Page 1

MODEL

373XXA

VECTOR NETWORK ANALYZER

MAINTENANCE MANUAL

490 JARVIS DRIVE l MORGAN HILL, CA 95037-2809

P/N: 10410-00185

REVISION: D

PRINTED: MARCH 2000

COPYRIGHT 1996 ANRITSU CO.

Page 2

WARRANTY

The ANRITSU product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for one year from the date of shipment.

ANRITSU’sobligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to ANRITSU

for warranty repairs. Obligation is limited to the original purchaser.ANRITSU is not liable for con

sequential damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to ANRITSU connectors that have failed due tonormal wear.

Also, the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer, unauthorized modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer’s sole and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

V Connector and K Connector are registered trademarks of ANRITSU Company.

ANACAT is a registered trademark of EEsof, Inc.

Ink Jet and Think Jet are registered trademarks of Hewlett-Packard Co.

MS-DOS is a registered trademark of Microsoft Corporation.

NOTICE

-

ANRITSU Company has prepared this manual for use by ANRITSU Company personnel and cus

tomers as a guide for the proper installation, operation and maintenance of ANRITSU Company

equipment and computer programs. The drawings, specifications, and information contained herein

are the property of ANRITSU Company, and any unauthorized use or disclosure of these drawings,

specifications, and information is prohibited; they shall not be reproduced, copied, or used in whole

or in part as the basis for manufacture or sale of the equipment or software programs without the

prior written consent of ANRITSU Company.

-

Page 3

Table of Contents, Narrative

Chapter 1 — General Service Information

This chapter provides a general description of Series373XXA Vector Network Analyzer systems, sys

tem serial numbers, and frequency ranges. It explains the level of maintenance covered in this man

ual and the service strategy used throughout this manual. It also contains static-sensitive component

handling precautions and a list of recommended test equipment.

Chapter 2 — Replaceable Parts

This chapter lists all replaceable subassemblies and components for all373XXA models. It explains

the ANRITSUexchange assembly program and provides parts ordering information.

Chapter 3 — Operational Tests

This chapter contains procedures that provide a means of fully testing the373XXA VNA system for

proper operation and signal stability. These tests are intended to be used as a periodic check of the

operational functionality of the373XXA.

Chapter 4 — Performance Verification Procedures

This chapter provides detailed procedures for verifying that the performance of the373XXA meets

minimum performance standards.

Chapter 5 — Troubleshooting

This chapter provides information for troubleshooting Series373XXA Vector Network Analyzer systems. The troubleshooting procedures contained in this chapter support fault isolation down to a replaceable subassembly.

-

-

Chapter 6 — Adjustments

This chapter provides adjustment procedures for all models of Series373XXA Vector Network Ana

lyzer systems. These procedures are used after replacement or repair of one or more critical subas

semblies, or as indicated by the Performance Verification Procedures contained in Chapter 4.

Chapter 7 — System Description

This chapter provides descriptions of the functional operation of the major assemblies contained in

Series373XXA Vector Network Analyzer systems. The operation of all major circuit blocks is de

scribed so that the reader may better understand the function of each assembly as part of the overall

operation.

Chapter 8— Removal and Replacement Procedures

This chapter describes how to gain access to all of the major assemblies and major parts for ¬trouble

shooting and/or replacement.

Appendix A — Diagnostic Menus

This appendix contains descriptions and usage information for the Diagnostic Menus that are avail

able via the front panel Option Menu key.

Appendix B — Error Codes/Messages

This appendix contains a listing of the Error Codes/Messages. Also included is a description of the in

formation fields that are part of the error messages.

-

-

-

-

-

-

373XXA MM i

Page 4

Appendix C — Connector Maintenance Check Procedures

This appendix contains procedures and information needed to perform maintenance checks (includ

ing pin-depth measurements) for the connectors on all ANRITSU supplied Calibration/Verification

Kit components, Through-cables, and other associated RF/microwave components.

Appendix D — Performance Specifications

Appendix E — Verification Software Users Guide

This appendix contains the Model 360X/372XXB VNA Performance Verification Software Users

Guide, P/N: 10410-00208. This Software Users Guide explains in detail the procedures to be used for

the installation and operation of the 373XXA VNA Verification Software on your computer/controller.

