Page 1

LightningÔ

37xxxE

Vector Network Analyzer

Operation Manual

490 JARVIS DRIVE · MORGAN HILL, CA 95037-2809

P/N: 10410-00300

REVISION: A

PRINTED: AUGUST 2010

COPYRIGHT 2010 ANRITSU CO.

Page 2

WARRANTY

The ANRITSU product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for three years from the date of shipment.

ANRITSU’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to ANRITSU for

warranty repairs. Obligation is limited to the original purchaser. ANRITSU is not liable for consequential

damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to ANRITSU connectors that have failed due to normal wear. Also,

the warranty does not apply to defects resulting from improper or inadequate maintenance by the Buyer,

unauthorized modification or misuse, or operation outside of the environmental specifications of the

product. No other warranty is expressed or implied, and the remedies provided herein are the Buyer’s sole

and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

V Connector and K Connector are registered trademarks of ANRITSU Company.

GPC-7 is a registered trademark of Amphenol Corporation.

ANACAT is a registered trademark of EEsof, Inc.

QuietJet and ThinkJet are registered trademarks of Hewlett-Packard Co.

Microsoft, Excel, and MS-DOS are registered trademarks of Microsoft Corporation.

Acrobat and Acrobat Reader are trademarks of Adobe Corporation.

Iomega and Zip are registered trademarks of Iomega Company.

NOTICE

ANRITSU Company has prepared this manual for use by ANRITSU Company personnel and customers as

a guide for the proper installation, operation and maintenance of ANRITSU Company equipment and

computer programs. The drawings, specifications, and information contained herein are the property of

ANRITSU Company, and any unauthorized use or disclosure of these drawings, specifications, and

information is prohibited; they shall not be reproduced, copied, or used in whole or in part as the basis for

manufacture or sale of the equipment or software programs without the prior written consent of ANRITSU

Company.

UPDATES

Updates to this manual, if any, may be downloaded from the Anritsu Internet site at:

http://www.us.anritsu.com.

Page 3

Page 4

Page 5

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully BEFORE operating the equipment.

Symbols used in manuals

DANGER

WARNING This indicates a hazardous procedure that could result in serious in

This indicates a very dangerous procedure that could result in serious

injury or death if not performed properly.

-

jury or death if not performed properly.

CAUTION This indicates a hazardous procedure or danger that could result in

light-to-severe injury, or loss related to equipment malfunction, if

proper precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

Some or all of the following five symbols may or may not be used on all Anritsu equipment. In addition, there

may be other labels attached to products that are not shown in the diagrams in this manual.

The following safety symbols are used inside or on the equipment near operation locations to provide infor

mation about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions BEFORE operating the equipment.

This indicates a prohibited operation. The prohibited operation is indi

cated symbolically in or near the barred circle.

-

-

his indicates a compulsory safety precaution. The required operation is

indicated symbolically in or near the circle.

This indicates warning or caution. The contents are indicated symboli

cally in or near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

37xxxE OM Safety-1

-

Page 6

For Safety

WARNING

Always refer to the operation manual when working near locations at

which the alert mark, shown on the left, is attached. If the operation,

etc., is performed without heeding the advice in the operation manual,

there is a risk of personal injury. In addition, the equipment perfor

mance may be reduced.

-

Repair

Moreover, this alert mark is sometimes used with other marks and de

scriptions indicating other dangers.

WARNING

When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet

is not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panel of the equipment to ground.

If power is supplied without grounding the equipment, there is a risk of

receiving a severe or fatal electric shock.

WARNING

This equipment can not be repaired by the operator. DO NOT attempt to

remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire

and shock hazards should service this equipment. There are

high-voltage parts in this equipment presenting a risk of severe injury

or fatal electric shock to untrained personnel. In addition, there is a risk

of damage to precision components.

-

WARNING

Use two or more people to lift and move this equipment, or use an

equipment cart. There is a risk of back injury, if this equipment is lifted

by one person.

Safety-2 37xxxE OM

Page 7

Narrative Table Of Contents

Chapter 1—General Information

This chapter provides a general description of the Anritsu Model 37xxxE Vector Network Analyzer

System and its major units: network analyzer, test set, and frequency source. It also provides

descriptions for the precision component kits, and equipment options. Additionally, it contains the

listing of recommended test equipment.

Chapter 2—Installation

This chapter provides instructions for performing an initial inspection, preparing the equipment for

use, setting up for operation over the IEEE-488.2 (GPIB) Bus, using a printer, and preparing the

units for storage and/or shipment. It also provides a listing of Anritsu Customer Service Centers.

Chapter 3—Network Analyzers, A Primer

This chapter provides an introduction to network analysis and the types of measurements that can

be made using them. It provides general and introductory description.

Chapter 4—Front Panel Operation

This chapter describes the front panel controls and provides flow diagrams for the menus called up

using the front panel controls. It contains the following sub-chapters:

· Front Panel Control-Group Descriptions

· Calibration Keys and Indicators, Detailed Description

· Save/Recall Menu Key and Menus, Key Description and Menu Flow

· Measurement Keys and Menus, Key Descriptions and Menu Flow

·

Channel Keys and Menu, Key Descriptions and Menu Flow

·

Display Keys and Menus, Key Descriptions and Menu Flow

·

Enhancement Keys and Menus, Key Descriptions and Menu Flow

·

Hard Copy Keys and Menus, Key Descriptions and Menu Flow

·

System State Keys and Menus, Key Descriptions and Menu Flow

·

Markers/limits Keys and Menus, Key Descriptions and Menu Flow

·

Disk Storage Interface, Detailed Description

Chapter 5—Error And Status Messages

This chapter describes the type of error messages you may encounter during operation and provides a

tabular listing. This listing describes and defines the error types.

Chapter 6—Data Displays

This chapter provides a detailed description of the various data displays. It describes the graph

types, frequency markers, measurement limit lines, status displays, and data display controls.

37xxxE OM i

Page 8

Narrative Table of Contents (Continued)

Chapter 7—Measurement Calibration

This chapter provides a discussion and tutorial on measurement calibration. It contains step-by-step

calibration procedures for the Standard (OSL), Offset-Short, TRM, and LRL/LRM methods. It also

has a procedure for calibrating using a sliding termination.

Chapter 8—Measurements

This chapter discusses measurements with the 37xxxE VNA. It contains sub-chapters that provide a

detailed descriptions for Transmission and Reflection, Low Level and Gain, Group Delay, Active

Device, Multiple Source Control, Adapter Removal, Gain Compression, and Receiver Mode

measurements

Chapter 9—Time Domain

This chapter describes the Option 2, Time Domain feature. It provides an operational procedure and

a flowchart of the time domain menus.

Chapter 10—AutoCal

This chapter describes the Automatic Calibrator (AutoCal) feature and provides operational information and procedures.

Chapter 11—Operational Checkout Procedures

This chapter provides a procedure for operational checkout

Appendix A—Front Panel Menus, Alphabetical Listing

This appendix shows all of the menus that are called up using the front panel controls. It provides a

replica of the menu and descriptive text for all of the various menu choices. The listing is alphabetical by the menu call letters mentioned and/or illustrated in Chapter 4.

Appendix B—Model 37xxxE VNA Rear Panel Connectors

This appendix describes the rear panel connectors. It also provides pinout listing.

Appendix C—Performance Specifications

For printed versions of this manual, Appendix C contains the Technical Data Sheet, part number

11410-00573, which provides performance specifications.

