A.O. Smith BTX-100 User Manual

Commercial Gas Water Heaters

96% THERMAL EFFICIENCY

VERSATILE POWER DIRECT-VENT

The Cyclone Xi™ is a light-duty, power direct-vent, fully condensing commercial gas water

heater with an internal helical heat exchanger. This helical heat exchanger helps Cyclone Xi

achieve 96% thermal efficiency and deliver outstanding hot water output.

HELICAL INTERNAL HEAT EXCHANGER

n

Completely surrounded by water in tank, provides much greater heat transfer

surface than standard straight flue tube

n

Produces 96% thermal efficiency, which saves money on operating costs,

increases hot water output compared to standard-efficiency water heaters

n

Minimizes standby losses by trapping heat in the tank

VERSATILE POWER DIRECT-VENT DESIGN

n

Power Direct-Vent System allows up to 120 feet using PVC, CPVC, or ABS pipe. Can be

vented vertically thru-the-roof or horizontally thru-the-wall

n

2” pipe, vents up to 20 equivalent feet

n

3” pipe, vents up to 60 equivalent feet

n

4” pipe, vents up to 120 equivalent feet

n

Optional concentric vent kit available

CONDENSING DESIGN

n

96% efficient condensing deign

n

Equipped with condensate drain tee

HIGH OUPUT WITH SMALL FOOTPRINT

n

22” diameter, combined with 96% efficiency, 50-gallon tank and 100,000 BTU

input means Cyclone Xi can be installed in less space than a larger 75-gallon

unit, with equal or better performance

n

Total height is 68-1/2” to top of unit

SIDE-MOUNTED HOT AND COLD RECIRCULATING TAPS

n

Allows Cyclone Xi to be installed as part of combination space heating/water

heating applications, or any system requiring a recirculating hot water loop

n

Plugs for the recirculating taps are factory installed

ADVANCED ELECTRONIC CONTROL

n

Large LCD display

n

Precise temperature control

n

Advanced diagnostics

PERMAGLAS® ULTRA COAT™ GLASS LINING

n

A. O. Smith exclusive process provides superior protection against corrosion

n

Protects all interior tank surfaces including inside and outside of helical

heat exchanger

TWO HEAVY-DUTY ANODE RODS

n

Provides advanced protection against corrosion

AVAILABLE IN NATURAL GAS AND PROPANE

®

TOP FIRED LOW-NOX GREEN CHOICE

n

“Eco-friendly” design reduces NOx emissions

and complies with Southern California and Texas requirements

FACTORY-INSTALLED TEMPERATURE AND PRESSURE RELIEF VALVE

MAXIMUM HYDROSTATIC WORKING PRESSURE: 150 PSI

CODES AND STANDARDS

n

Design-certified by UL (Underwriters Laboratories) according to

ANSI Z21.10.3-CSA4.3 standards governing storage-type water heaters

n

These models meet or exceed the thermal efficiency and standby loss requirements of

ASHRAE 90.1 (current standard)

GAS BURNER

BTX-100

GAS-FIRED GAS-FIRED

AOSCG10101April 2008

Page 1 of 2

Commercial Gas Water Heaters

96% THERMAL EFFICIENCY

VERSATILE POWER DIRECT-VENT

THREE-YEAR LIMITED TANK WARRANTY

n

For complete warranty details, consult written warranty shipped with heater or contact A. O. Smith

