 (18)

ACFS76030 609 (24)

ACFS76037 305 (12)

2

ACFS76036 381 (15)

ACFS76035 457 (18)

ACFS76034 609 (24)

ACFS76041 305 (12)

3

ACFS76040 381 (15)

ACFS76039 457 (18)

ACFS76038 609 (24)

ACFS76045 305 (12)

4

ACFS76044 381 (15)

ACFS76043 457 (18)

ACFS76042 609 (24)

ACFS76049 305 (12)

5

ACFS76048 381 (15)

ACFS76047 457 (18)

ACFS76046 609 (24)

Height

mm (in)

Width

mm (in)

Depth

mm (in)

960 (37.8) 864 (34)

1359 (53.5) 864 (34)

1712 (67.4) 864 (34)

2108 (83.0) 864 (34)

2512 (98.9) 864 (34)

9InRoom Precision AC Tech Data Manual

Page 14

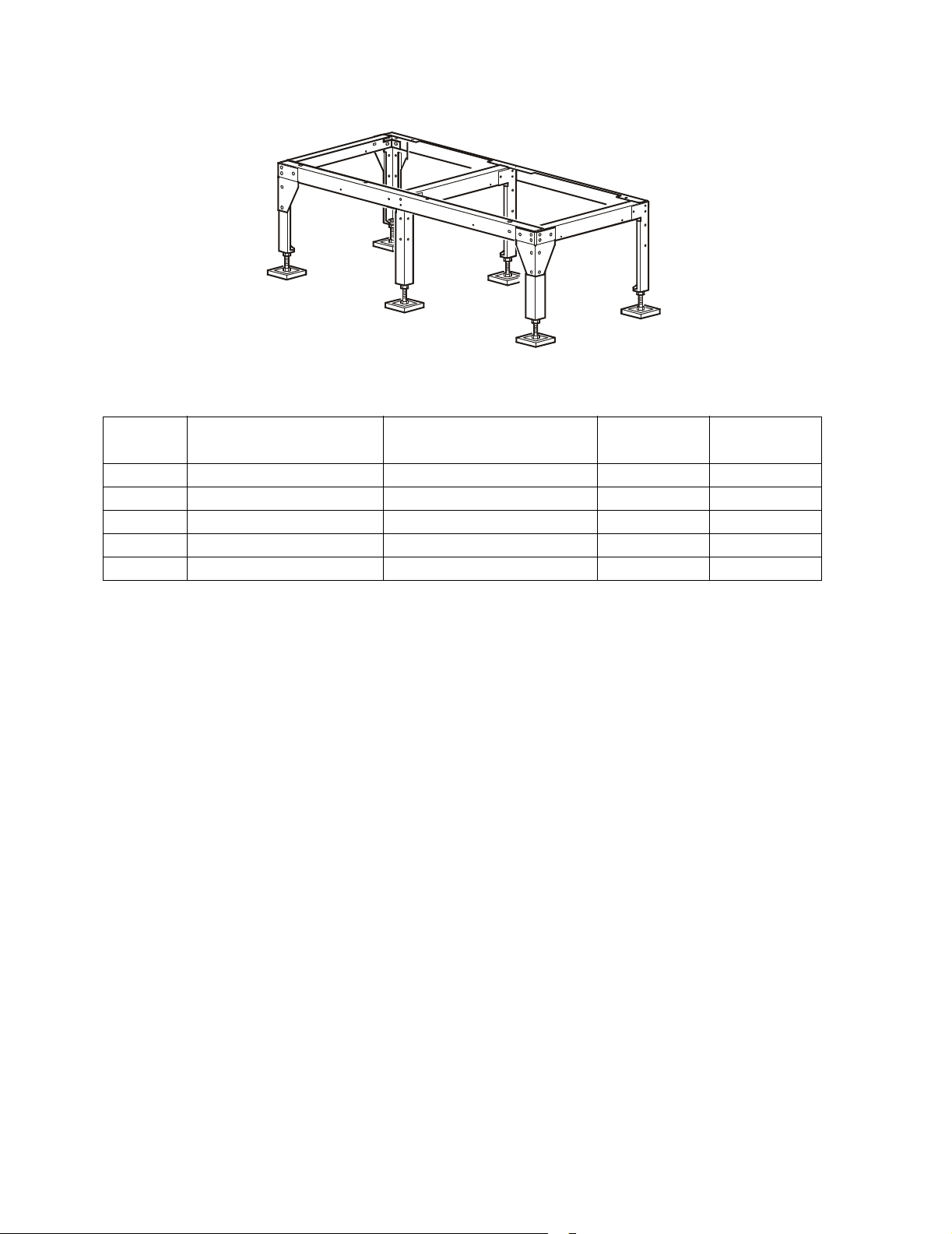

Floorstands for InRoom 50 HzCooling Units

na3087a

Cabinet

size Model

Height

mm (in)

Width

mm (in)

1 ACFS76025 250-500 (10-20) 960 (37.8) 864 (34)

2 ACFS76026 250-500 (10-20) 1359 (53.5) 864 (34)

3 ACFS76027 250-500 (10-20) 1712 (67.4) 864 (34)

4 ACFS76028 250-500 (10-20) 2108 (83.0) 864 (34)

5 ACFS76029 250-500 (10-20) 2512 (98.9) 864 (34)

Depth

mm (in)

InRoom Precision AC Tech Data Manual10

Page 15

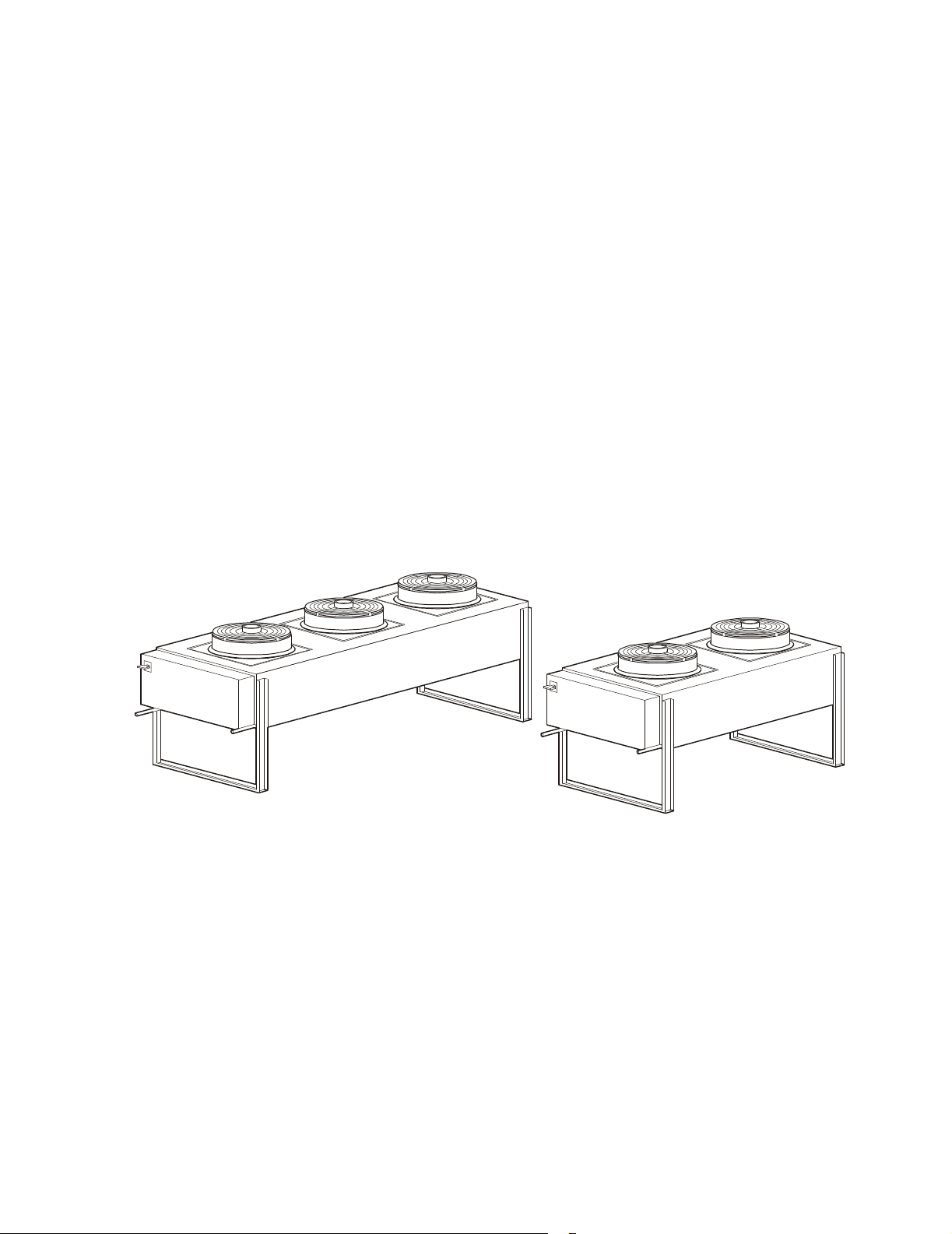

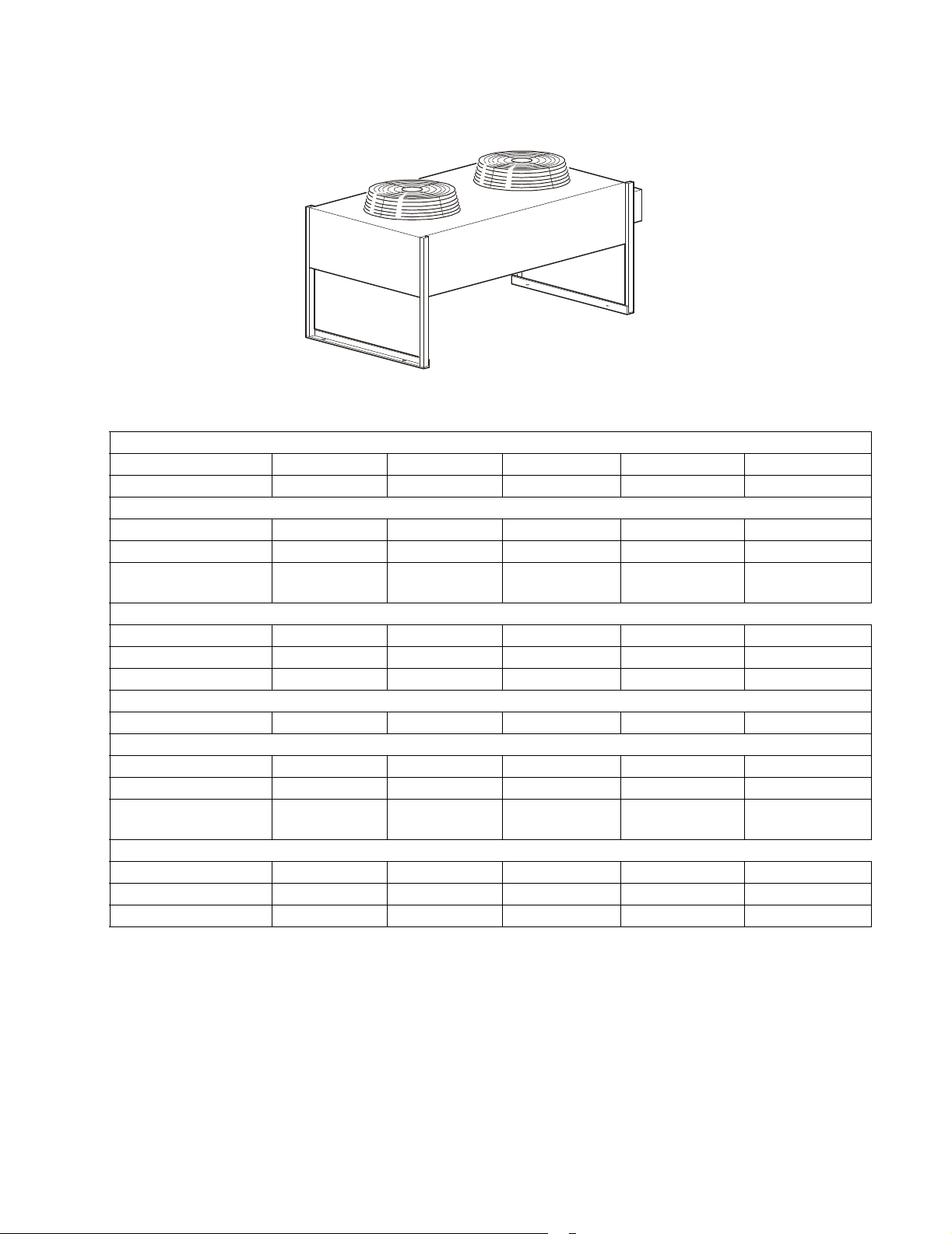

Condensers

na3012 a

60 Hz

Air cooled condensers are designed to reject heat from refrigerant based cooling equipment and are designed to

be installed outdoors. The condensers are self-contained in a lighweight aluminum cabinet designed for

mounting to a horizontal surface. The cabinet houses condenser coils and fan assemblies. Each condenser coil

is a copper turb, aluminum finned coil.

