1

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.TMmenu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

spare parts

useful conversions

warranties

update info

your ANGEL 3iR

TM

01

ANGEL 3iR

TM

Important Safety Instructions & Guidelines 03

Operating Instructions 04

Switching on your ANGEL iR3

TM

04

LED indicator 04

Charging 04 & 06

Propellant Air/Nitrogen supply 07

Macro line hose/connector attachment 07

macro line hose removal/re-attachment 07

Fitting the Hopper IntellifeedTM(optional extra) 08

OPTO board

TM

08

Bolt removal Rota breech

TM

09

Velocity adjustment 09

Gated Feed

TM

feature 09

External Electronic LCD menus whilst In SAFE 10

Back light feature 10

Temperature feature 10

Cycles (total shots) feature 10

Trip (shot counter) feature 10

ROF (rate of fire actually achieved by user feature) 10

MROF (maximum rate of fire feature with C.O.P.S.

TM

off) 10

CMROF (maximum rate of fire feature with C.O.P.S.

TM

on) 11

Game timer feature 11

Vibes (vibrator alarm feature) 11

Dwell feature 11

Mode feature (style of shooting) 11

Battery status feature 11

Hopper T (timer) 11

Hopper A (activation) 12

Infra-red menu 12

Send (infra-red) 12

Fetch (infra-red) 12

PIN number locking/unlocking 12

External Electronic LCD C.O.P.S.TMmenu whilst in LIVE 17

SENS – C.O.P.S.TMadjustment for sensitivity level 17

BAS – C.O.P.S.TMadjustment for firing rate 17-18

Internal Tournament Electronic LCD menus 19

Mode feature 19

Dwell feature 20

MROF (maximum rate of fire limit with C.O.P.S.TMoff) 20

CMROF (Maximum rate of fire with C.O.P.S.TMon) 20

Temperature feature 20

T.C.O.P.S. (C.O.P.S.TMTest features) 22

PIN number setting 22

Text setting 22

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

01

ANGEL iR3

TM

contents

• This operators and

users manual is in

English.

• It contains important

safety guidelines and

instructions.

• Should you be unsure

at any stage, or

unable to understand

the contents within

this manual you must

seek expert advice.

• Le mode d’emploi

est en anglais.

• Il contient des

instructions et

mesures de sécurité

importantes.

• En cas de doute,

ou s’il vous est

impossible de

comprendre le

contenu du monde

d’emploi, demandez

conseil à un expert.

• Este manual de

(operarios y) usarios

está en inglés

• Contiene importantes

normas de seguridad

e instrucciones.

• Si no esta seguro

de algún punto o no

entiende los

contenidos de este

manual debe conultar

con un experto.

• Diese Bedienungsund Benutzeranleitung

ist in Englisch.

• Sie enthält wichtige

Sicherheitsrichtlinien

und -bestimmungen.

• Sollten Sie sich in

irgendeiner Weise

unsicher sein, oder

den Inhalt dieses

Heftes nicht

verstehen, lassen Sie

sich bitte von einem

Experten beraten.

Figures

ON/OFF functions (fig.1) 05

Game timer (fig.2) 13

External menus whilst in SAFE (fig.3) 14-15

PIN number locking/unlocking (fig.4) 16

External LCD C.O.P.S.TMmenu whilst in LIVE (fig.5) 18

Internal tournament LCD menus (fig.6) 21

Internal tournament LCD menus - PIN number programming (fig.7) 23

Internal tournament LCD menus - Text programming (fig.8) 24

PCB Layout 25

Wiring connections: Intellifeed/Charger/14 way valve/Battery and C.O.P.S.

TM

25

General Assembly 26-27

Ram Assembly 28

LPR Assembly 28

3Styla

TM

Trigger Assembly 28

Exhaust Valve Stem and Guide Assembly 28

Mini Regulator Assembly 28

Maintenance 29

General care and cleaning 29

Low pressure regulator (LPR) adjustment 29-30

Exhaust valve removal 31

Ram stroke adjustment 31

Ram snap ring adjustment 32

3StylaTMtrigger adjustment 32

Testing pneumatics/electronics 34

Fault Finding Tables 35

Useful Conversions 36

Warranties ECC/Rest of World excluding USA/Canada 37-38

Warranties USA/Canada 38-39

Updates Information 39

Personal Details Relating To Your ANGEL iR3

TM

40

02

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

contents

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

03

ANGEL iR3

TM

IMPORTANT SAFETY INSTRUCTIONS & GUIDELINES

WARNINGS FOR SAFE ANGEL iR3TMHANDLING

important safety guidelines

• The ANGEL iR3TMis not a toy.

• Careless or improper use, including failure to follow instructions and warnings within this Operator’s Manual and

attached to the ANGEL iR3

TM

, could cause death or serious injury.

• Do not remove or deface any warnings attached to the ANGEL iR3

TM

.

• Paintball industry standard eye/face/ear and head protection designed specifically to stop paintballs and meeting

ASTM standard F1776 ( USA) or CE standard (Europe) must be worn by user and any person within range.

• Must be at least 18 years of age to purchase the ANGEL iR3

TM

.

• Persons under 18 years of age must have adult supervision when using or handling the ANGEL iR3

TM

.

• Observe all local and national laws, regulations and guidelines.

• Use only on professional paintball fields where codes of safety are strictly enforced.

• Use compressed air/nitrogen gas only. Do not use CO2

• Do not exceed 1200 psi (82 bar) input pressure.

• Always follow instructions, warnings and guidelines given with any first stage regulator you use with the ANGEL iR3

TM

.

• Use 0.68 calibre paintballs only.

• Keep the ANGEL iR3

TM

switched off until ready to shoot.

• Treat every marker as if it is loaded.

• Never point the Angel iR3

TM

at anything you do not intend to shoot.

• Do not shoot at persons at close range

• Do not shoot at fragile objects such as windows.

• Always measure your markers velocity before playing paintball, using a suitable chronograph.

• Never shoot at velocities in excess of 300 feet (91.44 meters) per second, or at velocities greater than local or

national laws allow

• Do not fire the ANGEL iR3

TM

with the breech open or without the bolt in the breech, as high pressure gas

will be admitted.

• Do not fire the ANGEL iR3

TM

with the pull knob in the unlocked position.

• Never look into the barrel or breech area of the ANGEL iR3

TM

, whilst the marker is switched on and able to fire.

• Never put your finger or any foreign objects into the paintball feed tube of the ANGEL iR3

TM

.

• Never allow pressurised gas to come into contact with any part of your body.

• Always switch off the ANGEL iR3

TM

when not in use.

• Always fit a barrel blocking device to your ANGEL iR3

TM

when not in use on the field of play.

• Always remove all paintballs from the Angel iR3 when not in use on the field of play.

• The Gated Feed is designed to retain a number of paintballs in the feed tube and breech area of the ANGEL iR3

TM

.

Always ensure that these paintballs are removed from the ANGEL iR3

TM

when it is not in use on the field of play.

• Always remove the first stage regulator and relieve all residual gas pressure from the ANGEL iR3

TM

before

disassembly.

• The ANGEL iR3

TM

can hold a small residual charge of gas, typically 2 shots, with the first stage regulator removed.

Always discharge the marker in a safe direction to relieve this residual gas pressure.

• Always remove first stage regulator and all residual gas pressure from the ANGEL iR3

TM

for transport and storage.

• Always follow warnings and guidelines given with your first stage regulator for safe transport and storage.

• Only charge the ANGEL iR3

TM

using the charger supplied.

• Only use 12Volt negative earth vehicles as a power supply for the charger.

• Do not leave the ANGEL iR3

TM

unattended whilst charging.

• Always store the ANGEL iR3

TM

in a secure place.

• THIS OPERATOR’S MANUAL MUST ALWAYS ACCOMPANY THE PRODUCT IN THE EVENT OF RESALE

OR NEW OWNERSHIP.

