A.O. Smith ATIO-710-N, ATIO-710-P, ATIO-710-AN, ATIO-710-AP Service manual

0

31:

Incorrect d

ipswitch setting

Maaiinntteennaannccee sshheeeett

A.

Troubleshooting

391: Air

-

fuel Ratio Rod failure

°C

roller termi nal on the PCB. (Normal:

Appendix B (For error code 611 and 621)

Change the

dipswitch

settings when the power supply is turning off.

DEFAULT is the factory setting.

AATTMM3322

6633TT114411

Single unit

DEFAULT

Easy-Link system

Parent

Unit Child Unit

Temperature set

100˚F

115˚F

120˚F

135˚F

145˚F

155˚F

165˚F

185˚F

DEFAULT

The

right

bank

has certain

The Gas Type dipswitch

Propane

Natural

A1

A3

D1

J

I

B

G A A2

C1

C2

F

C

E2

H2

H1

E1

E3 L K

C

C C

The

left

bank

has settings for three functions, shown be

low.

Left

bank

Right bank

Indoor

Outdoor

Direct

DEFAULT

M

If the error code is indicated on the 7-Seg LED on the PCB (Part #701) of the water heater (and/or

the remote controller), refer to Section B.

<< It takes long time to get hot water at the fixtures >>

・ The time it takes to deliver hot water from the water heater to your fixtures depends on

the length of piping between the two. The longer the distance or the bigger the pipes,

the longer it will take to get hot water.

・ If you would like to receive hot water to your fixtures quicker, you may want to consider a

hot water recirculation system.

<< The water is not hot enough or turns cold and stays cold >>

・ Compare the flow and temperature. Refer to the “Output temperature chart” of the

installation manual.

・ Check cross plumbing between cold water lines and hot water lines.

・ Check if the gas supply valve fully open, the gas line sized properly and the gas supplies

pressure enough. Refer to the “Gas supply and gas pipe sizing” of the installation manual.

・ Check the set temperature, and change the dipswitch setting. Refer to Section D.

・ Refer to “Water circuit” in this section.

<<The water is too hot>>

・ Check the set temperature, lower setting temperature.

<<The hot water is not available when a fixture is opened>>

・ Refer to the “Power supply circuit” and “Water circuit” in this section.

<<Fluctuation in hot water temperature>>

・ Check if the filter on the cold water inlet cleaned. (Part #408)

・ Check if the gas line sized properly and the supply gas pressure sufficient.

・ Check for cross connection between cold water lines and hot water lines.

・ Refer to “Water circuit” in this section.

<<Unit does not ignite when water goes through the water heater>>

・ Refer to the “Power supply circuit” and “Water circuit” in this section.

・

If you use the remote controller, turn the power button on an d then the green LED will light up.

・ Check if the filter on the cold water inlet cleaned. (Part #408)

B. Error codes

・ Check the dipswitch settings on the PCB. Refer to Section D.

101: Warning for the “991” error code

・

Check the gas type of the water heater. If it ’s wrong gas type mo del, replace the water heat er to correct o ne.

・ Check if there is any blockage (For example, Damper sticking, Vent Flaps installed on the

terminator, Snow build up around terminator, Installed in a closet (No ventilation or lack

of combustion air)) in the intake air and/or exhaust. Refer to the “Vent termination

clearances” of the installation manual.

・ If the water heater is installed as a direct-vent system, check whether there are enough

distance between the intake air terminal and the exhaust terminal. Refer to the “Vent

termination clearances” of the installation manual.

・ Check if the total vent length doesn’t exceed 50 ft and the # of elbows is less than 5Ea.

・ Check the altitude/elevation of area of where the water heater installed. Refer to the

“High-altitude function” of the Section D. And change the dipswitch settings.

・ Check if there is grease and/or dirt in the burner (Part #101), and the fan motor (Part

#115), especially if the water heater has been installed in a contaminated area.

・ Check if there is dust and lint in heat exchanger.

