Controlling Tomorrow’s World

Infinity Smoke Control Guide

Electronic Version

Andover Controls Corporation i

Downloaded from - http://www.guardianalarms.net

Version B

Reproduction or dis tribution for bidden.

Copyright 1995, 1996 Andover Controls.

Subject to change without notice.

Order No. 30-3001-446

Copyright 1995, 1996

Andover Controls Corporation

300 Brickstone Square

Andover, Massachusetts 01810

All Rights Reserved.

Published by the Engineering Department at Andover Controls Corporation.

IMPORTANT NOTICE

Examples in this book are for illustrative purposes only and have never been tested in an

actual building.

This product is subject to change without notice. This document does not constitute any

warranty, express or implied. Andover Controls Corporation reserves the right to alter capabilities, performance, and presentation of this product at any time.

The following trademarks are used in this manual:

CROSSTALK is a registered trademark of Digital Communica tions Associates, Inc.

IBM is a registered trademark of Internati onal Busi ness Machines, Inc.

VT is a trademark of Digital Equipment Corporation.

ii Infinity Smoke Control Guide

Chapter 1

The Fundamentals of Smoke

Control

One of the most hazardous situations that you can face in a building is

smoke. While fires themselves are often damaging, it is smoke that can

cause the most injuries. For example, at the World Trade Towers in

February 1993, over 1,000 were injured by the smoke that resulted from

the fire.

TOC

To protect your building’s occupants, as well as furnishings and

equipment that may be damaged by smoke, you need a smoke control

system. A smoke control system, as its name implies, controls the flow

of smoke in your building in the event of fire. It keeps smoke from

spreading throughout the building, giving the building’s occupants a

clear evacuation route, as well as preventing further damage to the

building’s interior.

This chapter gives you an overview of smoke control theory.

The Fundementals of Smoke Con trol

Understanding Types of Smoke Control Systems

Two types of smoke control systems exist—dedicated and

nondedicated. The dedicated smoke control system is installed in a

building for the sole purpose of controlling smoke. A nondedicated

smoke cont ro l syst em uses parts of the building’s HVAC system to

control smoke.

In most instances, a building has both nondedicated and dedicated

systems. Nondedicated systems are used throughout the building for

normal areas (offices, manufacturing). Dedicated systems are used for

special areas, such as elevator shafts, stairtowers, and other areas that

need special smoke control techniques.

The operation of the nondedicated smoke control equipment is verified

by the “comfort level” in the areas that are served by the equipment. In

other words, if the HVAC equipment is not functioning properly, the

building’s occupants will be aware of this and the problem will get

fixed.

TOC

The operation of the dedicated smoke control equipment is verified by

an automatic self-test that is performed on a weekly basis.

1-2 Infinity Smoke Control Guide

The Fundementals of Smoke Control

Using Pressure to Control Smoke

The basic concept behind controlling smoke, r egardless of whether it is

with a dedicated or nondedicated system, is to use air pressure to confine

and (if possible) vent smoke from the building.

You cannot confine smoke by simply closing all access ways (such as

doors and vents) to the room that has the fire in it. Even with these

passages closed off, smoke can disperse throughout a building via

cracks, holes made for pipes and electrical wires, and spaces around

doors and windows. Smoke is driven through these small openings by

the expanding gases from the fire. Smoke can also be driven onto other

floors by the stack effect, which causes air to r ise in buildings. The stack

effect is caused by the difference in the interior and exterior temperature

of the building. The following diagram shows how smoke can disperse

throughout a building.

TOC

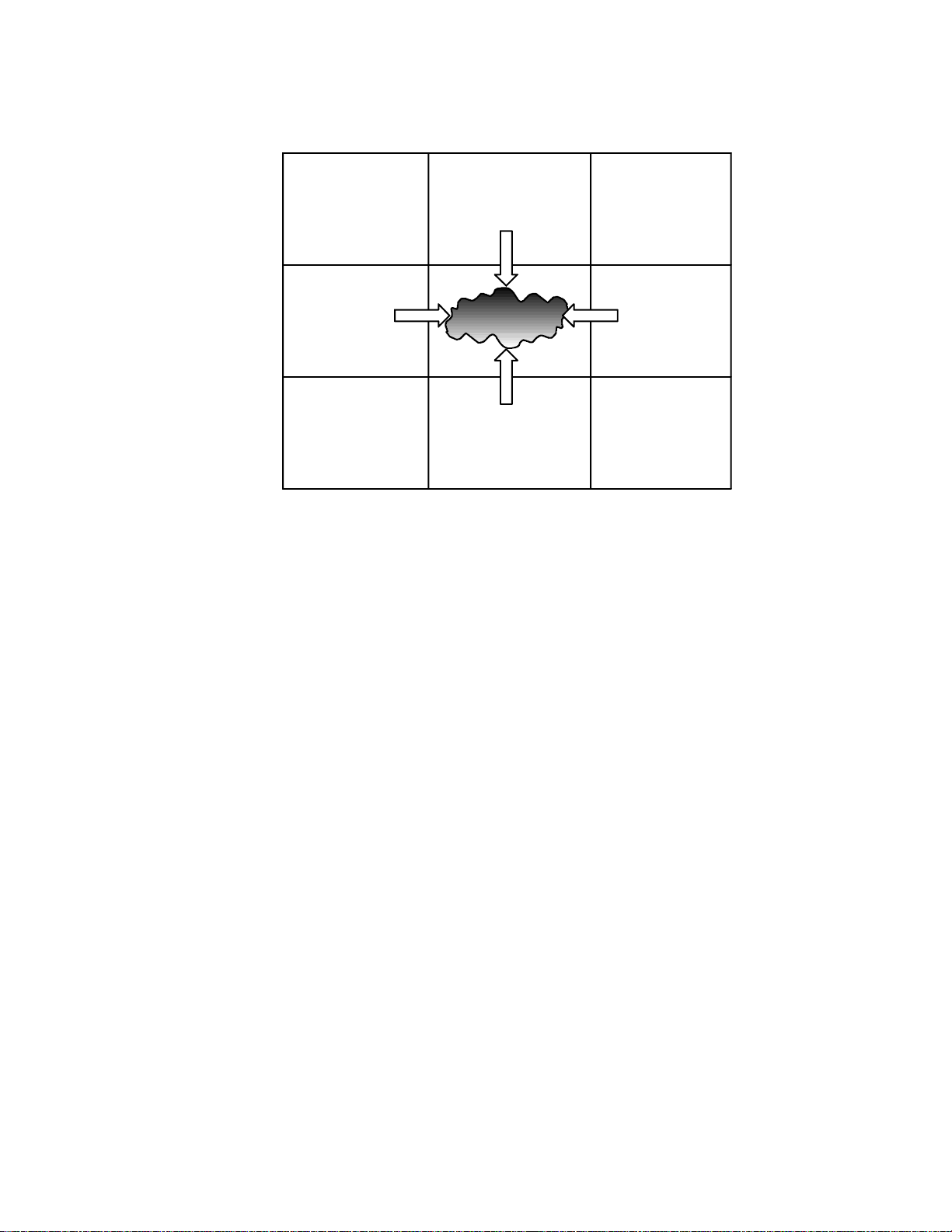

Figure 1-1. Smoke Infiltrating Areas Adjacent to the Fire

Adjacent

Area

Adjacent Area

Area on Fire

Adjacent Area

Since smoke is carried by the movement of air, you can stop the spread

of smoke throughout the building by lowering the air pressure in the area

containing the fire and by raising the air pressure in the surrounding

areas and floors. The difference in pressure (also called the pressure

differential) between the smoke-filled area and the surrounding areas

acts as a barrier to the smoke, pushing i t back into the smoke-filled area.

The next illustration shows how this works.

Andover Controls Corporation 1-3

The Fundementals of Smoke Con trol

Figure 1-2. Air Pressure Containing Smoke

TOC

Positive

Air Pressure

Positive

Air Pressure

Positive

Air Pressure

Positive

Air Pressure

Negative Pressure

Positive

Air Pressure

Positive

Air Pressure

Positive

Air Pressure

Positive

Air Pressure

You lower the air pre ssure in the smoke-f illed area by shutting off all air

flow into it and turning on the exhaust fans from the area to full capacity.

This technique pulls the smoke out of the area and vents it outside of the

building.

You pressurize the areas and floors surrounding the fire by turning off

all exhaust systems (including closing any exhaust dampers) and forcing

supply air to those areas at f ull capacity. The air in the pressurized areas

tends to leak into the smoke zone, using the same cracks and holes that

the smoke would use to get out. This airflow into the burning room

keeps the smoke from spreading.

Areas that are neither being pressurized nor depressurized (i.e. areas far

away from the fire) have both their air inlets and air return systems

turned off. Turning off the air return prevents the smoke that is being

vented into the return air system from coming into the area.

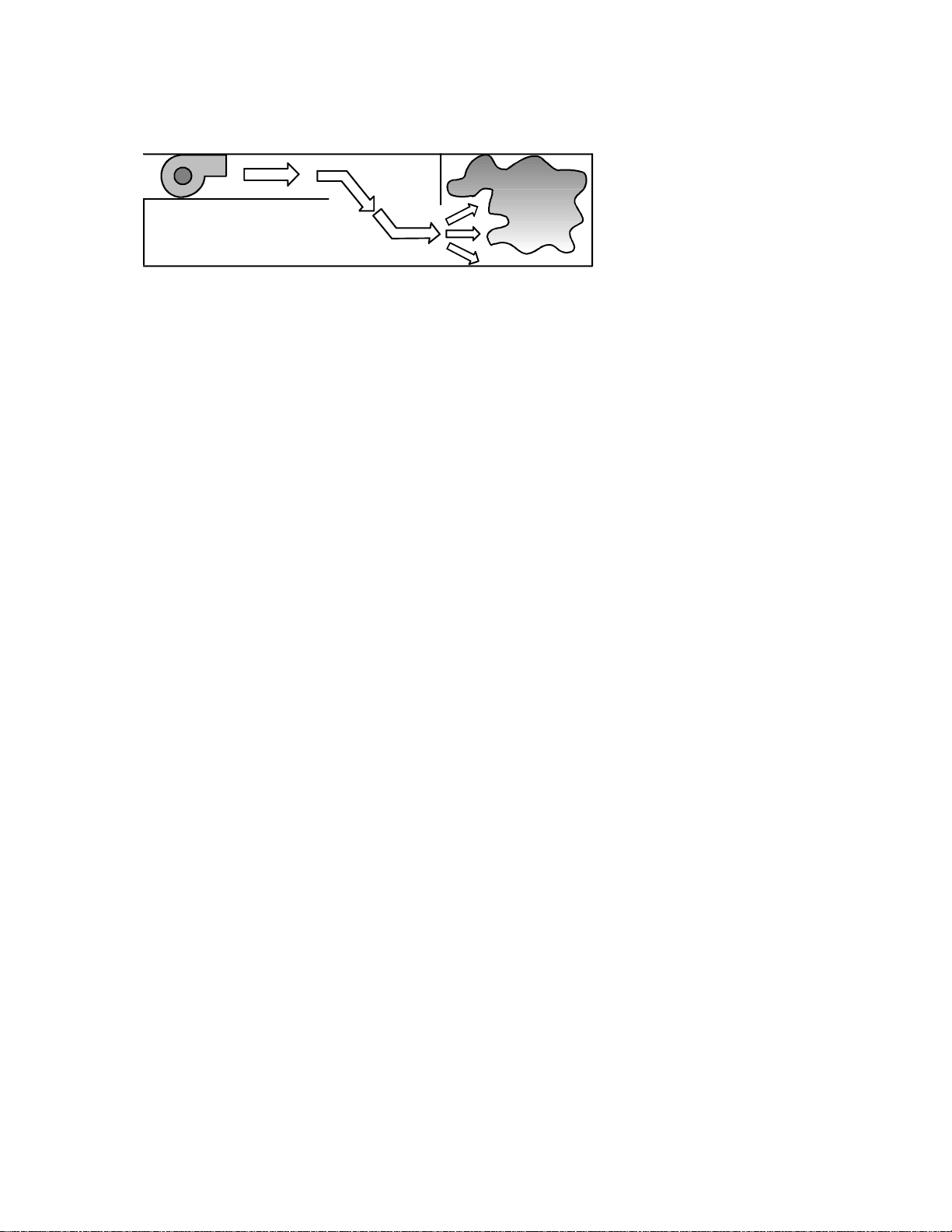

In cases where there are large openings (such as an open doorway)