• SHOULD YOU BE UNSURE AT ANY STAGE YOU MUST SEEK EXPERT ADVICE.

04

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

operating instructions

OPERATING INSTRUCTIONS

SWITCHING ON YOUR ANGEL iR3

TM

• Ensure a barrel blocking device is fitted to the ANGEL iR3

TM

• Ensure the hopper is removed from the ANGEL iR3

TM

• Ensure that there are no paintballs in the ANGEL iR3

TM

• Paintball industry standard eye/face/ear and head protection designed specifically to stop

paintballs and meeting ASTM standard F1776 ( USA) or CE standard (Europe) must be worn

by user and any person within range.

• To switch on your ANGEL iR3

TM

ensure the battery is charged and the isolator switch is in the ON

position. The display will now read “SAFE”. The LED on the rear of the frame will show GREEN.

• Press and hold the RED button for 2 seconds and the display will show “LIVE”.

The LED on the rear of the frame will show RED.

(fig.1, page 5).

LED INDICATOR

The LED on the rear of the grip frame will indicate the state of the ANGEL iR3TM,

the states indicated are:

NO LED = No charge present or isolator switch is OFF.

GREEN constantly on = SAFE mode.

RED constantly on = LIVE mode.

RED slow flashing = With C.O.P.S.

TM

on and in LIVE mode.

RED rapidly flashing = LIVE mode with C.O.P.S.

TM

menu access gained.

CHARGING

• This charger will become hot during use.

• Do not cover.

• Do not leave unattended.

• Do not exceed 14.5 Volts input.

• Do not immerse in water.

• Do not use this charger for any purpose other than charging the Angel iR3

TM

paintball marker.

• Check your vehicle handbook for voltage and current capabilities prior to use.

• Use only this charger for charging the Angel iR3

TM

Before initial use of the ANGEL iR3TMit is necessary to give the power pack a full charging cycle

of 4 hours prior to use as this will ensure a long life for the power pack.

Subsequent charges will be in the region of 3 hours for a full charge, the electronics will control

the charging cycle and ensure that your battery is fully charged.

Note: Supply voltage must be minimum 12V DC, maximum 14.5V DC, negative earth.

• The ANGEL iR3TMmay be left charging for prolonged periods without damage occurring

to the battery pack.

• A full charge will give sufficient power for approximately 350,000 consecutive shots with the

hopper also being powered.

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

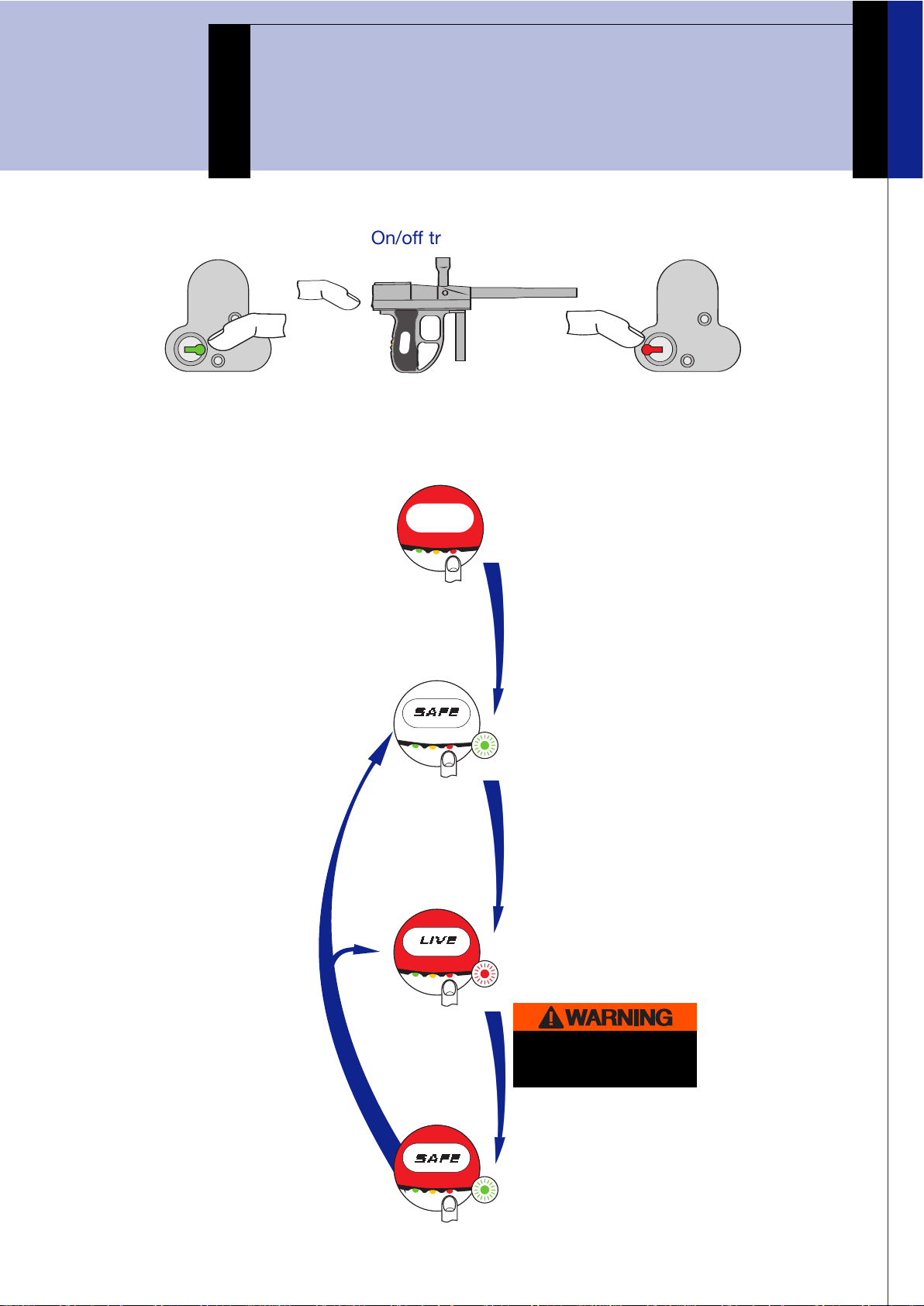

operating instructions – on/off modes (fig.1)

SAFE

LIVE

SAFE

s

s

s

On/off transit mode

On/off power saving mode

To switch power ON:

Move the toggle switch to the left

To switch power OFF:

Move the toggle switch to the right

toward the centre of the marker.

Switching power OFF results in

complete isolation of the electronics.

Power saving

will occur if the marker

is in safe mode after

2 hours of inactivity.

Switch shown

in OFF position

Switch shown

in ON position

Marker unable to fire.

To make ANGEL – LIVE.

Press and hold the red button for 2 secs.

Display will flash ‘LIVE ANGEL’ unless

personalised text has been added, then it will

flash ‘LIVE’ + the added text alternately.

To make ANGEL – SAFE.

Press and hold the red button for 2 secs.

THE MARKER IS LIVE

AND CAPABLE OF DISCHARGING.

OBSERVE ALL SAFETY

INSTRUCTIONS & GUIDELINES.

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

05

ANGEL iR3

TM

06

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

operating instructions

• A 1-hour charge at 12.5V DC will give sufficient power for approximately 16,000 consecutive shots

with the hopper also being powered.

• The ANGEL iR3

TM

will continue to use power even when in power saving sleep mode and

the battery will discharge in approximately 288 hours even if the marker is not being used.

To save the charge the isolator switch must be switched OFF to isolate the battery.

We recommend the isolating switch be placed in the off position when the ANGEL iR3

TM

is in storage, transit or not in use.

Stage 1

Insert cigar lighter adaptor into a negative earth socket as found in most motor vehicles (red light

on charger will illuminate to indicate that power is present).

Stage 2

Ensure the isolator switch is in the ON position at the rear panel of the ANGEL iR3TM.

