Page 1

WATER HEATERS

High Efficiency

Commercial Water Heater

VWH-500

through

FEATURES

The VF™ Water Heater series delivers an exceptionally high thermal efficiency by combining

an advanced modulating venturi-mixing gas/air ratio system with a vertical multi-pass

copper heat exchanger for outstanding efficiency of up to 87% and low NOx emissions

that meet the most stringent standards.

The VF™ Water Heater is capable of firing from 100% to 25% or a 4:1 turndown ratio of

rated input based on the current system demand. The VF’s modulating capability is virtually

limitless, and the water heater’s output is based strictly on the current system demand and the

required BTUs needed to maintain the desired system set point temperature.

ADVANCED HIGH EFFICIENCY, LOW NOx COMBUSTION TECHNOLOGY

■

Venturi-mixing gas/air ratio system - Works with variable speed blower to precisely mix

gas and air throughout firing range.

■

4:1 Turndown - Fully modulating capability prevents energy-stealing short cycling and

provides smooth system operation with higher overall system efficiencies

LOW NOx OPERATION

■

Complies with SCAQMD Rule 1146.2 and other Air Quality Management Districts with

similar requirements for low NOx emissions

ADVANCED MODULATING CONTROL

■

Includes remote tank temperature sensor to install in the storage tanks – allows the tank

temperature to be set at the water heater

■

Modulates the burner to maintain the desired tank temperature within +/-1 degree

■

Infinite burner firing rate, modulates between 25% and 100% fire

■

Building Management System (BMS) Integration with 0 - 10 VDC Input allows BMS to

control water heater firing rate

ALL BRONZE FACTORY SIZED PUMP STANDARD

■

Integrally pump control maximizes overall system efficiency by eliminating standby heat

loss and converts residual heat into usuable hot water

■

Factory-sized for proper flow between the water heater and storage tank

■

Allows 50 equivalent feet of piping between the water heater and tank

VWH-2000

HIGH EFFICIENCY COPPER FIN TUBE HEAT EXCHANGER

■

Vertical heat exchanger design encircles the burner with a combustion chamber that is

a 360° wall of copper fin tubes

■

Rust-resistant operation - All internal heat exchanger non-copper surfaces are

glasslined with A. O. Smith’s proprietary porcelain glass coating

■

Impervious to thermal shock

■

Heavy-Duty gasketless heat exchanger design

COMPACT, LOW-PROFILE DESIGN

■

Zero clearance on sides vertical heat exchanger design allows small footprint and units that

can fit through doors into elevators

■

Ideal for multiple water heater installations and side by side installation

FLEXIBLE VENTING SOLUTIONS

■

Multiple Category II and IV direct and sidewall venting options

■

Common Venting possible with engineered vent systems

FACTORY START-UP INCLUDED

■

Required for activating warranty and assuring maximum operating performance.

Contact your local sales representative or Authorized Start-Up Agent to arrange a

FREE Certified Start-Up.

