Page 1

SERIES

681XXC

SYNTHESIZED SIGNAL GENERATOR

OPERATION MANUAL

490 JARVIS DRIVE

MORGAN HILL, CA 95037-2809

P/N: 10370-10333

REVISION: B

PRINTED: APRIL 2001

COPYRIGHT 1999 ANRITSU CO.

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

Anritsu’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned toAnritsu for

warranty repairs. Obligation is limited to the original purchaser. Anritsu is not liable for conse

quential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear.

Also, the warranty does not apply to defects resultingfrom improper or inadequate maintenance by

the Buyer, unauthorized modification or misuse, or operation outside of the environmental specifications of theproduct. No other warranty isexpressed or implied,and the remediesprovided herein

are the Buyer’s sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

Adobe Acrobat is a registered trademark of Adobe Systems Incorporated.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers

as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment

and computor programs. The drawings, specifications, and information contained herein are the

property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifica

tions, and informationis prohibited; they shallnot be reproduced,copied, or used inwhole or inpart

as the basis for manufacture or sale of the equipment or software programs without the prior writt

ten consent of Anritsu Company.

-

-

-

Page 3

Page 4

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully BEFORE operating the equipment.

WARNING WARNING indicates a hazard. It calls attention to a procedure that

could result in personal injury or loss of life if not performed properly.

Do not proceed beyond a WARNING notice until the indicated condi

tions are fully understood and met.

CAUTION CAUTION indicates a hazard. It calls attention to a procedure which,

if not performed properly, could result in damage to or destruction of a

component of the instrument. Do not proceed beyond a CAUTION note

until the indicated conditions are fully understood and met.

The instrument is marked with this symbol to indicate that it is necessary for the user to refer to the instructions in the operation manual.

-

Indicates ground.

Indicates heavy weight equipment.

681XXC OM Safety-1

Page 5

For Safety

WARNING

When supplying power to this equipment, always use a

three-wire power cable connected to a three-wire power line

outlet. If power is supplied without grounding the equip

ment in this manner, there is a risk of receiving a severe or

fatal electric shock.

WARNING

Before changing the fuse, always remove the power cord

from the power outlet. There is the risk of receiving a fatal

electric shock if the fuse is replaced with the power cord

connected.

Always use a new fuse of the type and rating specified by

the fuse markings on the rear panel of the instrument.

-

WARNING

There are no operator serviceable components inside. Refer

servicing of the instrument to qualified service technicians.

To prevent the risk of electrical shock or damage to precision

components, do not remove the equipment covers.

WARNING

Use two or more people to lift and move this equipment, or

use an equipment cart. There is a risk of back injury, if this

equipment is lifted by one person.

WARNING

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment

may be impaired.

Safety-2 681XXC OM

Page 6

Table of Contents

Chapter 1 General Information

1-1 SCOPE OF MANUAL.................1-3

1-2 INTRODUCTION ...................1-3

1-3 DESCRIPTION ....................1-3

1-4 IDENTIFICATION NUMBER ............1-5

1-5 ELECTRONIC MANUAL...............1-5

1-6 RELATED MANUALS ................1-5

GPIB Programming Manual ...........1-5

SCPI Programming Manual ...........1-5

Maintenance Manual ..............1-6

1-7 OPTIONS .......................1-6

1-8 PERFORMANCE SPECIFICATIONS ........1-7

1-9 RECOMMENDED TEST EQUIPMENT .......1-8

Chapter 2 Installation

2-1 INTRODUCTION ...................2-3

2-2 INITIAL INSPECTION ................2-3

2-3 PREPARATION FOR USE ..............2-4

Power Requirements...............2-4

Line Voltage Selection ..............2-4

Power Connection ................2-4

Standby Operation................2-5

Warmup Time ..................2-6

Operating Environment .............2-6

2-4 GPIB SETUP AND INTERCONNECTION .....2-7

Interface Connector ...............2-7

Cable Length Restrictions ............2-7

GPIB Interconnection ..............2-7

Setting the GPIB Address ............2-7

Selecting the Line Terminator ..........2-9

Selecting the Interface Language.........2-9

2-5 RACK MOUNTING KIT INSTALLATION .....2-10

Preliminary ..................2-10

Procedure ...................2-10

681XXC OM i

Page 7

Table of Contents (Continued)

2-6 PREPARATION FOR STORAGE/SHIPMENT . . . 2-13

Preparation for Storage.............2-13

Preparation for Shipment............2-13

Chapter 3 Local (Front Panel) Operation

3-1 INTRODUCTION ...................3-5

3-2 FRONT PANEL LAYOUT...............3-6

Line Key ....................3-6

Data Display Area ................3-6

Data Entry Area.................3-7

RF Output Control Key .............3-7

Connectors ...................3-7

3-3 DATA DISPLAY AREA ................3-8

Menu Display Format ..............3-9

Menu Keys ...................3-10

3-4 DATA ENTRY AREA.................3-12

3-5 INSTRUMENT START-UP .............3-14

Powering Up the 681XXC............3-14

Start-Up Display ................3-14

Standby Operation ...............3-14

Self-Testing the 681XXC ............3-15

Resetting to Default Parameters ........3-15

3-10 POWER LEVEL SWEEP OPERATION.......3-53

Selecting CW Power Sweep Mode ........3-53

Setting CW Power Sweep Step Size and Dwell Time3-54

Selecting a CW Power Sweep Trigger ......3-55

Selecting a Power Level Sweep Range......3-56

Selecting a Sweep Frequency/Step Power Mode . 3-58

Setting Power Level Step Size .........3-59

3-11 LEVELING OPERATIONS .............3-60

Selecting a Leveling Mode ...........3-60

Attenuator Decoupling .............3-64

ALC Power Slope................3-65

User Cal (User Level Flatness Correction) . . . 3-67

3-12 SIGNAL MODULATION ..............3-73

Amplitude Modulation Operating Modes ....3-73

Providing Amplitude Modulation ........3-73

ii 681XXC OM

Page 8

Table of Contents (Continued)

Frequency Modulation Operating Modes ....3-74

Providing Frequency Modulation ........3-75

Square Wave Modulation Operating Modes . . . 3-77

Providing Square Wave Modulation .......3-77

3-13 SYSTEM CONFIGURATION ............3-80

Configuring the Front Panel ..........3-81

Configuring the Rear Panel...........3-82

Configuring the RF ...............3-83

Configuring the GPIB .............3-85

Setting Increment Sizes ............3-88

3-14 SAVING/RECALLING INSTRUMENT SETUPS . 3-89

Saving Setups .................3-89

Recalling Setups ................3-89

Erasing Stored Setups .............3-90

3-15 SECURE OPERATION ...............3-91

3-16 REFERENCE OSCILLATOR CALIBRATION . . . 3-92

Chapter 4 Local Operation–Menu Maps

4-1 INTRODUCTION ...................4-3

4-2 MENU MAP DESCRIPTION .............4-3

Chapter 5 Operation Verification

5-1 INTRODUCTION ...................5-3

5-2 TEST EQUIPMENT..................5-3

5-3 TEST RECORDS ...................5-3

5-4 INITIAL 681XXC CHECKOUT............5-4

Power Up ....................5-4

Self Test.....................5-4

Resetting the 681XXC ..............5-4

Warmup Time ..................5-4

5-5 CW FREQUENCY ACCURACY TEST........5-5

Test Setup....................5-5

Test Procedure..................5-6

5-6 POWER LEVEL ACCURACY AND FLATNESS

TESTS ........................5-13

Test Setup ...................5-13

681XXC OM iii

Page 9

Table of Contents (Continued)

Power Level Accuracy Test Procedure ......5-14

Power Level Flatness Test Procedure ......5-15

Chapter 6 Operator Maintenance

6-1 INTRODUCTION ...................6-3

6-2 ERROR AND WARNING/STATUS MESSAGES. . . 6-3

Self-Test Error Messages.............6-3

Normal Operation Error and Warning/ Status

Messages ....................6-8

6-3 TROUBLESHOOTING ...............6-10

6-4 ROUTINE MAINTENANCE ............6-13

Cleaning the Fan Filter.............6-13

Cleaning the Data Display ...........6-13

Replacing the Line Fuse ............6-14

Chapter 7 Use With Other Instruments

7-1 INTRODUCTION ...................7-3

7-2 MASTER-SLAVE OPERATION ...........7-4

Connecting the Instruments ...........7-4

Initiating Master-Slave Operation ........7-5

Master-Slave Operation .............7-7

Master-Slave Operation in VNA Mode ......7-7

Terminating Master-Slave Operation .......7-9

7-3 USE WITH A 56100ASCALAR NETWORK

ANALYZER......................7-10

Connecting the 681XXC to the 56100A .....7-10

7-4 USE WITH A 360B VECTOR NETWORK

ANALYZER......................7-11

Connecting the 681XXC to the 360B ......7-11

Modes of Operation...............7-12

Source Lock Mode ...............7-12

Tracking Mode .................7-14

7-5 USE WITH A HP8757D SCALAR NETWORK

ANALYZER......................7-16

Connecting the 681XXC to the HP8757D ....7-16

Setting Up the 681XXC.............7-17

Initiating HP8757D SNA Operation.......7-19

iv 681XXC OM

Page 10

Table of Contents (Continued)

Appendix A Rear Panel Connectors

A-1 INTRODUCTION...................A-1

A-2 REAR PANEL CONNECTORS ...........A-1

A-3 CONNECTOR PINOUT DIAGRAMS ........A-1

Appendix B Performance Specifications

681XXC OM v/vi

Page 11

Table of Contents (Continued)

Page 12

Chapter 1 General Information

Table of Contents

1-1 SCOPE OF MANUAL.................1-3

1-2 INTRODUCTION ...................1-3

1-3 DESCRIPTION ....................1-3

1-4 IDENTIFICATION NUMBER ............1-5

1-5 ELECTRONIC MANUAL...............1-5

1-6 RELATED MANUALS ................1-5

GPIB Programming Manual ...........1-5

SCPI Programming Manual ...........1-5

Maintenance Manual ..............1-6

1-7 OPTIONS .......................1-6

1-8 PERFORMANCE SPECIFICATIONS ........1-7

1-9 RECOMMENDED TEST EQUIPMENT .......1-7

Page 13

Figure 1-1. Series 681XXC Synthesized Signal Generator

Page 14

Chapter 1

General Information

1-1 SCOPE OF MANUAL This manual provides general information, installation, and operating

information for the Anritsu Series 681XXC Synthesized Signal Gen

erator. (Throughout this manual, the terms 681XXC and signal gen

erator will be used interchangeably to refer to the instrument.) Man

ual organization is shown in the table of contents.

1-2 INTRODUCTION This chapter contains general information about the series 681XXC

signal generators. It includes a general description of the instrument

and information on its identification number, related manuals, op

tions, and performance specifications. Alisting of recommended test

equipment is also provided.

1-3 DESCRIPTION The Series 681XXC Synthesized Signal Generators are microproces-

sor-based, synthesized signal sources with high resolution phase-lock

capability. They generate both broad (full range) and narrow band

sweeps and discrete CW frequencies across the frequency range of

10 MHz to 65 GHz. All functions of the signal generator are fully controllable locally from the front panel or remotely (except for power

on/standby) via the IEEE-488 General Purpose Interface Bus (GPIB).

-

-

-

-

The series presently consists of seven models covering a variety of fre

quency and power ranges. Table 1-1, page 1-4, lists models, frequency

ranges, and maximum leveled output.

681XXC OM 1-3

-

Page 15

GENERAL 681XXC

INFORMATION MODELS

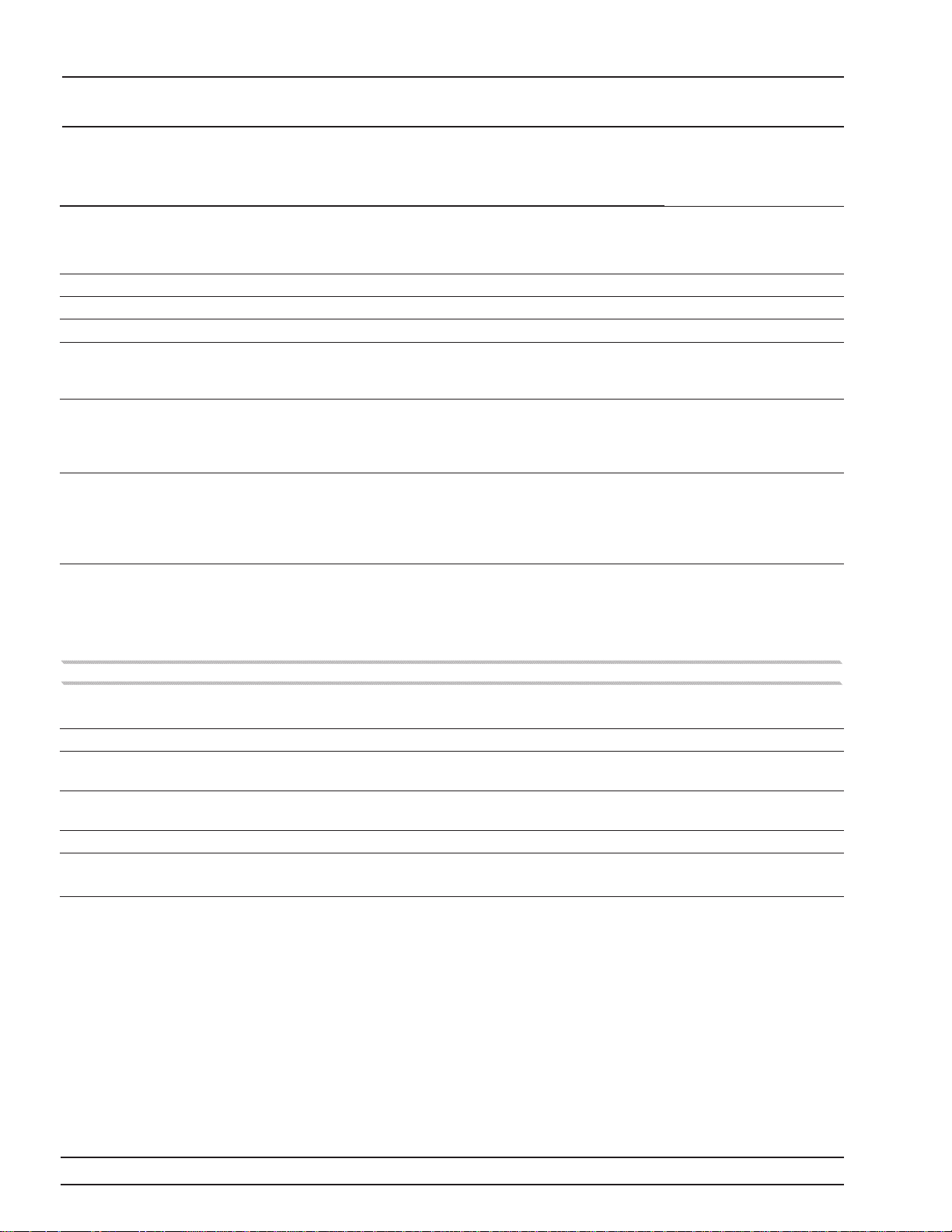

Table 1-1. Series 681XXC Models

681XXC

Model

68117C 0.01 – 8.4 GHz +13.0 dBm +11.0dBm +9.0 dBm

68137C 2.0 – 20.0 GHz +13.0 dBm +11.0 dBm +3.0 dBm

68147C 0.01 – 20.0 GHz +13.0 dBm +11.0 dBm +3.0 dBm

68167C

68177C

68187C

68197C

Frequency Output Power

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 – 60.0 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

20.0 – 40.0 GHz

40.0 – 50.0 GHz

50.0 — 65.0 GHz

+13.0 dBm

+9.0 dBm

+6.0 dBm

+11.0dBm

+10.0 dBm

+2.5 dBm

+2.5 dBm

+11.0dBm

+10.0 dBm

+2.5 dBm

+2.0 dBm

+2.0 dBm

+11.0dBm

+10.0 dBm

+2.5 dBm

0.0 dBm

–2.0 dBm

With Option 15A (High Power) Installed

Output Power

w/Step Attenuator

+11.0dBm

+7.0 dBm

+3.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.0 dBm

+10.0 dBm

+8.5 dBm

0.0 dBm

–1.5 dBm

–2.0 dBm

Not Available Not Available

Output Power

w/Electronic

Step Attenuator

Not Available

Not Available

Not Available

68117C

68137C 2.0 – 20.0 GHz +17.0 dBm +15.0 dBm +7.0 dBm

68147C

68167C

68177C 0.01 – 50.0 GHz Standard Standard Not Available

68187C 0.01 – 60.0 GHz Standard Standard Not Available

Note: In models with Option 22 that have a high-end frequency of £20 GHz, rated output power is reduced by 1 dB

In models with Option 22 that have a high-end frequency of >20 GHz, rated output power is reduced by 2 dB.