Index

ii 37xxxE OM

Page 9

Table of Contents

Chapter 1 General Information

1-1 SCOPE OF MANUAL .................................1-3

1-2 INTRODUCTION ...................................1-3

1-3 IDENTIFICATION NUMBER.............................1-3

1-4 ONLINE MANUALS..................................1-3

1-5 SYSTEM DESCRIPTION ...............................1-3

372xxE........................................1-4

373xxE........................................1-4

1-6 OPTIONS........................................1-4

1-7 PRECISION COMPONENT KITS ..........................1-5

Calibration Kits ...................................1-5

Verification Kits ...................................1-5

1-8 PERFORMANCE SPECIFICATIONS ........................1-6

1-9 PREVENTIVE MAINTENANCE ...........................1-6

Chapter 2 Installation

2-1 INTRODUCTION ...................................2-3

2-2 INITIAL INSPECTION ................................2-3

2-3 PREPARATION FOR USE ..............................2-3

Option 4, Additional SD Card for Secure Environments .............2-4

2-4 GPIB SETUP .....................................2-5

Interface Connector .................................2-5

Cable Length Restrictions .............................2-5

2-5 SYSTEM GPIB INTERCONNECTION........................2-6

GPIB Interface to an External Plotter .......................2-6

GPIB Addresses...................................2-6

2-6 ETHERNET SETUP AND INTERCONNECTION..................2-6

2-7 EXTERNAL MONITOR CONNECTOR .......................2-7

2-8 RACK MOUNT.....................................2-7

37xxxE OM iii

Page 10

Table of Contents (Continued)

2-9 STORAGE OR SHIPMENT .............................2-10

Preparation for Storage ..............................2-10

Preparation for Shipment .............................2-10

Chapter 3 Network Analyzers, A Primer

3-1 INTRODUCTION ...................................3-3

3-2 GENERAL DESCRIPTION ..............................3-3

Source Module....................................3-4

Test Set Module ...................................3-4

Analyzer Module ..................................3-4

3-3 NETWORK ANALYZERS ...............................3-5

Chapter 4 Front Panel Operation

4-1 INTRODUCTION ...................................4-3

4-2 KEY-GROUPS .....................................4-3

4-3 CALIBRATION KEY-GROUP ............................4-10

4-4 SAVE/RECALL MENU KEY.............................4-20

4-5 MEASUREMENT KEY-GROUP ..........................4-21

4-6 CHANNELS KEY-GROUP..............................4-24

4-7 DISPLAY KEY-GROUP ...............................4-25

4-8 ENHANCEMENT KEY-GROUP...........................4-29

4-9 HARD COPY KEY-GROUP .............................4-31

4-10 SYSTEM STATE KEY-GROUP ...........................4-33

4-11 MARKERS/LIMITS KEY-GROUP ..........................4-36

4-12 STORAGE INTERFACE ...............................4-40

Disk Files......................................4-40

Disk File Output Device..............................4-41

Formatting a Data File Drive ...........................4-41

Copying Data Files From Drive to Drive .....................4-41

Recovering From Drive Write/Read Errors....................4-41

iv 37xxxE OM

Page 11

Table of Contents (Continued)

4-13 COMMAND LINE ..................................4-41

Create Directory ..................................4-42

List Directory ...................................4-42

Change Directory .................................4-42

Delete Files.....................................4-42

Remove Directory .................................4-43

Copy Files .....................................4-43

Conventions ....................................4-43

Chapter 5 Error and Status Messages

5-1 INTRODUCTION ...................................5-3

5-2 ERROR MESSAGES..................................5-3

Chapter 6 Data Displays

6-1 INTRODUCTION ...................................6-3

6-2 DISPLAY MODES AND TYPES ...........................6-3

Single Channel Display: Ch 1, 2, 3, 4........................6-3

Dual Channel Display: Ch 1 and 3 or Ch 2 and 4 .................6-4

Four Channel Display: Ch 1, 2, 3, 4 ........................6-5

Dual Trace Overlay .................................6-6

Graph Data Types..................................6-7

6-3 FREQUENCY MARKERS ..............................6-11

Marker Designation ................................6-11

6-4 LIMITS ........................................6-11

6-5 STATUS DISPLAY ..................................6-12

Reference Position Marker ............................6-12

Scale Resolution ..................................6-12

Frequency Range .................................6-12

Analog Instrument Status.............................6-12

Measurement Status ...............................6-13

Sweep Indicator Marker..............................6-13

6-6 DATA DISPLAY CONTROL .............................6-13

S-parameter Selection ...............................6-14

Data Display Update ...............................6-14

Display of Markers.................................6-14

37xxxE OM v

Page 12

Table of Contents (Continued)

6-7 HARD COPY AND STORAGE OUTPUT ......................6-15

Tabular Printout ..................................6-15

Screen-Image Printout ..............................6-15

Plotter Output ...................................6-15

Storage Output...................................6-15

Chapter 7 Measurement Calibration

7-1 INTRODUCTION ...................................7-3

7-2 DISCUSSION .....................................7-3

Establishing the Test Ports.............................7-3

Understanding the Calibration System ......................7-5

Calibrating for a Measurement ..........................7-9

Evaluating the Calibration ............................7-11

Verification Kits ..................................7-11

7-3 SLIDING TERMINATION..............................7-13

7-4 SOLT CALIBRATION ................................7-19

7-5 OFFSET-SHORT CALIBRATION (SSLT) ......................7-28

7-6 TRIPLE OFFSET-SHORT CALIBRATION (SSST).................7-32

7-7 LRL/LRM CALIBRATION ..............................7-36

7-8 TRM CALIBRATION.................................7-46

7-9 MERGE CAL FILES APPLICATION ........................7-47

Chapter 8 Measurements

8-1 INTRODUCTION ...................................8-3

8-2 TRANSMISSION AND REFLECTION ........................8-3

8-3 LOW LEVEL AND GAIN ..............................8-12

8-4 GROUP DELAY ...................................8-20

8-5 ACTIVE DEVICE ..................................8-24

8-6 MULTIPLE SOURCE CONTROL ..........................8-29

Control Formula ..................................8-29

8-7 ADAPTER REMOVAL ................................8-34

vi 37xxxE OM

Page 13

Table of Contents (Continued)

8-8 GAIN COMPRESSION................................8-39

Power and VNAs ..................................8-39

Swept Power Gain Compression .........................8-41

Swept Frequency Gain Compression .......................8-41

8-9 RECEIVER MODE ..................................8-58

Source Lock Mode .................................8-58

Tracking Mode ...................................8-58

Set-on Mode ....................................8-58

Receiver Mode Block Diagram ..........................8-59

Receiver Mode Menus ...............................8-59

Procedure, Receiver Mode Operation .......................8-59

8-10 EMBEDDING/ DE-EMBEDDING..........................8-62

Embedding .....................................8-63

De-embedding ...................................8-64

8-11 OPTICAL APPLICATION ..............................8-65

E/O Measurements ................................8-65

O/E Measurements ................................8-68

Creating a Characterization (*.S2P) File for E/O and O/E Measurements . . . 8-74

Chapter 9 Time Domain

9-1 INTRODUCTION ...................................9-3

9-2 TIME DOMAIN MEASUREMENTS .........................9-3

9-3 OPERATING TIME DOMAIN ............................9-8

9-4 WINDOWING.....................................9-11

9-5 GATING........................................9-12

9-6 ANTI-GATING ....................................9-14

9-7 EXAMPLES,GATING AND ANTI-GATING ....................9-14

9-8 TIME DOMAIN MENUS...............................9-14

Chapter 10 AutoCal

10-1 INTRODUCTION...................................10-3

10-2 DESCRIPTION ....................................10-3

10-3 CALIBRATIONS ...................................10-4

10-4 DEFINITIONS ....................................10-4

37xxxE OM vii

Page 14

Table of Contents (Continued)

10-5 PHYSICAL SETUP..................................10-6

10-6 CHARACTERIZATION FILES ...........................10-7

10-7 USING AUTOCAL ..................................10-9

10-8 PIN DEPTH SPECIFICATIONS ..........................10-13

10-9 AUTOCAL MENUS FLOW DIAGRAM ......................10-14

Chapter 11 Operational Checkout Procedures

11-1 INTRODUCTION...................................11-3

11-2 REQUIRED EQUIPMENT..............................11-3

11-3 INITIAL SETUP ...................................11-3

11-4 SELF TEST ......................................11-3

11-5 NON-RATIO POWER ................................11-4

11-6 HIGH LEVEL NOISE TEST.............................11-6

Appendix A Front Panel Menus, Alphabetical Listing

Appendix B Rear Panel Connectors

Appendix C Performance Specifications

Subject Index

viii 37xxxE OM

Page 15

Chapter 1

General Information

Table of Contents

1-1 SCOPE OF MANUAL .................................1-3

1-2 INTRODUCTION ...................................1-3

1-3 IDENTIFICATION NUMBER.............................1-3

1-4 ONLINE MANUALS..................................1-3

1-5 SYSTEM DESCRIPTION ...............................1-3

372xxE........................................1-4

373xxE........................................1-4

1-6 OPTIONS........................................1-4

1-7 PRECISION COMPONENT KITS ..........................1-5

Calibration Kits ...................................1-5

Verification Kits ...................................1-5

1-8 PERFORMANCE SPECIFICATIONS ........................1-6

1-9 PREVENTIVE MAINTENANCE ...........................1-6

Page 16

Figure 1-1. Model 37347E Vector Network Analyzer System

Page 17

GENERAL INFORMATION SCOPE OF MANUAL

Chapter 1 General Information

1-1 SCOPE OF MANUAL This manual provides general information, installation, and operating

information for the Model 37xxxE Vector Network Analyzer (VNA)

system. (Throughout this manual, the terms VNA, 37xxxE VNA, and

37xxxE will be used interchangeably to refer to the system.)