・ Check the manifold pressure of the water heater. Refer to installation manual.

111: Ignition failure

1. Check gas supply and inlet gas pressure.

2. Check if the Hi-limit switch (Part #432) is properly functioning.

3. Check for connection/breakage of wires (Part #110, 403, 704, 707, 709), burn marks on

the computer board (Part #701), and/or soot on the flame rod (Part #106). And then if

O.H.C.F (Part #010, 403) is breakage, Consult the manufacturer.

4. Check if there is a buzzing spark ignition sound coming from the burner (Part #101) when

water heater prepares for combustion.

5. Listen for the double “clunk” sound coming from the gas valves assembly (Part #120)

when water heater goes into combustion.

6. (Only no sparking and/or kick sound) Check voltage on each wire to gas valves assembly

(Part #120) and/or the igniter (Part #125). Refer to the “Appendix A” in Section C.

*No sparking sound >>>>> Refer to the #1 at “Appendix A” in Section C.

*No kick sound >>>>> Refer to the #2 at “Appendix A” in Section C.

7. Check if there is leaking from heat exchanger (Part #210 or 211)

8. Check if there is dust and lint in nozzles of the manifold (Part #120).

9. Check current on the flame rod (Part #106). Refer to the #3 at “Appendix A” in Section C.

121: Loss of flame

1. Check gas supply and inlet gas pressure.

2. Check if the Hi-limit switch (Part #432) is properly functioning.

3. Check for connection/breakage of wires (Part #110, 403, 704, 707, 709), burn marks on

the computer board (Part #701), and/or soot on the flame rod (Part #106). And then if

O.H.C.F (Part #010, 403) is breakage, Consult the manufacturer.

4. Check if there is leakage from heat exchanger (Part #210 or 211).

5. Check if there is dust and lint in nozzles of the manifold (Part #120).

6. Check current on the flame rod (Part #106). Refer to the #3 at “Appendix A” in Section C.

311,321,331: Disconnected/short-circuited thermistor

・

Check for connection/breakage of wires and/or debris on thermistor (Part #

・ Check thermistor resistance. Refer to the “Appendix D” in Section C.

418, 422, 433, 705, 706

<<The fan motor still spinning after operation has stopped>>

・ This is normal. After operation has stopped, the fan motor keeps running for 35 seconds

in order to re-ignite quickly, as well as purge all the exhaust gas out of the flue.

<<Abnormal sound from water heater>>

・ An abnormal sound from the water heaters is caused by not enough air supply or wrong

installations. The water heater needs more combustion air. Refer to the “101” error code

in the Section B.

<<Power supply circuit>>

1. If the remote controller installed, press the “ON/OFF” button of the remote controller,

and make sure that the green LED on the “ON/OFF” button of the remote controller is lit.

Restart the water heater.

2. Check if that the 7-Seg LED on the PCB (Part #701) of the water heater is lit. If so, the

power supply circuit of the water heater is under normal condition. Next, refer to the

“Water circuit” in this section.

3. Check the fuse on the surge box (Part #715), and if it has a brown spot, need to replace it.

4. Check the power supply, and make sure that the water heater has 120 VAC.

5. If the 7-Seg LED on the PCB (Part #701) isn’t lit, some electrical parts can be broken.

Consult the manufacturer.

<<Water circuit>>

1. If you set the remote controlle r, turn the power button on and then the green LE D will light u p.

2. Open all hot water faucets, and make sure that there is enough water flow. This water

heater needs at least 0.5 GPM water flow to operate.

3. Check for reverse connection and cross connection.

4. Check if the filter on the cold water inlet cleaned. (Part #408)

5. Check if there is no debris or obstruction on the fixtures.

6. Check if water ways in the water heater are frozen. If so, unfreeze them. And refer to

installation manual to protect your water heater from freeze.

7. Check if the inlet water pressure is higher than 40 psi. And if it’s lower than 40 psi, need

to increase the pressure.

