Page 1

Commercial Electric

Water Heaters

STANDARD FEATURES

ADVANCED ELECTRONIC CONTROL (All Models 150kW and Down)

A. O. Smith’s new propriety electronic water heater control, provides precise + or - 1ºF temperature

control, that is ideal for industrial and food service applications where exact temperatures of

hot water are needed.

Plain Text – Animated icons display detailed operational and diagnostic information. Fault or Alert

messages appear if an operational issue occurs.

Low Water Cut Off – Factory standard on board low water cut-off uses a remote electronic immersion

type probe to prevent energizing of the elements in the event of low water

condition and eliminates accidental dry firing.

Progressive Modulating – Sizes the input of available elements to match

current load conditions. Rotates and lead lags element loads to provide

long life and equal wear .

Economy Mode Operation – Control system automatically lowers the operating

set point by a programmed value during user defined time periods. Seven-day

clock may be programmed for night set back and or weekend shutdown to

reduce operating cost and save money.

iCOMM™ Compatible - Units can be monitored from remote

locations. Call 1.888.WATER02 for more information.

Note: Units over 150KW use analog controls.

DVE-150 THRU 10,000

DHE-200 THRU 10,000

SOLID STATE MODULATING STEP CONTROL (All Models 180kW and up) –

Solid state electronic control device that modulates input to match load through progressive

sequencing of steps (up to 20 steps with maximum of one per contactor).

GLASSLINED TANK – Tank interior is coated with glass specially developed for use in water heaters.

Tanks rated at 125 psi working pressure; 150 psi or 160 psi working pressure is optional. Vermin proof

fiber glass insulation reduces costly heat loss. Constructed to Section IV of ASME code, and UL standards.

Tanks have channel skid base. A 4” x 6” handhole is furnished on 500, 600 and 700-gallon models;

11” x 15” manhole is furnished on 800-gallon and larger sizes.

INCOLOY IMMERSION HEATERS – Heavy-duty medium watt density elements (three/immersion heater)

have incoloy sheathing: provide excellent protection against oxidation and scaling. The input ranges

from 15KW to 3000KW (see accompanying chart).

FUSING – Control and power circuit fusing to meet N.E.C.

COMPLIANCE – Meets the standby loss requirements of the U.S. Department of Energy and

current edition of ASHRAE/IESNA 90.1.

MAGNETIC CONTACTOR(S) – Heavy duty UL rated for 100,000 cycles.

OTHER STANDARD FEATURES

Color-coded circuitry for easier servicing

Anode rods for maximum corrosion protection

Standard voltages include 208, 240, 480, 600 volt single or three-phase.

For other voltages consult factory.

Factory-installed terminal block(s)

Cabinet has baked enamel finish

Prewired element terminal leads

Temperature and pressure relief valve

2” dial temperature gauge

OPTIONAL DUAL-ENERGY SOURCE CAPABILITY – Provides emergency back up energy source or

winter/summer boiler operation. Can be specified with optional water to water or steam to water heat

exchangers. Both single and double-wall heat exchangers are available. Complete control packages can be

factory-installed for hook-up and run capability.

LIMITED WARRANTY OUTLINE – If the tank should leak any time during the first three years, under

the terms of the warranty, A. O. Smith will repair or replace the heater; installation, labor, handling

repair or replace the heater; installation, labor, handling and local delivery extra. THIS OUTLINE IS NOT

A WARRANTY. For complete information, consult the written warranty or A. O. Smith. Warranty does

not apply to product installed outside of the United States of America or its territorial possessions

and Canada.

