A.O. Smith BTH-120A, BTH-150A, BTH-199A, BTH-250A, BTH-300A Installation Manual

...

Instruction Manual

COMMERCIAL GAS WATER HEATERS

MODELS

BTH-120(A)/150(A)/199(A)/250(A)

SERIES 200 & 201

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.hotwater.com

INSTALLATION - OPERATION - SERVICE

- MAINTENANCE - LIMITED WARRANTY

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do

•

not use any phone in your building.

Immediately call your gas supplier

•

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

•

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Thank you for buying this energy efcient water heater.

We appreciate your condence in our products.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED 0514 327727-000

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE.......................................... 3

APPROVALS .......................................................................................... 3

GENERAL SAFETY INFORMATION ...................................................... 4

Precautions ........................................................................................ 4

Grounding Instructions ...................................................................... 4

Hydrogen Gas Flammable ................................................................. 4

INTRODUCTION .................................................................................... 6

Abbreviations Used ........................................................................... 6

Qualications ..................................................................................... 6

iCOMM™ & BACnet Compatible ....................................................... 6

Preparing For The Installation ...........................................................6

FEATURES AND COMPONENTS ......................................................... 7

Basic Operation ................................................................................. 7

Modulation ......................................................................................... 7

Blower/Burner Assembly Detail ......................................................... 7

Top View ............................................................................................ 8

Side Views ......................................................................................... 9

INSTALLATION CONSIDERATIONS ................................................... 10

Rough In Dimensions ......................................................................10

Locating The Water Heater ...............................................................11

Extended Vent Terminations ............................................................ 12

Optional Concentric & Low Prole Terminations.............................. 12

Hard Water ......................................................................................12

Circulation Pumps ........................................................................... 12

Insulation Blankets .......................................................................... 12

INSTALLATION REQUIREMENTS ...................................................... 13

Gas Supply Systems .......................................................................13

Supply Gas Regulator ..................................................................... 13

Power Supply .................................................................................. 13

Mixing Valves ................................................................................... 14

Dishwashing Machines .................................................................... 14

Closed Water Systems .................................................................... 14

Thermal Expansion .......................................................................... 14

Temperature-Pressure Relief Valve ................................................. 15

Condensate Drain ............................................................................ 16

Combustible Material Storage .........................................................16

Contaminated Air ............................................................................. 16

Air Requirements ............................................................................. 17

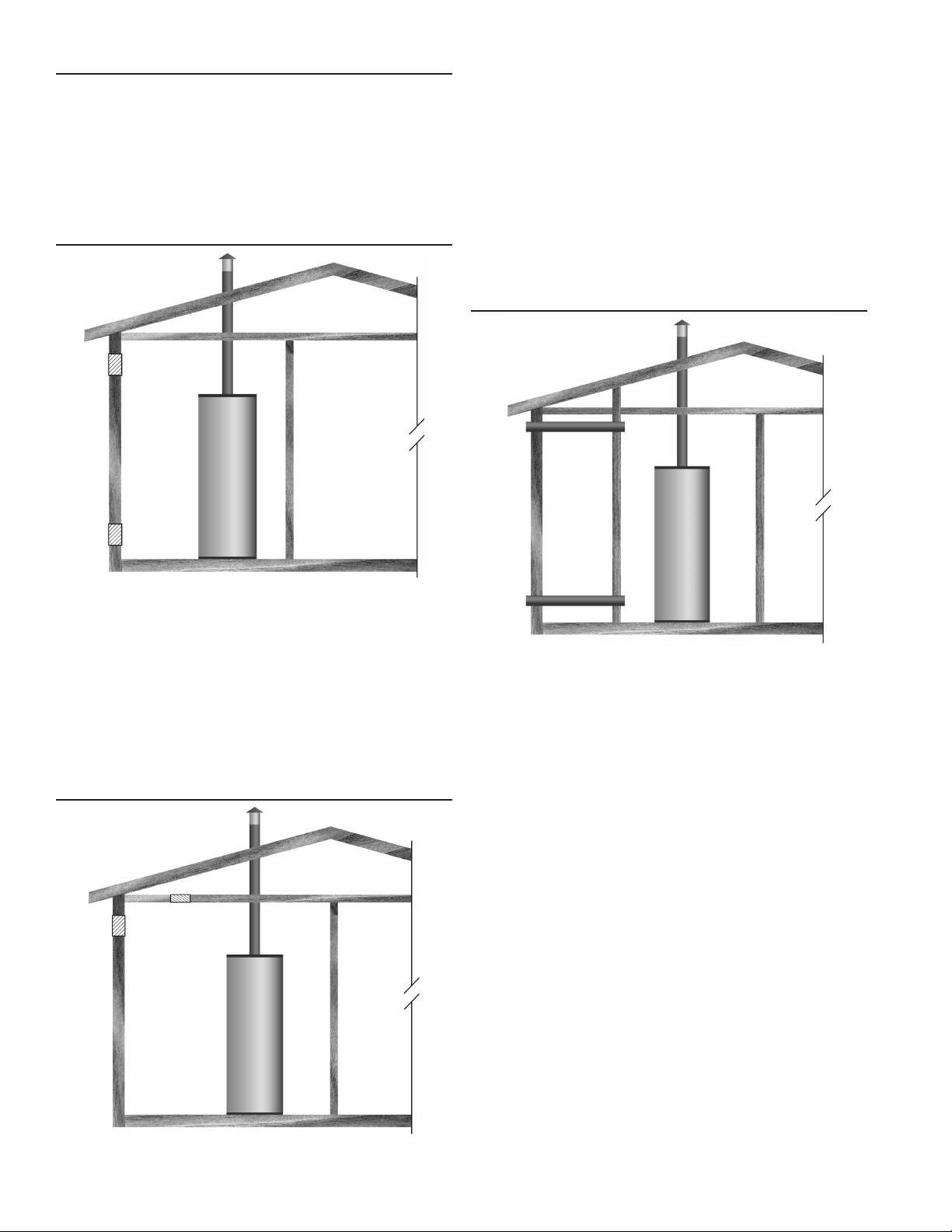

Unconned Space ...........................................................................17

Conned Space ............................................................................... 17

Fresh Air Openings For Conned Spaces ....................................... 18

Outdoor Air Through Two Openings ................................................ 18

Outdoor Air Through One Opening .................................................. 18

Outdoor Air Through Two Horizontal Ducts ..................................... 18

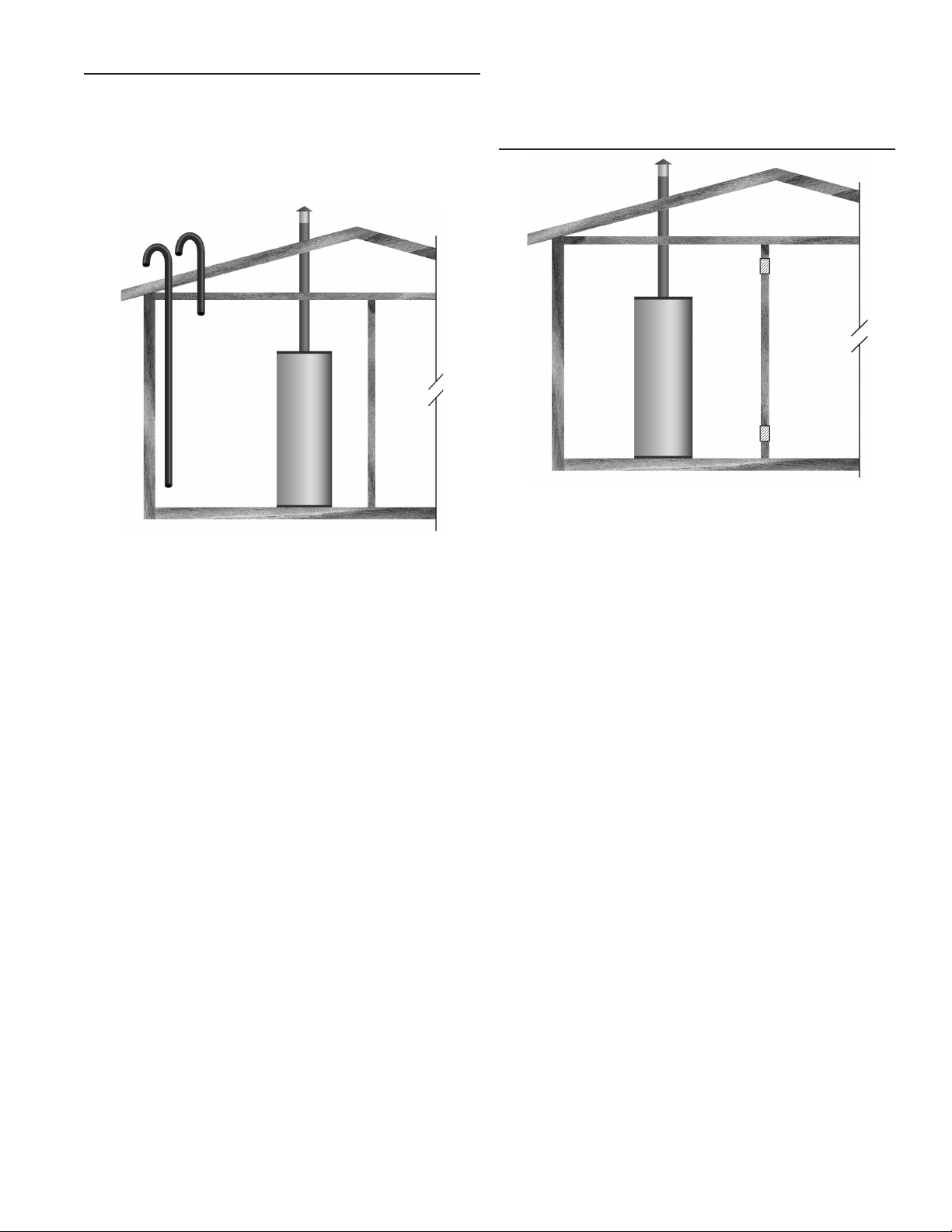

Outdoor Air Through Two Vertical Ducts .......................................... 19

Air From Other Indoor Spaces ......................................................... 19

INSTALLATION REQUIREMENTS - COMMONWEALTH OF

MASSACHUSETTS .............................................................................. 20

VENTING INSTALLATION ................................................................... 21

General Venting Information ............................................................ 21

General Venting Instructions ...........................................................21

Intake Air Connection ......................................................................22

Venting Requirements ..................................................................... 22

Venting Installation Sequence ......................................................... 23

Power Vent Installation .................................................................... 23

Direct Vent Installation ..................................................................... 24

Vertical Termination Installation ....................................................... 25

Sidewall Termination Installation...................................................... 27

Polypropylene Installations .............................................................. 28

AL29-4C® Vent Installations ........................................................... 29

Concentric Termination Installation .................................................. 30

4 Inch Concentric Termination Installation ....................................... 31

Low Prole Vent installation ............................................................. 34

Venting Arrangements ..................................................................... 35

Termination Clearances Sidewall Power Vent ................................. 37

Termination Clearances Sidewall Direct Vent .................................. 38

WATER HEATER INSTALLATION ........................................................ 39

Condensate Drain Installation ......................................................... 39

Supply Gas Line Installation ............................................................ 40

Gas Line Leak Testing ..................................................................... 41