8. Check for connections and breakage of wires (Part #423, 429).

9. Check if the motor drive of the water control valve (Part #423) is locked due to scale

buildup, and/or water leakage. Consult the manufacturer.

・

Check for connection/breakage of wires (Part #707) and/or soot on the AFR rod. (Part #106).

441: Flow Sensor failure (Only Easy-Link system)

・ Check

for

connection/breakage of wires and/or debris on impeller (Part #429, 705 or 706).

510,551: Abnormal Main and Gas Solenoid Valve

・ Check

・ Reset power supply of the water heater.

・ Check voltage on the each valve on the gas valves assembly (Part #120). Refer to the

for

connection/breakage of wires (Part #704) and/or burn marks on the computer

board (Part #701).

“Appendix C” in Section C.

611: Fan motor fault

・ Check

・ Check for frozen/corrosion of connectors of the fan motor (Part #115).

・ Check voltage between blue wire and each wire of the fan motor (Part #115) during

for

connection/breakage of wires, dust buildup in the fan motor (Part #115) and/or

burn marks on the computer board (Part #701).

operation. Refer to the “Appendix B” in Section C.

631: Abnormal External Pump

・ Check whether the pump connected to PCB (Part #701) works properly.

651,661: Water control valve fault (Only Easy-Link system)

・ Check the water control valve (Part #423), connection/breakage of wires (Part #423),

motor drive locked due to scale buildup, and/or water leakage.

・ Check voltage between black wire and red wire. Refer to the “Appendix F” in Section C.

701: Computer board fault

・ Check for connection/breakage of wires (Part #705 or 706) and/or burn marks on the

computer board (Part #701).

721: False flame detection

1. Clean the flame rod (Part #106).

2. For indoor models, check if condensate drain is installed on the vent collar of the water

heater.

3. Check if there is leaking from heat exchanger (Part #210 or 211).

741: Miscommunication between water heater and remote controller

1. Check the model type of the remote controller. Model No. 9007603005 is the correct one .

2. Inspect for the connections between the water heater and remote controller. Refer to

“Remote controller connections” section in the Installation manual.

3. Check the power supply of the water heater.

4. If this error code appears only the 7-Seg LED on the PCB (Part #701), check the voltage on the

remote controller terminal on the PCB. Refer to the

“Appendi x E” in

5. If this error code appears only remote controller, replace the PCB (Part #701).

6. If this error code appears both the PCB (Part #701) and the remote controller, replace the

remote controller.

761:

Miscommunication between Parent unit and Child units for Easy-link system

・ Check if connection between the parent unit and the child units are correct. Refer to “Easy

-Link system” section in the Installation manual.

991: Imperfect combustion

).

・ Refer to the “101” error code in this section.

Section C.