0.01 – 2.0 GHz

2.0 – 8.4 GHz

0.01 – 2.0 GHz

2.0 – 20.0 GHz

0.01 – 20.0 GHz

20.0 – 40.0 GHz

+13.0 dBm

+17.0 dBm

+13.0 dBm

+17.0 dBm

+13.0 dBm

+6.0 dBm

+11.0dBm

+15.0 dBm

+11.0dBm

+15.0 dBm

+11.0dBm

+3.0 dBm

Not Available

+11.0dBm

+11.0dBm

+11.0dBm

+7.0 dBm

1-4 681XXC OM

Page 16

GENERAL IDENTIFICATION

INFORMATION NUMBER

1-4 IDENTIFICATION

NUMBER

All Anritsu instruments are assigned a unique six-digit ID number,

such as “875012”. The ID number is imprinted on a decal that is af

fixed to the rear panel of the unit. Special-order instrument configura

tions also have an additional special serial number tag attached to the

rear panel of the unit.

When ordering parts or corresponding with Anritsu Customer Service,

please use the correct serial number with reference to the specific in

strument’s model number (i.e., Model 68147C Synthesized Signal Gen

erator, Serial No. 875012).

-

-

1-5 ELECTRONIC MANUAL This manual is available on CD ROM as an Adobe Acrobat Portable

Document Format (*.pdf) file. The file can be viewed using Acrobat

Reader, a free program that is also included on the CD ROM. The file

is “linked” such that the viewer can choose a topic to view from the

displayed “bookmark” list and “jump” to the manual page on which the

topic resides. The text can also be word-searched. Contact Anritsu

Customer Service for price and availability.

1-6 RELATED MANUALS This is one of a four manual set that consists of an Operation Manual,

a GPIB Programming Manual, a SCPI Programming Manual, and a

Maintenance Manual.

-

-

GPIB Programming

Manual

SCPI Pro

gramming

Manual

This manual provides information for remote operation of the signal generator with 681XXC Product

Specific commands sent from an external controller

via the IEEE 488 General Purpose Interface Bus

(GPIB). It contains a general description of the

GPIB and bus data transfer and control functions, a

complete listing and description of all 681XXC GPIB

Product Specific commands, and several program

ming examples. The Anritsu part number for the

GPIB Programming Manual is 10370-10334.

-

This manual provides information for remote opera

tion of the signal generator with Standard Com

mands for Programmable Instruments (SCPI)

commands sent from an external controller via the

IEEE 488 General Purpose Interface Bus (GPIB). It

contains a general description of the GPIB and bus

data transfer and control functions, a complete list

ing and description of each command in the 681XXC

SCPI command set, and examples of command us

age. The Anritsu part number for the SCPI Pro

gramming Manual is 10370-10335.

-

-

-

-

-

-

681XXC OM 1-5

Page 17

GENERAL

INFORMATION OPTIONS

Maintenance

Manual

The Maintenance Manual supplies service informa

tion for all models in the 681XXC series. The service

information includes functional circuit descriptions,

block diagrams, performance verification tests, cali

bration procedures, troubleshooting data, and as

sembly and component removal/replacement

procedures. The Anritsu part number for the Main

tenance Manual is 10370-10336.

1-7 OPTIONS The following options are available.

Option 1, Rack Mounting. Rack mount kit containing a set of

track slides (90° tilt capability), mounting ears, and front panel han

dles for mounting the instrument in a standard 19-inch equipment

rack.

Option 2A, 110 dB Step Attenuator. Adds a 10 dB per step

attenuator with a 110 dB range for models having a high-end frequency of £20 GHz. Output power is selected directly in dBm on the

front panel (or via GPIB). Rated RF output power is reduced.

Option 2B, 110 dB Step Attenuator. Adds a 10 dB per step

attenuator with a 110 dB range for models having a high-end frequency of £40 GHz. Output power is selected directly in dBm on the

front panel (or via GPIB). Rated RF output power is reduced.

-

-

-

-

-

Option 2C, 90 dB Step Attenuator. Adds a 10 dB per step

attenuator with a 90 dB range for models having a high-end frequency of £50 GHz. Output power is selected directly in dBm on the

front panel (or via GPIB). Rated RF output power is reduced.

Option 2D, 90 dB Step Attenuator. Adds a 10 dB per step

attenuator with a 90 dB range for models having a high-end fre

quency of £60 GHz. Output power is selected directly in dBm on the

front panel (or via GPIB). Rated RF output power is reduced.

Option 2E, 120 dB Electronic Step Attenuator. Addsa10dB

per step electronic attenuator with a 120 dB range for models hav

ing a high-end frequency of £8.4 GHz. Output power is selected di

rectly in dBm on the front panel (or via GPIB). Rated RF output

power is reduced.

Option 2F, 120 dB Electronic Step Attenuator. Addsa10dB

per step electronic attenuator with a 120 dB range for models hav

ing a high-end frequency of £20 GHz. Output power is selected di

rectly in dBm on the front panel (or via GPIB). Rated RF output

power is reduced.

Option 9, Rear Panel RF Output. Moves the RF output connector

to the rear panel.

Option 11, 0.1 Hz Frequency Resolution. Provides frequency

resolution of 0.1 Hz.

-

-

-

-

-

1-6 681XXC OM

Page 18

GENERAL PERFORMANCE

INFORMATION SPECIFICATIONS

Option 14, Rack Mounting without Chassis Slides. Modifies

rack mounting hardware to install unit in a console that has mount

ing shelves. Includes mounting ears and front panel handles.

-

Option 15A, High Power Output. Adds high-power RF compo

nents to the instrument providing increased RF output power in the

2–20 GHz frequency range. Option 15A is standard in models hav

ing a high-end frequency that is >40 GHz.

Option 16, High-Stability Time Base. Adds an ovenized, 10 MHz

crystal oscillator with <5 x 10

Option 17A, No Front Panel. Deletes the front panel for use in re

mote control applications where a front panel display or keyboard

control are not needed.

Option 18, mmWave Module Bias Output. Provides bias output

for 54000-xWRxx Millimeter Wave Source Modules. BNC Twinax

connector, rear panel.

Option 19, SCPI Programmability. Adds GPIB command mnemonics complying with Standard Commands for Programmable Instruments (SCPI), Version 1993.0. SCPI programming complies with

IEEE 488.2-1987.

Option 22, 0.1 Hz to 10 MHz Audio Frequency. Adds frequency

coverage below 10 MHz. In models having a high-end frequency of

£20 GHz, rated output power is reduced by 1 dB; in models having a

high-end frequency of >20 GHz, rated output power is reduced by

2 dB.

–10

/day frequency stability.

-

-

-

1-8 PERFORMANCE

SPECIFICATIONS

Series 681XXC Synthesized Signal Generator performance specifica

tions are provided in Appendix B.

-

681XXC OM 1-7

Page 19

GENERAL RECOMMENDED

INFORMATION TEST EQUIPMENT

1-9 RECOMMENDED TEST

EQUIPMENT

Table 1-2 lists the recommended test equipment for performing the Se

ries 681XXC Synthesized Signal Generator operation verification tests

in Chapter 5.

Table 1-2. Recommended Test Equipment

Instrument Critical Specification Recommended Manufacturer/Model

Frequency

Counter,

with

Cable Kit

and

External Mixer

Power Meter,

with

Power

Sensors

Oscilloscope Bandwidth: DC to 150 MHz

Range: 0.01 to 65 GHz

Input Z: 50W

Resolution: 1Hz

Other: External Time Base

Input

Range: –30 to +20 dBm

(1 mW to 100 mW)

Vertical Sensitivity: 2 mV/

division

Horiz Sensitivity: 50 ns/

division

EIP Microwave, Inc. Models 538B,

548B, or 578B,

with

Cable Kit: Option 590

and

External Mixer:

Option 91 (26.5 to 40 GHz)

Option 92 (40 to 60 GHz)

Option 93 (60 to 90 GHz)

Anritsu Model ML2437Aor ML2438A,

with

Power Sensors:

MA2474A (0.01 to 40 GHz)

MA2475A (0.01 to 50 GHz)

Tektronix, Inc. Model TAS485

-

1-8 681XXC OM

Page 20

Chapter 2 Installation

Table of Contents

2-1 INTRODUCTION ...................2-3

2-2 INITIAL INSPECTION ................2-3

2-3 PREPARATION FOR USE ..............2-4

Power Requirements...............2-4

Line Voltage Selection ..............2-4

Power Connection ................2-4

Standby Operation................2-5

Warmup Time ..................2-6

Operating Environment .............2-6

2-4 GPIB SETUP AND INTERCONNECTION .....2-7

Interface Connector ...............2-7

Cable Length Restrictions ............2-7

GPIB Interconnection ..............2-7

Setting the GPIB Address ............2-7

Selecting the Line Terminator ..........2-9

Selecting the Interface Language.........2-9

2-5 RACK MOUNTING KIT INSTALLATION .....2-10

Preliminary ..................2-10

Procedure ...................2-10

2-6 PREPARATION FOR STORAGE/SHIPMENT . . . 2-13

Preparation for Storage.............2-13

Preparation for Shipment............2-13

Page 21

Page 22

Chapter 2

Installation

2-1 INTRODUCTION This chapter provides installation instructions for the Series 681XXC

Synthesized Signal Generator. It includes information on initial in

spection, preparation for use, storage, and reshipment, and General

Purpose Interface Bus (GPIB) setup and interconnections.

WARNING

Use two or more people to lift and move this equipment, or

use an equipment cart. There is a risk of back injury, if this

equipment is lifted by one person.

2-2 INITIAL INSPECTION Inspect the shipping container for damage. If the shipping container or

cushioning material is damaged, retain until the contents of the shipment have been checked against the packing list and the signal generator has been checked for mechanical and electrical operation.

-

If the shipment is incomplete or if the signal generator is damaged

mechanically or electrically, notify your local sales representative or

Anritsu Customer Service. If either the shipping container is damaged

or the cushioning material shows signs of stress, notify the carrier as

well as Anritsu. Keep the shipping materials for the carrier’s inspec

tion.

-

681XXC OM 2-3

Page 23

PREPARATION

INSTALLATION FOR USE

2-3 PREPARATION FOR USE Preparation for use consists of checking that the rear panel line volt

age selector switch is set for the correct line voltage and connecting

the signal generator to the power source. The following paragraphs

provide these procedures along with information about power require

ments, warmup times, and the operating environment.

Power

Requirements

Before applying power, verify that the unit is set to match

the available line voltage and that the installed fuse is of

the correct type and rating.

Line Voltage

Selection

The signal generator accepts 90 to 132 Vac and 180

to 264 Vac, 48 to 440 Hz, single-phase power. Power

consumption is 400 VA maximum. The signal gen

erator is intended for Installation Category (Over

voltage Category) II.

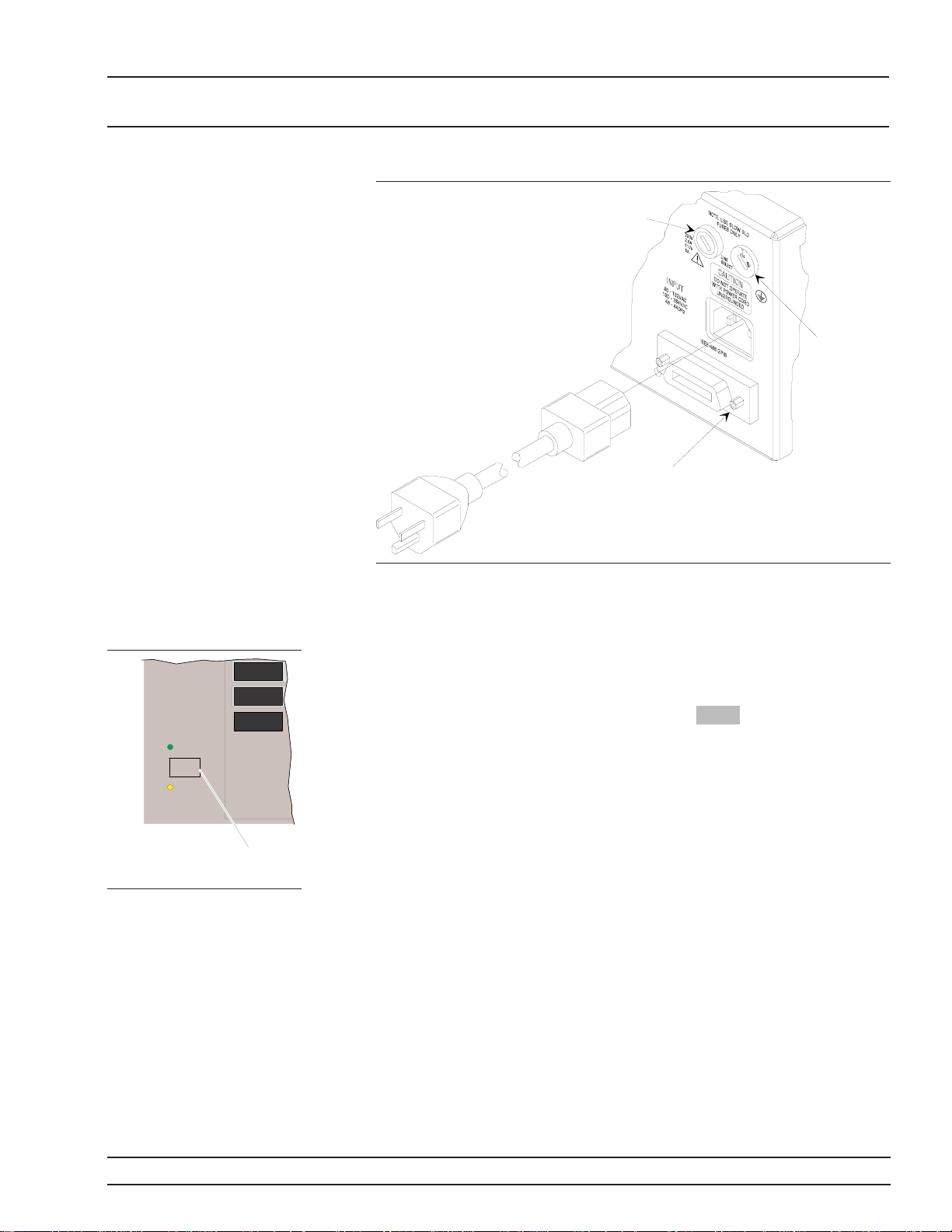

CAUTION

The line voltage selector switch on the rear panel

can be set for either 110 Vac or 220 Vac operation

(Figure 2-1). When the switch is set to 110 Vac, the

681XXC accepts 90 to 132 Vac line voltage. When

the switch is set to 220 Vac, the 681XXC accepts 180

to 264 Vac line voltage. If the selector setting is incorrect for the line voltage available, change it to

the correct setting.