Purging ............................................................................................41

Electrical Wiring ............................................................................... 41

Enable / Disable Circuit (For Building Management Systems) ........ 42

Water Line Connections ..................................................................43

T&P Valve Discharge Pipe ............................................................... 43

TEMPERATURE REGULATION .......................................................... 44

High Temperature Limit Control (ECO) ............................................ 44

Thermostat Control .......................................................................... 44

CONTROL SYSTEM OPERATION ...................................................... 45

Overview .......................................................................................... 45

Control System Navigation .............................................................. 45

User Settings & Control System Menus .......................................... 48

START UP ............................................................................................ 53

Prior to Start up ............................................................................... 53

Initial Start Up .................................................................................. 53

Lighting & Operation Labels ............................................................54

Checking The Firing Rate ................................................................ 56

High Altitude Installations ................................................................56

TROUBLESHOOTING ......................................................................... 57

Installation Checklist ........................................................................ 57

Sequence Of Operation ................................................................... 57

Sequence Of Operation Flow Chart ................................................ 58

Operational Problems ...................................................................... 59

Fault And Alert Conditions ............................................................... 60

MAINTENANCE ................................................................................... 63

General ............................................................................................ 63

Maintenance Schedule .................................................................... 63

Draining And Flushing .....................................................................63

Filling The Water Heater .................................................................. 64

Sediment Removal ..........................................................................64

Lime Scale Removal ........................................................................ 64

Powered Anode Rods ...................................................................... 65

Drain Valve and Access Panels ....................................................... 65

Vent System ....................................................................................65

DIAGRAMS .......................................................................................... 66

CCB - Central Control Board Layout ...............................................66

Wiring Diagram ................................................................................ 67

Circulation Pump Wiring Diagrams .................................................. 68

Water Piping Diagrams .................................................................... 69

NOTES ................................................................................................. 76

NOTES ................................................................................................. 77

NOTES ................................................................................................. 78

SERVICE INQUIRIES: ......................................................................... 79

COMMERCIAL ..................................................................................... 79

WATER HEATER ................................................................................. 79

LIMITED WARRANTY .......................................................................... 79

2

SAFE INSTALLATION, USE AND SERVICE

The proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and

others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important

that the meaning of each safety message is understood by you and others who install, use, or service this water heater.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

hazardous situation which, if not avoided,

will result in injury or death.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in injury or death.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message, and

how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances

known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of

potential exposure to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive harm. This

water heater can cause low level exposure to some of the substances listed in the Act.

symbol indicates a potentially hazardous

situation which, if not avoided, could result in

property damage.

APPROVALS

NOTE: ASME construction is optional on the water

heaters covered in this manual.

3

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS WATER HEATER IF ANY PART HAS

BEEN EXPOSED TO FLOODING OR WATER DAMAGE.

Immediately call a qualied service agency to inspect the

water heater and to make a determination on what steps

should be taken next.

If the unit is exposed to the following, do not operate heater

until all corrective steps have been made by a qualified

service agency.

1. External re.

2. Damage.

3. Firing without water.

GROUNDING INSTRUCTIONS

This water heater must be grounded in accordance with the

National Electrical Code and/or local codes. These must be

followed in all cases. Failure to ground this water heater

properly may also cause erratic control system operation.

This water heater must be connected to a grounded metal,

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment grounding terminal or lead on

the water heater.

Verify the power to the water heater is turned off before performing any service procedures.

The Enable /Disable switch on front panel disables the 24 volt gas valve. Electrical supply

must be turned off at circuit breaker serving water heater.

HYDROGEN GAS FLAMMABLE

Explosion Hazard

Flammable hydrogen gases

may be present.

Keep all ignition sources away

from faucet when turning on

hot water.

Hydrogen gas can be produced in a hot water system served

by this water heater that has not been used for a long period of

time (generally two weeks or more). Hydrogen gas is extremely

ammable. To reduce the risk of injury under these conditions, it is

recommended that a hot water faucet served by this water heater

be opened for several minutes before using any electrical appliance

connected to the hot water system. If hydrogen is present there will

probably be an unusual sound such as air escaping through the pipe

as the water begins to ow. THERE SHOULD BE NO SMOKING

OR OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

Explosion Hazard

Overheated water can cause

water tank explosion.

Properly sized temperature and

pressure relief valve must be

installed in the opening provided.

CAUTION

Improper installation, use and service may result

in property damage.

Do not operate water heater if exposed to flooding or

•

water damage.

Inspect anode rods regularly, replace if damaged.

•

Install in location with drainage.

•

Fill tank with water before operation.

•

Properly sized thermal expansion tanks are required on all

•

closed water systems.

Refer to this manual for installation and service.

4

GENERAL SAFETY INFORMATION

Fire or Explosion Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake

with insulating blanket.

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

CAUTION

Property Damage Hazard

All water heaters eventually leak.

•

Fire Hazard

For continued protection against

risk of fire:

Do not install water heater on

carpeted floor.

Do not operate water heater if

exposed to flooding or water

damage.

Fire and Explosion Hazard

Use joint compound or Teflon tape

compatible with propane gas.

Leak test gas connections before

placing water heater in operation.

Disconnect gas piping at main

gas shutoff valve before leak

testing heater.

Install sediment trap in

accordance with NFPA 54 or

CAN/CSA B149.1.

Fire and Explosion Hazard

Do not use water heater with any gas

other than the gas shown on the rating

label.

Excessive gas pressure to gas valve can

cause serious injury or death.

Turn off gas lines during installation.

Contact a qualified installer or service

agency for installation and service.

Do not install without adequate drainage.

•

Electrical Shock Hazard

Turn off power at the branch circuit

•

breaker serving the water heater

before performing any service.

Label all wires prior to disconnecting

•

when performing service. Wiring errors

can cause improper and dangerous

operation.

Verify proper operation after servicing.

•

Failure to follow these instructions can

•

result in personal injury or death.

Jumping out control circuits or components can

result in property damage, personal injury or death.

Service should only be performed by a qualified service

•

technician using proper test equipment.

Altering the water heater controls and/or wiring in any way

•

could result in permanent damage to the controls or water

heater and is not covered under the limited warranty.

Any bypass or alteration of the water

heater controls and/or wiring will result

in voiding the appliance warranty.

5

INTRODUCTION

Thank You for purchasing this water heater. Properly installed

and maintained, it should give you years of trouble free service.

ABBREVIATIONS USED

Abbreviations found in this Instruction Manual include :

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• AHRI - Air Conditioning, Heating and Refrigeration Institute

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratory

• CSA - Canadian Standards Association

QUALIFICATIONS

QUALIFIED INSTALLER OR SERVICE AGENCY

Installation and service of this water heater requires ability

equivalent to that of a Qualied Agency (as dened by ANSI

below) in the eld involved. Installation skills such as plumbing,

air supply, venting, gas supply and electrical supply are required

in addition to electrical testing skills when performing service.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualied Agency” - “Any

individual, rm, corporation or company that either in person or

through a representative is engaged in and is responsible for (a)

the installation, testing or replacement of gas piping or (b) the

connection, installation, testing, repair or servicing of appliances

and equipment; that is experienced in such work; that is familiar

with all precautions required; and that has complied with all the

requirements of the authority having jurisdiction.”

If you are not qualied (as dened by ANSI above) and licensed

or certied as required by the authority having jurisdiction

to perform a given task do not attempt to perform any of the

procedures described in this manual. If you do not understand

the instructions given in this manual do not attempt to perform

any procedures outlined in this manual.

ICOMM™ & BACNET COMPATIBLE

This water heater is compatible with the iCOMM™ remote

monitoring system. The iCOMM™ system hardware and

monitoring service is purchased separately. It allows users to

monitor critical operational, diagnostic and energy usage data

from a secure web site.

The iCOMM™ system can automatically notify selected

personnel via email and/or cellular phone text messages if

operational problems or user dened Alert Conditions occur.

iCOMM™ system hardware is compatible with BACnet compliant

supervisory controls and building management systems. For

more information call 888-928-3702.

PREPARING FOR THE INSTALLATION

1. Read the entire manual before attempting to install or operate

the water heater. Pay close attention to the General Safety

Information on page 4 and 5. If you don’t follow the safety

rules, the water heater may not operate safely. It could cause

property damage, injury and/or death.

This manual contains instructions for the installation,

operation, and maintenance of the water heater. It also

contains warnings throughout the manual that you must read

and be aware of. All warnings and all instructions are essential

to the proper operation of the water heater and your safety.

Detailed installation diagrams are also found in this manual.

These diagrams will serve to provide the installer with a

reference. It is essential that all venting, water piping, gas

piping and wiring be installed as shown.

Particular attention should be given to the installation

of thermometers at the locations indicated in the piping

diagrams as these are necessary for checking the operation

of the water heater.

The principal components of the water heater are identied

in Features And Components on page 7 in this manual. Use

this reference to locate and identify various components on

the water heater.

See the Installation Checklist and Troubleshooting on page

57. By using this checklist the user may be able to make minor

operational adjustments and avoid unnecessary service

calls. However, service and diagnostic procedures should

only be performed by a Qualied Service Agency.

NOTE: Costs to correct installation errors are not covered

under the limited warranty.

2. Be sure to turn off power when working on or near the

electrical system of the water heater. Never touch electrical

components with wet hands or when standing in water.

3. The installation must conform to all instructions contained in

this manual and the local code authority having jurisdiction.

These shall be carefully followed in all cases. Authorities

having jurisdiction should be consulted before installation

begins if there are any questions regarding compliance with

local, state or national codes.

In the absence of local codes, the installation must comply

with the current editions of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and the National Electrical Code, NFPA 70 or

CAN/CSA-B149.1, the Natural Gas and Propane Installation

Code and CSA C22.1, the Canadian Electrical Code. All

documents are available from the Canadian Standards

Association, 8501 East Pleasant Valley Road, Cleveland, OH

44131. NFPA documents are also available from the National

Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269.

4. If after reading this manual you have any questions or do

not understand any portion of the instructions, call the toll

free number on the back cover of this manual for technical

assistance. In order to expedite your request, please have the

full Model, Serial and Series number of the water heater you

are working with available for the technician. This information

is located on the water heater’s rating label.

5. Carefully plan the placement of the water heater. Examine

the location to ensure that it complies with the requirements

in Locating The Water Heater on page 11 and the Rough

In Dimensions on page 10.

6. For installation in California this water heater must be braced

or anchored to avoid falling or moving during an earthquake.

See instructions for correct installation procedures.

Instructions may be obtained from California Ofce of the

State Architect, 1102 Q Street, Suite 5100, Sacramento, CA

95811.

7. Massachusetts Code requires this water heater to be

installed in accordance with Massachusetts 248-CMR 2.00:

State Plumbing Code and 248-CMR 5. See Commonwealth

of Massachusetts on page 20.