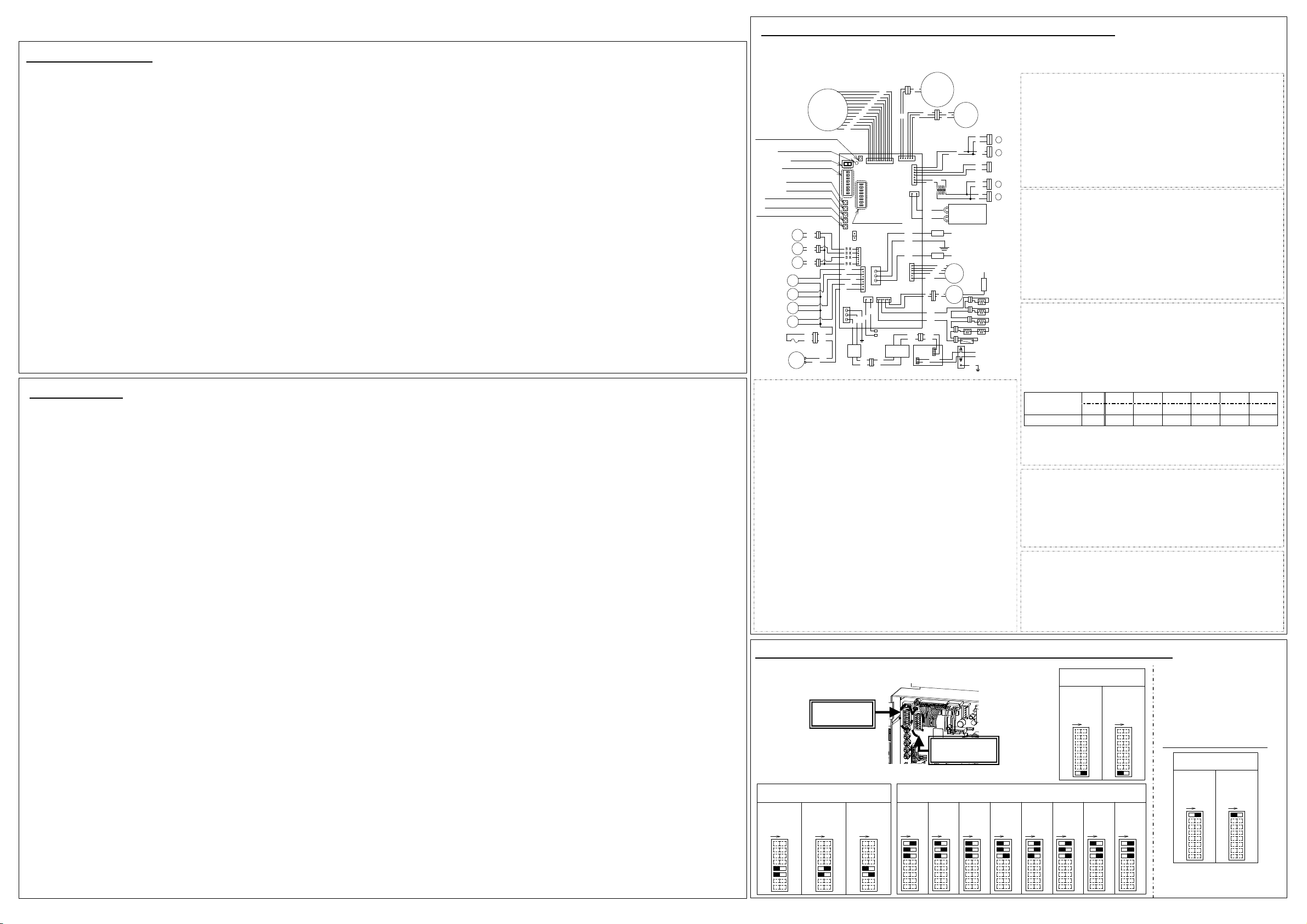

C. Wiring Diagram and check point of the Water heater

BK: BLACK

P: PURPLE

W: WHITE

Number d isplay button

Bu rn in g la mp

7 Se g LE D

Di ps wi tc he s

MA X bu tt on

MI N bu tt on

In cr ea se b ut to n

De cr ea se b ut to n

Er ro r ca ll b ut to n

Mixing

thermistor

Inlet

thermistor

Output

thermistor

SV2

SV1

SV3

MV

O.H.C.F

Hi li mit

Appendix A (For error code 111)

Check these points during ignition stage.

# 1. Refer check point “B” on the wiring diagram above.

Check voltage between purple wires.

(Normal: AC 90 to 110 V)

This Check point is normal?

Yes >> Replace the igniter (Part #125)

No >> Go to Next

# 2. Refer check point “C” and “H1” on the wiring diagram above.

Check the voltage bellows.

C: Between blue wire and light blue wire (#3).

C: Between blue wire and orange wire (#53).

H1: Check the voltage between white wire and red wire.

# 3. Check current thought the orange flame rod wire (Part #707).

(Normal: more than 1μA)

This check point is normal during operation?

