Page 1

Controlling Tomorrow’s World

EnergyLink 2000

Installation Guide

Electronic Version

Andover Controls Corporation i

Downloaded from - http://www.guardianalarms.net

Page 2

Version A

Reproduction or distribution forbidden.

Copyrigh t 1992–1996 by Andover Controls.

Subject to change without notice.

Order No. 30-3001-179

Copyright

1992–1996

Andover Controls Corporation

300 Brickstone Square

Andover, Massachusetts 01810

All Rights Reserved.

Published by the Engineering Departm ent at Andover Controls Corporation.

IMPORTANT NOTIC E

This product is subject to change without notice. This document does not constitute any warranty, express or implied. Andover Controls Corpor ation reserves the right to alte r cap ab ilities, performance , and pres en tation of this

product at any time.

ii EnergyLink 2000 Installation Guide

Page 3

Preface

EnergyLink 2000 Installatio n Guide

The

installing the EnergyLink 2000, 2100, and 2101 on EnergyNet. It first

presents how to prepare the site, including facts about proper grounding, then how to install the various EnergyLinks.

For basic information on local area networks (LANs), refer to the

presents instructions for

EnergyNet and Infinet Configuration Guide

.

Andover Controls Corporation iii

Page 4

iv EnergyLink 2000 Installation Guide

Page 5

Installing the EnergyLink 2000

EnergyNet

This manual covers installi ng the

have not planned out your network yet, read the

Configuration Guide

EnergyLink

s for your installation.

first. It contains details on how to select the best

EnergyL i nks

EnergyNet

on

EnergyNet and Infinet

. If you

Warranty Registration

Your warranty is effective for 18 months star ting on the date the

equipment is shipped.

Warning

All wiring must comply with all local , stat e, and nationa l ele ctrical

codes.

EnergyLink 2000 Installation Guide 1

Page 6

Preparing to Install EnergyLinks

Without

Acting as central active hubs, the

tributed star topology networks.

In addition,

cable length for all buses, but also increase the number of controllers allowed on a single bus. You can use

and to diagnose network problems. The

flexible and diverse.

Before you begin, you determine the exact kinds of links you require,

and the number of central hubs, cable switching links, and repeaters. If

you are not sure what you need or how to order it, read the

and Infinet Configuration Guide

Before you can install the

know some basic information about them: the types, their modu les,

their dimensions and enclosures, power requirements, grounding re-

EnergyLink

EnergyLinks

s, you can have only a bus topology

EnergyL ink

allow you to not only extend the maximum

EnergyLinks

.

EnergyLink 2000, 2100

s let you form star and dis-

to switch cable types

EnergyLink

, or

EnergyNet

family of links is

EnergyNet

2101

, you need to

.

quirements, and environmental requirem en ts .

Note

This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions in this manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

2 EnergyLink 2000 Insta llation Gu ide

Page 7

EnergyLink Dimensions

Each

side a hinged aluminum enclosure that meets UL standards.

The modules that you ordered with the

for either all coaxial cable, or mixed coaxial and fiber optic cable, or all

fiber optic. Each module is approximately 5.25H × 1W × 7D in.

Modules with coaxial cable ports have four ports. Modules with mixed

coaxial and fiber optic cable ports have two coaxial and two fiber optic

cable ports.

Each

are in sealed aluminum enclosures that meet UL standards.

EnergyLink 2000

EnergyLink 2100

is 5.75H × 10.43W × 8.66D in. The unit is in-

or

Power Requirements

Warning

EnergyLink 2000

2101

is 9.625H × 6.375W × 1.75D. The units

can have ports

Be sure your installation complies with local, state, and national

electrical codes.

