Page 1

UN-RELEASED

REVIEW COPY

2/20/98

Technical Manuals Online! - http://www.tech-man.com

Page 2

1998, Andover Controls Corporation

All Rights Reser ve d

No part of this publication may be reproduced, read or stored in a retrieval

system, or tr ansmitted, in an y for m or by any means, electron ic, mechan ical,

photocopying, re cord i ng, or otherwise, without prior written permission of

Andover Controls Corporation.

Produced in th e United States of America.

Infinity is a trademark of Andover Controls Corporation. All other trademarks

are the proper ty of their respective owners.

Continuum I/O R eference, Version: REVIEW February, 1998

Andover Controls part number: 30-3001-499

Th e i nforma tion in this book is furn ish ed for informat ion a l pur poses onl y, is

subject to change without notice, and should not be construed as a commitment

by Andover Controls Corporation. Andover Controls Corporation, assumes no

liability for any errors or inaccuracies that may appear in this document.

Related Do cumen t s

Continuum Power Supply Reference, 30-3001-702

Continuum CPU Reference, 30-3001-701

Continuum Display Module Reference, 30-3001-711

Andover Controls Corporation

300 Brickstone Square

Andover, MA 01810

(978) 470-0555

fax: (978) 470-0946

Andover Controls Corporation

Technical Manuals Online! - http://www.tech-man.com

Page 3

Radio Interference

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions in this manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Note

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Avis

Le pr ésent app areil nu mériqu e n ’é met pas de bruit s radioél e ctriq ue s dé passan t les limi tes

applicables aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage

radioélectrique édicté par le ministère des Communications du Canada.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

Page 4

Andover Controls Corporation

Technical Manuals Online! - http://www.tech-man.com

Page 5

Contents

Introduction......................................................................1

Mechanical Installation....................................................4

Overall Dimensions....................................................................7

Door-Mounted Modules..............................................................8

Power-CPU Connections...............................................10

Conne c tion of I/O Mo du le s.......................................................11

Maxim um N um be r of I/O Module s............................................12

Maximum Length of I/O Bus.....................................................12

Connecting Remote I/O Modules with RS-485.........................12

Termina t i on Guidel ine s............................................................13

Individual Module Characteristics................................17

General Wiring Concerns.........................................................17

INPUT Modules

UI-8-10 / UI-8-10-10V.................................................................19

DI-6-AC / DI-6-AC-HV................................................................35

DI-8............................................................................................43

MI-6............................................................................................53

OUTPUT Modules

DM-20........................................................................................61

AO-4-8 / AO-4-8-O.....................................................................73

DO-4-R / DO-4-R-O....................................................................83

DO-6-TR.................................................................................... 91

LO-2 / LO-2-O............................................................................99

MIXED Modules

AC-1 .........................................................................................113

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

Page 6

Andover Controls Corporation

Technical Manuals Online! - http://www.tech-man.com

Page 7

TCX 865

ÈNTINUUM

I/O Systems

This manual describes the installat ion, care and use of all Continuum I/O modules.

The

Continuum

various combinat ions of DIN rail-mounted moduleshigh density I/O, CPU and power

supply, and your c hoic e of several user interf ac e modulesin a

to meet your building’s control and monitoring needs. With the

your network gr ows , sim ply add or replace I /O m odules as needed.

Ethernet-based intelligent building system allows you to mix and match

single

Continuum

controller location

system, as

Continuum

The

convection cooling, and a 3-position fr ont cover for easy, hands-free ac c es s. B uilt-in

quick-release fasteners at the back of each I/O module are provided for DIN rail

mountingno tools r equir ed. These fasteners als o s nap into a locked position for panel

mounting. I nput and output connectors ar e located at the bottom of each I/O module and

are removable for eas y field acc es s and m aintenance. All

designed for mounting in an optional NEMA 1-style

The

Continuum

module. Like all

connectors on either side so network expansion is quic k and eas y . Both power

transmiss ion and c om m unic ation signals between the

NetController CP U m odule, and all I/O modules feed thr ough this connection. For added

convenience in cert ain applic ations, such as door c ontrol or lighting control, a s ingle

module or groups of I/ O modules c an be r em otely loc ated and connected using approv ed

cable and powered from a loc al 24 V DC power s upply . Eac h I/ O module features its own

push-button for quick and easy network commis s ioning.

This document covers the standard Input and Output modules. Fo r in format io n

regarding the speci al Continuum enclosure door- mount ed display modules

consult the Andover Con t rol s

I/O modules featur e a sleek, lightweight casing designed f or natural

I/O modules communicate with the

Continuum

modules, the I/ O modules s nap together directly via built-in

Continuum Display Modul e Ref erence

Continuum

Continuum

Continuum

Continuum

enclosure.

NetController CP U

modules are

power supply module,

.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

1

Page 8

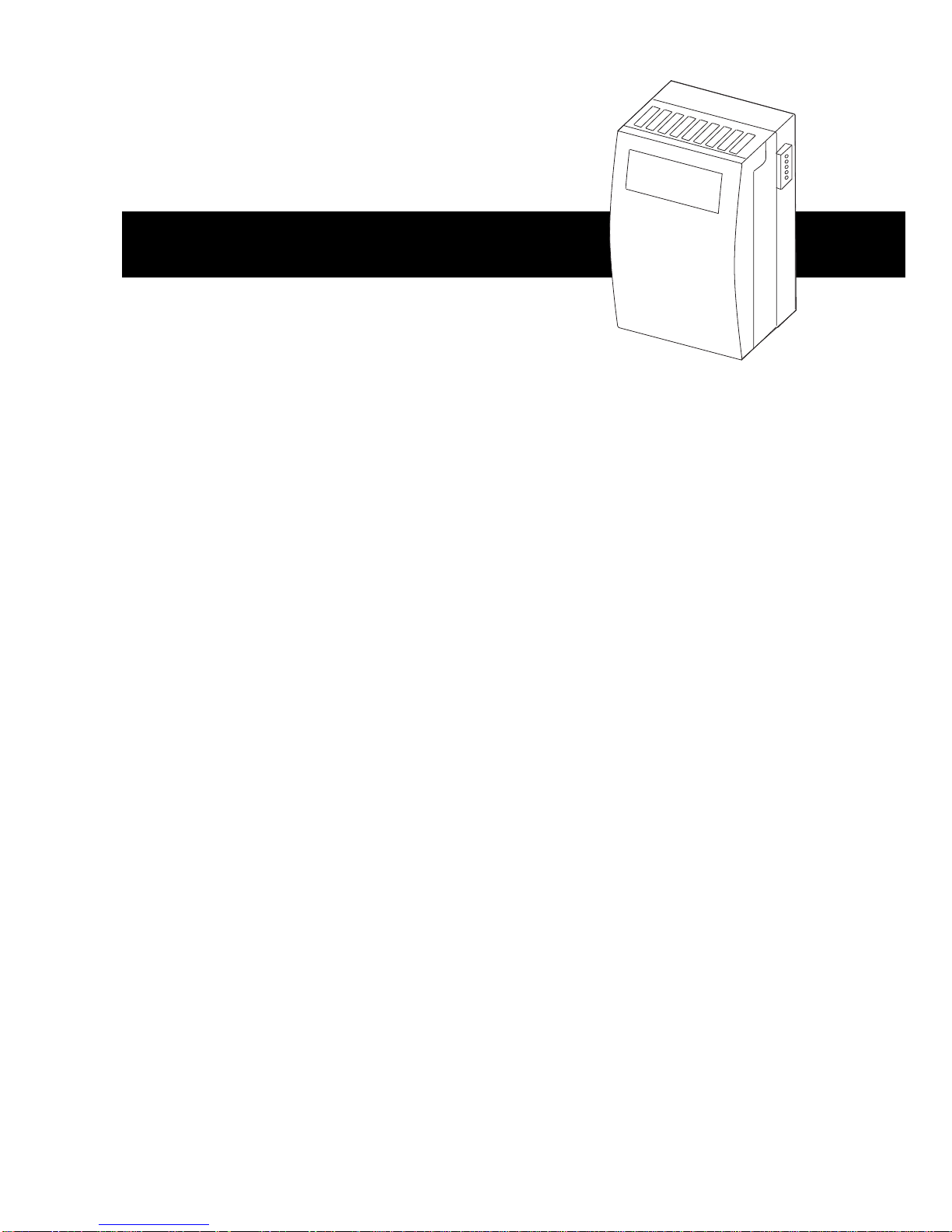

I/O System Introduction

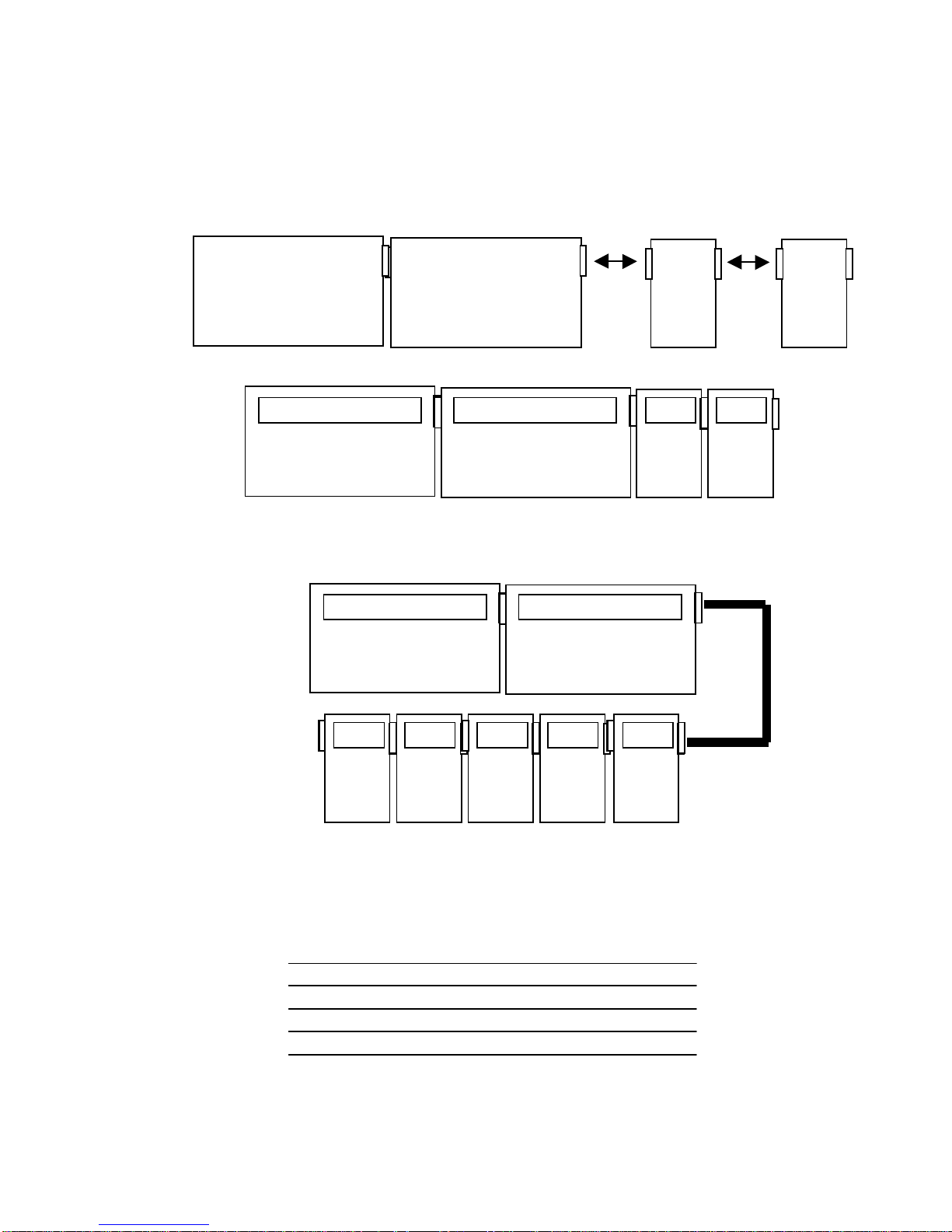

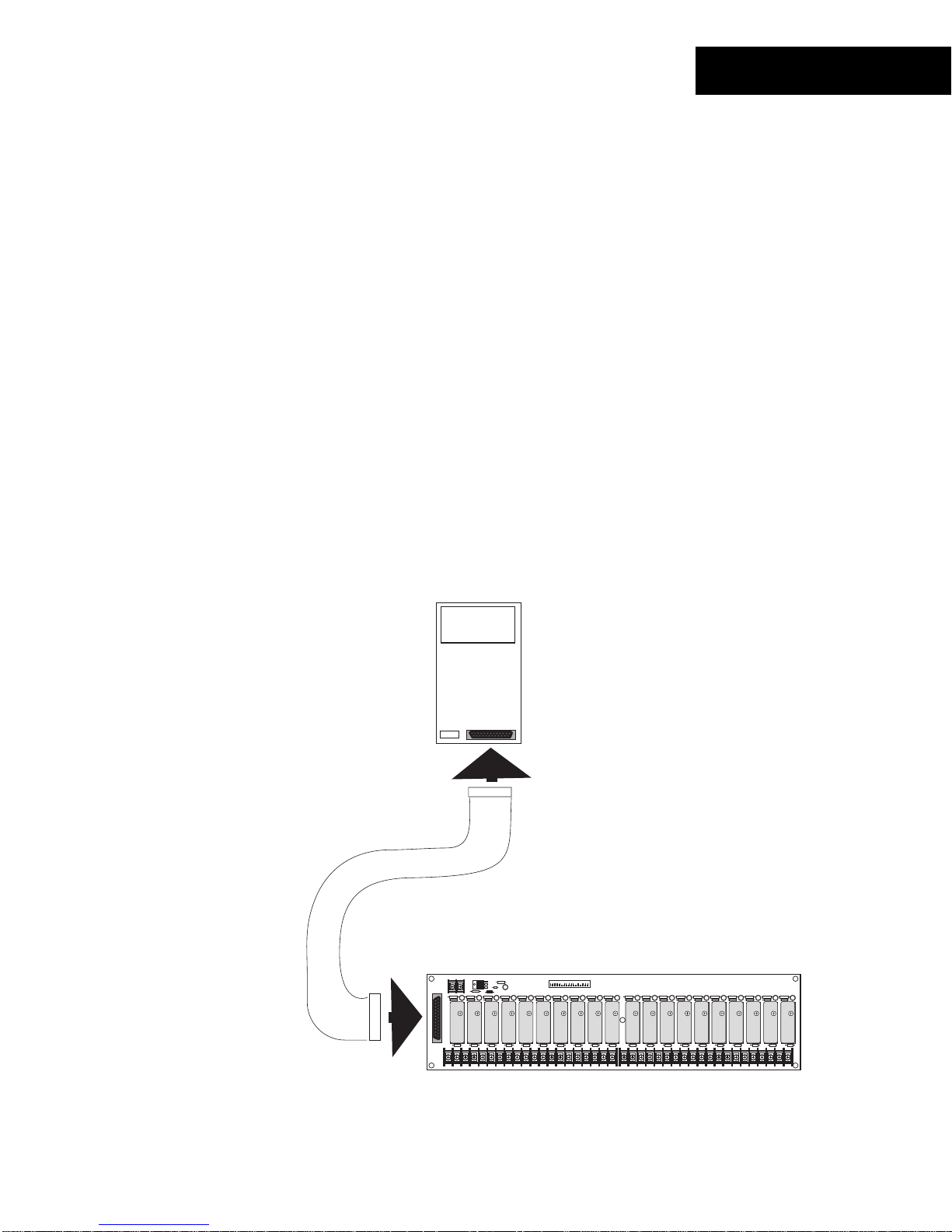

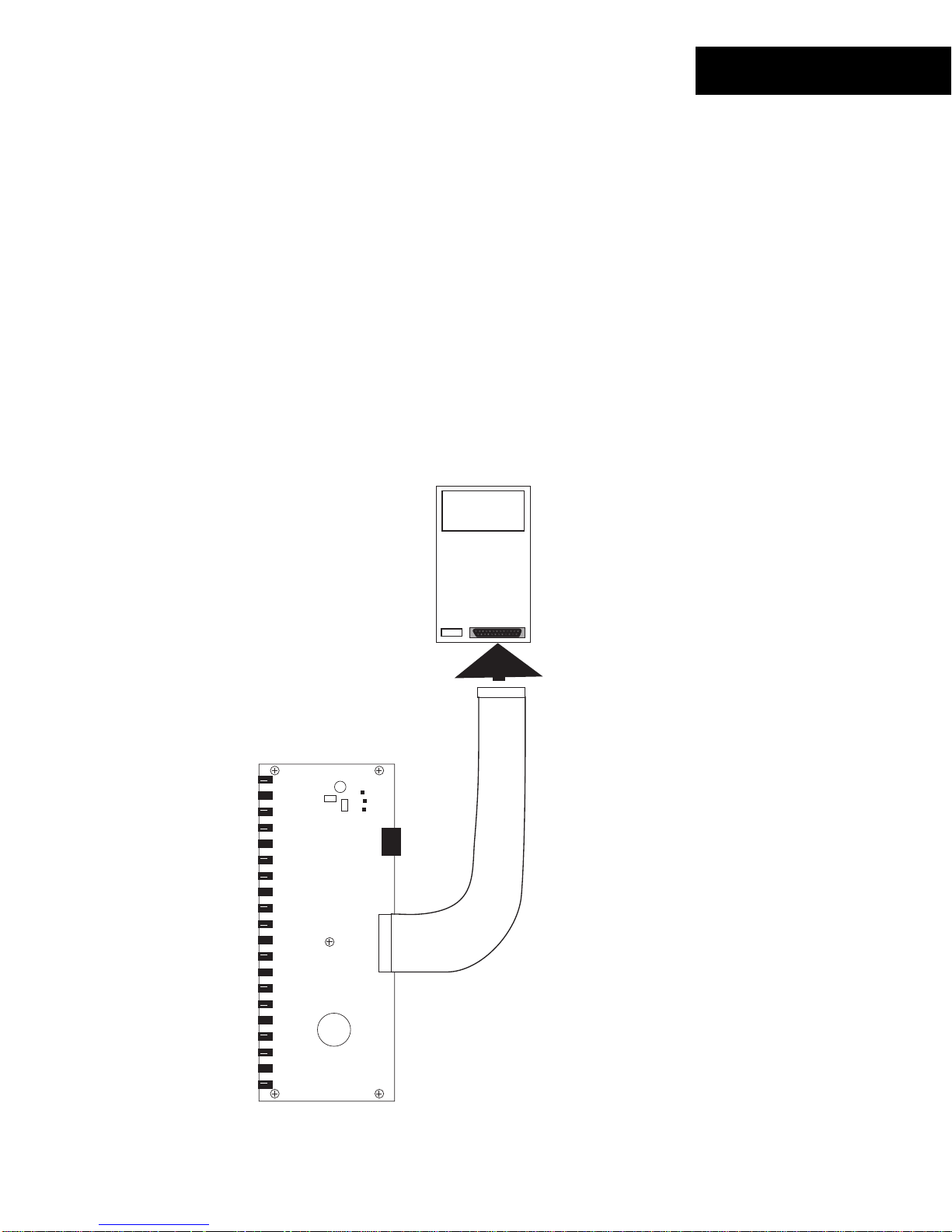

The Continuum I/O system is comprised of a series of modules separated by function

that connect via a common electrical communic ations bus. Each functional com ponent is

enclosed in a plastic c as e c ontaining all of its connections to the outside world. Modules

are connected t o a centr al c ontroller via a standard fiv e c onduc tor connector.