The capacity of the condenser is based on the rated capacity of the coil. In the case of dual circuit units, the

model number is based on the combined capacity of both coils. The coil is a closed-loop refrigerant condensing

heat exchanger in which refrigerant is continuously circulated by the pressure differential created by a

compressor.

The compressor increases refrigerant pressure to a level sufficiently high for it to be cooled and condensed into

liquid by the effect of ambient air being drawn over the condenser coil. The fans have corrosion resistant,

multi-blade impellers designed for high aerodynamic efficiency which results in lower power consumption,

lower noise levels and longer life. Each fan utilizes a direct driven motor with maintenance free bearings. The

fan motors are internally protected from overload. Fans have finger guard grilles to protect operators from

injury and keep large tools or other objects from falling into the fan.

Electrical controls are in a weather proof enclosure and isolated from the rest of the equipment. The electrical

box has a removable front access panel which is safety interlocked with the service disconnect switch,

preventing the panel from being removed when the switch is in the ON position. The switch must be turned off

to gain access to the electrical components.

11InRoom Precision AC Tech Data Manual

Page 16

InRoom Standard Condensers - 60 Hz

InRoom Remote Outdoor Condenser Data, 95°F ambient, 120°F condensation - R407C

InRoom Cabinet Size 1 2 3 4 5

Total Heat Rejection

(THR) BTU/h

CFM 8,394 19,325 18,609 17,604 27,963

Fan Diameter - in 19.69 24.80 24.80 24.80 24.80

Voltage Options

208-230/3/60 ACCD76000 ACCD76004 ACCD76008 ACCD76012 ACCD76016

Number of Fans 2 2 2 2 3

Fan RPM (Qty) 1490 1585(1), 1500(1) 1585(1), 1500(1) 1585(1), 1500(1) 1585(2), 1500(1)

Motor HP (Qty) 1.23 Hp(2) 3.58(1), 3.85(1) 3.58(1), 3.85(1) 3.58(1), 3.85(1) 3.58(2), 3.85(1)

Electrical Data

FLA 8.6 19.7 19.7 19.7 29.1

MCA 9.8 22.1 22.1 22.1 31.5

MFS 15 30 30 30 40

460-480/3/60 ACCD76010 ACCD76005 ACCD76009 ACCD76013 ACCD76017

Number of Fans 2 2 2 2 3

Fan RPM (Qty) 1450(1), 1570(1)1650(1), 1500(1) 1650(1), 1500(1) 1650(1), 1500(1) 1650(2), 1500(1)

Motor HP (Qty) 1.34(1), 1.64(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(2), 3.85(1)

Electrical Data

FLA 3.9 9.5 9.5 9.5 14.57

MCA 4.3 10.7 10.7 10.7 15.85

MFS 15 15 15 15 20

575-600/3/60 ACCD76022 ACCD76023 ACCD76024 ACCD76025 ACCD76026

Number of Fans 2 2 2 2 3

Fan RPM (Qty) 1450(1), 1570(1)1650(1), 1500(1) 1650(1), 1500(1) 1650(1), 1500(1) 1650(2), 1500(1)

Motor HP (Qty) 1.34(1), 1.64(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(2), 3.85(1)

Electrical Data

FLA 3.4 8.0 8.0 8.0 12.3

MCA 37 9.0 9.0 9.0 13.4

MFS 15.0 15.0 15.0 15.0 15.0

Refrigerant Connections*

Hot Gas Line - in 1 1/8 OD 1 1/8 OD 1 3/8 OD 1 3/8 OD 1 5/8 OD

Liquid Line - in 7/8 OD 7/8 OD 1 1/8 OD 1 1/8 OD 1 3/8 OD

Physical Data**

Dimensions -HxWxD in 35.5x32.75x76 48x108.5x48.25 48x108.5x48.25 48x108.5x48.25 48x155.5x48.25

Approximate Weight - lb. 240 455 495 555 835

96.219 165.496 225.435 279.262 380.436

* Condenser connections may not represent actual line sizing.

** Dimensions are overall. Electrical enclosure and fan guard are included. Actual fan guard height is 4 in.

Actual electrical enclosure depth is 6.5 in.

InRoom Precision AC Tech Data Manual12

Page 17

InRoom Low Temperature (-30ºF) Condensers - 60 Hz

InRoom Remote Outdoor Condenser Data, 95°F ambient, 120°F condensation - R407C

InRoom Cabinet Size 1 2 3 4 5

Total Heat Rejection

(THR) BTU/h

CFM 8,394 19,325 18,609 17,604 27,963

Fan Diameter - in 19.69 24.80 24.80 24.80 24.80

Voltage Options

208-230/3/60 ACCD76032 ACCD76033 ACCD76034 ACCD76035 ACCD76036

Number of Fans 2 2 2 2 3

Fan RPM (Qty) 1490 1585(1), 1500(1) 1585(1), 1500(1) 1585(1), 1500(1) 1585(2), 1500(1)

Motor HP (Qty) 1.23(2) 3.58(1), 3.85(1) 3.58(1), 3.85(1) 3.58(1), 3.85(1) 3.58(2), 3.85(1)

Electrical Data

FLA 8.6 19.7 19.7 19.7 29.1

MCA 9.8 22.1 22.1 22.1 31.5

MFS 15 30 30 30 40

460-480/3/60 ACCD76037 ACCD76038 ACCD76039 ACCD76040 ACCD76041

Number of Fans 2 2 2 2 3

Fan RPM (Qty) 1450(1), 1570(1)1650(1), 1500(1) 1650(1), 1500(1) 1650(1), 1500(1) 1650(2), 1500(1)

Motor HP (Qty) 1.34(1), 1.64(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(2), 3.85(1)

Electrical Data

FLA 3.9 9.5 9.5 9.5 14.57

MCA 4.3 10.7 10.7 10.7 15.85

MFS 15 15 15 15 20

575-600/3/60 ACCD76042 ACCD76043 ACCD76044 ACCD76045 ACCD76046

Number of Fans 2 2 2 2 3

Fan RPM (Qty) 1450(1), 1570(1)1650(1), 1500(1) 1650(1), 1500(1) 1650(1), 1500(1) 1650(2), 1500(1)

Motor HP (Qty) 1.34(1), 1.64(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(2), 3.85(1)

Electrical Data

FLA 3.7 8.3 8.3 8.3 12.8

MCA 4.0 9.3 9.3 9.3 13.9

MFS 15.0 15.0 15.0 15.0 15.0

Low Ambient Kit ACCD76106 ACCD76107 ACCD76109(2) ACCD76106(2) ACCD76107(2)

Refrigerant Connections*

Hot Gas Line - in 1 1/8 OD 1 1/8 OD 1 3/8 OD 1 3/8 OD 1 5/8 OD

Liquid Line - in 7/8 OD 7/8 OD 1 1/8 OD 1 1/8 OD 1 3/8 OD

Physical Data**

Dimensions -HxWxD in 35.5x32.75x76 48x108.5x48.25 48x108.5x48.25 48x108.5x48.25 48x155.5x48.25

Approximate Weight - lb. 240 455 495 555 835 each

96.219 165.496 225.435 279.262 380.436

* Condenser connections may not represent actual line sizing.

** Dimensions are overall. Electrical enclosure and fan guard are included. Actual fan guard height is 4 in.

Actual electrical enclosure depth is 6.5 in.

13InRoom Precision AC Tech Data Manual

Page 18

InRoom High Temperature Condensers - 60 Hz

InRoom Remote Outdoor Condenser Data, 105°F ambient, 125°F condensation - R407C

InRoom Cabinet Size 1 2 3 4 5

Total Heat Rejection

(THR) BTU/h

CFM 19,325 17,604 27,791 25,227 27,791 (2)

Fan Diameter - in 25.60 25.60 25.60 25.60 25.60

Voltage Options

208-230/3/60 ACCD76004 ACCD76006 ACCD76016 ACCD76014 ACCD76020(2)

Number of Fans 2 2 3 3 3

Fan RPM (Qty) 1585(1), 1500(1) 1585(1), 1500(1) 1585(2), 1500(1) 1585(1), 1350(1) 1585(2), 1500(1)

Motor HP (Qty) 3.58(1), 3.85(1) 3.58(1), 3.85(1) 3.58(2), 3.85(1) 3.58(2), 3.75(1) 3.58(2), 3.75(1)

Electrical Data

FLA 19.7 19.7 29.1 29.1 29.1

MCA 22.1 22.1 31.5 31.5 31.5

MFS 30 30 40 40 40

460-480/3/60 ACCD76005 ACCD76007 ACCD76017 ACCD76015 ACCD76021(2)

Number of Fans 2 2 3 3 3

Fan RPM (Qty) 1650(1), 1500(1) 1650(1), 1500(1) 1650(2), 1500(1) 1650(2), 1350(1) 1650(2), 1500(1)

Motor HP (Qty) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(2), 3.85(1) 3.90(2), 3.75(1) 3.90(2), 3.85(1)

Electrical Data

FLA 9.5 9.5 14.57 14.57 14.57

MCA 10.7 10.7 15.85 15.85 15.85

MFS 15 15 20 20 20

575-600/3/60 ACCD76027 ACCD76028 ACCD76029 ACCD76030 ACCD76031(2)

Number of Fans 2 2 3 3 3

Fan RPM (Qty) 1650(1), 1500(1) 1650(1), 1500(1) 1650(2), 1500(1) 1650(2), 1350(1) 1650(2), 1500(1)

Motor HP (Qty) 3.90(1), 3.85(1) 3.90(1), 3.85(1) 3.90(2), 3.85(1) 3.90(2), 3.75(1) 3.90(2), 3.85(1)

Electrical Data

FLA 8.0 8.0 12.3 12.3 12.3 (2)

MCA 9.0 9.0 13.4 13.4 13.4 (2)

MFS 15.0 15.0 15.0 15.0 15.0

Refrigerant Connections*

Hot Gas Line - in 1 1/8 OD 1 5/8 OD 1 5/8 OD 1 5/8 OD 2 1/8 OD

Liquid Line - in 7/8 OD 1 3/8 OD 1 3/8 OD 1 3/8 OD 2 1/8 OD

Physical Data**

Dimensions -HxWxD in 48x108.5x48.25 48x108.5x48.25 48x155.5x48.25 48x155.5x48.25 48x155.5x48.25

Approximate Weight - lb. 455 555 835 1000 835 (2)

154,105 247,501 331,845 448,600 331,845 (2)

* Condenser connections may not represent actual line sizing.

** Dimensions are overall. Electrical enclosure and fan guard are included. Actual fan guard height is 4 in.

Actual electrical enclosure depth is 6.5 in.

InRoom Precision AC Tech Data Manual14

Page 19

InRoom Condensers - 50 Hz

50 Hz

na2856a

InRoom Remote Outdoor Condenser Data, 97°F ambient, 120°F condensation - R407C

InRoom Cabinet Size 1 2 3 4 5

Condenser Model (Qty) ACCD76002 ACCD76003 ACCD76002 (2) ACCD76003 (2) ACCD76011(2)

Voltage 230/1/50 230/1/50 230/1/50 230/1/50 230/1/50

Number of Fans 2 2 3 3 3

Airflow m

Motor kW (HP) -

Refrigerant Connections*

Hot Gas Line - in 7/8 OD 7/8 OD 7/8 OD 1 3/8 OD 7/8 OD

Liquid Line - in 7/8 OD 7/8 OD 7/8 OD 7/8 OD 7/8 OD

Weight - kg (lb) 72 (158) 81 (178) 2 x 72 (2 x 158) 2 x 81 (2 x 178) 2 x 144 (2 x 317)

InRoom Remote Outdoor Condenser Data, 115°F ambient, 131°F condensation - R407C

Condenser Model (Qty) ACCD76003 ACCD76011 ACCD76001 (2) ACCD76011 (2) ACCD76019(2)

Voltage 230/1/50 230/1/50 230/1/50 230/1/50 230/1/50

Number of Fans 2 2 3 3 3

Airflow m

Motor kW (HP) -

Refrigerant Connections*

Hot Gas Line - in 7/8 OD 7/8 OD 7/8 OD 7/8 OD 1 3/8 OD

Liquid Line - in 7/8 OD 7/8 OD 7/8 OD 7/8 OD 7/8 OD

Weight - kg (lb) 81 (178) 144 (317) 2 x 81 (2 x 178) 2 x 144 (2 x 317) 2 x 200 (2 x 440)

3

/h (cfm) 13600 (8024) 13000 (7670) 13600 (8024) each 13000 (7670) each 16800 (9912) each

2 x 0.69

(2 x 0.92)

3

/h (cfm) 13000 (7670) 16800 (9912) 13000 (7670) each 16800 (9912) each 24000 (14160) each

2 x 0.69

(2 x 0.92)

2 x 0.69

(2 x 0.92)

3 x 0.69

(3 x 0.92)

2 x 0.69

(2 x 0.92)

2 x 0.69

(2 x 0.92)

2 x 0.69

(2 x 0.92)

2 x 0.69

(2 x 0.92)

3 x 0.69

(3 x 0.92)

3 x 0.62

(3 x 0.83)

* Condenser connections may not represent actual line sizing.

