Page 1

COMMERCIAL ELECTRIC

WATER HEATERS

DVE–125 THRU 10,000

DHE–200 THRU 10,000

STANDARD FEATURES

GLASS-LINED TANK — Tank interior is coated with glass

specially developed for use in water heaters. Tanks rated at

125 psi working pressure; 150 psi or 160 psi working pressure

is optional. Vermin proof fiber glass insulation reduces costly

heat loss. Constructed to Section IV of ASME code, and UL

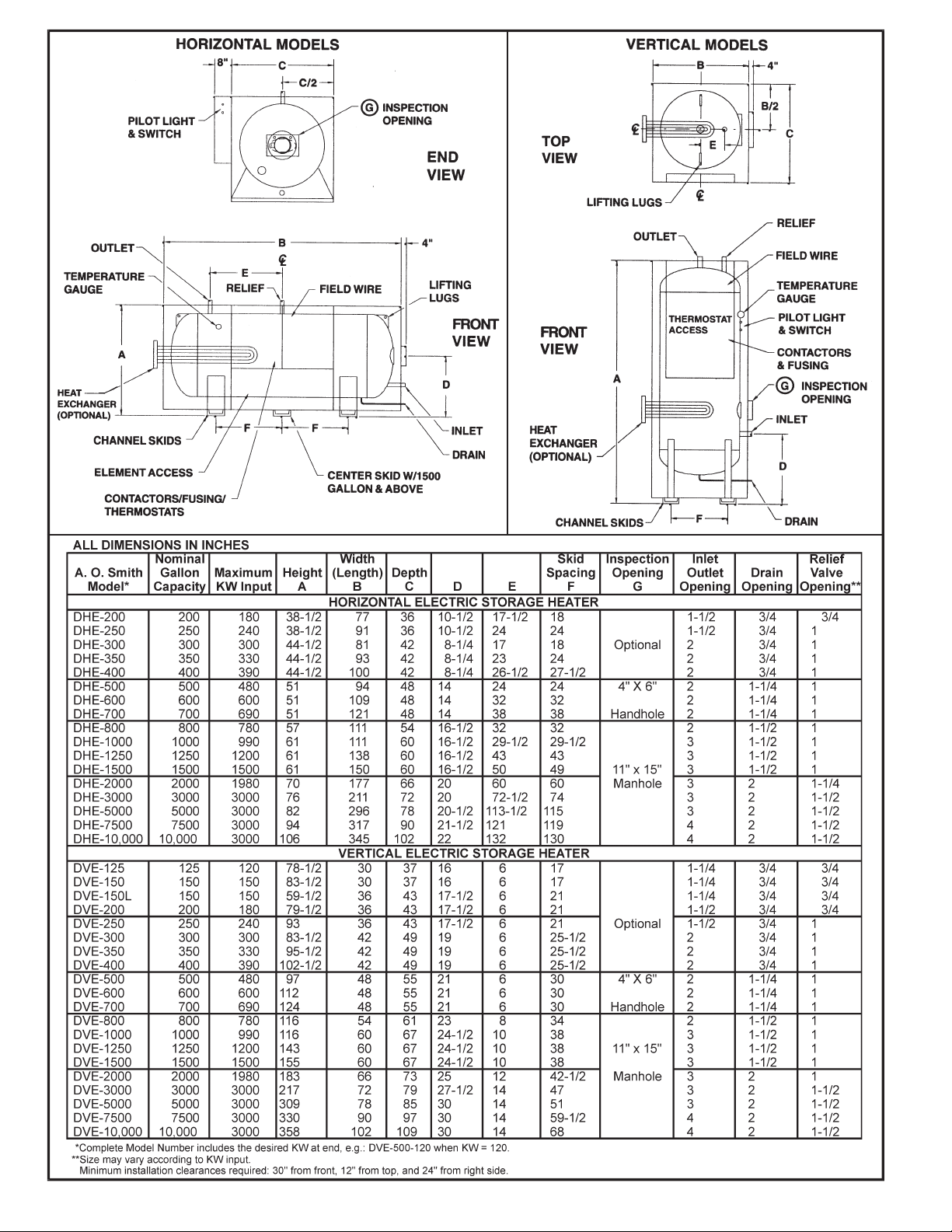

standards. Tanks have channel skid base. A 4" x 6" handhole

is furnished on 500, 600 and 700 gallon models; 11" x 15"

manhole is furnished on 800 gallon and larger sizes.

INCOLOY IMMERSION HEATERS — Heavy-duty medium watt

density elements (three/immersion heater) have incoloy

sheathing: provide excellent protection against oxidation and

scaling. The input ranges from 15KW to 3000KW (see

accompanying chart).