Revised January 2013

February 2010R

Low Lead Content

Page 1 of 4

AOSCE15500

Page 2

Commercial Electric

Water Heaters

Nominal

A. O. Smith

Model

DHE-200

DHE-250

DHE-300

DHE-350

DHE-400

DHE-500

DHE-600

DHE-700

DHE-800

DHE-1000

DHE-1250

DHE-1500

DHE-2000

DHE-3000

DHE-5000

DHE-7500

DHE-10,000

DVE-140

DVE-150

DVE-150L

DVE-200

DVE-250

DVE-300

DVE-350

DVE-400

DVE-500

DVE-600

DVE-700

DVE-800

DVE-1000

DVE-1250

DVE-1500

DVE-2000

DVE-3000

DVE-5000

DVE-7500

DVE-10,000

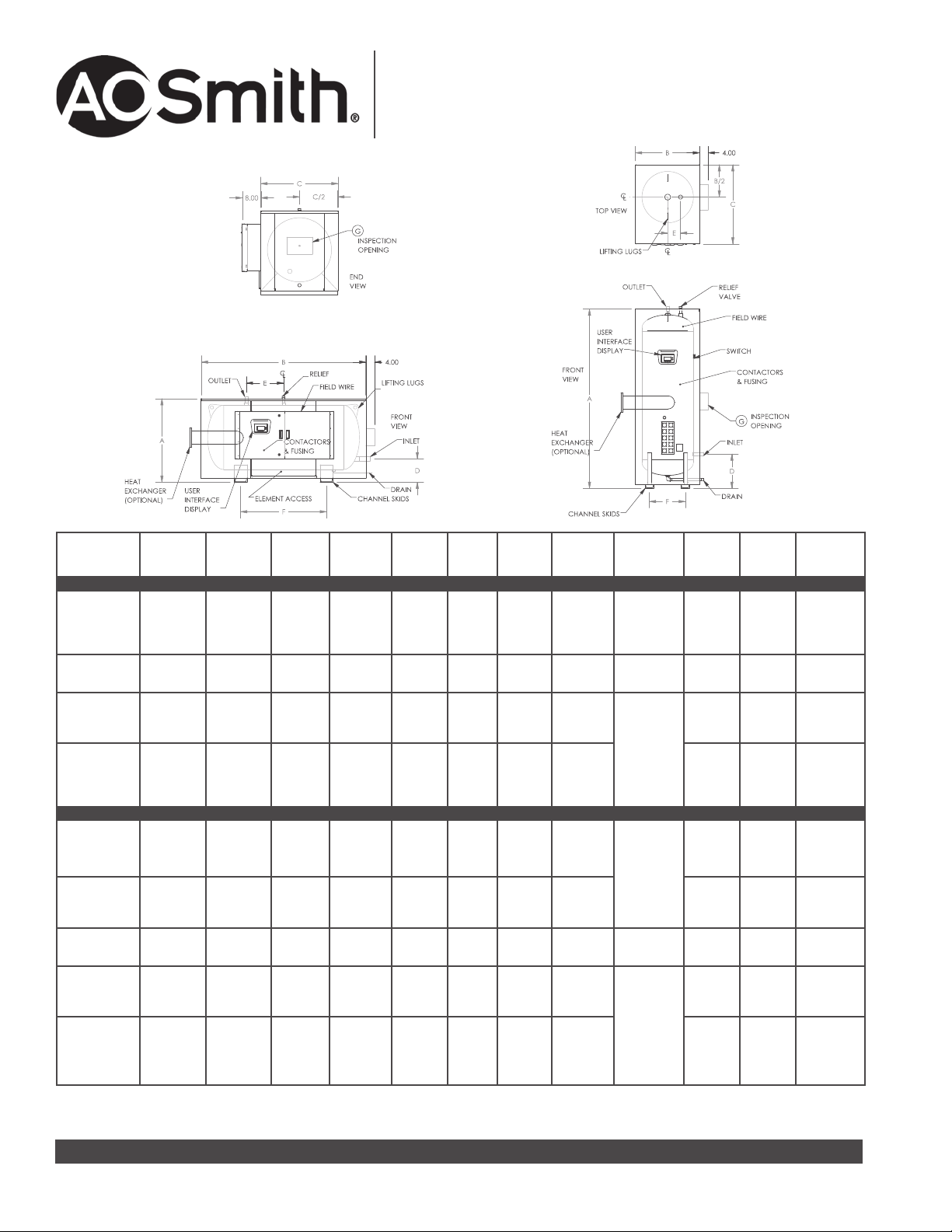

*Complete Model Number includes the desired kW at end, e.g.: DVE-500-120 when kW = 120.

**Size may vary according to kW input.

Minimum installation clearances required. 30” from front, 12” from top, and 24” from right side.