A. O. Smith Corporation • 500 Tennessee Waltz Parkway • Ashland City, TN 37015 • 800-527-1953 Toll-free USA

www.hotwater.com

HLW

Page 1 of 4

Revised July 2014 AOSDG25010

Page 2

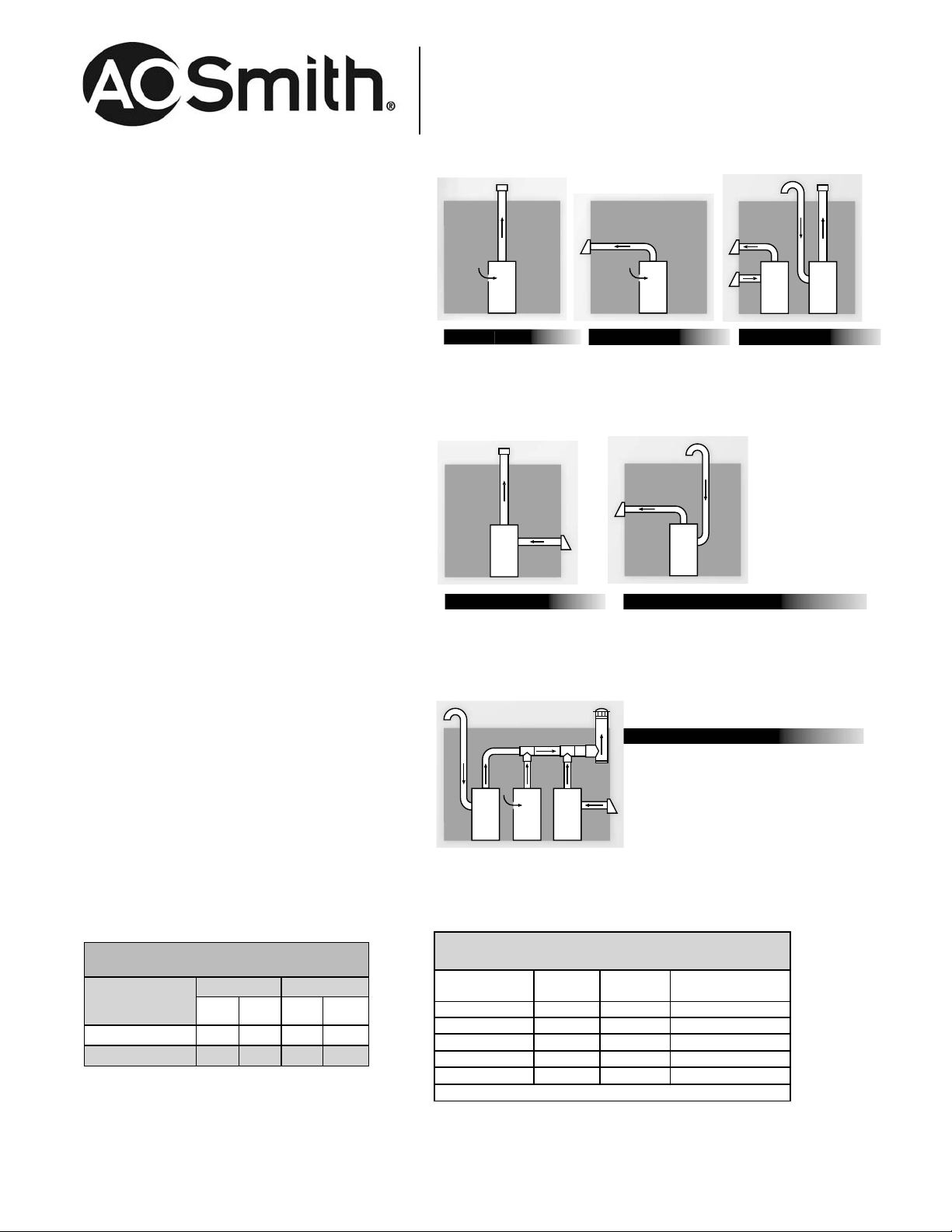

CATEGORY II and IV LISTED

LL

Maximum

Minimum

■

Requires AL29-4C gas tight rust resistant

venting material

PROFESSIONAL START-UP SERVICE INCLUDED

■

Assures optimum performance for each installation

MEETS THE THERMAL EFFICIENCY AND

STANDBY LOSS REQUIREMENTS OF THE

U. S. DEPARTMENT OF ENERGY AND

CURRENT EDITION ASHRAE/IESNA 90.1

5-YEAR LIMITED HEAT EXCHANGER

WARRANTY

■

For complete information, consult written

warranty or contact A. O. Smith

OTHER VF™ WATER HEATER FEATURES:

■

ASME CERTIFIED “HLW” STAMPED 160# W.P.

■

ASME RATED PRESSURE RELIEF VALVE, 125 PSI.