6

FEATURES AND COMPONENTS

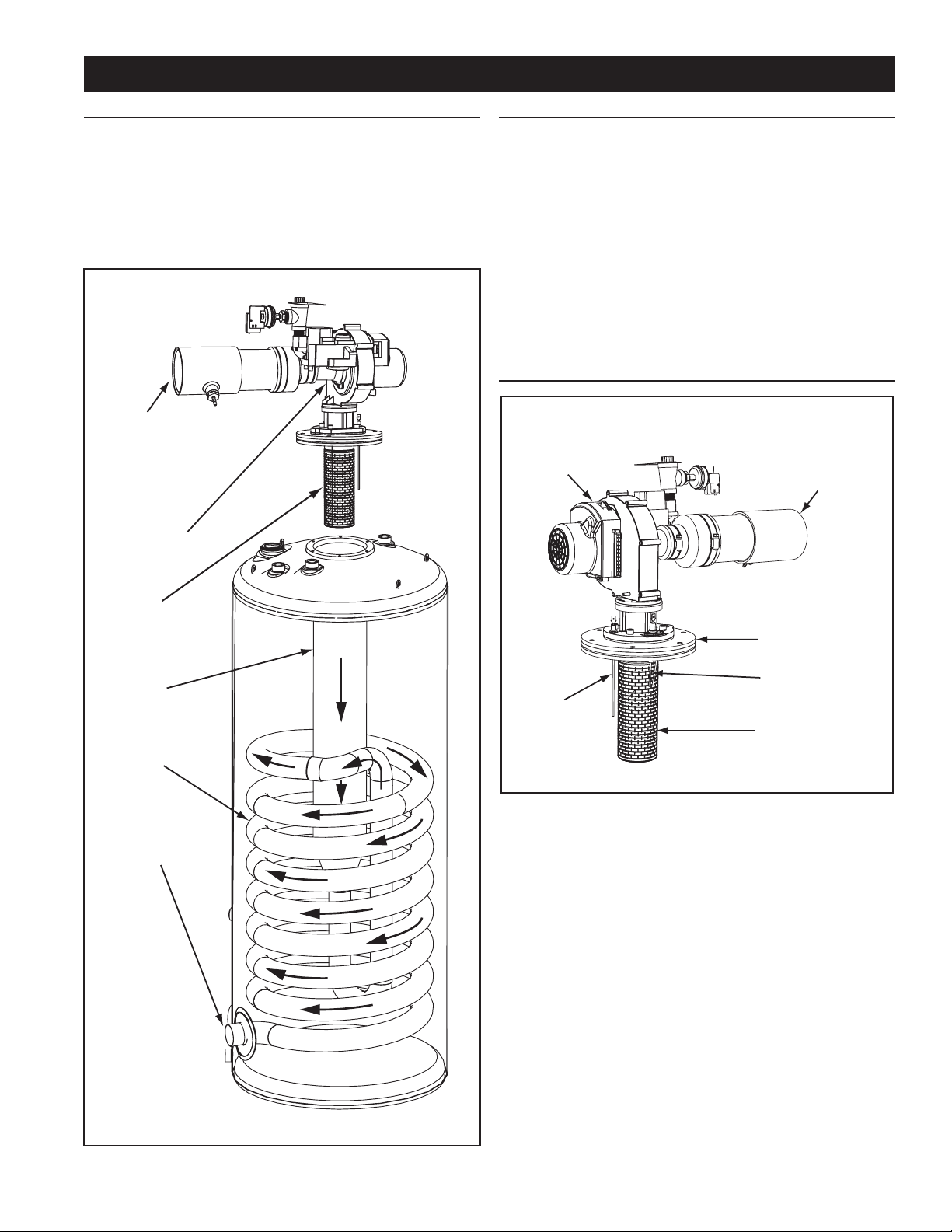

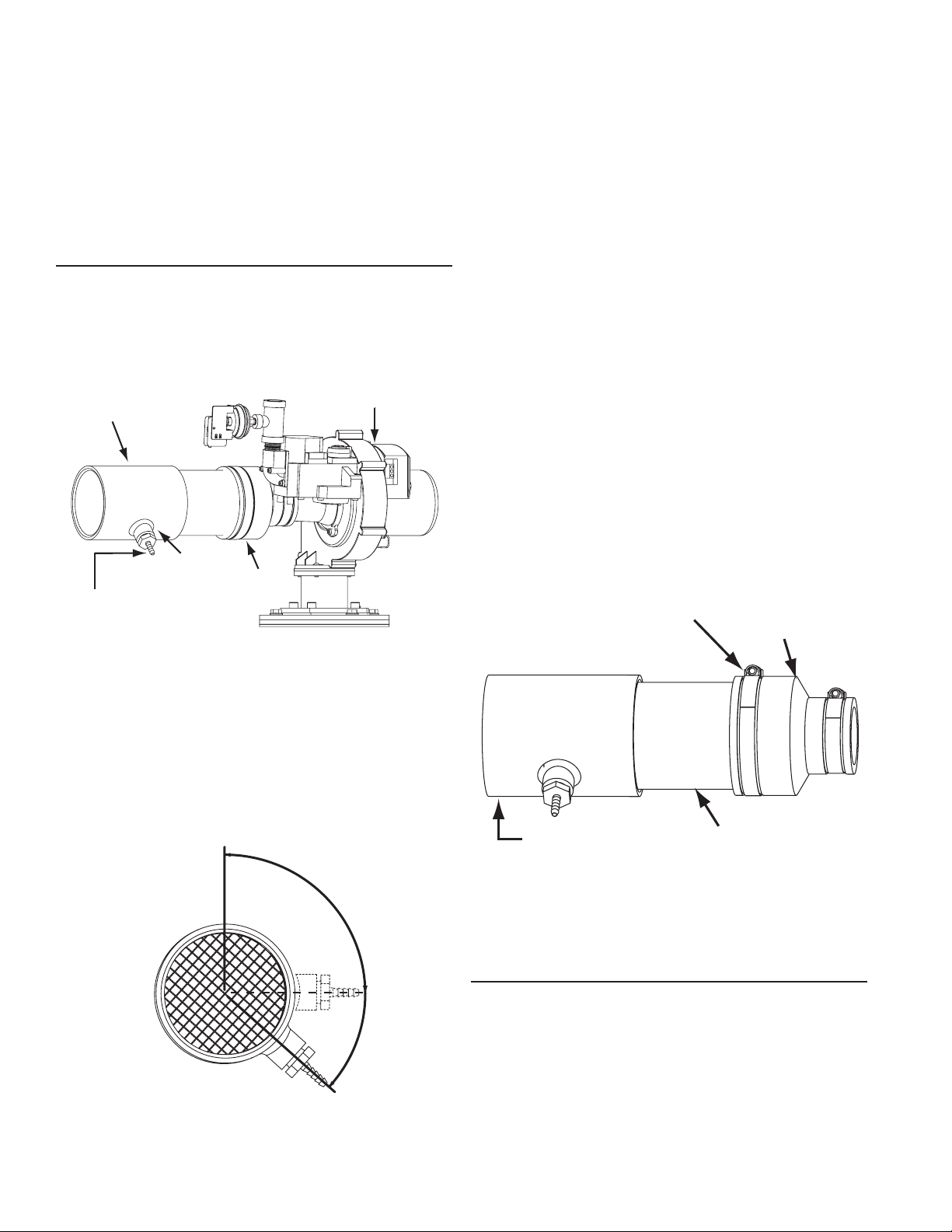

BASIC OPERATION

The water heaters covered in this manual have a helical coil

shaped heat exchanger that is submerged in the storage tank.

The water heater’s Main Burner is a radial design burner, it

is mounted on the top and res downward through the heat

exchanger. This is a forced draft burner; hot burning gases are

forced through the heat exchanger under pressure and exit

through the exhaust/vent connection located at the bottom of the

water heater. See Figure 1 and Figure 2.

INTAKE AIR

(combustion air)

CONNECTION

3 INCH PVC

BLOWER

BURNER

ASSEMBLY

MODULATION

The water heaters covered by this manual are capable of

modulating their ring rate. The CCB monitors the water

temperature in the tank and regulates the ring rate to achieve

the target temperature setpoint. The ring rate is dictated by

the hot water draw, proximity to the tank temperature setpoint,

and various other temperature limitations. Periodically, when the

heater is in modulation mode, the CCB will increase the blower

speed for a short period of time to clear out any condensation

that has accumulated in the heat exchanger then decreases

the blower speed back to the modulating ring rate required to

maintain the desired tank temperature setpoint. This ramping up

and down of the blower speed is considered normal operation of

the water heater.

BLOWER/BURNER ASSEMBLY DETAIL

COMBUSTION

BLOWER

ASSEMBLY

INTAKE AIR

(combustion air)

CONNECTION

3 INCH PVC

MAIN

BURNER

(radial design)

HEAT

EXCHANGER

HELICAL

COIL

VENT (exhaust)

OUTLET

BURNER

FLANGE

SPARK IGNITER

FLAME

SENSOR

Figure 2

Spark Igniter

The control system energizes the spark ignition control with 120

VAC during the ignition cycle. The spark ignition control then

sends a high-voltage current to the spark igniter which in turn

ignites the main burner air/gas mixture.

Flame Sensor

The control system also monitors the ame sensor to conrm

a ame is present at the Main Burner. If a ame is not veried

during the ignition trial period (3-5 seconds) the control system

will immediately de-energize the 24 Volt Gas Valve. See the

Sequence Of Operation Flow Chart on page 58.

MAIN

BURNER

(radial design)

Figure 1

7

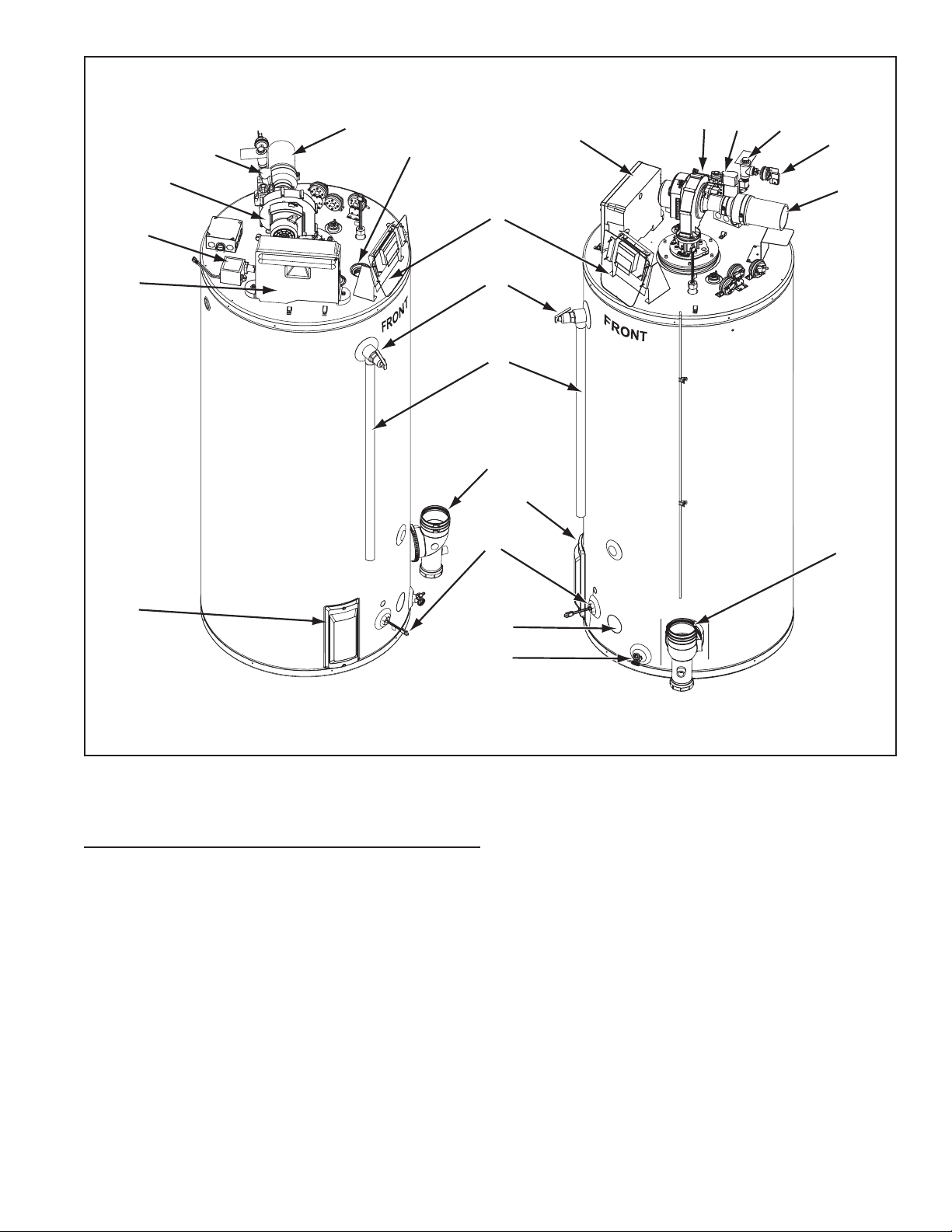

TOP VIEW OF ALL MODELS

TOP VIEW

6

5

2

18

4

8

9

11

2

13

3

14

16

1

FRONT

Figure 3

COMPONENTS (All Models)