Gallon

Capacity

200

250

300

350

400

500

600

700

800

1000

1250

1500

2000

3000

5000

7500

10,000

140

150

150

200

250

300

350

400

500

600

700

800

1000

1250

1500

2000

3000

5000

7500

10,000

Maximum

kW

Input

180

240

300

330

390

480

600

690

780

990

1200

1500

1980

3000

3000

3000

3000

150

150

150

180

240

300

330

390

480

600

690

780

990

1200

1500

1980

3000

3000

3000

3000

Height

A

38-1/2

38-1/2

44-1/2

44-1/2

44-1/2

51

51

51

57

61

61

61

70

76

82

94

106

83-1/2

83-1/2

59-1/2

79-1/2

93

83-1/2

95-1/2

102-1/2

97

112

124

116

116

143

155

183

217

309

330

358

Width

(Length) BDepth

HORIZONTAL ELECTRIC STORAGE HEATER

77

91

81

93

100

94

109

121

111

111

138

150

177

211

296

317

345

VERTICAL ELECTRIC STORAGE HEATER

30

30

36

36

36

42

42

42

48

48

48

54

60

60

60

66

72

78

90

102

CDE

36

36

42

42

42

48

48

48

54

60

60

60

66

72

78

90

102

37

37

43

43

43

49

49

49

55

55

55

61

67

67

67

73

79

85

97

109

10-1/2

10-1/2

8-1/4

8-1/4

8-1/4

14

14

14

16-1/2

16-1/2

16-1/2

16-1/2

20

20

20-1/2

21-1/2

22

16

16

17-1/2

17-1/2

17-1/2

19

19

19

21

21

21

23

24-1/2

24-1/2

24-1/2

25

27-1/2

30

30

30

17-1/2

24

17

23

26-1/2

24

32

38

32

29-1/2

43

50

60

72-1/2

113-1/2

121

132

6

6

6

6

6

6

6

6

6

6

6

8

10

10

10

12

14

14

14

14

Skid

Spacing

F

31

48

36

48

55

48

64

76

64

59

86

98

120

131

195

218

220

17

17

21

21

21

25-1/2

25-1/2

25-1/2

30

30

30

34

38

38

38

42-1/2

47

51

59-1/2

68

Inspection

Opening

G

Optional

4” x 6”

Handhole

11” x 15”

Manhole

Optional

4” x 6”

Handhole

11” x 15”

Manhole

Inlet

Outlet

Opening

1-1/2

1-1/2

2

2

2

2

2

2

2

3

3

3

3

3

3

4

4

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

2

2

2

2

2

2

2

3

3

3

3

3

3

4

4

Drain

Opening

3/4

3/4

3/4

3/4

3/4

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

1-1/2

1-1/2

2

2

2

2

2

3/4

3/4

3/4

3/4

3/4

3/4

3/4

3/4

1-1/4

1-1/4

1-1/4

1-1/2

1-1/2

1-1/2

1-1/2

2

2

2

2

2

Relief

Valve

Opening**

3/4

1

1

1

1

1

1

1

1

1

1

1

1-1/4

1-1/2

1-1/2

1-1/2

1-1/2

3/4

3/4

3/4

3/4

1

1

1

1

1

1

1

1

1

1

1

1

1-1/2

1-1/2

1-1/2

1-1/2

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith reserves the right to make product changes or improvements without prior notice.