Index

-

ii 373XXA MM

Page 5

Table of Contents, Detailed

Chapter 1 General Information

1-1 SCOPE OF MANUAL ·······················1-3

1-2 INTRODUCTION ·························1-3

1-3 IDENTIFICATION NUMBER ··················1-3

1-4 ONLINE MANUAL ························1-3

1-5 SYSTEM DESCRIPTION ·····················1-4

1-6 RELATED MANUALS·······················1-4

1-7 STANDARD OPTIONS ······················1-4

1-8 SERVICE STRATEGY·······················1-5

Functional Assembly Level Troubleshooting ···········1-5

Internal Hardware Adjustments and Calibrations········1-5

Internal Service Log ························1-5

System Test/Certification ·····················1-6

Preventive Service ·························1-6

Servicing Specially Modified Instruments ············1-6

1-9 SERVICE SUPPORT ·······················1-6

Technical Support ·························1-7

Field Service Kits ·························1-7

Service Software ··························1-7

Verification Kits ··························1-8

Test Fixtures/ Aids·························1-8

Failed Assembly Exchange Program ···············1-8

1-10 PERFORMANCE SPECIFICATIONS ··············1-9

1-11 SERVICE CENTERS ·······················1-9

1-12 STATIC SENSITIVE COMPONENT HANDLING

PROCEDURES ··························1-9

1-13 RECOMMENDED TEST EQUIPMENT ·············1-9

373XXA MM iii

Page 6

Chapter 2 Replaceable Parts

2-1 INTRODUCTION ·························2-3

2-2 EXCHANGE ASSEMBLY PROGRAM ··············2-3

2-3 REPLACEABLE SUBASSEMBLIES AND PARTS ·······2-3

2-4 PARTS ORDERING INFORMATION ··············2-4

Chapter 3 Operational Tests

3-1 INTRODUCTION ·························3-3

3-2 CHECKING THE SERVICE LOG ················3-4

3-3 SELF TEST ····························3-5

3-4 PERIPHERALS AND INTERFACES ··············3-6

LCDTest······························3-6

Front Panel Test ··························3-7

External Keyboard Interface Test·················3-7

Printer Interface Test ·······················3-7

GPIB Interface Test ························3-9

3-5 SIGNAL PATH ··························3-10

Chapter 4 Performance Verification

4-1 INTRODUCTION ·························4-3

4-2 CALIBRATION AND MEASUREMENT CONDITIONS ····4-3

Standard Conditions························4-3

Special Precautions: ························4-4

4-3 MEASUREMENT ACCURACY··················4-4

Verification Software ·······················4-4

Verification Result Determination ················4-5

4-4 VERIFICATION PROCEDURE ·················4-5

4-5 KEY SYSTEM PARAMETERS ·················4-6

Measurement Environment Considerations ···········4-6

Measurement Technique ·····················4-7

iv 373XXA MM

Page 7

Chapter 5 Troubleshooting

5-1 INTRODUCTION ·························5-3

5-2 ASSOCIATED INFORMATION IN THIS MANUAL ······5-3

5-3 RECOMMENDED TEST EQUIPMENT ·············5-4

5-4 SYSTEM DOES NOT POWER-UP ················5-4

Line Source and Interface Checks ················5-4

Power Supply Voltages Check ···················5-4

Power Supply Module Check ···················5-6

5-5 SYSTEM DOES NOT BOOT-UP ·················5-7

Boot-up Process Sequence·····················5-7

Troubleshooting Boot-up Problems ················5-8

Hard Disk Problem 1 ·······················5-8

Hard Disk Problem 2 ·······················5-9

Floppy Disk Problems ·······················5-9

Screen Display Problems·····················5-10

5-6 SYSTEM HAS ERROR CODE ·················5-10

Phase Lock Error Codes (6000 Series)··············5-11

Service Log Snap Shot Data ···················5-12

5-7 SOURCE/TEST SET/RECEIVER ················5-17

Signal Source Phase Lock Loop Assemblies···········5-17

Signal Source/Test Set Module Error Codes···········5-18

Isolation Procedures ·······················5-19

5-8 PERIPHERALS/ INTERFACE ·················5-21

CRT Display Test Failures: ···················5-21

Front Panel Test Failures: ····················5-22

External Keyboard Interface Test Failures:···········5-22

Printer Interface Test Failures: ·················5-22

GPIB Interface Test Failures: ··················5-22

5-9 MEASUREMENT IN QUESTION ···············5-22

Measurement Conditions Check List ··············5-23

Chapter 6 Adjustments

6-1 INTRODUCTION ·························6-3

6-2 LO1 CALIBRATION························6-3

Calibration Procedure ·······················6-3

Post Calibration Actions······················6-3

373XXA MM v

Page 8

6-3 LO 2 CALIBRATION ·······················6-4

Calibration Procedure ·······················6-4

Post Calibration Actions······················6-5

6-4 FREQUENCY CALIBRATION ··················6-5

Calibration Procedure ·······················6-6

Post Calibration Actions······················6-7

6-5 RF POWER/ALC CALIBRATION·················6-8

Calibration Procedure ·······················6-9

Post Calibration Actions ·····················6-10

6-6 SOURCE LOCK THRESHOLD ·················6-11

Calibration Procedure ······················6-12

Post Calibration Actions ·····················6-12

6-7 A8 ADJUSTMENT (37397A) ··················6-13

Calibration Procedure ······················6-13

Post Calibration Actions ·····················6-13

6-8 A21A2 ADJUSTMENT (37397A) ················6-14

Calibration Procedure ······················6-14

Post Calibration Actions ·····················6-15

Chapter 7 System Description

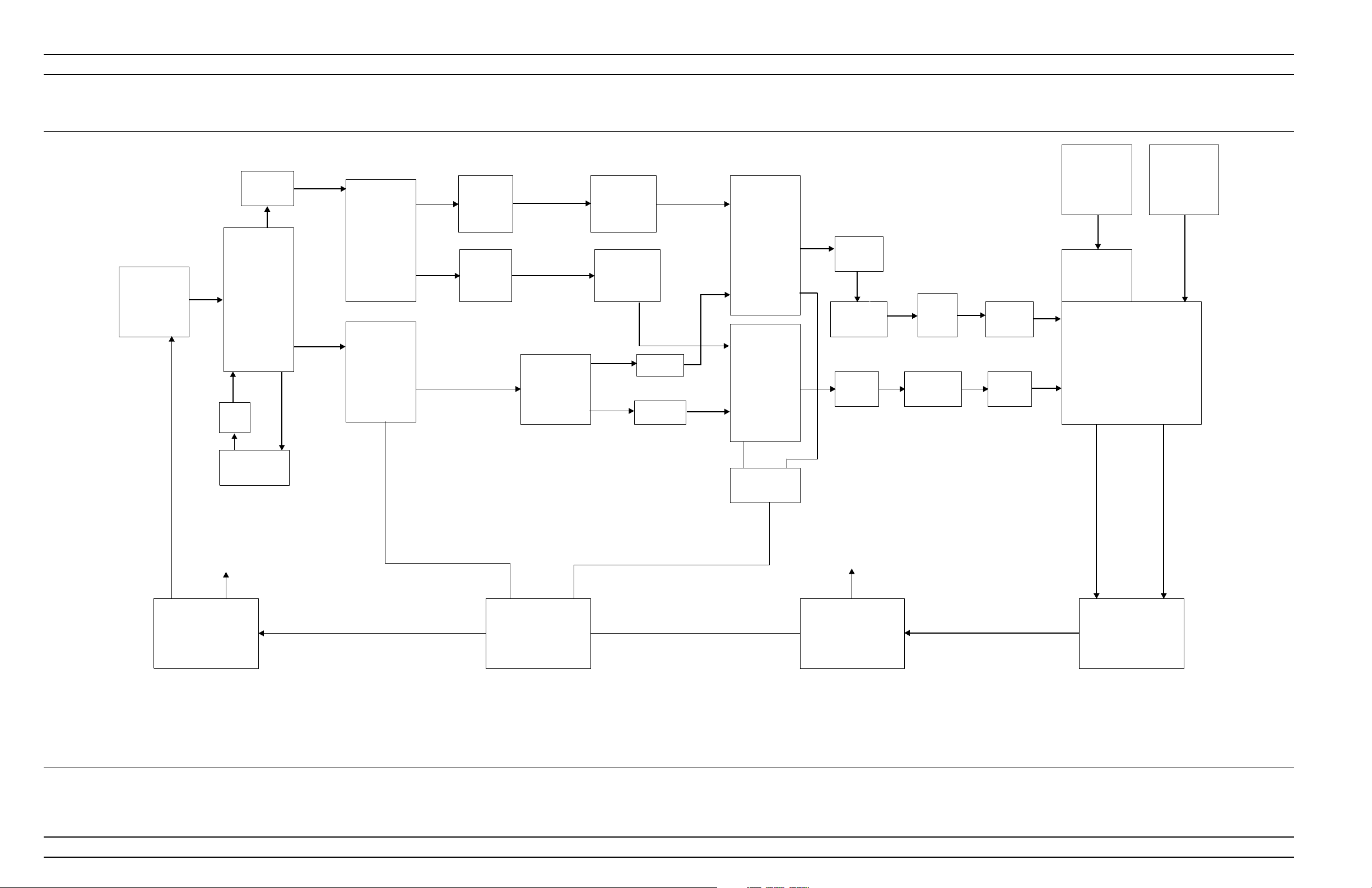

7-1 INTRODUCTION ·························7-3

7-2 SYSTEM OVERVIEW ·······················7-3

7-3 ANALOG SUBSYSTEM ASSEMBLIES ·············7-7

Signal Source Module ·······················7-7

Test Set Module ··························7-8

A7PCB, 10 MHz Timebase ···················7-9

Receiver Module ·························7-10

A8, Source Lock/ Signal Separation and Control PCB ·····7-11

IF Section ·····························7-11

A7PCB,LO3··························7-12

A5 A/D Converter PCB······················7-12

7-4 DIGITALSUBSYSTEM ASSEMBLIES·············7-13

A9 Main Processor PCB Assembly················7-13

A13 I/O Interface #1 PCB Assembly···············7-15

A14 I/O Interface #2 PCB Assembly···············7-15

A15 Graphics Processor PCB Assembly ·············7-16

A16 Hard Disk PCB Assembly··················7-16

Floppy Disk Drive Assembly···················7-16

A24 VME Bus Terminator PCB ·················7-16

vi 373XXA MM

Page 9

7-5 MAIN CHASSIS ASSEMBLIES·················7-16

A17 System Motherboard Assembly···············7-16

Front Panel Assembly ······················7-16

Rear Panel Assembly·······················7-17

A18 Rear Panel Interface PCB··················7-17

Power Supply Module ······················7-18

Internal VGA Monitor ······················7-19

Chapter 8 Remove and Replace Procedures

8-1 INTRODUCTION ·························8-3

8-2 EQUIPMENT REQUIRED ····················8-3

8-3 COVERS ······························8-4

8-4 A1–A9 AND A13–A16 PCBS ···················8-6

A1 – A9 PCBs ···························8-6

A13 – A16 PCB’s ··························8-6

8-5 A9 PCB BBRAM CHIP······················8-6

8-6 A9 PCB SRAM BATTERY····················8-10

8-7 A24 VME BUS TERMINATOR PCB ··············8-12

8-8 FRONT PANEL ASSEMBLY ··················8-12

8-9 VGA DISPLAY MONITOR ····················8-14

8-10 LIQUID CRYSTAL DISPLAY (LCD) ··············8-16

8-11 FLOPPY DISK DRIVE······················8-17

8-12 REAR PANEL ASSEMBLY ···················8-19

8-13 FAN ASSEMBLY ·························8-21

8-14 POWER SUPPLY MODULE···················8-21

8-15 A18 REAR PANEL PCB ·····················8-22

8-16 TEST SET MODULE ASSEMBLIES ··············8-25

Transfer Switch··························8-25

Input Coupler(s)/ Low Freq Bridge(s) ··············8-26

Power Amplifier ·························8-26

Buffer Amplifier/ Sampler(A31) ·················8-27

Switched Doubler Module Assembly···············8-28

373XXA MM vii

Page 10

8-17 SIGNAL SOURCE MODULES ·················8-29

Removal of Signal Source Module ················8-29

A21A2 Source Control PCB ···················8-31

A21A1 Source YIG Bias Control PCB ··············8-32

Switched Filter Assembly ····················8-33

Down Converter Assembly····················8-33

YIG Oscillator Assembly ·····················8-34

Appendix A Diagnostics Menus

A-1 INTRODUCTION ·························A-3

A-2 DIAGNOSTICS MENUS ·····················A-3

Start Self Test ···························A-3

Read Service Log ·························A-3

Installed Options ·························A-4

Peripheral Tests ··························A-4

Troubleshooting ··························A-4

H/W Calibrations ·························A-5

Appendix B Error Messages

B-1 INTRODUCTION ·························B-3

B-2 OPERATIONALERROR MESSAGES ··············B-3

B-3 DISK RELATED ERROR MESSAGES··············B-3

B-4 GPIB RELATED ERROR MESSAGES··············B-3

B-5 SERVICE LOG ERROR MESSAGES ··············B-3

0000 - 0099 ····························B-3

0100 - 3999 ····························B-3

4000 - 4999 ····························B-4

5000 - 5999 ····························B-4

6000 - 6999 ····························B-4

7000 - 7999 ····························B-4

8000 - 8999 ····························B-4

viii 373XXA MM

Page 11

Appendix C Connector Maintenance Check Procedures

C-1 INTRODUCTION ·························C-3

C-2 PRECAUTIONS ·························C-3

Pin Depth Problems ························C-3

Pin-Depth Tolerance························C-4

Avoid Over Torquing Connectors ·················C-4

Teflon Tuning Washers ······················C-4

Avoid Mechanical Shock ·····················C-4

Keep Connectors Clean ······················C-4

Visual Inspection ·························C-5

C-3 REPAIR/ MAINTENANCE···················C-5

Appendix D Performance Specifications

Appendix D Performance Specifications

Appendix E Performance Verification Software User’s Guide

Subject Index

373XXA MM ix/x

Page 12

Page 13

Chapter 1 General Information

Table of Contents

1-1 SCOPE OF MANUAL ·······················1-3

1-2 INTRODUCTION ·························1-3

1-3 IDENTIFICATION NUMBER ··················1-3

1-4 ONLINE MANUAL ························1-3

1-5 SYSTEM DESCRIPTION ·····················1-4

1-6 RELATED MANUALS·······················1-4

1-7 STANDARD OPTIONS ······················1-4

1-8 SERVICE STRATEGY·······················1-5

Functional Assembly Level Troubleshooting ···········1-5

Internal Hardware Adjustments and Calibrations········1-5

Internal Service Log ························1-5

System Test/Certification ·····················1-6

Preventive Service ·························1-6

Servicing Specially Modified Instruments ············1-6

1-9 SERVICE SUPPORT ·······················1-6

Technical Support ·························1-7

Field Service Kits ·························1-7

Service Software ··························1-7

Verification Kits ··························1-8

Test Fixtures/ Aids·························1-8

Failed Assembly Exchange Program ···············1-8

1-10 PERFORMANCE SPECIFICATIONS ··············1-9

1-11 SERVICE CENTERS ·······················1-9

1-12 STATIC SENSITIVE COMPONENT HANDLING

PROCEDURES ··························1-9

1-13 RECOMMENDED TEST EQUIPMENT ·············1-9

Page 14

Figure 1-1. Series 373XXA Vector Network Analyzer System

Page 15

Chapter 1

General Information

1-1 SCOPE OF MANUAL This manual provides general service and preventive maintenance in

formation for the ANRITSU 373XXA family of Vector Network

Analyzer (VNA) systems. It contains procedures for:

Testing the instrument for proper operation.

q

Verifying measurement accuracy and traceability to National In

q

stitute of Standards and Technology (NIST).

Troubleshooting a failed instrument to the exchange subassem

q

bly level or the subsystem requiring adjustment.

Adjusting instrument internal sub-systems.

q

Locating and replacing failed parts.

q

Throughout this manual, the terms “373XXA” and “373XXA VNA”

will be used interchangeably to refer to all Series 37300A Network

Analyzer system models, unless otherwise noted.

1-2 INTRODUCTION This chapter of the manual provides a general description of 373XXA

VNAsystems, system serial numbers, frequency ranges, and related

manuals. Also included is information about the level of maintenance cov

ered in this manual, service strategy,available service facilities, and

static-sensitive component handling precautions. Alist of recommended

test equipment is also provided.

-

-

-

-

1-3 IDENTIFICATION

NUMBER

All ANRITSU instruments are assigned a six-digit ID number, such as

“401001”. This number appears on a decal affixed to the rear panel.

Please use this identification number during any correspondence with

ANRITSU Customer Service about this instrument.

1-4 ONLINE MANUAL This manual is available on CD ROM as an Adobe Acrobat™ (*.pdf)

file. The file can be viewed using Acrobat Reader™, a free program

that is also available on the CD ROM. This file is “linked” such that

the viewer can choose a topic to view from the displayed “bookmark”

list and “jump” to the manual page on which the topic resides. The

text can also be word-searched. Contact ANRITSU Customer Service

for price and availability.