No charging can occur until the switch is in the ON position.

Stage 3

Insert remote plug from charger into the socket on the rear of the ANGEL iR3TM.

The socket is located on the rear of the grip frame under a rubber protection grommet.

CAUTION:

Care must be shown with the charger to ensure the remote plug is not pulled or twisted by the lead.

Shorting this lead can result in damage to the electronics in your ANGEL iR3

TM

.

Stage 4

• The LCD on the ANGEL iR3TMwill indicate the status of the charging cycle.

• The 4 bar segment will cascade and the display will read ‘CHARGE’ to indicate charge is being taken.

• When a full charge has been taken ALL 4 segments will be illuminated and the display will remain

constant.

• Removal of the charger before a full charge cycle has been completed will result in a short charge.

The indicator may show all segments illuminated when the charger is removed but it will indicate the

3

/4, 1/2, 1/4, status more quickly due to the battery not being fully charged.

Notes:

The charge cycle cannot operate under the following conditions and a warning will be given on the

LCD display. If the display shows “PWRON” this is advising you of one

or more of the following:

• The isolator switch on the back of the ANGEL iR3

TM

is not switched to the ON position.

• The battery is not plugged into the circuit board.

The insertion of the charger will change the mode of the ANGEL iR3TM from ‘LIVE’ to ‘SAFE’.

Stage 5

Unplug the charger from the ANGEL iR3TMand replace the rubber grommet cover on the rear of the grip

frame to prevent the entry of dirt.

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

07

ANGEL iR3

TM

operating instructions

PROPELLANT AIR/ NITROGEN SUPPLY

• Ensure a barrel blocking devise is fitted to the Angel iR3TM.

• Ensure the hopper is removed from the Angel iR3

TM

.

• Ensure there are no paintballs in the Angel iR3

TM

.

• Ensure the Angel iR3

TM

is switched off via the isolating switch at the rear of the marker prior to

fitting your first stage regulator.

• Paintball industry standard eye/face/ear and head protection designed specifically to stop

paintballs and meeting ASTM standard F1776 ( USA) or CE standard (Europe) must be worn

by user and any person within range.

• Always follow instructions, warnings and guidelines given with any first stage regulator you use

with the Angel iR3

TM

.

• Use compressed air/nitrogen gas only DO NOT USE CO2

• Only use a paintball regulator that has been designed for air or nitrogen gas.

• Do not exceed 1200 psi (82 bar) input pressure to the Angel iR3

TM

.

• Take suitable precautions when using sharp cutting instruments.

• The Macro Line hose must be cut back cleanly and square prior to attachment or re-attachment

to ensure secure fitment

• SHOULD YOU BE UNSURE AT ANY STAGE YOU MUST SEEK EXPERT ADVICE.

The ANGEL iR3

TM

is designed to operate on air/nitrogen gas. This needs to be supplied to the

ANGEL iR3

TM

at a regulated pressure of 700 psi (48 BAR) using a suitable first stage paintball

regulator, such as the ANGEL A.I.R.

NOTE: If you are using a regulator other than the ANGEL A.I.R., refer to the regulator

manufacturers operating instructions and guidelines regarding output pressure.

Connect the first stage regulator gas outlet to the second stage regulator gas inlet using the Macro

Line and

1

/8 NPT connectors supplied.

MACRO LINE HOSE/CONNECTOR ATTACHMENT

• Connect the Macro Line connector to your first stage regulator outlet port using a suitable wrench

or spanner

• If necessary shorten the Macro Line hose using a sharp knife to the required length to suit your

Angel iR3

TM

and first stage regulator set up.

• Push the free end of the hose firmly into the Macro Line connector attached to the Angel iR3

TM

second stage regulator.

MACRO LINE HOSE REMOVAL AND RE-ATTACHMENT

• All gas pressure must be relieved from the Angel iR3TMand second stage regulator prior to the

Macro Line hose removal.

• The Angel iR3

TM

can hold a small residual charge of gas, typically 2 shots with the first stage regulator

removed. Always discharge the marker in a safe direction to relieve this residual gas pressure.

• The Macro Line hose must be cut back cleanly and square prior to reattachment to ensure

secure fitment

• The Macro line hose may be removed from the Macro Line connectors to facilitate maintenance.

• Pull back the collet on the connector and keep the collect depressed.

• Pull the Macro Line hose out of the connector firmly.

• Cut back the Macro Line hose cleanly and square.

• Push the hose firmly into the Macro Line connector to re-attach.

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

08

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

operating instructions

FITTING THE HOPPER INTELLIFEEDTM(OPTIONAL EXTRA)

• Ensure the ANGEL iR3TMis switched off via the isolating switch on the rear of the marker

• Ensure a barrel blocking device is fitted to the ANGEL iR3

TM

• Ensure the hopper is removed from the ANGEL iR3

TM

• Ensure that there are no paintballs in the ANGEL iR3

TM

The ANGEL iR3TMhas the ability to power motorized hoppers with the agitation and electrical supply coming

directly from the ANGEL iR3

TM

. This IntellifeedTMsystem monitors your fire rate and switches on the agitator as

necessary. (See general assembly and wiring diagrams.)

• Remove the existing sight rail using suitable metric Allen key.

• Remove the breech block pull knob by opening the breech, then unscrewing the pull knob while

it is retracted.

• Remove the 2-countersunk Allen screws with suitable metric Allen key from the back plate.

CAUTION: A spring is located under the back plate.

• Remove the left-hand side grip cheek and unplug the battery and 14-way solenoid.

• Remove the grip frame screws and remove the frame.

CAUTION: Care must be shown as the trigger return spring is located under the frame.

• Insert the replacement sight rail and wiring loom, feeding the wire and white plug though the body

to exit at the underside by the other plugs.

• Refit the frame.

CAUTION: Care must be shown to ensure the spring is located correctly.

• Insert all plugs in their relevant sockets.

CAUTION: Care must be shown to ensure wires do not snag on the trigger mechanism.

• Refit grip cheek cover, rear back plate, breech block pull knob and the sight rail.

• The flying lead has a mating plug that fits to the socket on the sight rail, this should be soldered directly

to the hopper motor. All other electronics within the hopper must be removed prior to fitting this lead. Each lead

may be soldered to either of the motor connections.

NOTE: The hopper circuit has over current protection to sense a locked or jammed paddle. Should a jam

occur the hopper drive circuit will shut down until the jam is cleared. Ensure the the hopper motor is free

running and the gear box is fully operational as this can result in slow running speeds.

OPTO BOARD

TM

• Do not attempt to modify the OPTO boardTMassembly in any way as this will invalidate your warranty

and could lead to safety concerns.

The iR3

TM

incorporates the OPTO boardTM. This is the latest development in trigger sensing function.

When used in conjunction with the 3Styla

TM

trigger it achieves unsurpassed advancements in trigger

repeatability and sensitivity, its non-mechanical switching results in faster, shorter and lighter trigger strokes

that give the user higher prolonged achievable rates of fire.

NOTES:

• When accessing the Internal Tournament LCD menus the OPTO board

TM

should not be exposed to direct

sunlight or strong external sources of light without the grip cheek fitted as this light will induce a safety

feature, that will prevent the Angel iR3

TM

from firing whilst it remains exposed to the strong external light.

• The correct function of the OPTO board

TM

can be verified by the LCD display whilst the Angel iR3

TM

is at rest in safe mode the display will display “SAFE”.

• With trigger pulled and held the display will show the firing mode eg “SEMI”.

• The OPTO board

TM

is a non-mechanical switch that is silent in its operation and no audible “click” is present.

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

09

ANGEL iR3

TM

operating instructions

BOLT REMOVAL ROTOR BREECH

TM

• Do not fire the ANGEL iR3TMwith the breech open or without the bolt in the breech, as high

pressure gas will be admitted.

• Do not fire the ANGEL iR3

TM

with the pull knob in the unlocked position.