1-2 INTRODUCTION This section provides general information about the 37xxxE VNA

system and one or more precision-component calibration or

performance verification kits. The section also provides a listing of

recommended test equipment.

1-3 IDENTIFICATION

NUMBER

All Anritsu instruments are assigned a unique six- or seven-digit ID

number, such as “940101.”This number is affixed to a decal on the

rear panel of each unit. In any correspondence with Anritsu Customer

Service, please use this number.

1-4 ONLINE MANUALS Manual updates, if any, are available on Anritsu's Internet download

page (http://www.us.anritsu.com/downloads/).

1-5 SYSTEM DESCRIPTION The 37xxxE Network Analyzer (Figure 1-1) is a single-instrument sys

tem that contains a built-in source, test set, and analyzer. It is pro

duced in two series— 372xxE and 373xxE—described below. All mod

els provide up to 1601 measurement data points, a built-in SD Card

for storing and recalling front panel setups and measurement and cali

bration data. They also provide an on-screen display of total opera

tional time and dates of system calibrations. They support operation

over the IEEE 488.2 General Purpose Interface Bus (GPIB).

-

-

-

-

-

1-3 37xxxE OM

Page 18

OPTIONS GENERAL INFORMATION

372xxE The 372xxE is a fully functioning VNA for making passive-device mea-

surements. The series offers three models that cover a range from

40 MHz to 65 GHz. The models are shown below:

Model Frequency Range

37247E 40.0 MHz to 20.0 GHz

37269E 40.0 MHz to 40.0 GHz

37297E 40.0 MHz to 65.0 GHz

373xxE The 373xxE is a fully functioning VNA for making passive- and ac-

tive-device measurements. The series offers three models that cover a

range from 40 MHz to 65 GHz. The models are shown below.

Model Frequency Range

37347E 40.0 MHz to 20.0 GHz

37369E 40.0 MHz to 40.0 GHz

37397E 40.0 MHz to 65.0 GHz

1-6 OPTIONS The following instrument options are available:

q Option 1: Rack Mount Kit

q Option 2: Time (Distance) Domain Measurement Capability

q Option 4: Additional Secure Digital Memory Card (SD Card)

q Option 15: Flexible test set (provides access to all four samplers

and Source loops for each port)

1-4 37xxxE OM

Page 19

GENERAL INFORMATION PRECISION COMPONENT KITS

1-7 PRECISION COMPONENT

KITS

Calibration Kits Calibration kits contain components used to identify and separate er

Figure 1-2. Typical Model 365X

Calibration Kit

Two types of precision-component kits are available: calibration and

verification.

ror sources inherent in microwave test setups. The Model 365X Cali

bration Kits contain all of the precision components and tools required

to calibrate the VNA for 12-term error-corrected measurements of test

devices with the connector type specified. When applicable, compo

nents are included for calibrating both male and female test ports. The

kits also support calibrations with broadband loads.

Each of the available calibration kits are described in detail in the Vec

tor Network Analyzer Mechanical Calibration Kits Reference Manual,

PN: 10410-00278. A typical Model 365X Calibration Kit is shown in

Figure 1-2. The following is a list of available 365X Calibration Kits:

q Model 3650A SMA/3.5 mm Calibration Kit

q Model 3651A GPC–7 Calibration Kit

q Model 3652A K Connector Calibration Kit

q Model 3653A Type N Calibration Kit

q Model 3654D V Connector® Calibration Kit

-

-

-

Verification Kits The Model 366X Verification kits consist of precision components of

the connector type specified with characteristics traceable to the

National Institute of Standards and Technology (NIST). This type of

kit is usually kept in the metrology laboratory where it provides the

most dependable means of checking system accuracy. Each of these

-

-

Figure 1-3. Typical Model 366X

VerificationKit

kits contains a disk or USB drive providing factory-measured coeffi

cient or test data for each component, allowing for comparison with

customer-measured data.

A typical Model 365X Verification Kit is shown in Figure 1-3. The fol

lowing is a list of available 366X Verification Kits:

q

Model 3666 3.5 mm Verification Kit

q

Model 3667 GPC–7 Verification Kit

q

Model 3668 K Connector® Verification Kit

q

Model 3669/3669B V Connector® Verification Kits

37xxxE OM 1-5

Page 20

PERFORMANCE SPECIFICATIONS GENERAL INFORMATION

1-8 PERFORMANCE

SPECIFICATIONS

1-9 PREVENTIVE

MAINTENANCE

System performance specifications are provided in Appendix C.

The 37xxxE VNA system does not require any preventive

maintenance.

1-6 37xxxE OM

Page 21

Chapter 2

Installation

Table of Contents

2-1 INTRODUCTION ...................................2-3

2-2 INITIAL INSPECTION ................................2-3

2-3 PREPARATION FOR USE ..............................2-3

Option 4, External SCSI Drive Setup .......................2-4

2-4 GPIB SETUP .....................................2-5

Interface Connector .................................2-5

Cable Length Restrictions .............................2-5

2-5 SYSTEM GPIB INTERCONNECTION........................2-6

GPIB Interface to an External Plotter .......................2-6

GPIB Addresses...................................2-6

2-6 ETHERNET SETUP AND INTERCONNECTION..................2-6

2-7 EXTERNAL MONITOR CONNECTOR .......................2-7

2-8 RACK MOUNT.....................................2-7

2-9 STORAGE OR SHIPMENT .............................2-10

Preparation for Storage ..............................2-10

Preparation for Shipment .............................2-10

2-10 SERVICE CENTERS.................................2-11

Page 22

Page 23

Chapter 2 Installation

2-1 INTRODUCTION This chapter provides information for the initial inspection and

preparation for use of the 37xxxE Vector Network Analyzer.

Information for interfacing the 37xxxE to the IEEE-488 General

Purpose Interface Bus and reshipment and storage information is also

included.

2-2 INITIAL INSPECTION Inspect the shipping container for damage. If the container or cushion

ing material is damaged, retain until the contents of the shipment

have been checked against the packing list and the instrument has

been checked for mechanical and electrical operation.

If the 37xxxE is damaged mechanically, notify your local sales

representative or Anritsu Customer Service. If either the shipping

container is damaged or the cushioning material shows signs of stress,

notify the carrier as well as Anritsu. Keep the shipping materials for

the carrier’s inspection.

WARNING

Use two or more people to lift and move this equipment, or use an

equipment cart. There is a risk of back injury, if this equipment is lifted

by one person.

2-3 PREPARATION FOR USE Except for units with Option 4 (see following page), no initial setup is

required. After unpacking, the 37xxxE is ready for use. The 37xxxE is

equipped with automatic line-power sensing, and will operate with any

of the following line voltages: 100V, 120V, 220V, 240V +5%, –10%,

48–63 Hz, 350 VA. The 37xxxE is intended for Installation Category

(Overvoltage Category) II.

-

WARNING

When supplying power to this equipment, always use a three-wire

power cable connected to a three-wire power line outlet. If power is sup

plied without grounding the equipment, there is a risk of receiving a se

vere or fatal electric shock.

37xxxE OM 2-3

-

-

Page 24

PREPARATION FOR USE INSTALLATION

Option 4, Additional SD

Card for Secure

Environments

The 37xxxE is available with a second Secure Digital memory card

(SD Card) for use in secure environments. This allows the VNA to be

shipped with the System Software and Factory Cal Data on both the

standard and additional SD Cards. When the unit requires periodic

calibration, the 2nd SD Card is installed, allowing the VNA to come

out of the secure environment for calibration, while the initial SD

Card (containing proprietary customer data) remains within the se

cure environment.

-

2-4 37xxxE OM

Page 25

INSTALLATION GPIB SETUP

2-4 GPIB SETUP All functions of the 37xxxE (except power on/off and initialization of

the SD Card) can be controlled remotely by an external computer/con

troller via the IEEE-488.2 GPIB.The information in this section per

tains to interface connections and cable requirements for the rear

panel GPIB connector. Refer to the Model 37xxxE Programming Man

ual, Anritsu Part Number 10410-00301, for information about remote

operation of the 37xxxE using the GPIB.

The 37xxxE GPIB operates with any IBM XT, AT, or PS/2 compatible

computer/controller equipped with a National Instruments

GPIB-PCII/IIA interface card and software.