-

-

-

-

Whenever the selector setting is changed, the line

fuse must be changed to the correct value for the

line voltage selected. Line fuse values for the line

voltages are printed on the rear panel next to the

fuse holder.

WARNING

When supplying power to this equipment, always use a

three-wire power cable connected to a three-wire power line

outlet. If power is supplied without grounding the equip

ment in this manner, there is a risk of receiving a severe or

fatal electric shock.

Power

Connection

Connecting the 681XXC to line power automatically

places it in operation (front panel OPERATE LED

on). To connect it to the power source, plug the fe

male end of the power cable into the input line volt

age receptacle on the rear panel (Figure 2-1). Then

plug the male end of the power cord into a threewire power line outlet.

-

-

-

2-4 681XXC OM

Page 24

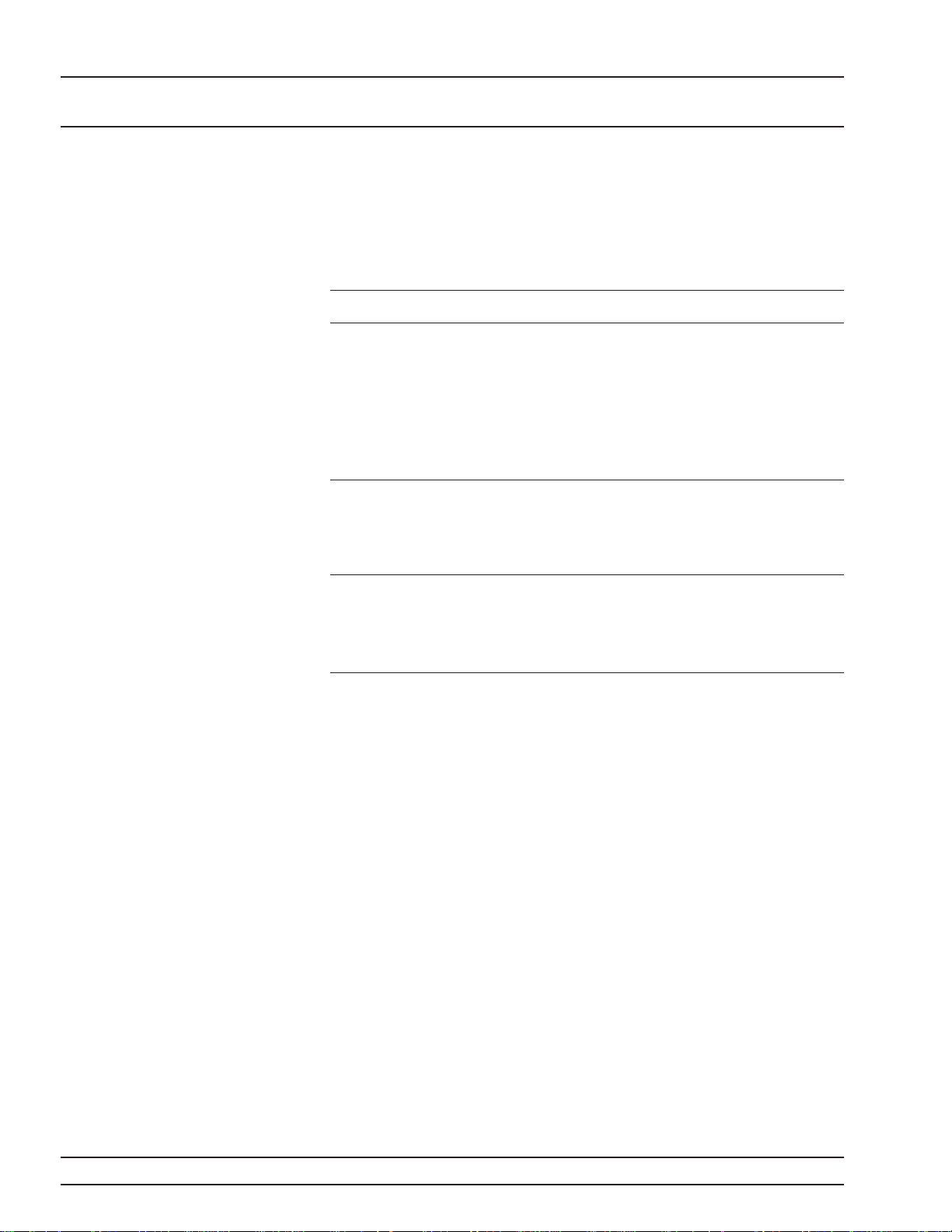

PREPARATION

INSTALLATION FOR USE

Line

Fuse

Line Voltage

Selector Switch

GPIB

Connector

OPERATE

LINE

STANDBY

LEVEL

CONTROL

MODULATION

SYSTEM

Line

Key

Figure 2-1. Signal Generator Rear Panel showing Power Connection

Standby

Operation

Whenever the signal generator is not being used it

should be left connected to the power source and

placed in standby. This keeps the internal timebase

frequency reference at operating temperature.

On the front panel, press LINE to switch the

681XXC from OPERATE (green LED on) to

STANDBY (orange LED on).

NOTE

During standby operation, the fan runs

continuously.

681XXC OM 2-5

Page 25

PREPARATION

INSTALLATION FOR USE

Warmup Time

Operating

Environment

From Standby–When placing the 681XXC in op

eration from stand-by, allow 30 minutes warmup to

assure stable operation.

From a Cold Start (0°C)–The signal generator re

quires approximately 120 hours (5 days) of warm up

to achieve specified frequency stability with aging.

NOTE

Instruments disconnected from AC power

for more than 72 hours require 30 days to

return to specified aging.

The 681XXC can be operated within the following

environmental limits.

Temperature. 0°Cto50°C.

q

Humidity. 5 to 95% relative at 40°C.

q

Altitude. up to 4600 meters.

q

Cooling. Internal cooling is provided by forced

q

airflow from the fan mounted on the rear

panel.

CAUTION

-

-

Before installing the 681XXC in its operating environment,

ensure that all airflow passages at the sides and rear of the

instrument are clear. This is of particular importance whenever the unit is being rack-mounted.

Keep the cooling fan filter clean so that the ventilation holes

are not obstructed. A blocked fan filter can cause the instru

ment to overheat and shut down.

-

2-6 681XXC OM

Page 26

GPIB SETUP AND

INSTALLATION INTERCONNECTION

2-4 GPIB SETUP AND

INTERCONNECTION

The 681XXC provides automated microwave signal generation via the

GPIB. The following paragraphs provide information about interface

connections, cable requirements, setting the GPIB operating parame

ters, and selecting the external interface language.

Interface

Connector

Cable Length

Restrictions

Interface between the signal generator and other de

vices on the GPIB is via a 24-wire interface cable.

This cable uses connector shells having two connec

tor faces. These double-faced connectors allow for

the parallel connection of two or more cables to a

single device. Figure 2-1 shows the location of the

rear panel GPIB connector.

The GPIB can accommodate up to 15 instruments at

any one time. To achieve design performance on the

bus, proper timing and voltage level relationships

must be maintained. If either the cable length be

tween separate instruments or the cumulative cable

length between all instruments is too long, the data

and control lines cannot be driven properly and the

system may fail to perform. Cable length restrictions are as follows:

q

No more than 15 instruments may be installed

on the bus.

q

Total cumulative cable length in meters may

not exceed two times the number of bus instruments or 20 meters—whichever is less.

-

-

-

-

NOTE

For low EMI applications, the GPIB cable

should be a fully shielded type, with

well-grounded metal-shell connectors

GPIB Inter

connection

Setting the

GPIB Address

-

The only interconnection required for GPIB opera

tion is between the signal generator and the control

ler. This interconnection is via a standard GPIB

cable. The Anritsu Part number for such a cable is

2000-1, -2, or -4 (1, 2, or 4 meters in length).

The default GPIB address is 5. If a different GPIB

address is desired, it can be set from the front panel

using the Configure GPIB Menu.

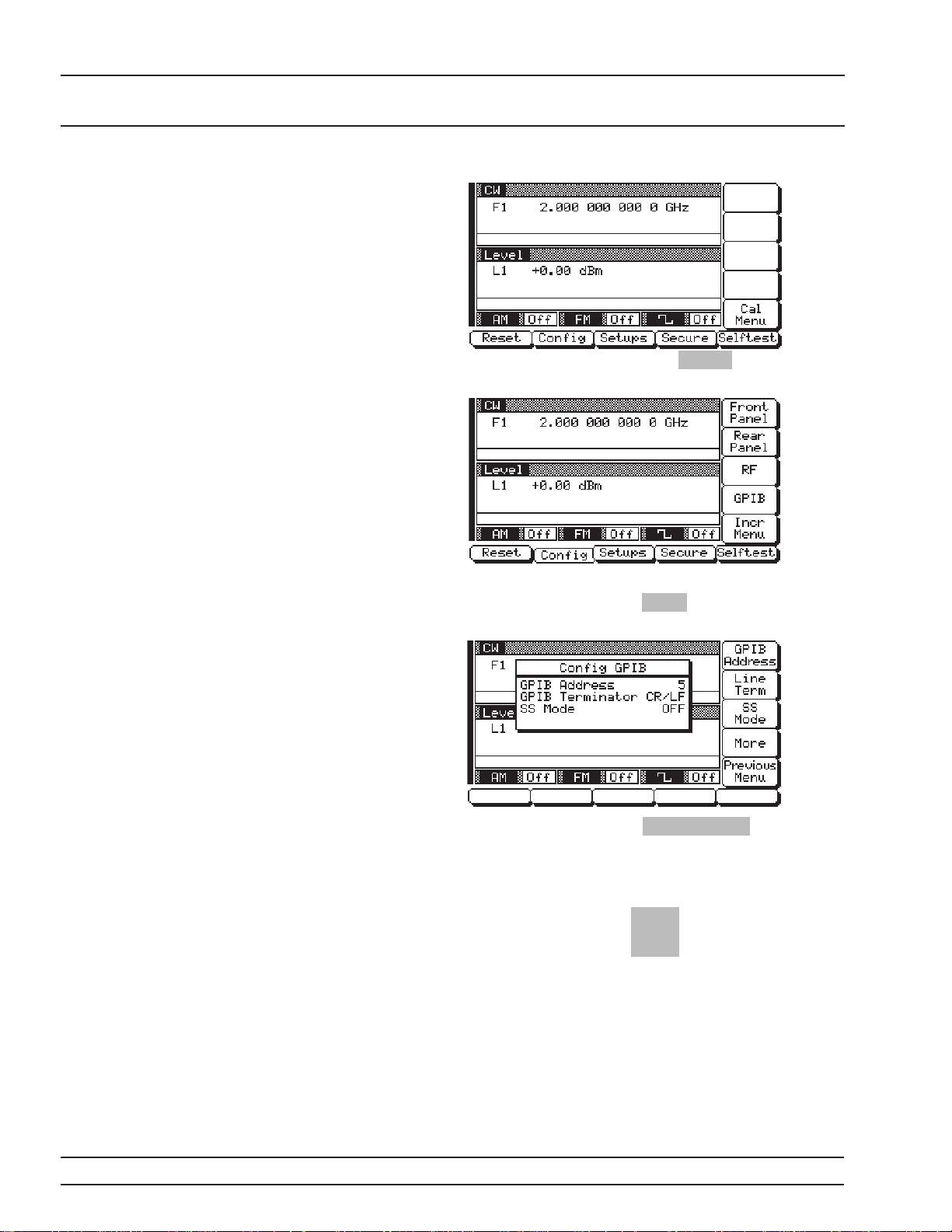

To change the GPIB address, first press the front

panel main menu key labeled SYSTEM . The Sys

tem Menu (shown on the following page) is dis

played.

-

-

-

681XXC OM 2-7

-

Page 27

GPIB SETUP AND

INSTALLATION INTERCONNECTION

Now press the menu soft-key Config . The System

Configuration Menu (below) is displayed.

To go to the Configure GPIB menu from this menu,

press the menu soft-key GPIB . The Configure GPIB

Menu (below) is displayed.

Press the menu soft-key GPIB Address to change

the current GPIB address of the signal generator.

Enter a new address using the cursor control key or

the data entry keypad and the terminator key

Hz

ns

ADRS

The new GPIB address will now appear on the dis

play. The entry must be between 1 and 30 to be rec

ognized as a valid GPIB address.

-

-

2-8 681XXC OM

Page 28

GPIB SETUP AND

INSTALLATION INTERCONNECTION

Selecting the

Line

Terminator

Selecting the

Interface

Language

Data is delimited on the GPIB by either the carriage

return (CR) ASCII character or both the carriage re

turn and line feed (CR/LF) ASCII characters. Which

character is used depends upon the requirements of

the system controller. Most modern controllers can

use either CR or CR/LF, while many older control

lers require one or the other. Consult the controller’s

manual for its particular requirements.

From the Configure GPIB Menu display, you can se

lect which GPIB terminator to use by pressing the

menu soft-key Line Term . This menu soft-key tog

gles the GPIB terminator between CR and CR/LF.

The current selection appears on the display.