Caution

EnergyLink 2000

The

unswitched circuit. Other

EnergyLink 2000

should receive power from its own independent,

EnergyLink

and do not require their own power source.

s are attached to a controller or

EnergyLink 2000 Installation Guide 3

Page 8

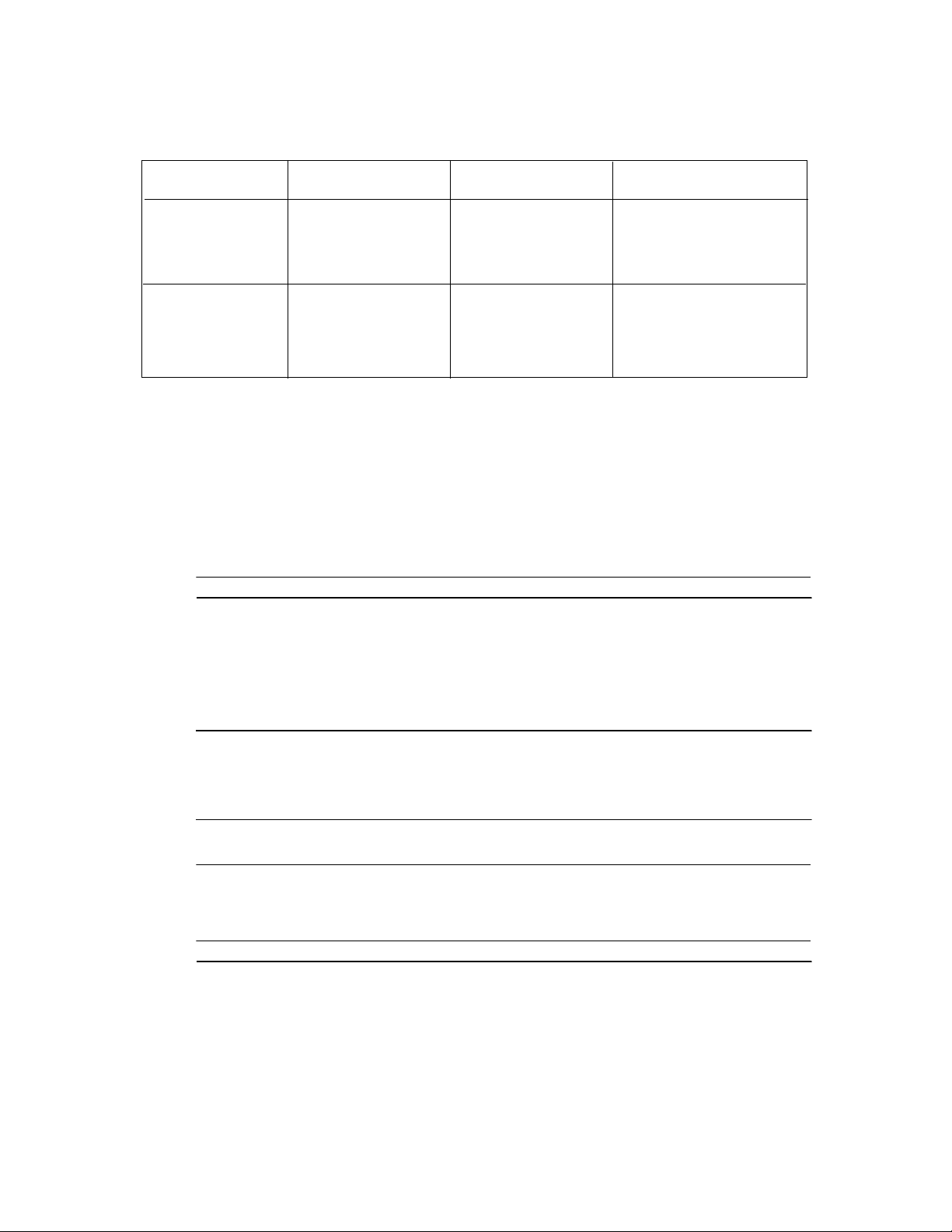

Table 1. Electrical Specifications

Location Input Power

United States 115 V +/–15%

@ 1/2 A

50-60 Hz

Europe 230 V +/–15%

@ 1/4 A

50-60Hz

Output Power Fuse Size/Rating

+5 V +/–5%

@ 3 A

50-60 Hz

+5 V +/–5%

@ 1/2 A

50-60 Hz

We ship it set to the correct setting with the correct fuse. If you want to

change the setting, follow the ins truc ti ons incl uded in the inst alla tion

information.

Building Ground Requirements

Warning

5 × 20 mm Fuse/

115 V 1 A slow

blow

5 × 20 mm Fuse/

230 V 1/2 A slow

blow

Be sure that all products from Andover Controls Corporation is

grounded to true earth ground. This kind of ground protects the

equipment from lightning strikes and other power surges in the area.