• Ensure the ANGEL iR3TMis in “SAFE” mode or the isolator switch is in the OFF position.

• Pull the ‘Pull knob’ and rotate 90 degrees so that the knob remains in the unlocked position.

• Swing out the Rotor Breech block so that the bolt is exposed. The breech will not open if the bolt is

in the forward position. Ensure it is retracted by either: momentarily gassing the ANGEL iR3

TM

or

pushing the bolt back with a squeegee.

• Extract the bolt by pulling rearwards.

• To replace the bolt. Follow stages in reverse order.

VELOCITY ADJUSTMENT

• The ANGEL iR3TMis live and capable of discharging.

• Paintball industry standard eye/face/ear and head protection designed specifically to stop

paintballs and meeting ASTM standard F1776 ( USA) or CE standard (Europe) must be worn

by user and any person within range.

• Always measure your markers velocity before playing paintball, using a suitable chronograph.

• Never shoot at velocities in excess of 300ft (91.44meters) per second, or at velocities greater

than local or national laws allow.

Decreasing velocity

• The velocity adjusting screw is located on the lower portion of the front grip.

• To decrease the velocity, insert 3mm A/F Allen key and rotate CLOCKWISE.

CAUTION: When reducing velocity, allow four shots for the complete system to be at the new

regulated pressure.

Increasing velocity

• The velocity adjusting screw is located on the lower portion of the front grip.

• To increase the velocity insert 3.0mm A/F Allen key and rotate COUNTER CLOCKWISE.

GATED FEEDTMFEATURE

• The Gated Feed

TM

is designed to retain a number of paintballs in the feed tube and breech area

of the Angel iR3

TM

. Always ensure that these paintballs are removed from the ANGEL iR3TMwhen

it is not in use on the field of play.

The Gated Feed

TM

is a feature that retains the paintballs in the breech to prevent them rolling back into

the hopper. The Gated Feed

TM

uses a retention system that offers minimal resistance to a paintball

as it travels into the breech and maximum resistance to a paintball returning up the feed tube.

The retainer is a removable item that may be replaced if it becomes damaged (see general assembly

diagram p. 26/27 for strip down).

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

10

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

external LCD menus whilst in SAFE

EXTERNAL ELECTRONIC LCD MENUS WHILST IN SAFE

• Ensure a barrel blocking device is fitted to the ANGEL iR3

TM

• Ensure the hopper is removed from the ANGEL iR3

TM

• Ensure that there are no paintballs in the ANGEL iR3

TM

The ANGEL iR3TMhas a number of features that can be adjusted to suit your individual needs.

These features are designed to enhance your play and also to supply you with a wealth of information.

These are accessible via the external menu list (See external menu diagrams fig.2 p 13, fig.3 p 14-15,

fig.4 p 16). You may also view certain critical settings that have been set via the internal menu list.

• You can only access the main menus when the marker is in “SAFE” mode with the isolator switch

in the ON position.

• Follow the external menu list diagrams for relevant settings.

• Should you wish to return to factory settings the ANGEL iR3

TM

has a unique feature that allows you

to return to the factory defaults. See internal menu diagram for instructions.

The ANGEL iR3

TM

also ensures any settings that you enter are stored in an E.D.S. (encrypted data storage)

memory to give added protection against data loss.

Back-light feature

This enables you to switch the back-lighting on your display ON or OFF .

(See external menu diagram fig.3 p14-15).

Temperature feature

This allows you to set the temperature display between Fahrenheit and Centigrade.

This feature is useful in determining the ambient temperature, allowing you to select your accessories

for the climatic conditions in the format you prefer. (See external menu diagram fig.3 p14-15).

Cycles (total shots) feature

This is a chronological record of the total number of shots fired by your ANGEL iR3TM.

The user cannot reset this. (See external menu diagram fig.3 p14-15).

Trip (shot counter) feature

This allows you to record the number of shots fired at any stage e.g: Per game, per event or per day.

It may be reset at any time you require. (See external menu diagram fig.3 p14-15).

ROF (rate of fire) feature

This records the highest rate of fire you actually achieved over a 1-second period.

The data will be constantly updated should the new reading exceed the previous reading.

You can zero the ROF feature at any time. (See external menu diagram fig.3 p14-15).

MROF feature (maximum rate of fire limit with C.O.P.S.TMoption OFF)

This allows you to tune your maximum rate of fire to your style of play and feed system. Certain modes

are capped or non-adjustable. The rate of fire should not be set greater than your feed system is capable

of delivering. This cannot be changed by the external menu (See internal menu diagram fig.6 p21).

See table on Modes for maximum allowable settings (p 21).

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

11

ANGEL iR3

TM

external LCD menus whilst in SAFE

CMROF feature (maximum rate of fire limit with C.O.P.S.TMoption ON)

This allows you to tune your maximum rate of fire to your style of play and feed system when the

C.O.P.S.

TM

option is selected. Certain modes are capped or non-adjustable. The rate of fire should not be

set greater than your feed system is capable of delivering. This cannot be changed by the external menu

(See internal menu diagram fig.6 p21). See table on Modes for maximum allowable settings (p 21).

Game timer with 3 interactive alarms (fig.2 page 13)

The “vibes” timer incorporates 3 independent alarms that take the stress out of game play. It will

also allow you to play set moves in unison with your team mates. The timer can be set in 30 second

increments from 0 to 30 minutes. The timer is started with your first shot, which allows you to

concentrate on your game play. The 3 alarms can be individually set in 30 second increments.

(See internal menu diagram fig.3 p 14-15)

Vibes game alarm feature (fig.3 page 14-15)

This feature allows you to switch the vibrator alarm ON or OFF. The vibes alarm is independent of the

game timer functions. (See external menu diagrams for setting.)

Dwell feature (fig.3 page 14-15)

Dwell controls the valve opening time. Longer dwell uses more gas and generates more noise but allows

the marker a greater tolerance to paint, temperature and pressure variables. Shorter dwell uses less gas

and reduces noise, but is less tolerant of poor quality paint.

CAUTION:

Adjustment is only recommended if you wish to fine-tune your marker to specific accessories.

Mode feature

• In certain countries local applicable laws or industry standards may mean certain modes may not

be enabled or allowed. Check with law enforcement office, or local professional paintball venue.

The current mode selected will be displayed. 26 modes of shooting may be selected, including 5 modes

that you may program yourself using the ANGEL INFRA RED LINK. (See Internal Tournament LCD

adjustments and diagrams for setting.)

Battery Status feature

The battery status is indicated at all times by the 4-segment display. Power is drawn whilst the ANGEL

iR3

TM

has power connected. A battery will last approximately 280 hours until it is discharged. To prevent

this discharge ensure the isolator switch is in the OFF position at the end of the day or event. The last

segment indicates that you have approximately 16,000 shots left with a hopper being powered.

Hopper T (Timer)

This allows the user to set the duration that the hopper motor is activated for.

It can be set between 0.1- 2.0 seconds.

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

12

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

external LCD menus whilst in SAFE

Hopper A (Activation)

This allows the user to set the activation point of the hopper. It can be set to activate on the ROF level that you

achieve. It can be set to the following parameters.

A1 = Activates on every shot.

A2 = Activates on a ROF of 2 shots or greater.

A3 = Activates on a ROF of 3 shots or greater.

A4 = Activates on a ROF of 4 shots or greater.

Infra Red Menu

This allows the user to select which menu to transmit to another Angel iR3TM.

IR M1 = All text messages.

IR M2 = All game timer settings and vibes ON.

IR M3 = All game timer settings, vibes ON and Reset trip counter.

IR M4 = All game timer settings.

Send (Infra Red)

This allows the user to switch the infra Red transmitter ON or OFF. The transmitter will only transmit for

a 30 second period, if it does not receive a fetch confirmation signature then it will default to OFF.

Notes:

• The Angel iR3

TM

that is to receive the data must be selected into the Fetch menu with the Fetch switched ON.