373XXA MM 1-3

Page 16

SYSTEM DESCRIPTION GENERAL INFORMATION

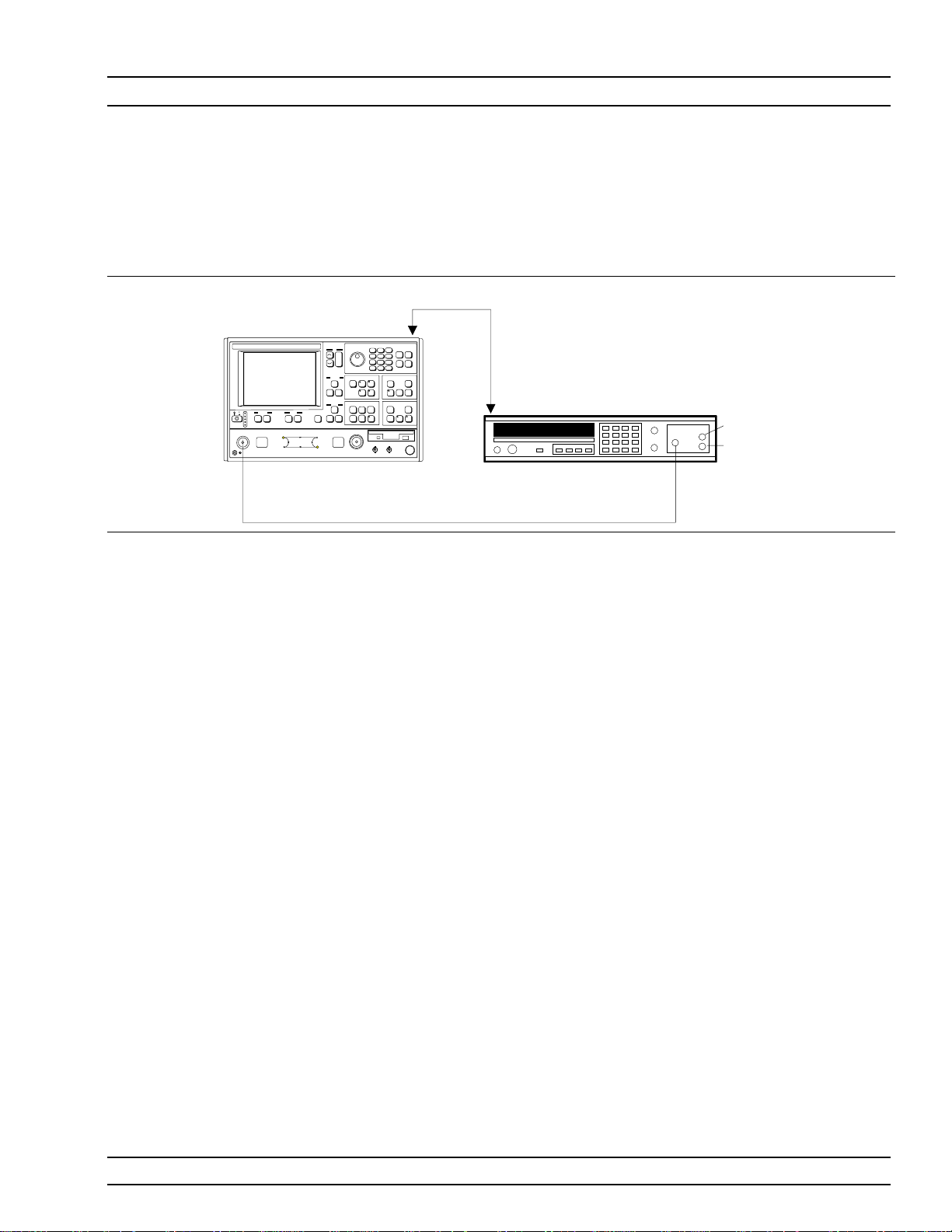

1-5 SYSTEM DESCRIPTION The 373XXA Analyzers are microprocessor controlled Vector Network

373XXA Model Frequencies

Model Freq Range

37317A 22.5 MHz to 8.6 GHz

37325A 40.0 MHz to 13.5 GHz

37347A 40.0 MHz to 20.0 GHz

37369A 40.0 MHz to 40.0 GHz

37397A 40.0 MHz to 65.0 GHz

Analyzers. Each is a single-instrument system that contains a built-in

signal source, a test set, and an analyzer subsystem. A typical model

(37369A) is shown in Figure 1-1. These analyzers are produced in five

models that cover a range of from 22.5 MHz to 65 GHz. The table at left

lists the frequencies for each model.

1-6 RELATED MANUALS The 373XXA Vector Network Analyzer Operation Manual (10410-00183)

describes the front panel operation for all 373XXAmodels. It also con

tains general information, specifications, and Performance V erification

procedures for all models.

-

The 37XXX Series Vector Network Analyzer Programming Manual

(10410-00200) describes all 373XXAGPIB commands and provides

programming information for operation of the 373XXA remotely via

the IEEE-488 General Purpose Interface Bus. Included at the rear of

this manual is the 37XXX Series Vector Network Analyzer GPIB

Quick Reference Guide (10410-00201).

Model 360X/373XXA VNA Performance Verification Software Users

Guide, P/N: 10410-00208 (located in Appendix E at the rear of this

manual). This Software Users Guide explains in detail the procedures

to be used for the installation and operation of the 373XXA VNA Veri

fication Software on your computer/controller.

-

1-7 STANDARD OPTIONS The standard 373XXA VNA options and their respective Upgrade Kit part

numbers are:

Option* Description Upgrade Kit

Opt 1 Rack Mount with slides ND39486

Opt 1A Rack Mount ND40916

Opt 2A Time Domain (Microwave

Units)

Opt 2B Time Domain (RF Units) ND40914

Opt 10A High Stability Ovenized Time

Base

ND39477

ND45045

∗ All options listed can be installed at ANRITSU Service Centers

1-4 373XXA MM

Page 17

GENERAL INFORMATION SERVICE STRATEGY

1-8 SERVICE STRATEGY This paragraph provides an overview of the 373XXAVNAservice strat

egy and available service facilities. It also provides references to the infor

mation in various locations in this manual needed to accomplish the serv

ice functions required for the 373XXA VNA.

Appendices - Refer to the Appendices at the rear of this manual for de

tailed descriptions of the following:

Diagnostics Menus and GPIB Commands.

q

Error Messages.

q

System Block Diagrams.

q

Parts Locator Diagrams.

q

Functional Assembly

Level Troubleshooting

The 373XXA modular design, extensive built-in diagnostics, and auto

mated service tools are designed to support fast exchange of functional as

sembly level repairs.

Failed assemblies are not field repairable. Once an assembly is found

to be faulty, it should be returned to an authorized ANRITSU Service

Center for exchange. Refer to the description of the Exchange Assembly Program in Chapter 2, Replaceable Parts.

The procedures for troubleshooting a failed 373XXA VNA are described in this manual in Chapter 5, Troubleshooting.

-

-

-

-

-

-

Internal Hardware

Adjustments and

Calibrations

Internal Service Log The 373XXA continuously monitors itself for proper operation. Should a

There are five automated internal hardware field calibrations. Two of

them are used to characterize the 373XXA frequency and power genera

tion sub-systems. These calibrations insure fast, consistent phase lock of

system frequencies and proper compensation, leveling, and flatness of

system power at the front panel test ports.

To conduct these calibrations, you need only connect the appropriate

test equipment (counter or power meter) to the 373XXA and initiate

the calibration. The 373XXAwill control itself and the externally con

nected test equipment to perform measurements and store calibration

constants in its internal battery backed RAM (BBRAM).

The procedures for adjusting the 373XXA VNA are described in this

manual in Chapter 6, Adjustments.

failure occur, it notifies the user via a failure message on the display

screen. (In remote-only operation, it also sets the GPIB Status Byte, if

enabled.) It also writes the error message along with some data pertinent

to the failure to an internal service log stored in battery backed memory .

The service log can be checked at any time to view (without erasing)

all error messages that were written into it. It is capable of storing

-

-

373XXA MM 1-5

Page 18

SERVICE SUPPORT GENERAL INFORMATION

more than 30 pages of service messages and data. The 373XXA will

automatically remove the oldest errors first to make room for new er

rors, if necessary. To check the contents of the service log, use the pro

cedure described in Chapter 3, Operational Tests.

NOTE

A printed or disk file copy of the Service Log (with the fail

ure in question) must be made available to ANRITSU

when exchanging a failed assembly, or when requesting

service support. Refer to Chapter 2, Replaceable Parts, for

further information.

-

-

-

System

Test/Certification

Preventive Service The 373XXA A9 Processor PCB contains a battery backed memory/real

Quick operational checkout of the system may be accomplished by the

system user or for incoming inspection purposes using the “Operational

Checkout” chapter in the 373XXAOperations Manual. Those procedures

are useful in quickly verifying that the instrument’s primary measure

ment functions are operational and stable.

Full operational testing of the system is detailed in Chapter 3, Operational Tests. These tests should be performed annually, or more often

depending on system use.

Verification of the system’s measurement accuracy and other key performance parameters may be done using the procedures in Chapter 4,

Performance Verification. This should be performed annually, or more

often depending on system use.

time clock chip (BBRAM) and a static memory (SRAM) backup battery.

These have a finite life span and should be replaced periodically per the

procedures in Chapter 8, Removal and Replacement Procedures.

The BBRAM chip has a rated life span of 4 years. The SRAM backup

battery has a worst case elapsed time for SRAM battery protection of

200 days. The SRAM battery life span will vary according to how the

system is used; that is, how often the system is powered off for ex

tended periods of time.

-

-

Servicing Specially

Modified Instruments

Instruments with customer requested special modifications performed by

ANRITSU will have an identifying Specials Modification number printed

on the rear panel. This number will be preceded with the letters SM, i.e.,

SM1234 is special modification number 1234.

Special instruments may have service requirements different from

those specified in this manual. Contact your local Service Center if you

need more information when servicing such instruments.

1-9 SERVICE SUPPORT The following paragraphs briefly describe the various service support

services and aids available to you to help you maintain your 373XXA.

1-6 373XXA MM

Page 19

GENERAL INFORMATION SERVICE SUPPORT

Technical Support Technical service support is available by contacting any ANRITSU

WorldwideService Center (refer to paragraph 1-11). Or, service support

may be obtained directly from the factory by contacting:

ANRITSU Company

ATTN: Customer Service

490 Jarvis Drive

Morgan Hill, CA95037-2809

Telephone: (408)-778-2000

FAX: (408)-778-0239

If servicing or repairing your own system and you need technical sup

port, you will need to FAX or mail a printout of the items listed below

to the ANRITSU Customer Support Engineer:

Measurement data in question

q

“Operational Tests” results

q

System state (from UTILITY menu)

q

Service Log (from DIAGNOSTICS menu)

q

Field Service Kits The field service kit listed below is available through your local ANRITSU

Sales or Service Center:

ND37200A-2, Field Service Kit

This kit provides for automated field test and performance verification

of the 373XXA. It is packaged in a hardened rolling case that also has

space for two, user supplied, verification and calibration kits and other

accessories.

The ND37200A-2, Field Service Kit is comprised of all major subas

-

semblies of all models 40 Ghz and below high-end frequency.

ND53269, Field Service Kit

This kit provides for automated field test and performance verification

of the 373XXA50 and 65 GHz models (37397A). It supplements kit

ND37200A-2.