We cannot guarantee that the controller system will operate as

documented unless you properly grou nd all control lers .

Warning

Be sure to have your grounds inspected before you begin the

installation process to be sure your municipality follows the National

4 EnergyLink 2000 Insta llation Gu ide

Page 9

Electrical Code.

substandard electrical grounds.

An example of a substandard ground is a galvanized steel cold water

pipe. As the pipe corrodes, it does not act as a true ground. The corrosion acts as an insulator, raising the potential of the pipe with respect to

the ground.

When lightning strikes in the area of the ins talla tion, it drastically

changes the potential of the earth.

Surges of much lower potential also impact the reliability of Andover

Controls equipment.

Since properly grounded Andover Controls units respond to changes in

Many muni cipa lities do not an d often have

potential more rapidly than poorly grounded electrical systems, a poorly grounded building tries to reach ground through the Andover

Controls system. The surge of current can destroy electronic components on the controller board.

Inspecting the Ground

You can check your ground as follows:

1. Check your ground by first inspecting the building power

distribution panel for earth ground termination. If the ground

termination is any of the following, it is not adequate and must be

corrected:

• Does not exist.

• Is connected to a corroded or galvanized pipe.

• Is connected using a small gauge wire (smaller than 14 AWG).

2. If your

be sure your

conductor that terminates at the distribution panel.

EnergyLink 2000 Installation Guide 5

EnergyLink

EnergyLink

will not be mounted inside an

is connected to the ground with a copper

9000

controller,

Page 10

Environmental Requirements

EnergyLinks

The

to 140° F and with humidity between 10 and 95%, non-condens ing.

operate in rooms with temperatures ranging from 32

6 EnergyLink 2000 Insta llation Gu ide

Page 11

Preparing Coaxial Cables

Each length of coaxial cable connecting to a controller, workstation,

EnergyLink 2000, EnergyLink 2100

BNC male connector at both ends. If the cables are not already prepared, you prepare them by attaching the male connectors.

Figure 1 shows a single piece of prepared coaxial

Each piece of coaxial cable from male connector to male connector

must be at least 6 ft long.

EnergyLink 2101

, or

must have a

EnergyNet

cable.

Figure 1. EnergyNet Coaxial Cable

6 ft minimum

Male Connectors

on either end of Coaxial Cable

—One end connects to the

the other to a controller or workstation

EnergyLink

,

Figure 2 shows the

Model # 2070). Do not use T connectors on the

EnergyNet

coaxial T connector (Andover Controls

EnergyLink 2000

ports.

Figure 2. EnergyNet Coaxial T Connector

Coaxial Cable

Never

EnergyLink 2000 Installation Guide 7

connects to an EnergyLink

Coaxial Cable

Page 12

Installing the EnergyLink 2000

Unpacking

Be careful when unpacking the unit to not damage the packaging

material—you must reuse it if you ship the produ ct back for repair.

Parts Required

•

1 or 2

• Modules

(Andover Controls Model No. 2001 has 4 coaxial ports,

Model No. 2002 has 2 coaxial and 2 fiber optic, Model No. 2003 has

4 fiber optic ports)

• Prepared Coaxial Cables

• Coaxial Cable

• BNC Connectors for Coaxial Cable

• Fiber Optic Cable with ST Connectors (Bayonet Style) (optional)

EnergyLink 2000

s

Setting the Input Voltage

Usually your

voltage (115 V or 230 V). If the input voltage is not correct, you can

switch it from one to the other by changing the position of a jumper

inside the hub. To change the jumper position, proceed as follows:

EnergyLink 2000

is shipped preset to the correct input

Warning

Be sure you disconnect the

before you remove the input voltage jumper.

1. Disconnect the

8 EnergyLink 2000 Insta llation Gu ide

EnergyLink 2000

EnergyLink 2000

from the AC power source.

from the AC power source

Page 13

2. Look at the sides of the

EnergyLink 2000

. Notice that three scr ews

are on each side. Remove all six screws.

3. Slide the top of the enclosure up and off the unit.

4. Position the

EnergyLi nk 2000

on its left side so the front is facing you.

