Page 1

Controlling Tomorrow’s World

TCX 865 VAV Controller

Family

Downloaded from - http://www.guardianalarms.net

Installation Guide

TCX 865

30-3001-497 Version D

Page 2

Page 3

Version D

Reproduction or distribution forbi dden.

Copyright 1997 by Andover Controls.

Subject to change without notice.

Order No. 30-3001-497

Copyright

1997

Andover Controls Corporation

300 Brickstone Square

Andover, Massachusetts 01810 USA

All Rights Reserved.

Published by the Engineering Department at Andover Controls Corporation.

IMPORTANT NOTICE

This product is subject to change without notice. This document does not constitute any

warranty, express or implied. Andover Controls Corporation reserves the right to alter capabilities, performance, and presentation of this product at any time.

TCX 865 Installation Guide

i

Page 4

Note

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions in this manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Note

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Avis

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant

les limites applicables aux appareils numériques de la class A prescrites dans

le Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

ii

Andover Controls Corpor ati on

Page 5

Contents

TCX 865 Series VAV Controller

TCX 86X Series Characteristics ........................................................................................2

What You Received ...........................................................................................................2

Parts Included with the TCX 86X Series .....................................................................2

Mechanical Installation ......................................................................................................3

Chassis Road Map .............................................................................................................5

Power Connection ..............................................................................................................6

Battery Connection & Replacement .................................. .......... .......... .......... .......... ..6

24 VAC Connection .....................................................................................................7

Building Ground Requirements ...................................................................................8

Inspecting the Ground ..................................................................................................8

Lightning Protection ....................................................................................................8

Infinet Network Connection ..............................................................................................9

Input Connections ................................................... .......... .......... .......... .......... .......... .......10

Universal Inputs .........................................................................................................10

Input Wiring ...............................................................................................................10

Wiring Concerns ........................................................................................................11

Thermistor Inputs .......................................................................................................11

Voltage Inputs ............................................................................................................14

Digital/Counter Inputs ...............................................................................................14

Air Flow Sensor Connection ............................................................................................15

Output Connections .........................................................................................................16

Output Wiring ............................................................................................................16

TCX 866 Analog Output Wiring ................................................................................16

Switching Loads with Triacs ......................................................................................17

Form A Outputs .........................................................................................................17

Form K Tri-state Outputs ...........................................................................................17

Analog Outputs...........................................................................................................18

Operation .........................................................................................................................19

TCX 865 Installation Guide

iii

Page 6

Service Tool ...............................................................................................................20

Pre-Operation Checks ..........................................................................................20

Initial Power-Up .......................................... ... .. ...... .... ...... .... ...... .... ...... .... ...... .... .20

Troubleshooting ...............................................................................................................21

CPU LED Is Not Blinking ...................................................................................21

Unit Appears Functional But Is Not Responding To CX Controller ...................21

One Input or Output Appears to Be Dysfunctional .............................................22

Internal Reset Switch............................................................................................22

Sample Applications ........................................................................................................23

iv

Andover Controls Corporation

Page 7

TCX 865

V AV Controller

This manual describes the installation and care of the TCX 865 Series VAV control

units.

The Infinity TCX 865 Series VAV controllers are unique VAV box controllers that come

equipped with a built-in damper actuator to streamline hardware installation.

The TCX 865 series features several combinations of universal inputs, an on-board

pressure transducer, Form A, and Tri-state outputs for flexible control configurations.

Metal oxide varistors and optocouplers provide 2500V isolation on each triac-based

output on theTCX 865 models to ensure noise-free operation and virtually elimina te

the need to install MOVs in the field.

Infinity

The Infinet’s true peer-to-peer communications protocol provides the

Infinity

with the ability to instantly communicate with an

CX 9200, as well as the entire network of Andover Infinet field controllers. Up to 254

TCX 865 series controllers can be networked to one CX series network controller.

network controller such as the

TCX 865

TCX 865 F amily Insta llatio n Gu id e

1

Page 8

TCX 865 Series Characteristics

The following table lists the features included in the TCX 865:

Model Outputs Inputs Special

TCX 865 3 Form A Triac outputs 2 Universal Inputs Damper Actuator

or 1Form K Tri-state output Airflow sensor (0-1” W.C.) RTC*

and 1 Form A Triac output

TCX 866 3 Form A Triac outputs 3 Universal Inputs Damper Actuator

or 1Form K Tri-state output Smart Sens or Input RTC*

and 1 Form A Triac output

2 Analog outputs Airflow sensor (0-1” W.C .)

* RTC: Hardware-based, battery-maintained real time clock.

What You Received

After unpacking the unit, take care to not damage the packaging material—you must reuse it if

you ship the product back for repair.

