Page 1

Page 2

CONTENTS

ANGEL FLY

1

• This Operators and Users Manual is in English.

• It contains important safety guidelines and Instructions.

• Should you be unsure at any stage, or unable to understand

the contents within this manual you must seek expert advice.

• Le mode d’emploi est en Anglais.

• Il contient des instructions et mesures de sécurité importantes.

• En cas de doute, ou s’il vous est impossible de comprendre

le contenu du monde d’emploi, demandez conseil à un expert.

• Este manual de (operarios y) usarios està en Inglés.

• Contiene importantes normas de seguridad e instrucciones.

• Si no esta seguro de algún punto o no entiende los contenidos

de este manual debe conultar con un experto.

• Diese Bedienungs- und Benutzeranleitung ist in Englisch.

• Sie enthält wichtige Sicherheitsrichtlinien und -bestimmungen.

• Sollten Sie sich in irgendeiner Weise unsicher sein, oder den Inhalt dieses

Heftes nicht verstehen, lassen Sie siche bitte von einem Experten beraten.

WARNINGS

Important Safety Instructions & Guidelines 2

OPERATING INSTRUCTIONS

Charging 3

Switching On Your ANGEL 3

Making the ANGEL Live / Safe 4

Switching Angel Eyes On/Off 4

Propellant Air/Nitrogen Supply 4

Macro Line Hose/Connector attachment 4

Macro Line Hose removal and re-attachment 5

Loaders (Hoppers) 5

Soft Nose Bolt Removal & Rotor Breech 5

Velocity Adjustment 6

Twist Lock Feed Collar 6

Volumizer Accessories 6

LCD MENUS

Basic Menu 7

Menu – Fetch – Timer – Angel Eyes Test

Advanced Menu 7 – 8

MROF – Hopper (Loader) T Time – Hopper

Hopper (Loader) Type – Temperature – Vibrator – Trip – Backlight

SEND IR – ROF – MODE – Dwell – Cycles – ID – Trigger Offset

Internal Electronic Menus 8

Factory Default Settings 8

(Loader) A Time

FIGURES

1 Basic & Advanced Menus 9

2 Internal Menu 10

3 Internal Text Programming 10

4 Internal PIN Programming 10

5 External PIN Lock/Unlock 11

6 Game Timer Activation

11

MAINTENANCE

General Care and Cleaning 12

General Assembly - Right Hand View 12

General Assembly - Left Hand View 13

Sub Assemblies 13

Cutaway – Right Hand View 14

Cutaway – Left Hand View 14

Mini-Regulator Service 15

Anti-Double Ball Detent Service 15

Angel Eyes Service, Removal, Test & Replacement 16

Micro-Pressure Indicator (Optional) 17

LPR Adjustment 17

LPR Assembly Removal 18

LPR Main Seal Replacement 18

Exhaust Guide Removal 19

Exhaust Valve Stem Removal 19

Ram Stroke Adjustment 20

Ram Removal 20

Ram Servicing 20

OPTO Board 21

Vernier Trigger Adjustments 21

Vernier Trigger Wheel Removal 22

Battery Removal 23

Wiring Connections 23

APPENDIX

Fault Finding Table 24

Useful Conversions 24

Terms of Warranty - EEC/R.O.W Exc USA/CAN 25

WDP Ltd. Express Warranty USA/CAN Only 26

Updates 27

Your Personal Details

Notes 28

27

© 2004 WDP LTD.

Page 3

2

ANGEL FLY

Warnings: Important Safety Instructions & GuidelinesWARNINGS

WARNING

AD HE RE S TR IC TLY TO T HE SE A ND A LL O TH ER S AF ET Y IN ST RU CT IO NS A ND G UI DE LI NE S

WARNINGS FOR SAFE ANGEL HANDLING

· The ANGEL is not a toy.

· Careless or improper use, including failure to follow instructions and warnings

within this Operator Manual and attached to the ANGEL could cause death or

serious injury.

· Do not remove or deface any warnings attached to the ANGEL.

· Paintball industry standard eye/face/ear and head protection designed

specifically to stop paintballs and meeting ASTM standard F1776 (USA) or CE

standard (Europe) must be worn by user and any person within range.

· Must be at least 18 years of age to purchase the ANGEL.

· Persons under 18 years of age must have adult supervision when using or

handling the ANGEL.

· Observe all local and national laws, regulations and guidelines.

· Use only on professional paintball fields where codes of safety are strictly

enforced.

· Use compressed air/nitrogen gas only. Do not use CO2.

· Do not exceed 850 psi (58 bar) input pressure.

· Always follow instructions, warnings and guidelines given with any first stage

regulator you use with the ANGEL.

· Use 0.68 calibre paintballs only.

· Keep the ANGEL switched off until ready to shoot.

· Treat every marker as if it is loaded.

· Never point the ANGEL at anything you do not intend to shoot.

· Do not shoot at persons at close range.

· Do not shoot at fragile objects such as windows.

· Always measure your markers velocity before playing paintball, using a suitable

chronograph.

· Never shoot at velocities in excess of 300 feet (91.44 meters) per second, or at

velocities greater than local or national laws allow.

· Do not fire the ANGEL with the breech open or without the bolt in the breech, as

high pressure gas will be emitted.

· Do not fire the ANGEL with the pull knob in the unlocked position.

· Never look into the barrel or breech area of the ANGEL whilst the marker is

switched on and able to fire.

· Never put your finger or any foreign objects into the paintball feed tube of the

ANGEL

· Never allow pressurised gas to come into contact with any part of your body.

· Always switch off the ANGEL when not in use.

· Always fit a barrel blocking device to your ANGEL when not in use on the field

of play.

· Always remove all paintballs from the ANGEL when not in use on the field of

play.

· The Twisted Lock Gated Feed™ is designed to retain a number of paintballs

in the feed tube and breech area of the ANGEL Always ensure that these

paintballs are removed from the ANGEL when it is not in use on the field of play.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction

to relieve this residual gas pressure.

· Always remove first stage regulator and all residual gas pressure from the

ANGEL for transport and storage.

· Always follow warnings and guidelines given with your first stage regulator for

safe transport and storage.

· Only charge the ANGEL using the charger supplied.

· Only use 12 Volt negative earth vehicles as a power supply for the charger.

· Do not leave the ANGEL unattended whilst charging.

· Always store the ANGEL in a secure place.

· THIS OPERATOR MANUAL MUST ALWAYS ACCOMPANY THE PRODUCT IN THE

EVENT OF RESALE OR NEW OWNERSHIP.

· SHOULD YOU BE UNSURE AT ANY STAGE YOU MUST SEEK EXPERT ADVICE.

© 2004 WDP LTD.

Page 4

OPERATIONCharging – Switching On Your ANGEL

ANGEL FLY

3

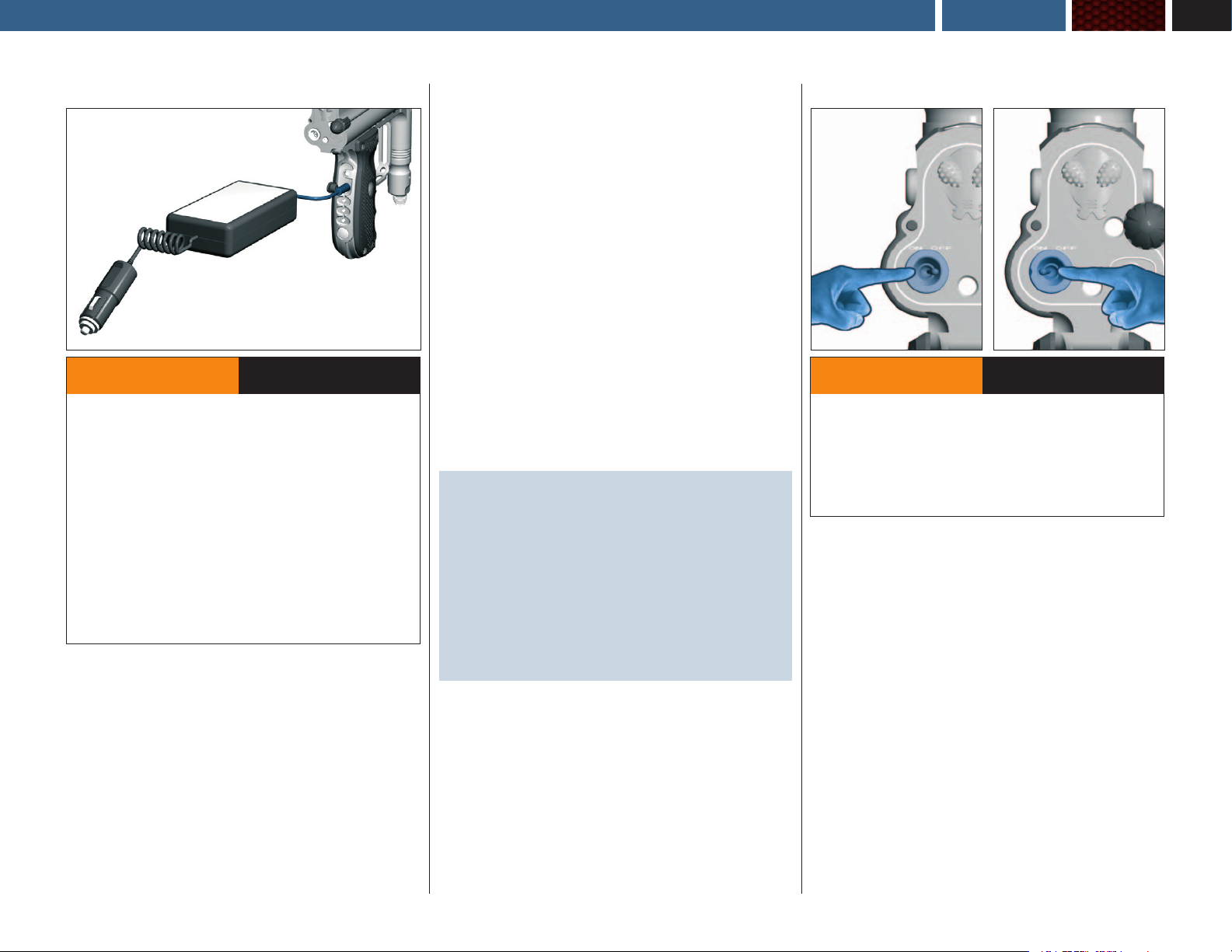

CHARGING

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Ensure the ANGEL is switched off via the isolating switch at the rear of the

marker prior to fitting your first stage regulator.