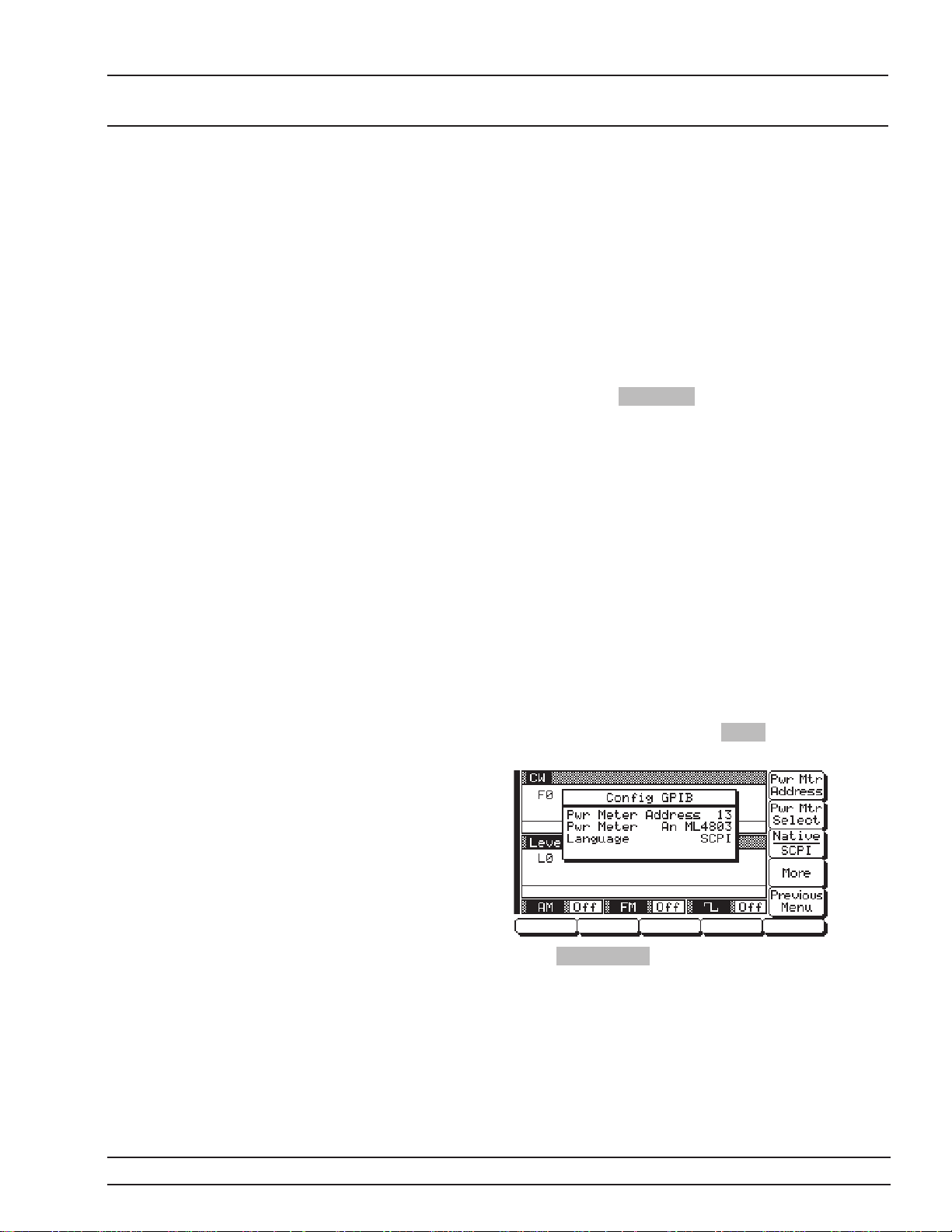

Series 681XXC Synthesized Signal Generators can

be remotely operated via the GPIB using one of two

external interface languages—Native or SCPI (Op

tion 19). The Native interface language uses a set of

681XXC GPIB Product Specific commands to control

the instrument; the SCPI interface language uses a

set of the Standard Commands for Programmable

Instruments commands to control the unit.

The Configure GPIB Menu has additional menu displays. For instruments with Option 19, selection of

which external interface language is to be used is

made from this additional menu. From the Configure GPIB Menu display, you can access the first

additional menu by pressing More . The first Addi

tional Configure GPIB Menu (below) is displayed.

-

-

-

-

-

-

Press Native SCPI to select the external interface

language to be used. This menu soft-key toggles the

language selection between Native and SCPI. The

current selection appears on the display.

681XXC OM 2-9

Page 29

RACK MOUNTING KIT

INSTALLATION INSTALLATION

2-5 RACK MOUNTING KIT

INSTALLATION

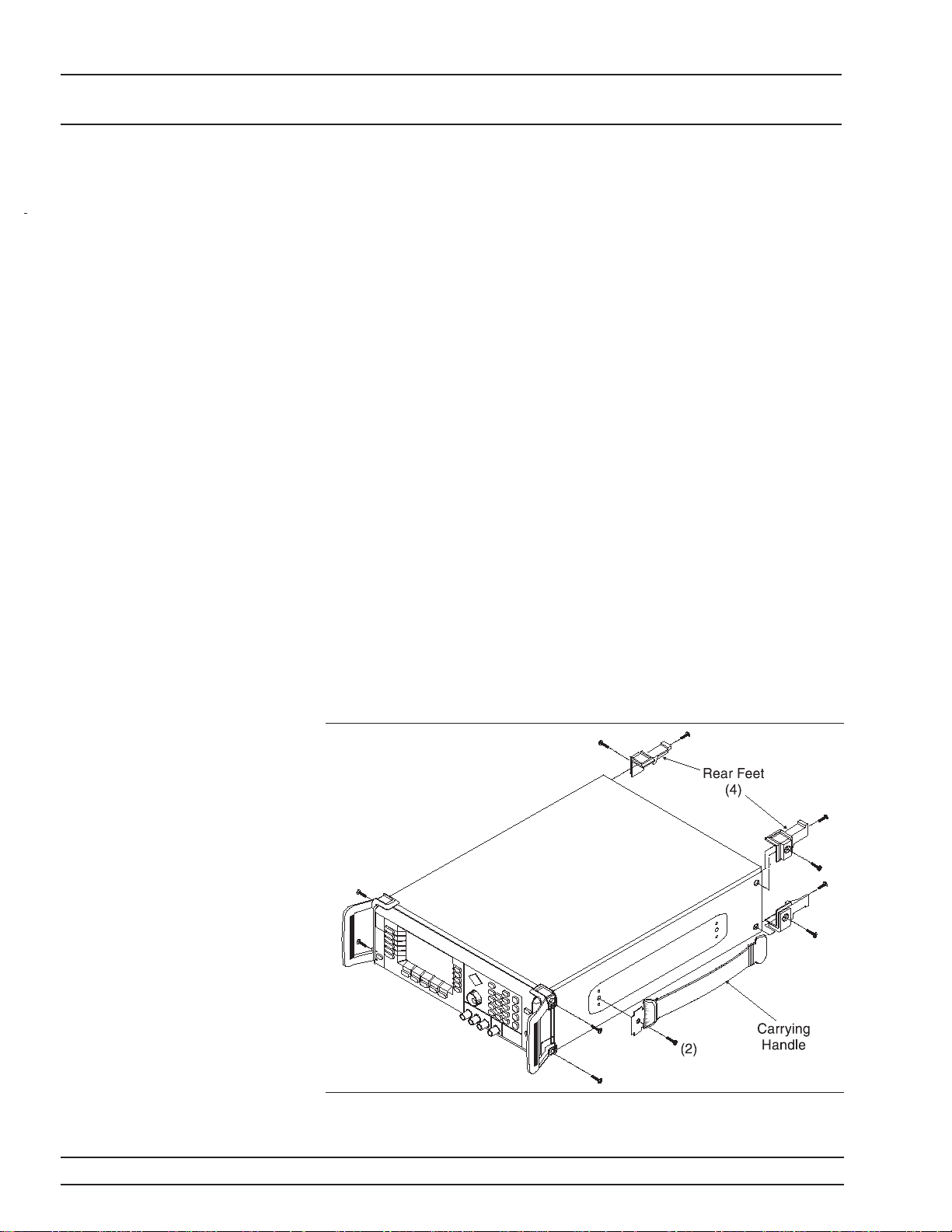

The rack mounting kit (Option 1) contains a set of track slides (90° tilt

capability), mounting ears, and front panel handles for mounting the

signal generator in a standard equipment rack. The following proce

dure provides instructions for installing the rack mounting hardware

on to the instrument. Refer to Figures 2-2 and 2-3 during this proce

dure.

Preliminary Disconnect the power cord and any other cables

from the instrument.

Procedure Install the rack mounting hardware as follows:

Step 1 Using a Phillips screwdriver, remove the

screws and the front handle assemblies

from the instrument. (For instruments

not having front handles, remove the

screws and the front top and bottom feet

from the instrument.) Retain the screws.

Step 2 Remove the four feet from the rear of the

instrument. Retain the screws.

Step 3 Remove the screws and the carrying han-

dle from the side handle cover. (The two

screws fastening the carrying handle

through the side handle cover to the chassis are accessable by lifting up the rubber

covering at each end of the handle.)

-

-

Figure 2-2. Front Handle, Feet, and Carrying Handle Removal

2-10 681XXC OM

Page 30

RACK MOUNTING KIT

INSTALLATION INSTALLATION

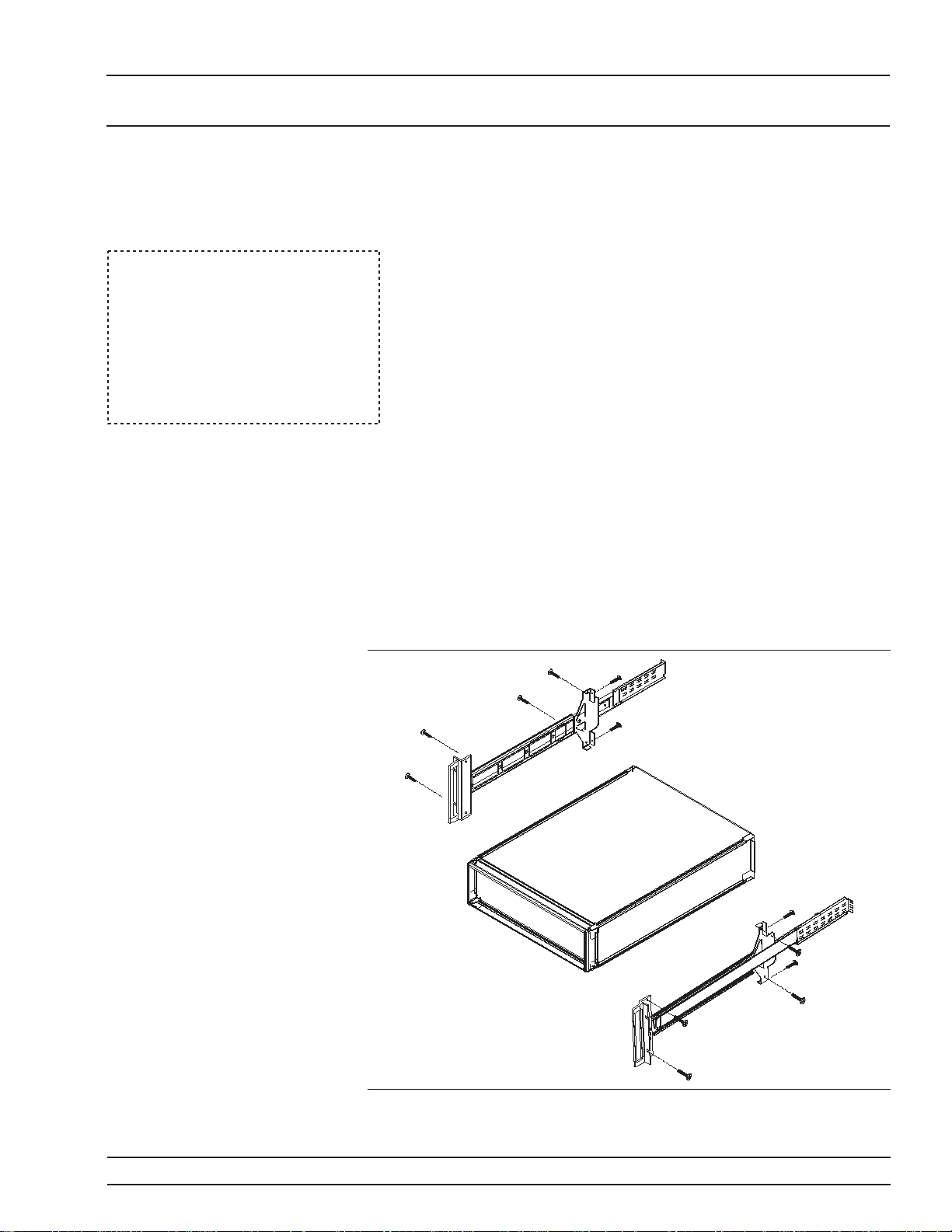

Step 4 Remove the inner slide assemblies from

the outer slide assemblies.

Step 5 Place the left side inner slide assembly

NOTE

The screws with green heads have

metric threads. When it becomes

necessary to replace any of these

screws, always use the exact re

placement green-headed screws

(Anritsu P/N 2000-560) to avoid

damage to the instrument.

Step 6 Insert two green-headed screws through

-

Step 7 Insert two green-headed screws through

onto the instrument case with the handle

towards the front of the instrument (Fig

ure 2-3).

the holes in the slide assembly behind the

handle and into the metric tapped holes

in the side of the instrument.

the holes near the rear of the slide assem

bly and into the metric tapped holes in

the side of the instrument.

-

-

Step 8 Insert the two SAE threaded screws (re

moved from the feet) through the 90° tabs

on the rear of the slide assembly and into

the rear panel of the instrument.

Step 9 Using the Phillips screwdriver, tighten all

screws holding the left side slide assembly to the instrument chassis.

-

Figure 2-3. Rack Mounting Hardware Installation

681XXC OM 2-11

Page 31

RACK MOUNTING KIT

INSTALLATION INSTALLATION

Step 10 Place the right side inner slide assembly

onto the instrument case with the handle

towards the front of the instrument.

Step 11 Insert two green-headed screws through

the holes in the slide assembly behind the

handle and into the metric tapped holes

in the side of the instrument.

Step 12 Insert two green-headed screws through

the holes near the rear of the slide assem

bly and into the metric tapped holes in

the side of the instrument.

-

Step 13 Insert the two SAE threaded screws (re

moved from the feet) through the 90° tabs

on the rear of the slide assembly and into

the rear panel of the instrument.

Step 14 Using the Phillips screwdriver, tighten all

screws holding the right side slide assembly to the instrument chassis.

Step 15 With the appropriate hardware, install

the outer slide assemblies onto the equipment rack.

Step 16 Lift the signal generator into position.

Align the inner and outer slide assemblies and slide the instrument into the

rack. Realign the hardware as needed for

smooth operation.

WARNING

Use two or more people to lift and move this equipment, or

use an equipment cart. There is a risk of back injury, if this

equipment is lifted by one person.

-

2-12 681XXC OM

Page 32

PREPARATION FOR

INSTALLATION STORAGE/SHIPMENT

2-6 PREPARATION FOR

STORAGE/SHIPMENT

The following paragraphs give instructions for preparing the 681XXC

for storage or shipment.

Preparation

for Storage

Preparation

for Shipment

Preparing the signal generator for storage consists

of cleaning the unit, packing the inside with mois

ture-absorbing desiccant crystals, and storing the

unit in a temperature environment that is main

tained between –40°C and +75°C.

To provide maximum protection against damage in

transit, the signal generator should be repackaged

in the original shipping container. If this container

is no longer available and the unit is being returned

to Anritsu for repair, advise Anritsu Customer Serv

ice; they will send a new shipping container free of

charge. In the event neither of these two options is

possible, instructions for packaging and shipment

are given below.

Use a Suitable Container.

Obtain a corrugated cardboard carton with a 125 kg

test strength. This carton should have inside dimensions of no less than 15 cm larger than the unit dimensions to allow for cushioning.

-

-

-

Protect the Instrument.

Surround the unit with polyethylene sheeting to

protect the finish.

Cushion the Instrument.

Cushion the instrument on all sides by tightly pack

ing dunnage or urethane foam between the carton

and the unit. Provide at least three inches of dun

nage on all sides.

Seal the Container.

Seal the carton by using either shipping tape or an

industrial stapler.

Address the Container.

If the instrument is being returned to Anritsu for

service, mark the address of the appropriate Anritsu

service center (Table 2-1) and your return address

on the carton in one or more prominent locations.

-

-

681XXC OM 2-13

Page 33

ANRITSU

INSTALLATION SERVICE CENTERS

Table 2-1. ANRITSU Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (201) 227-8999, 1-800-ANRITSU

FAX: 201-575-0092

ANRITSU COMPANY

1155E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo, 440, Sala 2401

CEP22250-040, Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 828-4090

FAX: (613) 828-5400

CHINA

ANRITSU ELECTRONICS (SHANGHAI) CO.