Service Software The service software listed below is contained on the diskette located at

the rear of this manual:

ANRITSU 37XXX Test Software (2300-178).

This software contains a series of automated tests designed to insure

the 373XXA signal paths are functioning properly and capable of sup

porting stable calibrations and measurements. See Operational Tests

Chapter for details.

ANRITSU 37XXX Performance Verification Software (2300-237).

This software is used to verify the 373XXA published measurement ac

curacy and traceability to the U.S. National Institute of Standards and

Technology (NIST). See Chapter 4, Performance Verification, for de

-

tails.

373XXA MM 1-7

-

Page 20

SERVICE SUPPORT GENERAL INFORMATION

Verification Kits The ANRITSU V erificationKits listed below are used in conjunction with

the 37XXX Performance V erificationSoftware (above). See Chapter 4, Per

formance Verification, for further information.

N Verification Kit (Model 3663)

Contains precision N Connector components with characteristics that

are traceable to the NIST.

Use for Models 37317Aand below with Option 7N and 7 NF.

3.5 mm Verification Kit (Model 3666)

Contains precision 3.5 mm Connector components with characteristics

that are traceable to the NIST.

Use for Models 37347Aand below with Option 7A.

GPC-7 Verification Kit (Model 3667)

Contains precision GPC-7 Connector components with characteristics

that are traceable to the NIST.

Use for Models 37317Aand below with Option 7A.

K Verification Kit (Model 3668)

Contains precision K Connector components that are traceable to the

NIST.

-

V Verification Kit (Model 3669B)

Contains precision V Connector components that are traceable to the

NIST.

Test Fixtures/ Aids The test fixtures and test aids listed below are available through your lo-

cal ANRITSU Sales or Service Center:

Rear Panel Printer Port Test Fixture (B39553).

This test fixture is used to check out digital printer interface circuits

on the rear panel assembly.

GPIB Cable (2100-2).

This cable is used to check out digital GPIB interface circuits on the

rear panel assembly.

Failed Assembly

Exchange Program

The exchange program allows a customer to quickly exchange a failed

subassembly for a factory refurbished, fully system-tested and unit that is

under warranty.This results in significant time and price savings as com

pared with ordering a new assembly.

Refer to Chapter 2, Replaceable Parts, for a complete list of exchange

able assemblies for all Series 373XXA models.

NOTE

When sending a failed assembly to the factory for ex

change, a copy of the Service Log must always accom

pany the failed assembly. Refer to Chapter 2, Replaceable

Parts, for further information.

-

-

-

-

1-8 373XXA MM

Page 21

GENERAL INFORMATION PERFORMANCE SPECIFICATIONS

1-10 PERFORMANCE

SPECIFICATIONS

The performance specifications for all Series 373XXA models are con

tained in the Technical Data Sheets that are located in Appendix D,

Performance Specifications.

-

1-11 SERVICE CENTERS ANRITSU Company offers a full range of repair and calibration services

at fully staffed and equipped service centers throughout the world. Table

2-1, located on page 2-4, lists all ANRITSU services centers.

1-12 STATIC SENSITIVE

COMPONENT

HANDLING

PROCEDURES

1-13 RECOMMENDED TEST

EQUIPMENT

The 373XXA contains components that can be damaged by static electric

ity. Figure 1-2 illustrates the precautions that should be followed when

handling static-sensitive subassemblies and components. If followed,

these precautions will minimize the possibilities of static-shock damage to

these items.

Table1-1 lists the recommended test equipment to be used for all mainte

nance activities for all Series 373XXA models. Note the “Use” codes

listed in the right hand column of the table. These codes list the applicable maintenance activities for the equipment listed.

-

-

373XXA MM 1-9

Page 22

RECOMMENDED TEST EQUIPMENT GENERAL INFORMATION

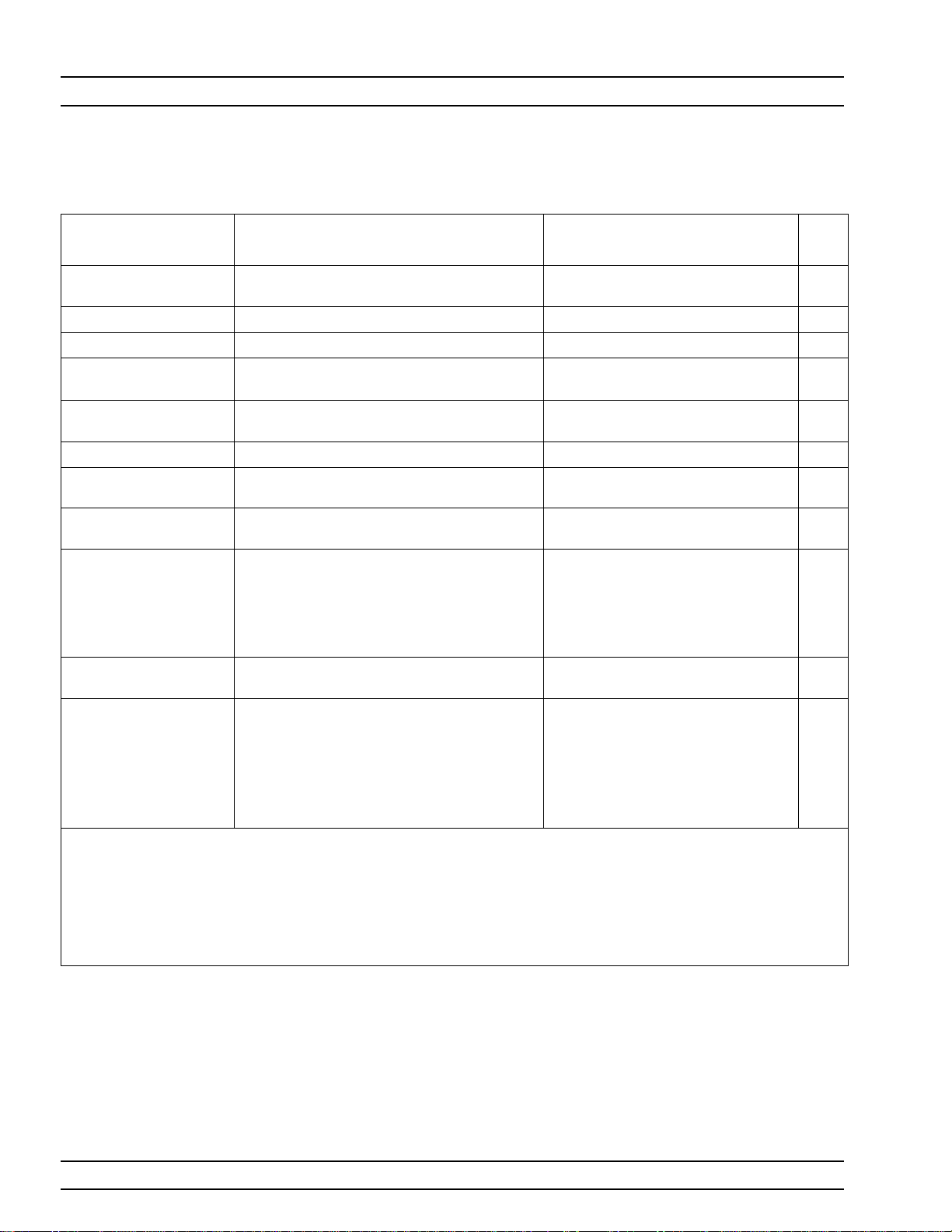

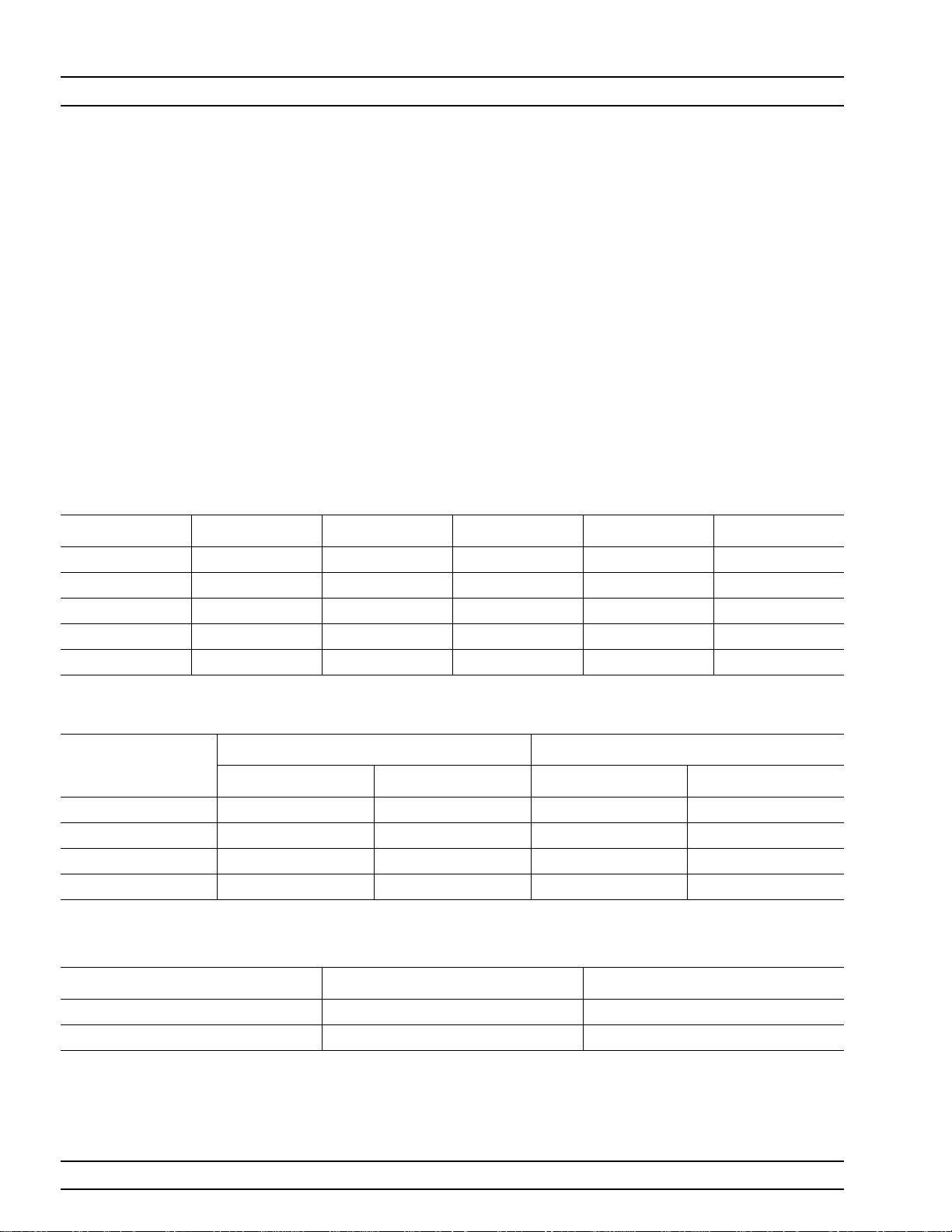

Table 1-1. Recommended Test Equipment (1 of 2)

INSTRUMENT

Computer/Controller PC with Windows 95 or later and National In

struments GPIB hardware and software.