Yes >> Replace the PCB. (Part #701)

No >> Replace the flame rod. (Part #106)

Water

Control

valve

BK

BK

BK

BL

BL

BL B L

BL

BL

LB:LIGHT BLUE

BL: BLUE

R: RED

Y

O

R

BR

BK

W

G

Y

R

OF F

12 34 56

OF F

12 34 56

78

78

Di ps wi tc he s

O

G

R

LB

BL

BK

W

W

G

BK

Ground

GFI

BR

BR

G: GREEN

Y: YELLOW

GY:GRAY

Transformer

W

R

W

WR

R

Y

G

O

BK

W

Surge

box

BL

BK

W

G

Pump

BR

BR

Proportional

Valve

BK

BK

GY

GY

W

BK

W

O

Y

BL

R

P P

P

P

BK

BK

BK

W

BK

W

O: ORANGE

BR:BROWN

Flow

W

R

Sensor

BK

BK

D2

Re mo te

co nt rol le r

Air-fuel

ratio rod

Ground

Flame rod

FM

IG

R

R

BL

BL

W

W

O

O

P

P

Elect rod

Thermostat

AC120V

G

Ground

(Normal: DC78 to 100 V)

(Normal: DC78 to 100 V)

(Normal: DC 1 to 15 V)

These check points are normal?

Yes >> Replace the gas valves assembly. (Part #120)

No >> Replace the PCB. (Part #701)

1

2

Parent

3

4

Heater

Heater

Heater

Heater

Refer check point “G” in the diagram to the left and followings.

・ Check voltage between red wire and blue wire.

(Normal: DC 110 to 160 V)

・ Check voltage between yellow wire and blue wire.

(Normal: DC 13 to 17 V)

・ Check voltage between orange wire and blue wire

(Normal: DC 2.0 to 6.5 V)

All check points are normal?

Yes >> Replace the fan motor. (Part #115)

No >> Replace the PCB. (Part #701)

Appendix C (For error code 510 and 551)

Refer check point “C” in the diagram to the left and followings.

Check voltage on the each valve on the gas valves assembly.

・

Between blue wire and light blue wire (#3). (Normal: DC 78 to 100 V)

・ Between blue wire and green wire. (#9). (Normal: DC 78 to 100 V)

・ Between blue wire and orange wire (#53). (Normal: DC 78 to 100 V)

・ Between blue wire and red wire (#73). (Normal: DC 78 to 100 V)

All check points are normal?

Yes >> Replace the gas valves assembly. (Part #120)

No >> Replace the PCB. (Part #701)

Appendix D (For error code 311, 321, 331, and 941)

・ Mixing thermistor (Find the marking of No.113 on the connector)

Check point “E1”

・ Output thermistor (Find t he marking of No.12 on the connector)

Check point “E2”

・ Inlet thermistor (Find the marking of No.42 on the connector)

Check point “E3”

Check resistance between black wire and black wire.

Temperature

Resistance kΩ 15.4 12.6 10.3 8.5 7.0 5.9

All check points are normal?

°F 50 59 68 77 86 95

10 15 20 25 30 35

Yes >> Replace the PCB. (Part #701)

No >> Replace the wrong thermistor. (Part #418, 422, 433)

Appendix E (For error code 741)

Refer check point “F” on the wiring diagram above.

C

heck voltage on the remote cont

DC 11 to 25 V)

This check point is normal?

Yes >> Replace the remote controller.

No >> Replace the PCB. (Part #701)

Appendix F (For error code 651 and 661)

Refer check point “J” on the wiring diagram above.

Check voltage between blue wire and brown wire.

(Normal: DC 13 to 16 V)

This check point is normal?