LTD.

2F, Rm B 52 Section Factory Building

No. 516 Fu Te Rd (W)

Shanghi 200131 China

Telephone: 21-58680226, 58680227

FAX: 21-58680588

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES (P) LTD.

23 Community Center

Kailash Colony Extension

New Delhi, India

Telephone: 91-11-6442700

FAX: 91-11-6442500

ISRAEL

TECH-CENT, LTD.

4 Raul ValenbergSt

Tel-Aviv 69719

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-99-711

FAX: (06) 50-22-4252

KOREA

ANRITSU CORPORATIONLTD.

8F, Seocho-Dong, Secho-Ku

Seoul, 137-070

South Korea

Telephone: 2-581-6603

FAX: 2-582-6603

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD.

6 New Industrial Road #06-01/02

Hoe Huat Industrial Bldg

Singapore 536199

Telephone: 282-2400

FAX: 282-2533

SOUTH AFRICA

ETECSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

FAX: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botivid Center

Fittja Backe 13A

S145 84 Stockholmn

Telephone: (08) 534-707-00

FAX: (08) 534-707-30

TAIWAN

ANRITSU CO., LTD.

6F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Telephone: (02) 515-6050

FAX: (02) 509-5519

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-433200

FAX: 015-82-731303

2-14 681XXC OM

Page 34

Chapter 3 Local (Front Panel) Operation

Table of Contents

3-1 INTRODUCTION ...................3-5

3-2 FRONT PANEL LAYOUT...............3-6

Line Key ....................3-6

Data Display Area ................3-6

Data Entry Area.................3-7

RF Output Control Key .............3-7

Connectors ...................3-7

3-3 DATA DISPLAY AREA ................3-8

Menu Display Format ..............3-9

Menu Keys ...................3-10

3-4 DATA ENTRY AREA.................3-12

3-5 INSTRUMENT START-UP .............3-14

Powering Up the 681XXC............3-14

Start-Up Display ................3-14

Standby Operation ...............3-14

Self-Testing the 681XXC ............3-15

Resetting to Default Parameters ........3-15

3-6 ENTERING DATA ..................3-18

Opening the Parameter.............3-18

Editing the Current Value ...........3-19

Entering a New Value .............3-20

Page 35

Table of Contents (Continued)