between the area on fire and an adjacent area, smoke can be confined by

a large volume of air. Pumping large amounts of air through the adjacent

space creates a constant draft through the opening into the smoke zone

(as shown in the next illustration). The draft through the open space

keeps back the smoke, confining it to the smoke zone. The amount of air

required to keep the smoke from penetrating the open space is quite

large, so you should avoid this sort of situation when possible.

1-4 Infinity Smoke Control Guide

The Fundementals of Smoke Control

Figure 1-3. Keeping Smoke Away from a Large Opening

TOC

Andover Controls Corporation 1-5

The Fundementals of Smoke Con trol

Creating Smoke Zones

In order to contain the smoke by using pressure, you must divide the

building into smoke control zones. A floor or several floors of the

building can be a single zone, or one floor can be br oken into a number

of zones. A zone must be separated from other zones by smoke dampers,

airtight doors, and smoke-proof barriers.

When a fire breaks out, the smoke control system can then pressurize all

of the zones around the one where the fire broke out (called the fire

zone), isolating the smoke to that single zone.

If the smoke control system is nondedicated, the layout of the smoke

control zones should take into consideration the layout of the HVAC

system. You should place multiple areas served by the same VAV boxes

in the same smoke control zone. Also, the smoke control zones must

conform to any fire control zones that have been established, because

the smoke detectors are tied into the fire detection system. Also, keeping

the smoke control zones and the fire control zones the same makes

coordinating the two systems simpler.

TOC

Smoke Control vs. Fire Control Systems

The smoke control system is usually separate from the fire control

system, since they have different goals. The fire control system’s goal is

to contain and extinguish the fire as fast as possible. These systems,

which halt the fire but not the smoke, are often triggered automatically,

relying on the heat of the fire to activate the system. Although smoke

control systems are also automatic, you must have manual overrides for

the automatic controls. Another difference between smoke control and

fire control systems is that where fire control systems, such as

sprinklers, often rely on only a water supply, smoke control systems

usually rely on electricity to run fans and dampers. So, some smoke

control systems have a standby power supply. Standby power provides

the smoke control system with electricity in case the main power fails.

The smoke control system should be designed to work with the fire

control system and not interfere with its operation. For instance, if the

building has a sprinkler system, then the smoke control system does not

need to control a large quantity of smoke, since the size of any fire

should be smaller.

1-6 Infinity Smoke Control Guide

The Fundementals of Smoke Control

A smoke control system may also have to be designed to work with

gas-based fire extinguishers, such as the halon gas systems installed in

many computer rooms. If the smoke contr ol system tried to vent a r oom

with such a system, it would probably vent the fire suppressing gas as

well. Removing the gas lets the fire continue burning. Also, pressurizing

the areas surrounding an extinguisher equipped room reduces the

effectiveness of the system as well. Air forced into the room from the

outside by pressure can provide the fire with the oxygen it needs to

continue burning. So, gas-based fire extinguishers and smoke control

systems should not be active at the same time in the same area.

The smoke control system receives the location of the fire from the fire

panel. The fire panel uses a combination of smoke and heat sensors to

determine where the fire is located.

In the event that signals are received from more than one smoke zone,

the smoke control system should continue automatic operation in the

mode determined by the first signal received.

TOC

Smoke control systems should never be triggered by manual pull boxes.

The risk of someone pulling a box someplace other than the fire zone is

too high for you to trust your smoke control system to this form of

activation.

All smoke control systems installed in buildings must meet the

standards established by the National Fire Protection Association in

their publication NFPA 92A, Smoke Control Systems, 1988 edition. You

can find additional information regarding fire alarm control units in the

Underwriters Laboratories Inc. Standard UL 864.

Andover Controls Corporation 1-7

The Fundementals of Smoke Con trol

Designing a Smoke Control System

What is the basic goal of the smoke control system? To maintain a

tenable environment. A tenable environment allows:

• The building’s occupants to evacuate safely

• The fire fighters to get to the fire zone

The first step you take in designing your smoke control system is to lay

out the smoke control zones, as previously explained. After the smoke

zones are established, you have to address the following design factors:

• The zone-by-zone smoke control strategies to use

• The amount of pressure needed to contain smoke

• Proper separation between zones

• The fans and ductwork used in the smoke control system

TOC

• Dampers required for smoke control

• The air inlets and outlets used in the smoke control system

• Duct smoke detectors

Devising a Smoke Control Strategy

For each zone in your building, you have to establish a smoke control

strategy. The smoke control strategy is a series of steps the smoke

control system must take to contain the smoke. For each zone, you must

decide:

• Whether you should depressurize the zone if a fire occurs.

• If the zone is to be depressurized, by how much you should

depressurize it.

• Which adjacent zones should be pressurized and how much pressure

is required.

Some zones in your building may need special consideration. As

mentioned earlier, zones that have gas fire extinguisher systems should

not be vented (depressurized) and the zones surrounding the fire zone

with such a system should not be pressurized. You may not be able to

pressurize other areas, such as hospital or animal labs, due to the risk of

contaminating surrounding areas.

Consider the number of zones surrounding the fire zone that should be

pressurized. While in theory, all you need to do is to pressurize all of the

1-8 Infinity Smoke Control Guide

The Fundementals of Smoke Control

zones immediately surrounding the fire zone, it is possible that smoke

can find its way around the pressurized areas and infiltrate zones far

away. Depending on the size of your building, and the capacity you plan

to have in the smoke control system, you may decide you want to

pressurize more than just the surrounding zones. But, the more zones

you want to pressurize, the larger your air supply system needs to be.

Write down the state that all fans, dampers, and other smoke control

equipment should be in to control smoke in each zone. Later, you have

to program this information into the smoke control system. This

information gives the smoke control system a strategy for containing

smoke in each possible fire zone.

TOC

Andover Controls Corporation 1-9

The Fundementals of Smoke Con trol

Determining the Amount of Pressure Needed

Since air pressure is what keeps smoke from spreading, the primary

design factors are the amount of pressure that you need to confine the

smoke and the size of the system used to create this pressure.

For the smoke control system to create a barrier of air pressure between

the smoke zone and surrounding zones, the amount of pressure required

varies with the height of the ceiling and whether or not the building has

a sprinkler system. The next table shows the minimum pressure

differential needed to keep smoke out of surrounding rooms.

Table 1-1. Minimum Pressure Differential to

Pressu rize Fir e Zone

TOC

Sprinkler

System

Yes Any 0.05

No 9 ft 0.10

No 15 ft 0.14

No 21 ft 0.18

Ceiling

Height

Minimum Pressure

Differential (wg)

For buildings without sprinklers and with ceiling heights not shown in

the table, you can use the following formula to determine the minimum

amount of pressure needed to keep smoke out:

1

MinimumPressure 7.64 H×

-----

T

1

----– SafetyFactor+×=

T

o

f

H is the distance between the fire space and a surrounding space where

2

the pressure differential is zero. A figure of the floor to ceiling height

--

3

is a conservative estimate.

To is the absolute room temperature of t he surrounding zones measured

in °R (degrees Rankine). Typically, To = 530° R (70° F). The conversion

from °R to °F is: °R = °F + 460.

Tf is the absolute temperature of the hot gases in the fire z one. It is a lso

measured in °R. Typically, Tf is 2160° R (1700° F).

1-10 Infinity Smoke Control Guide

The Fundementals of Smoke Control

SafetyFactor is a constant added to the results to make sure they are

sufficient. A value of 0.03 wg (inches water gauge) is recommended.

Pressure buildup in an area depends on how much leakage there is.

Leakage occurs through joints, cracks, openings for pipes and wires,

gaps between doors and their door jams, and so forth. The better the

zone is sealed off from its neighbors, the easier it is to maintain the

required pressure. Since larger openings, like doorways that are

normally open, require large amounts of air to maintain pressurization,

you should avoid this type of situation.

TOC

Andover Controls Corporation 1-11

The Fundementals of Smoke Con trol

Separating Zones

You must separate smoke zones from one another by smoke barriers,

which prevent smoke from passing through them. Smoke barriers can be

a wall, a floor, or a ceiling. Any openings in the smoke barrier must be

closed with a smoke-proof fitting. For example, all duct work going

through a smoke barrier must have a smoke damper in it. A smoke

damper is a damper that prevents smoke from passing through it when

fully closed. (Refer to the dampers section below for more information.)

During a smoke emergency all of the fittings should seal themselves, so

that smoke cannot penetrate the barrier.

Since the smoke control zones should be the same as the fire control

zones, you usually separate your zones with a fire ra ted partition. A fire

rated partition is a wall that is built of fire resistant materials and that

reaches from floor to ceiling. Different floors should be separated by a

fire rated ceiling, a ceiling made of fire resistant materia ls . Both fire

rated partitions and fire rated ceilings are rated for the amount of time

they can withstand a fire. Any openings in a fire rated partition or c eiling

must be sealable with a fire rated closure, such as fire rated doors or fire

damper.

TOC

Selecting Dampers

The dampers used to isolate the smoke zone must be smoke dampers.

Smoke dampers are dampers that meet the requirements given in UL

555S, Standard for Leakage Rated Dampers for Use in Smoke Control

Systems. Following this standard ensures that the dampers are able to

block the smoke when they are fully closed. These dampers may be

different from those you might use in an HVAC system that does not

perform smoke control.

In a smoke control system, the dampers must be able to travel to their

desired setting in 75 seconds. All dampers must be fitted with end

position microswitches to provide feedback to the smoke control

system. These switches let the control system know the position of the

dampers, since smoke dampers are usually either fully closed or fully

open.

Dampers sometimes function as both smoke dampers and fire dampers.