· Paintball industry standard eye/face/ear and head protection designed

specifically to stop paintballs and meeting ASTM standard F1776 (USA) or CE

standard (Europe) must be worn by user and any person within range.

· Always follow instructions, warnings and guidelines given with any first stage

regulator you use with the ANGEL.

· Use compressed air/nitrogen gas only DO NOT USE CO2.

· Only use a paintball regulator that has been designed for air or nitrogen gas.

· Do not exceed 850 psi (58bar) input pressure to the ANGEL.

· Take suitable precautions when using sharp cutting instruments.

· The Macro Line hose must be cut back cleanly and square prior to attachment

or re-attachment to ensure secure fitment.

· SHOULD YOU BE UNSURE AT ANY STAGE YOU MUST SEEK EXPERT ADVICE.

Before initial use of the ANGEL, it is necessary to give the power pack a full

charging cycle of 4 hours prior to use as this will ensure a long life for the power

pack.

Subsequent charges will be in the region of 3 hours for a full charge, the

electronics will control the charging cycle and ensure that your battery is fully

charged.

The ANGEL may be left charging for prolonged periods without damage

occurring to the battery pack.

· A full charge will give sufficient power for approximately 150,000

consecutive shots.

· A 1-hour charge at 12.5V DC will give sufficient power for approximately

40,000 consecutive shots.

The ANGEL will continue to use power whilst it is switched

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

ON.

To save the charge the isolator switch must be switched

battery.

We recommend the isolating switch be placed in the

ANGEL is in storage, transit or not in use.

· Insert cigar lighter adaptor into a negative earth socket as found in most

motor vehicles (red light on charger will illuminate to indicate that power

is present).

· Insert remote plug from charger into the socket on the rear of the

ANGEL. The socket is located on the rear of the grip frame under a

rubber protection grommet.

· Ensure the isolator switch is in the ON position at the rear panel of the

ANGEL. See SWITCHING ON YOUR ANGEL - right.

· The LCD on the ANGEL display will indicate the status of the charging

cycle, the bar graph segments on the display will cascade to indicate

charge is being taken.

· When a full charge has been taken the bar graph segments will remain

illuminated.

· Removal of the charger before a full charge cycle has been completed

will result in a short charge.

· Unplug the charger from the ANGEL and replace the rubber grommet

cover on the rear of the grip frame to prevent the entry of dirt or debris.

IMPORTANT NOTES: For Battery Charging

· Should the ANGEL be “LIVE” the insertion of the charger will make the ANGEL

“SAFE” and unable to fire and removal of the charger will cause the marker

to remain in this state until the ANGEL is made “LIVE” again by pressing and

holding the red button on the back of the grip frame for 2 seconds.

· Supply voltage must be minimum 12V DC, maximum 24V DC, negative earth.

· The isolator ON/OFF switch on the back of the ANGEL must be in the ON

position to charge the battery.

· The battery must be plugged into the circuit board.

· Removal of the charger before a full charge cycle has been completed will

result in a short charge. Check your vehicle handbook for voltage and current

capabilities prior to use.

· Use only the charger supplied for charging the ANGEL.

OFF to isolate the

OFF position when the

SWITCHING ON YOUR ANGEL

ONOFF

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Ensure the ANGEL is switched off via the isolating switch at the rear of the

marker prior to fitting your first stage regulator.

· Paintball industry standard eye/face/ear and head protection designed

specifically to stop paintballs and meeting ASTM standard F1776 (USA) or CE

standard (Europe) must be worn by user and any person within range.

· Ensure the battery is charged.

· Switch the isolator switch to the ON position.

· The LED on the rear of the grip frame will be Green.

· The LCD display will show software version and ‘SAFE’.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

© 2004 WDP LTD.

Page 5

4

ANGEL FLY

OPERATION Making the ANGEL Live – Switching ANGEL Eyes On/Off – Propellant Air/Nitrogen Supply

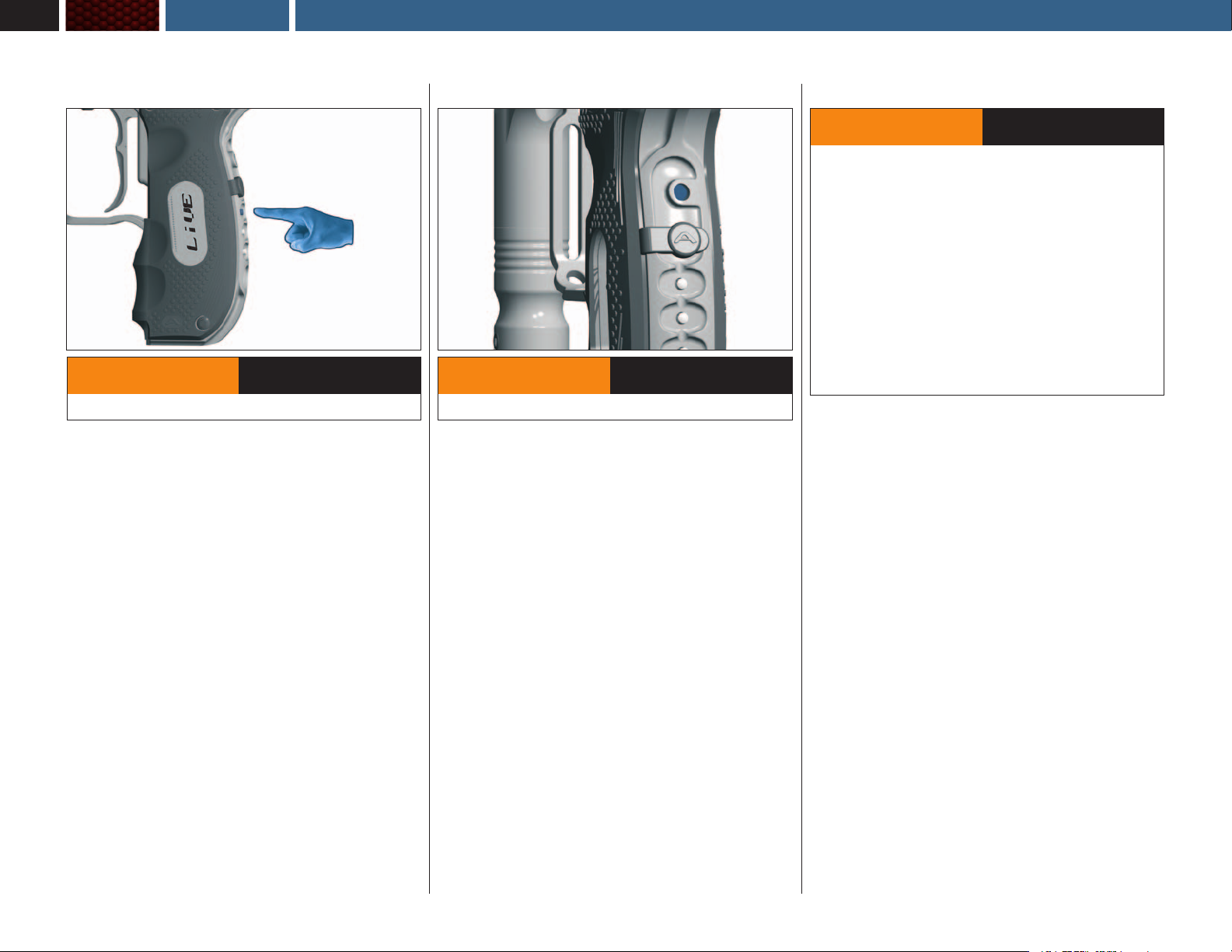

MAKING THE ANGEL LIVE

ADHERE STRICTLY TO THESE

WARNING

· THE ANGEL IS LIVE AND CAPABLE OF DISCHARGING.

· Ensure the ANGEL is switched ON. See SWITCHING ON YOUR ANGEL

- Page 3.

· Press the top button on the rear of the grip frame for 1 second until the

LED on the rear of the frame turns Red and the LCD displays ‘LIVE’.

MAKING THE ANGEL SAFE

Press and hold the top button on the rear of the grip frame for 2 seconds until

the display indicates ‘SAFE’, alternatively switch the ANGEL OFF via the isolator

switch on the rear of the ANGEL.

LED INDICATOR STATUS ON THE REAR OF THE FRAME

· NO LED = No charge present or isolator switch is OFF.