Parts Included with the TCX 865 Series

TCX 86X Controller

5-micron Ramay Filter

Hardware Reference Manual (this document)

2

Andover Controls Corpor ati on

Page 9

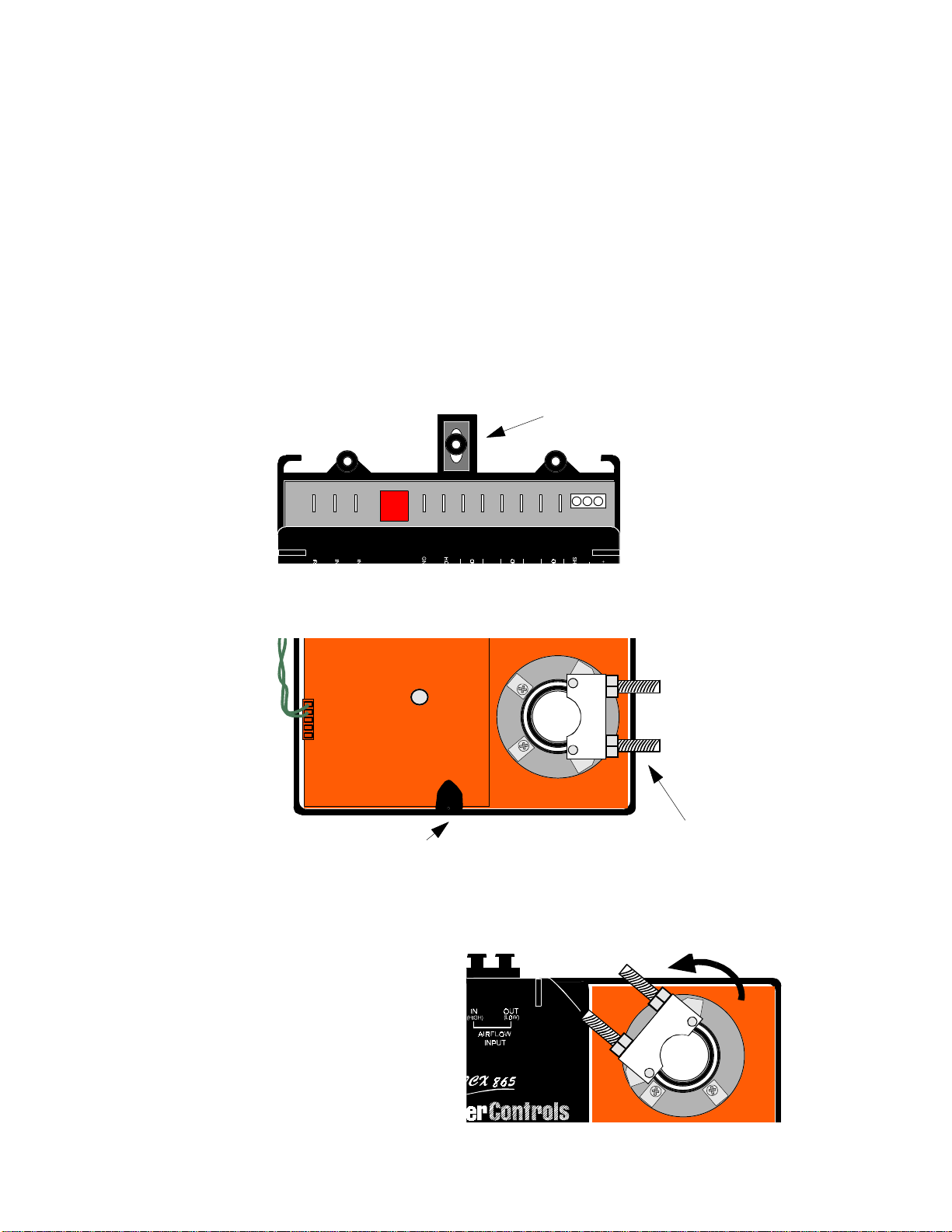

Mechanical Installation

The TCX 865 Series is designed to be mounted directly to the shaft of an air handler. The

shaft is inserted through the opening in the controller and secured using a U-bolt.

Note:

The unit requires that the VAV blade shaft be at least 1.5” (38 mm) in length and 1/4”-5/8” (616 mm) in diameter (1/4” - 7/16” (6-11 mm) square) for proper mounting.The unit may be

mounted in any orientation.

Attach the TCX 86X to the air handling unit using the procedure outlined below:

1. Center the movable grommet in its mounting trough as illustrated:

Center the Grommet

2. Loosen the nuts that attach the mounting U-bolt to the actuator motor.

Manual override button

3. Manually, position the damper blade at its fully closed position.

4. With the manual override button depressed, rotate the actuator clamp of the TCX 86X

motor counter clockwise to approximately 1/16 - 1/8” between the actuator stop and

clamp, depending on seal design.

U-b olt clamp wit h nu t s

TCX 865 F amily Insta llatio n Gu id e

3

Page 10

5. Position the unit at the proper perspective on the VAV box. Carefully insert the shaft of the

VAV unit into the opening of the actuator motor through the U-bolt. Make sure the TCX 86X

is flush with the VAV housing. Finger tighten the nuts to secure the shaft to the actuator.

6. Insert the supplied self-tapping screw through the grommet and secure the TCX 86X to the

housing.

Self-tapping screw

secures the unit to

the housing

Shaft inserted into

the actuator.