Test Software ANRITSU 2300-178

Floppy Disk Formatted, IBM PC format DS/HD 1.44 Mbyte

GPIB Cable ANRITSU 2100-2, or equivalent

RF/Microwave Cable DC – 40 GHz, K type connectors (male

or female), Length, 3 ft.

BNC Cable Length, 4 ft., 2 each Any

Printer Port Test

Fixture

Thru Line For models 37317A and below

For models 37325A and above:

Calibration Kit For models 37317A and below, with Opt 7A:

For models 37317A and below, with Opt 7N or

7NF:

For models 37325A and above:

For models 37325A and below, with Opt 7S:

For model 37397A

Performance Verification Software

Connector Verification

Kit

For models 37217B and below w/Opt 7A:

For models 37217B and below, with Opt 7N or

7NF:

For models 37225B and above:

For models 37247B and below, with Opt 7S:

For model 37397A

CRITICAL

SPECIFICATION

Any

-

Any

ANRITSU B39553

ANRITSU 3670A50-2, 3671A50-2

ANRITSU 3670K50-2, 3671K50-2

ANRITSU 3651-1*

ANRITSU 3653

ANRITSU 3652-1*

ANRITSU 3650-1*

ANRITSU 3654B

ANRITSU 2300-237

ANRITSU 3667

ANRITSU 3663

ANRITSU 3668

ANRITSU 3666

ANRITSU 3669B

RECOMMENDED

MANUFACTURER/MODEL

USE*

*

O, P

O

A

O, P,

A

P, A

O

O

O, P

O, P

P

P

∗ Calibration Kit sliding load (Option {-1}), required for Performance Verification only.

∗∗ USE CODES:

A Adjustment / Internal Hardware Calibration

O Operational Testing

P Performance Verification

T Troubleshooting

1-10 373XXA MM

Page 23

GENERAL INFORMATION RECOMMENDED TEST EQUIPMENT

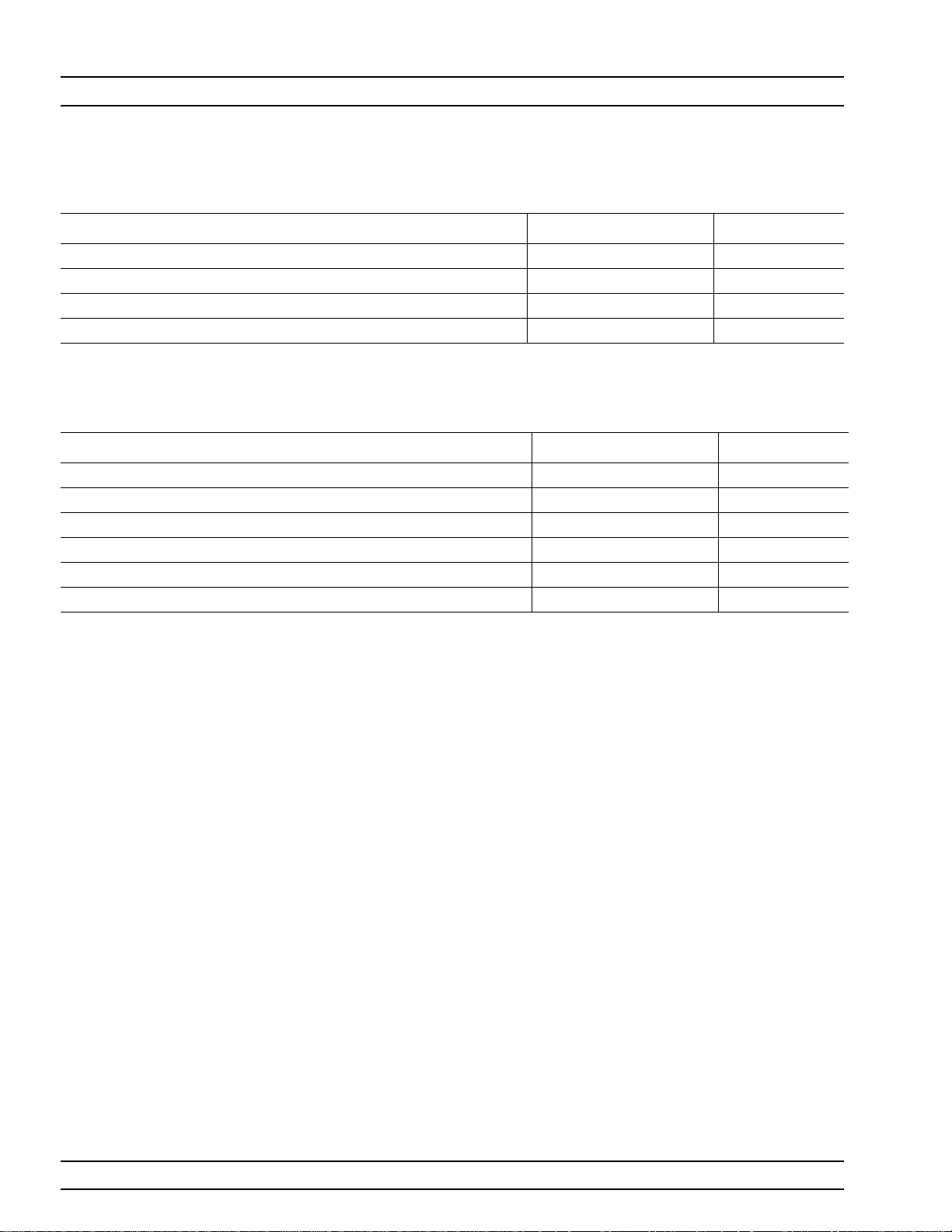

Table 1-1. Recommended Test Equipment (2 of 2)

INSTRUMENT

Assurance Air Line For models 37317A and below w/Opt 7A:

For models 37317A and below w/Opt 7N:

For models 37317A and below w/Opt 7NF:

For models 37317A and above:

For models 37317A and below w/Opt 7S:

Offset Termination For models 37317A and below w/Opt 7A, 7N,

7NF:

All other models

Frequency Counter Frequency: 0.1 to 26.5 GHz

Input Impedance:50Ω

Digital Multimeter Resolution: 4

DC Accuracy: 0.1 %

AC Accuracy: 0.1 %

Oscilloscope Bandwidth: DC to 100 MHz

Sensitivity: 2mV

Horiz. Sensitivity: 50 ns/division

Power Meter 1, with: Power Range: –30 to +20 dBm

Other: GPIB controllable

Power Sensor 1

or:

Power Meter 2, with:

Power Sensor 2

Power Meter and Power

Sensor

Gauging Set GPC-7 Gauging Set

Frequency Range: 0.05 to 50 GHz

Power Range: –70 to +47 dBm

Other: GPIB controllable

Frequency Range: 0.01 to 40 GHz

Frequency Range: to 65 GHz Anritsu Model ML24xxA Power Meter

K Connector Gauging Set

CRITICAL

SPECIFICATION

1

digits

2

(1 mW to 100 mW)

(100 pW to 50 W)

RECOMMENDED

MANUFACTURER/MODEL

ANRITSU 18A50

ANRITSU 18NF50

ANRITSU 18N50

ANRITSU T1519

ANRITSU T1147-2

ANRITSU 29A50-20

ANRITSU 29KF50-15

EIP Microwave, Inc., Model 578B

Any

Tektronix, Inc.

Model 2445

HP 437B with Option 22 (GPIB)

HP 8487A

Gigatronics 8541 or 8542

Gigatronics 80304A

and MA2474A (40 GHz and below)

and Model SC6230 (to 65 GHz)

Power Sensors

ANRITSU 01-161

ANRITSU 01-162

USE*

*

P

P

P, A

T

T

P, A

P, A

P, A

O, T

∗∗ USE CODES:

A Adjustment / Internal Hardware Calibration

O Operational Testing

P Performance Verification

T Troubleshooting

373XXA MM 1-11

Page 24

STATIC HANDLING GENERAL INFORMATION

Do not touch exposed contacts on

1.

any static sensitive component.

Wear a static-discharge wristband

4.

when working with static sensitive

components.

Do not slide static sensitive compo

2.

nent across any surface.

Label all static sensitive devices.

5.

Do not handle static sensitive com

-

3.

ponents in areas where the floor or

work surface covering is capable of

generating a static charge.

Keep component leads shorted to-

6.

gether whenever possible.

-

Handle PCBs only by their edges.

7.

Do not handle by the edge connec

tors.

-

Lift & handle solid state devices by

8.

their bodies – never by their leads.

Transport and store PCBs and

9.

other static sensitive devices in

static-shielded containers.

10. ADDITIONAL PRECAUTIONS:

•

Keep workspaces clean and free of any objects capable of holding or storing a static charge.

•

Connect soldering tools to an earth ground.

•

Use only special anti-static suction or wick-type desoldering tools.

Figure 1-2. Static Sensitive Component Handling Procedures

1-12 373XXA MM

Page 25

Chapter 2 Replaceable Parts

Table of Contents

2-1 INTRODUCTION ·························2-3

2-2 EXCHANGE ASSEMBLY PROGRAM ··············2-3

2-3 REPLACEABLE SUBASSEMBLIES AND PARTS ·······2-3

2-4 PARTS ORDERING INFORMATION ··············2-4

Page 26

Page 27

Chapter 2

Replaceable Parts

2-1 INTRODUCTION This chapter provides replaceable parts information for all 373XXA

models. The major replaceable 373XXA assemblies and parts are listed

in Tables2-2 through 2-8. The locations of these assemblies/parts are

shown in Figures 2-1 through 2-4.

2-2 EXCHANGE ASSEMBLY

PROGRAM

ANRITSU maintains a module exchange program for selected subassem

blies. If a malfunction occurs in one of these subassemblies, the defective

item can be exchanged. Upon receiving your request, ANRITSU will ship

the exchange subassembly to you, typically within 24 hours. Y outhen

have 45 days in which to return the defective item. All exchange subas

semblies or RF assemblies are warranted for 90 days from the date of

shipment, or for the balance of the original equipment warranty ,whichever is longer.

NOTE

When sending a failed assembly to the factory for exchange, a copy of the Service Log must always accompany the failed assembly. This copy may be a printout, or a

saved disk copy. Due to the importance of the service log

information to the ANRITSU factory Service Engineers,

the exchange prices are only valid if the service log data is

included with the failed assembly.

Please have the exact model number and serial number of your unit

available when requesting this service, as the information about your

unit is filed according to the instrument’s model and serial number.

For more information about the program, contact your local sales rep

resentative or call ANRITSU Customer Service direct (refer to para

graph 2-4.