· GREEN CONSTANTLY ON = SAFE mode.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

SWITCHING ANGEL EYES ON/OFF

ADHERE STRICTLY TO THESE

WARNING

· THE ANGEL IS LIVE AND CAPABLE OF DISCHARGING.

· Ensure the ANGEL is switched ON. See SWITCHING ON YOUR ANGEL

- Page 3.

· As default the Angel Eyes will always be ON whenever the ANGEL is

made LIVE.

· The Angel Eyes can only be switched off by pulling and holding the

trigger in for 2 seconds.

· In modes 2 to 5 and Demo, the Angel Eyes cannot be switched off.

· To switch the Angel Eyes back on whilst the ANGEL is LIVE you may

either switch the ANGEL OFF and ON via the isolator switch and then

make the ANGEL LIVE by pressing the top button, or alternatively make

the ANGEL SAFE then LIVE.

LED INDICATOR STATUS ON THE REAR OF THE FRAME

· RED CONSTANTLY ON = LIVE mode, ANGEL EYES OFF.

· RED SLOWLY FLASHING = LIVE mode, ANGEL EYES ON.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

PROPELLANT AIR / NITROGEN SUPPLY

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Ensure the ANGEL is switched off via the isolating switch at the rear of the

marker prior to fitting your first stage regulator.

· Paintball industry standard eye/face/ear and head protection designed

specifically to stop paintballs and meeting ASTM standard F1776 (USA) or CE

standard (Europe) must be worn by user and any person within range.

· Always follow instructions, warnings and guidelines given with any first stage

regulator you use with the ANGEL.

· Use compressed air/nitrogen gas only DO NOT USE CO2.

· Only use a paintball regulator that has been designed for air or nitrogen gas.

· Do not exceed 850 psi (58bar) input pressure to the ANGEL.

· Take suitable precautions when using sharp cutting instruments.

· The Macro Line hose must be cut back cleanly and square prior to attachment

or re-attachment to ensure secure fitment.

· SHOULD YOU BE UNSURE AT ANY STAGE YOU MUST SEEK EXPERT ADVICE.

The ANGEL is designed to operate on air/nitrogen gas. This needs to be supplied

to the ANGEL at an ideal regulated pressure of 400 psi (27.5 BAR) using a

suitable first stage paintball regulator, such as the ANGEL A.I.R.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

© 2004 WDP LTD.

Page 6

OPERATIONMacro Line Hose – Loaders – Soft Nose Bolt Removal & Rotor Breech

ANGEL FLY

5

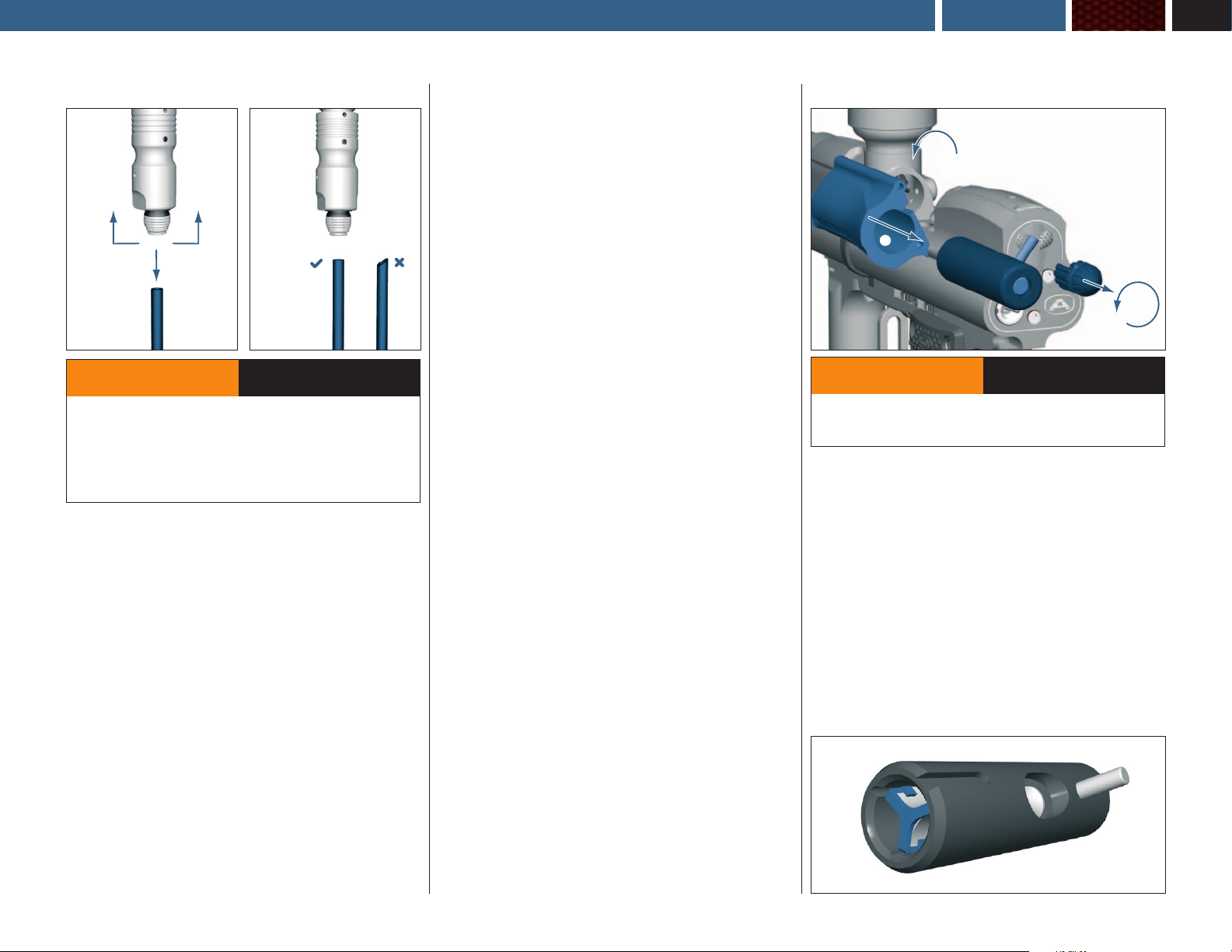

MACRO LINE HOSE

1

WARNING

· All gas pressure must be relieved from the ANGEL and second stage regulator

prior to the Macro Line hose removal.

· The ANGEL can hold a small residual charge of gas, typically 2 shots with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

· The Macro Line hose must be cut back cleanly and square prior to

re-attachment to ensure secure fitment.

MACRO LINE HOSE / CONNECTOR REPLACEMENT

· Connect the Macro Line connector to your first stage regulator outlet

port using a suitable wrench or spanner.

· If necessary shorten the Macro Line hose using a sharp knife to the

required length to suit your ANGEL and first stage regulator set up.

· Push the free end of the hose firmly into the Macro Line connector

attached to the ANGEL second stage regulator.

REMOVAL & RE-ATTACHMENT

· The Macro Line hose may be removed from the Macro Line connectors

to facilitate maintenance.

· Pull back the collet

· Pull the Macro Line hose 2 out of the connector firmly.

· Cut back the Macro Line hose cleanly and square.

· Push the hose firmly into the Macro Line connector to re-attach.

1

2

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1 on the connector and keep the collet depressed.

LOADERS (HOPPERS)

The ANGEL has been designed to work with all existing loaders and intelligently

self adjusts its program to suit the loaders feed rates for the type of loader

selected from the Advanced Menu - see page 7, but there are some important

things to remember about loaders:

· The Angel Eyes system will shoot paint as fast as your loader is capable of

feeding in combination with trigger pulls.

· Some loaders, particularly those with a reflective eye system DO NOT correctly

sense twin skin, marbleized or dark coloured paintballs, and as such, these

loaders are capable of breaking or cracking paintballs before they are even

loaded into the ANGEL.

· All loaders should only be used with fresh batteries.

· It is also essential that the loader and its optical system is kept clean at all

times.

· Force fed loaders, due to the nature of their design are less tolerant of fragile

and poor quality paint, causing breaks in the loader, and feed stack before they

are loaded into the ANGEL.

· Some loaders are not capable of sustained feed rates and you will be able to

outshoot the loader, causing the Angel Eyes to wait for verification of a paintball

before commencing the firing cycle.

· Poorly maintained or damaged loaders will impair the performance capability

of the ANGEL.

· To maximise the performance of the ANGEL, WDP recommends only using

reliable enhanced feed loaders.

SOFT NOSE BOLT REMOVAL & ROTOR BREECH

3

4

ADHERE STRICTLY TO THESE

WARNING

· Do not fire the ANGEL with the breech open or without the bolt in the breech,

as high pressure gas will be emitted.

· Do not fire the ANGEL with the pull knob in the unlocked position.

The bolt is manufactured from aluminium and plastic with the wear surfaces

being plastic, this is to ensure – due to its high operating speeds – it does not

seize within the body. Eventually this will show signs of wear dependent on

usage and its environment of use.

It is important that the bolt is kept clean and free of dirt or grit as this will cause

accelerated wear. We recommend that you clean your bolt after each day of play.

· Ensure the ANGEL isolator switch is in the OFF position or the ANGEL is

in SAFE mode.

· Pull the Pull knob

in the unlocked position.

· Swing out the Rotor Breech block

breech will not open if the bolt is in the forward position. Ensure it is

retracted by either: momentarily gassing the ANGEL or pushing the bolt

back with a squeegee.