7. Tighten the U-Bolt to the shaft using an 8 mm wrench.

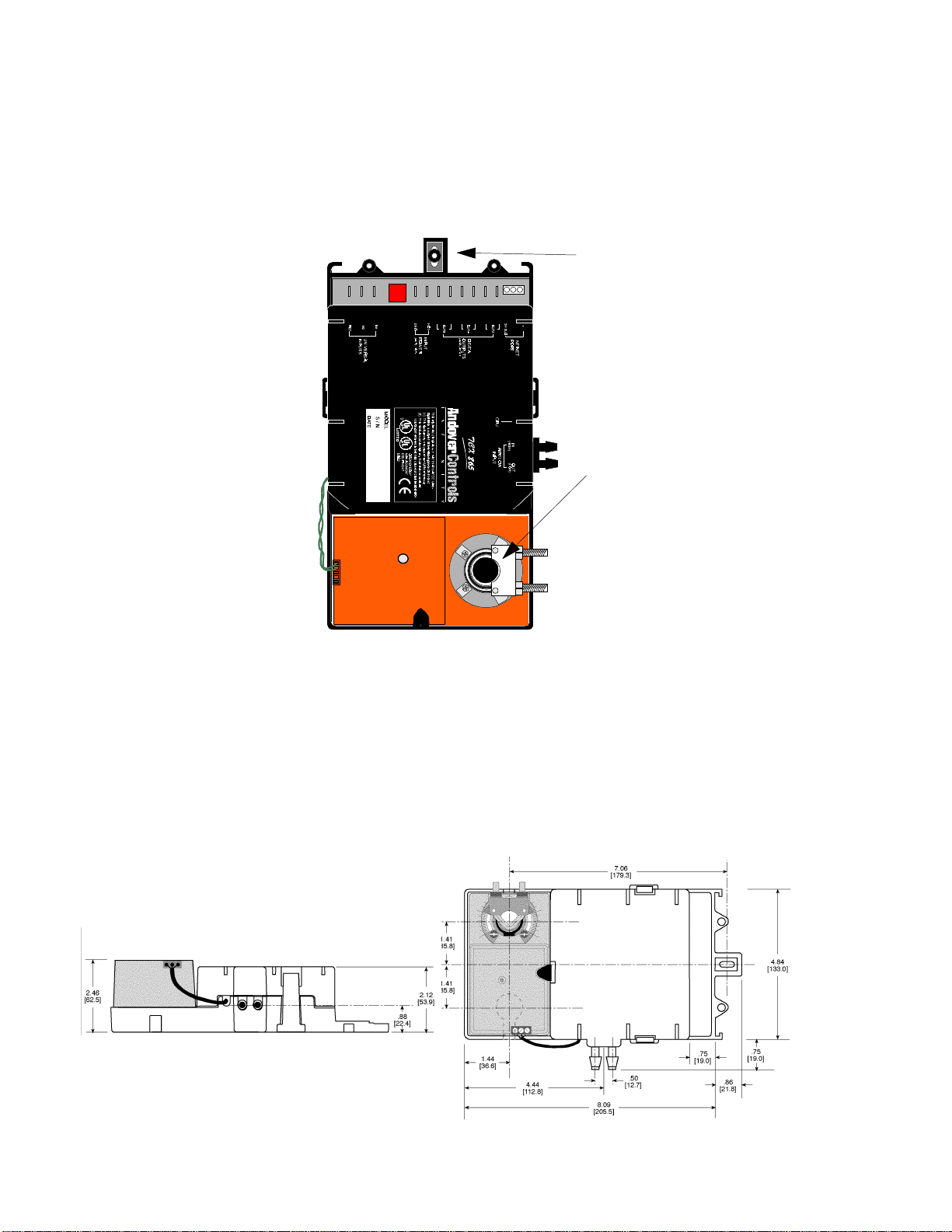

Overall Dimensions

The TCX 865 Series are designed to fit over an existing VAV shaft and be mounted to the housing. It is secured via one sheet metal screw. The overall dimensions of the unit are:

4

Andover Controls Corpor ati on

Page 11

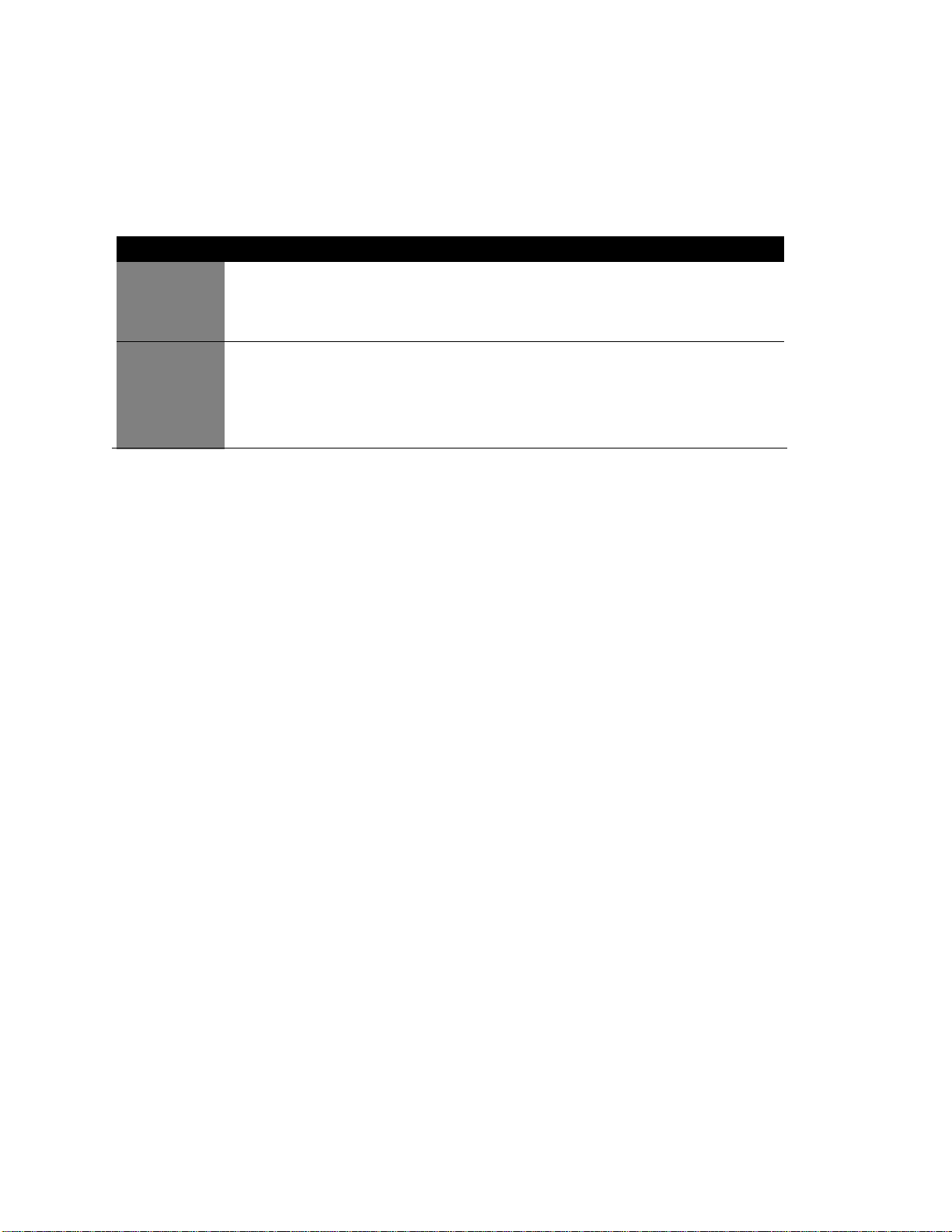

Chassis Road Map

The following diagr am indicates the locations of each of the main components and connection

points:

Digital

Outputs

24VAC

Power

Damper

Reset

Button

Infinet Connection

CPU

LED

Airflow Sensor

Damper

Actuator

Universal

Inputs

AnalogOutputs

& Other Inputs

(under removable cover)

TCX 865 F amily Insta llatio n Gu id e

5

Page 12

Power Connections

Power Connection

The TCX 865 Series Controllers are operated via an individual external 24 Volt AC source. An

internal power converter creates the necessary DC voltages to supply the microprocessor circuitry.

Should the AC source be interrupted during operation, backup power for the internal controller

state memory is provided by a coin-style 3 Volt Lithium battery. This battery can maintain

backup status for typically 3-years.

Battery Connection & Replacement

To access the battery holder, the main electronics housing cover must be removed. The cover

is secured via two force fitting plastic clamps. To remove the cover gently pry the two clamps

outward using your thumbs while lifting the cover.

Once the cover is removed the printed circuit board is accessible. The following illustrates the

location of the battery in relation to the board.

Battery is locat ed

here.

During shipment, an insulating plastic tab is inserted under the clip on the battery to prevent it

from draining prior to installation. To activate the battery, this tab must be removed.

Should it become necessary to replace the battery, The battery is placed in a coin-style holder.

The battery used in the TCX865 Series are a type CR 1225, 38 mAhr 3.0 V primary Lithium

battery.

CAUTION

There is danger of explosion if the battery is incorrectly replaced.

Replace only with the same or equivalent type recommended above.

Dispose of used batteries according to manufacturer’s instructions.

Andover Controls Corpor ati on

6

Page 13

Power Connections

24 VAC Connection

The TCX 865 Series controllers are powered by an external 24 VAC source . This power supply

is connected via three terminals located near the center of the I/O connection area. The unit

should receive power from its own independent, 24 VAC +10% /– 15%, 50 or 60 Hz, 10 VA ,

unswitched circuit.

OUT 4

OUT 5

24VAC

GND

24 VAC Step-Down

Transform er

AC Line

Power

choose a voltage rating appropriate to the

input voltage applied. i.e 130V or 250V

Optional Varistor

Optional 39V Varistor

for extremely noisy environments

X1

X2

Black

White or

Green

The 24 VAC connection consists of both terminals from the secondar y of a power-line to 24

VAC transformer and a common ground line. Connection to the Controller is through push-on

quick-disconnect type connectors. The ground wire should not exceed 12” in length and it

must be connected to a good earth ground.