5. Inside, find the jumper wire to the right of the heat sink. It is labeled

P3 on the printed circuit board.

Figure 3 shows the jumper positions for 115 V and 230 V with the

EnergyLink 2000

front facing you.

Figure 3. Setting of the EnergyLink 2000 Input Voltage Jumper for

115 V or 230 V, Front Top View

115 V Position

115

230

P3

230 V Position

115

230

P3

Exposed Pin

Below Jumper

Pins When

Jumper

Exposed Pin

Above Jumper

Removed

6. To switch from 115 V to 230 V, remove the jumper and move it

down one pin. Placing the jumper in the 230 V position effectively

disconnects it, but keeps it in a safe pl ace if you ever want to switch

back.

To switch from 230 V to 115 V, remove the jumper and move it up

one pin.

7. Check to be sure you have the correct fuse. The fuse is on the far

right side of the printed circuit board in approximately the verti cal

center.

EnergyLink 2000 Installation Guide 9

Page 14

Figure 4 shows the location of the input power fuse.

Figure 4. Location of EnergyLink 2000 Input Power Fu se, Front

Right Side View of Printed Circuit Board

Heat

Sink

Input

Jumper

Power

Fuse

8. If switching from 115 V to 230 V, replace the fuse with a 5 × 20 mm

230 V 1/2 A slow blow fuse.

If switching from 230 V to 115 V, replace the fuse with a 5 × 20 mm

115 V 1 A slow blow fuse.

10 EnergyLink 2000 Installation Guide

Page 15

Installing the Modules

Before you proceed, you must install the modules in the

2000.

metal front piece. The four ports are on the metal front.

The modul es each sli de into one of th e four slot s on the

Figure 5 shows the module slots on the

and bottom of each slot is a groove, shown in the close-up on the slot.

Each module is a printed circuit board “card” attached to a flat

EnergyLink 2000.

Figure 5. Module Slots on EnergyLink 2000

Grooves

EnergyLink

EnergyLin k 2000

Along the top

.

Openings (Slots) Wh ere

You Insert Modules

EnergyLink 2000 Installation Guide 11

Page 16

Figure 6 shows a module.

Figure 6. An EnergyLink 2000 Module

Permanently

Attached

Screws

Each module has permanently attached screws at the top and bottom.

To insert a module, carry out the following steps:

1. Insert the module printed circuit board “card” in the groove of the

module opening.

2. Slide the card all the way in.

3. Tighten the top and bottom screws by hand.

4. If you want the module held more tightly, use a flathead screwdriver

to more firmly tighten the module’s screws.

12 EnergyLink 2000 Installation Guide

Page 17

Mounting

You can choose to mount a single

one on top the other. Proceed as follows:

EnergyLink 2000

or several of them,

Warning

Never drill holes in the

A metal shaving could easily short circuit the electronics.

1. Insert four screws in the wall in positions for the two eyelets and two

screw holes in the side tab of the

Figure 7 shows the location of the four

2. Hang the unit on the screws and screw the unit dir ec tly to the wal l.

EnergyLink 2000

EnergyLink 2000

cabinet or any of the modules.

.

EnergyLink

four eyelets.

3. If you are installing multiple hubs, cascaded, one on top the other,

place the second on top of the first and screw it to the wall.

4. Repeat step 3 until you have cascaded the number of hubs you need.

(You can stack up to eight hubs.) See the section called Cascading

EnergyLinks

for information on how to run the cables.

EnergyLink 2000 Installation Guide 13

Page 18

Figure 7. Locations of Screw Holes to Mount EnergyLink 2000

Back of

EnergyLink 2000

.5 in. holes, 4 places

(see Detail)

Enclosure

10.43 in.

9.53 in.

.34

2.08 in.

5.75 in.

3.0 in.

.84 in.

.22

.50

Detail

(4 places)

.86 in.

14 EnergyLink 2000 Installation Guide

Page 19

Connecting Controllers and Workstations to EnergyLink 2000

To connect the controllers and workstations to the

proceed as follows:

1. Connect the coaxial

workstations.