15InRoom Precision AC Tech Data Manual

Page 20

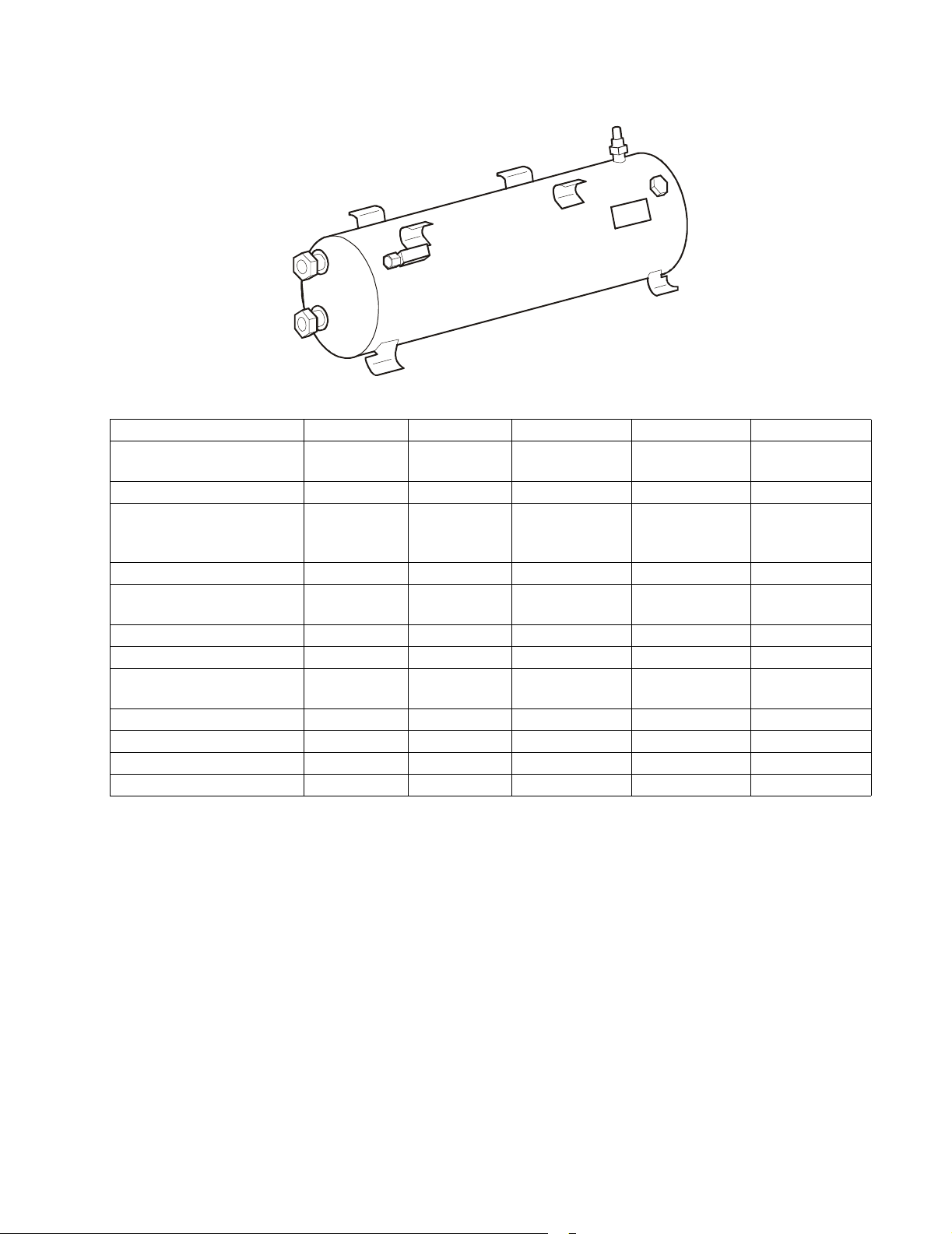

Receivers

na2892a

A B

S (Safety)

P (Refrigerant Inlet)

Q (Refrigerant Outlet)

60 Hz

Conformance. Each receiver conforms to UL, CSA or ASME requirements for 450 psi maximum

working pressure. Models with an internal diameter under six inches are UL listed. All larger models are

made according to ASME code and labeled appropriately.

Pumpdown and refrigerant charge. All pumpdowns are calculated at 80% capacity of liquid.

Approximately 10% of pumpdown capacity is required to operate the receiver properly.

Pumpdown = (overall length – length correction) x (pumpdown per inch)

Overall length = (pumpdown required / pumpdown per inch) = (length correction)

H

D

InRoom Cabinet Size 1 2 3 4 5

60 Hz Air-Cooled

Condenser Model

60 Hz Receiver Model (Qty) ACAC76106 ACAC76107 ACAC76109 (2) ACAC76106 (2) ACAC76107 (2)

Pumpdown capacities for R407C kg (lb) *

Length correction mm (in) 45.7 (1.8) 58.4 (2.3) 45.7 (1.8) 45.7 (1.8) 66 (2.6)

End to weld mm (in) 79.4 (3 1/8) 114.3 (4 1/2) 79.4 (3 1/8) 79.4 (3 1/8) 139.7 (5 1/2)

D (OD) mm (in) 219 (8 5/8) 273 (10 3/4) 219 (8 5/8) 219 (8 5/8) 324 (12 3/4)

H mm (in) 406.4 (16) 457.2 (18) 304.8 (12) 406.4 (16) 457.2 (18)

A mm (in) 127 (5) 152.4 (6) 127 (5) 127 (5) 168.2 (6 5/8)

B mm (in) 279.4 (11) 292.1 (11 1/2) 177.8 (7) 279.4 (11) 288.8 (11 3/8)

P (ID) mm (in) 15.9 (5/8) 28.4 (1 1/8) 15.9 (5/8) 15.9 (5/8) 28.4 (1 1/8)

Q (ID) mm (in) 15.9 (5/8) 22.2 (7/8) 15.9 (5/8) 15.9 (5/8) 28.4 (1 1/8)

S (FPT) mm (in) 9.5 (3/8) 22.2 (7/8) 9.5 (3/8) 9.5 (3/8) 12.7 (1/2)

Shipping Weight kg (lb) 15.87 (35) 27.2 (60) 13.15 (29) each 15.87 (35) each 36.28 (80) each

Receiver Heater

Watts 125 125 200 125 (2) 125 (2)

Heater Width - mm (in) 25 (1) 25 (1) 25 (1) 25 (1) 25 (1)

Heater Length - mm (in) 635 (25) 635 (25) 1015 (40) 635 (25) 635 (25)

Lead Length - mm (in) ** 305 (12) 305 (12) 305 (12) 305 (12) 305 (12)

Thermostat Setting 60/75 60/75 60/75 60/75 60/75

* All pumpdowns are calculated at 80% of receiver volume.

** 12 inches, UL 1180, Teflon® silicon rubber wire, round elements, rated @ 5 Watts per square inch

ACCD76032

ACCD76037

ACCD76042

11.79 (26) 19.58 (44) 8.1 (18) each 11.79 (26) each 27.7 (61) each

ACCD76033

ACCD76038

ACCD76043

ACCD76034

ACCD76039

ACCD76044

ACCD76035

ACCD76040

ACCD76045

ACCD76036

ACCD76041

ACCD76046

InRoom Precision AC Tech Data Manual16

Page 21

InRoom Receivers - 50 Hz

50 Hz

InRoom Cabinet Size 1 2 3 4 5

50 Hz Air-Cooled

Condenser Model

50 Hz Receiver Model (Qty) ACAC76101 ACAC76102 ACAC76103 (2) ACAC76104 (2) ACAC76105 (2)

Max Refrigerant Charge 90%

at 20

°C (68°F)

R-407C kg (lb) *

Connection inlet - mm (in) 22 (7/8) 22 (7/8) 22 (7/8) 22 (7/8) 22 (7/8)

Connection thread/flange

Connection outlet - mm (in) 22 (7/8) 22 (7/8) 22 (7/8) 22 (7/8) 22 (7/8)

Gauge 7/16 (20 UNF) 7/16 (20 UNF) 7/16 (20 UNF) 7/16 (20 UNF) 7/16 (20 UNF)

Pressure relief valve

connection

Height - mm (in) 287 (11.3) 287 (11.3) 287 (11.3) each 287 (11.3) each 287 (11.3) each

Depth - mm (in) 276 (10.9) 276 (10.9) 276 (10.9) each 276 (10.9) each 276 (10.9) each

Width - mm (in) 824 (32.4) 824 (32.4) 824 (32.4) each 824 (32.4) each 824 (32.4) each

Weight - kg (lb) 23.6 (52) 23.6 (52) 23.6 (52) each 23.6 (52) each 23.6 (52)each

ACCD76002 ACCD76003 ACCD76002 (2) ACCD76003 (2) ACCD76011 (2)

24.0 (53) 24.0 (53) 24.0 (53) each 24.0 (53) each 24.0 (53) each

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

1 1/4 in

(12 UNF)

17InRoom Precision AC Tech Data Manual

Page 22

Display Interface

na277 3a

• External Alarm

• Pump Failure

• Drycooler Failure

• Water Detector

• Room Temp To o High

• Room Humidity Too High

• Supply Temp Too High

• Supply Humidity Too High

• Room Temp To o Low

• Room Humidity Too Low

• Supply Te mp Too Lo w

• Supply Humidity Too Low

• Water Temp Too High

• Water Temp Too Low

• Fire/Smoke Detector

• Sensor Failure

• Sensor Broken

• Local Stop

• Compressor Low Pressure

• Compressor Failure

• E-heating Failure

• Humidifier Failure

• Humidifier 5uS

• Humidifier 20uS

• Fan Error

• Filter Clocked

The display interface is standard on

each system. The display interface

provides precision control for the

demanding requirements of these

environments:

• Data centers

• Control rooms

• Clean rooms

• Switch rooms

• UPS rooms

The easy-to-use display allows the operator to select options from the display interface to control and monitor

the InRoom precision air conditioning system.

Logging

The display interface displays the most recent alarms. Each alarm log contains a time/date stamp as well as

operating conditions at the time of occurrence. The display interface also displays run time, in hours, for major

components (compressors, heaters, humidifier, fans).

Control Type

The display interface utilizes proportional and integral derivative (PID), a time-proven precision

environmental control method. This allows for custom tuning of control variables to achieve the desired

system response.

Functions

• Audible and Visual Alarms

• Sensor Status (Temperature, Humidity, and Pressure)

• Component State (On/Off, %)

• Component Runtimes

• Event Logging

• Configuration and Alarm Settings

• Password Protection

Open Architecture

The InRoom precision air conditioning system is open for integration with all building management systems.

The display interface on the system supports Modbus RTU RS485.