Warning

Make sure that 24 VAC is

the controller, or you could receive an electrical shock that is life-threatening.

connected to the power cable while you are wiring

not

TCX 865 F amily Insta llatio n Gu id e

7

Page 14

Power Connections

Building Ground Requirements

Be sure that all equipment from Andover Controls is grounded to true Earth ground. True

Earth ground protects the equipment from transients and other power surges in the area. We

cannot guarante e that the contro l ler system will operate as documented wit hout a proper ly

grounded installation.

An example of a sub-standard ground is a galvanized steel cold water pipe. As the pipe corrodes, it does not act as a true ground. The corrosion acts as an insulator, raising the potential

of the pipe with respect to the ground.

When lightning strikes in the area of the installation, it drastically changes the potential of the

Earth. Since properly grounded Andover Controls units respond to changes in potential more

rapidly than poorly grounded electrical systems, a poorly grounded building tries to reach

ground through the Andover Controls system. The surge of current can destroy electronic

components on the controller board. Surges of much lower potential than lightning also impact

the reliability of the equipment.

Inspecting the Ground

Be sure to have your grounds inspected before you begin the installation process to be sure

your municipality follows the National Electrical Code.

code and often have substandard electrical grounds.

Check your ground as follows:

Inspect the building power distribution panel for Earth-ground termination. If the ground termi-

nation is any of the following, it is not adequate and must be corrected:

• Does not exist.

• Is connected to a corroded or galvanized pipe.

• Is connected using a small gauge wire (less than 14 AWG).

Be sure your Andover Controls cabinet is connected to the ground with a copper conductor

that terminates at the distribution panel.

Many municipalities do not follow the

Lightning Protection

Although metal oxide varistors are built into the board to protect against power line transients,

this protection is not sufficient to protect against lightning. Lightning arresters are required at

Infinet

each point where

ommended:

Andover Controls # 01-2100-299, Tw o pair gas tube lightning arrester

cables enter or exit a building. The following lightning arrester is rec-

Andover Controls Corpor ati on

8

Page 15

Infinet Connections

Infinet Network Connection

The TCX 865 Series controllers include an interface to the Andover Controls proprietary Infinet

network. Connection to the Infinet allows multiple controllers to communicate and be controlled by a larger “host” controller.

Connection to the Infinet requires access to an Infinet network cable. This cable consists of

two wires and a shield. A screw-type terminal block Infinet connector is provided on the printed

circuit board.

Connect the Infinet

Here.

To wire the Controller to the Infinet, follow the steps below:

8. Trim the outer jacket of the Infinet cable to reveal the internal wires.

9. Strip the insulation from the white* wire and loosen the screw labeled ‘+’

10. Insert the stripped end of the white* wire into the ’+’ receptacle of the terminal block.

Tighten t he screw.

11. Strip the insulation from the black* wire and loosen the screw labeled ‘-’

12. Insert the stripped end of the black* wire into the ’-’ receptacle of the terminal block.

Tighten t he screw.

13. Insert the shield wire into the ‘SHIELD’ receptacle of the terminal block. Tighten the screw .

* Wire colors are included for clarity. The colors of your cable may vary . However, make sure that all Infinet connections are consistent on their connections.

White

Black

+ -

Infinet Cables.

White

SHLD

Shield

OUT 3

TCX 865 F amily Insta llatio n Gu id e

9

Page 16

Input Connections

Input Connections

Universal Inputs

The TCX 865 Series controllers include Andover Controls Universal Inputs that are unique in

that they are software configurable to handle any one of a number of input types:

Thermistor

Voltage

Digital/Counter

Input Wir i ng

The actual input terminations are located as shown. Connection is via a 0.250” (6.35 mm)

male spade lug.

Connect Inputs

1 and 2 Here

IN1 IN2

RET

The inputs labeled IN1,and IN2 are followed by a connection labeled RET for the input signal

return. Although there is only one return terminal (RET) supplied, it is recommended that a

separate return wire be used for each input. All return wires should be crimped into one female

spade lug for connection to the RET terminal.

TCX 866 Inputs labeled IN3,and IN4 are found on the screw terminal strip at the top right of

the daughter board mounted over the main PC board under the removable plastic cover. To

remove the cover, simply pull outward on the two opposite tabs that lock the cover to the base

and pull upward. IN3 is used for the Smart Sensor only. For more information regarding the

Smart Sensor, refer to its installation manual. IN4 is f ollow ed by a connection labeled RET for

the input signal return. A separate shield may be connected to the SHLD terminal.

Andover Controls Corporation

10

TCX 866 Extra Input Connections

IN3

IN4

RET

SHLD

Page 17

Input Connections

Wiring Concern s

Do not remotely ground any part of the sensor wiring. Remote grounds connected to the TCX

865 Series return terminal could make the controller operate incorrectly or damage the equipment. The signal return is not true earth ground. It is an electronic reference point necessary

to interpret the sensor properly.

It is recommended that you run input wiring in a conduit separate from AC power or output wiring and avoid long wiring runs.

For reliable input operation, follow these input wiring guidelines:

• Never lay wires across the surface of the printed circuit board.

• Wires should never be within 1 in. or 25 mm of any component on the printed circuit board.

• Use shielded input wire.

• Terminate the shield of the input wires at one end of the run only—preferably at the end

where your controller is located.