Yes >> Replace the Water control valve. (Part #423)

No >> Replace the PCB. (Part #701)

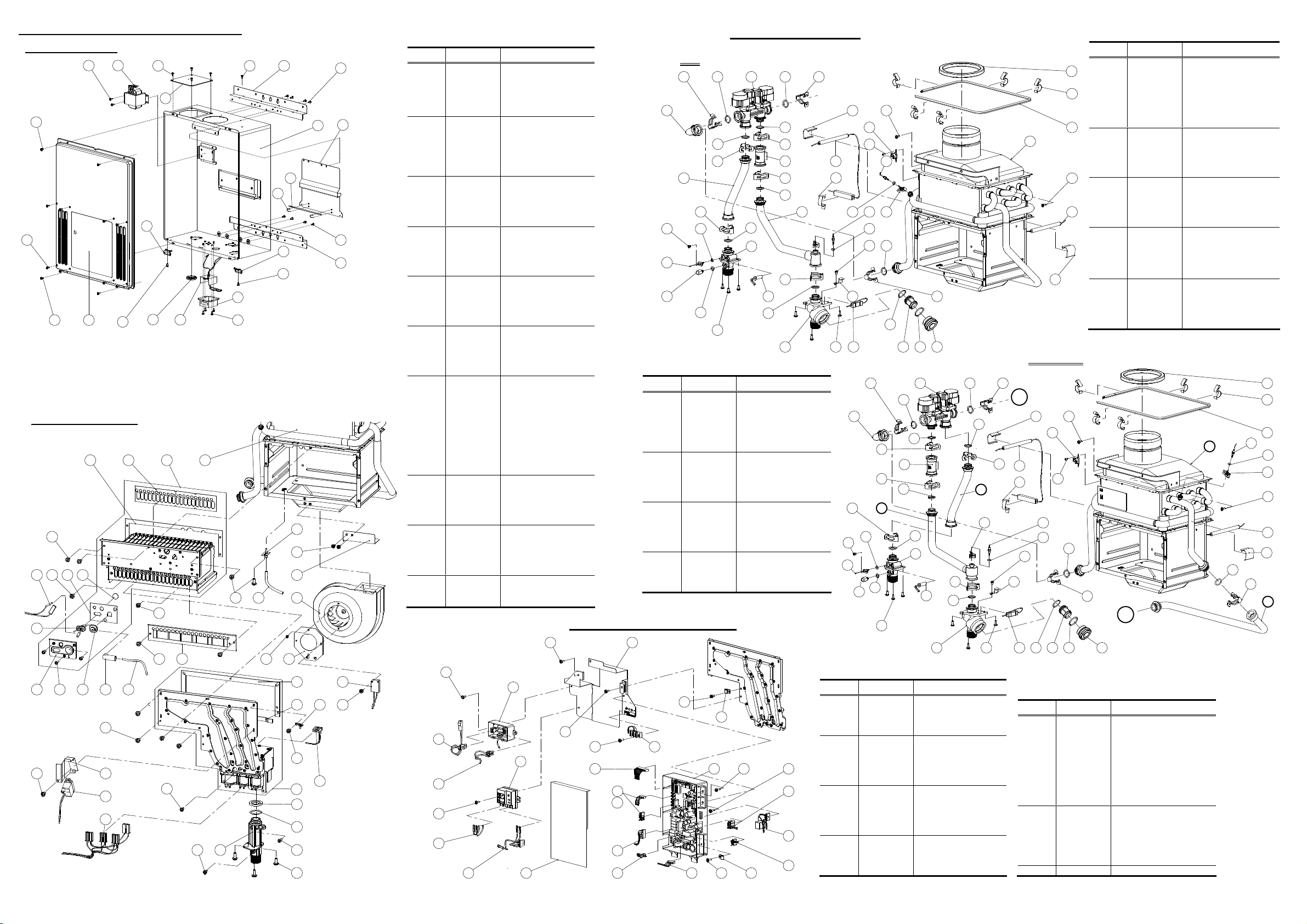

D. Dipswitch Settings on the computer board of the water heater

The dark square is the direction the dipswitch should be set to.

is the same

<Left bank of dipswitches>

Installation type

vent

N

N

O

1

2

3

4

5

6

7

8

O

1

2

3

4

5

6

7

8

as the child

unit.