Interface Connector Interface between the 37xxxE and other devices on the GPIB is via a

standard 24-wire GPIB interface cable. For proper operation, order

Anritsu part number 2100-1, -2, -4, or -5 (1, 2, 4, or 0.5 meter length)

cables through your local sales representative. This cable uses a

double-sided connector; one connector face is a plug, the other a

receptacle. These double-function connectors allow parallel connection

of two or more cables to a single instrument connector. The pin

assignments for the rear panel GPIB connector are shown in Figure

B-2, located in Appendix B.

-

-

-

Cable Length Restrictions The GPIB system can accommodate up to 15 instruments at any one

time. To achieve design performance on the bus, proper timing and

voltage level relationships must be maintained. If either the cable

length between separate instruments or the accumulated cable length

between all instruments is too long, the data and control lines cannot

be driven properly and the system may fail to perform. Cable length

restrictions are as follows:

q

No more than 15 instruments may be installed on the bus.

q

Total accumulative cable length in meters may not exceed two

times the number of bus instruments or 20 meters—whichever is

less.

NOTE

For low EMI applications, the GPIB cable should be a fully

shielded type, with well-grounded metal-shell connec

tors. (Use Anritsu 2100-series cables.)

-

37xxxE OM 2-5

Page 26

SYSTEM GPIB INTERCONNECTION

INSTALLATION

2-5 SYSTEM GPIB

INTERCONNECTION

GPIB Interface to an

External Plotter

GPIB Addresses The 37xxxE leaves the factory with the default GPIB address set to

2-6 ETHERNET SETUP AND

INTERCONNECTION

There are two rear panel GPIB IEEE-488 connectors. The IEEE 488.2

connector used to interface the 37xxxE to an external computer/

controller via a standard GPIB cable. The Dedicated GPIB connector is

used to interface to plotters and a second source for multiple source

operation via a standard GPIB cable.

The 37xxxE GPIB interface can be configured to control a suitable

external plotter (refer to Chapter 6, Data Displays). In this mode of

operation, the GPIB is dedicated to this application and only the

37xxxE and the plotter are connected to the GPIB.Standard GPIB

cables are used to interconnect to the plotter.

six. This address may be changed using the GP7 menu (see Appendix

A).

The 37xxxE model requires two IP addresses. One is internal and is

used only by the VNA for internal communication, and the other is the

IP address that can be used externally to communicate with the VNA.

The current implementation requires a continuous internal connection

and IP validity is checked as well as monitored.

The internal IP automatically updates when changes happen to the IP

address. It is highly recommended to allow the VNA to change the

internal IP automatically and retain that IP as long as it is in

operation. If it is required to assign two static IP addresses, then

changing the internal IP address is allowed, but assure that the IP is

valid, and, more importantly, available, especially if the instrument is

connected onto your LAN.

NOTE

Five classes of IP ranges are available: Class A, Class B,

Class C,Class D, and Class E. While only Classes A, B,

and C are commonly used, the VNA will accept any IP in

any range with the exception of reserved IPs. Anritsu

highly recommends IP addresses that are either Private

(Class A) or that belong to your own network. The

following Table shows a quick summary of the classes and

the IP assignments:

Class Range

A 1.0.0.1 to 126.255.255.254

B 128.1.0.1 to 191.255.255.254

C 192.0.1.1 to 223.255.254.254

D 224.0.0.0 to 239.255.255.255

E 240.0.0.0 to 254.255.255.254

2-6 37xxxE OM

Page 27

INSTALLATION ETHERNET SETUP AND INTERCONNECTION

One known inconvenience is the actual assigned IP values do not

refresh automatically on the screen. A quick way to do get them

refreshed is to manually re-access the Network Utilities Menu, which

will then display them correctly.

The 37xxxE can be remotely controlled via a network server and an

Ethernet connection via the standard RJ45 connector on the rear

panel. The 37xxxE software supports the TCP/IP network protocol.

The TCP/IP protocol setup requires the following:

q IP Address: Every computer/electronic device in a TCP/IP net-

work requires an IP address. An IP address has four numbers

(each between 0 and 255) separated by periods. For example:

128.111.122.42 is a valid IP address

q Internal IP: An IP address has four numbers (each between 0

and 255) separated by periods. For example, "128.111.122.42" is a

valid IP address.

q Subnet Mask: The subnet mask distinguishes the portion of the

IP address that is the network ID from the portion that is the

station ID.The subnet mask 255.255.0.0, when applied to the IP

address given above, would identify the network ID as 128.111

and the station ID as 122.42. All stations in the same Local Area

Network (LAN) should have the same network ID but different

station IDs

q Default Gateway: A TCP/IP network can have a gateway to com-

municate beyond the LAN identified by the network ID.A gateway is a computer or electronic device that is connected to two

different networks and can move TCP/IP data from one network

to the other. A single LAN that is not connected to other LANs

requires a default gateway setting of 0.0.0.0. This (0.0.0.0) is

Lightning’s default gateway setting. If you have a gateway, then

the default gateway would be set to the appropriate value of your

gateway.

NOTE

The default gateway setting is only activated after the system power is recycled.

q Ethernet Address: An Ethernet address is a unique 48-bit value

that identifies a network interface card to the rest of the network. Every network card has a unique ethernet address permanently stored into its memory Inappropriate setting of the Default Gateway IP Address will cause the Lightning system to

appear to be locked up at start up. The instrument will appear to

stop working at the following message:

Application loaded successfully, starting system…

37xxxE OM 2-7

Page 28

EXTERNAL MONITOR CONNECTOR INSTALLATION

2-7 EXTERNAL MONITOR

CONNECTOR

The rear panel External Monitor connector allows the internal display

information of the 37xxxE to be connected to an external VGA monitor

(either color or monochrome). The pinout of this 15-pin Type D

connector is shown in Figure B-5, located in Appendix B.

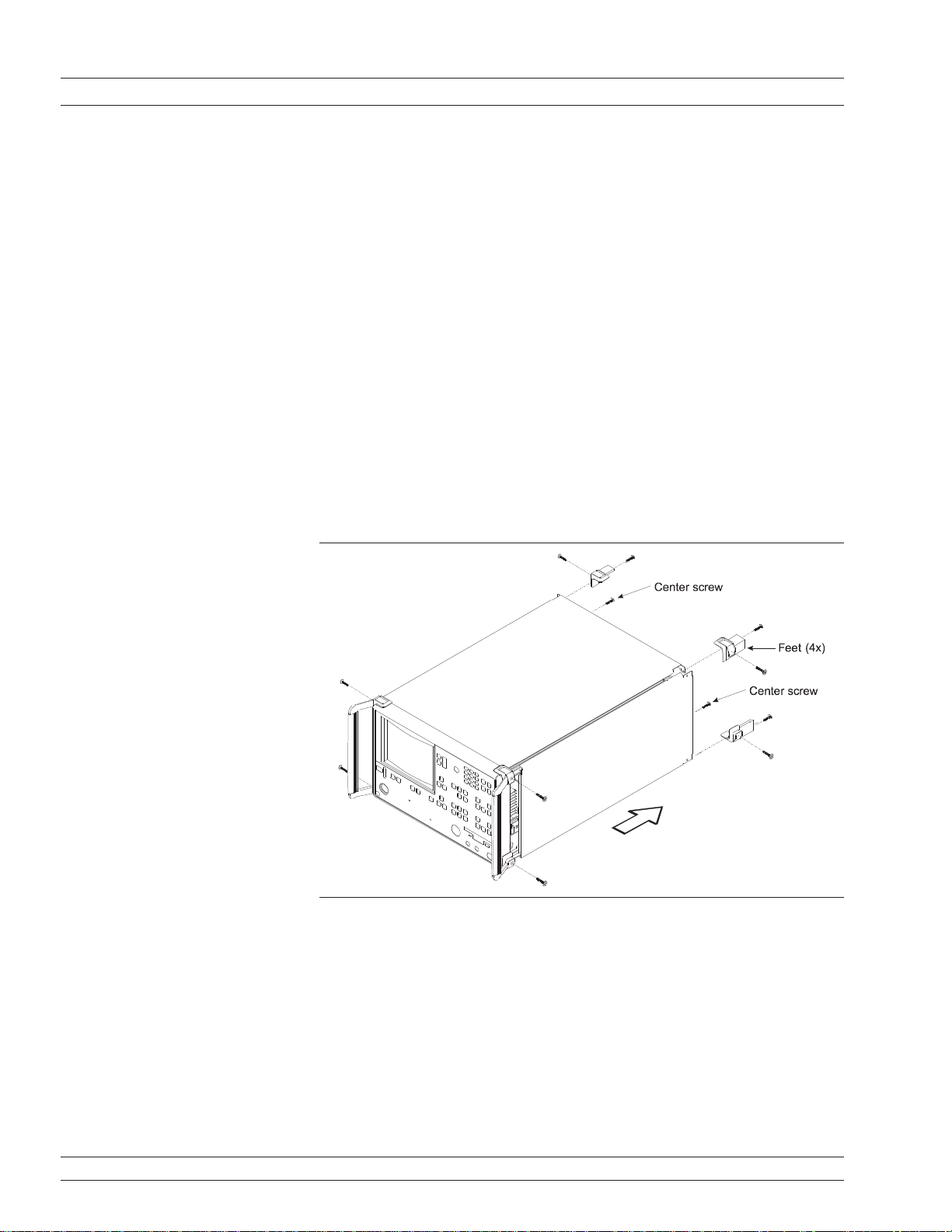

2-8 RACK MOUNT To install the Option 1 Rack Mount rails, refer to the below-listed pro-

cedure.