• Be careful when stripping wire not to drop small pieces of wire inside the cabinet.

• Don’t run your input wiring in the same conduit with AC power.

• Don’t run your input wiring in the same conduit with your output wiring.

Caution

Do not externally ground any input connected to the Controller. This may damage

the unit. Signal return terminals are not connected to Ear t h Ground.

Thermistor Inputs

The TCX 865 Series inputs may be configured to sense temperature by connecting a resistive

thermistor to any one of the input terminals. The following is a schematic representation of the

connection:

One lead connects to the numbered input terminal, the other to a return terminal.

INx

Thermistor

RET (return)

Caution

Never apply a voltage to a thermistor—doing so alters the thermistor’s accuracy

and reliability. In fact, it’s a good idea to replace any thermistor that has had any

sort of voltage applied to it.

TCX 865 Family Installation Guide

11

Page 18

Input Connections

Special Factors for Thermistors

To keep thermistor errors minimal, limit the length of wire runs to the maximum for the gauge

wire you select.

The following three tables indicate the maximum length runs for wires of various gauges to

keep errors within certain temperature limits when using thermistor elements.

Gauge

#14

2.5 mm

2

#16

1.5 mm

2

#18

1.0 mm

2

#20

0.5 mm

2

#22

0.35 mm

Wire Gauges and Corresponding Maximum Runs for Sensing Temperatures Up to

70

F (21°C)

°

Gauge

#14

2.5 mm

2

1

/

° F (.28 ° C) Error

2

26,700 ft

8150 m

16,700 ft

5120 m

10,500 ft

3200 m

6,600 ft

2000 m

4,100 ft

2

1250 m

1

/

° F (.28° C) Error

2

12,600 ft

3800 m

1

/

° F (.14 ° C) Error

4

13,300 ft

4000 m

8,300 ft

2500 m

5,200 ft

1600 m

3,300 ft

1000 m

2,000 ft

600 m

1

/

° F (.14° C) Error

4

6,300 ft

1900 m

1

/

° F (.06° C) Error

10

5,300 ft

1600 m

3,300 ft

1000 m

2,100 ft

640 m

1,300 ft

400 m

800 ft

250 m

1

/

° F (.06° C) Error

10

2,500 ft

760 m

#16

1.5 mm

2

#18

1.0 mm

2

#20

0.5 mm

2

#22

0.35 mm

Wire Gauges and Corresponding Maximum Runs for Sensing Temperatures Up to

F (38°C)

100

°

Andover Controls Corporation

12

7,900 ft

2400 m

5,000 ft

1500 m

3,100 ft

950 m

1,900 ft

2

580 m

3,900 ft

1200 m

2,500 ft

760 m

1,500 ft

450 m

900 ft

275 m

1,500 ft

450 m

1,000 ft

300 m

600 ft

180 m

300 ft

90 m

Page 19

Input Connections

Gauge

#14

2.5 mm

2

#16

1.5 mm

2

#18

1.0 mm

2

#20

0.5 mm

2

#22

0.35 mm

Wire Gauges and Corresponding Maximum Runs for Sensing Temperatures Up to

150

°

F (65°C)

1

/

° F (.28 ° C) Error

2

4,100 ft

1250 m

2,600 ft

800 m

1,600 ft

500 m

1,000 ft

300 m

600 ft

2

180 m

Thermistor Input Specifications

Range

–30 to 230 °F

(–34 to 110 °C)

Accuracy

(Using an Andover Controls Thermistor)

+/– 1 °F over a 10 °F to 150 °F range

+/– 0.55 °C over a –23.3 to 65.5 °C range

1

/

° F (.14 ° C) Error

4

2,000 ft

600 m

1,300 ft

400 m

800 ft

240 m

500 ft

150 m

300 ft

90 m

1

/

° F (.06° C) Error

10

800 ft

240 m

500 ft

150 m

300 ft

90 m

200 ft

60 m

100 ft

30 m

TCX 865 Family Installation Guide

13

Page 20

Input Connections

Voltage Inputs

The TCX 865 Series inputs may be configured to sense voltage by connecting the input terminals to a voltage source. The following is a schematic representation of the connection:

One lead connects to the numbered input terminal, the other to a return terminal.

INx

+

V

-

RET (return)

Voltage Input Specifications

Vo lta ge Range

Resolution

Accuracy

Input Impedance

Filtering

Calibration

0 to 5.115 V

0.005 V

+/–0.015 V

10KΩ referenced to 5.120 V

Corner Frequency at 15 Hz, –20 db/decade

Permanent (factory)

Digital/Counter Inputs

The TCX 865 Series inputs may be configured to sense a contact closure by connecting the

input terminals to a digital or counter input source. The followi ng is a schematic representation

of the connection:

One lead connects to the numbered input terminal, the other to a return terminal.

INx

RET (return)

Digital/Counter Input Specifications

Inpu t Type

Maxi mum Pulse Freque ncy

Pulse Width

Andover Controls Corporation

14

Contact Closure

4 Hz at a duty cycle of 50%

125 ms minimum

Page 21

Air Flow Sensor C on ne ct i on s

Air Flow Sensor Connection

All models of the TCX 865 Series controllers include an airflow sensor.