3-7 CW FREQUENCY OPERATION ..........3-21

Selecting CW Mode...............3-21

Selecting a CW Frequency ...........3-22

Selecting a Power Level.............3-24

CW Ramp ...................3-25

3-8 SWEEP FREQUENCY OPERATION........3-26

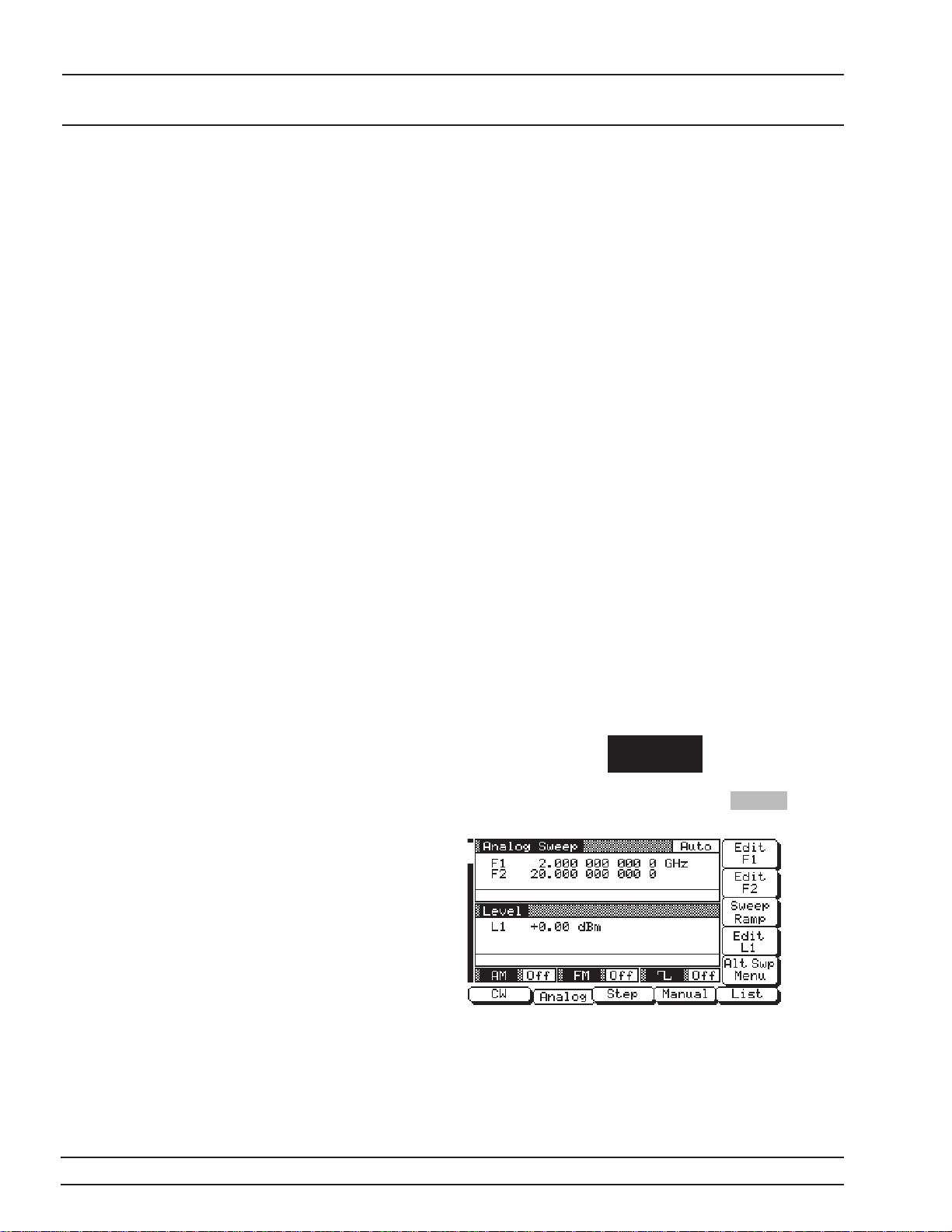

Analog Sweep Mode ..............3-26

Selecting Analog Sweep Mode..........3-26

Setting the Analog Sweep Time.........3-27

Selecting a Sweep Trigger ...........3-28

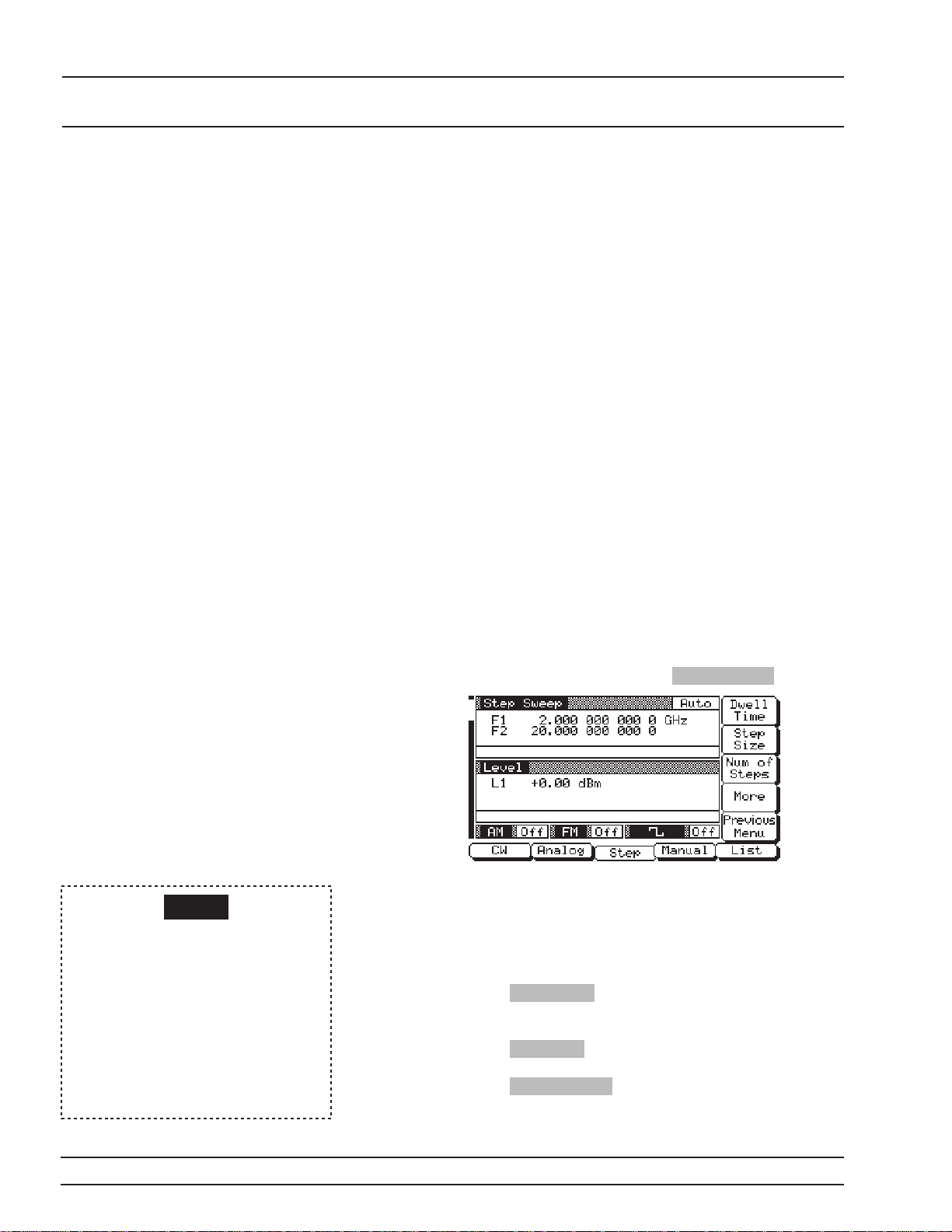

Step Sweep Mode................3-29

Selecting Step Sweep Mode ...........3-29

Setting Step Size, Dwell Time, and Sweep Time. 3-29

Manual Sweep Mode ..............3-32

Selecting Manual Sweep Mode .........3-32

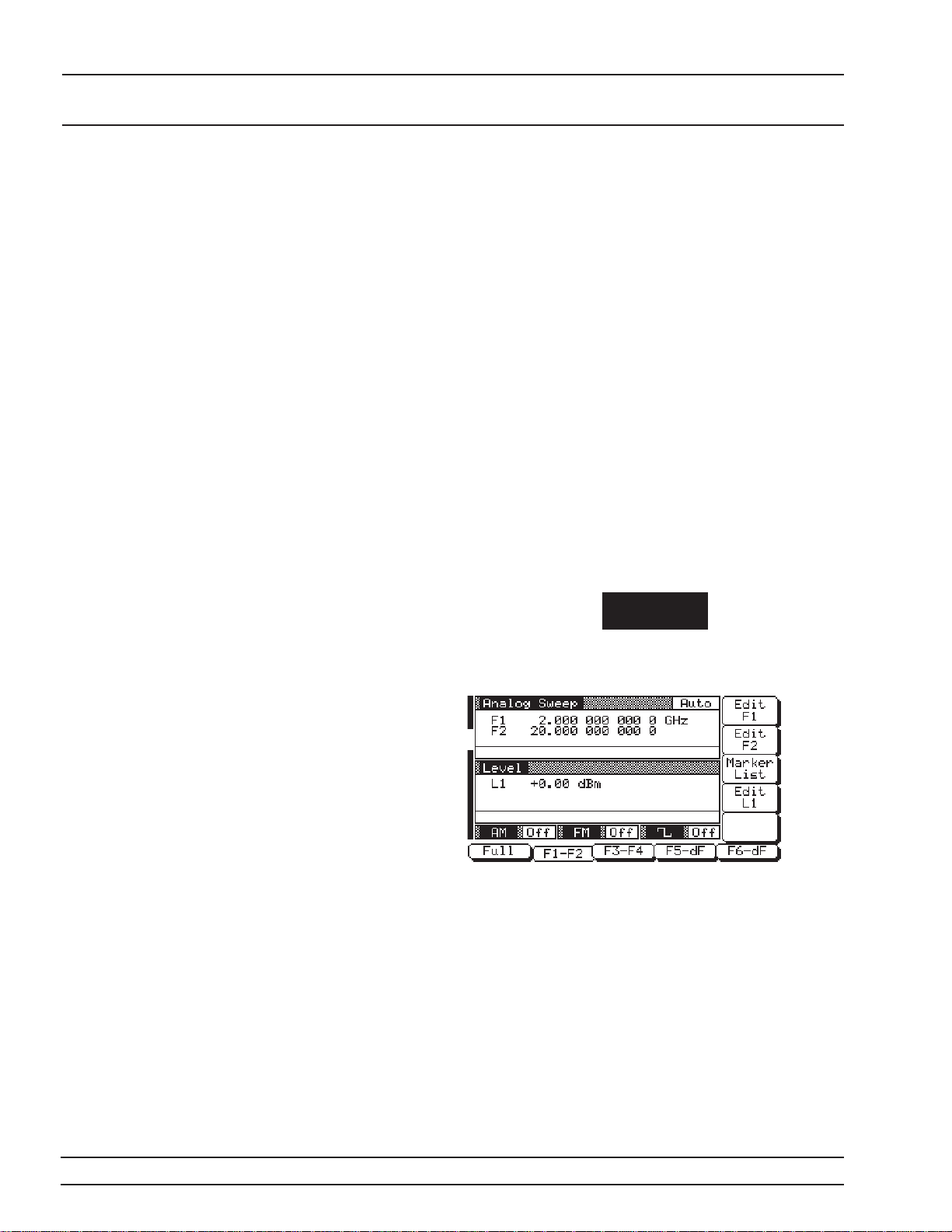

Selecting a Sweep Range ............3-33

Selecting a Power Level.............3-35

Frequency Markers...............3-36

Selecting Alternate Sweep Mode ........3-38

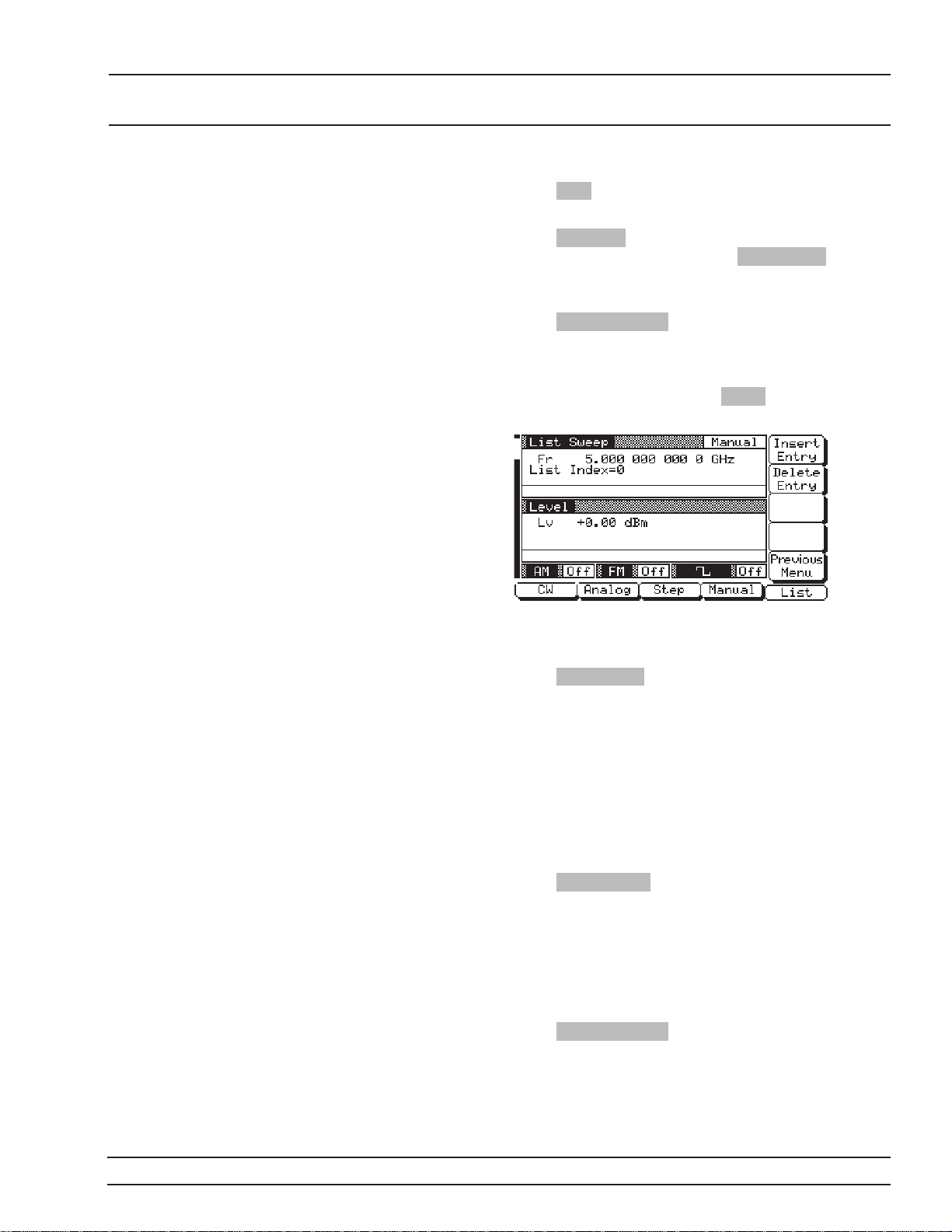

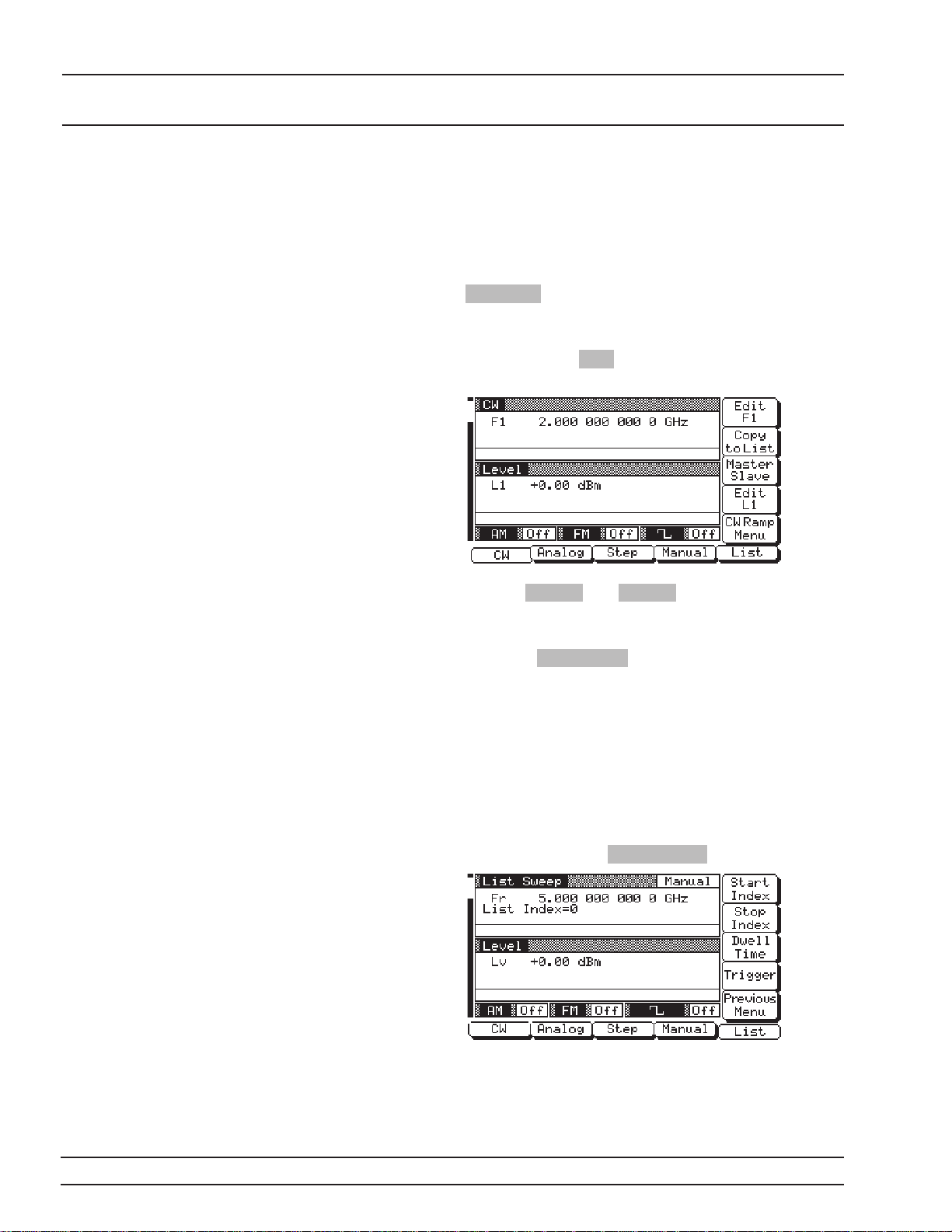

List Sweep Mode ................3-41

Selecting List Sweep Mode ...........3-42

Editing the List ................3-43

Selecting a List Sweep Range..........3-46

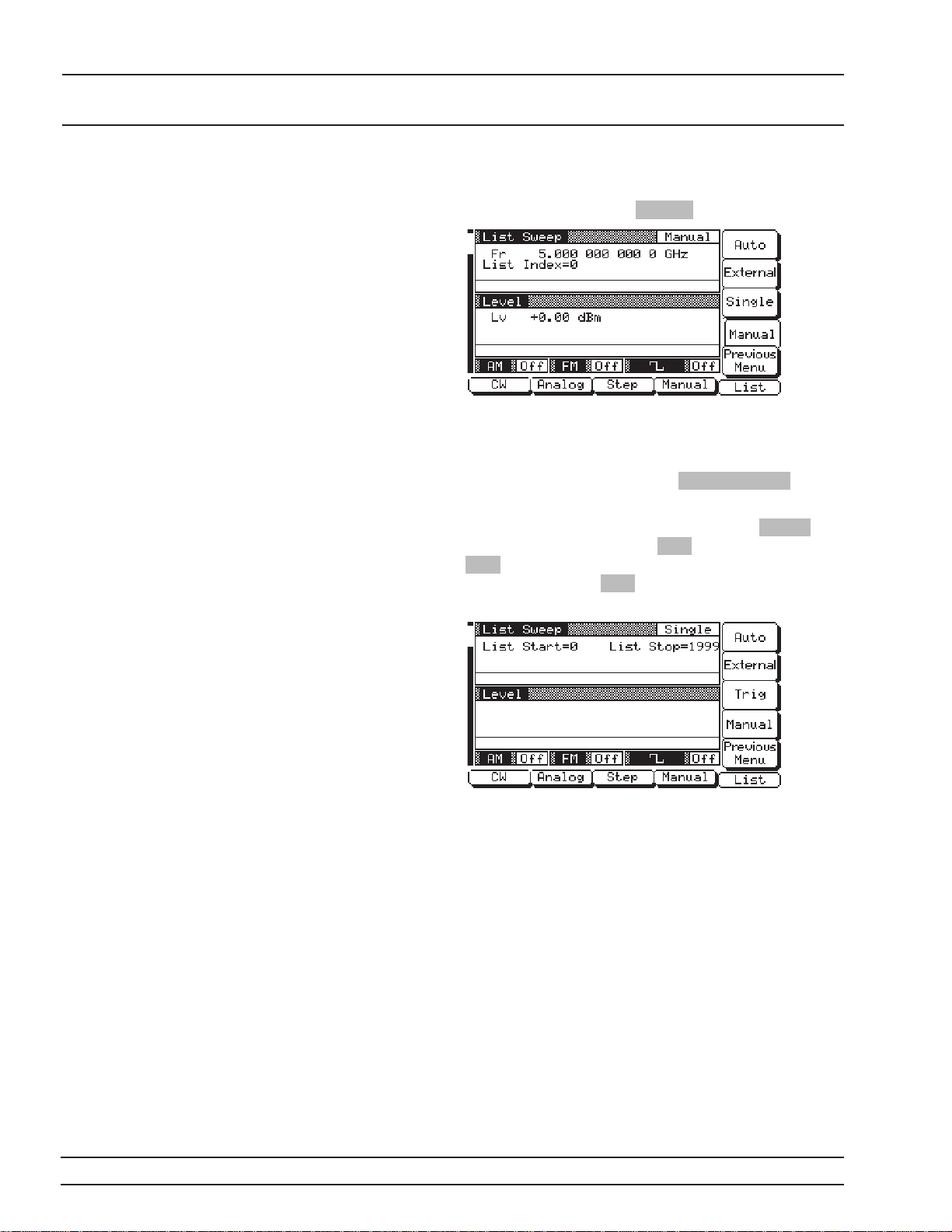

Selecting a List Sweep Trigger .........3-47

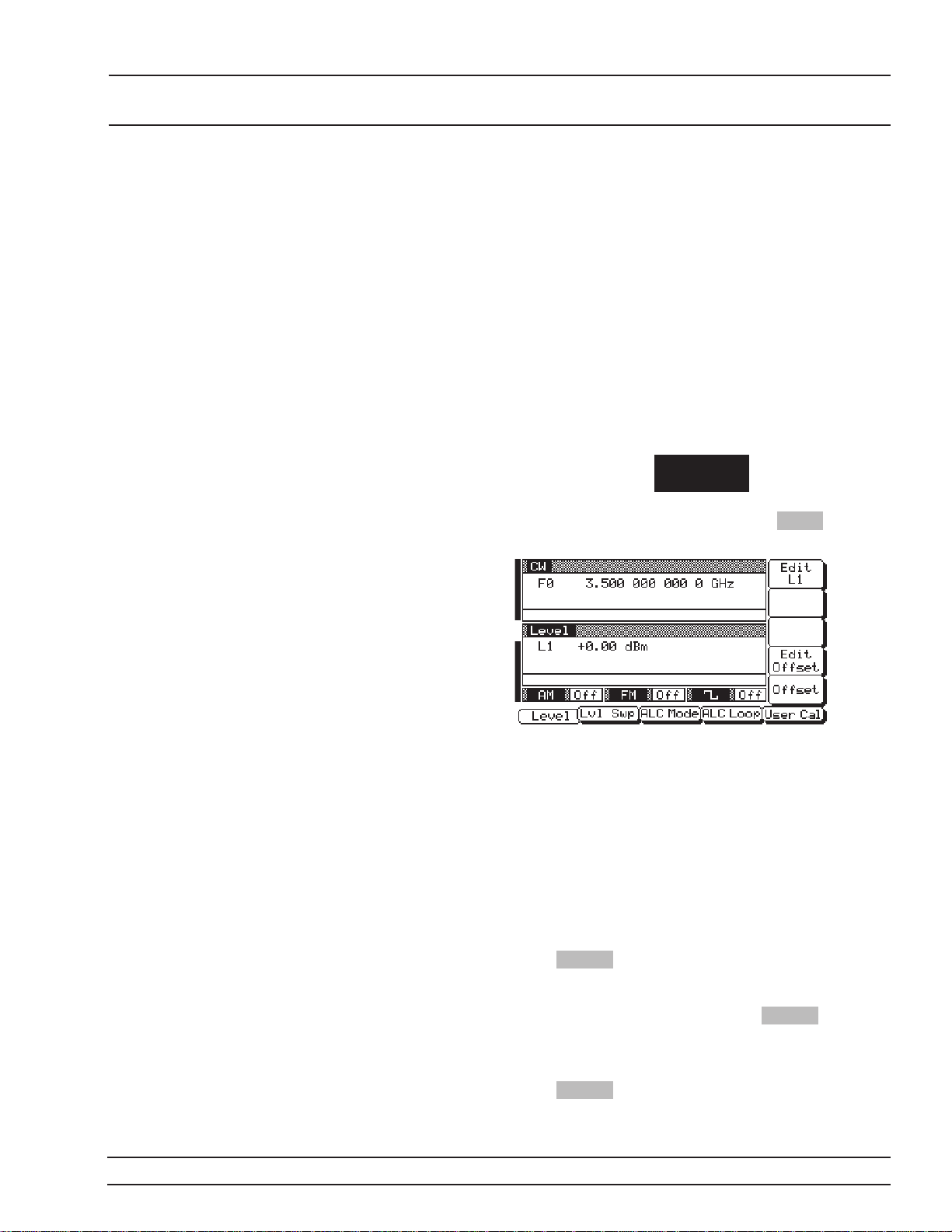

3-9 FIXED POWER LEVEL OPERATION .......3-49

Selecting Fixed Power Level Mode .......3-49

Selecting a Power Level.............3-49

Level Offset ..................3-52

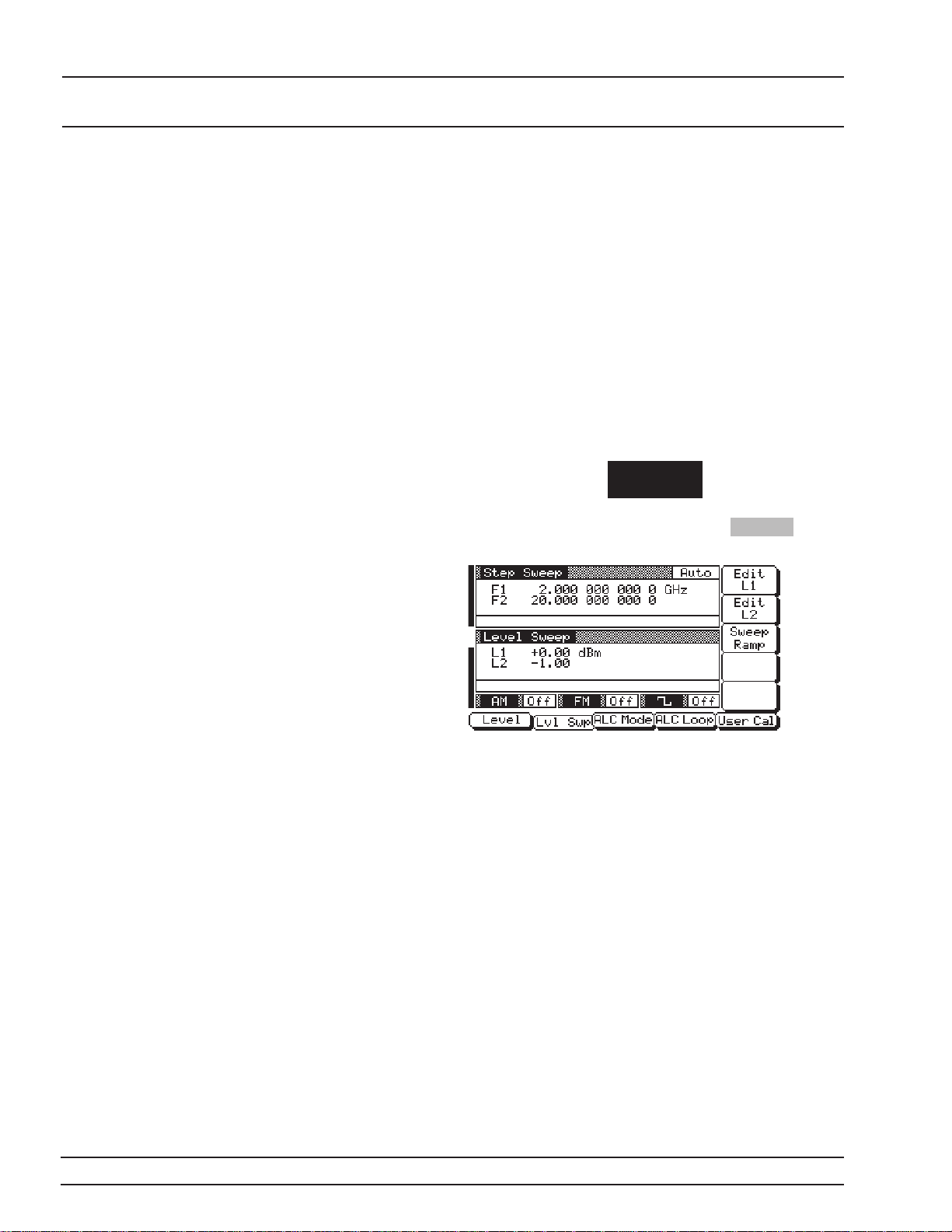

3-10 POWER LEVEL SWEEP OPERATION.......3-53

Selecting CW Power Sweep Mode ........3-53

Setting CW Power Sweep Step Size and

Dwell Time ..................3-54

Selecting a CW Power Sweep Trigger ......3-55

Selecting a Power Level Sweep Range......3-56

Selecting a Sweep Frequency/Step Power Mode . 3-58

Setting Power Level Step Size .........3-59

3-2 681XXC OM

Page 36

Table of Contents (Continued)

3-11 LEVELING OPERATIONS .............3-60

Selecting a Leveling Mode ...........3-60

Attenuator Decoupling .............3-64

ALC Power Slope................3-65

User Cal (User Level Flatness Correction) . . . 3-67

3-12 SIGNAL MODULATION ..............3-73

Amplitude Modulation Operating Modes ....3-73

Providing Amplitude Modulation ........3-73

Frequency Modulation Operating Modes ....3-74

Providing Frequency Modulation ........3-75

Square Wave Modulation Operating Modes . . . 3-77

Providing Square Wave Modulation .......3-77

3-13 SYSTEM CONFIGURATION ............3-80

Configuring the Front Panel ..........3-81

Configuring the Rear Panel...........3-82

Configuring the RF ...............3-83

Configuring the GPIB .............3-85

Setting Increment Sizes ............3-88

3-14 SAVING/RECALLING INSTRUMENT SETUPS . 3-89

Saving Setups .................3-89

Recalling Setups ................3-89

Erasing Stored Setups .............3-90

3-15 SECURE OPERATION ...............3-91

3-16 REFERENCE OSCILLATOR CALIBRATION . . . 3-92

681XXC OM 3-3

Page 37

Page 38

Chapter 3

Local (Front Panel) Operation

3-1 INTRODUCTION This chapter provides information and instructions on operating the

Series 681XXC Synthesized Signal Generator using the front panel

controls. It contains the following:

Illustrations and diagrams of the front panel, data display area,

q

and data entry area that identify and describe all front panel

controls, inputs, and outputs.

An annotated diagram of the menu display format showing

q

where the current frequency, power, and modulation information

is displayed.

Instructions for performing signal generator operations; namely,

q

frequency and frequency sweep, power level and power sweep,

signal modulation, saving and recalling instrument setups, and

system configuration.

681XXC OM 3-5

Page 39

LOCAL (FRONT FRONT PANEL

PANEL) OPERATION LAYOUT

3-2 FRONT PANELLAYOUT The 681XXC front panel is divided into two main areas—the data dis

play area and the data entry area. The following paragraphs provide a

brief description of the front panel controls, inputs, outputs, and data

display and data entry areas as shown in Figure 3-1. Detailed descrip

tions of the data display and data entry areas are contained in para

graphs 3-3 and 3-4.

R F O u t p u t

C o n t r o l

s

K e y

O u t p u t

O f f

O n

R F O u t p u t

5 0

W

C A U T I O N

R F O u t p u t

M a y E x c e e d 1 0 0 m W

S y n t h e s i z e d

S i g n a l

G e n e r a t o r

O p e r a t e

L i n e

S t a n d b y

C W / S W E E P

S E L E C T

F R E Q U E N C Y

C O N T R O L

L E V E L / A L C

S E L E C T

L E V E L

C O N T R O L

M O D U L A T I O N

S Y S T E M

D a t a D i s p l a y D a t a E n t r y

C l e a r

E n t r y

7

0

M o d u l a t i o n

F M I n

A M I n

E x t e r n a l

A L C I n

I n

B a c k

G H z

S p a c e

2 31

S e c

d B m

98

M H z

m s

d B

654

k H z

m

S t e p

H z

n s

A d r s

-

-

-

L i n e

K e y

M e n u

K e y s

Figure 3-1. Front Panel, 681XXC Synthesized Signal Generator

Line Key

The line key provides for turning the signal genera

tor on and off. STANDBY (off) is indicated by an or

ange LED; OPERATE (on) by a green LED.

Data Display

Area

The data display area consists of the data display

and the surrounding menu keys.

Data Display

The data display provides information about the

current status of the 681XXC in a menu display for

mat. This information includes the operating mode

of the instrument, the value of the active frequency