■

FACTORY MOUNTED FLOW SWITCH

■

CONTACTS FOR 0-10 VDC BMS EXTERNAL CONTROL

■

CONACTS FOR ALARM OR ANY FAILURE

■

DIGITAL INLET/OUTLET TEMPERATURE READOUT

■

MANUAL RESET HI-LIMIT

■

ALL BRONZE FACTORY SUPPLIED PUMP

High Efficiency

Commercial Water Heater

Vertical Venting

Using Category IV

vent materials

Sidewall Venting*

Horizontal venting up to

50 equivalent feet using

Category IV vent materials.

Direct Venting*

Horizontal or vertical venting up to 50 equivalent feet.

Draws combustion air up to

50 feet from the same pressure zone using Category IV

vent materials.

VF™ OPTIONS:

■

SEQUENCING PANEL - Can manage 1 to 4

modulating units

- Includes remote Tank sensor and sensor well

- Uses the 0-10Vdc to control the water heater’s

firing rate

- Modulates the water heater(s) firing rate to meet

system demand

- Provides Cascade/Lead-Lag operation when

multiple units are connected

■

ALARM BELL

■

LOW WATER CUTOFF W/MANUAL RESET AND TEST

■

PROPANE (LP) GAS

■

VENT KITS:

- Horizontal Exhaust Cap

- Horizontal Air Intake Cap

- Horizontal Direct Vent Kit

- Category II Conversion Kit (Required for

Common Venting)

■

International Voltage (230V 50Hz)

INLET GAS PRESSURE

Max.

w.c.

P

MODEL

500 -1000 14.0 4.0 13.0 11.0

1500 - 2000 14.0 4.0 14.0 8.0

inlet gas pressure must not exceed the value specified.

value listed is for the purposes of input adjustment.

NATURA

Max.

Min.

w.c.

w.c.

Min.

w.c.

Ducted Air Vertical*

Vertical venting up to 50 equivalent

feet. Draws combustion air up to

50 feet from a different pressure

zone using Category IV vent

materials.

Ducted Air Horizontal*

Vents horizontally up to 50 equivalent

feet and draws combustion air up to

50 feet from a different pressure zone

using Category IV vent materials.

Common Venting*

Vents multiple units horizontally

through one vent termination and

draws combustion air from the room,

roof or sidewall. Category IV to II

conversion kit required.

*Requires factory-supplied vent kit.

See Specification Chart for specific venting sizes based on venting materials category type.

AMP DRAW DATA

Model

Blower &

Controls

Pump FLA*

500 6.7 8.8 15.5

750 6.7 8.8 15.5

1000 6.7 8.8 15.5

1500 6.5 8.8 15.3

2000 6.5 8.8 15.3

*Standard Pump Supplied with Water Heaters

Approximate Total

Amps @ 120 VAC

A. O. Smith Corporation • 500 Tennessee Waltz Parkway • Ashland City, TN 37015 • 800-527-1953 Toll-free USA

www.hotwater.com

Page 2 of 4

AOSDG25010

Page 3

High Efficiency

D2

P

Commercial Water Heater

VF™ Water Heater Dimensions and Specifications

F

GAS

CONNECTION

INLET

A

E

DRAINS

B C

D1

(3/4" NPT)

SIDE VIEW

*Pump shipped loose

Model

Number A B C D1 D2 E F G H J K L M N P

REAR VIEW

(VWH0500N-VWH1000N)

G

M

N

P

AIR

INLET

H

OUTLET

EXHAUST

VENT

K

J

L

GAS

CONNECTION

INLET

E

DRAINS

(3/4" NPT)

(VWH1500N-VWH2000N)

F

G

M

N

REAR VIEW

AIR

INLET

H

OUTLET

J

L

EXHAUST

VENT

VWH0500N 44-1/2” 30-3/8” 6” 12-1/2” 15-1/8” 34-1/8” 19-5/8” 7-3/4” 7-3/8” 11-3/8” 23” 6-1/2” 11-1/2” 17-1/2” 23-1/8”