Fire dampers are dampers that block a fire from penetrating a fire rated

partition via a duct. These dampers are normally open, held in place by

a fus ible link. The f usible link is a heat-sensitive device that releases the

1-12 Infinity Smoke Control Guide

The Fundementals of Smoke Control

dampers when it is heated to a certain temperature. Once the fusible link

releases, the dampers close by the force of gravity. So, fire dampers

operate even if the electricity has failed. The specif ications for fire

dampers appear in the document UL555, Standard for Fire Dampers.

If you want a damper to function as both a smoke damper and a fire

damper, it must meet the requirements for both devices. These dampers

can be operated by electric motors or pneumatics. But it must, however,

also have a fusible link or other means of closing automatically, like a

regular fire damper. The control system can override the closure due to

temperature. The damper needs the fusible link in case the automatic

control of the damper by the control system is interrupted.

Choosing Fans and Duct Work

The fans and duct work used in the smoke control system must be

capable of providing the amount of pressure you calculated earlier. In a

nondedicated system, this may mean that you need to install fans that

have a higher capacity than the HVAC system calls for. The ducts must

be capable of taking the pressurization (or the depressurization, for the

fire zone’s return duct) that the smoke control system will exert.

TOC

Both the fans and the ducts should meet the requirements stated in

NFPA 90A, Standard for the Installation of Air Conditioning and

Ventilating Systems.

Fans for a smoke control system normally do not have to meet any

special heat resistance rating. In a smoke control system, fans must be

able to reach the required setting in 60 seconds. Each fan must have a

pressure monitor mounted so that the smoke control system can receive

feedback on the status of the fan to determine whether it is actually

operating or not.

In some climates, the outside air can be so cold that drawing it directly

inside the building can damage the building’s interior (freeze pipes or

damage temperature-sensitive equipment, for example). In these cases,

some sort of preheater needs to be installed on the air inlet. The smoke

control system does not have to control the heater as closely as one in an

HVAC system, since maintaining comfort levels is not an issue. It

simply has to make sure the air sent into an area is not going to damage

the building’s interior.

Andover Controls Corporation 1-13

The Fundementals of Smoke Con trol

Positioning Air Inlets and Outlets

You need to carefully consider the placement of the air inlets and outlets

on your building. If you place an outlet that vents smoke too close to an

air inlet, the air intake can draw the smoke back into the building.

Since smoke rises, the exhausts that vent smoke should be placed well

above air inlets. The exhausts should be placed at least 3 ft above the

roof level, to allow space for the smoke to rise and disperse.

Keeping smoke outlets far away from air inlets does not guarantee that

the air brought into the building is always smoke free. You may want to

place smoke detectors in air inlets that operate during a smoke

emergency. If the detector finds smoke in the incoming air, it alerts the

control system. The control system has to decide whether or not to shut

down the air inlet.

TOC

You should refer to NFPA 90A for more information on smoke

detectors in inlets and outlets.

1-14 Infinity Smoke Control Guide

The Fundementals of Smoke Control

Employing Dedicated Smoke Control Systems

Most of the systems discussed so far have been nondedicated systems.

Even in a building whose primary smoke control system is

nondedicated, you may have special zones or functions where you need

to use a dedicated system. The most common dedicated system is a

dedicated smoke control system for a stairtower.

StairTowers

Stairtowers are stairwells with a ventilation system and are isolated

from the main building. The only connection between the building and

the stairtower is fire-rated doors on each floor. Since the building’s

occupants should use the stairtower to leave during an evacuation,

keeping the stairtower smoke free is vital.

TOC

A stairtower has its own dedicated system that pressurizes the stairwell

to keep smoke out. This dedicated system can take several forms, from

a fan mounted in the roof of the stairtower, to a duct system that delivers

air to each level.

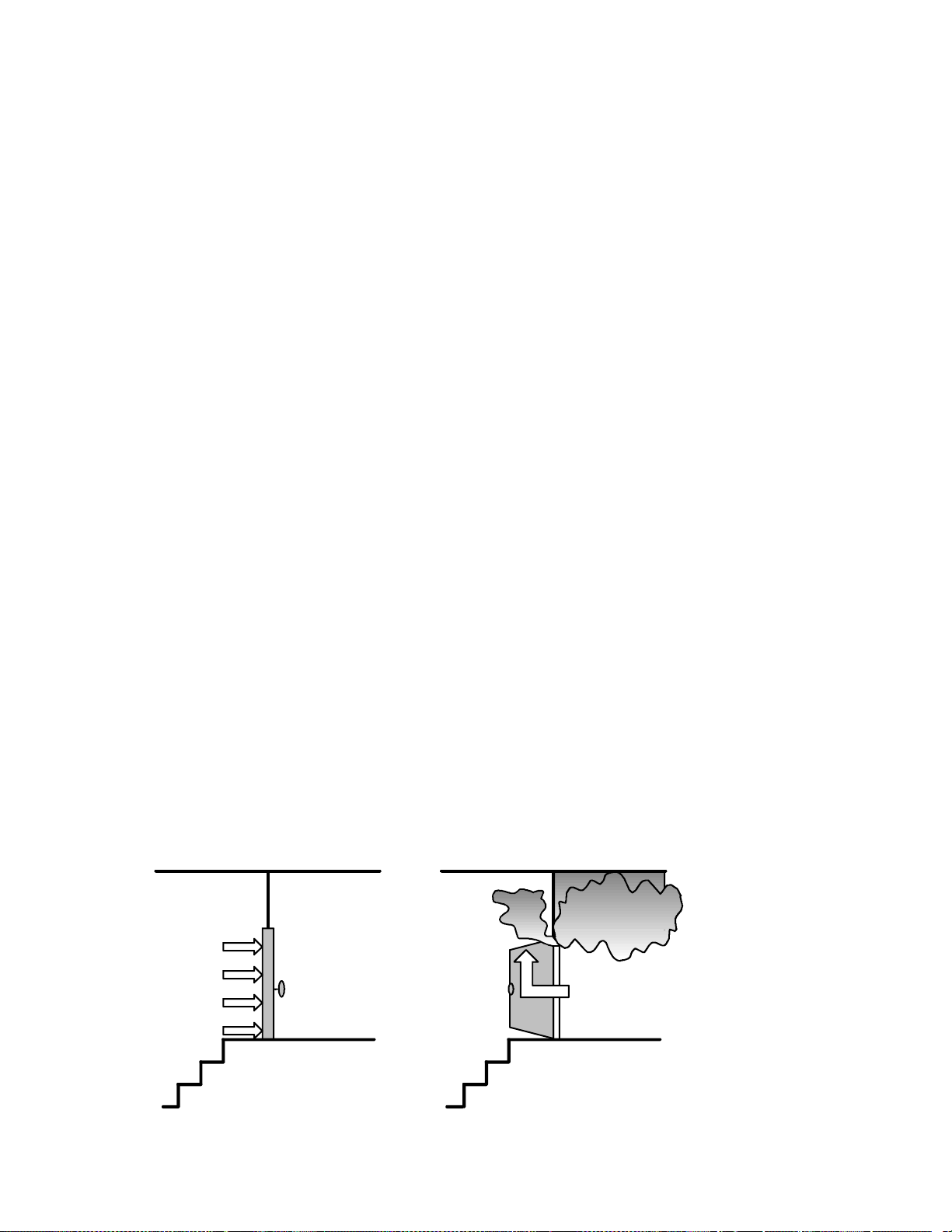

You must pressurize a stairtower enough to keep smoke out. However,

if the pressure in the stairtower is too great, then opening the doors

leading into the stairtower can be difficult. You must strike a balance.

The stairtower smoke control system must pressurize the stairway

enough to keep the smoke out, but it must not pressurize it so much that

the doors cannot be opened.