• Whilst the Angel iR3

TM

is in send mode the Infra Red icon will flash.

Fetch (Infra Red)

This allows the user to switch the infra Red receiver ON or OFF.

The receiver will only receive for a 30 second period if it does not receive a send confirmation signature then

it will default to OFF.

Note:

• The Angel iR3

TM

that is transmitting the data must be selected into the Send menu with the send switched ON.

• Whilst the Angel iR3

TM

is in fetch mode the Infra Red icon will flash.

PIN number locking /unlocking (fig4. Page 16)

This feature can be used to add another level of security to your Angel iR3TM. After setting your PIN number

(fig7. Page 23) the PIN number can be locked when the marker is not in use. In this locked state te marker

will be restricted SAFE mode until the correct PIN number is entered.

ANGEL iR3

TM

EXTERNAL ELECTRONIC LCD MENUS WHILST IN SAFE. PAGES 10-12.

ANGEL iR3 OPERATOR’S MANUAL ADDENDUMS

Relating to External Electronic LCD menus whilst in safe.

Pages 10-12.

New menu order as it appears on the iR3’s LCD screen

to aid ease of operation for Palm interface.

Fetch (infra-red)

Infrared menu

Send (infra-red)

Back light feature

Cycles (total shots) feature

Trip (shot counter) feature

ID (unique identification number)

ROF (rate of fire actually achieved by user feature)

MROF (maximum rate of fire feature with C.O.P.S off)

CMROF (maximum rate of fire feature with C.O.P.S on)

Game timer feature

Vibes (vibrator alarm feature)

Mode feature (style of shooting)

Dwell feature

Hopper T (timer)

Hopper A (activation)

Temperature feature

T.C.O.P.S. C.O.P.S. (test feature)

HUD

ADDENDUM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

13

ANGEL iR3

TM

external LCD menus whilst in SAFE – game timer (fig.2)

SAFE

LIVE

LIVE

19:59

LIVE

SAFE

• Switch the power on by operating the

back plate toggle switch to the left.

• Press and hold for 2 secs. Power saving

will only occur if the marker is in safe

mode after 2 hrs of inactivity.

Automatic test displayed for 1 sec.

Amber and green buttons

remain operative for menus.

To make marker SAFE

press and hold button for 2 secs.

To make marker LIVE

press and hold button for 2 secs.

Timer Armed

- Vibes activates for 5 secs as confirmation.

- Display flashes between the set time and LIVE.

- Timer will start countdown on first shot.

Note: If vibes has been switched off Vibes

countdown signal will not occur.

Confirmation still occurs.

First shot starts timer countdown.

- Timer starts countdown.

- Alarms A1, A2 and A3

become active.

Note:

Timer, alarm and

vibes must be set

via external menu.

- Timer stops.

- Alarm stops.

THE MARKER IS LIVE

AND CAPABLE OF DISCHARGING.

OBSERVE ALL SAFETY

INSTRUCTIONS & GUIDELINES.

THE MARKER IS LIVE

AND CAPABLE OF DISCHARGING.

OBSERVE ALL SAFETY

INSTRUCTIONS & GUIDELINES.

THE MARKER IS LIVE

AND CAPABLE OF DISCHARGING.

OBSERVE ALL SAFETY

INSTRUCTIONS & GUIDELINES.

THE MARKER IS LIVE

AND CAPABLE OF DISCHARGING.

OBSERVE ALL SAFETY

INSTRUCTIONS & GUIDELINES.

14

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

external LCD menus whilst in SAFE (fig.3)

u

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

ON

Back

light

OFF

HUD

HUD

On/Off

No

Access

00000

TRIP

0

ROF

13

ROF

00674

CYCLES

00674

CYCLES

00674

TRIP

00000

ID

00000

ID

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

ASTM

Specification

ASTM

SEMI

SEMI

No sub menu

T0.2

HOPPER

14

DWELL

14

DWELL

TO.1

HOPPER

Total

shots

Factory

reset only

Shot

counter

Reset

to zero

I.D.

number

No

sub-menu

Achieved

rate of fire

Reset

to zero

Firing

mode

No sub menu

Valve

dwell

No access

externally

Hopper

motor

running

time

0.1-2.0 secs.

In 0.1 sec

increments

u

s

s

s

s

OFF

ON

Vibes

game

alarm

On/off

Note:

Access is not granted if:Power is not on or marker

is live, ready to fire.

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

15

ANGEL iR3

TM

external LCD menus whilst in SAFE (fig.3)

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

13

MROF

13

MROF

20:00

TIMER

15:00

TIMER

5:30

5:00

1:30

1:00

5:30

5:00

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

u

s

s

s

s

21ºC

30ºF

IRM2

IRM1

OFF

SEND1

OFF

FETCH

DROPB

TCOPS

A1

HOPPER

A2

HOPPER

PASS

SAFE

SAFE

0:00

0:00

0:00

0:00

Max

rate

of fire

No external

access

u

s

s

s

s

C 13

MROF

C 13

MROF

Max

rate

of fire

No external

access

Game

timer

1-30 mins.

In 30 sec

increments.

Alarm 1.

(icon will

flash)

In 30 sec

increments.

Default 0:00

Alarm 2

Increments.

Default 1:00

Alarm 3

In 30 sec

increments.

Default 5:00

Defaults to ‘SAFE’

status after 10 sec.

The marker is unable

to fire when “SAFE’

or reading menus.

Amber and green

buttons remain

operative for menus.

Defaults to ‘SAFE’

status after 10 sec.

The marker is unable

to fire when “SAFE’

or reading menus.

By holding the button

in the timer will return

to 0:00

By holding the button

in the timer will return

to 0:00

By holding the button

in the timer will return

to 0:00

By holding the button

in the timer will return

to 0:00

Hopper

activation

Hopper activates

after each shot or

after 2, 3, 4 shots

per second or

greater.

Temperature

Centigrade

or Fahrenheit

Infra-red

send

On/Off.

If no signal detected

it will default to

off in 30 secs.

Infra-red

receive

On/Off.

If no signal detected

it will default to off.

Crystal

Operated

Paint

Sensor

The infra-red menu that has

been selected from the internal

menu is the information that will

be transmitted.

IRM1

- All text messages.

IRM2

- All game timer settings.

- VIBES on.

IRM3

- All game timer settings.

- VIBES on.

- Reset shot counter.

IRM4

- All game timer settings.

C.O.P.S test mode

Drop 1 paintball into the breech.

If a paintball is detected ‘PASS’

will be displayed.

If display remains ‘DROPB’ the

C.O.P.S. sensitivity will need

adjusting (see C.O.P.S.

TM

menu).

16

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

external LCD menus whilst in SAFE – PIN number locking/unlocking (fig. 4)

s

s

s

s

s

s

s

s

s

s

01234

0----

2----

2----

24---

24---

246--

246--

2468-

2468-

24680

SAFE

PIN

SAFE

PIN

s

s

s

s

To Unlock To Lock

Press and hold trigger

throughout the PIN number

entering operation.

Unique ID number displayed.

Scroll through 1st

flashing digit using

the external

ORANGE button.

Confirm number

entry using

the external

GREEN button.

Scroll through 2nd

flashing digit using

the external

ORANGE button.

Confirm number

entry using

the external

GREEN button.

Scroll through 3rd

flashing digit using

the external

ORANGE button.

Confirm number

entry using

the external

GREEN button.

Scroll through 4th

flashing digit using

the external

ORANGE button.

Confirm number

entry using

the external

GREEN button.

Confirm full PIN number entry

using the external RED button

Unlocked Locked

NOTE:

• PIN LOCK and UNLOCK

CAN ONLY BE DONE

WITH THE MARKER

IN ‘SAFE’ MODE.

• FACTORY DEFAULT WILL

OVERRIDE THE PIN

NUMBER LOCK.