-

-

-

-

2-3 REPLACEABLE

SUBASSEMBLIES AND

PARTS

Tables2-2 through 2-5, (starting page 2-5) list the major replaceable sub

assemblies and parts for the 373XXA. These assemblies/parts are pres

ently covered by the ANRITSU exchange assembly program. Table 2-6

(page 2-6) lists disposable parts for the 373XXA, and Table 2-7 and 2-8

lists factory-repairable parts for the 373XXA. (The parts listed in Tables

2-6 through 2-8 are not presently on the exchange assembly program.)

NOTE

The 373XXA A17 Motherboard PCB Assembly is not a

field-replaceable item.

-

-

373XXA MM 2-3

Page 28

PARTS ORDERING INFORMATION REPLACEABLE PARTS

2-4 PARTS ORDERING

INFORMATION

Table 2-1. ANRITSU Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 778-2000

FAX: (408) 778-0239

ANRITSU ANRITSU COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

FAX: (408) 776-1744

ANRITSU ANRITSU COMPANY

10 Kingsbridge Road

Fairfield, NJ 07004

Telephone: (201) 227-8999

FAX: (201) 575-0092

AUSTRALIA

ANRITSU PTY. LTD.

Level 2, 410 Church Street

North Parramatta

NSW 2151 Australia

Telephone: 026-30-81-66

Fax: 026-83-68-84

BRAZIL

ANRITSU ANRITSU ELECTRONICA

LTDA.

Praia de Botafogo, 440-SL 2401-Botafogo

2225-Rio de Janeiro-RJ-Brasil

Telephone: 021-28-69-141

Fax: 021-53-71-456

CANADA

ANRITSU ANRITSU INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 828-4090

FAX: (613) 828-5400

CHINA

ANRITSU BEIJING SERVICE

CENTER

All parts listed in T ables2-2 through 2- 8 may be ordered from your local

ANRITSU service center (Table2-1). Or ,they may be ordered directly

from the factory at the following address:

ANRITSU Company

ATTN: Customer Service

490 Jarvis Drive

Morgan Hill, CA95037-2809

Telephone: (408)-778-2000

FAX: (408)-778-0239

416W Beijing Fortune Building

5 Dong San Huan Bei Lu

Chao Yang Qu, Beijing 100004, China

Telephone: 86-1-50-17-559

FAX: 86-1-50-17-558

FRANCE

ANRITSU ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-44-66-546

FAX: 016-44-61-065

GERMANY

ANRITSU ANRITSU GmbH

Rudolf Diesel Strabe 17

8031 Gilching

Telephone: 08-10-58-055

FAX: 08-10-51-700

INDIA

MEERA AGENCIES (P) LTD.

A-23 Hauz Khas

New Delhi 110 016

Telephone: 011-685-3959

FAX: 011-686-6720

ISRAEL

TECH-CENT, LTD

Haarad St. No. 7, Ramat Haahayal

Tel-Aviv 69701

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-22-666

FAX: (06) 50-22-4252

JAPAN

ANRITSU CORPORATION

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-23-1111

FAX: 0462-25-8379

KOREA

ANRITSU CORPORATION

#2103 Korea World Trade Center

159-1 Samsung-Dong

Kangnam-ku, Seoul

Telephone: (02) 551-2250

FAX: (02) 551-4941

SINGAPORE

ANRITSU ANRITSU (SINGAPORE) PTE

LTD

3 Shenton Way #24-03

Shenton House

Singapore 0106

Telephone: 011-65-2265206

FAX: 011-65-2265207

SWEDEN

ANRITSU ANRITSU AB

Box 247

S-127 25 Skarholmen

Telephone: (08) 74-05-840

FAX: (08) 71-09-960

TAIWAN

ANRITSU CO., LTD.

8F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Telephone: (02) 515-6050

FAX: (02) 509-5519

UNITED KINGDOM

ANRITSU ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 05-82-41-88-53

FAX: 05-82-31-303

2-4 373XXA MM

Page 29

REPLACEABLE PARTS PARTS ORDERING INFORMATION

Table 2-2. Printed Circuit Board Assemblies

Reference

Designator

A1

A1

A2

A3

A4

A4

A5

A6

A7

A7

A8

A8

A9

A13

A14

A15

A16

A18

A19**

A20**

A21A1

A21A1

A21A2

A21A2

A24

373XXA

Option

LO1

LO1

LO2

Test A IF

Reference IF

Reference IF

A/D

TestBIF

LO3

Opt 10 LO3

Source Lock/ Separation Control

Source Lock/ Separation Control

Main Processor

I/O #1

I/O #2

Graphics Processor

Hard Disk (w/ PCB)

Rear Panel PCB

Front Panel Switch PCB See Table 2-5

Front Panel Control PCB

Source YIG/Bias Control (p/o Signal Source Module)

Source YIG/Bias Control (p/o Signal Source Module)

Source Control (p/o Signal Source Module)

Source Control (p/o Signal Source Module)

VME Bus Terminator

Assembly / Part Part Number

D46866-3

D86866-4*

D50725-3

D38503-4

D41794-3

D41794-4*

D38505-3

D38503-5

D38507-3

D38507-4

D47488-3

D49334-3*

B38509

D38513-3

D38514-3

D44281-3

D41041-3

D44255-3

D48516-3

D48512-3*

D41841-3

D48513-3*

D38524-3

∗ Required for 37397A

∗∗ Part of the Front Panel Assembly (refer to Table 2-5).

373XXA MM 2-5

Page 30

PARTS ORDERING INFORMATION REPLACEABLE PARTS

Table 2-3. Test Set Assembly RF/Microwave Components, 37317A, 37325A, 37347A, 37369A

Assembly / Part 373XXA Model / Option Part Number

Transfer Switch

Step Attenuator, 70 dB

Low Frequency Bridge w/ Bias Tee 37311A,37317A D28985

Coupler w/ Bias Tee 37325A and higher D28967

40 GHz Quad Buffer Amp/Power Amplifier

Switched Doubler Module (SDM)

Port 2 Step Attenuator

6dBPad

20 dB Pad

20 GHz Quad Buffer Amp/Power Amplifier

* Used on serial numbers 975004, 975101, 975103, 980102, 980104, 980201, 980302, 980402, 980403, 980405,

980406, 980407, 980602, 980603, 980701, and above.

Table 2-4. Test Set Assembly RF/Microwave Components, 37397A

Assembly / Part Part Number

Pinswitch 29855

Switched Doubler Module (SDM) 47520

Quadrupler (SQM) 48998

37GHz High Pass Filter 49247

Mux Coupler (Port 1) 49470

Mux Coupler (Port 2) 49480

Shaped Pad 52956

Bias Tee 53409

16.8 GHz Lowpass Filter B28912

Access Loops (Front and Rear Panel) B35569-195

Transfer Switch D27030

3 dB Fixed Attenuator ND26178

Step Attenuator ND52564

Coupler ND52929

Quad Buffer Amplifier/Power Amplifier ND53249

37347A and below

All except 37369A

All

All

37369A only

37369A only

All

37369A only

D28580-1

46535*

4612K

ND47533

D28685

4612K

43KC-10

43KC-20

ND47532

2-6 373XXA MM

Page 31

REPLACEABLE PARTS PARTS ORDERING INFORMATION

Table 2-5. Miscellaneous /Integrated Assemblies

Assembly / Part 373XXA Model / Option Part Number

10 MHz Ovenized Oscillator

Power Supply Module

VGA Monitor

Floppy Disk Assy

Front Panel Assy (w/ Front Panel, A19 and A20 PCB’s, and all Model

ID Overlays)

Fan Assembly, Rear Panel

Front Panel Assy (incudes front panel, A19 and A20 PCBs, and all

model ID overlays)

Power Supply

Liquid Crystal Display (LCD)

Liquid Crystal Display (LCD)

Liquid Crystal Display (LCD)

Table 2-6. Consummsable Parts

Opt 10 only

All

All

All

All

All

LCD Equipped

LCD Equipped

LCD Equipped

LCD Equipped

SN:972701 and above

LCD Equipped

SN:994600 and above

ND39476

40-116

2000-322

C38550

ND42700

B38533

ND44606

40-114

15-88

15-92

15-100

Assembly / Part 373XXA Model / Option Part Number

System Software

Front Panel Encoder Knob

Front Panel Amber Lens

Fuse, 8A, Fast Blow 3AG Cartridge type (F1 Line fuse for power

supply assembly)

Battery Backed RAM

Back-Up Battery

LCD Back Light Driver PCB

LCD Back Light Lamp

All

All

All

All

All

All

LCD Equipped

LCD Equipped

2300-212

2000-577

790-412

631-72

54-1350

633-20

2000-770

632-55

373XXA MM 2-7

Page 32

PARTS ORDERING INFORMATION REPLACEABLE PARTS

Table 2-7. Signal Source Module RF/Microwave Components

Assembly / Part 373XXA Model / Option Part Number

YIG Oscillator (2 - 20 GHz)

Down Converter

Switched Filter

Switched Filter

Table 2-8. Factory Repairable Non-Exchange Parts

Assembly / Part 373XXA Model / Option Part Number

Test Port Connector, K-Male All 34UK50

Test Port Connector, GPC-7 Opt 7A only 34UA50

Test Port Connector, 3.5 mm Opt 7S only 34US50

Test Port Connector, type N Opt 7N only 34UN50

Test Port Connector, type NF Opt 7NF only 34UNF50

Test Port Connector, V 37397A 34YV50

37317A and below

37325A and above

All

All

C21620-1

D27532

D45243

D45244

2-8 373XXA MM

Page 33

REPLACEABLE PARTS PARTS ORDERING INFORMATION

Ovenized Reference Oscillator

(Option 10 only)

Power

Printed Circuit

Board Assemblies,

A13-A16

Supply

Module

Fan Assembly

VGA Monitor

Assembly

Front PanelAssembly

(Includes Front Panel PCB)

Printed Circuit Board

Assemblies, A1-A9

Signal

Source

Module

Figure 2-1. Major Assemblies Location Diagram (Top

3

4

View)

373XXA MM 2-9

Page 34

PARTS ORDERING INFORMATION REPLACEABLE PARTS

StepAttenuator

70dB

Transfer

Switch

Power

Amplifier

20/40 GHz

Quad Buffer

Amp/Sampler*

Port 1

Coupler/Bridge*

Switched Doubler

Module**

Port 2 Step

Attenuator

Port 2

Coupler/Bridge*

Floppy Disk Drive

Assembly

A17 Motherboard

PCB Assembly

A24 VME Bus

Terminator

PCB Assembly

Refer to Table2-3

*

Model 37369A Only

**

10dB/20dB Pads*

A18 Rear Panel

PCB Assembly

Figure 2-2. Major Assemblies Location Diagram (Bottom View) (Not 37397A)

2-10 373XXA MM

Page 35

REPLACEABLE PARTS PARTS ORDERING INFORMATION

Port 1 Bias Tee

Port 1 Step Attenuator

Port 1 MUX Coupler

Port 2 MUX Coupler

Transfer Switch

SPDT Switch

Power Amplifier

Port 1 Coupler

Port 2 Step Attenuator

Port 2 Bias Tee

Port 2 Coupler

Floppy Disk Drive Assy

Switched Doubler Module

Port 2 37 GHz Hipass Filter

Port 2 SQM

A17 PCB

Port 1 37 GHz Hipass Filter

Sampler/BufferAmplifier

Shaped Pads

A24 PCB

A18 Rear Panel PCB

Figure 2-3. Major Assemblies Location Diagram (Bottom View) (37397A)

Port 1 SQM

373XXA MM 2-11

Page 36

PARTS ORDERING INFORMATION REPLACEABLE PARTS

Figure 2-4. Signal Source Parts Location Diagram

2-12 373XXA MM

Page 37

Chapter 3 Operational Tests

Table of Contents

3-1 INTRODUCTION ·························3-3

3-2 CHECKING THE SERVICE LOG ················3-4

3-3 SELF TEST ····························3-5

3-4 PERIPHERALS AND INTERFACES ··············3-6

LCDTest······························3-6

Front Panel Test ··························3-7

External Keyboard Interface Test·················3-7

Printer Interface Test ·······················3-7

GPIB Interface Test ························3-9

3-5 SIGNAL PATH ··························3-10

Page 38

Page 39

Chapter 3

Operational Tests

3-1 INTRODUCTION The tests in this section provide a means of fully testing the 373XXA VNA

system for proper operation and signal stability. These tests are intended

to be used as a periodic check of the operational functionality of the

373XXA.