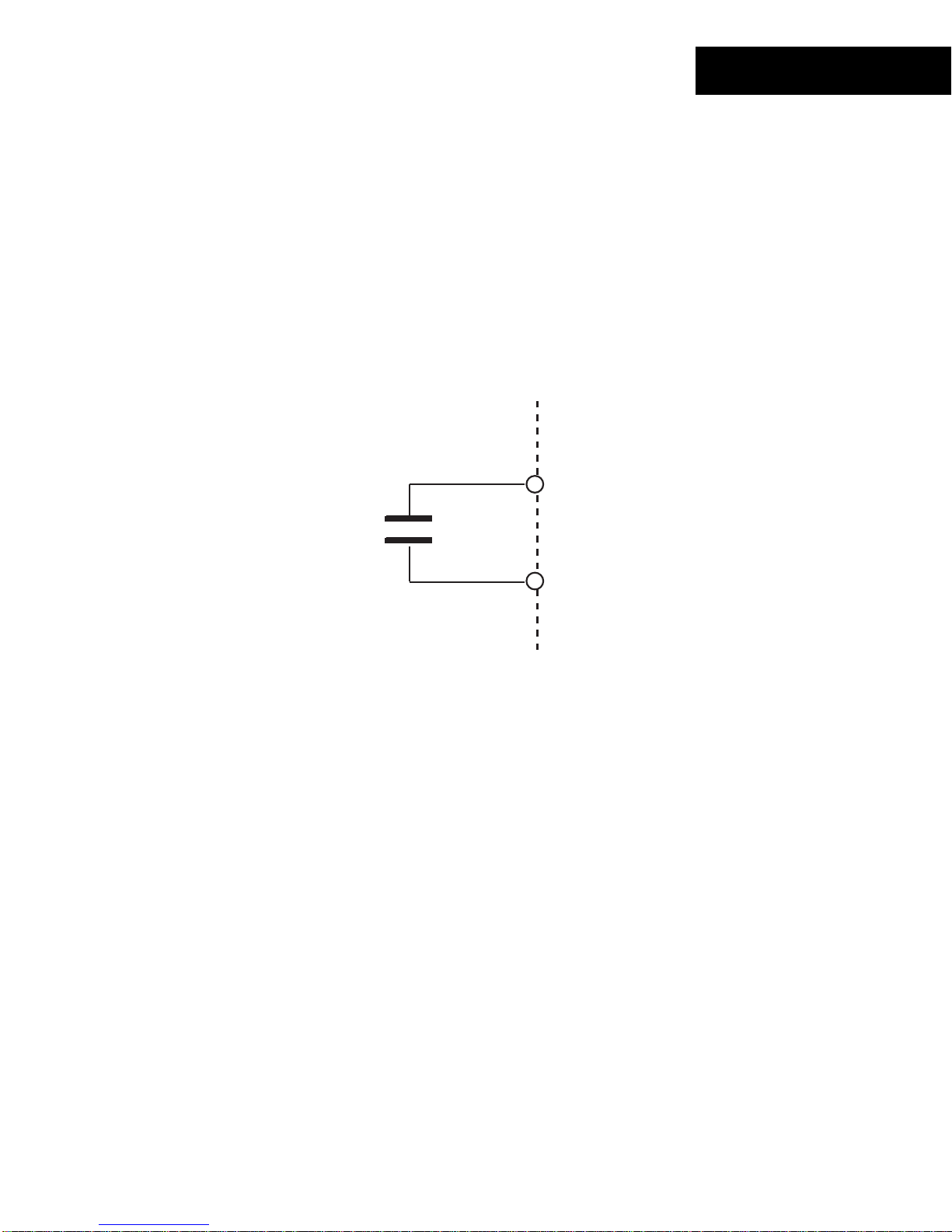

The Continuum sy stem inc ludes at least one power supply and a single cont r oller

module. I/O m odules pr ov ide the controller with the ability to interface with t he outside

world. They c onnec t direc tly and communicate with the CPU. T he following is a typical

architecture drawing of a Cont inuum System:

Power Supply

Controller

I/O Modules

Continuum I/ O modules ar e av ailable in INPUT, OUTPUT, MIXED and DISPLAY

varieties.

2

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 9

The INPUT modules av ailable ar e:

UI-8-10; Univ er s al Input Module

•

UI-8-10-10V; Universal Input Module

•

DI-6 AC; AC Digital Input Module

•

DI-6 AC HV; AC Digital Input Module

•

DI-8; Digit al Input Module

•

DM-20; Digital Input/Output Module (for DIO-20)

•

MI-6; MilliAmp Input Module

•

The OUTPUT modules available ar e:

AO-4-8-O; Analog Output Module (with override)

•

AO-4-8; Analog O utput Module

•

DO-4-R-O; Relay Out put Module (with override)

•

DO-4-R; Relay Out put Module

•

DO-6-TR; Triac Output Module

•

LO-2-O; Light ing Output Module (with over r ide)

•

LO-2; Light ing Output Module

•

The MIXED modules av ailable ar e:

AC-1; Door, Access Control, Wiegand Module

•

AC-1-ABA; Door, Access Control, ABA Module

•

The DISPLAY modules av ailable ar e:

LB-8; 8-Channel LED B ar Dis play / 8 Push Button Module

•

LS-8; 8-Channel, 3 Digit 7-Segment LED Display/ 16 Push Butt on M odule

•

LC-1; 2-Line LCD Display/ 12 Push Button Module

•

VM-1; Voice Record and Playback Module

•

GA-40; Graphic A nnunc iator Panel

•

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

3

Page 10

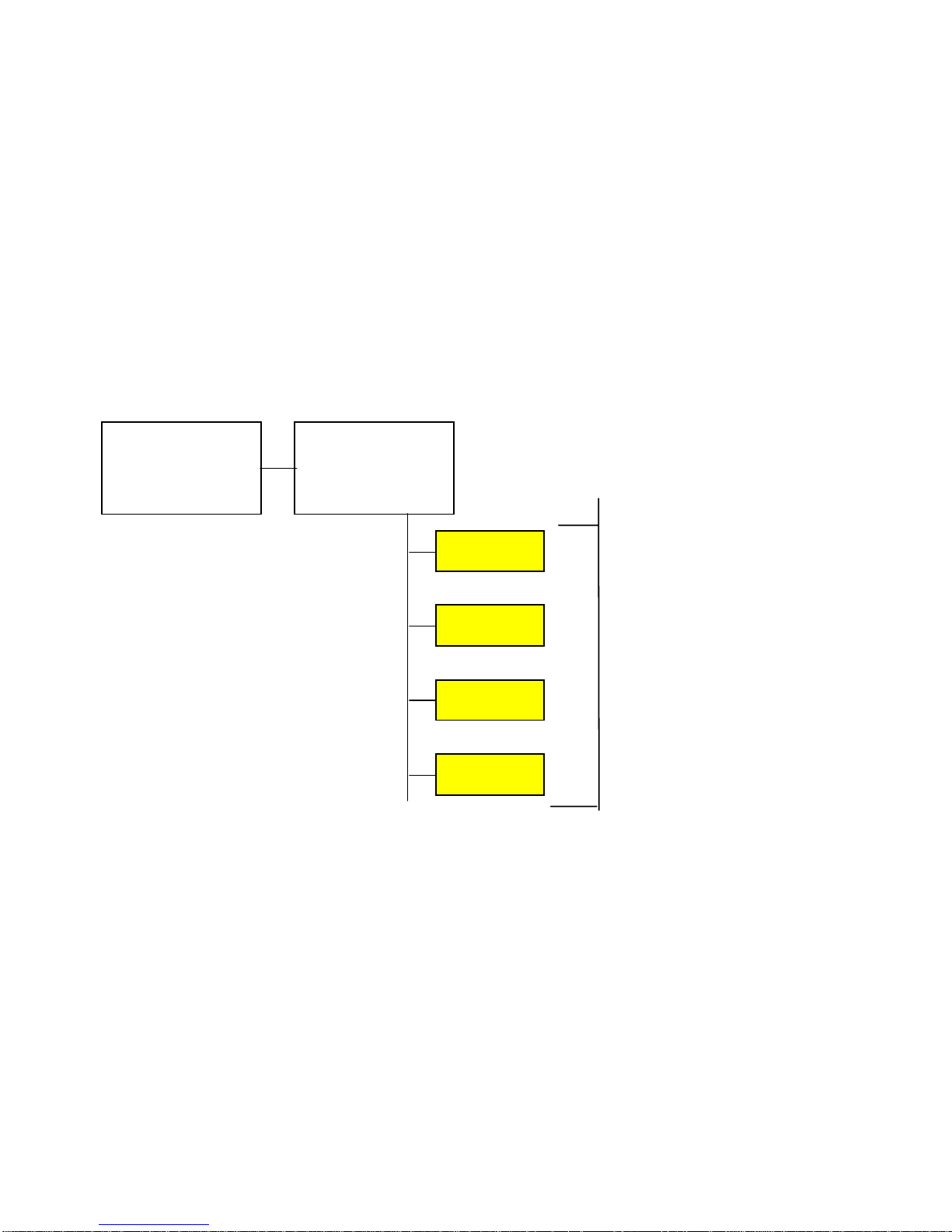

Mechanical Installation

q

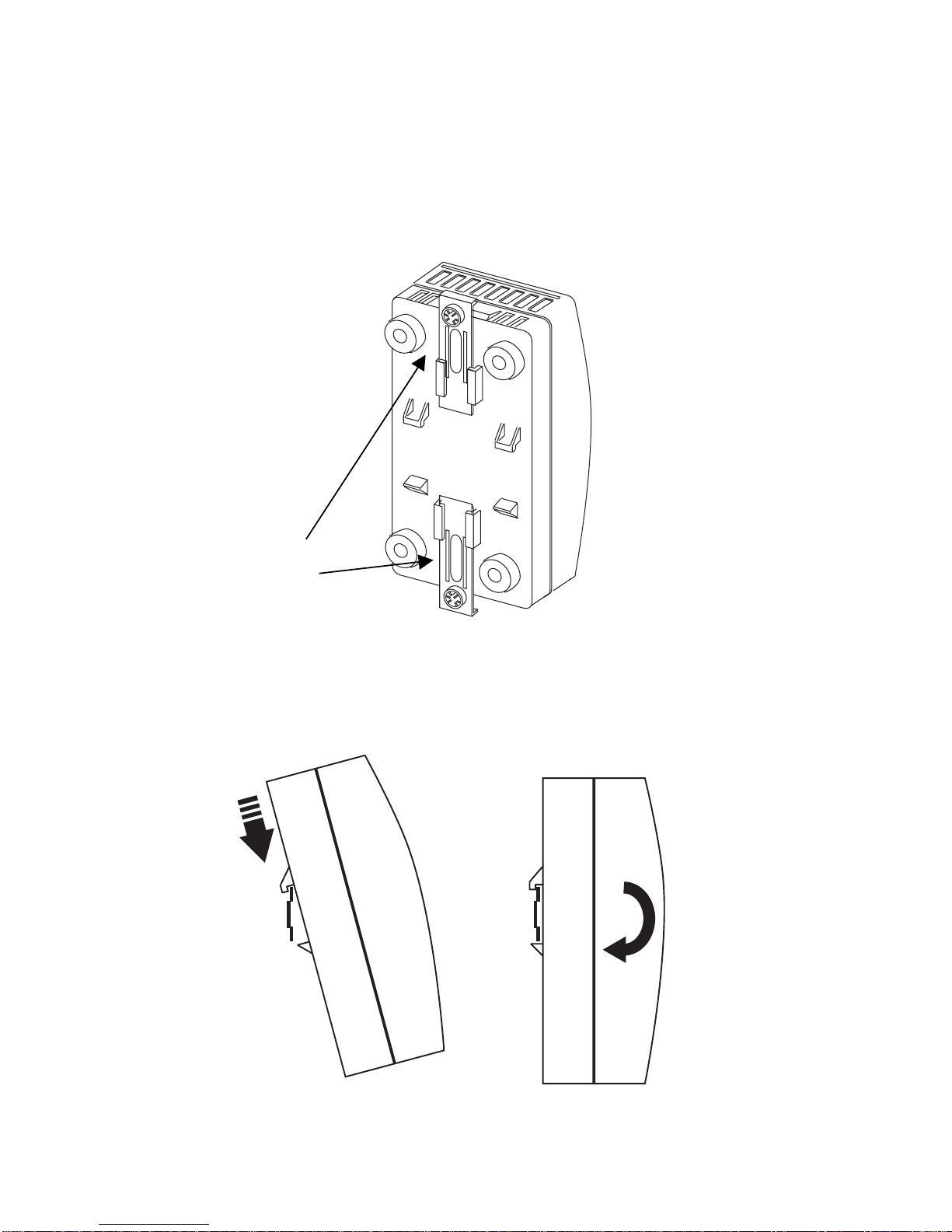

Each I/O module, exc ept the Display variety, is enc los ed in the same standard plastic

case that is designed t o be m ounted on a standard DIN rail or fastened to a panel.

Note: In order to meet agency requirements, it is necessary that t he modules along

with the power supply and controller be housed in another metal enclosure i.e., a

NEMA box or the new Andover Controls Con t in uu m enclosure.

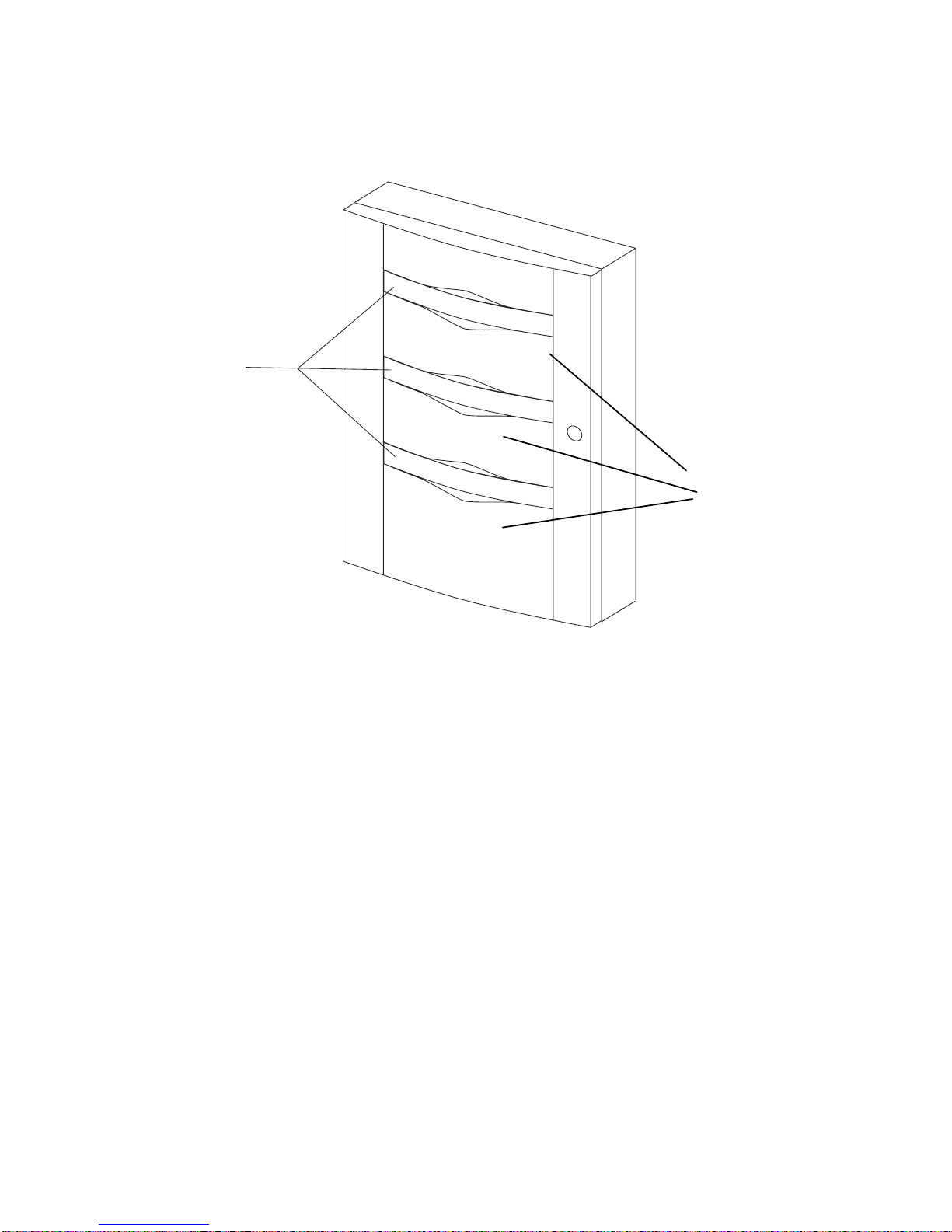

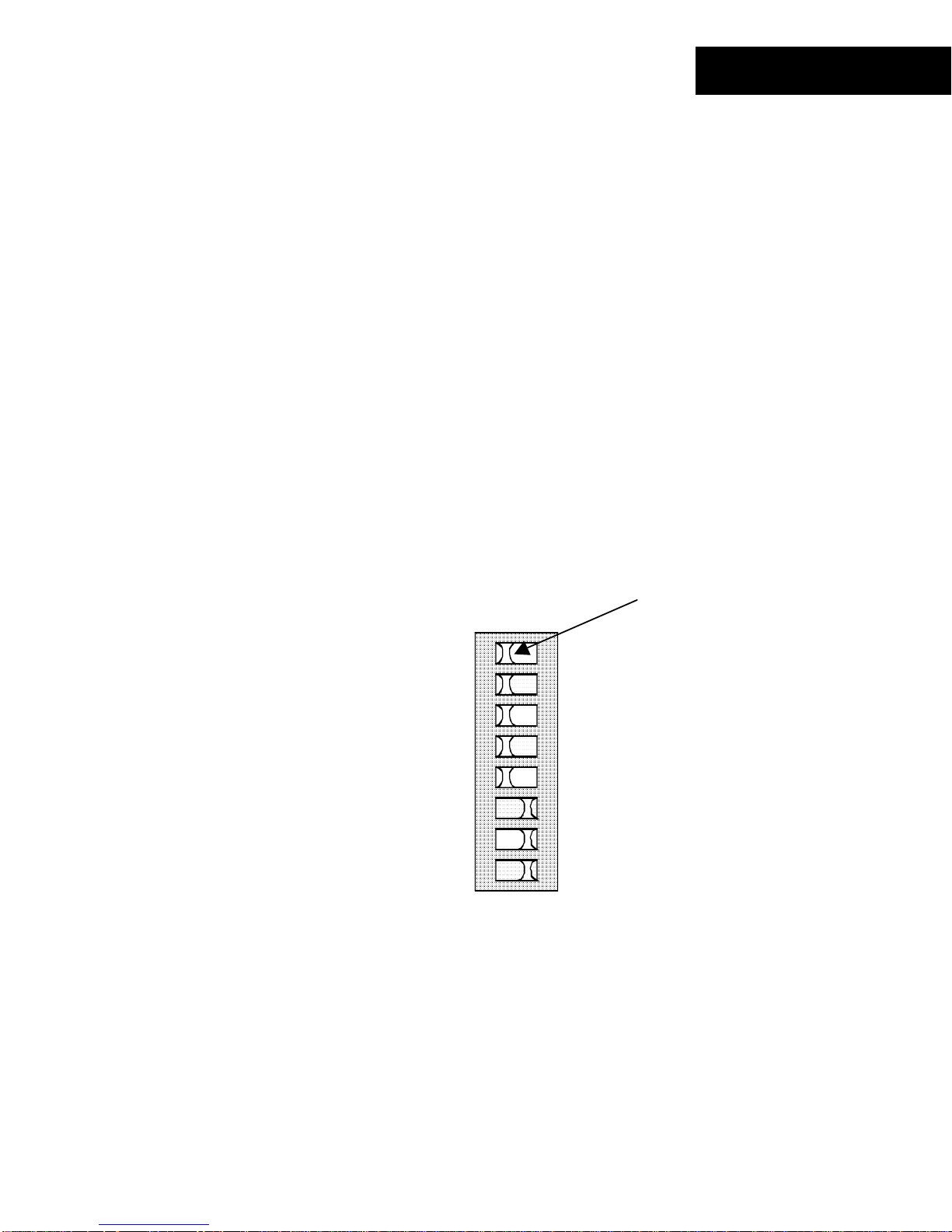

The standard I/ O module plas tic case is illustrat ed below:

Status Indicators

& some switches

Status indic ators and operator switc hes ar e located on the indicator panel. Ot her

switches available for module configuration may be accessed by lifting the hinged door to

the module as shown.

Connections to

controlled/sensed

uipment

e

4

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 11

Wiring to controlled points or sensors is accomplished via a standard removable screw

terminal block loc ated at the bottom of the module behind t he door . An open area at the

bottom of the c as e allows wires to exit in an appropriate manner.