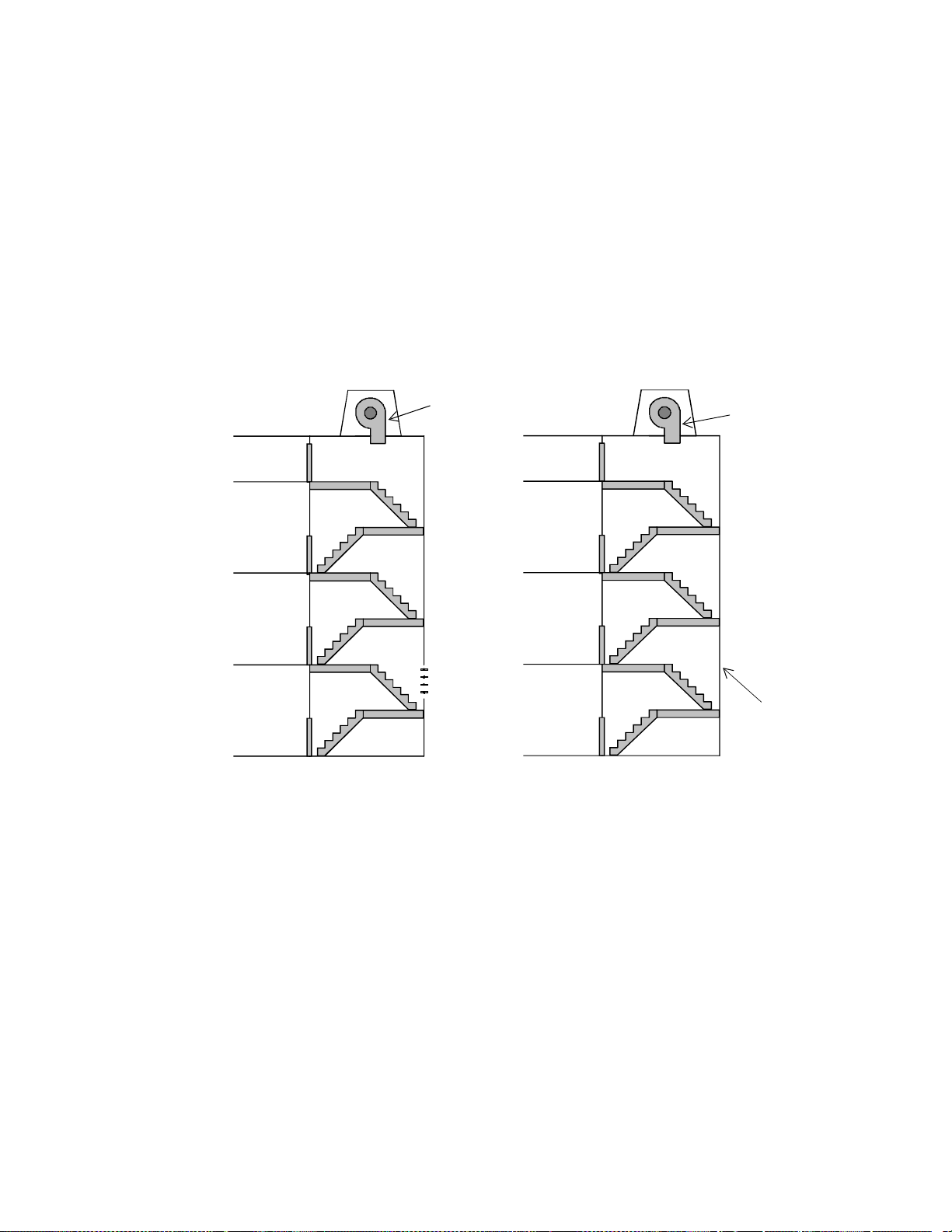

Figure 1-4. The Effects of Too Much and Too Little Pressure

Too Much Pressure

Too Little Pressure

Stairtower BuildingStairtower Building

Andover Controls Corporation 1-15

The Fundementals of Smoke Con trol

TOC

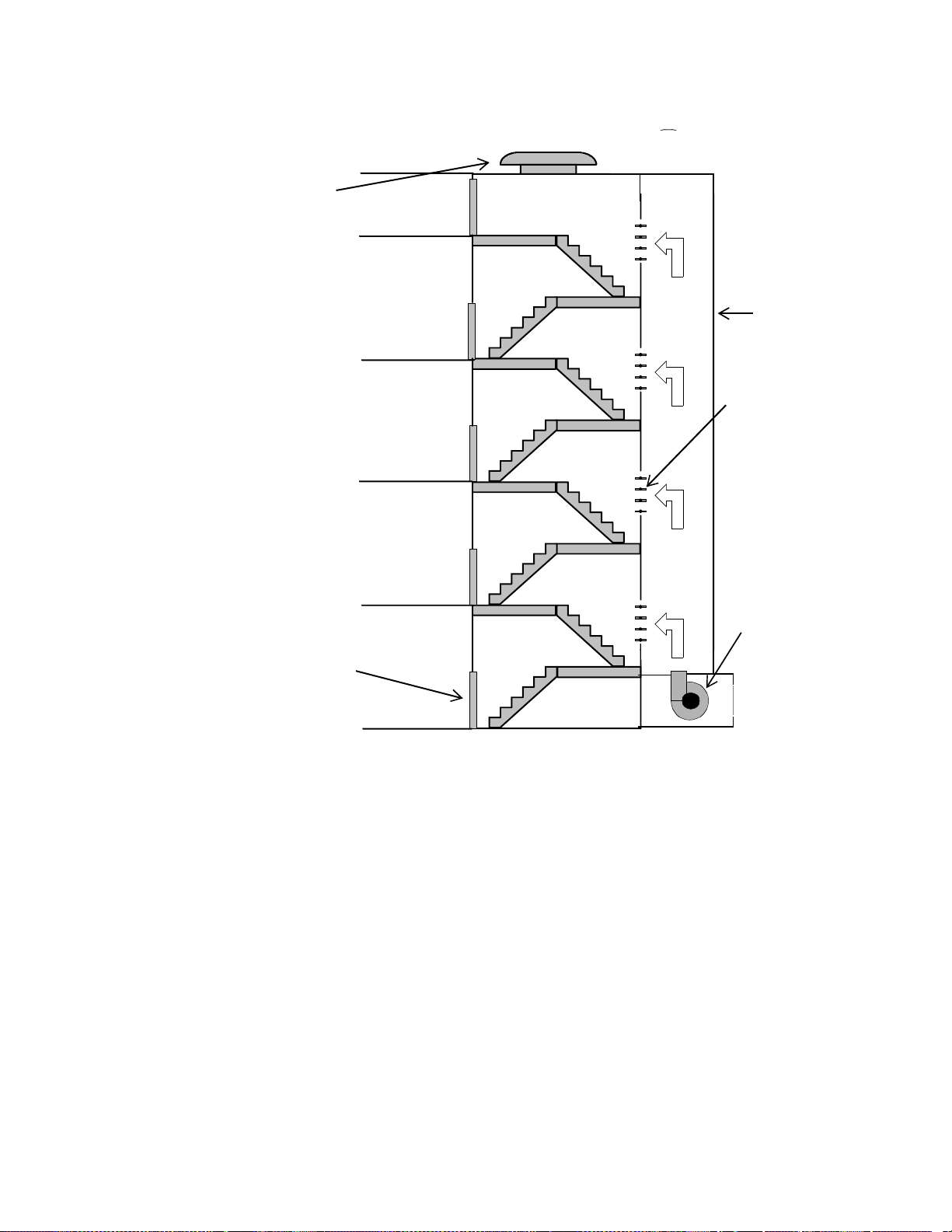

Figure 1-5. Parts of a Stairtower System

Exhaust Fan

or Vent

Air

Supply

Duct

Pressure

Vents

Fire Rated Door

Supply Fan

StairtowerBuilding

1-16 Infinity Smoke Control Guide

The Fundementals of Smoke Control

Ensuring Doors Can Be Opened

The table below shows the maximum allowable pressure differential

across a door in inches water gauge based on how wide the door is and

how much force the automatic door closing mechanism exerts. At the

pressures shown in the table, the door requires 30 lbf (pound of force) to

open, the maximum limit suggested by the NFPA Life Safety Code.

Table 1-2. Pressure Differential Across Doors

TOC

Door Closer

Force (lbf)

6 0.45 0.40 0.37 0.34 0.31

8 0.41 0.37 0.34 0.31 0.28

10 0.37 0.34 0.30 0.28 0.26

12 0.34 0.30 0.27 0.25 0.23

14 0.30 0.27 0.24 0.22 0.21

Pressure Differential for Various

Door Widt h s (inches)

32 in 36 in 40 in 44 in 48 in

The table above assumes a door height of 7 ft and a distance from the

doorknob to the knob side of the door of 3 in. If your door does not meet

these requirements, or has opening hardware other than a doorknob,

such as panic hardware, then refer to the ASHRAE publication Design

of Smoke Control Systems for Buildings for a formula to calculate the

proper opening force. The door widths in the table are only valid for

doors that are hinged at one end. For other types of doors, see the

ASHRAE document.

Many door closers vary the amount of force as the door opens. They

provide less resistance in the early stages of opening t he door than they

do later, when the door is almost fully open. The force to open the door

shown in the previous table represents the force needed to open the door

only enough to let air flow through the opening. Once air is able to flow,

the force exerted by the difference in air pressure on the door lessens.

Therefore, when calculating the force required to open the door, you

may need to lower the door closer force.

Andover Controls Corporation 1-17

The Fundementals of Smoke Con trol

Controlling Pressure in a Stairtower

Stairtower smoke control systems are divided into two categories—

noncompensated and compensated. Noncompensated systems simply

turn on a fan to pressurize the stairtower. The fan’s speed does not

change to compensate for doors opening and closing. The more doors

that are open, the more the pressure differential between the stairwe ll

and the building drops.

Figure 1-6. Compensated and Noncompensated Stairtower

Systems

Constant

Speed

Fan

VariableSpeed

Fan

TOC

Vent

A compensated system adjusts the airflow to make up for pressure lost

through open doors. It can use dampers to relieve excess pressure in the

stairtower to ensure that the pressure does not go over the maximum

limit.

There are a number of ways compensated stairtower smoke control

systems can control pressurization. In a basic system with a roofmounted fan blowing air into the stairtower, pressure can be regulat ed by

varying the speed of the fan, the pitch of the fan’s blade, the inl et vanes,

or the number of fans operating (assuming there is more than one).

More sophisticated systems use ducts to deliver air to several points in

the stairtower. The dampers can be controlled to maintain the

appropriate pressure in their zone.

1-18 Infinity Smoke Control Guide

The Fundementals of Smoke Control

TOC

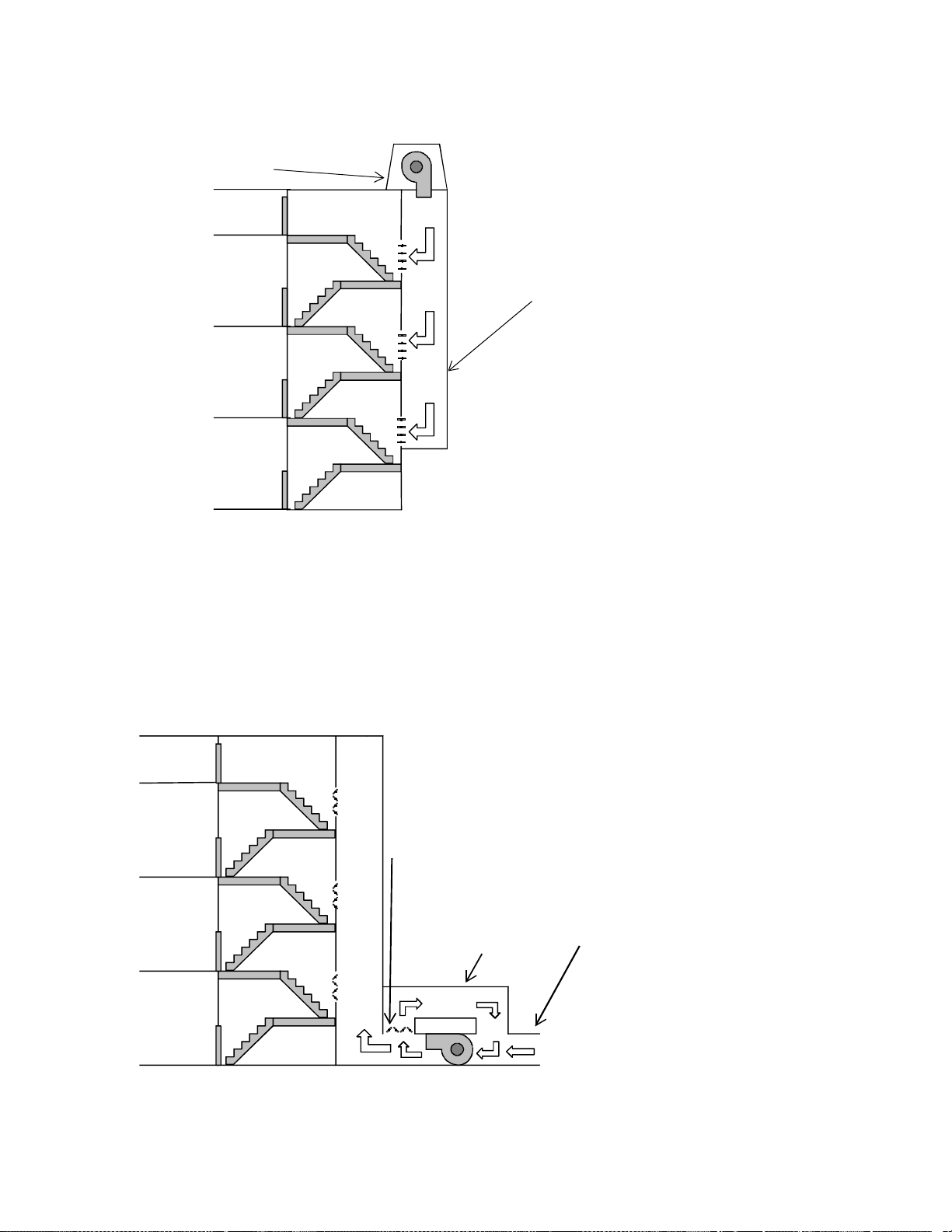

Figure 1-7. Examples of Controlling Stairtower Pressure

Pressurizati o n Fan

Air Pressure

Duct

Duct systems can also use bypass dampers and ducts to control the

amount of air flowing from the fan to the outlets. The bypass dampers

are opened when the stairtower is at the proper pressure, so that excess

air flows not into the duct system, but into the bypass duct and back to

the air inlet. See the next diagram for an example of a bypass duct

system.