IMPORTANT. The Enable/Disable switch listed in this manual is

NOT an "on/off" switch and does not disconnect 120 volt power

to the CCB and other heater components.

1. Water Heater’s Enable/Disable Switch. When in the "Disabled"

position the switch removes electrical power from the gas

valve and blower so that water heating is disabled. The

display, CCB, and other electrical components will still be

energized and the display will read "Water Heating Disabled".

2. Powered anode rods. The water heaters covered in this

manual are equipped with powered (non sacricial) anode

rods. The BTH 120 has one powered anode, all other models

will have two. Protective current is fed by the control system

to the titanium electrodes at the end of each anode rod. This

current ows through the water to the conductive surfaces

inside the storage tank which diminishes the corrosive effect

(rusting) of water when it comes in contact with steel.

3. Central Control Board (CCB) enclosure. This enclosure

houses the control system’s main circuit board, power supply

board, power transformer, and conguration key. The CCB

regulates water temperature and controls all water heater

functions, see Control System Operation on page 45.

4. Combustion Blower Assembly includes, Gas Valve and

Venturi gas feed system.

5. 120 VAC junction box. Incoming power supply, ground

connections, and other eld installed electrical connections

are made here. See Power Supply on page 13.

6. Water heater's 24 Volt Gas Valve.

7. Blocked Intake Air switch. Normally closed contacts that

open on fall in pressure. This switch is used to insure intake

(combustion) air to the water heater is not restricted. The

control system monitors this switch and will disable heating

operation if its contacts are open during a heating cycle.

8. Supply gas line connection. See the requirements for the

Gas Supply Systems on page 13.

9. Low Gas Pressure switch. Normally open contacts that close

on a rise in pressure. This switch is used to insure supply

7

12

10

15

17

gas pressure is above minimum requirements. The control

system monitors this switch and will disable heating operation

if its contacts are open during a heating cycle. See Gas

Pressure Requirements and Table 3 on page 11.

10. Vent connection (exhaust / condensate elbow) - three inch

aluminum.

11. Intake air connection - 3 inch PVC.

12. Blocked Exhaust (vent) switch. Normally closed contacts that

open on a rise in pressure. This switch is used to insure the

Exhaust (vent) piping connected to the water heater is not

restricted. The control system monitors this switch and will

disable heating operation if its contacts are open during a

heating cycle.

13. Blower Prover switch. Normally open contacts that close on a

rise in pressure. This switch is used to insure the Combustion

Blower is operating properly at blower start-up. The control

system monitors this switch and will disable heating operation

if its contacts are closed before the Combustion Blower is

energized. See Sequence Of Operation on page 57.

14. Temperature-Pressure Relief Valve. See TemperaturePressure Relief Valve on page 15.

15. Upper Temperature Probe, 1 of 2 temperature probes. The

water heater’s control system monitors this probe to detect

water temperature in the upper portion of the storage tank.

The Upper Temperature Probe also houses the ECO (energy

cut out) switch. This is a non adjustable high temperature

limit switch. The ECO switch contacts are normally closed

and will open on a temperature rise. See High Temperature

Limit Control (ECO) on page 44.

16. Water outlet connection 1 1/2” NPT.

17. UIM (user interface module). The UIM includes the display

circuit board, the control system’s LCD display and

operational buttons. Used to adjust various user settings and

view operational information. See Control System Operation

on page 45.

18. Spark Ignition Control. When energized, sends the electrical

current to the spark igniter.

8

5

4

3

4

6

2

13

14

16

2

1

5

3

7

8

9

15

1

10

15

11

LEFT SIDE RIGHT SIDE

Figure 4

SIDE VIEWS

1. Cleanout access panel, covers water heater cleanout

opening.

2. CCB enclosure - see item 3 on page 8 for description.

3. Intake air connection - 3 inch PVC.

4. Water heater 24 Volt Gas Valve.

5. Combustion Blower.

6. Water outlet - 1 1/2” NPT connection.

7. UIM (user interface module). The UIM includes the display

circuit board, the control system’s LCD display and

operational buttons. Used to adjust various user settings and

view operational information. See Control System Operation

on page 45.

8. Temperature-Pressure Relief Valve. See TemperaturePressure Relief Valve on page 15.

12

9. Temperature-Pressure Relief Valve discharge pipe - see T&P

Valve Discharge Pipe Requirements: on page 15.

10. Lower Temperature Probe, 1 of 2 temperature probes. The

water heater’s control system monitors this probe to detect

water temperature in the lower portion of the storage tank.

11. Water inlet - 1 1/2” NPT connection.

12. Water heater drain valve.

13. Supply gas line connection. See Gas Supply Systems on

page 13.

14. Low Gas Pressure switch, see description under beginning

on page 8. See Gas Pressure Requirements and Table

3 on page 11.

15. Vent Connection (Exhaust/Condensate Elbow) 3" Aluminum.

16. Spark Ignition Control. When energized, sends the electrical

current to the spark igniter.