· Extract the bolt

· To replace the bolt follow the stages in reverse order.

1 and rotate 90 degrees 2 so that the knob remains

4 by pulling rearwards.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

3 so that the bolt is exposed. The

1

2

© 2004 WDP LTD.

Page 7

6

ANGEL FLY

Velocity Adjustment – Twist Lock Feed Collar – Volumizer AccessoriesOPERATION

VELOCITY ADJUSTMENT

ADHERE STRICTLY TO THESE

WARNING

· THE ANGEL IS LIVE AND CAPABLE OF DISCHARGING

· Paintball industry standard eye/face/ear and head protection designed

specifically to stop paintballs and meeting ASTM standard F1776 (USA) or CE

standard (EU) must be worn by user and any person within range.

· Always measure your markers velocity before playing paintball, using a suitable

chronograph.

· Never shoot at velocities in excess of 300ft (91.44 meters) per second, or at

velocities greater than local or national laws allow.

DECREASING VELOCITY

The velocity adjusting screw is located on the lower portion of the front grip.

· To decrease the velocity, insert a 3.0mm A/F Allen key and rotate

CLOCKWISE.

· The new input pressure to the ANGEL may be observed from the micro

pressure indicator on the flash tank.

INCREASING VELOCITY

The velocity adjusting screw is located on the lower portion of the front grip.

· To increase the velocity, insert a 3.0mm A/F Allen key and rotate

ANTI-CLOCKWISE.

· The new input pressure to the ANGEL may be observed from the micro

pressure indicator on the flash tank.

IMPORTANT NOTE:

· When reducing velocity, allow four shots for the complete system to be at the

new regulated pressure.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

.

TWIST LOCK COLLAR FEED

3

2

1

The Twist Lock Feed Collar is a dual feature that retains your loader securely to

the ANGEL.

TWIST LOCK COLLAR

· To secure your loader, first ensure the Twist Lock collar is backed off by

rotating it counter-clockwise.

· The Twist Lock Collar feature has been supplied with two sizes of ‘O’

rings 1 to ensure that the full range of loader neck sizes are covered. If

the loader is difficult to insert when 5 has been backed off, follow the

procedure to replace the ‘O’ rings:

· Unscrew

· Extract spacer

· Extract ‘O’ rings

· Re-assemble in reverse order.

· Insert the loader into the feed neck and rotate the Twist Lock collar

5 by rotating counter clockwise.

2.

1 and replace with compatible size.

clockwise to secure the loader.

VOLUMIZER ACCESSORIES

3

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

The ANGEL has been designed to accept volumizers that attach to the front

of the ANGEL. Attachment of volumizers will allow the working pressure of the

ANGEL to be reduced to suit specific performance requirements.

The volumizer supplied with your ANGEL will reduce the operating pressure to

aproximately 150 psi.

· Unscrew and remove the mini regulator.

· Remove the left end cap

· Ensure the valve spring, support bobbin

remain in place.

· Replace the left hand cap with the volumizer - 3

IMPORTANT NOTES: For re-assembly of components

· Ensure the valve spring, support bobbin and exhaust valve stem remain in

place.

· Ensure the end cap is located correctly.

1

2

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1 using suitable metric 4.0mm A/F Allen key.

2 and exhaust valve stem

© 2004 WDP LTD.

Page 8

LCD MENUSDual External LCD Menus in Safe Mode: Basic Menu – Advanced Menu

ANGEL FLY

7

DUAL EXTERNAL LCD MENUS IN SAFE MODE

– BASIC MENU

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

FEATURE

MENU BASIC YES YES Basic/Adv

FETCH BASIC YES YES ON/OFF

TIMER BASIC YES YES 0.5-30min

A1 BASIC YES YES 0.5-30min

A2 BASIC YES YES 0.5-30min

A3 BASIC YES YES 0.5-30min

ANGEL EYE TEST

VIEWABLE EXTERNAL MENU

The ANGEL has a number of features that may only be adjusted or viewed

on the LCD screen. The menu that is displayed can be split into two main

categories - Basic and Advanced. There is a division between basic and

advanced menus. As default, the menu divisions are factory set.

· This is a basic viewing menu that is designed for speed of use and allows you

to quickly view basic menu items; these are settings for the items you are most

likely to use whilst at a tournament.

· Any menu items that may change the performance of the ANGEL CANNOT be

adjusted externally e.g. Dwell, Trigger Offset and Mode.

FACTORY DEFAULT BASIC MENU SETTINGS

MENU

Allows you to select either Basic or Advanced menu options.

FETCH

Allows you to put your ANGEL in receiver mode so that it will receive data/

settings transmitted from other ANGEL markers or PDA’s.

TIMER, A1, A2, A3 FEATURE

This is a fully interactive game timer with 3 independent alarms and will allow

you and your team members to play in unison. The timer may be set in 30

second increments from 0 to 30 minutes. The 3 independent alarms may also

be set in 30 second increments giving you a very versatile game timer and

alarm system. Once the alarms are set they will be activated by the first trigger

pull after making the ANGEL LIVE.

ANGEL EYE TEST FEATURE – Whilst the ANGEL is in SAFE Mode.

· From the Basic or Advanced menu select Angel Eyes Test option using

the middle button externally or the blue button internally.

· Press the bottom button externally and the display will show ‘dropB’.

· Drop a paintball into the breech.

· When the paintball is detected the display will show ‘PASS’.

· Failure to obtain the ‘PASS’ message is an indication that the Angel Eyes

need cleaning or servicing.

MENU

ALLOCATION

BASIC NO YES Pass/Fail

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

EXTERNAL

VIEW

EXTERNAL

ADJUST

PARAMETER

DUAL EXTERNAL LCD MENUS IN SAFE MODE

– ADVANCED MENU

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

FEATURE

MENU ADV & BASIC YES YES Basic/Adv

FETCH ADV & BASIC YES YES ON/OFF

TIMER ADV & BASIC YES YES 0.5-30min

A1 ADV & BASIC YES YES 0.5-30min

A2 ADV & BASIC YES YES 0.5-30min

A3 ADV & BASIC YES YES 0.5-30min

ANGEL EYE TEST

MROF ADVANCED YES YES 8-25bps

Hopper T Time ADVANCED

Hopper A Time ADVANCED YES YES 1-4 Shots

Hopper Type ADVANCED

TEMP ADVANCED YES YES °C / °F

VIBRATOR ADVANCED

TRIP ADVANCED YES YES Re-Zero

BACKLIGHT ADVANCED YES YES ON/OFF

SEND ADVANCED YES YES ON/OFF

ROF ADVANCED YES YES Re-Zero

MODE ADVANCED YES NO Where Applicable

DWELL ADVANCED YES NO 9-20m/s

TRIGGER OFFSET ADVANCED YES NO 1-20 Levels

CYCLES ADVANCED YES NO Non-Resetable

ID ADVANCED YES NO Non-Resetable

MENU

ALLOCATION

ADV & BASIC NO YES Pass/Fail

VIEWABLE EXTERNAL MENU

· This is an advanced viewing menu that allows you to view the full menu for the

items you are most likely to use whilst setting up your ANGEL.

· Any menu items that may change the performance of the ANGEL CANNOT be

adjusted externally e.g. Dwell, Trigger Offset and Mode.

FACTORY DEFAULT ADVANCED MENU SETTINGS

In addition to the seven items in the Basic menu, the Advanced menu contains

the following:

MROF

This allows you to tune your maximum rate of fire whilst the Angel Eyes modes

are OFF. The MROF should not be set greater than your loader is capable of

delivering. Whilst the user is in Angel Eyes mode, all limitations to the MROF are

removed enabling you to fire at the fastest possible rates.

HOPPER (LOADER) T TIME FEATURE

This allows the user to set the hopper (loader) activation time and is settable

from 0.1 to 2.0 seconds. This is the time period that the intellifeed will supply a

signal output for the hopper (loader).

EXTERNAL

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

EXTERNAL

VIEW

ADJUST

YES YES 0.01-1.0 Secs

YES YES STD/MED/FAST/SFAST

YES YES ON/OFF

PARAMETER

HOPPER (LOADER) A ACTIVATION FEATURE

This allows the user to set the hopper (loader) activation point and can be set to

activate on the following;

A1 = Activates on every shot

A2 = Activates of a ROF of 2 shots or greater

A3 = Activates of a ROF of 3 shots or greater

A4 = Activates of a ROF of 4 shots or greater

HOPPER (LOADER) TYPE

This allows you toselect the correct Angel Eye settings for the type of loader

that you are using. Once you have selected the correct setting the Angel Eyes

program will intelligently adjust itself to the variable speeds of your loader.

STD = 9v Agitator type loaders

MED = 12-18v Agitator type loaders

FAST = Force-fed type loaders

SFAST = Fast force-fed type loaders

TEMP FEATURE

This allows you to select Fahrenheit or Centigrade and monitors the

environmental temperature that the marker is exposed to.

VIBRATOR FEATURE

Should the game timer vibrator alarm function not be required this feature

allows you to disable the vibrator. The game timer will still function with the

vibrator disabled but no interactive alarms will activate.

TRIP FEATURE

This is a resettable shot counter that allows you to view the total number of

shots you have fired, and can be referred to at any stage, eg. per game, per day

or per event.

BACKLIGHT FEATURE

This allows you to switch the display backlight on/off.