Revised January 2013

February 2010R

www.hotwater.com

Page 2 of 4

AOSCE15500

Page 3

Commercial Electric

Water Heaters

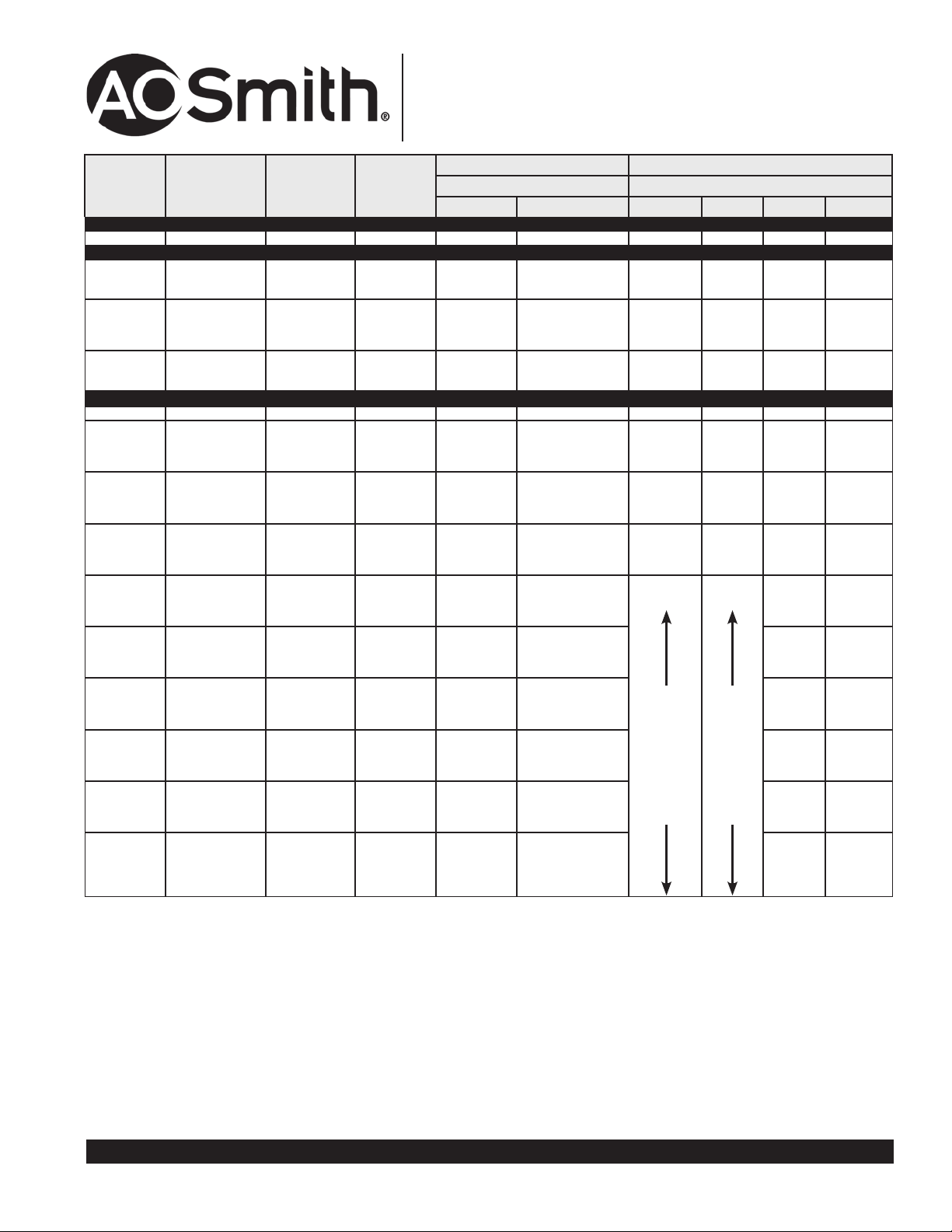

NUMBER OF 50A CONTACTORS AMPERAGE DRAW

STANDARD

KW RATINGS

XI ON/OFF

15 1-15kW 51,195 61 1 1 42 37 19 15

XI PROGRESSIVE

24

30

36

45

60

75

90

105

120

150

SOLID STATE STEP CONTROL

180 12-15kW 614,340 738 12 6 499 433 217 173

210

240

270

300

330

360

390

420

450

480

510

540

570

600

630

660

690

720

810

900

990

1080

1170

1260

1350

1440

1530

1620

1800

1980

2040

2220

2250

2400

2540

2820

3000

NUMBER OF

IMMERSION

HEATERS

2-12kW

2-15kW

3-12kW

3-15kW

4-15kW

5-15kW

6-15kW

7-15kW

8-15kW

10-15kW

14-15kW

16-15kW

18-15kW

20-15kW

22-15kW

24-15kW

26-15kW

28-15kW

30-15kW

32-15kW

34-15kW

36-15kW

38-15kW

40-15kW

42-15kW

44-15kW

46-15kW

48-15kW

54-15kW

60-15kW

66-15kW

72-15kW

78-15kW

84-15kW

90-15kW

96-15kW

102-15kW

108-15kW

120-15kW

132-15kW

136-15kW

148-15kW

150-15kW

160-15kW

176-15kW

188-15kW

200-15kW

BTU INPUT

& OUTPUT

81,912

102,390

122,868

153,585

204,720

255,975

307,170

358,365

409,560

511,950

716,730

819,120

921,510

1,023,900

1,126,290

1,228,680

1,331,070

1,433,460

1,535,850

1,638,240

1,740,630

1,843,020

1,945,410

2,047,800

2,150,190

2,252,580

2,345,970

2,457,360

2,764,530

3,071,700

3,378,870

3,686,040

3,993,210

4,300,380

4,607,550

4,914,720

5,221,890

5,529,060

6,141,600

6,757,740

6,962,520

7,576,860

7,679,250

8,188,800

9,010,320

9,624,660

10,236,000

GPH

RECOVER

100°F RISE

98

123

147

184

246

307

369

430

492

615

861

984

1,107

1,230

1,353

1,476

1,599

1,722

1,845

1,968

2,091

2,214

2,337

2,460

2,583

2,706

2,829

2,952

3,321

3,690

4,059

4,428

4,797

5,166

5,535

5,904

6,273

6,642

7,380

8,118

8,364

9,102

9,225

9,840

10,824

11,562

12,300

208V, 240V 480V, 600V 208V 240V 480V 600V

2

2

3

3

4

5

6

7

8

10

14

16

18

20

22

24

26

28

30

32

34

36

38

40

100

1

1

1

2

2

3

3

4

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

27

30

33

36

39

42

45

48

51

54

60

66

68

74

75

80

88

94

67

83

100

126

167

208

250