and power level parameters, and the modulation

status.

Menu Keys

Menu keys provide for selecting the operating mode,

parameters, and configuration of the signal genera

tor.

M o d u l a t i o n

C o n n e c t o r s

E x t e r n a l

A L C

C o n n e c t o r

R F O u t p u t

C o n n e c t o r

-

-

-

-

3-6 681XXC OM

Page 40

LOCAL (FRONT FRONT PANEL

PANEL) OPERATION LAYOUT

Data Entry

Area

RF Output

Control Key

Connectors The front panel has both input and output connec

The data entry area consists of data entry keys and

controls that provide for (1) changing values for

each 681XXC parameter, and (2) terminating the

value entry and assigning the appropriate units

(GHz, MHz, dBm, etc.).

The RF output control key provides for turning the

RF output power on and off. OUTPUT OFF is indi

cated by a red LED; OUTPUT ON by a yellow LED.

tors.

Modulation Connectors

The modulation connectors provide for applying ex

ternal AM, FM, or Square Wave modulation to the

RF output signal.

External ALC Connector

The external ALC connector provides for leveling

the RF output signal externally using either a detector or a power meter.

RF Output Connector

The RF output connector provides RF output from a

50W source.

-

-

-

NOTE

To prevent power losses due to an imped

ance mismatch, the mating connector and

cable should also be rated at 50W.

-

681XXC OM 3-7

Page 41

LOCAL (FRONT DATA DISPLAY

y

PANEL) OPERATION AREA

3-3 DATA DISPLAY AREA The data display area consists of the data display and the surrounding

menu keys. The data display is a dot matrix liquid crystal display

(LCD) that provides 16 lines of 40 characters each. Information is pre

sented on the LCD in the form of menu displays. The menu keys ei

ther select the main menu to be displayed, select a sub-menu of the

current menu display, or control a function on the current menu dis

play.

Figure 3-2 shows the format of the menu display and identifies the

display elements. It also shows the placement of the menu keys in re

lation to the display. The paragraphs that follow provide descriptions

of the menu display elements and the menu keys.

-

-

-

-

Main Menu

Keys

MODULATION

Main Menu

Key Cursor

CW/SWEEP

SELECT

FREQUENCY

CONTROL

LEVEL/ALC

SELECT

LEVEL

CONTROL

SYSTEM

Frequency

Mode

Title Bar

Modulation

Title Bars

Frequency

Parameters

Area

Level Mode

Title Bar

Level

Parameters

Area

Menu

Labels

Side Keys

Menu

Soft-Keys

Modulation

Status Areas

Figure 3-2. Front Panel Data Display Area

Menu

Soft-Keys

Menu Labels

Bottom Ke

s

3-8 681XXC OM

Page 42

LOCAL (FRONT DATA DISPLAY

PANEL) OPERATION AREA

Menu Display

Format

The menu display is divided into specific areas that

show the frequency, power level, and modulation in

formation for the current signal generator setup.

Menu labels for the current menu’s soft-keys appear

along the bottom and right side of the display.

Title Bars

A shaded title bar identifies each parameter area.

Mode information is displayed in reverse video on

the title bars.

Frequency Mode Title Bar—The current

q

frequency mode (CW, Analog Sweep, Step

Sweep, Manual Sweep, or List Sweep) appears

on the left side of the bar. In an analog, step, or

list sweep mode, the type of sweep trigger ap

pears on the right side.

Level Mode Title Bar—The current power

q

level mode (Level or Level Sweep) appears on

the left side of the bar. In a level sweep mode,

the type of sweep trigger appears on the right

side of the bar.

Modulation Title Bars—Each type of signal

q

modulation (AM, FM, Square Wave) has a

separate title bar on the display.

-

Parameter Areas

The parameter areas show the frequency, power

level, and modulation information for the current

681XXC setup.

q

Frequency Parameters Area—The current

CW frequency in GHz, the start and stop fre

quencies of the current frequency sweep range

in GHz, the current list index and frequency, or

the start and stop indexes for the list sweep

are displayed in this area.

q

Power Level Parameters Area—The cur

rent power level in dBm or mV, or the start

and stop levels of the current power level

sweep range in dBm or mV are displayed in

this area.

q

Modulation Status Areas—These areas dis

play ON or OFF to indicate the status of signal

modulation for the current setup.

Menu Labels

Each of the menu soft-keys, located below and to the

right of the display, has a corresponding menu label

area on the display. These labels identify the func

-

tion of the soft-keys for the current menu display. In

681XXC OM 3-9

Page 43

LOCAL (FRONT DATA DISPLAY

PANEL) OPERATION AREA

most cases, when a menu soft-key is pressed, its

menu label changes appearance to visually show the

On/Off condition.

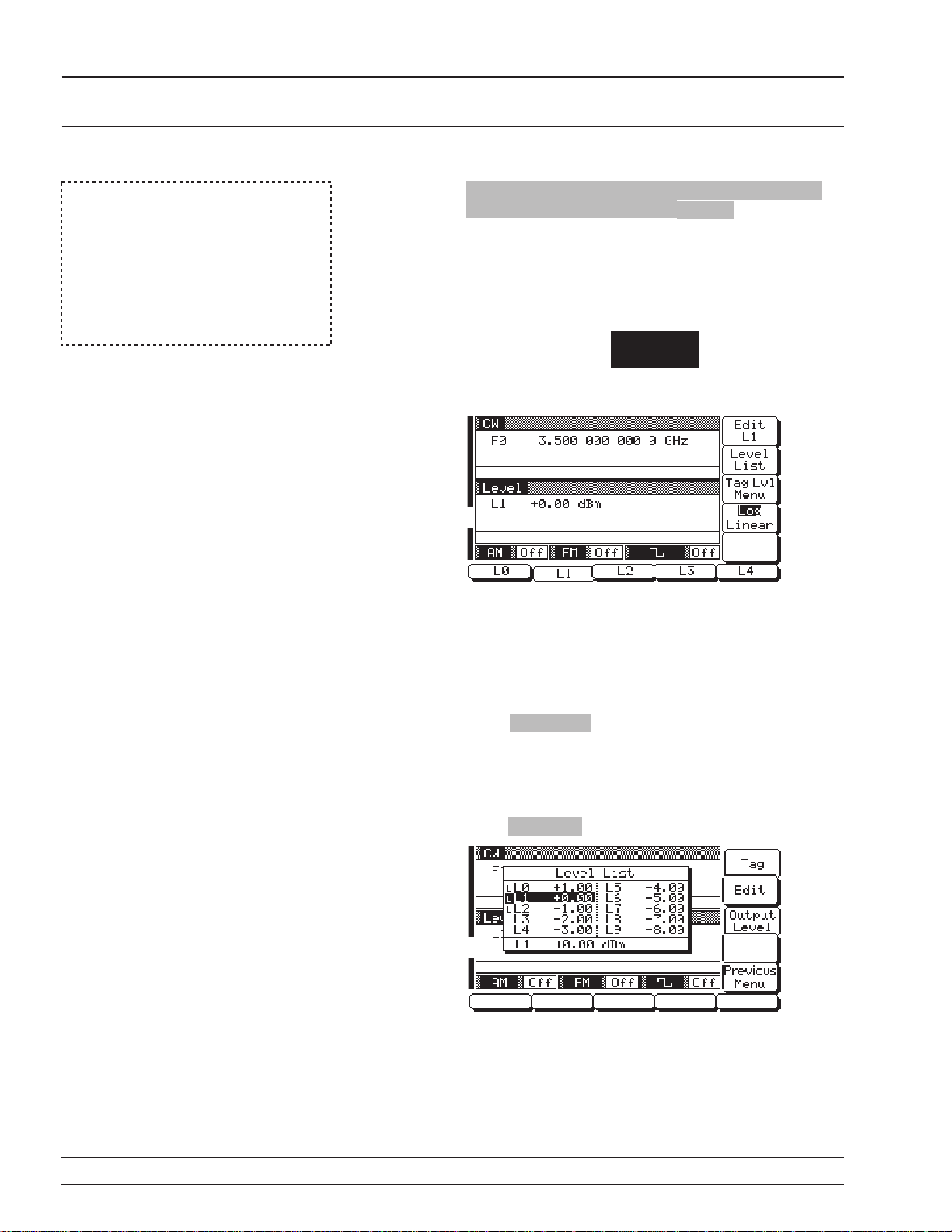

Window Display

A window display that overlays a portion of the cur

rent menu display is used to (1) show the parameter

being edited; (2) display selection lists of preset fre

quencies, power levels, markers, etc.; (3) show the

modulation and system configuration choices and

current selections; or (4) show self-test error mes

sages. Atypical window display is shown on the left.

Menu Keys As shown in Figure 3-2, there are two types of menu

keys that surround the data display—main menu

keys and menu soft-keys. The main menu keys are

positioned to the left of the data display. The menu

soft-keys are located at the bottom and to the right

of the data display.