SEND IR FEATURE

This allows you to switch on the infra red transmitter and be capable of

transmitting infra red data to other ANGELs. SEND IR will transmit the Game

Timer and its alarms information and will also switch on the vibrator and reset

the trip meter.

ROF FEATURE

This will record your highest rate of fire achieved shooting your ANGEL. The data

is constantly updated with the highest reading achieved should it exceed the

previous readings to ensure that you record the latest data. You can reset this

when necessary.

© 2004 WDP LTD.

Page 9

8

ANGEL FLY

LCD MENUS Dual External LCD Menus in Safe Mode: Advanced Menu – Internal Electronic LCD Menus – Factory Default Setting

MODE FEATURE

ADHERE STRICTLY TO THESE

WARNING

· In certain countries local applicable laws or industry standards may mean

certain modes may not be enabled or allowed. Check with law enforcement

office, or local professional paintball venue.

• MODE 1: SEMI MODE WITH ANGEL EYES

The ANGEL Semi Mode with Angel Eyes works on the following principles:

· The Angel Eyes will default to ON whenever the ANGEL is made LIVE via the top

button located at the rear of the frame.

· The ANGEL will only fire when a paintball is present.

· The Angel Eyes system is a break beam system that is not affected by colour,

shape or finish of paintballs.

· The ANGELs MROF with Angel Eyes is non-capped at 31 BPS.

· To switch the Angel Eyes OFF the trigger must be held down for 2 seconds.

• MODE 1: SEMI MODE

The ANGEL Semi Mode works on the following principles:

· In this mode the Angel Eyes are de-activated.

· The ANGEL will fire whether a ball is present or not.

· To activate the Angel Eyes after it has been switched off the ANGEL may either

be switched OFF, then ON again or made SAFE then LIVE.

· The MROF with the Angel Eyes OFF will be at whatever MROF you have

previously set it to.

• MODE 2: AUTO MODE

The ANGEL Auto Mode works on the following principles:

• The Angel Eyes will default to ON whenever the ANGEL is switched ON via the

SAFE LIVE top button located on the rear of the frame.

• This is full auto and will fire for as long as the trigger is held or until a paintball

is not present.

• This mode is limited to a MROF of 15 balls per second.

• This mode will only work with Angel Eyes on and it cannot be deactivated.

• MODE 3: 3 SHOT BURST MODE

The ANGEL 3 Shot Burst Mode works on the following principles:

• The Angel Eyes will default to ON.

• This is a 3 shot burst and will fire for as long as the trigger is held for up to 3

shots or until a paintball is not present.

• This mode is limited to a MROF of 15 balls per second.

• This mode will only work with Angel Eyes on and it cannot be deactivated.

• MODE 4: RAMP MODE

The ANGEL Ramp Mode works on the following principles:

• The Angel Eyes will default to ON.

• This is an 8 shot burst and will fire for as long as the trigger is held for up to 8

shots or until a paintball is not present.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

• The BPS that these 8 balls will be fired, increases over the string of 8 shots.

• This mode is limited to a MROF of 15 balls per second.

• This mode will only work with Angel Eyes on and it cannot be deactivated.

• MODE 5: ACCUM MODE

The ANGEL Accumulator Mode works on the following principles:

• The Angel Eyes will default to ON.

• This is a BPS enhancer that will fire more balls than trigger pulls.

• This mode is limited to a MROF of 15 balls per second.

• This mode will only work with Angel Eyes on and it cannot be deactivated.

• DEMO MODE

This is a dry firing mode for firing the ANGEL when on display and is designed to

demonstrate the rate of fire achievable. It should only be used for demonstration

purposes, as the Angel Eyes feature is reverse functioned so that it cannot fire

paintballs. Should a paintball be detected it will prevent the ANGEL from firing.

DWELL FEATURE

This controls the valve opening time. Longer Dwell will use more gas and will

generate more noise but allows the ANGEL to be more tolerant to paintball

variations. Shorter Dwell will generate less noise and use less gas but will not

tolerate poor paint quality.

CYCLES FEATURE

This is the ANGEL equivalent of a milometer and will register the total shot count

that the ANGEL has fired.

ID FEATURE

This is a unique serial number identification that is factory set.

TRIGGER OFFSET FEATURE

ADHERE STRICTLY TO THESE

WARNING

· Never adjust your trigger offset so finely that accidental discharge may occur

due to shock loads or vibrations.

This allows the user to set the trigger snubber and can be used to ensure that

trigger bounce is reduced on triggers that have been set. It should be used to

eliminate trigger bounce and not used to induce trigger bounce. The level of

snubbing required will be dependent on the users setting of the mechanical

adjustments of the trigger. The snubber will be automatically set to the highest

level of protection on all non semi modes. It is the user’s responsibility to ensure

that the setting they have selected does not cause accidental discharges.

Level 1 is the maximum trigger damping and increasing the level, reduces the

damping.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

INTERNAL ELECTRONIC LCD MENUS

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

The ANGEL has a number of features that can be adjusted to suit your individual

needs. These features can change the performance of your marker and are only

adjustable via the internal menu. This is to ensure that they pass tournament

and field operator requirements.

The settings you have selected may be viewed externally but cannot be adjusted

externally.

The menus can only be accessed when the marker is switched ON and in SAFE.

Remove left hand grip cover screws to expose the circuit board.

Follow the internal menu list diagrams for relevant settings.

The ANGEL has the unique feature that allows you to return to the factory

defaults settings by pressing and holding the internal menu button for 2

seconds.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

© 2004 WDP LTD.

Page 10

Figure 1: Basic & Advanced Menus LCD MENUS

KEY

Press Top Button

Press Middle Button

Press Bottom Button

ADVANCED MENU

TO BACKLIGHT

SUB MENU

MROF

Maximum Rate Of Fire

8 to 25 bps

HOPPER ‘T’ TIME

Hopper Motor Running Time

0.05 to 1.0 Seconds

HOPPER ‘A’ TIME

Activates after each shot or after

2, 3 or 4 shot per/sec or greater.

HOPPER TYPE

Hopper (Loader) type: STD, MED

FAST, SFAS

T

TEMPERATURE

Centigrade

or Fahrenheit

VIBRATOR

Vibes Game Alert

On or Of

f

TRIP

Shot Counter

Hold to return to zero

8

9

10

11

12

13

14

14

ADVANCED MENU SUB MENU

Achieved Rate of Fire

Hold to return to zero

SEND

IR Send - On/Off - If no signal,

defaults to Off after 30 sec inactivity

.

ROF

MODE

Firing Mode

No External Access - see fig.

2

Va

lve Dwell

No External Access - see fig.

2

Trigger Offset

No External Access - see fig.

2

DWELL

TRIGGER OFFSET

CYCLES

Total Shots

Non Resetable

15

16

17

18

21

19

20

TO MENU

1

BASIC/ADV MENU SUB MENU

MENU

Basic / Advanced

Advanced includes Basic Items.

FETCH

ON / OFF – If no signal detected,

will default to OFF in 30 Secs

.

TIMER

Game Timer – 0.5 to 30 mins.

Hold to return to 0:00

ALARM 1

Icon will flash – 0.5 to 30 mins.

Hold to return to 0:00

ALARM 2

Icon will flash – 0.5 to 30 mins.

Hold to return to 0:00

ALARM 3

Icon will flash – 0.5 to 30 mins.

Hold to return to 0:00

ANGEL EYE TEST

Drop 1 paintball into breech.

If detected, ‘PASS’ will be shown

.

1

2

3

4

5

6

7

BASIC TO ADV TO

1 8

BACKLIGHT

On or Off

ANGEL FLY

9

© 2004 WDP LTD.

Page 11

10

PIN PROGRAMMING NOTES

SCROLL

CONFIRM DIGIT

INITIATE

PIN

TRIGGER

Programming the PIN number

can only be completed with

the trigger held in and the

ANGEL in ‘SAFE’ Mode.

CONFIRM PIN

Press Internal to enter

PIN Mode

.

Press again to initiate

PIN number entry.

Press to scroll through

digits 0 to 9.

Press to confirm digit

.

Repeat Steps 4 and 5 until

PIN complete.

Upon confirmation,

the LCD will display ‘SET’

Press to confirm PIN

.

If PIN correct, ANGEL will enter

‘SAFE’ Unlocked Mode.

Or press to clear and return

to Step 4.

PIN SET

1

2

3

4

5

6

7

TEXT PROGRAMMING NOTES

SCROLL

CONFIRM DIGIT

INITIATE

TEXT

TRIGGER

Text Programming can only

be completed with

the trigger held in and the

ANGEL in ‘SAFE’ Mode

.

CONFIRM TEXT

Press Internal to enter

TEXT Mode.

Press again to initiate

TEXT entry

.

Press to scroll through

digits 0 to 9 and A to Z.

Press to confirm digit

.

Repeat Steps 4 and 5 until

TEXT complete.

Upon confirmation,

the LCD will display ‘SET’

Press to confirm TEXT.

Or press to clear and return

to Step 4.

TEXT SET

1

2

3

4

5

6

7

INTERNAL MENU SUB MENU

DWELL

Valve Dwell

10 - 24 milliseconds

Defaults to SAFE after10 secs.

Firing disabled in SAFE or menus.

1

TRIGGER OFFSET

Range 1 - 20, the lower the

number, the lower the offset

.

2

MODE

Firing Mode - only enabled if the

specification permits.

3

RESET

Resets to default

factory settings.