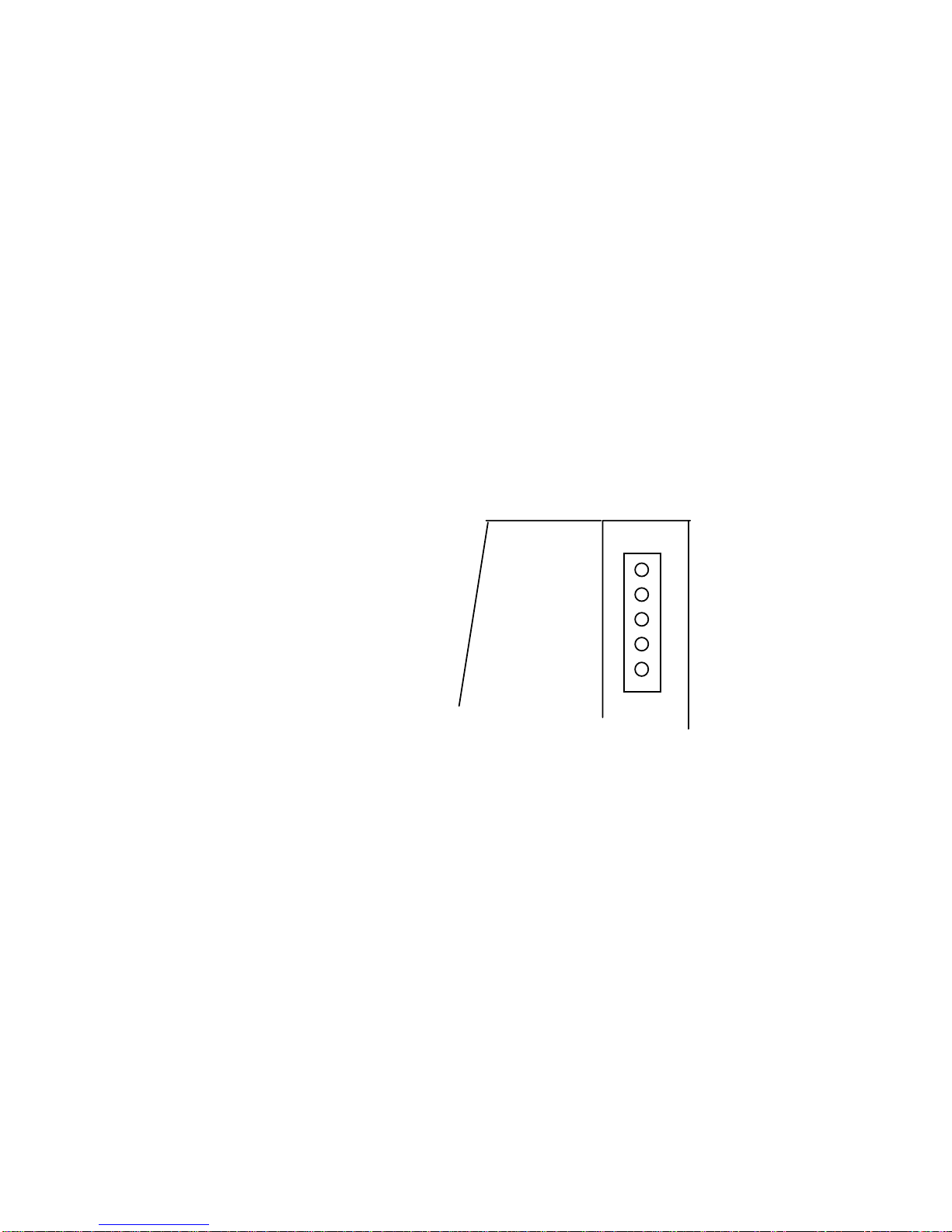

On the back of each module are molded DIN rail guide fingers. The design allows the

module to easily hook onto and slide along a standard DI N rail.

Locking Fingers

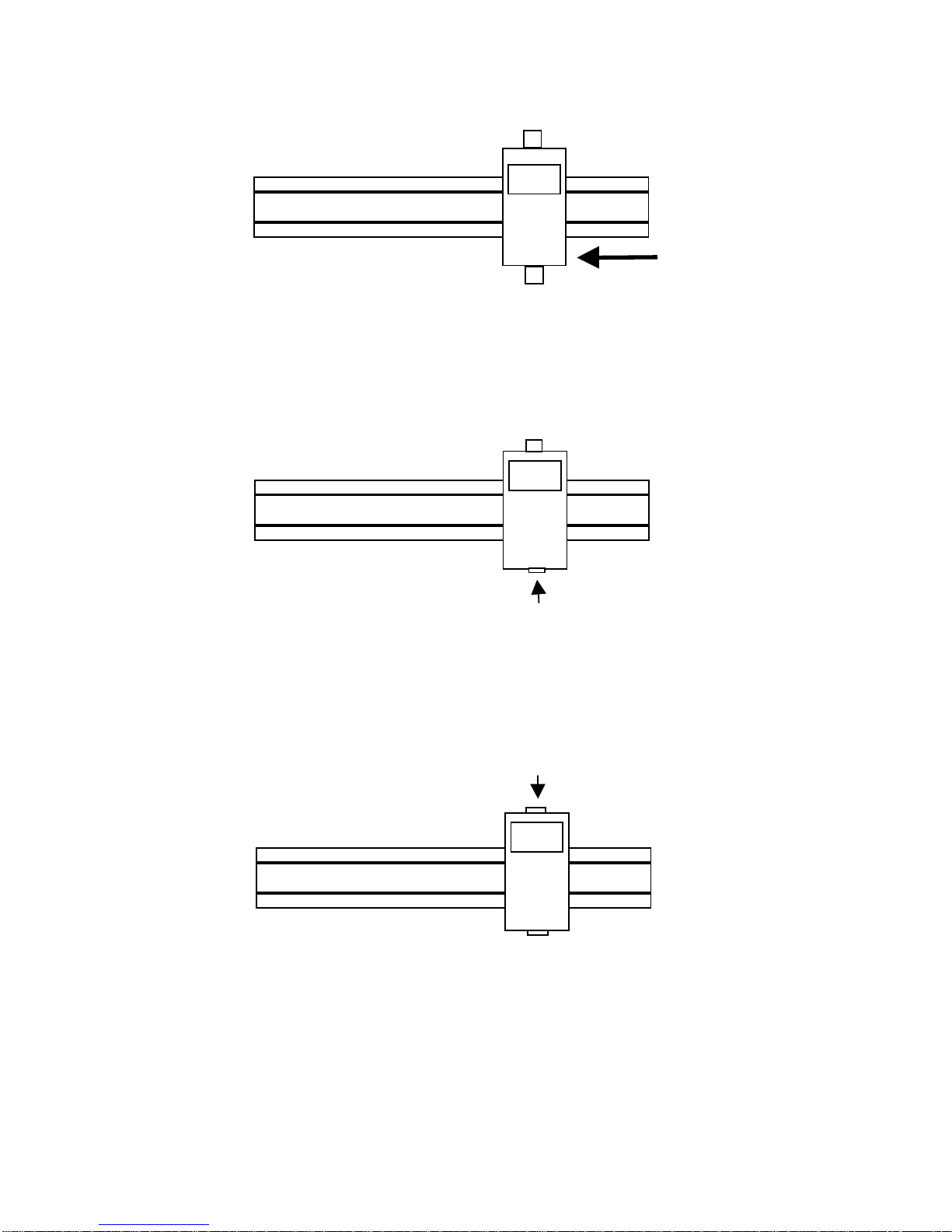

With the mounting br ac k ets extended outward, hook the module onto the DIN rail as

shown below:

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

5

Page 12

Slide the module into pos ition.

Press the lower mounting bracket inward until it locks the module in place.

Press the upper br ac k et int o its loc k ed pos ition as well.

Once the module is in the des ir ed pos ition, it is locked to the rail by pushing t he bottom

clamps inward. A ft er the bottom is secure, press the top clamp inward to complete the

operation.

6

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 13

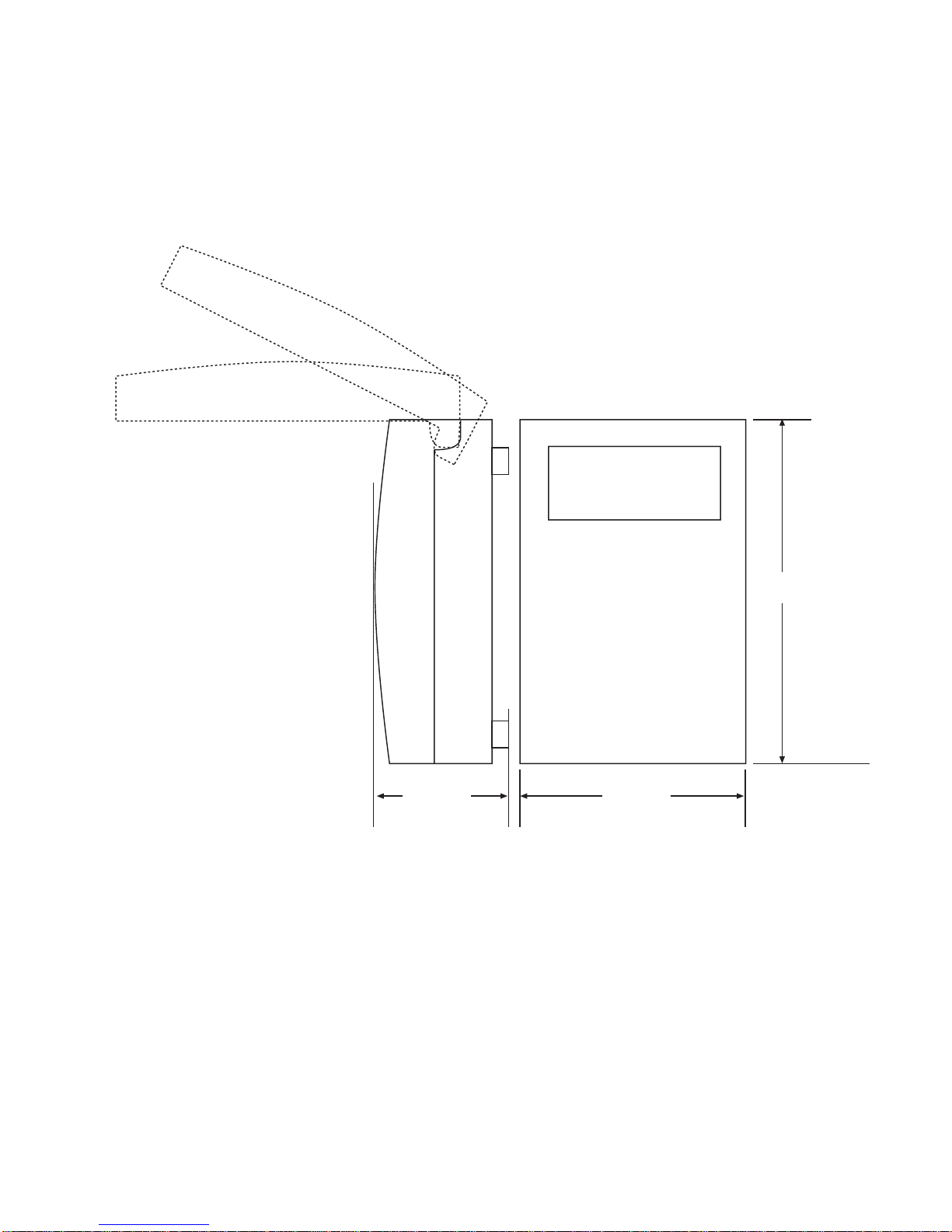

Overall Dimensions

The overall dimensions of the standard I/O case are as shown:

6.70''

(170.2 mm)

2.50 ''

(63.5 mm)

Technical Manuals Online! - http://www.tech-man.com

3.50 ''

(88.5 mm)

Continuum I/O System Reference

7

Page 14

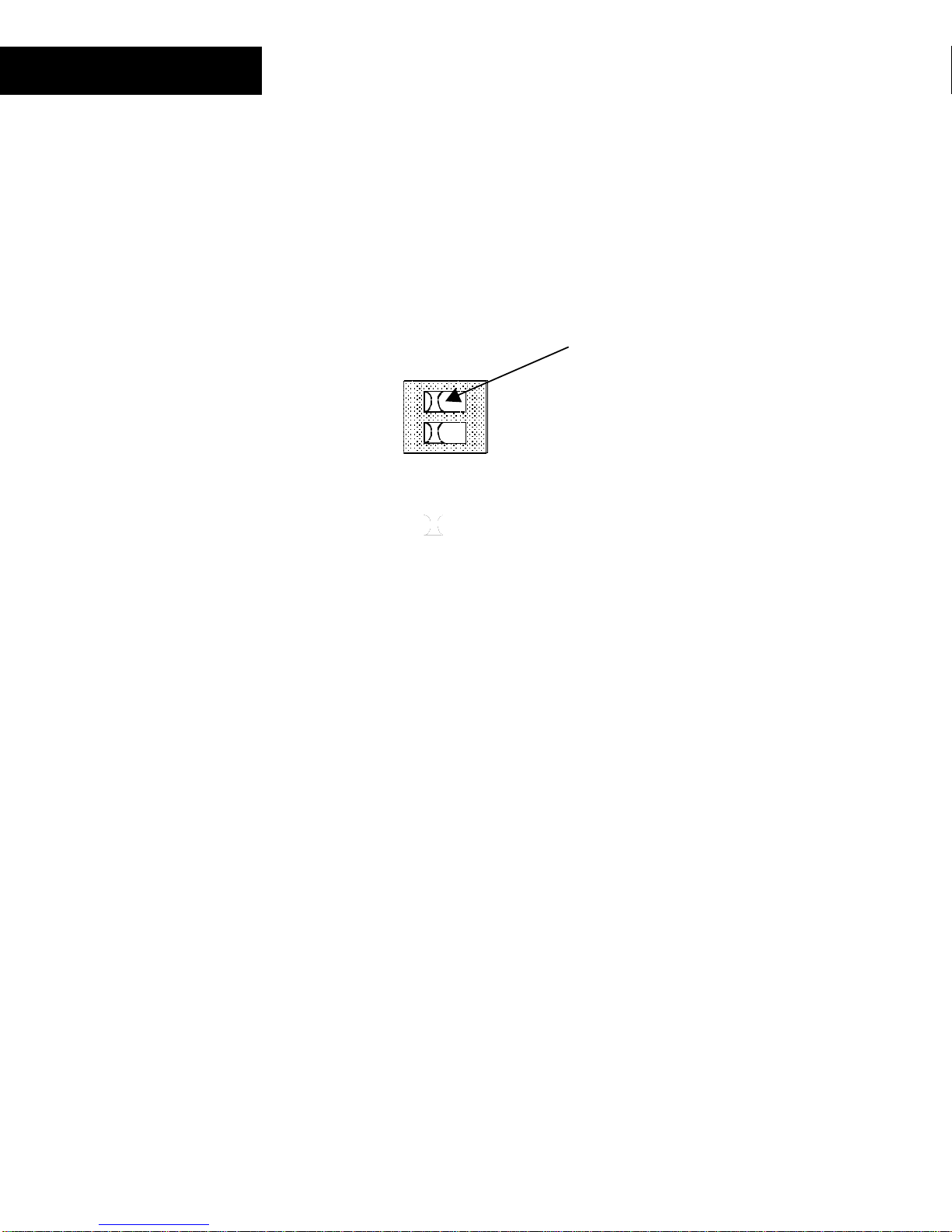

Enclosure-Mounted Modules

The modules that are des igned to be mounted to the new Andover Contr ols Continuum

enclosure fit into openings left by removing panels in the front door.

The new enclosure prov ides a plac e to mount a power supply, CPU and up to ten DIN rail

mounted I/O m odules . Sev er al dis play m odules c an be aff ix ed to the front panel.

The enclosure is a 6” deep NEMA box with integral display panels, DIN rails, cable

troughs and a battery storage compartment.

DIN Rail

Cable Trough

Battery

Storage

The enclosure f eatures three DIN rails and cable management accessories. Use of t he

new enclosure is not r equir ed, however, it provides a c onv enient method of construct ing

small local systems.

8

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 15

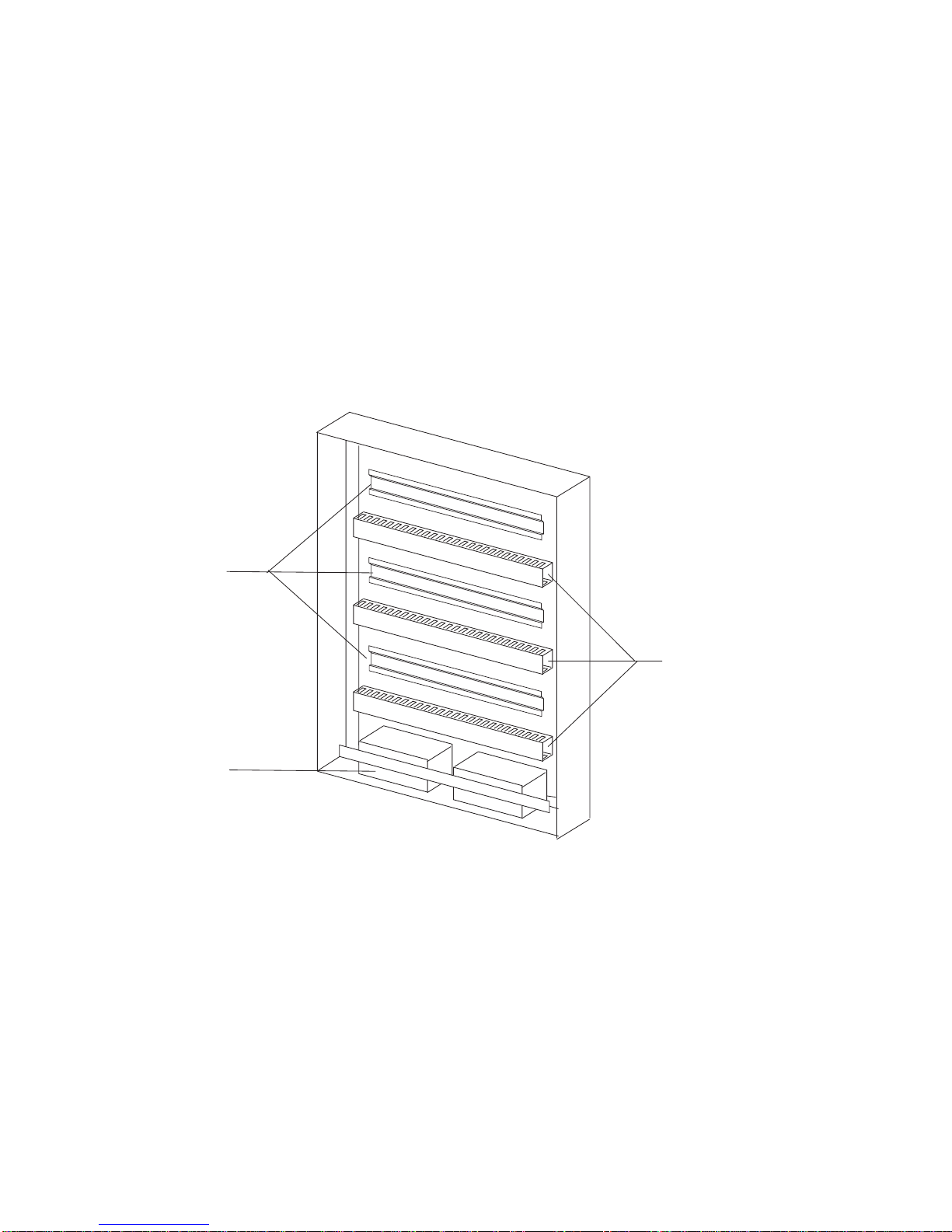

The front door of the enclos ur e c ontains removable sections into which special operator

display and control m odules m ay be m ounted. Alternately, Plex iglas panels m ay be us ed

to view the stat us lights of all internal modules when t he door is closed.

Removable

Display Panels

Spacers for

Additional Displays

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

9

Page 16

Power-CPU Connections

The Continuum Net Controller CPU module includes a c onnec tor on the upper right

side of its case f or fur ther distribution of the 24 VDC input power and s pec ial I/O

communications s ignals to all I/O modules. Continuum I/ O modules us e these signals

for power and comm unic ations as well.

The power-I/O c onnec tor is a five pin male assembly that is designed to eas ily ins er t

directly int o the left side (input) connect or of any I/ O module. The signals within that

connector are as follows:

PIN Function

5 +24 VDC

4 24 VDC Return

3 Ground

2 Comm B

1 Comm A

The system power s upply gener ates a +24 VDC source for all modules in the syst em.

This power sourc e is received through the input power c onnec tor on the left side of

the CPU module and sent through to pins 4 and 5 of this connector. Pin 3 (Ground) is

intended as a signal ground connec tion.

Communications between the CPU and I/O modules is through a two-signal serial

interface that can be internally conf igur ed as either RS 485 or Echelon LON FTT-10.

Pins 1 and 2 (Comm B and Comm A) provide the electrical connection for this

interface.

5

10

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 17

Connecti on of I/O Modul es

y

The CPU can directly c onnec t to I/O without the use of cables thr ough a system of

built-in plugs and jacks. All I/O modules include two complementary module interconnectors.

Creating a system is as simple as physically plugging the modules together.

Power Suppl

CPU

I/O

I/O

In vertical extended systems, I/O modules may be located above or below other

modules. In this c as e, cable as s em blies br idge the I/O modules together .

The cable necessar y to connect the CPU and external I/O modules is f iv e c onduc tor

and would be attached using a plug-in screw terminal connector. Connect ion

between the modules is one- to-one straightfor war d wir ing as s hown below:

5

4

3

2

This connect or is available f r om A ndov er Controls under part number 01-2050- 283;

Wieland manufactures it under part number 25.340.0553.0.

Technical Manuals Online! - http://www.tech-man.com

5

4

3

2

Continuum I/O System Reference

11

Page 18

Maximum Number of I/O Modules

There is no operat ional lim it to the number of I/O modules connected to the CPU except

the capacity of t he power s upply . It is pos s ible to insert auxiliary power supplies into the

I/O bus to increase the number of modules support ed.

To determine the maximum number of I/O modules your system can support, subtract the

power requirements for each module from the maximum available f r om y our power

supply.

PS 120/240 AC 50 U, UPS power supply pr ov ides 35 Watts of power

•

PS 120/240 AC 50, non-UPS power s upply pr ov ides 50 Watts of power

•

PS –48 DC 50, Battery operated power supply provides 50 Wat ts of power

•

NetController r equir es 15 Watts of power

•

Start by subt r acting the NetController from the power av ailable from your power supply .