AVAILABLE WITH OPTIONAL GOLDENROD ELEMENTS —

All models are available with the Goldenrod 24K gold plated

elements (patent pending). Goldenrod Elements provide longlife and five times the scaling resistance of standard incoloy

elements. Goldenrod Elements carry a three-year warranty

against failure due to scale.

FUSING — Control and power circuit fusing to meet N.E.C.

PILOT SWITCH AND LIGHT — Provided on front of heater;

permits manual starting and stopping of heater by interrupting

power to control circuit.

OTHER STANDARD FEATURES

• Color coded circuitry for easier servicing • Anode rods for

maximum corrosion protection • Standard voltages include 208,

240, 480, 600 volt single or three-phase. For other voltages

consult factory. • Factory installed terminal block(s) • Cabinet

has baked enamel finish • Prewired element terminal leads •

Temperature and pressure relief valve • 2" dial temperature

gauge • Immersion type thermostat and high limit for faster

response.

OPTIONAL DUAL ENERGY SOURCE CAPABILITY —

Provides emergency back up energy source or winter/summer

boiler operation. Can be specified with optional water to water

or steam to water heat exchangers. Both single and double

wall heat exchangers are available. Complete control packages

can be factory installed for hook-up and run capability.

MEETS OR EXCEEDS THE

REQUIREMENTS OF ASHRAE

90.1b-1990 STANDARD FOR

ENERGY EFFICIENCIES.

ASME

MAGNETIC CONTACTOR(S) — Heavy duty UL rated for

100,000 cycles.

LOW WATER CUTOFF — Probe type electric low water cutoff

prevents energizing of elements in the event of low water

condition.

120 VOLT CONTROL CIRCUIT — 120 volt control circuit is

powered by fused transformer.

IMMERSION THERMOSTAT — Immersion temperature control

(one per 60KW) is adjustable to 180°F; high temperature cutoff

is manual reset, adjustable type.

LIMITED WARRANTY OUTLINE

If the tank should leak any time during the first three

years, under the terms of the warranty, A. O. Smith will

repair or replace the heater; installation, labor, handling

and local delivery extra. THIS OUTLINE IS NOT A

WARRANTY. For complete information, consult the

written warranty or A. O. Smith Water Products Company.

Warranty does not apply to product installed outside of

the United States of America or its territorial possessions

and Canada.

July 2007R

ACESS00607

Page 1 of 4

Page 2

ACESS00607

Page 2 of 4

Page 3

➤➤

➤➤

➤

➤➤

➤➤

➤

➤

➤➤

➤➤

d

e

dn

e

mm

o

ceR

t

o

N

d

e

dne

m

m

o

c

e

R

t

o

N

➤

➤

➤

➤

➤

SAMPLE SPECIFICATIONS

The heater(s) shall be A.O. Smith Dura-Power Commercial Electric Model Number ___________________ or an approved

equal. Heater(s) shall be rated at _______ KW, _______ V, _______ phase, 60 cycle AC. The heater shall be for (vertical/

horizontal) installation with lifting lugs and channel skid base. Vessel shall be constructed to Section IV of the ASME Code for

125 psi working pressure. Vessel shall be glass-lined with anodic protection. Entire vessel and electrical controls are to be

encased in a rectangular sheet metal enclosure with baked enamel finish. Tank to be insulated with fiber glass insulation.

Separate 2" dial type temperature gauge will be mounted on the front of the enclosure. Enclosure to have hinged locking door

over electric controls. There shall be ____________ individually replaceable _______ KW, 4 bolt flange mounted, incoloy

sheathed heating elements each complete with prewired terminal leads. These elements will be switched by magnetic contactors

which are operated by a 120V fused control circuit protected by manual reset high limit. Control circuit is activated by a master

pilot switch and electronic low water cutoff. The thermostatic control of the contacts shall be in _______ stages through solid

state modulating step control which will balance the water heating input to the demand. This control shall prevent the entire

electrical load from being switched on instantaneously. The control shall have even load progressive sequencing which utilizes

the "first on, first off" principle thereby equalizing the operating time of heating elements and contactors. Each magnetic contactor

and heating element circuit will be protected by a maximum of 60 amp cartridge type fuses with a minimum of 100,000 amp

interrupting capacity. The entire water heating package shall be prewired to solderless terminal lugs, factory tested, complete

with ASME temperature and pressure relief valve and bear the Underwriters' Laboratories label. Heater(s) shall have a 3 year

limited warranty as outlined in the written warranty. Fully illustrated instruction manual included.