Step 1. Disconnect the line cord and any other attachments from the instru-

ment.

Step 2. Carefully place the instrument on its top (bottom-side up) on a secure

and stable work surface.

Step 3. Using a Phillips screwdriver, remove the two handles or four bumper

assemblies (and tilt bail, if installed) from the front of the unit, and

the four feet at the rear (Figure 2-1). Save the screws for later use.

Figure 2-1. Removing Cover

NOTES

q The green-headed screws are metric threads and must be used

only in the appropriately tapped holes

q The feet, handles, and bumpers are not reused in this application

Step 4. Remove the center screws from the rear of the left and right side cov

ers.

-

2-8 37xxxE OM

Page 29

INSTALLATION

RACK MOUNT

Step 5. Remove the two side carrying handle screws (if so equipped) located

under the plastic handle ends.

Step 6. Remove the left and right side covers. These side covers are not reused

in this application.

Step 7. Install the two Rack Mount Handles using the green-headed screws

removed earlier.

Refer to Figure 2-2, on the following page, for the remainder of the

assembly procedure.

Step 8. Secure the new left cover (2) from this retrofit kit to the left side chas-

sis of the instrument by installing the two center screws (6) to the top

and bottom and the previously removed center screw at the rear of the

left cover.

Step 9. Secure the slide assembly (4) to the left cover by installing the four

mounting screws (5) to the left chassis.

Figure 2-2. Mounting Rails

37xxxE OM 2-9

Page 30

STORAGE OR SHIPMENT INSTALLATION

Step 10. Secure the new right cover (3) from this retrofit kit to the right side

chassis of the instrument by installing the center screw (6) through

the center of the right side cover and the previously removed center

screw at the rear of the right side cover.

Step 11. Secure the slide assembly (4) to the right cover by installing the four

mounting screws (5) to the right chassis.

This completes the installation of the slide assembly.

2-9 STORAGE OR SHIPMENT The following paragraphs describe the procedure for preparing the

37xxxE for storage or shipment.

Preparation for Storage Preparing the 37xxxE for storage consists of cleaning the unit, packing

the inside with moisture-absorbing desiccant crystals, and storing the

unit in a temperature environment that is maintained between –40

and +70 degrees centigrade (–40 to 156 degrees Fahrenheit).

Preparation for Shipment To provide maximum protection against damage in transit, the 37xxxE

should be repackaged in the original shipping container. If this

container is no longer available and the 37xxxE is being returned to

Anritsu for repair, advise Anritsu Customer Service; they will send a

new shipping container free of charge. In the event neither of these

two options is possible, instructions for packaging and shipment are

given below.

Use a Suitable Container

Obtain a corrugated cardboard carton with a 275-pound test strength.

This carton should have inside dimensions of no less than six inches

larger than the instrument dimensions to allow for cushioning.

Protect the Instrument

Surround the instrument with polyethylene sheeting to protect the finish.

Cushion the Instrument

Cushion the instrument on all sides by tightly packing dunnage or

urethane foam between the carton and the instrument. Provide at

least three inches of dunnage on all sides.

Seal the Container

Seal the carton by using either shipping tape or an industrial stapler.

Address the Container

If the instrument is being returned to Anritsu for service, mark the

Anritsu address and your return address on the carton in one or more

prominent locations.

2-10 37xxxE OM

Page 31

Chapter 3

Network Analyzers,

A Primer

Table of Contents

3-1 INTRODUCTION ...................................3-3

3-2 GENERAL DESCRIPTION ..............................3-3

Source Module....................................3-4

Test Set Module ...................................3-4

Analyzer Module ..................................3-4

3-3 NETWORK ANALYZERS ...............................3-5

Page 32

Page 33

Chapter 3

TRANSMITTEDINCIDENT

TEST

DEVICE

Gain (dB)

Insertion Loss (dB)

Insertion Phase (degrees)

Transmission Coefficients (S12, S21)

Separation of Transmission

Components (Real and Imaginary)

Electrical Length (m)

Electrical Delay (s)

Deviation from Linear Phase (degrees)

Group Delay (s)

Network Analyzers,

A Primer

3-1 INTRODUCTION This section provides front panel operating and measurement applica

tion information and data. It includes discussions on the following top

ics:

System description

q

General discussion about network analyzers

q

Basic measurements and how to make them

q

q Error correction

q General discussion on test sets

3-2 GENERAL DESCRIPTION The Model 37xxxE Vector Network Analyzer System measures the

magnitude and phase characteristics of networks, amplifiers,

attenuators, and antennas. It compares the incident signal that leaves

the analyzer with either the signal that is transmitted through the

test device or the signal that is reflected from its input. Figure 3-1 and

Figure 3-2 illustrate the types of measurements that the 37xxxE can

make.

-

-

37xxxE OM 3-3

Figure 3-1. Transmission Measurements

Page 34

GENERAL DESCRIPTION NETWORK ANALYZERS, A PRIMER

REFLECTED

INCIDENT

TERMINATION

TEST

DEVICE

Return Loss (dB)

Reflection Coefficients (S11, S22)

Reflection Coefficients vs D istance

(Fourier Transform)

Impedance (R + j X)

SWR

Figure 3-2. Reflection Measurements

The 37xxxE is a self-contained, fully integrated measurement system

that includes an optional time domain capability. The system

hardware consists of the following:

q Analyzer

q Precision components required for calibration and performance

verification

q Optional use of Anritsu 67XXB, 68XXXA/B/C,or 69XXXA/B as a

second source

The 37xxxE internal system modules perform the following functions:

Source Module This module provides the stimulus to the device under test (DUT). The

frequency range of the source and test set modules establish the

frequency range of the system. The frequency stability of the source is

an important factor in the accuracy (especially phase accuracy) of the

network analyzer. Hence, the 37xxxE always phase locks the source to

an internal 10 MHz crystal reference.

Test Set Module The test set module routes the stimulus signal to the DUT and sam

ples the reflected and transmitted signals. The type of connector used

is important, as is the “Auto Reversing” feature. Auto Reversing means

that it applies the stimulus signal in both the forward and reverse di

rection. The direction is reversed automatically. This saves you from

having to reverse the test device physically to measure all four scatter

ing parameters (S-parameters). Frequency conversion (1st and 2nd

IFs) occurs in the test set module.

-

-

-

Analyzer Module The analyzer module down-converts, receives, and interprets the 3rd

IF signal for phase and magnitude data. It then displays the results of

this analysis on a large, 190 mm (7-1/2 inch) diagonal color display.

This display can show all four S-parameters simultaneously. In addi

tion to the installed display, you can also view the measurement re

sults on an external color monitor.

3-4 37xxxE OM

-

-

Page 35

NETWORK ANALYZERS, A PRIMER NETWORK ANALYZERS

SCALAR NE TWORK ANALYZERS

MICROWAVE

SIGNAL

MICROWAVE

DETECTOR

DETECTOR

OUTPUT

VOLTAGE

DETECTOR OUTPUT VOLTAGE I S PROPORTIONAL

TO SIGNAL AMPLITUDE.

3-3 NETWORK ANALYZERS We will begin this discussion with a subject familiar to most Anritsu

customers: scalar network analysis. After showing comparisons,we

will proceed to the fundamentals of network analyzer terminology and

techniques. This discussion serves as an introduction to topics pre

sented in greater detail later in this section. This discussion will touch

on new concepts that include the following:

Reference Delay

q

S-parameters: what they are and how they are displayed

q

Complex Impedance and Smith Charts

q

Scalar Analyzer Comparison

Network Analyzers do everything that scalar analyzers do except dis

play absolute power. In addition, they add the ability to measure the

phase characteristics of microwave devices and allow greater dynamic

range.