PS 120/240 AC 50 U

35 – 15 = 20 Watts of available power f or I/ O

PS 120/240 AC 50

50 – 15 = 35 Watts of available power f or I/ O

PS –48 DC 50

50 – 15 = 35 Watts of available power f or I/ O

The power requirements for each I/O module is list ed in the

Reference Guide

ACC # 30-3001-499 and can be found on indiv idual data sheets.

Continuum I/O System

Maximum Length of I/O Bus

A repeater is nec es s ar y if the cable lengths get too long. The following are

recommendations r egar ding c able lengths for both RS - 485 and FTT- 10 interfaces:

RS-485 Repeater required if length is >2000 ft. (610 m) or after 32 m odules .

FTT-10 Repeater required if length is >8858 ft. (2700 m) bus topology

>1640 ft. (500 m) free topology

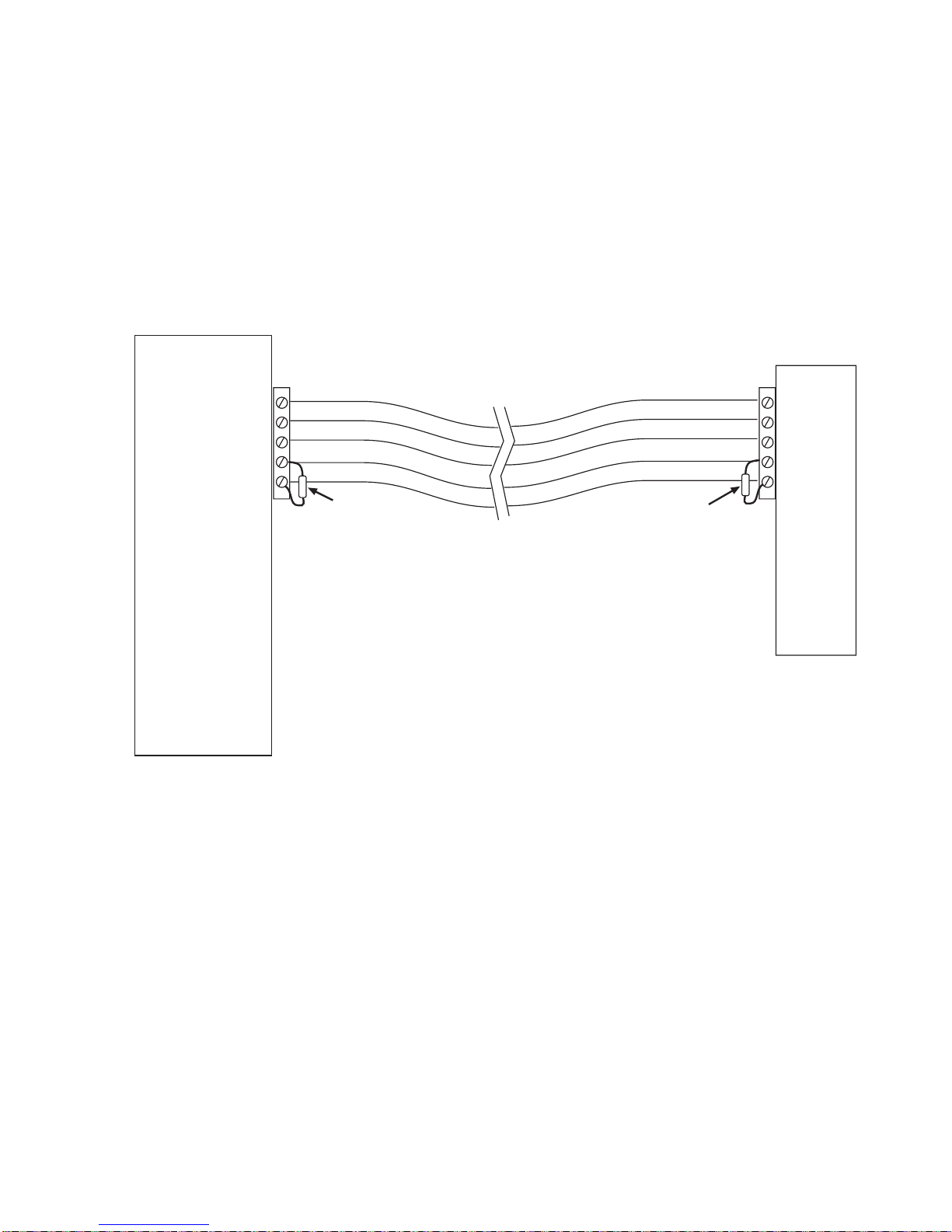

Connecting Remote I/ O Modules with RS-485

The Continuum sy stem allows I/ O modules to be placed in a remote location from the

CPU (NetContr oller ) . However, long cable lengths can c aus e s ignal c om m unic ations

problems on the Power /I - O bus.

When locating an I /O module remotely it is necessary to add a 120

terminator to the

Ω

bus to compensate for the distance. The terminat or m ust be c onnec ted at both ends of

the bus for proper operation.

12

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 19

Termina t i on Guidel ine s

The following are t y pic al ins tallations that indic ate the placement of the terminat or :

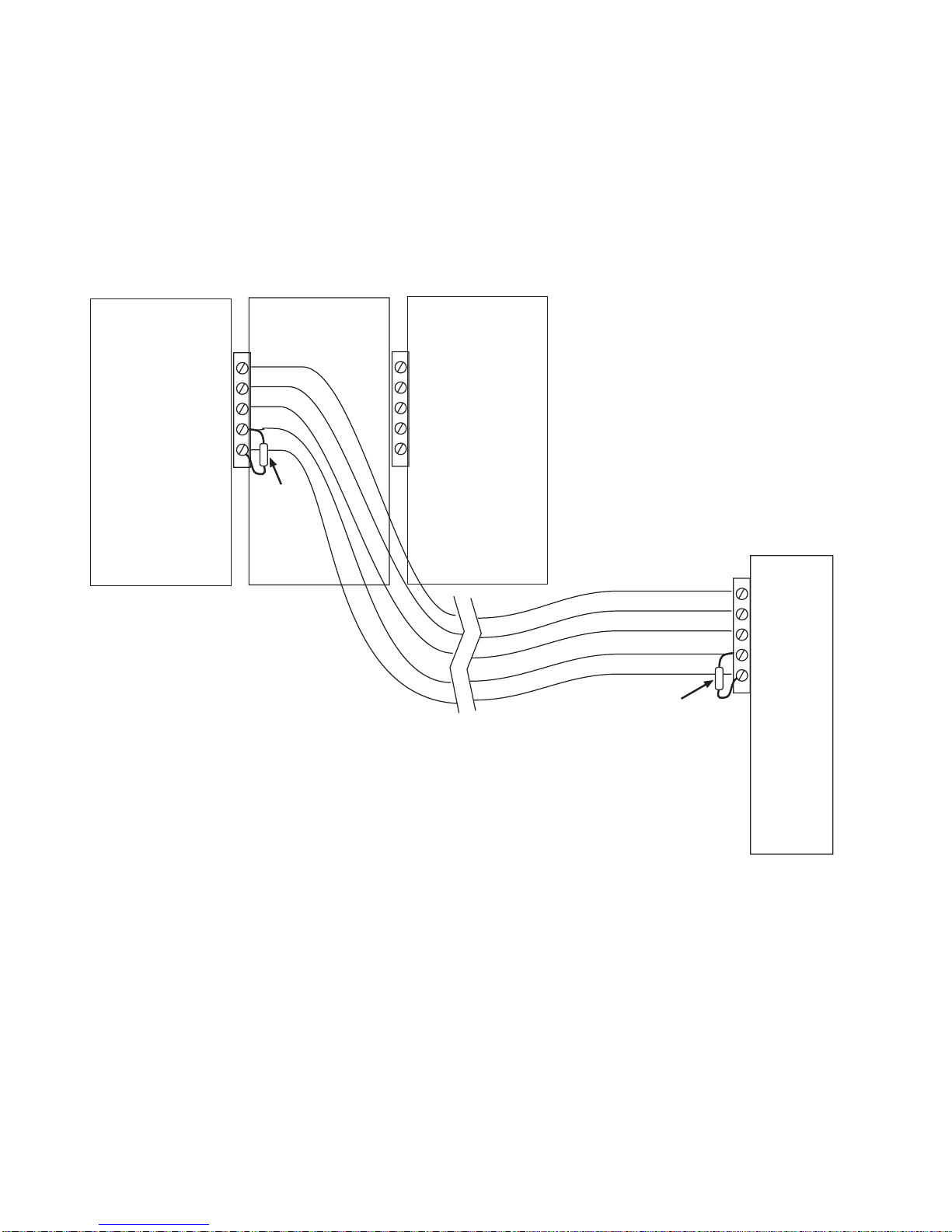

Simple CPU and 1 remot e I/O Module:

The I/O Bus that needs to be terminated is the one formed by the cable at taching the

remote module t o the CPU. I n this c as e, a t erminat or r es is tor is connected across the

communications lines ( pins 1 & 2) directly at the NetController and again at the remote

I/O module.

CPU

5

4

3

2

1

120 Ω

Resistor

120 Ω

Resistor

5

4

3

2

1

Remote

I/O

Module

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

13

Page 20

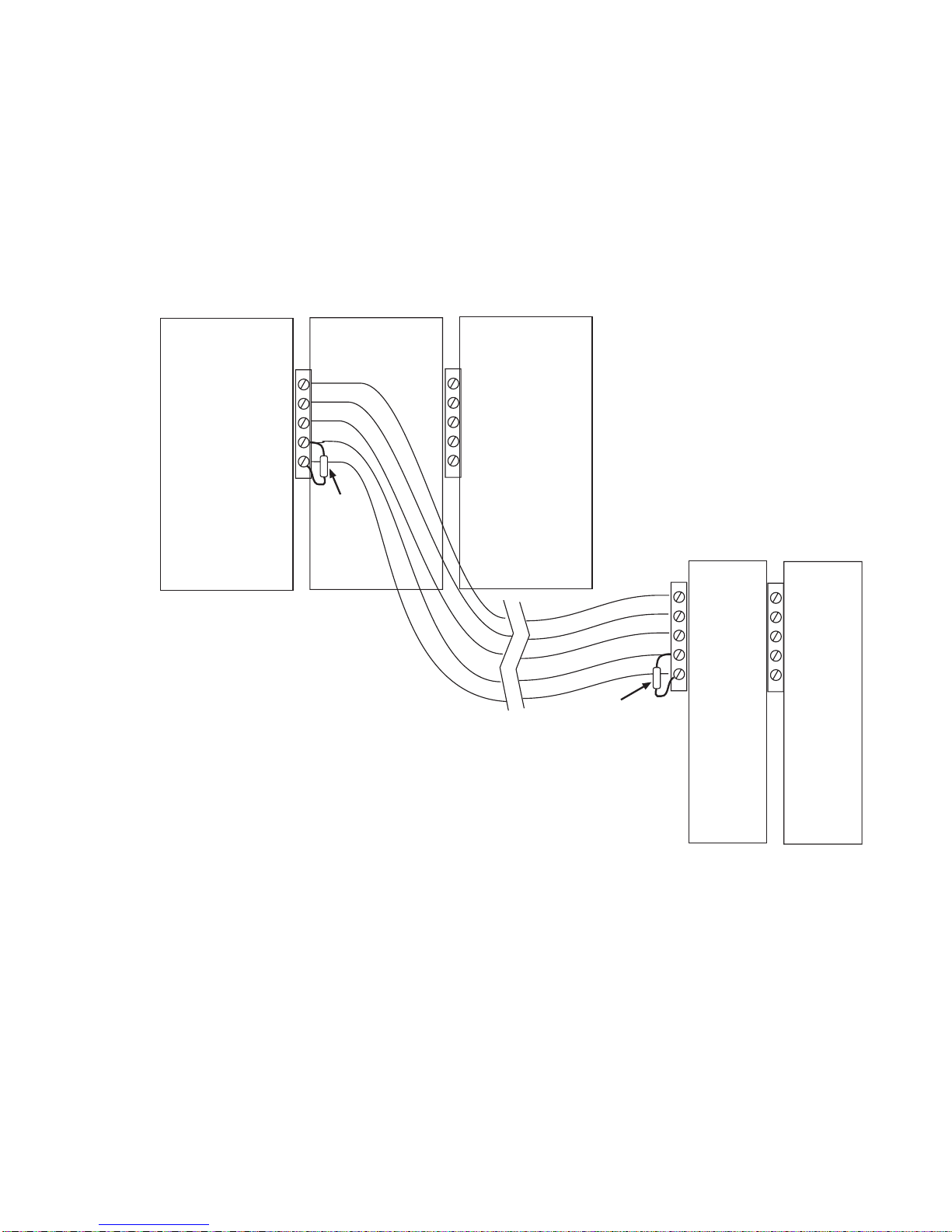

CPU with local and 1 remote I/O Module:

The I/O Bus that needs to be terminated is the one formed by the cable t hat starts at

the NetContr oller and ends at the remote module. The bus that ext ends from the

NetController through the local I/O stac k does not need termination. In this cas e, t he

terminator r es is tor is connected direct ly acros s the c om m unic ations lines ( pins 1 & 2) at

the NetContr oller and again at the remote I/O module.

CPU

120 Ω

Resistor

Local

I/O

5

4

3

2

1

5

4

3

2

1

Local

I/O

120 Ω

Resistor

5

4

3

2

1

Remote

I/O

Module

14

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 21

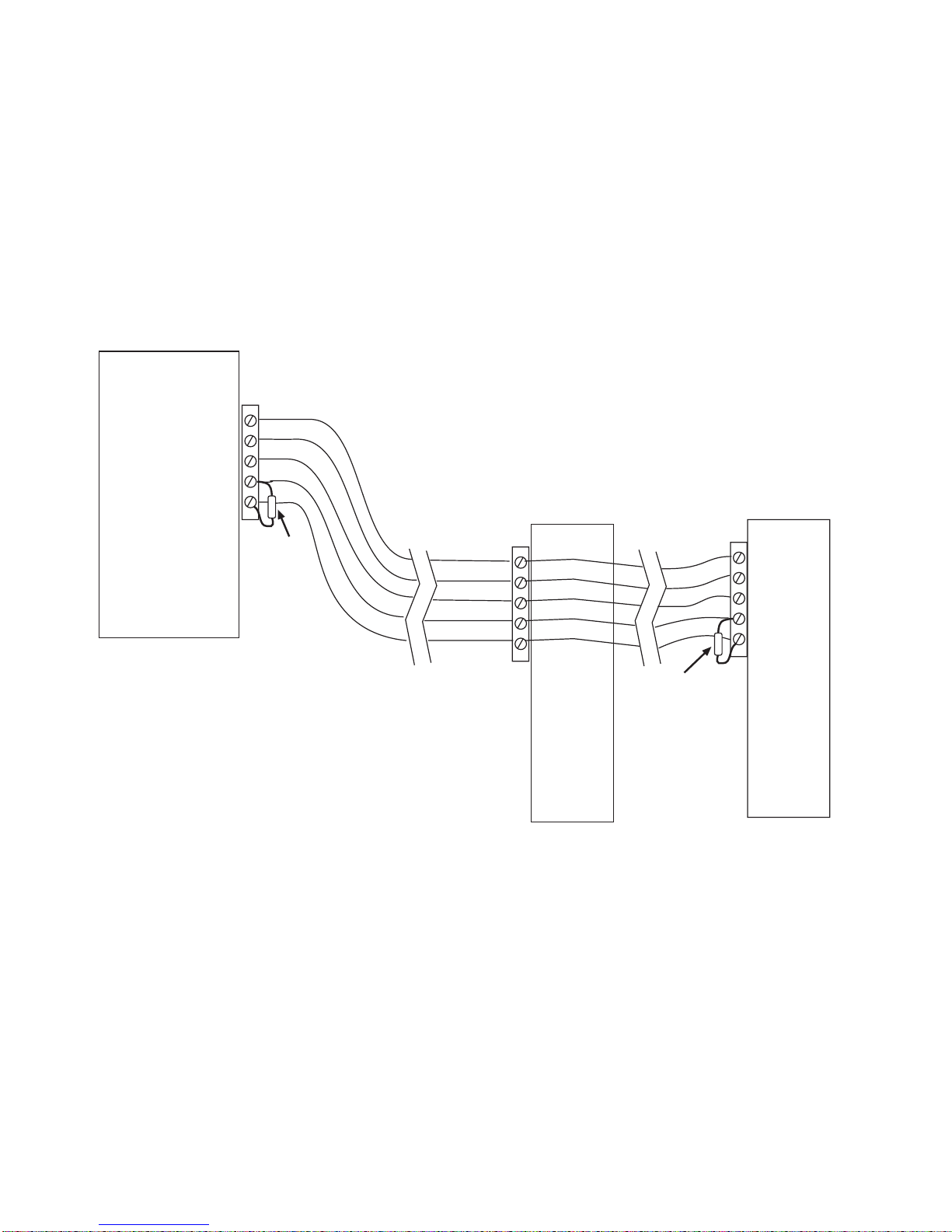

CPU with local and sever al r em ote I/O Modules:

The I/O Bus that needs to be terminated is the one formed by the cable t hat starts at

the NetContr oller and ends at the first remote module. The bus that extends from the

NetController through the local I/O stac k and the one that starts at the first remote

module and extends t hr ough s ubs equent modules do not need terminat ion. In this

case, the term inator resistor is connected dir ec tly across the communicat ions lines

(pins 1 & 2) at the NetContr oller and again at the first remote I/O module.

CPU

120 Ω

Resistor

Local

I/O

5

4

3

2

1

5

4

3

2

1

Local

I/O

120 Ω

Resistor

5

4

3

2

1

Remote

I/O

Module

5

4

3

2

1

Remote

I/O

Module

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

15

Page 22

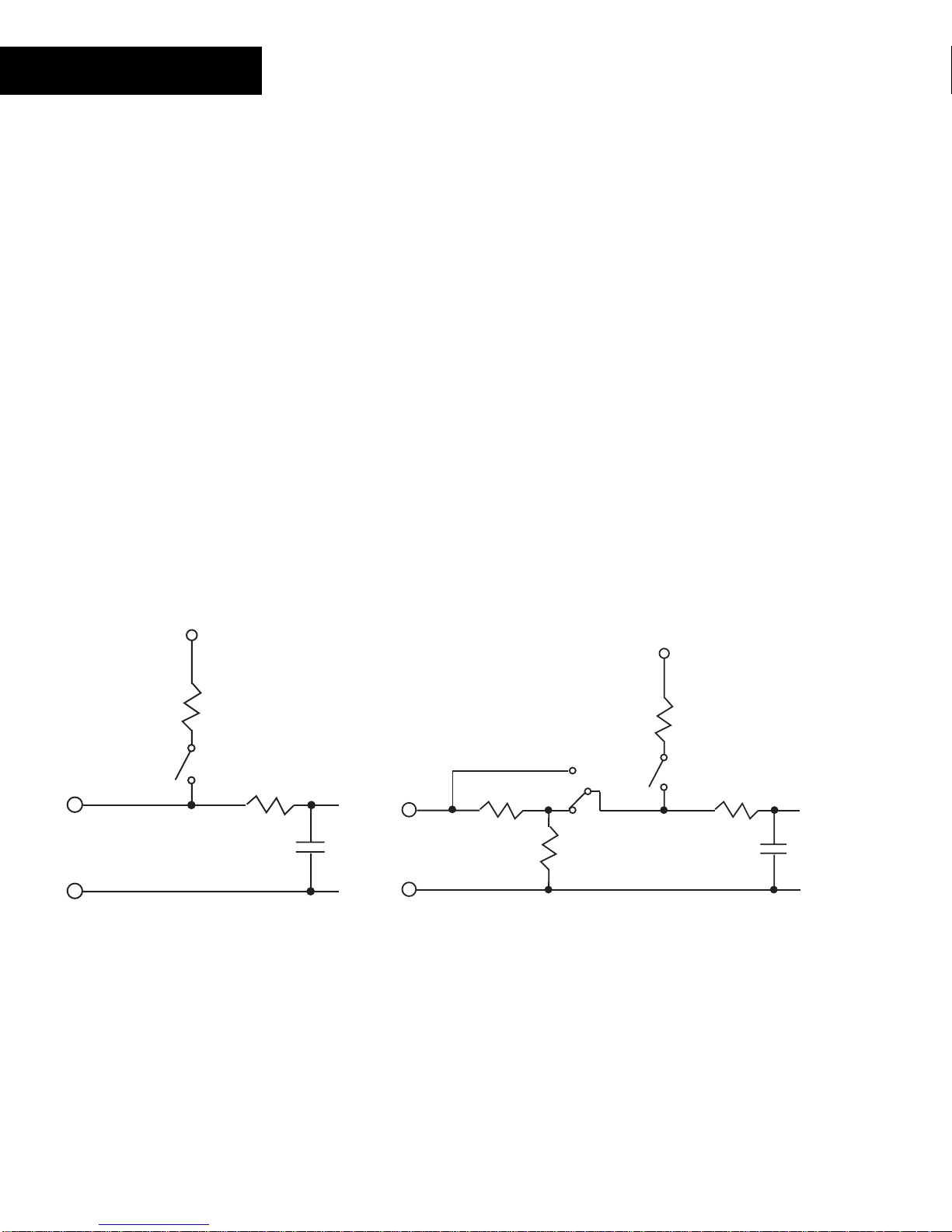

CPU with two remote m odules s epar ated by distance:

The I/O Bus that needs to be terminated is the one formed by bot h cables on eit her

end of the first remot e I/O m odule. In this case, the bus begins at the Net Controller,

flows by the firs t rem ote module and ends at the second. The term inator resistor is

connected directly across the communicat ions lines ( pins 1 & 2) at the Net Controller

and again at the last r emote I/ O module. If the last module is actually a stac k of

directly connec ted I/O modules, the term inator is placed at the first module of the

stack as indicated in the scenario described on the previous page.