ACESS00607

Page 3 of 4

Page 4

OPTIONS

CONTROL OPTIONS

TANK LININGS

CEMENT – A special formulation of cement providing excel-

lent corrosion protection. Available on 200 gallon and larger

tanks.

EPOXY – A solventless two component epoxy lining applied

to a minimum ten-mil (.010") dry thickness. Available on

200 gallon and larger tanks.

GOLDENROD ELEMENTS – Available with Optional

Goldenrod Elements - All DVE/DHE models are available with

the Goldenrod 24K gold plated elements (patent pending).

Goldenrod Elements provide long-life and five times the

scaling resistance of standard incoloy elements. Goldenrod

Elements carry a three-year warranty against failure due to

scale.

SPECIAL CONSTRUCTION

SILICON BRONZE VESSELS – Are available for special

applications or very corrosive water conditions. Consult factory for specific sizes.

STAINLESS STEEL VESSELS – Are available for deionized

water. Built with stainless steel under rules of Section IV of

the ASME Boiler and Pressure Vessel Code for operation on

deionized water having a minimum specific resistivity of 10

megohm/cm.

150 OR 160 PSI WORKING PRESSURE – Must be specified at time of order.

OTHER OPTIONAL FEATURES

TEMPERATURE AND PRESSURE RELIEF VALVES – For

working pressures other than standard; consult factory.

HORIZONTAL OR VERTICAL – See specifications, most

gallon capacities may be obtained in vertical or horizontal

construction.

CIRCULATING PUMP PACKAGE – Circulating pump and

piping sized to turn over entire storage capacity of tank once

each hour. Recommended to optimize available water at

temperature in horizontal tanks particularly where low draw

conditions are anticipated.

OPTIONAL INTERNATIONAL VOLTAGES – 380 and 415

volts three phase.

COPPER TUBE TANK HEATER – Double wall copper tube

tank heaters are designed for heating potable water with both

potable or non-potable liquids or steam, and are specifically

engineered for installation in models DVE and DHE for dual

energy applications. Tank heaters have a positive fail-safe

means of leak detection in the event of either tube failure to

prevent mixture of heating medium and potable water. Single

wall heat exchangers are also available. Refer to pages A

412.3 and A 412.4 for more information.

THERMOSTATIC STEP CONTROL – The simplest form of

modulation. Allows elements to be stepped on in groups by

specifying additional thermostats (up to one per contactor).

It is recommended that number of thermostats not exceed

five.

SOLID STATE MODULATING STEP CONTROL – Solid state

electronic control device that modulates input to match load

through progressive sequencing of steps (up to 20 steps with

maximum of one per contactor).

SEQUENCER – Up to 5 stage time delay sequencer provides for stepping of elements in groups or individually (maximum of one step per contactor). Units supplied with this

option will have a 120/24 volt control circuit.

TERMINAL BLOCKS – Allows for remote connection to building demand limiter or other functions.

AUTOMATIC RESET HIGH LIMIT – A control that in the

event of high temperature, interrupts power, de-energizing

elements, automatic reset. (Standard with modulating step

control).

INDICATING LIGHTS – Denotes heating stage(s) in operation. Up to one light per contactor is available.

OVERRIDE SWITCHES – A simple means of load control

allows all or part of unit input to be controlled manually. Up

to one switch per contactor is available.

SAFETY DOOR INTERLOCK – Prevents opening of control

panel door when heater power supply is on. NOTE: Once

door is opened heater may be energized if necessary for

service diagnosis.

SHUNT TRIP CIRCUIT BREAKER – A safety device (circuit

breaker) which disconnects power to heater in the event of

overcurrent, high temperature or low water level, breaker must

be manually reset.

3-1/2" DIAL TYPE PRESSURE GAUGE – Factory installed.

3-1/2" DIAL TYPE TEMPERATURE GAUGE – Factory in-

stalled.

11" x 15" MANHOLE – Available as option on tanks 700

gallons or smaller.

A. O. Smith Water Products Company, Inc On Line

ACESS00607

Page 4 of 4

www.hotwater.com

For Technical information and

Automated fax Service,

Phone: 800-527-1953

CIRCUIT BREAKER – A safety device which disconnects

power to the heater in the event of overcurrent.

A. O. Smith

Water Products Company

Irving, TX

A Division of A. O. Smith Corporation

A. O. Smith Corporation reserves the right to make product changes

or improvements at any time without notice.

Printed in U.S.A.© A. O. Smith Corp., 1999

Loading...

Loading...