The tests should be performed in their entirety at least once annually.

Although there is no requirement to do so, the tests should generally

be run in the sequence presented.

NOTE

The procedures presented in Chapter 4, Performance Verification, provide the means to test the accuracy of the tests

performed by the 373XXA.

Please ensure you have read and fully understand the servicing concepts for the 373XXApresented in Chapter 1 prior to continuing with

this chapter.

Operational Tests for the 373XXA consist of the following:

q

Checking the Service Log

q

Self Test

q

Peripherals and Interface Testing

q

Signal Path Tests (includes Checking the Service Log and Self

Test.)

These tests are described in paragraphs 3-2 through 3-5, which start

on the next page.

373XXA MM 3-3

Page 40

CHECKING THE SERVICE LOG OPERATIONAL TESTS

3-2 CHECKING THE

SERVICE LOG

OPTIONS

TRIGGERS

REAR PANEL

OUTPUT

DIAGNOSTICS

MULTIPLE SOURCE

CONTROL

PRESS <ENTER> TO

SELECT

START SELF TEST

READ SERVICE LOG

INSTALLED OPTIONS

PERIPHERAL TESTS

TROUBLESHOOTING

(FOR SERVICE

ONLY)

HW CALIBRATIONS

(FOR SERVICE

ONLY)

PRESS <ENTER>

DIAGNOSTICS

TO SELECT

Checking the service log consists of viewing the entries written into the

log.

CAUTION

The service log contains historical information about in

strument condition and any failures that may have oc

-

curred. It should be cleared only by a qualified service

engineer. Such clearing shuld be accomplished only upon

determining that the errors need not be saved to disk, or

printed out for service purposes.

Procedure:

Step 1. Press the Option Menu key (Enhancement key group) to dis

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu (left); then select

READ SERVICE LOG from the DIAGNOSTICS menu.

The 373XXA will now display the contents of the service

log. The display consists of a header and an error listing.

The header contains a variety of system service information. The error listing contains error messages for failures

that may have occurred during operation.

NOTE

• Errors 7201–7209, GPIB remote operation programming errors, report that one

or more external GPIB programming er

rors has been detected. These messages

do not indicate a 373XXA system fault.

-

•

Informational messages 0000–0099 report

the pass/fail status of a peripheral access.

These messages do not indicate a 373XXA

system fault.

Any other error messages in the service log may indicate

an instrument problem and should be investigated. Refer

to the Chapter 5, Troubleshooting, for further information.

CAUTION

The CLEAR SERVICE LOG menu selec

tion will immediately and permanently clear

all the error message entries from the ser

vice log. (However, it will not clear the

header information.) See Caution message

at top of page.

3-4 373XXA MM

Page 41

OPERATIONAL TESTS SELF TEST

3-3 SELF TEST The self test performs a series of tests that verify that various internal

373XXAcircuits are functional and operating properly.

To start the self test:

Step 1. Press the Option Menu key (Enhancement key group) to dis

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu; then select START

SELF TEST (below).

OPTIONS

TRIGGERS

REAR PANEL

OUTPUT

DIAGNOSTICS

MULTIPLE SOURCE

CONTROL

PRESS <ENTER> TO

SELECT

DIAGNOSTICS

START SELF TEST

READ SERVICE LOG

INSTALLED OPTIONS

PERIPHERAL TESTS

TROUBLESHOOTING

(FOR SERVICE

ONLY)

HW CALIBRATIONS

(FOR SERVICE

ONLY)

PRESS <ENTER> TO

SELECT

Step 3. Wait for test sequence to complete. (Once invoked, this test

requires no user interaction or external equipment.)

Upon completion, the net pass/fail result of the self test is shown on

the CRT display. If the 373XXA is in remote-only operation, the re

sults are reported via the GPIB output buffer. If the self test fails, de

tailed error messages will be written into the service log.

-

-

If self test fails:

q

Check the service log to view failure messages.

q

Proceed to Chapter 5, Troubleshooting.

373XXA MM 3-5

Page 42

PERIPHERALS AND INTERFACES OPERATIONAL TESTS

3-4 PERIPHERALS AND

INTERFACES

LCD Test This test verifies that the 373XXALCD is functioning correctly.

These tests are used to verify the operation of the liquid-crystal display

(LCD), front panel keys, and peripheral devices that are used with the

373XXA. They consist of the following:

LCD Test

q

Front Panel Test

q

External Keyboard Interface Test

q

Printer Interface Test

q

GPIB Interface Test

q

NOTE

The External VGAOut Connector can also be tested when

using this procedure if an external VGA monitor is con

-

nected.

Procedure:

Step 1. Press the Option Menu key (Enhancement key group) to dis-

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu; then in sequence select: PERIPHERAL TESTS, and then CRT DISPLAY.

See diagram below.

OPTIONS

TRIGGERS

REAR PANEL

OUTPUT

DIAGNOSTICS

MULTIPLE SOURCE

CONTROL

PRESS <ENTER> TO

SELECT

DIAGNOSTICS

START SELF TEST

READ SERVICE LOG

INSTALLED OPTIONS

PERIPHERAL TESTS

TROUBLESHOOTING

(FOR SERVICE

ONLY)

HW CALIBRATIONS

(FOR SERVICE

ONLY)

PRESS <ENTER> TO

SELECT

Step 3. Follow instructions on the CRT screen until test is com

PERIPHERAL TESTS

CRT DISPLAY

FRONT PANEL

EXTERNAL KEY

BOARD

PRINTER INTERFACE

GPIB INTERFACE

PREVIOUS MENU

PRESS <ENTER> TO

-

SELECT

-

pleted.

If test fails, proceed to Chapter 5, Troubleshooting.

3-6 373XXA MM

Page 43

OPERATIONAL TESTS PERIPHERALS AND INTERFACES

Front Panel Test This test verifies that the control keys in each of the 373XXA key groups

are functioning correctly .

Procedure:

External Keyboard

Interface Test

Step 1. Press the Option Menu key (Enhancement key group) to dis

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu; then in sequence se

lect: PERIPHERAL TESTS, and then FRONT PANEL.

See diagram below.

OPTIONS

TRIGGERS

REAR PANEL

OUTPUT

DIAGNOSTICS

MULTIPLE SOURCE

CONTROL

PRESS <ENTER> TO

SELECT

DIAGNOSTICS

START SELF TEST

READ SERVICE LOG

INSTALLED OPTIONS

PERIPHERAL TESTS

TROUBLESHOOTING

(FOR SERVICE

ONLY)

HW CALIBRATIONS

(FOR SERVICE

ONLY)

PRESS <ENTER> TO

SELECT

PERIPHERAL TESTS

CRT DISPLAY

FRONT PANEL

EXTERNAL KEY

BOARD

PRINTER INTERFACE

GPIB INTERFACE

PREVIOUS MENU

PRESS <ENTER> TO

-

SELECT

Step 3. Follow instructions on the screen until test is completed.

If test fails, proceed to Chapter 5, Troubleshooting.

This test verifies that the 373XXA external keyboard interface is func

-

tioning correctly.

-

Equipment Required:

An IBM compatible keyboard is required for this test.

Procedure:

Step 1. Press the Option Menu key (Enhancement key group) to dis

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu; then in sequence se

lect: PERIPHERAL TESTS, and then EXTERNAL KEY

BOARD. See diagram above.

Step 3. Follow instructions on the screen until test is completed.

If test fails, proceed to Chapter 5, Troubleshooting.

Printer Interface Test This test verifies that the 373XXAprinter interface is functioning cor

-

rectly.

373XXA MM 3-7

-

-

Page 44

PERIPHERALS AND INTERFACES OPERATIONAL TESTS

Equipment Required:

Printer Test Fixture (ANRITSU PN: B39553)

Procedure:

Step 1. Press the Option Menu key (Enhancement key group) to dis

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu; then in sequence se

lect: PERIPHERAL TESTS, and then PRINTER IN

-

-

TERFACE. See diagram below.

OPTIONS

TRIGGERS

REAR PANEL

OUTPUT

DIAGNOSTICS

MULTIPLE SOURCE

CONTROL

PRESS <ENTER> TO

SELECT

DIAGNOSTICS

START SELF TEST

READ SERVICE LOG

INSTALLED OPTIONS

PERIPHERAL TESTS

TROUBLESHOOTING

(FOR SERVICE

ONLY)

HW CALIBRATIONS

(FOR SERVICE

ONLY)

PRESS <ENTER> TO

SELECT

PERIPHERAL TESTS

CRT DISPLAY

FRONT PANEL

EXTERNAL KEY

BOARD

PRINTER INTERFACE

GPIB INTERFACE

PREVIOUS MENU

PRESS <ENTER> TO

-

SELECT

Step 3. Follow instructions on the screen until test is completed.

If test fails, proceed to Chapter 5, Troubleshooting.

-

3-8 373XXA MM

Page 45

OPERATIONAL TESTS PERIPHERALS AND INTERFACES

GPIB Interface Test This test verifies that the 373XXAprinter interface is functioning cor

rectly.

Equipment Required:

GPIB cable (ANRITSU PN: 2100-2), or equivalent

CAUTION

Insure that no other cables are connected to either of the

two rear panel GPIB ports when performing this test.

Procedure:

Step 1. Press the Option Menu key (Enhancement key group) to dis

play the OPTIONS menu.

Step 2.

Select DIAGNOSTICS from menu; then in sequence se

lect: PERIPHERAL TESTS, and then GPIB INTER

FACE. See diagram below.