292

333

416

583

666

750

832

916

999

1,083

1,166

1,249

1,332

1,416

1,499

1,582

1,664

Not Recommended

58

72

87

109

145

181

217

253

289

361

505

577

650

722

794

866

938

1,010

1,083

1,155

1,227

1,299

1,371

1,443

Not Recommended

1,083

1,083

1,191

1,299

1,408

1,516

1,624

1,732

1,841

1,949

2,707

2,887

3,175

3,392

3,608

ESAHP-EERHTESAHP-EERHT

109

127

145

180

253

289

325

361

397

433

469

505

542

578

613

650

686

722

758

794

830

866

974

830

866

974

27

36

43

54

72

90

23

29

35

44

58

72

87

101

115

144

202

231

260

289

318

346

375

404

433

462

491

520

548

577

606

635

664

693

779

866

953

1,039

1,126

1,213

1,300

1,386

1,473

1,559

1,732

1,905

1,963

2,136

2,165

2,310

2,540

2,714

2,887

The heater(s) shall be A. O. Smith Commercial Electric Model Number ___________________ or an approved equal. Heater(s) shall be rated at _______ kW,

_______ V, _______ phase, 60 cycle AC. The heater shall be for (vertical/horizontal) installation with lifting lugs and channel skid base. Vessel shall be

constructed to Section IV of the ASME Code for 125 psi working pressure. Vessel shall be glass-lined with anodic protection. Entire vessel and electrical

controls are to be encased in a rectangular sheet metal enclosure with baked enamel finish. Tank to be insulated with fiberglass insulation. Separate 2” dial type

temperature gauge will be mounted on the front of the enclosure. Enclosure to have hinged locking door over electric controls. There shall be ____________

individually replaceable _______ kW, 4 bolt flange mounted, incoloy sheathed heating elements each complete with prewired terminal leads. These elements

will be switched by magnetic contactors which are operated by a 120V fused control circuit protected by manual reset high limit. Control circuit is activated by

a master pilot switch and electronic low water cutoff. The thermostatic control of the contacts shall be in _______ stages through solid state modulating step

control which will balance the water heating input to the demand. This control shall prevent the entire electrical load from being switched on instantaneously.