If all a Network Analyzer added was the capability for measuring

phase characteristics, its usefulness would be limited. While phase

measurements are important in themselves, it is the availability of

this phase information that unlocks many new features for complex

measurements. These features include Smith Charts, Time Domain,

and Group Delay. Phase information also allows greater accuracy

through vector error correction of the measured signal.

-

-

Figure 3-3. Scalar Analyzer

Detection

First, let us look at scalar network analyzers (SNAs). SNAs measure

microwave signals by converting them to a DC voltage using a diode

detector (Figure 3-3). This DC voltage is proportional to the magnitude

of the incoming signal. The detection process, however, ignores any

information regarding the phase of the microwave signal.

In a network analyzer, access is needed to both the magnitude and

phase of a microwave signal. There are several different ways to per

form the measurement. The method Anritsu employs (called Harmonic

Sampling or Harmonic Mixing) is to down-convert the signal to a lower

intermediate frequency (IF). This signal can then be measured directly

by a tuned receiver. The tuned receiver approach gives the system

greater dynamic range. The system is also much less sensitive to inter

fering signals, including harmonics.

-

37xxxE OM 3-5

Page 36

NETWORK ANALYZERS NETWORK ANALYZERS, A PRIMER

PHASE MEASUREMENT

TIME

TEST

SIGNAL

REFERENCE

SIGNAL

90

REFERENCE

SIGNAL

SPLITTER

TEST

SIGNAL

MICROWAVE

SOURCE

LONGER

PATH

LENGTH

PHASE

DETECTOR

A NETWORK ANALYZER IS A TUNED RECEIVER

TUNABLE

LOCAL

OSCILLATOR

INTERMEDIATE

FREQUENCY (IF)

MICROWAVE

SIGNAL

• GREATERDYNAMIC RANGE

• LESSSENSIVITY TO INTERFERINGSIGNALS

DUT

PHASE

DETECTOR

REFERENCE

SIGNAL

SPLITTER

TEST

SIGNAL

MICROWAVE

SOURCE

Vector Network Analyzer Basics

The network analyzer is a tuned receiver (Figure 3-4, left). The

microwave signal is down converted into the passband of the IF. To

measure the phase of this signal, we must have a reference to compare

it with. If the phase of a signal is 90 degrees, it is 90 degrees different

from the reference signal (Figure 3-5, left). The network analyzer

would read this as –90 degrees, since the test signal is delayed by 90

degrees with respect to the reference signal.

This phase reference can be obtained by splitting off some of the

microwave signal before the measurement (Figure 3-7, below).

Figure 3-4. Network Analyzer is

a Tuned Receiver

Figure 3-5. Signals with a

90 Degree Phase

Difference

a Length of Line

Replaces the DUT

Figure 3-6. Split Signal where

3-6 37xxxE OM

Figure 3-7. Splitting the Microwave Signal

The phase of the microwave signal after it has passed through the de

vice under test (DUT) is then compared with the reference signal. A

network analyzer test set automatically samples the reference signal,

so no external hardware is needed.

Let us consider for a moment that you remove the DUT and substitute

a length of transmission line (Figure 3-6, left). Note that the path

length of the test signal is longer than that of the reference signal.

Now let us see how this affects our measurement.

-

Page 37

NETWORK ANALYZERS, A PRIMER NETWORK ANALYZERS

REFERENCE

SIGNAL

SPLITTER

TEST

SIGNAL

MICROWAVE

SOURCE

PHASE

DETECTOR

LONGER BY

ONE WAVELENGTH

LENGTH (360 degrees)

REFERENCE

SIGNAL

SPLITTER

TEST

SIGNAL

MICROWAVE

SOURCE

SAME PATH

LENGTH -BUTWAVELENGTH

IS NOW SHORTER

1.1 WAVELENGTHS = 396 degrees

PHASE

DETECTOR

+180

+90

0

-90

-180

1.1

1.2

1.3

1.4

FREQUENCY,

GHz

MEASURED PHASE

Assume that we are making a measurement at 1 GHz and that the

difference in path-length between the two signals is exactly 1

wavelength. This means that test signal is lagging the reference signal

by 360 degrees (Figure 3-8). We cannot really tell the difference

between one sine wave maxima and the next (they are all identical), so

the network analyzer would measure a phase difference of 0 degrees.

Now consider that we make this same measurement at 1.1 GHz. The

frequency is higher by 10 percent so therefore the wavelength is

shorter by 10 percent. The test signal path length is now 0.1

wavelength longer than that of the reference signal (Figure 3-9). This

test signal is:

Figure 3-8. Split Signal where

Path Length Differs

by Exactly One

Wavelength

Figure 3-9. Split Signal where

Path Length is

Longer than One

1.1 X 360 = 396 degrees

This is 36 degrees different from the phase measurement at 1 GHz.

The network analyzer will display this phase difference as –36 de

-

grees.

The test signal at 1.1 GHz is delayed by 36 degrees more than the test

signal at 1 GHz.

You can see that if the measurement frequency is 1.2 GHz, we will get

a reading of –72 degrees, –108 degrees for 1.3 GHz, etc.(Figure 3-10).

There is an electrical delay between the reference and test signals.For

this delay we will use the common industry term of reference delay.

You also may hear it called phase delay. In older network analyzers

you had to equalize the length of the reference arm with that of the

test arm to make an appropriate measurement of phase vs. frequency.

To measure phase on a DUT, we want to remove this

phase-change-vs.-frequency due to changes in the electrical length.

This will allow us to view the actual phase characteristics. These char

acteristics may be much smaller than the phase change due to

electrical length difference.

-

Figure 3-10. Electrical Delay

37xxxE OM 3-7

Page 38

NETWORK ANALYZERS NETWORK ANALYZERS, A PRIMER

PHASE

DETECTOR

REFERENCE

SIGNAL

SPLITTER

TEST

SIGNAL

MICROWAVE

SOURCE

BOTH LINE

LENGTHS

NOW EQUAL

+180

+90

0

-90

-180

1.1

1.2

1.3

1.4

FREQUENCY,

GHz

MEASURED PHASE

SUBTRACT LINEAR

PHASE FROM

MEASURED PHASE

0

1.1

1.2

1.3

1.4

FREQUENCY,

GHz

+2

+1

-1

-2

RESULTANT PHASE

There are two ways of accomplishing this. The most obvious way is to

insert a length of line into the reference signal path to make both

paths of equal length (Figure 3-11, below). With perfect transmission

lines and a perfect splitter, we would then measure a constant phase

as we change the frequency. The problem using this approach is that

we must change the line length with each measurement setup.

Figure 3-12. Phase Difference

Increases Linearly

with Frequency

Figure 3-11. Split Signal where Paths are of Equal Length

Another approach is to handle the path length difference in software.

Figure 3-12 (left) displays the phase-vs.-frequency of a device. This

device has different effects on the output phase at different

frequencies. Because of these differences, we do not have a perfectly

linear phase response. We can easily detect this phase deviation by

compensating for the linear phase. The size of the phase difference

increases linearly with frequency so we can modify the phase display

to eliminate this delay.

The 37xxxE offers automatic reference delay compensation with the

push of a button. Figure 3-13 (left) shows the resultant measurement

when we compensate path length. In a system application you can

usually correct for length differences; however,the residual phase

Figure 3-13. Resultant Phase

with Path

Length

3-8 37xxxE OM

characteristics are critical.

Page 39

NETWORK ANALYZERS, A PRIMER NETWORK ANALYZERS

FORWARD

REFLECTION

REVERSE

REFLECTION

PORT 1 PORT 2

DUT

S12 REVERSE TRANSMISSION

PORT 1 PORT 2

S11 FORWARD

REFLECTION

S22 REVERSE

REFLECTION

S21 FORWARD TRANSMISSION

DUT

+180

0

-180

PHASE

FREQUENCY

Network Analyzer Measurements

Now let us consider measuring the DUT. Consider a two port device;

that is, a device with a connector on each end. What measurements

would be of interest?

First, we could measure the reflection characteristics at either end

with the other end terminated into 50 ohms. If we designate one end

as the normal place for the input that gives a reference. We can then

define the reflection characteristics from the reference end as forward

reflection, and those from the other end as reverse reflection

(Figure 3-14).