Alarms

InRoom Precision AC Tech Data Manual18

Page 23

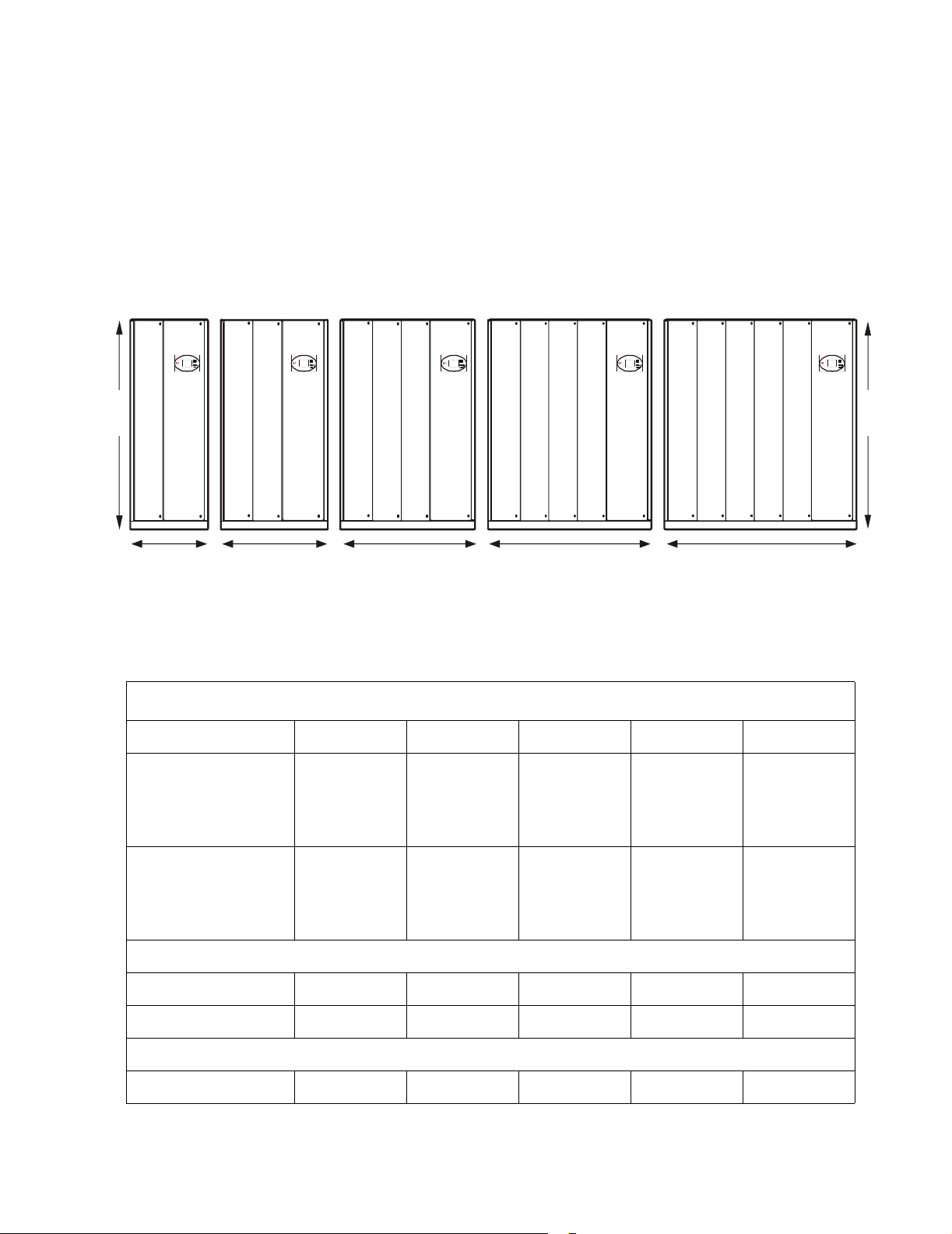

InRoom Model Sizes

1980

1000

(77.95)

(

)

(

)

1400

(

)

1750

(

)

2150

(

)

2550

(100.39)

12 3 4 5

Different variations of the InRoom product range are defined by the airflow direction, the number of

refrigerant circuits, and the type of cooling system. There are five cabinet sizes. The front service access for all

cabinet sizes of the InRoom Precision Air Conditioner is 1 m (39 in).

The InRoom Fluid Cooled (Glycol) system with Economizer Coil differs from the other versions by having a

larger cabinet size, not a larger capacity. There are no Fluid Cooled (Glycol ) systems with Economizer Coils in

Cabinet Size 1.

1980

77.95

na2835a

39.37

55.11

68.90

84.65

*Dimensions are in mm (in).

Depth of all models is 890 mm (35 in).

InRoom Direct Expansion Model Sizes

Cabinet Size12345

PA2 11

1 refrigerant circuit

PG211

PAC W2 11

PGCW211

2 refrigerant circuits

PA3 11

PG311

PAC W3 11

PGCW311

PA4 52

PG452

PAC W4 52

PGCW452

PA6 12

PG612

PAC W6 12

PGCW612

PA8 62

PG862

PAC W8 62

PGCW862

InRoom Fluid Cooled (Glycol) with Economizer Model Sizes

1 refrigerant circuit PGE211 PGE311

2 refrigerant circuits PGE452 PGE612

InRoom Chilled Water Model Sizes

PCW400 PCW660 PCW900 PCW1100 PCW1500

19InRoom Precision AC Tech Data Manual

Page 24

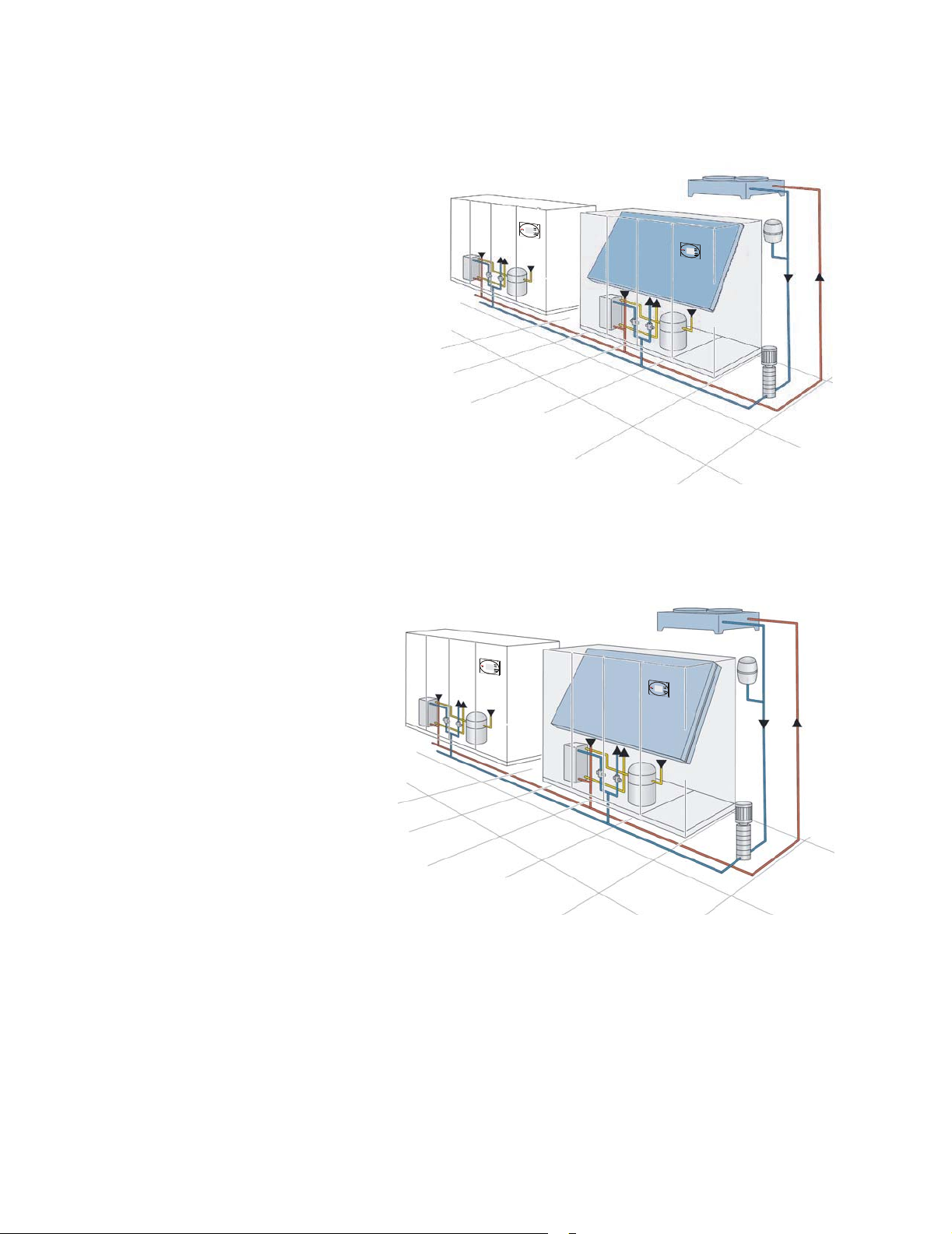

InRoom Cooling Unit Configurations

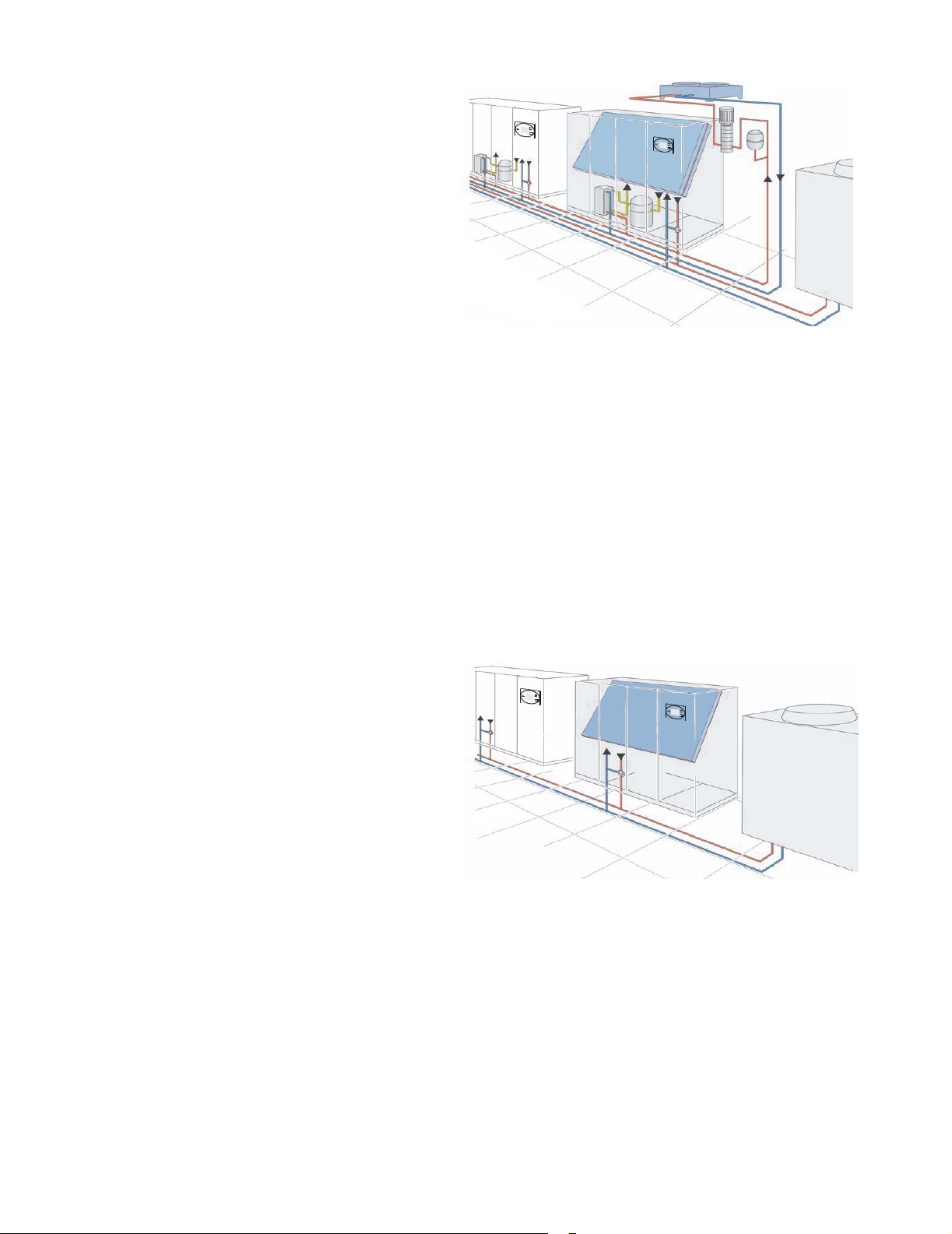

Fluid Cooled (Glycol) System

na2836a

Fluid Cooled (Glycol) System with Economizer

Fluid Cooled (Glycol)

InRoom Fluid Cooled (Glycol) systems are

completely charged and factory tested in a sealed

system for reliability. In mid to low ambient

climates, an economizer coil can be used to

increase efficiency and extend compressor life.

Economizer operation greatly reduces the energy

consumption of the system. Water regulating

valves control head pressure.

• System is used with a fluid cooler.

• Factory-tested as a sealed system.