Figure 1-8. A Bypass Pressure Control System

Bypass Duct Dampers

Bypa ss Duct

Air Intake

Andover Controls Corporation 1-19

The Fundementals of Smoke Con trol

There are also a number of ways a compensated stairtower smoke control

system can get rid of excess air pressure, to ensure that the doors leading into

the stairtower can open properly. One or more vents to the building’s

exterior (with dampers) can be used in the stairtower to release excess

pressure. These dampers can be barometrically controlled (being forced

open by the excess air pressure) or controlled by electric motors or

pneumatics as in conventional HVAC systems. In both cases, the dampers

must be placed far enough away from the air s upply to prevent venting of

air that has not yet been able to disperse through the stairtower. Vents can

also lead into the building, but you should consider carefully the impact of

venting extra pressure into the building before using this type of vent.

In some cases, a ground-level stairtower door can be used in place of

dampers. This door automatically opens and closes to maintain the

proper amount of pressure in the stairtower. The door is usually locked,

for security reasons. During an emergency, the smoke control system

has to be able to override the lock. Using a door in this manner has its

problems, since wind effects close to the base of a building could

prevent the air from escaping through the door.

TOC

Figure 1-9. Methods of Controlling Stairtower Pressure

Roof-mounted Exhaust Fan

Vent to Outside with Barometrically

or Automatically Controlled Dampers

Automatic Door Used to Vent Pressure

You can al so use an exhaust fan to vent th e excess pressure f r om t he

stairtower. Such a f an should be d esigned to op er ate only when th e

stairtower is overpressurized. It should never be on when the pressure

differential between t he building and the s tairtower i s below the lowest

limit.

1-20 Infinity Smoke Control Guide

The Fundementals of Smoke Control

Elevators

Elevator shafts present a special menace with regards to smoke control.

The elevator shafts form perfect chimneys to draw smoke into the upper

levels of a building. Since elevators usually have openings on each floor,

and the seals on the elevator doors are often poor, the elevator shaft can

become a mechanism to spread smoke throughout a building. Smoke

control in an elevator shaft is an important consideration in the overall

smoke control plan.

Figure 1-10. Smoke Control For Elevator Shafts

Low Pressure Area

Created by Elevator

TOC

Speci a l Smoke

Proof Elevator

Doors

Low Pressure Area

Created by Elevator

Pressurization Fan

for Elevator Shaft

If you could manage to make them safe during smoke emergencies,

elevators would ease the evacuation of the building, especially for

people in wheelchairs. To have the elevators usable during a smoke

emergency, you need to pressurize the elevator shafts the same way you

pressurize a stairtower.

However, pressurizing the elevator shaft presents a number of problems.

While the elevator doors can be fitted with improved seals and rubber

sweeps, these systems will no t totally e liminate air leakage. Also, most

elevator shafts are not designed to be pressurized. They often have large

openings at the top where the cables feed into the winding room. Shafts

are often constructed of porous material that cannot contain the air

pressure. And since most shafts are not designed to be inspected after the

elevators are installed, finding and repairing cracks that would let smoke

infiltrate or pressure esc ap e is difficult.

Andover Controls Corporation 1-21

The Fundementals of Smoke Con trol

Another primary problem with letting elevators run during a smoke

emergency is the localized pressure differences that the cars create as

they travel up and down the shafts. For example, a car moving down

from the top of the shaft may create a small low air pressure zone near

the shaft’s top, which can pull smoke from the fire zone into the shaft.

At the present time , these issues have not be en resolved. Pressur izing the

elevator shafts so that the elevators can operate during a smoke

emergency is still being studied. In general, elevators should not be used

as an escape route during an evacuation.

TOC

1-22 Infinity Smoke Control Guide

The Fundementals of Smoke Control

Detecting Smoke

The fire control system is the system that is connected to the smoke and

fire detectors. Every smoke zone should have a Listed smoke and fire

detector installed in it. The detectors should be located so that they will

detect the presence of smoke or fire before it spreads beyond the zone.

Once the fire control system detects the fire, it relays to the smoke

control system the zone and the type of alarm that was triggered. The

smoke control system then takes action.

Never use manual pull stations to start the smoke control system. There

is no guarantee that the person pulling the alarm is in the same smoke

zone as the fire. The automatic smoke control system should take only

those actions that are common to all smoke strategies when a manual

pull station is activated. For example, the stairwell can be pressurized in

response to a manual pull box alarm. Implementing a specific smoke

control strategy must wait until the smoke detectors locate the fire zone.

TOC

Configuring and Mon itoring a S moke Control

System

The smoke control system should be able to act on its own in response

to detecting smoke. When it detects smoke, the system enacts the

strategy you planned out (as discussed in the design section of this

article). The automatic smoke control should stick with the strategy to

control smoke in the first zone that smoke is detected in. It would be

difficult for you to create strategies for controlling smoke in all possible

combination of zones.

The automatic smoke control system must have the highest priority over

all other automatic control systems in the building. It must override

energy management, occupancy schedules, or other controls. The

smoke emergency will probably last only several hours, so the impact

on energy management should be minimal. The only systems that

should be able to automatically override the smoke control system are

such safety systems as high pressure limiters.

Considering how unpredictable smoke is, you must have a manual

control panel from which the smoke control system can be monitored

and overridden. This panel, called a Firefighter’s Smoke Control Station

(FSCS), allows firefighting personnel to take manual control of the

smoke control system.

Andover Controls Corporation 1-23

The Fundementals of Smoke Con trol

Firefighter’s Smoke Control Station

The Firefighter’s Smoke Control Station (FSCS) is a graphic

annunciating control panel that gives firefighters information about the

state of the smoke control system as well as manual control over all of

its components. The FSCS should be located in a secure room or cabinet

to prevent unauthorized personnel from tampering with it. The room or

cabinet should be clearly marked so that firefighters can quickly locate

the FSCS.

The Fireman’s Smoke Control Station panel has a diagram of the

building showing the entire smoke control system, along with status

lights and override switches for all of the system’s components. The

diagram of the building should include all smoke control zones, all of

the ducts leading to and from the zones with arrows indicating the

direction of air flow in the ducts, and a clear indication of which zone

each piece of equipment serves.

TOC

The panel must have controls to activate all fans, dampers, and other

equipment related to the smoke control system. These manual controls

must be able to override all automatic control of smoke control

equipment. In particular, the FSCS must be able to override:

• Hand/off/auto switches

• Local start/stop switches on fan motor controllers

• Freeze detection devices

• Duct smoke detectors

The FSCS must not override such safety controls as:

• Electrical overload protection

• Maintenance personnel’s electrical disconnects

• High limit pressure switches

• Any fire/smoke damper thermal control as required by UL33

(standard for heat responsive links for fire protection service), heat

responsive links, or UL555S (the standard used for leakage rated

dampers for use in smoke control systems).

In non-dedicated systems, local motor controller’s hand/off/auto

switches can remain in-circuit with the FSCS panel. But, they can

remain in-circuit only if the switches are in a locked room accessible

only to authorized personnel. Also, if such a switch is thrown, a trouble

alarm must sound in the building’s main control center.

1-24 Infinity Smoke Control Guide

The Fundementals of Smoke Control

The indicator lights on the FSCS provide information about the

functioning of the system. The following colors should be used for the

FSCS indicators:

• Green—Fans and other equipment are running or dampers are open.

• Yellow—Dampers are in the closed position.

• Orange or Amber—The equipment has failed.

• Red—A fire has been detected in the area.

The FSCS has a lamp te st button that turns on all t he panel’s li ghts. Use

this button regularly to make sure none of the lights has burned out.

The FSCS gets information on the status of the smoke control system’s

equipment from proof monitors on the equipment itself. Each fan that

has a capacity over 2,000 cfm capacity should be mounted with a

pressure monitor. Smoke dampers should be fitted with end-range

microswitches to indicate that they are fully opened or fully closed.

TOC

All of the failure lights on the FSCS (the orange or amber ones)

represent the state of the equipment as determined by the proof sensors.

The failure light comes on if the piece of equipment is not in the state its

control is set for within its trouble indication time. This time is 60

seconds for a fan and 75 seconds for a damper. If, within that time, the

proof sensors do not report that the piece of equipment has responded to

the control system’s command, the FSCS indicates that the piece of

equipment has failed.

Andover Controls Corporation 1-25

The Fundementals of Smoke Con trol

Testing the System

During the installation, you should perform operational tests that make

sure the components and subsystems of the smoke control system are

installed correctly. After the installation is done, you must perform

acceptance tests, to prove that the smoke control system is capable of

doing what it was designed to do. The testing procedures are covered in

a later chapter of this manual.

Bibliography

The National Fire Prot ection As sociation. NFP A 90A, Standard for the

Installation of Air Conditioning and Ventilating Systems. The National

Fire Protection Association.

The National Fire Protection Association. 1988. NFPA 92A,

Recommended Practices for Smoke Control Systems. The National Fire

Protection Association.

TOC

Underwriters Laboratories, Inc. UL 555S, Standard for Leakage Rated

Dampers for Use in Smoke Control Systems. Underwriters Laboratories,

Inc.

Underwriters Laboratories, Inc. UL 555, Fire Dampers. Underwriters

Laboratories, Inc.

Underwriters Laboratories, Inc. UL 864, Control Units for Fire-

Protective Signaling Systems. Underwriters Laboratories, Inc.

1-26 Infinity Smoke Control Guide

Chapter 2

Infi nity Smoke Contr o l

System Components

This chapter presents a general overview of the Infinity smoke control

system and describes the UL listed system components used, the

features of each component, and their role within the system. The

following components are described:

• CX9200 main controller

• SCX920S controller

TOC

• TCX840 series controllers

• TCX850 series controllers

• TCX860/865 series controllers

• EnergyLink 2500 repeater

• InfiLink 200 repeater

• InfiLink 210 repeater

• FSCS (Firefighter’s Smoke Control Station)