• THE MARKER BECOMES

PIN NUMBER SECURE

ONLY WHEN THE PIN IS

ENTERED TO LOCK THE

MARKER.

s

24680

0----

Scroll through 5th

flashing digit

using the external

ORANGE button.

s

Clear display

to start again.

ANGEL iR3

TM

ANGEL iR3 OPERATOR’S MANUAL ADDENDUMS - RELATING TO MEM 6 & MEM 6A OPTO

TM

BOARDS

External Electronics LCD C.O.P.S menu whilst live.

The ANGEL iR3 has the C.O.P.S (crystal operated paintball sensor) feature that can be adjusted to suit

your individual needs. This feature is designed to enhance your play by allowing you to minimise the

likelihood of a paintball breaking in the breech during rapid fire. This menu is accessible via the external

buttons. You can also read the settings that have been set via the external live menu list. The menu can

only be accessed when the marker is in “LIVE” mode with the isolator switch in the ON position.

The LED on the rear of the ANGEL iR3 will show the following states:

GREEN constantly on = SAFE mode

RED constantly on = LIVE mode

RED slow flashing = C.O.P.S on and in LIVE mod

RED rapidly flashing = C.O.P.S menu access gained and in LIVE mode

SENS (sensitivity Level)

The Angel iR3 will fire at the rate of fire that you pull the trigger and will also reduce the firing cycle

speed should a paintball not be present in the breech. This reduction in rate of fire is dependant

on your hoppers capability to feed paintballs. If you shoot your marker at speeds in excess of your

hoppers capability the C.O.P.S feature will activate once the SENS has been correctly set.

To set your SENS correctly follow these guidelines

1. Ensure C.O.P.S is switched on.

2. Set SENS level to 12.

3. Set BAS level to 20.

4. Ensure no paint is present in the ANGEL iR3.

5. Fire the Angel iR3 (the marker should fire rapidly SENS level too sensitive).

6. Reduce the SENS level until the marker starts to shoot slower at the BAS speed 20) note the SENS

level eg level 9.

7. Fill your hopper with paintballs and ensure the hopper functions correctly.

8. Attach your hopper to the ANGEL iR3.

9. Shoot your ANGEL iR3 rapidly.

10. Minor adjustments may be done at this stage by increasing or reducing the SENS by 1 level at

a time. Verify your settings by switching your hopper off and the rate of fire must reduce. If this

does not occur adjust the SENS level down eg 8.

BAS (Base level of shots)

In the instance where a paintball has not fallen fully into the breech, this feature allows the user to set the

window of opportunity that occurs after the trigger is pulled before the iR3 will complete its firing cycle.

This feature will only activate if a paintball is not present in the breech when the trigger is pulled and

can result in a pause in the ANGEL iR3 firing cycle when set at the higher levels of its adjustment

range. Once a paintball has been detected the rate of fire will return to the CMROF setting as set

in the internal menu. There are 20 levels of adjustment to suit your shooting style, the default level is 7.

Prior to fine tuning the BAS ensure you have followed the SENS procedure as above.

Level 1

The smaller the window of opportunity.

The larger the risk of a chopped paintball.

Level 20

The larger the window of opportunity.

The smaller the risk of a chopped paintball.

ANGEL iR3 OPERATOR’S MANUAL ADDENDUMS

RELATING TO MEM 6 & MEM 6A OPTO

TM

BOARDS.

Pages 17 - 18.

Instructions to the following areas have changed in the user manual. See text below.

• THIS MENU IS ONLY SETTABLE WHILST THE ANGEL iR3TMIS LIVE AND CAPABLE OF

DISCHARGING.

• Paintball industry standard eye/face/ear and head protection designed specifically to stop

paintballs and meeting ASTM standard F1776 ( USA) or CE standard (Europe) must be worn

by user and any person within range.

• Never point the Angel iR3

TM

at anything you do not intend to shoot.

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADDENDUM

ANGEL iR3

TM

ANGEL iR3 USER MANUAL - ADDENDUMS RELATING TO MEM 6 & MEM 6A OPTO

TM

BOARDS

s

s

s

BAS1

COPS

ss

s

s

s

s

s

s

s

s

s

s

SAFE

LIVE

LIVE

COPS

LIVE

COPS

SENS2

COPS

BAS1

COPS

LIVE

COPS

LIVE

LIVE

SENS1

COPS

SENS3

COPS

BAS20

COPS

Marker unable to fire.

Red, orange and green

buttons operative.

To make ANGEL – LIVE.

Press and hold the red button

for 2 secs.

Press orange button momentarily

to switch C.O.P.S.

TM

off.

Press and hold

orange button

for 5 secs.

Press the green button

to scroll through the

sensitivity menus.

Press the green button

to scroll through the

sensitivity menus 1-12.

Press the orange button to select MROF BAS

level that the marker will default to when the

C.O.P.S.

TM

engages. This will not affect the

MROF that is set in the internal menu.

Press the orange button

to exit C.O.P.S.

TM

menu.

FAST

FAST

FAST

FAST

FAST

FAST

The sensor is not affected by colour or surface

finish of the paintballs and is designed to be

unaffected by paint fill.

BAS 1 = • Smaller window of opportunity for

a paintball to fall into the breech.

• Larger risk of chopping a paintball.

BAS 20 = • Larger window of opportunity for

a paintball to fall into the breech.

• Smaller risk of chopping a paintball.

THE MARKER IS LIVE

AND CAPABLE OF DISCHARGING.

OBSERVE ALL SAFETY

INSTRUCTIONS & GUIDELINES.

ANGEL iR3 OPERATOR’S MANUAL ADDENDUMS

RELATING TO MEM 6 & MEM 6A OPTO

TM

BOARDS.

Pages 17 - 18.

Instructions to the following areas have changed in the user manual. See text below.

ADDENDUM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

19

ANGEL iR3

TM

internal tournament LCD menus

INTERNAL TOURNAMENT LCD MENUS

• Ensure a barrel blocking device is fitted to the ANGEL iR3

TM

• Ensure the hopper is removed from the ANGEL iR3

TM

• Ensure that there are no paintballs in the ANGEL iR3

TM

• The ANGEL iR3TMhas a number of features that can be adjusted to suit your individual

needs

(fig. 6 page 21). These features that can change the performance of the gun are only accessible

via the internal menu list. This is to ensure that they pass tournament and field operator requirements.

• The menus can only be accessed when the marker is in “SAFE” mode and the isolator switch

is in the ON position.

• Remove left hand grip cover screws to expose the circuit board.

• Follow the internal menu list diagrams for relevant settings.

Should you wish to return to factory settings the ANGEL iR3

TM

has the unique feature that allows you

to return to the factory defaults. (See internal menu diagram for instructions.)

• The ANGEL iR3

TM

also has the unique feature that ensures any settings that you enter are stored in an

E.D.S. (encrypted data storage) memory to give added protection against data loss.

Mode feature

In certain countries local applicable laws or industry standards may mean certain modes may not be

enabled or allowed. Check with law enforcement office, or local professional paintball venue.

Where applicable 26 modes of shooting may be selected. The firing modes listed below are programmed in

the ANGEL iR3

TM

. Including 5 modes that you may program yourself using the ANGEL IR LINK.