(46°C)

N

O

1

2

3

4

5

6

7

8

(49°C)

N

O

1

2

3

4

5

6

7

8

(57°C)

N

O

1

2

3

4

5

6

7

8

(63°C)

N

O

1

2

3

4

5

6

7

8

(38°C)

N

N

O

1

2

3

4

5

6

7

8

O

1

2

3

4

5

6

7

8

(68°C)

N

N

O

1

2

3

4

5

6

7

8

(74°C)

(85°C)

O

N

O

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

<Right bank of dipswitches>

N

O

1

2

special functions and generally

3

should not need adjustment.

4

5

6

7

8

N

O

1

2

3

4

5

6

7

8

Gas type

Gas

N

O

1

2

3

4

5

6

7

8

should already be properly

preset from the factory.

N

O

1

2

3

4

5

6

7

8

E. Components Diagram / Parts List

706: For 710 ASME

Case assembly

70 2

05 2

05 0

05 1

05 0

00 2

Burner assembly

10 3 10 110 2 40 1

15 2

10 410 51 527 07

10 6

10 7 15 1 10 8 1 09 1 1 0

15 2

15 2

12 4

12 5

70 4

05 2

05 1 05 1 0 0 4

00 3

00 7

00 6

00 8

70 3

15 2

15 2 11 1

15 9

05 2

15 2 11 2

12 315 9

01 1

00 7

05 2

15 4 11 6

01 0

11 3

15 3

11 4

11 5

11 8

11 9 1 21

15 2

12 0

12 2

15 6

15 7

15 8

00 1

70 4

05 2

05 2

00 4

00 5

11 7

15 5

Item# Part# Description

001

002

003

004

005

006

007

008

010

011

051

052

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

151

152

153

154

155

156

157

158

159

160

319143-287

319143-303

319143-285

319143-225

319143-283

319143-014

319143-335

319143-334

319143-016

319143-017

319143-325

319143-026

319143-299

319143-300

319143-301

319143-033

319143-034

319143-035

319143-036

319143-037

319143-038

319143-345

319143-298

319143-346

319143-042

319143-281

319143-043

319143-282

319143-185

319143-304

319143-336

319143-305

319143-306

319143-048

319143-342

319143-307

319143-051

319143-052

319143-059

319143-060

319143-061

319143-330

319143-327

319143-351

319143-062

319143-325

319143-063

319143-090

05 2

71 4

71 3

05 2

71 1

71 0 72 0

Case assembly

Front cover

Air blockage plate

Bracket

Back guard panel

Junction box

Fixing plate

Rubber bush

Overheat-cut-off-fuse for

combustion chamber

Fastener

Screw M4x10 (W/Washer)

S

crew M4x10 (Coated)

Burner assembly

Burner gasket

Guide plate gasket

Burner window

Rod holder gasket

Flame rod

Rod holder

Igniter rod

Rod cap

High voltage ignite cable

Damper

Urethane tube

Pressure port

Fan motor fixing plate

Fan motor

Fan damper

Freeze protect ion thermo stat

Manifold gasket A

Manifold gasket B

Manifold assembly

with gas valve

assembly LP

Manifold assembly

with gas valve

assembly NA

Wire cramp

Gas inlet ring

Gas inlet

Igniter plate

Igniter

Pan screw M4x8

Screw M4x10

Pan scre w M4x12 (W/Washer )

Screw M3x6

Screw M3x10

O-ring P26 NBR (Black)

Pan screw M4x10

Screw M4x10 (W/Washer)

Hex head screw M4x8

Pan screw M4x6

(W/Waher)

71 5

05 2

71 2

Water way assembly

710

41 4 42 0 42 3 42 0

43 1

43 0

41 4

42 7

41 8

41 6

Item# Part# Description

424

425

426

427

428

429

430

431

432

433

434

435

436

437

439

440

441

41 9

41 7

319143-087

319143-125

319143-321

319143-090

319143-091

319143-092

319143-289

319143-318

319143-095

319143-096

319143-097

319143-098

319143-099

319143-349

319143-316

319143-315

319143-317

42 0

05 2

Computer board assembly

71 8 71 7

42 3

70 5:F or T- M3 2

70 6:F or T- M3 2 ASM E

71 605 2

05 2

70 8

70 5

70 6

705: For 710

70 4

70 3 70 9 0 5 2 7 08

43 6

41 4

42 9

41 4

42 8

42 1

42 0

43 5

41 4

41 5

41 2

41 1

Screw M3x6

Heater fixing plate 16

Pipe heater 212

Pan screw M4x6

(W/Washer)