CPU

5

4

3

2

1

120 Ω

Resistor

5

4

3

2

1

Remote

I/O

Module

120 Ω

Resistor

5

4

3

2

1

Remote

I/O

Module

16

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 23

Individual Module Characteristics

This section of the document describes the various I/O modules and presents interfacing

information. Each module is presented in it s own mini-sec tion. The part number

designator for the module being described is printed on the outer edge of each page.

General Wiring Concerns for All Modules

Do not remotely gr ound any part of t he input sensor wiring. Remote gr ounds c onnec ted

to the return t er m inal c ould m ak e the syst em oper ate incorrectly or damage the

equipment. T he s ignal r eturn is not true earth ground. It is an elect r onic r eferenc e point

necessary t o interpret the sensor properly.

It is recommended that you run input wiring in a conduit s epar ate from AC power or

output wiring and avoid long wir ing r uns .

For reliable input oper ation, follow thes e input wiring guidelines:

Never lay wires acr os s the surfac e of a printed circuit board.

•

Wires should never be within 1 in. or 25 mm of any component on a printed

•

circuit board.

Use shielded input wire.

•

Terminate the shield of the input wires at one end of the r un only—preferably at

•

the end where your I/O module is loc ated.

Be careful when stripping wire not to drop small piec es of wire ins ide the cabinet.

•

Don’t run your input wir ing in the same conduit with AC power.

•

Don’t run your input wir ing in the same conduit with your output wir ing.

•

Grounding the Modules

Each module includes a screw terminal connection for Earth ground. It is important that

this connect ion be m ade as c los e to the module as pos s ible.

Caution

Do not externally ground any input signal connected to the modul e. This may

damage the unit. Sign al return terminals are not connected to Eart h G round.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

17

Page 24

18

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 25

UI-8-10

The UI-8-10,

Continuum

’s universal input m odule, provides 8 universal inputs, software

configurable as voltage, thermis tor, digital, or counter point types. Each point can also be

configured as a super v is ed input for security monitor ing, providing separate indic ation of

alarm and trouble conditions. This module is a perfect choice for any mix of temperat ur e,

pressure, flow, status points, and similar inputs in a cont rol system, with a 0-5 volt input

range and 10 bit A/D c onv er s ion.

The UI-8-10- 10V m odel is available f or 0- 10V applic ations. It provides the identical point

type select ion; but is equipped with individual voltage div ider DIP switches on each input,

allowing each to be configur ed for a 0-10 volt range.

FEATURES

POWER

COMM

STATUS

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

INPUT TYPE REFERENCE RANGE

TEMPERATURE ON 5 V

5V RANGE OFF 5 V

10V RANGE OFF 10 V

READER

POWER

+

V

IN1

123456789101112

12

SWITCH SETTINGS

REFERENCE

RESISTOR

OFF ON

+ 5V, 100mA

+ 12V, 180mA

READER

G

DC

A

N

T

D

A

/

1

3

IN1

IN2

IN3

IN4

SUPERVISED

IN5

INPUTS(0-5V)

IN6

IN7

1

23

L

E

D

IN8

L

A

O

D

K

U

O

ANALOG INPUTS

X

R

/

0

IN3 IN4 RETIN2 RET IN5 IN6 RET IN7 IN8 RET

4

56

7

ON

OFF

AUTO

R

E

X

8

1-DOOR

VOLTAGE

RANGE

5V 10V

CONTACT RATING:

DIGITAL OUTPUTS

1-DOOR

R

E

T

10 11 12

9

COMMISSION

RESET

UI-8

ON

OFF

AUTO

13 14 15

OUT 2

OUT2

•

•

•

•

8 Universal Input s

10 bit Resolution

0-5V or 0-10V Input Range

Supports Voltage, Thermistor, Digital,

Counter and Supervis ed E lec trical

Types

•

Pull-up Resistor Dis able S witches

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

19

Page 26

UI-8-10

SPECIFICATIONS

ELECTRICAL

Power Consumption:

0.7 Watt at 24VDC max.; normally provided by

supply module.

Continuum

power

Overload Protection:

INPUTS

Number of Inputs:

Input Types:

Input Protection:

Input Impedance:

Input Connections:

Voltage: UI-8-1 0 (0-5V) UI-8-1 0-10V (0-10V mo d e)

Range: 0-5 volts 0-10 volts

Resolution: 5 mV 10 mV

Accuracy: ±15 mV (± 0.3% FSR) ±40 mV (±0.4% FSR)

Filtering: Corner Frequency at 15 Hz, –20 db/decade

Calibration: Permanent (factory)

Thermistor:

Type: 10 KΩ, Type III Thermistor

Range: -30 to 230°F

0.5A resettable fuse with transient voltage suppressor (TVS) and

reverse polarity protection.

8 Universal inputs; 10 bit resolution

Voltage, Thermistor, Digital, Counter, and Supervised

24V AC/DC allowed to any single input

(40V transient voltage suppressor on each input – UI-8-10-10V)

5 MΩ w/pull-up disabled; 10 KΩ w/pull-up enabled – UI-8-10

(4.4 KΩ w/pull-up enabled in 0-10V mode UI-8-10-10V)

Two-piece, 13-position removable terminal block

(-34 to 110°C)

Resolution: 40 to 100°F range 0.20°F typical

(4 to 38°C) (0.11°C typical)

Accuracy: 40 to 100°F range ± 1.0°F (includes 0.36° error for thermistor)

(4 to 38°C) (±0.55°C)

Digital & Counter:

Input Type: Contact Closure

Frequency: 4 Hz max.

Pulse Width: 125 ms min.

Supervised:

Input Type: Single or Double Resistor Supervision, Parallel or Series Circuit

20

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 27

UI-8-10

I/O Connections

The actual input connect ions are located on a twelve-position removable screw terminal

connector located at the bottom of the module. Input wir es s hould enter from either the

top or bott om wiring t r oughs , and should c om e from the left side of the rack (by

convention).

The inputs are labeled IN1, IN2, IN3, and so fort h. Eac h pair of inputs is followed by a

connection labeled RET for the input signal retur n, resulting in a sequence of I N1, I N2,

RET, IN3, IN4, RET, and s o on. F or any given input, you should use the closest r eturn

terminal either before or after that input —the nex t return terminal goes with t he next two

inputs, and so on.

The twelve-pos ition connector allows for eight inputs and four signal ret ur ns .

The diagram below indicat es wher e eac h input number is located in the terminal block.

Shield/Eart h Ground

1.

2.

3.

4.

5.

6.

7.

8.

9.

IN 1

IN 2

RETURN

IN 3

IN 4

RETURN

IN 5

IN 6

RETURN

10. IN 7

11. IN 8

12. RETURN

READER

POWER

Technical Manuals Online! - http://www.tech-man.com

POWER

COMM

STATUS

COMMISSION

RESET

UI-8

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

ON

OFF

AUTO

IN1

IN2

IN3

IN4

SUPERVISED

IN5

INPUTS(0-5V)

IN6

IN7

23

D

IN8

R

O

E

O

X

R

7

8

1-DOOR

VOLTAGE

RANGE

5V 10V

CONTACT RATING:

DIGITAL OUTPUTS

1-DOOR

R

E

T

10 11 12

9

SWITCH SETTINGS

INPUT TYPE REFERENCE RANGE

TEMPERATURE ON 5 V

5V RANGE OFF 5 V

10V RANGE OFF 10 V

REFERENCE

RESISTOR

OFF ON

+ 5V, 100mA

+ 12V, 180mA

READER

+

G

DC

A

N

V

T

D

A

/

1

IN1

Continuum I/O System Reference

123456789101112

12

3

1

L

E

L

A

D

K

U

ANALOG INPUTS

X

/

0

IN3 IN4 RETIN2 RET IN5 IN6 RET IN7 IN8 RET

4

56

OUT 2

ON

OFF

AUTO

OUT2

13 14 15

21

Page 28

UI-8-10

Input Circuitry

UI-8-10 Inputs are essentially volt m eters. Universal inputs can be conf igur ed through

software to become one of five different input c ir c uits:

Temperature

♦

Voltage

♦

Digital

♦

Counter

♦

During configurat ion, the value of the Electrical Type attribute y ou s elec t t ells the

controller how t o interpret the reading fr om each input . Each Universal input is read ev er y

100 milliseconds. This reading is independent of the controller sc an time.

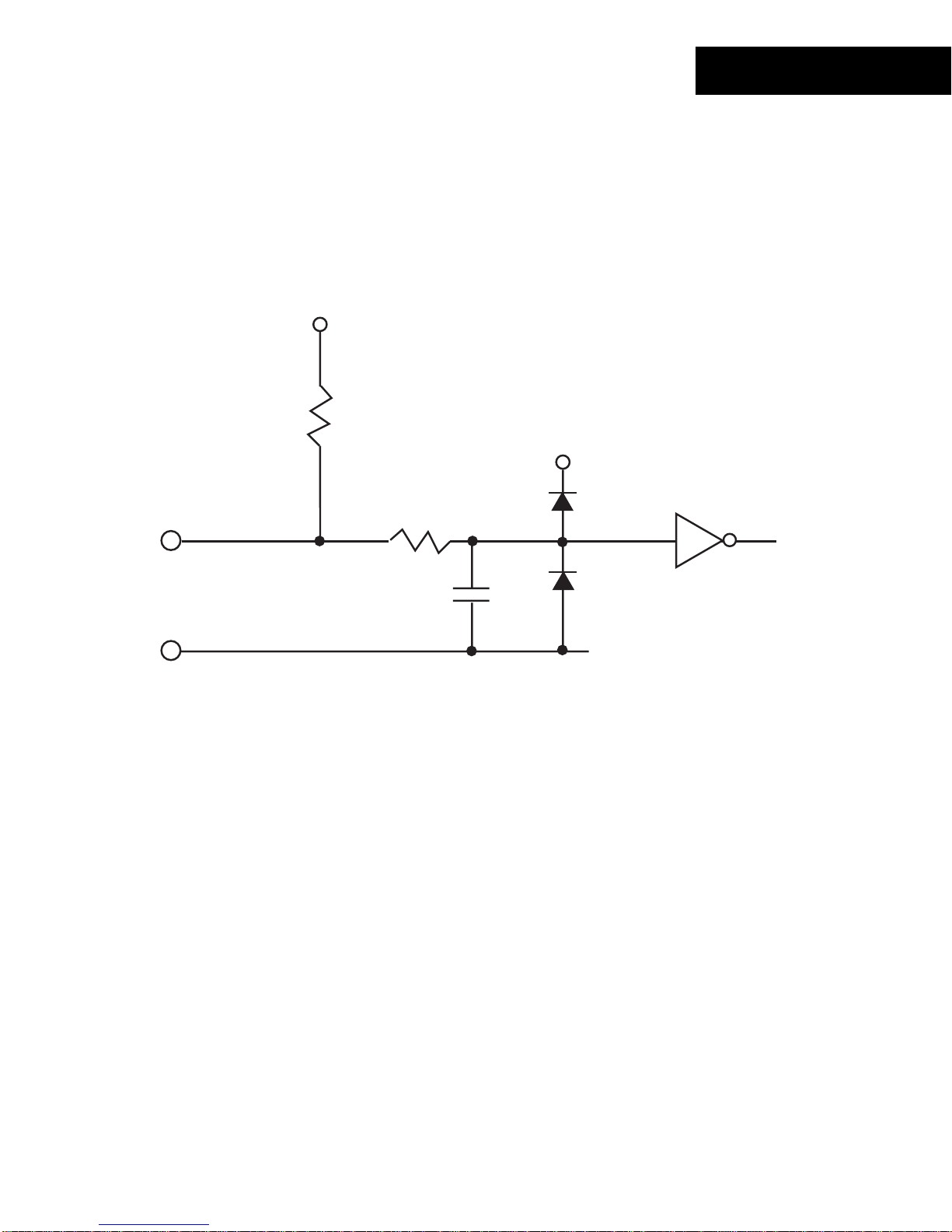

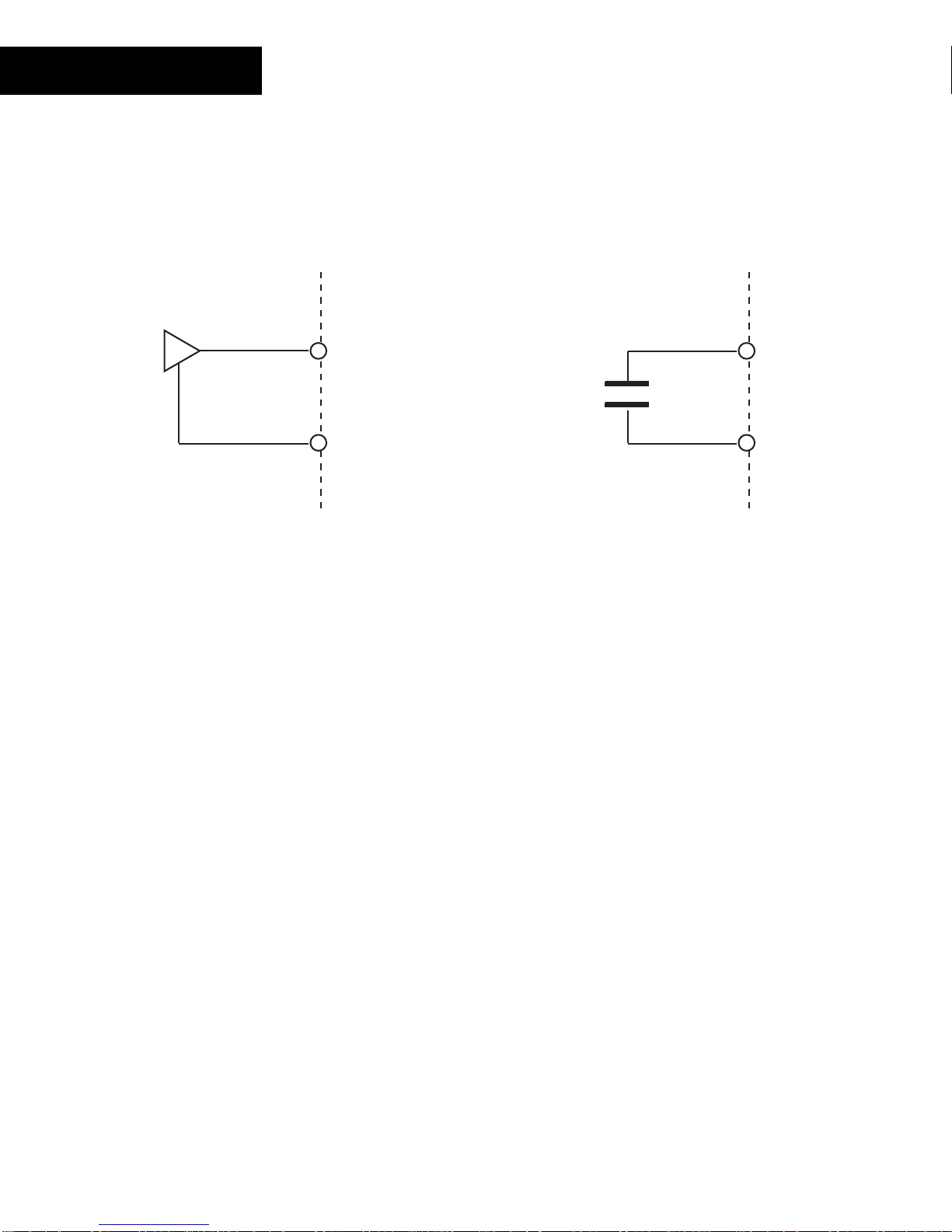

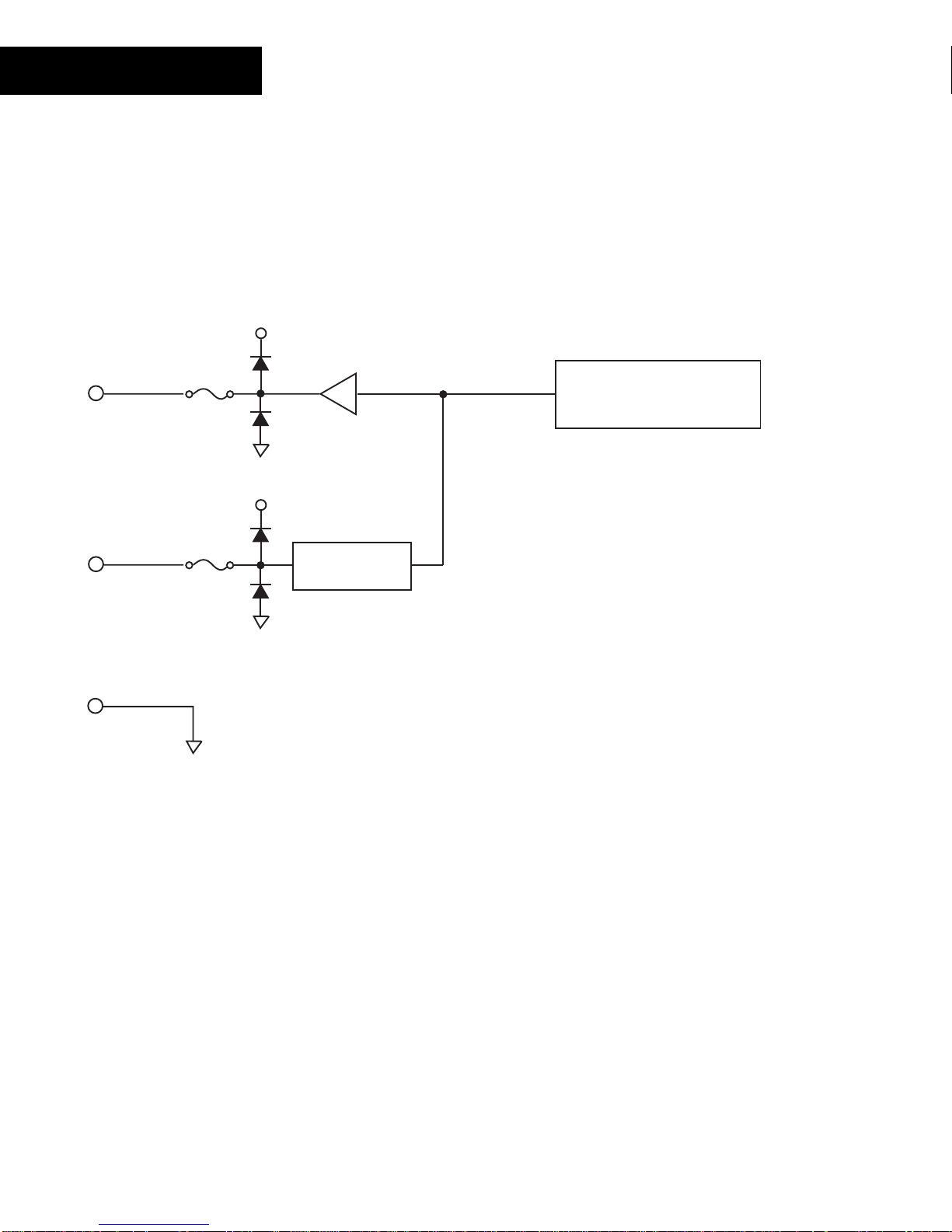

The following is a sim plified schematic of bot h the UI - 8- 10 and the UI - 8- 10- 10V Univ er s al

inputs:

Vref

Vref

IN x

RET

Rref

Swdis

UI-8-10

IN x

RET

2.21K

0-5V

Range

0-10V

2.21K

UI-8-10-10V

Rref

Swdis

The main diff er enc e between the two is the UI-8-10-10V circ uit includes a switch

selectable fr ont-end voltage divider that effectiv ely divides the 10V input signal by two.

22

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 29

UI-8-10

Each input includes a low- pas s filter after the pull-up f or m ed by a series r es is tor and a

parallel capacitor. The resist or is utiliz ed for over-voltage prot ec tion in limiting current t o

two protection diodes (not shown). Not e als o that all input returns are combined and must

be directly connec ted to earth ground. It is possible to have more than one input share a

single return wire. Keep in mind that the current through eac h input is approximately

0.3mA, so volt age dr ops oc c ur with long r uns of sm all gauge wir e.