VWH0750N 52-1/8” 30-3/8” 6” 12-1/2” 15-1/8” 41-3/4” 19-5/8” 7-3/4” 7-3/8” 11-3/8” 30-1/2” 6-1/2” 11-1/2” 17-1/2” 23-1/8”

VWH1000N 59-1/4” 30-3/8” 6” 12-1/2” 15-1/8” 48-7/8” 19-5/8” 7-3/4” 7-3/8” 11-3/8” 37-5/8” 6-1/2” 11-1/2” 17-1/2” 23-1/8”

VWH1500N 65-3/8” 31-5/8” 8” 16-1/2” 19-3/8” 58-3/4” 21-1/8” 9-1/2” 10” 22” 43-1/4” 5-3/4” 13-1/2” 21-3/8” 27-1/8”

VWH2000N 76-5/8” 31-5/8” 8” 16-1/2” 19-3/8” 70” 21-1/8” 9-1/2” 10” 27-3/8” 54-3/8” 5-3/4” 13-1/2” 21-3/8” 27-1/8”

K

Model

Number

BTU/Hr

Input

GPH @

40°F Rise

GPH @

100°F Rise

GPH @

140°F Rise

Gas

Connection

Combustion

Air Inlet

Vent Size

Category II

Vent Size

Category IV

VWH0500N 500,000 1318 527 377 1” 5” 7” 4” 573

VWH0750N 750,000 1977 791 565 1-1/4” 5” 9” 5” 622

VWH1000N 999,999 2636 1054 753 1-1/4” 6” 10” 6” 662

VWH1500N 1,500,000 3955 1582 1130 1-1/2” 6” 8” 6” 1,118

VWH2000N 2,000,000 5273 2109 1506 1-1/2” 8” 10” 8 ” 1,187

Change ‘N’ to ‘L’ for LP gas model

No deration on LP models

GPH calculations based on ring rate of 100%

All water connections are 2-1/2”

A. O. Smith Corporation • 500 Tennessee Waltz Parkway • Ashland City, TN 37015 • 800-527-1953 Toll-free USA

www.hotwater.com

AOSDG25010

Approximate

Shipping

Weight (lbs.)

Page 3 of 4

Page 4

High Efficiency

Commercial Water Heater

Specifications

The WATER HEATER(S) shall be A. O. Smith VF™ Water Heater model number VWH_______ having an input rating of _________ Btu/Hr, a recovery capacity of

_________ gallons per hour and shall be operated on Natural Gas (LP Gas).

The water containing section shall consist of a heat exchanger constructed of a “Fin Tube” design, with straight copper tubes having extruded integral fins spaced

seven (7) fins per inch. These tubes shall be “rolled” securely into glass-lined, cast iron headers. Removable access plugs shall be provided on the heat exchanger

headers for the purposes of inspection, cleaning or repair. Water Heater drains shall be provided, having external access. The heat exchanger shall be mounted in

a stress free jacket assembly in order to provide a “free floating design” able to withstand the effects of thermal shock. The WATER HEATER shall bear the ASME

“HLW” stamp for 160 psi working pressure and shall be National Board listed. The complete heat exchanger assembly shall carry a five (5) year limited warranty

against failure caused by defective workmanship or material.

The WATER HEATER(S) combustion chamber shall be constructed of stainless steel and sealed for leak proof operation. The burner surface shall be constructed of

heavy-duty ceramic material and fire in a vertical plane within the combustion chamber. The burner shall employ a special perforated flame injection tube extending

the entire length of the heat exchanger. The burner shall fire in a full 360-degree pattern resulting in uniform heat transfer upon every inch of heating surface. A

viewing port shall be provided, permitting visual observation of burner operation.

The WATER HEATER(S) must be capable of firing at a complete blue flame with maximum gas and air input, as well as firing infrared when gas and air are reduced.

The burner must be capable of firing from 25 percent up to 100 percent of rated input when supplied with 4 inches water column of inlet gas pressure for a

turndown ratio of 4:1.