• Fire Panel

Infinity Smoke Control System Components

Smoke Control System Overview

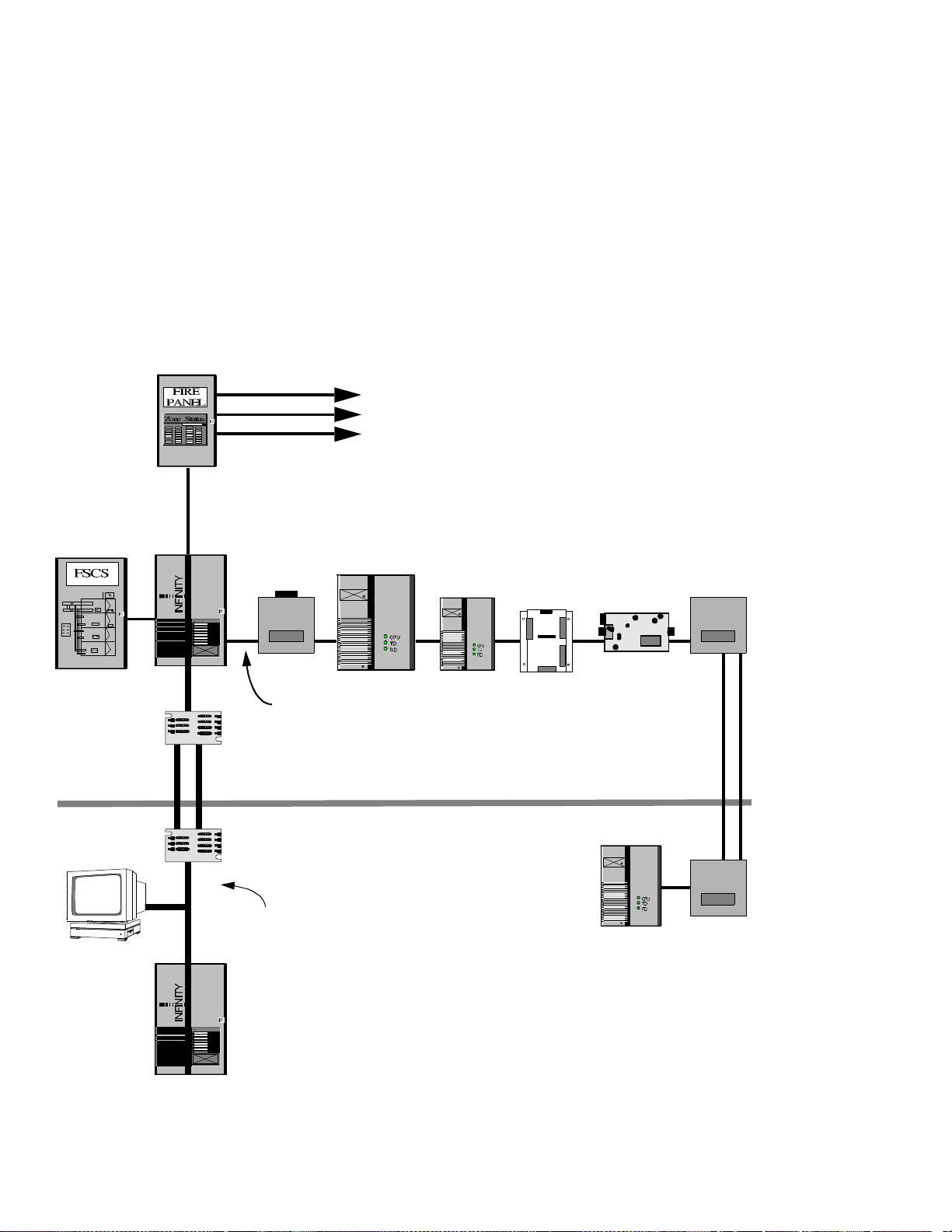

Figure 2-1 shows the components that are used in an Infinity smoke

control system and how they are connected together. The component

descriptions in the re mai nder of this chapter describe in more detail the

role of each component in the system. Notice that the smoke control

system itself is electricall y isol ated from the non-smoke control

components.

Figure 2-1. Smoke Control System Overview

Smoke Detectors,

Fire Detectors,

Manual Pull Boxes,

Etc.

TOC

RS-232

Cable

RS-232

Cable

fiber opti c

cable

SX8000

Workstation

CX9200

Infilink

200

Infi n et Cable

EnergyLink 2500

EnergyNet

Cable

SCX920S

UL Listed Smoke C ont rol Compon ents

Non-Sm oke Contr ol C omponent s

TCX 850

series series

TCX 840

series

TCX 860/5

fiber optic

cable

Infilink

210

2-2 Infinity Smoke Control Guide

Infinity Smoke Control System Components

CX9200 Controller

The CX9200 serves as the central controller in the Infinity smoke

control system. It controls the communication between the other system

components within the smoke control system. The C X9200 can be used

in a dedicated or a non-dedicated smoke control application. The

CX9200 connects to other controllers in the following ways:

• The CX9200 connects to other CX9200 controllers via the E nergyNet

network.

• The CX9200 connects to the Infinet controlle rs, such as the SCX920S,

the TCX850 series, TCX 840 series, or the TCX860/865 series, via

the Infinet network.

• The CX9200 also connects to both the FSCS and Fire panel using 2

RS-232 ports.

TOC

When the CX9200 is utilized for smoke control, it performs the

following functions:

• Initializes the smoke control system.

• Receives fire alarms from the Fire Panel and instructs the Infinet

controllers to execute a smoke control strategy.

• Reads the manual override settings and updates the LEDs and alarm

on the FSCS.

• Performs weekly self-tests on all the dedicated components in the

smoke control system.

• Monitors the controllers in the smoke control system and signals the

FSCS when there is a communication fault or output override.

Features

• Plain English programming language

•1 Energynet communications port

• 3 RS-232/RS-485 communications ports

• 1 RS-232/RS-485/RS-422 communications port

• Supports up to 254 Infinet controllers

• Battery backup: 1 hour full UPS to 72 hours for memory only

• 115V/230V AC power input

• DCX250 touch-screen display option

• 9600 bps Infinity Modem option

• ENL2500 Energynet repeater option

Andover Controls Corporation 2-3

Infinity Smoke Control System Components

SCX920S Controller

The SCX920S controller is used to control a large piece of equipment,

such an AHU (Air Handling Unit), or several smaller pieces of

equipment, such as smoke dampers. The SCX920S communicates with

the CX9200, as well as other Infinet controllers, via the Infinet network.

The SCX920S can be used in a dedicated or a non-dedicated smoke

control application.

Features

• Plain English programming language

• 16 Universal inputs that can be configured to measure Voltage,

Current, Temperature, or Digital (contact closure) values

• 8 Outputs that can be either FormC relay contacts, Voltage outputs,

or Current outputs

TOC

• 1 RS-485 Infinet port

• Lithium battery backup for memory and Real Time Clock

• 24V/115V/230V AC power input

• Available in either an open class plastic housing, designed to be

placed in a Listed enclosure, or as a fully enclosed unit with a locking

door

• Optional Local Display/Keypad option

2-4 Infinity Smoke Control Guide

Infinity Smoke Control System Components

TCX840 Series Controllers

The TCX840 series includes the TCX840, TCX843, TCX845, TCX846

controllers. The TCX840 series controlle rs are used to control small

pieces of equipment that require fewer I/O points than an SCX920S,

such as VAV boxes or stairwell fans. The TCX840 series communicates

with the CX9200, as well as other Infinet controllers, via the Infinet

network. The TCX840 series can be used in a dedicated or a nondedicated smoke control application.

Features

• Plain English programming language

• Universal inputs that can be configured to measure Voltage, Current,

Temperature, or Digital (contact closure) values

TOC

• Analog outputs can be either voltage or current

• Air-flow sensor that measures differential pressure

• 1 RS-485 Infinet port

• Lithium battery backup for memory

• 24V AC power input

Table 2-1 lists the I nput/Output capabiliti es of each of the controlle rs in

the TCX840 series.

Table 2-1. TCX840 series I/O capabilities

TCX840 TCX843 TCX845 TCX846

Universal Inputs

Form A Outputs

Tri-State Outputs

Analog Outputs

0 - 1" Air-flow Sensors

2244

2555

1222

0022

1101

Andover Controls Corporation 2-5

Infinity Smoke Control System Components

TCX850 Series Controllers

The TCX850 series includes the TCX850, TCX851, TCX852, TCX853,

and TCX855 controllers. The TCX850 series controllers are used to

control small pieces of equipment that require fewer I/O points than an

SCX920S, such as VAV boxes or stairwell fans. The TCX850 series

communicates with the CX9200, as well as other Infinet controllers, via

the Infinet network. The TCX850 series can be used in a dedicated or a

non-dedicated smoke control application.

Features

• Plain English programming language

• Universal inputs that can be configured to measure Voltage, Current,

Temperature, or Digital (contact closure) values

• Air-flow sensors that measure di ffer enti al pressu r e

TOC

• 1 RS-485 Infinet port

• Lithium battery backup for memory

• 24V AC power input

Table 2-1 lists the Input/Output capabilities of each of the controllers in

the TCX850 series .

Table 2-1. TCX850 series I/O capabilities

TCX850 TCX851 TCX852 TCX853 TCX855

Universal Inputs

Form A Outputs

Tri-State Outputs

0 - 1" Air-flow Sensors

0 - 0.2" Air-flow Sensors

44264

33133

11111

10120

00001

2-6 Infinity Smoke Control Guide

Infinity Smoke Control System Components

TCX860 Series Controllers

The TCX860 series includes the TCX860, TCX861, TCX862, and

TCX863 controllers. Like the TCX850 series, the TCX860 series

controllers are used to control VAV boxes. The TCX860 series

communicates with the CX9200, as well as other Infinet controllers, via

the Infinet network. The TCX860 series can be used in a dedicated or a

non-dedicated smoke control application.

The TCX860 series controllers have a built-in motor and gear assembly

for direct control of a damper.

Features

• Plain English programming language

• Universal inputs that can be configured to measure Voltage, Current,

Temperature, or Digital (contact closure) values

TOC

• Analog outputs can be either Voltage or Current

• Air-flow sensors that measure differential pressure from 0 to 1 inches

water gauge

• One RS-485 Infinet port

• Lithium battery backup for memory

• 24 V AC power input

Table 2-2 lists the I nput/Output capa bilities of each of the controlle rs in

the TCX860 series.

Table 2-2. TCX860 Series I/O Capabilities

Input/Output Types TCX 860 TCX 861 TCX 862 TCX 863

Universal Inputs

Form A Outputs

Analog Outputs

Airflow Sensors

4424

3333

—222

1111

Damper Motor

EMX170 ports

Powerfail PCB

Andover Controls Corporation 2-7

111—

—111

——1 —

Infinity Smoke Control System Components

TCX865 Series Controllers

The TCX865 series includes the TCX865, TCX866, TCX867, TCX868 and

TCX869 controllers. Like the TCX860 series, the TCX865 series controllers are

used to control VAV boxes. The TCX865 series communicates with the

CX9200, as well as other Infinet controllers, via the Infinet network. The

TCX865 series can be used in a dedicated or a non-dedicated smoke control

application.

The TCX865 series controllers have a built-in motor and gear assembly for

direct control of a damper.

Features

• Plain English programming language

• Universal inputs that can be configured to measure Voltage, Temperature, or

Digital (contact closure) values

TOC

• Analog outputs can be either Voltage or Current

• Air-flow sensors that measure differential pressure from 0 to 1 inches water

gauge

• One RS-485 Infinet port

• Lithium battery backup for memory

• 24 V AC power input

Table 2-1 lists the Input/Output capabilities of each of the controllers in the

TCX865 series.

Table 2-1. TCX865 Series I/O Capabilities

Input/Output Types TCX 865 TCX 866 TCX 867 TCX868 TCX 869

Universal Inputs

Form A Outputs

Analog Outputs

Airflow Sensors

22222

33033

00002

11111

Damper Motor

Sensor ports

Real Time Clock

2-8 Infinity Smoke Control Guide

111 —

00011

01011

Infinity Smoke Control System Components

EnergyLink 2500

The EnergyLink 2500 is an active network hub for the EnergyNet

network that has slots for plugging in various media interface modules.