• Eliminates the need for field refrigerant

piping.

• No requirement for water treatment.

• Economizer option provides high

efficiency.

• Low maintenance.

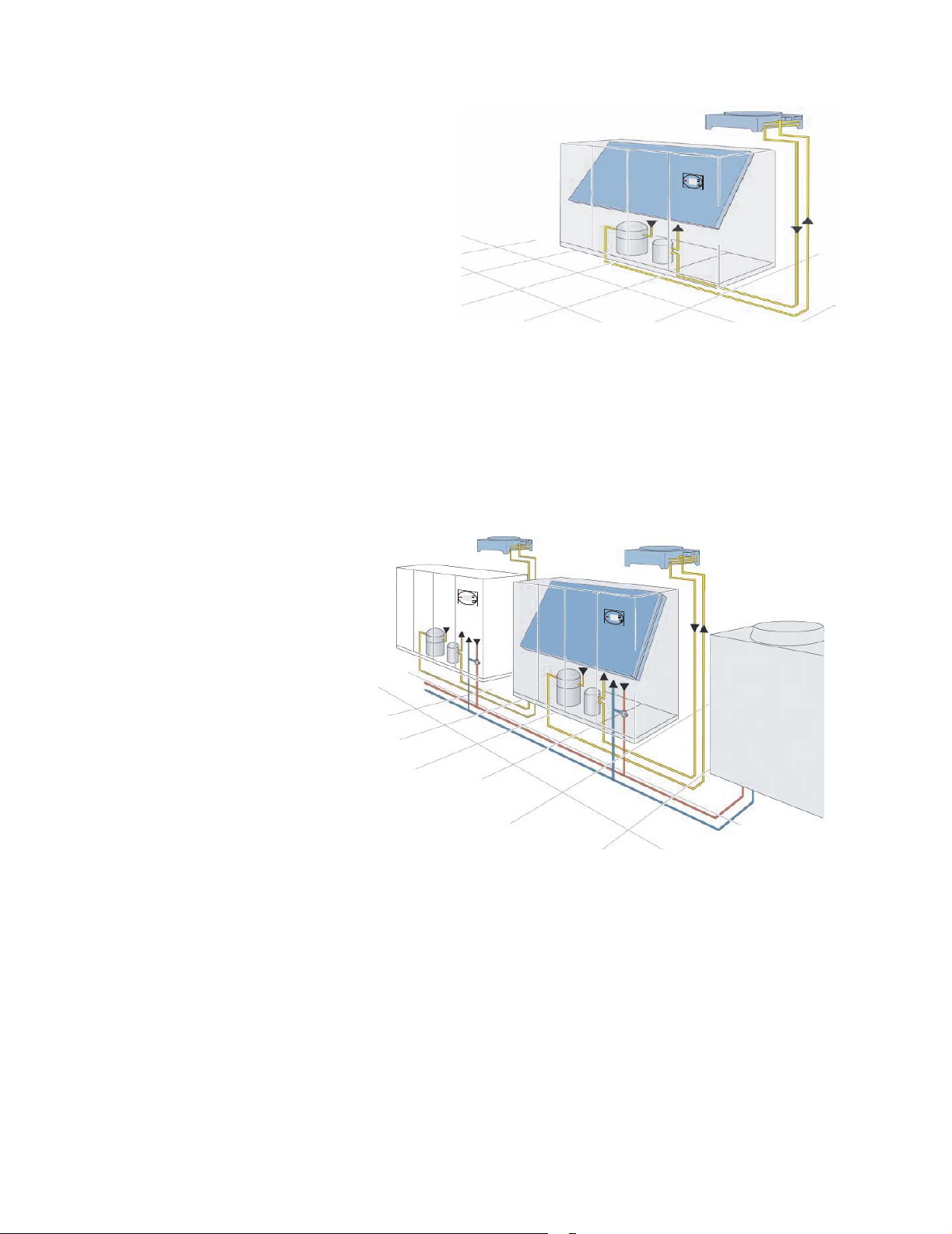

na2837a

The InRoom Fluid Cooled (Glycol)

System with Economizer is configured

with both the glycol factory sealed system

and an Economizer coil. During cold

ambient conditions, the compressorized

system will shut down and utilize the cold

outdoor air to cool the glycol system,

rerouting it from the heat exchanger to the

Economizer coil for efficient operation.

InRoom Precision AC Tech Data Manual20

Page 25

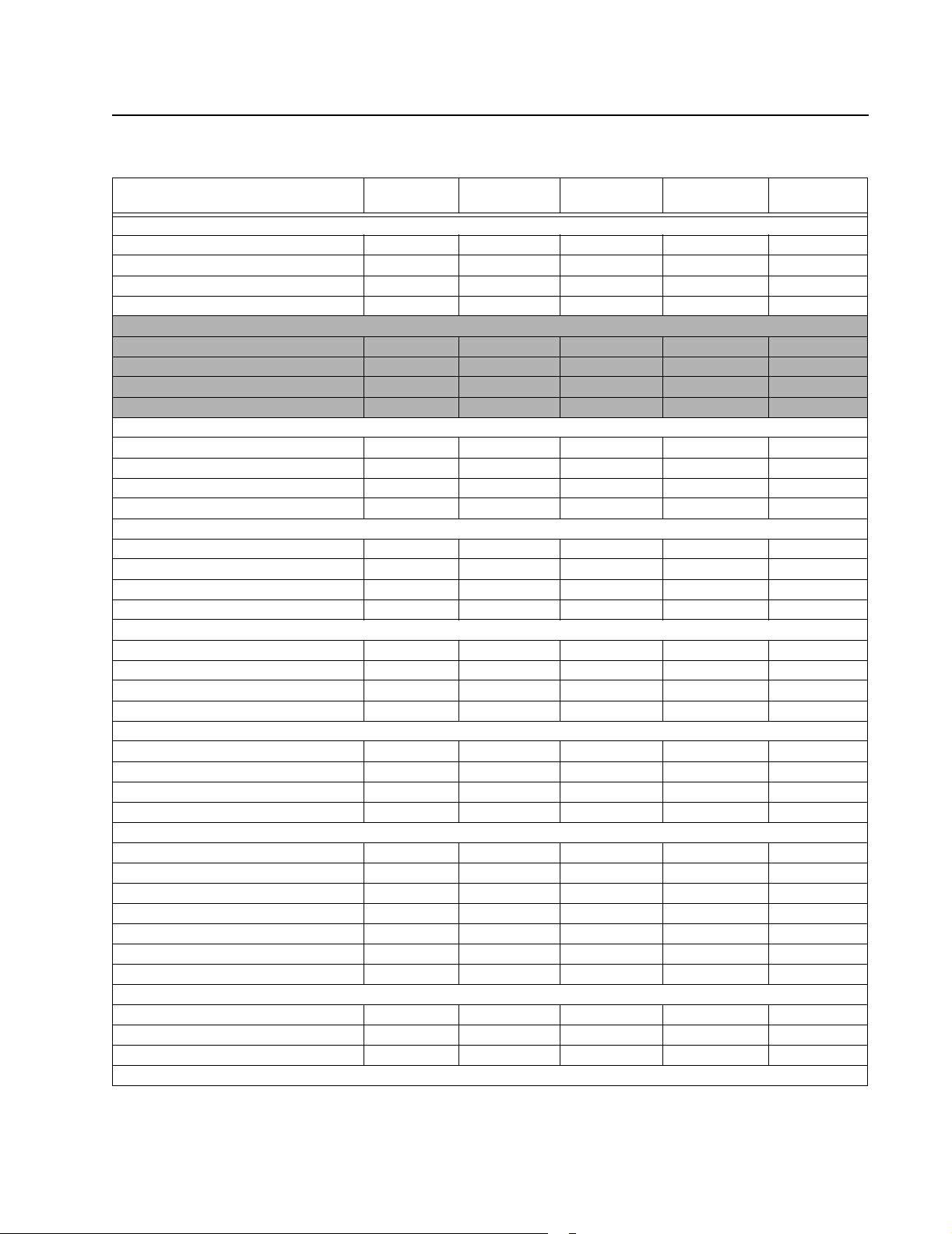

The InRoom Fluid Cooled (Glycol) System

na2843a

Fluid Cooled (Glycol) System with

Chilled Water Cooling System

na284 4a

Chilled Water Cooling System

with Chilled Water System is a combination of a

factory sealed glycol system and a chilled water

system and contains two separate cooling coils.

The controller microprocessor manages the

systems to allow the glycol system to operate as

standby to the chilled water system or vice

versa, giving the added security of back-up

cooling to the computer room.

Chilled Water

InRoom Chilled Water systems are available in a

packaged fan-coil design. Room air is

recirculated through the cooling coil, which

transfers the heat load directly into the chilled

water ring main. Water flow rate is regulated by

a 2- or 3-way valve controlled by the controller

microprocessor. Cooling towers are used as a

source of heat rejection and can be used to serve

multiple indoor units. Towers utilizing outdoor

air require water treatment.

• The system is used with a cooling tower or

other source of water.

• Factory sealed and tested system.

• The need for field refrigerant piping is

eliminated.

21InRoom Precision AC Tech Data Manual

Page 26

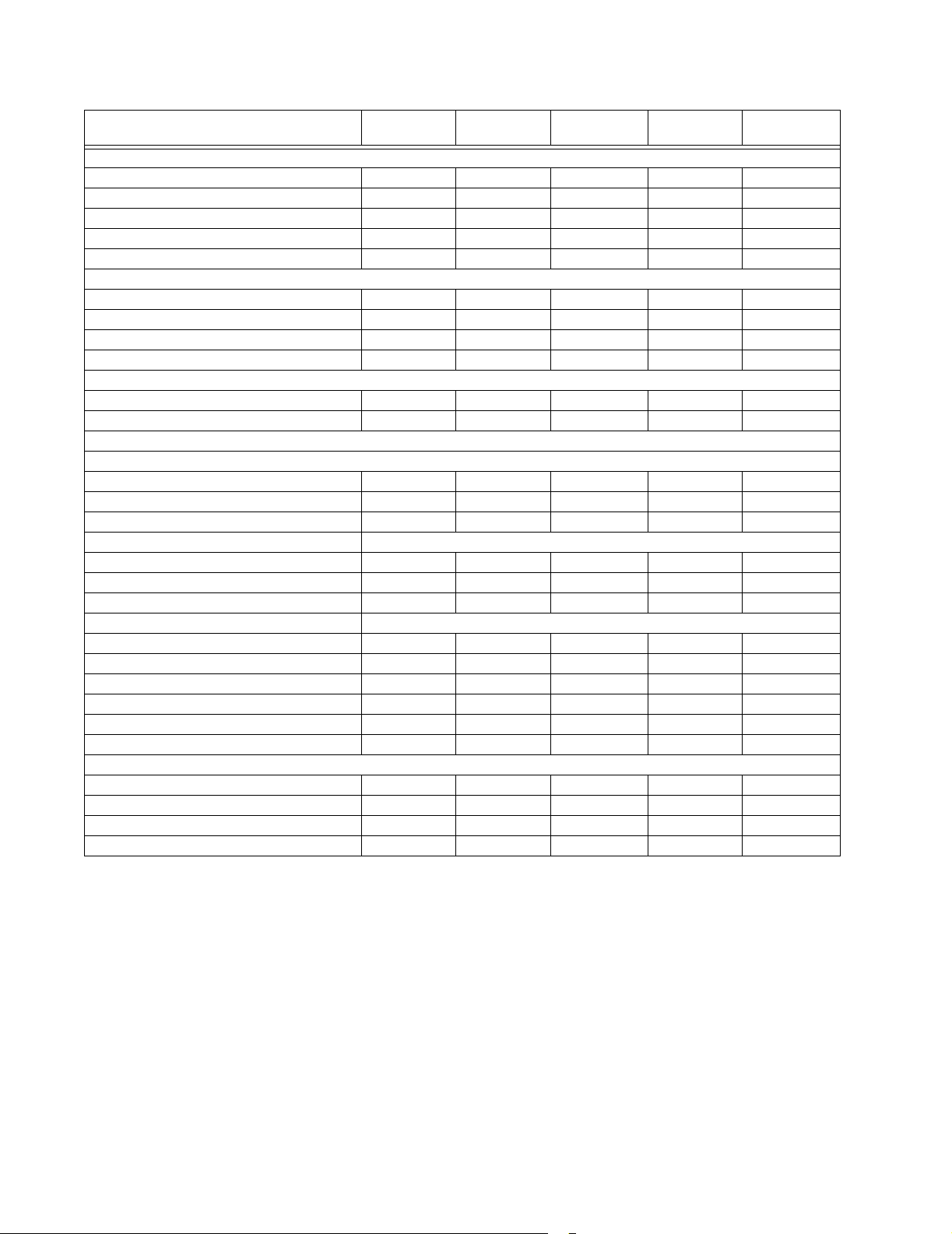

Air Cooled (DX)

na2845a

Air Cooled System

na2846a

MultiCool - Air Cooled System with

Chilled Water Cooling System

Air cooled systems are not pre-charged from the

factory and require field refrigerant piping. Each

installation requires an engineered piping solution.