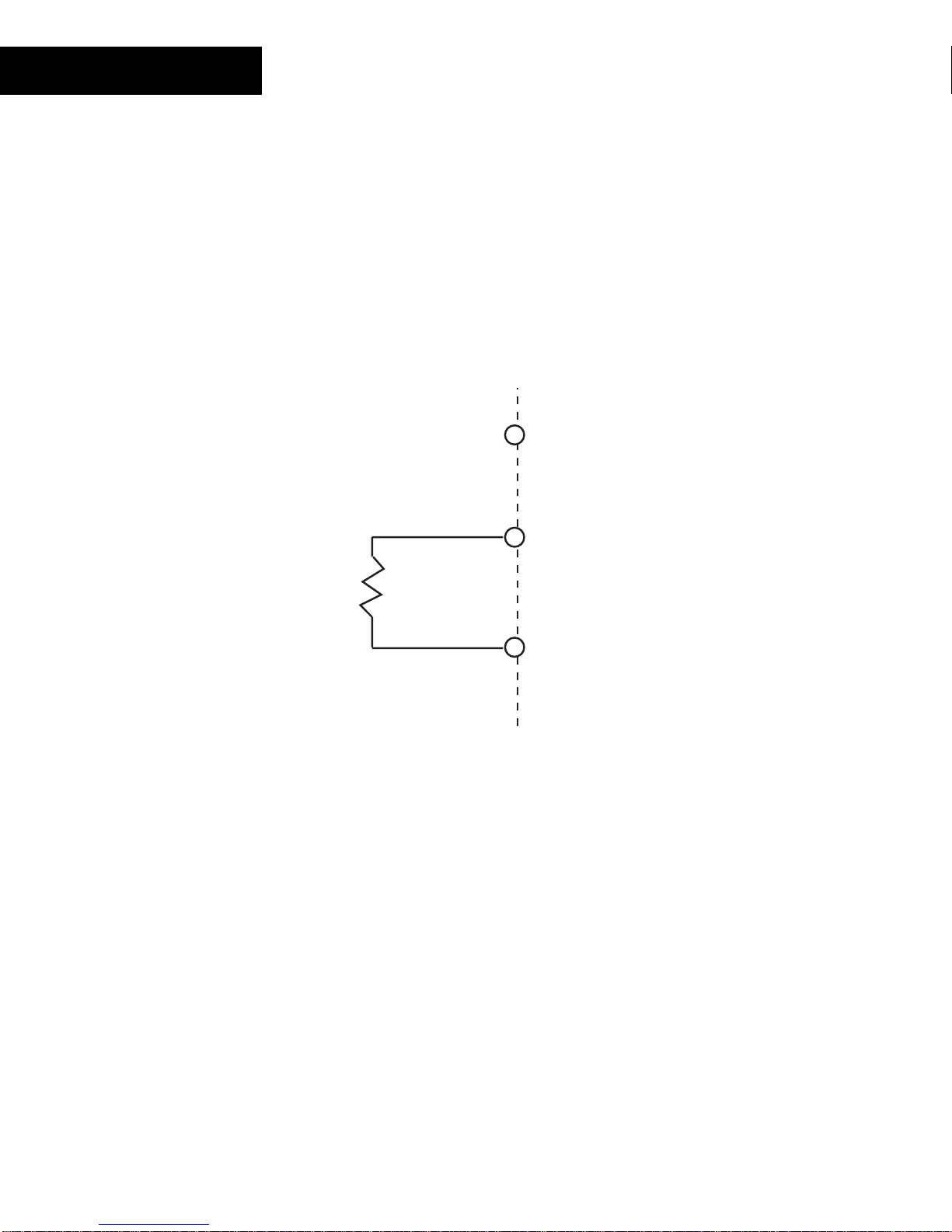

Pull-up Ref erence Resistor Selection Switches

In some measuring inst anc es it is desirable that ther e be no pull-up resis tor. Instead of

physically remov ing or c utting the resistor off the pr inted circuit board, the input m odule

includes a pull-up resistor selection switch (labeled Swdis in the diagr am ) for each input

position. T his s witch allows you to select whether or not y ou want a pull-up r es is tor in the

circuit. A small 8- pos ition switch module is access ible from the front of the module when

the door is opened.

Slide marker

moves left and right

12345678

O N

These switc h modules are c om m only c alled “ DIP Switches” and require a small object

such as the tip of a pen or a small screwdriver to operate them. Each switch position acts

as a “slide switc h” . Pr es s ing the rais ed s lide m ar k er to t he side mark ed “ on” closes or

enables the switc h. To open or disable the switch posit ion, press the slide marker over to

the “off ” side.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

23

Page 30

UI-8-10

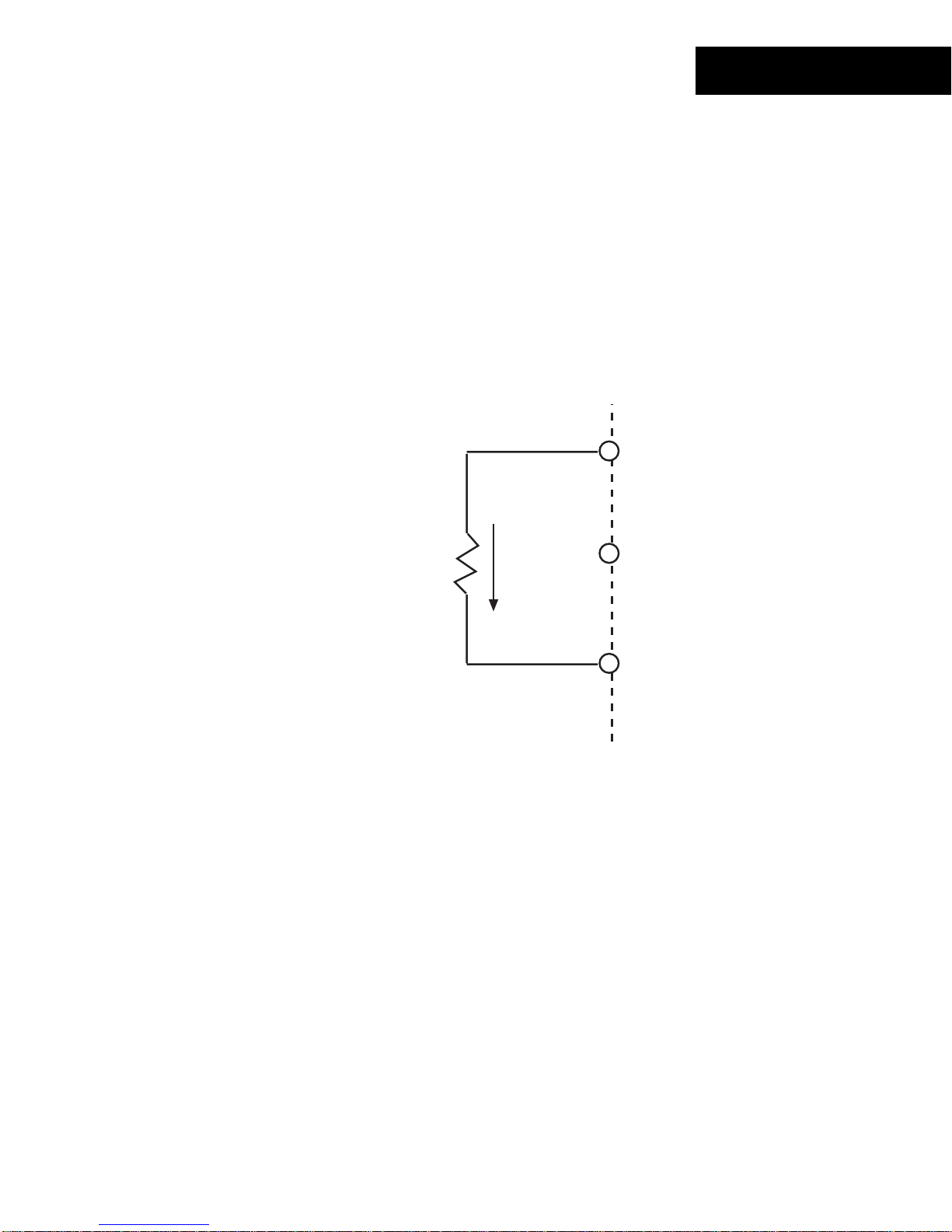

Input Voltage Range Selection Switches (UI-8-10-10V Only)

The UI-8-10- 10V m odule allows y ou to choose from two input voltage ranges. Selection

is accomplished by us ing a s witch arrangement that is sim ilar to the operation of the pullup resistor s witches. The Voltage Range switc hes allow y ou to select a range (0-5 V) or

(0-10 V) for each input .

The 0-5V range allows c onnec tions to signals that do not exc eed 5.00V. The 0-10V range

allows connection t o s ignals up to 10.00V. In this mode the circ uit actually uses the same

input measuring cir c uit as the 0-5V range, however , it div ides the voltage present by two

thereby limit ing the internal circuitry to 0-5V. When you read a 0-10V input the actual

reading will be 0-5V. You m us t adjust your readings for the higher r ange v ia formula.

Switching to 10V inputs dramatically low ers the imp edance of the input to

4.4 KΩ.

This small 8-pos ition switch module is located to the right of the pull-up selector s witch

and is accessible f r om the f r ont of the m odule when the door is opened.

24

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 31

Measuring Tem per at ur e

UI-8-10 inputs m ay be conf igur ed to sense temperature by conf igur ing one of the

module’s inputs appropr iately. This is done by s ett ing the Electrical Type to eit her

or

Temp (DEG F)

ACC Temp (DEG C)

input terminal. The following is a schemat ic r epr es entation of the connection:

Thermistor

. Connect a resistive t her m istor s ens or to that

IN x

RET

UI-8-10

ACC

One lead connects to a numbered input terminal, the other to a return terminal.

To use the input for temper ature sensing, the pull-up reference resist or must be

connected into the circuit, ther efore,

be placed in the ‘on’ position

the reference resistor switch for this input must

. When the input point is configured as a temperature

input, the c ontroller utilizes a look-up t able to convert from a voltage reading to a

temperatur e r eading in degr ees Fahrenheit or Celsius.

Caution

Never apply a voltage to a thermistor—doing so alter s the t her m istor ’s ac c ur ac y and

reliability . In fact, it’s a good idea to replac e any therm is tor that has had any sort of

voltage applied to it .

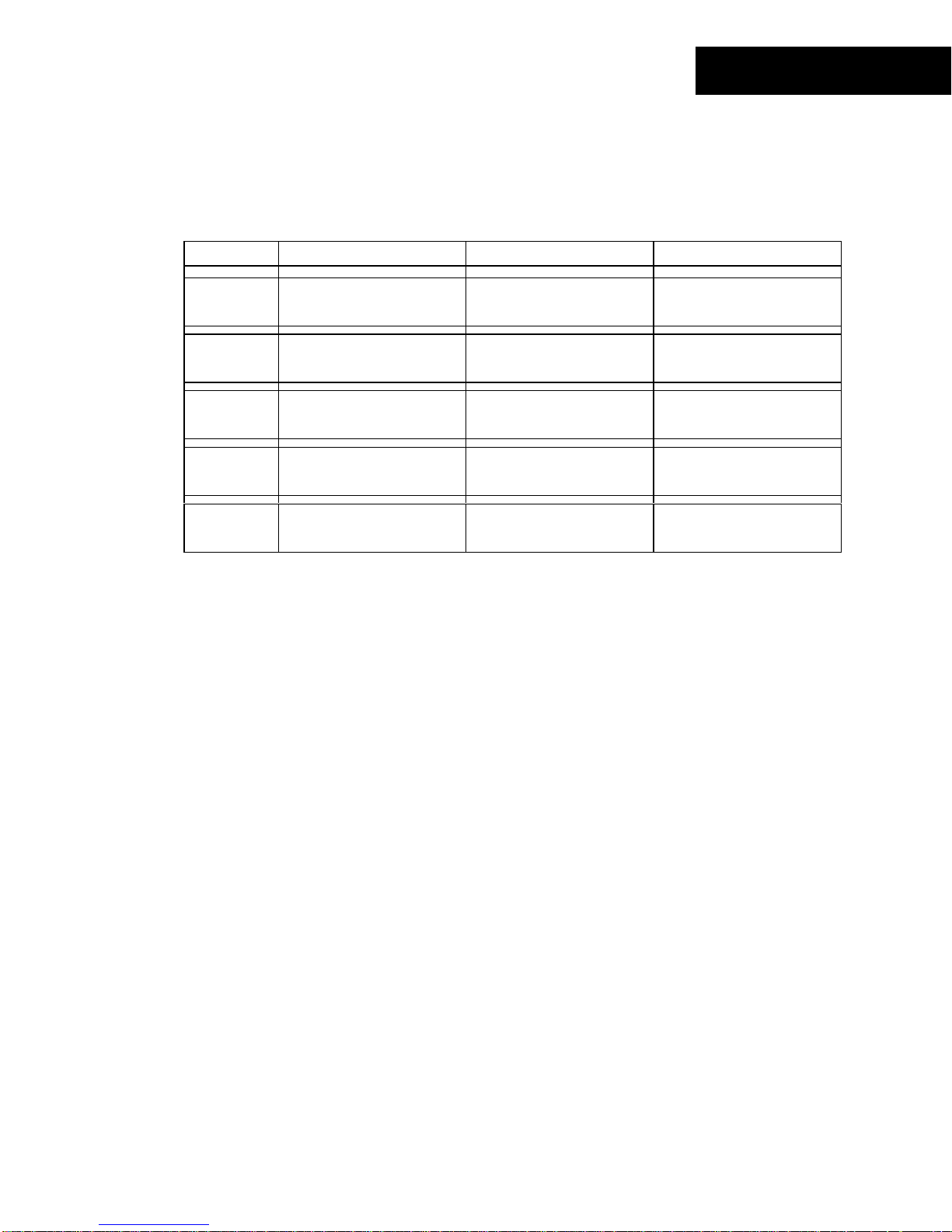

Maximum Wire Run s for Thermist ors

To keep therm istor er r or s minimal, limit the length of wire runs to t he maximum for the

gauge wire you select.

The following two pages inc lude three tables that indicate the maximum length runs for

wires of various gauges to keep errors within certain t em per ature limits when using

thermist or elem ents.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

25

Page 32

UI-8-10

Wire Gauges and Corresponding Maximum Runs for

Sensing Temperatures Up to 70 °F (21 °C)

Gauge

°F (.28 °C) Error 1/4

1/2

°F (.14 °C) Error 1/10

°F (.06 °C) Error

#14 26,700 ft. 13,300 ft. 5,300 ft.

2.5 mm

2

8150 m 4000 m 1600 m

#16 16,700 ft. 8,300 ft. 3,300 ft.

1.5 mm

2

5120 m 2500 m 1000 m

#18 10,500 ft. 5,200 ft. 2,100 ft.

1.0 mm

2

3200 m 1600 m 640 m

#20 6600 ft. 3,300 ft. 1,300 ft.

0.5 mm

2

2000 m 1000 m 400 m

#22 4,100 ft. 2,000 ft. 800 ft.

0.35 mm

2

1250 m 600 m 250 m

Wire Gauges and Corresponding Maximum Runs for

Sensing Temperatures Up to 100 °F (38 °C)

Gauge

°F (.28 °C) Error 1/4

1/2

°F (.14 °C) Error 1/10

°F (.06 °C) Error

#14 12,600 ft. 6,300 ft. 2,500 ft.

2.5 mm

2

3800 m 1900 m 760 m

#16 7,900 ft. 3,900 ft. 1,500 ft.

1.5 mm

2

2400 m 1200 m 450 m

#18 5,000 ft. 2,500 ft. 1,000 ft.

1.0 mm

2

1500 m 760 m 300 m

#20 3,100 ft. 1,500 ft. 600 ft.

0.5 mm

2

950 m 450 m 180 m

#22 1,900 ft. 900 ft. 300 ft.

0.35 mm

2

580 m 275 m 90 m

26

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 33

Wire Gauges and Corresponding Maximum Runs for

Sensing Temperatures Up to 150 °F (65 °C)

UI-8-10

Gauge

°F (.28 °C) Error 1/4

1/2

°F (.14 °C) Error 1/10

°F (.06 °C) Error

#14 4,100 ft. 2,000 ft. 800 ft.

2.5 mm

2

1250 m 600 m 240 m

#16 2,600 ft. 1,300 ft. 500 ft.

1.5 mm

2

800 m 400 m 150 m

#18 1,600 ft. 800 ft. 300 ft.

1.0 mm

2

500 m 240 m 90 m

#20 1,000 ft. 500 ft. 200 ft.

0.5 mm

2

300 m 150 m 60 m

#22 600 ft. 300 ft. 100 ft.

0.35 mm

2

180 m 90 m 30 m

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

27

Page 34

(

)

UI-8-10

Measuring DC Voltages

The UI-8-10 inputs may be configured to sense DC voltage by s ett ing the Electrical Type

to

Voltage

the module’s input s pec ifications. The f ollowing is a s c hem atic representation of the

connection:

One lead connects to the numbered input terminal, the other to a return terminal.

When interf ac ing to a voltage output sensor, s pec ific information on the trans duc er may

and connecting the input terminals to a DC voltage sourc e within the range of

INx

+

V

-

RET

return

be required. The pull- up r es is tor of the input circuit will affect the output of the trans duc er .

It is suggested that you disable (set to OFF) the pull-up reference resist or on volt age

•

inputs.

10V Input Notes

It should be not ed that although the 10V input configuration allows you to measure a

higher voltage, y ou s till read a value of 0-5V. You have to convert the reading in your

program.

28

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 35

UI-8-10

Voltage Di vid ers

There are inst anc es when it is nec es s ar y to interface to a voltage source that is higher

than the input r ange of t he m odule. In these cases a voltage divider is neces s ar y .

DC input Voltage Divider

Two resist or values s et up a ratio of voltage drop. These res istor s m ust be sized

appropriately (v alue and wattage) for the source being monitored. The higher the

resistance v alues , the less loading effect t her e will be on the source.

Vref

Rref

Swdis

R1

Vsource

R2

IN x

RET

The circuit s hown abov e is a simple two-resistor volt age div ider c onnec ted to one of the

UI-8-10 module’s inputs. The input circ uitry of the module can measure a maximum of

either 5 Volts or 10 Volt s (UI - 8- 10- 10V only ) . T her efore, the voltage measured acr os s

Rinput must not exc eed this maximum.

In this cas e, be sur e to switch the pull-up resistor out of t he circuit.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

29

Page 36

UI-8-10

Assuming you know the maximum voltage reading you are trying to measure (

source

V

),

perform t he following steps to determine the r es istanc e v alues nec es s ar y to condition the

input for t he module.

1. First, det er m ine the current that will flow through t he div ider . Pick a value that your

source can supply. Let’s say 20 mA. This value will be repres ented by the variable

total

in the following equ ations.

I

2. Determine the total resistance value r equir ed of the entire divider (R1 + R2) to create

20mA given the sour c e voltage by s olv ing the following:

total

R

I

= V

source

total

Example, if you are meas ur ing a s our c e that can supply 0- 30 V:

total

R

= 30 V

20 mA

total

R

= 30 V

.02 A

total

R

= 1500

Ω

The current is constant through the two resistors. Knowing this and the fact that our

input can’t exc eed 5V ( or 10V) c an determine the value of the resistor labeled

3. Determine the v alue of

R

I

R2 = 5 V

2

by solving the following:

R

2

input

= V

total

(assuming you are solving f or 0-5V input)

.02 A

2

R

= 250

Ω

Through subtr ac tion, you can determine the remaining r es is tor value:

total

= R1 + R

R

R1 = 1500 Ω - 250

2

Ω

R

2

.

30

Andover Controls

R1 = 1250

Ω

Technical Manuals Online! - http://www.tech-man.com

Page 37

UI-8-10

Sensing Digital Inputs or Contact Closures

Digital input points ar e des igned to allow the monitoring of logic level signals or contact

closures acros s an input (contact wired bet ween the input and r eturn).

When monitoring a digital logic level signal, t he pull- up r es is tor must be disabled (set

•

to OFF).

To sense a contact closure, the pull-up resistor m us t be enabled (s et to ON).

•

IN x

Contact

Closure

RET

To sense a digital input or contact closure, c onfigure an input point with an Electrical

Type of

Digital

.

A digital input is c ons ider ed “ ON” whenever the voltage acr os s its input meets or exceeds

the ON Threshold. For a c ontact closure, this is 0 (zero) volt s. S im ilar ly , an OFF condition

meets, or is lower than, the Off Threshold. With a contact closure, this is the value of

Vref.

: When configuring a Digital point, ther e is a ‘Polarity’ attribute. If this att r ibute is

Note

enabled, readings are rev er s ed: ‘On’ will occur when t he input is at Vref because the

contact is open, and ‘O ff ’ oc c ur s when the input is at 0 volts because the contact is

closed.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

31

Page 38

UI-8-10

Counting Pulsing Signals or Contact Closures

Counter inputs ar e des igned to allow the monitoring of digital pulse trains or cont act

closures acros s an input just like digital inputs, but they accumulate a total of those

closures and act lik e a c ounter.