4

TO DWELL

1

KEY

Press Top Button

Press Middle Button

Press Bottom Butto

n

Press BLUE Internal

Press YELLOW Internal

ANGEL FLY

LCD MENUS Figure 2: Internal Menu – Figure 3: Internal Text Programming – Figure 4: Internal PIN Programming

© 2004 WDP LTD.

Page 12

LCD MENUSFigure 5: External PIN Lock/Unlock – Figure 6: Game Timer Activation

PIN LOCK / UNLOCK NOTES

INITIATE

Press to initiate PIN

number entr

y

SCROLL

UNLOCKED

LOCKED

If the ANGEL is Locked,

the LCD will display ‘PIN’

.

Enter PIN to Unlock the ANGEL.

If the ANGEL is Unlocked, th

e

LCD will flash between th

e

Firing Mode and the ID Number

.

Enter PIN To Lock the ANGEL.

TRIGGER

PIN Lock and Unlock can only

becompleted with the trigger

held in and the ANGEL

in ‘SAFE’ Mode.

CONFIRM DIGIT

Press to scroll through

digits 0 to 9.

Press to confirm digit

.

Repeat Steps 4 to 6 until

PIN complete.

Press to confirm PIN

.

If PIN correct, ANGEL will enter

‘SAFE’ Unlocked Mode.

Or press to clear and return

to Step 4.

CONFIRM PIN

1

2

3

4

5

6

7

GAME TIMER NOTES

FIRST SHOT COMMENCES COUNTDOWN

RETURN TO SAFE

SAFE

Switch ANGEL On.

Orange and Green buttons

remain operative for menus

LIVE

Press to

make the ANGEL Live.

TIMER ARMED

Vibrates for 3 seconds

as confirmation.

Timer will commence countdown

on first shot.

NOTE: If Vibes is OFF, timer

activation will occur but the se

t

alarms will not activate and

countdown will be visually only.

Timer starts countdown.

Alarms A1 - A3 become active.

To make the ANGEL Safe,

Hold for 2 seconds

.

Press to stop countdown.

Timer and Alarms Stop.

ACTIVE

STOP

MAKE SAFE

KEY

Press Top Button

Press Middle Button

Press Bottom Button

ANGEL FLY

11

© 2004 WDP LTD.

Page 13

12

ANGEL FLY

General Care & Cleaning – General Assembly: Right Hand ViewMAINTENANCE

GENERAL CARE & CLEANING

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

The ANGEL should only be cleaned externally using a synthetic oil moistened

cloth only. Under no circumstances should you use hydrocarbon based oils, as

these will cause irrevocable damage to the internal seals, e.g.: WD40, Vaseline,

Duck Oil, Engine oil, Plus Gas, 3in1. The suitable oil is Love Juice Oil.

The ram shaft and internal parts that are accessible during disassembly and

re-assembly should be lubricated with Love Juice Extreme Grease.

The frequency of lubrication should be every event or at least 8000 shots for oil

lubrication and 20,000 shots for grease lubrication. The ANGEL should never be

immersed into water otherwise damage may occur to the electronics.

The electronics are moisture/damp proof to IP65. Ensure correct tools are used.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

SOLENOID

EXHAUST VALVE

END PLUG

COVER PLATE

FLASH TANK

IMPORTANT NOTES: For General Maintenance

· No solvents or abrasive cleaning products should be used. All external and

internal accessible moving parts should be lubricated using light synthetic

oil only.

· All threads are metric except gun accessory mountings onto the grip frame,

which is industry standard 10/32 UNF at centres 0.75 inches. The screw

thread length must not exceed 0.375 inches (10mm) into the bottom of the

frame otherwise damage will occur to the electronics. We recommend that

you remove the left-hand cheek cover and ensure the screws do not project

into the circuit board cavity when fitting.

PULL PIN

BACK PLATE

ANGEL EYES

RAM

MINI-REGULATOR

GRIP FRAME

© 2004 WDP LTD.

Page 14

LPR

TWIST LOCK GATED FEED

General Assembly: Left Hand View – Sub Assemblies MAINTENANCE

BATTERY

ANTI DOUBLE BALL

BATTERY SPACER

SOLENOID ASSEMBLY

ANGEL FLY

13

© 2004 WDP LTD.

VERNIER WHEELS

END PLUG

FLASH TANK

CONTROL BUTTONS

GRIP FRAME

PCB OPTO BOARD

ANGEL EYES SENSOR

MINI-REGULATOR

GRIP CHEEK

Page 15

14

ANGEL FLY

MAINTENANCE Cut Away Views: Right Hand – Left Hand

© 2004 WDP LTD.

Page 16

Mini-Regulator Service – Anti-Double Ball Detent Service MAINTENANCE

ANGEL FLY

15

MINI-REGULATOR SERVICE

SERVICEABLE O-RINGS

3

SPRING STACK

ORDER

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

The mini-regulator is a second stage regulator that is used to control the velocity

and regulate the gas pressure. It can be deleted, but only if a suitable first stage

regulator is used that incorporates a high flow and good regulation properties

across the tank pressure range. The thread interface is to ASTM industry

standard form.

· Remove the macro line hose from the mini regulator by following the

procedure and warnings given in PROPELLANT AIR/NITROGEN SUPPLY

- Page 4.

· Remove the mini-regulator from the flash tank by screwing counterclockwise.

· Remove the circlip

· Invert the mini-regulator body and tap it down firmly onto a smooth

surface to shock the internals out of the mini-regulator body.

· Ensure the large piston

bearing 5 are removed.

· Inspect the O rings for damage and replace if necessary.

· Inspect the small piston face seal for damage and replace the whole

small piston 4 if necessary.

· Inspect the large piston

damage and replace if necessary.

1 using circlip pliers.

5

4

2

1

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

2, Spring stack 3, small piston 4 and the ball

2 and small piston 4 sealing faces for

IMPORTANT NOTES: For re-assembly of components

· Due care and attention must be shown to ensure you do not score or

damage the bores within the mini-regulator body whilst performing

maintenance.

· If the small piston or large piston seal faces are damaged they must be

replaced.

· We recommend that you lubricate the parts during re-assembly with Love

Juice Extreme Grease.

· Ensure the spring stack

· Ensure the circlip

· Ensure you follow the procedure and warnings given in PROPELLANT AIR/

NITROGEN SUPPLY - Page 4, when re-attaching the micro-line hose.

3 is in the correct order.

1 is re-located correctly in the groove.

ANTI-DOUBLE BALL DETENT SERVICE

2

1

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

There are two anti-double ball assemblies that can be removed and the internal

parts serviced if necessary. These are located on either side of the body below

the feed tube.

· Using a 2.0mm Allen key, remove the covers

· Remove the spring

· Remove the anti-double ball

· Repeat for other side.

· Inspect parts and replace if necessary.

IMPORTANT NOTES: For re-assembly of components

· Ensure the anti-double ball

· Ensure the spring

· Ensure the anti-double ball covers 1 are inserted correctly into the ANGEL

body.

· Ensure that the Angel Eyes are not moved or trapped.

3

3

2

1

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1.

2.

3.

3 is re-located correctly.

2 is located correctly onto the anti-double ball.

© 2004 WDP LTD.

Page 17

16

ANGEL FLY

ANGEL EYES

MAINTENANCE ANGEL Eyes Service, Removal, Test and Sensor Replacement

1

2

4

3

1

2

4

3

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fi tted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

The ANGEL uses a dual optical eye (break beam) system to detect when a ball is

in position and ready to fi re.

SERVICE

Prior to servicing the Angel Eyes you should carry out the Angel Eye test to

ensure that they are not functioning prior to servicing. See Angel Eye Test - Right.

The Angel Eyes are located under the same cover plates as the anti double balls

and the internal parts can be serviced if necessary. These are located on either

side of the body below the feed tube.

· Using a 2.0mm Allen key, remove the covers

· Remove the anti double ball assembly

· Carefully remove the rubber protective strap from its location

· Carefully extract the Angel Eye from its location hole and clean if

necessary

· Inspect parts and clean if necessary.

IMPORTANT NOTES: For re-assembly of components

· Ensure the anti-double ball is re-located correctly.

· Ensure the spring is located correctly onto the anti-double ball.

· Ensure the cover plates are inserted correctly into the ANGEL body

· Ensure that the Angel Eyes are not moved or trapped.

4.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1.

2.

3.

6

5

5

5

REMOVAL

The whole of the Angel Eyes system may be removed should it become

damaged, should this prove necessary follow the procedure listed below;

· Remove the Angel Eyes from the body as per the service instructions.

· Remove the grip cheek screws using a suitable 2.5mm Allen Key

· Carefully unplug the ribbon cable from the PCB

· Carefully unplug all remaining plugs from the PCB

· Remove the grip frame from the body using a suitable 3.0mm

Allen Key 7.

· Remove the protective strap assembly from the body

· Remove the vernier trigger wheels

REMOVAL SECTION - Page 22.

· Carefully remove the Angel Eyes fl exible PCB and replace if

necessary

bk.

9 See VERNIER TRIGGER WHEEL

6.

6.

8.

TEST

· Whilst the ANGEL is in SAFE mode.

· From the Basic or Advanced menu select the Angel Eyes Test option,

using the middle button externally or the blue button internally.

· Press the bottom button externally and the display will show dropB.

· Drop a paintball into the feed tube so that it falls into the breech.

· When the paintball is detected the display will give the message PASS.

· Repeat this several times to ensure the Angel Eyes are functioning

correctly.