APC strongly recommends installation by a highly

qualified refrigeration contractor to avoid improper

elevation and long piping runs. The Air Cooled

system uses refrigerant as the heat transfer medium.

Room air recirculates through the InRoom unit

which houses the evaporator coil, scroll compressor,

and refrigeration system. A remotely mounted aircooled condenser is connected to the unit. The

sealed refrigeration circuit will absorb the room heat

load and reject it to the outside atmosphere.

• System used with a remote air cooled condenser

• Field installed refrigerant piping is required

• Low maintenance

The MultiCool System is a combination

of the Air Cooled System and the

Chilled Water System and contains two

separate cooling coils. The controller

microprocessor manages the MultiCool

System to allow the air cooled by the Air

Cooled system to operate as a standby

system to the Chilled Water (CW)

system or vice versa, giving the added

security of back-up cooling to the

computer room.

InRoom Precision AC Tech Data Manual22

Page 27

60Hz Performance Specifications

Chilled Water (CW) – 60Hz

Chilled Water PCW400

Cabinet Size 1

26.7°C DB, 19.4°C WB (80°F DB, 67°F WB) 50% RH

Total - kW (BTU/hr) 53.6 (182,800) 86.1 (293,800) 120.1 (409,800) 153.4 (553,400) 197.8 (675,000)

Sensible - kW (BTU/hr) 35.8 (128,999) 58.4 (206,099) 82.7 (288,999) 102.4 (356,199) 134.3 (465,099)

Flow Rate - L/m (GPM) 139.3 (36.8) 229.4 (60.6) 324.0 (85.6) 410.3 (108.4) 534.1 (141.0)

Total Pressure Drop Water Side - Kpa (ft) 91.8 (30.7) 129.2 (43.2) 112.1 (37.5) 124.7 (41.7) 189.0 (63.2)

23.9°C DB, 16.9°C WB (75°F DB, 62.5°F WB) 50% RH

Total - kW (BTU/hr) 29.4 (100,300) 54.5 (186,000) 65.5 (223,500) 82.5 (281,500) 104.8 (357,600)

Sensible - kW (BTU/hr) * 25.5 (93,799) 45.5 (162,099) 59.1 (208,499) 73.9 (258,999) 95.3 (331,999)

Flow Rate - L/m (GPM) 80.3 (21.2) 147.6 (39.0) 182.8 (48.3) 227.1 (60.0) 293.4 (77.5)

Total Pressure Drop Water Side - Kpa (ft) 29.6 (9.9) 62.8 (21.0) 38.9 (13.0) 43.4 (14.5) 59.8 (20.0)

23.9°C DB, 16.1°C WB (75°F DB, 61°F WB) 45% RH

Total - kW (BTU/hr) 29.9 (102,000) 49.8 (169,900) 66.3 (226,200) 82.2 (280,500) 105.8 (361,000)

Sensible - kW (BTU/hr) 27.9 (101,999) 47.8 (169,899) 64.3 (226,199) 80.2 (280,499) 103.8 (360,999)

Flow Rate - L/m (GPM) 81.4 (21.5) 135.5 (35.8) 185.1 (48.9) 226.4 (59.8) 296.0 (78.2)

Total Pressure Drop Water Side - Kpa (ft) 31.4 (10.5) 52.3 (17.5) 39.5 (13.2) 43.1 (14.54) 60.4 (20.2)

22.2°C DB, 15.5°C WB (72°F DB, 60°F WB) 50% RH

Total - kW (BTU/hr) 25.0 (85,300) 42.0 (143,300) 54.8 (187,000) 68.2 (232,700) 86.3 (294,500)

Sensible - kW (BTU/hr) 23.0 (85,299) 40.0 (143,299) 52.8 (186,999) 66.2 (232,699) 84.3 (294,499)

Flow Rate - L/m (GPM) 68.9 (18.2) 115.1 (30.4) 155.2 (41.0) 190.0 (50.2) 245.7 (64.9)

Total Pressure Drop Water Side - Kpa (ft) 22.4 (7.5) 39.8 (13.3) 28.4 (9.5) 31.1 (10.4) 42.5 (14.2)

22.2°C DB, 14.8°C WB (72°F DB, 58.6°F WB) 45% RH

Total - kW (BTU/hr) 25.0 (85,300) 42.0 (143,300) 54.8 (187,000) 68.2 (232,700) 86.3 (294,500)

Sensible - kW (BTU/hr) 23.0 (85,299) 40.0 (143,299) 52.8 (186,999) 66.2 (232,699) 84.3 (294,499)

Flow Rate - L/m (GPM) 68.9 (18.2) 115.1 (30.4) 155.2 (41.0) 190.0 (50.2) 245.7 (64.9)

Total Pressure Drop Water Side - Kpa (ft) 22.4 (7.5) 39.8 (13.3) 28.4 (9.5) 31.1 (10.4) 42.5 (14.2)

21.1°C DB, 14.0°C WB(70°F DB, 58.5°F WB) 50% RH

Total - kW (BTU/hr) 21.7 (74,000) 36.6 (124,900) 47.0 (160,400) 58.5 (199,600) 72.9 (248,700)

Sensible - kW (BTU/hr) 19.7 (73,999) 34.6 (124,899) 45.0 (160,399) 56.5 (199,599) 70.9 (248,699)

Flow Rate - L/m (GPM) 60.6 (16.0) 101.1 (26.7) 135.1 (35.7) 165.0 (43.6) 210.8 (55.7)

Total Pressure Drop Water Side - Kpa (ft) 16.7 (5.6) 32.6 (10.9) 23.0 (7.7) 25.7 (8.6) 31.7 (10.6)

21.1°C DB, 14.0°C WB(70°F DB, 57.2°F WB) 45% RH

Total - kW (BTU/hr) 21.7 (74,000) 36.6 (124,900) 47.0 (160,400) 58.5 (199,600) 72.9 (248,700)

Sensible - kW (BTU/hr) 19.7 (73,999) 34.6 (124,899) 45.0 (160,399) 56.5 (199,599) 70.9 (248,699)

Flow Rate - L/m (GPM) 60.6 (16.0) 101.1 (26.7) 135.1 (35.7) 165.0 (43.6) 210.8 (55.7)

Total Pressure Drop Water Side - Kpa (ft) 16.7 (5.6) 32.6 (10.9) 23.0 (7.7) 25.7 (8.6) 31.7 (10.6)

Valve Size - mm (in) 32 (1 1/4) 38.1 (1.5) 50 (2.0) 50 (2.0) 50 (2.0)

Temperature medium in - °C (°F) 7.2°C (45°F) 7.2°C (45°F) 7.2°C (45°F) 7.2°C (45°F) 7.2°C (45°F)

Temperature medium in - °C (°F) 12.8°C (55°F) 12.8°C (55°F) 12.8°C (55°F) 12.8°C (55°F) 12.8°C (55°F)

Chilled Water Coil

Face Area - m² (ft²) 1.09 (11.77) 1.66 (17.82) 1.53 (16.52) 1.94 (20.86) 2.31 (24.88)

Rows Deep 5 5 5 5 5

Face Velocity - m/min (ft/min) 130 (428) 132 (432) 112 (367) 102 (336) 114 (373)

* Nominal Rating Point

PCW660

Cabinet Size 2

PCW900

Cabinet Size 3

PCW1100

Cabinet Size 4

PCW1500

Cabinet Size 5

23InRoom Precision AC Tech Data Manual

Page 28

Chilled Water Continued PCW400

Cabinet Size 1

Fan Information

Number of Fans 1 1 2 2 3

Air Flow - M³/hr (CFM) 8495 (5,000) 12997 (7,650) 18995 (11,180) 22002 (12,950) 29495 (17,360)

External Static Pressure - Pa (in WC) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2)

Sound Power Level - dBA 72.1 75.2 71.0 74.4 73.10

Total Fan Power Consumption - kW (hp) 1.7 (2.3) 2.6 (3.5) 5.3 (7.1) 5.4 (7.2) 8.8 (11.8)

Connection Sizes

Upflow Chilled Water In/Out - mm (in) 35 (1 3/8) 42 (1 5/8) 54 (2 1/8) 70 (2 3/4) 70 (2 3/4)

Downflow Chilled Water In/Out - mm (in) 35 (1 3/8) 42 (1 5/8 54 (2 1/8) 54 (2 1/8) 54 (2 1/8)

Humidifier Supply Line - mm (in) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4)

Condensate Drain Line - mm OD (in ID) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4)

Humidification – Solid State Electrode, Canister

Flush Cycle Automatic Automatic Automatic Automatic Automatic

kg/hr (lb/hr) 8.0 (17.6) 8.0 (17.6) 15.0 (33.1) 15.0 (33.1 15.0 (33.1)

Electric Reheat – Equally Loaded Three (3) phase

Capacity - kW (BTU/hr) - Includes Motor Heat

460 V 12.0 (40982.4) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

230 V 9.0 (30736.8) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

Number of Stages 1 2 2 3 3

Downflow Filters - mm Quantities

836 x 546 x 92 G4 N/A N/A 3 3 3

836 x 393 x 92 G4 N/A 1 N/A 1 2

836 x 446 x 92 G4 2 2 N/A N/A N/A

Upflow Filters - mm Quantities

795 x 508 x 92 G4 N/A N/A 1 2 2

795 x 341 x 92 G4 1 1 N/A 1 1

795 x 333 x 92 G4 N/A 1 N/A N/A 1

795 x 365 x 92 G4 N/A N/A 1 1 1

795 x 516 x 92 G4 N/A N/A 1 N/A N/A

795 x 502 x 92 G4 1 1 N/A N/A N/A

Physical Data

Weight - kg (lb) 307 (677) 362 (798) 547 (1206) 568 (1252) 755 (1664)

Height - mm (in) 1980 (77.95) 1980 (77.95) 1980 (77.95) 1980 (77.95) 1980 (77.95)

Width - mm (in) 1000 (39.37) 1400 (55.12) 1750 (68.90) 2150 (84.65) 2550 (100.39)

Depth - mm (in) 890 (35) 890 (35) 890.0 (35) 890.0 (35) 890 (35)

PCW660

Cabinet Size 2

PCW900

Cabinet Size 3

PCW1100

Cabinet Size 4

PCW1500

Cabinet Size 5

InRoom Precision AC Tech Data Manual24

Page 29

Air Cooled (DX) System – 60Hz

Air Cooled PA211

Cabinet Size 1

26.7°C DB, 19.4°C WB (80°F DB, 67°F WB) 50% RH

Total - kW (BTU/hr) 19.8 (67,450) 29.9 (102,000) 44.2 (151,000) 55.2 (188,290) 84.9 (290,000)

Sensible - kW (BTU/hr) 19.8 (67,450) 29.9 (102,000) 41.3 (141,000) 55.2 (188,290) 75.4 (257,000)

23.9°C DB, 16.9°C WB (75°F DB, 62.5°F WB) 50% RH

Total - kW (BTU/hr) 18.1 (61,940) 27.6 (94,000) 40.5 (138,000) 50.8 (173,470) 78.8 (269,000)

Sensible - kW (BTU/hr) * 18.1 (61,940) 27.6 (94,000) 40.5 (138,000) 50.8 (173,470) 72.8 (249,000)

23.9°C DB, 16.1°C WB (75°F DB, 61°F WB) 45% RH

Total - kW (BTU/hr) 18.1 (61,940) 27.6 (94,000) 40.5 (138,000) 50.8 (173,470) 77.2 (264,000)

Sensible - kW (BTU/hr) 18.1 (61,940) 27.6 (94,000) 40.5 (138,000) 50.8 (173,470) 77.2 (264,000)

22.2°C DB, 15.5°C WB (72°F DB, 60°F WB) 50% RH

Total - kW (BTU/hr) 17.1 (58,330) 26.4 (90,000) 38.7 (132,000) 48.2 (164,635) 75.1 (256,000)

Sensible - kW (BTU/hr) 17.1 (58,330) 26.4 (90,000) 38.7 (132,000) 48.2 (164,635) 71.0 (242,000)

22.2°C DB, 14.8°C WB (72°F DB, 58.6°F WB) 45% RH

Total - kW (BTU/hr) 17.1 (58,330) 26.4 (90,000) 38.6 (132,000) 48.2 (164,635) 75.1 (256,000)