Second, we can measure the forward and reverse transmission

Figure 3-14. Forward and

Reverse

Measurements

characteristics. However, instead of saying “forward,”“reverse,”

“reflection,”and “transmission” all the time, we use a shorthand. That

is all that S-parameters are, a shorthand! The “S” stands for

scattering. The second number is the device port that the signal is

being injected into, while the first is the device port that the signal is

leaving.S

, therefore, is the signal being injected into port 1 relative

11

to the signal leaving port 1. The four scattering parameters

(Figure 3-15) are:

Figure 3-15. S-parameters

Figure 3-16. Linear

37xxxE OM 3-9

Phase-with-frequen

cy Waveform

q S

Forward Reflection

11

q S

Forward Transmission

21

q S

Reverse Reflection

22

q S

Reverse Transmission

12

S-parameters can be displayed in many ways.An S-parameter consists

of a magnitude and a phase. We can display the magnitude in dB, just

like a scalar network analyzer. We often call this term log magnitude.

We can display phase as “linear phase” (Figure 3-16). As discussed

earlier, we can’t tell the difference between one cycle and the next.

Therefore, after going through 360 degrees we are back to where we

began. We can display the measurement from –180 to +180 degrees.

The –180 to +180 approach is more common. It keeps the display

discontinuity removed from the important 0 degree area used as the

phase reference.

Page 40

NETWORK ANALYZERS NETWORK ANALYZERS, A PRIMER

-90

180

90

0

POLAR DISPLAY

50

INDUCTIVE

CAPACITIVE

SMITH CHART

There are several ways in which all the information can be displayed

on one trace. One method is a polar display (Figure 3-17). The radial

parameter (distance from the center) is magnitude. The rotation

around the circle is phase. We sometimes use polar displays to view

transmission measurements, especially on cascaded devices (devices in

series). The transmission result is the addition of the phase and log

magnitude (dB) information of each device’s polar display.

Figure 3-17. Polar Display

Figure 3-18. Smith Chart

As we have discussed, the signal reflected from a DUT has both mag

nitude and phase. This is because the impedance of the device has

both a resistive and a reactive term of the form r+jx. We refer to the r

as the real or resistive term, while we call x the imaginary or reactive

term. The j, which we sometimes denote as i, is an imaginary number.

It is the square root of –1. If x is positive, the impedance is inductive; if

x is negative, the impedance is capacitive.

The size and polarity of the reactive component x is important in im

pedance matching. The best match to a complex impedance is the com

plex conjugate. This complex-sounding term simply means an impedance with the same value of r and x, but with x of opposite polarity.

This term is best analyzed using a Smith Chart (Figure 3-18), which is

a plot of r and x.

To display all the information on a single S-parameter requires one or

two traces, depending upon the format we want. A very common

requirement is to view forward reflection on a Smith Chart (one trace)

while observing forward transmission in Log Magnitude and Phase

(two traces). Let us see how to accomplish this in the 37xxxE.

The 37xxxE has four channels. Each channel can display a complete

S-parameter in any format on either one or two traces. All four

S-parameters can be seen simultaneously in any desired format. A

total of eight traces can be viewed at the same time. While this is a lot

of information to digest, the 37xxxE’s large color display makes

recognizing and analyzing the data surprisingly easy.

-

3-10 37xxxE OM

Page 41

NETWORK ANALYZERS, A PRIMER NETWORK ANALYZERS

VECTOR ERROR CORRECTION

THEN THE RESULTANT VECTOR IS

APPLIED MATHEMATICALLY, HENCE

MAGNITUDE AND PHASE OF

EACH ERROR SIGNAL IS MEASURED

MAG

PHASE

Another important parameter we can measure when phase informa

tion is available is group delay. In linear devices, the phase change

through the DUT is linear-with-frequency. Thus, doubling the fre

quency also doubles the phase change. An important measurement, es

pecially for communications system users, is the rate of

change-of-phase-vs.-frequency (group delay). If the rate of

phase-change-vs.-frequency is not constant, the DUT is nonlinear. This

nonlinearity can create distortion in communications systems.

Measurement Error Correction

Since we can measure microwave signals in both magnitude and

phase, it is possible to correct for six major error terms:

Source Test Port Match

q

Load Test Port Match

q

Directivity

q

q Isolation

q Transmission Frequency Response

q Reflection Frequency Response

We can correct for each of these six error terms in both the forward

and reverse directions, hence the name 12-term error correction. Since

12-term error correction requires both forward and reverse measurement information, the test set must be reversing. “Reversing” means

that it must be able to apply the measurement signal in either the forward or reverse direction.

-

Figure 3-19. Magnitude and

37xxxE OM 3-11/3-12

Phase

To accomplish this error correction, we measure the magnitude and

phase of each error signal (Figure 3-19). Magnitude and phase infor

mation appear as a vector that is mathematically applied to the mea

-

-

surement signal. This process is termed vector error correction.

Summary

A vector network analyzer is similar to a scalar network analyzer. The

major difference is that it adds the capability for measuring phase as

well as amplitude. With phase measurements comes scattering, or

S-parameters, which are a shorthand method for identifying forward

and reverse transmission and reflection characteristics. The ability to

measure phase introduces two new displays,polar and Smith Chart. It

also adds vector error correction to the measurement trace. With vec

tor error correction, errors introduced by the measurement system are

compensated for and measurement uncertainty is minimized. Phase

measurements also add the capability for measuring group delay,

which is the rate of change-of-phase vs.frequency (group delay). All in

all, using a network analyzer provides for making a more complete

analysis of your test device.

Page 42

Page 43

Chapter 4

Front Panel Operation

Table of Contents

4-1 INTRODUCTION ...................................4-3

4-2 KEY-GROUPS .....................................4-3

4-3 CALIBRATION KEY-GROUP ............................4-10

4-4 SAVE/RECALL MENU KEY.............................4-20

4-5 MEASUREMENT KEY-GROUP ..........................4-21

4-6 CHANNELS KEY-GROUP..............................4-24

4-7 DISPLAY KEY-GROUP ...............................4-25

4-8 ENHANCEMENT KEY-GROUP...........................4-29

4-9 HARD COPY KEY-GROUP .............................4-31

4-10 SYSTEM STATE KEY-GROUP ...........................4-33

4-11 MARKERS/LIMITS KEY-GROUP ..........................4-36

4-12 STORAGE INTERFACE ...............................4-40

Disk Files......................................4-40

Disk File Output Device..............................4-41

Formatting a Data File Drive ...........................4-41

Copying Data Files From Drive to Drive .....................4-41

Recovering From Drive Write/Read Errors....................4-41

4-13 COMMAND LINE ..................................4-42

Create Directory ..................................4-42

List Directory ...................................4-42

Change Directory .................................4-42

Delete Files.....................................4-42

Remove Directory .................................4-43

Copy Files .....................................4-43

Conventions ....................................4-43

Page 44

Calibration

Menu

Hard Copy

Markers/Limits

System State

Local Lockout

SRQ

Listen

Tal k

Remote

GPIB

Power

Default

Program

Utility

Menu

Begin

Cal

Apply

Cal

Save/

Recall

Menu

Start

Print

Stop

Print

Menu

Limits

Marker

Menu

Readout

Marker

Graph

Type

Set

Scale

Auto

Scale

S

Params

Ref

Plane

Trace

Memory

Channel

Menu

Ch 1

Ch 2

Ch 3

Ch 4

Option

Menu

Video

IF BW

Avg/

Smooth

Menu

Trace

Smooth

Average

Setup

Menu

Data

Points

Hold

Domain

Appl

Enter

789

4

5

6

12

3

0

.

-

MHz

nsX1cm

GHz

10

3

us

m

kHz

ps

10

-3

mm

Clear

Ret Loc

Measurement

Enhancement

Channels

Data Entry

Display

Port 1

Source

Port 2

Source

Port 2

Port 2Port 1

Bias Input

Port 1

CAUTION

+30 dBm MAX

40 VDC MAX

AVOIDSTATIC

DISCHARGE

CAUTION

+30 dBm MAX

40 VDC MAX

AVOIDSTATIC

DISCHARGE

a

2

a

1

b

1

b

2

!

+30 dBm

!

0.5AMAX

!

+24 dBm

!

+30 dBm

!

+24 dBm

!

+27 dBm

!

+27 dBm

!

+20 dBm

!

+20 dBm

20

13

12

76

5

4

3

2

1

18

17

16

15

14

11

10

9

8

19

21

22

23

24

Figure 4-1. Model 37xxxE Front Panel

Page 45

Chapter 4 Front Panel Operation

4-1 INTRODUCTION This chapter describes the front panel keys, controls, and menus. The

chapter is organized into an overall description of the front panel

key-groups and detailed descriptions of individual keys within the

key-groups.