-

-

-

CW/SWEEP

SELECT

FREQUENCY

CONTROL

LEVEL/ALC

SELECT

LEVEL

CONTROL

MODULATION

SYSTEM

Main Menu Keys

Each of the main menu keys, shown on the left, selects a main (top-level) menu display. These menus

let you select the operating mode, operating parameters, and configuration of the instrument. A

brief functional description of each main menu follows.

q

CW/SWEEP SELECT—This menu lets you

select between CW, Analog, Step, Manual, and

List Sweep frequency modes.

q

FREQUENCY CONTROL—In CW frequency

mode, this menu lets you select the CW fre

quency parameter (F0-F9 or M0-M9) to use. In

the Analog, Step, or Manual Sweep frequency

mode, this menu lets you select the sweep

range parameters (Full, F1-F2, F3-F4, F5-dF,

or F6-dF) to use. In Analog or Step Sweep fre

quency mode, the menu also lets you select up

to 20 independent, pre-settable frequency

markers.

q

LEVEL/ALC SELECT—This menu lets you

select power level and ALC modes (Level,

Level Sweep, Level Offset, ALC on or off, inter

nal or external ALC, ALC/attenuator decou

pling, ALC slope, and user level flatness cor

-

-

rection).

q

LEVEL CONTROL—In Level mode, this

menu lets you select the level parameter (L0L9) to use for a CW frequency or a frequency

-

-

3-10 681XXC OM

Page 44

LOCAL (FRONT DATA DISPLAY

PANEL) OPERATION AREA

sweep. In the Level Sweep mode, this menu

lets you select the power sweep range parame

ters to use.

MODULATION—This menu provides you

q

with access to sub-menus that let you select

the type of signal modulation (AM, FM, or

Square Wave) and control the option settings

for each type.

SYSTEM—This menu provides you with ac

q

cess to sub-menus that let you (1) reset the in

strument to factory-selected default values; (2)

configure the front panel, rear panel, RF, and

GPIB; (3) set incremental sizes for editing fre

quency, power level, and time parameters; (4)

save or recall instrument setups; (5) disable

front panel data display; (6) perform instru

ment self-test; and (7) perform reference oscil

lator calibration.

-

-

-

-

-

-

CW/SWEEP

SELECT

FREQUENCY

CONTROL

LEVEL/ALC

SELECT

CONTROL

MODULATION

SYSTEM

Main Menu Key Cursor

With the exception of the SYSTEM key, when any

main menu key is pressed, the main menu that is

displayed contains a cursor positioned adjacent to

the pressed key (Figure 3-2). The cursor is displayed

on all sub-menus of the current menu until a different main menu key is pressed.

When the SYSTEM key is pressed, the System

menu is displayed. The System menu and its submenus do not contain a main menu key cursor.

Menu Soft-Keys

As shown on the left, five menu soft-keys are located

below the data display and five menu soft-keys are

located to the right of the data display. In general,

the menu soft-keys located below the data display

LEVEL

select a sub-menu of the current main (top-level)

menu display; the menu soft-keys located to the

right of the data display either control a function on

the current menu display or select an additional

sub-menu. Menu labels that identify the current

function of each soft-key are shown on the menu dis

-

play adjacent to the soft-keys.

681XXC OM 3-11

Page 45

LOCAL (FRONT DATA ENTRY

PANEL) OPERATION AREA

3-4 DATA ENTRYAREA The value of a selected 681XXC parameter can be changed using the

rotary data knob and/or keys of the data entry area. Each element of

the data entry area is identified in Figure 3-3 and described in the fol

lowing paragraphs.

-

Cursor

Control

Key

Rotary

Data

Knob

Figure 3-3. Front Panel Data Entry Area

Clear

Entry

Key

CLEAR

ENTRY

4

1

0

Space

87

5

2

Keypad

Back

Key

BACK

SPACE

9

6

3

Terminator

Keys

GHz

Sec

dBm

MHz

ms

dB

kHz

m

s

STEPS

Hz

ns

ADRS

Cursor Control Key

In general, this diamond-shaped key controls the

movement of the cursor on the display. When a pa

rameter is opened for editing, a cursor appears un

-

der the open parameter. Each time the < or > pad is

pressed, the cursor moves left or right by one digit.

The Ù or Ú pad can then be used to increase or de

crease the value of the parameter. The unit size of

the increase or decrease that occurs each time the Ù

or Ú pad is pressed is determined by the cursor posi

tion.

In addition, when editing frequency, power level,

and time parameters, the incremental size can be

set to a specific value using the system configura

tion increment menu (paragraph 3-13). Once set and

activated, each time the Ù or Ú pad is pressed, the

parameter’s value increases or decreases by the set

amount.

3-12 681XXC OM

-

Page 46

LOCAL (FRONT DATA ENTRY

PANEL) OPERATION AREA

Rotary Data Knob

The rotary data knob can be used to change the

value of a parameter that is open for editing. The

cursor is moved under the open parameter using the

< and > pads of the cursor control key. Then, by

slowly turning the knob clockwise or counterclockwise the value of the parameter is increased or

decreased by the unit size. The unit size is deter

mined by the cursor placement. Turning the knob

rapidly changes the value of the parameter in larger

steps.

-

NOTE

When Linear power level units are

selected, use the followingtermina

tor keys for power level data

entries.

GHz / Sec / dBm for V

MHz/ms/dBfor mV

kHz / ms / STEPS for mV

When editing frequency, power level, and time pa

rameters, the incremental size can be set to a spe

cific value using the system configuration increment

menu (paragraph 3-13). Once set and activated,

each time the knob is turned clockwise or counterclockwise, the param-eter’s value increases or de

creases by the set amount.

KEYPAD

The numeric keypad provides for entering frequency, power level, time, and number-of-steps parameters and GPIB address values. The “–” key

functions as a “change sign” key during any keypad

entry.

CLEAR ENTRY Key

When a parameter is open for editing, the CLEAR

ENTRY key is used to clear the parameter entry.

BACK SPACE Key

The BACK SPACE key is used to correct keypad

data entry errors by deleting the last number, “–”, or

decimal point entered.

Terminator Keys

The terminator keys are used to terminate keypad

data entries and change the parameter values in

memory. If the entered value is outside the allow

-

able range of the open parameter, an error message

will be displayed along with an audible “beep”. The

terminator keys are as follows:

GHz / Sec / dBm

MHz/ms/dB

kHz / ms / STEPS

Hz / ns / ADRS

-

-

-

-

681XXC OM 3-13

Page 47

LOCAL (FRONT INSTRUMENT

PANEL) OPERATION START-UP

3-5 INSTRUMENT START-UP Now that you have familiarized yourself with the layout of the signal

generator’s front panel controls and data display, you are ready to be

gin operating the instrument. Begin by powering it up.

-

LEVEL

CONTROL

MODULATION

SYSTEM

Powering Up

the 681XXC

Start-Up

Display

Standby

Operation

Connect the 681XXC to an ac power source by fol

lowing the procedure in the Installation chapter.

This automatically places the instrument in opera

-

tion (front panel OPERATE LED on).

During power up, the message Please Wait...

LOADING PROGRAMS appears on the data display.

When all programs have been loaded, the start-up

screen (below) is displayed. It provides you with the

model number of the signal generator and the revi

sion level of the installed firmware.

The 681XXC then returns to the exact configuration

it was in when last turned off.

Whenever the signal generator is not being used, it

should be left connected to the power source and

placed in standby. Standby operation provides

power to keep the internal time base at operating

temperature. This assures specified frequency accu

racy and stability when the 681XXC is place in op

-

eration.

-

-

OPERATE

LINE

STANDBY

During standby operation, the fan runs

continuously.

NOTE

Press LINE to switch the 681XXC from OPERATE

Line

(green LED on) to STANDBY (orange LED on).

Key

NOTE

When switching to operate from standby,

allow at least a 30-minute warmup before

beginning signal generator operations.

3-14 681XXC OM

Page 48

LOCAL (FRONT INSTRUMENT

PANEL) OPERATION START-UP

Self-Testing

the 681XXC

During self-test with RF OUTPUT set to ON, the output

power level is set to 0 dBm. Always disconnect sensitive

equipment from the unit before performing self-test.

The 681XXC firmware includes internal diagnostics

that self-test the instrument. These self-test diag

nostics perform a brief go/no-go test of most of the

PCBs and other internal assemblies. If the signal

generator fails self-test, an error message is dis

played on the data display. Error messages and de

scriptions are listed in the Operator Maintenance

chapter of this manual.

CAUTION

You can perform a self-test of the signal generator at

any time during normal operation. To perform a

self-test from any menu, press SYSTEM . Then,

when the System Menu (below) is displayed, press

Selftest .

-

-

-

Resetting to

Default

Parameters

You can reset the 681XXC to the factory-selected

default parameter values at any time during normal

operation. The default parameters are shown in

Table 3-1 on the following page.

NOTE

Resetting the instrument clears the setup

presently in place. If these parameter val

ues are needed for future testing, save

them as a stored setup before resetting

the signal generator. (For information on

saving/recalling instrument setups, refer

to paragraph 3-14.)

To reset the signal generator, press SYSTEM .

When the System Menu (above) is displayed, press

Reset .

-

681XXC OM 3-15

Page 49

LOCAL (FRONT RESET (DEFAULT)

PANEL) OPERATION PARAMETERS

Table 3-1. Reset (Default) Paramenters (1 of 2)

681XXC

MODEL

NUMBER

68117C 3.5 2.0 8.4 2.0 5.0 8.0 8.4 8.4 8.4 8.4 3.5 2.0 8.4 2.0 5.0 8.0 8.4 8.4 8.4 8.4 1.0

68137C 3.5 2.0 20.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 3.5 2.0 20.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 1.0

68147C 3.5 2.0 20.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 3.5 2.0 20.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 1.0

68167C 3.5 2.0 40.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 3.5 2.0 40.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 1.0

68177C 3.5 2.0 50.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 3.5 2.0 50.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 1.0

68187C 3.5 2.0 60.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 3.5 2.0 60.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 1.0

68197C 3.5 2.0 65.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 3.5 2.0 65.0 2.0 5.0 8.0 11.0 14.0 17.0 20.0 1.0

F0 F1 F2 F3 F4 F5 F6 F7 F8 F9 M0 M1 M2 M3 M4 M5 M6 M7 M8 M9 DF

FREQUENCY PARAMETERS (GHz)

681XXC

MODEL

NUMBER

68117C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

68137C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

68147C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

68167C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

68177C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

68187C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

68197C +1.0 0.0 –1.0 –2.0 –3.0 –4.0 –5.0 –6.0 –7.0 –8.0

L0 L1 L2 L3 L4 L5 L6 L7 L8 L9

POWER LEVEL PARAMETERS (dBm)

3-16 681XXC OM

Page 50

LOCAL (FRONT RESET (DEFAULT)

PANEL) OPERATION PARAMETERS

Table 3-1. Reset (Default) Paramenters (2 of 2)

681XXC

MODEL

NUMBER

68117C 50 ms 1 ms 50 50 ms 50 0.0 dB

68137C 50 ms 1 ms 50 50 ms 50 0.0 dB

68147C 50 ms 1 ms 50 50 ms 50 0.0 dB

68167C 50 ms 1 ms 50 50 ms 50 0.0 dB

68177C 50 ms 1 ms 50 50 ms 50 0.0 dB

68187C 50 ms 1 ms 50 50 ms 50 0.0 dB

68197C 50 ms 1 ms 50 50 ms 50 0.0 dB

SWEEP

TIME

DWELL TIME

STEP SWEEP LEVEL SWEEP

NUMBER OF

STEPS

DWELL TIME

NUMBER OF

STEPS

LEVEL

OFFSET

681XXC OM 3-17

Page 51

LOCAL (FRONT ENTERING

PANEL) OPERATION DATA

3-6 ENTERING DATA Before proceeding to the various modes of signal generator operation,

you need to know how to enter data from the front panel. Entering

data refers to changing a parameter’s value by editing its current

value or entering a new value to replace the current value. The follow

ing instructions describe how to (1) open a parameter, (2) edit its cur

rent value, and (3) enter a new value.

A typical 681XXC menu display (below) is used throughout the data

entry instructions. At this menu display, you can edit both the CW fre

quency and the output power level parameters.

-

-

-

If you wish to follow along on your 681XXC, you can obtain this same

menu display by resetting your instrument (press SYSTEM , then

press Reset ).

Opening the

Parameter

In order for the value of a parameter to be changed,

the parameter must first be opened.

To open the frequency parameter from the above

menu, press Edit F1 . The menu display now

changes to show that the menu soft-key Edit F1 has

been pressed and that the frequency parameter has

been opened. An open parameter is indicated by

placing it in a window with a movable cursor under

its digits.

Only one parameter can be open at a time. If you

press Edit L1 then the frequency parameter will

close and the power level parameter will open.

3-18 681XXC OM

Page 52

LOCAL (FRONT ENTERING

PANEL) OPERATION DATA

Cursor

Control

Key

Rotary

Data

Knob

Editing the

Current Value

To change the current value of a parameter by edit

ing, you can use either the cursor control key or the

rotary data knob.

Using the Cursor Control Key

Using the < and > pads of the cursor control key,

move the cursor under the digit where you want to

begin editing. Then increase or decrease the value of

the parameter using the Ù or Ú pad of the cursor

control key. The unit size of the increase or decrease

that occurs each time the Ù or Ù pad is pressed is de

termined by the cursor position.

Using the Rotary Data Knob

You can also increase or decrease the value of the

parameter using the rotary data knob. Once you

have positioned the cursor under the digit where

you want to begin editing, slowly turn the knob

clockwise or counter-clockwise to increase or decrease the value of the parameter by the unit size.

Turning the knob rapidly changes the value of the

parameter in larger steps.

Using a Set Increment

When editing frequency, power level, and time parameters, you can increase or decrease the parameter’s value by a set amount each time the Ù or Ú pad

is pressed or the rotary data knob is turned clockwise or counter-clockwise. For instructions on set

-

ting the increment size, refer to paragraph 3-13.

-

Now, try changing the current value of the CW fre

quency displayed on your synthesizer from 2.0 GHz

to 6.395 GHz. Use both the cursor control key’s Ù

and Ú pads and the rotary data knob to make the

value changes. When you are finished, your menu

display should look like the example below.

To close the open parameter when you are finished

editing , press Edit F1 or make another menu selec

tion.

681XXC OM 3-19

-

Page 53

LOCAL (FRONT ENTERING

yp

PANEL) OPERATION DATA

Clear

Entry

Key

CLEAR

ENTRY

4

1

0

Ke

Back

Space

87

5

2

ad

Key

BACK

SPACE

9

6

3

Terminator

Keys

GHz

Sec

dBm

MHz

ms

dB

kHz

m

s

STEPS

Hz

ns

ADRS

Entering a

New Value

To change the current value of a parameter by en

tering a new value for the parameter, use the data

entry keypad and termination keys.

As soon as you press one of the keys on the data en

try keypad, the current parameter display clears for

entry of a new value. Enter the new value for the

parameter, then press the appropriate terminator

key to store it in memory. If the entered value is out

side the allowable range of the open parameter, the

entry is not accepted and the previous value for the

parameter is displayed.

NOTE

A frequency entry may be terminated in

GHz, MHz, kHz, or Hz; however, it is al

ways displayed on the data display in

GHz. Atime entry may be terminated in

Sec, ms, ms, or ns; however it is always

displayed on the data display in Sec.

If you make an error during data entry, either (1)

press BACK SPACE to delete the entry one character at a time starting from the last character entered, or (2) delete the entire entry by pressing

CLEAR ENTRY . Then, reenter the correct value.

-

-

Now, try entering a new value for the CW frequency

displayed on your synthesizer using the data entry

keypad and termination keys.

To close the open parameter when you are finished

entering data, press Edit F1 or make another menu

selection.

3-20 681XXC OM

Page 54

LOCAL (FRONT CW FREQUENCY

PANEL) OPERATION OPERATION

3-7 CW FREQUENCY