ASTM = TRUE SEMI Max of 20/sec (ALL OTHER MODES ARE DISABLED)

EXTRA = ALL MODES ARE ENABLED

• AUTO = Full Auto to a max 20/sec

• 2SHOT = 2 shot burst variable rate to a Max of 20/sec

• 3SHOT = 3 shot burst variable rate to a Max of 20/sec

• 4SHOT = 4 shot burst variable rate to a Max of 20/sec

• 5SHOT = 5 shot burst variable rate to a Max of 20/sec

• 6SHOT = 6 shot burst variable rate to a Max of 20/sec

• 7SHOT = 7 shot burst variable rate to a Max of 20/sec

• 8SHOT = 8 shot burst variable rate to a Max of 20/sec

• 2ZIP = 2 shot ZIP fixed rate of 8.75/sec

• 3ZIP = 3 shot ZIP fixed rate of 8.75/sec

• 4ZIP = 4 shot ZIP fixed rate of 8.75/sec

• 5ZIP = 5 shot ZIP fixed rate of 8.75/sec

• 6ZIP = 6 shot ZIP fixed rate of 8.75/sec

• 7ZIP = 7 shot ZIP fixed rate of 8.75/sec

• 8ZIP = 8 shot ZIP fixed rate of 8.75/sec

• RAMP1 =10 ms reduction between shots ramp Max rate of 13/sec

• RAMP2 = 20 ms reduction between shots ramp Max rate of 13/sec

• RAMP3 = 40 ms reduction between shots ramp Max rate of 13/sec

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

20

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

internal tournament LCD menus

• PROG1 = Programmable mode via IR link Max rate of 20/sec

• PROG2 = Programmable mode via IR link Max rate of 20/sec

• PROG3 = Programmable mode via IR link Max rate of 20/sec

• PROG4 = Programmable mode via IR link Max rate of 20/sec

• PROG5 = Programmable mode via IR link Max rate of 20/sec

• MULTI = Multiplier

• TT = TT multiplier

Dwell feature (fig.6 page 21)

Dwell controls the valve opening time. Longer dwell time uses more gas and generates more noise but

allows the marker a greater tolerance to paint, temperature and pressure variables. Shorter dwell time uses

less gas and reduces noise but is less tolerant of poor paint and pressure variables. Adjustment is only

recommended if you wish to fine-tune your marker to specific accessories.

Adjustment ranges 10 milliseconds to 24 milliseconds.

MROF maximum rate of fire limit with C.O.P.S.TMoption OFF (fig.6 page 21)

This allows you to tune your maximum rate of fire when C.O.P.S. option is OFF to your style of play and

feed system. Certain modes are capped or non-adjustable. The rate of fire should not be set to greater

than your feed system is capable of delivering. See table on Modes for maximum allowable settings p21.

CMROF maximum rate of fire limit with C.O.P.S.TMoption ON (fig.6 page 21)

This allows you to tune your maximum rate of fire when C.O.P.S.TMoption is ON to your style of play and

feed system. Certain modes are capped or non-adjustable. The rate of fire should not be set to greater

than your feed system is capable of delivering. See table on Modes for maximum allowable settings p21.

Temperature feature (fig.6 page 21)

This allows you to set the temperature display between Fahrenheit and centigrade. This feature is useful

in determining the ambient temperature to allow you to select your accessories for the climatic conditions

in the format you prefer.

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

21

ANGEL iR3

TM

internal tournament LCD menus (fig.6)

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

ASTM

SEMI

COPS

77ºF

13

MROF

C13

MROF

HUD

XTRA

AUTOF

DROPB25°

C

14

MROF

C14

MROF

ON

Note: Menus shown are the ones denied

access to via the external menu.

All external menus may also be accessed via

the internal menu. Please refer to the external

menu flow diagram.

s

PASS

s

s

SAFE

SAFE

Note: Access is not granted if:-

• Power is not on.

• Marker in live ready to fire.

Main menu Sub menu

UK and USA

specification

Access may be denied. text will

display ‘NOACC’ due to applicable

county guidelines. ‘XTRA’ enables

up to 26 modes of firing.

Firing mode Only enabled if the

specification permits modes

of firing. Up to 26 available.

C.O.P.S. UK and USA

specification

Temperature Centigrade

or Fahrenheit

Max rate of fire

possible without

C.O.P.S.

Adjustable rate of fire when C.O.P.S.

option is not selected.

Max rate of fire

possible with

C.O.P.S.

Adjustable rate of fire when C.O.P.S.

option is selected

s

s

s

s

14

DWELL

15

DWELL

Valve dwell

Range: 10-24 milliseconds

H.U.D.

Head Up Display

Access may be denied depending on

specification. Switches H.U.D. on/off.

C.O.P.S. test mode

Drop 1 paintball into the breech.

If a paintball is detected ‘PASS’

will be displayed.

If display remains ‘DROPB’ the

C.O.P.S. sensitivity will need

adjusting (see C.O.P.S. menu).

Press and hold

both buttons for

2 seconds.

RESETS

Defaults to safe status after

10 secs. The marker is

unable to fire when safe

or reading menus.

Defaults to safe status after

10 secs. The marker is

unable to fire when safe

or reading menus.

RESET DEFAULTS

Vibes On

Backlight On

Cycle N/A

Trip 00000

ROF 00

Timer 20mins

Alarm 1 0:00

Alarm 2 0:00

Alarm 3 1:00

Dwell 14m/sec

IR menu IR M1

ID number N/A

H.U.D. Off

C.O.P.S. Off

Spec ASTM

Mode Semi

Hopper motor run time 0.3 sec

Hopper activation 1st ball

Infra-red send Off

Infra-red fetch Off

Temperature °F

BAS 1

Sense 9

MROF with C.O.P.S. 16

MROF without C.O.P.S. 11

T.C.O.P.S. (C.O.P.S.TMTest Feature) (fig.6 page 21)

• Paintball industry standard eye/face/ear and head protection designed specifically to stop

paintballs and meeting ASTM standard F1776 ( USA) or CE standard (Europe) must be worn

by user and any person within range.

• Ensure a barrel blocking device is fitted to the ANGEL iR3

TM

• Ensure the hopper is removed from the ANGEL iR3

TM

• Ensure that there are no paintballs in the ANGEL iR3

TM

The T.C.O.P.S. feature is the Crystal Operated Paint Sensor test mode. This allows the user to drop

a paintball into the breech to verify that the sensor is operating correctly.

NOTE: The C.O.P.S.TMfeature is designed to reduce the rate of fire when a paintball is not present

in the breech.

To test the sensor:

• Remove Gated Feed

TM

for easier access.

• Select the sub menu and the message DROPB is displayed.

• Drop a paintball into the breech.

• When a paintball is detected the message PASS is displayed.

• Failure to obtain a PASS message may mean that the C.O.P.S.

TM

sensitivity will need adjustment (see

C.O.P.S.

TM

menu) or that the sensor is fouled or has been damaged.

CAUTION:

• Remove paintballs used for testing C.O.P.S.

TM

.

• Do not press the black actuator located in the bottom of the breech with sharp objects as damage

will occur to the sensor.

• Do not use after market bolts that are not designed to be used with the C.O.P.S. feature.

Pin number setting feature (fig.7 page 23)

This allows you to set your own 5 digit personal pin number for added security. When the pin number

is enabled the ANGEL iR3

TM

is locked and incapable of firing to prevent unauthorized use.

We recommend you use this security feature to protect your ANGEL iR3

TM

from misuse.

(See PIN number locking and unlocking fig. 4 page 16)

CAUTION:

• Once the pin number is set should you forget your pin code, and cannot unlock the ANGEL iR3

TM

you

need to return the ANGEL iR3

TM

to its original factory setting by using the factory default procedure.

(See Pin number menu diagram fig.7 p 23).

Text setting feature (fig.8 page 24)

• Factory resetting will clear any text message that you have entered into the ANGEL iR3

TM

• Do not enter any text that may cause confusion to the indicated live status of the

ANGEL iR3

TM

, eg: “SAFE, STOP, OFF” etc.

This allows you to set your own personal text to enhance and personalize your ANGEL iR3

TM

.

This text will appear in conjunction with the live message and appear as a scrolling message only when

the ANGEL iR3

TM

is live. You may enter a maximum of 5 characters.

22

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

internal tournament LCD menus

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ADHERE STRICTLY TO THESE AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

23

ANGEL iR3

TM

internal tournament LCD menus - PIN number programming (fig.7)

s

SAFE

StPIN

2----

24---

246--

2468-

24680

0----

2----

24---

246--

2468

PINSt

s s

s

s

NOTE:

• PROGRAMMING CAN ONLY BE DONE

WITH THE MARKER IN ‘SAFE’ MODE.