2. Run the unconnected ends of the cables up to the hub.

Coaxial Cable

Fasten the open end of the cable to the coaxial cable port on the front

panel of the

1. Attach a straight BNC connector to the cable.

2. Insert the end of the connector into the port.

EnergyLink 2000

Fiber Optic Cable

EnergyNet

as follows:

EnergyLink 2000

cables to the controlle rs an d

,

Notice that the open end of the fiber optic cable has two ST connectors.

You connect them to a fiber optic port on the front panel of the

EnergyLink 2000

1. Unscrew the plastic caps from the first pair of ports.

2. Insert the bayonet-style ends into each port.

On a fiber optic cable module or a mixed module, you must use the

first two adjacent fiber optic ports for the first cable and the second

two adjacent ports for the next cable.

as fol low s:

EnergyLink 2000 Installation Guide 15

Page 20

Installing the Energy Link 2100 or 2101

Unpacking

Be careful when unpacking the unit to not damage the packaging

material—you must reuse it if you ship the produ ct back for repair.

Parts Required

• EnergyLink 2100

• One Metal Plate (included with

• Four No. 6 Screws (included with

• 1-ft coaxial cabl e wit h att enu ator (included with

• Prepared Coaxial Cables

• BNC Connectors for Coaxial Cable Ports

• Fiber Optic Cable with ST Connectors (Bayonet-Style) (optional)

or

2101

s

EnergyLink

EnergyLink

Mounting EnergyLink 2100 or 2101 Inside a 9000 Controller

You can install an

controller.

Figure 8 shows the positioning of the modem and

inside of the

mount the plate that comes with

9000

EnergyLink 2100

controller’s door. (If you have no modem, you must

EnergyLink

or

2101

inside the door of a

and then mount the

)

)

EnergyLink

EnergyLink

)

9000

on the

EnergyLink

16 EnergyLink 2000 Installation Guide

on it.)

Page 21

Figure 8. Position of EnergyLink 2100 (or 2101) Mounted Insi de

9000 Controller Front Door, Side View

9000

Door

EnergyLink 2100

Mounting Plate

Modem (Optional)

Is Here

EnergyLink 2000 Installation Guide 17

Page 22

To mount the link on the door, proceed as follows:

1. Open the

9000

controller cabinet and look on the inside front door

to the lower right. Notice the three st an doff s. Posi tion the me tal

plate so the screw holes in it align with those on the standoffs.

2. Screw the metal plate secur ely to the stand offs using three No. 6

Phillips screws.

3. Notice that the metal plate has three metal studs only about 1/8 in.

high.

Figure 9 shows the studs.

Figure 9. EnergyLink 2100 (or 2101), Back View

EYELET

EYELET

SCREW HOLE

4. Look at the back side of the

EnergyLink

EYELET

. In three corners you see

eyelets. In the fourth, you see a screw hole.

5. Put the

EnergyLink

on the plate so the largest ends of the three

eyelets each go over one of the metal studs.

18 EnergyLink 2000 Installation Guide

Page 23

6. Gently pull the

EnergyLink

down as far as it can move. Now the

screw hole on the lower right front should line up with the hole in

the metal plate.

7. Insert the No. 6 Phillips screw in the hole and tighten it.

8. Look at the 1-ft coaxial cable. Notice that one end has the usual

BNC connector and the other end has a longer piece. This longer

piece is an attenuator to make up for the cable being less than the

minimum length required (3 ft).

9. Connect the end of the 1-ft coaxial cable with the attenuator to the

coaxial port on the

to the ENL PWR coaxial connector on the

Figure 10 shows the

EnergyLink

and the end with the BNC connector

EnergyLink 2101

9000

controller.

completely ins talled.

Figure 10. Installed EnergyLink 2100 (or 2101), Front View

Fiber Optic Port

Coaxial Port

14

2 3

ENERGYLINK

ACTIVITY 4

ACTIVITY 3

ACTIVITY 2

ACTIVITY 1

RECONFIG

TIMING

Mounting Plate

Screw To Tighten

EnergyLink 2000 Installation Guide 19

Page 24

EnergyLink 2100

The

power supply so you need not connect it to a power supply.

or

2101

uses power from the

9000

controller

Now connect the various cables to the ports on the

Cascading EnergyLinks

You can cascade

to an open port on each one.

Figure 11 shows three cascaded

Figure 11. Stacked EnergyLink 2000 Hubs Cascaded with

Coaxial Cable

EnergyLink

s by connecting a prepared coaxial cable

EnergyLink 2000

EnergyLink

hubs.