Interf ac ing is s im ilar to a digit al input, however, you set the Elect r ic al Type attribute to

Counter

When using an input as a counter , you must take into account the fr equenc y of t he input

signal being counted. Univ er s al inputs do not allow for v er y high s peed c ontact counting.

This module allows counting up to a maximum of 4 Hz or 4 contact closur es or digit al

pulses per second.

instead.

Counter Dut y Cycle

To achieve the m ax imum counter frequency, the amount of time t he signal is O N as

opposed to being OF F must be at least 125 milliseconds.

32

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 39

Status/Control P a nel

Status In dic a t or s

The UI-8-10 m odule inc ludes a c om plete indicator status panel on the front of the

module.

UI-8-10

POWER

COMM

STATUS

COMMISSION

RESET

UI-8

This panel includes indicators reporting on the status of the following:

POWER

COMM

STATUS

This green indicat or illum inates when DC power is applied through the

Power/IO Bus .

This yellow indicat or illum inates when data is tr ans m itt ed from the

module to the Net Controller. In normal operation, data is only transmit ted

when an input value changes.

This indicator will als o flash periodically as t he NetController check s the

I/O bus periodically .

This red indicat or is nor m ally off . If it is alway s on or flas hing at a fast

rate there is a problem wit h the module.

This indicator c an be m anually illum inated from the Continuum

workstation and used as a troubleshooting aid when locat ing a particular

module. More inf or m ation on using this indicator may be found in t he

Troubleshooting

section of this manual.

This panel also includes two operator swit c hes that perfor m the f ollowing:

COMMISSION

After phy s ic al installation and during configurat ion through the

Continuum workstation, pressing this button registers the module’s

address with t he s yst em. For m or e information, refer to the section on

RESET

Configuring I/ O

Should the module become inoper able, pressing this button resets the

found earlier in this manual.

module. It does not er as e its m emory.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

33

Page 40

34

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 41

DI-6-AC

The DI-6-A C, Cont inuum ’s digital AC input module, has six digital (“wet”) AC inputs for

cost-ef fective ON-OFF status indicat ion of fan motor starters, solenoid valv es , control

relays, or exter nal power s upplies , and similar applications that require a quick and eas y

way to detect voltage. The DI-6-AC monitor s the abs enc e or presenc e of AC voltage

levels directly , with no interposing r elay s needed.

The DI-6-A C can monit or voltages from 24-120V. A DI-6-AC-HV model is als o av ailable

for sensing higher v oltages120-240V. Bot h models can als o ac c ept DC voltages. All

inputs are optic ally c oupled with 2500V isolation on each input for noise-free oper ation.

FEATURES

POWER

COMM

STATUS

INPUT

INPUT

1

2

3

4

5

6

COMMISSION

RESET

6 optically-coupled, digital AC input

•

channels

DI-6

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

WARNING:

HIGH VOLTAGE INSIDE-DANGEROUS TO

UNQUALIFIED PERSONS.

AVERTISSEMENT:

CAUTION:

READER

POWER

MORE THAN ONE DISCONNECT MAY BE

REQUIRED TO DE-ENERGIZE THIS EQUIPMENT.

+ 5V, 100mA

VOLTAGE RANGE(VAC) 50/60 HZ 20 - 132 90 - 280

INPUT CURRENT(mA) 0.4 - 9.0 0.4 - 3.0

+ 12V, 180mA

READER

+

G

DC

A

N

V

L

IN1

IN2 IN3 IN4 IN5 IN6

T

D

K

A

/

/

1

0

123456789101112

4

12

56

3

1-DOOR

ON

OFF

AUTO

HAUTE TENSION A L'INTERIEUR-DANGER

POUR LES PERSONNES NON-QUALIFIER.

DI-6-AC DI-6-AC-HV

CONTACT RATING:

23

D

O

O

R

7

R

E

X

8

24VAC/DC, 5A

DIGITAL OUTPUTS

1-DOOR

R

E

T

10 11 12

9

L

E

D

SUPERVISED

INPUTS(0-5V)

1

A

U

X

DIGITAL INPUTS

ON

OFF

AUTO

OUT 2

OUT2

13 14 15

Will accept A C or DC inputs

•

24-120V AC Input Range

•

120-240V AC Input Range ( DI-6-AC-HV)

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

35

Page 42

DI-6-AC

SPECIFICATIONS

ELECTRICAL

Power Consumption:

0.7 Watt at 24VDC max.; normally provided by

supply module.

Continuum

power

Overload Protection:

INPUTS

Number of Inputs:

Input Protection:

Input Connections:

Input Range:

Input Current:

AC Voltage “ON” Threshold:

(Above this voltage is considered “ON”)

AC Voltage “OFF” Threshold:

(Below this voltage is considered “OFF”)

Input Resistance

(±5%): 30KΩ 200KΩ

0.5A resettable fuse with transient voltage suppressor (TVS) and

reverse polarity protection.

6 Digital AC voltage inputs

2500V isolation on each input

Each input has a 270V MOV.

Two-piece, 13-position removable terminal block

DI-6-AC DI-6-AC-HV

20-132 Vrms 90-250 Vrms

5 mA max. 2 mA ma x.

DI-6-AC DI-6-AC-HV

16 Vrms 75 Vrms

8 Vrms 30 Vrms

Ma xim um Turn ON Time:

Maximum Turn OFF Time:

DC Input Voltage Range:

DC Input Current:

DC Voltage “ON” Threshold:

(Above this voltage is considered “ON”)

DC Voltage “OFF” Threshold:

(Below this voltage is considered “OFF”)

36

Andover Controls

20 mS 20 mS

60 mS 60 mS

20-132V 90-250V

5mA max. 2mA max.

20V 90V

12V 45V

Technical Manuals Online! - http://www.tech-man.com

Page 43

DI-6-AC

I/O Connections

The actual input connect ions are located on a twelve-position removable screw terminal

connector located at the bottom of the module. Input wir es s hould enter from either the

top or bott om wiring t r oughs , and should c om e from the left side of the rack (by

convention).

The inputs are labeled IN1, IN2, IN3, and so fort h. Eac h pair of term inals c or r es ponds to

one input. With both AC and DC signals there is no polarity to obs er v e dur ing c onnec tion.

The diagram below indicat es wher e eac h input number is located in the terminal block.

Shield/Eart h Ground

IN 1

1.

IN 1

2.

IN 2

3.

IN 2

4.

IN 3

5.

IN 3

6.

IN 4

7.

IN 4

8.

IN 5

9.

10. IN 5

11. IN 6

12. IN 6

POWER

COMM

STATUS

WARNING:

INPUT

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

HIGH VOLTAGE INSIDE-DANGEROUS TO

UNQUALIFIED PERSONS.

AVERTISSEMENT:

CAUTION:

MORE THAN ONE DISCONNECT MAY BE

REQUIRED TO DE-ENERGIZE THIS EQUIPMENT.

1

2

3

4

INPUT

5

COMMISSION

6

RESET

DI-6

1-DOOR

ON

OFF

AUTO

HAUTE TENSION A L'INTERIEUR-DANGER

POUR LES PERSONNES NON-QUALIFIER.

OUT 2

ON

OFF

AUTO

READER

POWER

Technical Manuals Online! - http://www.tech-man.com

+ 5V, 100mA

VOLTAGE RANGE(VAC) 50/60 HZ 20 - 132 90 - 280

INPUT CURRENT(mA) 0.4 - 9.0 0.4 - 3.0

+ 12V, 180mA

READER

+

G

N

V

IN1

D

123456789101112

12

L

DC

A

E

L

IN2 IN3 IN4 IN5 IN6

T

D

K

A

/

/

1

0

4

56

3

DI-6-AC DI-6-AC-HV

SUPERVISED

INPUTS(0-5V)

DIGITAL INPUTS

1

23

D

A

U

X

R

R

O

E

O

X

R

7

9

8

CONTACT RATING:

24VAC/DC, 5A

DIGITAL OUTPUTS

1-DOOR

E

T

10 11 12

OUT2

13 14 15

Continuum I/O System Reference

37

Page 44

DI-6-AC

Input Circuitry

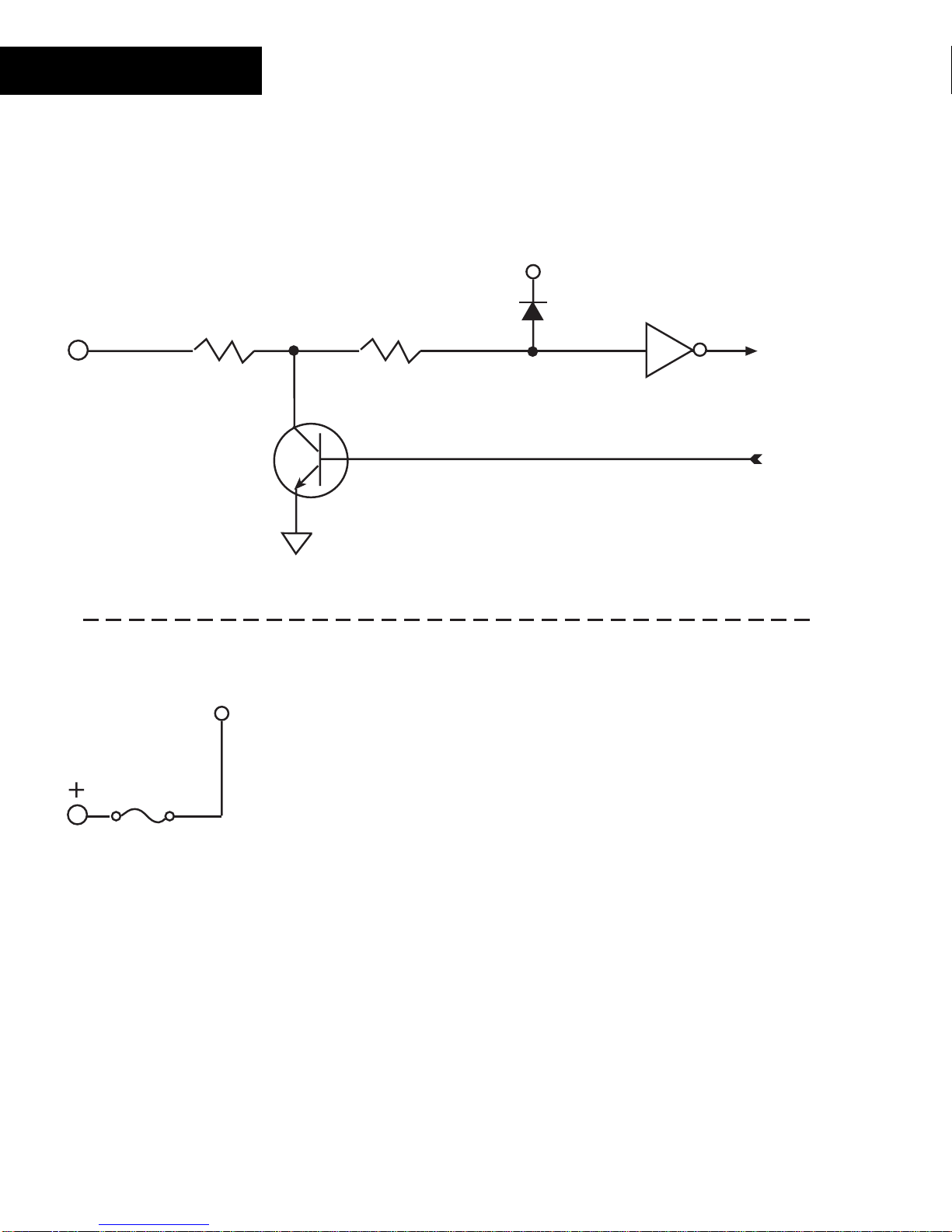

The following is a sim plified schematic of bot h the DI - 6- A C and the DI-6-A C- HV Digital

Input module:

AC

IN x

15K

OptoCoupler

RET

IN x

RET

275V

MOV

15K

DI-6-AC

100K

275V

MOV

100K

DI-6-AC-HV

10V

40V

AC

OptoCoupler

AC to DC

Converter

AC to DC

Converter

II

II

The main diff er enc e between the two is the DI-6-AC-HV circuit inc ludes a front end that

supports t he higher v oltages.

38

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 45

DI-6-AC

Sensing AC or DC Digital Inputs

Digital input points ar e des igned to provide an ON or OFF reading of a signal ( wir ed

between the input and r eturn). Normally you would ass oc iate an AC or DC voltage input

with a value measurem ent, however, the DI-6 modules include a voltage level trigger t hat

senses the pres enc e of a range of voltages and converts thos e r eadings to ON and OFF

indications.

AC

Signal

IN x

Polarity

Independent

DC

Signal

IN x

To sense an AC or DC digital input , configure an input point wit h an Elect r ic al Type of

Digital

.

The determination of ON or OFF is based upon the following measurement thresholds:

DI-6-AC DI-6-AC- HV

AC Voltage “ON” Threshold:

(Above this voltage is considered “ON”)

AC Voltage “OFF” Threshold:

(Below this voltage is considered “OFF”)

DC Voltage “ON” Threshold:

(Above this voltage is considered “ON”)

16 Vrms 75 Vrms

8 Vrms 30 Vrms

20V 90V

DC Voltage “OFF” Threshold:

(Below this voltage is considered “OFF”)

: When configuring a Digital point, ther e is a ‘Polarity’ attribute. If this att r ibute is

Note

12V 45V

enabled, readings are rev er s ed: ‘ON’ will occur when t he input is at the normal OFF

threshold. OF F occ ur s at t he normal O N thres hold.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

39

Page 46

DI-6-AC

Status/Control P a nel

Status In dic a t or s

The DI-6-A C module includes a c om plete indicator st atus panel on the front of the

module.

POWER

COMM

STATUS

INPUT

1

2

3

4

INPUT

5

6

COMMISSION

RESET

DI-6

This panel includes indicators reporting on the status of the following:

POWER

COMM

STATUS

This green indicat or illum inates when DC power is applied through the

Power/IO Bus .

This yellow indicat or illum inates when data is tr ans m itt ed from the

module to the Net Controller. In normal operation, data is only transmit ted

when an input value changes.

This indicator will als o flash periodically as t he NetController check s the

I/O bus periodically .

This red indicat or is nor m ally off . If it is alway s on or flas hing at a fast

rate there is a problem wit h the module.

This indicator c an be m anually illum inated from the Continuum

workstation and used as a troubleshooting aid when locat ing a particular

module. More inf or m ation on using this indicator may be found in t he

INPUT

Troubleshooting

These red indicat or s ( one for eac h c hannel) illum inate when an ‘ON’

section of this manual.

condition is sensed.

40

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 47

This panel also includes two operator swit c hes that perfor m the f ollowing:

DI-6-AC

COMMISSION

RESET

After phy s ic al installation and during configurat ion through the

Continuum workstation, pressing this button registers the module’s

address with t he s yst em. For m or e information, refer to the section on

Configuring I/ O

found earlier in this manual.

Should the module become inoper able, pressing this button resets the

module. It does not er as e its m emory.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

41

Page 48

42

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 49

The DI-8, Continuum ’s digital input module, is us ed for c os t-effective sensing of multiple

dry digital inputs in applic ations such as equipment s tatus monitoring or alarm point

monitoring. The DI-8 has eight digital input seach can be software configured to accept

a digital (contac t closure or 0-5 volt input ) or counter signal. Counter fr equenc y is 10Hz

on all eight inputs. In addition, high speed counting up to 10KHz max. is available (via a

DIP switc h) on Channels 1 and 2 f or high-speed m etering and industrial applications.

40V transient s uppr es s or s on all eight inputs protect against high v oltage short duration

transients ev ents. The DI-8 is designed to accept dry contact inputs or 0-5 volts and can

withstand up t o 24 VAC/ DC continuous v oltage on four channels.

FEATURES

POWER

COMM

STATUS

INPUT

INPUT

1

5

6

7

8

COMMISSION

RESET

Allows interf ac e to relay contact closures or 0- 5v

•

digital signals.

2

3

4

DI-8

DI-8

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

READER

HIGH SPEED

POWER

COUNTER

+ 5V, 100mA

OFF ON

+ 12V, 180mA

READER

+

INPUTS: 0-5V/DRY CONTACTS

G

DC

A

N

V

L

T

D

K

A

/

/

1

0

IN1

IN3 IN4 RETIN2 RET IN5 IN6 RET IN7 IN8 RET

123456789101112

4

12

3

1-DOOR

ON

OFF

AUTO

IN1

SUPERVISED

IN2

INPUTS(0-5V)

1

23

L

E

D

R

A

R

O

D

DIGITAL / COUNTER INPUTS

56

E

U

E

O

T

X

X

R

7

10 11 12

9

8

OUT 2

ON

OFF

AUTO

CONTACT RATING:

24VAC/DC, 5A

DIGITAL OUTPUTS

1-DOOR

13 14 15

OUT2

Allows high speed counting on c hannels 1 and 2.

•

Input prot ec tion allows accidental wiring of

•

24VAC to inputs .

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

43

Page 50

DI-8

SPECIFICATIONS

ELECTRICAL

Power Consumption:

0.8 Watt at 24VDC max.; normally provided by

supply module.

Continuum

power

Overload Protection:

INPUTS

Number of Inputs:

Input Types:

Input Protection:

Input Impedance:

Input Connections:

Digital:

Input Type:

Pulse Width:

Curren t:

Counter:

Input Type:

Channels 1 and 2 in HI-speed mode:

Frequency:

Pulse Width:

Current:

0.5A resettable fuse with transient voltage suppressor (TVS) and

reverse polarity protection.

8 Digital inputs

Digital or Cou nte r, software selectab le

24V AC/DC applied to 4 channels max.

(40V transient protection on each input)

10KΩ pull-up resistor referenced to +5 volts

Two-piece, 13-position removable terminal block

Contact closure or 0-5V input

50 ms min imum

0.5mA

Contact closure or 0-5V input

10KHz max.

50 µs min.

0.5mA

Channels 3 through 8; and Channel 1 and 2 in LO-speed mode:

Frequency:

Pulse Width:

Curren t:

44

Andover Controls

10Hz max.

50 ms min.

0.5mA

Technical Manuals Online! - http://www.tech-man.com

Page 51

I/O Connections

The actual input connect ions are located on a twelve-position removable screw terminal

connector located at the bottom of the module. Input wir es s hould enter from either the

top or bott om wiring t r oughs , and should c om e from the left side of the rack (by

convention).

The inputs are labeled IN1, IN2, IN3, and so fort h. Eac h pair of inputs is followed by a

connection labeled RET for the input signal retur n, resulting in a sequence of I N1, I N2,

RET, IN3, IN4, RET, and s o on. F or any given input, you should use the closest r eturn

terminal either before or after that input —the nex t return terminal goes with t he next two

inputs, and so on.

The twelve-pos ition connector allows for eight inputs and four signal ret ur ns .

The diagram below indicat es wher e eac h input number is located in the terminal block.

DI-8

Shield/Eart h Ground

1.

2.

3.

4.

5.

6.

7.

8.

9.

IN 1

IN 2

RETURN

IN 3

IN 4

RETURN

IN 5

IN 6

RETURN

10. IN 7

11. IN 8

12. RETURN

POWER

COMM

STATUS

INPUT

1

2

3

4

INPUT

5

6

7

8

COMMISSION

RESET

DI-8

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

1-DOOR

ON

OFF

AUTO

READER

POWER

HIGH SPEED

COUNTER

+ 5V, 100mA

OFF ON

+ 12V, 180mA

READER

+

V

IN1

123456789101112

12

INPUTS: 0-5V/DRY CONTACTS

G

DC

A

N

L

T

D

K

A

/

/

1

0

4

3

IN1

SUPERVISED

IN2

INPUTS(0-5V)

1

23

L

E

D

A

O

D

DIGITAL / COUNTER INPUTS

U

O

X

R

IN3 IN4 RETIN2 RET IN5 IN6 RET IN7 IN8 RET

56

7

R

R

E

E

T

X

9

8

CONTACT RATING:

24VAC/DC, 5A

DIGITAL OUTPUTS

1-DOOR

10 11 12

OUT 2

ON

OFF

AUTO

OUT2

13 14 15

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

45

Page 52

DI-8

High Speed Counter S election Switches

The DI-8 input module allows input c hannels 1 and 2 to be configured with the capability

of counting input puls es or c ontact closures at a rate of up to 10KHz. A select ion s witch is

included for each of these two input channels. This s witch allows you to select whether or

not you want the high speed input c onnec ted. A small 2-position s witch module is

accessible fr om the front of the module when the door is opened.

Slide marker

moves left and right

1

2

O

N

These switc h modules are c om m only c alled “ DIP Switches” and require a small object

such as the tip of a pen or a small screwdriver to operate them. Each switch position acts

as a “slide switc h” . Pr es s ing the rais ed s lide m ar k er to t he side mark ed “ ON” c los es or

enables the switc h thereby enabling high speed counting. To open or disable the s witch

position, pres s the slide marker over to the “OFF” side.