4-2 KEY-GROUPS The following pages provide descriptions of the front panel key-groups

illustrated in Figure 4-1 on the previous page.

Index 1. LCD display: Displays any or all of the four mea

surement channels, plus menus.

Index 2. Power: Turns the 37xxxE on and off.When on, the

operating program runs a self test then recalls the

parameters and functions in effect when previously

powered down.

Index 3. GPIB Indicators:

Remote: Lights when the 37xxxE switches to

remote (GPIB) control. It remains lit until the unit

returns to local control.

Talk: Lights when you address the 37xxxE to talk

and remains lit until unaddressed.

Listen: Lights when you address the 37xxxE to

listen and remains lit until unaddressed.

SRQ: Lights when the 37xxxE sends a Service

Requests (SRQ) to the external controller. The LED

remains lit until the 37xxxE receives a serial poll or

until the controller resets the SRQ function.

-

Local Lockout: Lights when a local lockout

message is received. The LED remains lit until the

message is rescinded. When lit, you cannot return

the 37xxxE to local control via the front panel.

37xxxE OM 4-3

Page 46

KEY-GROUPS FRONT PANEL OPERATION

Index 4. System State Keys: (Refer to section 4-10,

page 4-33, for details and menu flow diagrams.)

Default Program: Resets the front panel to the fac

tory-preset state and displays Menu SU1 or SU3

(Appendix A). Pressing this key in conjunction with

the “0” or “1” key resets certain internal memories

and front panel key states (refer to sections 4-5 and

4-10).

NOTE

Use of the Default Program key will destroy

front panel and calibration setup data, un

less they have been saved to disk.

Utility Menu: Displays the first in a series of menus

that let you perform storage and other utility-type

functions and operations.

Index 5. Port 1 Test Connector: Provides an input test con-

nection for the device-under-test (DUT).

Index 6. Port 1 Source Loop: Provides for inserting addi-

tional amplification on Port 1 before the coupler.

Index 7. Calibration Keys: (Refer to section 4-3, page 4-10,

for details and menu flow diagrams.)

-

-

Begin Cal: Calls up the first in a sequence of

menus that guide you through a measurement cali

bration. Refer to section 4-3 for a detailed discussion

of the calibration keys, indicators, and menus.

Apply Cal: Turns on and off the applied error cor

rection and tune mode.

Index 8. a1 Loop: Provides direct access to Reference A

channel on Port 1 over the entire frequency range.

Refer to the front panel for damage levels.

Index 9. a2 Loop: Provides direct access to Reference B

channel on Port 2 over the entire frequency range.

Refer to the front panel for damage levels.

Index 10. b1 Loop: Provides direct access to Test A channel

on Port 1 over the entire frequency range. Refer to

the front panel for damage levels.

Index 11. b2 Loop: Provides direct access to Test B channel

on Port 2 over the entire frequency range. Refer to

the front panel for damage levels.

-

-

4-4 37xxxE OM

Page 47

FRONT PANEL OPERATION KEY-GROUPS

Index 12. Save/Recall Menu Key: Displays the first of several

menus that let you save the current calibration or

front panel setup or recall a previously saved cali

bration or setup. Refer to section 4-4, page 4-20, for

menu flow diagram.

Index 13. Markers/Limits Keys: (Refer to section 4-11,

page 4-36, for details and menu flow diagrams.)

Marker Menu: Displays the first in a series of

menus that let you set and manipulate marker fre

quencies, times, and distances.

Readout Marker: Displays a menu that lists all of

the active markers. If no markers are active, the

marker menu is displayed.

-

-

Limits: Displays one of the menus that let you ma

nipulate the limit lines.

Index 14. Port 2 Source: Provides for inserting additional

amplification on Port 2 before the coupler.

Index 15. Hard Copy Keys: (Refer to section 4-9, page 4-31,

for details and menu flow diagrams.)

Menu: Displays option menus that let you define

what will happen each time you press the Start

Print key. The displayed menu also selects disk I/O

operations.

Start Print: Tells the printer or plotter to start out

put based on the current selections.

Stop Print: Immediately stops printing the data,

clears the print buffer, and sends a form-feed com

mand to the printer.

Index 16. Port 2 Test Connector: Provides an input test con

nection for the device-under-test (DUT).

-

-

-

-

37xxxE OM 4-5

Page 48

KEY-GROUPS FRONT PANEL OPERATION

Index 17. Display Keys: (Refer to section 4-7, page 4-25, for

details and menu flow diagrams.)

Graph Type: Displays the two menus that let you

choose the graph type for the active channel.

Set Scale: Displays the appropriate scaling menu,

based on the graph type for the active channel.

Auto Scale: Automatically scales the active chan

nel for optimum viewing.

S Params: Displays Menu SP (Appendix A), which

lets you choose between S11, S12, S21, or S22. You

may display the same parameter on two or more

channels.

Ref Plane: Displays the first of two menus that let

you set the reference plane for the active channel in

time or distance. For a correct distance readout, you

must set the dielectric constant to the correct value.

Refer to the discussion in menu RD2 (Appendix A).

Trace Memory: Displays the menus that let you do

any of the following. (1) Store the measured data in

memory. (2) View the stored data. (3) Add, subtract,

multiply, or divide the measured data from the

stored data (normalize to the stored memory). (4)

View both the measured and the stored data simultaneously on the active channel. (5) Store/Recall

saved data to disk. Four memories exist—one for

each channel. This lets you normalize the data in

each channel independently. The LED on this but

ton lights when the active channel is displaying

memory data or measurement data normalized to

memory.

-

-

Index 18. Bias Input Connectors:

Port 1: Provides for supplying a bias voltage for the

Port 1 input.

Port 2: Provides for supplying a bias voltage for the

Port 2 input.

4-6 37xxxE OM

Page 49

FRONT PANEL OPERATION KEY-GROUPS

Index 19. Enhancement Keys: (Refer to section 4-8,

page 4-29 for details and menu flow diagrams.)

Option Menu: Displays a series of menus showing

the choice of optional features.

Video IF BW: Displays a menu that lets you chose

between 10 kHz, 1 kHz, 100 Hz, or 10 Hz intermedi

ate frequency (IF) bandwidth filters.

Avg/Smooth Menu: Displays a menu that lets you

enter values for Averaging and Smoothing.

Trace Smooth: Turns the trace smoothing function

on and off.

Average: Turns the average function on and off.

Index 20. USB Connector: Provides a USB connector used to

store selected front panel setups and calibrations.

-

NOTE

The USB interface CANNOT be used for

Printers and other USB peripherals. Refer

to Section 4-12 for storage information.

37xxxE OM 4-7

Page 50

KEY-GROUPS FRONT PANEL OPERATION

Index 21. Channels Keys: (Refer to section 4-6, page 4-24, for

details and menu flow diagrams.)

Channel Menu: Displays a menu that lets you se

lect the format for the number of channels dis

played.

Ch 1: Makes Channel 1 the active channel. The ac

tive channel is the one acted on by the keys in the

Display section. Only one channel can be active at

any one time.

Ch 2: Makes Channel 2 the active channel.

Ch 3: Makes Channel 3 the active channel.

Ch 4: Makes Channel 4 the active channel.

Index 22. Measurement Keys: (Refer to section 4-5, page 4-21

for details and menu flow diagrams.)

Setup Menu: Displays the first of several menus

that let you select functions affecting measurements.

Data Points: Displays a menu that lets you select

between 1601, 801, 401, 201, 101, or 51 data points.

-

-

-

Hold: Toggles the instrument in and out of the hold

mode; or it triggers a sweep, depending on the func

tion selected in menu SU4 (Appendix A).

Domain: Displays the first in a series of menus that

let you set the Time Domain display parameters.

(This key is only active if your 37xxxE is equipped

with the Time Domain option.)

•

If already in the Domain menus, pressing this

key will return to the first menu in the sequence.

•

If in the Domain menus and another (non-time

domain) menu is displayed by pushing a menu

key, the last displayed domain menu redisplays

when the Domain key is next pressed.

Applications Menu: Displays the first in a series of

menus that provide instructions for adapter removal

and gain compression.

-

4-8 37xxxE OM

Page 51

FRONT PANEL OPERATION KEY-GROUPS

Index 23. Data Entry Keys:

Rotary Knob: Used to alter measurement values

for the active parameter (Start Frequency, Stop Fre

quency, Offset, etc.).