.

Coaxial

Cable

Stacking

you can have connected in one area.

You can also cascade and stack other members of the

family, but when you do, you reduce their already limited number of

ports, so they are not as practical a choice for connecting multiple stars.

EnergyLink 2000

s dramatically increases the number of nodes

EnergyLink 2000

20 EnergyLink 2000 Installation Guide

Page 25

Extending a Bus with an EnergyLink

To increase the number of feet of coaxial cable between two controllers,

you use an

EnergyLink 2100

or

2101

, as follows:

Caution

Remember that every

Each one reduces the total number of workstations and controllers you

can have on the network.

1. Disconnect one male end of a connected coaxial cable from the last

controller and connect it to the first open port of the

2. Connect the end of a new prepared coaxial cable to a second open

port of the

EnergyLink

EnergyLink

.

counts as a node on the network.

EnergyLink

.

Figure 12 shows how the

EnergyLink

connection looks.

EnergyLink 2000 Installation Guide 21

Page 26

Figure 12. Connecting an EnergyLink 2100 to Extend a Bus

EnergyLink 2100

First

Coaxial

Cable

Second

T Connector for

Workstation with

Coaxial

Cable

PS/2 Card

Connect to the

Next Controller

on the N etwork

3. Connect the new coaxial cable to the next controller or workstation

on the network.

4. Be sure that workstation is properly terminated if it is at the end of

the bus.

22 EnergyLink 2000 Installation Guide

Page 27

Powering Up the EnergyLink 2000

Turn on the power to the

switch located on the lower right corner of the front panel. The unit

starts operating immediately.

Once the

are installing or removing modules from it. You may connect and disconnect cables at ports without any damage to the

without affecting

EnergyLink 2000

EnergyNet

EnergyLink 2000

is on, we recommend it be left on unless you

operation.

Understanding the LEDs

EnergyLink 2000

to each port. The LEDs to the right of the rightmost module are for timing and re-configuration. Here’s how each LED responds:

TIMING—The timing light blinks to indicate

and transmitting signals.

RECON—The reconfiguration light turns on briefly when you start up

EnergyLink 2000

the

also has LED lights on its front panel that correspond

. It indicates that the network is being configured.

by depressing the power

EnergyLink 2000

EnergyNet

is receiving

and

Other than at power up, the network re-configures itself only when you

remove a node, so this light should remain off most of the time.

+PWR and –PWR—These lights indicate power is being supplied to the

EnergyLink 2000

are on.

All modules have activity li ghts, one associ ated with each port. Her e’s

how each LED responds:

ACTIVITY—Each activity LED blinks to indicate that its port is re-

ceiving and transmitting data. The LED blinks in a pulsing fashion as

long as the unit is operating properly.

If you run into problems with the network after powering up the

EnergyLink 2000,

Guide

.

. As long as the unit is operating properly, these lights

refer to the

EnergyNet and Infinet Configuration

EnergyLink 2000 Installation Guide 23

Page 28

Powering Up the EnergyLink 2100 or 2101

EnergyLink 2100

The

troller’s power supply.

Once you connect the power to the

installation guide, the

immediately.

2101

and

EnergyLink 2100 or 2101

Understanding the LEDs

Below is how the

9000

ACTIVITY—The activity LEDs blink to indicate that the corresponding port (ports are numbered left to right, 1 through 4) is receiving and

transmitting data. So they blink in a pulsing fashion as long as the unit

is operating properly.

TIMING—The timing light blinks to indicate

and transmitting signals.

controller is powered up:

EnergyLink 2100 or 2101

both receive power from a

9000

controller as instructed in the

starts operating

LEDs respond once the

EnergyNet

is receiving

9000

con-

RECONFIG—The reconfiguration light turns on briefly after you power up. It indicates that the network is being configured. Other than at

power up, the network reconfigures itself only when you remove a

node, so this light should remain off mo st of the time.

If you run into problems with the network after powering up a unit with

EnergyLink 2100

an

Configuration Guide

or

.

2101,

refer to the

EnergyNet and Infinet

24 EnergyLink 2000 Installation Guide

Loading...

Loading...