• FACTORY DEFAULT WILL CLEAR PIN

NUMBER PROGRAMMING.

• THE MARKER BECOMES PIN NUMBER

SECURE ONLY BY THE USER ENTERING

THE PIN TO LOCK THE MARKER.

Press and hold trigger

throughout the PIN number

entering operation.

Press and hold

button for 1 sec.

Press and hold

button for 1 sec.

Scroll through

1st flashing digit

using the external

ORANGE button.

Confirm number

entry using the

external GREEN

button.

Scroll through

2nd flashing digit

using the external

ORANGE button.

Confirm number entry

using the external

GREEN button.

Scroll through

3rd flashing digit

using the external

ORANGE button.

Confirm number

entry using the

external GREEN

button.

Scroll through

4th flashing digit

using the external

ORANGE button.

Confirm number

entry using the

external GREEN

button.

Confirm full PIN number

entry using the external

RED button.

YOUR PIN NUMBER

s

s

ss

ss

s

0----

Clear display

to start again.

24680

Scroll through

5th flashing digit

using the external

ORANGE button.

ss

s

1

1

Go to point 1.

24

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

internal tournament LCD menus - text programming (fig.8)

SAFE

TEXT

-----

A

----

A

----

AN

---AN---

ANG

--

ANG

--

ANGE

-

ANGE

-

ANGEL

ANGEL

SET

s

s

s

s

ss

s

ss

s

Hold trigger

Note:

• Factory default will

clear any text entered

• Words that cannot be

entered are:

‘SAFE’ and ‘STOP’

• Programming can only

be done with the

marker in ‘SAFE’ mode.

• Text entered will only

be displayed when the

marker is live.

Hold trigger

Press button twice

Scroll through to 1st character or

number. External ORANGE button.

Hold trigger

Hold trigger Hold trigger

Hold

trigger

Confirm character

entry. External

GREEN button.

Scroll through to

2nd character.

External ORANGE

button.

Confirm character

entry. External

GREEN button.

Hold trigger

Scroll through to

3rd character.

External ORANGE

button.

Confirm character

entry. External

GREEN button.

Hold trigger Hold trigger Hold trigger

Hold

trigger

Scroll through to

4th character.

External ORANGE

button.

ANGEL

Confirm character

entry. External

GREEN button.

Scroll through to

5th character.

External ORANGE

button.

Clear display

to start again

Hold trigger

Setting.

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

25

ANGEL iR3

TM

PCB layout and wiring connections

TO HOPPER MOTOR

TEST POINT

14-WAY VALVE

C.O.P.S. SENSOR

SIGHT RAIL

ISOLATOR SWITCH

METAL HYDRIDE 6.0V

LED

LCD DISPLAY

RETAINING CLIPS

6 PIN SOCKET

AUTOMOBILE CHARGER

CAUTION:

VOLTAGE MUST NOT EXCEED 14.5V DC

HOPPER CONVERSION KIT

CAUTION:

DO NOT HANDLE THE

LCD SCREEN IN THE

DIRECTION SHOWN.

DAMAGE WILL OCCUR

TO THE RIBBON CABLE.

METAL HYDRIDE CHARGER

C.O.P.S. SENSOR SOCKET

14-WAY VALVE SOCKET

HOPPER SOCKET

BATTERY SOCKET

CHARGER SOCKET

RED BUTTON

(SWITCH 2)

• EXTERNAL ON/OFF

• C.O.P.S. MENU

ORANGE BUTTON

(SWITCH 3)

• EXTERNAL MAIN MENU

• PIN SELECT

• C.O.P.S. MENU

GREEN BUTTON

(SWITCH 4)

• EXTERNAL SUB MENU

• TIMER ARM/STOP

• PIN ENTER

• C.O.P.S. MENU

BUTTON (SWITCH 6)

•INTERNAL SUB MENU

• RESET DEFAULT

BUTTON (SWITCH 5)

•INTERNAL MENU

• RESET DEFAULT

BACK LIT LCD DISPLAY

OPTO TRIGGER

TM

• TIMER START

• PIN ACCESS

26

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

figures – general assembly

LPR PRESSURE TESTER.

(optional accessory)

ANTI DOUBLE BALL

VALVE GUIDE

VALVE STEM

VALVE

SPRING

LPR ASSEMBLY

END

CAP

PISTON EXTRACTOR

(optional accessory)

MANIFOLD SEALS

FLASH TANK MANIFOLD

FLASH TANK

CAP M5 x 18mm

MINI REGULATOR

BUTTON

M5 x 12mm

BUTTON

M5 x 16mm

GUIDE

LOCK

PIN

LPR

LOCK PIN

BOLT

DIVERTER

SEALS

DIVERTER

PLATE

ACTIVATOR

ROD

GATED

FEED

FEED TUBE COLLAR

FEED TUBE

NECK

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

27

ANGEL iR3

TM

figures – general assembly

BUTTON

M5 x 12mm

GRIP FRAME

M2.5 x 12mm M2.5 x 12mm

SIGHT RAIL

CLAMP PLATE

GRUB M5 x 8mm

14-WAY VALVE

VALVE MANIFOLD

MANIFOLD GASKET

BACK PLATE

CSK M3 x 6mm

BREECH BLOCK LOCK PIN

BREECH BLOCK

PULL KNOB

BREECH BLOCK

SPRING

TOGGLE SWITCH

HAMMER SNAP

‘O’ RING

SNAP

RING SCREW

RAM AND CLAMP PLATE ALIGNMENT TOOL

(optional accessory)

RAM EXTRACTOR ROD

(optional accessory)

FUNCTION

BUTTONS

PCB

C.O.P.S.

TM

SENSOR

28

ANGEL iR3

TM

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

figures – major parts detail

SEAL PISTON SPRING

STACK

SHIMS SEAL BODY

HAMMER

BUMPER

SEAL SEAL SNAP RING

SCREW

TRIGGER

OVER TRAVEL

ADJUSTMENT

SEALSEALSEAL

LPR assembly

SUPA-GLIDE RAM assembly

SEAL SEALVALVE STEMSPRING

VALVE GUIDE

Exhaust valve stem and guide assembly

3STYLA

TM

Trigger assembly

BALL

BEARING

SMALL PISTON LARGE PISTON

SPRING STACK 7 X OFF

SEAL

SEAL SEAL

CIRCLIP

MACRO LINE

CONNECTOR

BODY

SEAL

GRUB SCREWVELOCITY

ADJUSTER

SCREW

Mini regulator assembly

TRIGGER

PIVOT

POINTS

TRIGGER

RETURN STROKE

ADJUSTMENT

TRIGGER SPRING

contents

important safety

guidelines

operating instructions

external LCD menus

whilst in SAFE

external LCD C.O.P.S.

menu whilst LIVE

internal tournament

LCD menus

figures

maintenance

fault finding tables

useful conversions

warranties

update info

your ANGEL iR3

TM

29

ANGEL iR3

TM

maintenance

MAINTENANCE

• Always wear industrial standard eye protection when performing any maintenance on the ANGEL iR3TM.

GENERAL CARE AND CLEANING

• Ensure a barrel blocking device is fitted to the ANGEL iR3

TM

• Ensure the hopper is removed from the ANGEL iR3

TM

• Ensure that there are no paintballs in the ANGEL iR3

TM

• Always remove the first stage regulator and relieve all residual gas pressure from the ANGEL iR3

TM

before disassembly.

• The ANGEL iR3

TM

can hold a small residual charge of gas, typically 2 shots, with the first stage

regulator removed. Always discharge the marker in a safe direction to relieve this residual gas pressure.

The ANGEL iR3

TM

is fitted with a unique MAS (Maintenance Advice System) which monitors the operating

conditions of the ANGEL iR3

TM