Page 1

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 1/8

Product Name : Fog Liquid

Trade Name : FLP-700

Product Type : Stage / Security / Theater Accessory

Details of the supplier of the material safety data sheet

Manufacturer/Supplier:

Antari Lighting & Effects Ltd.

No.8, Ln. 231, Sec. 1, Nankan Rd., Luzhu Dist., Taoyuan City 338, Taiwan (R.O.C.)

Tel: +886 33225829

Further information obtainable from: Antari Lighting & Effects Ltd.

Emergency telephone number:

Jason Ho

Tel: +886 33225829

Email: jasonho@antari.com.tw

Classification of the substance or mixture

Not a hazardous substance or mixture according to Regulation (EC) No. 1272/2008.

This substance is not classified as dangerous according to Directive 67/548/EEC.

Label elements

The product does not need to be labelled in accordance

with EC directives or respective national laws.

Other hazards

This substance/mixture contains no components considered to be either persistent,

bioaccumulative and toxic (PBT), or very persistent and very bioaccumulative (vPvB)

at levels of 0.1% or higher.

Product description:Compounding

Component CAS No. Concentration

Propane-1,2-diol 57-55-6 34 ~ 37%

Glycerol 56-81-5 3 ~ 6%

Distilled Water 7732-18-5 55 ~ 60%

Nitrogen 7727-37-9 10g

Note(s): This is not a dangerous substance

MATERIAL SAFETY DATA SHEET

Section 1. PRODUCT AND COMPANY IDENTIFICATION

Section 3. COMPOSITION / INFORMATION ON INGREDIENTS

Section 2. HAZARDS IDENTIFICATION

Page 2

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 2/8

Section 4. FIRST AID MEASURES

After inhalation: Supply fresh air; consult doctor in case of complainte.

After skin contact: Immediately wash with water and soap and rinse thoroughly.

If skin irritation continues, consult a doctor.

After eye contact: Rinse opened eye for several minutes under running water.

If symptoms persist, consult a doctor.

After swallowing: if symptoms persist consult doctor.

Suitable extinguishing agents: Use fire fighting measures that suit the environment.

Special hazards arising from the substance or mixture No further relevant information available.

Protectove equipment: Mouth respiratory protective device.

Section 6. ACCIDENTAL RELEASE MEASURES

Personal precautions, protective equipment and emergency procedures

Mount respiratory protective device.

Environmental precautions:

Dilute with plenty of water.

Do not allow to enter sewers / surface or ground water.

Methods and material for containment and cleaning up:

Absorb with liquid-binding material (sand, diatomite, acid binders, universal binders, sawdust).

Section 7. HANDLING AND STORAGE

Handling:

Precautions for safe handling: Keep receptacles tightly sealed.

Information about protection against explosions and fires: Keep ignition sources away.

Storage:

Requirements to be met by storerooms and receptacles: Store in a cool location.

Information about storage in one common storage facility:

Store away from foodstuffs.

Store away from flammable substances.

Further information about storage conditions: Keep receptacle tightly sealed.