The WATER HEATER(S) shall use a combustion air blower, utilizing pulse width modulation, to draw a precise mixture of fuel and air into the combustion chamber

for maximum efficiency. The combustion air blower shall operate for a pre-purge period before burner ignition and a post-purge period after burner operation to

clear the combustion chamber. The WATER HEATER shall be equipped with a replaceable combustion air filter to protect the blower and burner from contaminants

and debris.

The WATER HEATER shall incorporate a gas train consisting of a pre-mix gas valve to supply gas and combustion air in exact proportions to allow burner input to

vary based on load. The pre-mix gas valve shall perform the functions of safety shutoff, constant pressure regulation and air/gas ratio control. Full closing of the

valve seat shall occur in less than 0.8 seconds when the valve is de-energized.

The WATER HEATER shall be constructed with an 18 gauge pre-painted steel jacket assembly. The interior of the combustion chamber and flue collector shall be

stainless steel. All inner jacket panels shall be fully gasketed and sealed. The jacket assembly shall be primed and pre-painted on both sides. All models shall be

certified for installation on combustible floors without additional safety provisions. The WATER HEATER shall be suitable for installation with zero clearance from

combustible material on the left and right side.

The WATER HEATER’S standard construction shall include an air pressure switch to prove combustion air flow, a flow switch to prove water flow, downstream test

valve and a factory installed ASME temperature and pressure relief valve. Standard controls shall include manual reset high limit, pump control for dedicated water

heater pump. Standard construction shall include terminal strips for supply voltage connection, pump control connections, contacts for any failure, contacts for air

louvers and run time contacts. The manufacturer shall verify proper operation of the burners, all controls and the heat exchanger by connection to gas, water and

venting for a full factory fire test.

The WATER HEATER(S) shall be equipped with an Electronic Integrated Control Module with a microprocessor-based platform incorporating software customized

for operation of the water heater. All internal safety, operating and ignition controls shall be included in the electronic integrated control module. The electronic

integrated control module shall provide on/off control of the gas supply to the burner, operation of the combustion air blower, ignition of the gas-air mixture, flame

proving, control of water temperature set points, and monitoring of all safety functions.

The WATER HEATER(S) shall allow 0-10 VDC input connection for BMS control. Supply voltage shall be 120 volt / 60 hertz / single phase.

The WATER HEATER(S) standard control system shall include an electronically proven Hot Surface Ignition system with full flame monitoring capability and a built-in

low gas pressure regulator. A 24 VAC control circuit and components shall be used. All components shall be easily accessed and serviceable from the front and

top of the unit. Standard operating controls shall utilize a return water temperature sensor, an outlet water temperature sensor and a flue temperature sensor. An

adjustable immersion type, manual reset safety high limit shall be provided to limit water temperature.

The WATER HEATER(S) shall be designed to allow installation of multiple venting options of Category II or IV configurations. All flue and air inlet pipe shall be

provided by the installing contractor. The vent and combustion air intake terminals shall be supplied by A. O. Smith.

The WATER HEATER(S) shall be supplied with a circulating pump of sufficient capacity to ensure scale-free heater performance. The pump shall be all bronze and

provided for operation on 120 volt. 60 hertz, 1 phase power supply (unless otherwise specified).

The WATER HEATER(S) shall be certified and listed by C.S.A. International under the latest edition of the harmonized ANSI Z21.13 test standard for the U.S. and

Canada. The WATER HEATER(S) shall comply with the energy efficiency requirements of the latest edition of the ASHRAE 90.1 Standard. The WATER HEATER(S)

shall operate at up to 87% thermal efficiency. The WATER HEATER(S) shall be certified for Oxides of Nitrogen (NOx) of less than 10 ppm corrected to 3% O

independent laboratory.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

A. O. Smith Corporation • 500 Tennessee Waltz Parkway • Ashland City, TN 37015 • 800-527-1953 Toll-free USA

www.hotwater.com Revised July 2014

by an

2

Page 4 of 4

AOSDG25010

Loading...

Loading...