Sensible - kW (BTU/hr) 17.1 (58,330) 26.4 (90,000) 38.6 (132,000) 48.2 (164,635) 71.0 (242,000)

21.1°C DB, 14.0°C WB (70°F DB, 58.5°F WB) 50% RH

Total - kW (BTU/hr) 16.7 (57,095) 25.6 (87,000) 37.4 (128,000) 47.1 (160,740) 74.4 (253,840)

Sensible - kW (BTU/hr) 16.7 (57,095) 25.6 (87,000) 37.4 (128,000) 47.1 (160,740) 74.4 (253,840)

21.1°C DB, 14.0°C WB (70°F DB, 57.2°F WB) 45% RH

Total - kW (BTU/hr) 16.7 (57,095) 25.6 (87,000) 37.4 (128,000) 47.1 (160,740) 74.4 (253,840)

Sensible - kW (BTU/hr) 16.7 (57,095) 25.6 (87,000) 37.4 (128,000) 47.1 (160,740) 74.4 (253,840)

Condensing temperature for all above conditions: 52°C (125° F)

Refrigerant type for all models: R-407C

Refrigerant Charge per Circuit - kg (lbs) 2.8 (6.17) 3.9 (8.6) 4.4 (9.7) 3.9 (8.6) 4.6 (10.1)

Compressor Information – COP** (ARI*** Conditions): 7.2°C (45°F) Evaporating, 54°C (130°F) Condensing

Number of compressors 1 1 2 2 2

COP 3.0 3.0 3.0 3.0 3.1

Evaporator Coil

Face Area - m² (ft²) 0.77 (8.32) 1.17 (12.63) 1.46 (15.72) 1.86 (20.02) 2.22 (23.90)

Rows Deep 4 4 4 4 5

Face Velocity - m/min (ft/min) 125 (410) 104 (342) 117 (383) 130 (428) 141 (461)

* Nominal Rating Point

** Coefficient of Performance

*** Air Conditioning and Refrigeration Institute

PA311

Cabinet Size 2

PA452

Cabinet Size 3

PA612

Cabinet Size 4

PA862

Cabinet Size 5

25InRoom Precision AC Tech Data Manual

Page 30

Air Cooled (DX) Continued PA211

Cabinet Size 1

Fan Information

Number of Fans 1 1 2 2 3

Air Flow - M³/hr (CFM) 7493 (4,410) 10007 (5,890) 14000 (8,240) 20116 (11,890) 24007 (14,130)

External Static Pressure - Pa (in WC) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2)

Sound Power Level - dBA 75.40 79.30 77.40 83.20 81.50

Total Fan Power Consumption - kW (hp) 1.7 (2.3) 2.1 (2.8) 3.1 (4.2) 6.1 (8.2) 6.2 (8.3)

Connection Sizes

Number of DX Circuits 1 1 2 2 2

Liquid Line O.D. - mm (in) 12 (1/2) 16 (5/8) 16 (5/8) 16 (5/8) 16 (5/8)

Discharge Line O.D. - mm (in) 16 (5/8) 22 (7/8) 22 (7/8) 22 (5/8) 22 (5/8)

Humidifier Supply Line - mm (in) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4)

Condensate Drain Line - mm OD (in ID) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4)

Humidification – Solid State Electrode, Canister

Flush Cycle Automatic Automatic Automatic Automatic Automatic

kg/hr (lb/hr) 8.0 (17.6) 8.0 (17.6) 15.0 (33.1) 15.0 (33.1) 15.0 (33.1)

Electric Reheat – Equally Loaded Three (3) phase

Capacity - kW (BTU/hr) - Includes Motor Heat

460 V 12.0 (40982.4) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

230 V 9.0 (30736.8) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

Number of Stages 2 3 3 3 3

Downflow Filters - mm Quantities

1050 x 453 x 47 G4 2 2 1 1 1

1050 x 398 x 47 G4 N/A 1 3 4 5

Upflow Filters - mm Quantities

700 x 340 x 47 G4 1 1 N/A 1 1

700 x 332 x 47 G4 N/A 1 N/A N/A 1

700 x 502 x 47 G4 1 1 1 1 1

700 x 508 x 47 G4 N/A N/A 1 2 2

700 x 508 x 47 G4 N/A N/A 1 N/A N/A

Physical Data

Weight - kg (lb) 353 (778) 453 (999) 556 (1226) 680 (1499) 807 (1779)

Height - mm (in) 1980 (77.95) 1980 (77.95) 1980 (77.95) 1980 (77.95) 1980 (77.95)

Width - mm (in) 1000 (39.37) 1400 (55.11) 1750 (68.90) 2150 (84.65) 2550 (100.39)

Depth - mm (in) 890 (35) 890 (35) 890 (35) 890 (35) 890 (35)

PA311

Cabinet Size 2

PA452

Cabinet Size 3

PA612

Cabinet Size 4

PA862

Cabinet Size 5

InRoom Precision AC Tech Data Manual26

Page 31

MultiCool – Air Cooled (DX) with CW

– 60Hz

Operational Mode: Air Cooled (DX)

Net Cooling Capacity PACW211

Cabinet Size 1

26.7°C DB, 19.4°C WB (80°F DB, 67°F WB) 50% RH

Total - kW (BTU/hr) 19.2 (65,455) 29.7 (101,460) 43.7 (149,150) 54.5 (186,105) 83.9 (286,235)

Sensible - kW (BTU/hr) 19.2 (65,455) 29.7 (101,460) 40.8 (139,365) 54.5 (186,105) 74.4 (253,840)

23.9°C DB, 16.9°C WB (75°F DB, 62.5°F WB) 50% RH

Total - kW (BTU/hr) 17.8 (60,895) 27.6 (94,050) 40.0 (136,515) 50.3 (171,760) 77.8 (265,525)

Sensible - kW (BTU/hr) * 17.8 (60,895) 27.6 (94,050) 40.0 (136,515) 50.3 (171,760) 71.8 (245,100)

23.9°C DB, 16.1°C WB (75°F DB, 61°F WB) 45% RH

Total - kW (BTU/hr) 17.8 (60,895) 27.6 (94,050) 40.0 (136,515) 50.3 (171,760) 76.2 (260,015)

Sensible - kW (BTU/hr) 17.8 (61,895) 27.6 (94,050) 40.0 (136,515) 50.2 (171,475) 76.2 (260,015)

22.2°C DB, 15.5°C WB (72°F DB, 60°F WB) 50% RH

Total - kW (BTU/hr) 16.8 (57,380) 26.3 (89,775) 38.2 (130,340) 47.8 (163,020) 74.1 (252,890)

Sensible - kW (BTU/hr) 16.8 (57,380) 26.3 (89,775) 38.2 (130,340) 47.8 (163,020) 70.0 (238,825)

22.2°C DB, 14.8°C WB (72°F DB, 58.6°F WB) 45% RH

Total - kW (BTU/hr) 16.8 (57,380) 26.3 (89,775) 38.2 (130,340) 47.7 (163,020) 73.3 (250,230)

Sensible - kW (BTU/hr) 16.8 (57,380) 26.3 (89,775) 38.2 (130,340) 47.7 (163,020) 73.3 (250,230)

21.1°C DB, 14.0°C WB (70°F DB, 58.5°F WB) 50% RH

Total - kW (BTU/hr) 16.4 (56,050) 25.6 (87,485) 36.9 (126,065) 46.1 (157,225) 71.1 (242,820)

Sensible - kW (BTU/hr) 16.4 (56,050) 25.6 (87,485) 36.9 (126,065) 46.1 (157,225) 71.1 (242,820)

21.1°C DB, 14.0°C WB (70°F DB, 57.2°F WB) 45% RH

Total - kW (BTU/hr) 16.4 (56,050) 25.6 (87,485) 36.9 (126,065) 46.1 (157,225) 71.1 (242,820)

Sensible - kW (BTU/hr) 16.4 (56,050) 25.6 (87,485) 36.9 (126,065) 46.1 (157,225) 71.1 (242,820)

Condensing temperature for all above conditions: 52°C (125°F)

Refrigerant type for all models: R-407C

Refrigerant Charge per Circuit - kg (lbs) 2.8 (6.17) 3.9 (8.6) 4.4 (9.7) 3.9 (8.6) 4.6 (10.1)

Compressor Information – COP** (ARI*** Conditions): 7.2°C (45°F) Evaporating, 54°C (130°F) Condensing

Number of compressors11222

COP 3.0 3.0 3.0 3.0 3.1

Connection Sizes

Liquid Line OD - mm (in) 12 (1/2) 16 (5/8) 16 (5/8) 16 (5/8) 16 (5/8)

Discharge Line OD - mm (in) 16 (5/8) 22 (7/8) 22 (7/8) 22 (7/8) 22 (7/8)

Evaporator Coil

Face Area - m² (ft²) 0.77 (8.32) 1.17 (12.63) 1.46 (15.72) 1.86 (20.02) 2.22 (23.90)

Rows Deep 44444

Face Velocity - m/min (ft/min) 125 (410) 104 (342) 117 (383) 124 (407) 141 (461)

* Nominal Rating Point

** Coefficient of Performance

*** Air Conditioning and Refrigeration Institute

PACW311

Cabinet Size 2

PACW452

Cabinet Size 3

PACW612

Cabinet Size 4

PACW862

Cabinet Size 5

27InRoom Precision AC Tech Data Manual

Page 32

Operational Mode: Chilled Water (CW)

Net Cooling Capacity - 7.2°C (45°F) EWT PACW211

Cabinet Size 1

26.7°C DB, 19.4°C WB (80°F DB, 67°F WB) 50% RH

Total - kW (BTU/hr) 34.3 (117,040) 48.6 (165,965) 63.4 (216,505) 83.9 (286,520) 104.3 (355,965)

Sensible - kW (BTU/hr) 25.9 (88,540) 36.6 (124,830) 47.9 (163,400) 63.3 (215935) 78.5 (268,090)

Flow Rate - L/m (GPM) 98.4 (26.0) 138.2 (36.5) 182.1 (48.1) 244.5 (64.6) 302.5 (79.9)

Total Pressure Drop Water Side - Kpa (ft) 88.8 (29.7) 58.0 (19.4) 79.5 (26.6) 76.5 (25.6) 58.6 (19.6)

23.9°C DB, 16.9°C WB (75°F DB, 62.5°F WB) 50% RH

Total - kW (BTU/hr) 20.0 (68,115) 27.7 (94,620) 36.9 (125,780) 48.1 (164,065) 60.2 (205,485)

Sensible - kW (BTU/hr) * 20.0 (68,115) 27.7 (94,620) 36.9 (125,780) 48.1 (164,065) 57.6 (196,460)

Flow Rate - L/m (GPM) 59.4 (15.7) 81.4 (21.5) 109.4 (28.9) 146.9 (38.8) 182.8 (48.3)

Total Pressure Drop Water Side Kpa (ft) 32.0 (10.7) 19.1 (6.4) 28.1 (9.4) 27.2 (9.1) 20.3 (6.8)

23.9°C DB, 16.1°C WB (75°F DB, 61°F WB) 45% RH

Total - kW (BTU/hr) 20.0 (68,115) 27.7 (94,620) 36.9 (125,780) 48.1 (164,065) 61.7 (210,425)

Sensible - kW (BTU/hr) 20.0 (68,115) 27.7 (94,620) 36.9 (125,780) 48.1 (164,065) 61.7 (210,425)

Flow Rate - L/m (GPM) 59.4 (15.7) 81.4 (21.5) 109.4 (28.9) 146.9 (38.8) 186.6 (49.3)

Total Pressure Drop Water Side - Kpa (ft) 32.0 (10.7) 19.1 (6.4) 28.1 (9.4) 27.2 (9.1) 21.8 (7.3)

22.2°C DB, 15.5°C WB (72°F DB, 60°F WB) 50% RH

Total - kW (BTU/hr) 16.1 (55,100) 22.4 (76,475) 29.3 (100,130) 37.4 (127,680) 48.6 (165,965)

Sensible - kW (BTU/hr) 16.1 (55,100) 22.4 (76,475) 29.3 (100,130) 37.4 (127,680) 48.5 (165,680)

Flow Rate - L/m (GPM) 49.2 (13.0) 67.0 (17.7) 89.3 (23.6) 118.1 (31.1) 151.0 (39.9)

Total Pressure Drop Water Side - Kpa (ft) 21.8 (7.3) 13.2 (4.4) 19.4 (6.5) 18.5 (6.2) 14.4 (4.7)