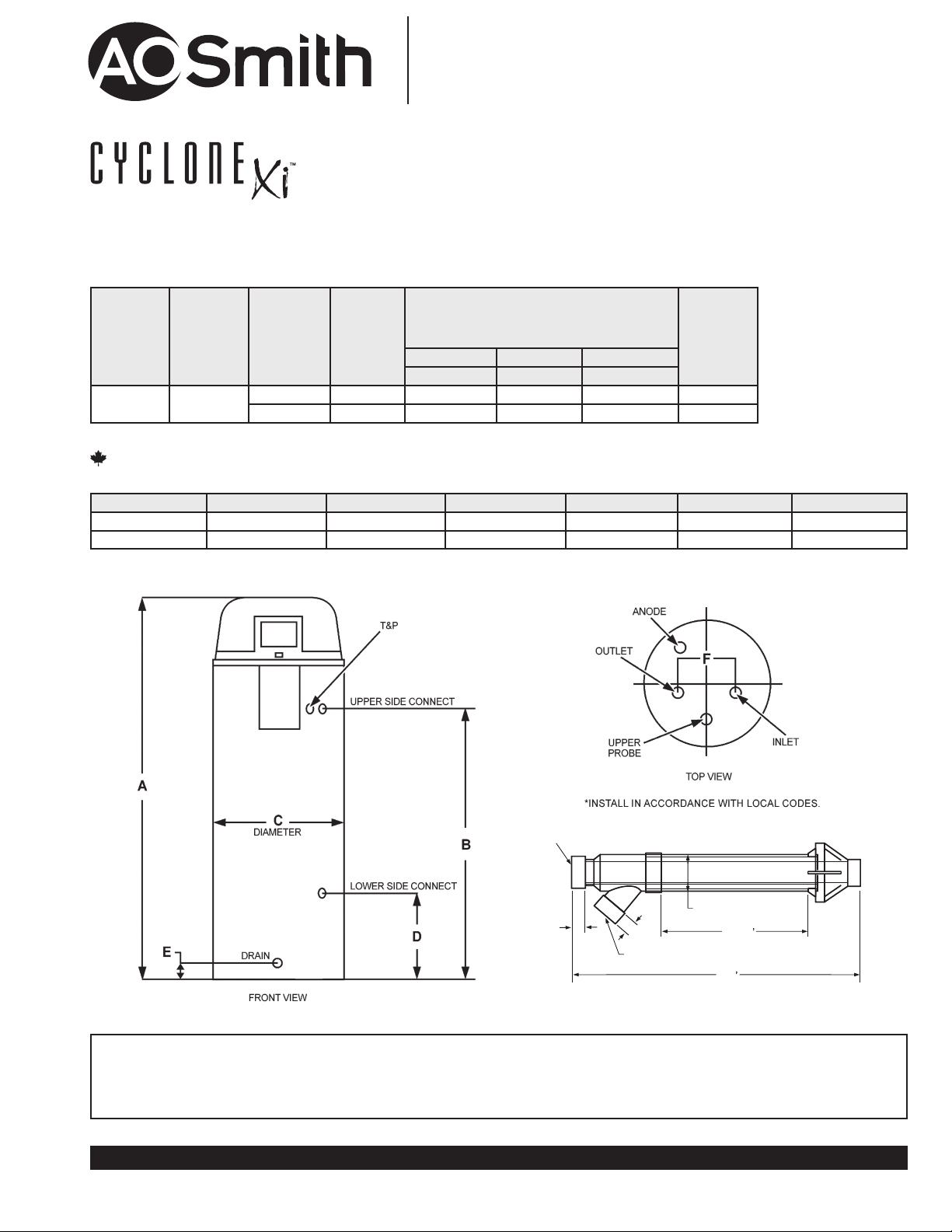

SPECIFICATIONS

MODEL

NUMBER

INPUT

PER

HOUR

BTX-100 100,000

Maximum Supply Pressure: 14 inches W.C. (3.48kPa) n Minimum Supply Pressure for Natural Gas: 3.50” (.87kPa) n Minimum Supply Pressure for Propane Gas: 8.00” (1.99kPa)

Minimum pressure must be maintained under both load and no load (dynamic and static) conditions. n Electrical Characteristics - 120V, 60Hz, Amperes <5

Approved for Canada

BTU

GALLONS

OR

LITRES

Gallons

Litres

TANK

SIZE

50 291 116 83 255 lbs

189 1102 439 314 115.7 kg’s

DIMENSIONS

BTX-100 A B C D

INCHES 68-1/2 49-1/4

CM 174 125.09 55.88 40 7.62

Top inlet and outlet: 3/4” male NPT n Side inlet and outlet: 3/4 ” female NPT n Gas inlet: 1/2” NPT n Availabl e natural gas a nd propane

RECOVERY - GALLONS OR

LITRES PER HOUR AT

DEGREE RISE

40°F 100°F 140°F

22°C 56°C 78°C

22 15-3/4 3 8

SHIPPING

WEIGHT

E

F

20.32

3” DIAMETER

PVC VENT/EXHAUST

4 1/2” DIAMETER

*21 1/8”

**39”

1 1/2”

1 3/16”

3” DIAMETER PVC

INTAKE/COMBUSTION AIR

OPTIONAL CONCENTRIC VENT KIT

SUGGESTED SPECIFICATION

(Natural or Propane) gas water heater(s) shall be A. O. Smith Cyclone Xi model # BTX-100, with 96% thermal efciency, a storage capacity of 50 gallons, an input rating of 100,000 BTUs per hour, a

recovery rating of 116 gallons per hour at 100ºF rise and a maximum hydrostatic working pressure of 150 psi. Water heater(s) shall be of power direct-vent design, using 2”, 3” or 4” PVC pipe for

horizontal and/or vertical vent runs. Water heater(s) shall have: 1: Seamless, glass lined steel tank construction and a spiral-shaped heat exchanger placed entirely inside the tank, which shall be glass

lined on the ue gas side to protect against acidic condensate. 2: Advanced electronic control w/ LCD display and actual diagnotic. 3: A 3-year limited warranty against tank leaks. Water heater(s) shall

meet or exceed ASHRAE 90.1 (current standard), and be design-certied by UL (Underwriters Laboratories) according to ANSI Z21.10.3-CSA4.3 standards governing storage tank water heaters.

For Technical Information and Automated Fax Service, call 800-527-1953. A.O. Smith Corporation reserves the right to make product changes or improvements without prior notice.

Page 2 of 2

www.hotwater.com

AOSCG10101

Loading...

Loading...