The control shall have even load progressive sequencing which utilizes the “first on, first off” principle thereby equalizing the operating time of heating

elements and contactors. Each magnetic contactor and heating element circuit will be protected by a maximum of 60 amp cartridge type fuses with a minimum

of 100,000 amp interrupting capacity. The entire water heating package shall be prewired to solderless terminal lugs, factory tested, complete with a CSA

Certified and ASME Rated T&P relief valve and bear the Underwriters’ Laboratories label. Heater(s) shall have a 3-year limited warranty as outlined in the written

warranty. Fully illustrated instruction manual included. Water heater units 150kW standard ratings and below should incorporate the iCOMM™ system for

remote monitoring, leak detection and fault alert.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith reserves the right to make product changes or improvements without prior notice.

Revised January 2013

February 2010R

www.hotwater.com

SAMPLE SPECIFICATIONS

Page 3 of 4

AOSCE15500

Page 4

Commercial Electric

Water Heaters

OPTIONS

TANK LININGS

CEMENT – A special formulation of cement providing

excellent corrosion protection. Available on 200 gallon and

larger tanks.

EPOXY – A solventless two component epoxy lining applied

to a minimum ten-mil (.010”) dry thickness. Available on 200

gallon and larger tanks.

GOLDENROD

Goldenrod

with the Goldenrod

pending). Goldenrod

times the scaling resistance of standard incoloy elements.

Goldenrod

failure due to scale buildup.

SPECIAL CONSTRUCTION

SILICON BRONZE VESSELS – Are available for special

applications or very corrosive water conditions. Consult

factory for specific sizes.

STAINLESS STEEL VESSELS – Are available for deionized

water. Built with stainless steel under rules of Section IV of

the ASME Boiler and Pressure Vessel Code for operation on

deionized water having a minimum specific resistivity of 10

megohm/cm.

®

ELEMENTS – Available with Optional

®

Elements - All DVE/DHE models are available

®

Elements carry a three-year warranty against

®

24K gold plated elements (patent

®

Elements provide long-life and five

CONTROL OPTIONS

COPPER TUBE TANK HEATER – Double wall copper tube

tank heaters are designed for heating potable water with

both potable or non-potable liquids or steam, and are

specifically engineered for installation in models DVE and

DHE for dual-energy applications. Tank heaters have a

positive fail-safe means of leak detection in the event of

either tube failure to prevent mixture of heating medium

and potable water. Singlewall heat exchangers are also

available.

TERMINAL BLOCKS – Allows for remote connection to

building demand limiter or other functions.

AUTOMATIC RESET HIGH LIMIT – A control that in the

event of high temperature, interrupts power, de-energizing

elements, automatic reset. (Standard with modulating step

control).

INDICATING LIGHTS – Denotes heating stage(s) in

operation. Up to one light per contactor is available.

OVERRIDE SWITCHES – A simple means of load control

allows all or part of unit input to be controlled manually. Up

to one switch per contactor is available

SAFETY DOOR INTERLOCK – Prevents opening of control

panel door when heater power supply is on. NOTE: Once

door is opened heater may be energized if necessary for

service diagnosis.

150 OR 160 PSI WORKING PRESSURE – Must be specified

at time of order.

OTHER OPTIONAL FEATURES

TEMPERATURE AND PRESSURE RELIEF VALVES – For

working pressures other than standard; consult factory.

HORIZONTAL OR VERTICAL – See specifications, most

gallon capacities may be obtained in vertical or horizontal

construction.

CIRCULATING PUMP PACKAGE – Circulating pump and

piping sized to turn over entire storage capacity of tank

once each hour. Recommended to optimize available water

at temperature in horizontal tanks particularly where low

draw conditions are anticipated.

OPTIONAL INTERNATIONAL VOLTAGES – 380 and 415 volts

three-phase.

3-1/2” DIAL-TYPE PRESSURE GAUGE – Factory-installed.

3-1/2” DIAL-TYPE TEMPERATURE GAUGE – Factory-

installed.

11” x 15” MANHOLE – Available as option on tanks 700

gallons or smaller.

SHUNT TRIP CIRCUIT BREAKER – A safety device (circuit

breaker) which disconnects power to heater in the event of

over-current, high temperature or low water level, breaker

must be manually reset.

CIRCUIT BREAKER – A safety device which disconnects

power to the heater in the event of overcurrent.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith reserves the right to make product changes or improvements without prior notice.

Revised January 2013

February 2010R

www.hotwater.com

Page 4 of 4

AOSCE15500

Loading...

Loading...