9

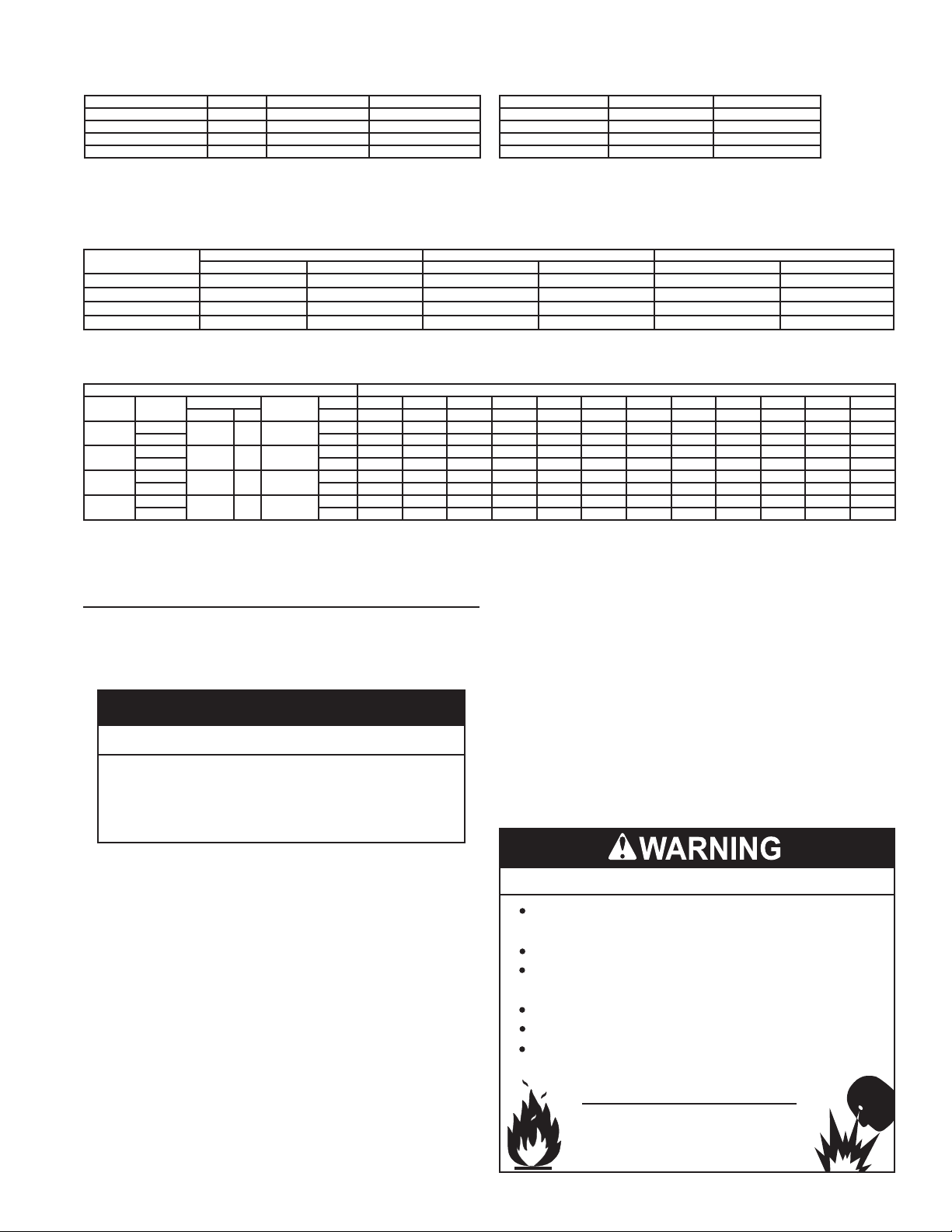

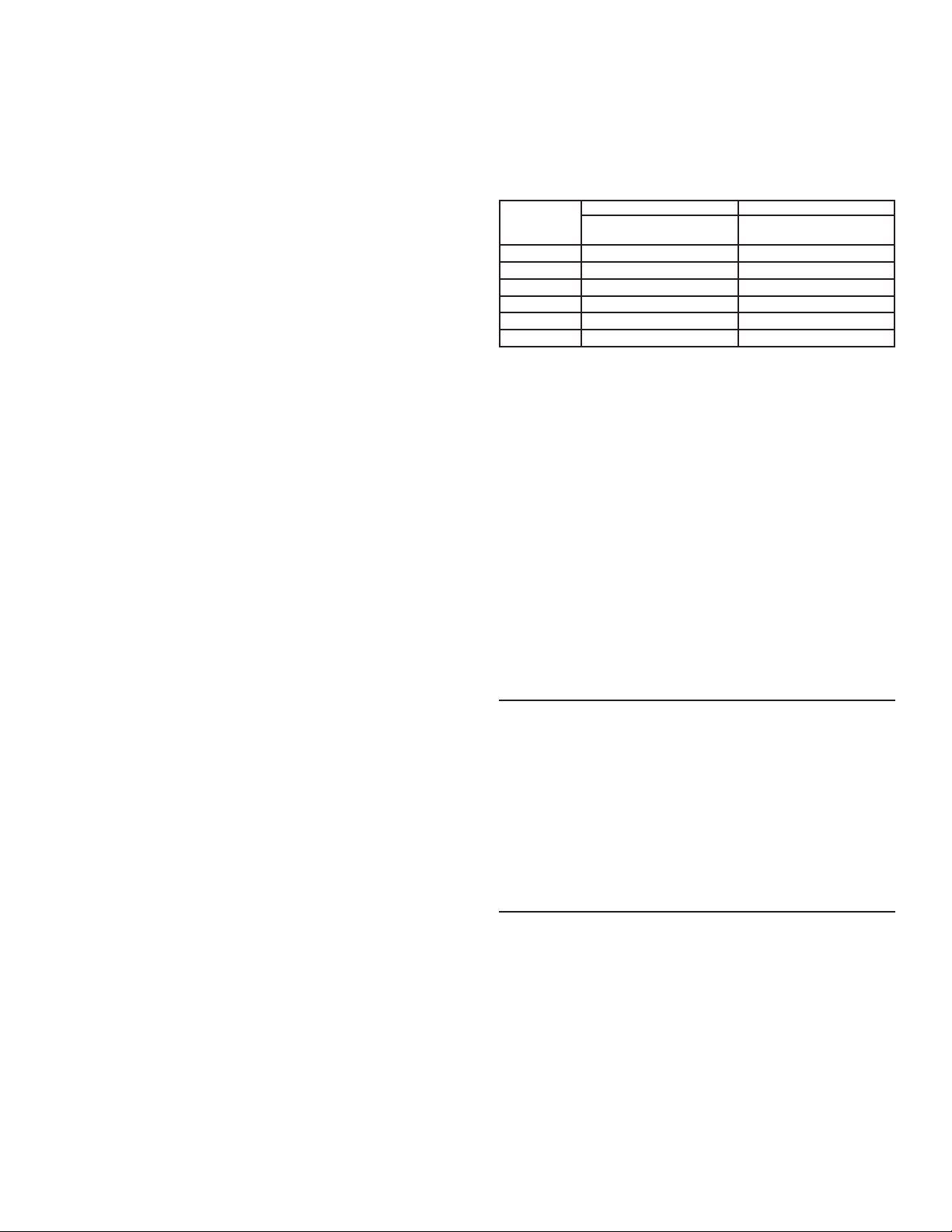

ROUGH IN DIMENSIONS

INSTALLATION CONSIDERATIONS

INTAKE AIR

CONNECTION

3 INCH PVC

WATER

OUTLET

HEIGHT

SUPPLY GAS

CONNECTION

T & P VALV E

D

LOWER

TEMPERATURE

PROBE

CLEANOUT

C

FRONT

3/4” NPT

RECIRCULATION

RETURN

1 1/2” NPT

WATER

INLET

B

VENT

CONNECTION

3 INCH PVC

(exhaust elbow)

3/4” NPT

DRAIN

BACK

E E

I

H

J

G

A

These designs comply with the current edition of the American National Standard for Gas Water Heaters, Volume III, ANSI Z21.10.3 / CSA 4.3

as an automatic circulating tank water heater, and automatic storage water heaters.

TOP VIEW

ALL MODELS

GAS

90°

AIR INTAKE

26°

F

MODEL

BTH 120

BTH 150

BTH 199

BTH 250

1½" NPT WATER

OUTLET

FRONT

42°

EXHAUST

SHIP

WEIGHT

STD

SHIP

WEIGHT

ASME

DRAIN

VALVE

CLEAN OUT

T&P VALVE

30°

45°

* Center line of water outlet on top of the water heaters is approximately 7 inches from the front edge of the water heater.

18°

DIMENSIONS

A B C D E F G H I J

INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM INCHES/CM LBS/KG LBS/KG

3/7.62 27.75/70.5 6.3/16 35/88.9 55.5/141 53.5/135.9 11.25/28.6 42.25/107.32 48.5/123.2 18.25/46.36 460/208 490/220

3/7.62 27.75/70.5 6.3/16 56.38/143.2 76/193.04 75.75/192.4 11.25/28.6 64/162.6 70/177.8 18.25/46.36 523/237 553/251

3/7.62 27.75/70.5 6.3/16 56.38/143.2 76/193.04 75.75/192.4 11.25/28.6 64/162.6 70/177.8 18.25/46.36 523/237 553/251

3/7.62 27.75/70.5 6.3/16 56.38/143.2 76/193.04 75.75/192.4 11.25/28.6 64/162.6 70/177.8 18.25/46.36 523/237 553/251

Figure 5

10

GAS LINE CONNECTION SIZE

CAUTION

TABLE 1

† MODEL SERIES NATURAL GAS PROPANE GAS

BTH 120 200/201 3/4 "NPT 3/4 "NPT

BTH 150 200/201 3/4 "NPT 3/4 "NPT

BTH 199 200/201 3/4 "NPT 3/4 "NPT

BTH 250 200/201 3/4 "NPT 3/4 "NPT

† Depending on the installed equivalent length, and/or the number of appliances connected, the

supply gas line size may have to be increased beyond the minimum required sizes - see Gas

Line Sizing on page 40.

STORAGE CAPACITIES

TABLE 2

MODEL U. S. GALLONS LITERS

BTH 120 60 227

BTH 150 100 379

BTH 199 100 379

BTH 250 100 379

GAS PRESSURE REQUIREMENTS

TABLE 3

MODEL

BTH 120 0" W.C. (0 kPa) 0" W.C. (0 kPa) 4.4” W. C. (1.10 kPa) 8.5” W. C. (2.12 kPa) 14” W. C. (3.49 kPa) 14” W. C. (3.49 kPa)

BTH 150 0" W.C. (0 kPa) 0" W.C. (0 kPa) 4.4” W. C. (1.10 kPa) 8.5” W. C. (2.12 kPa) 14” W. C. (3.49 kPa) 14” W. C. (3.49 kPa)

BTH 199 0” W. C. (0 kPa) 0” W. C. (0 kPa) 4.4” W. C. (1.10 kPa) 8.5” W. C. (2.12 kPa) 14” W. C. (3.49 kPa 14” W. C. (3.49 kPa)

BTH 250 0” W. C. (0 kPa) 0” W. C. (0 kPa) 4.4” W. C. (1.10 kPa) 8.5” W. C. (2.12 kPa) 14” W. C. (3.49 kPa) 14” W. C. (3.49 kPa)

NATURAL GAS PROPANE GAS NATURAL GAS PROPANE GAS NATURAL GAS PROPANE GAS

MANIFOLD PRESSURE MINIMUM SUPPLY PRESSURE MAXIMUM SUPPLY PRESSURE

RECOVERY CAPACITIES

TABLE 4

U. S. GALLONS/HR & LITERS/HR AT TEMPERATURE RISE INDICATED

Model

BTH 120

BTH 150

BTH 199

BTH 250

Type of

Gas

Natural

Propane LPH 1743 1308 1046 872 747 654 581 523 475 436 402 374

Natural

Propane LPH 2248 1686 1349 1124 963 843 749 674 613 562 519 482

Natural

Propane LPH 2965 2224 1779 1483 1271 1112 988 890 809 741 684 635

Natural

Propane LPH 3670 2753 2202 1835 1573 1376 1223 1101 1001 918 847 786

Input

Btu/hr kW °C 17°C 22°C 28°C 33°C 39°C 44°C 50°C 56°C 61°C 67°C 72°C 78°C

120,000 35 95

150,000 44 98

199,900 58 97

250,000 73 96

Thermal

Efciency%

°F 30°F 40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F 140°F

GPH 461 345 276 230 197 173 154 138 126 11 5 106 99

GPH 594 445 356 297 255 223 198 178 162 148 137 127

GPH 783 588 470 392 336 294 261 235 214 196 181 168

GPH 970 727 582 485 416 364 323 291 264 242 224 208

LOCATING THE WATER HEATER

Carefully choose a location for the new water heater. The

placement is a very important consideration for the safety of the

occupants in the building and for the most economical use of the

water heater.

Property Damage Hazard

All water heaters eventually leak.

•

Do not install without adequate drainage.

•

Whether replacing an existing water heater or installing the water

heater in a new location observe the following critical points:

1. The water heater must be located indoors.

2. The water heater must not be located in an area where it will

be subject to freezing temperatures.

3. Locate the water heater so it is protected and not subject to

physical damage by a moving vehicle.

4. Locate the water heater on a level surface.

5. Locate the water heater near a oor drain. The water heater should

be located in an area where leakage of the tank or connections

will not result in damage to the area adjacent to the water heater

or to lower oors of the structure. When such locations cannot be

avoided, it is recommended that a metal drain pan, adequately

drained, be installed under the water heater.

6. Locate the water heater close to the point of major hot water usage.

7. Locate the water heater close to a 120 VAC power supply.

See Power Supply on page 13 for requirements.

8. Locate the water heater where an adequate supply of fresh

air for combustion and ventilation can be obtained. See Air

Requirements on page 17.

9. Locate the water heater where the vent and intake air piping,

when installed, will remain within the maximum equivalent

lengths allowed. See Venting Requirements on page 22.

10. Do not locate the water heater where noise (such as

the Combustion Blower) during normal operation will be

objectionable in adjacent areas.

11. Do not locate the water heater where the subsequent

installation of the vent (exhaust) or intake air terminations

would be objectionable due to noise at the termination(s).

This includes locations close to or across from windows and

doors. See Venting Installation on page 21.

Fire or Explosion Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

11

There is a risk in using fuel burning appliances such as gas

water heaters in rooms, garages or other areas where gasoline,

other ammable liquids or engine driven equipment or vehicles

are stored, operated or repaired. Flammable vapors are heavy

and travel along the oor and may be ignited by the water

heater’s igniter or Main Burner ames causing re or explosion.

Flammable items, pressurized containers or any other potential

re hazardous articles must never be placed on or adjacent to

the water heater.

CLEARANCE TO COMBUSTIBLE MATERIALS

The water heaters covered in this manual are approved for

installation on combustible ooring. The clearance to combustible

and non combustible construction materials is 0 inches on the

back and sides of the water heater. These water heaters are also

approved for installation in an alcove.

When the water heater is installed directly on carpeting, the water

heater shall be installed on a metal or wood panel extending

beyond the full width and depth of the water heater by at least

3 in (76.2 mm) in any direction or, if the water heater is installed

in an alcove or closet, the entire oor shall be covered by the

panel. The panel must be strong enough to carry the weight of

the heater when full of water.

NOTE: Adequate clearance for servicing should be maintained

on all installations. See Service Clearance below.