46

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 53

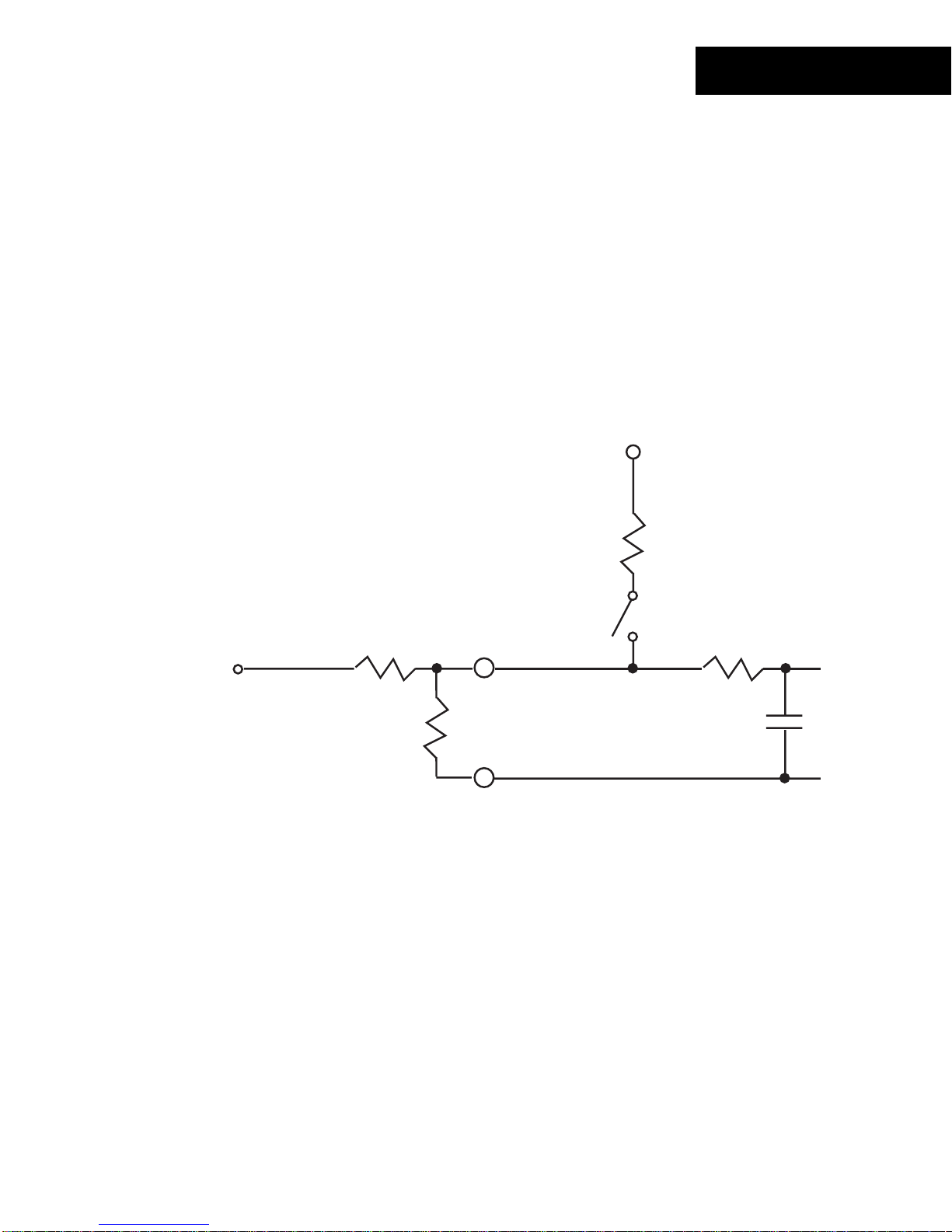

Input Circuitry

The following is a sim plified schematic of t he DI-8 Digital Input module:

5V

10K

5V

DI-8

IN x

RET

Channels 1 and 2 can be configured to allow high speed counting. The switches on the

front of the module substitute different value components for the low pass filt er formed by

the combination of R and C. These values support higher frequency inputs.

R

II

C

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

47

Page 54

DI-8

Sensing Digital Inputs or Contact Closures

Digital input points ar e des igned to provide an ON or OFF reading of a signal ( wir ed

between the input and r eturn).

Digital logic

Signal

IN x

RET

IN x

Contact

Closure

RET

To sense a digital input or contact closure, c onfigure an input point with an Electrical

Type of

Digital

.

A digital input is c ons ider ed “ ON” whenever the voltage acr os s its input meets or exceeds

the ON Threshold. For a c ontact closure, this is 0 (zero) volt s. S im ilar ly , an OFF condition

meets, or is lower than, the Off Threshold. With a contact closure, this is the value of

Vref.

: When configuring a Digital point, ther e is a ‘Polarity’ attribute. If this att r ibute is

Note

enabled, readings are rev er s ed: ‘On’ will occur when t he input is at Vref because the

contact is open, and ‘O ff ’ oc c ur s when the input is at 0 volts because the contact is

closed.

48

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 55

Counting Pulsing Signals or Contact Closures

Counter inputs ar e des igned to allow the monitoring of digital pulse trains or cont act

closures acros s an input just like digital inputs, but they accumulate a total of those

closures and act lik e a c ounter.

Interf ac ing is s im ilar to a digit al input, however, you set the Elect r ic al Type attribute to

DI-8

Counter

When using an input as a counter , you must take into account the fr equenc y of t he input

signal being counted. Inputs 3-8 do not allow for v er y high speed contact counting. T hes e

channels allow counting up t o a m ax im um of 10 Hz or 10 cont act c los ur es or digital

pulses per second.

In high-speed mode, c hannels 1 and 2 c an be c onfigured (via front panel switch) to count

to a maximum of 10Khz or 10, 000 c ontact closures or digital pulses per s ec ond.

instead.

Counter Dut y Cycle

To achieve the m ax imum counter frequency, the amount of time t he signal is O N as

opposed to being OF F must be at least 125 milliseconds.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

49

Page 56

DI-8

Status/Control P a nel

Status In dic a t or s

The DI-8 module includes a com plete indicator st atus panel on the front of the module.

POWER

COMM

STATUS

INPUT

1

2

3

4

INPUT

5

6

7

8

COMMISSION

RESET

DI-8

This panel includes indicators reporting on the status of the following:

POWER

This green indicat or illum inates when DC power is applied through the

Power/IO Bus .

COMM

This yellow indicat or illum inates when data is tr ans m itt ed from the

module to the Net Controller. In normal operation, data is only transmit ted

when an input value changes.

This indicator will als o flash periodically as t he NetController check s the

I/O bus periodically .

STATUS

This red indicat or is nor m ally off . If it is alway s on or flas hing at a fast

rate there is a problem wit h the module.

This indicator c an be m anually illum inated from the Continuum

workstation and used as a troubleshooting aid when locat ing a particular

module. More inf or m ation on using this indicator may be found in t he

INPUT

Troubleshooting

These red indicat or s ( one for eac h c hannel) illum inate when an ‘ON’

section of this manual.

condition is sensed.

50

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 57

This panel also includes two operator swit c hes that perfor m the f ollowing:

DI-8

COMMISSION

RESET

After phy s ic al installation and during configurat ion through the

Continuum workstation, pressing this button registers the module’s

address with t he s yst em. For m or e information, refer to the section on

Configuring I/ O

found earlier in this manual.

Should the module become inoper able, pressing this button resets the

module. It does not er as e its m emory.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

51

Page 58

52

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 59

The MI-6, Cont inuum ’s m illiam p input module, allows for a direct connection of a 2-wire

0-20mA or 4-20mA sensor to any of the module’s six inputs. The need for an exter nal

resistor and an ex ternal power supply are eliminated. The MI-6 module is a perfect mat c h

for temper ature transmitters, humidity and pressure transduc er s , gas m onitors, and other

industry-standard sensors with either a 0-20mA or 4-20mA output. The six inputs on the

MI-6 module have a 0- 20m A range and 10 bit A/D c onv er s ion.

FEATURES

EXTERNAL

POWER

COMM

STATUS

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

ON

OFF

AUTO

1-DOOR

COMMISSION

RESET

MI-6

ON

OFF

AUTO

OUT 2

6 current meas ur ing Inputs

•

0-20mA Range

•

10 Bit A/D Convert er

•

MI-6

READER

POWER

+ 5V, 100mA

INPUT RANGE: 0 - 20mA

SENSOR VOLTAGE: 24VDC

+ 12V, 180mA

SUPERVISED

READER

+

G

N

V

D

IN1

+ -

123456789101112

12

INPUTS(0-5V)

MILLIAMP INPUTS

1

L

DC

A

E

L

A

T

D

IN2 IN3 IN4 IN5 IN6

K

A

U

X

/

/

+ -

+ -

1

0

4

56

3

23

D

O

O

R

7

R

R

E

E

T

X

+ -

9

8

CONTACT RATING:

24VAC/DC, 5A

DIGITAL OUTPUTS

1-DOOR

+ - + -

10 11 12

13 14 15

OUT2

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

53

Page 60

MI-6

SPECIFICATIONS

ELECTRICAL

Power Consumption:

3.8 Watts at 24VDC max.; normally provided by

power supply module (including up to 20mA senso r power

for each input).

Continuum

Overload Protection:

INPUTS

Number of Inputs:

Input Range:

Resolution:

Accuracy:

Drift:

Input Resistance:

Maximum Input Current:

Voltage Supply to Sensors:

Input Protection:

Input Connections:

0.5A resettable fuse with transient voltage suppressor

(TVS) and reverse polarity protection.

6 Milliamp inputs

0-20 mA

20 µA

±80 µA max.

±50ppm/DegC max.

249Ω, 0.1%

±30 mA

19.0 to 26.0V (varies with +24V DC input voltage)

Each input and the Sensor voltage output includes a

transient voltage suppressor (TVS) and a resettable fuse.

Two-piece, 13-position removable terminal block

54

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 61

I/O Connections

The actual input connect ions are located on a thirteen-position removable screw terminal

connector located at the bottom of the module. Input wir es s hould enter from either the

top or bott om wiring t r oughs , and should c om e from the left side of the rack (by

convention).

The inputs are labeled IN1, IN2, IN3, and so fort h. Eac h input occ upies a pair of

terminals, r es ulting in a sequence of IN1+, IN1-, IN2+, IN2-, and so on. For any given

input, observ e the polarity for that input , + connec ts to the Supply terminal of the input.

The minus terminal connec ts to the Signal input.

The diagram below indicat es wher e eac h input number is located in the terminal block.

Shield/Eart h Ground

IN 1 +

1.

IN 1 -

10.

11.

12.

2.

3.

4.

5.

6.

7.

8.

9.

IN 2 +

IN 2 IN 3 +

IN 3 IN 4 +

IN 4 IN 5 +

IN 5 IN 6 +

IN 6 -

POWER

COMM

STATUS

EXTERNAL

USE COPPER CONDUCTORS ONLY

USE COPPER CONDUCTORS ONLY

1-DOOR

ON

OFF

AUTO

COMMISSION

RESET

MI-6

OUT 2

ON

OFF

AUTO

MI-6

Technical Manuals Online! - http://www.tech-man.com

READER

POWER

+ 5V, 100mA

INPUT RANGE: 0 - 20mA

SENSOR VOLTAGE: 24VDC

+ 12V, 180mA

READER

+

G

DC

A

N

V

T

D

IN1

A

/

+ -

1

123456789101112

12

3

SUPERVISED

INPUTS(0-5V)

MILLIAMP INPUTS

1

23

L

E

A

D

U

X

+ -

56

D

O

O

R

7

L

IN2 IN3 IN4 IN5 IN6

K

/

+ -

0

4

R

E

X

8

R

E

T

+ -

9

CONTACT RATING:

24VAC/DC, 5A

DIGITAL OUTPUTS

1-DOOR

+ - + -

10 11 12

13 14 15

OUT2

Continuum I/O System Reference

55

Page 62

MI-6

Input Circuitry

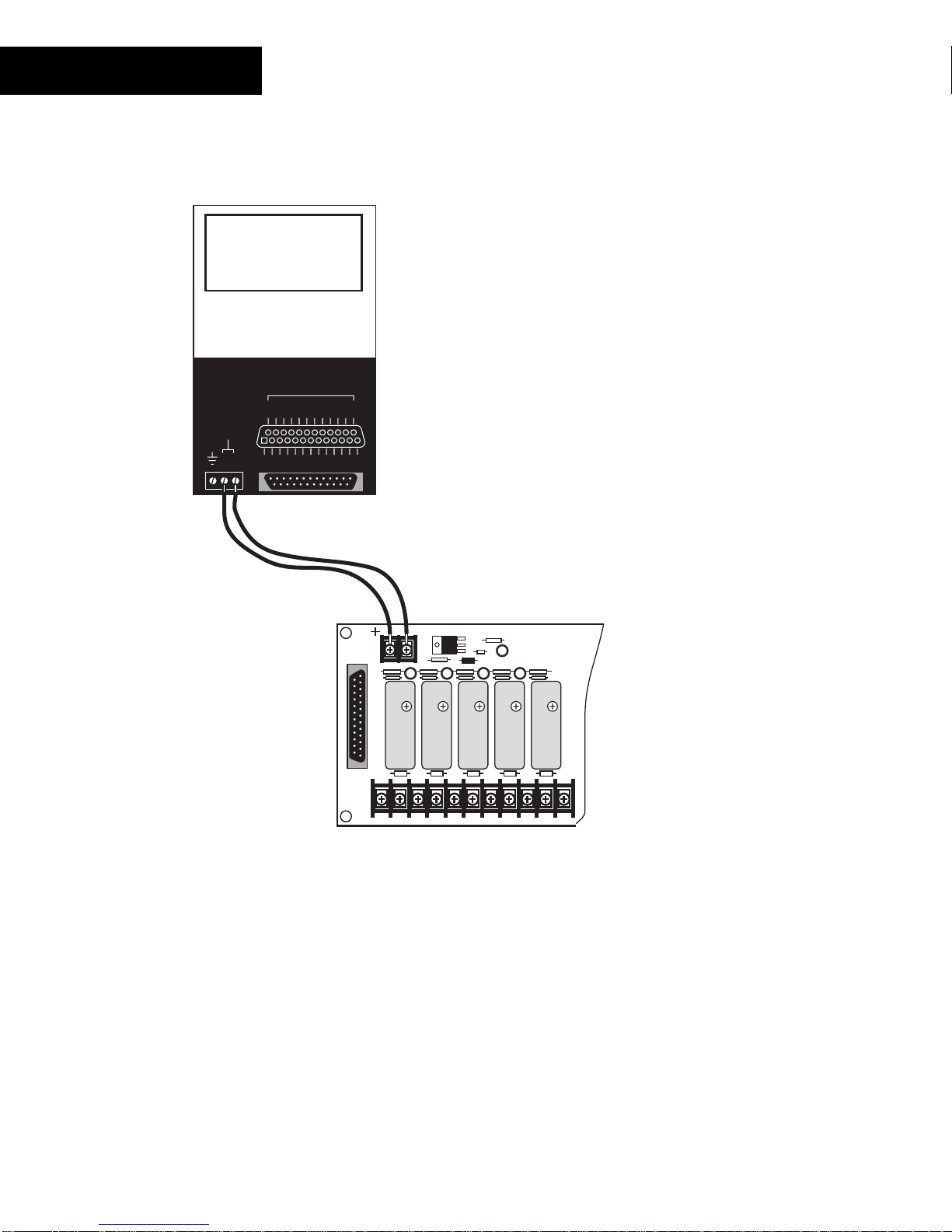

The following is a sim plified schematic of t he MI- 6 Milliamp I nput module:

24V

300mA

Resettable

Fuse

5V

100mA

Resettable

Fuse

249

Ω

R

C

To

Analog/Digital

Converter

All six input pairs inc lude their own automatic ally r es ett able fuses. These devices are

designed to open when sensing an over-current. T hey reset when the current supplied is

within range.

Note: In some extreme inst ances, the fuses may require that you remove power to

the module tempo rarily to reset their state.

56

Andover Controls

Technical Manuals Online! - http://www.tech-man.com

Page 63

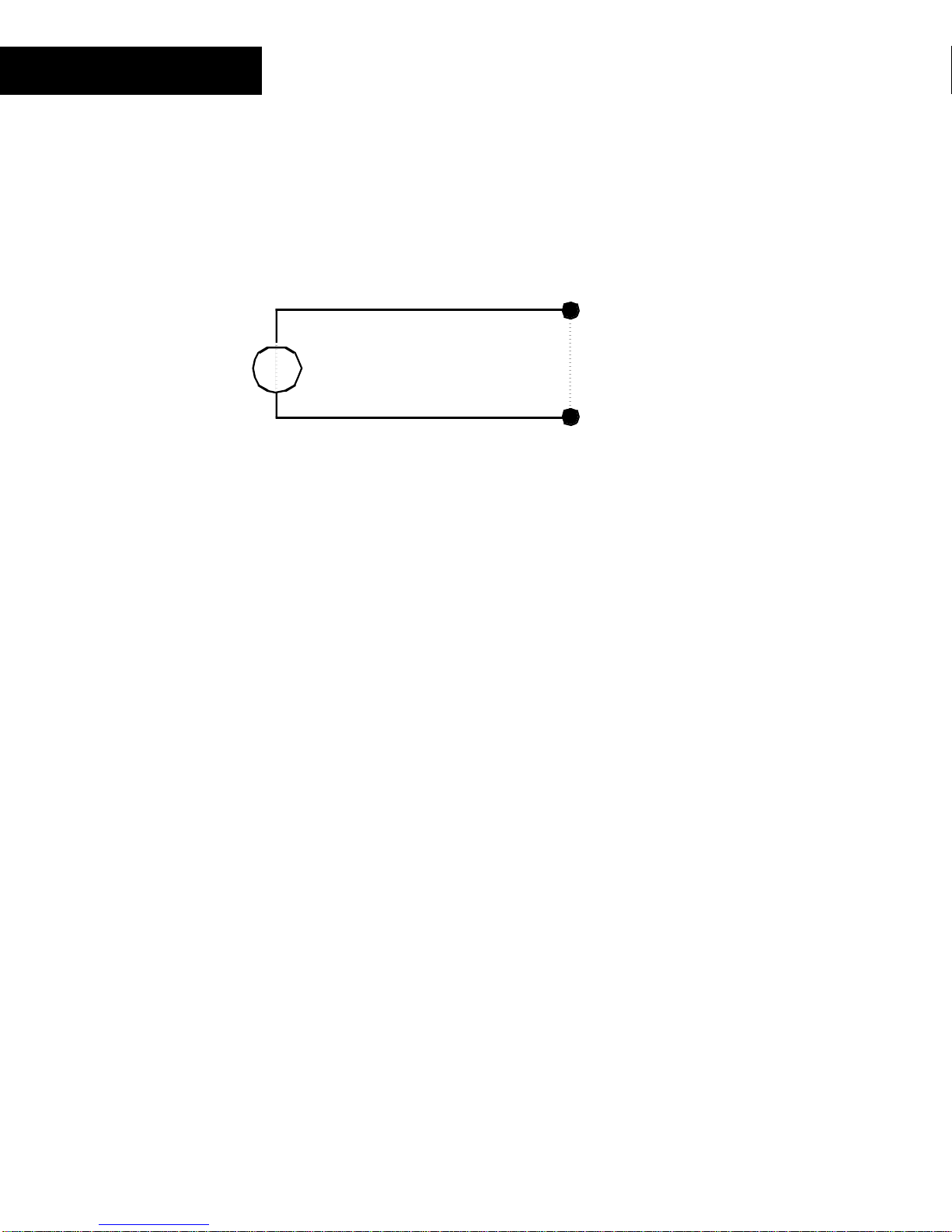

Sensing Current

The current supplying sens or is c onnec ted as indicated in the following illustration:

Supply

24V

Loop-Powered

Sensor

Signal

INx

MI-6

To measure cur r ent on an input , configure an input point wit h an Elect r ic al Type of

Current

.

Technical Manuals Online! - http://www.tech-man.com

Continuum I/O System Reference

57

Page 64

MI-6

Status/Control P a nel

Status In dic a t or s

The MI-6 module includes a c om plete indicator st atus panel on the front of the module.

POWER

COMM

STATUS

EXTERNAL

COMMISSION

RESET

MI-6

This panel includes indicators reporting on the status of the following:

POWER

This green indicat or illum inates when DC power is applied through the

Power/IO Bus .

COMM

This yellow indicat or illum inates when data is tr ans m itt ed from the

module to the Net Controller. In normal operation, data is only transmit ted

when an input value changes.

This indicator will als o flash periodically as t he NetController check s the

I/O bus periodically .

STATUS

This red indicat or is nor m ally off . If it is alway s on or flas hing at a fast

rate there is a problem wit h the module.

This indicator c an be m anually illum inated from the Continuum

workstation and used as a troubleshooting aid when locat ing a particular

module. More inf or m ation on using this indicator may be found in t he

EXTERNAL

Troubleshooting

This green indicat or illum inates when 24V DC power is available t o

section of this manual.

external sensor s .

58

Andover Controls