Section 5. FIRE-FIGHTING MEASURES

MATERIAL SAFETY DATA SHEET

Page 3

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 3/8

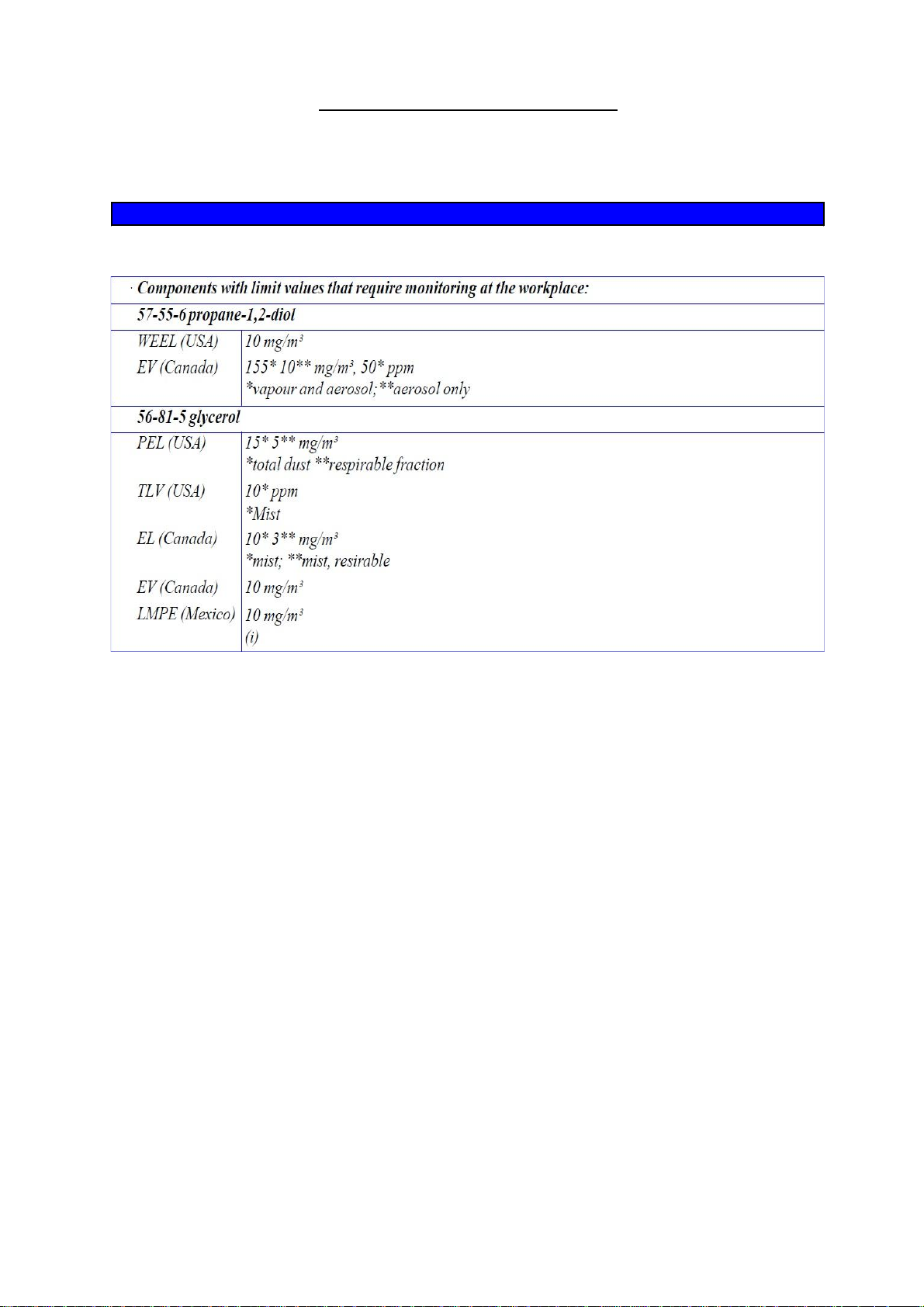

Section 8. EXPOSURE CONTROLS / PERSONAL PROTECTION

Additional information about design of technical systems: No further data; see item 7.

Additional information: The lists that were valid during the creation were used as basis.

Based on the composition shown in section 3, the following measures are suggested for occupational

safety measure

General protective and hygienic measures:

The usual precautionary measures for handling chemicals should be followed.

Breathing equipment: Suitable respiratory protective device recommended.

Protection of hands:

The glove material has to be impermeable and resistant to the product/ the substance/ the preparation.

Due to missing tests no recommendation to the glove material can be given for the product/ the preparation/

the chemical mixture.

Selection of the glove material on consideration of the penetration times, rates of diffusion and the

degradation

Material of gloves

The selection of the suitable gloves does not only depend on the material, but also on further marks of

quality and varies from manufacturer to manufacturer. As the product is a preparation of several

substances, the resistance of the glove material can not be calculated in advance and has therefore to be

checked prior to the application.

Penetration time of glove material

The exact break trough time has to be found out by the manufacturer of the protective gloves and has to be

observed.

Eye protection:

Goggles recommended during refilling.

MATERIAL SAFETY DATA SHEET

Page 4

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 4/8

General Information

Appearance:

Form:

Liquid

Color:

Transparent

Odor:

Odorless

Odour threshold:

Not available

pH-value:

Not available

Change in condition

Melting point/Melting range:

Not available

Freezing point:

Not available

Boiling point/Boiling range:

Not available

Flash point:

Not available

Flammability (solid, gaseous):

Not available

Auto-Ignition temperature:

Not available

Decomposition temperature:

Not available

Explosion limits:

Lower:

Not available

Upper:

Not available

Vapor pressure:

Not available

Density:

Not available

Relative density:

Not available

Vapour density:

Not available

Evaporation rate:

Not available

Solubility in / Miscibility with

Water:

Not available

Partition coefficient (n-octanol/water):

Not available

Viscosity:

Dynamic:

Not available

Kinematic:

Not available

Reactivity: No decomposition if used according to specifications.

Chemical stability: Stable under recommended storage conditions.

Possibility of hazardous reactions: No dangerous reactions known.

Conditions to avoid: No further relevant information available.

Incompatible materials: No further relevant information available.

Hazardous decomposition products: No dangerous decomposition products known.