The air flow sensor is located at the top of the controller chassis:

Filter

IN

(HIGH)

CPU

Side marked

‘IN’ Here

AIRFLOW

INPUT

The following steps explain the connection of the air flow sensor:

OUT

(LOW)

1. Using a small piece of 1/4” (6.35 mm) I.D. pneumatic tubing, attach the ‘OUT’ side of a 5

micron filter to the input connection (the side marked ‘IN’) of the sensor as shown above.

2. Connect a 1/4” I.D. pneumatic tube from the other end of the filter (the side marked ‘IN’) to

the ‘HI’ opening on a VAV box.

3. Connect a 1/4” I.D. pneumatic tube from the output connector (the side marked ‘OUT’) of

the air flow sensor to the ‘LO’ opening on a VAV box.

Note: Keep tubing to a maxi mum of 15 in ches (380.99 mm) in length.

Air Flow Input Specifications

Range

Resolution

Accuracy

0 to 1” WC (0-249 Pa)

0.005” WC (1.25 Pa) @ 73 °F (23 °C) @ Standard Air Conditions

+/– 0.05” WC (12.5 Pa) @ 73 °F (23 °C) @ Standard Air Conditions

TCX 865 Family Installation Guide

15

Page 22

Output Connections

Output Connections

The TCX 865 Series controllers include 3 Form A Triacs that can be used separately or be

configured into 1 Form K Tr i-s tate output with a free triac output remaining.

TCX 866 controllers include 2 analog outputs.

Output Wiring

Triac output terminations are located along the left side of the chassis. Connection is via a

0.250” (6.35 mm) male spade lug.

Connect Triac

Outputs Here

TCX 866 analog output termination s are found on the screw terminal strip at the top right of

the daughter board mounted over the main PC board under the removable plastic cover. To

remove the cover, simply pull outward on the two opposite tabs that lock the cover to the base

and pull upward. Corresponding signal returns labeled RET are provided to either

side of the output terminals. A separate shield input is provided as well.

TCX 866 Analog Output Connections

RET

OUT6

OUT7

RET

SHLD

Andover Controls Corporation

16

Page 23

Output Connections

Switching Loads with Triacs

Although the Triac-based outputs provided with this unit appear as relay contacts in the schematics provided, they are actually solid-state switches that have limitations on the loads they

can switch.

AC vs. DC

The first limitation is that they cannot be used with DC loads.

Minimum Load Current

The second limitation involves the minimum load current.

must detect at least 30 ma of current from the load

induce the required load by connecting a resistor across the load (not directly at the Triac!).

Check the current draw specification on your field device, and if it does not meet this minimum,

add a resistor in parallel with the device being driven sized to achieve the minimum loading.

Use the following formulas to determine resistance and wattage:

Resistance (ohms) =Voltage

Current Resistance

Power (Watts) = (Voltage)

. If your load is less than 30 ma you can

A Triac switches AC only

In order f or t he Triac to switch it

2

.

Form A Triac Outputs

The TCX 865 Series includes three Form A Triac outputs. The following is a functional schematic representation of the connection:

C

NO

When the output is activated, the connection between the ‘C’ and ‘NO’ terminals becomes a

virtual short circuit. Using the Form A connection you can control anything that would normally

be controlled (within specifications) via a switch or relay contact closure.

Form K Tri-state Outp uts

Two Form A triac outputs can be connected to provide one Form K Tri-state output. OUT3 and

OUT4 or OUT4 and OUT5 can be configured as a tristate output.

The following is a schematic representation and the actual wiring of the connection:

C

OUT 4

–ON

+ON

–ON

C

OUT 3

+ON

TCX 865 Family Installation Guide

17

Page 24

Output Connections

Note that all tristate outputs fail in the OFF state if there is no power. They are forced to the

OFF position for 2 minutes upon reset or powerup before being program controlled.

Form A and Form K Output Specifications

Current

0.5 A @ 24VAC @50 °C

Resolution

0.1 sec for PWM

TCX 866 Analog Outputs

The TCX 866 includes two 0-10 V Analog outputs on the internal daughterboard.

The following is a schematic representation and the actual wiring of the connection:

Analog Output Specifications

Range

Resolution

Accuracy

Current

0 to 10.00 V

0.05 V

+/– 0.10 V

5 mA maximum

OUTx

RET

(return)

+

RL >= 2K

–

Load

Andover Controls Corporation

18

Page 25

Operation

Operation

The TCX 865 Series controllers are designed to be programmed by an external source.

Therefore, programmers should refer to the Programmer’s Guide for their particular controller

or the SX 8000 Programmer’s Guide for specific information regarding configuration of input

and output points.