The EnergyLink 2500 can perform the following functions:

• Allows the Energynet to be used in a star configuration

• Extends the length of an Energynet network

• Connects different Energynet media types together

• Allows for electrical isolation on an Energynet network by using fiber optics.

Features

• Slots for up to 7 media interface modules

TOC

• Mounts inside the CX9200 cabinet

• Power (+5V DC) supplied by the CX9200 power supply

Table 2-3 lists the 3 different media interface modules that are available

for the EnergyLink 2500.

Table 2-3. EnergyLink 2500 Media Interface Modules

Media Type Media Interface Module

Twi s te d Pair (10 BASE-T) ENL2501

Thin Coaxial (10BASE-2) ENL2502

Fiber Optic (10BASE-FL) ENL2503

Andover Controls Corporation 2-9

Infinity Smoke Control System Components

Infilink 200

The InfiLin k 200 is a repeater and network expander for the Infinet

network.

The InfiLink 200 can perform the following functions:

• Amplify an RS-485 Infinet signal, thus allowing for extension

beyond 4,000 feet

• Expand an RS-485 Infinet signal into 4 more RS-485 channels, thus

allowing for up to 127 Infinet controllers on a network

• Convert an RS-485 signal into an RS-232 signal

Features

• 5 RS-485 ports

TOC

• 1 RS-232 port

• Switch selectable baud rates

• Enclosure is standard

• 115V/230V AC power input

2-10 Infinity Smoke Control Guide

Infinity Smoke Control System Components

Infilink 210

The InfiLi nk 210 is a fiber optic repeater for the Infinet network. The

InfiLink 210 is used to convert a single RS-485 Infinet signal into 2 fiber

optic Infinet channels. Therefore, if an Infilink 210 is used at each Infinet

controller, the entire network can use fiber optics. The Infilink 210 can

be used to electrically isolate one section of the Infinet network from

another section.

Features

• 1 RS-485 port

• 2 fiber optic ports. Each port has a Receive Data connection and a

Transmit Data connection.

• Switch selectable baud rates

• Enclosure is standard

TOC

• 115V/230V AC power input

Andover Controls Corporation 2-11

Infinity Smoke Control System Components

The FSCS

The Firefighter’s Smoke Control Station (FSCS) is a custom panel that

provides full monitoring and manual control capability over all smoke

control equipment. In the event of an emergency, it is used by the fire

department to override the smoke control system.

Features

The FSCS should contain a building diagram that clearly indicates the

type and location of all smoke control equipment, and the areas served

by the equipment (smoke control zones). Since the FSCS uses a

graphical depiction of the building, each FSCS will be unique and must

be custom made.

The FSCS graphic must show all fans in excess of 2000 CFM, all

dampers or groups of VAV boxes, and all major ducts and how the ducts

are connected together. The FSCS graphic must provide a clear

indication of the direction of airflow in the ducts.

TOC

If the FSCS graphic is t oo la rge to fit on a single panel, multiple pane ls

may be used.

Manual Overrides

The FSCS must provide manual controls that will override any piece of

equipment in the smoke control system. The FSCS must have the

highest priority in the smoke control system. The FSCS must be able to

override any other manual or automatic control that is being used in the

system, except when these controls are intended to protect against

electrical overloads, provide for personal safety, or prevent major

system damage. VAV boxes that are all located within and serve one

designated smoke control zone may be controlled collectively.

Fans require a 3-position control that provides ON-AUTO-OFF

capabilities. Dampers require a 3-position control that provides OPENAUTO-CLOSE capabilities. The AUTO position is removed if the

override is for a piece of equipment that can only be controlled by the

FSCS.

In addition to the controls mentioned above, you can also have a 3position control for each zone that provides PRESSURIZE-AUTOEXHAUST capabilities.

2-12 Infinity Smoke Control Guide

Infinity Smoke Control System Components

Status Indicators

The actual status of the smoke control equipment must be clearly

indicated on the FSCS by the use of visual indicators with appropriate

legends.

Fans must have a single indicator that turns on when the fan’s

differential pressure “proof sensor” indicates that the fan is operating.

Dampers must have 2 indicators: one that turns on when the damper’s

end-limit “proof sensor” indicates that the damper is closed , and one that

turns on when the damper’s other end-limi t “proof sensor” indicates that

the damper is open. Both indicators should be off when the damper is

positioned between the open and closed positions.

The FSCS should provide a status indicator for each zone that signals

whether or not the zone is in an alarm condition.

TOC

The FSCS should provide status indicators for each piece of equipment

that signals when there has been an equipment failure. For instance, if

the fans do not turn on within 60 seconds, or the dampers do not reach

the desired position within 75 seconds, the fault indicator should turn on.

Table 2-4 lists the status indicator colors that m ust be used on the FSCS

Table 2-4. FSCS Status Indicator colors

Status Color

Damper OPEN or Fan ON Green

Damper CLOSED Yellow

System or Equipment FAULT Amber/Orange

Zone ALARM Red

Andover Controls Corporation 2-13

Infinity Smoke Control System Components

Other Features

The FSCS will also have the following features:

• Master Key – This key will silence the audible alarm and enable all

of the controls on the FSCS. This key must be made available to

authorized personnel only.

• Clear Faults Button -- This momentary push-button will clear all of

the fault indicators on the FSCS. This push-button is not enabled

unless the Master key is ON. If the fault corrects itself, the fault

indicator will automatically turn off. If the fault returns, the fault

indicator will turn on again. If there is a fault detected during the

weekly self-test of a dedicated controller, the fault indicator for that

piece of equipment will stay on until it is cleared. The C lear Faults

push-button is wired to an input on the FSCS, just like any other

switch.

• Lamp Test Button - This momentary push-button turns on all of the

status indicators on the FSCS, thus allowing the operator to

determine if there is a bad indicator.

TOC

• Audible Alarm – The alarm sounds when there is a smoke emergency

or when there is an equipment fault. Turning the Master key ON is

the only way to silence the alarm.

Ordering Information

Andover Controls’ UL listing includes a custom FSCS panel that is

manufactured by Automation Displays Incorporated. For ordering

information, contact:

Automation Displays Inc.

3533 North White Avenue

Eau Claire, Wisconsin 54703

(715) 834-9595

2-14 Infinity Smoke Control Guide

Infinity Smoke Control System Components

Design Guidelines

In order to have the FSCS built to your specifications, you will need to

supply the following:

• An accurate drawing of the smoke control system. This drawing will

be used to create the FSCS front panel graphic.

• A second copy of the FSCS drawing indicating the colors of the

status indicators.

• A third copy of the FSCS drawing indicating the colors that are to be

used for the front panel graphic. Consult Automation Displays, Inc.

for a list of options.

• Specify whether you need a flush-mount or a surface-mount panel.

• Specify whether or not you need a transparent cover for the FSCS.

• Specify whether or not you need a terminal block wired to the FSCS

inputs, to be used for Zoned Wiring to the Fire Panel.

TOC

Automation Displays, Inc. will provide you with a copy of the FSCS

drawing that indicates the I/O numbers that correspond to each LED

output and each switch input on the FSCS. Each 2 position switch

requires 1 input and each 3 position switch requires 2 inputs.

The FSCS you order from Automation Displays Inc. will contain the

following:

• An Automation displays’ Autoface IV graphic door with a keylock.

• Switches and Status Indicators for each piece of smoke control

equipment.

• A “Master” keyswitch, a “Clear Faults” push-button, a “Lamp Test”

push-button and a sonalert audible annunciator.

• An Automation Displays’ Q-Card CPU board with the “Andover

Data Interface” firmware that is wired to an RS232 Protection PCB.

• An Automation Displays’ 80 Point Driver card for every 80 status

indicators.

• An Automation Displays’ 80 Point Driver card for reading the FSCS

switches. A 2 position switch requires 1 input and a 3 position switch

requires 2 inputs. A Switch Protection PCB is also included.

• A 5V DC power supply for the Q-Card, the 80 Point Driver cards,

and the FSCS Status Indicators.

Refer to Chapter 5 for a drawing of an example FSCS graphic.

Andover Controls Corporation 2-15

Infinity Smoke Control System Components

The Fire Panel

The Fire Panel connects to all of the smoke detectors, fire detectors,

manual pull boxes, fire alarms, etc. within the buil ding. When one of the

Fire Panel sensors detects a problem, the Fire Panel informs the Infinity

smoke control which sensor is in an alarm condition and what the alarm

condition is. The Infinity smoke control system receives all of it’s alarm

information from the Fire Panel. The smoke control zones must

correspond to the Fire Panel’s fire zones.

There are two methods for connecting the Fire Panel to the Infinity

smoke control system: using an RS-232 communications channel or by

the Zoned Wiring method.

RS-232 Communications

As part of Andover Controls’ UL Listing, the following Fire Panels can

communicate directly with the CX9200 via RS-232:

TOC

Simplex Time Recorder Co. Series 4100

1 Simplex Plaza

Gardner, Massachusetts 01441

(508) 632-2500

Edwards Systems Technology, Inc. Model # IRC-3

195 Farmington Avenue

Farmington, Connecticut 06032

(203) 678-0410

Zoned Wiring

If you are using a Fire Panel that is not listed above, you will have to

connect to the Infinity smoke control system using the Zoned Wiring

method. This requires running a set of wires for each zone from a contact

closure output on the Fire Panel to inputs on the FSCS. The CX9200 will

poll the FSCS to determine when a zone is in an alarm condition. If you

plan on using this method, you must specify that a terminal block be

provided with the FSCS that connects to the FSCS inputs. See the

following chapter for more details.

2-16 Infinity Smoke Control Guide

Chapter 3

Installation and Layout

This chapter gives instructions for installing and interconnecting the

Infinity smoke control system components.

All wiring in an Infinity smoke control system must comply with the

National Electric Code (NFPA 70), as well as any state or local

regulations.

Special requirements for using Infinity equipment to perform smoke

control is covered in detail in this chapter. For general installation

instructions, see the installation guides for each individual component.

These installation guides are shipped with the Infinity controllers.

Topics covered in this chapter are:

TOC

• Installing the CX9200

• Installing Infinet Controllers

— The SCX920S

— The TCX840 series

— The TCX850 series

—The TCX860/865 series

— The Infilink 200

— The Infilink 210

• Installing the FSCS

• Installing the Fire Panel

Installation and Layout

Installing the CX9200

For detailed information on how to mount and connect the wiring to the

CX9200 and it’s peripherals, refer to the following Andover Controls

documentation:

TOC

Infinity CX9200 Hardware Installation Guide

Energylink 2500 Installation Guide

DCX250 Installation Guide

Infinity Modem Guide

(P/N 30-3001-196)

(P/N 30-3001-404)

(P/N 30-3001-393)

(P/N 30-3001-347)

Cable Li m i ta tions

• The RS-232 cable between the CX9200 and the FSCS must be no

longer than 20 feet, and must be enclosed in conduit.

• The RS-232 cable between the CX9200 and the Fire Panel must be

no longer than 20 feet, and must be enclosed in conduit.