OPTIONS

TRIGGERS

REAR PANEL

OUTPUT

DIAGNOSTICS

MULTIPLE SOURCE

CONTROL

PRESS <ENTER> TO

SELECT

DIAGNOSTICS

START SELF TEST

READ SERVICE LOG

INSTALLED OPTIONS

PERIPHERAL TESTS

TROUBLESHOOTING

(FOR SERVICE

ONLY)

HW CALIBRATIONS

(FOR SERVICE

ONLY)

PRESS <ENTER> TO

SELECT

PERIPHERAL TESTS

CRT DISPLAY

FRONT PANEL

EXTERNAL KEY-

BOARD

PRINTER INTERFACE

GPIB INTERFACE

PREVIOUS MENU

PRESS <ENTER> TO

SELECT

-

-

-

-

Step 3. Follow instructions on the screen until test is completed.

If test fails, proceed to Chapter 5, Troubleshooting.

373XXA MM 3-9

Page 46

SIGNAL PATH OPERATIONAL TESTS

3-5 SIGNAL PATH These are a series of automated tests designed to insure the 373XXA in

ternal signal paths are functioning properly and are capable of support

ing stable calibrations and measurements. These test are performed us

ing a software test program and an external computer/controller.

The test software performs the following operations and tests:

Service Log Check

q

Self Test

q

Basic Sweep Operation and Speed Test

q

High Level Noise Test

q

System Stability Test

q

RF Power Generation and Control Test

q

Step Attenuators Accuracy and Repeatability Test

q

Video IF Bandwidth Filters Operation Test

q

Sampler Efficiency and Stability Test

q

LO1/LO2 Linearity Test

q

q Source FM/Lock Signal Linearity Test

Equipment required:

-

-

-

37XXX Test Software (ANRITSU PN: 2300-178)

External computer/controller; refer to Table 1-1 located on page 1-9.

GPIB cable (ANRITSU PN: 2100-2), or equivalent

Procedure:

Step 1.

Refer

to file “Readme.txt” of the distribution disk for in

-

formation regarding setup of the computer/controller.

Step 2. Using the GPIB cable, connect the external computer/con

troller to the IEEE 488.2 GPIB Interface port on the

373XXA rear panel.

Step 3. Program may be run from floppy disk or copied to any

folder in the computer and run from there.

Step 4. Peform Non-Ratio and Transmission tests.

If any tests fail, refer to the Troubleshooting and Help selections of the

Test Software menu for assistance.

-

3-10 373XXA MM

Page 47

Chapter 4 Performance Verification

Table of Contents

4-1 INTRODUCTION ·························4-3

4-2 CALIBRATION AND MEASUREMENT CONDITIONS ····4-3

Standard Conditions························4-3

Special Precautions: ························4-4

4-3 MEASUREMENT ACCURACY··················4-4

Verification Software ·······················4-4

Verification Result Determination ················4-5

4-4 VERIFICATION PROCEDURE··················4-5

4-5 KEY SYSTEM PARAMETERS ·················4-6

Measurement Environment Considerations ···········4-6

Measurement Technique ·····················4-7

373XXA MM 4-1

Page 48

4-2 373XXA MM

Page 49

Chapter 4

Performance Verification

4-1 INTRODUCTION This chapter provides specific procedures to be used to verify that the

373XXAis making accurate, traceable S-parameter measurements. You

should perform the verification procedures in paragraph 4-3, “Verifying

Measurement Accuracy,”at least once annually.

Additionally, this chapter includes procedures that may be used to

measure the following key system performance parameters:

Effective Source Match

q

Effective Directivity

q

System Dynamic Range

q

Frequency Accuracy

q

Power Level Accuracy

q

The Operational Tests described in Chapter 3 should be performed

prior to verifying system performance.

4-2 CALIBRATION AND

MEASUREMENT

CONDITIONS

Standard Conditions The standard conditions specified below must be observed when perform

Please ensure you have read and fully understand the servicing concepts for the 373XXApresented in Chapter 1 prior to continuing with

this chapter.

Extremes in the surrounding environmental conditions and the condition

and stability of the test port connectors, through-cable, and calibration kit

determine system measurement integrity to a large extent.

These are all user controlled conditions, and as such, should be evalu

ated periodically for impact on system performance. If these conditions

vary significantly with time, the system verification procedures should

be performed more often than the recommended annual cycle.

ing any of the operations in this chapter — both during calibration and

during measurement.

Warm-up Time: One hour minimum.

Environmental Conditions:

Temperature: 23 +/- 3 deg C

Relative Humidity: 20-50% recommended.

-

-

373XXA MM 4-3

Page 50

MEASUREMENT ACCURACY PERFORMANCE VERIFICATION

Error Correction:

Perform software-guided 12 term calibration.

Special Precautions: When performing the procedures in this chapter ,observe the following

precautions:

4-3 MEASUREMENT

ACCURACY

Verification Software These procedures use the ANRITSU VNA Verification Software, PN:

Minimize vibration and movement of system and attached compo

q

nents and through-cable.

Clean and check pin depth and condition of all adapters,

q

through-cable(s), and calibration components.

Pre-shape the through-cable(s) so as to minimize its movement dur

q

ing calibration and measurement activities.

Ensure the system remains motion free in stable environmental

q

conditions as defined above throughout warm-up, calibration, and

measurement activities.

The verification procedures described in the following paragraphs verify

the published measurement accuracy and measurement traceability* for

the 373XXA.

2300-237, and the NIST traceable impedance transfer standards contained in the appropriate ANRITSU Verification Kit. The Standard Conditions and Special Precautions described in paragraph 4-2 should be

observed when performing these procedures.

The appropriate ANRITSU Verification Kit to be used for performing

these procedures is model dependent, as follows:

q

Models 37317A and below, with Opt 7A: Verification Kit 3667

q

All Models using K Connector test ports: Verification Kit 3668

q

Models 37397A: Verification Kit 3669B

-

-

The impedance transfer standards contained in these kits are:

q

20 dB Attenuation Standard

q

50 dB Attenuation Standard

q

50 Ohm Air Line Standard

q

25 Ohm Mismatch (Beatty) Standard

The verification software performs the following functions:

q

It guides the user through a full 12 Term calibration of the 373XXA.

q

It guides the user through the measurement of the S-parameters of

the NIST traceable impedance transfer standards (below).

q

It verifies the measured values are within the specified measure

-

ment uncertainty limits.

q

It indicates the pass/fail status of the measurements on the CRT

display. It can also provide a hard copy printout of the measured

∗ Traceability to the U.S. National Institute of Standards and Technology (NIST)

4-4 373XXA MM

Page 51

PERFORMANCE VERIFICATION VERIFICATION PROCEDURE

Verification Result

Determination

data, measurement uncertainties, and the impedance transfer stan

dards used.

NOTE

The total verification uncertainty in these

373XXA measurements includes the mea

surement uncertainty of the verification

standards and the 373XXAmeasurement

uncertainty.

The software verification process compares the measured S-parameter

data of the impedance transfer standards against the original standard

data for those devices that was obtained using the Factory Standard 360

Vector Network Analyzer System (at ANRITSU). The factory Standard

360 system is traceable to NIST through the ANRITSU Calibration Labo

ratory’s Impedance Standards. These standards are traceable to NIST

through precision mechanical measurements, NIST approved microwave

theory impedance derivation methods, and electrical impedance compari

son measurements.

The quality of the verification results is very dependent on the degree

of care taken by the user in maintaining, calibrating, and using the

system. The most critical factors are:

q

The stability and quality of the devices in the calibration and verification kits.

q

The condition of 373XXAtest port connectors and through-cables.

q

The pin depths of all connectors, and the proper torquing of connections. These same factors also affect 373XXA measurement quality.

-

-

-

-

-

-

-

4-4 VERIFICATION

PROCEDURE

Consult the Operating Manuals supplied with the ANRITSU Calibra

tion and Verification Kits for proper use, care, and maintenance of the

devices contained in these kits.

The performance verification procedure for the ANRITSU 373XXAVNA

is described below.Refer also to the Model 360X/37XXX VNA Perfor

mance Verification Software Users Guide, P/N: 10410-00162, which is lo

cated in Appendix E at the rear of this manual. This Software Users

Guide explains in detail the procedures to be used for the installation and

operation of the V erificationSoftware on your computer/controller.

Equipment required:

ANRITSU 37300A Verification Software, PN: 2300-237 (Version 3.1

or above of 2300-237 software is necessary to verify the 37397A).

External computer/controller; refer to Table 1-1 located on page 1-9.

373XXA MM 4-5

Page 52

KEY SYSTEM PARAMETERS PERFORMANCE VERIFICATION

ANRITSU Verification Kit appropriate for the 373XXA model; refer

to paragraph 4-3.

GPIB cable (ANRITSU PN: 2100-2), or equivalent

Procedure:

4-5 KEY SYSTEM

PARAMETERS

Step 1. Using the GPIB cable, connect the external computer/con

troller to the IEEE 488.2 GPIB Interface port on the

373XXA rear panel.

Step 2. Insert the CD ROM into its drive and install the 2300-237

software.

Step 3. Follow the directions displayed on the computer screen to

perform all tests.

If the calibration fails, check the connectors of the calibra

tion kit devices and the impedance transfer standards for

damage, cleanliness, and proper connection and torquing.

These are the most common causes for verification failures.

If the problem persists, check system Directivity, Match,

and Dynamic Range, as described in the next paragraph.

The following paragraphs describe procedures for automated measurement of the key system performance parameters listed below. Measurement of these parameters is not required for system verification; however,

it is highly recommended to ensure that the complete 373XXA measurement environment is stable and capable of supporting accurate measure

ments.

q

Effective Source Match

-

q

Effective Directivity

q

System Dynamic Range

q

Frequency Accuracy

q

Power Level Accuracy

Measurement

Environment

Considerations

As with the verification procedures, the quality of the measurement of the

system performance parameters listed above is very dependent on the

measurement environment.

The complete 373XXAmeasurement environment consists of:

q

Condition and stability of the test ports, through-cable, and calibra

tion kit mating connectors.

q

Settings and stability of the surrounding environment, especially

temperature, humidity, and vibration. To maintain the highest sys

tem performance, avoid changing these conditions, especially tem

-

-

4-6 373XXA MM

-

Page 53

PERFORMANCE VERIFICATION KEY SYSTEM PARAMETERS

Measurement

Technique

perature, during warm-up, calibration, and when making measure

ments on your DUT.

The use of proper microwave connector mating techniques.

q

The measurements of the key system performance parameters are per

-

formed using the ANRITSU 37XXX Test Software, PN: 2300-178.

NOTE

The Standard Conditions and Special Precautions de

scribed in paragraph 4-2 should be observed when per

-

-

forming these measurements.

The software will use the following standards to determine system per

formance values:

Assurance Air Line Set

q

Offset Termination

q

Frequency Counter

q

Power Meter

q

Equipment required:

37XXX Test Software (ANRITSU PN: 2300-178)

External computer/controller; refer to Table 1-1 located on page 1-9.

GPIB cable (ANRITSU PN: 2100-2), or equivalent

-

-

Measurement Procedure:

Step 1.