22.2°C DB, 14.8°C WB (72°F DB, 58.6°F WB) 45% RH

Total - kW (BTU/hr) 14.7 (50,255) 22.4 (76,475) 29.3 (100,130) 37.4 (127,680) 48.5 (165,680)

Sensible - kW (BTU/hr) 14.7 (50,255) 22.4 (76,475) 29.3 (100,130) 37.4 (127,680) 48.5 (165,680)

Flow Rate - L/m (GPM) 49.2 (13.0) 67.0 (17.7) 89.3 (23.6) 118.1 (31.1) 151.0 (39.9)

Total Pressure Drop Water Side - Kpa (ft) 21.8 (7.3) 13.2 (4.4) 19.4 (6.5) 18.5 (6.2) 14.4 (4.7)

21.1°C DB, 14.0°C WB (70°F DB, 58.5°F WB) 50% RH

Total - kW (BTU/hr) 13.7 (46,645) 18.9 (64,505) 24.2 (82,650) 29.9 (102,125) 39.1 (133,570)

Sensible - kW (BTU/hr) 13.7 (46,645) 18.9 (64,505) 24.2 (82,650) 29.9 (102,125) 39.1 (133,570)

Flow Rate - L/m (GPM) 42.4 (11.2) 57.2 (15.1) 75.3 (19.9) 97.7 (25.8) 125.3 (33.1)

Total Pressure Drop Water Side - Kpa (ft) 16.1 (5.4) 9.6 (3.2) 14.1 (4.7) 12.3 (4.1) 10.5 (3.5)

21.1°C DB, 14.0°C WB (70°F DB, 57.2°F WB) 45% RH

Total - kW (BTU/hr) 13.7 (46,645) 18.9 (64,505) 24.2 (82,650) 29.9 (102,125) 39.1 (133,570)

Sensible - kW (BTU/hr) 13.7 (46,645) 18.9 (64,505) 24.2 (82,650) 29.9 (102,125) 39.1 (133,570)

Flow Rate - L/m (GPM) 42.4 (11.2) 57.2 (15.1) 75.3 (19.9) 97.7 (25.8) 125.3 (33.1)

Total Pressure Drop Water Side - Kpa (ft) 16.1 (5.4) 9.6 (3.2) 14.1 (4.7) 12.3 (4.1) 10.5 (3.5)

Valve Size - mm (in) 25 (1.0) 32 (1.25) 32 (1.25) 40 (1.5) 50 (2.0)

Temperature medium in - °C (°F) 7.2°C (45°F) 7.2°C (45°F) 7.2°C (45°F) 7.2°C (45°F) 7.2°C (45°F)

Temperature medium in - °C (°F) 12.8°C (55°F) 12.8°C (55°F) 12.8°C (55°F) 12.8°C (55°F) 12.8°C (55°F)

Chilled Water Coil

Face Area - m² (ft²) 0.77 (8.32) 1.17 (12.63) 1.46 (15.72) 1.86 (20.02) 2.22 (23.90)

Rows Deep 4 4 4 4 5

Face Velocity - m/min (ft/min) 161 (529) 142 (466) 160 (524) 173 (569) 179 (588)

Connection Sizes

Chilled Water In/Out. - mm (in) 35 (1 3/8) 35 (1 3/8) 42 (1 5/8) 54 (2 1/8) 54 (2 1/8)

* Nominal Rating Point

PACW311

Cabinet Size 2

PACW452

Cabinet Size 3

PACW612

Cabinet Size 4

PACW862

Cabinet Size 5

InRoom Precision AC Tech Data Manual28

Page 33

Information common to both modes PACW211

Cabinet Size 1

Connection Sizes

Humidifier Supply Line - mm (in) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4)

Condensate Drain Line - mm OD (in ID) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4)

Fan Information

Number of Fans11223

Air Flow M³/hr (CFM) 7034 (4,140) 10007 (5,890) 14000 (8,240) 19386 (11,410) 24007 (14,130)

External Static Pressure - Pa (in WC) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2)

Sound Power Level - dBA 76.6 79.7 78.6 83.4 82.7

Total Fan Power Consumption - kW (hp) 2.0 (2.7) 2.3 (3.1) 3.6 (4.8) 6.3 (8.4) 7.3 (9.8)

Humidification - Solid State Electrode, Canister

Flush Cycle Automatic Automatic Automatic Automatic Automatic

kg/hr (lb/hr) 8.0 (17.6) 8.0 (17.6) 15.0 (33.1) 15.0 (33.1 15.0 (33.1)

Electric Reheat – Equally Loaded Three (3) phase

Capacity - kW (BTU/hr) - Includes Motor Heat

460 V 12.0 (40982.4) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

230 V 9.0 (30736.8) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

Number of Stages23333

Downflow Filters - mm Quantities

1050 x 453 x 47 G4 22111

1050 x 398 x 47 G4 N/A 1345

Upflow Filters - mm Quantities

700 x 340 x 47 G4 1 1 N/A 1 1

700 x 332 x 47 G4 N/A 1 N/A N/A 1

700 x 502 x 47 G4 11111

700 x 508 x 47 G4 N/A N/A 1 2 2

700 x 508 x 47 G4 N/A N/A 1 N/A N/A

Physical Data

Weight - kg (lb) 372 (820) 480 (1056) 600 (1322) 740 (1631) 884 (1949)

Height - mm (in) 1980 (77.95) 1980 (77.95) 1980 (77.95) 1980 (77.95) 1980 (77.95)

Width - mm (in) 1000 (39.37) 1400 (55.11) 1750 (68.90) 2150 (84.65) 2550 (100.39)

Depth - mm (in) 890 (35) 890 (35) 890 (35) 890 (35) 890 (35)

PACW311

Cabinet Size 2

PACW452

Cabinet Size 3

PACW612

Cabinet Size 4

Cabinet Size 5

PACW862

29InRoom Precision AC Tech Data Manual

Page 34

Fluid Cooled (Glycol 40%) – 60Hz

Net Cooling Capacity PG211

Cabinet Size 1

26.7°C DB, 19.4°C WB (80°F DB, 67°F WB) 50% RH

Total - kW (BTU/hr) 19.8 (67,450) 30.0 (102,410) 44.2 (150,785) 55.2 (188,290) 84.9 (289,750)

Sensible - kW (BTU/hr) 19.8 (67,450) 30.0 (102,410) 41.3 (140,980) 55.2 (188,290) 75.4 (257,355)

23.9°C DB, 16.9°C WB (75°F DB, 62.5°F WB) 50% RH

Total - kW (BTU/hr) 18.1 (61,940) 27.8 (95,000) 40.5 (138,130) 50.8 (173,470) 78.8 (269,040)

Sensible - kW (BTU/hr) * 18.1 (61,940) 27.8 (95,000) 40.5 (138,130) 50.8 (173,470) 72.8 (248,615)

23.9°C DB, 16.1°C WB (75°F DB, 61°F WB) 45% RH

Total - kW (BTU/hr) 18.1 (61,940) 27.8 (95,000) 40.5 (138,130) 50.8 (173,470) 77.2 (263,530)

Sensible - kW (BTU/hr) 18.1 (61,940) 27.8 (95,000) 40.5 (138,130) 50.8 (173,470) 77.2 (263,530)

22.2°C DB, 15.5°C WB (72°F DB, 60°F WB) 50% RH

Total - kW (BTU/hr) 17.1 (58,330) 26.6 (90,725) 38.7 (131,955) 48.2 (164,635) 75.1 (256,405)

Sensible - kW (BTU/hr) 17.1 (58,330) 26.6 (90,725) 38.7 (131,955) 48.2 (164,635) 71.0 (242,440)

22.2°C DB, 14.8°C WB (72°F DB, 58.6°F WB) 45% RH

Total - kW (BTU/hr) 17.1 (58,330) 26.4 (90,725) 38.7 (131,955) 48.2 (164,635) 74.4 (253,840)

Sensible - kW (BTU/hr) 17.1 (58,330) 26.4 (90,725) 38.7 (131,955) 48.2 (164,635) 74.4 (253,840)

21.1°C DB, 14.0°C WB (70°F DB, 58.5°F WB) 50% RH

Total - kW (BTU/hr) 16.7 (57,095) 25.9 (88,540) 37.4 (127,680) 47.1 (160,740) 72.2 (246,335)

Sensible - kW (BTU/hr) 16.7 (57,095) 25.9 (88,540) 37.4 (127,680) 47.1 (160,740) 72.2 (246,335)

21.1°C DB, 14.0°C WB (70°F DB, 57.2°F WB) 45% RH

Total - kW (BTU/hr) 16.7 (57,095) 25.9 (88,540) 37.4 (127,680) 47.4 (161,785) 72.2 (246,335)

Sensible - kW (BTU/hr) 16.7 (57,095) 25.9 (88,540) 37.4 (127,680) 47.1 (160,740) 72.2 (246,335)

Condensing temperature for all above conditions: 52°C (125°F)

Refrigerant type for all models: R-407C

Refrigerant Charge per Circuit - kg (lbs) 2.8 (6.17) 3.9 (8.6) 4.4 (9.7) 3.9 (8.6) 4.6 (10.1)

Compressor Information – COP** (ARI*** Conditions): 7.2°C (45°F) Evaporating, 54°C (130°F) Condensing

Number of compressors11222

COP 3.0 3.0 3.0 3.0 3.1

Evaporator Coil

Face Area - m² (ft²) 0.77 (8.32) 1.17 (12.63) 1.46 (15.72) 1.86 (20.02) 2.22 (23.90)

Rows Deep 44445

Face Velocity - m/min (ft/min) 125 (410) 104 (342) 117 (383) 130 (428) 141 (461)

* Nominal Rating Point

** Coefficient of Performance

*** Air Conditioning and Refrigeration Institute

PG311

Cabinet Size 2

PG452

Cabinet Size 3

PG612

Cabinet Size 4

PG862

Cabinet Size 5

InRoom Precision AC Tech Data Manual30

Page 35

Fluid Cooled (Glycol 40%) Continued PG211

Cabinet Size 1

Fan Information

Number of Fans 1 1 2 2 3

Air Flow - M³/hr (CFM) 7493 (4,410) 10007 (5,890) 14000 (8,240) 20116 (11,890) 24007 (14,130)

External Static Pressure - Pa (in WC) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2) 50 (0.2)

Sound Power Level - dBA 75.4 79.2 77.4 83.2 83.2

Total Fan Power Consumption - kW (hp) 1.7 (2.3) 2.0 (2.7) 3.1 (4.2) 6.1 (8.2) 6.2 (8.3)

Condenser Data

Total Heat Rejection (THR) - kW (BTU/hr) 27.4 (93,400) 41.3 (141,100) 61.0 (208,200) 79.2 (270,400) 118.8 (405,600)

Flow rate - L/m (GPM) 61.7 (16.3) 53.4 (14.1) 133.2 (35.2) 176.8 (46.7) 265.0 (70.0)

Total pressure drop water side - kPa (ft) 87.3 (29.2) 34.1 (11.4) 84.9 (28.4) 106.4 (35.6) 141.7 (47.4)

Valve size - mm (in) 20 (0.75) 25 (1.0) 32 (1.25) 32 (1.25) 40 (1.5)

Connection Sizes

Condenser In/Out - mm (in) 28 (1 1/8) 35 (1 3/8) 35 (1 3/8) 35 (1 3/8) 42 (1 5/8)

Humidifier Supply Line - mm (in) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4) 6 (1/4)

Condensate Drain Line - mm OD (in ID) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4) 21 (3/4)

Humidification – Solid State Electrode, Canister

Flush Cycle Automatic Automatic Automatic Automatic Automatic

kg/hr (lb/hr) 8.0 (17.6) 8.0 (17.6) 15.0 (33.1) 15.0 (33.1 15.0 (33.1)

Electric Reheat – Equally Loaded Three (3) phase

Capacity - kW (BTU) - Includes Motor Heat

460 V 12.0 (40982.4) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

230 V 9.0 (30736.8) 18 (61473.6) 18 (61473.6) 27 (92210.4) 27 (92210.4)

Number of Stages 2 3 3 3 3

Downflow Filters - mm Quantities

700 x 508 x 47 G4 1 N/A N/A N/A N/A

1050 x 453 x 47 G4 N/A 2 1 1 1

1050 x 398 x 47 G4 N/A 1 3 4 5

Upflow Filters - mm Quantities

700 x 340 x 47 G4 N/A 1 N/A 1 1

700 x 332 x 47 G4 N/A 1 N/A N/A 1

700 x 502 x 47 G4 N/A 1 1 1 1

700 x 508 x 47 G4 N/A N/A 1 1 2

700 x 516 x 47 G4 1 N/A 1 N/A N/A

Physical Data