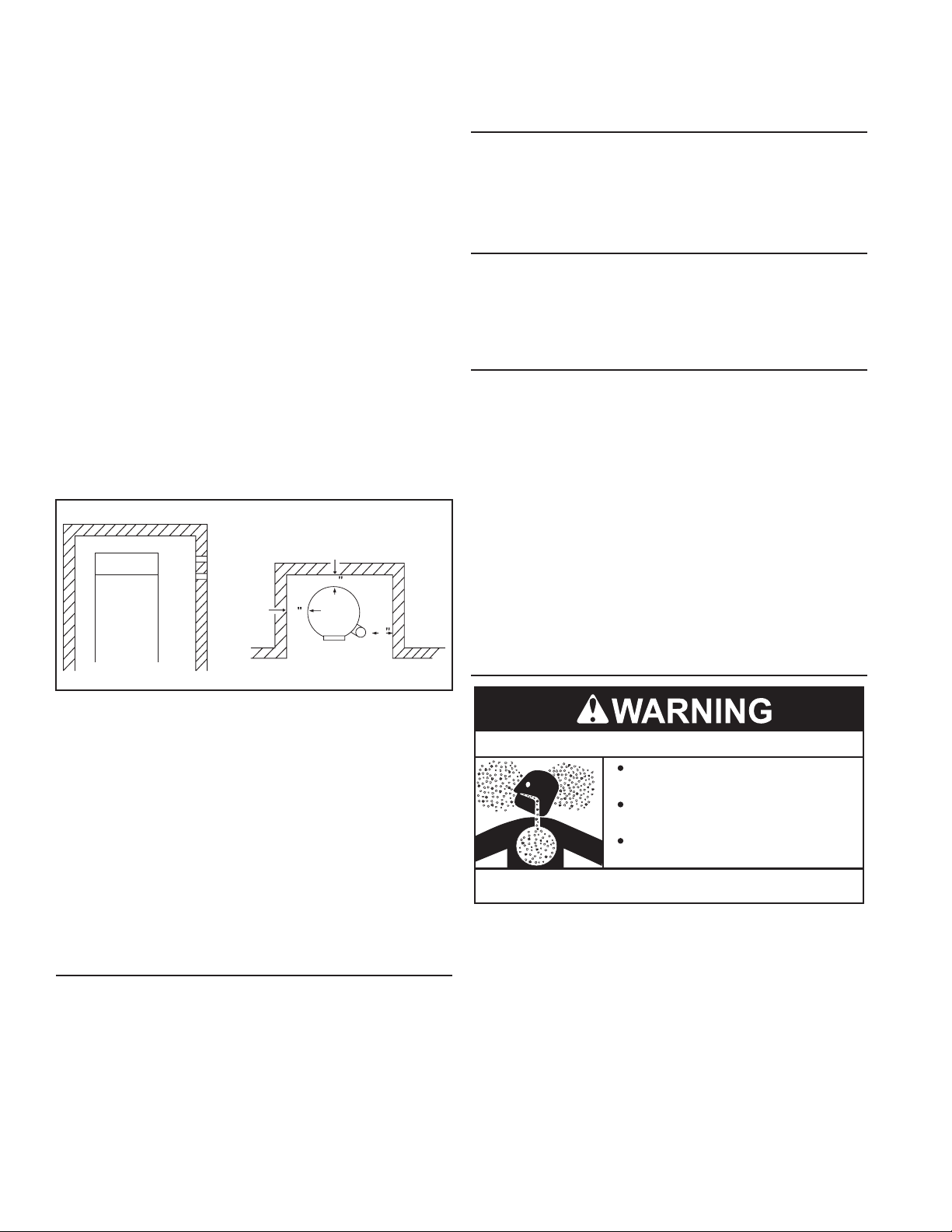

ALCOVE

TOP COVER

WATER

HEATER

FRONT

FRONT VIEW

CLEARANCES TO COMBUSTIBLE

AND NON COMBUSTIBLE

CONSTRUCTION MATERIALS

0

0

0

FRONT

TOP VIEW

Contact your local distributor or call the parts department phone

number listed on the back cover of this manual to order 4 inch

termination(s).

OPTIONAL CONCENTRIC & LOW PROFILE TERMINATIONS

The water heaters covered in this manual can be installed in

a Direct Vent conguration using optional concentric or Low

Prole terminations. See Concentric Termination Installation

on page 30 and Low Prole Vent Termination Installation on

page 34.

HARD WATER

Where hard water conditions exist, water softening or the

threshold type of water treatment is recommended. This will

protect the dishwashers, coffee urns, water heaters, water

piping and other equipment. See Maintenance on page 63 for

sediment and lime scale removal procedures.

CIRCULATION PUMPS

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the water

heater. The tank is provided with a 3/4" NPT recirculation loop

return connection. See the Water Piping Diagrams beginning on

page 69 for installation location of circulating pumps.

See Circulation Pump Wiring Diagrams on page 68 for

electrical hookup information. Install in accordance with the

current edition of the National Electrical Code, NFPA 70 or the

Canadian Electrical Code, CSA C22.1.

Stainless steel circulating pumps are recommended for use with

commercial water heaters.

Some circulating pumps are manufactured with sealed bearings

and do not require further lubrication. Some circulating pumps

must be periodically oiled. Refer to the pump manufacturer’s

instructions for lubrication requirements.

INSULATION BLANKETS

Figure 6

SERVICE CLEARANCE

A service clearance of 24 inches (61 cm) should be maintained

from serviceable parts such as the T&P valve, control system

components, gas valve, clean out opening, drain valve, the vent

connection (exhaust/condensate elbow). Leave as much room as

possible above the water heater and near the exhaust elbow for

this reason. See Figure 8 on page 16.

INTAKE AIR AND VENT PIPE CLEARANCES

The minimum clearance from combustible materials for the vent

(exhaust) and intake air piping shall be 0 inches. Vent or intake

air piping passing through a combustible wall or ceiling must be

a continuous run (no joints).

EXTENDED VENT TERMINATIONS

The water heaters covered by this manual can be installed using

3 inch pipe for the intake air and/or vent piping up to a maximum

of 50 equivalent feet (15.2 m). The intake air and/or vent piping

can be extended up to 120 equivalent feet (36.5 m) by installing

4 inch pipe. See the Venting Requirements on page 22.

The water heater ships from the factory with two (2) 3 inch

terminations that are 45° PVC elbows with a debris screen

installed. When 4 inch intake air or vent pipe is installed, factory

supplied 4 inch terminations must be used.

Breathing Hazard - Carbon Monoxide Gas

Do not obstruct water heater air intake

with insulating blanket.

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Insulation blankets are available to the general public for

external use on gas water heaters but are not necessary

with these products. The purpose of an insulation blanket is

to reduce the standby heat loss encountered with storage

tank heaters. The water heaters covered by this manual meet

or exceed the Energy Policy Act standards with respect to

insulation and standby heat loss requirements, making an

insulation blanket unnecessary.

Should you choose to apply an insulation blanket to this

heater, you should follow these instructions. See the Features

and Components section of this manual for identication

of components mentioned below. Failure to follow these

instructions can restrict the air ow required for proper

12

combustion, potentially resulting in re, asphyxiation, serious

personal injury or death.

• DO NOT apply insulation to the top of the water heater, as

this will interfere with safe operation of the blower assembly.

• DO NOT cover the control system LCD on top of the water

heater.

• DO NOT cover the Temperature-Pressure Relief Valve.

INSTALLATION REQUIREMENTS

• DO NOT cover the instruction manual. Keep it on the side of

the water heater or nearby for future reference.

• DO obtain new warning and instruction labels from the

manufacturer for placement on the blanket directly over the

existing labels.

• DO inspect the insulation blanket frequently to make certain it

does not sag, thereby obstructing combustion air ow.

GAS SUPPLY SYSTEMS

Low pressure building gas supply systems are dened as

those systems that cannot under any circumstances exceed

14” W.C. (1/2 PSI Gauge). These systems do not require

pressure regulation. Measurements should be taken to insure

that gas pressures are stable and fall within the requirements

stated on the water heater rating plate. Readings should be

taken with all gas burning equipment off (static pressure)

and with all gas burning equipment running at maximum rate

(dynamic pressure). The gas supply pressure must be stable

within 1.5” W.C. from static to dynamic pressure to provide

good performance. Pressure drops that exceed 1.5” W.C. may

cause rough starting, noisy combustion or nuisance outages.

Increases or spikes in static pressure during off cycles may

cause failure to ignite or in severe cases damage to appliance

gas valves. If your low pressure system does NOT meet these

requirements, the installer is responsible for the corrections.

High Pressure building supply systems use pressures that

exceed 14” W.C. (1/2 PSI Gauge). These systems must use

eld supplied regulators to lower the gas pressure to less than

14” W.C. (1/2 PSI Gauge). Water heaters require gas regulators

that are properly sized for the water heater input and deliver

the rating plate specied pressures. Gas supply systems where

pressure exceeds 5 PSI often require multiple regulators to

achieve desired pressures. Systems in excess of 5 PSI building

pressure should be designed by gas delivery professionals

for best performance. Water heaters connected to gas supply

systems that exceed 14” W.C. (1/2 PSI Gauge) at any time

must be equipped with a gas supply regulator.

All models require a minimum gas supply pressure of 4.4" W.C.

for natural gas and 8.5" W.C. for propane gas. The minimum

supply pressure is measured while gas is owing (dynamic

pressure). The supply pressure should never fall below 4.4"

W.C. for natural gas and 8.5" W.C. for propane gas. The supply

pressure should be measured with all gas red appliances

connected to the common main ring at full capacity. If the supply

pressure drops more than 1.5” W.C. as gas begins to ow to

the water heater then the supply gas system including the gas

line and/or the gas regulator may be restricted or undersized.

See Supply Gas Regulator section and Gas Piping section of

this manual. The gas valve on all models has a maximum gas

supply pressure limit of 14” W.C. The maximum supply pressure

is measured while gas is not owing (static pressure).

SUPPLY GAS REGULATOR

The maximum allowable gas supply pressure for this water

heater is 14.0 inches W.C. (3.49 kPa) for natural and propane

gas. Install a positive lock-up gas pressure regulator in the gas

supply line if inlet gas pressure can exceed these pressures at

any time.

If a positive lock-up regulator is required follow these instructions:

1. Positive lock-up gas pressure regulators must be rated

at or above the input Btu/hr rating of the water heater

they supply.

2. Supply gas regulators shall have inlet and outlet connections

not less than the minimum supply gas line size for the water

heater they supply. See Table 11, page 40.

3. Positive lock-up gas pressure regulator(s) should be installed

no closer than 3 feet (1 meter) and no farther than 8 feet (2.4

meters) from the water heater’s inlet gas connection.

4. After installing the positive lock-up gas pressure regulator(s)

an initial nominal supply pressure setting of 7.0” W.C.

while the water heater is operating is recommended and

will generally provide good water heater operation. Some

addition adjustment maybe required later to maintain a

steady gas supply pressure.

5. When installing multiple water heaters in the same gas

supply system it is recommended that individual positive

lock-up gas pressure regulators be installed at each unit

from the supply gas connection on the water heater.

POWER SUPPLY

The water heaters covered in this manual require a 120 VAC,

1Ø (single phase), 60Hz, 15 amp power supply and must also

be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70 or the Canadian Electrical Code, CSA C22.1.

DEDICATED POWER WIRING AND BREAKERS

Dedicated power supply wires, ground wiring and dedicated

circuit breakers often prevent electrical line noise and are

required when installing the water heater.

POWER FLUCTUATIONS AND ELECTRICAL NOISE

The water heater’s control system requires a source of

stable clean electricity for proper operation. Connecting the

water heater to a branch circuit that is subject to uctuations

in voltage level or electrical line noise such as EMI (electro

magnetic interference) or RFI (radio frequency interference)

may cause erratic control system operation and malfunction.