O-ring P15 FKM

Flow sensor

Hot pipe for 710

L joint

Hi-limit switch

Output thermistor

Fastener “4-11”

Water outlet

O-ring JASO# 1017 FKM

O-ring P18 FKM

Hot pipe for 710 ASME

Cold pipe for 710

ASME

Connection pipe for

710 ASME

71 970 1

71 9

70 7

70 3

11 5

41 4

r

e

e

h

g

t

n

a

o

h

T

c

x

e

t

a

e

H

40 5

42 6

42 5

41 3

41 0052

41 4

42 7

41 8

43 1

41 6

41 9

43 2

42 4

42 2

41 9

42 7

41 4

41 7

41 4

41 4

44 0

05 2

15 0

43 341 4

43 441 9

43 7

40 9

42 0

42 9

42 8

41 4

40 640 740 8

42 3 42 0

43 6

42 0

43 5

41 4

41 5

41 2

41 1

Item# Part# Description

701

319143-279

702

319143-309

703

319143-322

704

319143-290

705 319143-293 “Flow sensor, Gas

706 319143-324 “Flow sensor, Gas

707

319143-292

708

319143-143

709

319143-320

710 PCB

Transformer

Junction box inner plate

Gas valve wire

proportional valve

connection and

Thermistors” wire for

710

proportional valve

connection and

Thermistors” wire for

710 ASME

Flame rod wire

Nylon clamp

Igniter & Freeze

protection wire

21 0

40 5

Item# Part# Description

210

40 1

40 2

40 3

15 0

40 4

211

401

402

403

404

405

406

407

408

409

410

411

412

413

414

415

416

417

418

419

420

421

422

423

319143-302

319143-314

319143-065

319143-066

319143-286

319143-224

319143-088

319143-070

319143-071

319143-072

319143-073

319143-068

319143-074

319143-075

319143-076

319143-077

319143-078

319143-079

319143-080

319143-081

319143-082

319143-083

319143-288

319143-085

319143-086

Heat exchanger assembly

Overheat-cut-off fuse

O-ring JASO# 1021 FKM

O-ring JASO# 1016 FKM

Heat exchanger

assembly for 710

for 710 ASME

Silicon ring

Fuse fixing plate 18

Pipe heater 122

Heater fixing plate

Filter plug

O-ringP25 FKM

Water inlet filter

Heater 101

Water inlet

Heater plate

Fastener “16AG”

Heater

Outlet drain plug

O-ring P6 FKM

Mixing thermistor

O-ring P4 FKM

O-ring P16 FKM

Cold pipe for 710

Inlet thermistor

Water control valve

710 ASME

41 4

A

40 5

42 0

43 9

43 4

41 4

42 6

42 5

42 7

41 3

15 0

43 2

21 1

42 4

42 2

41 9

43 7

43 7

41 4

A

40 64 0740 84 094 1005 2

Item# Part# Description

710

319143-291

711

319143-297

712

713

714

715

716

717

718

719

319143-227

319143-296

319143-295

319143-284

319143-280

319143-294

319143-331

319143-343

720 319143-323

AC 100V wire

AC100V Transformer

connecting wire

Ground fault circuit

interrupter

Power supply code

assembly

AC120V Transformer

connecting wire

Surge box

PCB fixing plate

Remote controller

terminal

Screw M3x12

Screw M4x12

PCB cover

40 1

40 2

40 3

43 3

41 9

43 4

15 0

40 4

40 5

41 4

44 1

Loading...

Loading...