· Failure to obtain the PASS message can be an indication that the Angel

Eyes need to be cleaned or replaced.

5.

bk

7

8

9

7

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fi tted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

SENSOR REPLACEMENT

· Remove the grip cheek cover by removing the 6 retaining screws and

using a metric 2.5mm A/F Allen key.

· Unplug the battery and solenoid plugs

· Remove the Angel Eyes ribbon cable from the ZIF socket on the circuit

6.

board

· Ensure the vernier trigger wheels are locked.

· Remove the Anti double ball covers using a metric 2.0 mm

A/F Allen key

· Remove the 2 grip frame screws holding the frame to the body using a

suitable 3mm A/F Allen key

· Remove the grip frame from the body.

· Remove the Angel Eyes sensors and its shields from the body

IMPORTANT NOTES: For re-assembly of components

· Ensure no wires become trapped between the body and grip frame during

re-assembly.

· Ensure the plugs are located in the correct sockets

1.

7.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

6.

7

8bk.

© 2004 WDP LTD.

Page 18

17

ANGEL FLY

© 2004 WDP LTD.

Micro Pressure Indicator (Optional Accessory) – LPR Adjustment MAINTENANCE

MICRO PRESSURE INDICATOR (OPTIONAL)

The micro pressure indicator is located above the mini regulator and is provided

to give you the pressure that is being supplied to the ANGEL from the mini

regulator. It is a non-serviceable item and should only be replaced with a

genuine ANGEL micro pressure indicator.

· Unscrew by hand and remove the mini regulator

1.

· Removal of the micro pressure indicator

2 is by hand by rotating

counter clockwise.

· Remove fl ash tank external retaining screw

3 using a 3.0mm A/F Allen

key.

· Remove the fl ash tank internal retaining screw

4 using a 4.0mm A/F

Allen key.

· Ensure the fl ash tank O ring

5 is not lost.

IMPORTANT NOTES: For removal and re-assembly of components

· Do not apply any thread sealant to the micro pressure indicator threads.

· Do not expose the micro pressure indicator to pressures above 500 psi

otherwise damage may occur and its readings will be incorrect.

· Do not use any form of grips or clamps on the micro pressure indicator body.

· Do not attempt to fi t any other pressure indicator to the assembly.

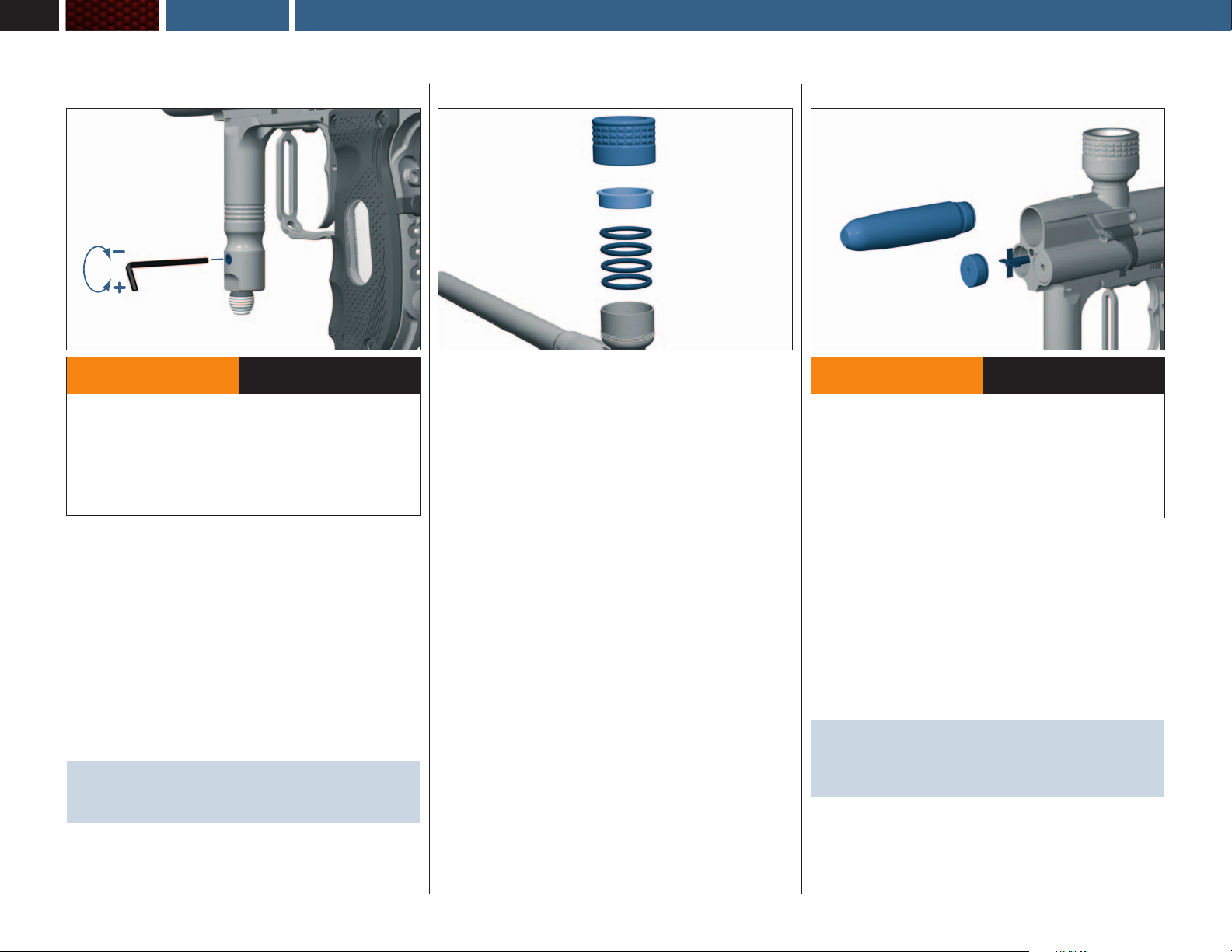

LPR ADJUSTMENT

The low-pressure regulator controls the pneumatic cycle of the ANGEL and is

located in the left-hand chamber at the front of the ANGEL body. The pressure

needs to be at 82 PSI (5.7) output at a pressure of 350 PSI at the second stage

regulator.

LPR adjustment is achieved by the removal of shims. Each shim equals

approximately 5 PSI/0.35 BAR. We recommend the use of the optional service

tools and lubrication of parts with Love Juice Extreme GREASE only. See General

Assembly diagrams - pages 12-13.

· Ensure the ANGEL is de-gassed and switched OFF.

· Remove the left end cap

1 using suitable metric 4.0 A/F Allen key.

· Insert the optional pressure gauge adaptor into the hole that the end cap

1 was removed from.

· Re-Gas the ANGEL and switch the ANGEL to LIVE.

· Fire 6 shots with NO paintballs present to stabilize the LPR pressure.

Note the pressure reading. Should the reading be too high or low, proceed to the

next stage.

· Ensure the ANGEL is de-gassed and switched OFF.

· Remove the pressure gauge adaptor and insert an M 2.5mm screw or

the piston extracting tool (optional extra) into the brass piston

2 and

withdraw slowly.

· Remove the four piston springs

3.

· Add or subtract shims

4 as necessary, note the number of shims may

vary from the diagram shown (maximum 20).

· Replace piston springs 3 in correct order onto the piston.

· Re-insert the piston 2 ensuring that it is located correctly.

· Insert the optional pressure gauge adaptor into the hole that the end cap

1 was removed from.

· Re-Gas the ANGEL and switch the ANGEL to LIVE.

Verify the LPR pressure by following the procedure described above.

Once the desired pressure has been achieved proceed to the next stage.

· Ensure the ANGEL is de-gassed and switched OFF.

· Remove the pressure gauge adaptor & replace the end cap

1.

· Ensure a barrel blocking device is fi tted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

· Ensure a barrel blocking device is fi tted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

· THE ANGEL IS LIVE AND CAPABLE OF DISCHARGING.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

· THE ANGEL IS LIVE AND CAPABLE OF DISCHARGING.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

SPRING STACK

ORDER

1

3

2

4

5

3

1

2

4

Page 19

18

ANGEL FLY

© 2004 WDP LTD.

LPR Assembly Removal – LPR Main Seal ReplacementMAINTENANCE

LPR ASSEMBLY REMOVAL

· Unscrew and remove the mini regulator 1.

· Remove the fl ash tank internal retaining screw

2 using a 4.0mm

A/F Allen key.

· Remove the micro-pressure indicator if fi tted (optional accessory).

· Remove fl ash tank external retaining screw

3 using a 3.0mm

A/F Allen key.

· Ensure O ring

4 is not lost.

· Remove LPR retaining pin

5 using suitable grips.

· Remove the right end cap

6 using suitable metric 4.0mm A/F Allen key.

· Insert an M 2.5mm screw or the piston extracting tool (optional extra)

into the brass piston

7 and withdraw slowly.

· Remove the 4 piston spring stack

8.

· Remove the shims

9, Note: the number of shims may vary from shown

diagram.

· Using a suitable blunt pick, carefully withdraw the LPR body

bk.

IMPORTANT NOTES: For re-assembly of components

· Care must be taken so that the bore is not scored or the seals damaged.

· Ensure the LPR’s pin location hole is aligned with the pin retaining hole within

the ANGEL body prior to insertion.

· Ensure the spring stack

8 is inserted in the correct order.

· We recommend that you verify your LPR pressure if it has been removed.