A high quality power supply lter/suppressor such as the

Kleen Line model SELF/T-10 Series SC-L or equivalent must

be installed if the above conditions exist. Call the technical

support phone number listed on the back cover of this manual

for more information.

NOTE: Malfunctions caused by the power supply and costs to

install power supply lters are not covered under the limited

warranty.

13

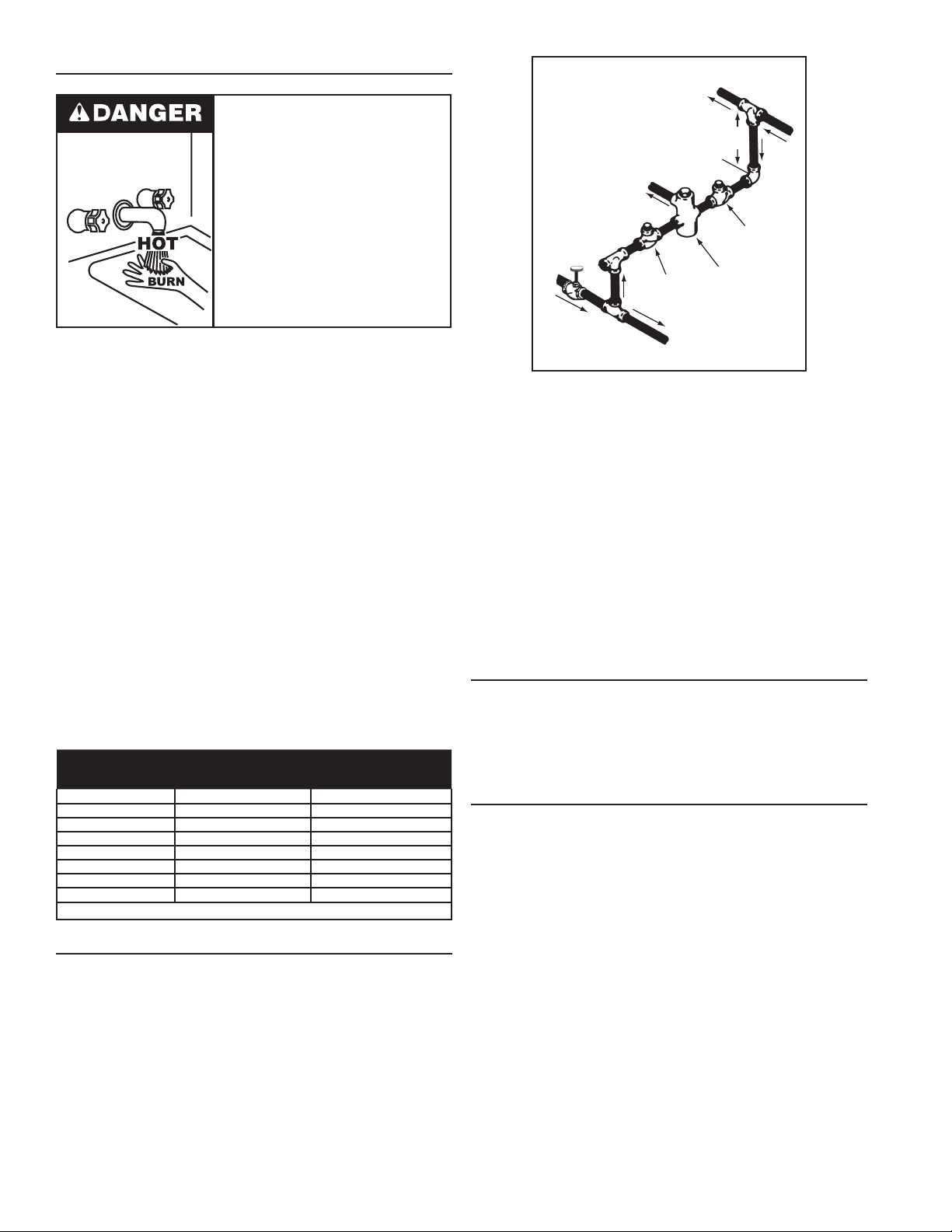

MIXING VALVES

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting devices such as

mixing valves must be installed

when required by codes and to

ensure safe temperatures at fixtures.

Water heated to a temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald and cause

permanent injury upon contact. Short repeated heating cycles

caused by small hot water uses can cause temperatures at the

point of use to exceed the water heater’s temperature setting by

up to 20°F (11°C).

Some people are more likely to be permanently injured by

hot water than others. These include the elderly, children, the

inrm and the physically/mentally disabled. Table 5 shows the

approximate time-to-burn relationship for normal adult skin.

If anyone using hot water provided by the water heater being

installed ts into one of these groups or if there is a local code

or state law requiring a certain water temperature at the point of

use, then special precautions must be taken.

In addition to using the lowest possible temperature setting that

satises the demand of the application a Mixing Valve should be

installed at the water heater (see Figure 7) or at the hot water

taps to further reduce system water temperature.

Mixing valves are available at plumbing supply stores. Consult

a Qualied Installer or Service Agency. Follow mixing valve

manufacturer’s instructions for installation of the valves.

TABLE 5

Water Temperature

°F (°C)

110 (43) (normal shower temp.)

116 (47) (pain threshold)

116 (47) 35 minutes 45 minutes

122 (50) 1 minute 5 minutes

131 (55) 5 seconds 25 seconds

140 (60) 2 seconds 5 seconds

149 (65) 1 second 2 seconds

154 (68) instantaneous 1 second

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong, Sept. 15, 1978)

Time for 1st Degree Burn

(Less Severe Burns)

Time for Permanent Burns

2nd & 3rd Degree

(Most Severe Burns)

DISHWASHING MACHINES

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water

ow pressures between 15 and 25 pounds per square inch (103

kPa and 173 kPa). Flow pressures above 25 pounds per square

inch (173 kPa), or below 15 pounds per square inch (103 kPa),

will result in improperly sanitized dishes. Where pressures are

high, a water pressure reducing or ow regulating control valve

should be used in the 180°F (82°C) line to the dishwashing

machine and should be adjusted to deliver water pressure

between these limits.

HOT WATER

OUTLET

12” TO 15”

(30-38 cm)

TEMPERED WATER

OUTLET

COLD

WATER

INLET

CHECK

VALV E

TO TANK

INLET

CHECK

VALV E

MIXING

VALV E

Figure 7

The National Sanitation Foundation also recommends circulation

of 180°F (82°C) water. Where this is done, the circulation should

be very gentle so that it does not cause any unnecessary

turbulence inside the water heater. The circulation should be just

enough to provide 180°F (82°C) water at the point of take-off to

the dishwashing machine.

Adjust ow by throttling a full port ball valve installed in the

circulating line on the outlet side of the pump. Never throttle ow

on the suction side of a pump. See the Water Piping Diagrams

beginning on page 69.

NOTE: To comply with NSF Standard 5 installation requirements

the bottom of the water heater must be sealed to the oor with a

silicone based sealant or elevated 6 inches above the oor.

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check

valves, and back ow preventers. Devices such as these cause

the water system to be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a

closed system the volume of water will grow when it is heated.

As the volume of water grows there will be a corresponding

increase in water pressure due to thermal expansion. Thermal

expansion can cause premature tank failure (leakage). This

type of failure is not covered under the limited warranty.

Thermal expansion can also cause intermittent TemperaturePressure Relief Valve operation: water discharged from the

valve due to excessive pressure build up. This condition is

not covered under the limited warranty. The TemperaturePressure Relief Valve is not intended for the constant relief

of thermal expansion.

A properly sized thermal expansion tank must be installed on

all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed.

See Water Line Connections on page 43 and the Water Piping

Diagrams beginning on page 69.

14

CAUTION

TEMPERATURE-PRESSURE RELIEF VALVE

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22CSA 4.4 and ASME code.

Properly sized temperaturepressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

This water heater is provided with a properly rated/sized and

certied combination Temperature-Pressure Relief Valve (T&P

valve) by the manufacturer. The valve is certied by a nationally

recognized testing laboratory that maintains periodic inspection

of production of listed equipment of materials as meeting the

requirements for Relief Valves for Hot Water Supply Systems,

ANSI Z21.22 • CSA 4.4, and the code requirements of ASME.

If replaced, the new T&P valve must meet the requirements

of local codes, but not less than a combination TemperaturePressure Relief Valve rated/sized and certied as indicated in

the above paragraph. The new valve must be marked with a

maximum set pressure not to exceed the marked hydrostatic

working pressure of the water heater (150 psi = 1,035 kPa) and

a discharge capacity not less than the water heater Btu/hr or kW

input rate as shown on the water heater’s model rating label.

NOTE: In addition to the factory installed Temperature-Pressure

Relief Valve on the water heater, each remote storage tank that

may be installed and piped to a water heating appliance must also

have its own properly sized, rated and approved TemperaturePressure Relief Valve installed. Call the toll free technical

support phone number listed on the back cover of this manual

for technical assistance in sizing a Temperature-Pressure Relief

Valve for remote storage tanks.

For safe operation of the water heater, the Temperature-Pressure

Relief Valve must not be removed from its designated opening

nor plugged. The Temperature-Pressure Relief Valve must be

installed directly into the tting of the water heater designed for the

relief valve. Install discharge piping so that any discharge will exit

the pipe within 6 inches (15.2 cm) above an adequate oor drain,

or external to the building. In cold climates it is recommended

that it be terminated at an adequate drain inside the building. Be

certain that no contact is made with any live electrical part. The

discharge opening must not be blocked or reduced in size under

any circumstances. Excessive length, over 30 feet (9.14 m), or

use of more than four elbows can cause restriction and reduce

the discharge capacity of the valve.

No valve or other obstruction is to be placed between the

Temperature-Pressure Relief Valve and the tank. Do not connect

discharge piping directly to the drain unless a 6” (15.2 cm)

air gap is provided. To prevent bodily injury, hazard to life, or

property damage, the relief valve must be allowed to discharge

water in adequate quantities should circumstances demand. If

the discharge pipe is not connected to a drain or other suitable

means, the water ow may cause property damage.

Water Damage Hazard

Temperature-Pressure Relief Valve discharge

•

pipe must terminate at adequate drain.

T&P Valve Discharge Pipe Requirements:

• Shall not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall not be exposed to freezing temperatures.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both the

Temperature-Pressure Relief Valve and the discharge pipe.

• Must terminate a maximum of six inches above a oor drain

or external to the building. In cold climates, it is recommended

that the discharge pipe be terminated at an adequate drain

inside the building.

• Shall not have any valve or other obstruction between the

relief valve and the drain.

Burn hazard.

Hot water discharge.

Keep clear of TemperaturePressure Relief Valve

discharge outlet.

The Temperature-Pressure Relief Valve must be manually

operated at least twice a year. Caution should be taken to

ensure that (1) no one is in front of or around the outlet of the

Temperature-Pressure Relief Valve discharge line, and (2) the

water manually discharged will not cause any bodily injury or

property damage because the water may be extremely hot. If

after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold water

inlet to the water heater, follow the draining instructions in this

manual, and replace the Temperature-Pressure Relief Valve with

a properly rated/sized new one.