Section 10. STABILITY AND REACTIVITY

Section 9. PHYSICAL AND CHEMICAL PROPERTIES

MATERIAL SAFETY DATA SHEET

Page 5

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 5/8

Acute toxicity:

Primary irritant effect:

on the skin: Irritating effect possible

on the eye: Irritating effect possible

Sensitization: Sensitization possible through skin contact.

Additional toxicological information:

The product is not subject to classification according to internally approved calculation methods

for preparations:

When used and handled according to specifications, the product does not have any harmful

effects according to our experience and the information provided to us.

Carcinogenic categories

MATERIAL SAFETY DATA SHEET

Section 11. TOXICOLOGICAL INFORMATION

IARC (International Agency for Research on Cancer)

None of the ingredients is listed.

NTP (National Toxicology Program)

None of the ingredients is listed.

Page 6

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 6/8

Toxicity

Aquatic toxicity: No further relevant information available.

Persistence and degradability: No further relevant information available.

Bioaccumulative potential: No further relevant information available.

Mobility in soil: No further relevant information available.

Additional ecological information:

General notes:

Water hazard class 1 (Self-assessment): slightly hazardous for water

Do not allow undiluted product or large quantities of it to reach ground water,

water course or sewage system.

Waste treatment methods

Recommendation: Smaller quantities can be disposed of with household waste.

Uncleaned packagings:

Recommendation: Disposal must be made according to official regulations.

Recommended cleansing agent: Water, if necessary with cleansing agents.

UN-Number

DOT, IMDG, IATA

Not applicable

UN proper shipping name

DOT, IMDG, IATA

Not applicable

Transport hazard class(es)

DOT, ADN, IMDG, IATA

Class

Not applicable

Packing group

DOT, IMDG, IATA

Not applicable

Environmental hazards:

Marine pollutant:

No

Special precautions for user

Not applicable

EMS Number:

Not applicable

Transport in bulk according to Annex II of

MARPOL73/78 and the IBC Code

Not applicable

MATERIAL SAFETY DATA SHEET

Section 12. ECOLOGICAL INFORMATION

Section 13. DISPOSAL CONSIDERATIONS

Section 14. TRANSPORT INFORMATION

Page 7

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 7/8

Safety, health and environmental regulations/legislation specific for the substance

or mixture

Sara

Section 355 (extremely hazardous substances):

None of the ingredient is listed.

Section 313 (Specific toxic chemical listings):

Substance is not listed.

None of the ingredients is listed.

TSCA (Toxic Substances Control Act):

All ingredients are listed.

Proposition 65

Chemicals known to cause cancer:

None of the ingredients is listed.

Chemicals known to cause reproductive toxicity for females:

None of the ingredients is listed.

Chemicals known to cause reproductive toxicity for males:

None of the ingredients is listed.

Chemicals known to cause developmental toxicity:

None of the ingredients is listed.

Cancerogenity categories

EPA (Environmental Protection Agency)

None of the ingredients is listed.

TLV (Threshold Limit Value established by ACGIH)

None of the ingredients is listed.

NIOSH-Ca (National Institute for Occupational Safety and Health)

None of the ingredients is listed.

OSHA-Ca (Occupational Safety & Health Administration)

None of the ingredients is listed.

National regulations:

Water hazard class: Water hazard class 1 (Self-assessment): slightly hazardous for water.

Section 15. REGULATORY INFORMATION

MATERIAL SAFETY DATA SHEET

Page 8

Formula:Stage, Fog Liquid Revision: 1.1

Issue Date: Mar. 20, 2017

Page: 8/8

The contents and format of this MSDS/SDS are in accordance with 29 CFR 1910.1200(g).

DISCLAIMER OF LIABILITY

The information in this MSDS/SDS was obtained from sources which we believe are reliable.

However, the information is provided without any warranty, express or implied, regarding its

correctness. The conditions or methods of handling, storage, use or disposal of the product are

beyond our control and may be beyond our knowledge. For this and other reasons, we do not

assume responsibility and expressly disclaim liability for loss, damage or expense arising out of

or in any way connected with the handling, storage, use or disposal of the product.

This MSDS/SDS was prepared and is to be used only for this product. If the product is used

asa component in another product, this MSDS/SDS information may not be applicable.

Abbreviations and acronyms:

IMDG: International Maritime Code for Dangerous Goods

DOT: US Department of Transportation

IATA: International Air Transport Association

ACGIH: American Conference of Governmental Industrial Hygienists

NFPA: National Fire Protection Association (USA)

HMIS: Hazardous Materials Identification System (USA)

LC50: Lethal concentration, 50 percent

LD50: Lethal dose, 50 percent

End of Document

MATERIAL SAFETY DATA SHEET

Section 16. OTHER INFORMATION

Loading...

Loading...