I/O Point Assignments

The TCX 865 Series can be programmed using the following point assignments:

Function Point

Function Input Point Assignment Electrical Type

TCX 865 TCX 866

Universal Input 1 1 1

Universal Input 2 2 2

--

Universal Input 4 - 4

Airflow Sensor Input 7 7

Function Output Point Assignment Electrical Type

TCX 865 TCX 866

Actuator 1 1 Tri-State

Output 3 3 3 Digital, Tri-State

Output 4 4 4 Digital

Output 5 5 5 Digital

Output 6 - 6 Analog (V oltage only)

Output 7 - 7 Analog (V oltage only)

* Note 1: valid E-Ty pes are Analog

Voltage

ACC_TEMP_DEGF

ACC_TEMP_DEGC

Digital

Counter

* see note 1

* see note 1

* see note 1

Voltage

Actuator Programming & Use

The actuator motor provided in the TCX 865 Series units are controlled by sending a pulse

(positive or negative) to the output that corresponds to the desired position of the damper

blade. The minimum pulse width is 1 second.

Note: Whenever the manual override button is pressed and the actuator is moved manually it is necessary that you press the Damper Reset push button.

Caution

Be sure that the actuator has come to a full stop before changing directions.

TCX 865 Family Installation Guide

19

Page 26

Operation

Service Tool

Access is provided to the controller via the Andover Controls lap-top service tool. A special

port is provided behind the Infinet connector inside the plastic cover where a service tool

adapter cable may be wired. This adapter cable converts the separate wires connected to the

TCX unit into the standard RJ11 connector used by the service tool.

Connection of the service port adapter cable is through a 4-pin Berg-type connector.

Pre-Operation Checks

1 Make sure the internal battery is present or the external battery is connected.

2. Make sure the 24VAC power is wired properly. Check to be sure that both wires have

3. Make sure the controller has a true earth ground.

4. Make sure you have used the proper cables and wires at correct lengths.

5. Make sure the Infinet cables and shields has been properly wired.

Initial Power-Up

1 Enable the AC power source (or close the power connection). The controller starts auto-

2. The CPU light flashes every quarter second. There is a distinguishable off time.

3. If the CPU light flashes very fast (no distinguishable off time), the CPU has failed an inter-

4. Press the Damper Reset pushbutton (see diagram below). This tells the controller that the

been connected.

matically . If the controller has been off, outputs remain off. If you have pressed the internal

RESET button, outputs turn off.

nal test. In this case, recheck your connections and contact your Andover Controls representative.

actuator has been moved manually.

Damper Reset

Button

Andover Controls Corporation

20

Page 27

Troubleshooting

Troubleshooting

With any electronic device it is possible that the unit may enter a confused or non-operational state

depending upon unexpected outside stimulus. The following is a guide to follow should you decide

the unit is not functioning properly:

CPU LED Is Not Blinking

If the CPU LED is not blinking then the unit is not operating. This could be due to the loss of primary AC power or other internal disfunction.

• Check that 24VAC is available and connected properly to the power terminals.

This can be done using a multimeter reading the voltage across the 24V HOT and GND

terminals.

2 Amp, 125V

picofuse

• If power appears to be OK, remove power and all other connections from the unit. Open the

plastic electronics cover . Remove the plug-in power fuse component and check it for continuity

with an Ohm meter. If the fuse is bl own, replace it wi th a similar 2 Amp picofuse (it resides in a

socket). After replacement, take care that the board is reinsert ed into the chassis properly

before re-mounting the cover.

Unit Appears Functional But Is Not Responding To CX Controller

If the CPU LED is blinking norma lly chances are that the unit is operational. However, in that the

TCX 86X is a programmable unit, it is possible that there is a programming problem. Try attaching

an Andover Controls Lap-T op Service Tool to determine the source of the problem.

Monitoring Infinet Activity

Infinet communications can be monitored simply by observing the status of two miniature LED

indicators mounted on the board just behind the Infinet connector as indicated on the drawing on

the following page. During Infinet communications, both of these LEDs should show activity.

TCX 865 Family Installation Guide

21

Page 28

Troubleshooting

One Input or Output Appears to Be Dysfunctional

If the CPU LED is operating and other inputs/outputs are operating properly there could be two

reasons for the failure:

• The Input or Output has been damaged. In this case contact an Andover Controls representative for assistance.

• If this is the first time using the controller, perhaps the program controlling the input/output is

not correct. Re-check your program.

Internal Reset Switch

Should the controller appear to be non responsive and all other attempts to revive it fail, try pressing the internal reset switch. The switch is located on the board behind the cover as shown below:

Infinet Activity

monitor LEDs

Internal RESET

switch

* These varistors would be added only in very noisy environments.

Andover Controls Corporation

22

Page 29

Sample Applications

Sample Applications

The following two illustrations detail the connections to a simpl e VAV Box.

The first application is a cooling-only scenario. It shows the connections for the Air Flow sensor

and the 24VAC Power Source. External varistors are shown in appropriate locations.

IN

Ramay Filter

LO

HI

IN OUT

Optional Varistors

See Note*

HOT

GND

X1

24VAC Step Down

X2

Transform er

TCX 86X

TCX 865 Family Installation Guide

23

Page 30

Sample Applicati on s

LO HI

IN

Ramay Filter

IN OUT

OUT 5

HOT

GND

TCX 86X

TCX 866

Optional Varistors

See Note*

24VAC Step Down

Transformer

The second application shows a VAV Box with re-heating capability. A single output controls the

relay that activates the heating unit

* These varistors would be added only in very noisy environments.

Andover Controls Corporation

24

Page 31

Page 32

30-3001-497 Version D

Loading...

Loading...