NOTE: The purpose of a Temperature-Pressure Relief Valve is

to prevent excessive temperatures and pressures in the storage

tank. The T&P valve is not intended for the constant relief of

thermal expansion. A properly sized thermal expansion tank must

be installed on all closed systems to control thermal expansion,

see Closed Water Systems and Thermal Expansion on page 14.

If you do not understand these instructions or have any

questions regarding the Temperature-Pressure Relief Valve call

the toll free number listed on the back cover of this manual for

technical assistance.

15

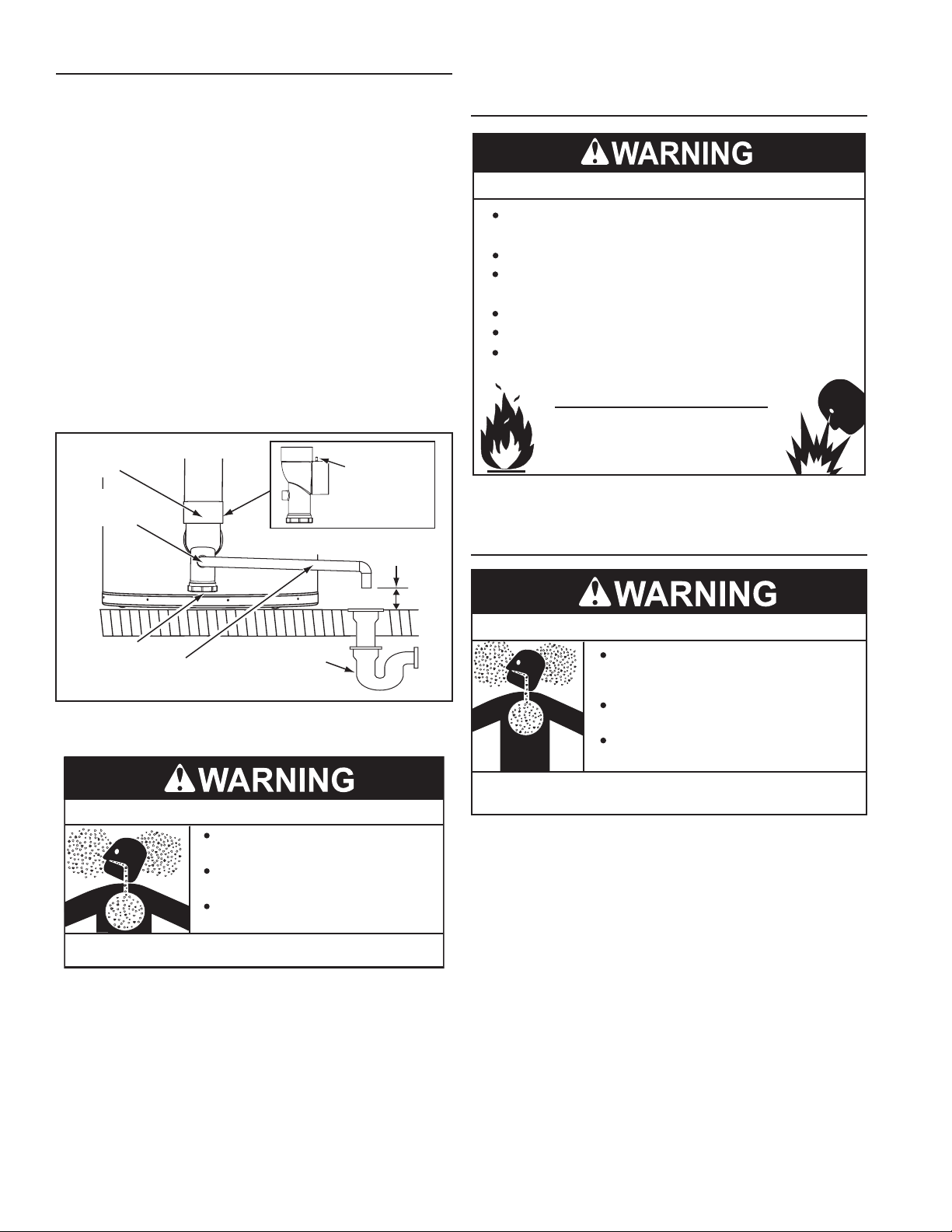

CONDENSATE DRAIN

The water heaters covered in this manual are condensing

appliances and require a building drain to be located in close

proximity to allow the condensate to drain safely.

Condensate drains from the water heater at the exhaust elbow

located at the bottom. The eld installed condensate drain line

must not be elevated above the condensate drain connection

on the condensate trap, see Figure 8. If the condensate does

not drain properly it will build up in the exhaust (vent) elbow.

This will restrict the ow of ue gases and cause the Blocked

Exhaust pressure switch to open its contacts. The control system

monitors all pressure switches, if the Blocked Exhaust Switch

contacts are open the control system will lock out and disable

heating operation. The “Blocked Exhaust” Fault message will

be displayed on the control system’s LCD, see Fault And Alert

Conditions beginning on page 60.

The Condensate Cleanout Cap must be on and tight when unit

is in operation.

NOTE: If the “Blocked Exhaust “ Fault message is ever displayed

on the control system LCD, check the condensate drain rst and

ensure it is not blocked.

EXHAUST (VENT)

ELBOW

CONDENSATE

DRAIN LINE

CONNECTION

DRAIN LINE TO TERMINATE NO

MORE THAN 6 INCHES (15.2cm)

THIS SIDE VIEW

OF EXHAUST

ELBOW AND

ARROW INDICATE

THE LOCATION OF

THE PRESSURE

PORT

ABOVE DRAIN

line, such as copper, to the water heater for this reason. See

Condensate Drain Installation on page 39.

COMBUSTIBLE MATERIAL STORAGE

Fire or Explosion Hazard

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Avoid all ignition sources if you smell gas.

Do not expose water heater controls to excessive gas

pressure.

Use only the gas shown on the water heater rating label.

Maintain required clearances to combustibles.

Keep ignition sources away from faucets after extended

periods of non-use.

Read instruction manual before

installing, using or servicing

water heater.

Keep water heater area clear and free of combustible materials,

gasoline and other ammable vapors and liquids.

CONTAMINATED AIR

CONDENSATE

CLEANOUT CAP

CONDENSATE DRAIN

LINE - FIELD INSTALLED

BUILDING

DRAIN

Figure 8

CONDENSATE DRAIN WATER TRAP

Breathing Hazard - Carbon Monoxide Gas

Ensure a functioning water trap is

installed in the condensate drain.

Gas and carbon monoxide detectors

are available.

Install water heater in accordance with

the instruction manual.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

DO NOT remove the factory installed exhaust/condensate elbow

for any reason, see Figure 8. The water heater’s vent pipe is

under a slight positive pressure while unit is in operation. The

water trap inside of the exhaust/condensate elbow prevents ue

gases from escaping into the installed space. See Condensate

Drain Installation on page 39.

CONDENSATE PH LEVEL

The condensate drains from the water heater’s covered in

this manual have PH levels between 4.3 and 5.0. Install a

commercially available neutralizing kit if required by local codes.

NOTE: Lower PH levels are acidic. Do not connect a metal drain

Breathing Hazard - Carbon Monoxide Gas

Install water heater in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

Corrosion of the ue ways and vent system may occur if air for

combustion contains certain chemical vapors. Such corrosion

may result in failure and risk of asphyxiation.

Combustion air that is contaminated can greatly diminish the

life span of the water heater and water heater components such

as igniters and burners. Propellants of aerosol sprays, beauty

shop supplies, water softener chemicals and chemicals used

in dry cleaning processes that are present in the combustion,

ventilation or ambient air can cause such damage.

Do not store products of this sort near the water heater. Air which

is brought in contact with the water heater should not contain any

of these chemicals. If necessary, uncontaminated air should be

obtained from remote or outdoor sources. The limited warranty is

voided when failure of water heater is due to a corrosive atmosphere.

(See limited warranty for complete terms and conditions).

If the water heater will be used in beauty shops, barber shops,

cleaning establishments, or self-service laundries with dry

cleaning equipment, it is imperative that the water heater(s) be

installed in a Direct Vent conguration so that all air for combustion

is derived directly from the outdoor atmosphere through a sealed

intake air pipe. See Venting Installation on page 21.

16

AIR REQUIREMENTS

Breathing Hazard - Carbon Monoxide Gas

Install water heater in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

For safe operation an adequate supply of fresh uncontaminated

air for combustion and ventilation must be provided.

An insufcient supply of air can cause recirculation of

combustion products resulting in contamination that may be

hazardous to life. Such a condition often will result in a yellow,

luminous burner ame, causing sooting of the combustion

chamber, burners and ue tubes and creates a risk of

asphyxiation.

Do not install the water heater in a conned space unless an

adequate supply of air for combustion and ventilation is brought

in to that space using the methods described in the Conned

Space section that follows.

Never obstruct the ow of ventilation air. If you have any doubts

or questions at all, call your gas supplier. Failure to provide the

proper amount of combustion air can result in a re or explosion

and cause property damage, serious bodily injury or death.

UNCONFINED SPACE

An Unconned Space is one whose volume IS NOT LESS THAN

50 cubic feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the

total input rating of all appliances installed in the space. Rooms

communicating directly with the space, in which the appliances

are installed, through openings not furnished with doors, are

considered a part of the unconned space.

Makeup air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers and replaces shall

also be considered in determining the adequacy of a space to

provide combustion, ventilation and dilution air.

UNUSUALLY TIGHT CONSTRUCTION

In unconned spaces in buildings, inltration may be adequate

to provide air for combustion, ventilation and dilution of ue

gases. However, in buildings of unusually tight construction (for

example, weather stripping, heavily insulated, caulked, vapor

barrier, etc.) additional air must be provided using the methods

described in the Conned Space section that follows.

CONFINED SPACE

A Conned Space is one whose volume IS LESS THAN 50 cubic

feet per 1,000 Btu/hr (4.8 cm per kW) of the total input rating of

all appliances installed in the space.

Openings must be installed to provide fresh air for combustion,

ventilation and dilution in conned spaces. The required size for

the openings is dependent on the method used to provide fresh

air to the conned space AND the total Btu/hr input rating of all

appliances installed in the space.

DIRECT VENT APPLIANCES

Appliances installed in a Direct Vent conguration that derive all

air for combustion from the outdoor atmosphere through sealed

intake air piping are not factored in the total appliance input Btu/

hr calculations used to determine the size of openings providing

fresh air into conned spaces.

EXHAUST FANS

Where exhaust fans are installed, additional air shall be provided

to replace the exhausted air. When an exhaust fan is installed

in the same space with a water heater, sufcient openings to

provide fresh air must be provided that accommodate the

requirements for all appliances in the room and the exhaust fan.

Undersized openings will cause air to be drawn into the room

through the water heater’s vent system causing poor combustion.

Sooting, serious damage to the water heater and the risk of re

or explosion may result. It can also create a risk of asphyxiation.

LOUVERS AND GRILLES

The free areas of the fresh air openings in the instructions that

follow do not take in to account the presence of louvers, grilles or

screens in the openings.

The required size of openings for combustion, ventilation and

dilution air shall be based on the “net free area” of each opening.

Where the free area through a design of louver or grille or screen

is known, it shall be used in calculating the size of opening

required to provide the free area specied. Where the louver and

grille design and free area are not known, it shall be assumed