Comm Port Assignments

In a smoke control system, it is recommended that you use the following

Comm Port assignments:

• COMM1 – FSCS panel RS-232

•COMM2 – Infinet Network

• COMM3 – User terminal

• COMM4 – Fire Panel RS-232

Isolating Energynet Controllers

In a system that performs smoke control, the CX9200s have to be

electrically isolated from other Energynet devices using the Energylink

2500 and the ENL2503 fiber optic module. This is done in order to

ensure that a fault on one of these devices will not interfere with the

operation of the smoke control system. The Energylink 2500 is only

required when connecting CX9200s to other Energynet devices, it is not

required between CX9200s.

The Energylink 2500 mounts in the CX9200 cabinet and receives it’s

power from the CX9200 power supply.

Figure 3-1 shows the use of the Energylink 2500 to isolate the CX9200

from other Energynet controllers.

3-2 Infinity Smoke Control Guide

Installation and Layout

Figure 3-1. Isolating the CX9200

CX9200

CX9200

with

Energylink 2500

TOC

Energynet

Smoke Control Components

Fiber

Optics

Energynet

Other Energynet Components

Andover Controls Corporation 3-3

Installation and Layout

Installing Infinet Controllers

For detailed information on how to mount and connect the wiring to the

various Infinet controllers and repeaters, refer t o the following Andover

Controls documentation:

TOC

SCX920 Installation Guide

TCX840 Installation Guide

TCX850 Installation Guide

TCX860 Installation Guide

TCX865 Installation Guide

Infilink 200 Installation Guide

Infilink 210 Installation Guide

(P/N 30-3001-170)

(P/N 30-3001-493)

(P/N 30-3001-173)

(P/N 30-3001-390)

(P/N 30-3001-497)

(P/N 30-3001-178)

(P/N 30-3001-394)

Smoke Control Requirements

In addition to the information contained in each installation guide, the

following requirements apply when using the Infinet controllers and

repeaters in a smoke control system .

The SCX920S

• When using the SCX920S in a dedicated smoke control application,

the manual overrides must be disabled. The SCX920 installation

guide explains this process in detail.

• When using the SCX920S in a non-dedicated smoke control

application, you must do one of the following:

— Disable the manual overrides, or

— Locate the SCX920S in area only accessable to authorized

personnel, and provide an OVERRIDE status indicator on the

FSCS that turns on when the outputs are overridden. The FSCS

audible indicator must also turn on.

• If the AC input voltage is to be set to 24 V, an Andover Controls’

Listed transformer must be used to supply the 24V AC input power .

These transformers must be placed in a Listed enclosure and must be

wired according to the National Electric Code, as well as any state or

local regulations.

Table 3-1 lists the step-down transformers that are available from

Andover Controls.

3-4 Infinity Smoke Control Guide

Installation and Layout

The TCX840 and TCX 850 serie s

• Only an Andover Controls’ Listed transformer may be used to supply the 24V AC

input power for the TCX840 and TCX850 series. These transformers must be placed

in a Listed enclosure and must be wired according to the National Electric Code, as

well as any state or local regulations.

Table 3-1 lists the step-down transformers that are available from Andover Controls.

• All of the Input and Output wiring on the TCX840 and TCX850 series must remain in

the same room.

The TCX860/865 series

• Only an Andover Controls’ Listed transformer may be used to supply the 24V AC

input power for the TCX860/865 series. These transformers must be placed in a Listed enclosure and must be wired according to the National Electric Code, as well as

any state or local regulations.

TOC

Table 3-1 lists the step-down transformers that are available from Andover Controls.

Table 3-1. Listed 24V Step-down Transformers

Primary and

Voltage PRI:SEC VA Rating Part Number

115V : 24V 40 VA 01-2100-378 Solderless Lug

115V : 24V 40 VA 01-2100-323 Wires

277V : 24V 50 VA 01-2100-379 Solderless Lug

208/240V : 24V 40 VA 01-2100-407 Wires

Secondary

Connec t io ns

• All of the Input and Output wiring on the TCX860/865 series must remain in the s ame

room.

The Infilink 200

• Any cables connected to the RS-232 port must be less than 20 feet in length, and must

be enclosed in conduit.

The Infilink 210

• The Infilink 210 must be used to electrically isolate the Infinet controllers that are

performing smoke control from the non-smoke control Infinet controllers. This is

Andover Controls Corporation 3-5

CX9200

TOC

Installation and Layout

done in order to ensure that a fault on one of these devices will not

interfere with the operation of the smoke control system. The Infilink

210 is not required between every Infinet controller, it is only

required between groups of controllers that are performing smoke

control and groups of controllers not performing smoke control.

Figure 3-2 shows the use of the Infilink 210 to isolate the Infinet

smoke control components.

Figure 3-2. Isolating the Infinet Controllers

SCX920S

TCX840 series

TCX850 series

TCX860/865 series

Infilink 200

Smoke Control Components

Infilink

210

Fiber

Optics

Infilink

210

Infinet

Other Infinet Controllers

3-6 Infinity Smoke Control Guide

Installation and Layout

Installing the FSCS

For detailed information on how to mount the FSCS, refer to:

Automation Displays Inc.

3533 North White Avenue

Eau Claire, Wisconsin 54703

(715) 834-9595

Location and Access

The FSCS should be located close to the other fire fighter’s systems that

are in the building. Means should be provided to ensure only authorized

access to the FSCS. When acceptable to the authority having

jurisdiction, the FSCS should be located in a room that is separated from

public areas by a suitably marked and locked door. The location, room

size, access means, and other physical design considerations of the

FSCS location must be acceptable to the authority having jurisdiction.

TOC

Inside the FSCS

Figure 3-3 shows what the typical components inside an FSCS wil l look

like. Since the FSCS is custom made for each application, the internal

layout will vary from panel to panel.

Andover Controls Corporation 3-7

SWITCH

PROTECTION

PCB

TOC

Installation and Layout

Figure 3-3. Typical Internal Components in an FSCS

80 POINT LED DRIVER CARD

80 POINT SWITCH INPUT CARD

WIRING

TROUGH

+5V

+5V

COM

COM

12 3 4

Q-CARD PROCESSOR PCB

+5V DC POWER SUPPLY

ON

1 A

POWER SWITCH

AND LINE FUSE

RS-232

PROTECTIO N

PCB

OUT IN COM

RS-232 FIELD

WIRING TERMINALS

AC POWER

H

FIELD WIRING

N

TERMINALS

G

3-8 Infinity Smoke Control Guide

Installation and Layout

Field Wiring Te r m inals

The following are the only field connections that are required when

installing an FSCS. All field wiring must be installed by qualified

personnel and must comply with the National Electric Code, as well as

any state or local regulations.

AC Power Wiring

The AC input voltage is connected to the AC POWER FIELD WIRING

TERMINALS.

Figure 3-4 shows this terminal block and how it is wired.

Figure 3-4. AC Power Terminal Block

TOC

H

N

G

The HOT Terminal (Black wire)

The NEUTRA L Te rm inal (White w ire )

The GROUND Terminal (Green wire)

RS-232 Communication Port Wiring

The RS-232 cable from the CX9200 connects to the FSCS at the RS-232

FIELD WIRING TERMINALS. This cable must be less than 20 feet in

length, and must be enclosed in conduit.

Figure 3-5 shows this terminal block and how it is wired to the CX9200.

Andover Controls Corporation 3-9

Figure 3-5. RS-232 Terminal Block

RS-232

PROTECTION

PCB

OUT IN COM

TOC

Installation and Layout

COMMON

DATA IN

DATA OUT

Wire to pin 7 on the CX9200 RS-232 port

Wire to pin 2 on the CX9200 RS-232 port

Wire to pin 3 on the CX9200 RS-232 port

Zoned Alarm Contact Wiring (Optional)

As stated in the previous chapter, if you are not using a Fire Panel that

is part of the Andover Controls Listing, you will have to connect the Fire

Panel to the smoke control system using the Zoned Wiring method. This

involves connecting a set of wires for each zone from the Fire Panel to

the FSCS. Each contact closure output on the Fire Panel will be wired to

an input on the FSCS, which is read by the CX9200. These FSCS inputs

will be wired at a terminal block in the FSCS (not shown). This wiring

must be less than 20 feet in length, and must be enclosed in conduit.

The Q-Card Processor PCB

The Q-Card controls the RS-232 communications with the CX9200,

reads the FSCS switch inputs from the 80 Point Switch I nput cards, and

controls which Status Indicators will be turned on by the 80 Point LED

Driver cards.

The Q-Card has a Reset switch and an Options dipswitch. Pressing the

Reset switch re sets the pr ocessor, but maintains t he curre nt status of the

LEDs. The Options dipswitch is used to s et the RS-232 baud r ate and to

enable the auto-blanking feature. When the auto-blanking feature is on,

the status LEDs will be cleared if the FSCS does not receive any data

from the CX9200 within 10 seconds. The Q-Card only reads the Options

dipswitch after a Reset.

3-10 Infinity Smoke Control Guide

Installation and Layout

Table 3-2 shows the settings for the Options dipswitch..

Table 3-2. Q-Card Options Dipswitch Settings

Switch Position: 1234

Auto-blanking ON ON

Auto-blanking OFF OFF

9600 Baud OFF OFF OFF

7200 Baud OFF OFF ON

4800 Baud OFF ON OFF

3600 Baud OFF ON ON

2400 Baud ON OFF OFF

1200 Baud ON OFF ON

600 Baud ON ON OFF

TOC

300 Baud ON ON ON

Andover Controls recommends setting the FSCS for 9600 baud, with

auto-blanking disabled, therefore all the dipswitches are OFF.

Figure 3-6 shows the location of the switches on the Q-Card.

Figure 3-6. The Q-Card switch settings

Reset Switch Options Dipswitch

1 2 3 4

Q-CARD PROCES SOR PCB

Andover Controls Corporation 3-11

Installation and Layout

Installing the Fire Panel

Refer to the Fire Panel manufacturer’s documentation for installation

and wiring instructions.

The Fire Panel connects to the CX9200 through an RS-232 cable. This

cable should be no longer than 20 feet in length, and must be enclosed

in conduit.

Figure 3-7 shows how to wire the RS-232 cable from the Fire Panel to

the CX9200.

Figure 3-7. Fire Panel RS-232 Wiring

a. Simplex Model 4020

TOC

Port A

XMIT

RTS

RCV

CTS

GND

CX9200 DB-25

b. Edwards Systems Technology Model IRC-3

TB1

TXD

RXD

COMM

CX9200 DB-25

Pin 2 (TD)

Pin 3 (RD)

Pin 7 (GND)

Pin 2 (TD)

Pin 3 (RD)

Pin 7 (GND)

3-12 Infinity Smoke Control Guide

Chapter 4

Configuring the System

This chapter briefly describes how to configure the smoke control

system and how to communicate with the various smoke control system

components. For more detailed information concerning these and other

topics, refer to the following Andover Controls manual:

Infinity CX Programmer’s Guide (P/N 30-3001-166)

This chapter does not attempt to explain the system’s programming

language or how to write smoke control application programs. Refer to

Chapter 5 for example smoke control programs.

Topics covered in the chapter are:

TOC

• Logging On to the CX9200

• Using the Command Window

• Using the Menus

• Logging Off the CX9200

• Assigning Security Levels to Users

• Setting the System Date and Time