See LPR ADJUSTMENT - Page 17.

· Ensure the end cap

6 is located correctly.

· Ensure the springs or shims are not lost (see LPR assembly). Insert or

remove shims as necessary.

· Each shim equals approximately 5 PSI/0.35 BAR

LPR MAIN SEAL REPLACEMENT

The LPR may be serviced once it has been removed by following the LPR

ASSEMBLY REMOVAL - Left. The serviceable parts are the external O rings and

the internal main seal.

· Remove the LPR piston

1.

· Remove the LPR spring stack noting the order

2.

· Remove the LPR shims

3, Note: the number of shims may vary from

shown diagram.

· Remove the LPR main seal retainer nut

6 from the LPR body 4 using

a suitable tool. To prevent the body from rotating in your hand you may

insert the LPR lock pin into the LPR body to give some leverage.

· Remove the main seal

5 noting the radius on the edge of the seal.

· Discard the main seal

5 and replace with new item.

IMPORTANT NOTES: For re-assembly of components

· Ensure the new main seal is replaced with the radius edge going in fi rst.

· Ensure the seal retainer nut is tight and fl ush with the LPR body.

· Ensure the spring stack is in the correct order.

· Ensure that the LPR pressure is reset as per LPR ADJUSTMENT - Page 17.

· Ensure a barrel blocking device is fi tted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

· Ensure a barrel blocking device is fi tted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the fi rst stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

fi rst stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

WARNING

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

SPRING STACK

ORDER

SPRING STACK

ORDER

RADIUS

1

2

3

4

5

6

8

bk

7

9

1

2

3

5

4

6

5

4

6

Page 20

Exhaust Guide Removal – Exhaust Valve Stem Removal MAINTENANCE

ANGEL FLY

19

EXHAUST GUIDE REMOVAL

6

7

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

· Remove the grip cheek cover by removing the 6 retaining screws 1

using a metric 2.5mm A/F Allen key.

· Unplug the Angel Eyes, battery and solenoid plugs

· Remove the 2 grip frame screws

a suitable 3mm A/F Allen key.

· Remove the grip frame

· Pull out the exhaust valve retaining pin

suitable grips.

· Remove the left end cap

· Remove the valve spring support bobbin

· Remove the valve spring

· Remove exhaust valve stem

· Using a suitable blunt hooked pick carefully retract exhaust valve guide

bk by inserting the pick into the exhaust valve hole that the exhaust

valve stem located into.

· Inspect and service parts as necessary.

8

9

bk

5

2

3

4

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

2.

3 holding the frame to the body using

4 from the body.

5 located in the body using

6 using suitable metric 4.0mm A/F Allen key.

7.

8.

9.

3

IMPORTANT NOTES: For re-assembly of components

· Care must be taken so that the bore is not scored or the seals damaged.

· Ensure the exhaust valve guide body is free from damage that may score

the bore.

· Ensure you do not damage the exhaust valve guide sealing face.

· Ensure the location hole in the exhaust valve guide is in the correct

orientation to the lock hole within the main body prior to refitting.

· Slowly insert the valve guide pushing it down with a blunt soft faced rod,

· When the holes line up insert the lock pin into the hole.

· Ensure no wires become trapped between the body and grip frame during

re-assembly.

1

· Ensure the plugs are located in the correct sockets.

EXHAUST VALVE STEM REMOVAL

2

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

The exhaust valve stem is a consumable item that will eventually wear out.

Premature failure of the exhaust valve stem is caused by dirty air or failure to

lubricate it at service intervals, to replace the exhaust valve stem follow the

procedures listed below.

· Unscrew and remove the mini regulator

· Remove the left end cap

A/F Allen key.

· Remove the valve spring support bobbin

· Remove the valve spring

· Remove exhaust valve stem

IMPORTANT NOTES: For re-assembly of components

· Ensure exhaust valve is located in exhaust body within the ANGEL.

· Ensure the spring

· Ensure the spring 4 is located onto the valve spring support bobbin 3.

· Ensure the end cap 2 is located correctly

3 4 5

1

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1.

2 or volumizer using suitable metric 4.0mm

3.

4.

5.

4 is located onto the exhaust valve stem 5.

© 2004 WDP LTD.

Page 21

20

ANGEL FLY

Ram Stroke Adjustment – Ram Removal – Ram ServicingMAINTENANCE

RAM STROKE ADJUSTMENT

5

4

7

ADHERE STRICTLY TO THESE

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Ensure the ANGEL is gassed and switched OFF.

· Ensure bolt is fully retracted.

· Remove the breech block pull knob

counter-clockwise.

· Remove the countersunk screws

Allen key.

· Carefully lift the back plate

· Retract the spring

· Using circlip pliers or the ram location tool

ram assemblies 7 clockwise until slight resistance is felt in opening

the breech block. If rotated too far the breech will not open so rotate

counter-clockwise and repeat operation. The ram must always be

rotated clockwise when setting.

3 off.

4 and breech block lock pin 5.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1 by gently pulling and unscrewing

2, using a suitable 2.0mm A/F metric

3

2

6

6 optional accessory rotate

RAM REMOVAL

1

7

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

· Ensure the ANGEL is de-gassed and switched OFF.

· Open the breech block and remove the bolt.

· Remove the breech block pull knob

counter-clockwise.

· Remove the countersunk screws

Allen key.

· Carefully lift the back plate

· Retract the spring

· Using circlip pliers or the ram location tool

rotate ram assembly 7 counter clockwise and withdraw the ram.

3 off.

4 and breech block lock pin 5.

5

4

3

1

2

6

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

1 by gently pulling and unscrewing

2, using a suitable 2.0mm A/F metric

6 (optional accessory)

RAM SERVICING

1

2

3

4

5

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

· The ram must be removed as per RAM REMOVAL – Left, prior to

servicing. The ram has three components that may be replaced these

are the following: Hammer 2, Bumper 3, Ram clamp seal 4 and Ram

Body O rings

· Remove the ram hammer lock screw 1 using a suitable 2.0 mm metric

Allen key.

· Remove the hammer 2 from the ram rod using suitable SOFT faced

grips.

· Remove the bumper 3 and inspect for damage, replace if necessary.

· Remove the ram clamp seal 4 and replace.

IMPORTANT NOTES: For re-assembly of components

· The ram clamp seal

· We recommend that Loctite medium strength adhesive is applied to the

hammer 2 if removed.

· We recommend that Loctite medium strength adhesive is applied to the

hammer lock screw

· We recommend that you lubricate the ram shaft with Love Juice

Extreme Grease.

5.

5

ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

4 must be replaced with a new item if removed.

1 if removed.

IMPORTANT NOTES: For re-assembly of components

· There are wires and a spring

be taken so that the wires are not pulled or trapped during maintenance.

7 must always be rotated clockwise when setting.

· The ram

· Ensure the spring

· Ensure the breech block opens correctly after refitting the breech block

knob 1.

· Ensure that no wires become trapped during re-assembly.

4 is located under the back plate 3. Care must

4 is replaced correctly

IMPORTANT NOTES: For re-assembly of components

· There are wires and a spring

must be taken so that the wires are not pulled or trapped during maintenance.

· Ensure the ram assembly is lubricated with Love juice Extreme Grease prior

to re-fitment.

· Ensure the ram assembly external O rings are not damaged.

· Ensure the ram assembly is inserted slowly to prevent damage to the O rings.

· See RAM STROKE ADJUSTMENT - Left, for setting the ram position.

4 is located under the back plate 3. Care

© 2004 WDP LTD.

Page 22

MAINTENANCEOpto Board – Vernier Trigger Adjustments

ANGEL FLY

21

OPTO BOARD

ADHERE STRICTLY TO THESE

WARNING

· Do not attempt to modify the OPTO™ board assembly in any way as this will

invalidate your warranty and could lead to safety concerns.

The ANGEL incorporates the OPTO™ board. This is the latest development

in trigger sensing function. It achieves unsurpassed advancements in trigger

repeatability and sensitivity, its non-mechanical switching results in faster,

shorter and lighter trigger strokes that give the user higher prolonged achievable

rates of fire.

IMPORTANT NOTES:

· When accessing the Internal Tournament LED menus the OPTO™ board

should not be exposed to direct sunlight or strong external sources of light

without the grip cheek fitted as this light will induce a safety feature, that

will prevent the ANGEL from firing whilst it remains exposed to the strong

external light.

· The OPTO™ board is a non-mechanical switch that is silent in its operation

and no audible click is present.

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

VERNIER TRIGGER ADJUSTMENTS

4

2

WARNING

· Ensure a barrel blocking device is fitted to the ANGEL.

· Ensure the hopper is removed from the ANGEL.

· Ensure that there are no paintballs in the ANGEL.

· Always remove the first stage regulator and relieve all residual gas pressure

from the ANGEL before disassembly.

· The ANGEL can hold a small residual charge of gas, typically 2 shots, with the

first stage regulator removed. Always discharge the marker in a safe direction to

relieve this residual gas pressure.

· Never adjust your trigger so fine that accidental discharge can occur due to

shock loads or vibration.

The trigger return stroke, over-travel and toe adjustments should be carried

out in the order shown and will enable the user to have total adjustment on the

tactile feel and trigger movement.

· Using a suitable Allen key undo the trigger adjustment locking screw

located between the thumb wheels by rotating counter clockwise.

· Remove the grip cheek retaining screws and expose the circuit board

· Using a suitable Allen key back off the toe adjustment screw